Patents

Literature

79 results about "Absolute zero" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Absolute zero is the lowest limit of the thermodynamic temperature scale, a state at which the enthalpy and entropy of a cooled ideal gas reach their minimum value, taken as 0°. The fundamental particles of nature have minimum vibrational motion, retaining only quantum mechanical, zero-point energy-induced particle motion. The theoretical temperature is determined by extrapolating the ideal gas law; by international agreement, absolute zero is taken as −273.15° on the Celsius scale (International System of Units), which equals −459.67° on the Fahrenheit scale (United States customary units or Imperial units). The corresponding Kelvin and Rankine temperature scales set their zero points at absolute zero by definition.

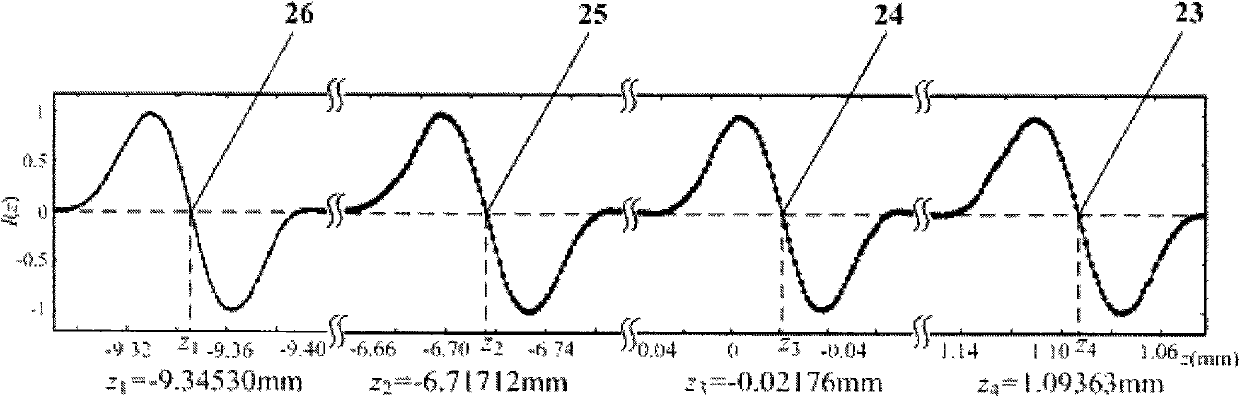

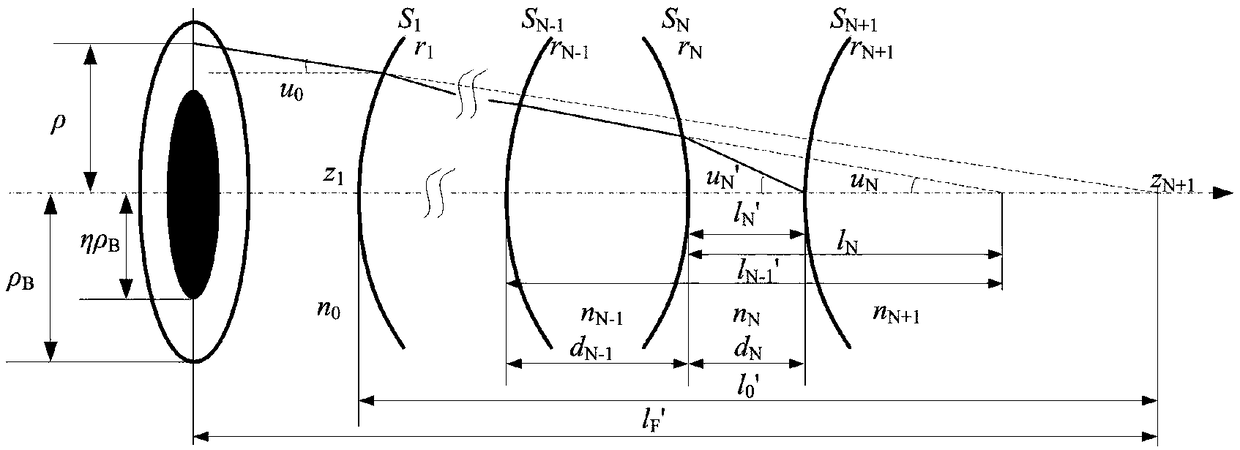

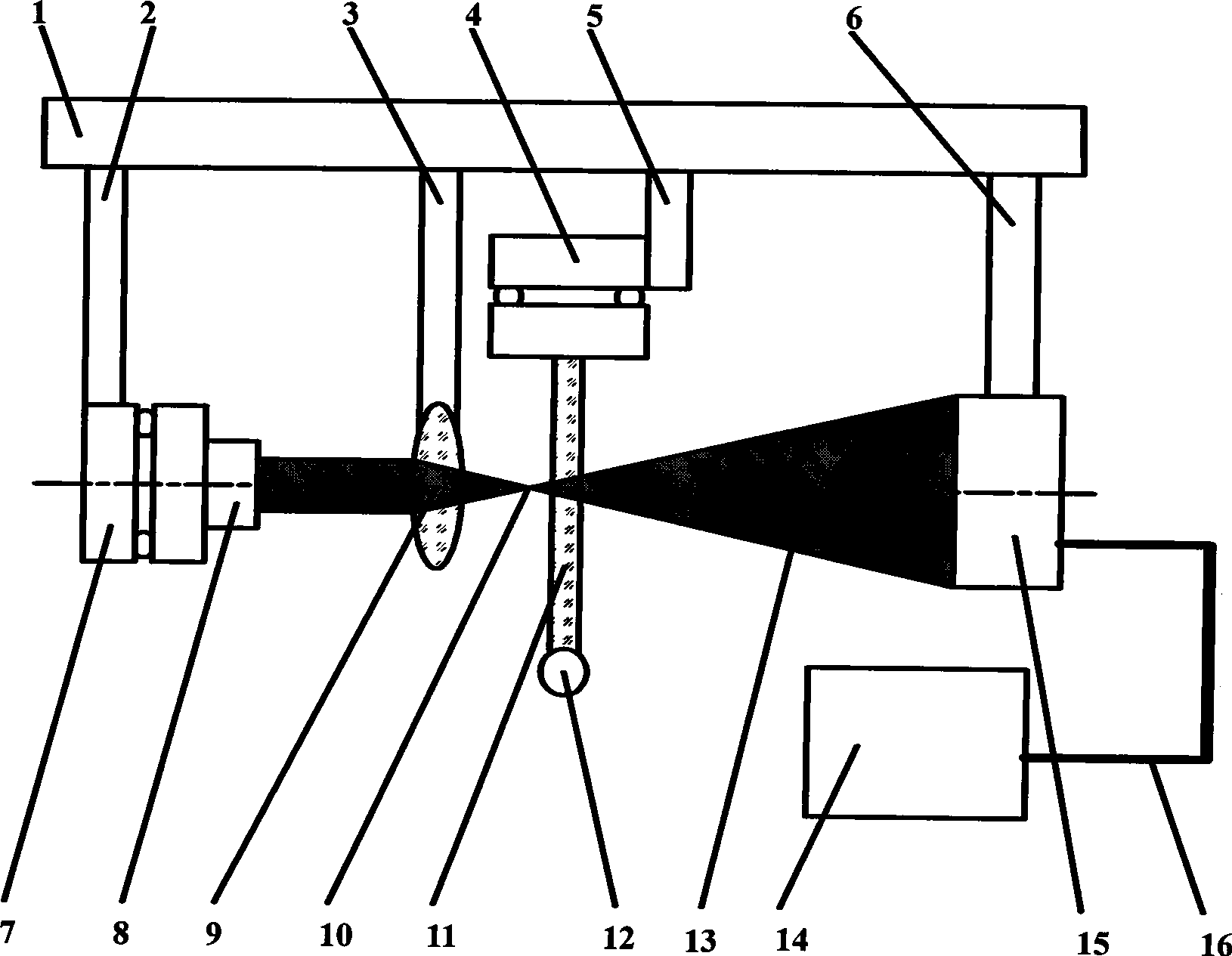

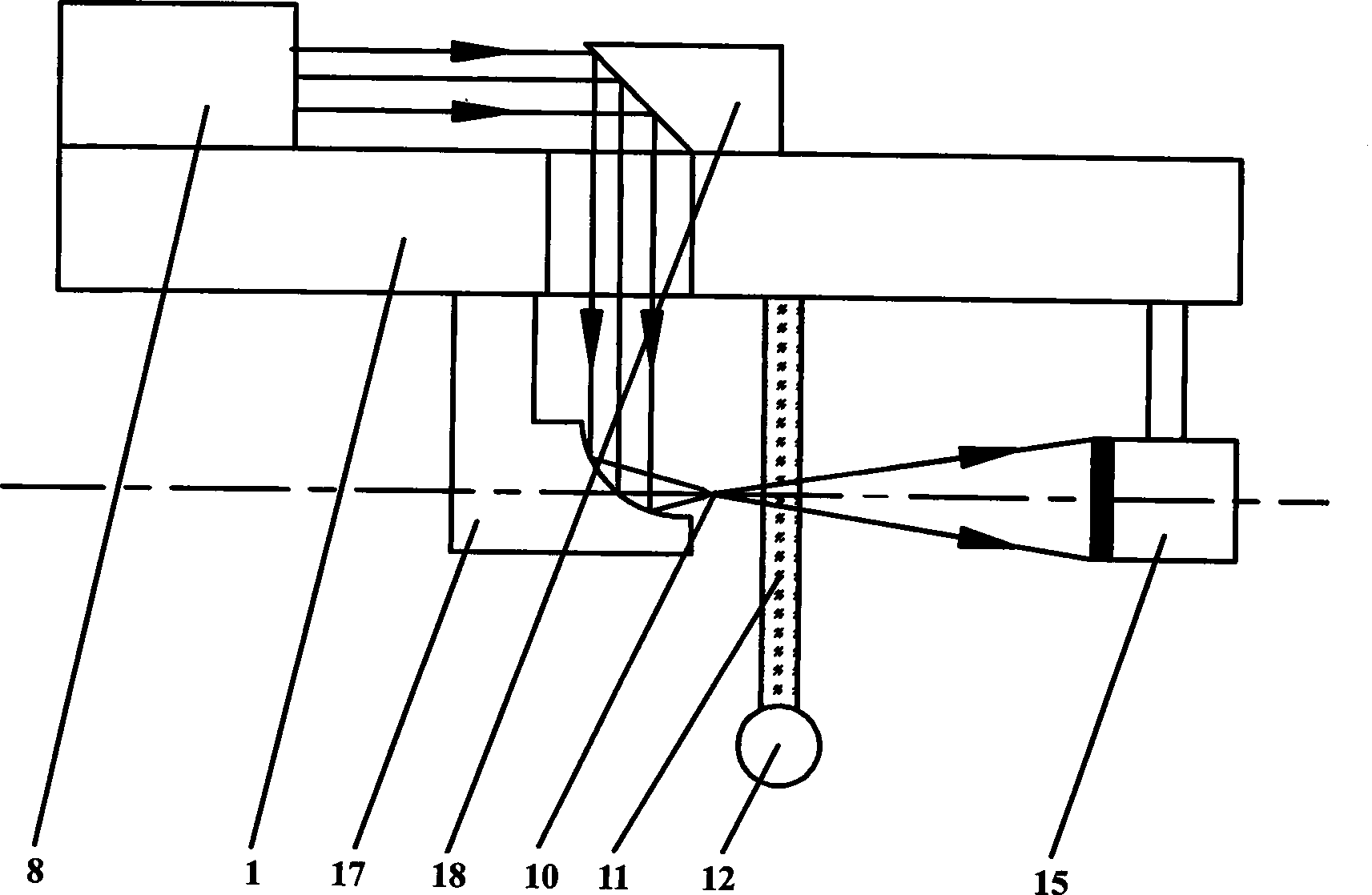

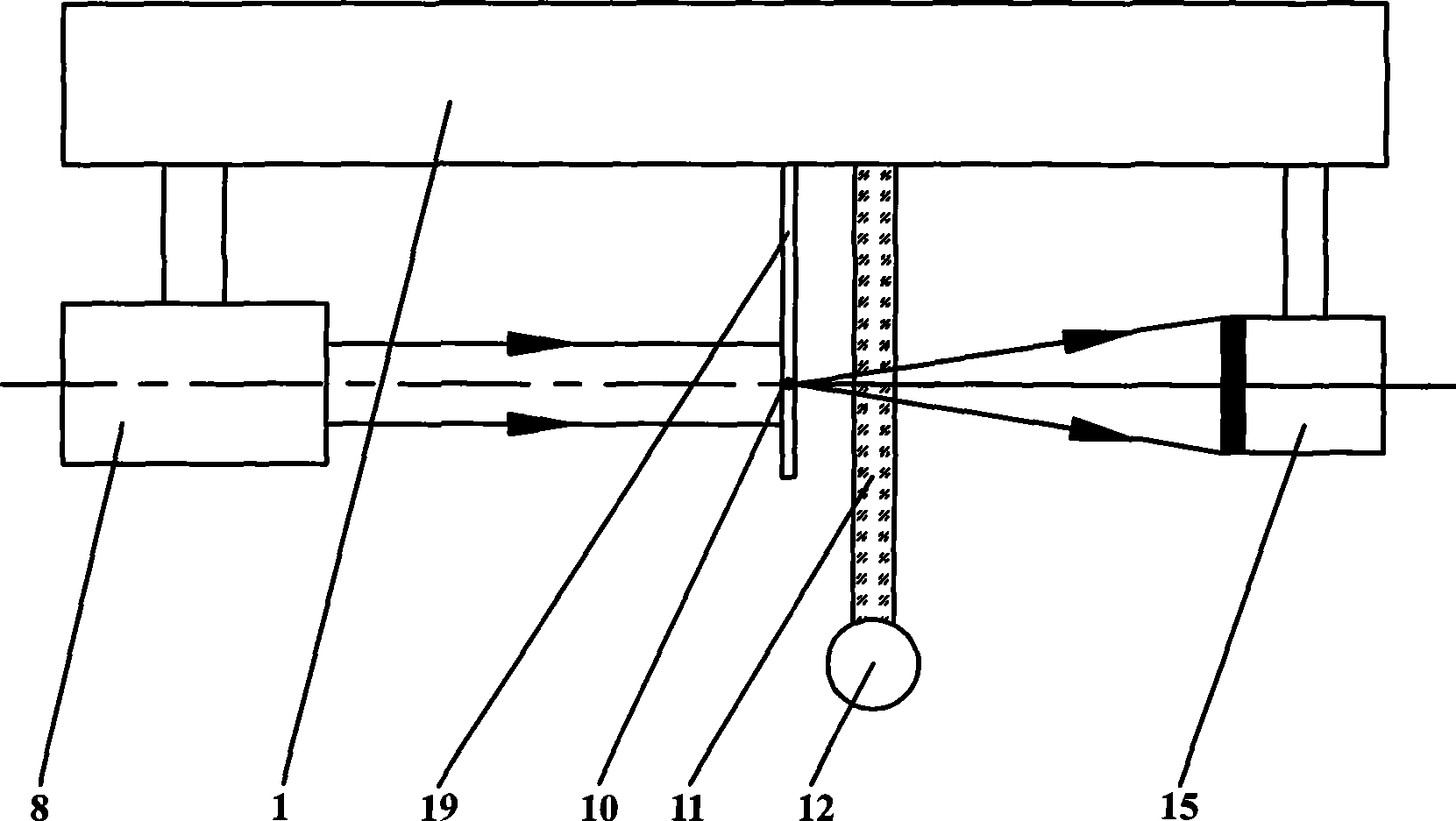

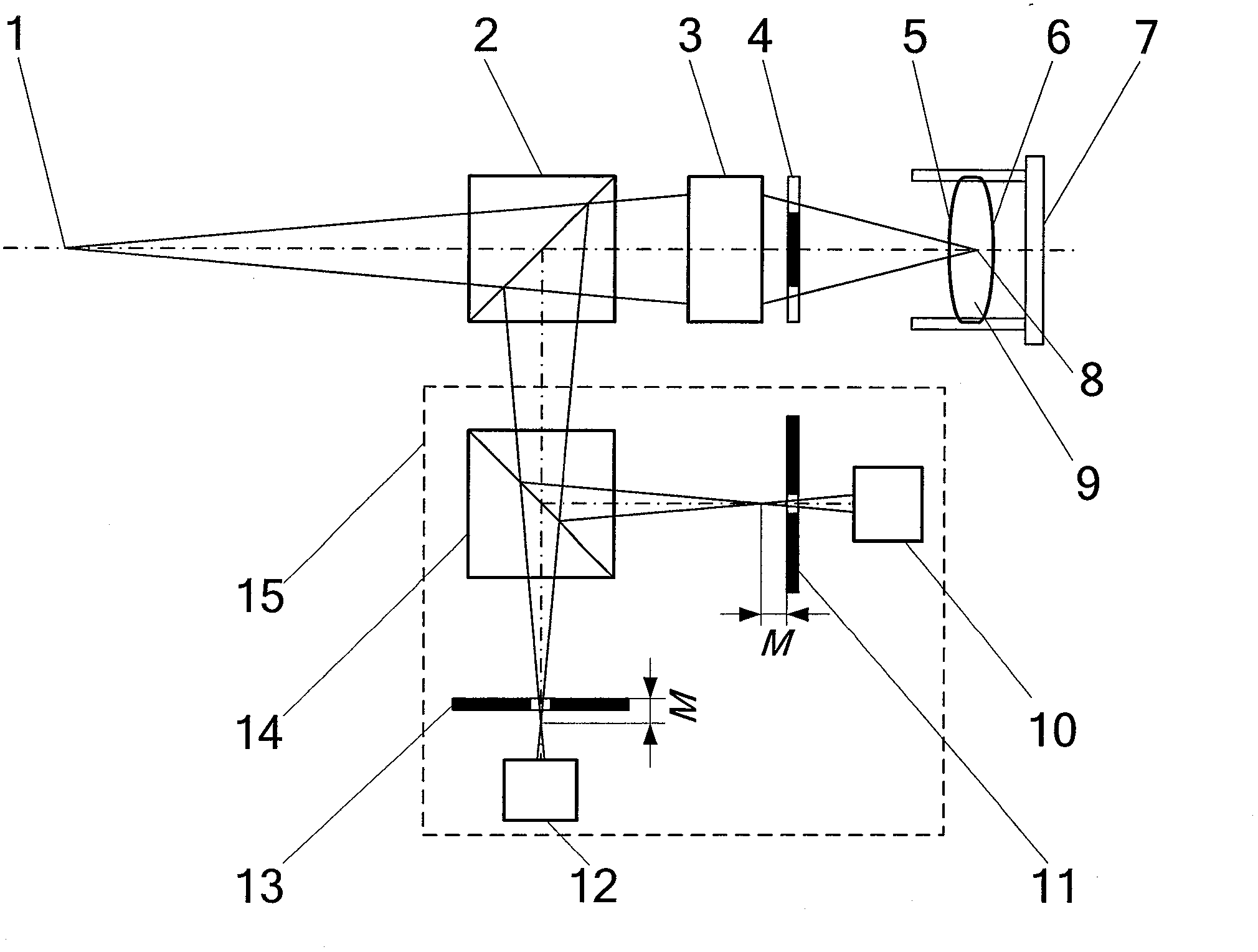

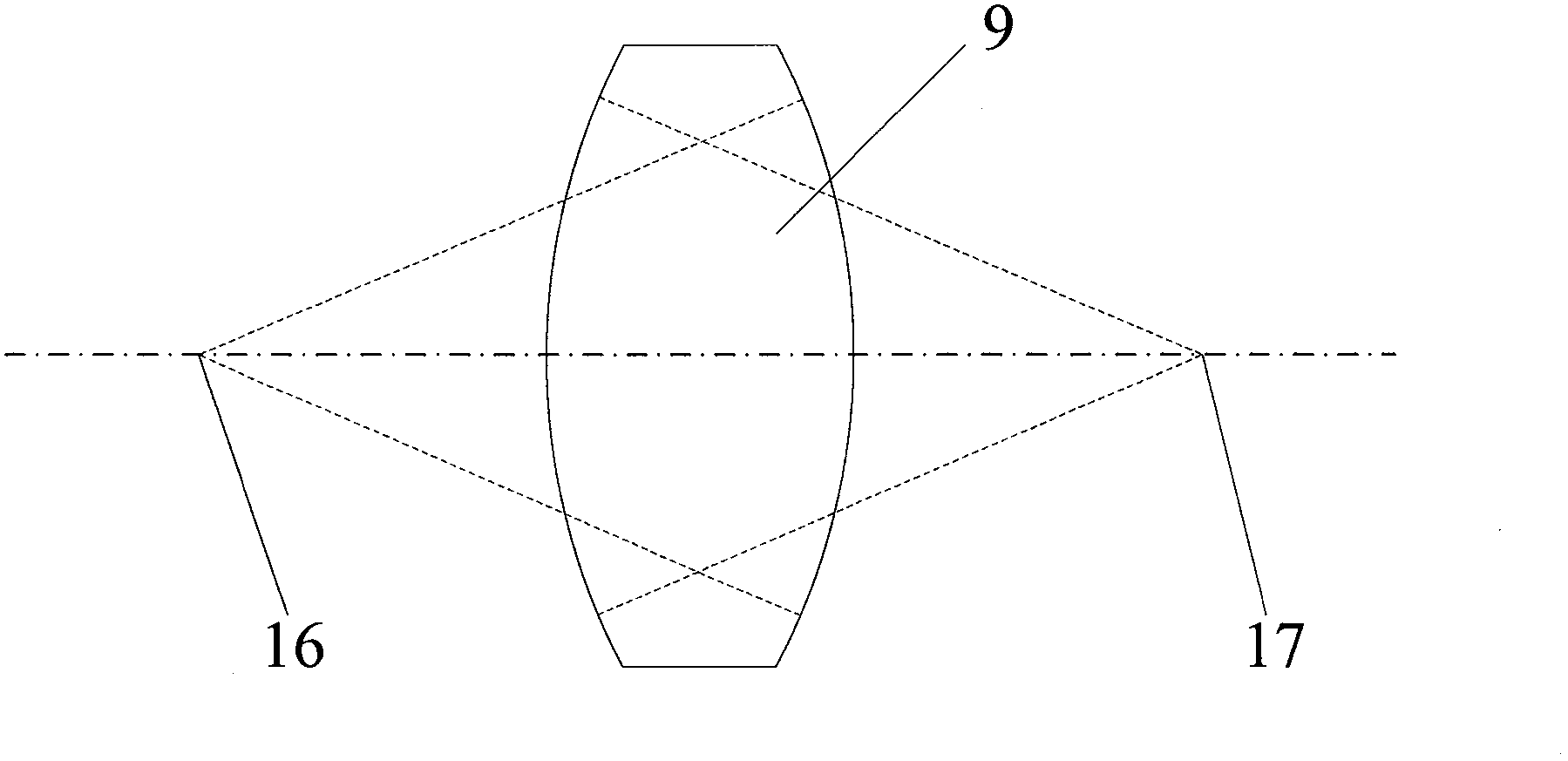

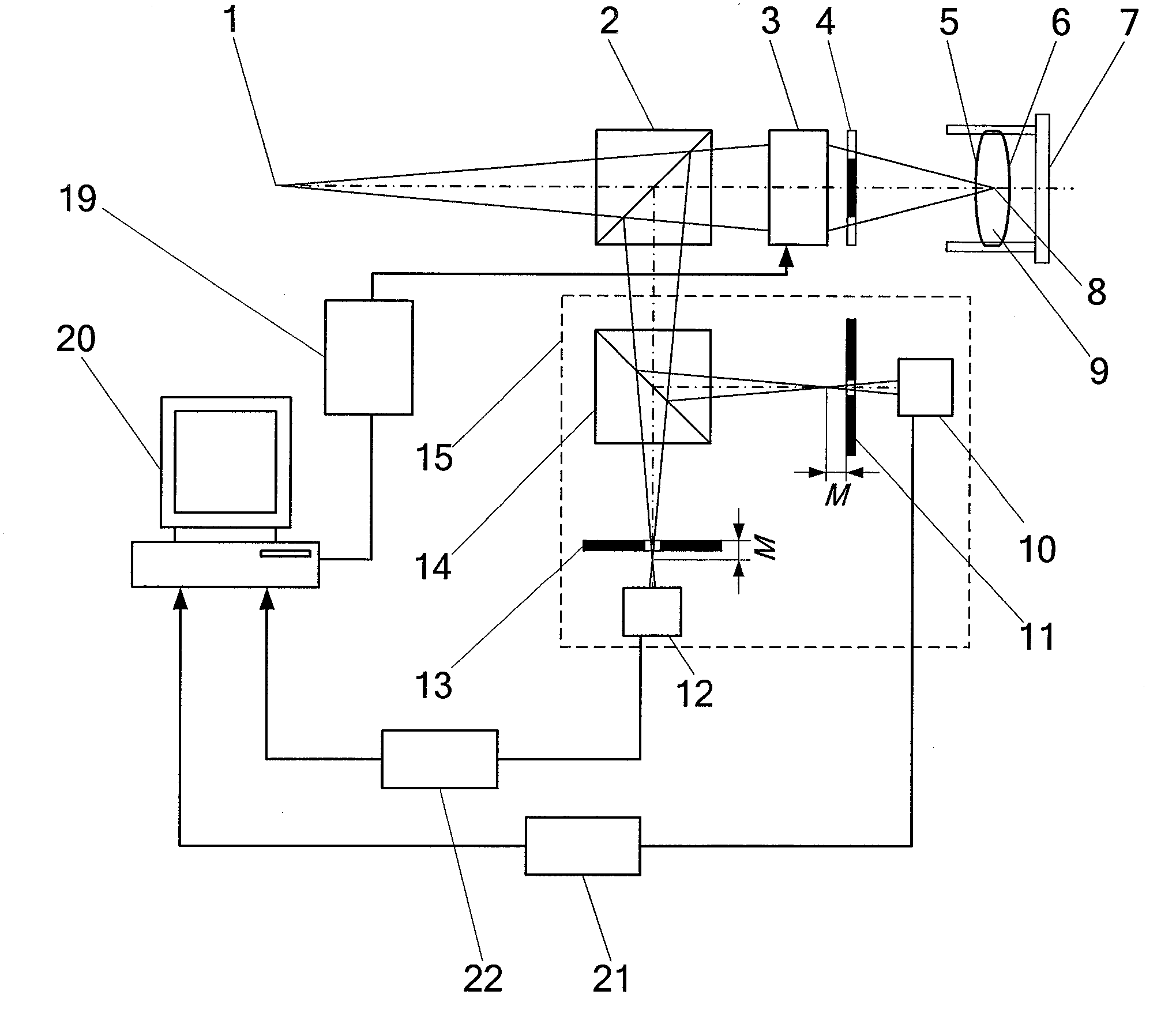

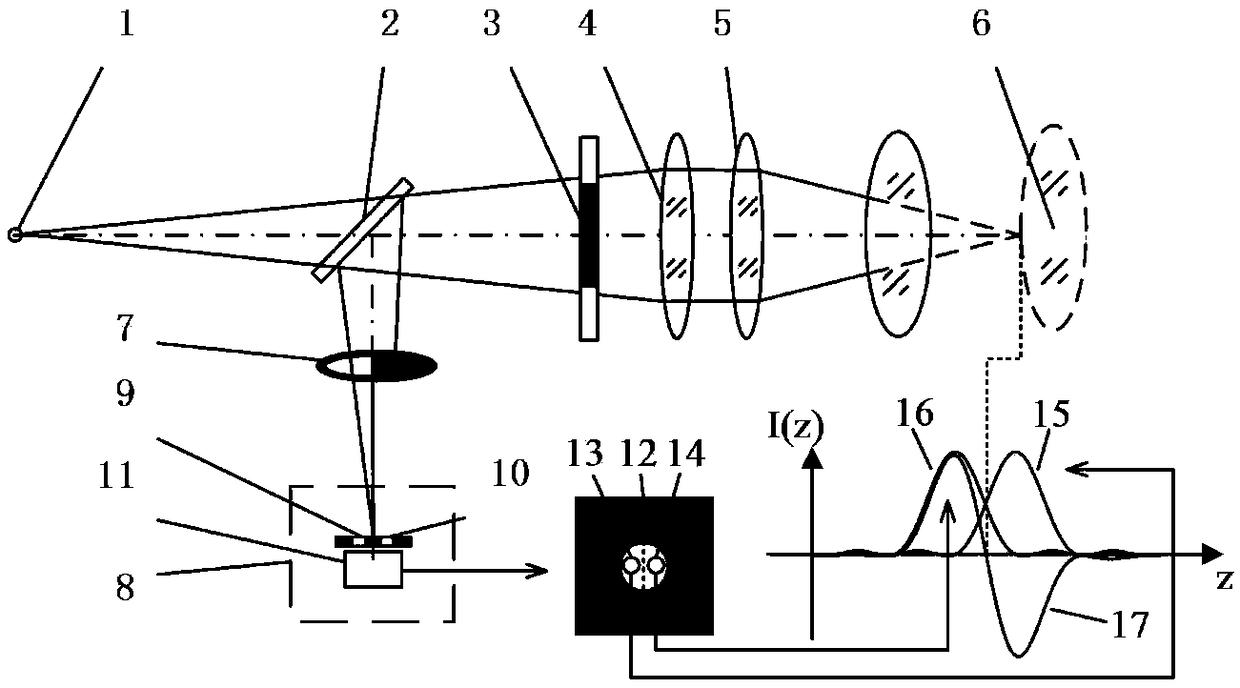

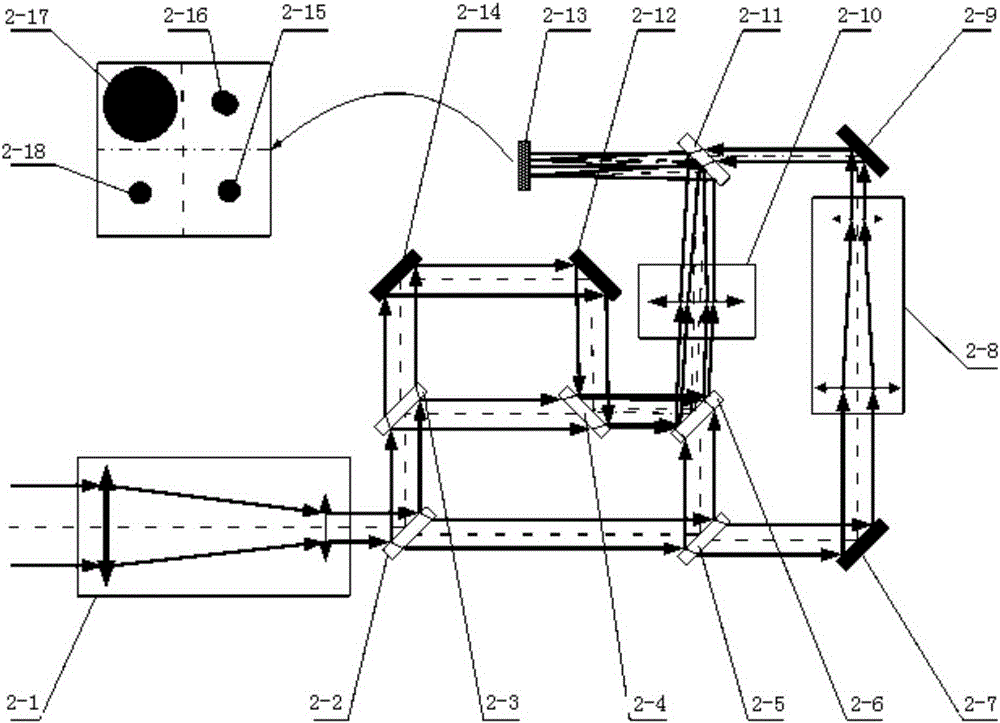

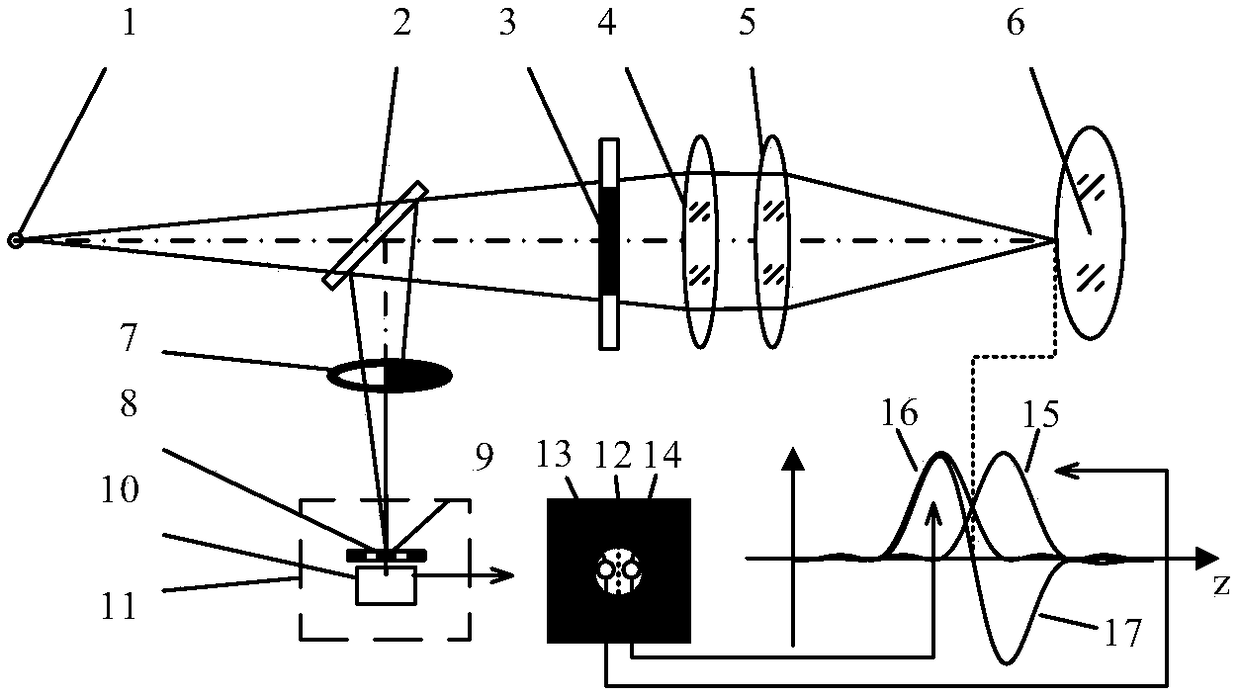

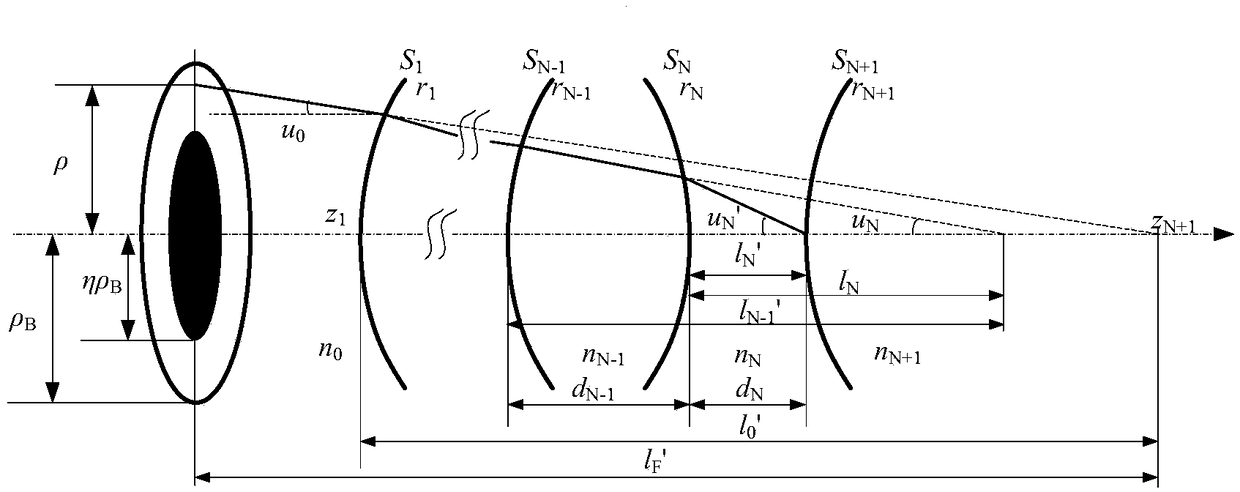

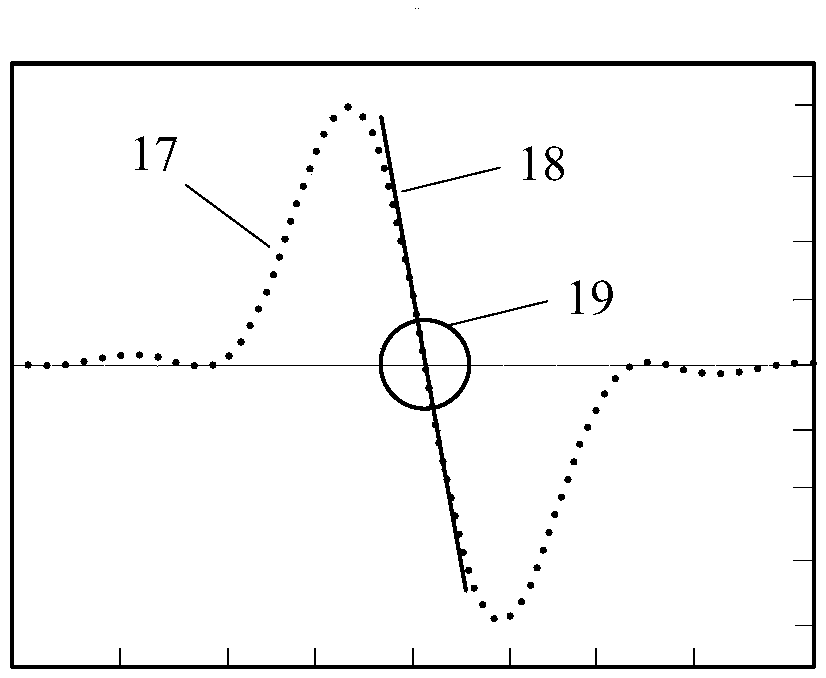

Lens refractive index and thickness measuring method and device based on differential confocal technology

