Patents

Literature

76 results about "Positive displacement meter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

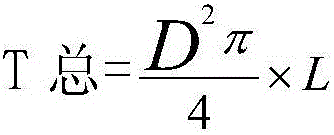

A positive displacement meter is a type of flow meter that requires fluid to mechanically displace components in the meter in order for flow measurement. Positive displacement (PD) flow meters measure the volumetric flow rate of a moving fluid or gas by dividing the media into fixed, metered volumes (finite increments or volumes of the fluid). A basic analogy would be holding a bucket below a tap, filling it to a set level, then quickly replacing it with another bucket and timing the rate at which the buckets are filled (or the total number of buckets for the “totalized” flow). With appropriate pressure and temperature compensation, the mass flow rate can be accurately determined.

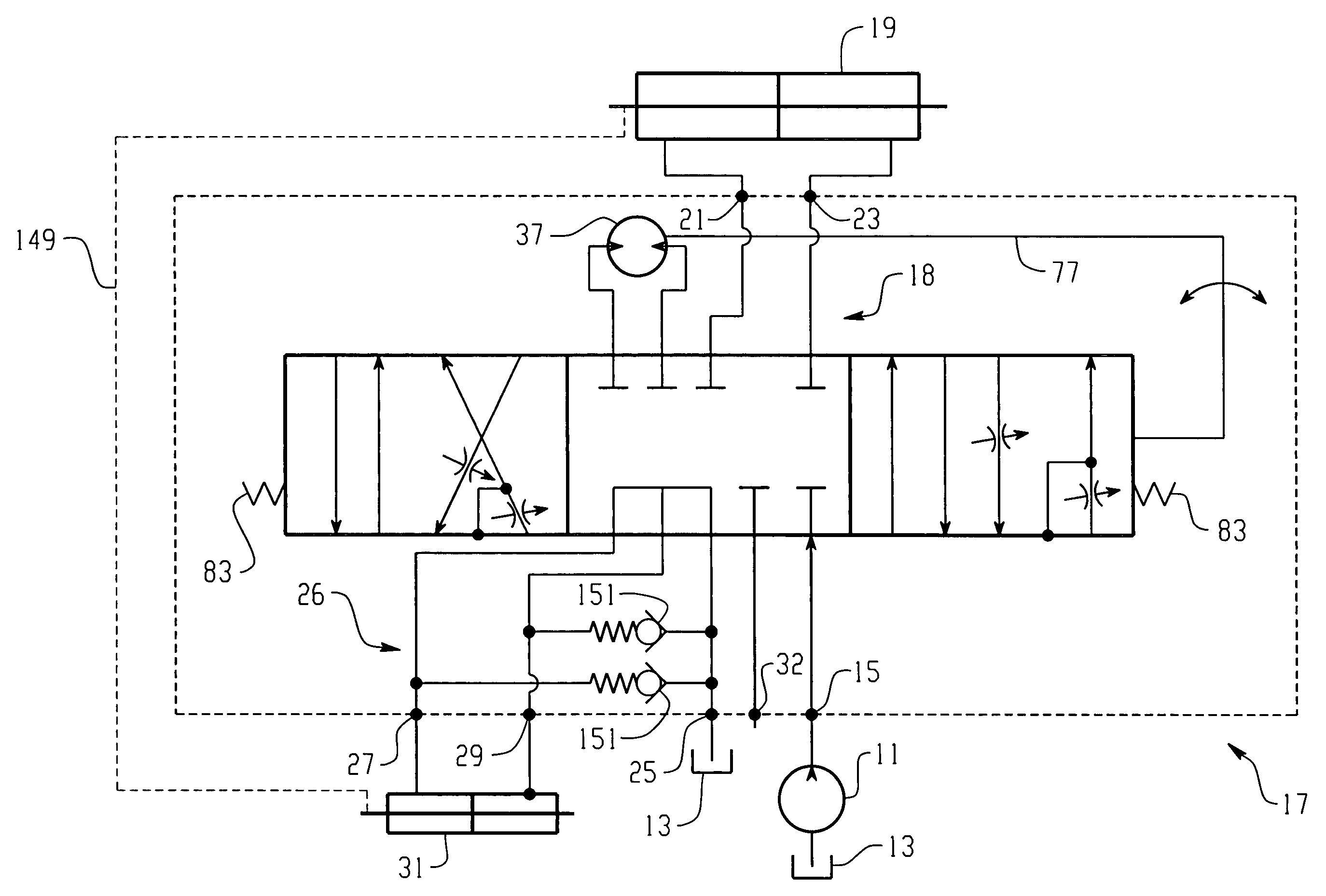

High efficiency positive displacement thermodynamic system

ActiveUS20100050628A1Without decreasing volumetric efficiencySave heatInternal combustion piston enginesCombination enginesPower modeWorking fluid

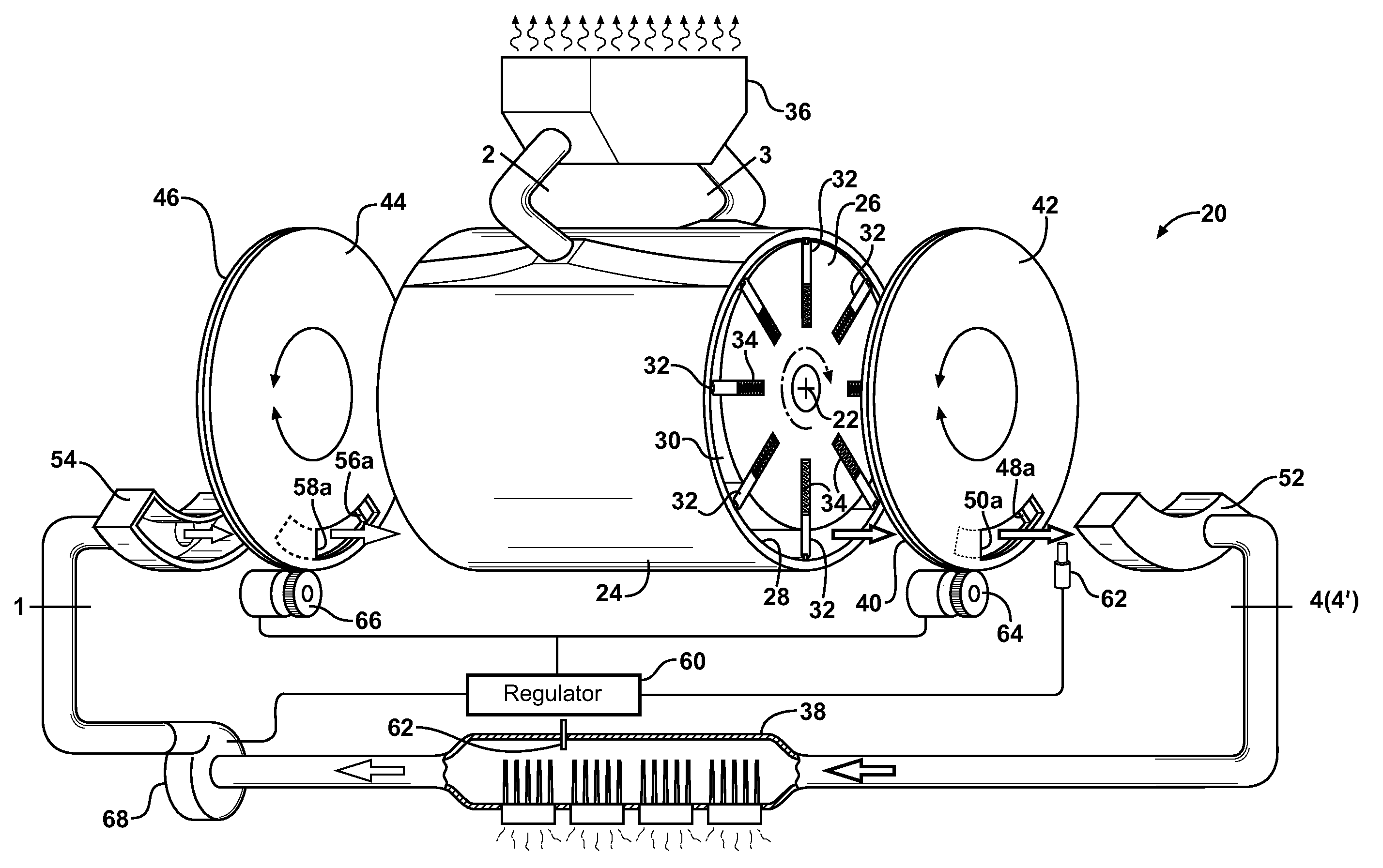

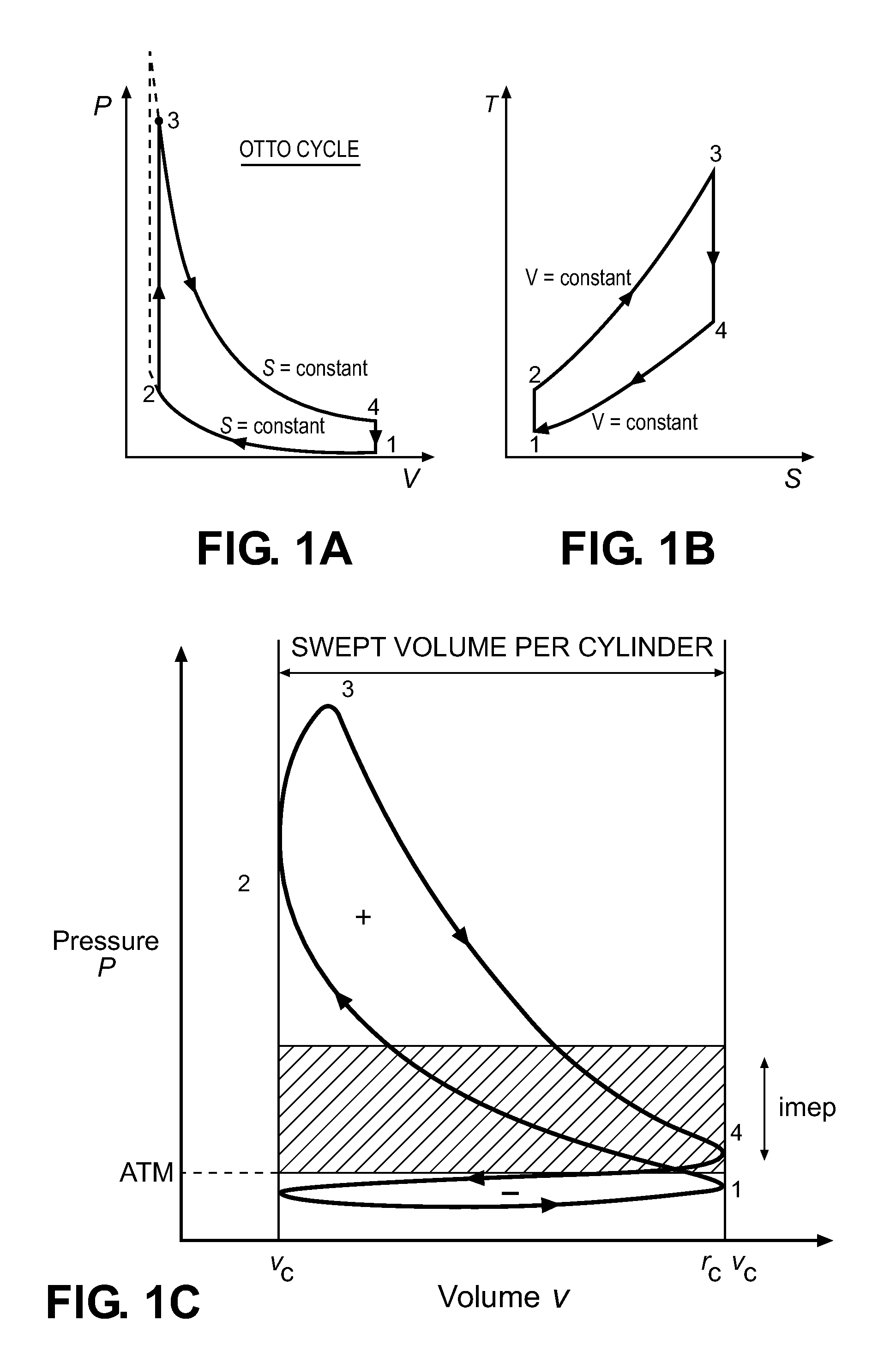

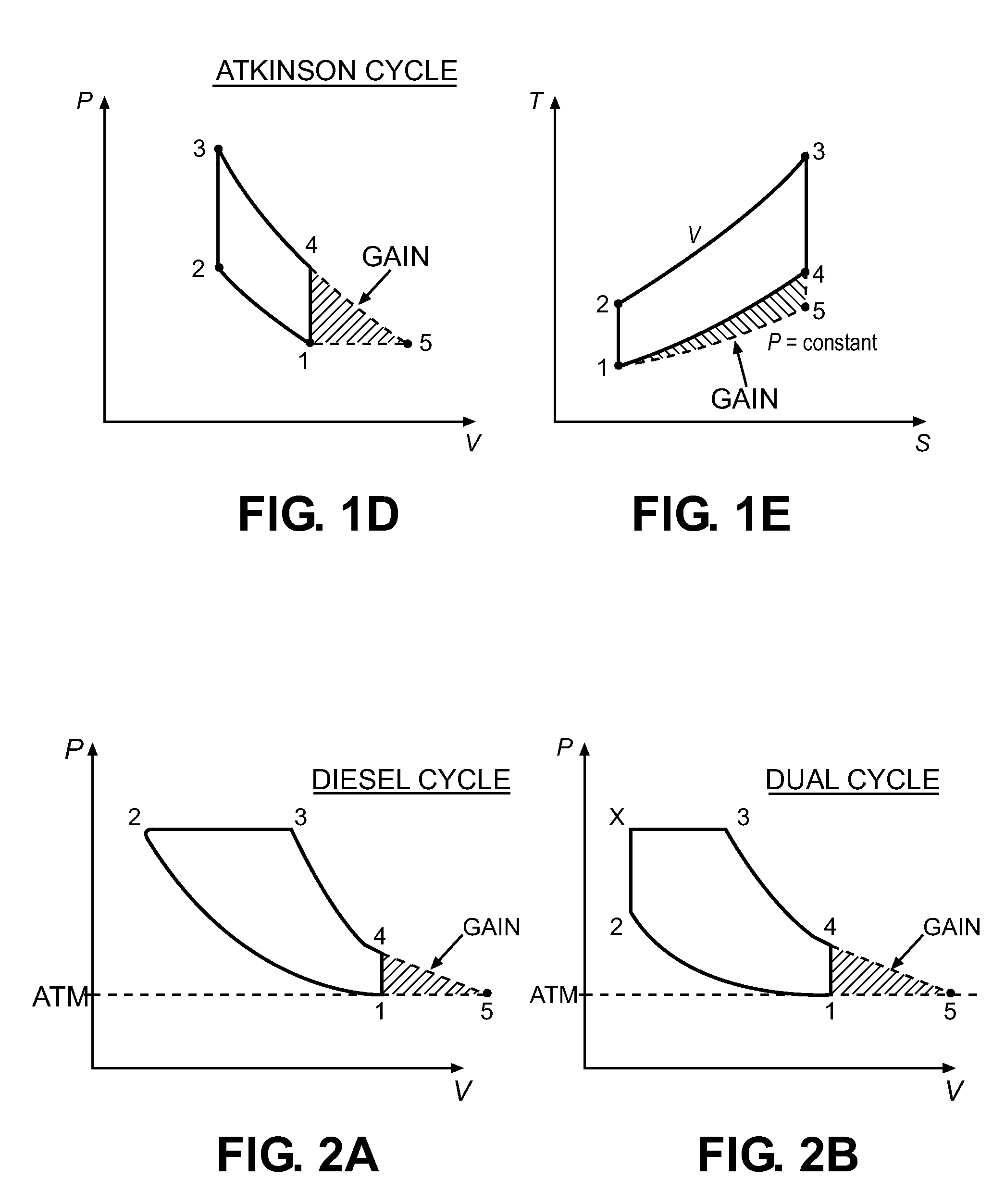

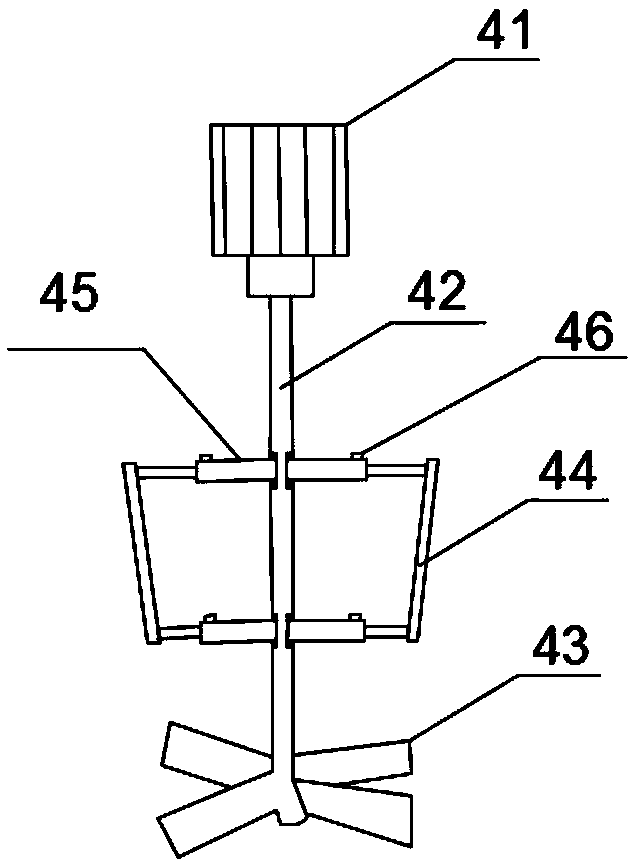

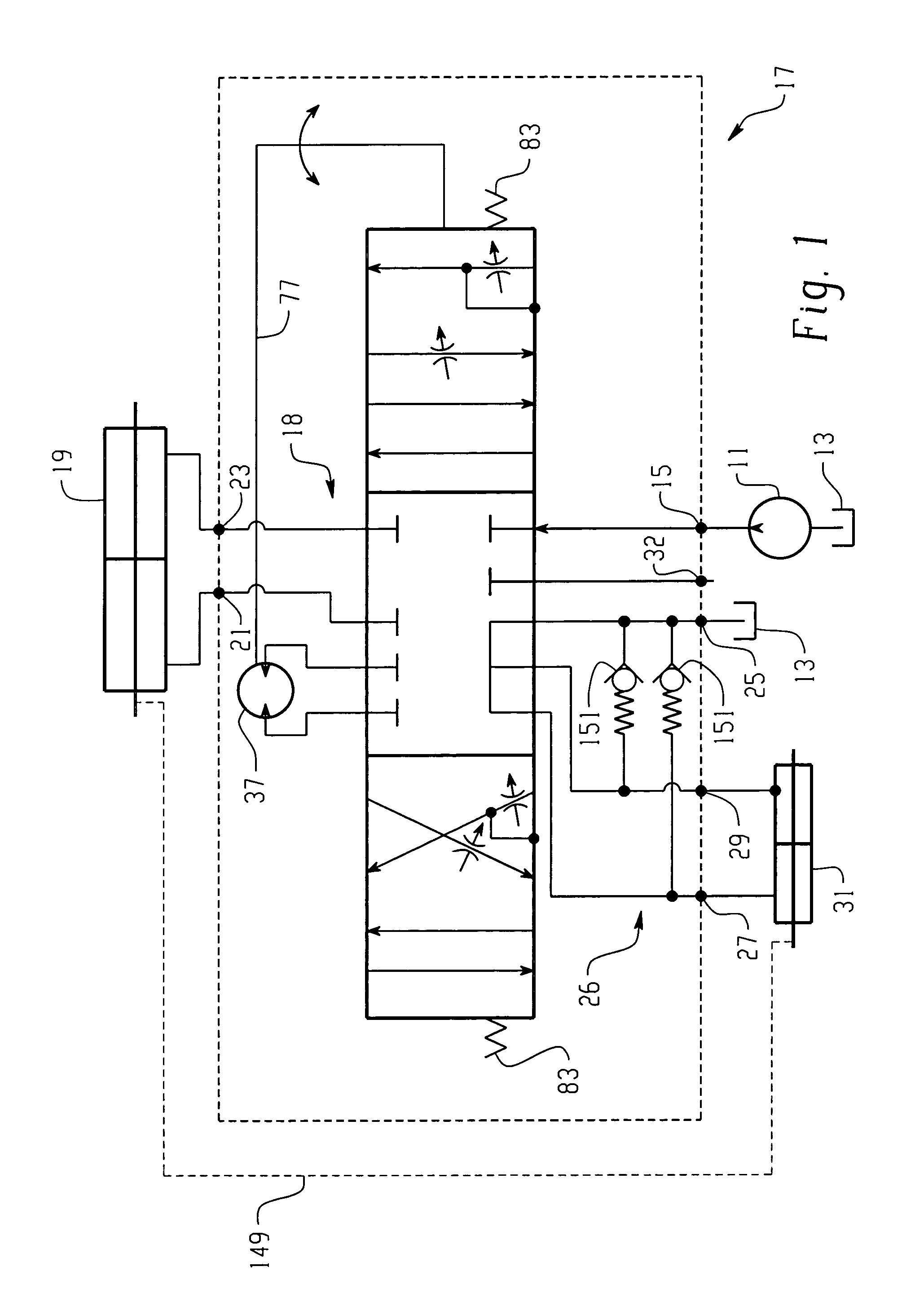

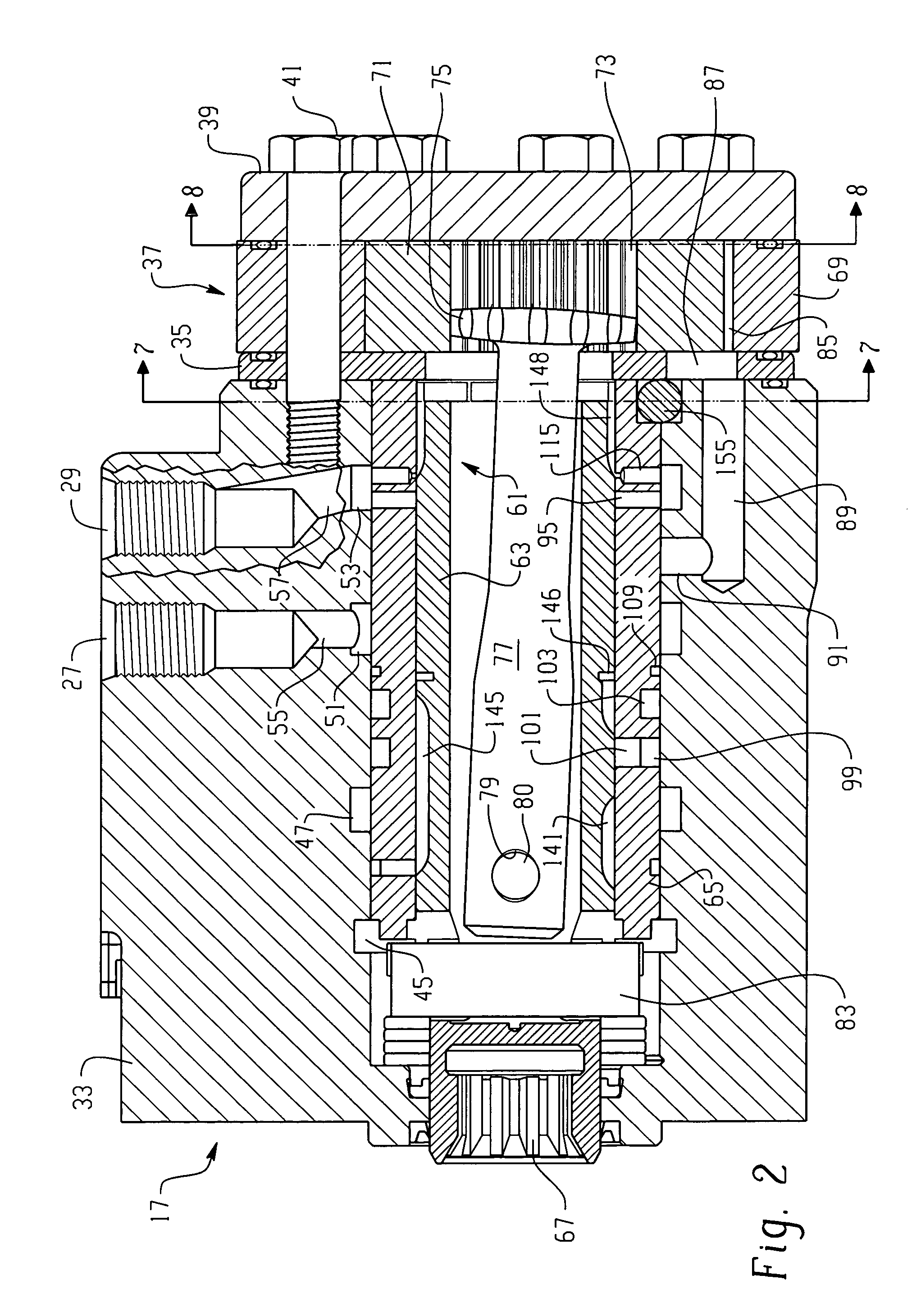

Devices and methods for moving a working fluid through a controlled thermodynamic cycle in a positive displacement fluid-handling device (20, 20′, 20″) with minimal energy input include continuously varying the relative compression and expansion ratios of the working fluid in respective compressor and expander sections without diminishing volumetric efficiency. In one embodiment, a rotating valve plate arrangement (40, 42, 44, 46) is provided with moveable apertures or windows (48, 50, 56, 58) for conducting the passage of the working fluid in a manner which enables on-the-fly management of the thermodynamic efficiency of the device (20) under varying conditions in order to maximize the amount of mechanical work needed to move the target quantity of heat absorbed and released by the working fluid. When operated in refrigeration modes, the work required to move the heat is minimized. In power modes, the work extracted for the given input heat is maximized.

Owner:STAFFEND GILBERT

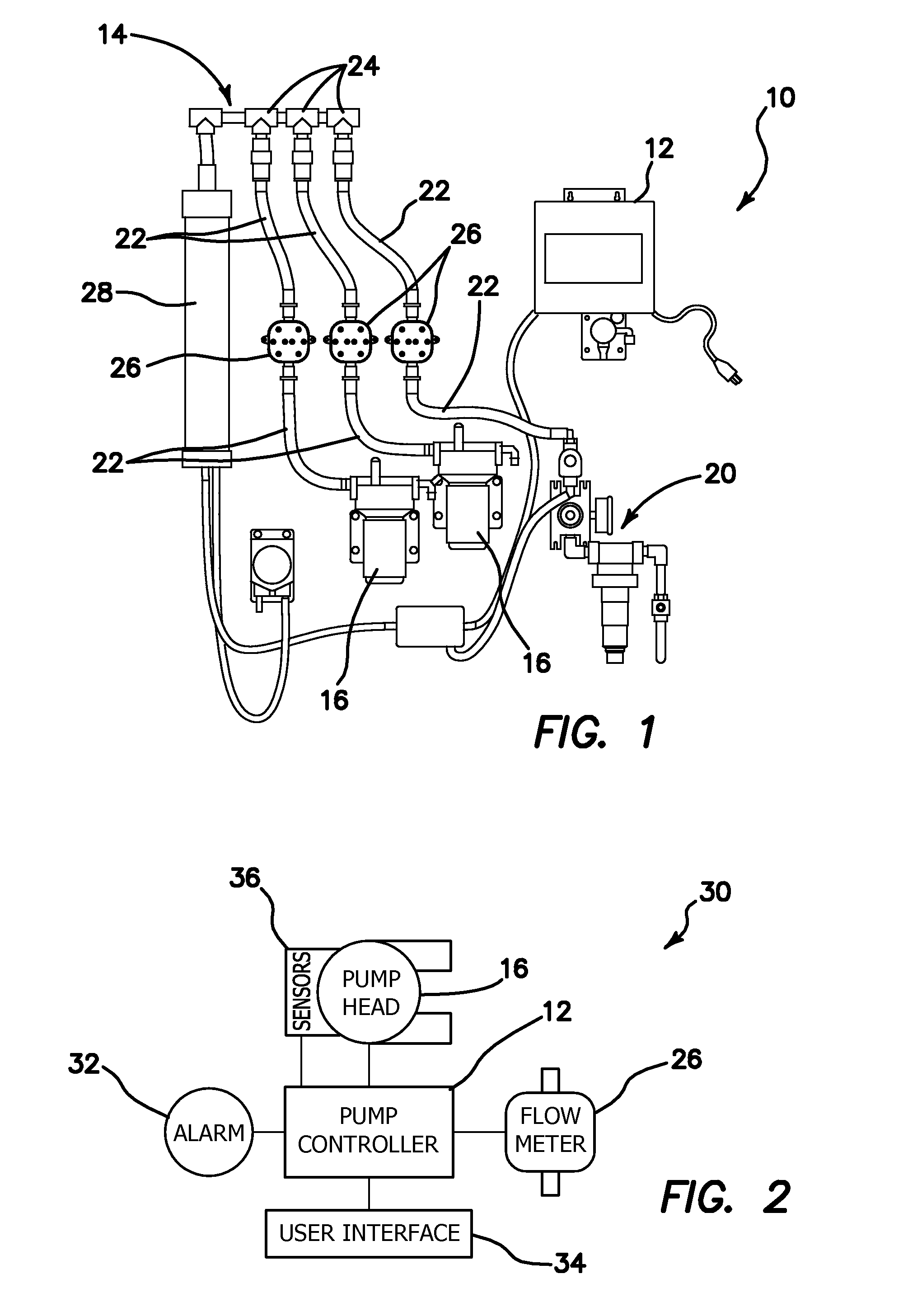

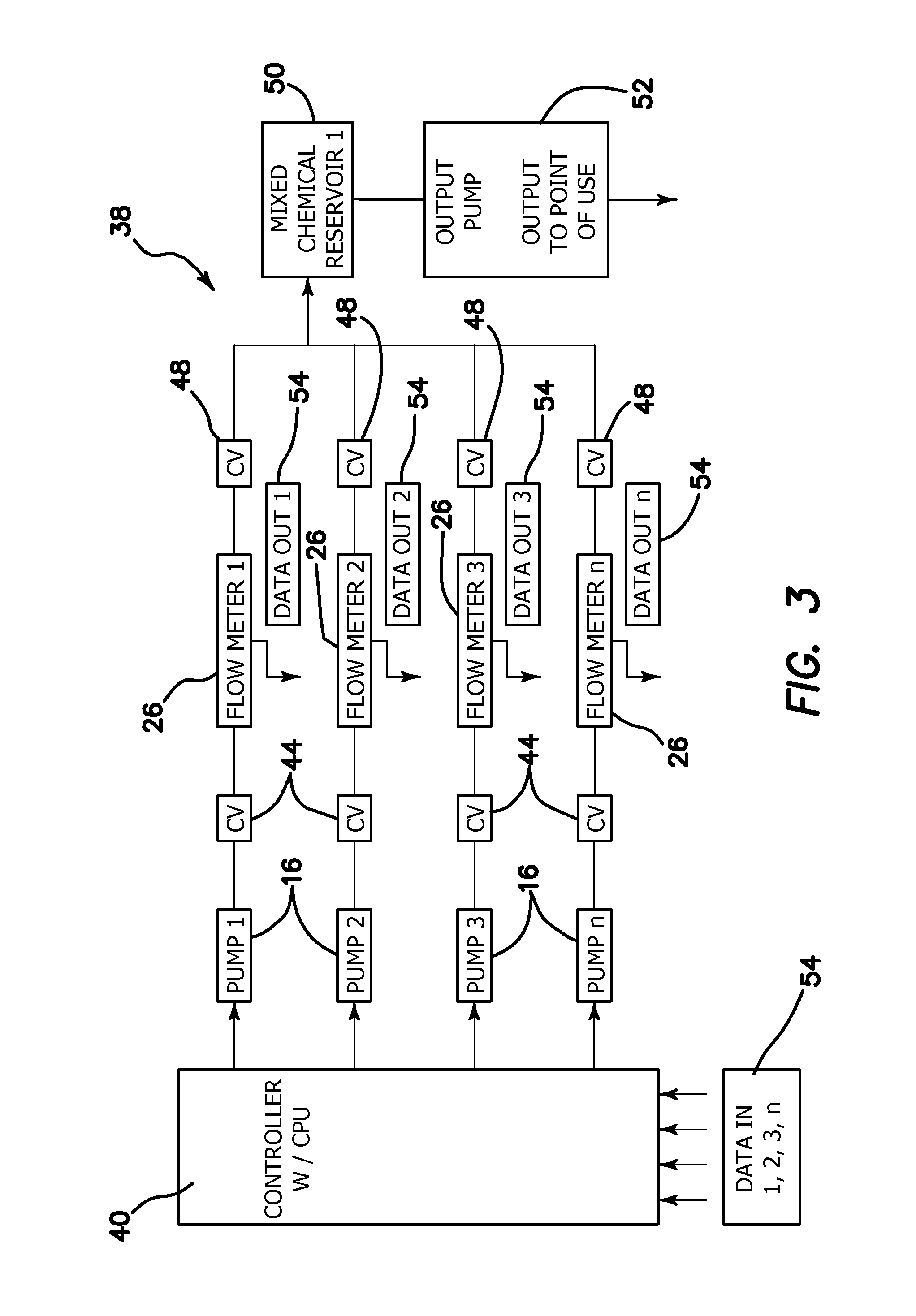

Chemical dispensing systems and positive displacement flow meters therefor

InactiveUS20110031272A1Testing/calibration apparatusVolume/mass flow by electric/magnetic effectsEngineeringMicroprocessor

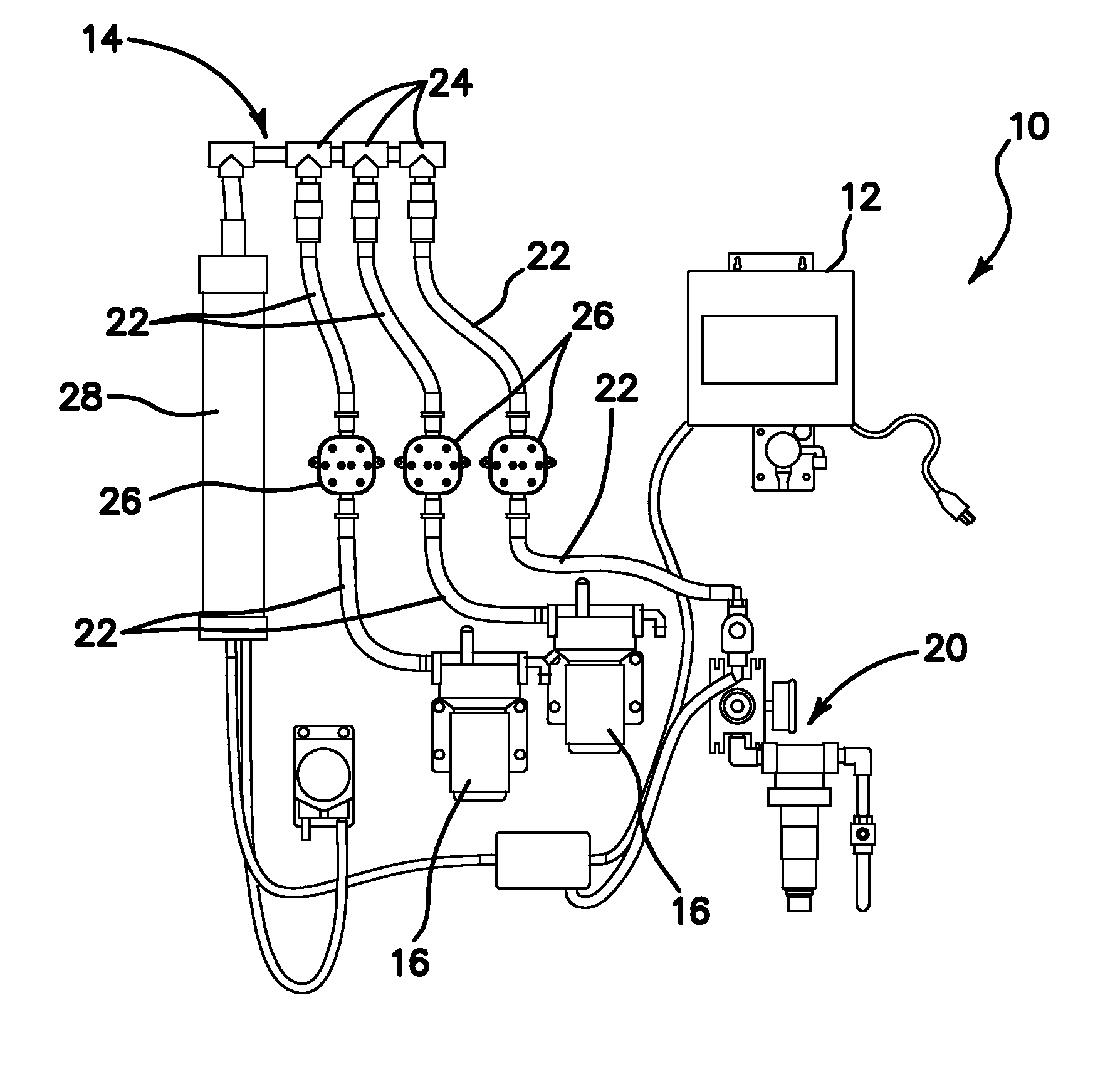

A volume-based, rather than time-based, system for dispensing fluid incorporates a microprocessor-based controller, software, pump, and positive displacement flow meter. The volume being pumped and the time it takes to pump that volume is calculated and tracked by the software, giving a flow rate. This rate is then tracked by the software for any changes. Any conditional changes that occur, affecting this rate, are tracked, and if the rate becomes too excessive outside of the normal rate established at initial calibration, then an alarm or other indication is provided to the operator.

