Patents

Literature

40 results about "Thick fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fast Flow. All other liquids (besides thin) including milk and any juice not classified as thin (Source: Academy of Nutrition and Dietetics Nutrition Informatics Committee 2013).

Preparation process of rice high fructose syrup

InactiveCN101979643APromote deep processingUse valueFermentationIsomerizationHigh-fructose corn syrup

The invention relates to a preparation process of rice high fructose syrup, which belongs to the technical field of biological enzymolysis. The preparation process is characterized by comprising the following process steps of: washed rice soaking; thick fluid grinding; liquefaction and enzyme inactivation; rice dreg filtration; saccharification and enzyme inactivation; decolorization and filtration; ion exchange and concentration; isomerization; secondary decolorization and filtration; and secondary ion exchange and vacuum concentration, wherein when the syrup concentration reaches 70 to 75 percent, the concentration is stopped to obtain a finished product, namely 42% high fructose syrup. The preparation process directly takes rice as a raw material to produce the high fructose syrup through a biological enzymolysis technique, thereby not only saving a process step of preparing starch from foodstuff and greatly reducing the production cost, but also promoting intensive processing of the rice, bringing the utilization value of the rice into play to the utmost extent, and strongly promoting the diversified development of grain processing enterprises.

Owner:曾爱民

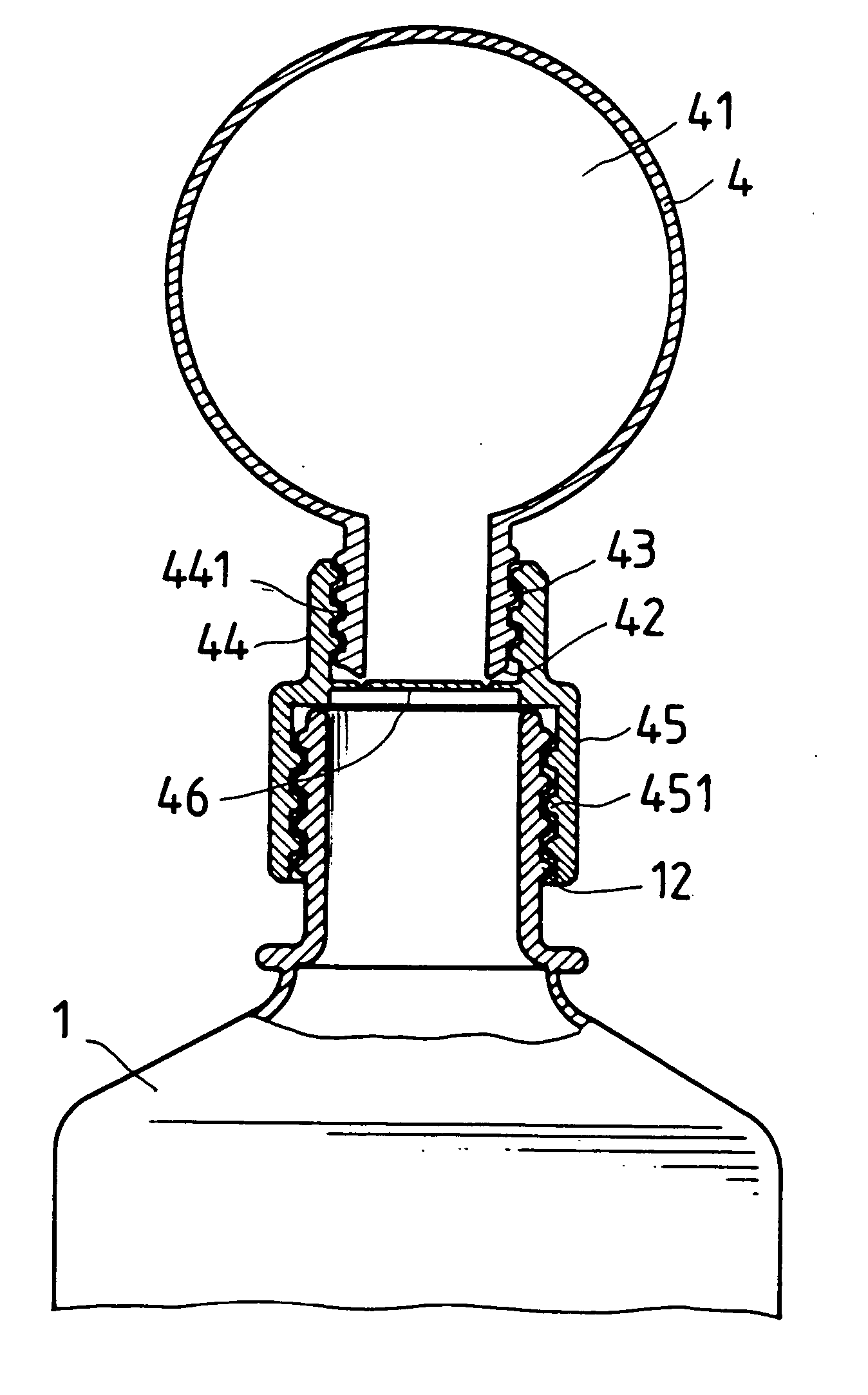

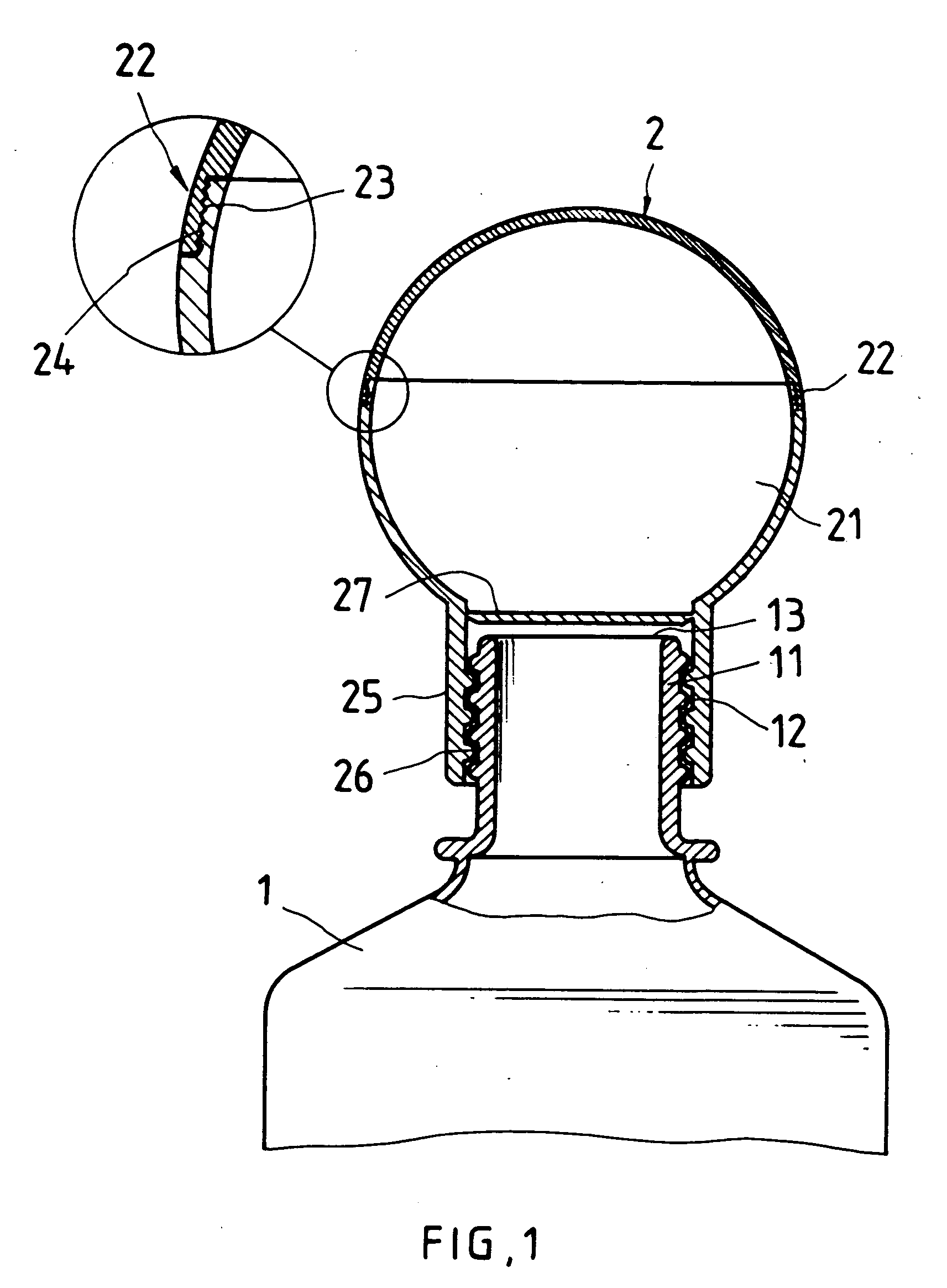

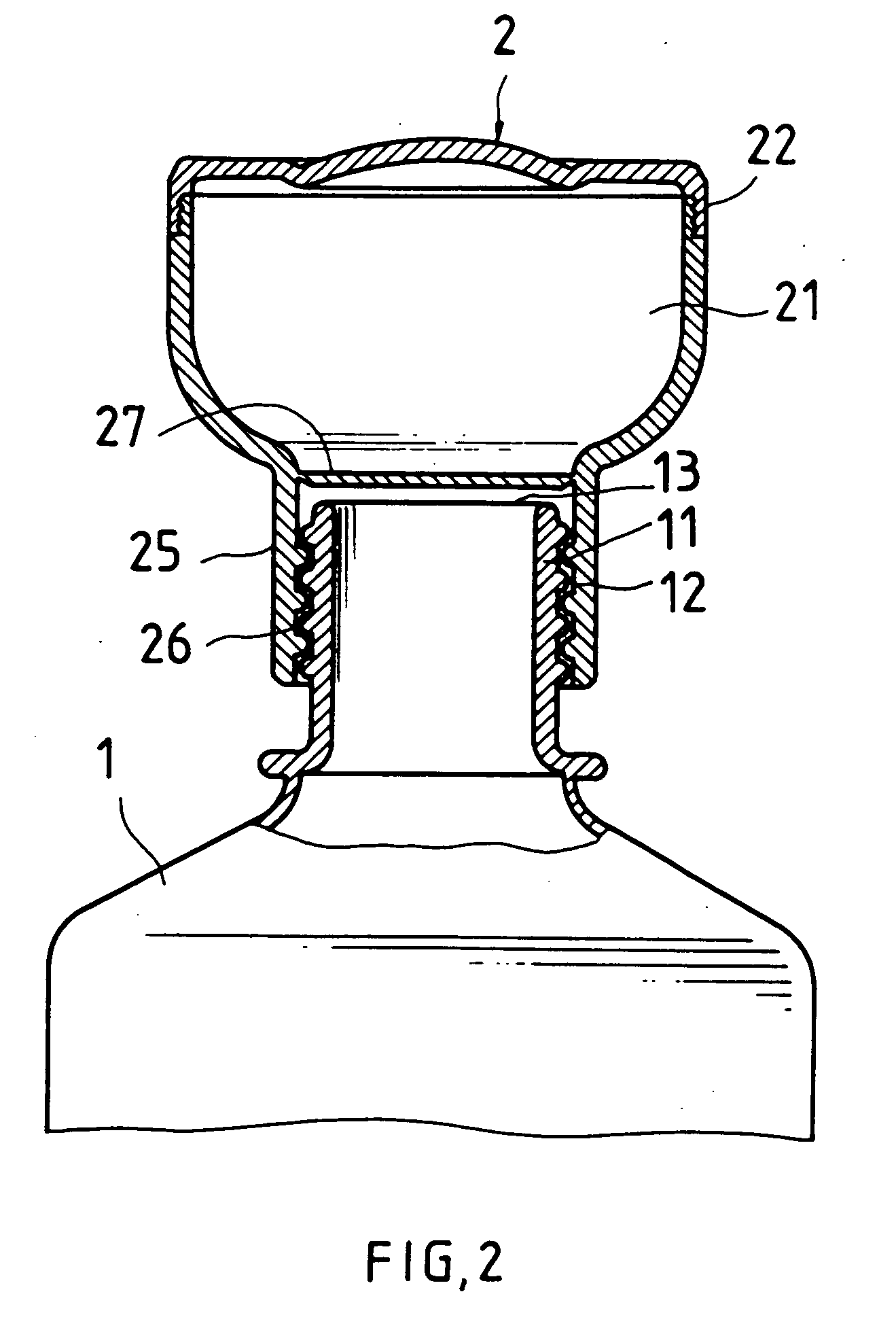

Bottle head structure

Provided is a bottle comprising a water reservoir, a threaded neck having an opening, and a top reservoir in one embodiment including an upper portion, a lower portion releasably secured to the upper portion, a cylindrical coupling member projected downwardly from the lower portion and having internal threads secured to the neck, and a seal formed at a top of the coupling member and above the opening, the seal being adapted to separate the contents (e.g., powder or thick fluid) in the top reservoir from water in the water reservoir. Screwing down the top reservoir to lift the opening until the seal is broken will drop the contents in the top reservoir into the water reservoir to mix for making beverage.