InactiveCN101769821AHigh measurement accuracySimple and fast operationUsing optical meansTesting optical propertiesOptical axisRefractive index

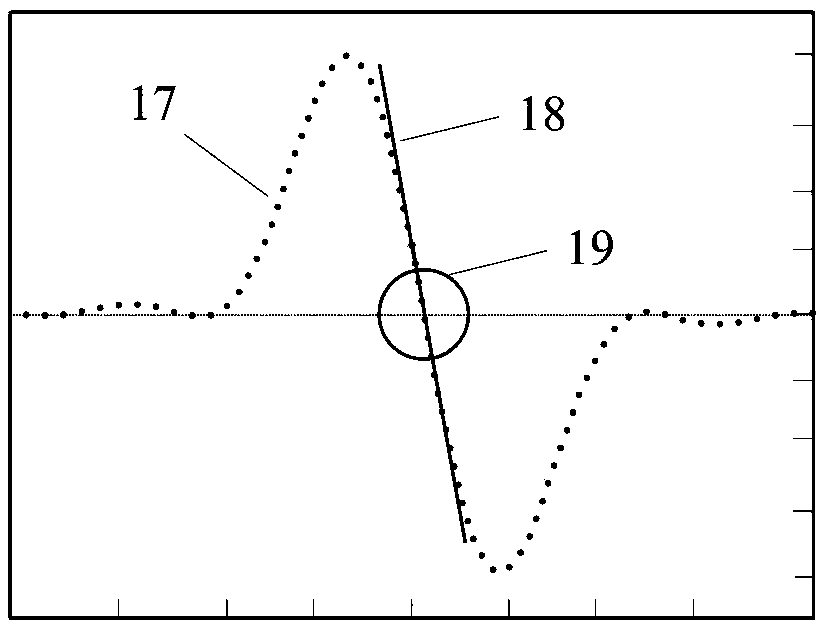

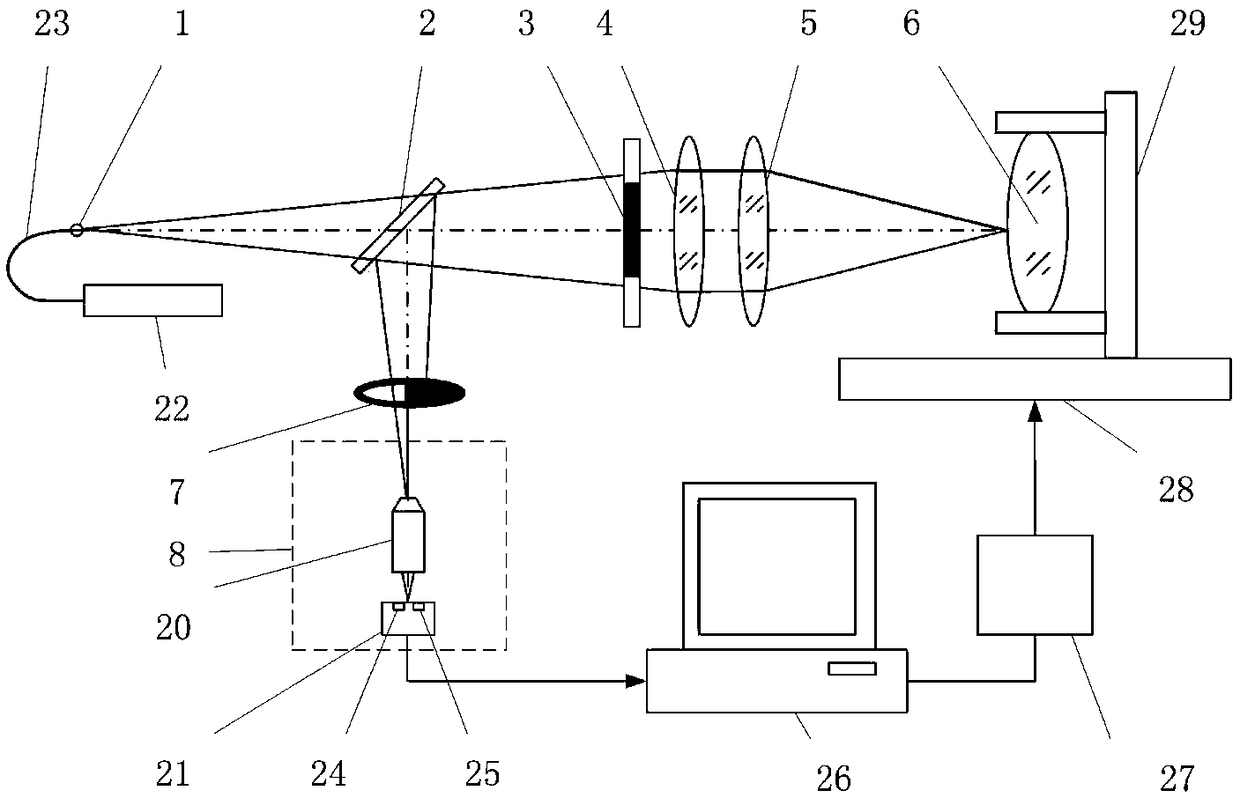

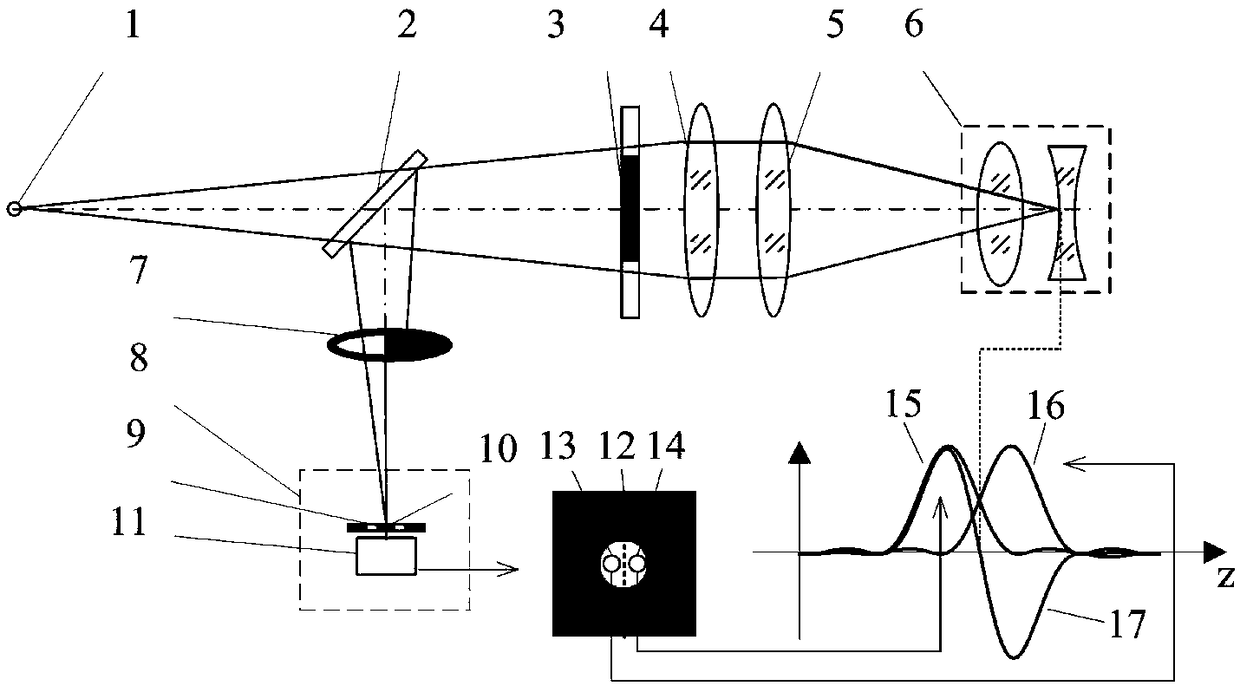

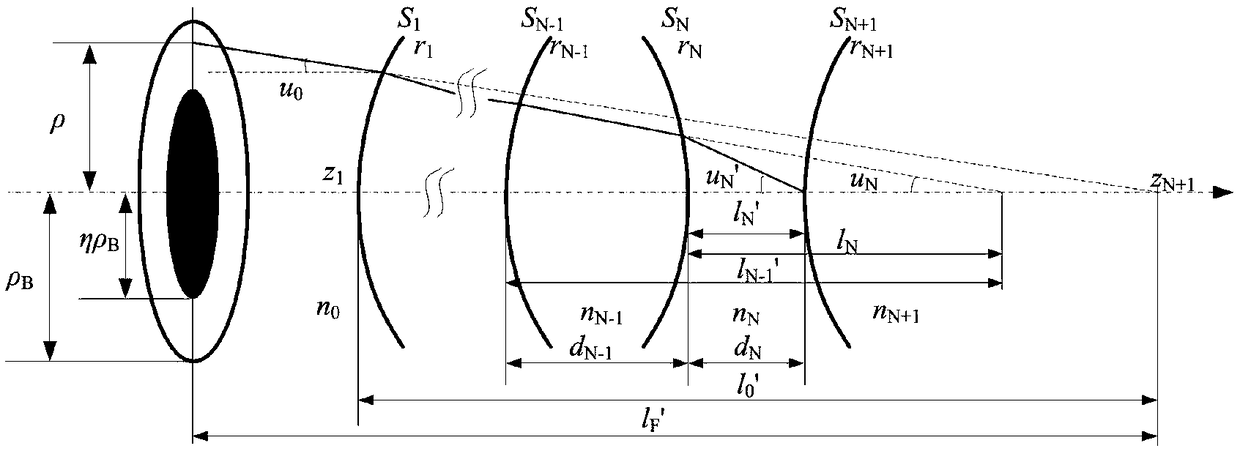

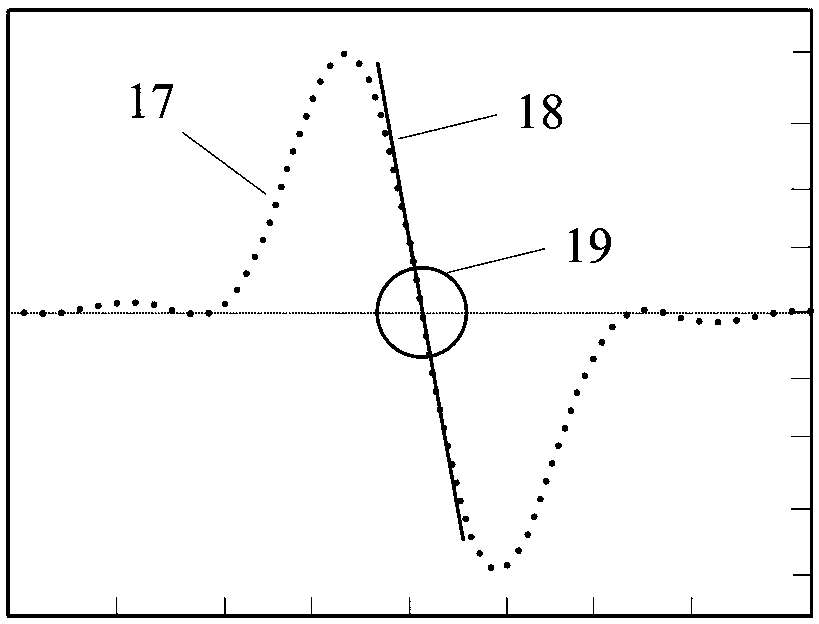

The invention relates to a lens refractive index and thickness measuring method and a device based on the differential confocal technology, which belong to the technical field of optical precise measurement. The invention is used for the high-precision measurement of the refractive index and the thickness of a spherical lens. The invention is based on a ray tracing principle, utilizes an absolute zero point of a laser differential confocal responding curve for accurately determining the intersection point of the front surface of the lens to be measured and an optical axis, the intersection point of the back surface of the lens to be measured and the optical axis, and the position of a measuring lens with or without the lens to be measured, then, the position of the measuring lens and the curvature radius, the focal length and the pupil of the measuring lens which are measured in advance are utilized for carrying out facet ray tracing calculation on two spherical surfaces of the lens to be measured and the reference reflecting surface, and finally, the high-precision nondestructive measurement on the refractive index and the thickness of the lens to be measured is realized. The invention has the obvious advantages of simple operation, high measuring precision, strong environmental disturbance resistance capability and the like, and can be widely applied to the refractive index and thickness measurement of various spherical lenses, particularly the refractive index and thickness measurement field of thin lenses.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