Owner:KNIGHT

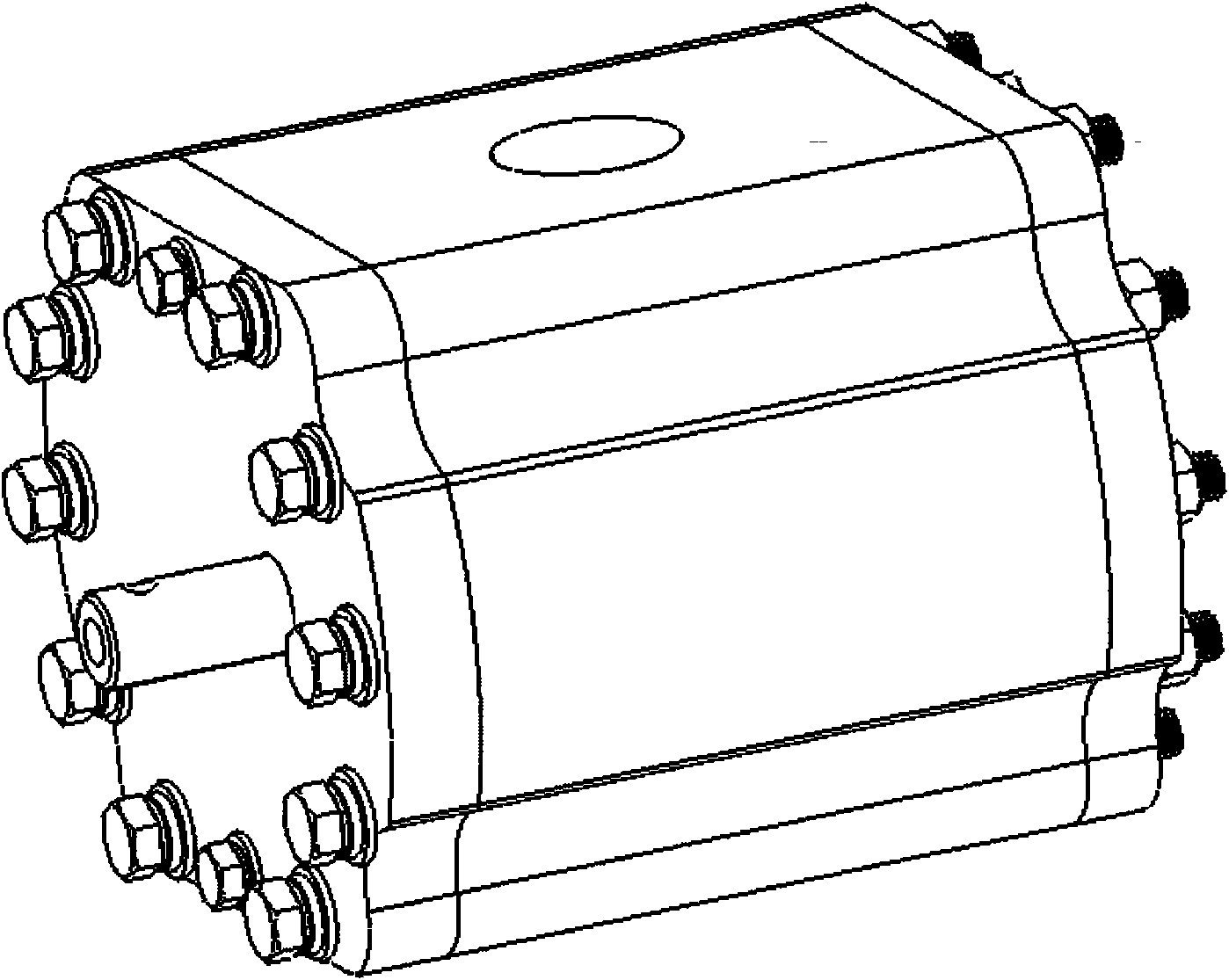

High pressure, high flow rate tubing assembly for a positive displacement pump

InactiveUS20110180172A1Increased tube lifeReduce replacement costsFlexible member pumpsPipe elementsPeristaltic pumpWorking life

A tubing assembly is provided that can comprise a plurality of tubes or lumens that can be disposed within a head of a peristaltic pump. The tubing assembly can provide a flow rate or volume capacity that is generally equal to or greater than that achieved with a comparable prior art tube while operating at higher pressures than that possible using the prior art tube. Further, in accordance with some embodiments, the tubing assembly can achieve a longer working life than a comparable prior art tube, and the load on the pump motor can be reduced such that the pump life is increased and / or a larger pump motor is not required to achieve such advantageous results.

Owner:BLUE WHITE INDS

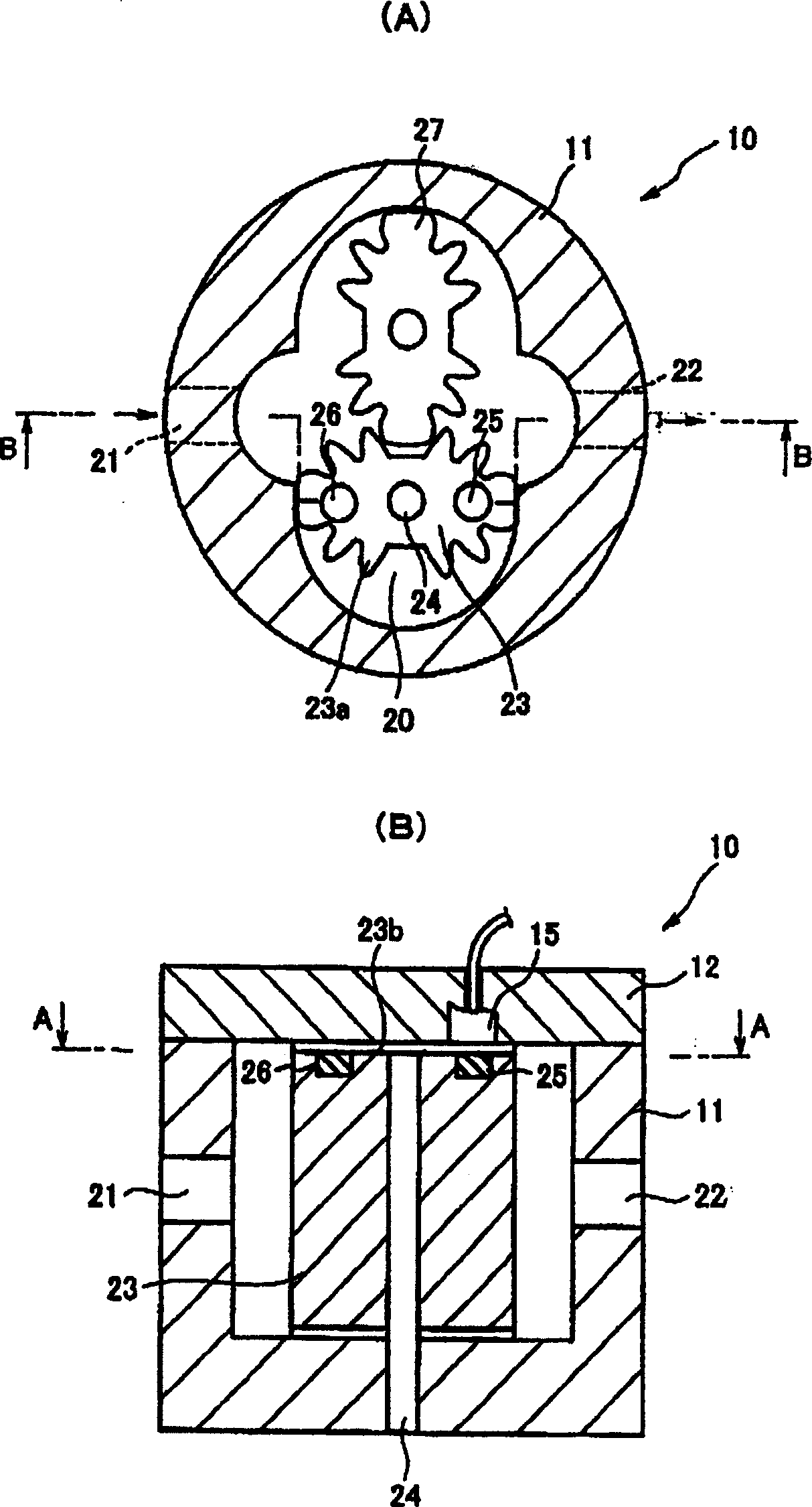

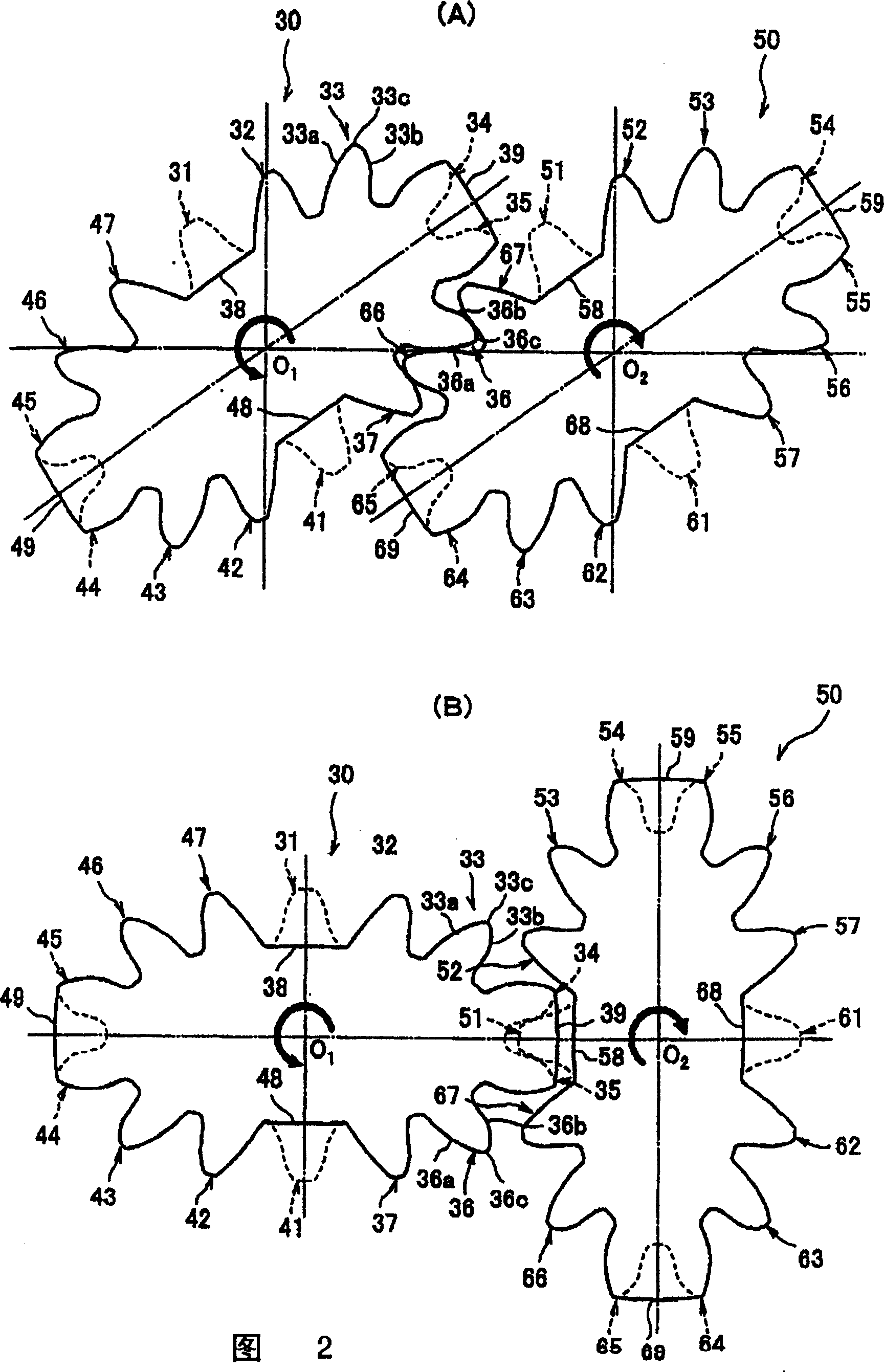

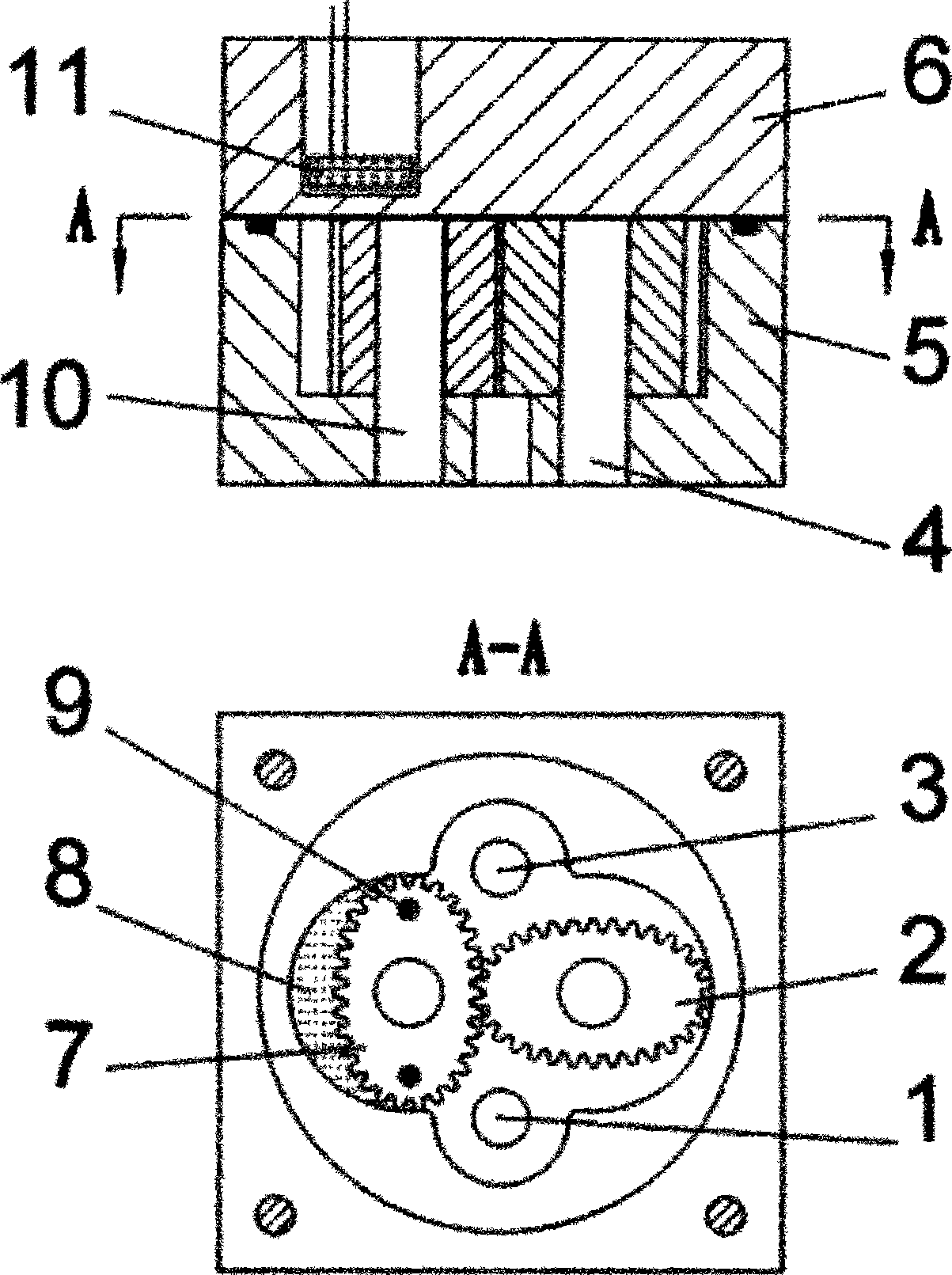

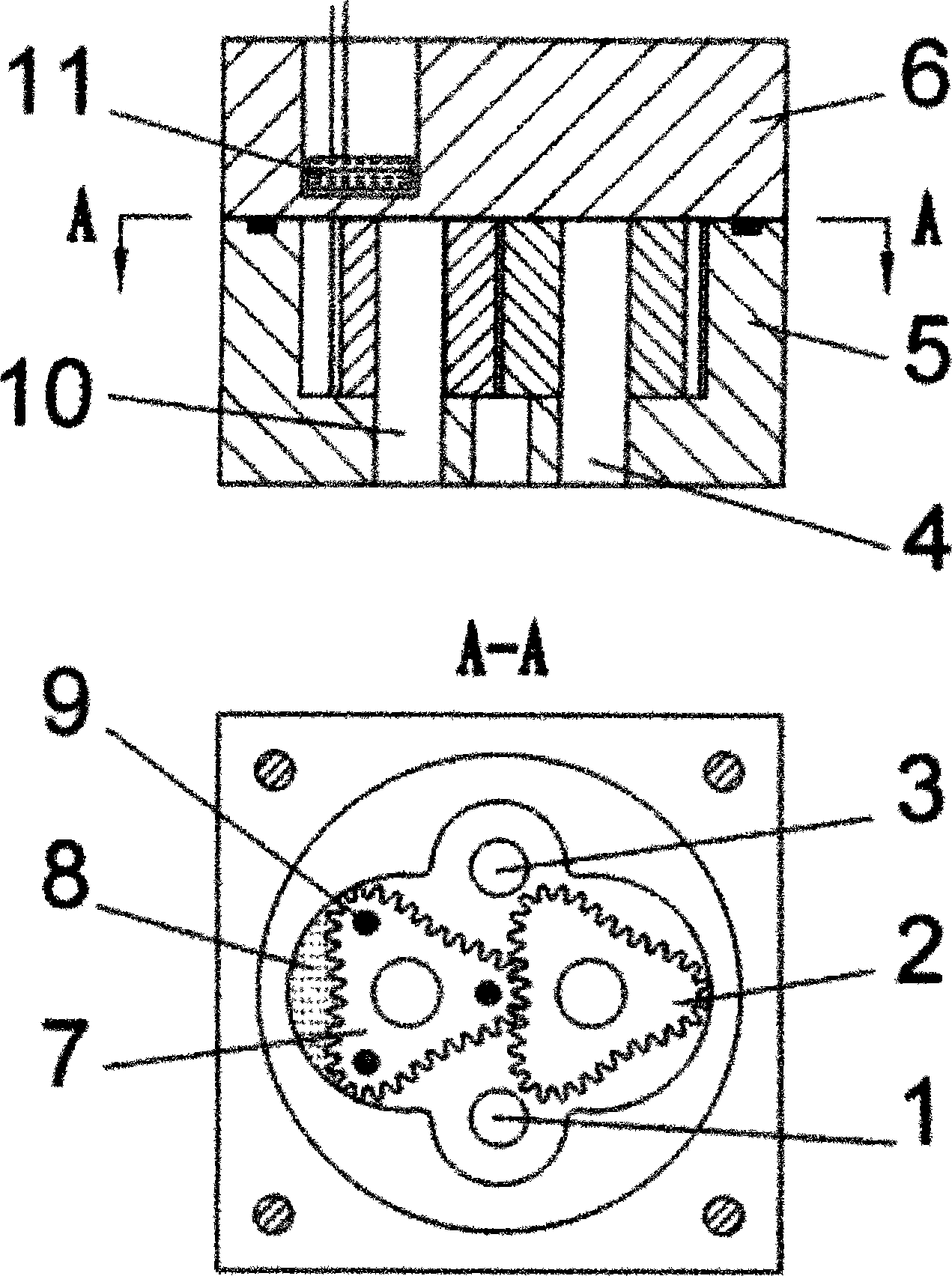

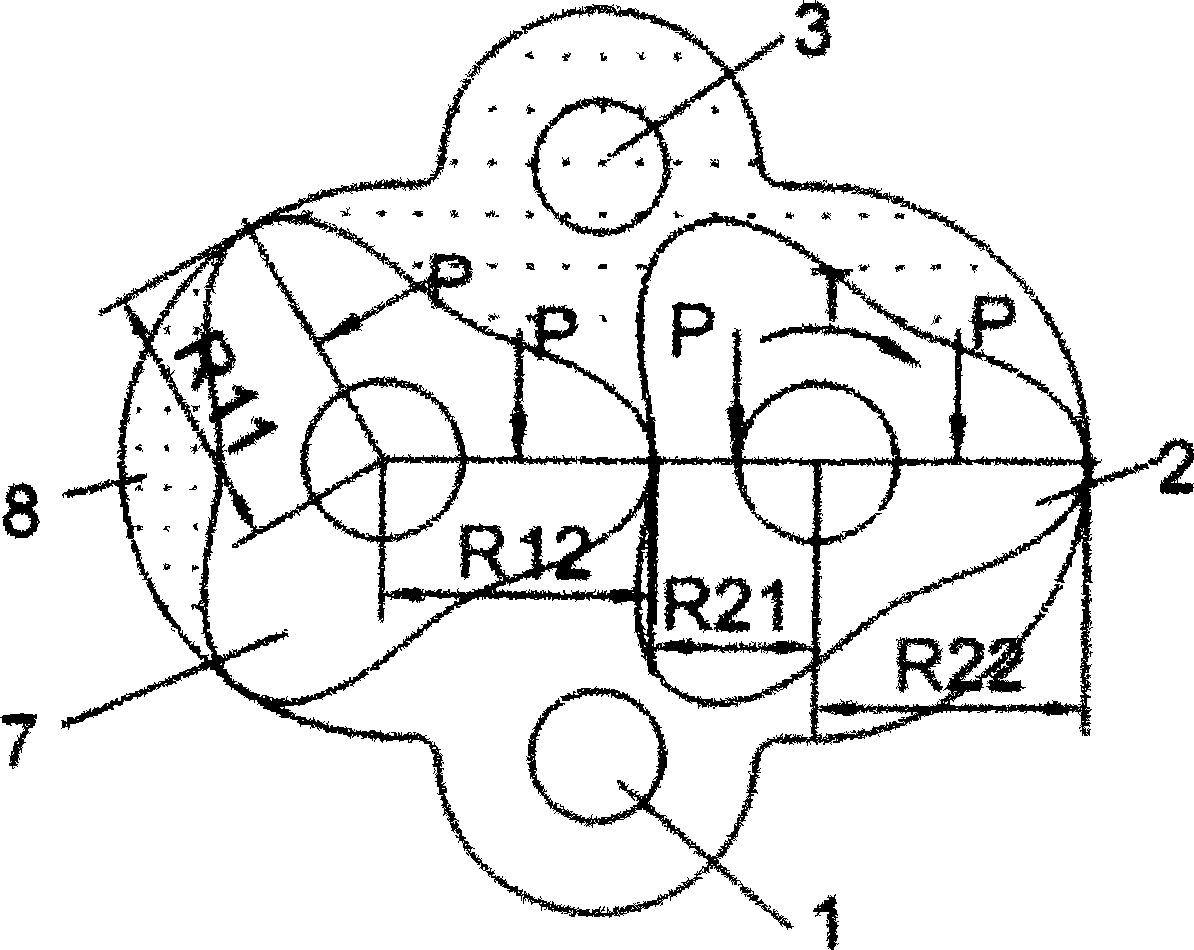

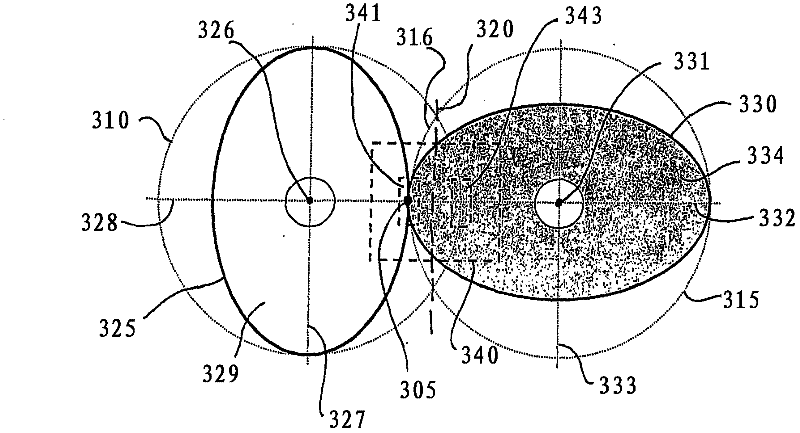

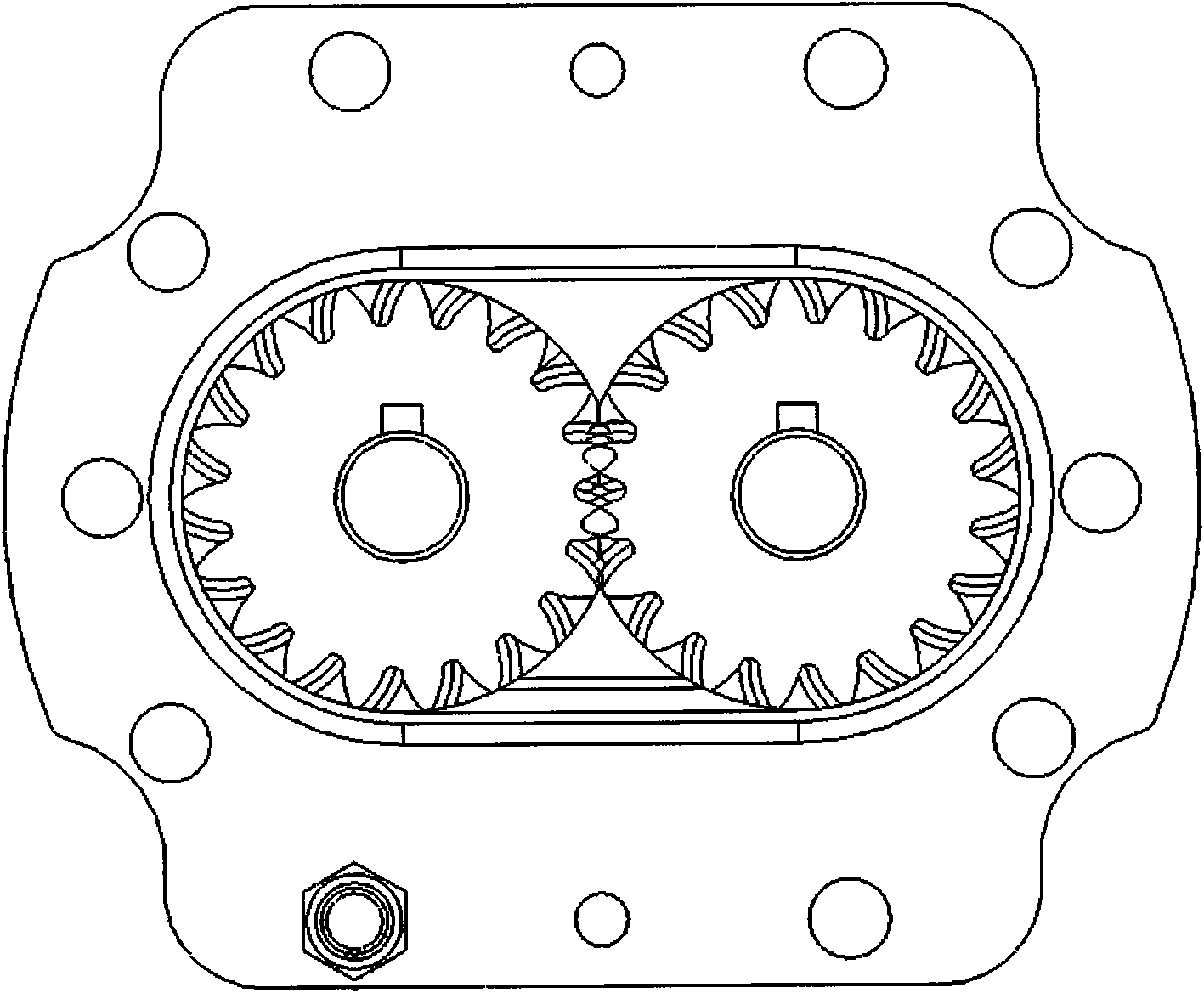

Non round gear and volumetric flowmeter using same

InactiveCN1573302ALittle changeEasy to set upVolume/mass flow measurementRotary piston pumpsEllipseEngineering

The number of teeth is set to 4n+2 (n is a natural number), both the ends on a long axis are set to be teeth grooves, both the ends on a short axis are set to be tips, a pitch curve is set to be, for example, an ellipse, and tooth marks 31-37, 41-47 are set to be basic tooth mark curves. With the tooth mark curve, the engagement teeth surface is set to be an involute curve, a non-engagement tooth surface is set to be a cycloid curve, and the tool pressure angle of each tooth mark is set by an undercut limit and a point limit. The non-circular gears 30, 50 bury the recess between two tooth marks, holding the tooth space located at both the ends on the long axis, based on the basic tooth mark curve, and have a shape, where the tooth section including the tip at both the ends on the short axis are scraped off, and the number of teeth completed is finally set to 4n-2. Accordingly, it is able to obtain a non-circular gear that reduces the change in an engagement pressure angle, is advantageous for setting the tool pressure angle of an engagement teeth surface, can reduce the number of teeth without forming an overhang section, and can fully secure the sealing performance with the inner wall of a casing to be installed.