Owner:SUNHOLD ENTERPRISE INT

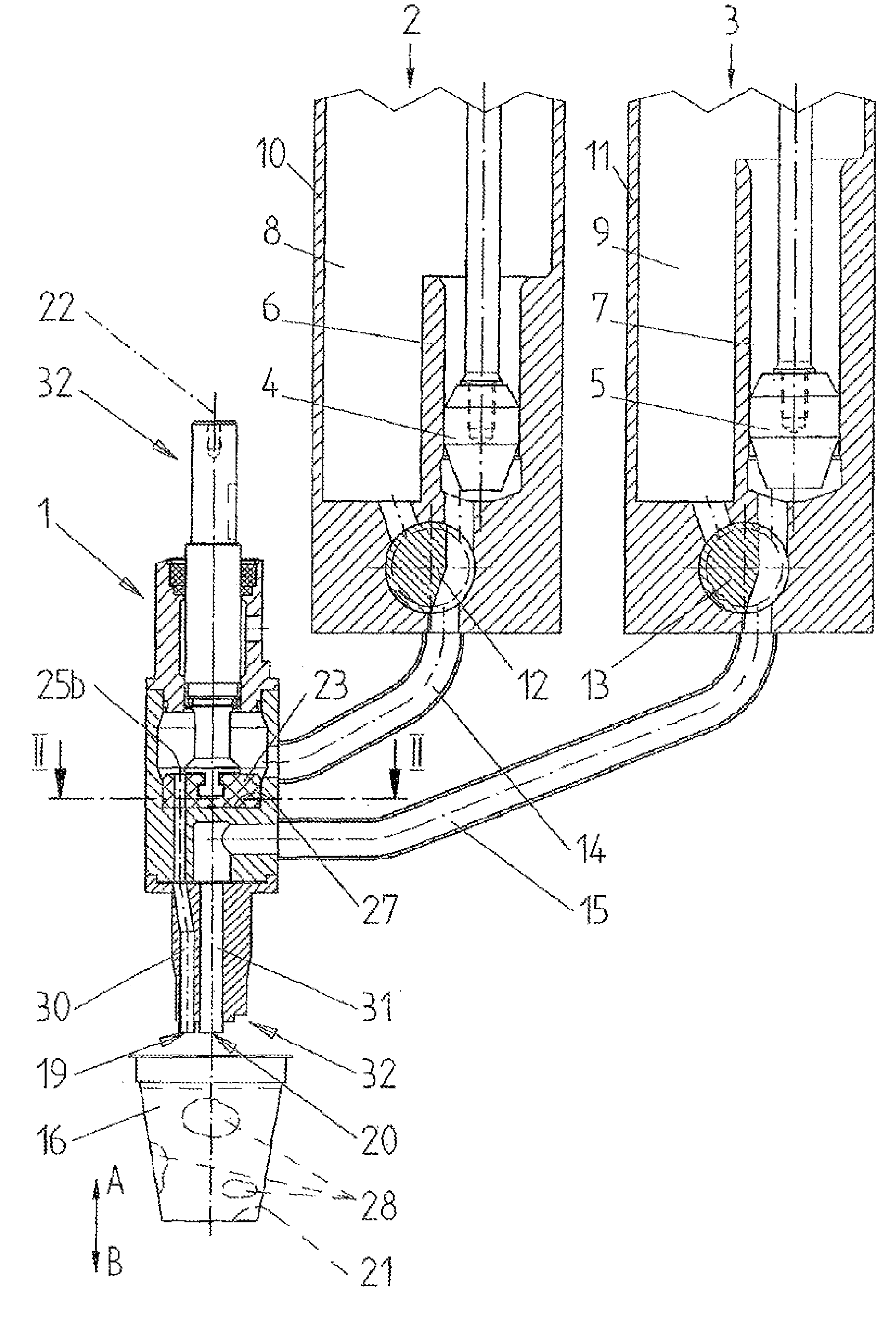

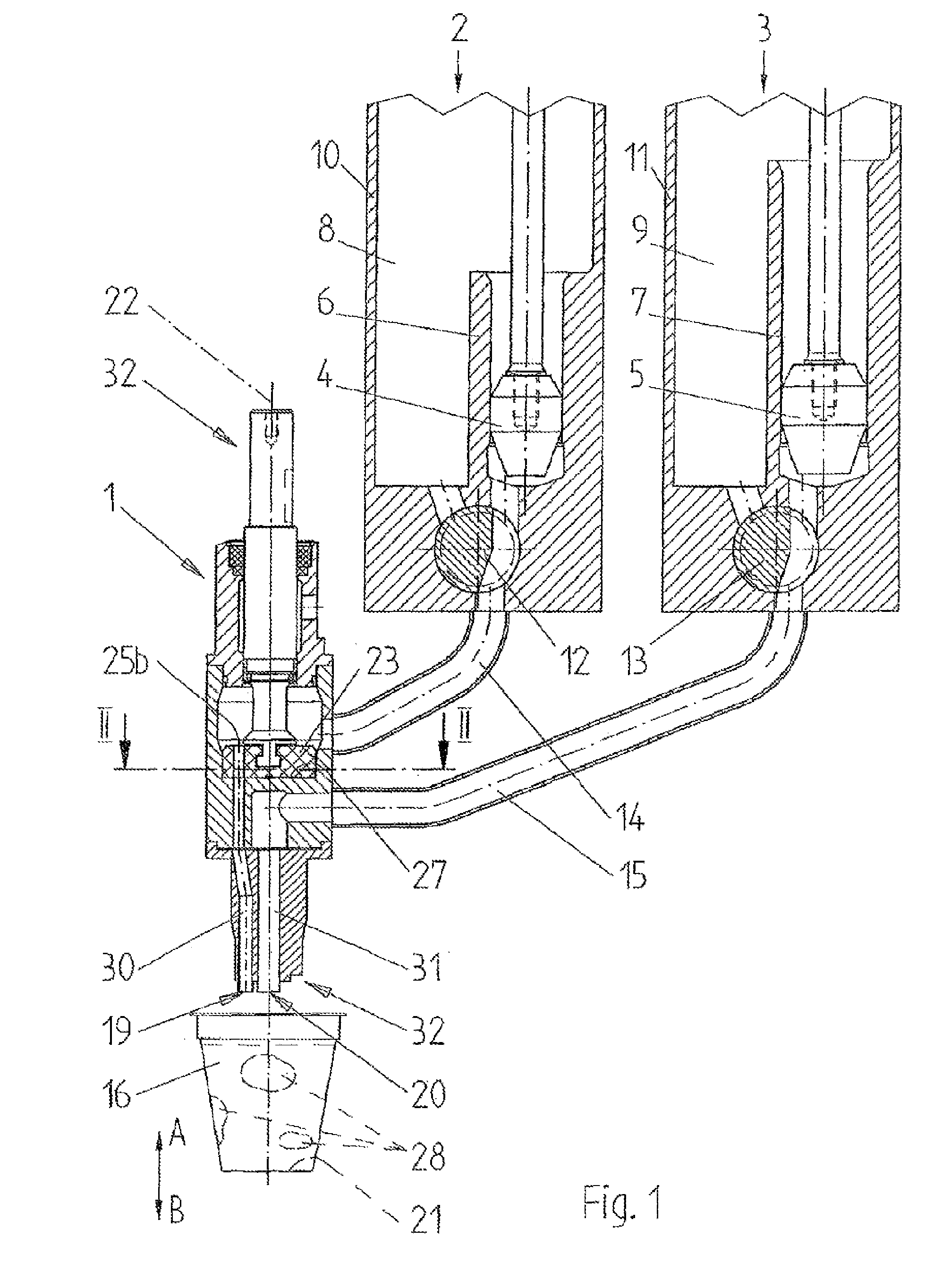

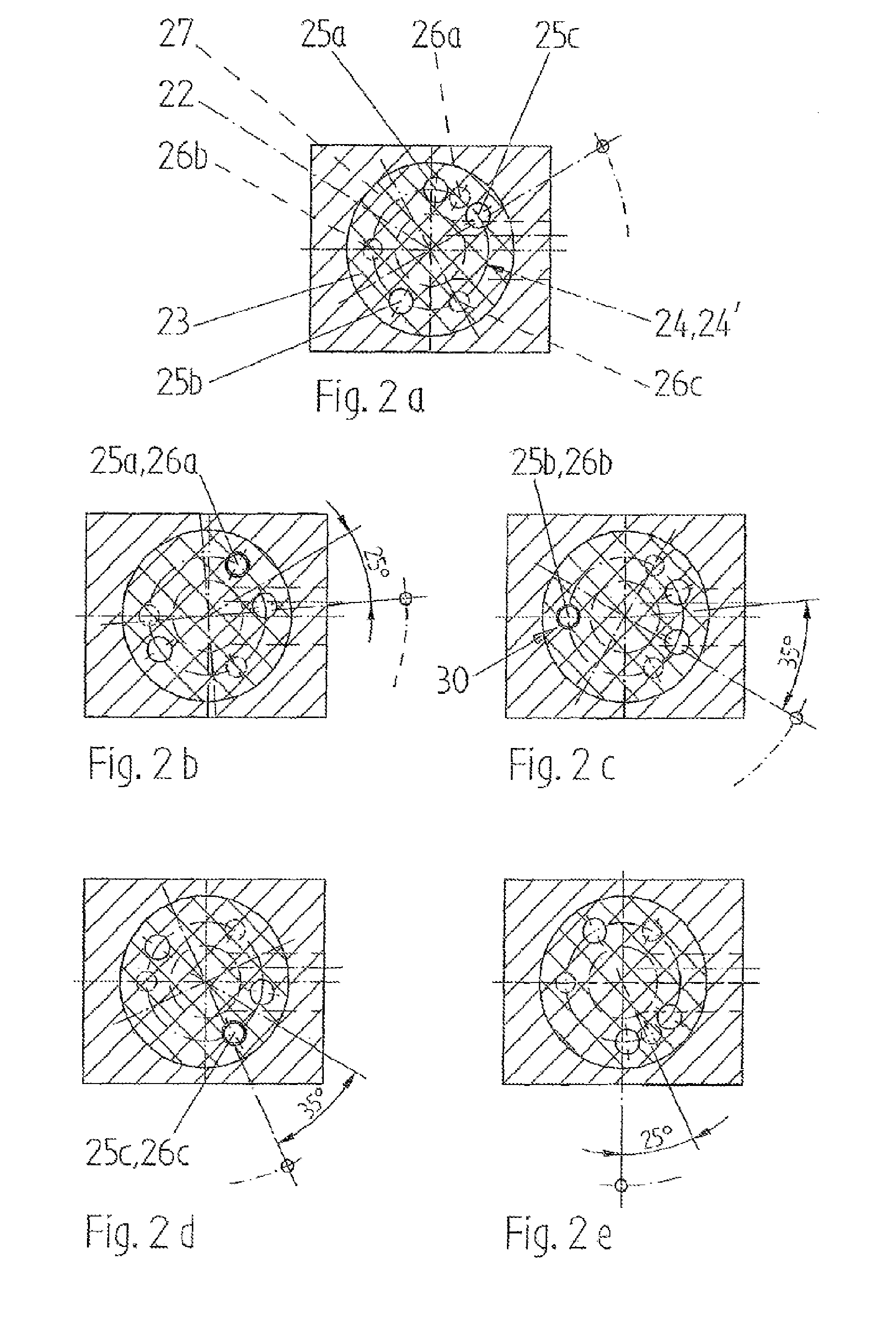