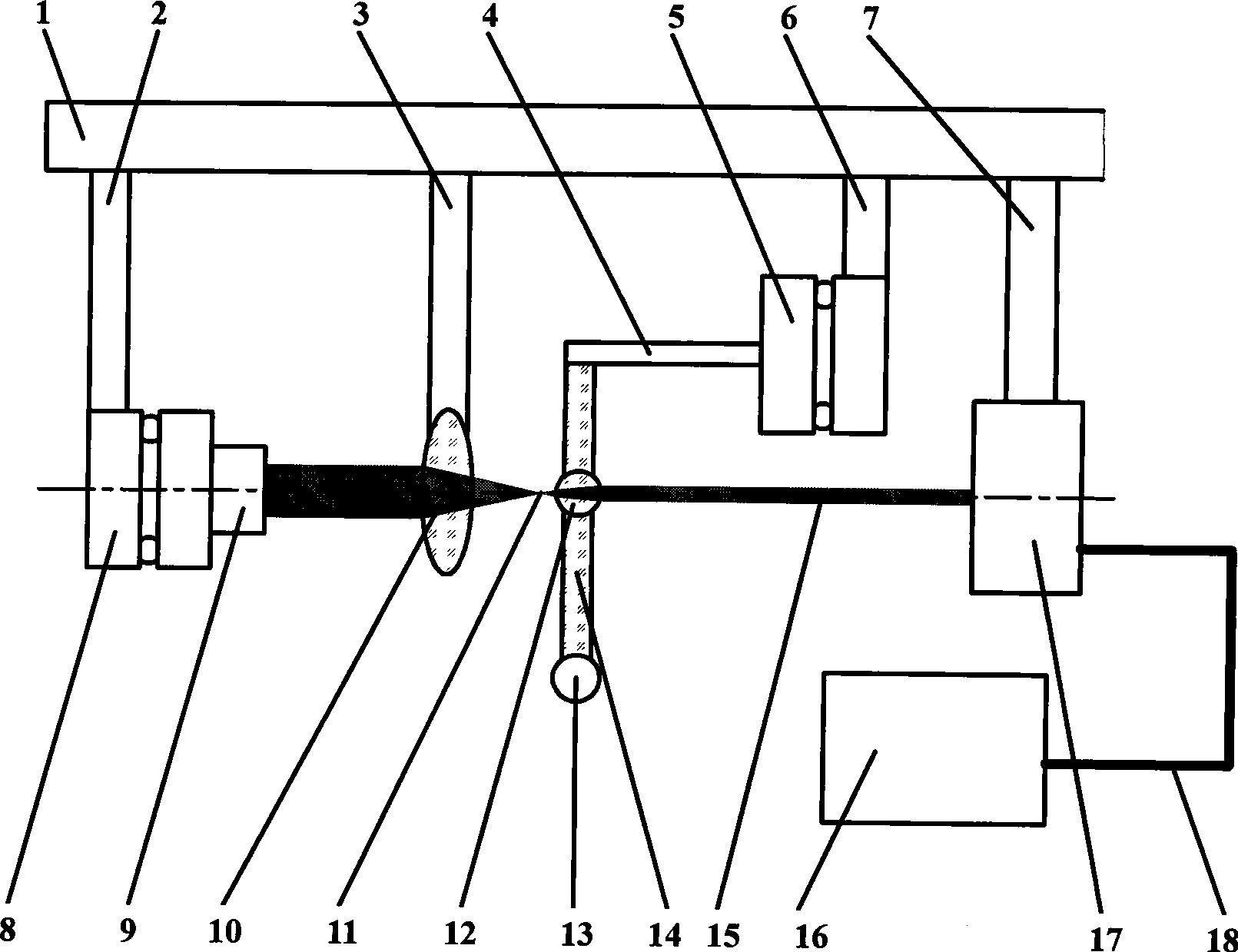

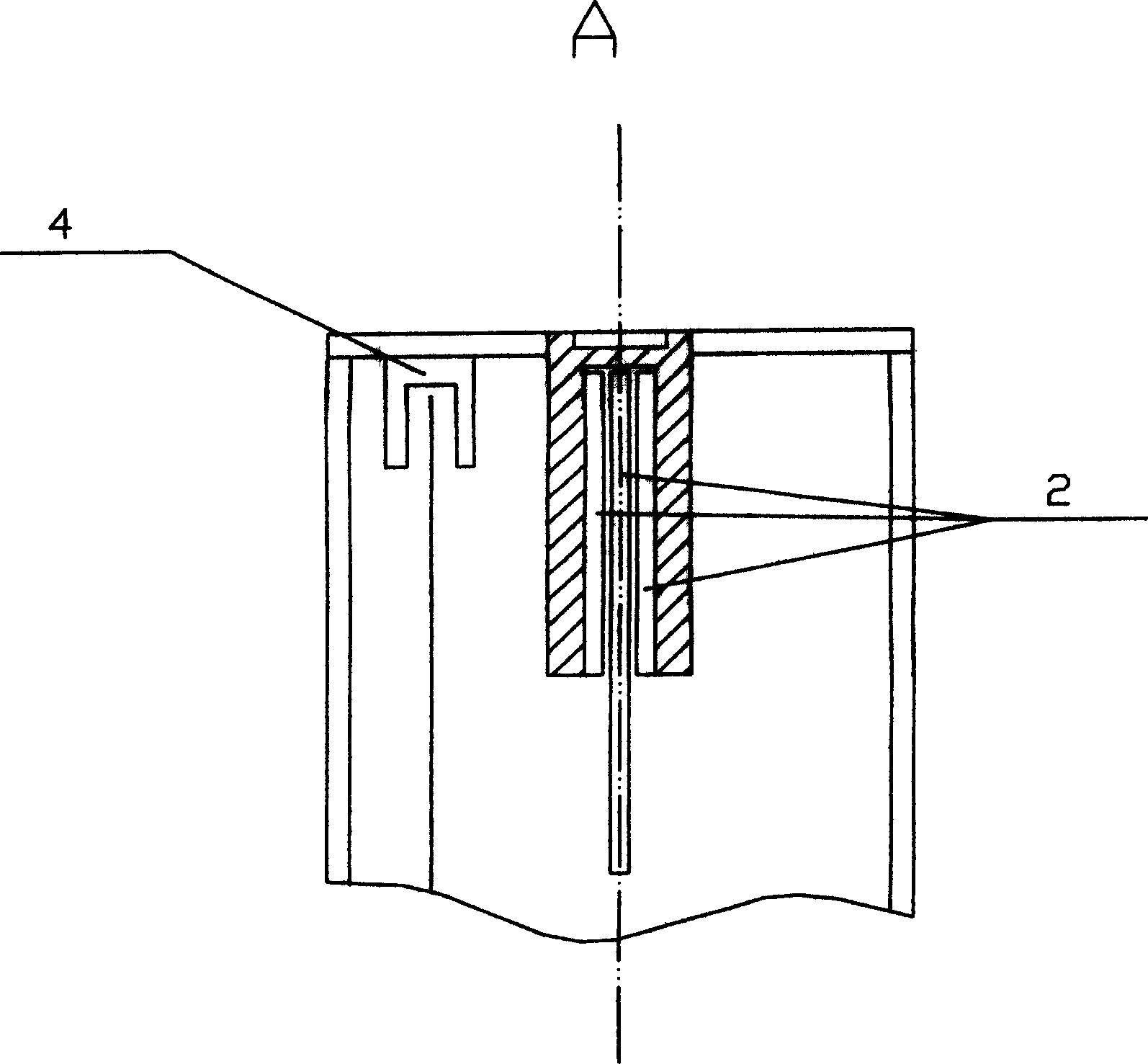

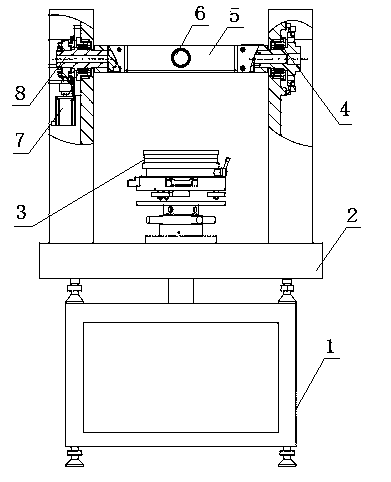

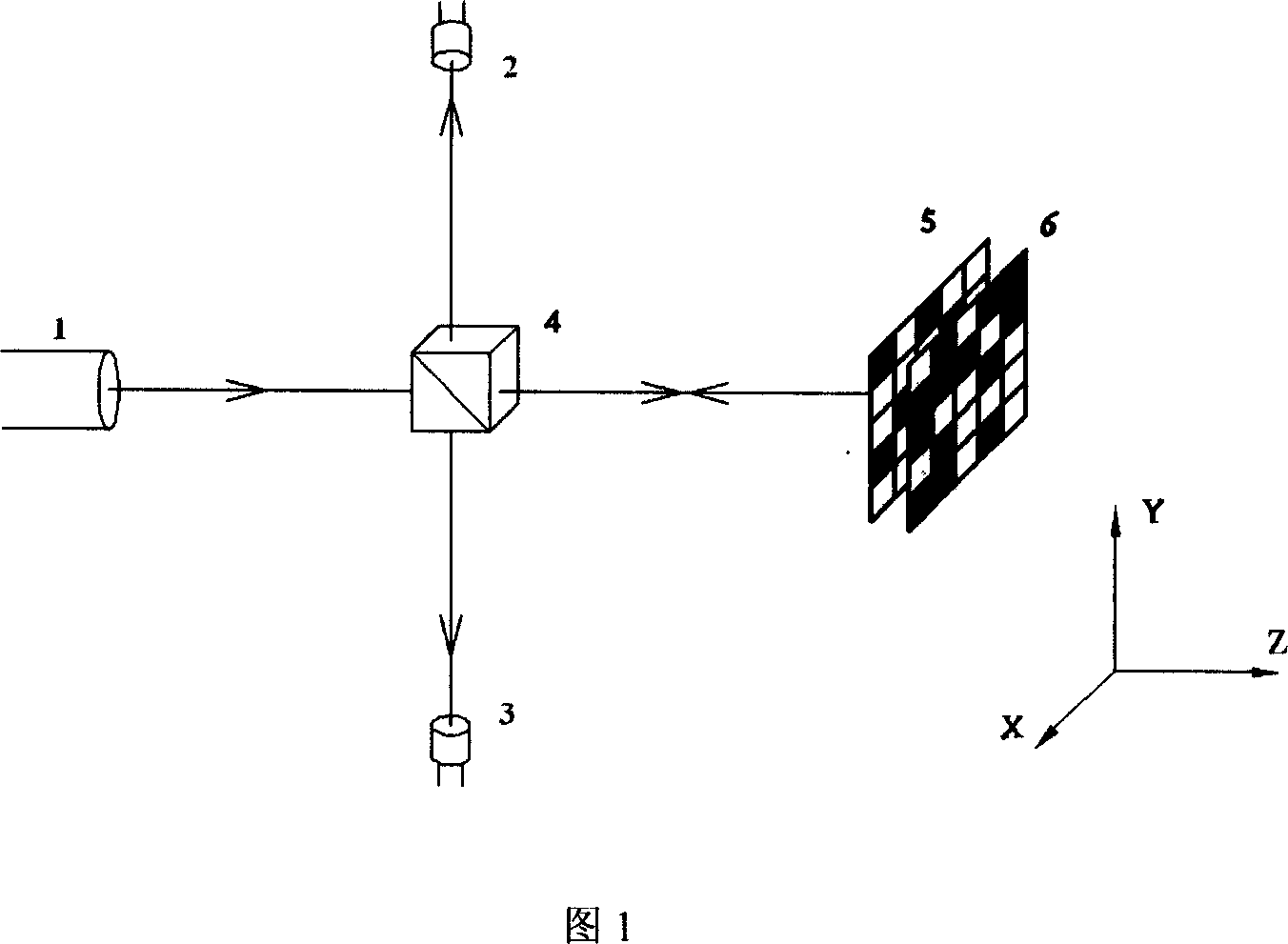

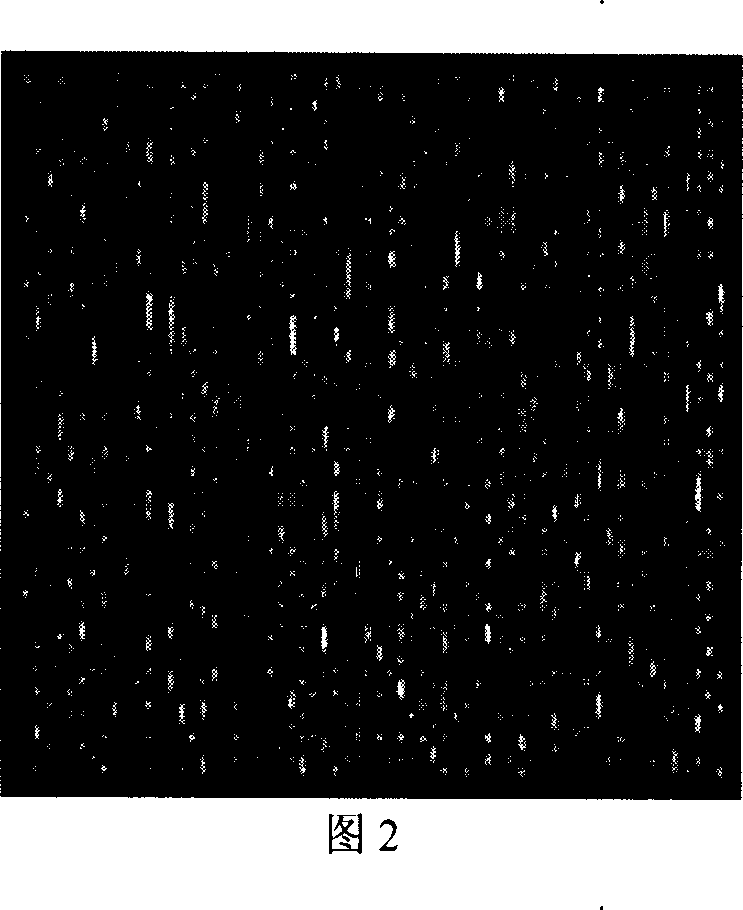

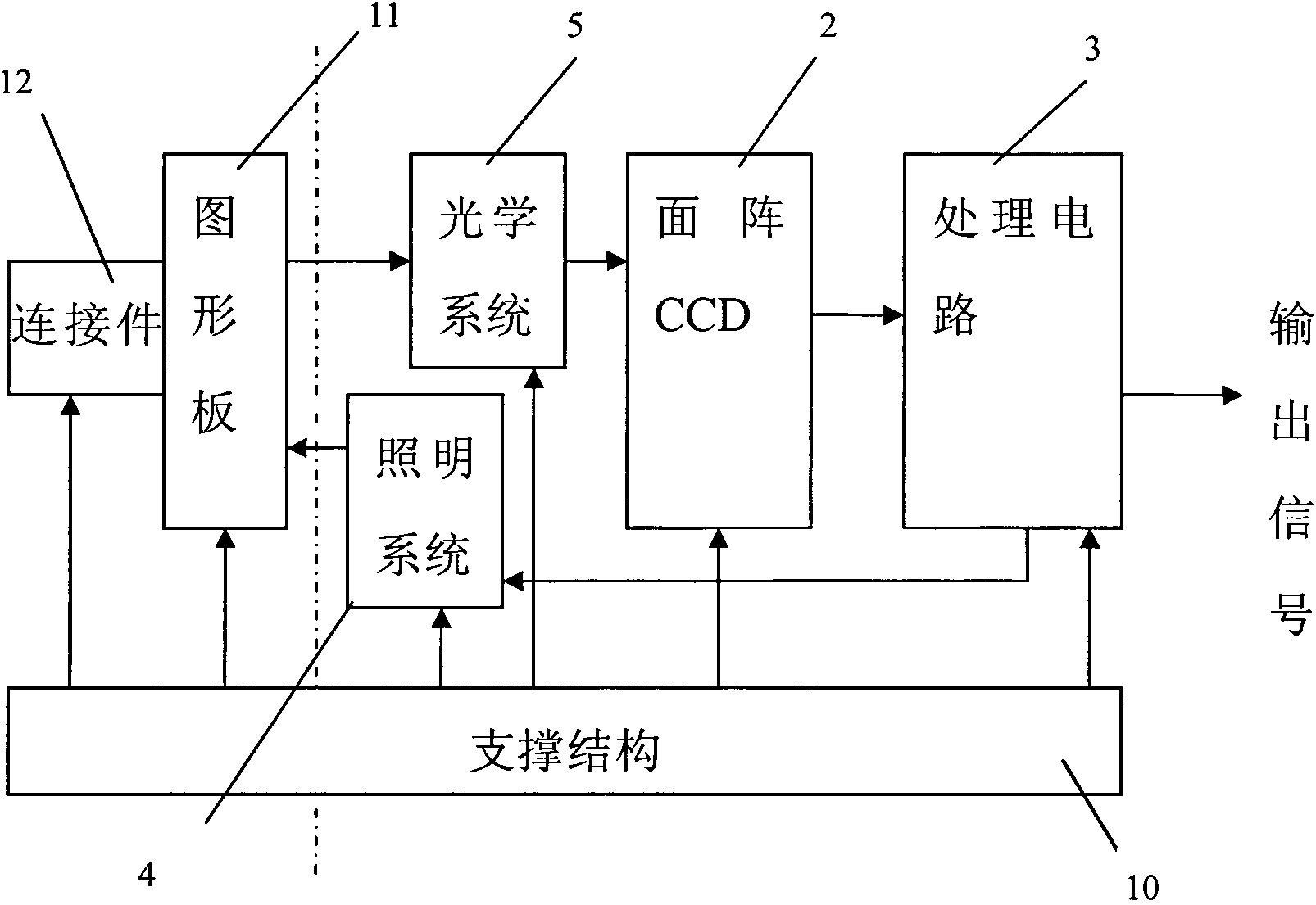

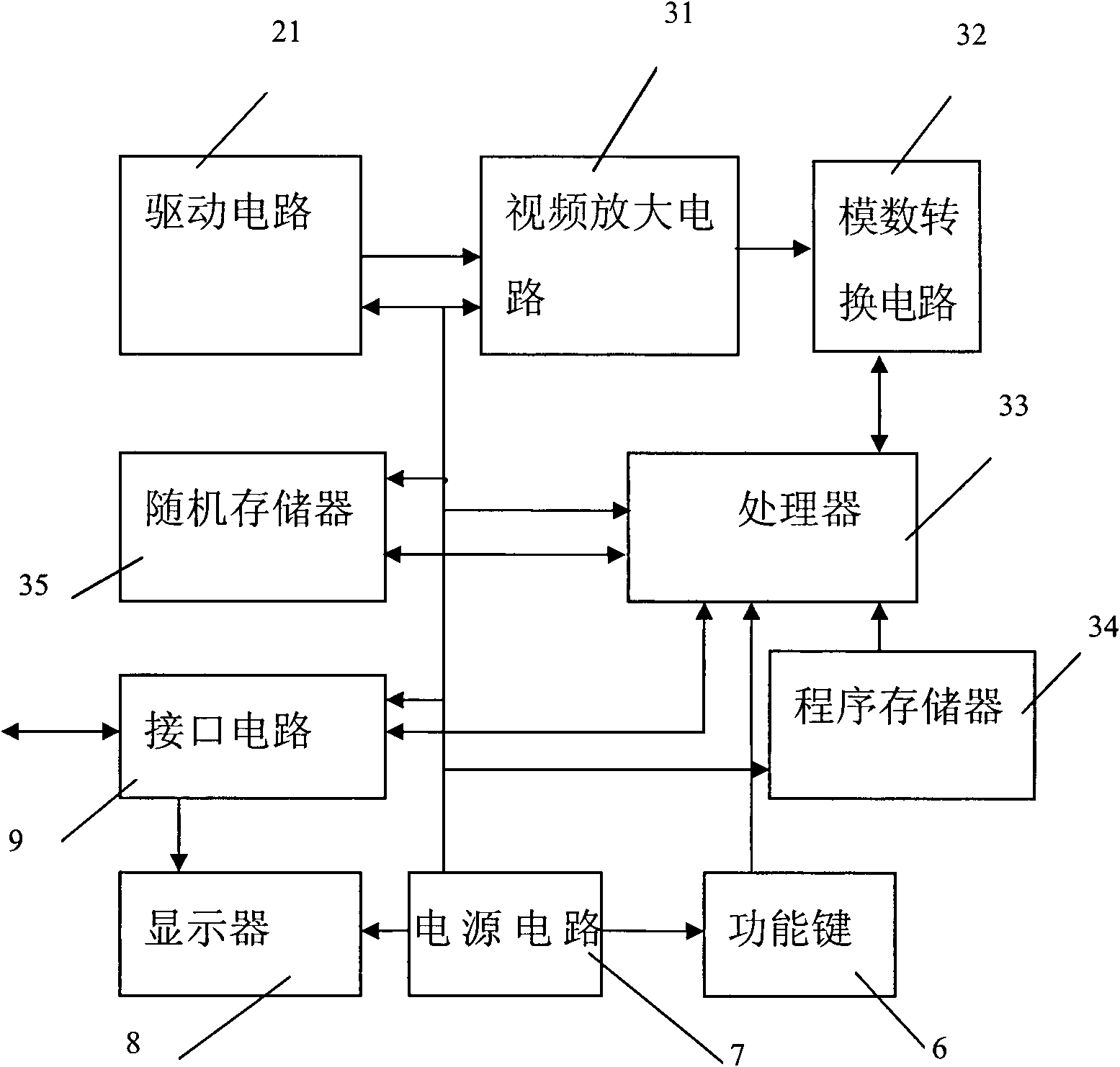

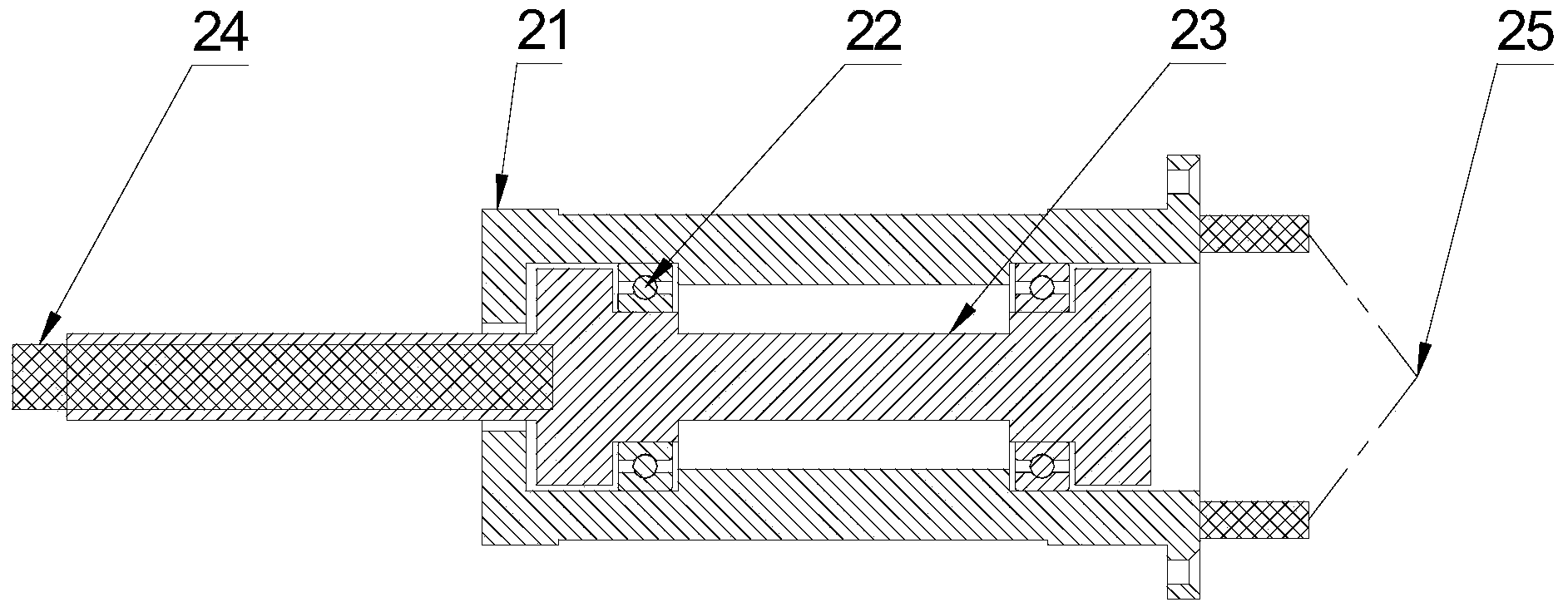

Sensing method and device for micro inner cavity size and three-dimensional coordinate based on two-dimensional micro-focus collimation

InactiveCN101520313AGenerate displacement sensitivityEfficient extractionUsing optical meansPoint lightThree dimensional measurement

The invention relates to a sensing method and a device for micro inner cavity size and three-dimensional coordinate based on two-dimensional micro-focus collimation, belonging to the technical filed of precise instrument manufacture and measurement, in particular to a sensing method and a device for micro and complex inner cavity size and three-dimensional coordinate in the filed of sub-macroscopy, which is especially suitable for the three-dimensional detection of blind holes with large depth-diameter ratio. The device combines a micro spherical biconvex lens and an optical fiber probe measuring rod, and establishes a point light two-dimensional micro-focus collimation imaging light path by using the micro spherical biconvex lens, thereby realizing the high magnification and the sensing for the three-dimensional displacement of the optical fiber probe measuring rod by utilizing the light path. The invention has the characteristics of small measured force of a single optical fiber probe, easy miniaturization, large measured depth-diameter ratio, simple system structure, good real-time performance, easy practical application, and has obvious advantages for carrying out the quick and ultra-precise measurement and calibration for the inner cavity micro-size and the three-dimensional coordinate. Especially, the top of the resolution capability can reach the deep sub-nanometer magnitude, and an absolute zero position exists in the three-dimensional measurement direction.

Owner:HARBIN INST OF TECH

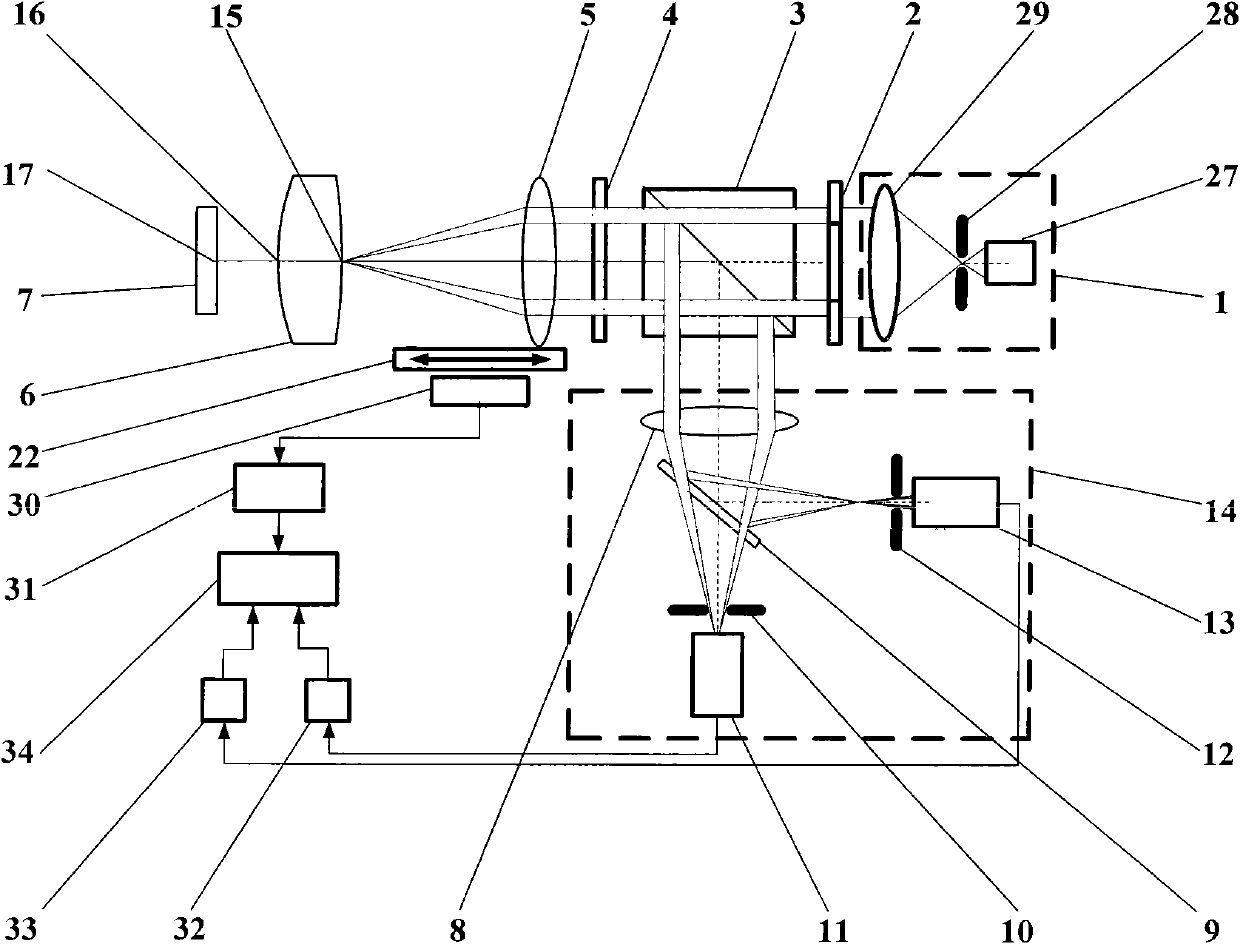

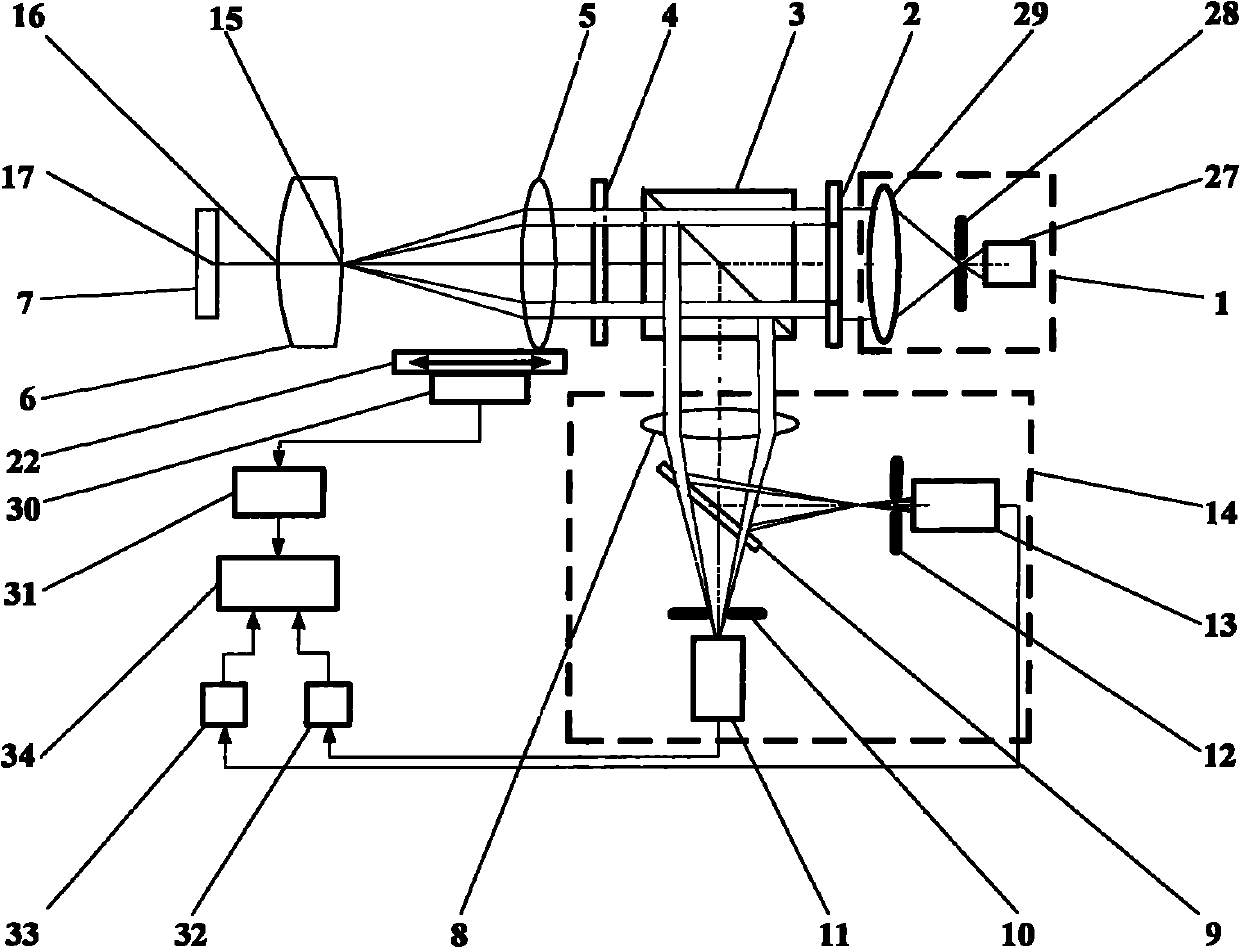

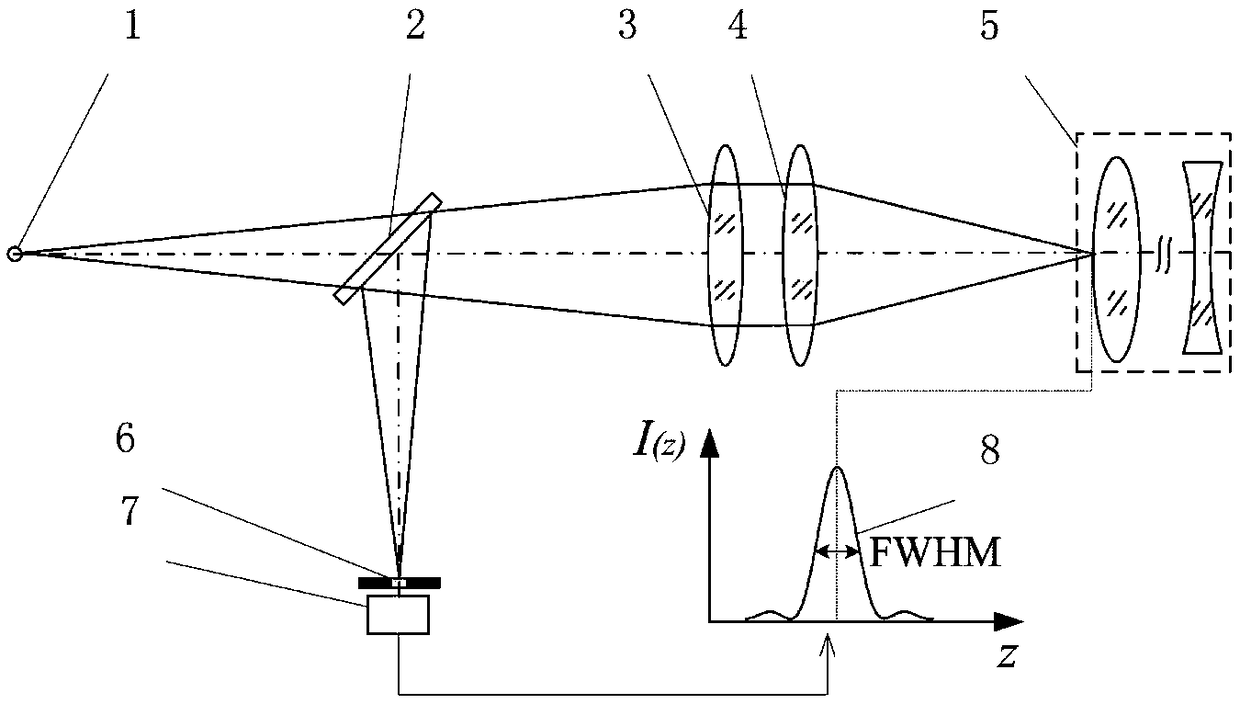

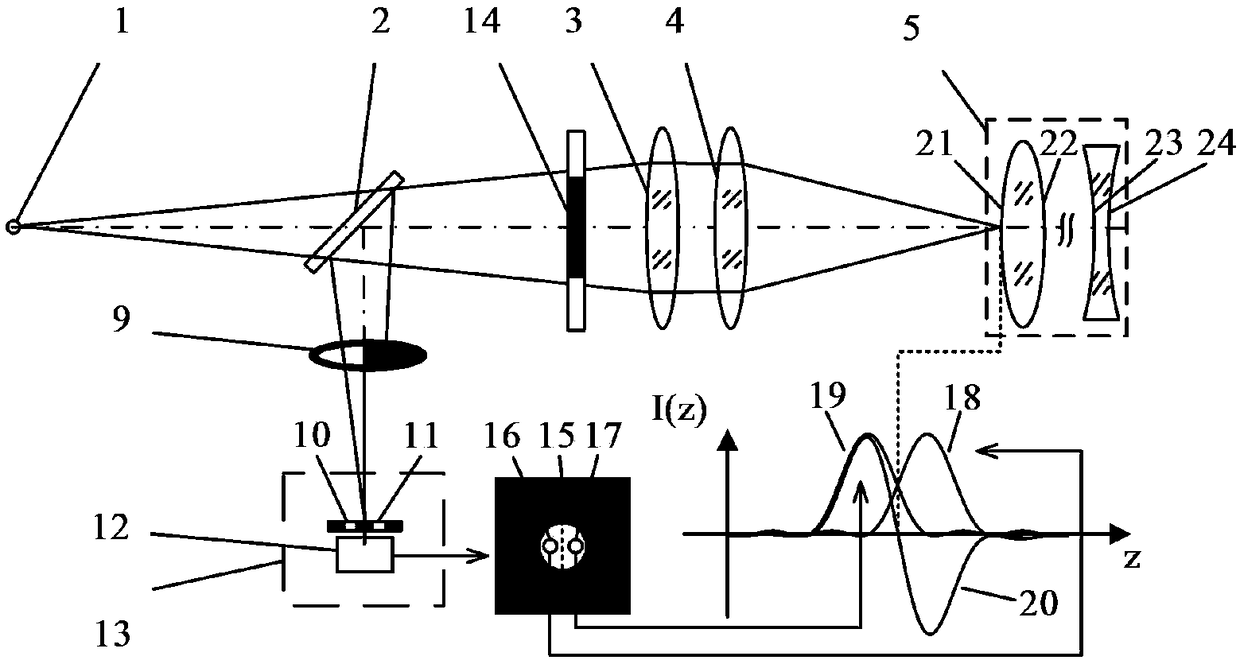

Laser differential confocal tomography focusing method and device

ActiveCN109253989AImprove focus accuracyReduce the impactAnalysis by material excitationLight beamTomography

The present invention relates to a laser differential confocal tomography focusing method and device, and relates to the technical field of optical imaging and detection. The method uses a rear pupilto block half of a measurement beam, uses a spectroscopic differential confocal detection system to detect the unblocked measurement beam, and uses an absolute zero point of a differential confocal response curve to achieve high precision tomographic focusing. The method organically combines a laser differential confocal technique and a ray tracing technique to establish a ray tracing and compensation model to eliminate influence among each fixed focal surface parameters, and achieves fast trigger of focus through data near a linearly fitting absolute zero point. The method can obtain the differential confocal response curve by using only one detector, and realizes the tomographic focusing through the absolute zero point of the differential confocal response curve, greatly simplifies system structure, in the same time, avoids error introduced by adjustment inaccuracy, and greatly improves precision of focusing. The method will provide a new technical approach to the field of confocal imaging / detection.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Sensing method and device for micro inner cavity and two-dimensional coordinate based on one-dimensional micro-focus collimation

InactiveCN101520314AHigh speed extractionEasy to handleUsing optical meansDiameter ratioMiniaturization

The invention relates to a sensing method and a device for micro inner cavity and two-dimensional coordinate based on one-dimensional micro-focus collimation, belonging to the technical filed of precise instrument manufacture and measurement, in particular to a sensing method and a device for micro and complex inner cavity structure size and two-dimensional coordinate in the filed of sub-macroscopy, which is especially suitable for the measurement of micro-holes with large depth-diameter ratio. By using the structure characteristics of super large curvature and micro-cylindrical lens of an optical fiber probe measuring rod, a point light source one-dimensional micro-focus collimation imaging light path is established, thereby realizing the high magnification and the sensing of the two-dimensional displacement of the optical fiber probe measuring rod by utilizing the light path. The invention has the characteristics of small measured force of a single optical fiber probe, easy miniaturization, large measured depth-diameter ratio, simple system structure, good real-time performance, easy practical application, and has obvious advantages for carrying out the quick and ultra-precise measurement and calibration for the inner cavity micro-size and the two-dimensional coordinate. Especially, the top of the resolution capability can reach the deep sub-nanometer magnitude, and an absolute zero position exists in the two-dimensional measurement direction.

Owner:HARBIN INST OF TECH

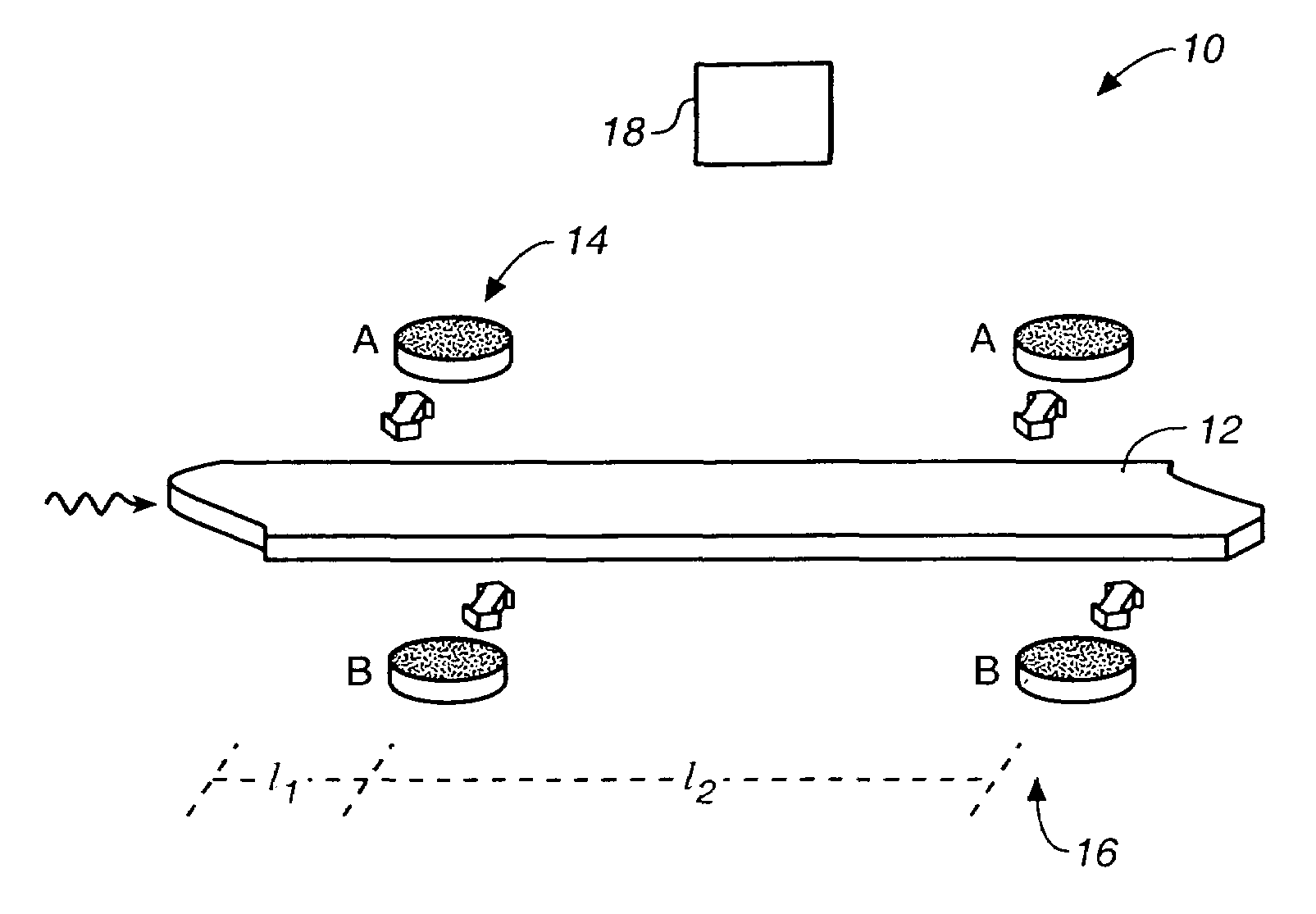

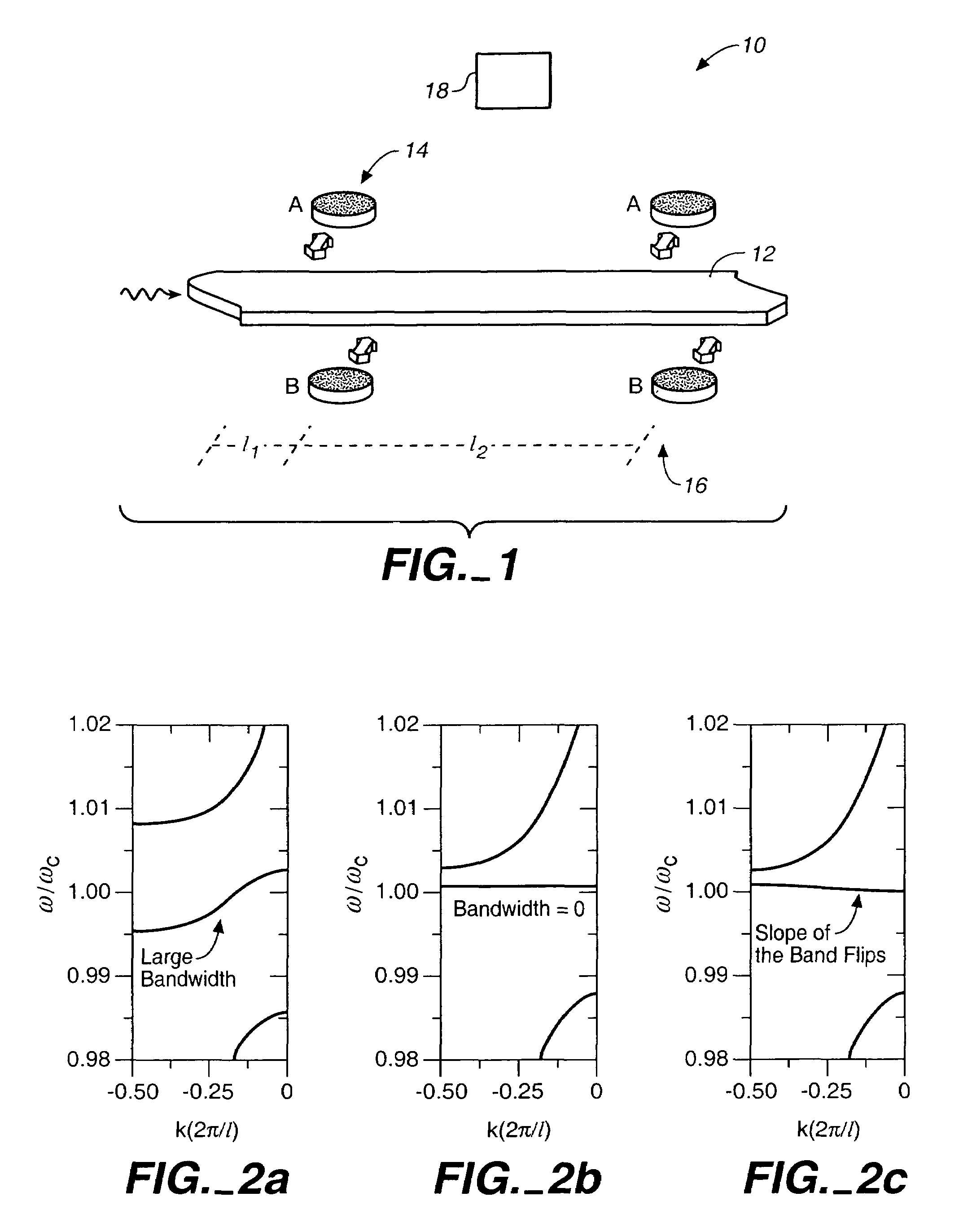

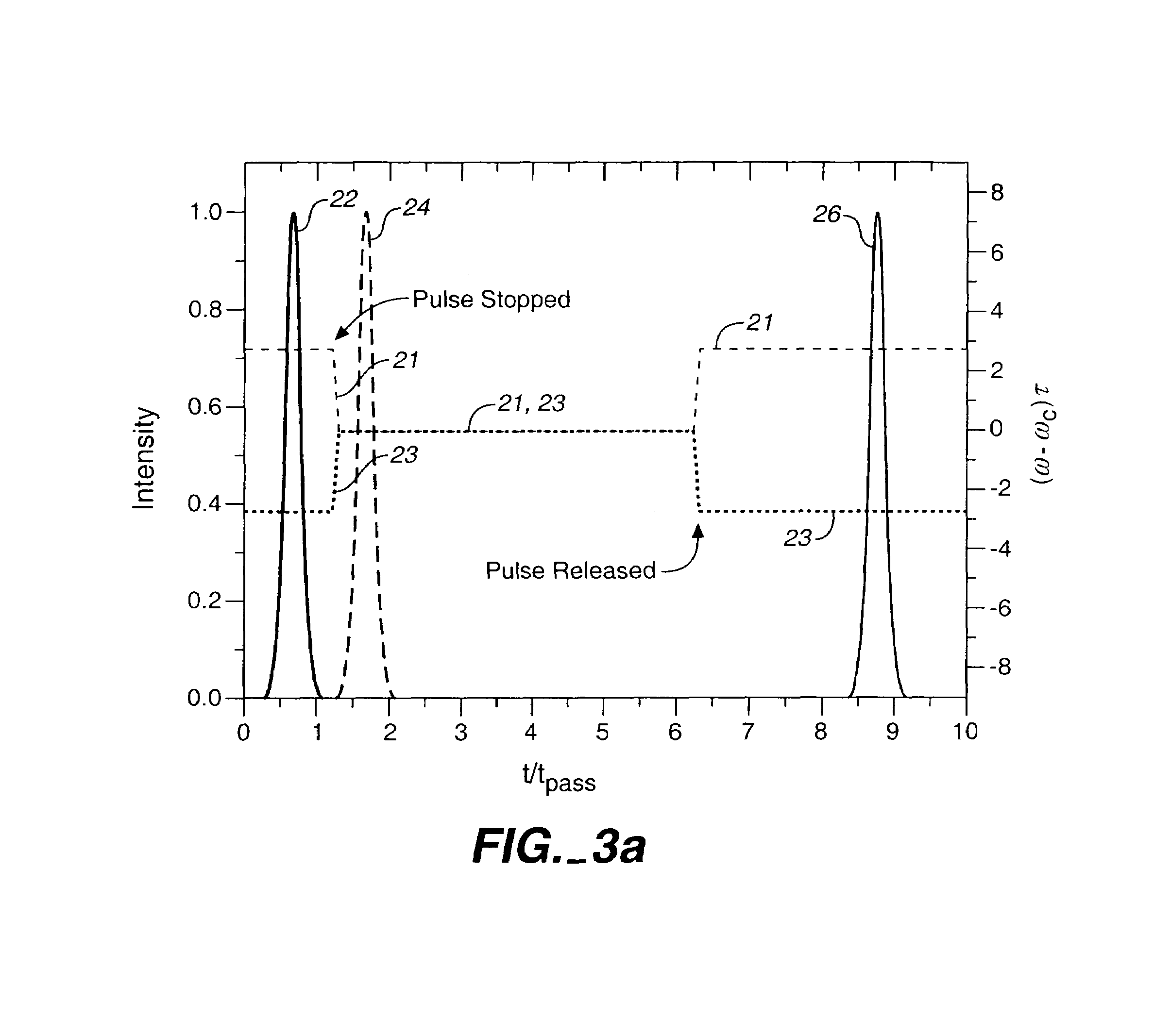

Stopping and time reversing light in a waveguide with an all-optical system

We introduce a new all-optical mechanism that can compress the bandwidth of light pulses to absolute zero, and bring them to a complete stop. The mechanism can be realized in a system consisting of a waveguide side-coupled to tunable resonators, which generates a photonic band structure that represents a classical analogue of the Electromagnetically Induced Transparency. The same system can also achieve a time-reversal operation. We demonstrate the operation of such a system by finite-difference time-domain simulations of an implementation in photonic crystals.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