Owner:OVAL CORP

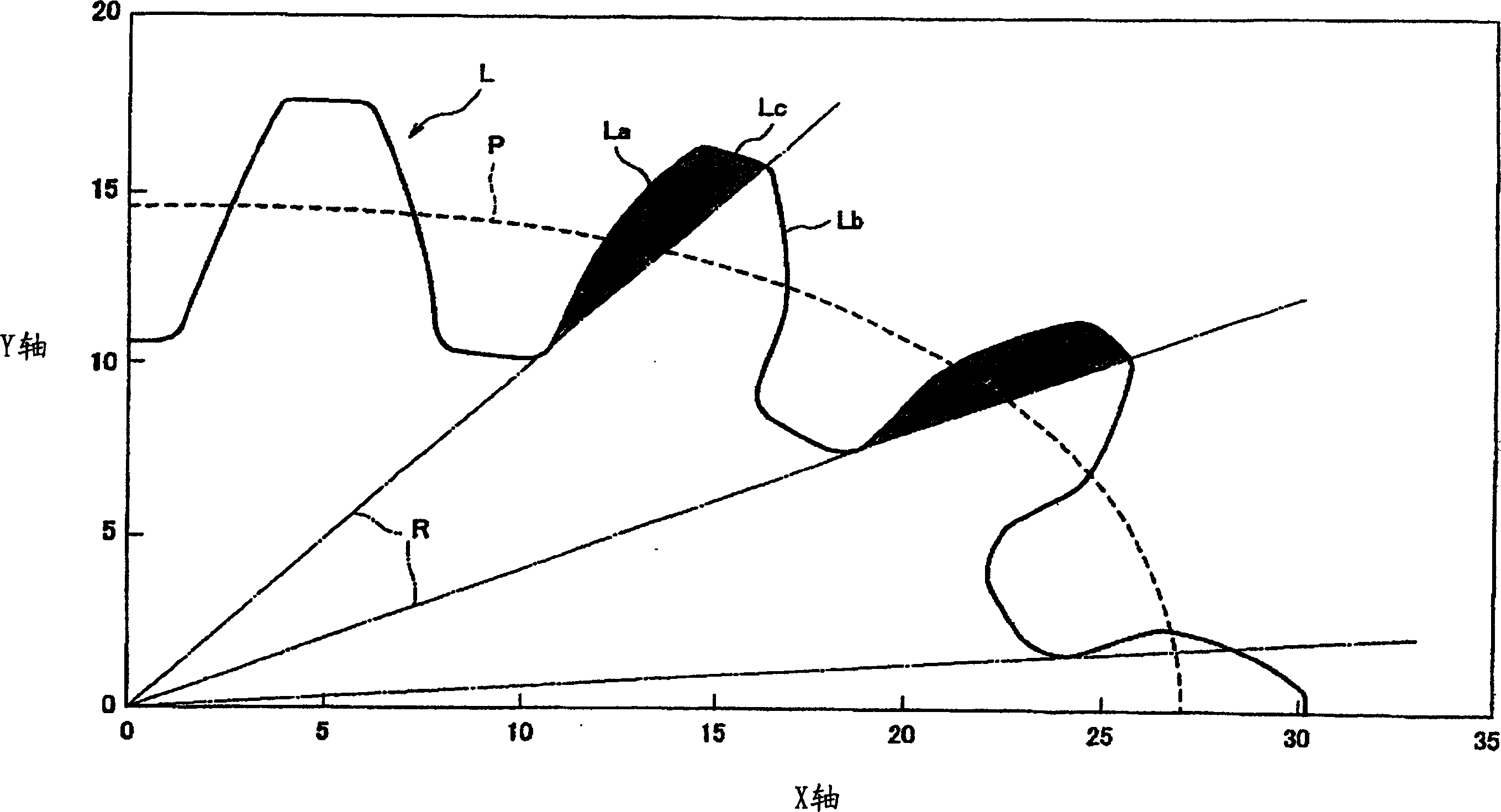

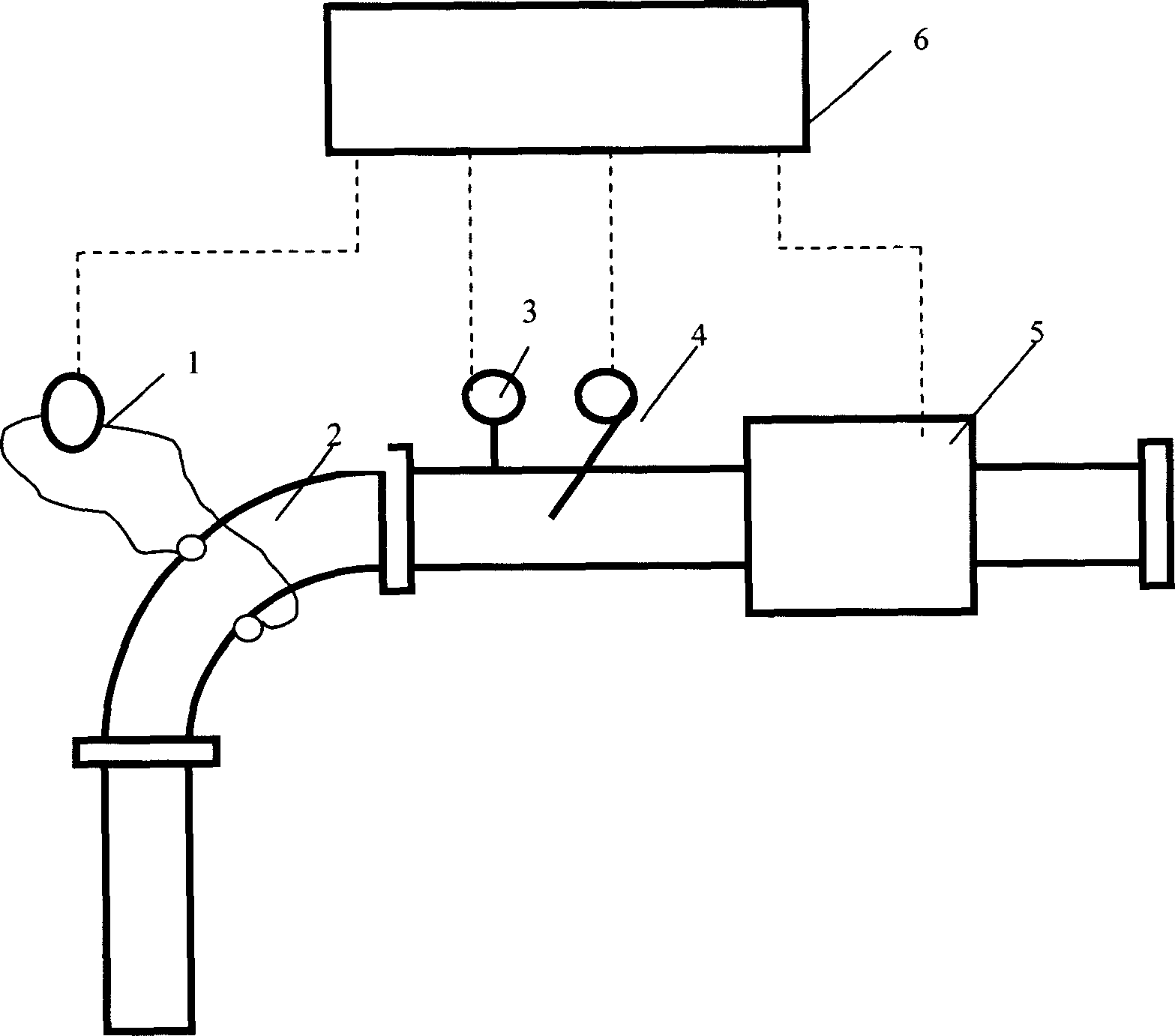

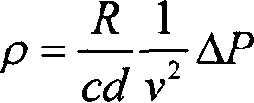

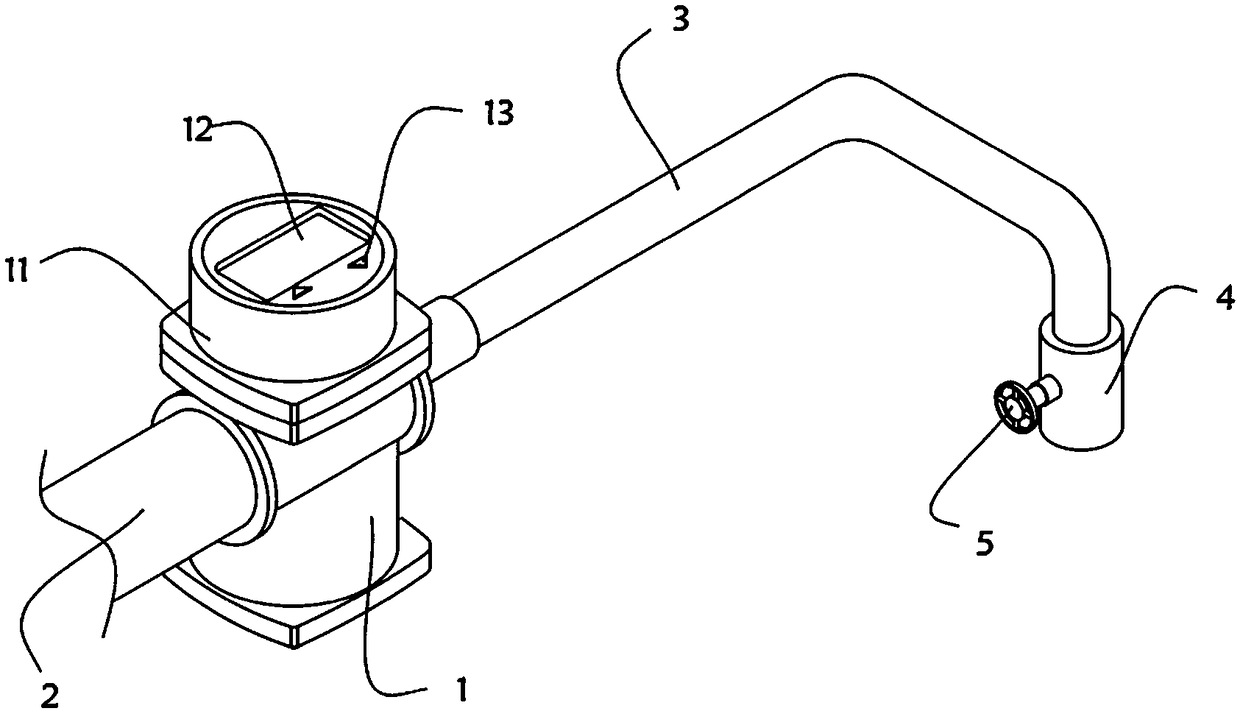

Two-phase flow and dual parameter measurement with bent tube and flowmeter combination and system thereof

InactiveCN1746632ASolve the simultaneous measurement of two-phase flowSolving the Phase Holdup ConundrumVolume flow proportion measurementVolume/mass flow by differential pressureDifferential pressureEngineering

A method of measuring double parameter of two ¿C phase stream by elbow and flow meter integrated system includes utilizing said system to obtain flow rate signal, differential pressure signal, fluid pressure signal and temperature signal; calculating out fluid average flow speed as per pipe section area based on obtained signals; obtaining mixed fluid density based on function relation of fluid density to elbow differential pressure and average flow rate; calculating out phase content rate of each fluid and flow rate of each phase as per fluid density of each phase . The elbow and flow meter integrated system is also provided.

Owner:薛国民

Volume type high order elliptic gear flowmeter

The invention discloses a volumetric flowmeter with a rotor which is a high-order elliptic gear. The flowmeter consists of three parts which are a shell, two high-order elliptic gear rotors with the same size and a signal acquisition part. A function expression of a pitch curve of the high-order elliptic gear is as follows: r(phi)=A(1-k)) / (1-k*cosn phi), wherein, n is a natural number greater than 2. The flowmeter which takes the high-order elliptic gear as the rotor is characterized by small pulsation, low noise, enhanced sealing performance, increased signal acquisition amount and improved overall performance.

Owner:胡平

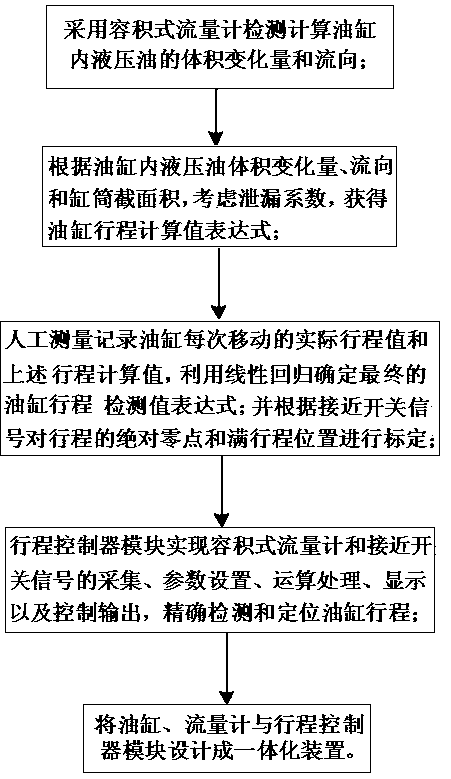

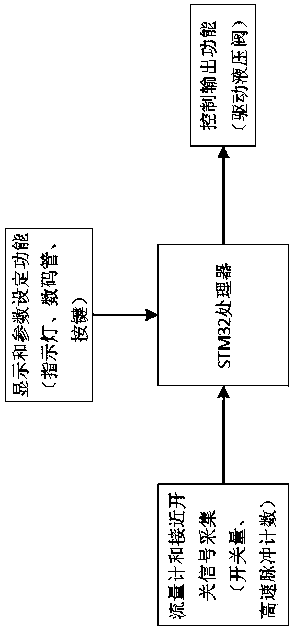

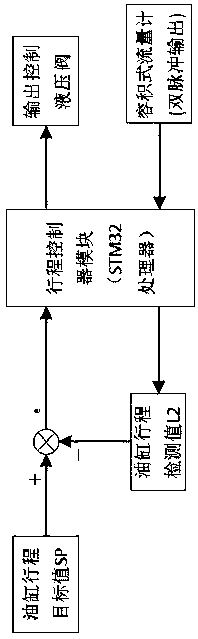

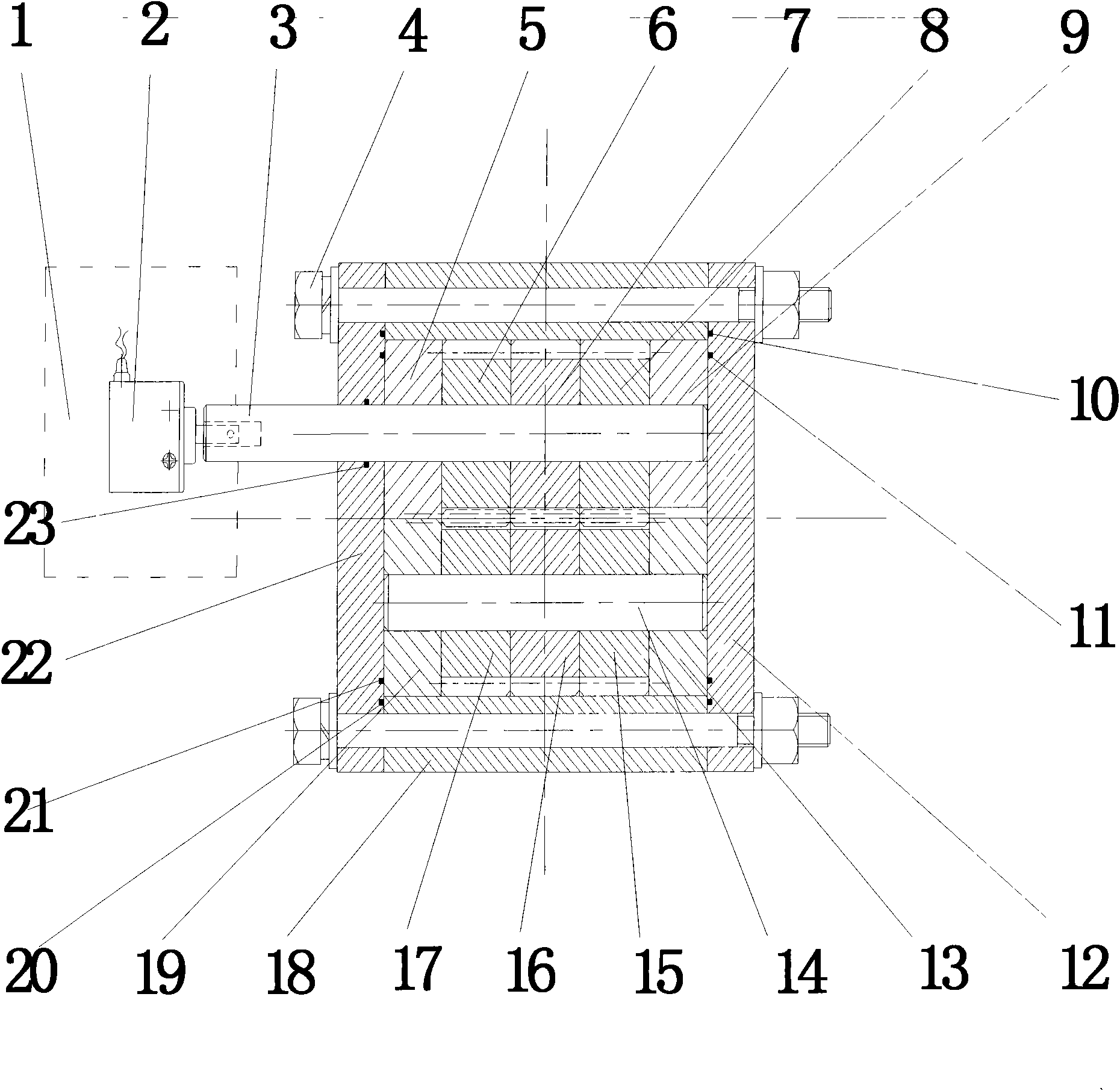

Oil cylinder stroke detection and control method based on hydraulic oil volume flow

ActiveCN108916158AReduce power consumptionHigh precisionFluid-pressure actuator componentsSwitching signalLinear regression

The invention discloses an oil cylinder stroke detection and control method based on hydraulic oil volume flow. The oil cylinder stroke detection and control method is characterized by comprising thefollowing steps that the volume change amount and the flow direction of the hydraulic oil in the oil cylinder are calculated by adopting a volumetric flow meter; the leakage coefficient is considered,according to the volume change amount of the hydraulic oil in the oil cylinder, the flow direction and the sectional area of the cylinder barrel, an oil cylinder stroke calculation value expression is obtained; the actual stroke value of each time of the oil cylinder is measured and recorded manually, the obtained oil cylinder stroke calculation value is combined, the final oil cylinder stroke detection value expression is determined through linear regression, and the absolute zero point and the full stroke position of the stroke are calibrated according to the proximity switch signal; the travel controller module is used for realizing collection, parameter setting, operational processing, display and control output of the volumetric flow meter and the proximity switch signal, and the oilcylinder stroke is accurately detected and positioned; the oil cylinder, the flow meter and the travel controller module are designed into an integrated device. The oil cylinder stroke detection andcontrol method is compact in structure, is not influenced by the stroke of an oil cylinder and is low in cost, does not need special machining of the oil cylinder body, and is easy to realize.

Owner:YANTAI FUTURE AUTOMATIC EQUIP

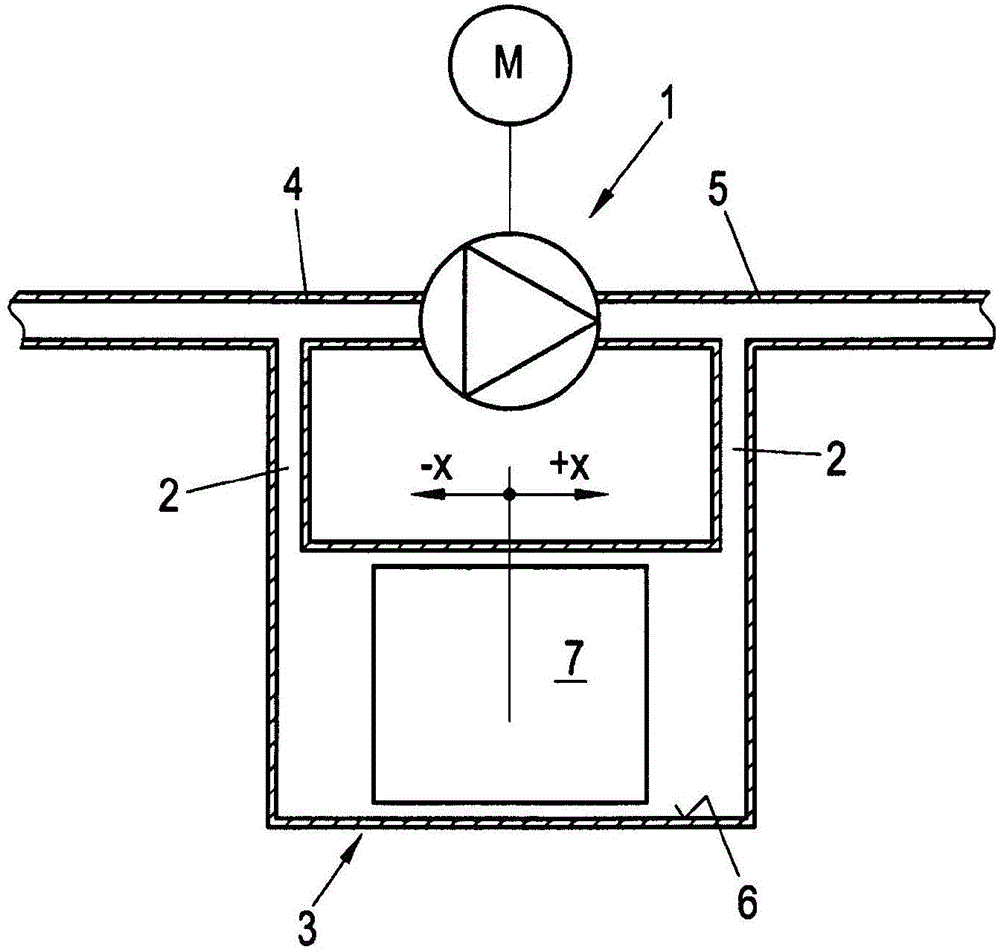

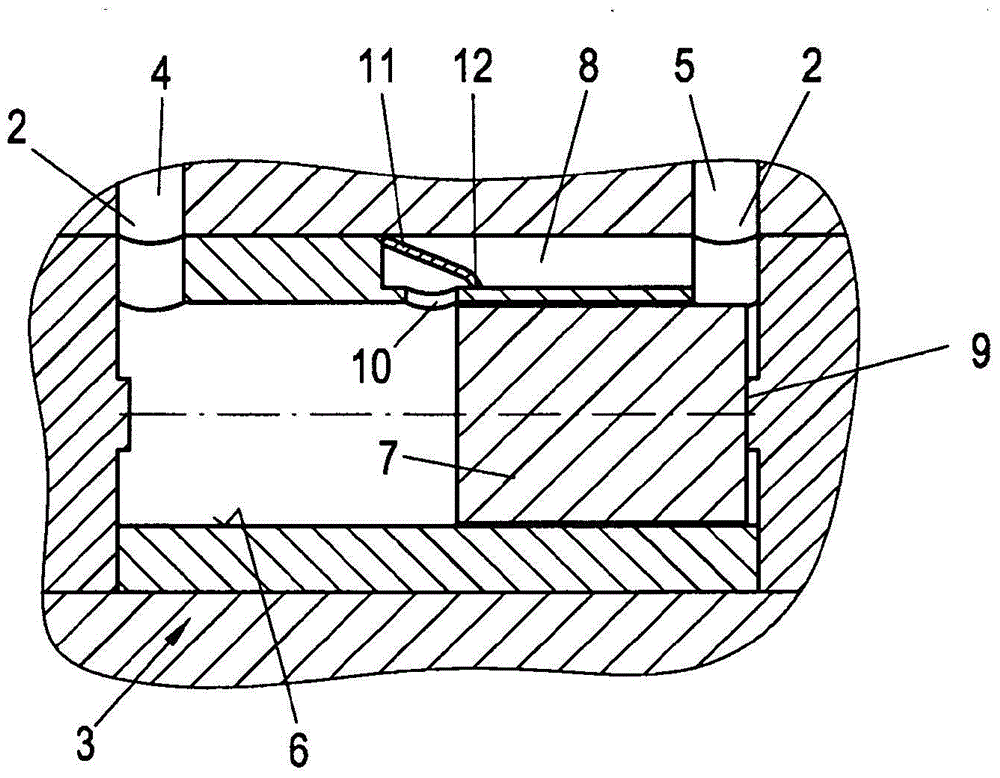

Flowmeter

InactiveCN104956191AVolume/mass flow measurementVolume variation compensation/correction apparatusEngineeringCheck valve

In a flowmeter having a displacement meter (1), a pressure different sensor (3) connected in parallel has a bypass channel (8) which, when the piston (7) is at the maximum travel stop (9) thereof, enables a connection between the inflow and outflow sides (4, 5). A check valve (11) which prevents the return flow from the outflow side to the inflow side (5, 4) and therefore enables a purely pressure-induced return of the piston (7) is arranged in the bypass channel (8).

Owner:AVL LIST GMBH

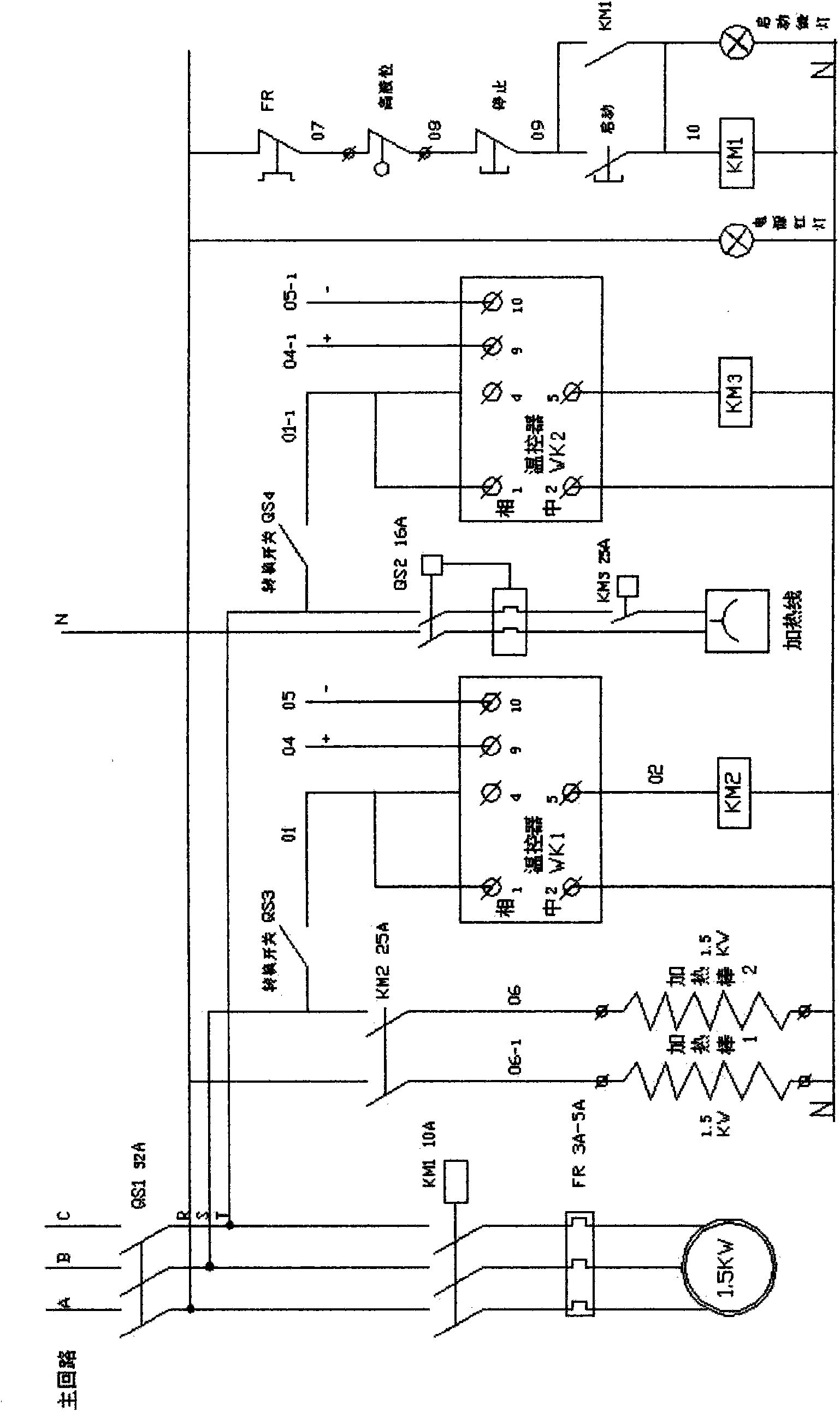

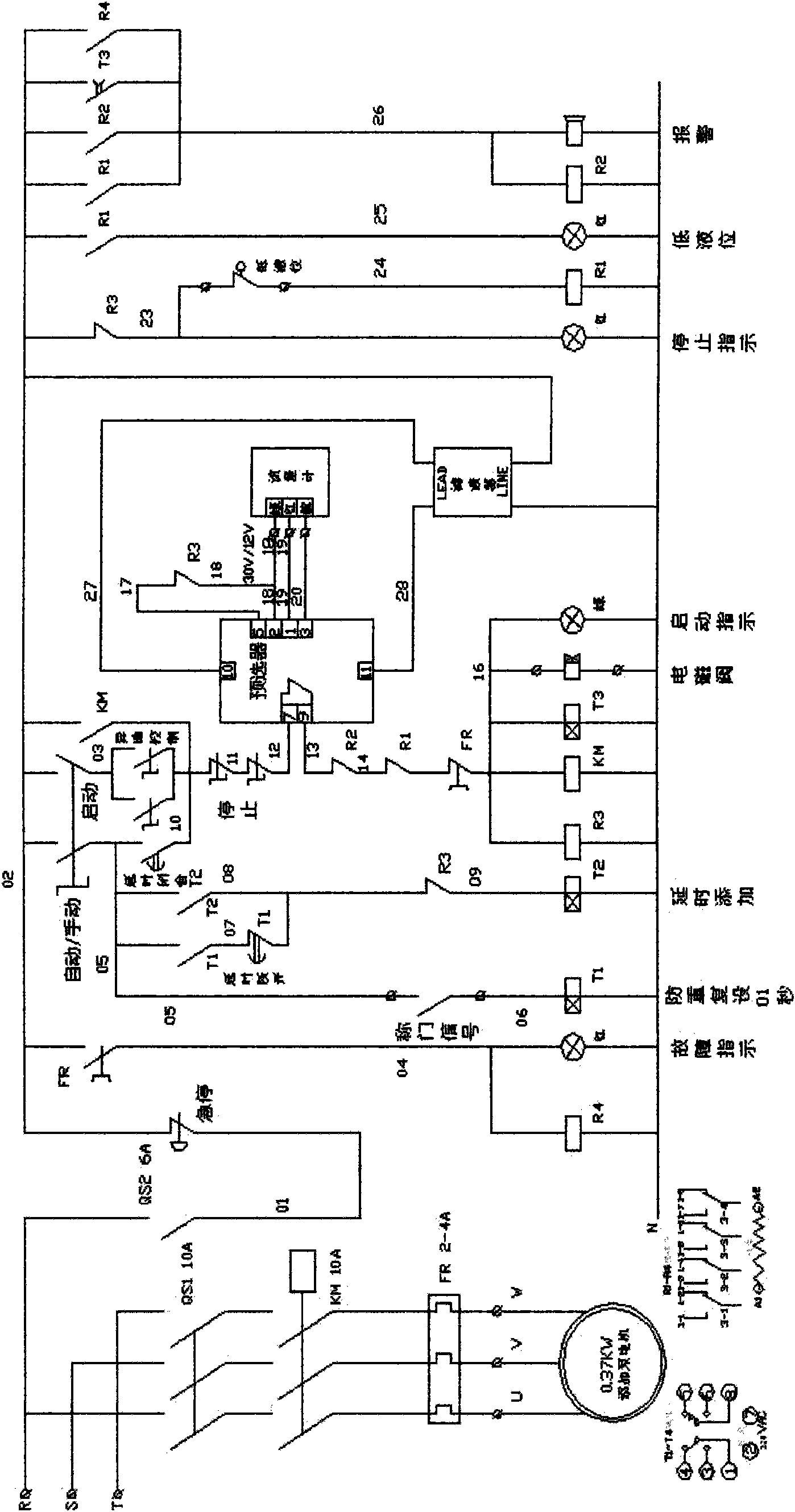

Device and method for adding liquid additive

ActiveCN102090701AReduce wasteAccurate and Stable Adding PrecisionFeeding-stuffTemperature controlGear wheel

The invention provides a device and a method for adding a liquid additive. The device comprises a storage tank, a material barrel, a connecting pipe, filters, an input pump, a central controller, a temperature controller, liquid level meters, nozzles, an adding pump, a flow meter and a control valve, wherein, the flow meter is a gear volumetric flow meter; a shell of the flow meter is internally equipped with two rotors which are directly meshed with each other and rotate under the action of pressure difference between an inlet and an outlet of the flow meter; the flow meter continuously discharges fluid which is filled in a metering space between a gear and the shell by means of rotation of the gear; and the flow meter obtains the fluid passing through the same by measuring rotating times of the gear. The device has the advantages of high and stable adding precision and accurate electrical control, thus effectively reducing labor consumption and raw material waste during the production process, and reaching an optimal service condition during the production process.

