Laser differential confocal tomography focusing method and device

A differential confocal and laser technology, which is used in the measurement of aspheric components, optical components, optical imaging and detection, and optical systems, can solve the problem of poor anti-scattering ability of the surface, limited ability of confocal microscope axial resolution, measurement Long time and other problems, to achieve the effect of simplifying the system structure and assembly process, improving the accuracy of optical focusing, and high-precision tomographic focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

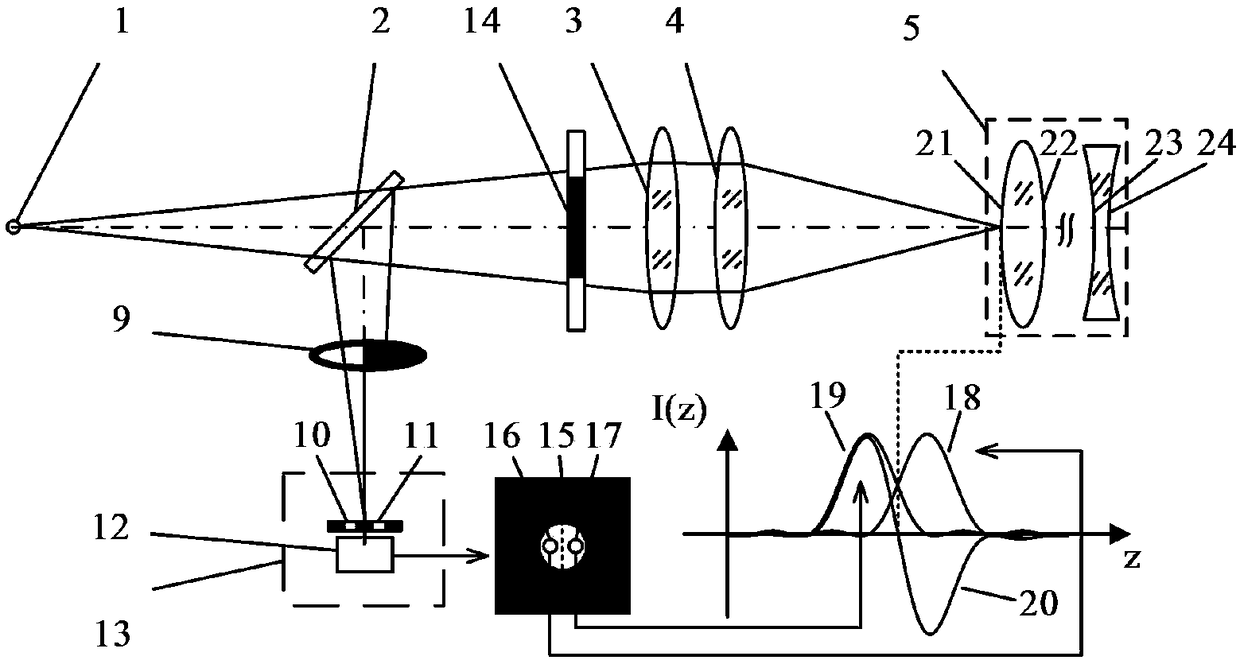

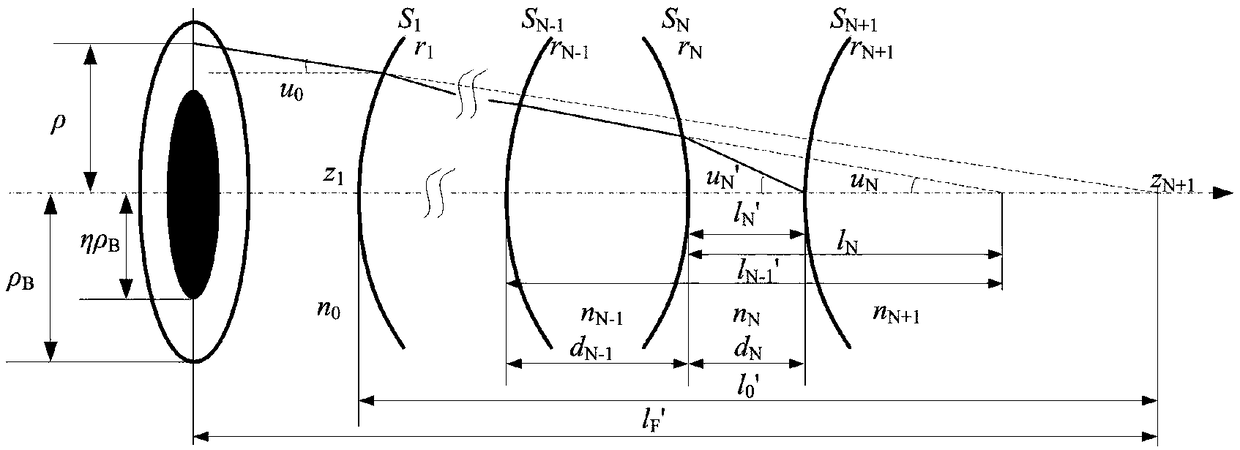

[0054] as attached Figure 5 As shown, a laser differential confocal tomographic fixed focus device includes a laser 31, an optical fiber 32, and a point light source 1, and a beam splitter 2, a collimator lens 3, and an objective lens 4 placed in the light emitting direction of the point light source 1 in sequence, It also includes a D-shaped rear