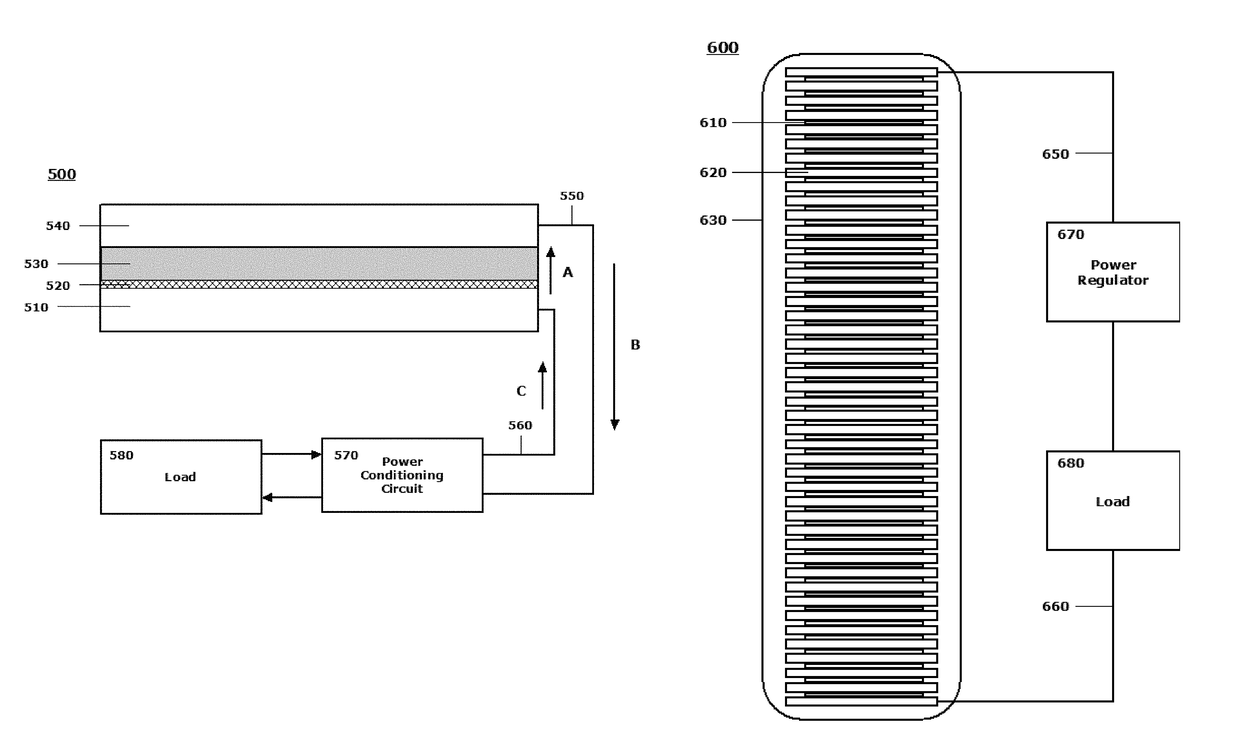

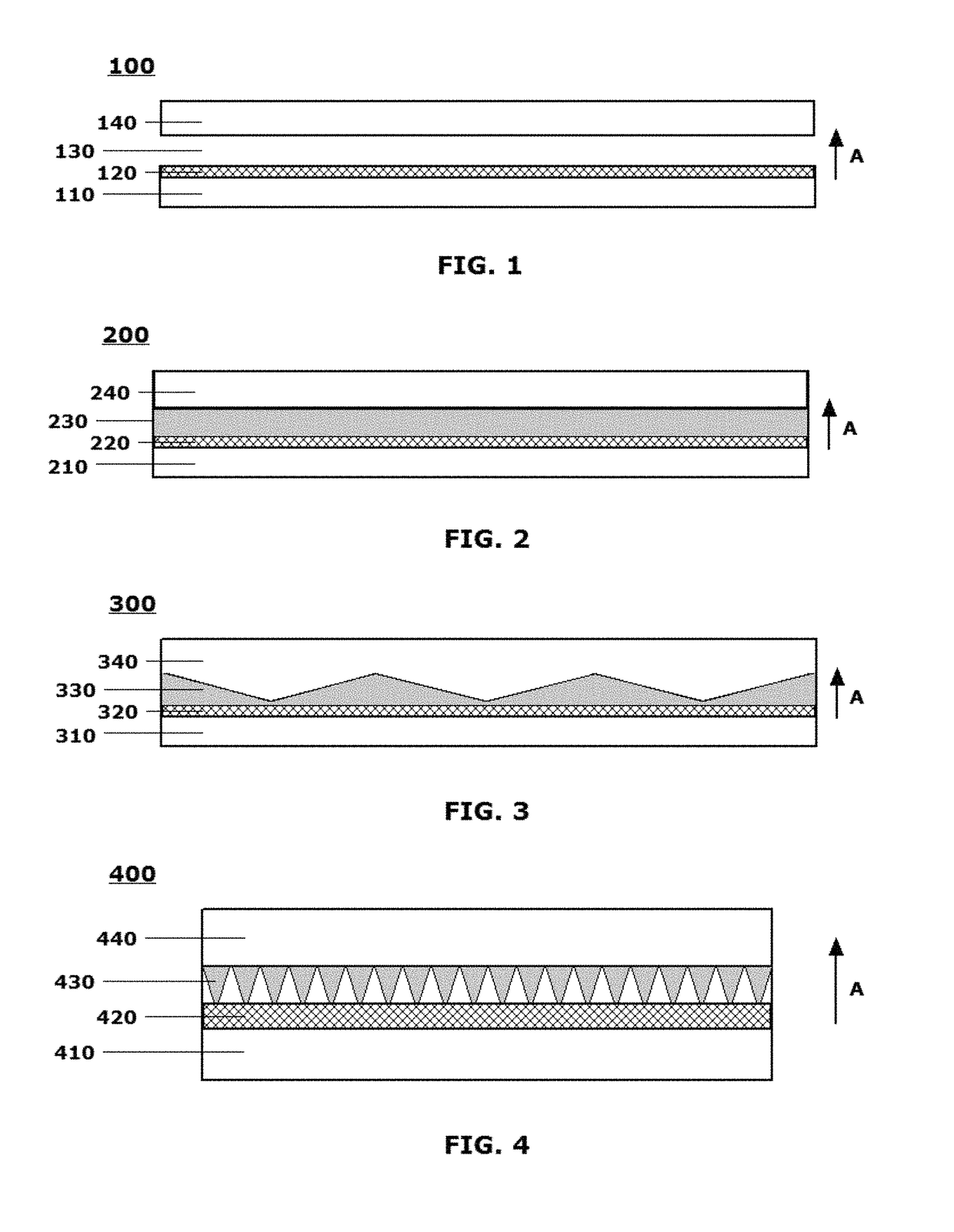

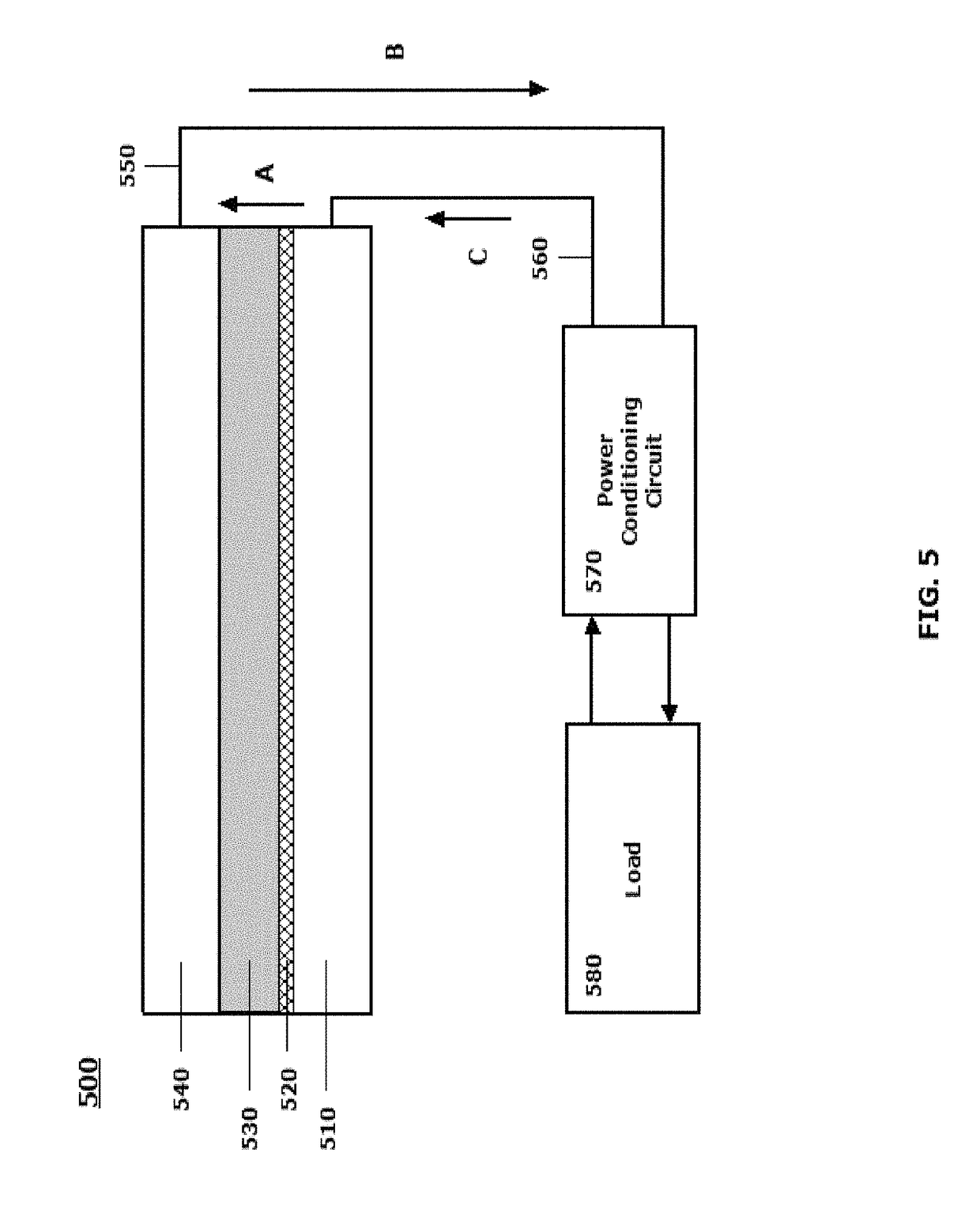

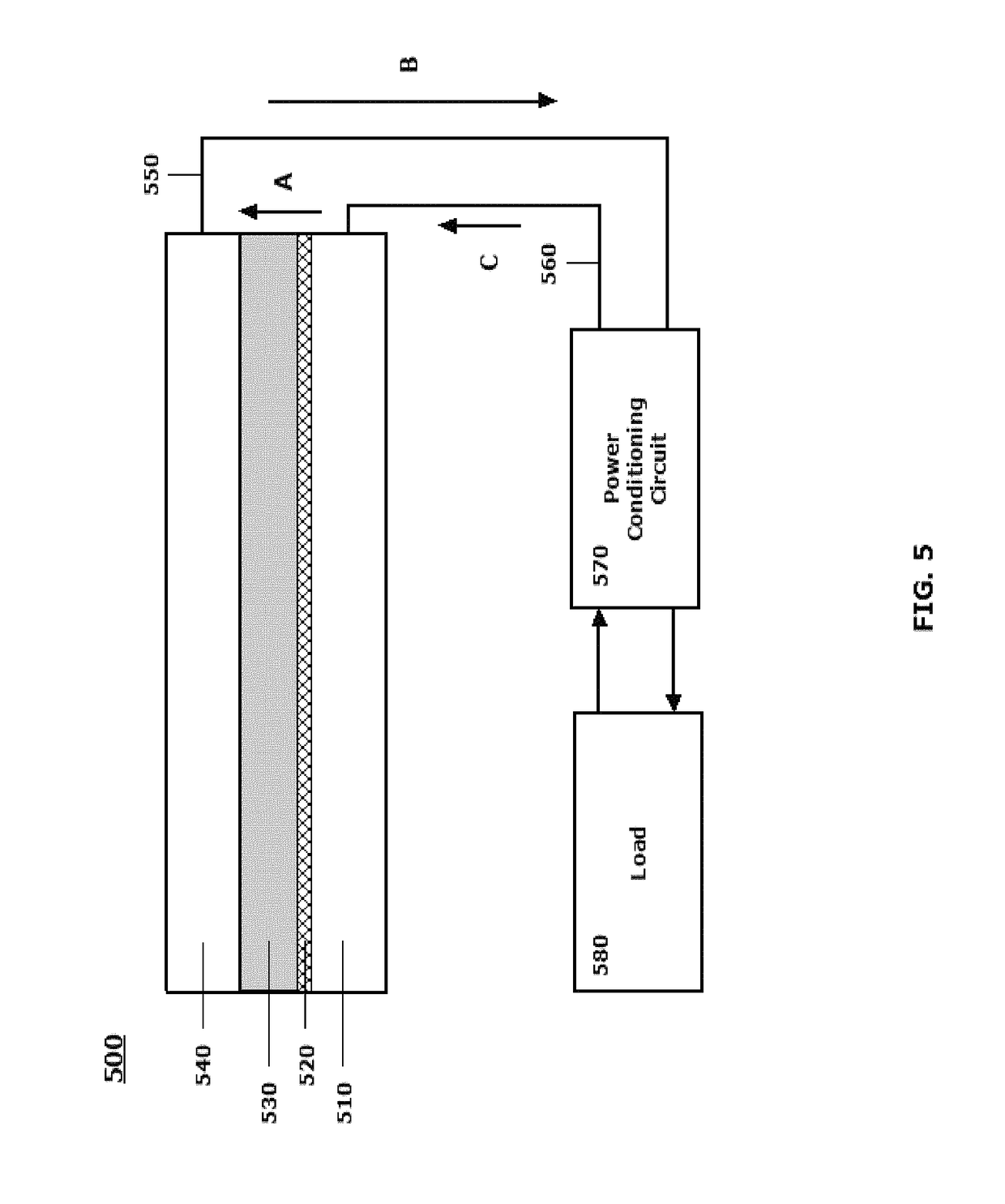

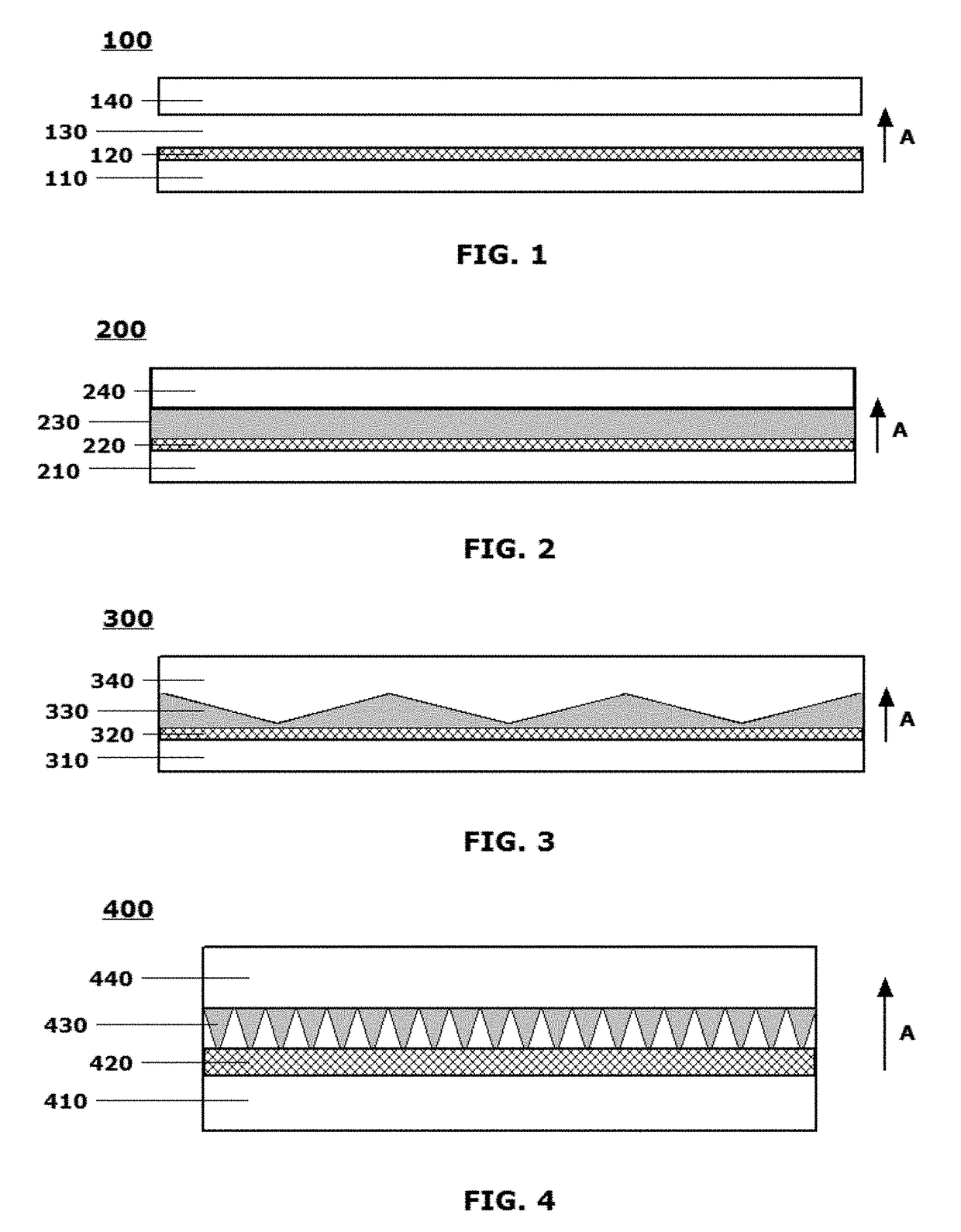

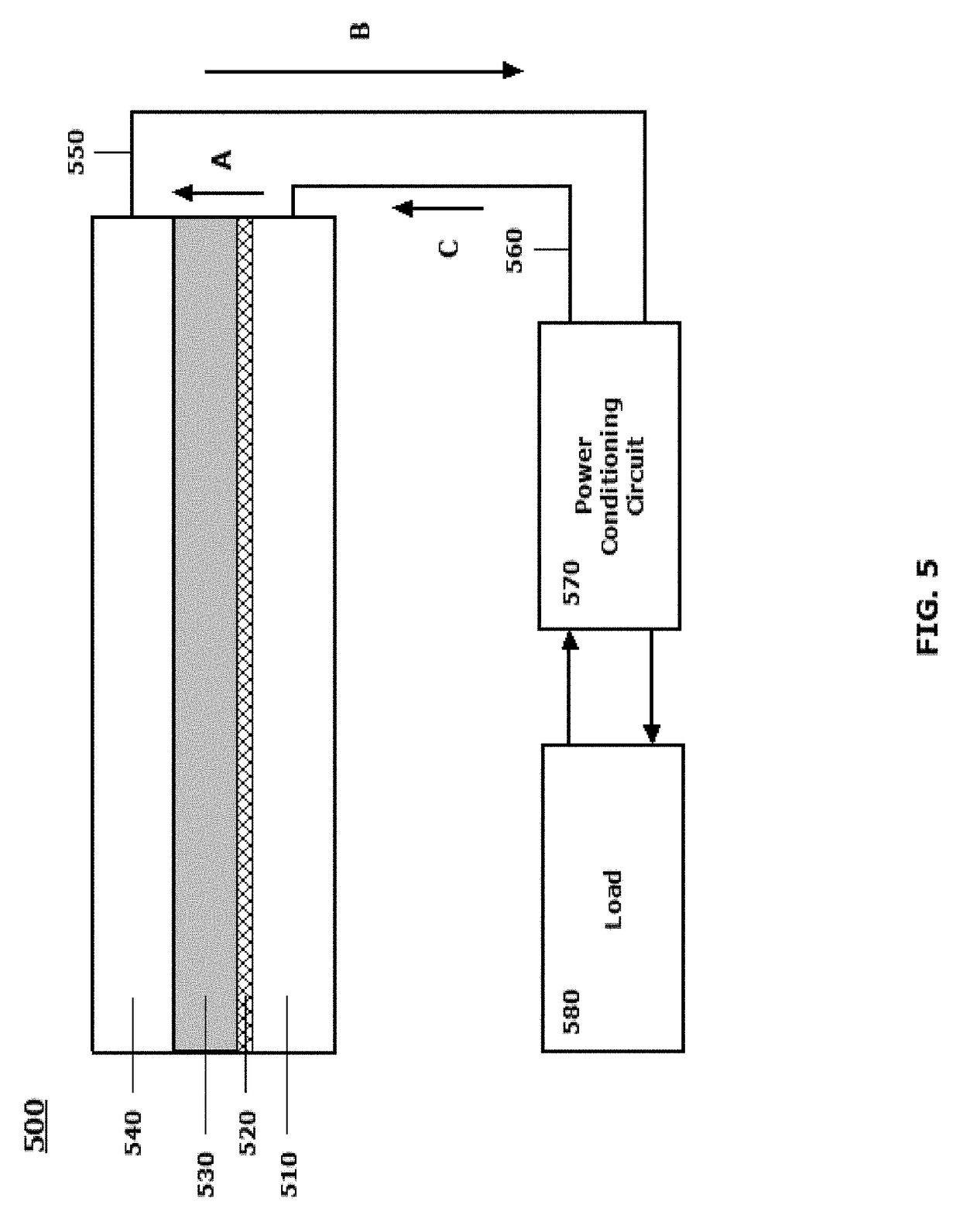

Structurally embedded and inhospitable environment systems and devices having autonomous electrical power sources

ActiveUS10014461B1Different functionsGreat motionElectrotherapyBatteries circuit arrangementsThermal energyElectric power

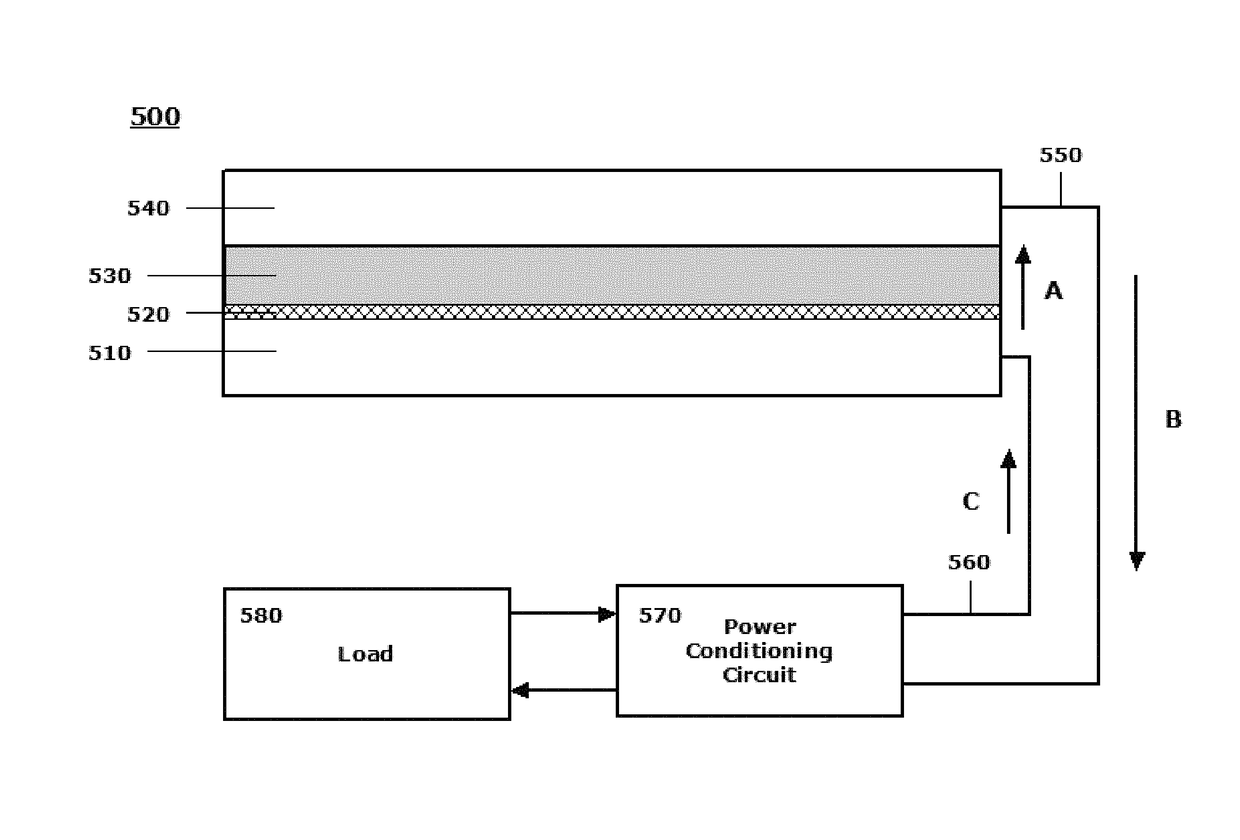

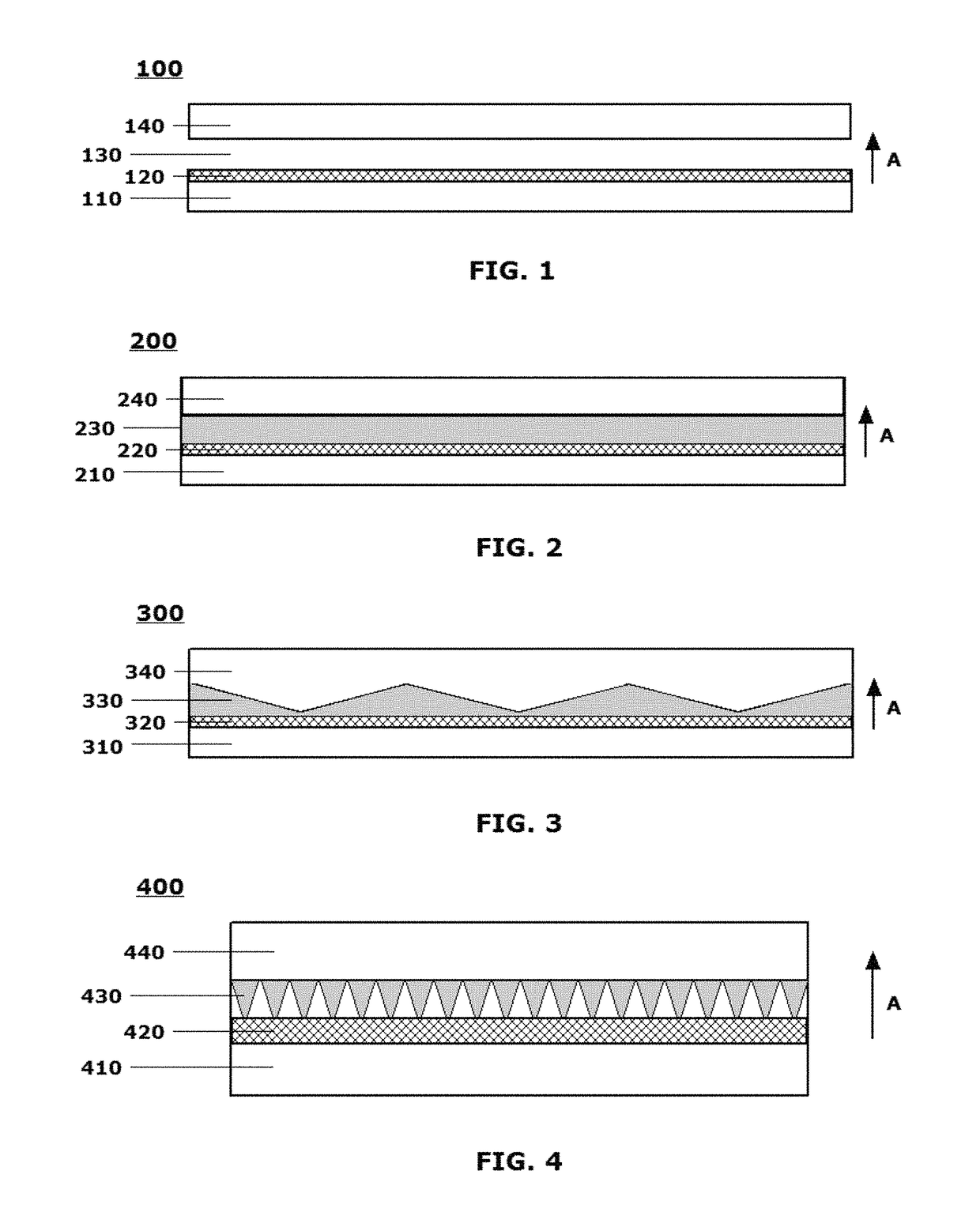

A method is provided for producing an electrically-powered device and / or component that is embeddable in a solid structural component, and a system, a produced device and / or a produced component is provided. The produced electrically powered device includes an attached autonomous electrical power source in a form of a unique, environmentally-friendly structure configured to transform thermal energy at any temperature above absolute zero to an electric potential without any external stimulus including physical movement or deformation energy. The autonomous electrical power source component provides a mechanism for generating renewable energy as primary power for the electrically-powered device and / or component once an integrated structure including the device and / or component is deployed in an environment that restricts future access to the electrical power source for servicing, recharge, replacement, replenishment or the like.