Owner:青岛宝佳智能装备股份有限公司

flow meter

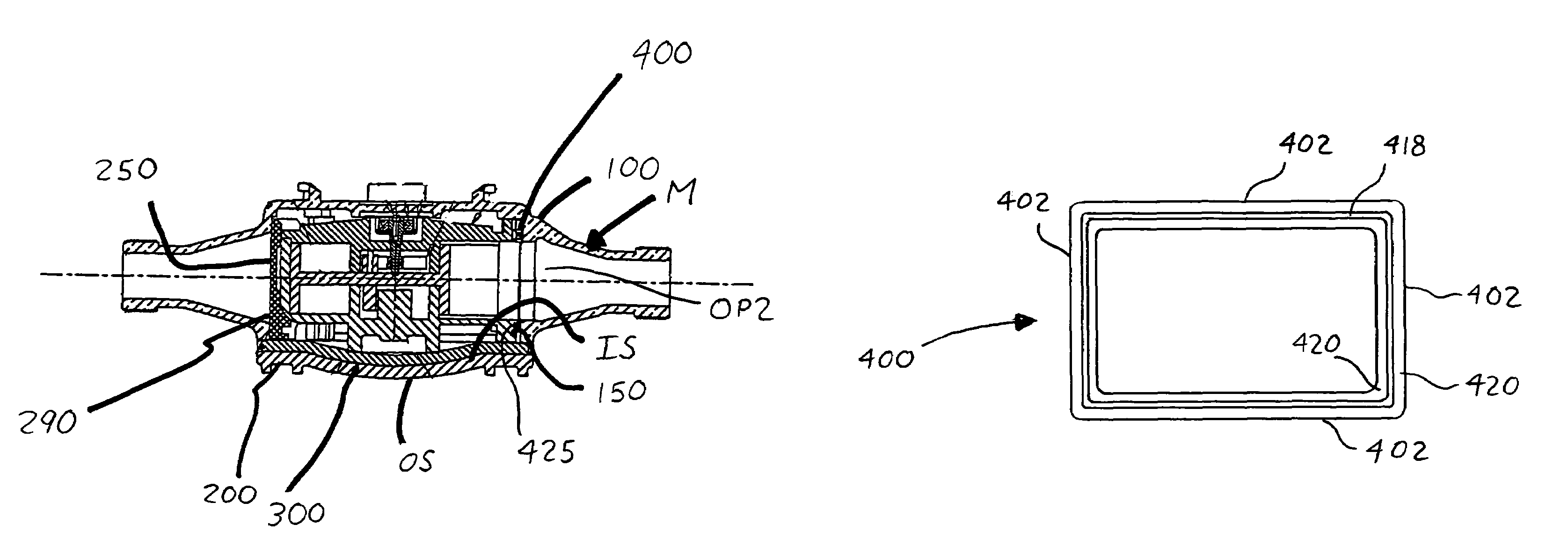

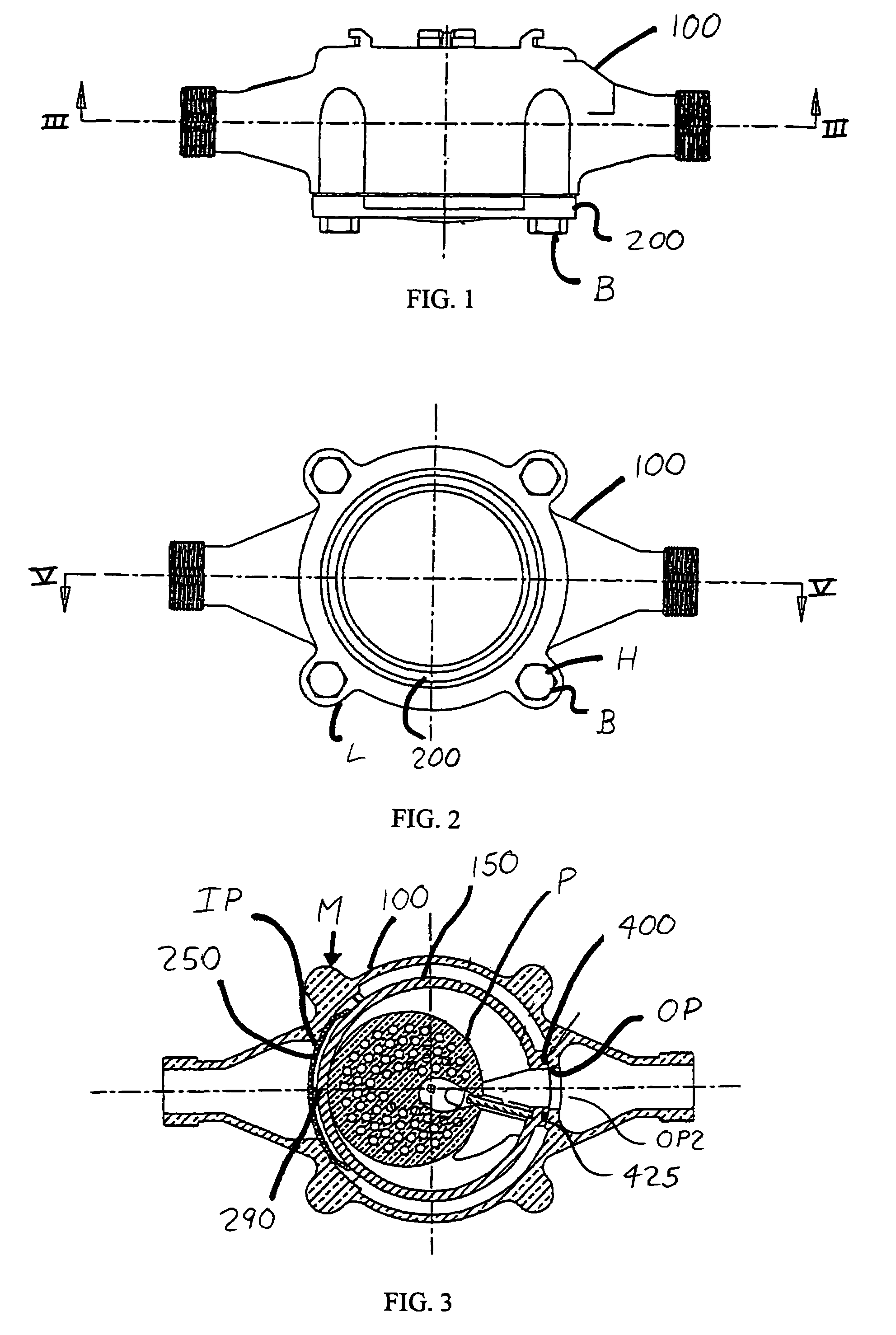

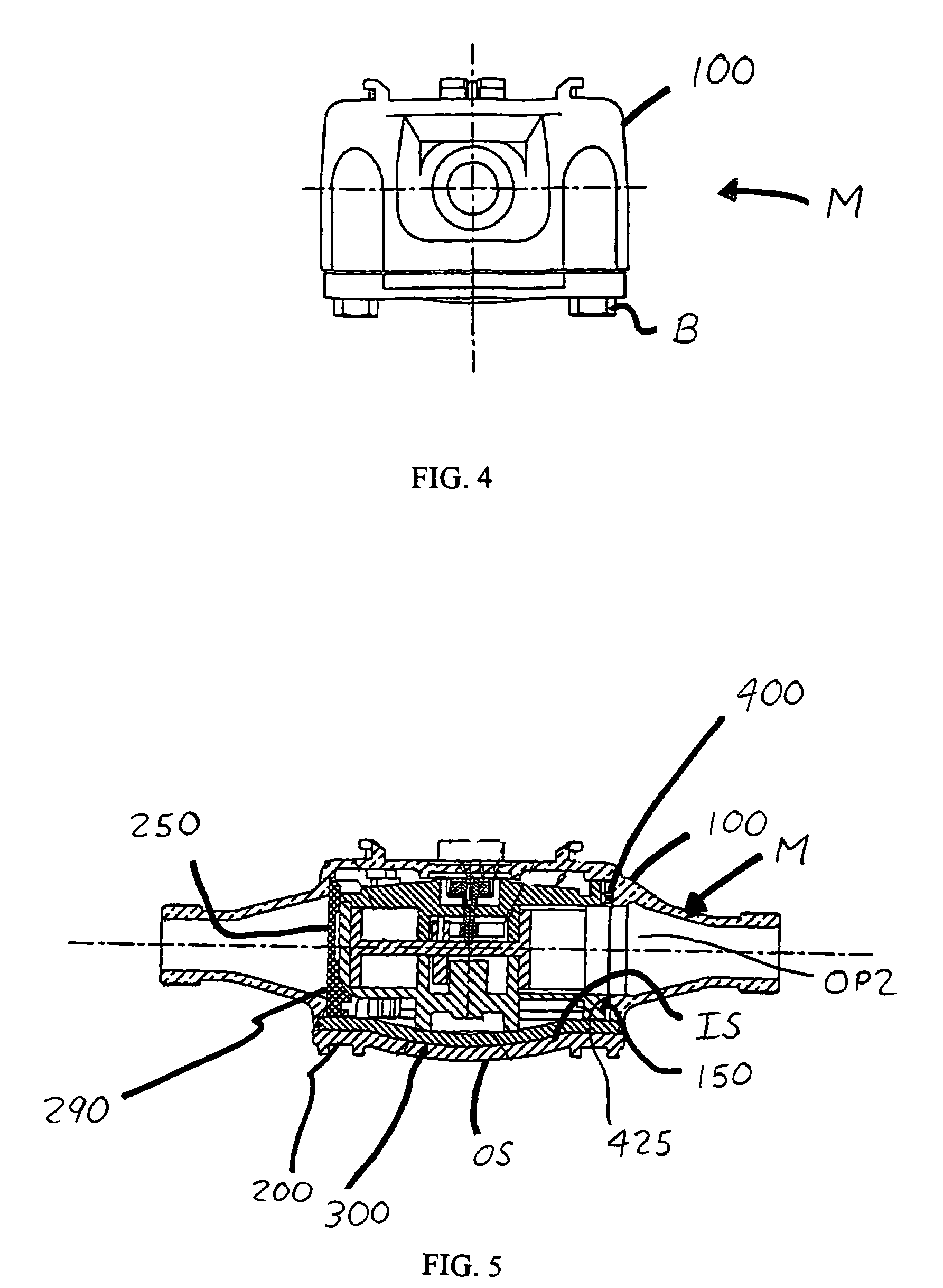

ActiveCN102301209AReduce the likelihood of damageEasy to manufactureVolume/mass flow by mechanical effectsConverting sensor output opticallyStreamflowBiomedical engineering

Embodiments of the invention provide devices and methods for measuring fluid volume. Devices according to some embodiments include a chamber, having a pair of gears rotatably mounted therewithin. Fluid flow through the chamber causes rotation of the gears, such that each rotation and / or partial rotation results in a known volume of the fluid passing through the chamber. An optical sensor positioned outside of the chamber, can view the rotating gears through a substantially transparent chamber wall. The optical sensor can view an optical characteristic of one or both of the gears, and based upon this data, fluid volume, flow rate, and / or flow direction can be determined. Devices and methods disclosed herein can provide for improved precision in fluid flow meter measurement. In addition, the devices and methods used herein can be more durable and easier to fabricate than previously known positive displacement flow meters.

Owner:ECOLAB USA INC

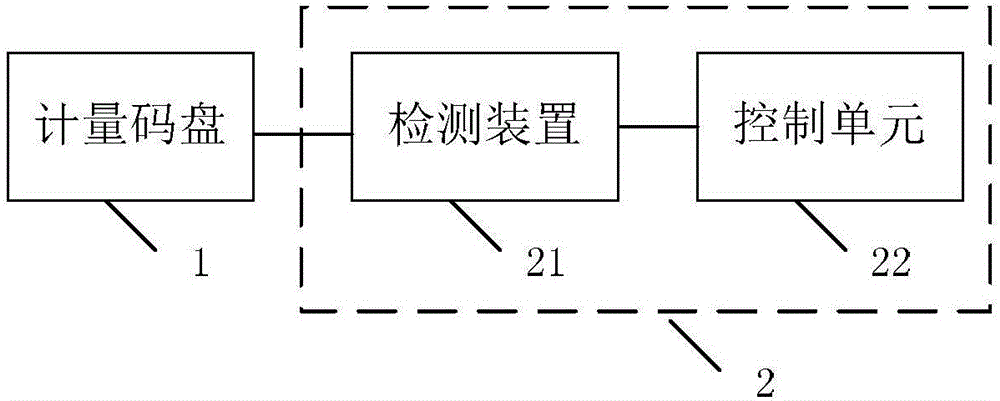

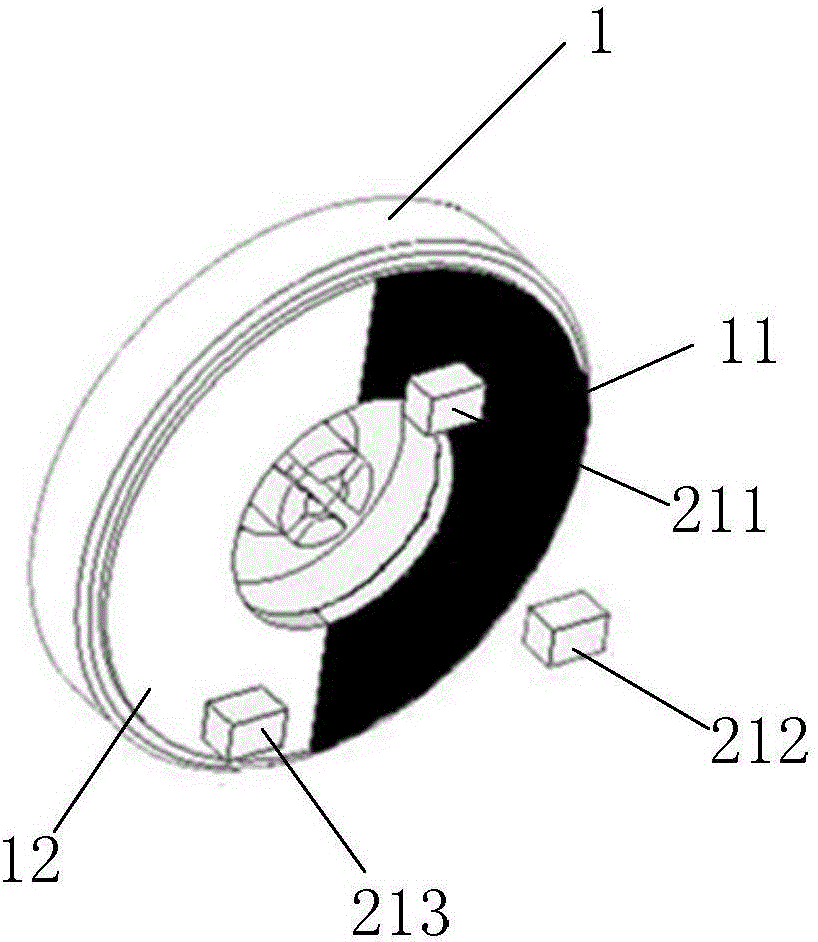

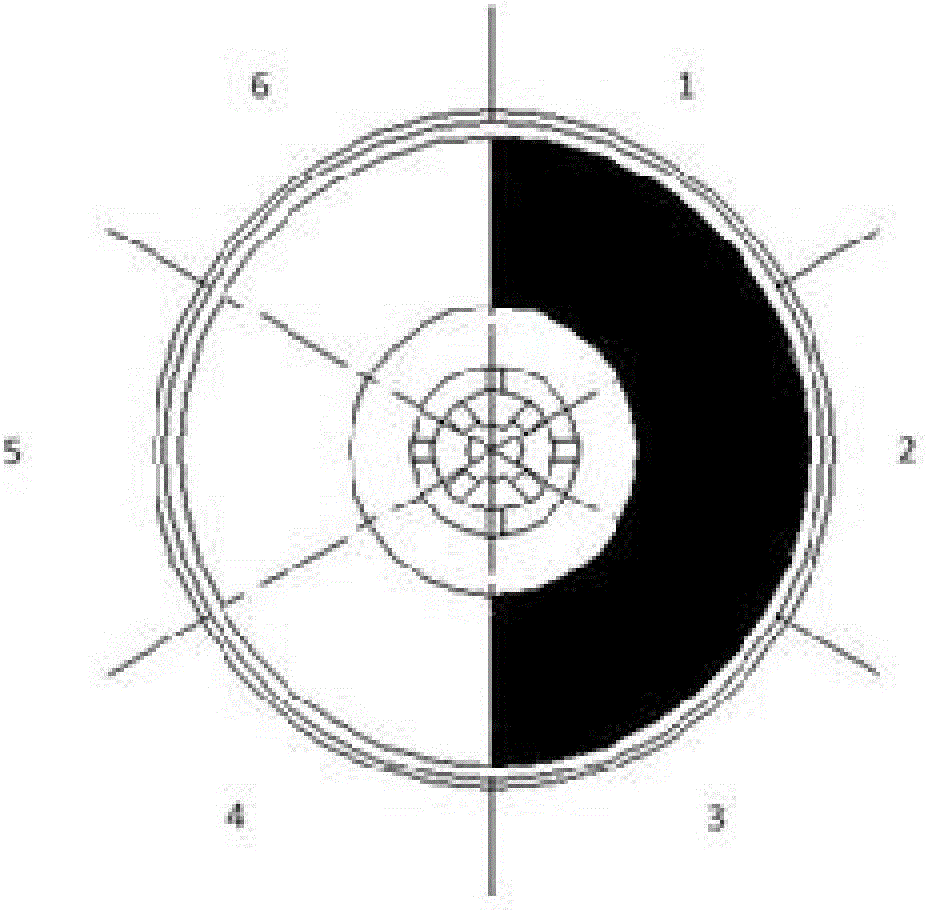

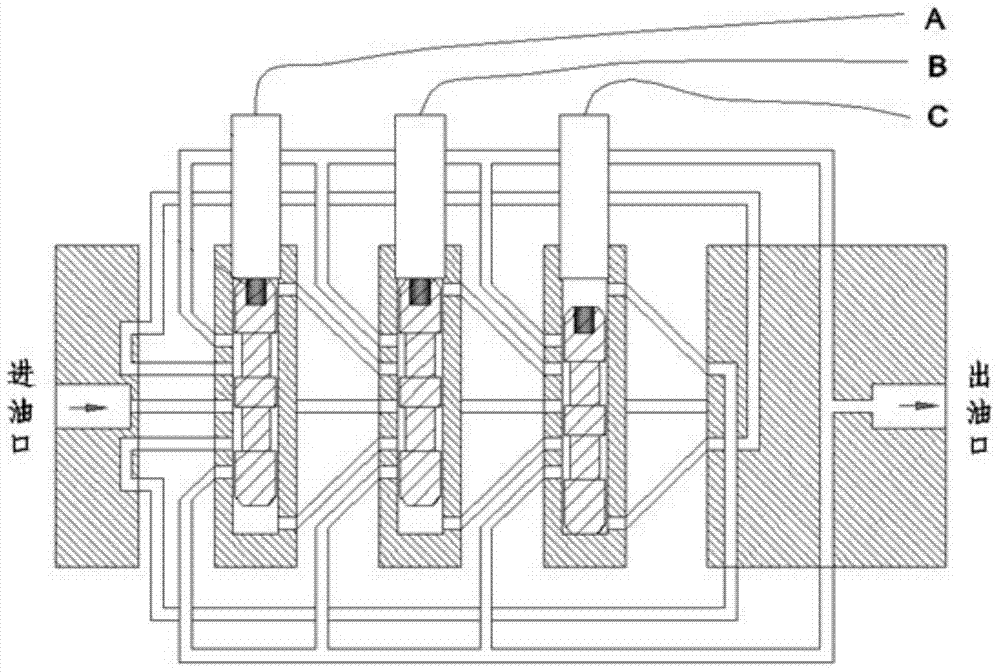

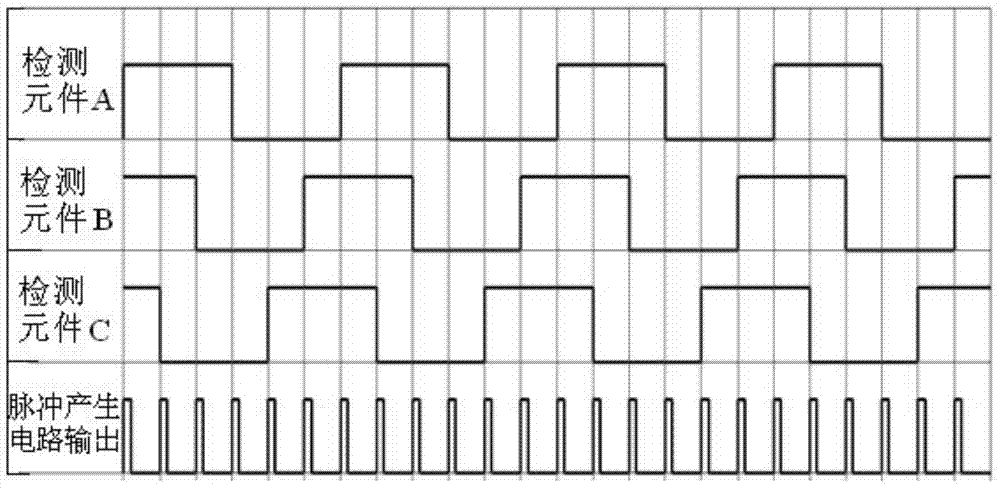

Volumetric flowmeter metering device and metering method thereof

ActiveCN106706059AHigh precisionAchieve statisticsVolume indication and recording devicesControl theoryStreamflow

The invention discloses a volumetric flowmeter metering device which comprises a metering coded disc and a sampling control module. The metering coded disc is provided with at least two metering reflection zones, the sampling control module comprises multiple detection devices and a control unit. The metering reflection zones and installing positions of the multiple detection devices divide the metering coded disc into multiple segmentation zones, and position states of the metering coded disc is represented by the segmentation zones detected by the multiple detection devices. In addition, the invention further discloses a metering method of the volumetric flowmeter metering device. By adopting the volumetric flowmeter metering device, the detection frequency is improved, and energy consumption is reduced.