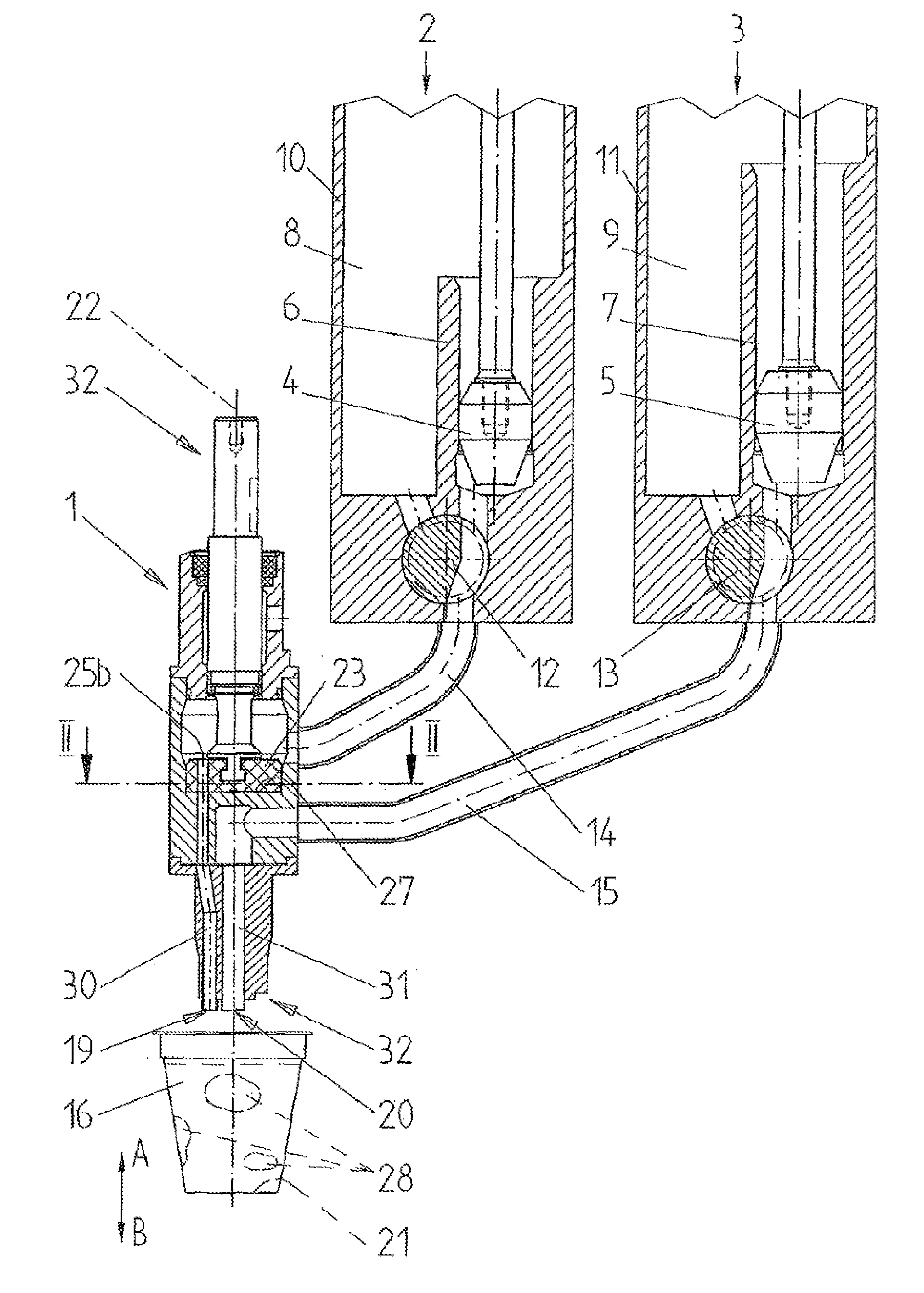

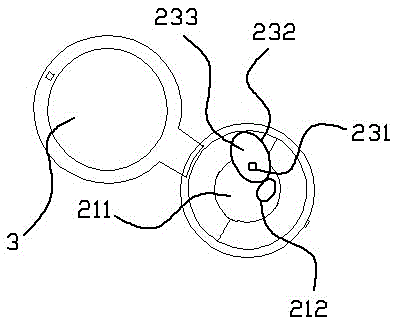

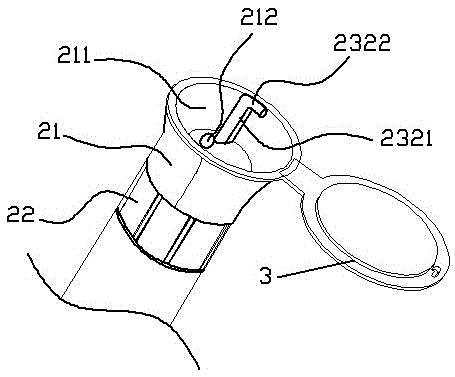