Owner:FACE INT

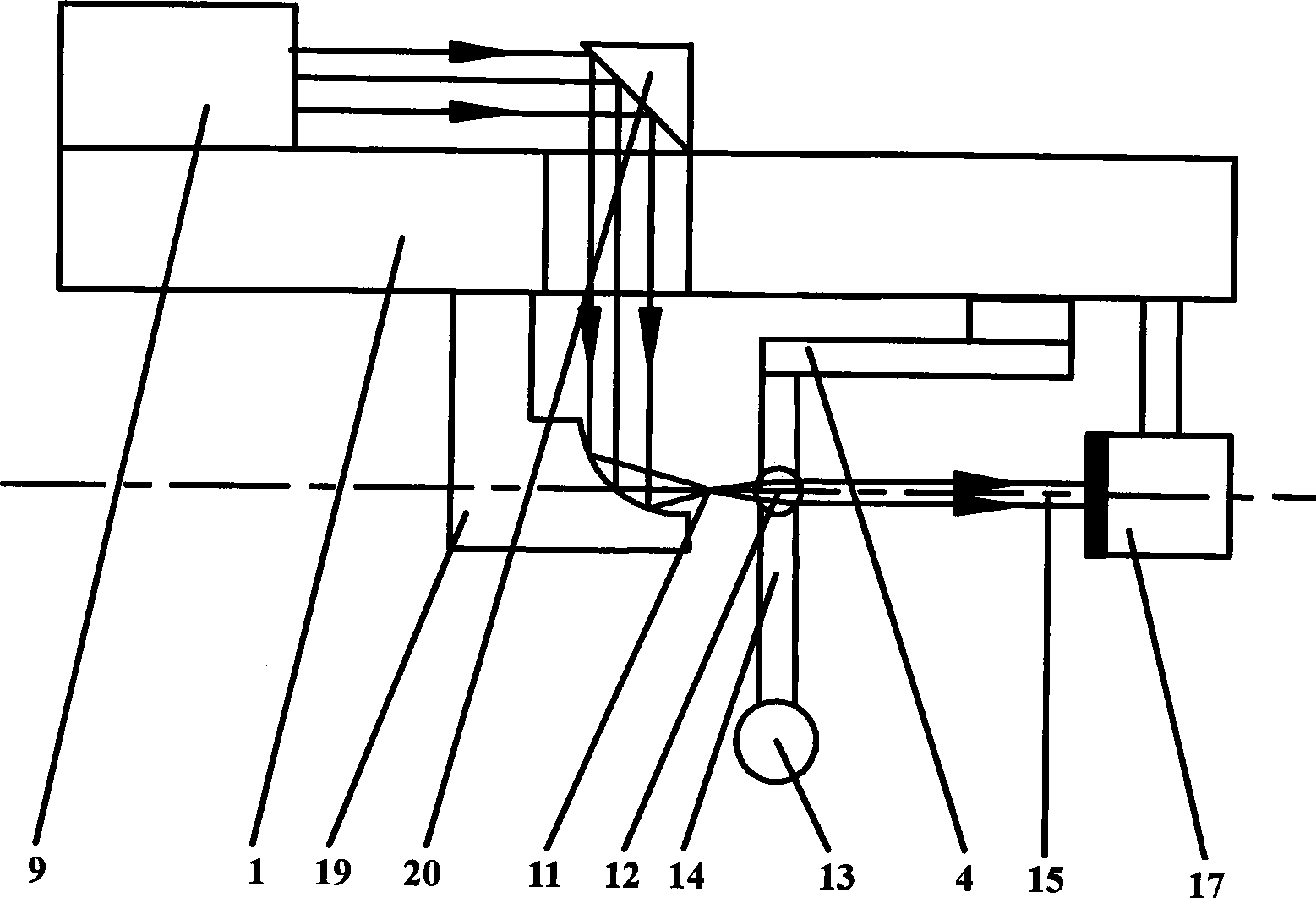

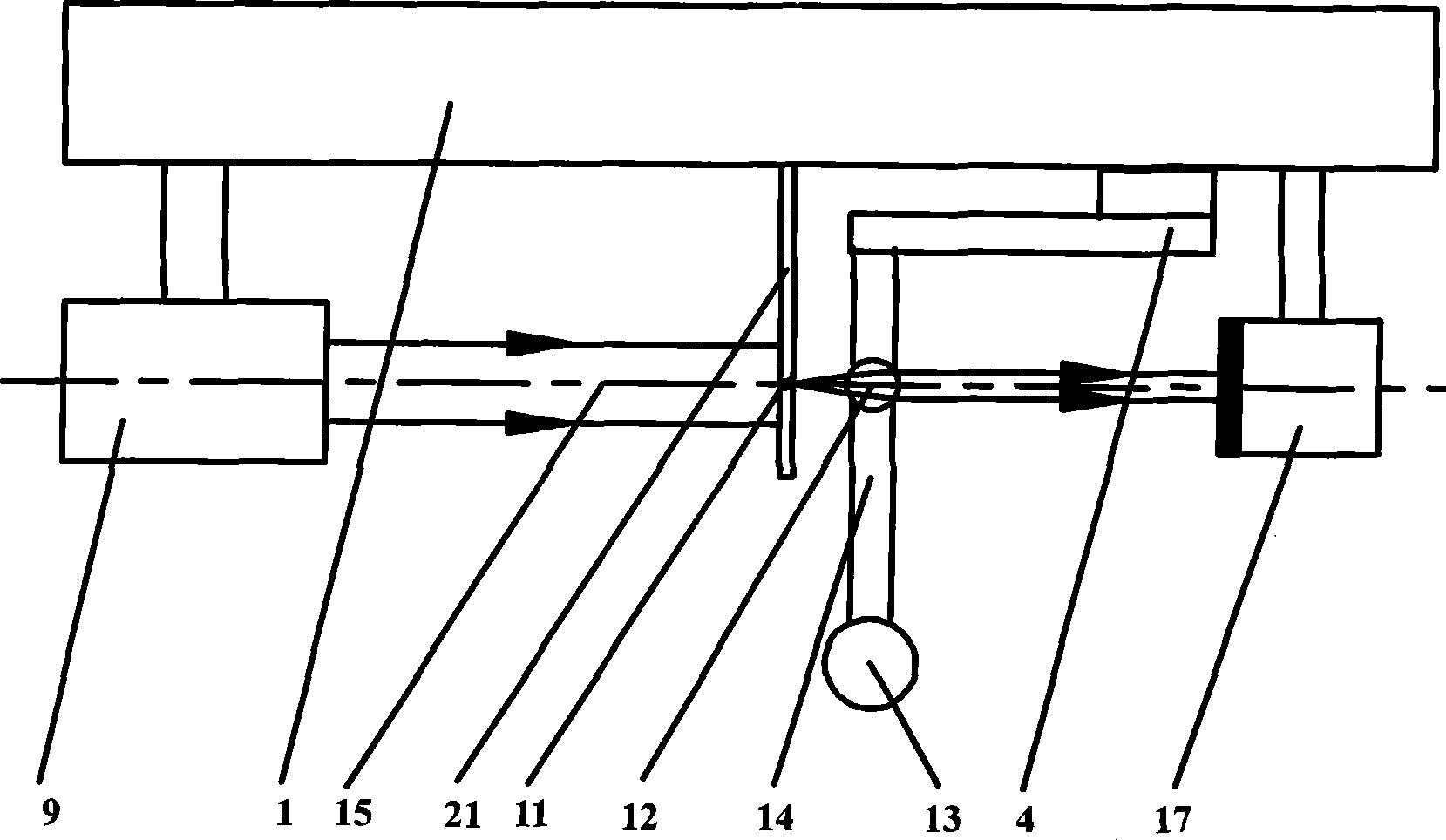

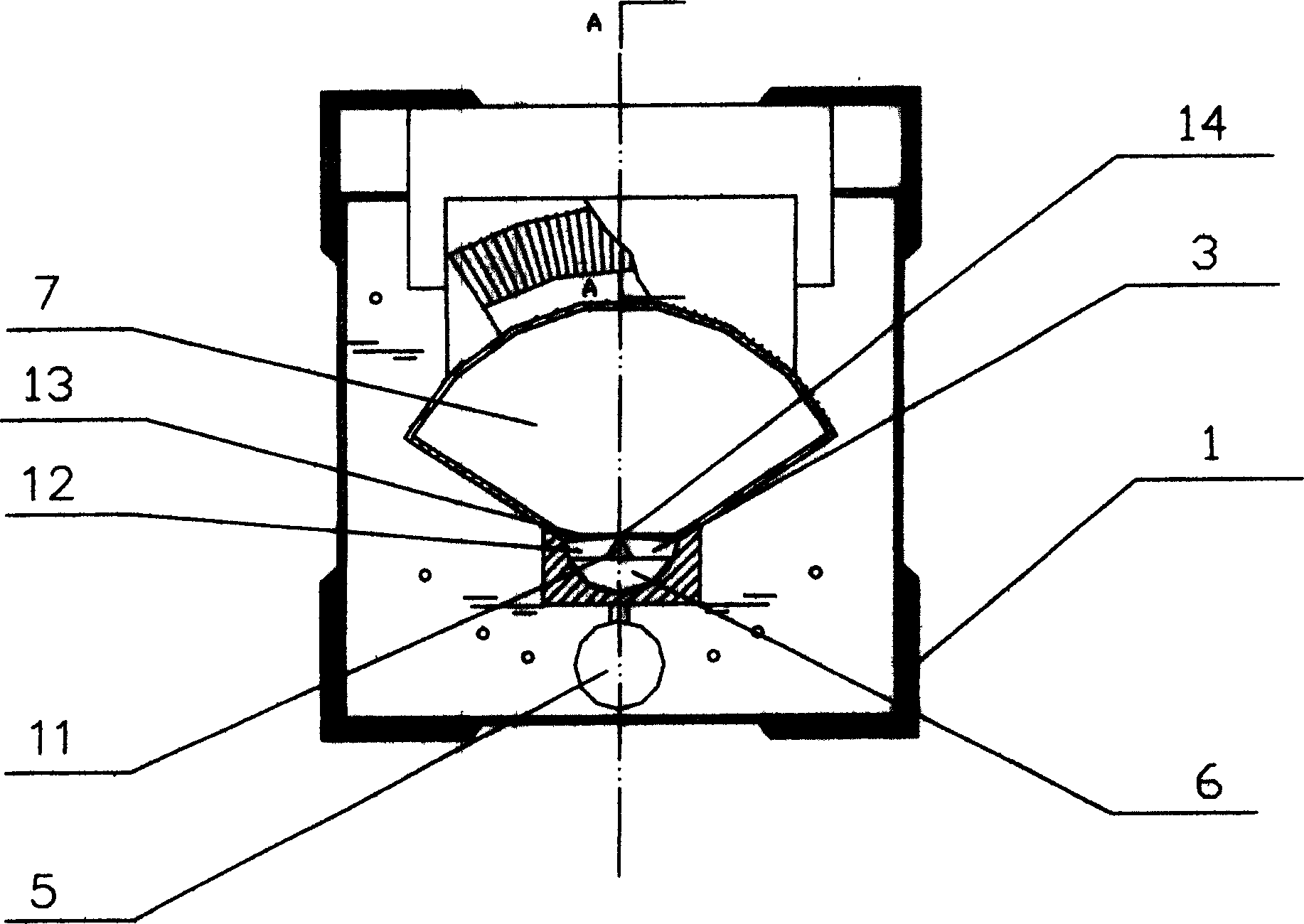

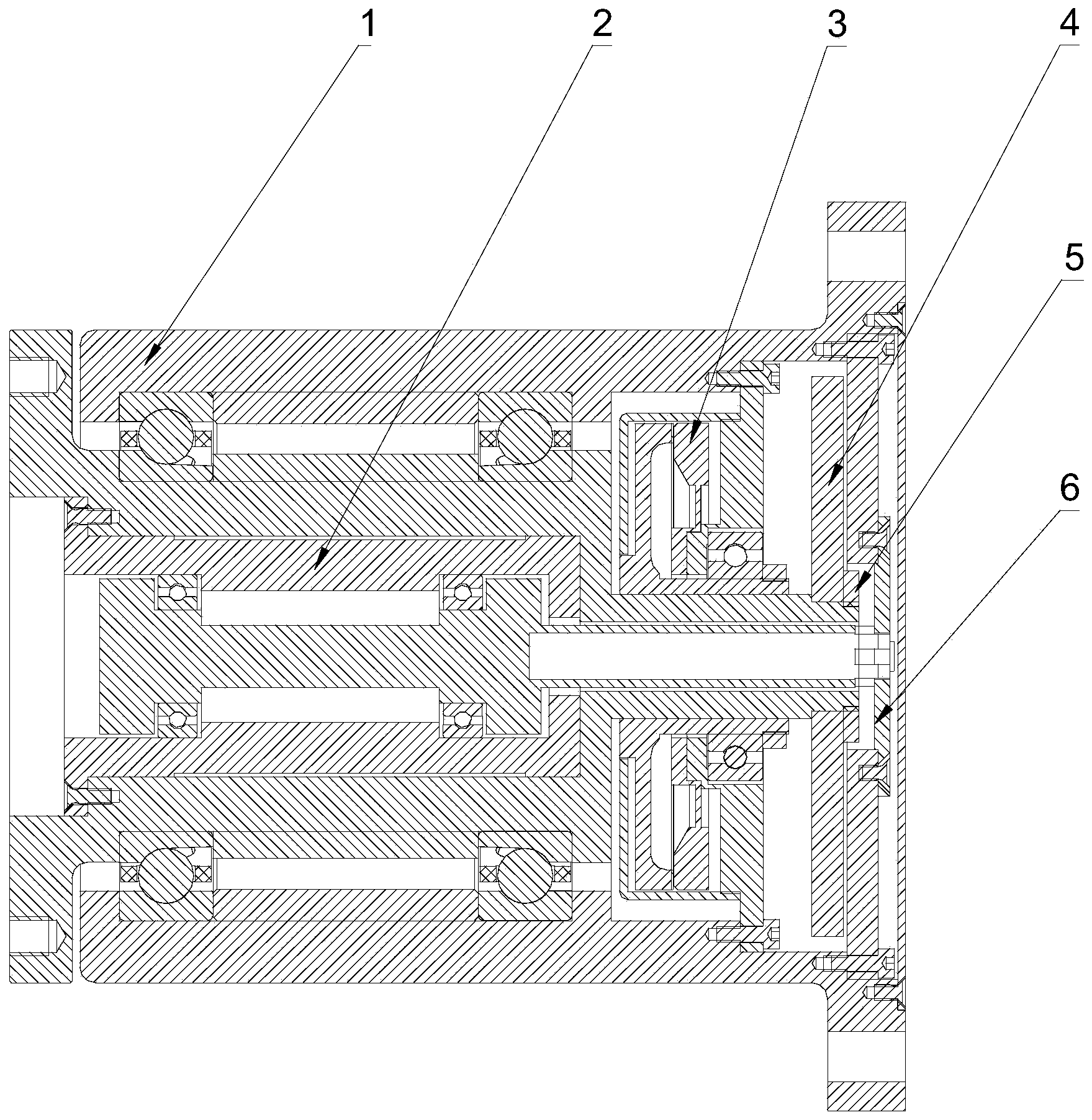

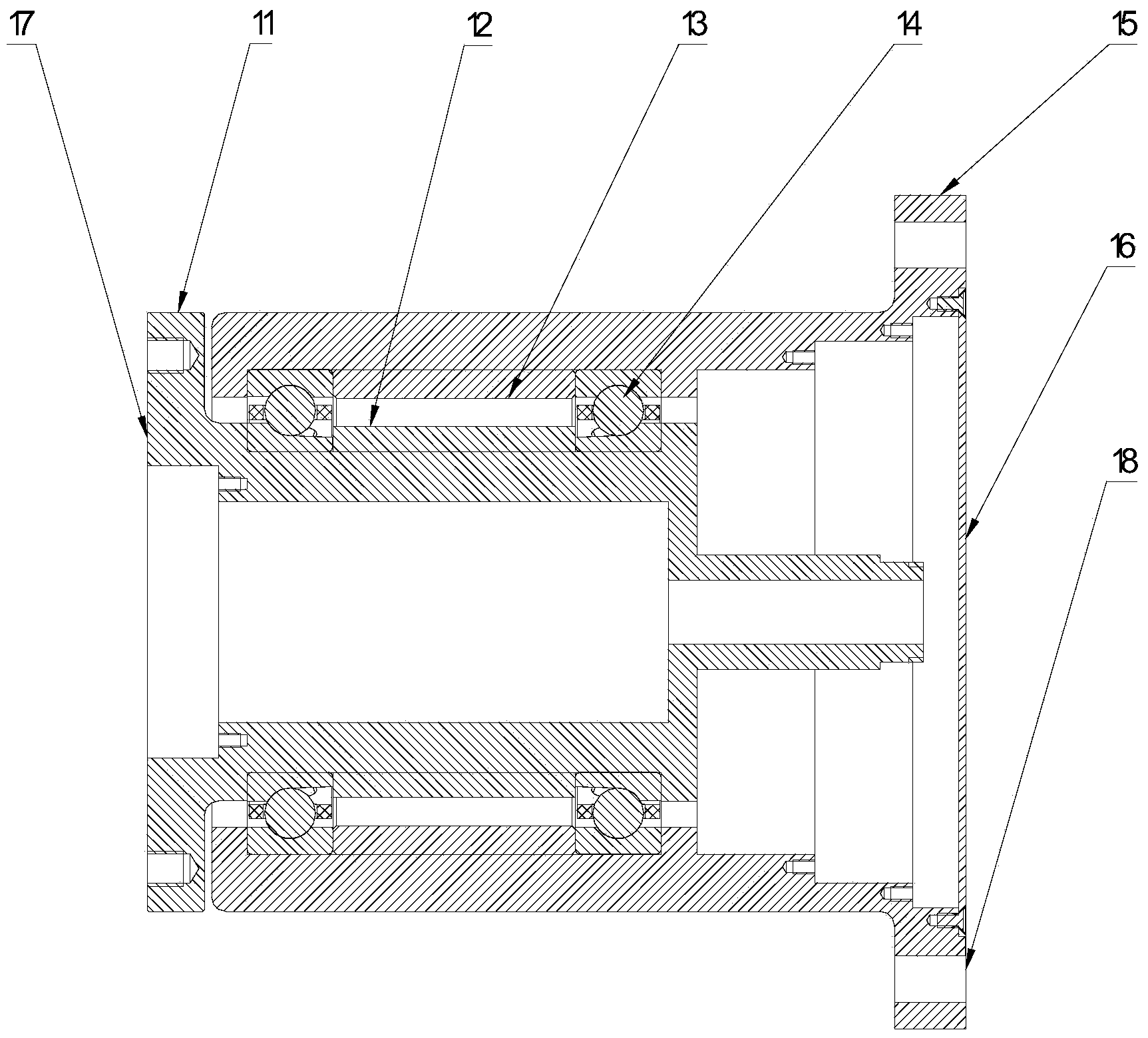

Optical axis and thickness measurement method and device of differential confocal internal-focusing lens

InactiveCN103123251ANo damageFast measurementUsing optical meansTesting optical propertiesContact highOptical axis

The invention belongs to the technical field of optical precision measurement and relates to an optical axis and thickness measurement method and a device of a differential confocal internal-focusing lens. By means of an internal-focusing objective lens, the method utilizes an auto-collimation method to adjust the optical axis of the lens precisely; utilizes the characteristic that when a differential confocal response curve passes the absolute zero point, the vertex of a differential confocal light cone and the surface vertex of the lens to be measured can coincide to achieve the precise positioning of the surface vertex of the lens and to obtain a numerical aperture angle of emergent lights in two-time positioning of the vertex of the differential confocal light cone; and utilizes a ray tracing formula to calculate the central thickness of the lens. Meanwhile, an annular pupil is introduced during the light path measurement, the influence of aberration on a measurement result is reduced. By combining differential confocalization with internal focusing for the first time, and providing optical axis and thickness measurement principle of the differential confocal internal-focusing lens, the lens optical axis and thickness measurement method and device of the differential confocal internal-focusing lens has the advantages of being high in measurement speed, high in precision, high in sensitivity, simple in structure and long in working distance, and is applicable to non-contact high-precision measurement of the light axis and the central thickness of lens.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

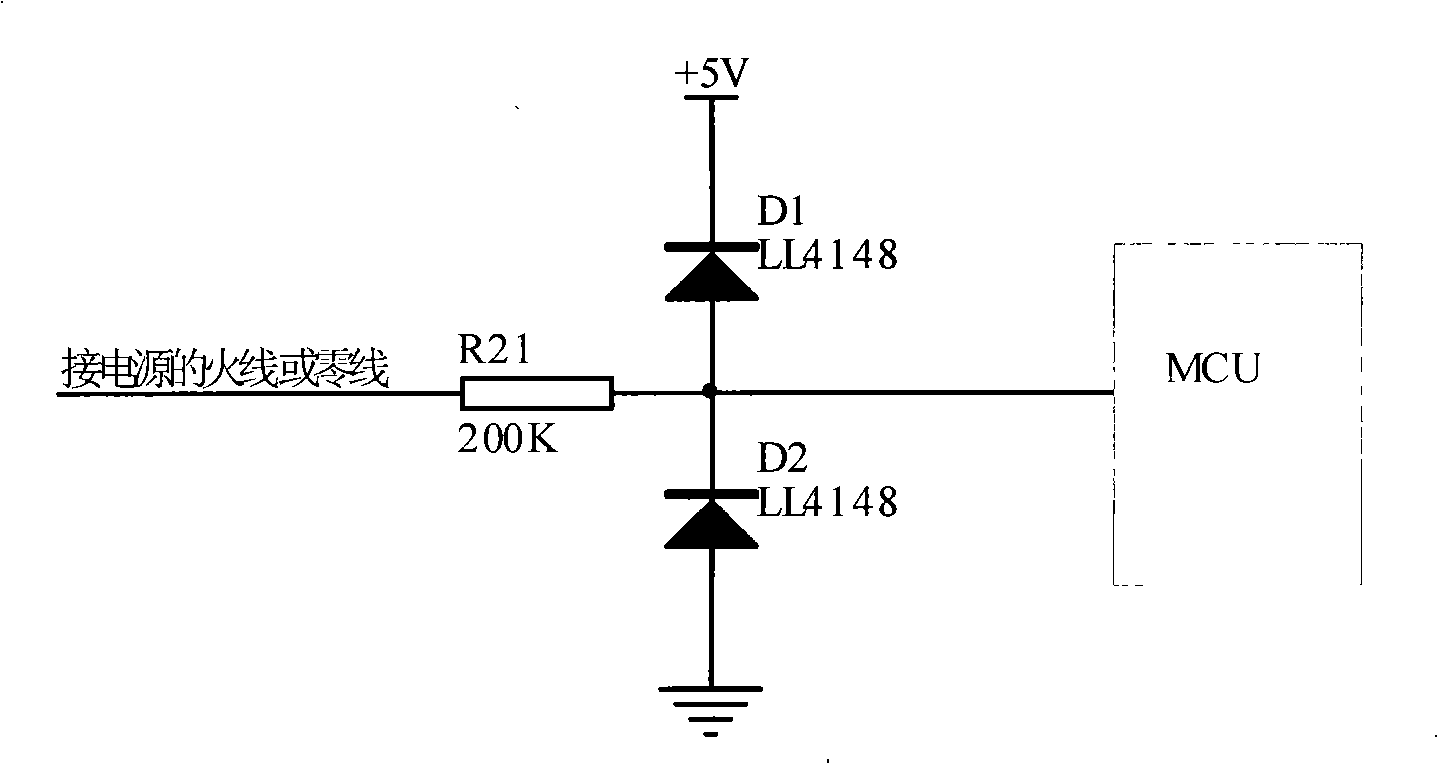

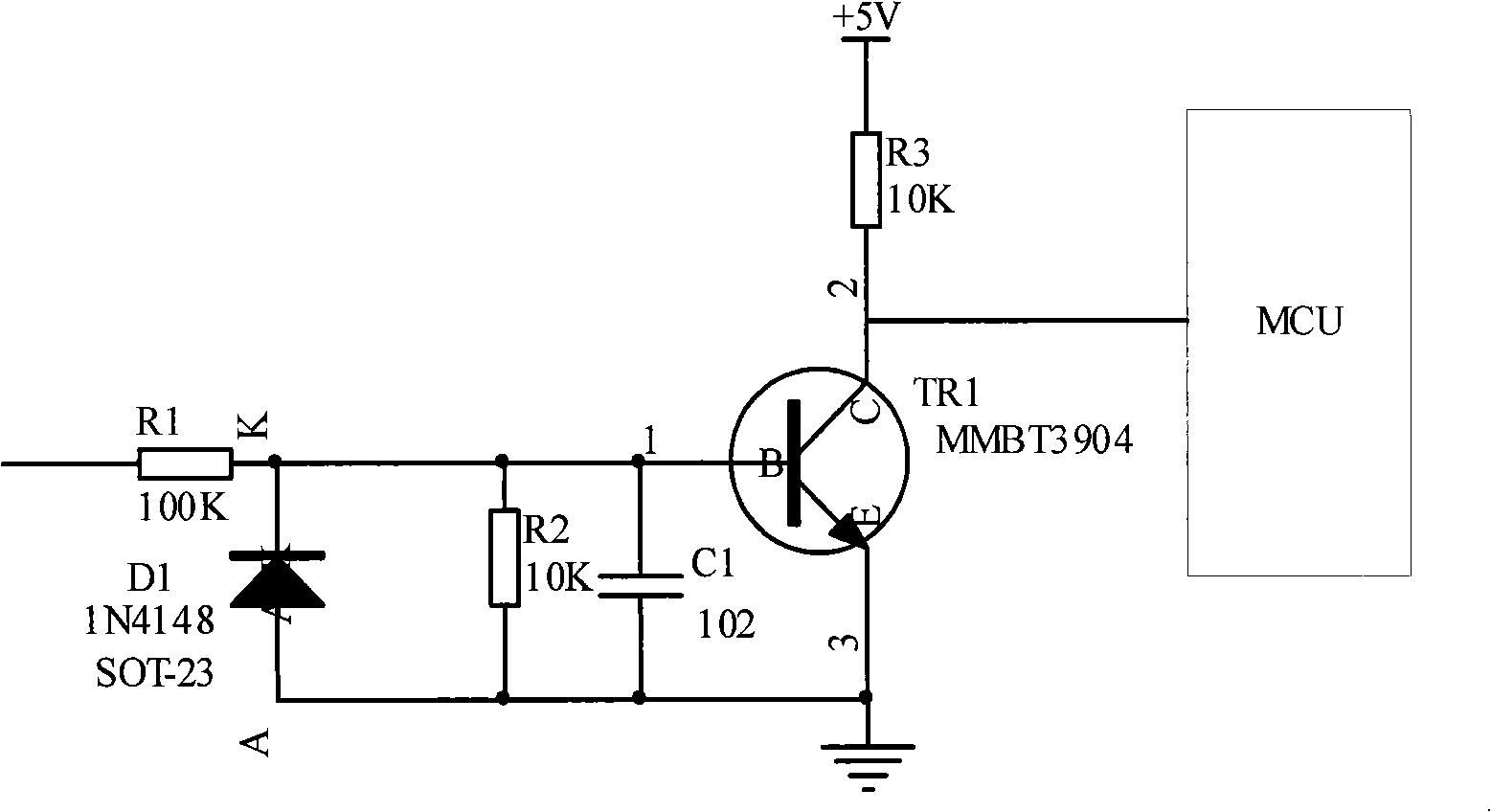

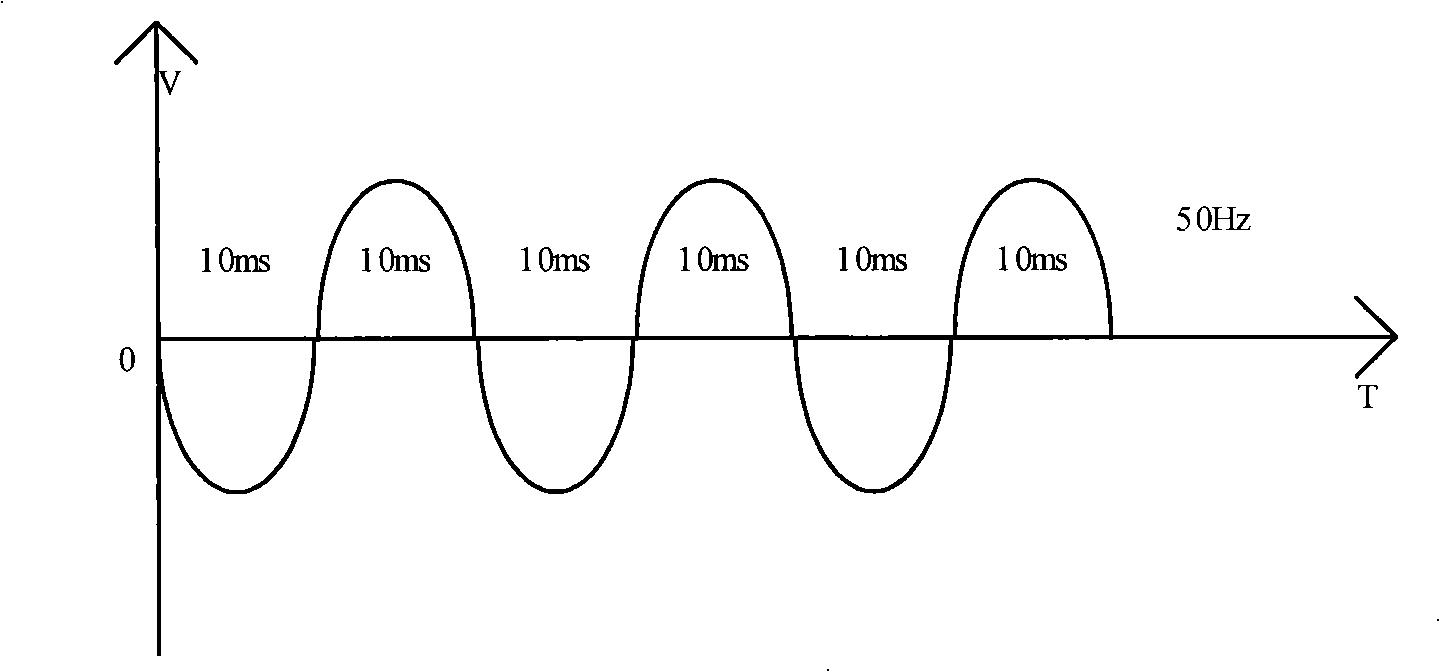

Method and apparatus for compensating voltage zero-cross detection

InactiveCN101303376ANo additional costThe zero-crossing interrupt signal is accurateCurrent/voltage measurementTimerStart up

The invention discloses a zero passage voltage detection and compensation method which is characterized by including the steps that: a timer is started up after zero passage voltage interrupt signals are received and the timing time of the timer is the offset time of a zero crossing point of voltage; the interrupt point of the timer is determined as the zero crossing point of the voltage after the interrupt signals of the timer are received. The invention also discloses a corresponding zero passage voltage detection and compensation device. The method and the device of the invention can accurately detect an absolute zero crossing point of the voltage without adding hardware cost and can be applied to occasions demanding very accurate zero passage signals.

