High-pressure dynamic internal gear flowmeter

An internal gear and flow meter technology, applied in the field of dynamic flow test of fluid transmission, can solve the problems of difficult dynamic flow measurement of hydraulic system, difficult high-pressure dynamic flow measurement, large moment of inertia, etc. Simple, large measuring range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

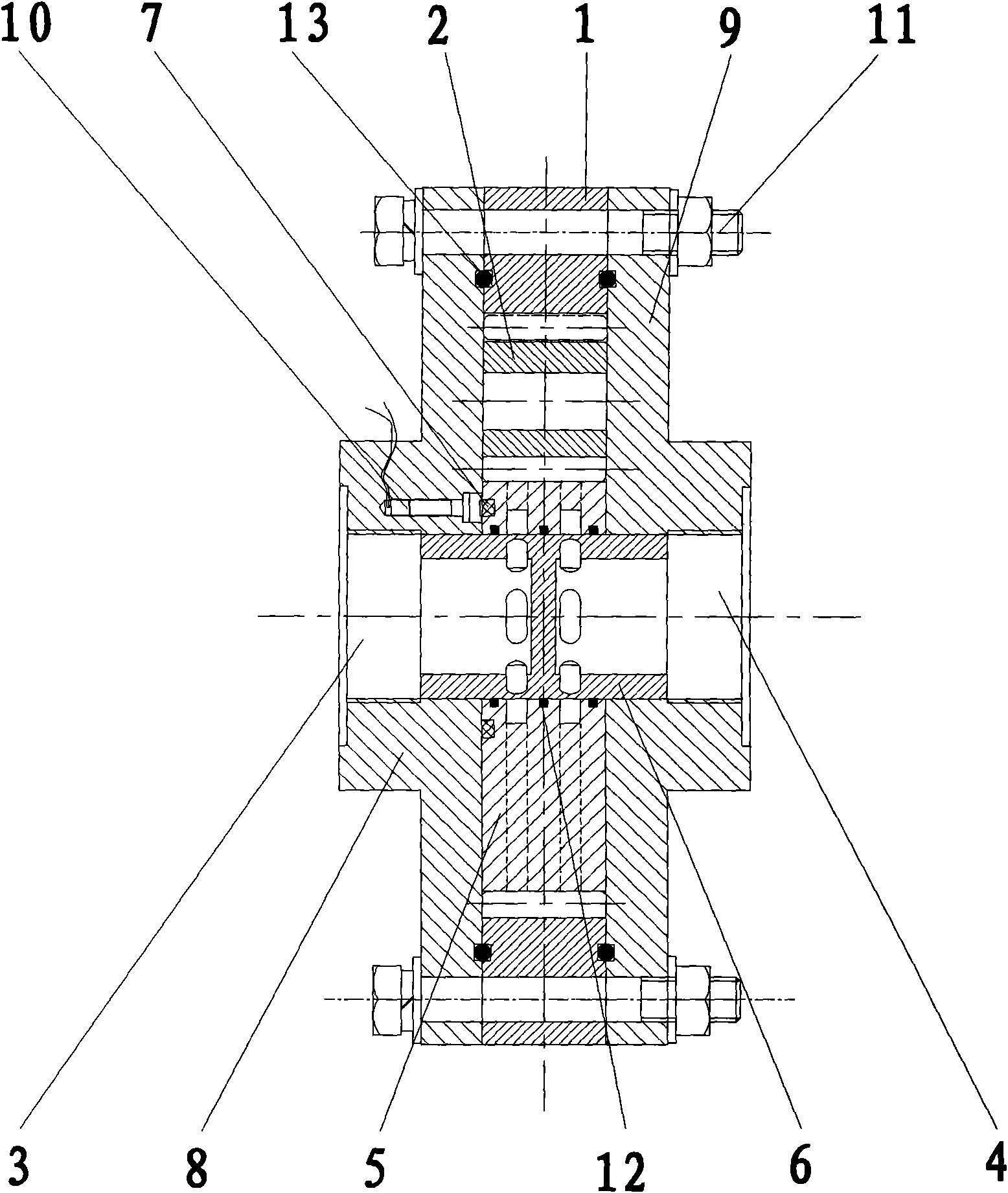

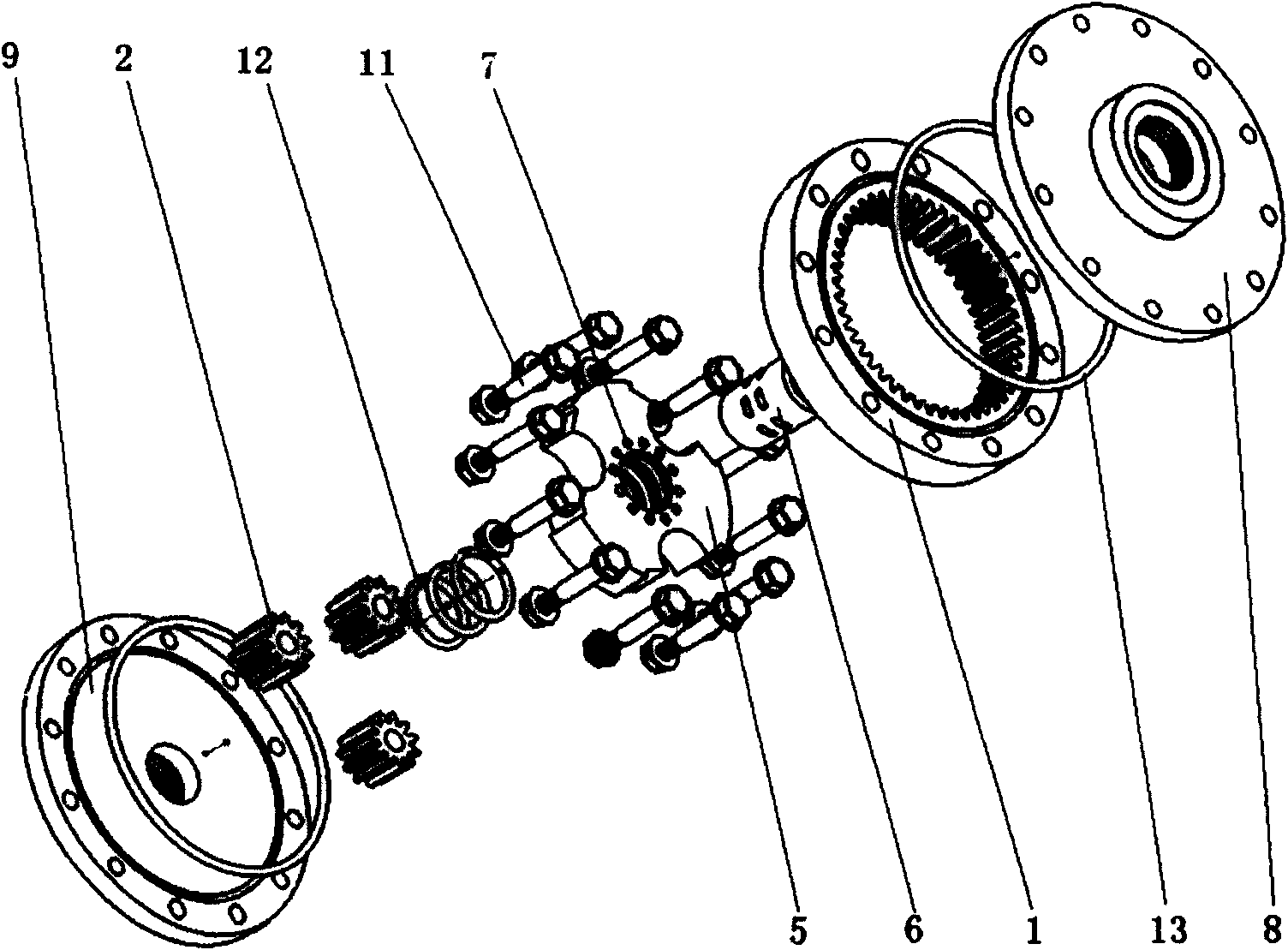

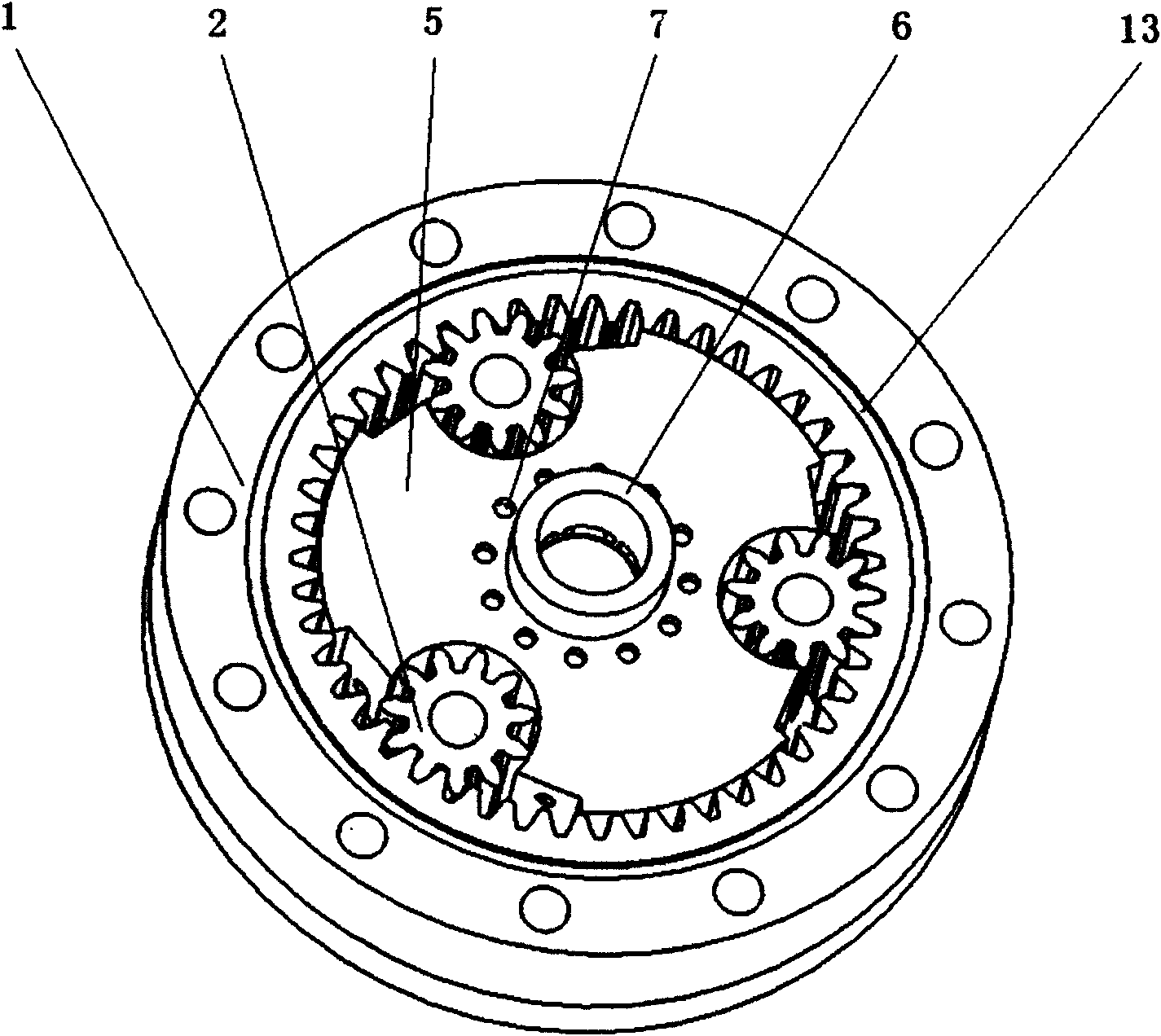

[0019] like figure 1 , 2 , 3, 4, 5, 6, and 7, three pinion gears (2) are evenly distributed in the fixed internal gear (1), and together with the cage (5), the distribution shaft (6 ) support. The front casing (8), the rear casing (9), together with the internal gear (1), three pinion gears (2), the cage (5) and the flow distribution shaft (6) form three airtight oil inlets ( 3), three oil outlets (4), a liquid inlet is arranged on the front housing (8), and a liquid outlet is arranged on the rear housing (9). Internal gear (1) and figure 2 The front housing (8) and the rear housing (9) are fixed together, the cage (5) is equipped with a uniformly distributed magnet (7) for speed measurement, and the front housing (8) is equipped with a gear speed sensor (10) , the front housing (8), the rear housing (9) and the internal gear (1) are sealed with O-rings (13), connected with bolts (11), and the cage (5) is provided with a cage for oil inlet The mouth ring groove (14) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com