Multi-stage evaporation and air-vapour hybrid system and method thereof

A multi-stage evaporation and vaporization technology, applied in the direction of mixing methods, chemical instruments and methods, evaporation, etc., to achieve the effect of promoting full evaporation, small footprint, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

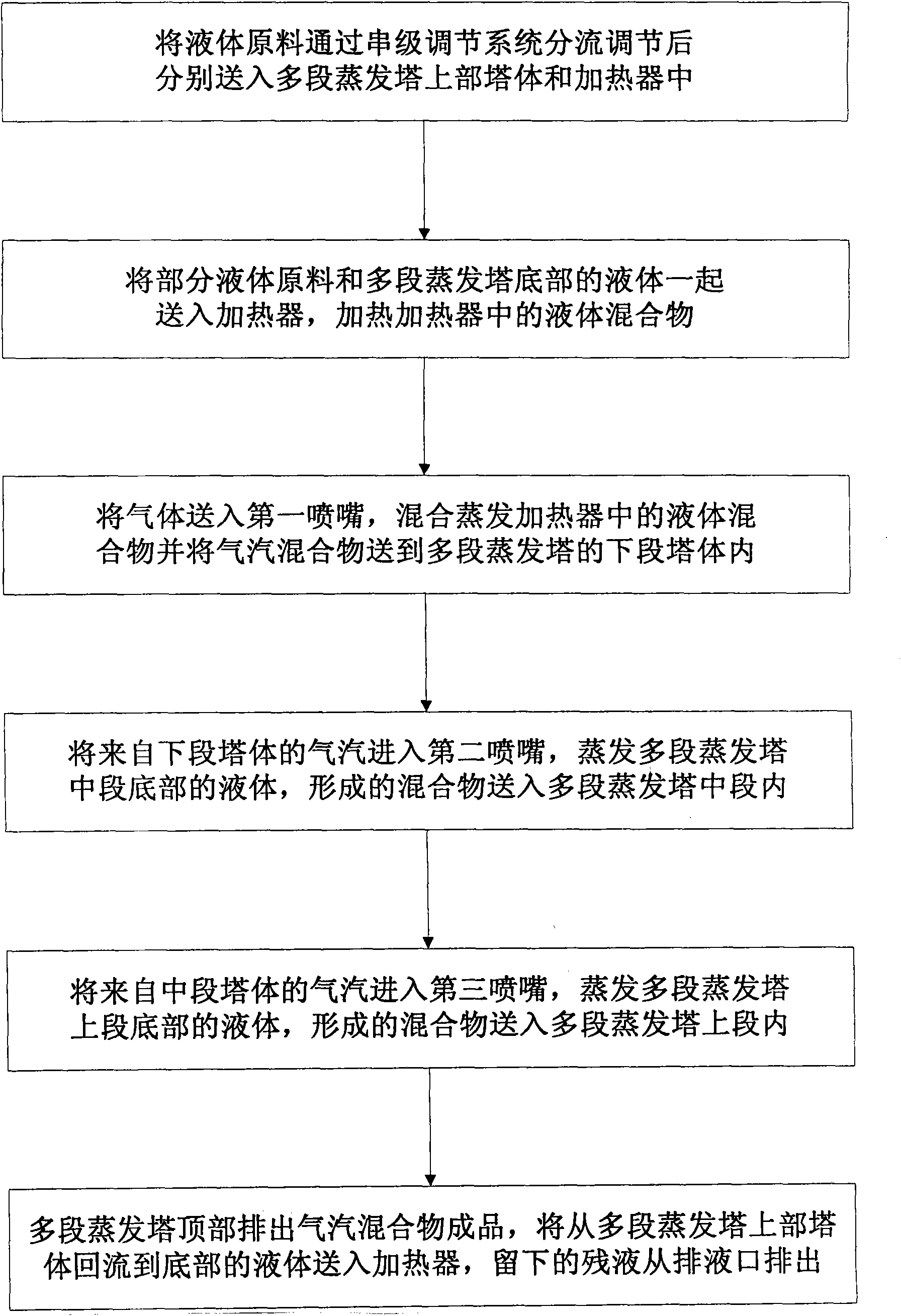

[0034] Attached below Figure 1~3 A preferred embodiment of the multi-stage evaporation and gas-vapor mixing system of the present invention will be described in detail.