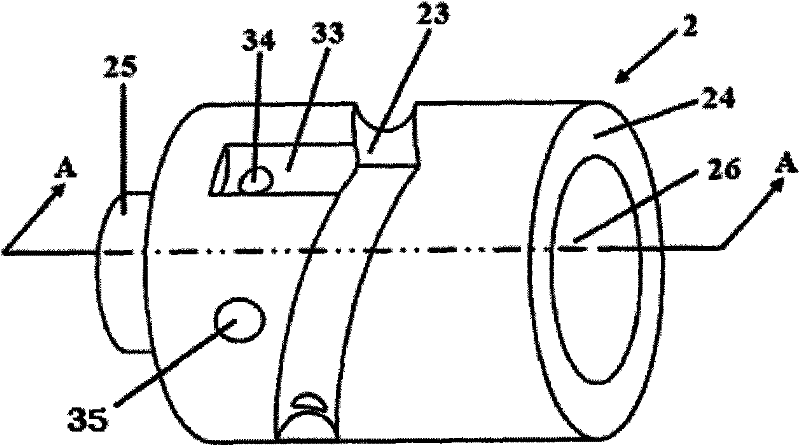

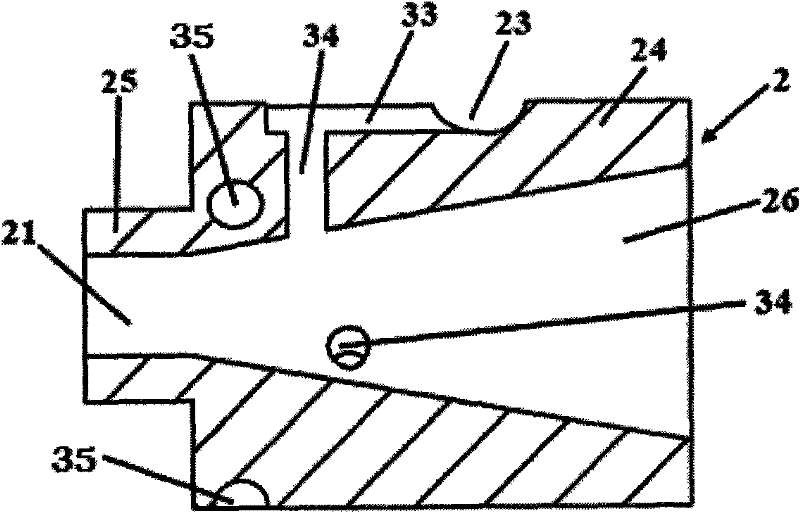

Device for simultaneously filling at least two foods of different compositions into one container

ActiveUS20140326360A1Simple waySmall amount of expenditureLiquid fillingSolid materialEngineeringControl circuit