Owner:GOLDCARD HIGH TECH

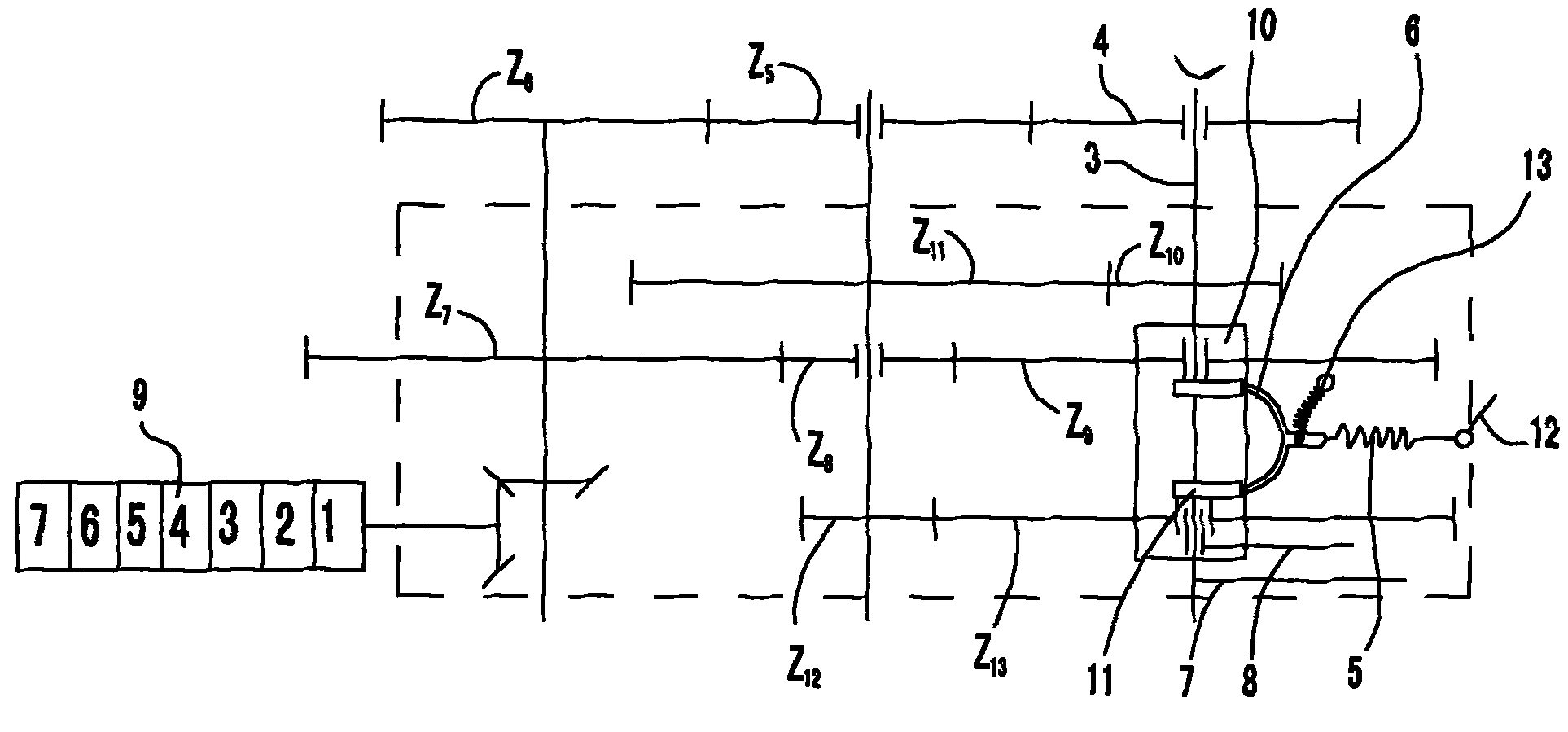

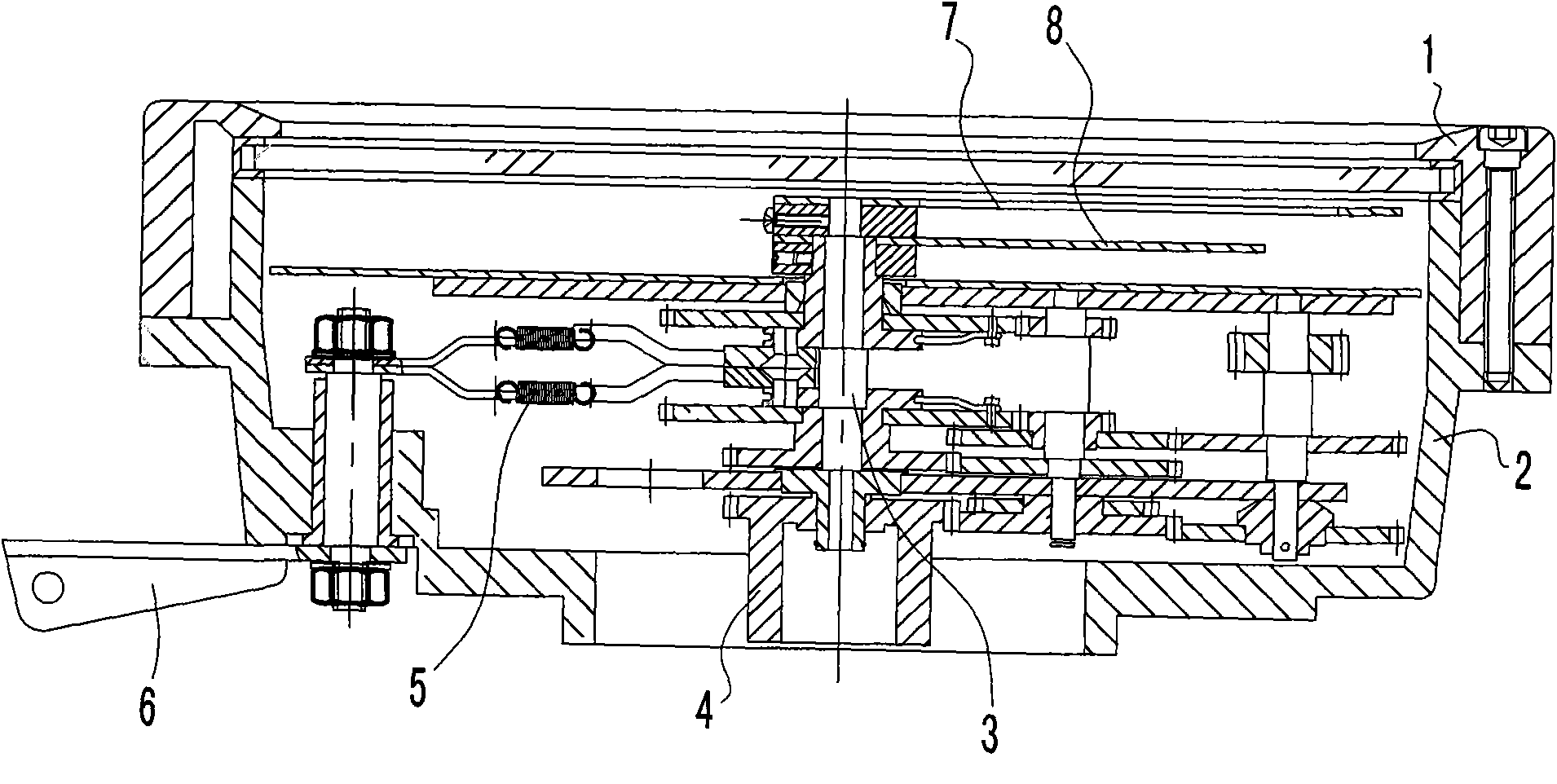

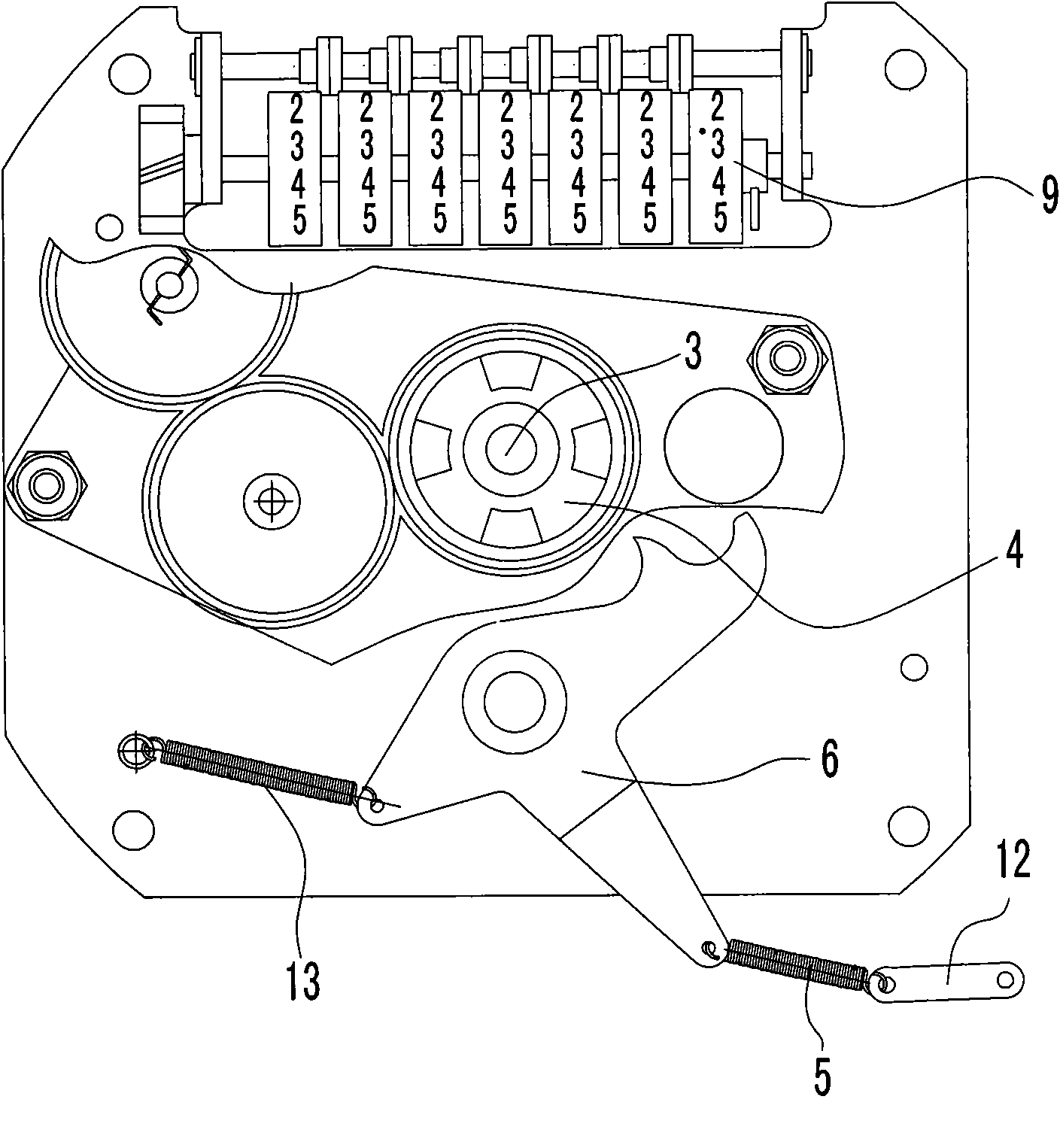

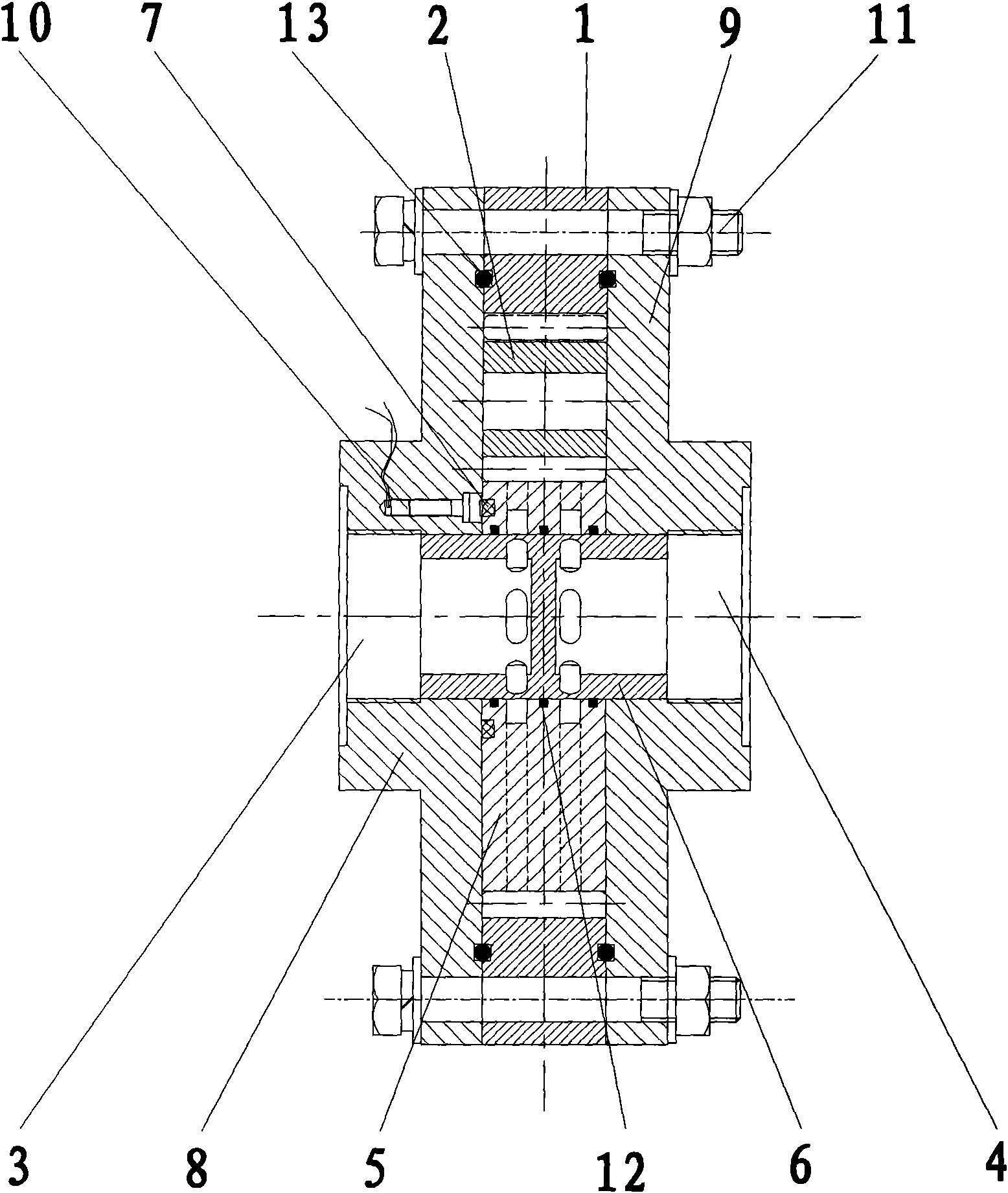

Zeroing counter for volumetric flowmeter

The invention discloses a zeroing counter for a volumetric flowmeter. The zeroing counter is characterized by comprising a dual-pointer single-flow metering unit consisting of a minute hand and a hour hand, a total accumulation metering unit formed by a print wheel group, a four-jaw wheel gear connected with the transmission shaft of a flowmeter governor and a zeroing operation mechanism. The invention is the zeroing counter for the volume type flow meter which has convenient, quick and accurate counting without calculation, can directly acquire online continuous metering values and single metering values.

Owner:HEFEI JINGDA INSTR

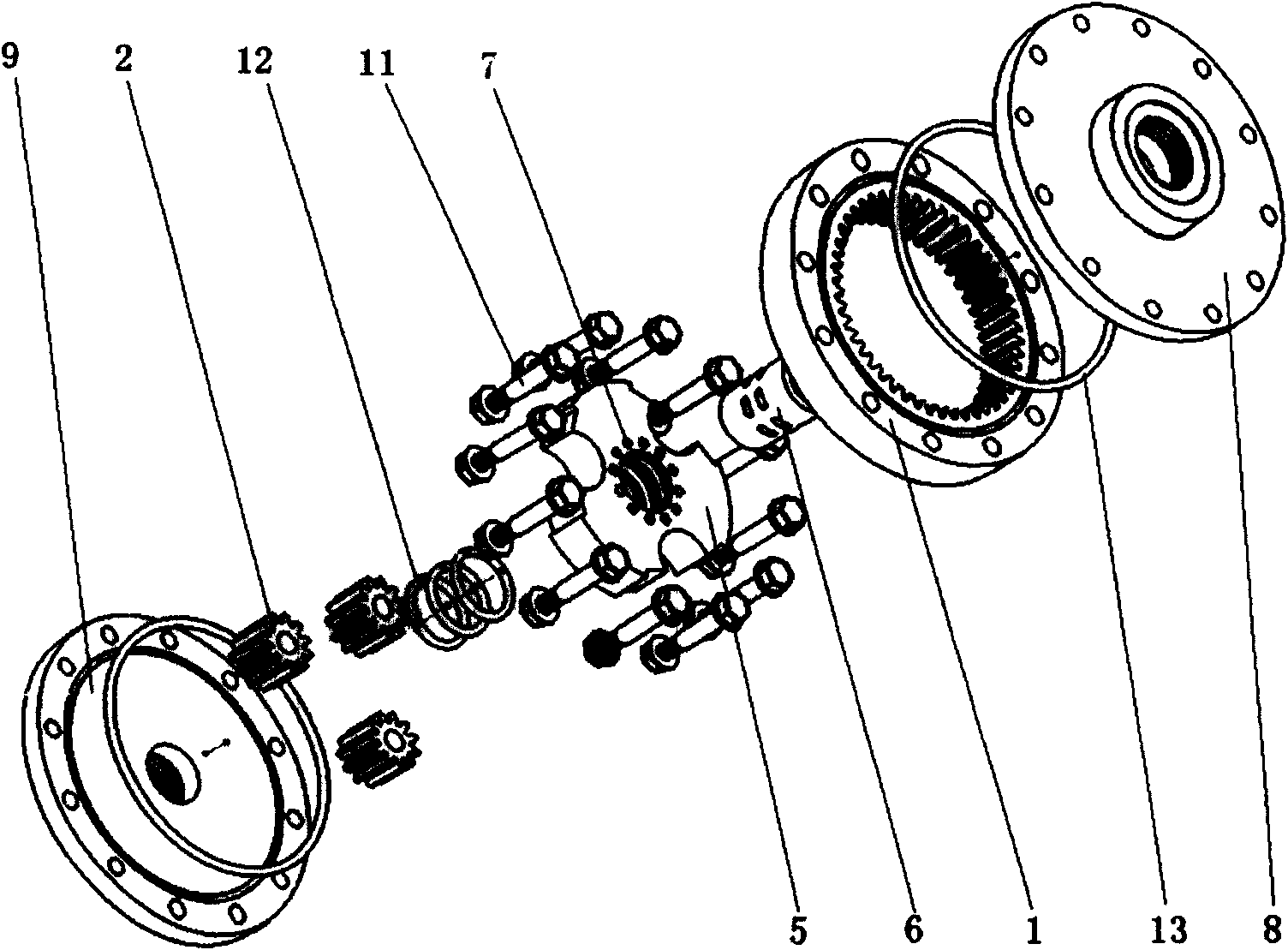

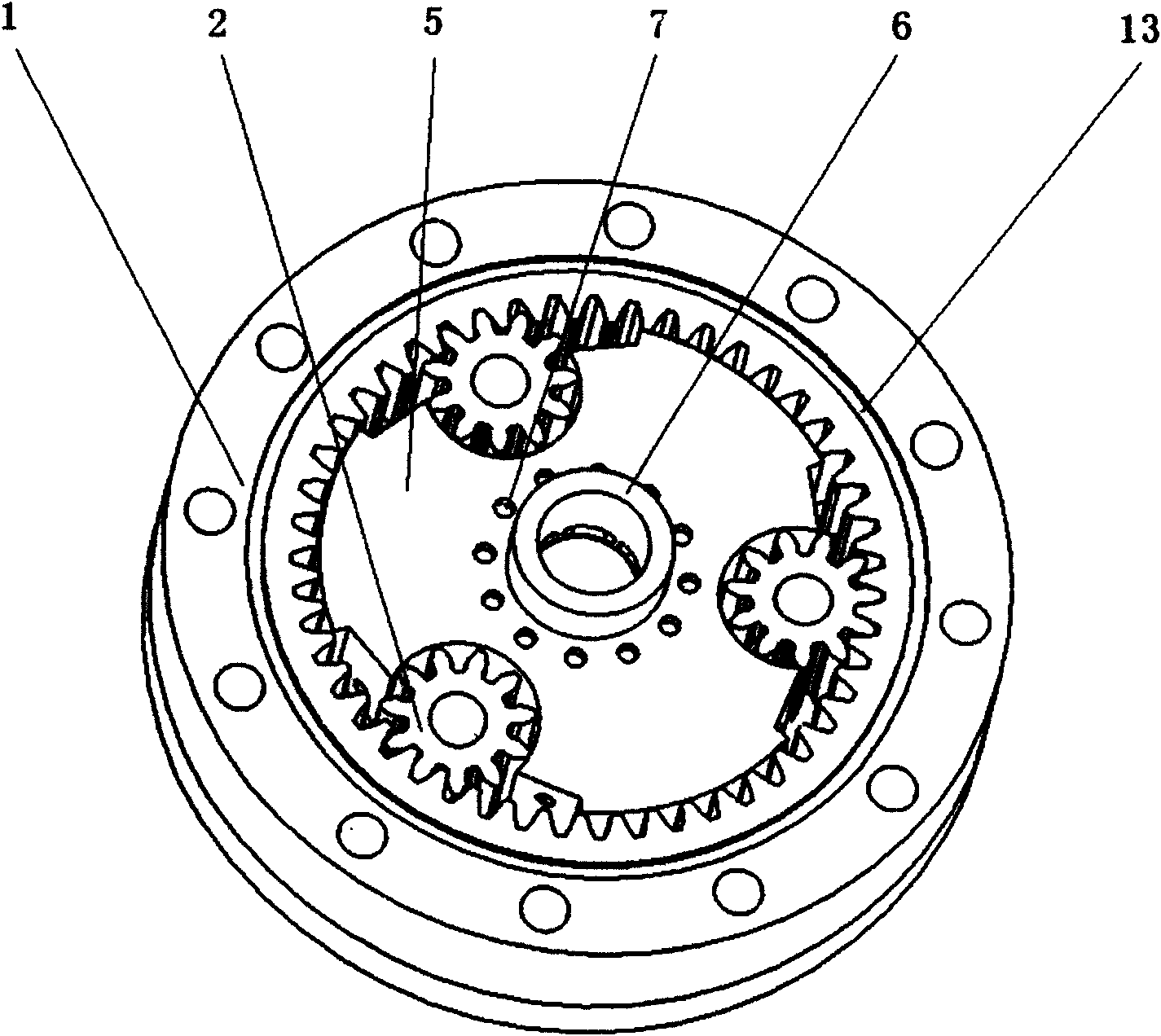

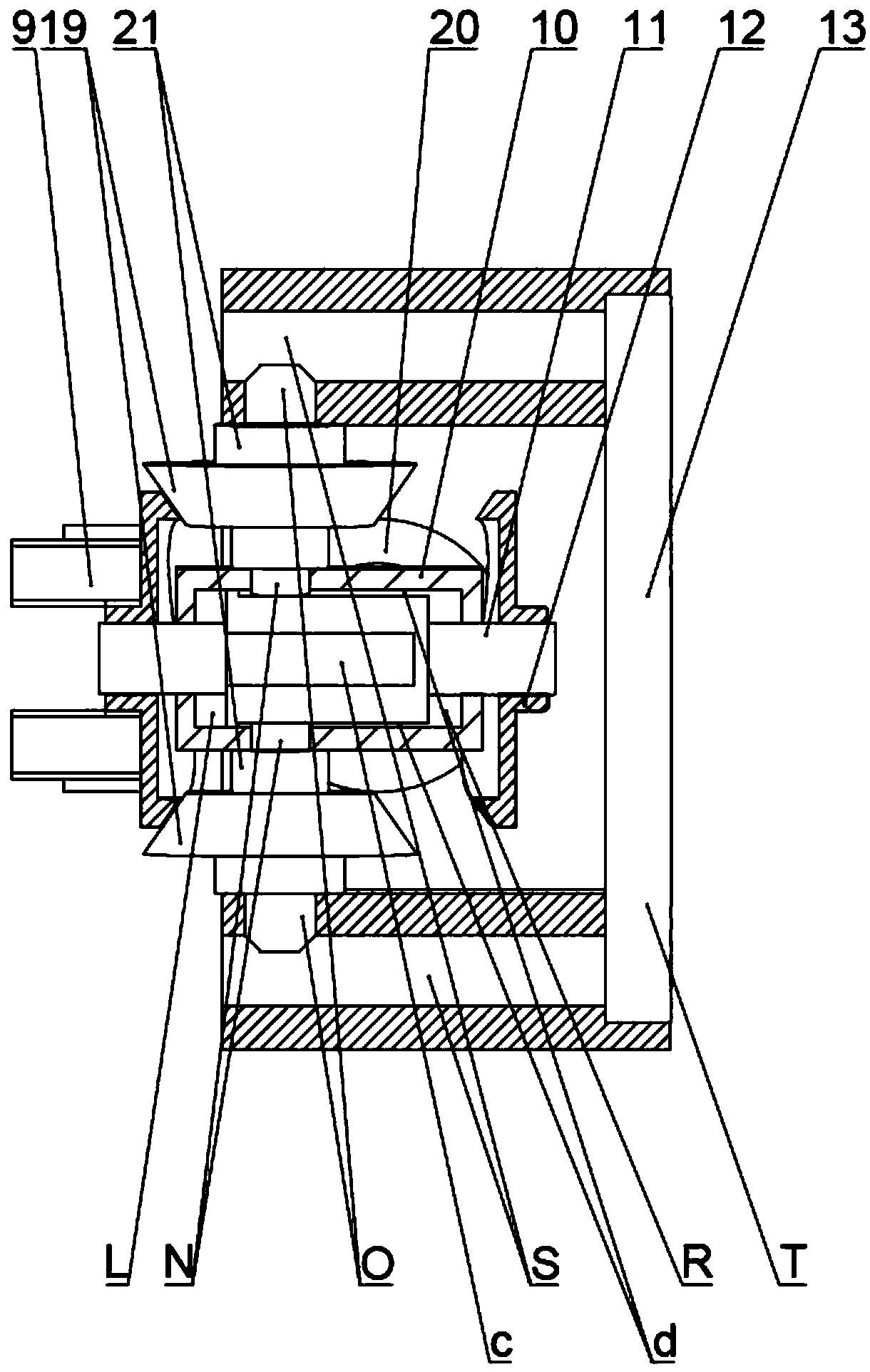

High-pressure dynamic internal gear flowmeter

InactiveCN101526379ASmall flow pulsationImproved traffic qualityVolume/mass flow by mechanical effectsWear resistantEngineering

The invention discloses a high-temperature dynamic internal gear flowmeter. An internal gear and a shell are fixed together, and the number of small pinions can be 2 to 4. Three pinions are taken as instance for description as follows: a liquid to be measured passes through a pintle valve and a retainer through an oil inlet to enter three oil inlet cavities of the internal gear; the three pinions and the retainer are pushed to move so as to bring the oil into three oil outlet cavities of the internal gear; the oil passes through the retainer and the pintle valve to reach an oil outlet; a flow rate signal of the liquid to be measured is converted to a rotating speed signal of the retainer, and the rotating speed signal is converted to an electric signal by a rotary transducer; and the dynamic flow rate of a system to be measured is determined by the measured electric signal finally. The pinions and the retainer are made of light wear resistant materials and have small moment of inertia; the tooth number of the internal gear is a non-three interger multiple, and the flow rate realizes dislocation and superposition; the flow pulsation of the flowmeter is very small, and the flow quality is obviously improved; and because the flowmeter belongs to a volumetric flowmeter, the flowmeter is not influenced by testing environmental conditions, can accurately measure the high-pressure flow rate of a hydraulic system, has the advantages of wide measuring range, high precision, good reliability and the like, and can be widely used for measuring the flow rate of high-pressure hydraulic systems in the industries such as chemical engineering, coal mine, metallurgy and the like.

Owner:ANHUI UNIV OF SCI & TECH

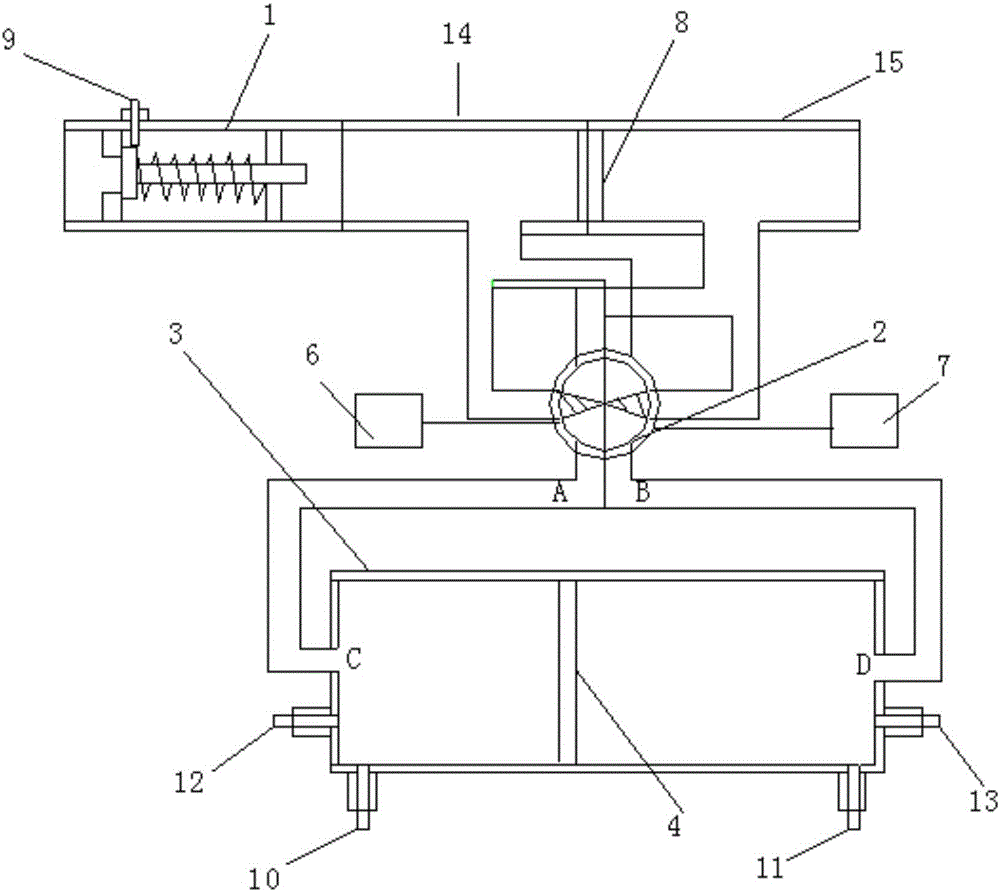

Special gas, oil and water flowmeter for pumping unit and flow calculating method

The invention relates to a special gas, oil and water flowmeter for a pumping unit and a flow calculating method. The special gas, oil and water flowmeter for the pumping unit comprises a one-way valve, a double three-way valve, a volumetric flowmeter, a pressure sensor, an eddy current sensor, an oil-water proportional sensor and a controller, wherein the one-way valve is connected with the double three-way valve; a port A of the double three-way valve is connected with a port C of the volumetric flowmeter; a port B of the double three-way valve is connected with a port D of the volumetric flowmeter; the eddy current sensor is connected with the one-way valve; the volumetric flowmeter is respectively connected with the eddy current sensor, the pressure sensor and the oil-water proportional sensor; and the controller is respectively connected with the eddy current sensor, the pressure sensor and the oil-water proportional sensor. By the special gas, oil and water flowmeter for the pumping unit and the flow calculating method, gas flow, oil flow and water flow can be measured and calculated uniquely. The special gas, oil and water flowmeter for the pumping unit is matched with an intelligent controller and a remote background system, is small in size, simple in structure, convenient to operate and low in construction cost, runs reliably, and is a real-time online measurement metering device which is urgent in oil exploitation at present.

Owner:陕西景行环保科技有限公司

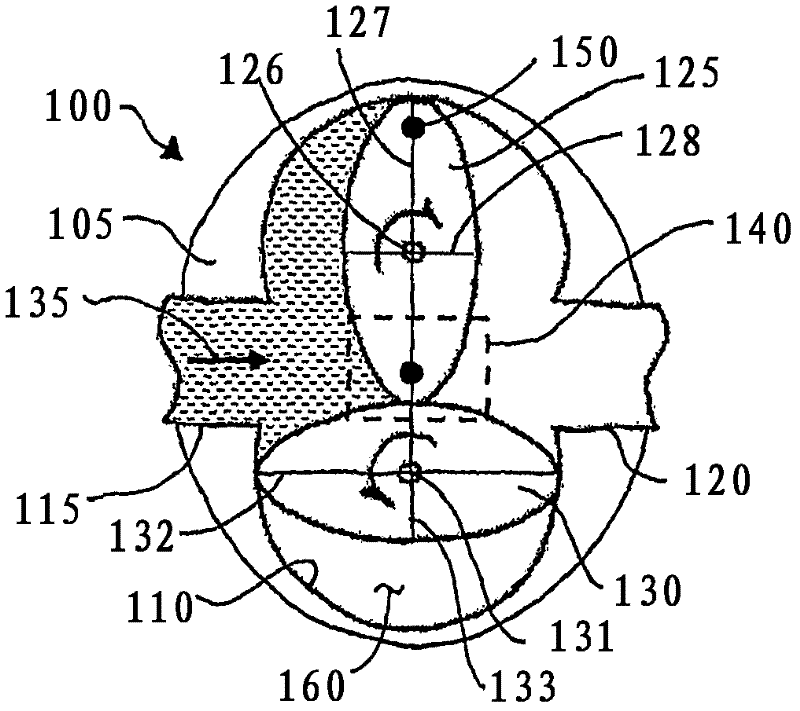

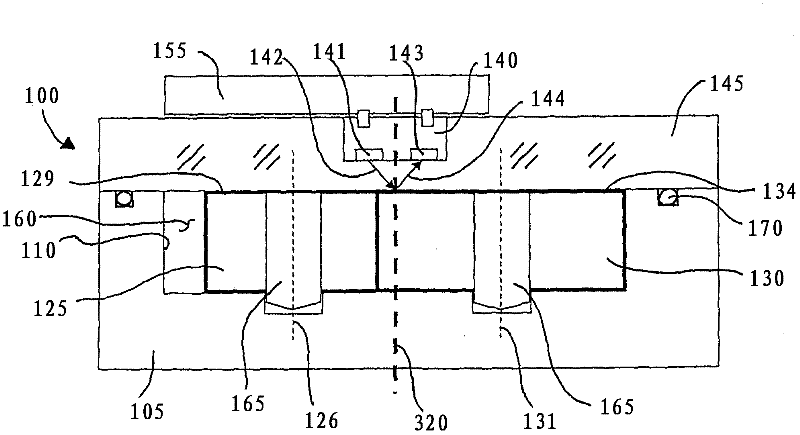

Positive displacement meter seal scheme

A positive displacement water meter includes a measuring chamber having an outlet port defined therein, wherein the outlet port includes a channel defined around the outlet port. A seal includes a planar surface and a curved surface, wherein the planar surface is substantially parallel to the curved surface, and the planar surface is situated within the channel. A meter casing includes an outlet port defined therein, wherein the meter casing receives the measuring chamber therein such that the outlet port of the measuring chamber is substantially aligned with the outlet port of the meter casing. The curved surface of the seal abuts a periphery of the outlet port of the meter casing forming a seal therewith. Due to the substantially arcuate cross section, the seal is adapted to resist the dislodging thereof from the channel during assembly of the positive displacement water meter.