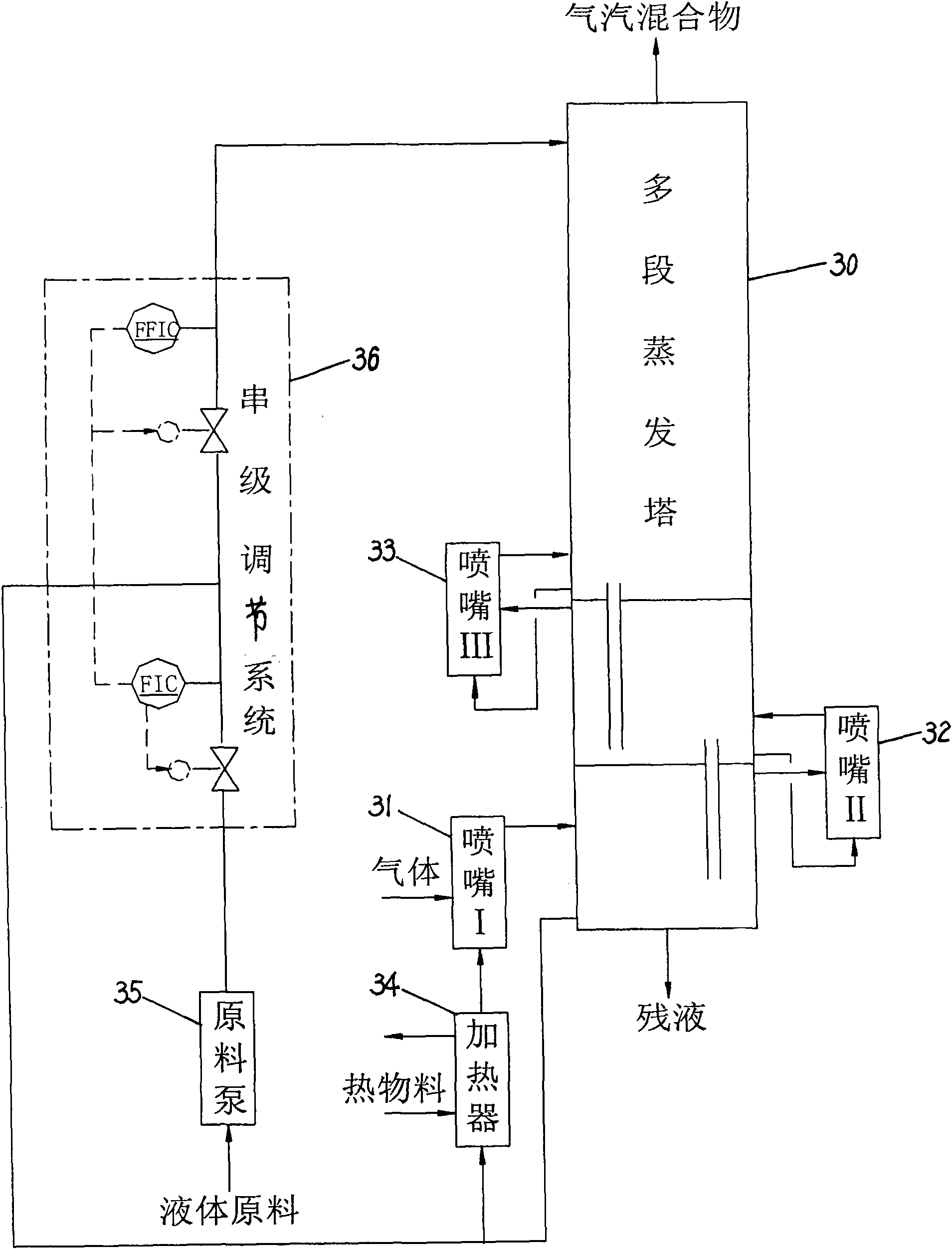

[0035] see figure 1 , A multi-stage evaporation and gas-vapor mixing system of the present invention consists of a multi-stage evaporation tower 30, a cascade adjustment system 36 for feeding liquid raw materials, a heater 34 and three nozzles 31, 32, 33.

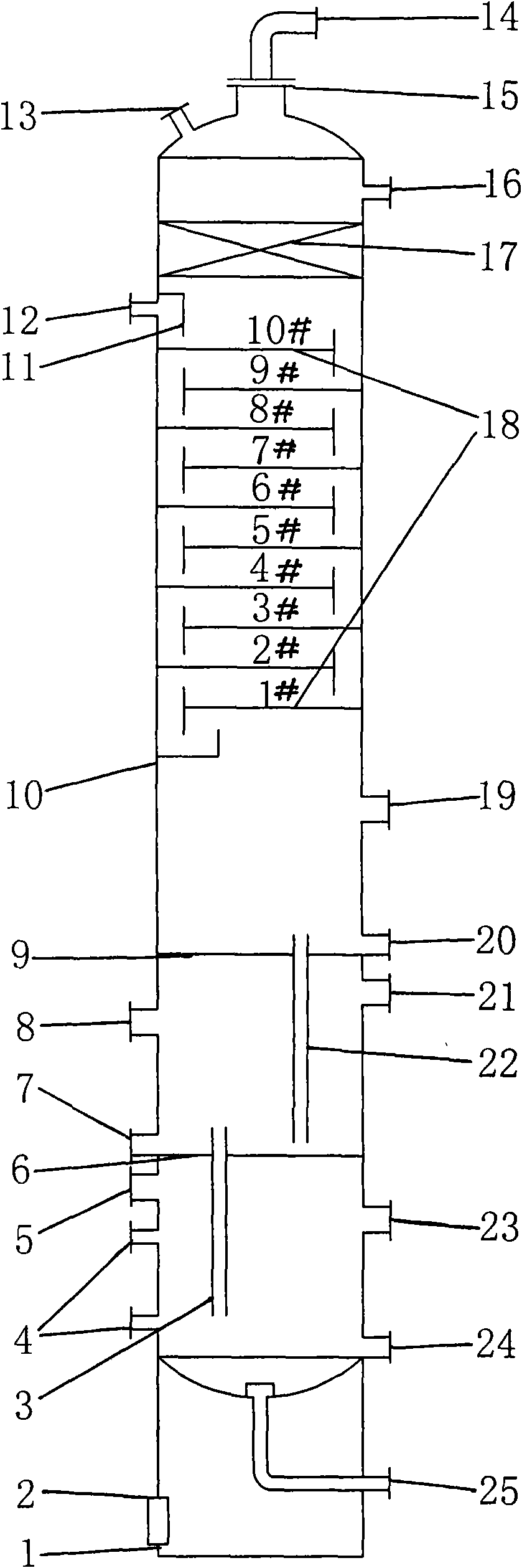

[0036] see figure 2 , The multi-stage evaporation tower 30 is composed of a tower base 1 and a tower body 10 . The tower body 10 is a tower body 10 divided into three sections by two broken tower plates 6, 9, and the downcomers 3, 22 connecting the upper and lower two sections of the tower body are arranged on the broken tower plates 6, 9. The tower base 1 and the tower body 10 are connected by welding, and all liquid evaporation and gas-liquid mixing steps are performed in the tower body 10 .

[0037] Inside the tower body, the broken tower plates 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com