SiO2 aerogel and preparation method thereof

A technology of airgel and gel method, applied in the field of airgel, can solve problems such as hole collapse, airgel skeleton shrinkage and cracking, and achieve the effect of preventing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

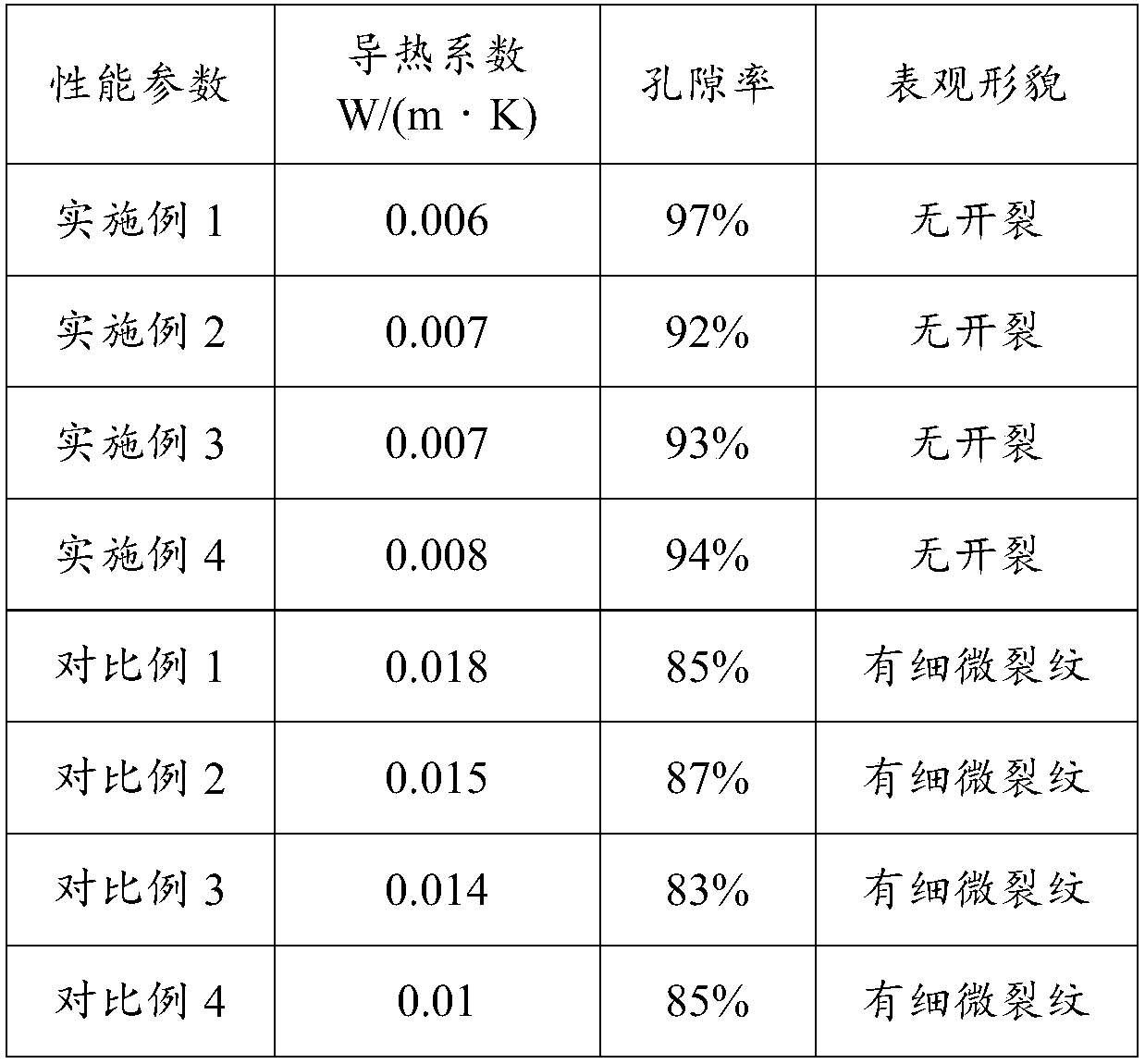

Examples

preparation example Construction

[0021] One aspect of the present invention provides a SiO 2 The preparation method of airgel, utilizes the SiO that adopts sol-gel method to prepare by supercritical drying method 2 The wet gel was dried to obtain SiO 2 Airgel, the supercritical drying includes: under an inert atmosphere and within the pressure range of 2-7MPa, gradually increase the pressure to perform gradient segmental drying, and then increase the pressure to 11-12MPa for constant pressure drying, and the drying temperature is 270 -280°C.

[0022] SiO provided by the present invention 2 In the preparation method of aerogel, the SiO 2 The wet gel is dried to make the SiO 2 The ethanol in the wet gel can be fully evaporated to prevent SiO 2 Wet gels crack during drying. This drying treatment method will not damage SiO 2 The three-dimensional network structure of the airgel to prevent the collapse of the pores in the airgel. SiO with a complete network structure can be obtained by using the dry treatm...

Embodiment 1

[0040] This example is a SiO 2 The preparation method of airgel, comprises the following steps:

[0041] Step a) Preparation of SiO by sol-gel method 2 Wet gel: hydrochloric acid is added dropwise in water glass for catalytic reaction, and after the reaction is completed, SiO is obtained by aging, alcohol replacement and modification. 2 wet gel;

[0042] Among them, the weight ratio of sodium silicate to water in water glass is 1:3, the concentration of hydrochloric acid is 0.03mol / L, the aging temperature is 50°C, and the aging time is 24h;

[0043] Step b) using the supercritical drying method to prepare the SiO obtained by the sol-gel method 2 The wet gel was dried to obtain SiO 2 Airgel, the supercritical drying method in this embodiment is: first dry under the pressure of 2.5MPa for 40min, then dry under the pressure of 3.5MPa for 50min, then dry under the pressure of 4.5MPa for 50min, and then dry it under the pressure of 5.5MPa Dry under the pressure of MPa for 60m...

Embodiment 2

[0046]This example is a SiO 2 The preparation method of airgel, comprises the following steps:

[0047] Step a) Preparation of SiO by sol-gel method 2 Wet gel: hydrochloric acid is added dropwise in water glass for catalytic reaction, and after the reaction is completed, SiO is obtained by aging, alcohol replacement and modification. 2 wet gel;

[0048] Among them, the weight ratio of sodium silicate to water in water glass is 1:4, the concentration of hydrochloric acid is 0.04mol / L, the aging temperature is 55°C, and the aging time is 22h;

[0049] Step b) using the supercritical drying method to prepare the SiO obtained by the sol-gel method 2 The wet gel was dried to obtain SiO 2 Airgel, the supercritical drying method in this embodiment is: first dry under the pressure of 3.5MPa for 50min, then dry under the pressure of 5MPa for 60min, and then dry under the pressure of 6MPa for 40min to complete the gradient segmental drying; After the gradient drying is completed, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com