Owner:MASTER METER

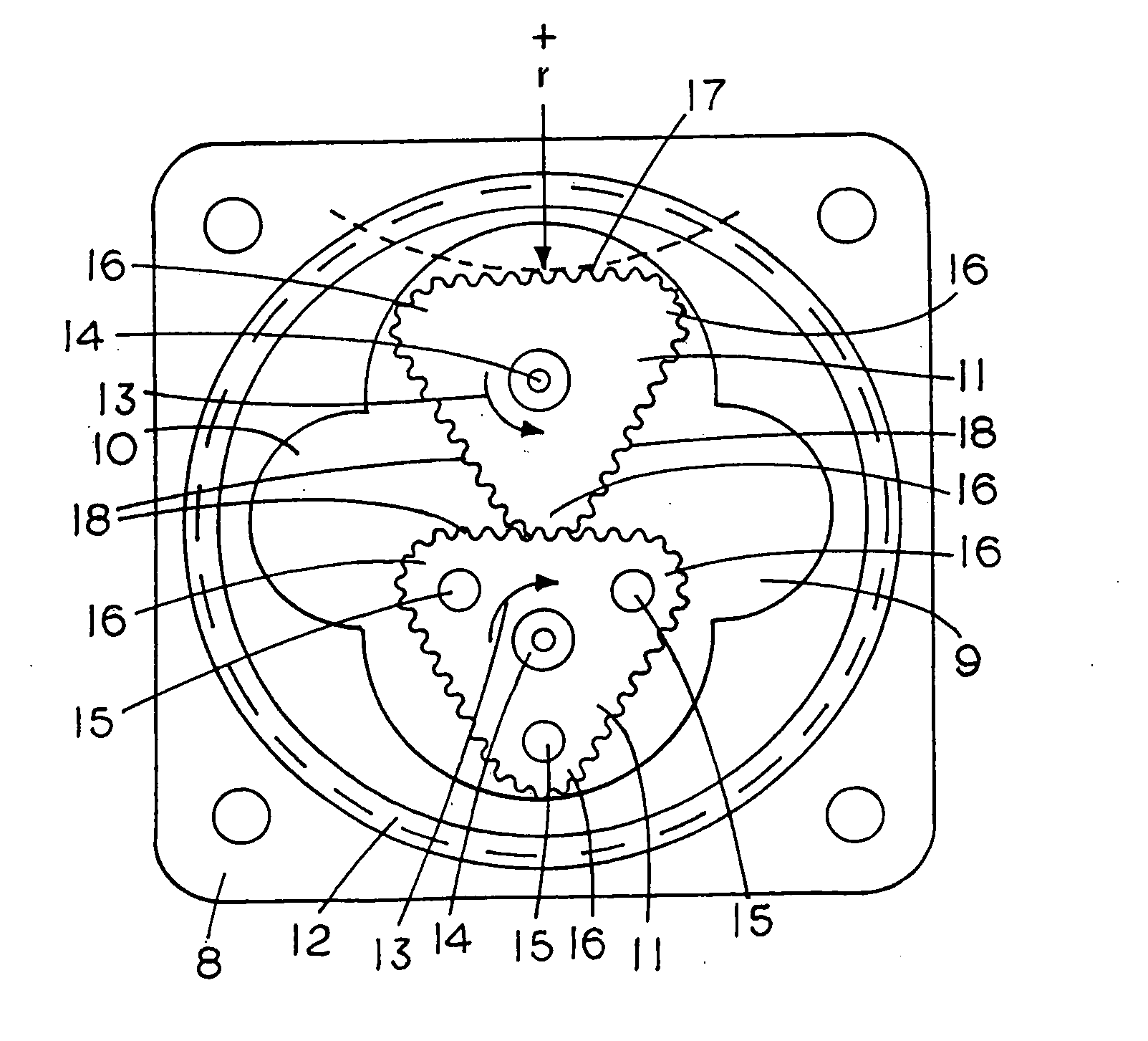

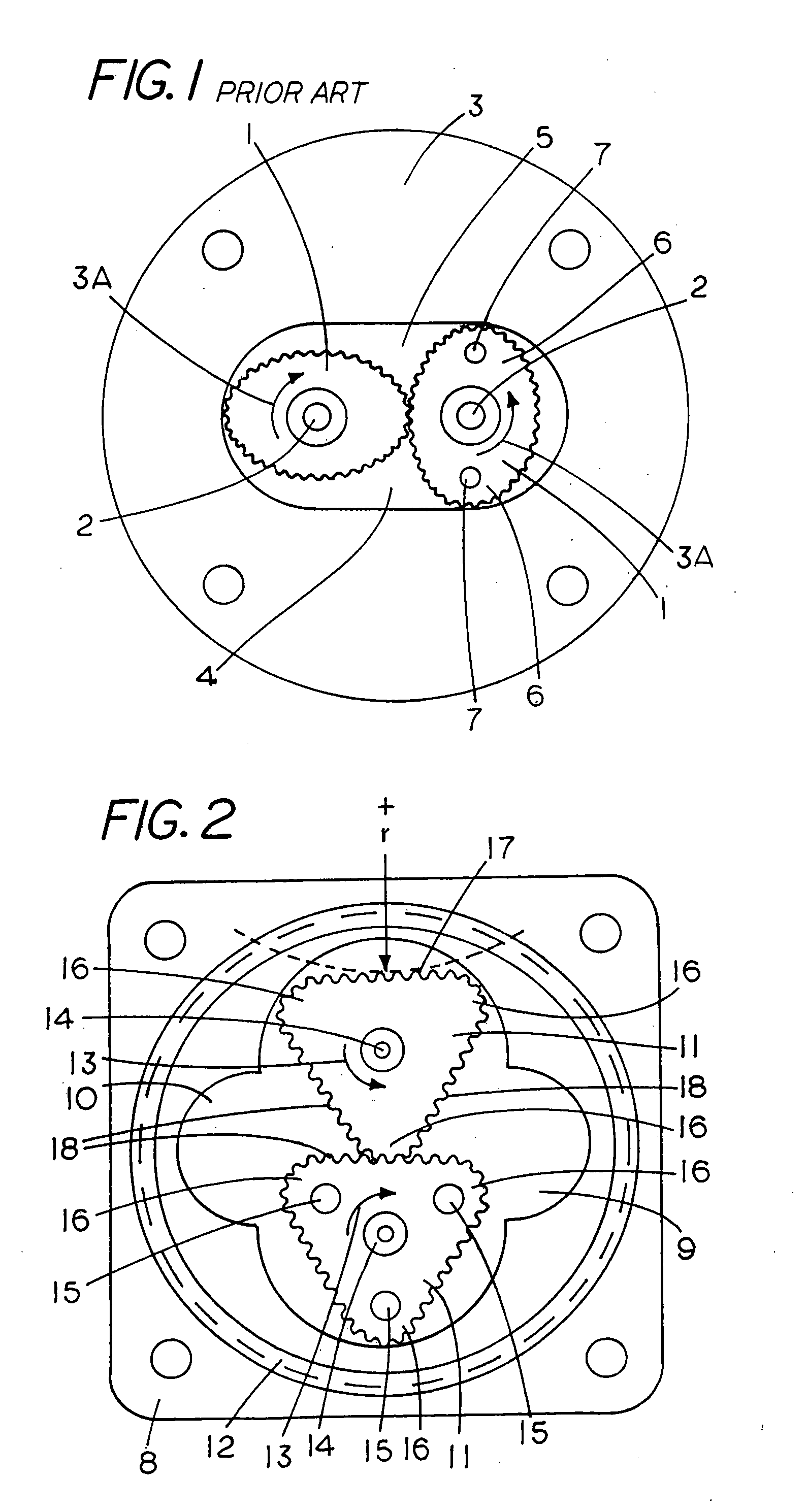

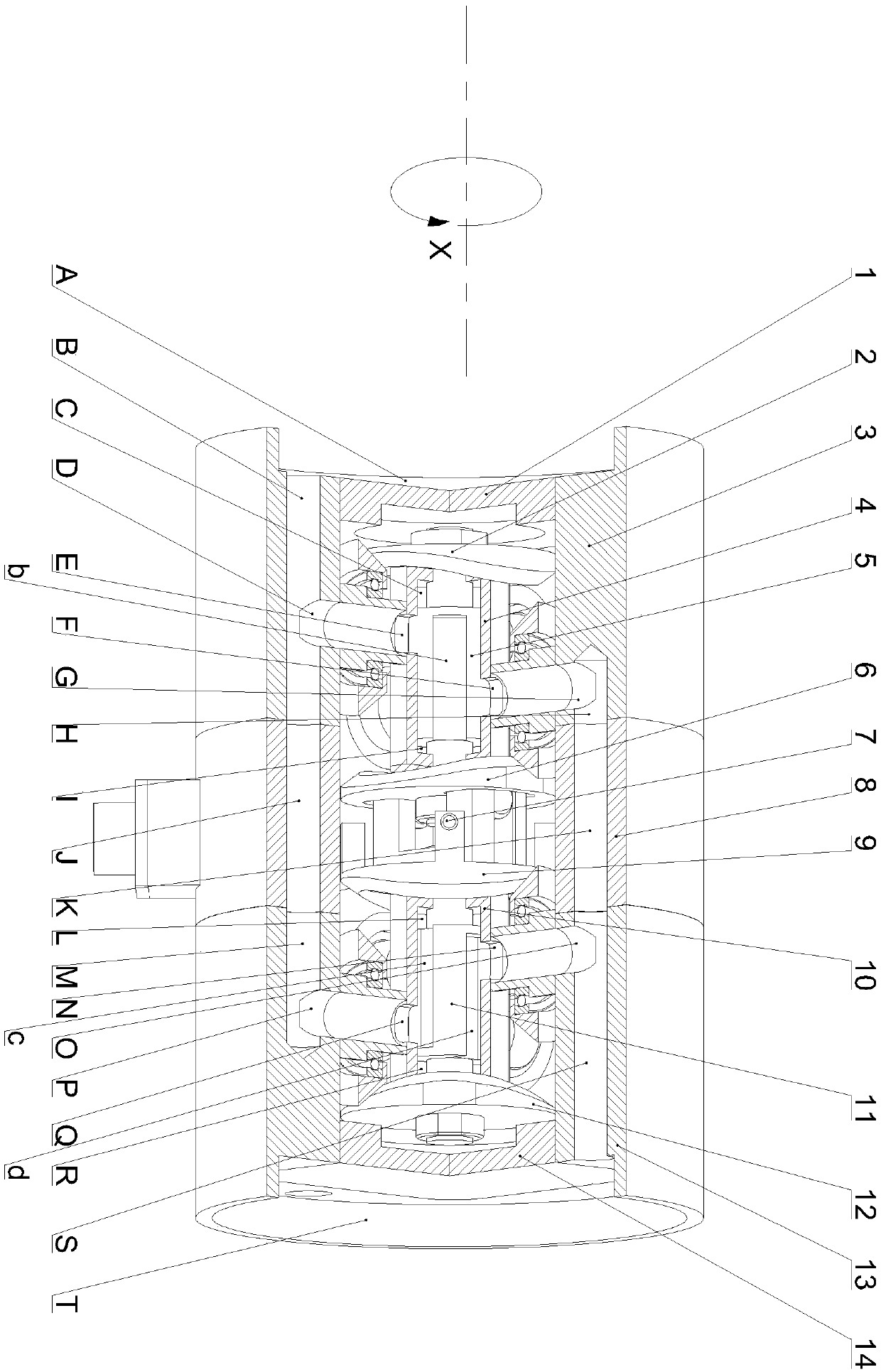

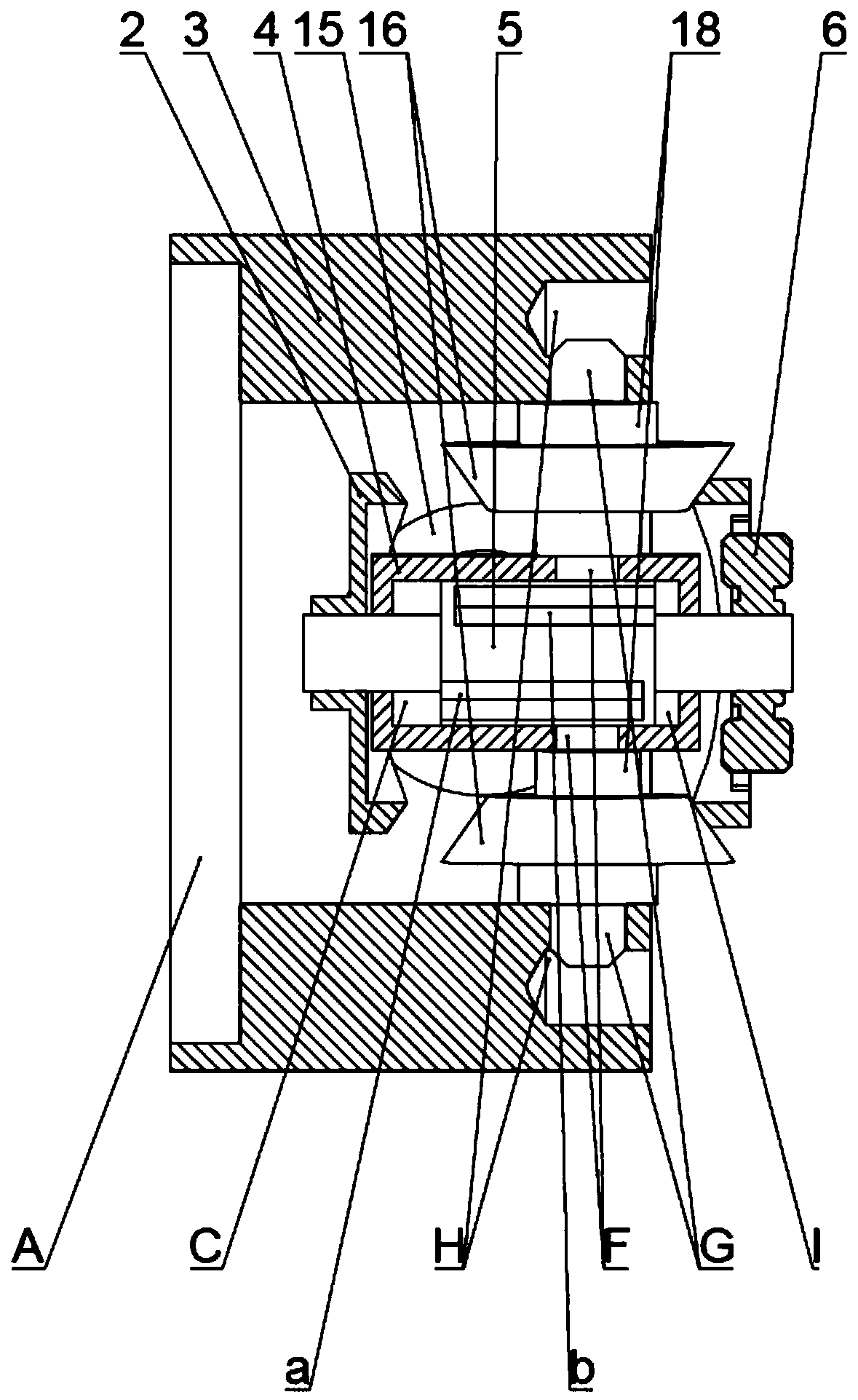

Positive displacement flow meter

InactiveUS20130025365A1Pump componentsOscillating piston enginesGear toothPositive displacement meter

Owner:LUKER GRAHAM JAMES

Movable guide rail type flowmeter

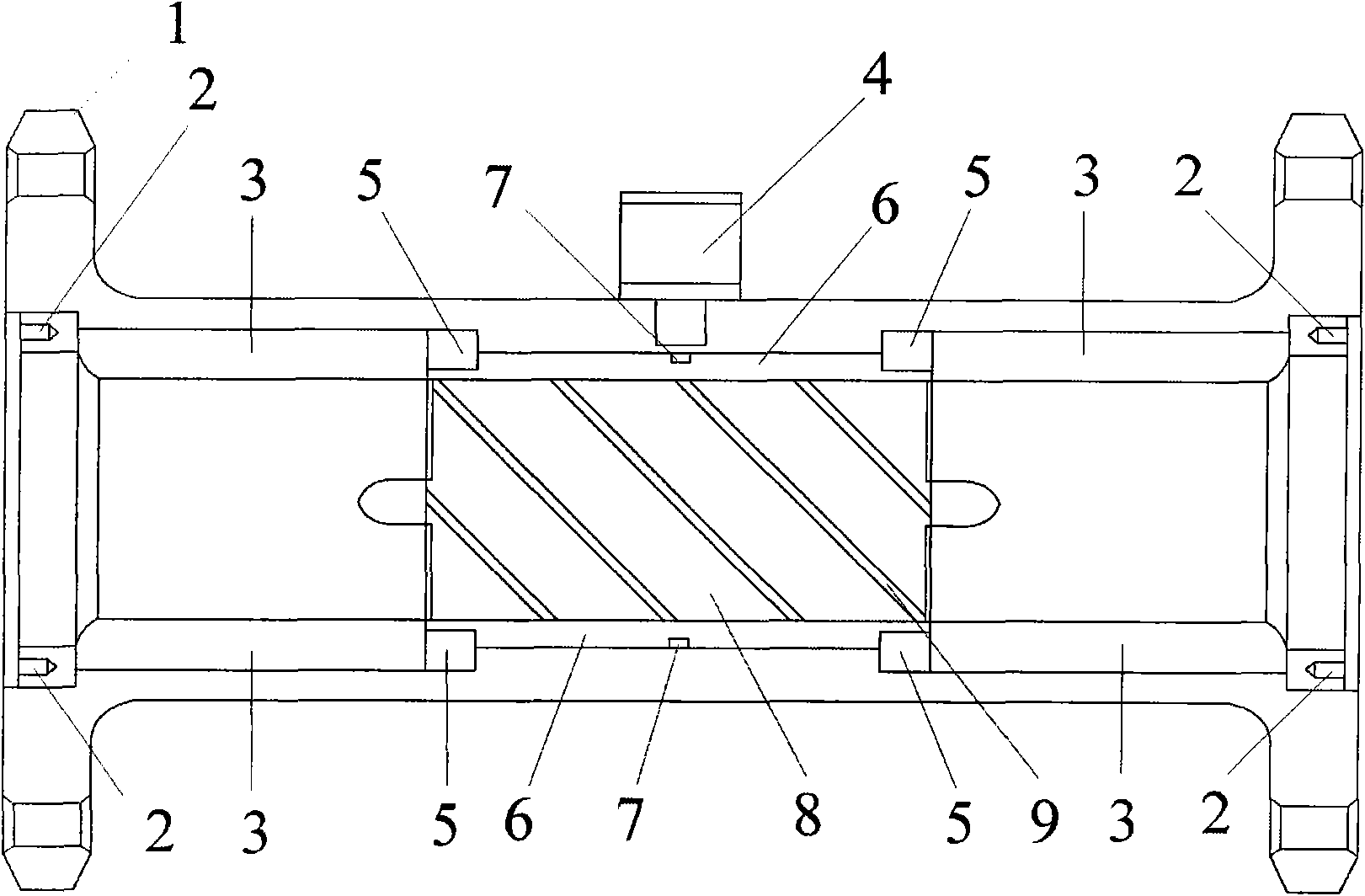

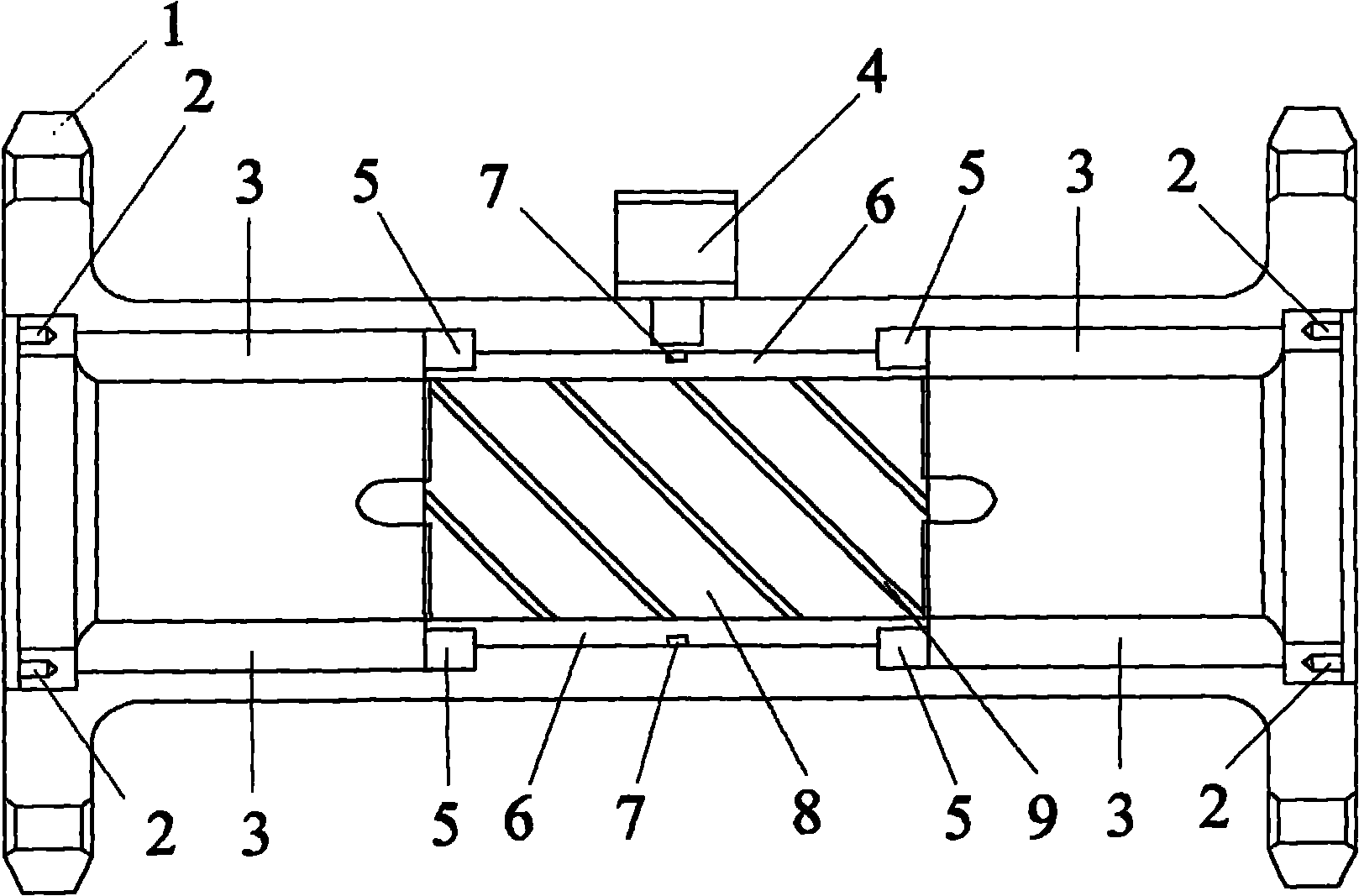

PendingCN111366206AReduce resistanceReduced kinetic energy lossMovable measuring chambersHall elementEngineering

The invention discloses a movable guide rail type flowmeter. The movable guide rail type flowmeter comprises a left shell and a right shell, the left shell and the right shell are communicated in a sealed mode through a middle shell, a left metering unit is arranged in the left shell, a right metering unit is arranged in the right shell, a liquid is fed and discharged from the left shell through the left metering unit, and a liquid is fed and discharged from the right shell through the right metering unit; and a measured fluid flow channel is separated from a moving part through a sealing component; a Hall element is arranged on the outer wall of the middle shell, magnetic steel inducting the Hall element is arranged in the middle shell, and a central processing unit receives pulse electric signals sent by the Hall element and calculates flow according to the pulse electric signals. The problem of overlarge inlet and outlet pressure drop of an existing volumetric flowmeter is solved, and the beneficial effects of reducing the pressure drop of the inlet and outlet of the flowmeter, balancing the flow pulsation of a liquid outlet, reducing the internal leakage of the flowmeter, improving the measurement precision and reducing the volume of the flowmeter are achieved.

Owner:ZHEJIANG UNIV OF TECH

Flowmeter

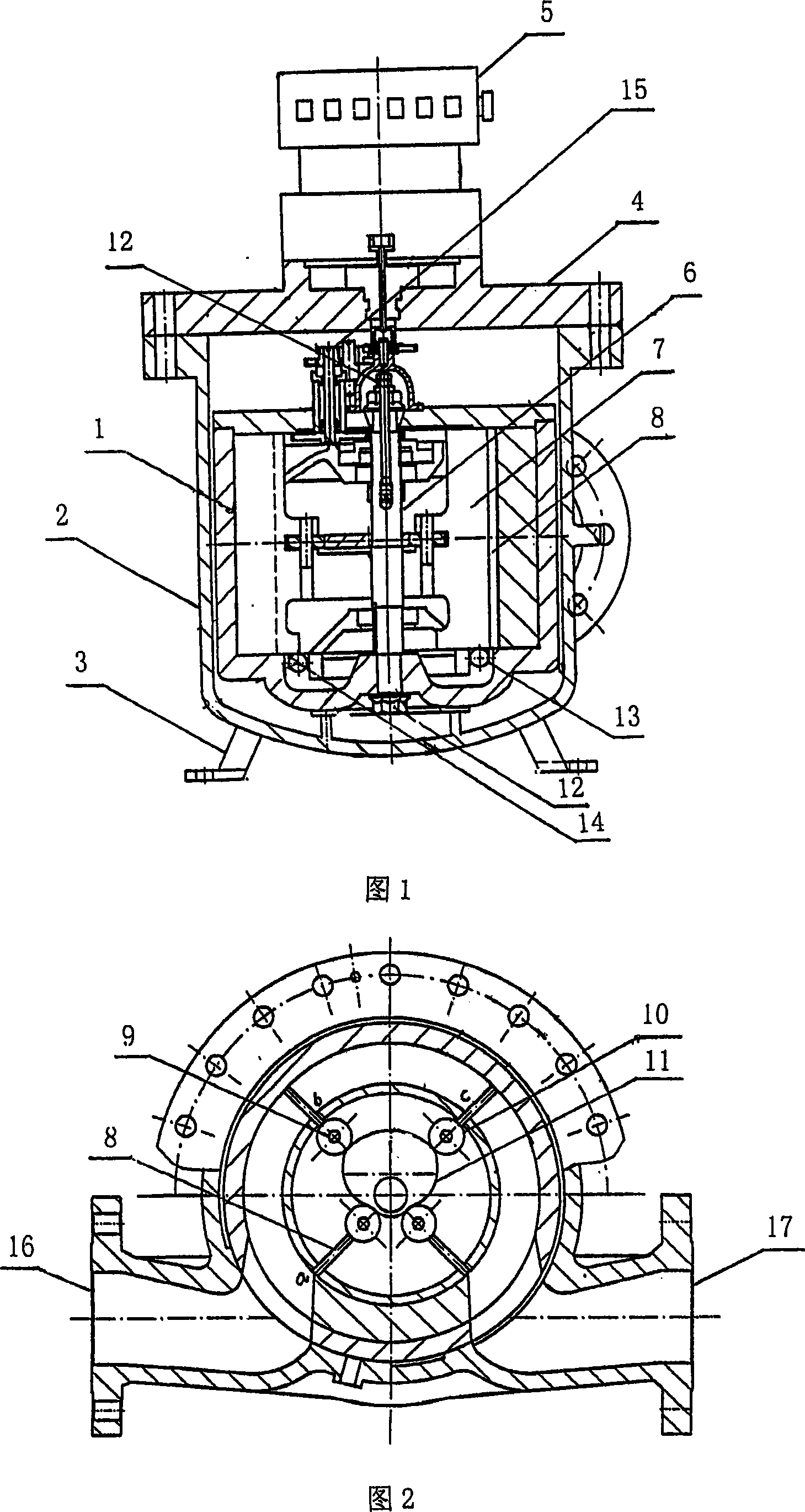

InactiveCN101144734AFlow state is stableNot easy to wearStationary measuring chambersPetroleum productEngineering

The invention discloses a flow meter with smooth operation, high measuring precision and long service life, and the flow meter comprises a metering body, a casing, a supporting seat, an upper cover, and a large print wheel counter, wherein, a plurality of pairs of mutually connected scrapers which are symmetrically distributed with the chief axis as the center are arranged inside the metering body, a circular cylinder model rotor adopts the chief axis as the center is arranged inside the metering body, the outer ends of the scrapers penetrate a gutter bar reserved on the rotor wall and can be expanded backward and forward along the radial direction, the inner ends of the scrapers contact with a cam fixed on the chief axis through a roller with a bearing, and the two ends of the rotor is connected with the bearing arranged on the two ends of the chief axis with. The volumetric flow meter is a metering device for continuously measuring the volume flow of the liquid inside a sealed pipeline. The invention is suitable for the transportation of crude oil and varieties of petroleum products.

Owner:陈还喜

Novel turbine volumetric flowmeter with high precision

ActiveCN102052939ASimple structureHigh sensitivityMovable measuring chambersVolume/mass flow by mechanical effectsH shapedMagnet

The invention relates to a novel turbine volumetric flowmeter with high precision, comprising a shell, lock nuts, two guide cylinders, a sensor, bearings, a turbine rotor body, a magnet steel, a large lead deep groove and a large helical turbine piece. The shell is H-shaped, and the two guide cylinders are connected with the shell by the lock nuts. One end of each guide cylinder is connected with the lock nuts, and the other end of each guide cylinder is connected with the bearings. The sensor is arranged at the middle part of the shell, and the bearings are arranged at the two ends of the large lead deep groove. The turbine rotor body is arranged at the outside of the large lead deep groove, the magnet steel is arranged on the turbine rotor body, and the large helical turbine piece is arranged in the large lead deep groove. Compared with the prior art, the flowmeter provided by the invention integrates the advantages of the velocity type flowmeter and the advantages of volumetric flowmeter, has the characteristics of simple structure, less pressure loss, high sensitivity, low cost, good stability, high precision, less purity requirement for media, and no requirement for the front and rear straight pipes of the flowmeter in the installation process, and can measure the instantaneous flow and the accumulated flow.

Owner:上海方龙流量校验设备制造有限公司

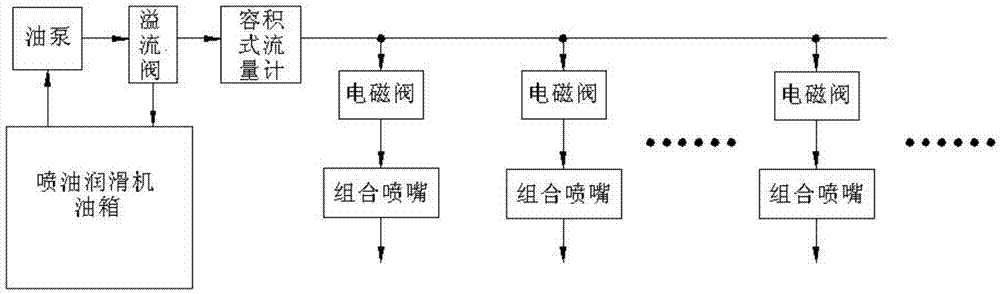

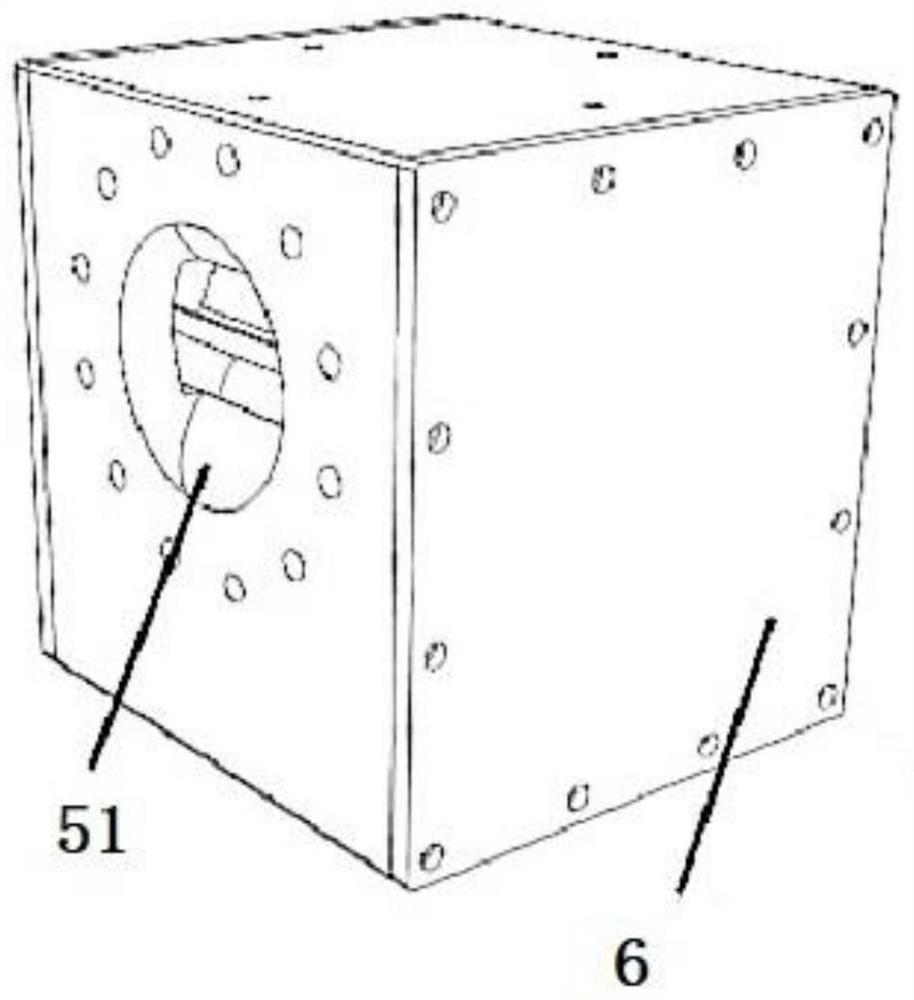

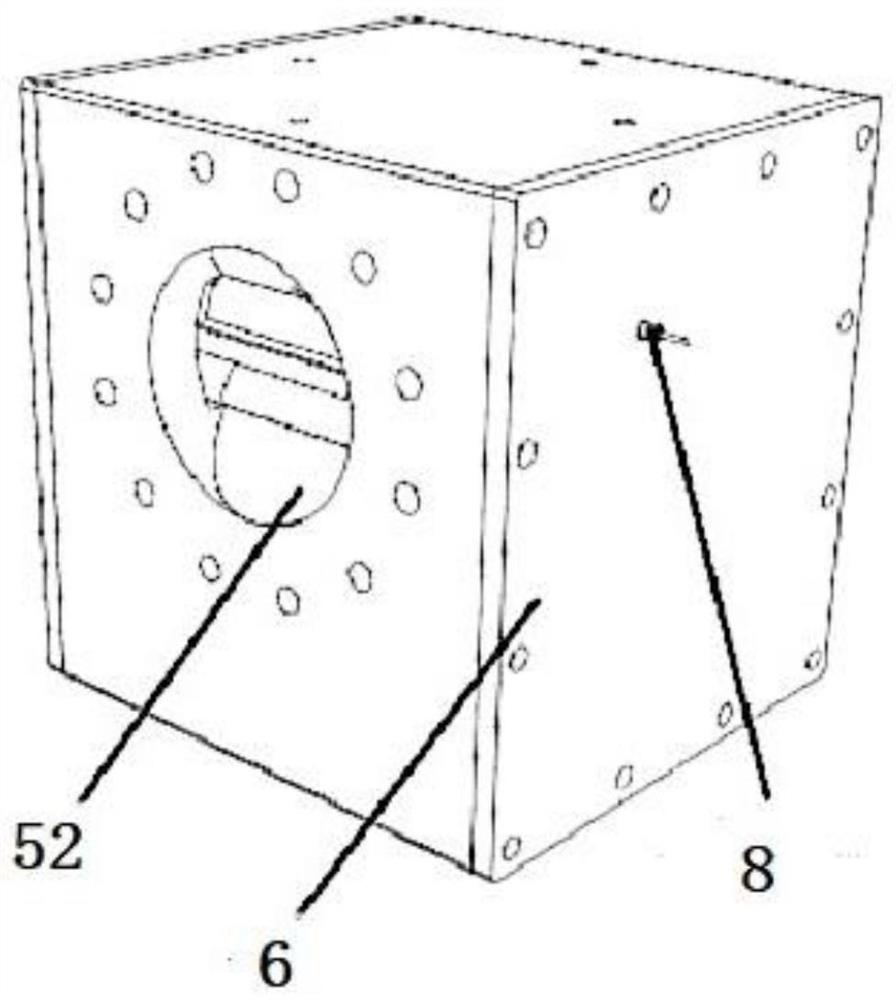

Volume measurement type concentrated oil spray lubrication system

InactiveCN103697309AGuaranteed to workReduce the numberProportioning devicesVolume measurementsSpray nozzle

The invention relates to a volume measurement type concentrated oil spray lubrication system which comprises an oil spray lubrication machine oil tank, an oil pump, an overflow valve and a plurality of combined nozzles, wherein each combined nozzle is provided with an electromagnetic valve used for controlling; the oil in the oil spray lubrication machine oil tank is conveyed into the plurality of combined nozzles by the oil pump through the overflow valve; the overflow valve is connected with the oil spray lubrication machine oil tank by a return pipe; a volumetric flow meter is also arranged behind the overflow valve, and is used for measuring the quantity of oil flowing into the combined nozzles; when the quantity of the oil sprayed by one combined nozzle reaches the set oil quantity, the oil is transferred into the next combined nozzle for lubricating a lubricating point. After the volume measurement type concentrated oil spray lubrication system is adopted, the pressure of all the nozzles is uniform.

