Oil cylinder stroke detection and control method based on hydraulic oil volume flow

A stroke detection and volume flow technology, applied in fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., and can solve problems such as affecting measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0054] The specific embodiment: the specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

Embodiment

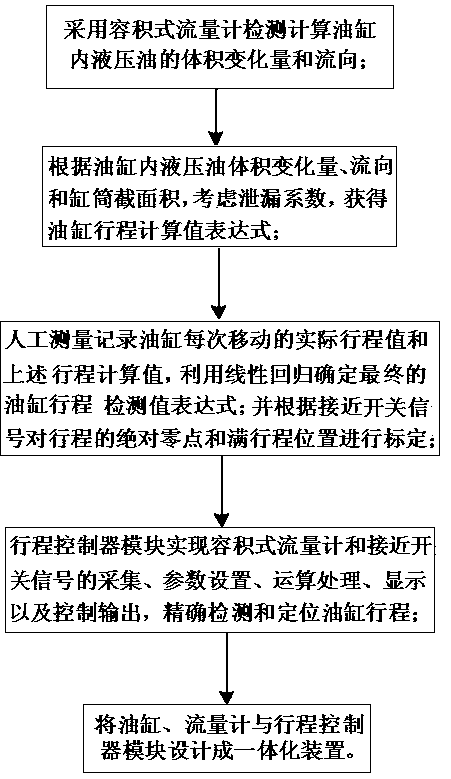

[0055] Embodiment: a method and device for cylinder stroke detection and control based on hydraulic oil volume flow, which includes the following steps:

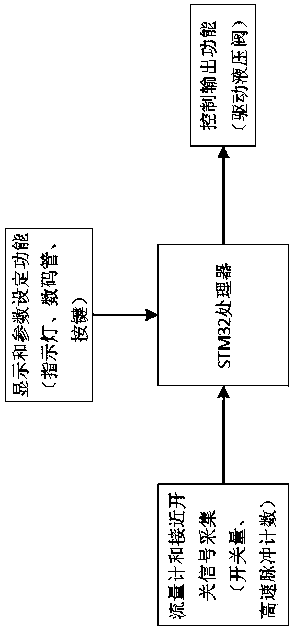

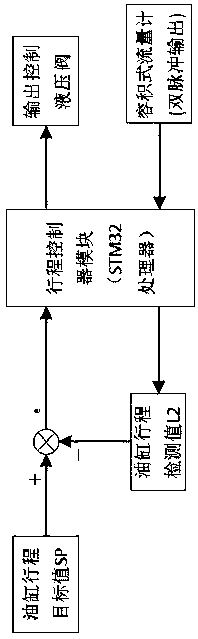

[0056] 1) Reference Figure 4 , The positive displacement flowmeter and stroke controller module are integrated and installed on the oil cylinder. The model of the volumetric flowmeter is FGR200-G1 / 4-S-BB-NBR-GD-S, powered by 24V, the volumetric flowmeter outputs a double pulse signal with a 90° phase difference to the I / O terminal of the stroke control module ;Measure the volume of hydraulic oil in the two-way flow cylinder and identify the flow direction;

[0057] It is known that the pulse volume coefficient of positive displacement flowmeter is Q1, and the unit is (Number of pulses per liter); if within a certain stroke, the number of pulses output by the positive displacement flowmeter is (pieces), then the oil volume change V is:

[0058] ;

[0059] When the pulse output 1 of the positive displacement flowmete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com