Laser cutting device and focusing method and system thereof

A technology of laser cutting and laser cutting head, used in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of poor versatility, poor focusing accuracy, and slow focusing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

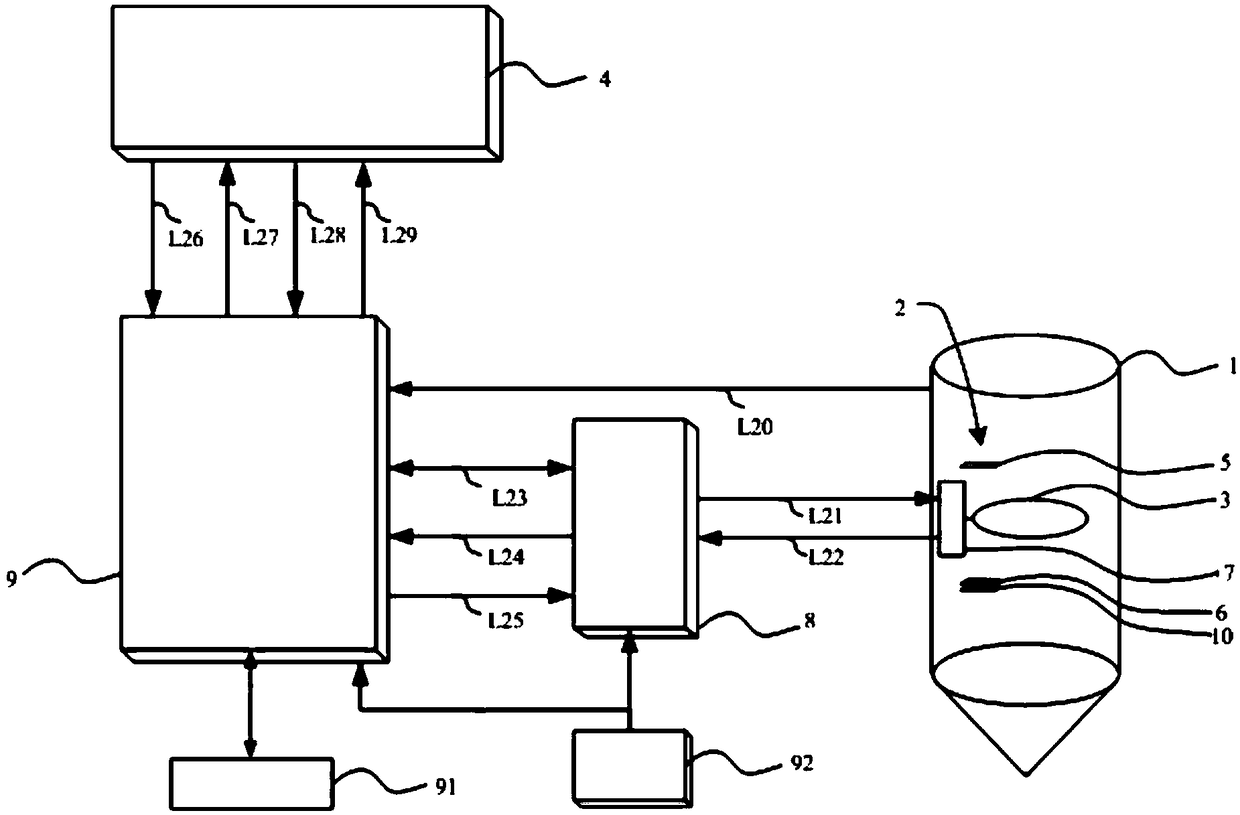

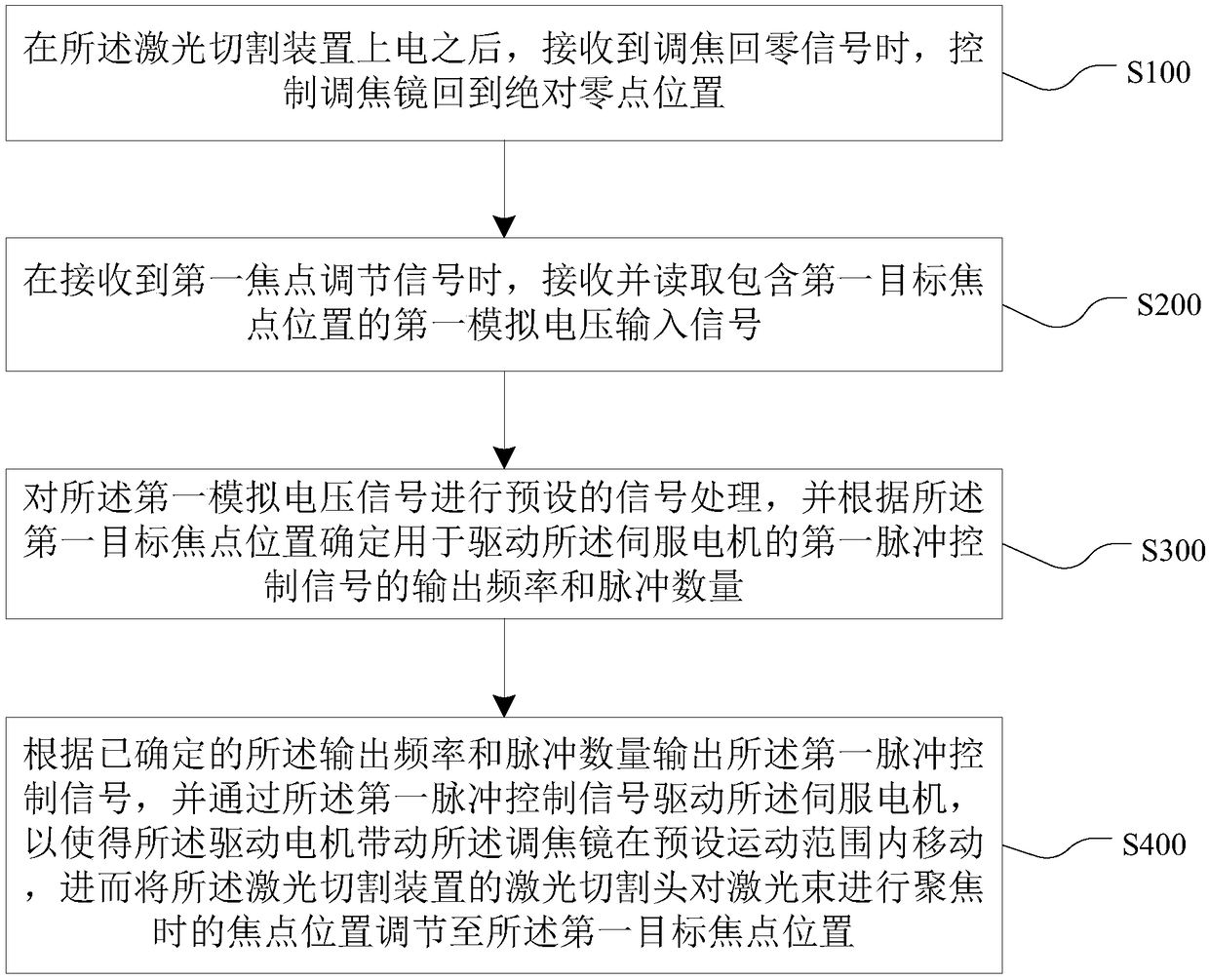

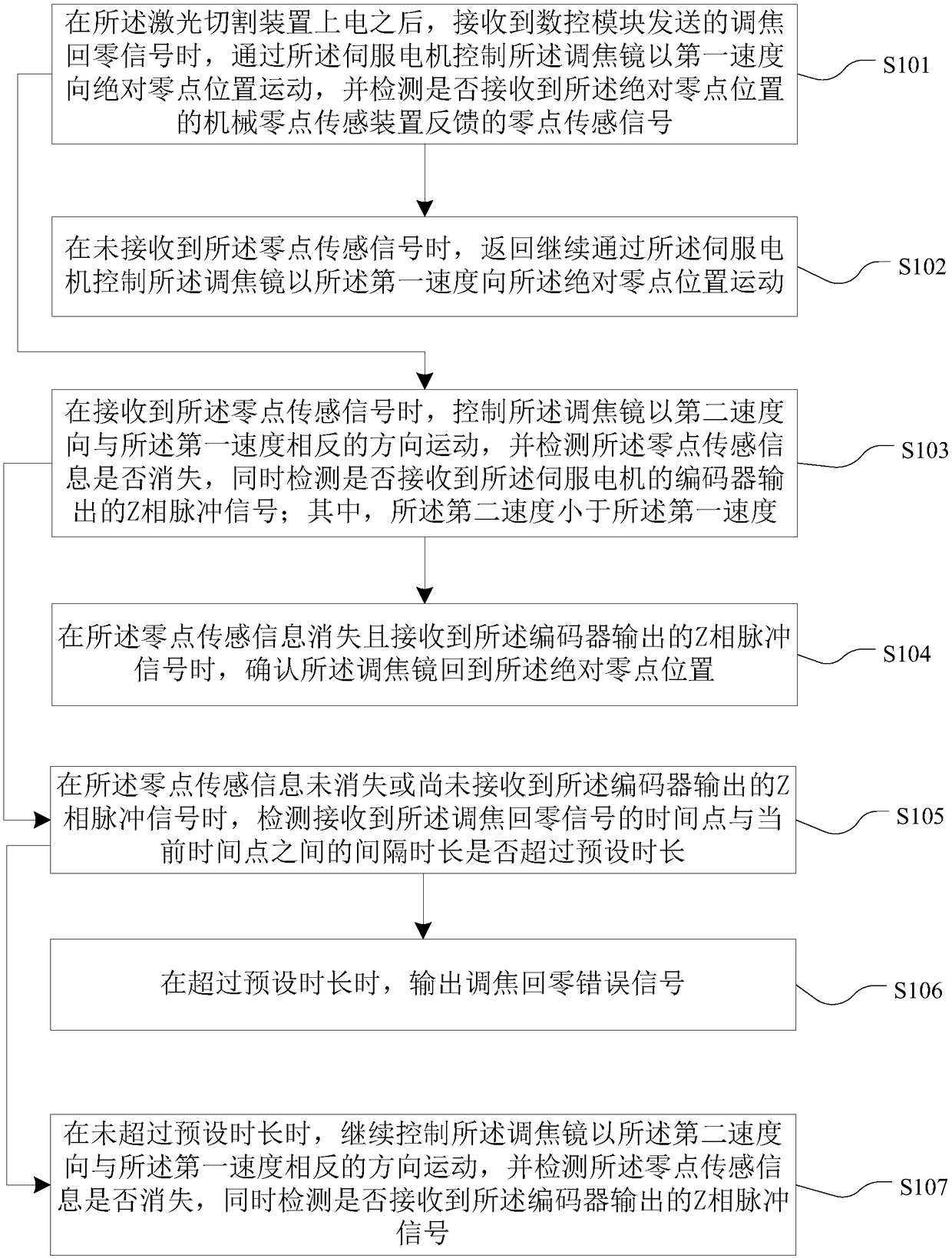

[0091] Furthermore, please also refer to Figure 1 to Figure 3 , as a specific implementation of the focusing method of the laser cutting device provided by the present invention, the step S100 includes:

[0092] S101, after the laser cutting device is powered on, when receiving the focus return-to-zero signal sent by the numerical control module, control the focus mirror 3 to move to the absolute zero position at a first speed through the servo motor 7, and detect Whether to receive the zero point sensing signal fed back by the mechanical zero point sensing device 10 of the absolute zero point position.

[0093] That is, in this embodiment, after the laser cutting device is powered on, the focusing system 9 will wait to receive the focus return-to-zero signal sent by the numerical control module. , first output the pulse control signal to control the servo motor 7 (the servo motor 7 drives the focusing mirror 3) to move towards the zero point sensing device (that is, the abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com