Owner:NANTONG BAOSTEEL IRON & STEEL CO LTD +1

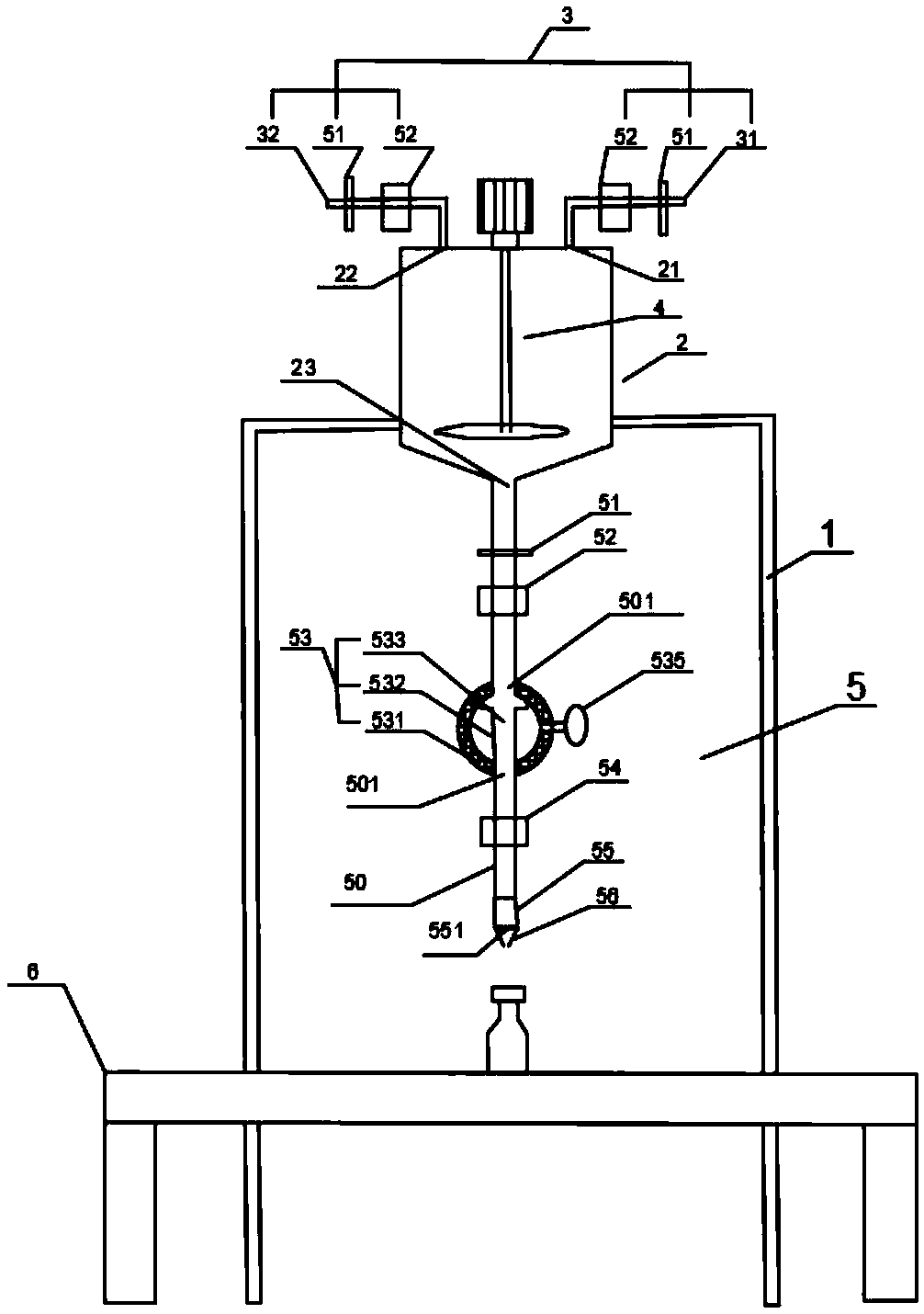

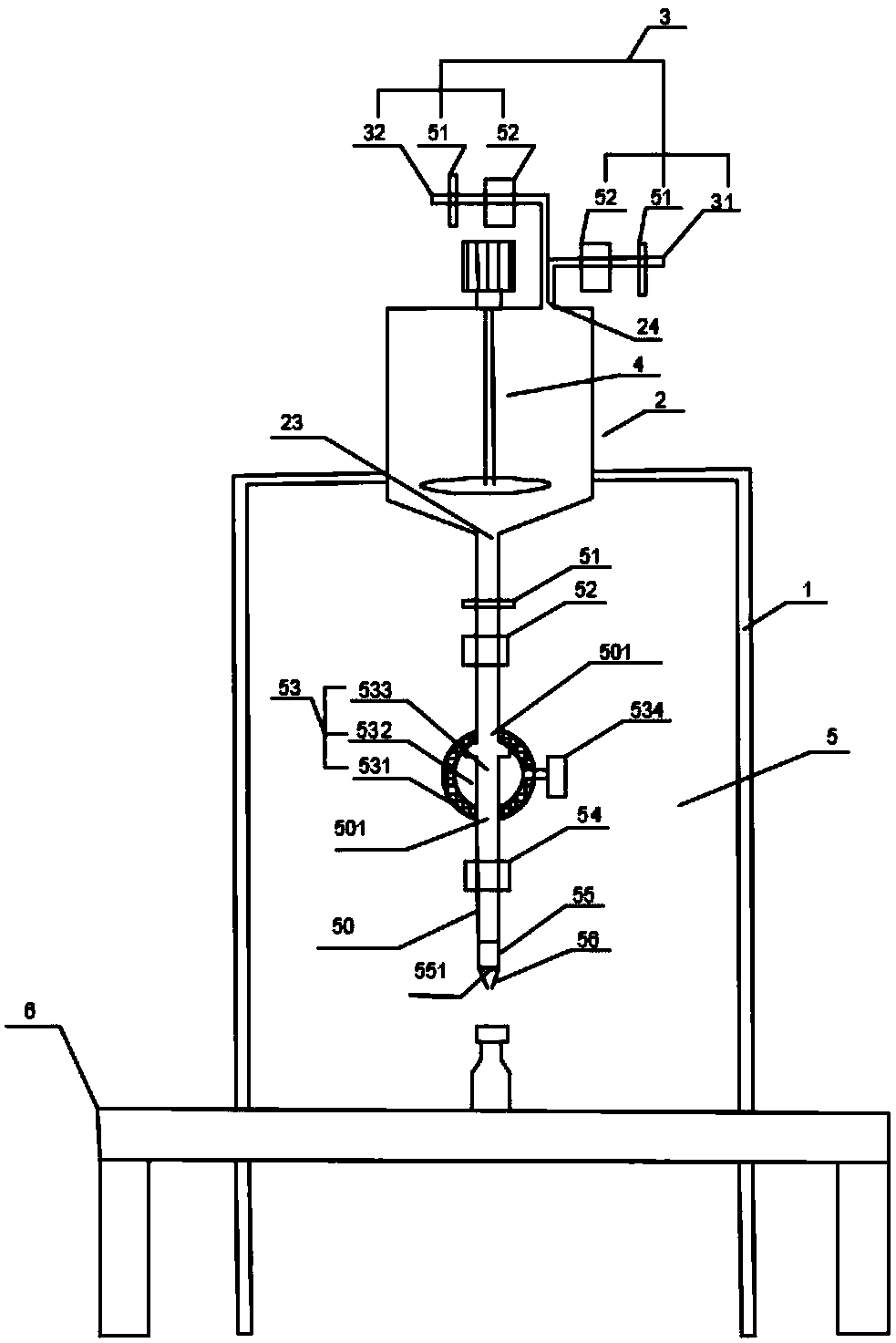

Automatic filling equipment for emulsion skin care product

The invention discloses automatic filling equipment for an emulsion skin care product. The automatic filling equipment comprises a bracket, a mixing tank, a feeding device, a stirrer, a filling mechanism and a conveying device. The mixing tank is fixed to the bracket. The feeding device is installed on the upper portion of the mixing tank. The stirrer is arranged in an accommodating cavity of themixing tank. The filling mechanism comprises a filling pipeline. One end of the filling pipeline communicates with a discharging outlet in the bottom end of the mixing tank, and the other end of the filling pipeline communicates with a filling opening. The filling pipeline is sequentially provided with an electromagnetic control pneumatic valve, an electronic flowmeter, a liquid switching device,a volumetric flowmeter and a leakage-proof valve. The liquid switching device comprises a valve sleeve and a valve element. The valve element is internally provided with a T-shaped flowing channel hole. The filling pipeline is provided with a through hole matched with the T-shaped flowing channel hole. The automatic filling equipment is simple in structure, the to-be-filled skin care product is mixed fully and evenly and filled quickly and quantitatively, liquid leakage is avoided after filling is completed, and waste is reduced.

Owner:陈大祥

Low-pulsation gear flowmeter of composite gear type

InactiveCN101608937ASmall flow pulsationImproved traffic qualityVolume/mass flow by mechanical effectsChemical industryGear wheel

The invention discloses a low-pulsation gear flowmeter of a composite gear type, which is formed by enabling 2 shafts to respectively support a composite gear comprising gears 6, 7 and 8 and a composite gear comprising gears 17, 16 and 15. Each composite gear can comprise 2-4 gears axially mounted and peripherally staggered. A composite gear comprising three gears is used for explanation. Liquid to be measured enters an oil feeding cavity of the flowmeter from an oil feeding hole of the flowmeter and pushes the mutually engaged gears to rotate so that oil liquid is driven to an oil discharge cavity of the gears and is discharged from an oil discharge hole of the flowmeter, and a flow signal of the liquid to be measured is converted into a rotating speed signal of the shaft 1; then, the rotating speed signal is converted into an electric signal by an angle coder mounted on the shaft 1 to confirm the dynamic flow of a system to be measured; the mutually engaged gears, the shaft 1 and a shaft 2 can be made of light wear-resistant materials and have small rotational inertia; the number of the gears is a multiple of an integer not equal to 3, and the flow can realize staggered superposition. The flowmeter has extremely little flow pulsation, obviously improves the flow quality, belongs to a volume-type flowmeter to avoid the influence of test environmental conditions, accurately measures the dynamic flow of the high pressure of a hydraulic system, has the advantages of wide measurinog range, high precision, good reliability, and the like and can be widely applied to the flow measurement of the high-pressure hydraulic system of industries, such as aerospace, military industry, chemical industry, coal mine, metallurgy, and the like.

Owner:ANHUI UNIV OF SCI & TECH

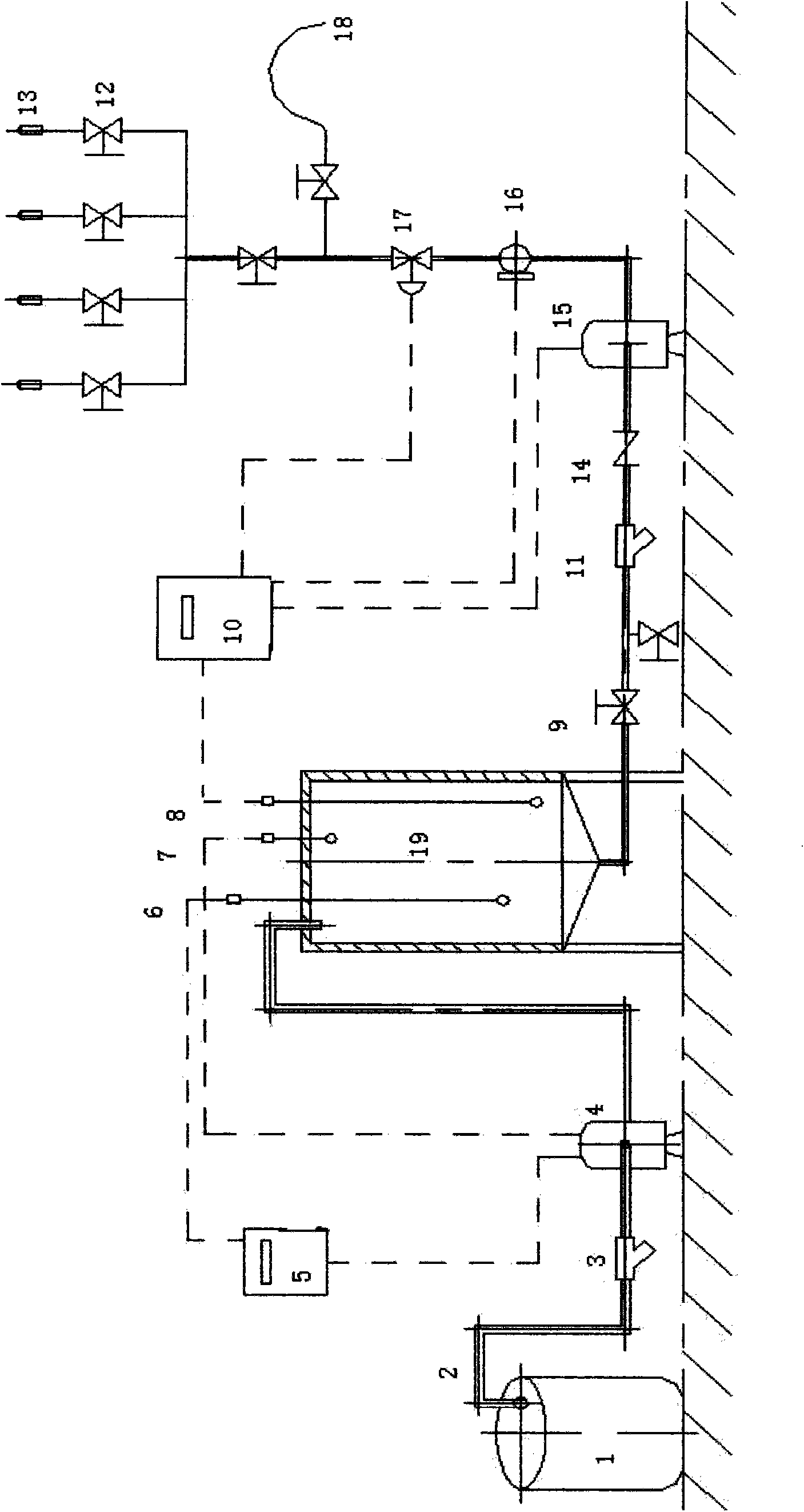

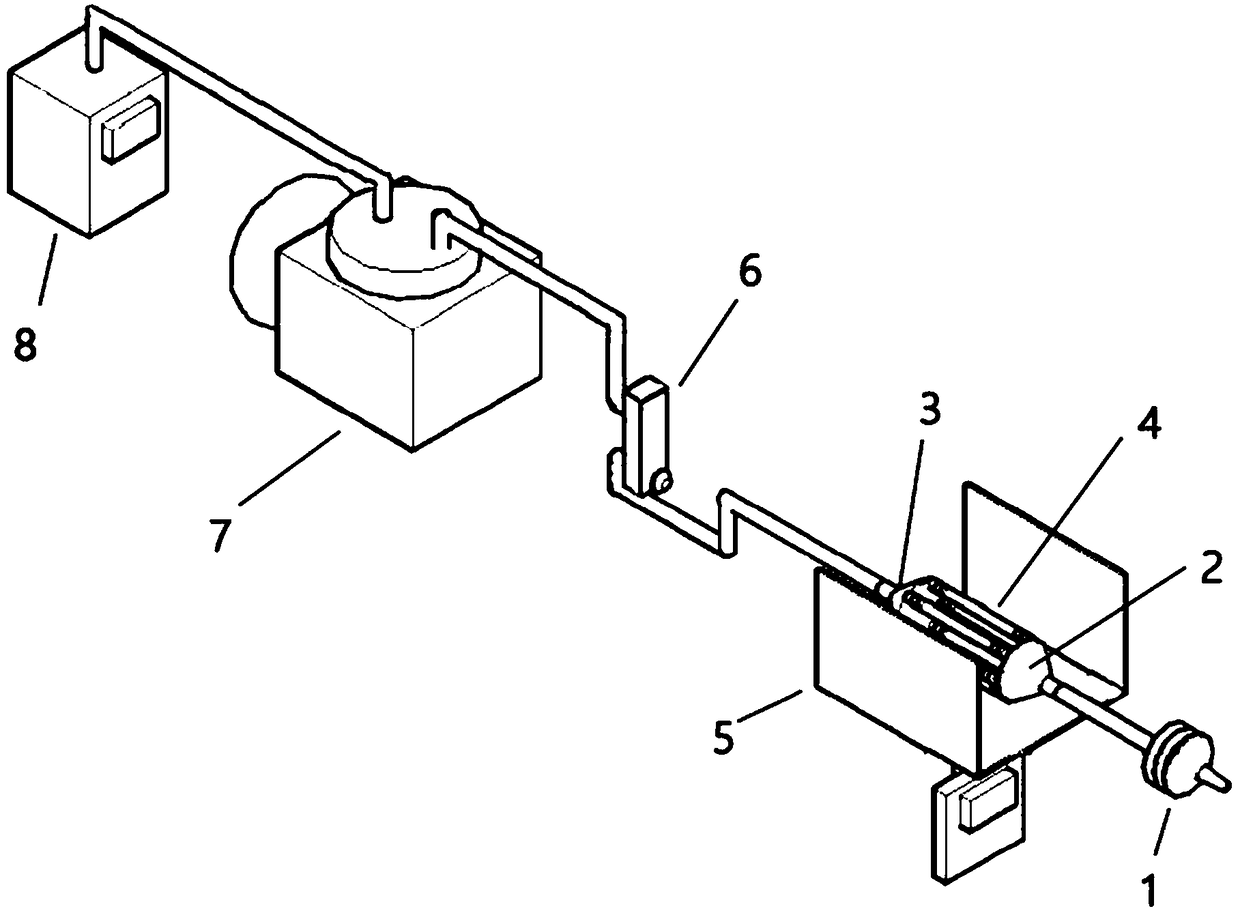

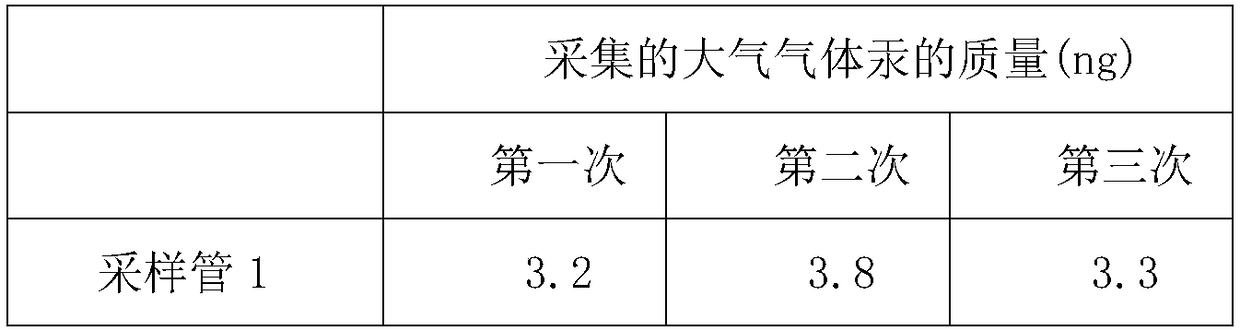

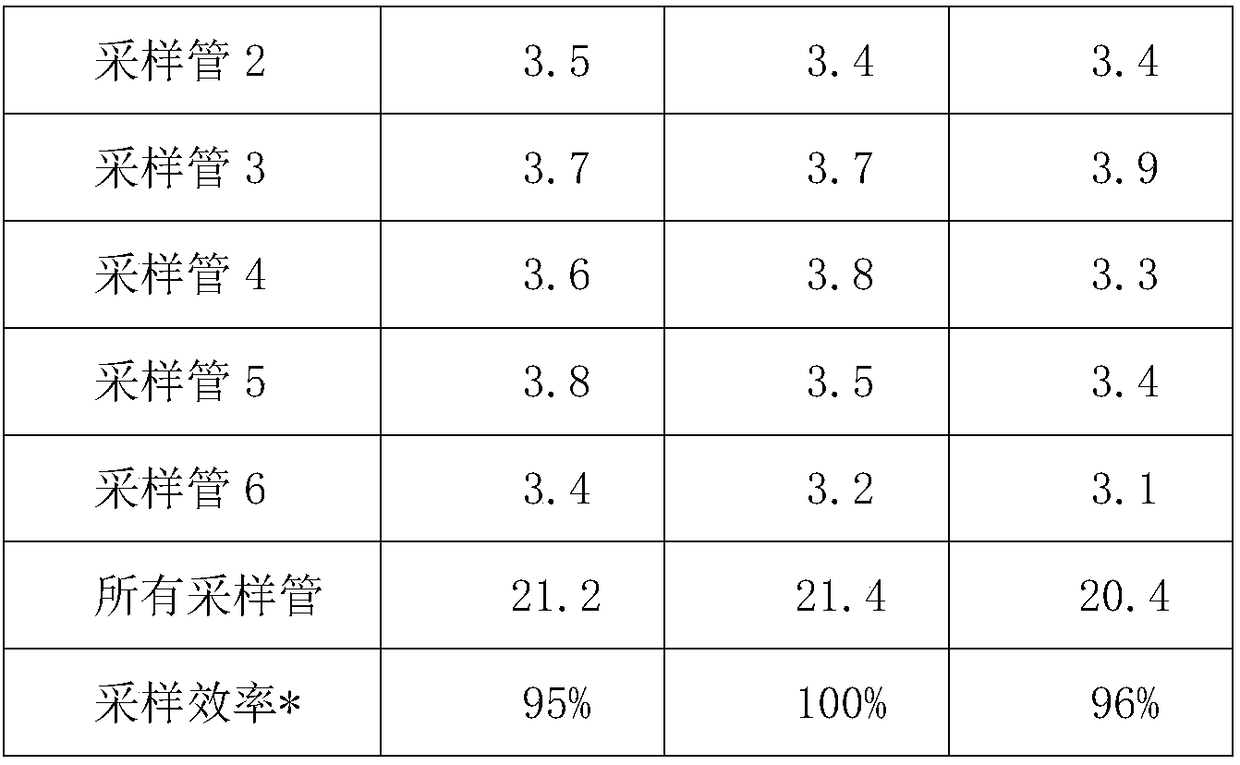

Sampling device and sampling method for massively collecting atmospheric gaseous mercury in short term

InactiveCN109506992AImprove sampling efficiencyHigh trafficWithdrawing sample devicesParticulatesGaseous mercury

The invention discloses a sampling device and sampling method for massively collecting atmospheric gaseous mercury in a short term. The sampling device comprises a filter membrane box for filtering away atmospheric particulate matter, an atmospheric gaseous mercury sampling unit connected with an outlet of the filter membrane box, an instantaneous flow meter connected with the outlet end of the atmospheric gaseous mercury sampling unit, a vacuum pump connected with the outlet end of the flow meter, and a volumetric flow meter connected with an outlet of the vacuum pump, wherein the atmosphericgaseous mercury sampling unit is composed of six gold-plated quartz sand tubes and two modified conical funnels. The sampling device is capable of collecting a sufficient amount of atmospheric gaseous mercury for isotope analysis within a few hours; and equipment in the sampling device is easy to assemble and disassemble and easy to operate; sampling is simple and easy; and the accuracy is high.

Owner:TIANJIN UNIV

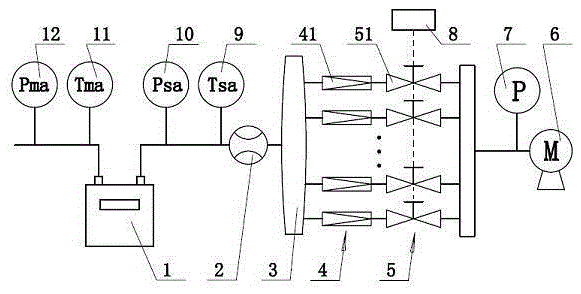

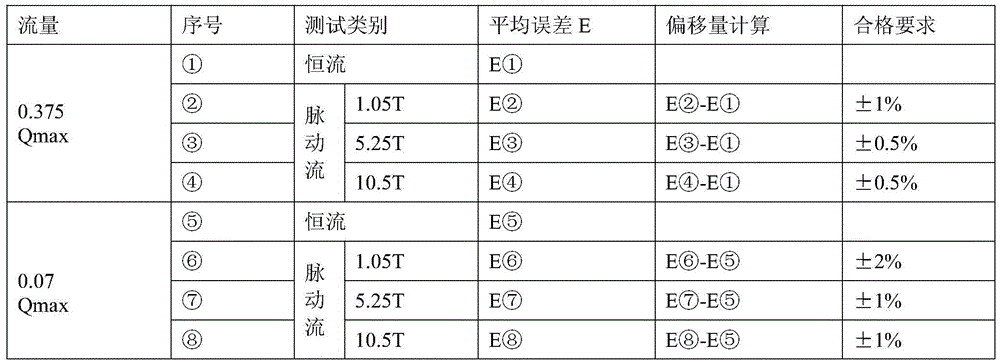

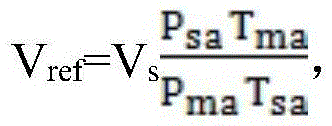

Combustion gas meter pulsating flow error double-standard detection system and method

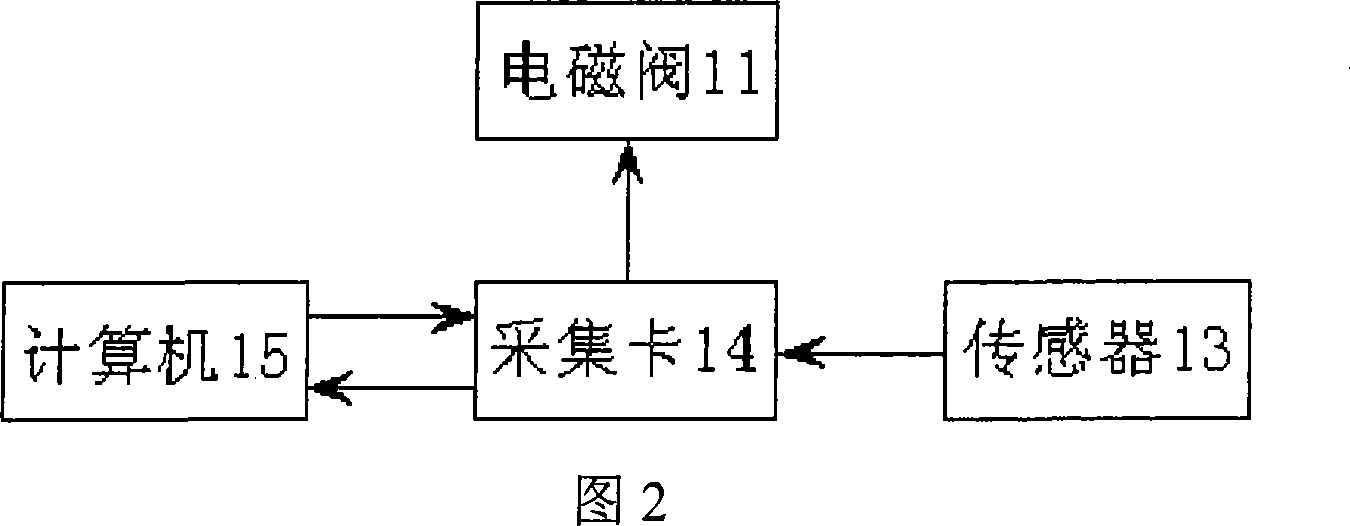

ActiveCN105466529AAccurately test the pulsation error valueIncrease production capacityTesting/calibration apparatusSolenoid valveGas meter

The invention provides a combustion gas meter pulsating flow error double-standard detection system and method and relates to the technical field of combustion gas meter detection. The combustion gas meter pulsating flow error double-standard detection system comprises a to-be-detected combustion gas meter. The to-be-detected combustion gas meter is orderly connected with a positive displacement flow meter, a venture nozzle, a solenoid valve set and a vacuum pump, wherein the solenoid valve set is connected with a time controller; solenoid valve on-off time and frequency can be set by the time controller; a comparison is made between the to-be-detected combustion gas meter and a volume value of the positive displacement flow meter, so one-time pulsating flow error of the to-be-detected combustion gas meter can be calculated; and the average error of the to-be-detected combustion gas meter can be achieved according to the average value of several one-time values. A technical problem of difficulty for electronic combustion gas meter pulsating flow error detection by a present detection apparatus can be solved. The beneficial effects are that with a combination of two standards of instantaneous volume flow rate standard and an accumulated volume flow rate standard, pulsating flow error of the combustion gas meter can be accurately detected; and the combustion gas meter pulsating flow error double-standard detection system is simply and rationally structured and conveniently operated, and brings great convenience to combustion gas meter production control and product acceptance.

Owner:GOLDCARD HIGH TECH

Intelligent positive displacement flow meter

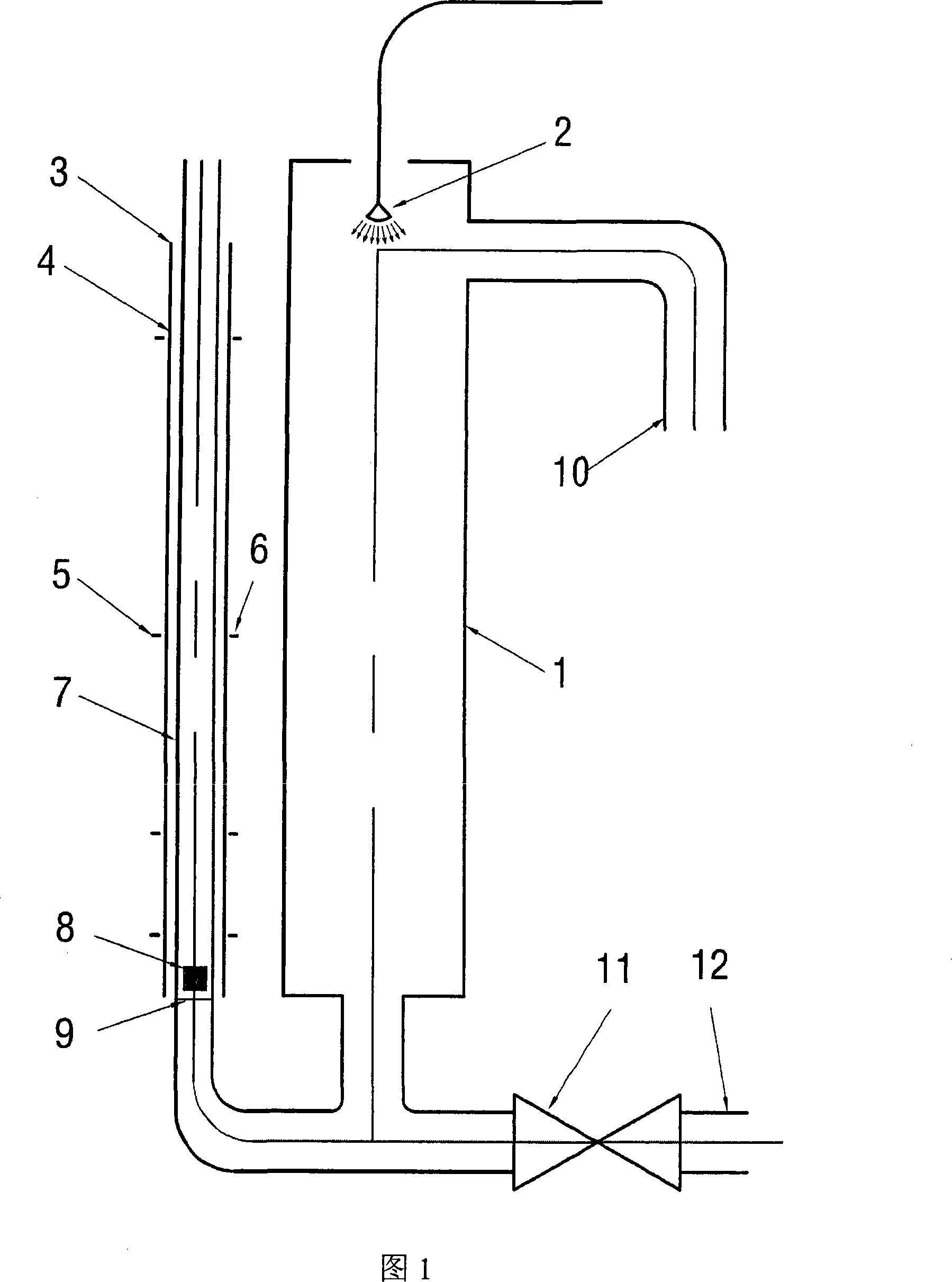

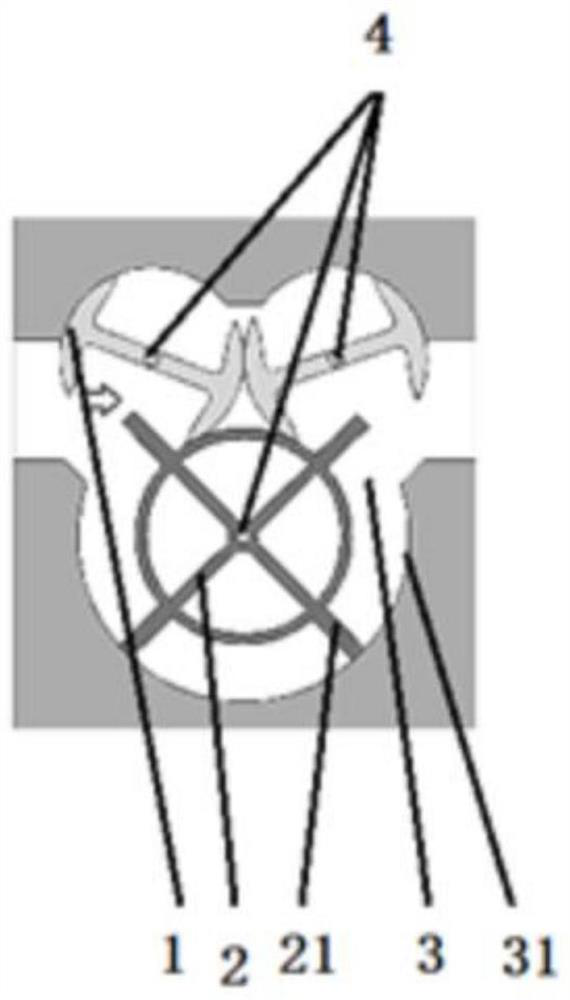

InactiveCN101162166AImprove adaptabilityImprove test accuracyVolume measurement and fluid deliveryEngineeringLight-emitting diode

An intelligent volumetric flowmeter comprises a liquid container and a communicating pipe and a lower liquid pipe which are connected with the liquid container into a whole; a nozzle is arranged on the liquid inlet of the liquid container; an electromagnetic valve is arranged on the lower liquid pipe; the communicating pipe is provided with a floater; a test tube is also sleeved on the outer side of the communicating pipe; a plurality of sets of test holes are symmetrically arranged on the test tube; the test holes are provided inside with a sensor consisting of a light-emitting diode and a reception diode. The invention leads the tested liquid to the liquid container; when the liquid is tested, the electromagnetic valve in the bottom of the liquid container is closed; the liquid level in the liquid container rises synchronously with the liquid level in the communicating pipe connected with the liquid container and drives the floater to rise. Test points are arranged outside the communicating pipe; when the floater passes, direct light emitted from the light-emitting diode is baffled and time is recorded; when the floater leaves, time is recorded; the volume between two test points is divided by the passing time to achieve the average volume flow during the time. The method has high testing precision and good adaptability of flow scope.