Owner:SHENZHEN H&T INTELLIGENT CONTROL

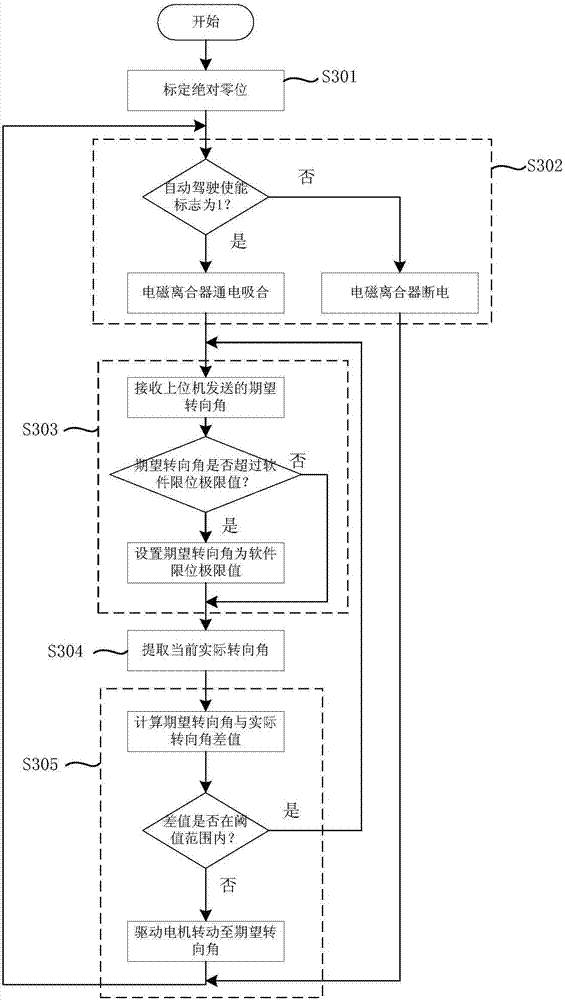

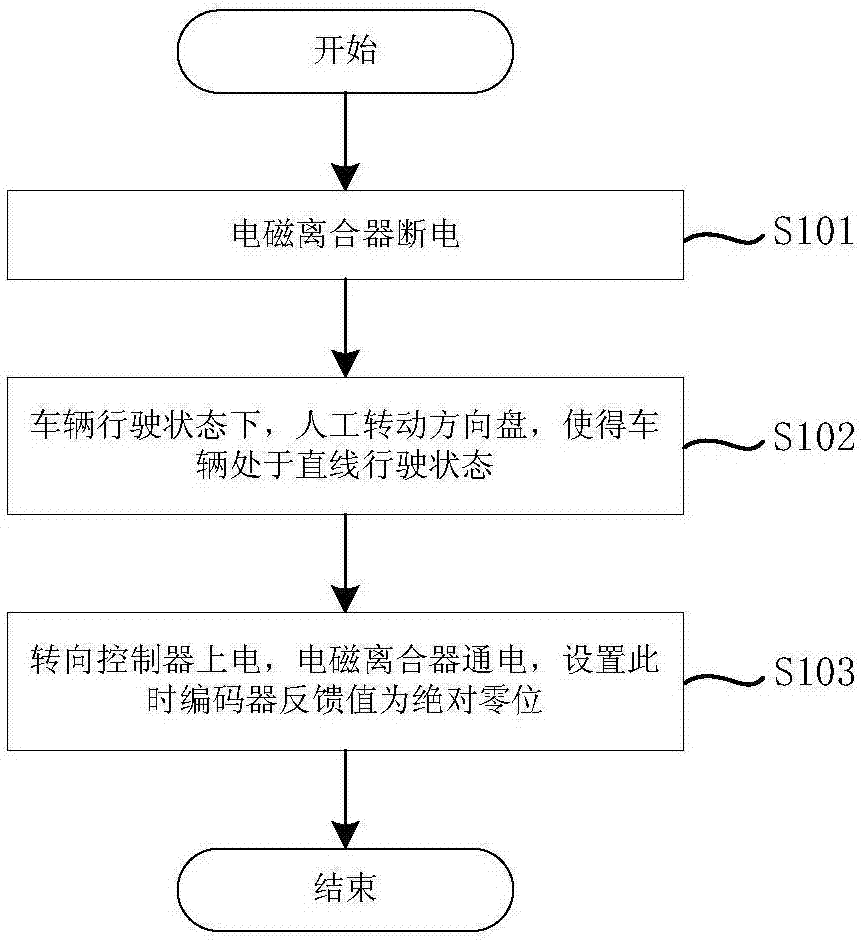

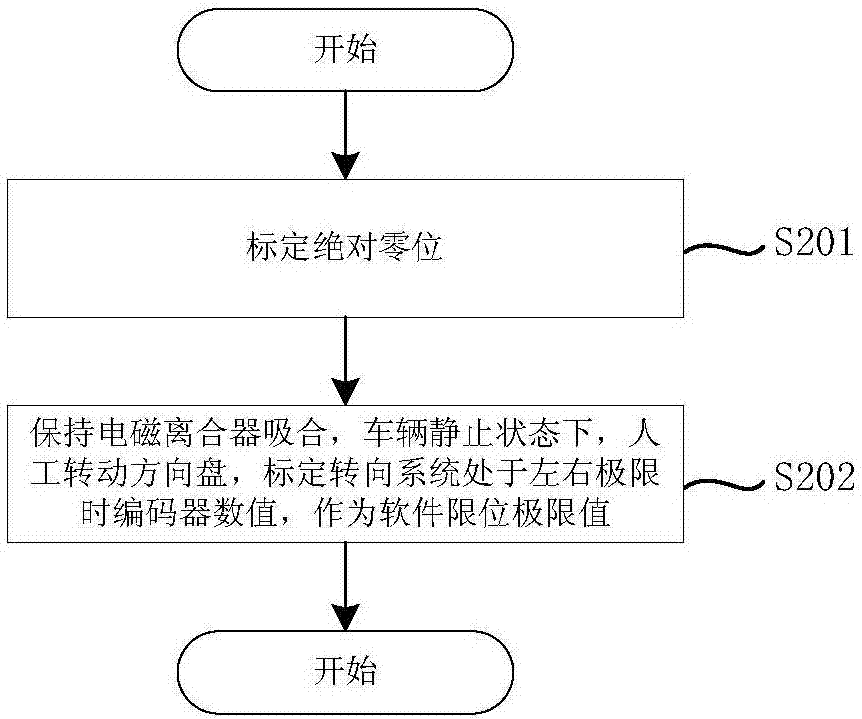

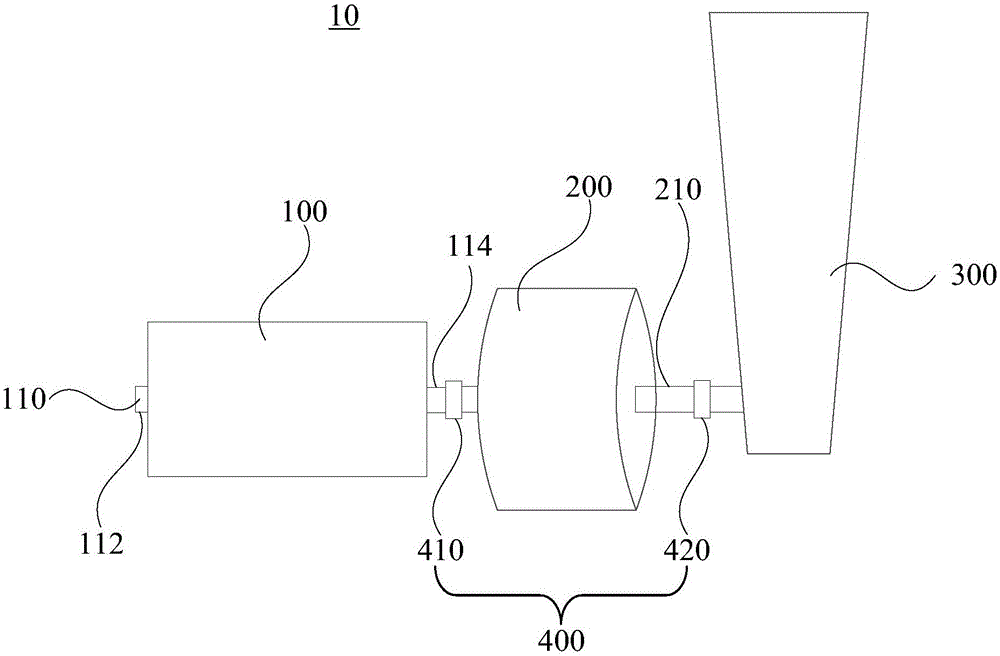

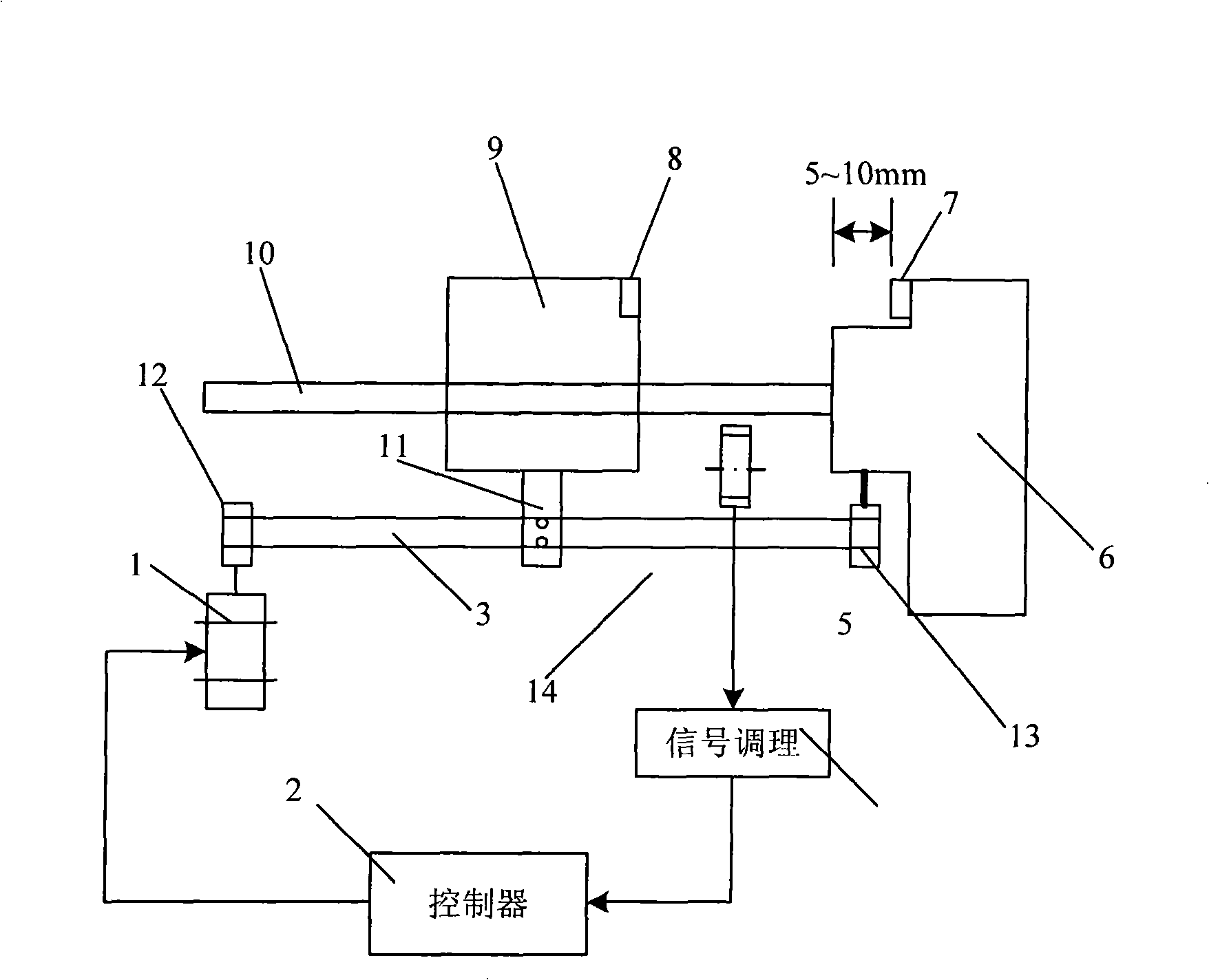

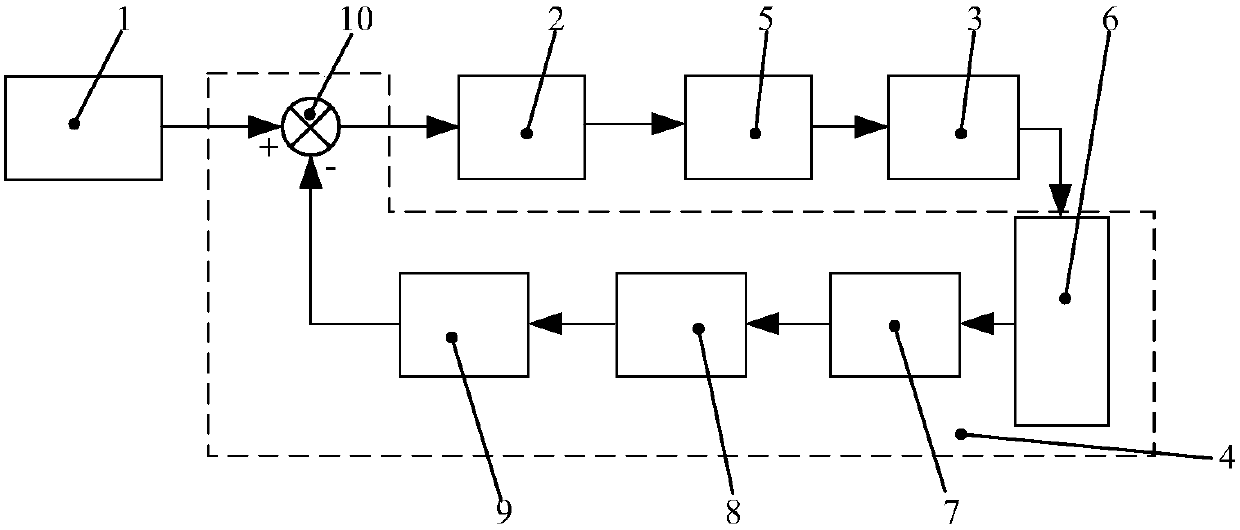

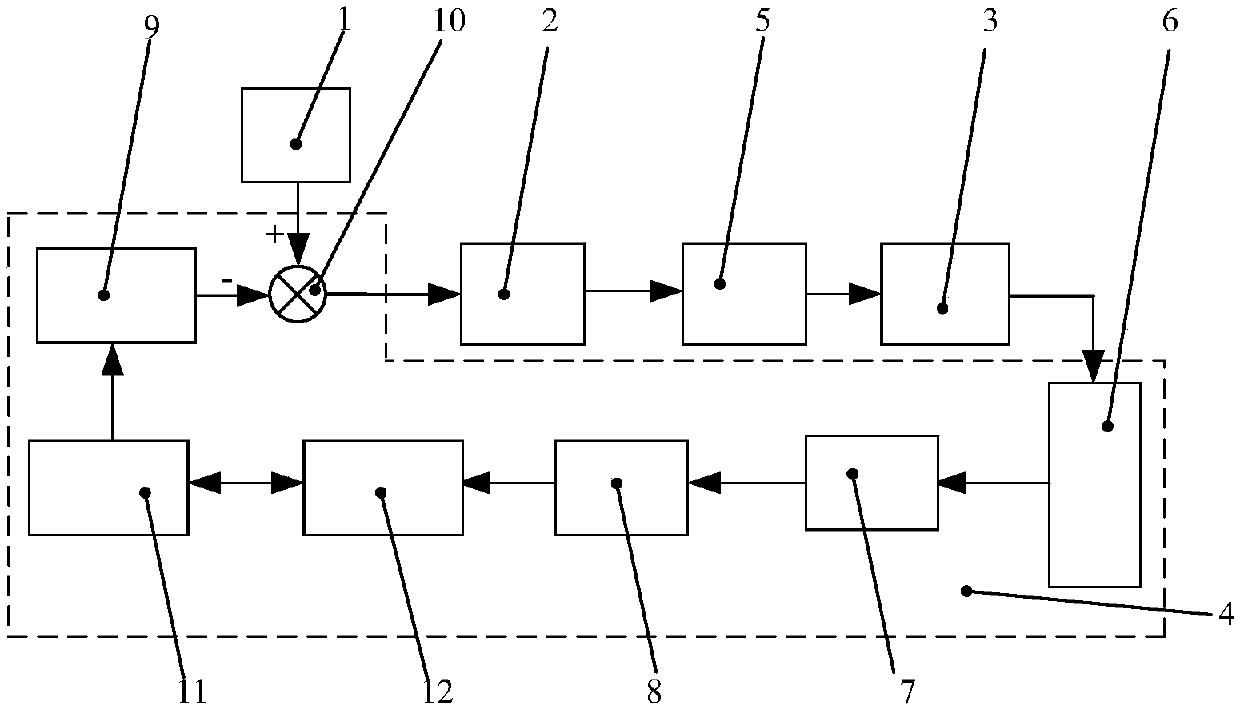

Steering controlling method of automatic steering device of unmanned vehicle

The invention provides a steering controlling method of an automatic steering device of an unmanned vehicle. The steering controlling method comprises the following steps that an absolute zero position is demarcated; a steering controller controls the unmanned vehicle to enter an automatic driving mode; the steering controller amends an expected steering angle of an output shaft of a motor (111); the steering controller obtains an actual steering angle of the output shaft of the current motor (111) through an encoder (115); and the steering controller controls an algebraic difference value of the expected steering angle and the actual steering angle, and steering is achieved. The controlling steps are simple; switching between manual driving and automatic driving can be completed; software is adopted to conduct limiting; setting is relatively flexible; the phenomenon of overlarge steering of a steering wheel can be effectively prevented; and precise steering is achieved.

Owner:BIT INTELLIGENT VEHICLE TECH CO LTD

Laser differential confocal curvature radius measuring method and device

The invention relates to a laser differential confocal curvature radius measuring method and a laser differential confocal curvature radius measuring device, which belong to the technical field of optical precision measurement. The laser differential confocal curvature radius measuring method utilizes a post-positioned pupil to block half of a measuring beam, uses a light splitting pupil differential confocal detection system for detecting a measuring beam to obtain a differential confocal response curve, and utilizes an absolute zero point of the differential confocal response curve to perform precise focus fixation on a surface vertex position and a sphere center position of a spherical element separately, so as to obtain a curvature radius of the element. According to the laser differential confocal curvature radius measuring method and the laser differential confocal curvature radius measuring device, the post-positioned light splitting pupil laser differential confocal technologyis applied to the high-precision detection of the curvature radius of the spherical element for the first time, the differential confocal focus fixation and curvature radius measurement is realized byusing only one path of detector, the system structure is simple, the assembly and debugging difficulty is reduced, the possible decrease of focus fixation precision caused by replacement of a measured lens is avoided, further the measurement precision is improved; and data near a zero point of the differential confocal response curve is subjected to linear fitting, so as to achieve fast triggering of the focus fixation and measurement, thus the measurement speed and precision as well as the scattering resistance are greatly improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

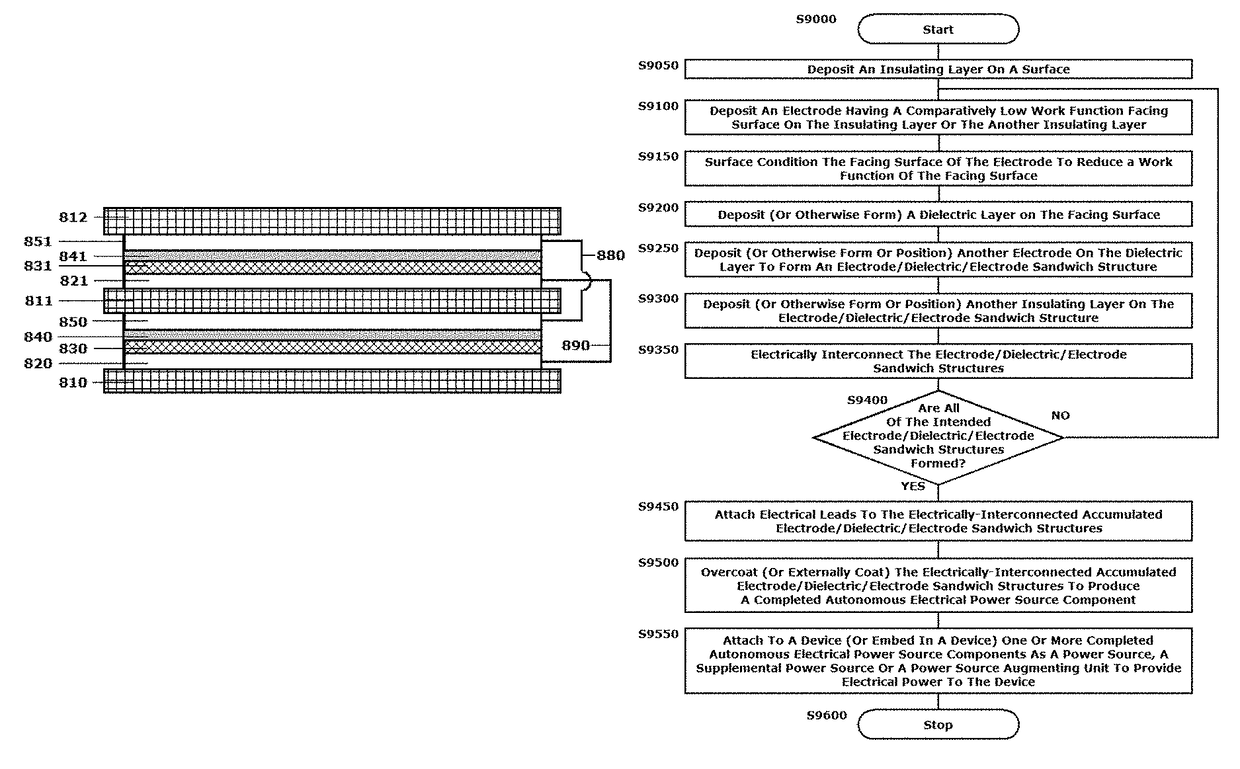

Methods for fabrication, manufacture and production of an autonomous electrical power source

ActiveUS10109781B1Different functionsGreat motionThermoelectric device with peltier/seeback effectElectric discharge tubesThermal energyMicron scale

Owner:FACE INT

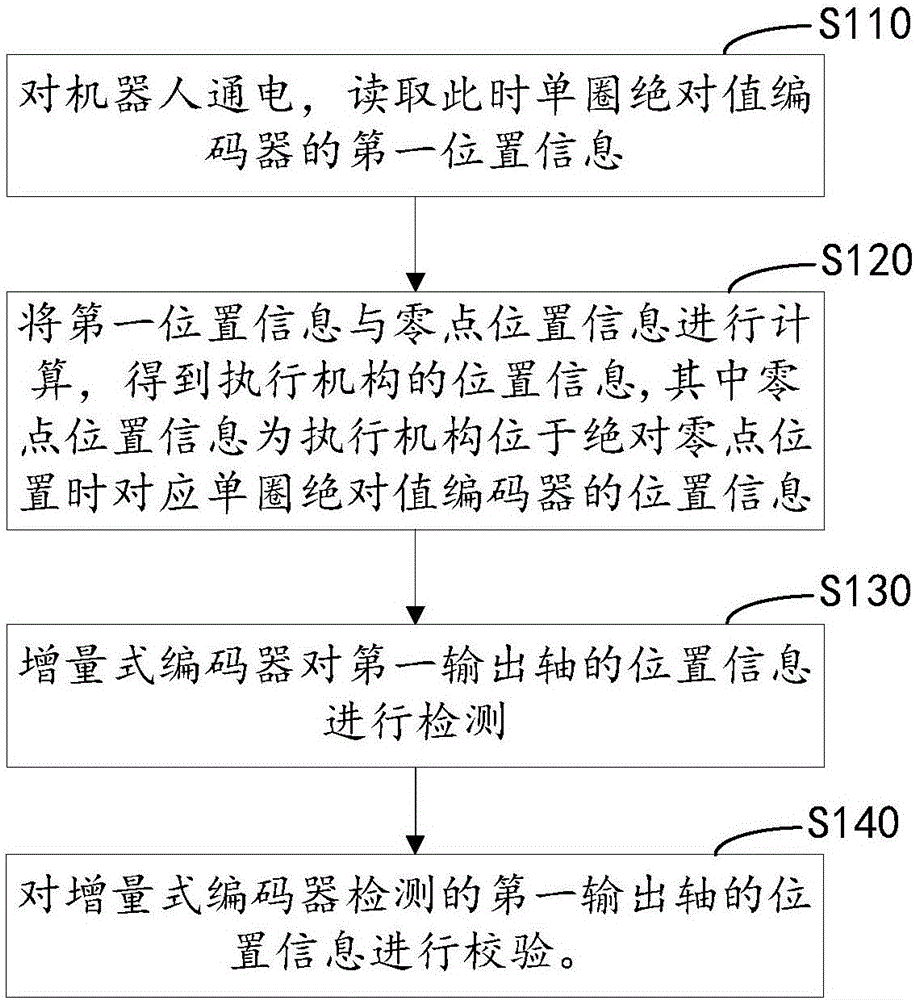

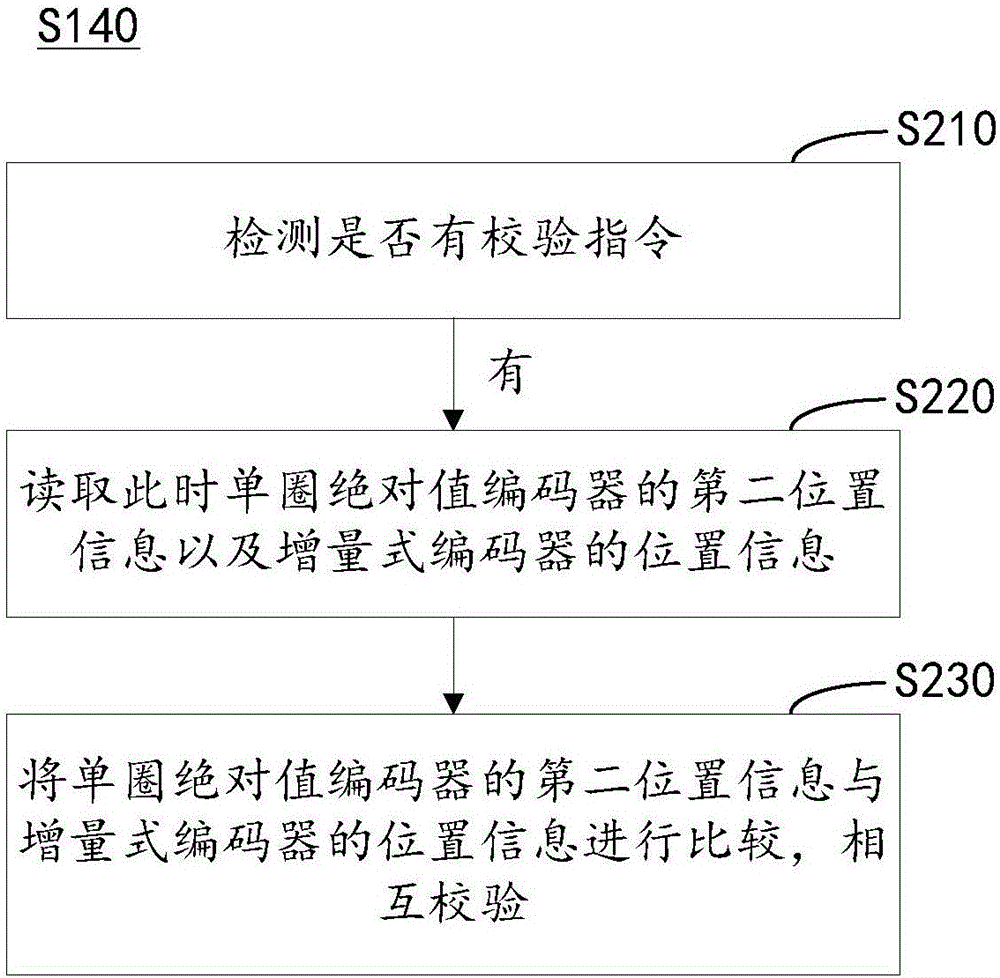

Robot position detecting device and method

ActiveCN106363623AImprove efficiencyImprove work efficiencyProgramme-controlled manipulatorRobot positionSimulation

The invention relates to a robot position detecting device and method. The method includes the steps that a robot is powered on, and the first position information of a single-ring absolute value encoder at this moment is read; the first position information and zero-point position information are calculated, so that position information of an actuating mechanism is obtained, and the zero-point position information is the position information corresponding to the single-ring absolute value encoder when the actuating mechanism is located at an absolute zero point position; and afterwards, an incremental encoder is used for detecting the position information of a first output shaft. No back-to-zero operation is required when the robot is restarted after power failure, the battery memory position does not need to be added after power failure, either, and there is no need to obtain the actual position of the robot by finding reference points again. Assembling is easy, the structure is flexible, and cost is low. The update speed of the position information is high, and precision is also high. The response performance and working efficiency of the robot can be better improved.

Owner:SHENZHEN TONGCHUAN TECH

Structurally embedded and inhospitable environment systems and devices having autonomous electrical power sources

ActiveUS9893261B1Different functionsGreat motionElectrotherapyBatteries circuit arrangementsThermal energyEngineering

A method for producing an electrically-powered device and / or component that is embeddable in a solid structural component is provided. The electrically powered device includes an attached autonomous electrical power source in a form of a unique, environmentally-friendly structure that is configured to transform thermal energy at any temperature above absolute zero to an electric potential without any external stimulus including physical movement or deformation energy. The autonomous electrical power source component provides a mechanism for generating renewable energy as primary for the electrically-powered device and / or component once an integrated structure including the electrically-powered device is deployed in an environment that restricts future access to the electrical power source for servicing, recharge, replacement, replenishment or the like. The structure of the autonomous electrical power source component converts minimal thermal energy to a usable electrical power potential over a sustained period of time without external disturbance to the power source.

Owner:FACE INT

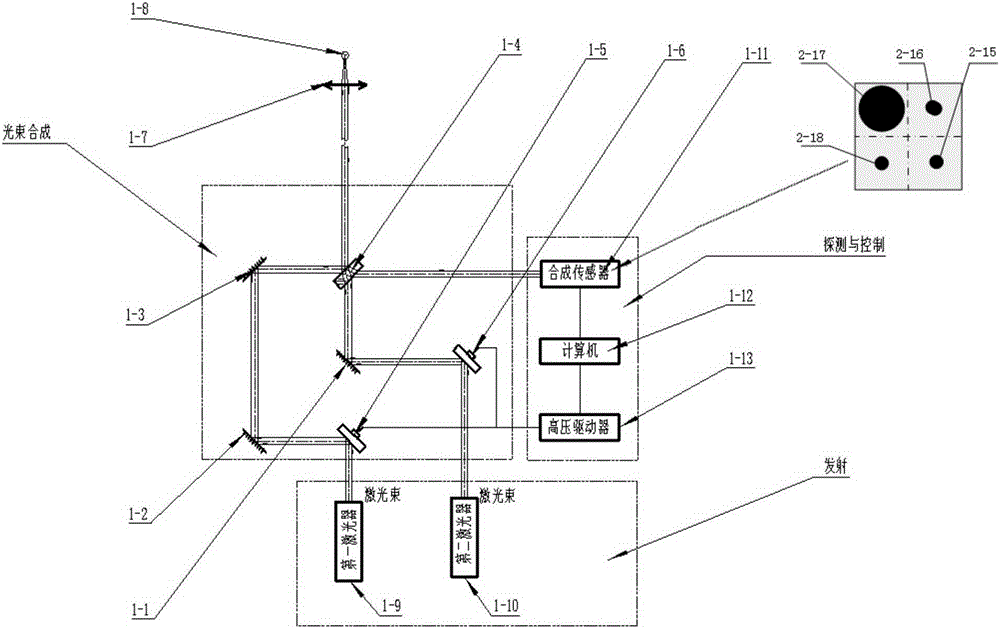

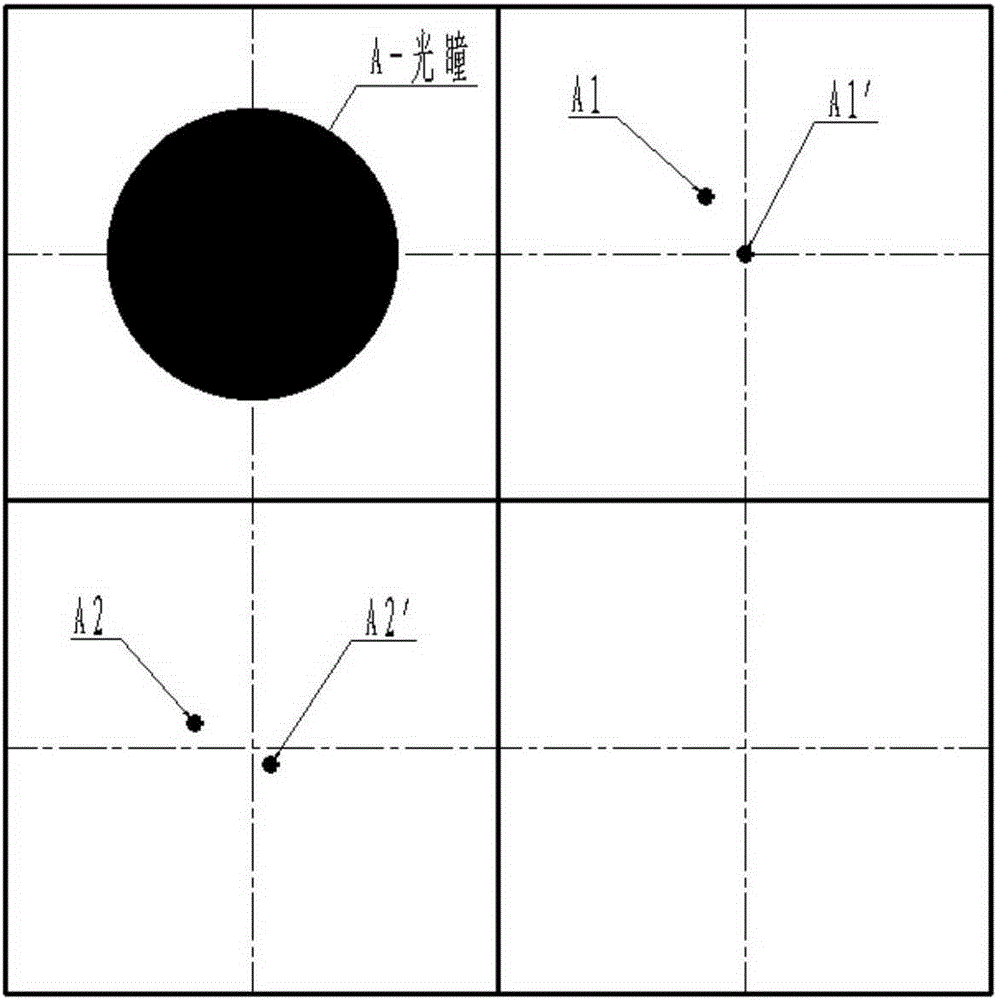

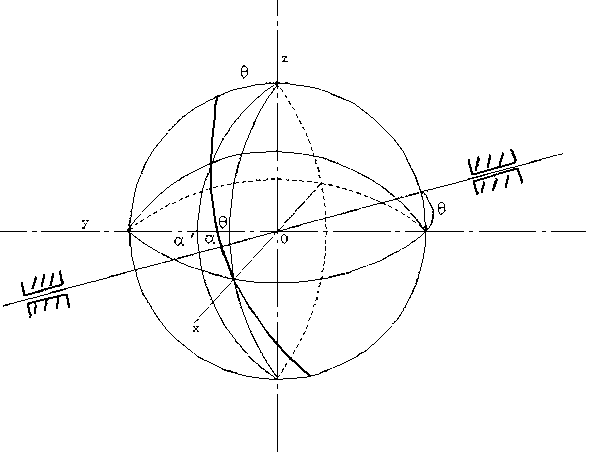

Calibration method for synthesizing far field through single detector to improve double-beam synthesis precision and pointing accuracy

ActiveCN105334028AAvoid thermal driftGuaranteed identityTesting optical propertiesAbsolute zeroOptical axis

The invention discloses a calibration method for synthesizing a far field through a single detector to improve double-beam synthesis precision and pointing precision. According to the calibration method, the detection target surface of the same detector is subjected to area division, and four paths of measurement information are adjusted into four different areas which correspond to the real-time state information of a beam combination pupil, beam combination optical axes, a path A laser optical axis and a path B laser optical axis respectively. A path of laser and B path of laser are used for emitting light in the calibration process, the beam combination optical axes A1' and B1' are located on the absolute zero point of the center of the area in a closed loop mode, and after the coordinates of the beam combination optical axes A2' and B2' are respectively calculated, closed loop work is performed with the beam combination optical axes A2' and B2' as zero points. By means of the calibration method, calibration cost can be substantially reduced, a calibration structure is simplified, errors caused by equipment environment temperature and vibration are effectively eliminated, synthesis precision and stabilization precision of double beams on the target face of the detector are guaranteed, and therefore the synthesis precision and the pointing precision of output laser beams are improved.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

