Duplex external gear pump

A technology of external meshing and gear pumps, which is applied in the direction of pumps, pump components, pump control, etc., to achieve the effects of optimizing the control structure, improving the working conditions and efficiency, and simplifying the switching control operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

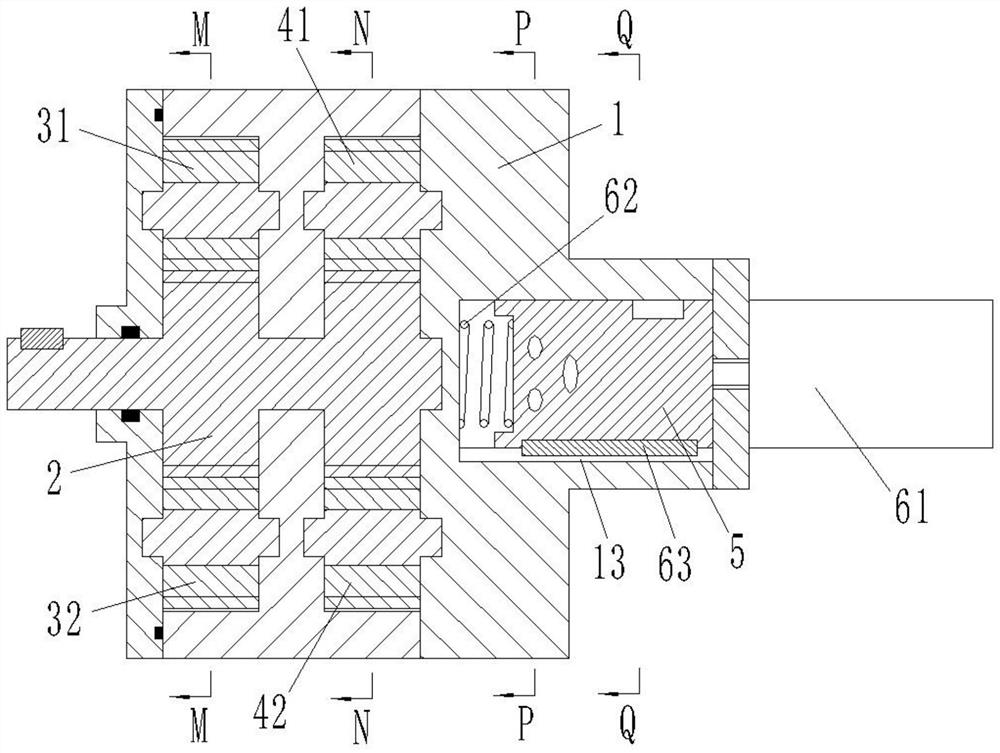

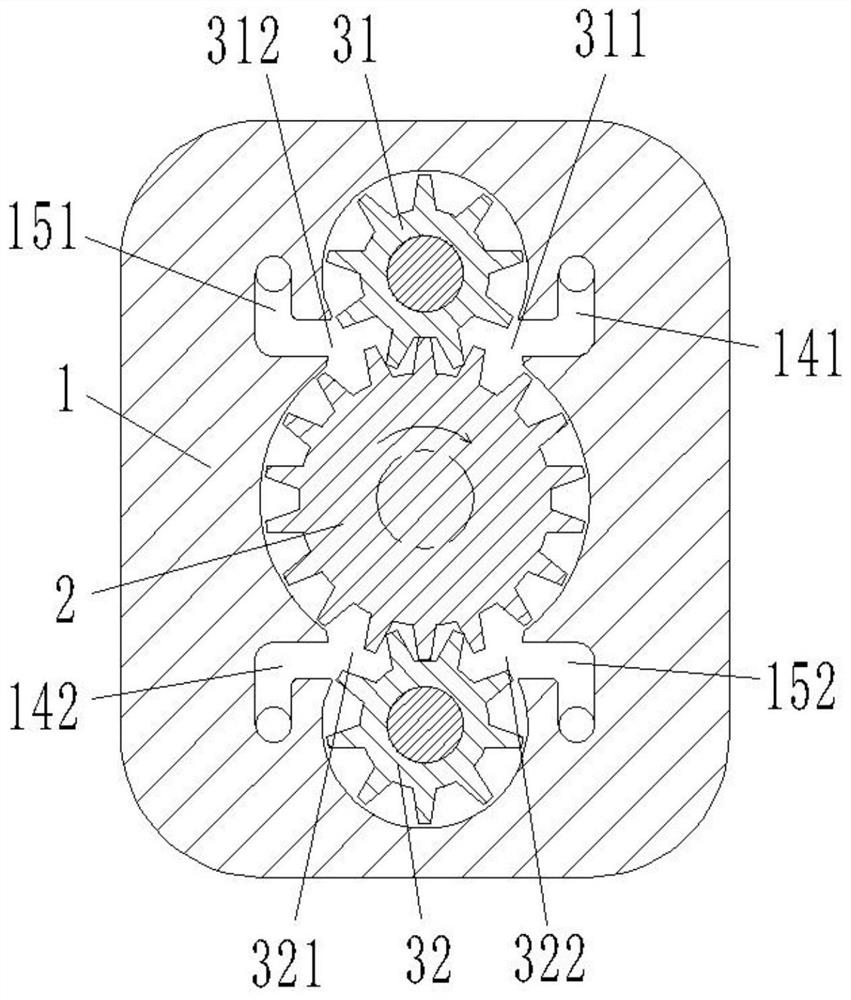

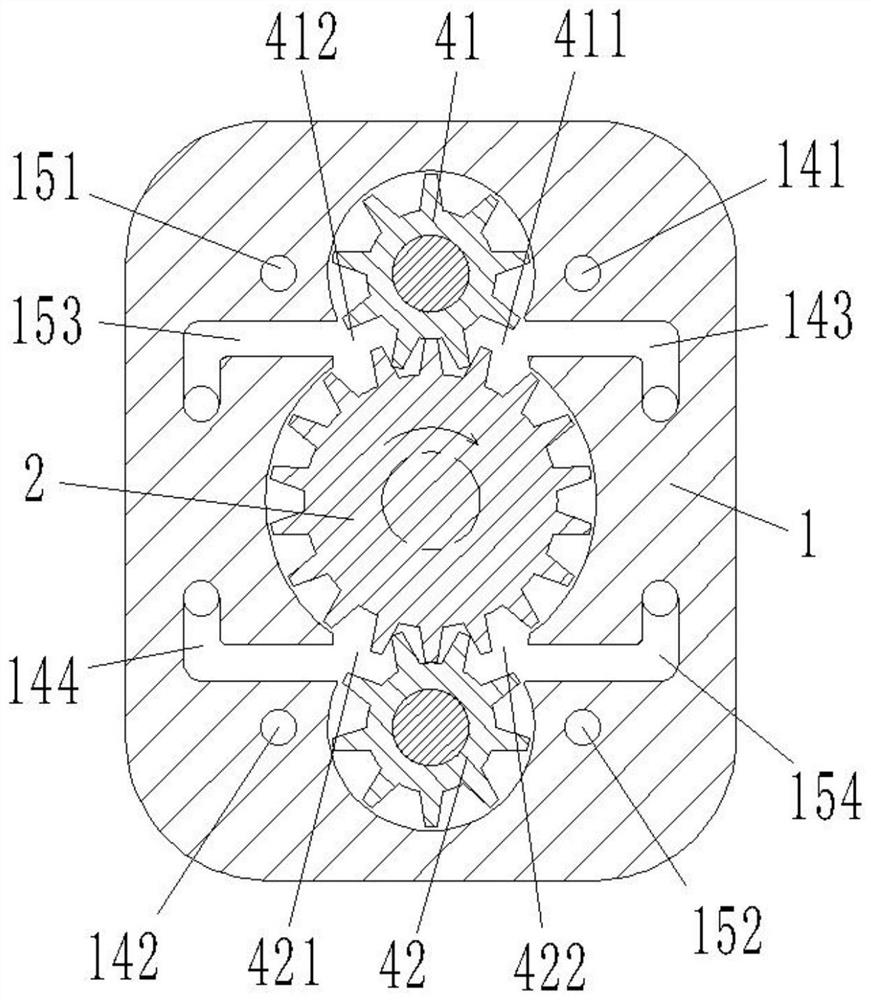

[0027] combine Figure 1 to Figure 7 As shown, the double-connected external gear pump of this embodiment includes a pump body 1 , a driving gear 2 , a primary driven gear set, a secondary driven gear set and a variable plunger 5 .

[0028] The pump body 1 is provided with an oil inlet 11 connected to an external low-pressure pipeline and an oil outlet 12 connected to an external high-pressure pipeline. The driving gear 2 adopts a double gear shaft structure, and one end is located outside the pump body 1 to connect with external driving equipment, and the other end is provided with two parallel gears and is located inside the pump body 1 .

[0029] The first-stage driven gear set is made up of the first-stage driven gear 31 and the second-stage driven gear 32, and the first-stage driven gear 31 and the second-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com