pupil 9 placed in the reflection direction of the beam splitter 2 and a split-pupil differential confocal detection system 13 composed of a microscopic objective lens 27 and a CCD 28; the main control computer 33 is connected with a motor drive system 34, It drives the linear guide rail 35 to drive the measured sample 5 to scan along the optical axis.

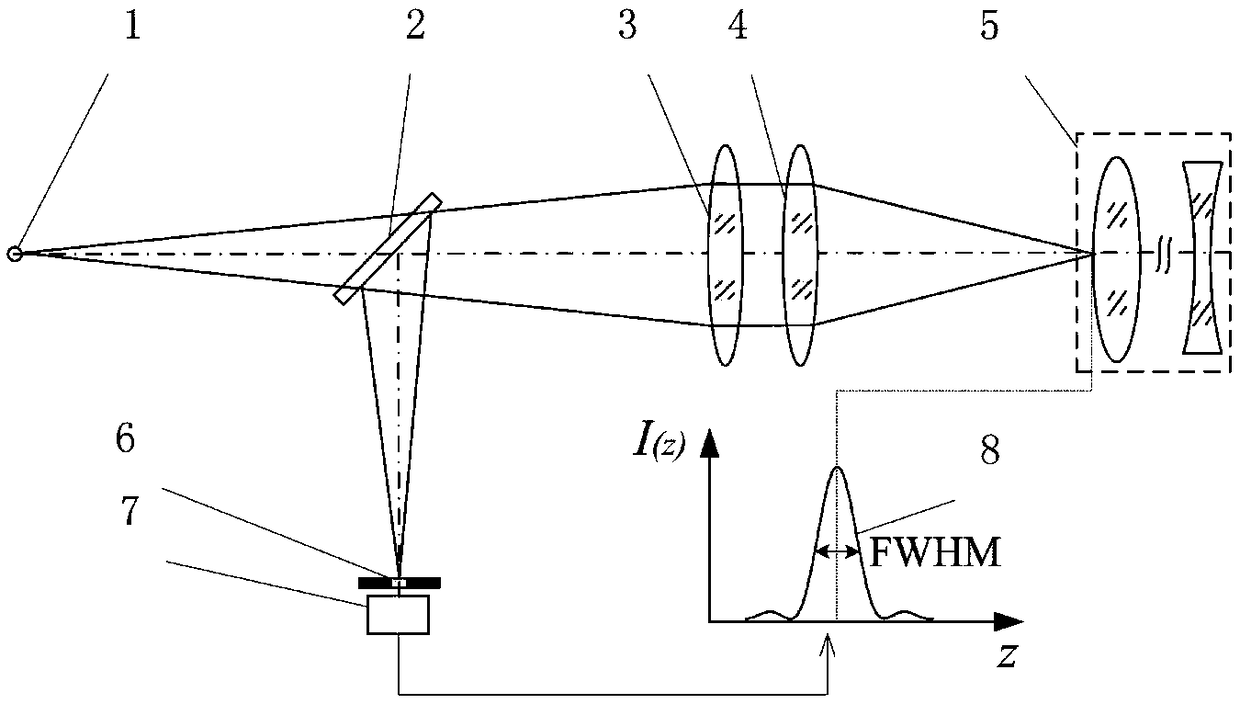

[0055] Usually the split-pupil differential confocal detection system 13 has two forms, one is the attached figure 2 The split-pupil differential confocal detection system using pinhole detection is shown, and the other is the attached Figure 5 A split-pupil differential confocal...

Embodiment 2

[0069] Such as Image 6 As shown, a laser differential confocal tomographic fixed focus device, its measurement steps are the same as in Embodiment 1, the difference is that a circular rear pupil 37 is used to block the measurement beam, and then realize the laser differential confocal Tomographic focus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com