Owner:XI AN JIAOTONG UNIV

Three-rotor pulseless volumetric flow meter

PendingCN112325951ASpeed up the flowAvoid and reduce noiseVolume meteringVolume/mass flow by dynamic fluid flow effectEngineeringImpulse generator

The invention provides a three-rotor gas volumetric flow meter which comprises a shell and a pulse generator arranged on an end cover of the shell. The meter further comprises two metering rotors anda balance rotor which are arranged in a measuring chamber in a shell, and a rotating shaft penetrates through the metering rotors and the balance rotor. The two ends of the rotating shaft abut againstand are fixed to the inner side faces of a front shell end cover and a rear shell end cover respectively, the longitudinal section of the metering rotor is H-shaped, the balance rotor is provided with a plurality of driving blades, the middle of the balance rotor is of a cylindrical structure, and the balance rotor and the metering rotors are periodically sealed and attached during rotation. TheI-shaped metering rotors are periodically attached to the introduced balance rotor in a sealed mode, the balance rotor is matched with the metering rotors to rotate together, the airflow flows more stably, balloon pulsation is effectively reduced, and equipment stability is improved.

Owner:南京深度系统工程有限公司

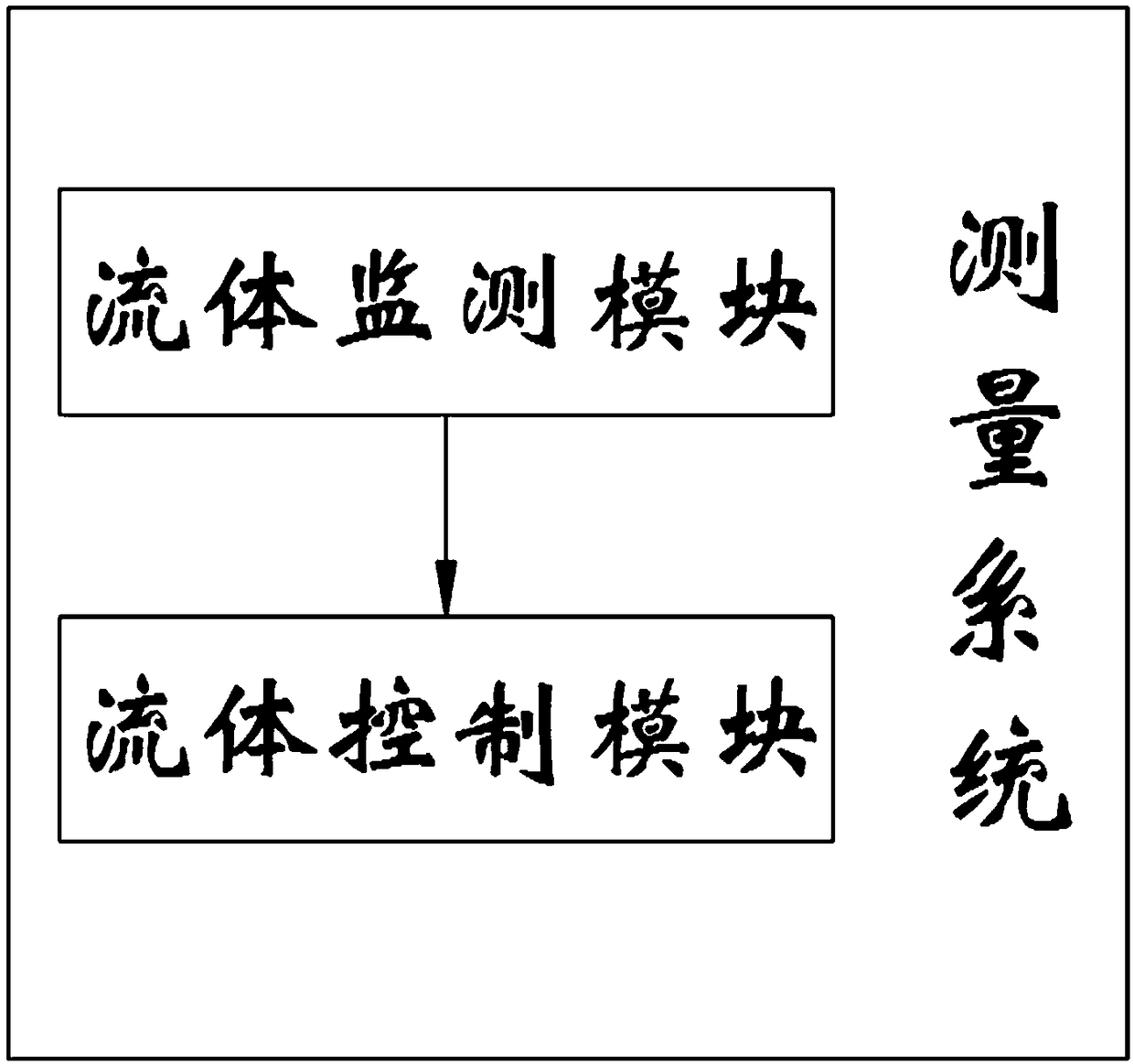

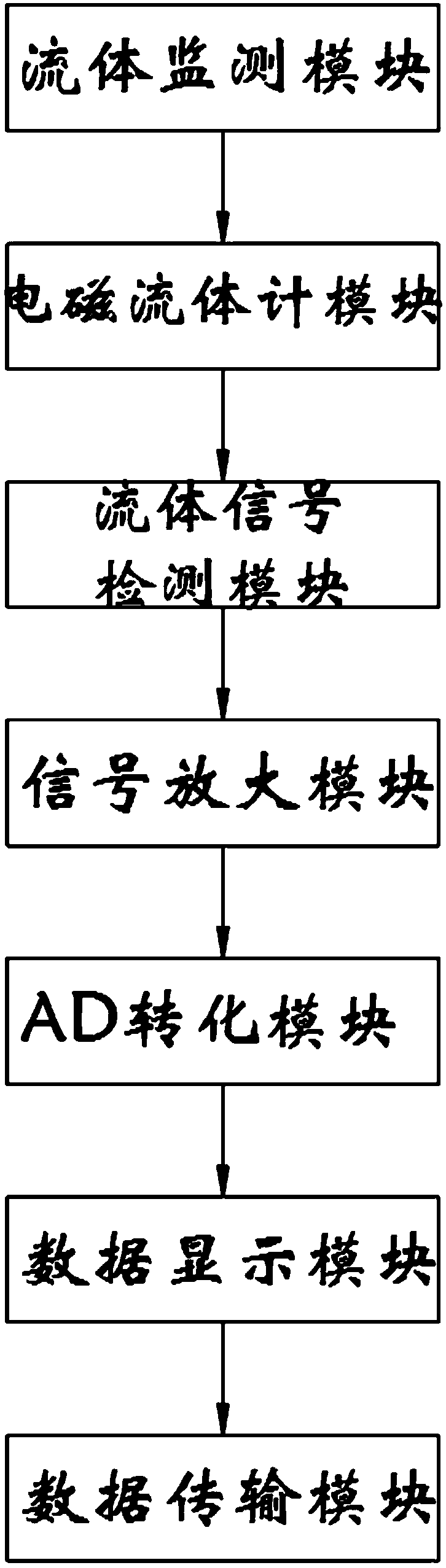

Water quantity recording meter

PendingCN109489746ARealize real-time monitoringEasy to controlFlow control using electric meansVolume indication and recording devicesMicrocontrollerData display

The invention relates to the technical field of machinery, in particular to a water quantity recording meter comprising a volumetric flow meter. The top of the volumetric flow meter is equipped with ameasuring system. The measuring system internally comprises a fluid monitoring module and a fluid control module. The water quantity recording meter is provided with the fluid monitoring module, an electromagnetic fluid meter module is used as a flow sensor to collect fluid flow information, the continuous analog quantity is converted into the discrete digital quantity acceptable to a single chipcomputer through an AD conversion module, and finally a data display module is adopted to display the detected fluid flow on a display screen digitally to achieve real-time monitoring of the fluid flow. Through the set fluid control module, control system data is formed by linear combination of proportional, integral and differential of the deviation by a PID system module, and a valve module iscontrolled through a motor module. At the same time, the fluid flow is set through a keyboard inputting module and displayed digitally on the display screen to achieve control of the fluid flow.

Owner:南京市江宁医院

Steer valve with hydraulic vehicle position feedback

Owner:DANFOSS AS

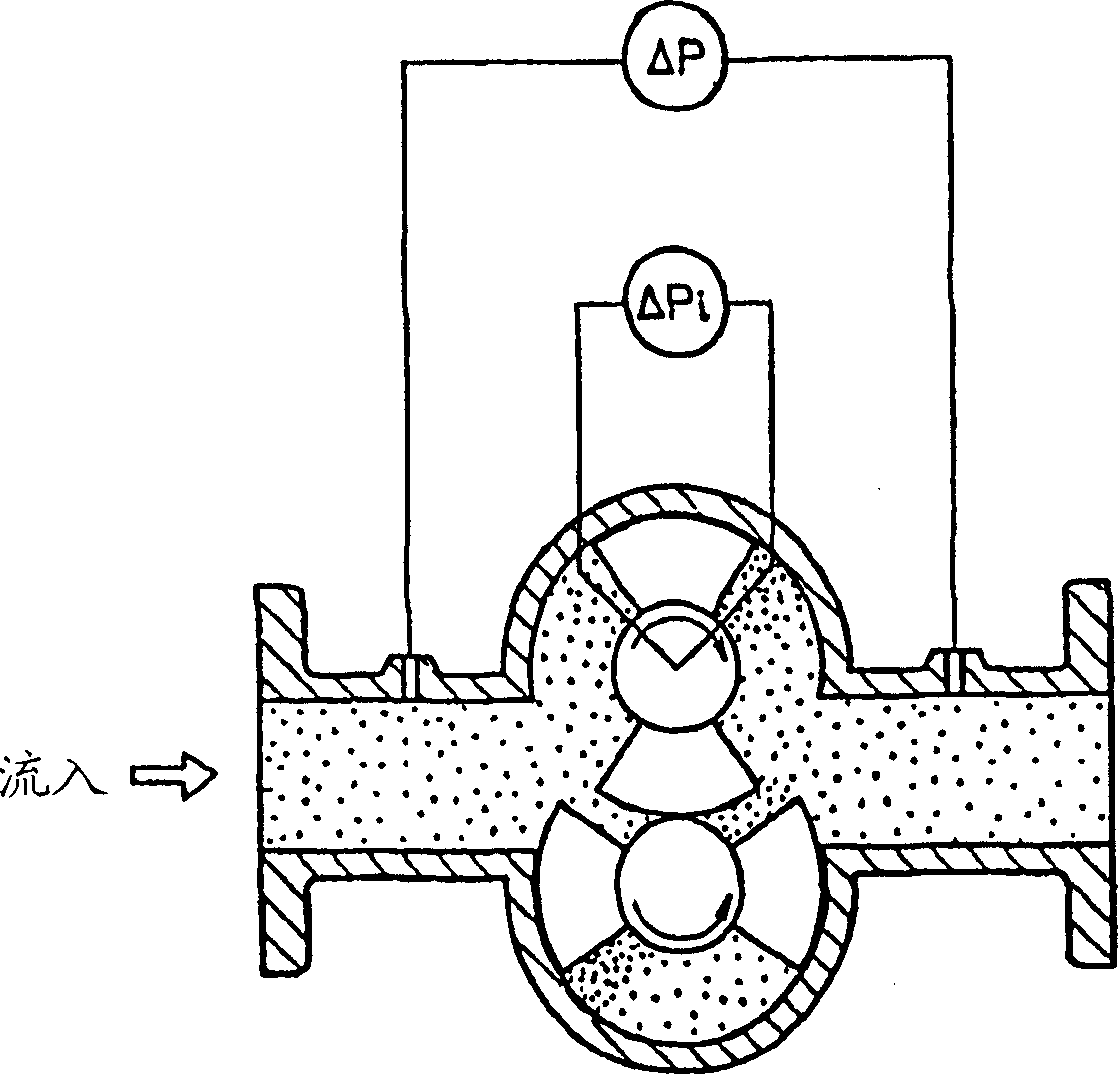

Servo type volumetric flowmeter

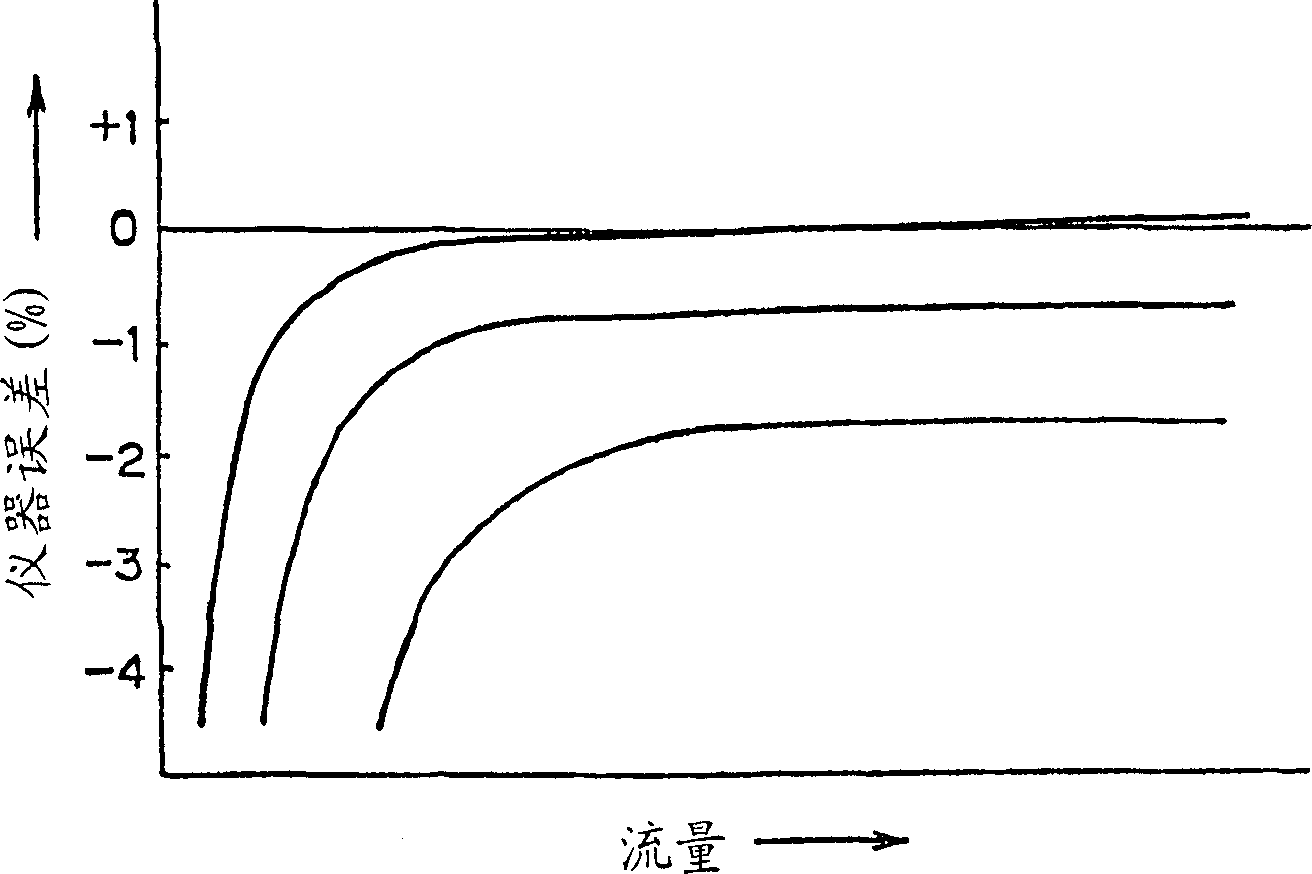

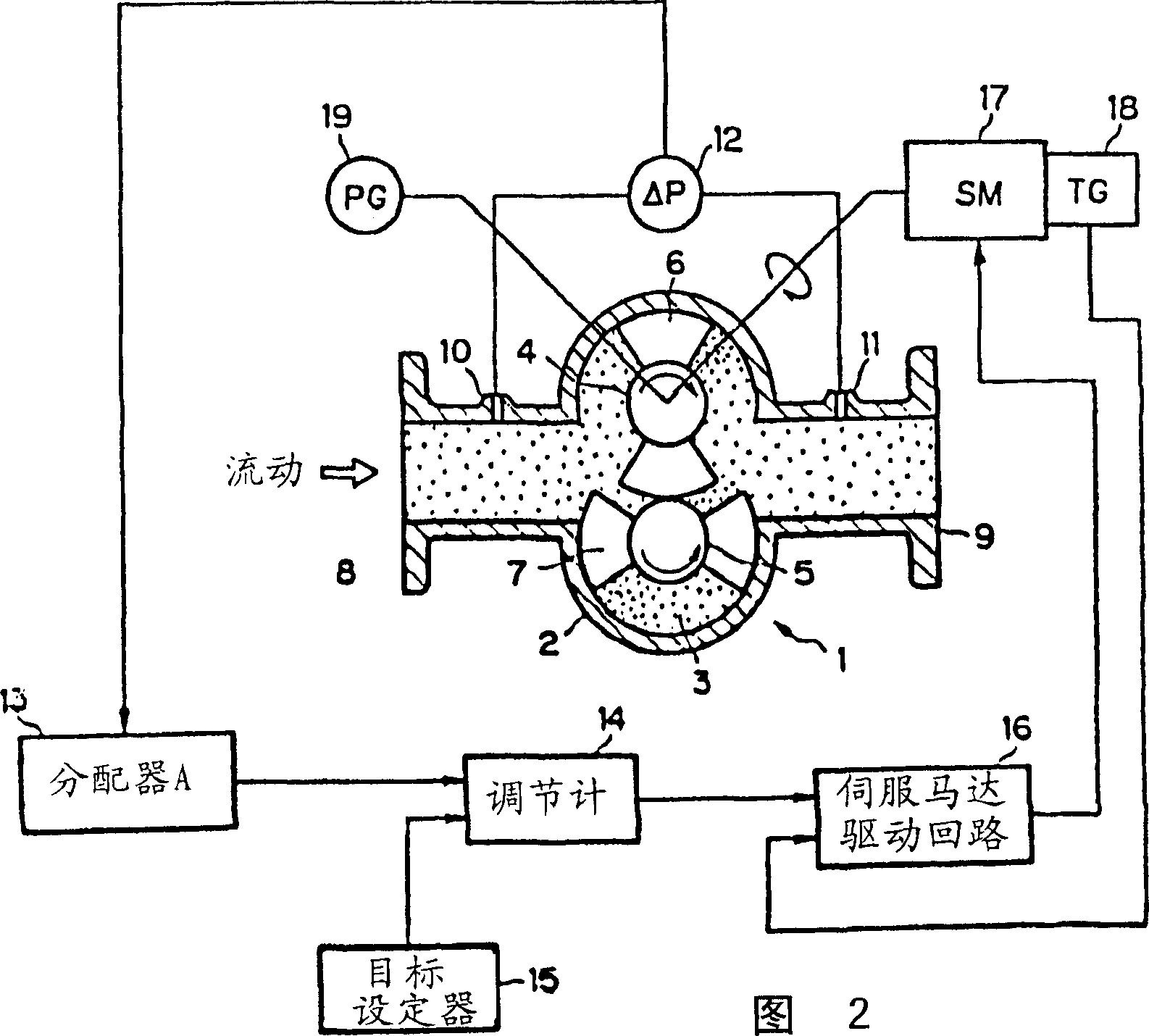

A servo-type volumetric flowmeter, which includes: a metering chamber arranged in a flow path, a pair of first and second rotors that rotate in the metering chamber and flow out a certain volume of fluid each time they rotate, and detect the aforementioned metering chamber The first differential pressure gauge for the pressure difference between the upstream side and the downstream side of the flow path is arranged in series in the aforementioned flow path, and the throttling mechanism for narrowing the flow path is used to detect the pressure difference between the upstream side and the downstream side of the throttling mechanism. The second differential pressure gauge, and use the differential pressure signal from the second differential pressure gauge to adjust the differential pressure signal from the first differential pressure gauge to obtain a target value, and follow the target value to drive the first or the first differential pressure gauge Servo mechanism for any one of the two rotors.

Owner:OVAL CORP

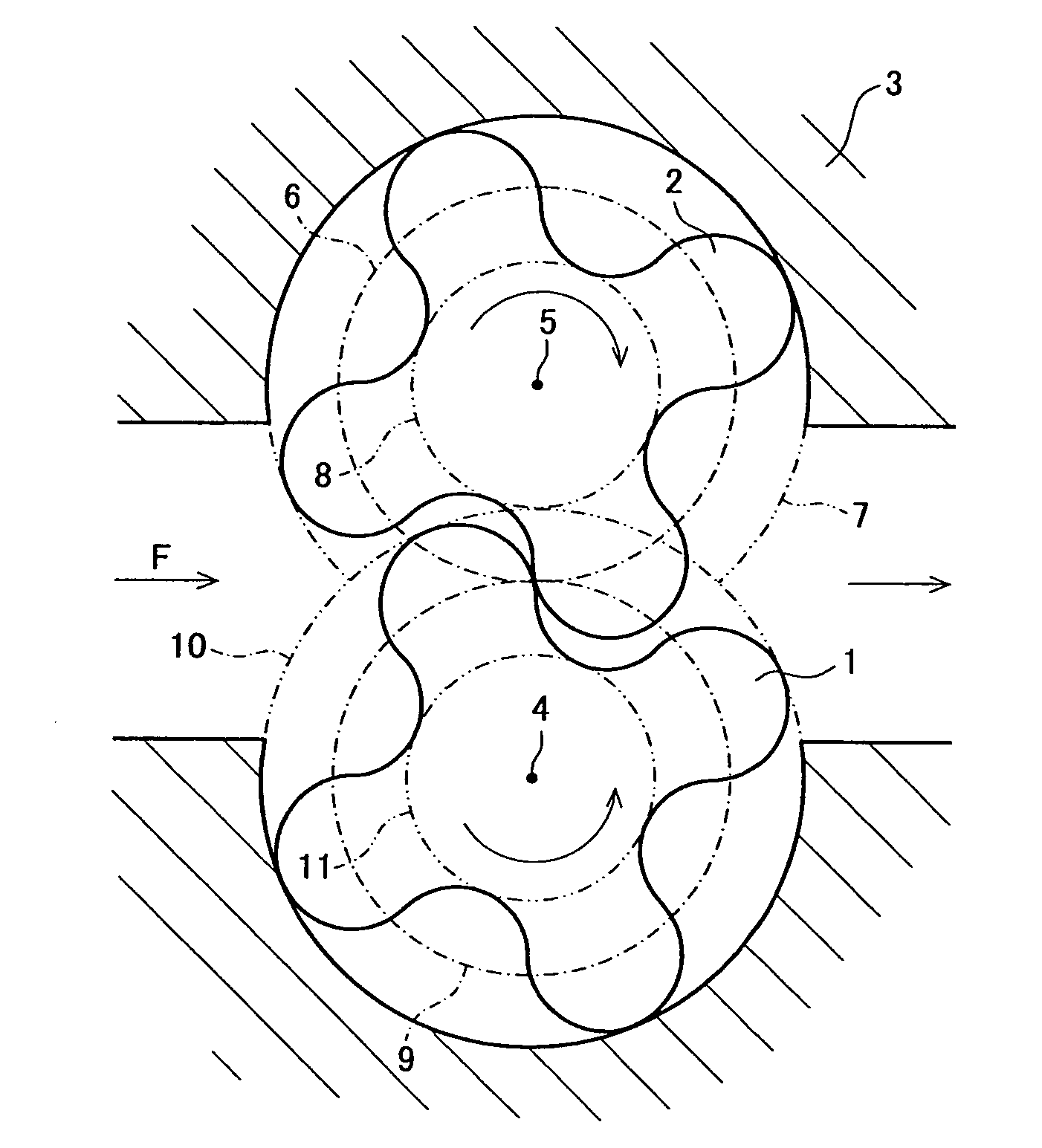

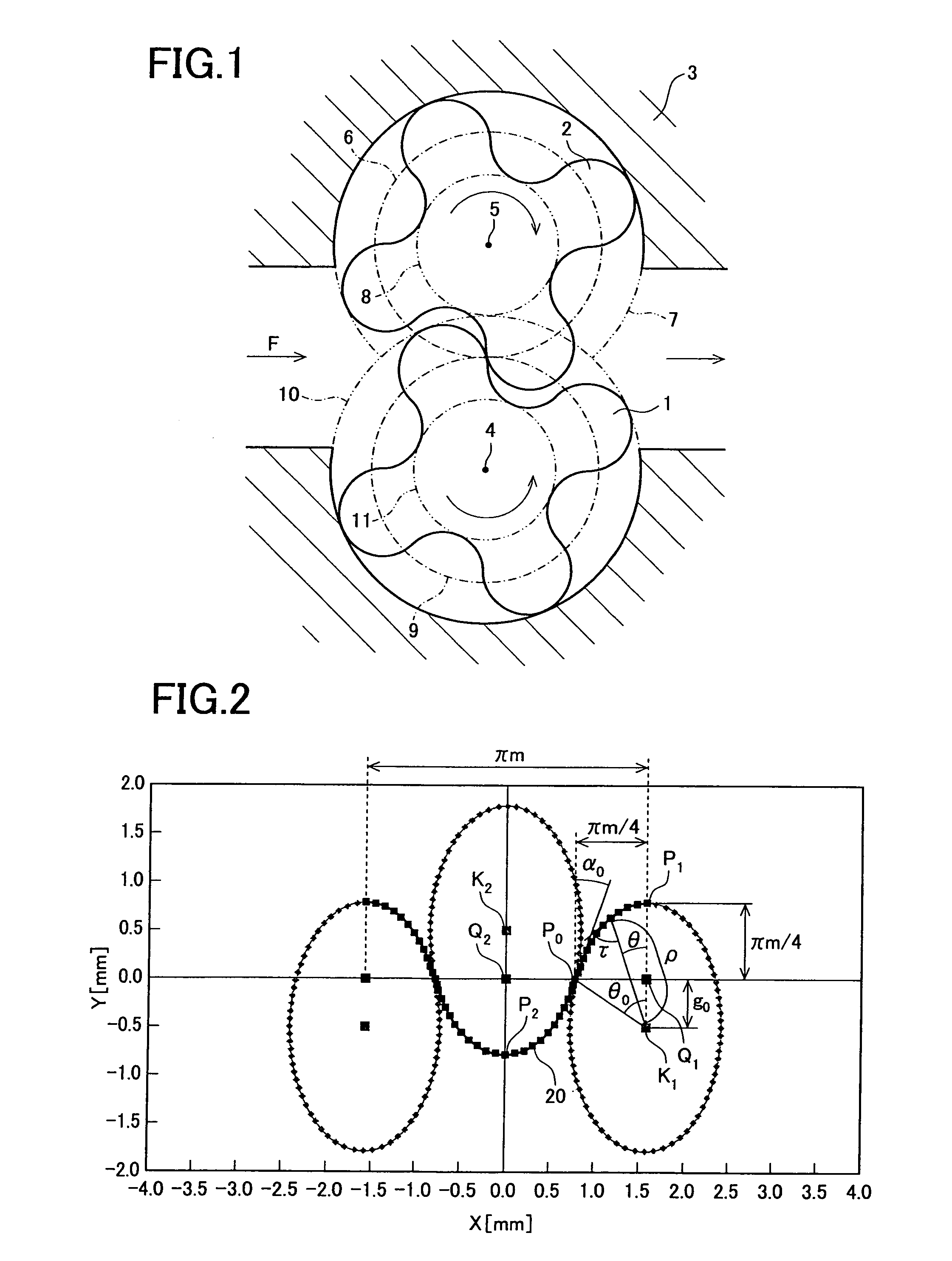

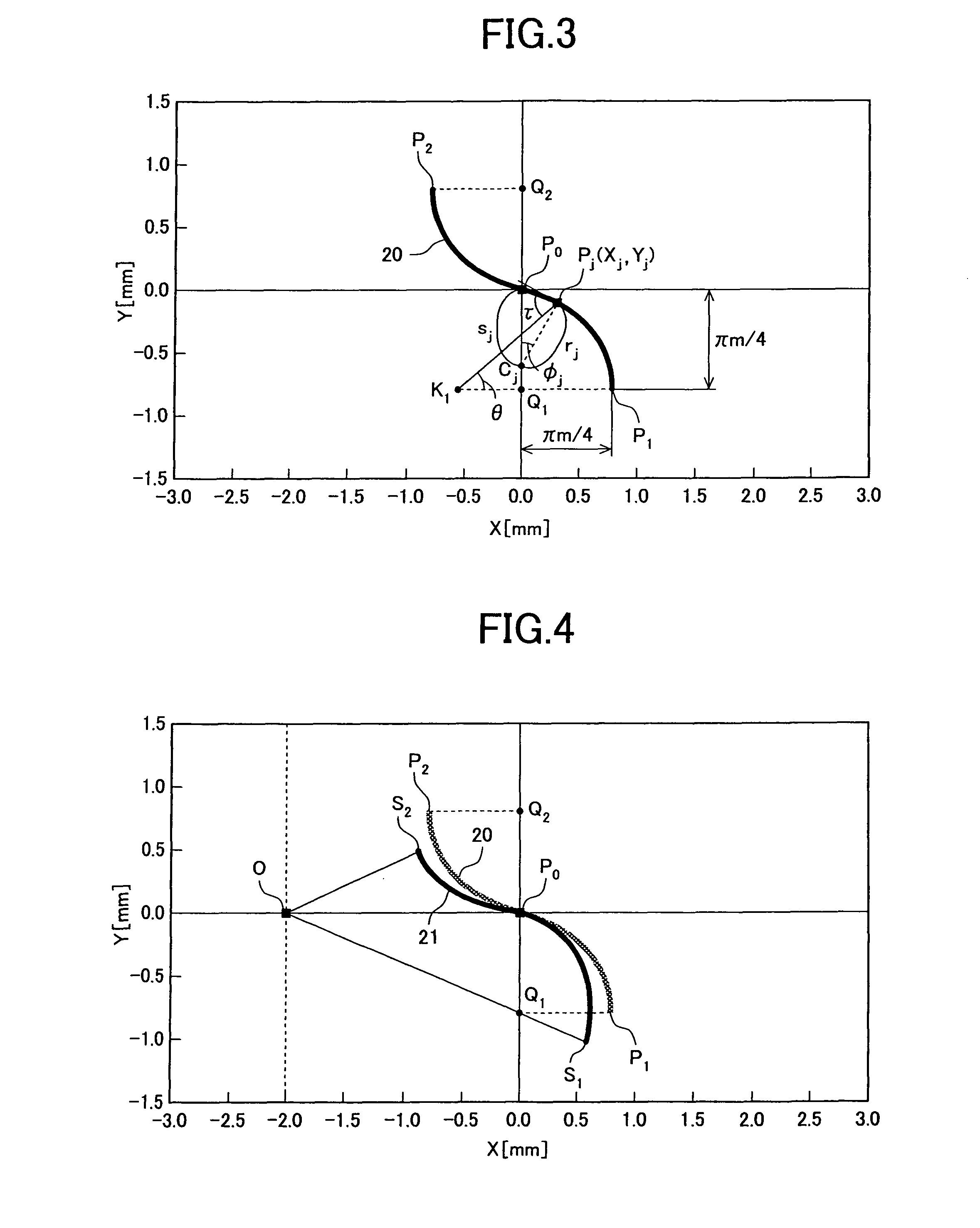

Positive displacement flowmeter and helical gear

InactiveUS8425212B2High surfaceSpecific slidingOscillating piston enginesVolume/mass flow measurementEllipseEngineering

Flowmeter with a pair of helical gears using an oval pitch curve as a reference rack tooth profile. The tooth height ratio of the reference rack tooth profile is π / 4. The reference rack tooth profile is an oval pitch curve of two or less leaves. The moving radius of the oval pitch curve is expressed by ρ=a / (1−b cos nθ), where ρ is a moving radius which is a distance between the center of rotation and the oval pitch curve, “a” is a similarity factor, “b” is a degree of flatness, n (n≦2) is the number of leaves, and θ is an argument. The tooth height ratio is h=a / (1−b)−g0, where g0 is a distance between poles of the oval pitch curve and pitch line, wherein g0=a cos θ0 / (1−b cos nθ0). Values for the similarity factor “a”, degree of flatness “b”, and distance g0 are determined so that the tooth height ratio may be πm / 4.

Owner:OVAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com