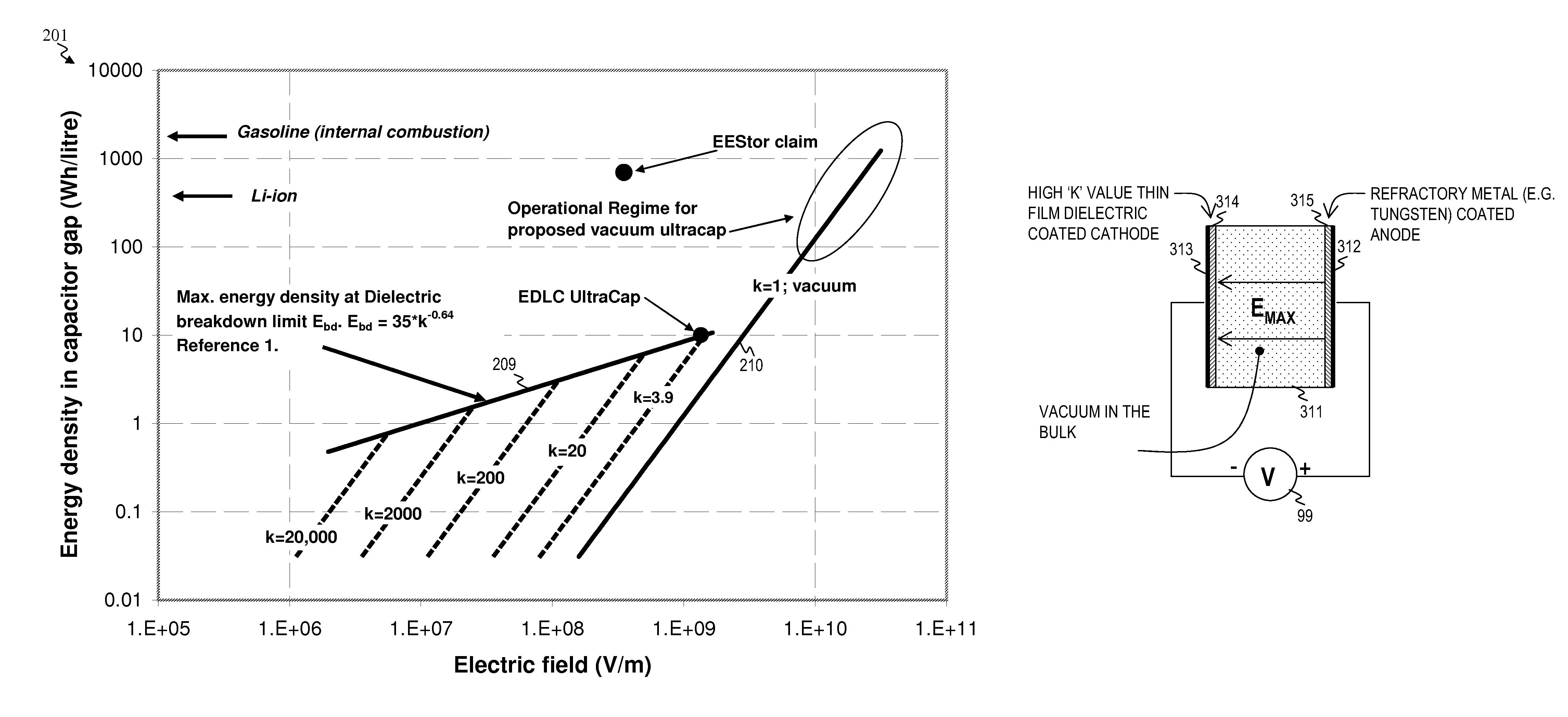

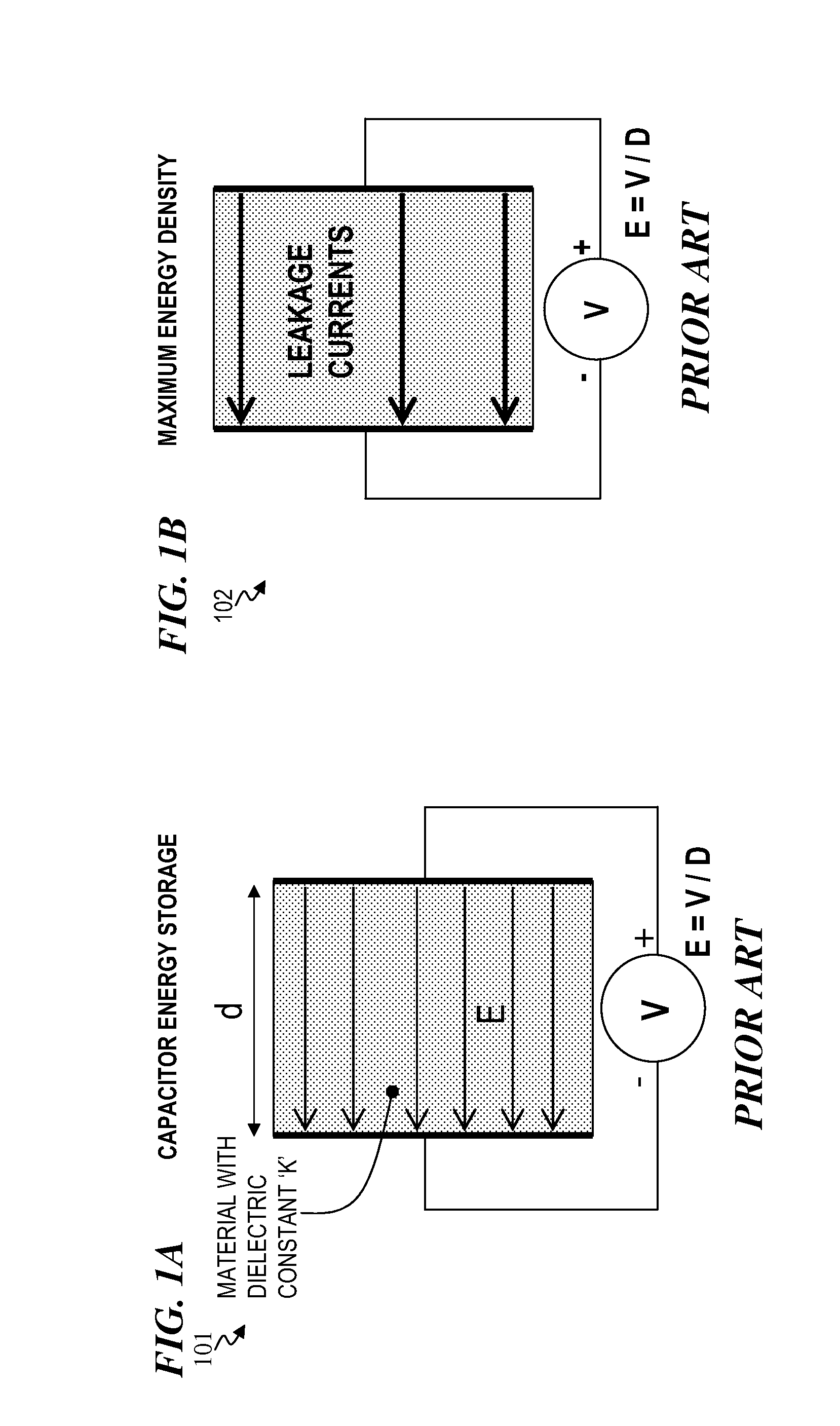

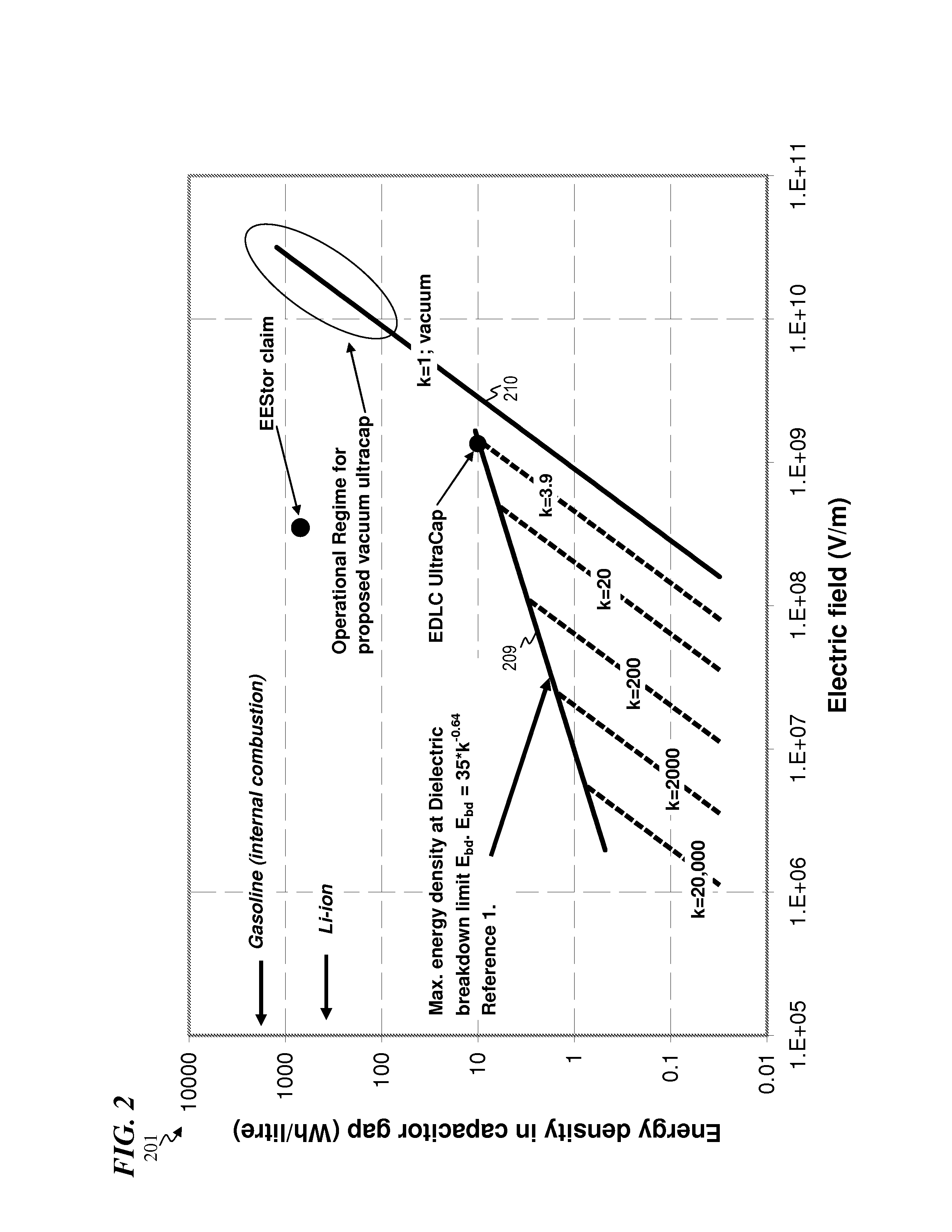

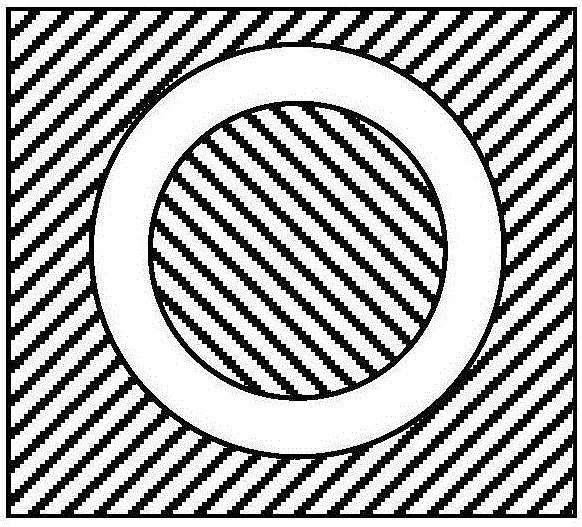

Apparatus and method for capacitors having engineered electrodes with very high energy density

An apparatus and associated method for an energy-storage device (e.g., a capacitor) having a plurality of electrically conducting electrodes including a first electrode and a second electrode separated by a non-electrically conducting region, and wherein the non-electrically conducting region further includes a non-uniform permittivity (K) value. In some embodiments, the method includes providing a substrate; fabricating a first electrode on the substrate; and fabricating a second electrode such that the second electrode is separated from the first electrode by a non-electrically conducting region, wherein the non-electrically conducting region has a non-uniform permittivity (K) value. The capacitor devices will find benefit for use in electric vehicles, of all kinds, uninterruptible power supplies, wind turbines, mobile phones, and the like requiring wide temperature ranges from several hundreds of degrees C. down to absolute zero, consumer electronics operating in a temperature range of −55 degrees C. to 125 degrees C.

Owner:GRANBLUETECH L L C

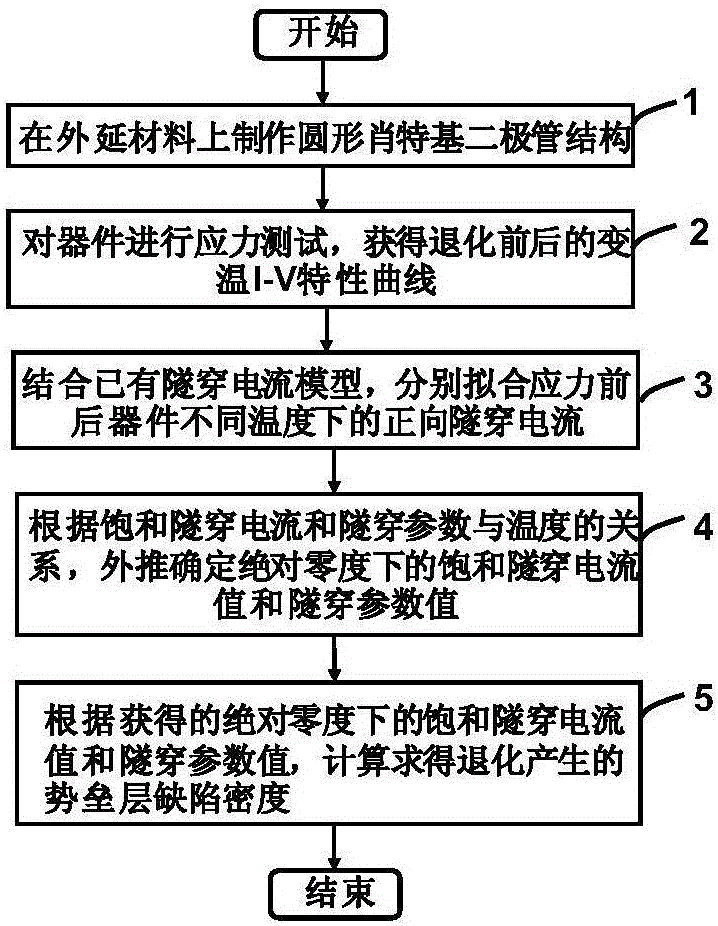

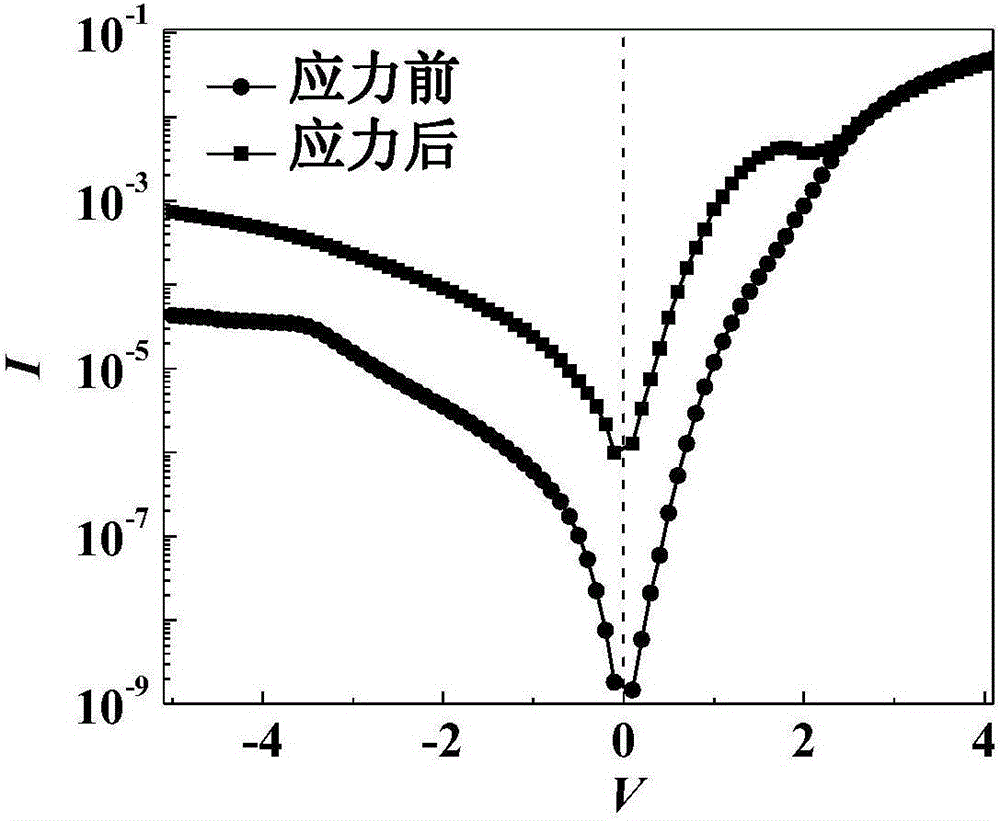

Method for detecting GaN-based HEMT degradation through current fitting

ActiveCN105891693ALower requirementAccurate detection of defect densityElectronic circuit testingCurrent/voltage measurementGate leakage currentPower flow

The invention discloses a method for detecting GaN-based HEMT degradation through current fitting. The method comprises the steps: firstly making a circular Schottky diode structure facilitating the analysis of gate leakage current characteristics, applying a continuous reverse stress to the circular Schottky diode structure, and measuring the curves of temperature dependent on current-voltage before and after stress; secondly employing extrapolation to determine the saturation tunneling current value and tunneling parameter value of a device under the absolute zero temperature before and after stress through the fitting of forwarding tunneling currents under different temperatures according to the relation between the saturation tunneling current and tunneling parameter and the temperature; finally calculating the change, caused by stress, of the defect density of a barrier layer, and achieving the detection of the GaN-based HEMT degradation. The simple method is employed for achieving the detection of the change, caused by the stress, of the defect density of the barrier layer, and facilitates the analysis of the degradation mechanism and process of a GaN-based HEMT device.

Owner:JIANGNAN UNIV

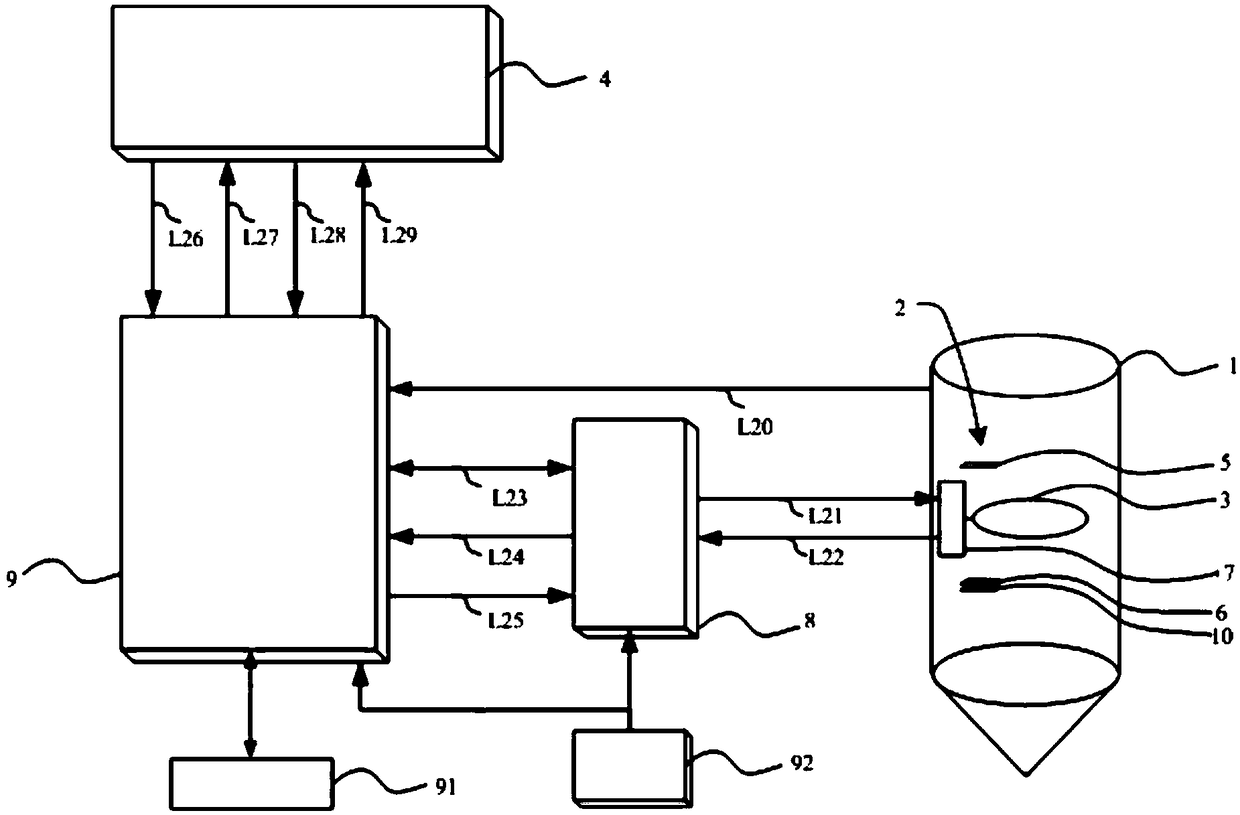

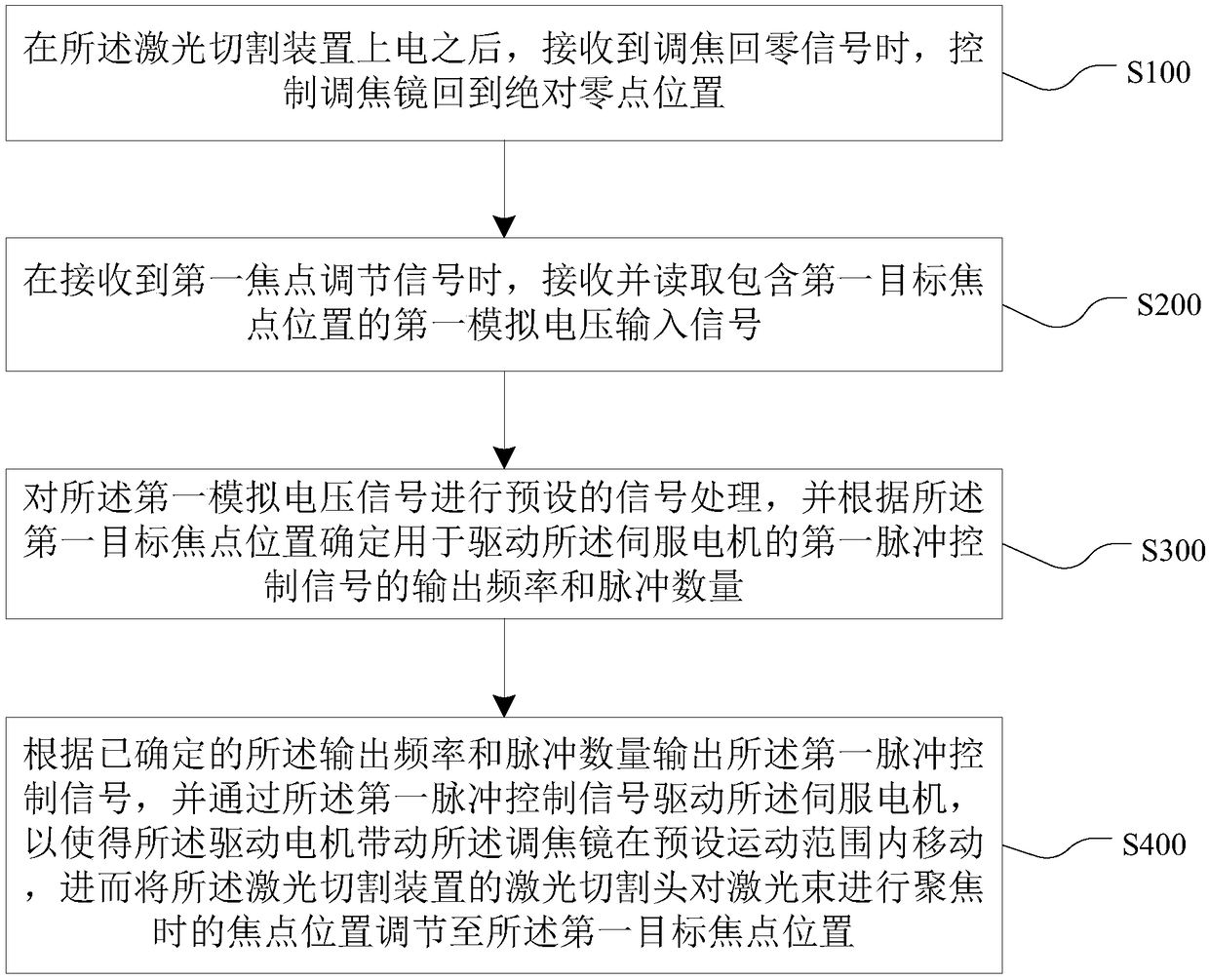

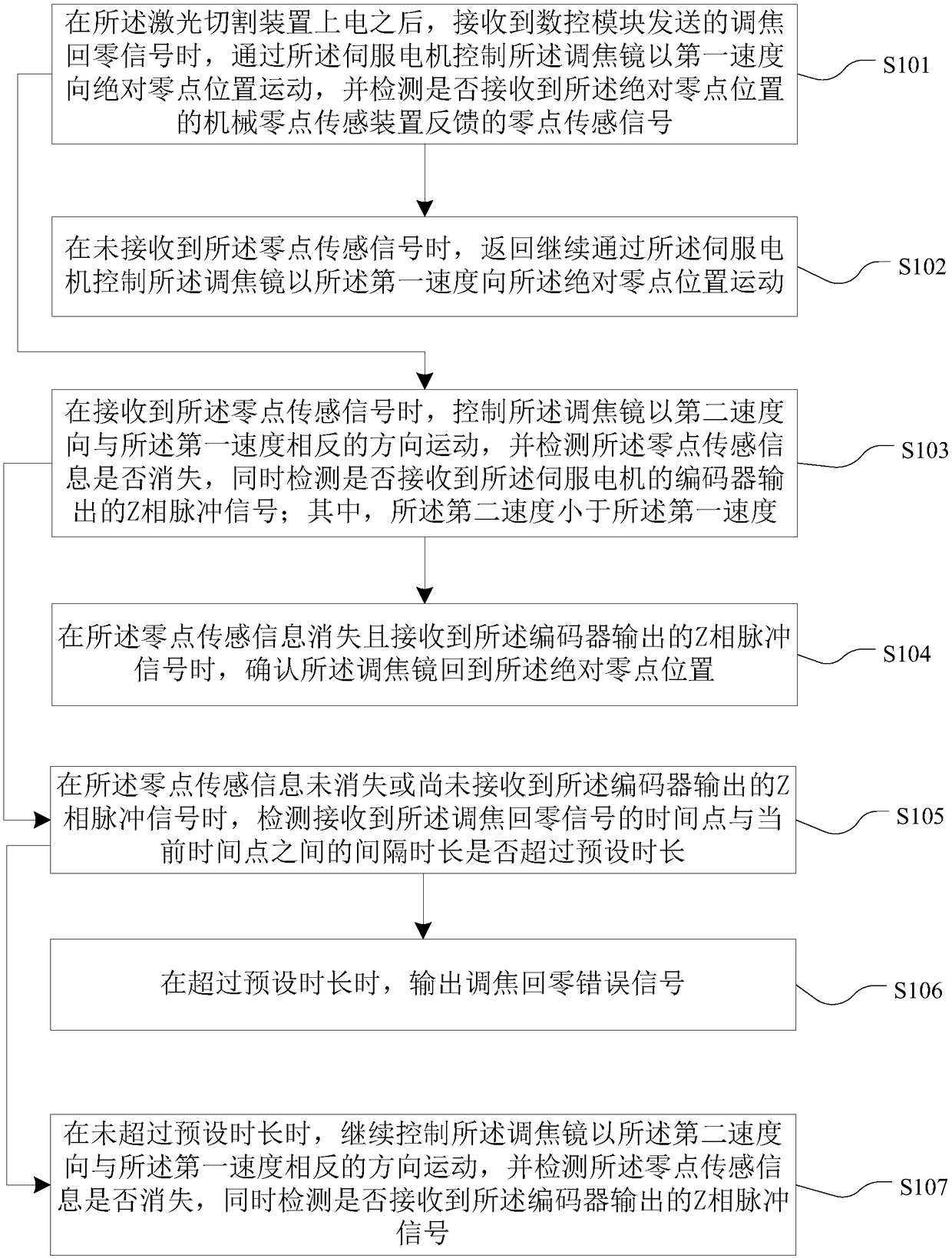

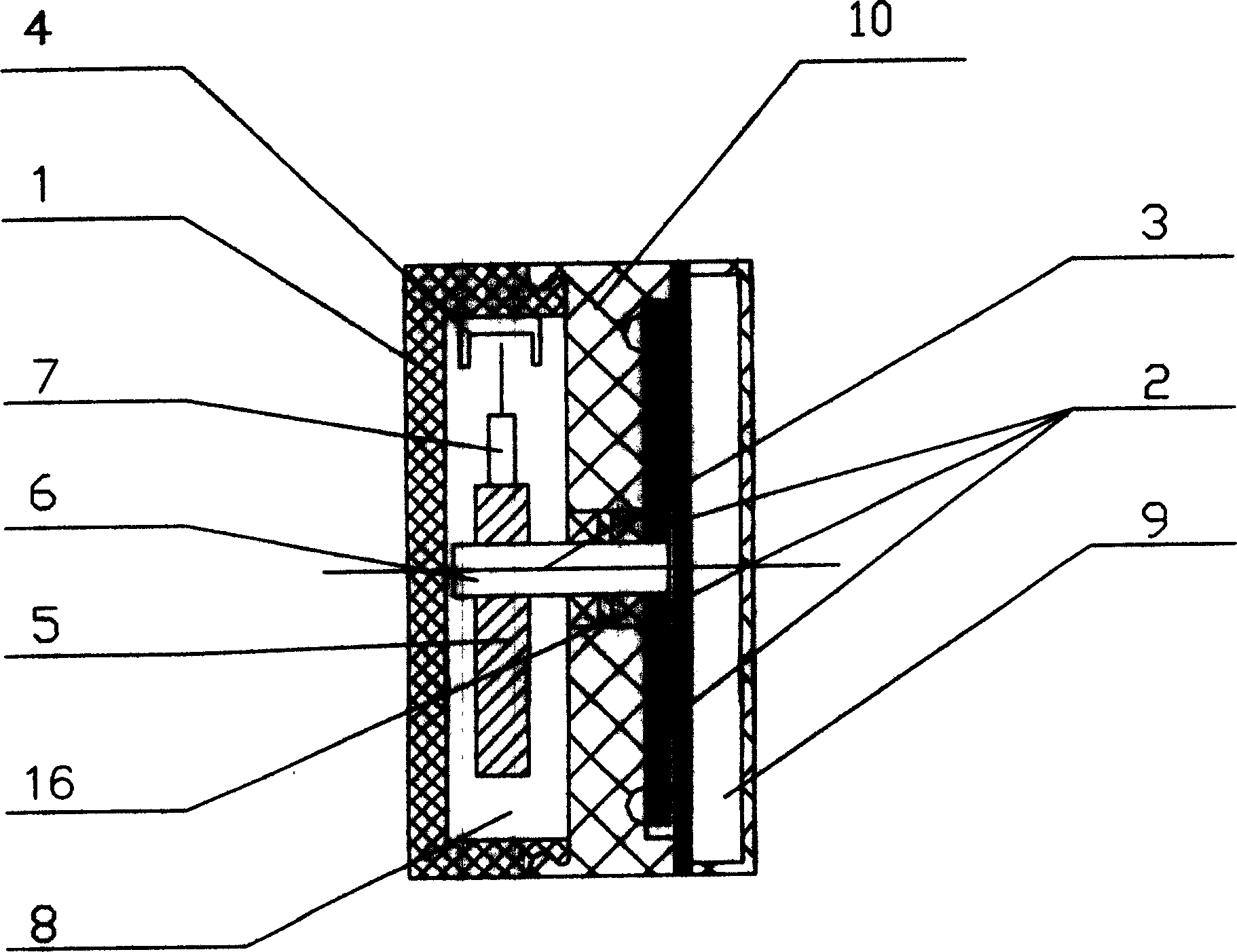

Laser cutting device and focusing method and system thereof

ActiveCN109483049AComplete structureSimple control logicLaser beam welding apparatusPulse controlElectricity

The invention provides a laser cutting device and a focusing method and system thereof. The focusing method comprises the steps that after the laser cutting device is powered on, a focusing mirror iscontrolled to return to the absolute zero point position when a focusing zero returning signal is received; when a first focus adjusting signal is received, a first analog voltage input signal containing a first target focus position is read and subjected to preset signal treatment, and the output frequency and the pulse quantity of a first pulse control signal for driving a servo motor are determined according to the first target focus position; the first pulse control signal is output according to the determined output frequency and the determined pulse quantity, the servo motor is driven through the first pulse control signal so that the servo motor can drive the focusing mirror to move within the preset motion range, and accordingly, the focus position is adjusted to the first target focus position when a laser cutting head of the laser cutting device conducts focusing on a laser beam. According to the laser cutting device and the focusing method and system thereof, the focusing precision and the focusing speed are improved, in addition, operation is easy and convenient, and the universality is high.

Owner:HANS LASER TECH IND GRP CO LTD +1

Digital display horizontal and dip measurer

The digital display horizontal and dip measurer includes casing and angle measurer. The angle measurer is capacitive angle measurer, and the casing is connected and fixed to the main grating or subsidiary grating of the capacitive angle measurer. There are also a gravitational vertical device always in vertical state connected and fixed to the subsidiary grating or main grating of the capacitive angle measurer for coaxial rotation inside the casing; and a precise position switch to determine the absolute zero position on the casing. The gravitational vertical device consists of weight, bearing shaft and float with position and shape axially symmetrical about the weight axis. The present invention has simple structure, low cost, precise measurement and stable performance, and may be used in harsh environment.

Owner:赵志强 +2

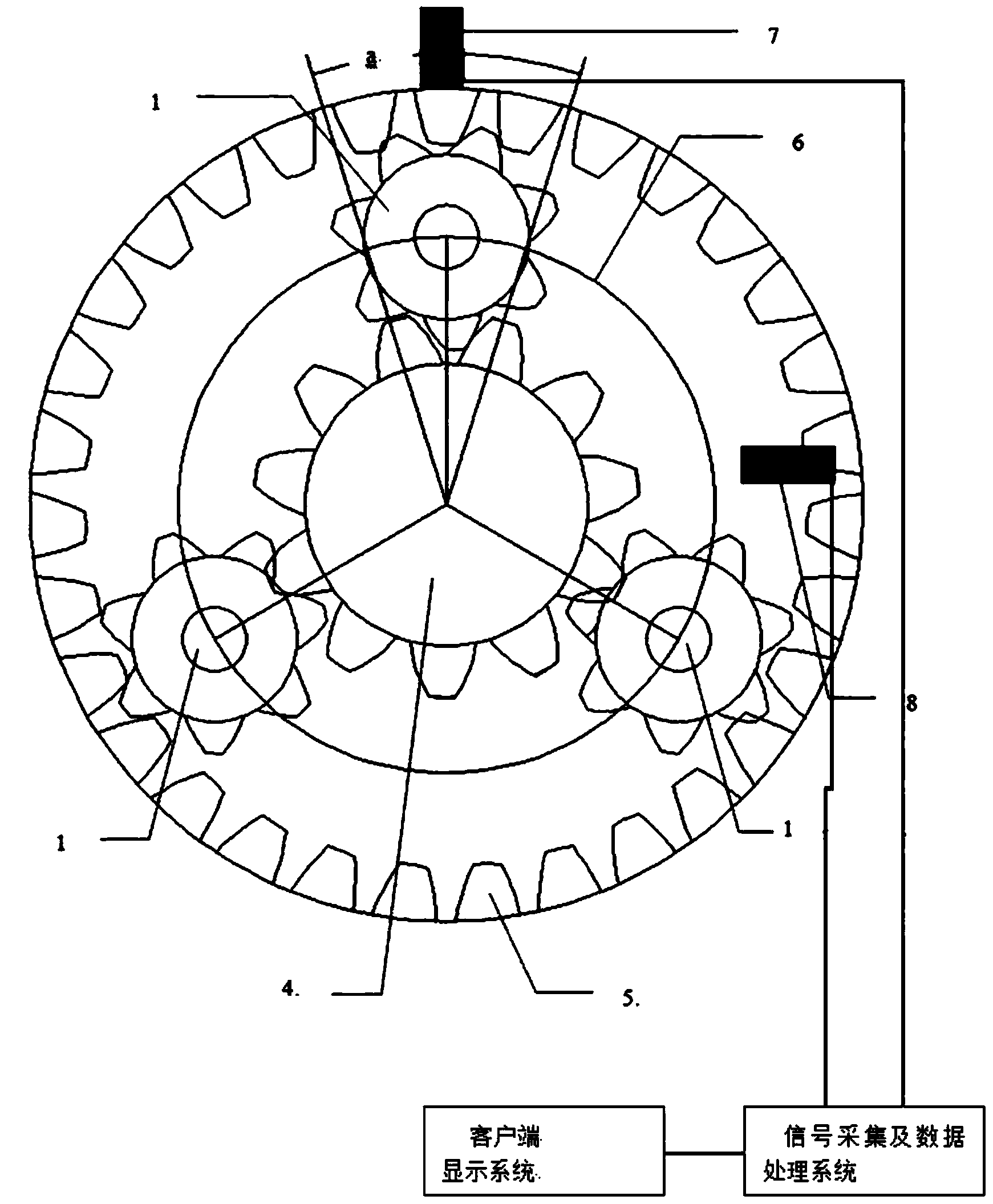

System and method for monitoring unbalance loading of planet gears of wind turbine generator system

ActiveCN103711875ATo make up for the inability to monitor the eccentric load phenomenonAvoid damageWind energy generationGearing detailsEngineeringData treatment

The invention relates to a system and method for monitoring unbalance loading of planet gears of a wind turbine generator system. A gearbox of the wind turbine generator system comprises a sun gear, the planet gears and an annular gear. The method includes the following steps of installing an acceleration sensor on the annular gear, determining the absolute zero positions, when the planet gears arrive at the absolute zero positions, enabling the acceleration sensor to start collecting data and collecting phase angle signals at the same time, determining the meshed areas of the planet gears and the annular gear, calculating the impact energy in the meshing process, obtaining differences between the magnitudes of impact energy of all the planet gears, and confirming that unbalance loading happens to the planet gears if any difference value exceeds a limiting value. The system comprises the acceleration sensor arranged on the annular gear, and a signal collection and data processing system connected with the acceleration sensor. The system and the method overcome the defect that the unbalance loading phenomenon can not be monitored in the running process of the planet gear train of the wind power gear box, and solve the problems that damage to the planet gears and a bearing is accelerated when unbalance loading happens to the planet gears and the planet gears are not timely repaired.

Owner:GUODIAN UNITED POWER TECH

Robot integrated joint location detecting method based on double-rotation change coaxial design

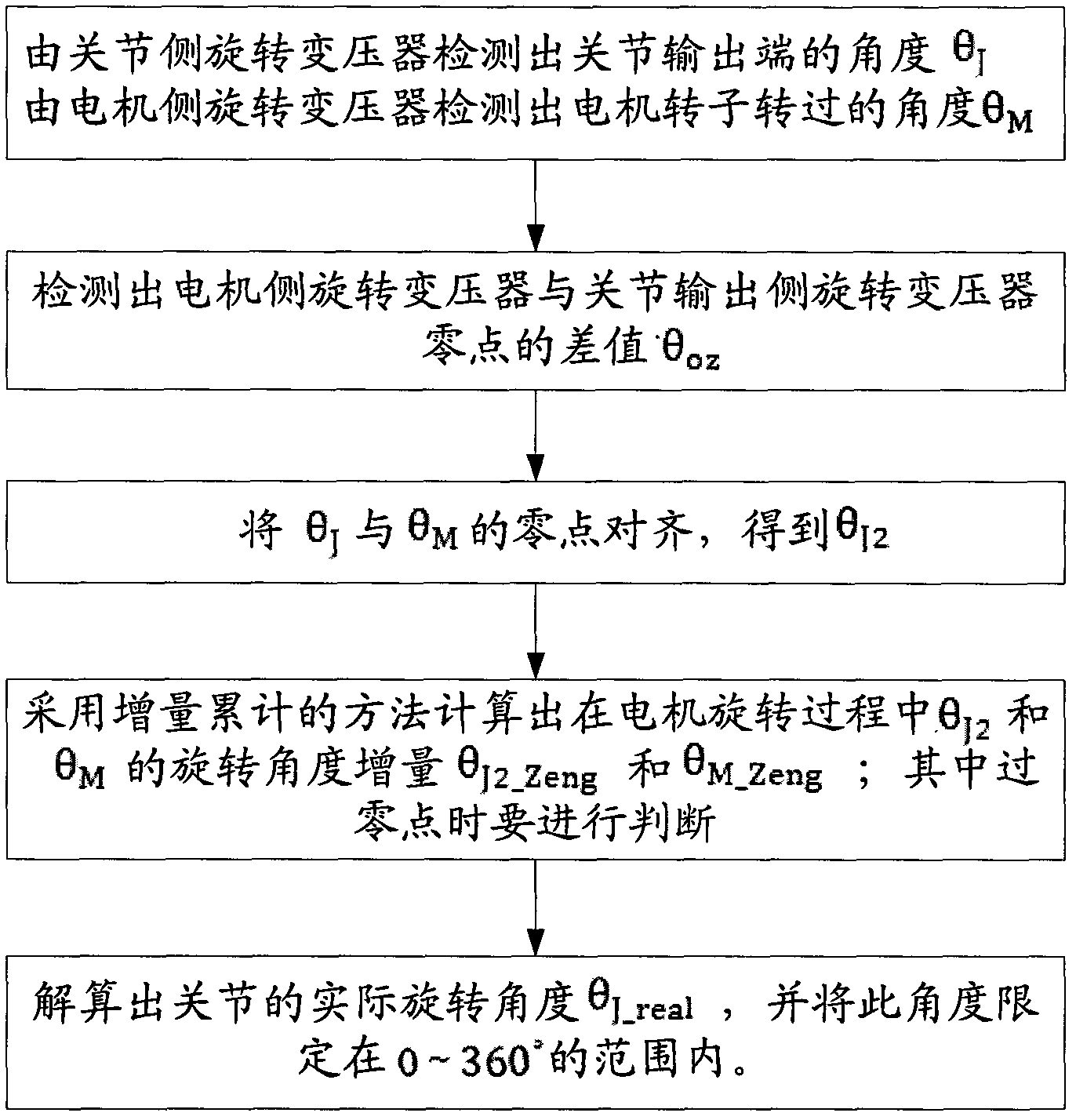

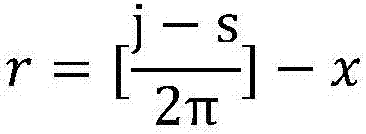

The invention discloses a robot integrated joint location detecting method based on double-rotation change coaxial design. The method comprises the following steps: firstly, determining a difference value between absolute zero points of rotary transformers on two sides; then, using an angel increment accumulation method to accumulate increments of an angle theta M measured at the rotary transformer on a motor side and an angle theta J2 measured at the rotary transformer on a joint side during the motor rotation, and obtaining the difference value through one angle minus the other, which is the actual rotation angle of the joint. At the same time, when calculating the angle increment, the moment of crossing the zero points is specially treated, that is to say, the maximum probable value between the angle difference values at the next moment and the last moment of the motor is obtained to be taken as the critical value for judgment according to the time difference value between the maximum rotating speed of the motor and the resolved angle of the rotary transformers.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Force moment zero-searching method for elastic drive joint

ActiveCN107443381ARealize homingSimple structureProgramme-controlled manipulatorElastomerElectricity

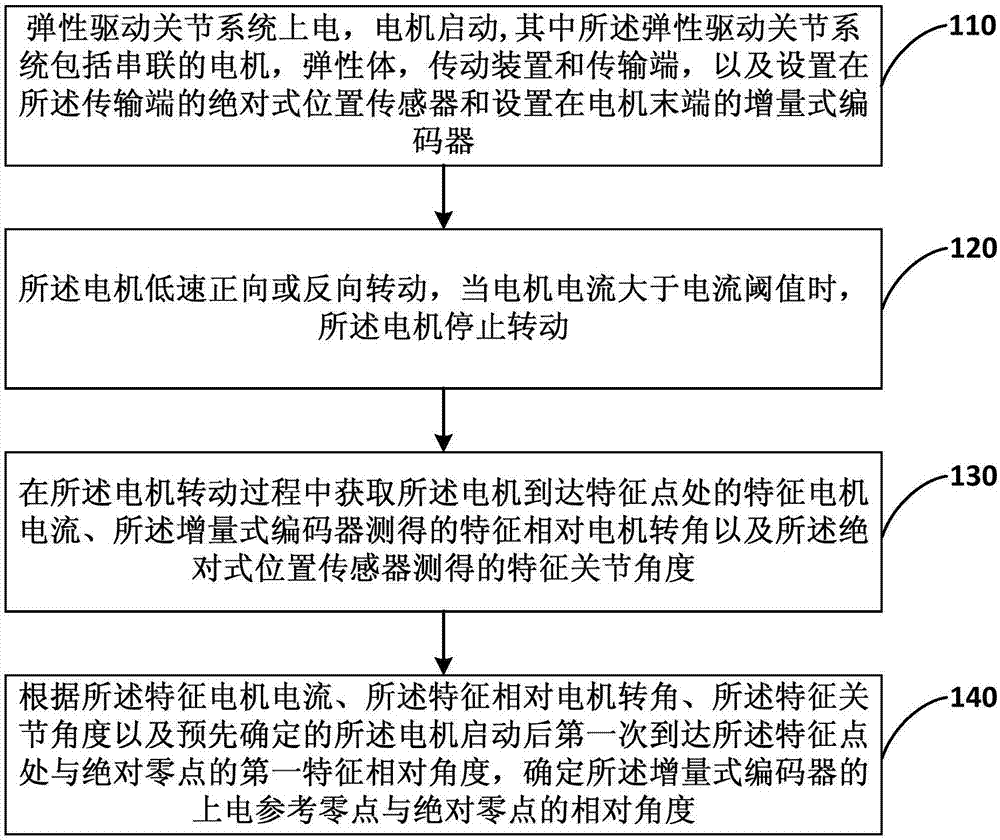

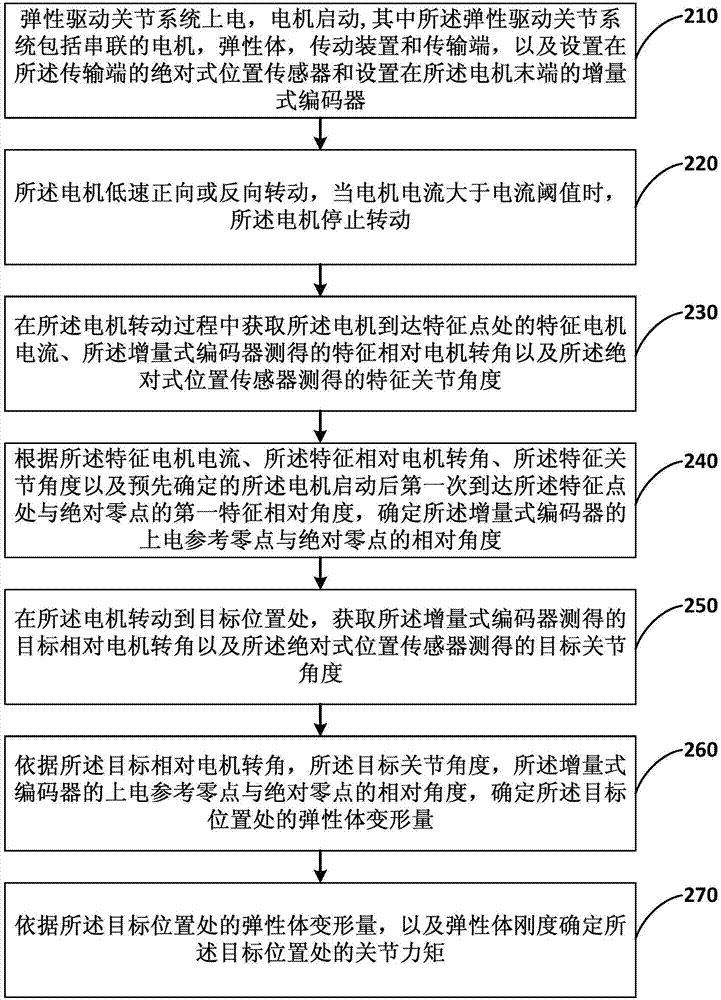

The invention discloses a force moment zero-searching method for an elastic drive joint. The method comprises the following steps of: systemically electrifying the elastic drive joint, and starting a motor; positively or negatively rotating the motor at low speed, and stopping rotation of the motor when current of the motor is greater than a current threshold value; obtaining feature motor current when the motor reaches a feature point, a feature relative motor rotation angle measured by an incremental coder and a feature joint angle measured by an absolute type position sensor in a rotation process of the motor; and determining a relative angle between an electrifying reference zero point and an absolute zero point on the incremental coder according to the feature motor current, the feature relative motor rotation angle, the feature joint angle as well as a pre-determined first feature relative angle when the motor reaches a feature point and an absolute zero point at the first time after starting. The force moment zero-searching method disclosed by the invention realizes zero-searching of the incremental coder, so that the incremental coder can be used for measuring deformation amount of an elastomer; and moreover, an SEA joint structure is simplified, and the production cost is reduced.

Owner:SIASUN CO LTD

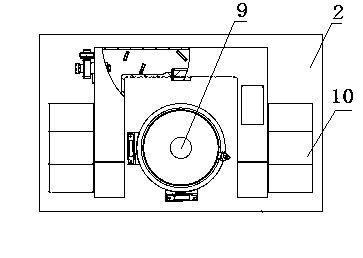

Method for treating errors of angle measurement of circular grating and compensating skew of shafting

ActiveCN103162712AAccurate Angle Measurement RequirementsImprove angle measurement accuracyMeasurement devicesTurn angleGrating

The invention discloses a method for treating errors of the angle measurement of a circular grating and compensating the skew of a shafting. The method comprises the following specific steps: the real-time location information of a rotation angle acquired by a reading head which is matched with a circular grating disc is collected by a field programmable gate array (FPGA); after calculation and treatment, the FPGA outputs an angle count value which corresponds to the position of the rotation angle and transmits the angle count value to a central processing unit; the central processing unit calculates the rotation angle value relative to an absolute zero position of the current rotation angle position and displays and outputs calculation results; and the vertical angle error caused by the skew of the shafting is compensated and corrected. The method has the beneficial effects that by the method of correcting angles by the piecewise linearity, angle values are corrected piecewise and the skew errors of the shafting are compensated in real time in the working range of the circular grating, so that the requirements of precise angle measurement in complex environment and under limited condition of high-precise circular gratings are realized and the accuracy of the angle measurement of calibration instruments of angle measuring and orienting equipment is increased.

Owner:NO 63908 TROOPS PLA

Method and device for measuring refractive index of rear spectrophotometric pupil laser differential confocal lens

ActiveCN109187430AEliminate interactionReduce the impactPhase-affecting property measurementsRefractive indexLight beam

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for producing absolute zero-position alignment marks by semi-reflective zero-position grating

InactiveCN1924711AAlignment AccuracyOvercoming structural problems that prevent the use of transmissive 2D null gratingsSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusGratingLight beam

This invention relates to one method by use of transmission grating to generate zero calibration mark, which adopts two blocks of grating with special coding zero mark an comprises the following steps: putting the grating on z direction and beam goes vertical to the grating; then fixing the reflection grating on the back of transmission grating along z direction parallel to the transmission grating and is reflected back and making two gratings calibrate through adjusting reflection grating angle and position to get the absolute zero position in X-Y plane; adding split prism on the light path to set photoelectricity receiver to receive light signal for judging and reading.

Owner:UNIV OF SCI & TECH OF CHINA

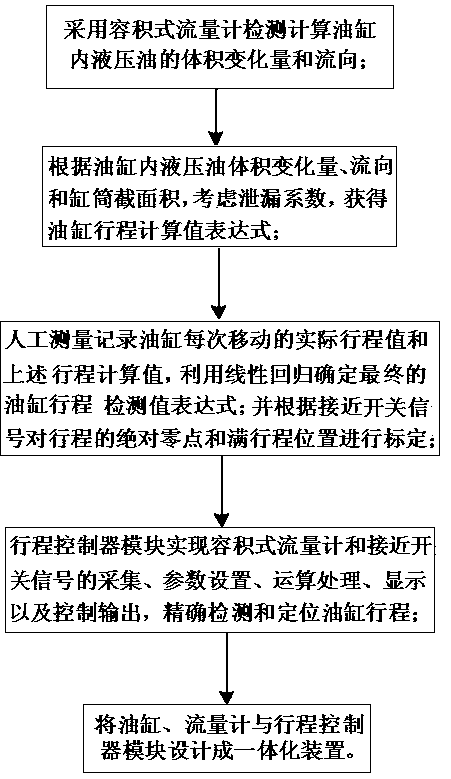

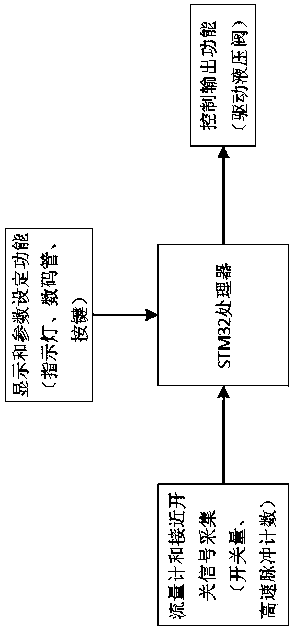

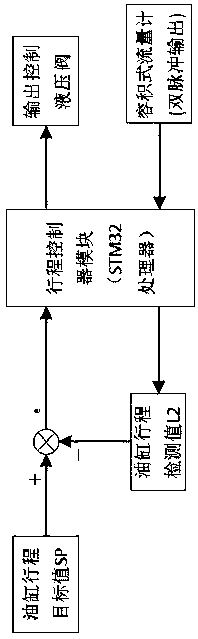

Oil cylinder stroke detection and control method based on hydraulic oil volume flow

ActiveCN108916158AReduce power consumptionHigh precisionFluid-pressure actuator componentsSwitching signalLinear regression

The invention discloses an oil cylinder stroke detection and control method based on hydraulic oil volume flow. The oil cylinder stroke detection and control method is characterized by comprising thefollowing steps that the volume change amount and the flow direction of the hydraulic oil in the oil cylinder are calculated by adopting a volumetric flow meter; the leakage coefficient is considered,according to the volume change amount of the hydraulic oil in the oil cylinder, the flow direction and the sectional area of the cylinder barrel, an oil cylinder stroke calculation value expression is obtained; the actual stroke value of each time of the oil cylinder is measured and recorded manually, the obtained oil cylinder stroke calculation value is combined, the final oil cylinder stroke detection value expression is determined through linear regression, and the absolute zero point and the full stroke position of the stroke are calibrated according to the proximity switch signal; the travel controller module is used for realizing collection, parameter setting, operational processing, display and control output of the volumetric flow meter and the proximity switch signal, and the oilcylinder stroke is accurately detected and positioned; the oil cylinder, the flow meter and the travel controller module are designed into an integrated device. The oil cylinder stroke detection andcontrol method is compact in structure, is not influenced by the stroke of an oil cylinder and is low in cost, does not need special machining of the oil cylinder body, and is easy to realize.

Owner:YANTAI FUTURE AUTOMATIC EQUIP

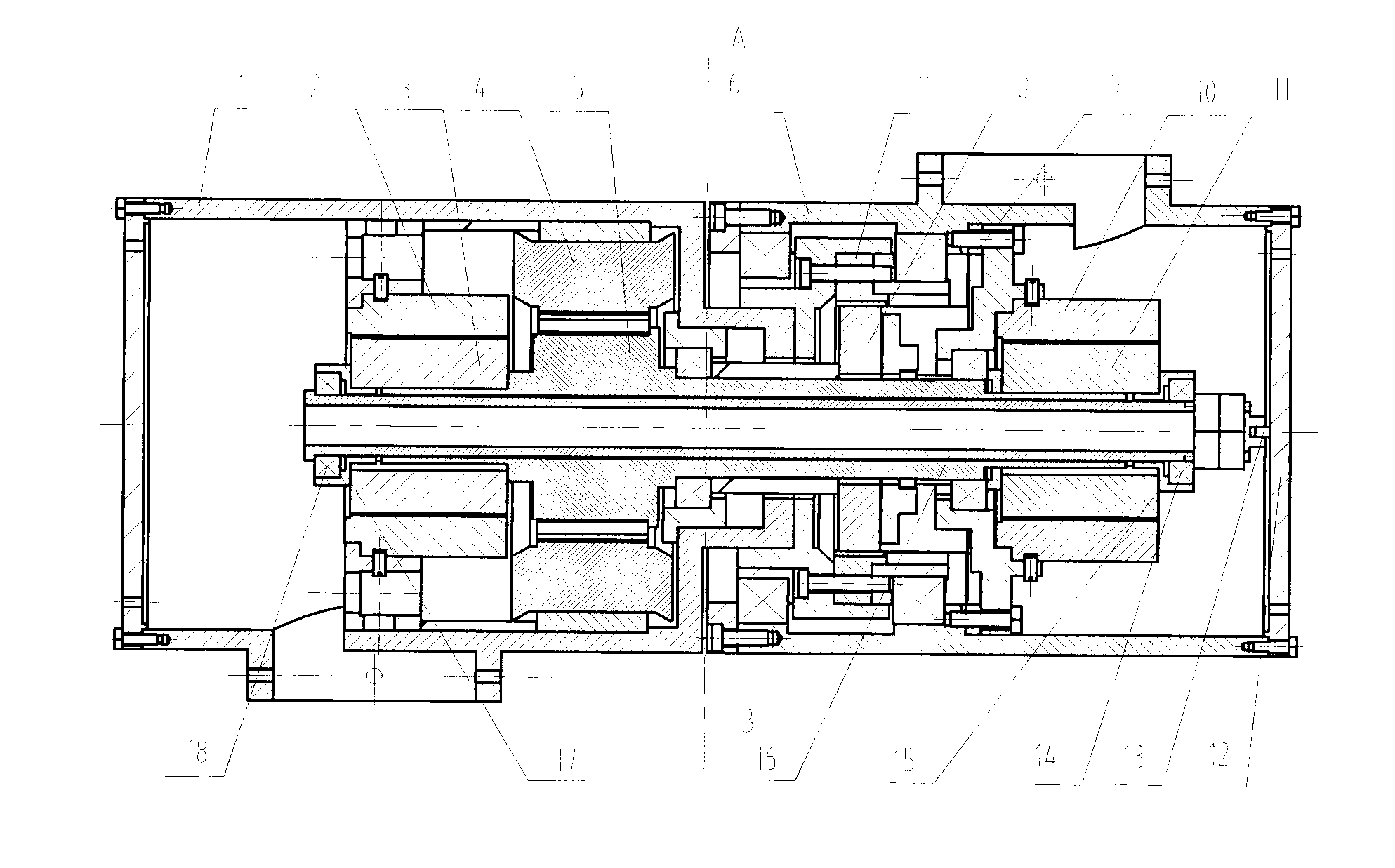

Method and device for measuring axial clearance of rear spectrophotometric pupil laser differential confocal lens group

The invention relates to a method and device for measuring the axial clearance of a rear spectrophotometric pupil laser differential confocal lens group, and belongs to the technical field of opticalprecision measurement. According to the method in the invention, half measurement beams are kept out by utilization of a rear pupil; measurement beams are detected by utilization of a spectrophotometric pupil laser differential confocal detection system; various surface positions of the measured lens group are respectively fixed by utilization of the absolute zero point of a differential confocalresponse curve; and each axial clearance in the lens group is calculated through tracing and a compensation model thereof. According to the method and the device in the invention, a rear spectrophotometric pupil laser differential confocal technology is used for high-precision detection of the axial clearance of the lens group for the first time; differential confocal focus-fixing can be realizedonly by one detector; a laser differential confocal technology and a ray tracing technology are organically fused; influence among various focused surface parameters is eliminated; furthermore, the data near the absolute zero point is linearly fitted, so that quick trigger focusing is realized; the problem that the focus-fixing precision is decreased possibly due to replacement of the measured lens is avoided; and the measurement speed and precision and the anti-scattering capability are greatly improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Control method and apparatus for mechanical absolute zero position in stepper motor transmission system

InactiveCN101304230AReliable methodLow costDynamo-electric converter controlControl using feedbackElectricitySystems design

A mechanical absolute zero position controlling method in a stepping motor driving system adopts a two-step positioning method. The method is as follows: firstly, an in place sensor is used for receiving an in place signal of the distance between a moving machine moving to a baffle block and the preset gap; the signal is transformed and conditioned and then is transmitted to a controller; the controller switches off electricity to a stepping motor as soon as receiving the signal, which is a coarse positioning; then, the heteropolar magnets which are arranged face to face at the corresponding position of the end of the moving machine and the stepping motor are pulled in each other to achieve a precise position, that is an absolute zero position. The mechanical absolute zero position controlling method in the stepping motor driving system designed by the method is provided with the stepping motor controlled by a controller; the stepping motor drives the moving machine to move along a guide rail to the baffle block in a straight line. The end of the moving machine is provided with an in place sensor, an in place sensor output connected with the controller by a adjusting and shaping circuit. Two heteropolar magnets are arranged face to face on the corresponding position of the end of the moving machine and a dead baffle block respectively.

Owner:JIANGSU UNIV

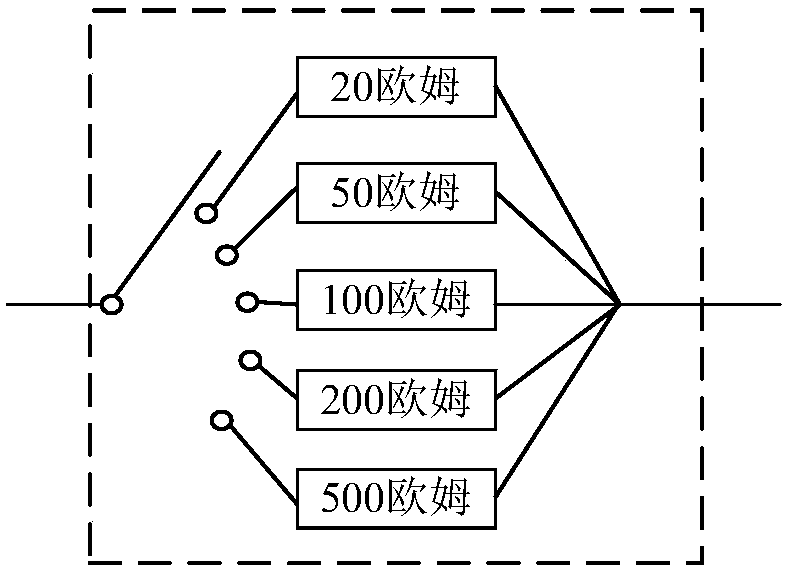

Electromagnetic shake table using absolute position feedback to realize active positive rigidity resilient support

InactiveCN108051165AGood effectWith non-contact measurementSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansElectrical resistance and conductanceRelative displacement

An electromagnetic shake table using absolute position feedback to realize active positive rigidity resilient support belongs to the vibration metering technical field; the active positive rigidity resilient support method employs an absolute type linear raster ruler as a feedback displacement sensor, and outputs a Lorentz force in a constant proportion with the relative displacement of the absolute zero point position, thus enabling an electromagnetic shake table moving-coil to have the linearity rigidity resilient support in large stroke motions; the electromagnetic shake table moving-coil is connected in series with multistage power resistors so as to increase the load impedance, thus allowing a power amplifier to have a high signal to noise ratio while outputting a milliampere level ultralow frequency current; the electromagnetic shake table can combine the large stroke with the linear resilient support and the high signal to noise ratio, thus providing a large stroke high performance electromagnetic shake table control technology scheme for the ultralow frequency vibration calibration.

Owner:HARBIN INST OF TECH

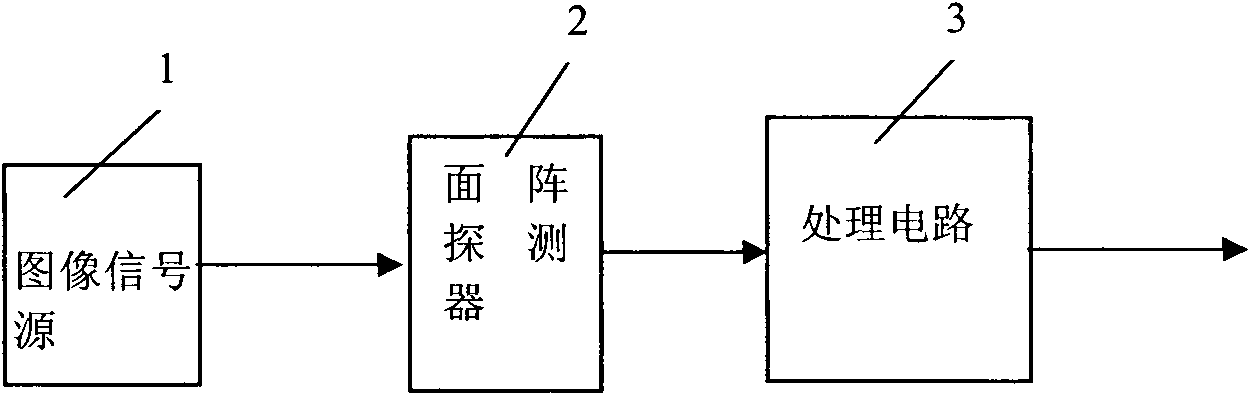

Displacement and velocity sensor

ActiveCN101614525AHigh precisionSimple preparation processUsing optical meansDevices using optical meansFlat panel detectorImage signal

The invention relates to a displacement and velocity sensor. The sensor comprises an image signal source, a flat-panel detector and a processing circuit; the flat-panel detector carries out imaging on the image signal source, converts image signals into electrical signals and then transmits to the processing circuit; and the processing circuit calculates and processes received electrical signals, and outputs signals indicating the displacement and velocity physical quantities of objects to be detected. By adopting the invention, the measurement values of displacement and velocity with higher accuracy can be obtained easily; the sensor can be installed and debugged with an object to be detected without the need of separately setting absolute zero information, then absolute zero is set, after installation and utilization, the sensor can be easily adjusted, even disposal methods can be changed, thus the sensor is convenient for installation and debugging, and easy for correction and function expansion.

Owner:长春长光启衡传感技术有限公司

Frame drive power supply integrated component

ActiveCN103471576AMiniaturizationCompact structureSpeed measurement using gyroscopic effectsRotary gyroscopesElectric machineControl theory

The invention discloses a frame drive power supply integrated component, belonging to the field of space actuating mechanisms. The frame drive power supply integrated component comprises a frame supporting component, a conducting ring component, an ultrasonic motor component, a double-channel absolute zero circular inductosyn component, a synchronizer rotor locking nut and a conducting ring fixing plate. The frame drive power supply integrated component implements integration design of the frame drive component and the frame power supply component; the frame motor adopts the novel ultrasonic motor; the angular measurer adopts the double-channel absolute zero circular inductosyn component, thereby implementing high precision, low power consumption and light weight; and the frame drive power supply integrated component is suitable for small satellites.

Owner:BEIJING INST OF CONTROL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com