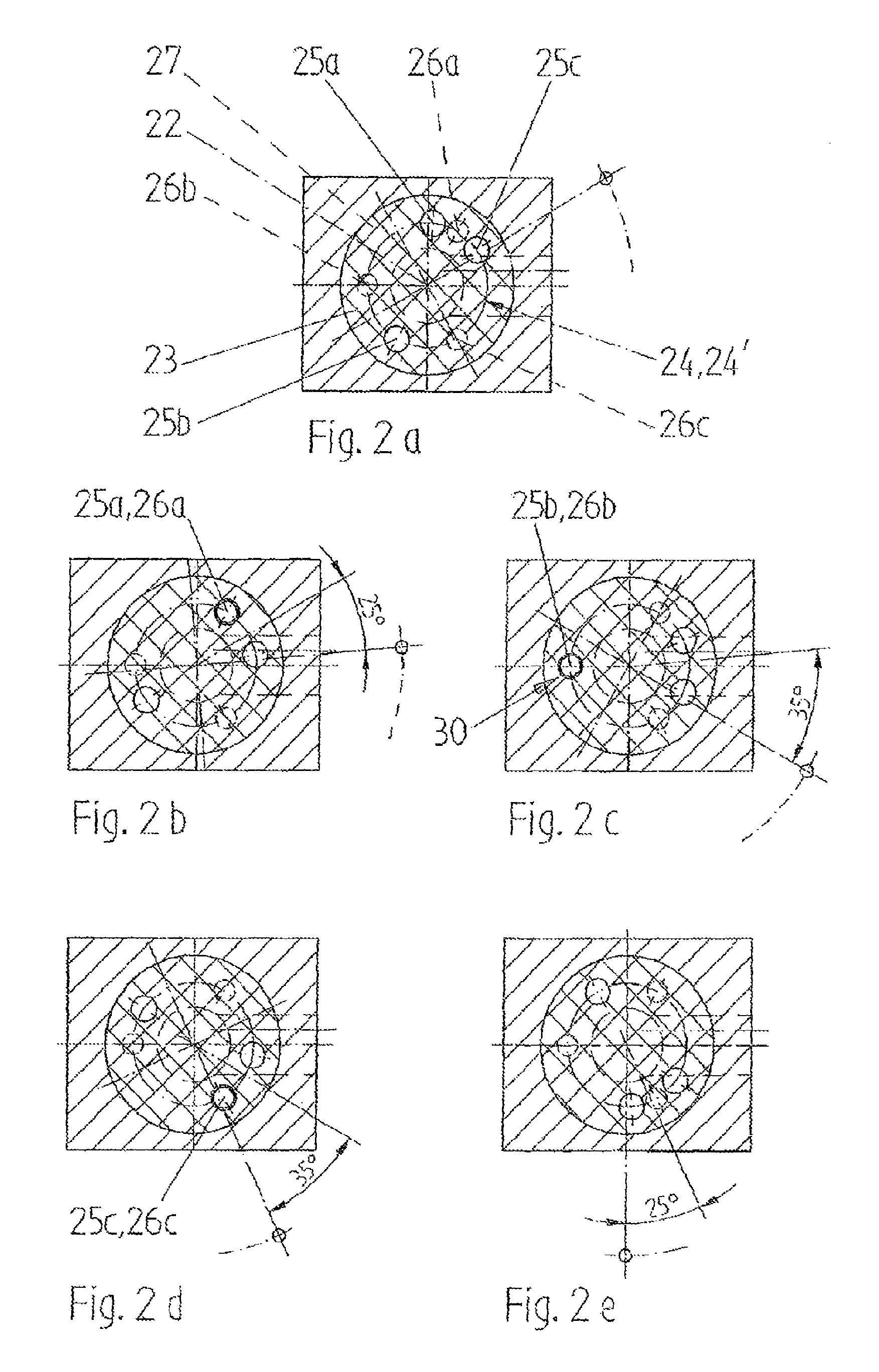

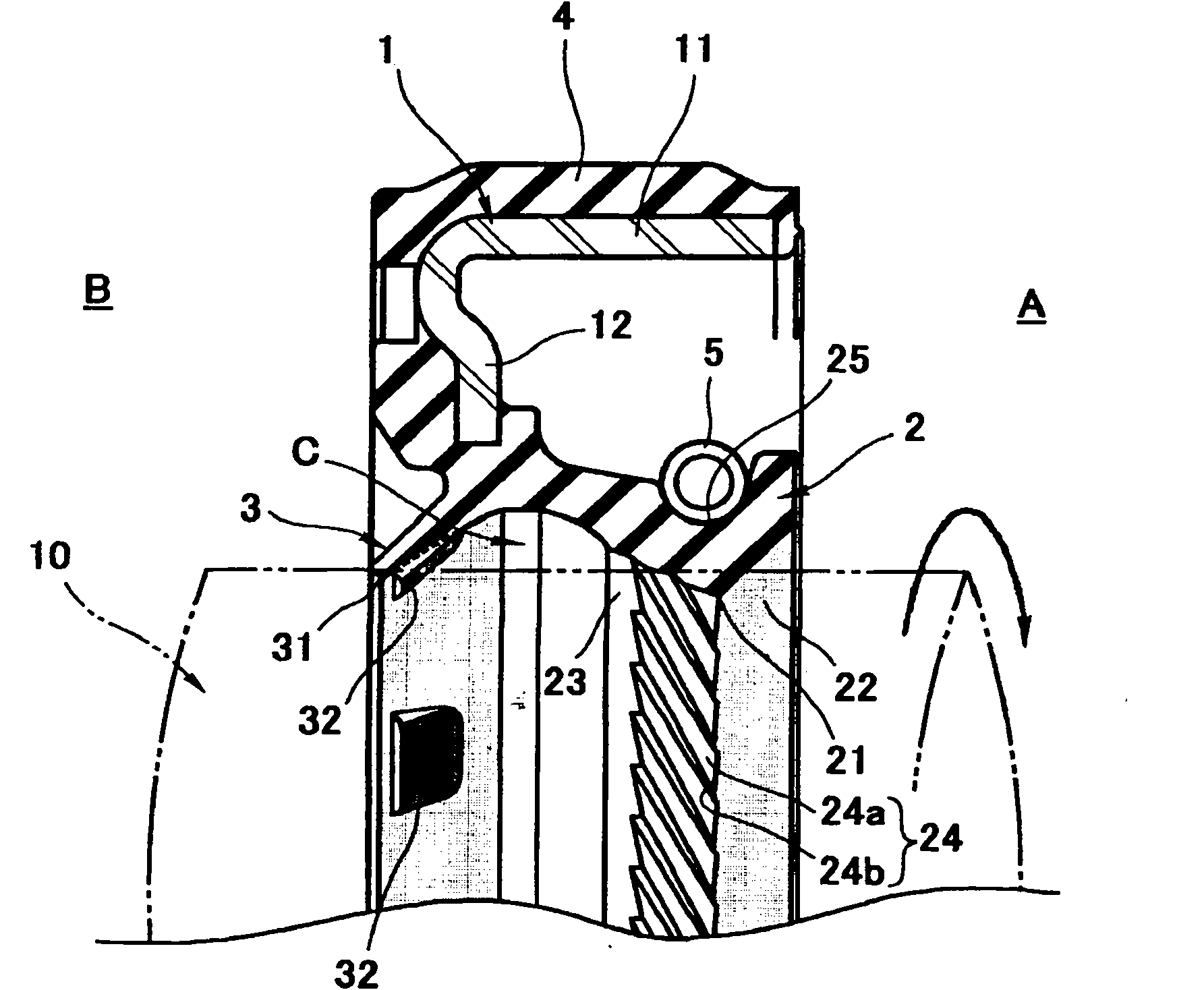

A device for simultaneously filling at least two foods of different compositions, predominantly in a thick fluid and / or pasty form, into a container, particularly a transparent plastic cup, having a valve head with a nozzle inlet opening and nozzle outlet openings for the food and fed by dosing devices, wherein the controller has a control disc (23) rotatable about a longitudinal axis (22) in the valve head (1) having control openings (25a, 25b, 25c) distributed about said longitudinal axis (22) on a first control circuit path (24), said control openings being alignable during an incremental rotation of the control disc (23) alternating in succession with auxiliary nozzle inlet openings (26a, 26b, 26c) of a stationary control surface (27) of the valve head (1) lying below in a planar manner, wherein auxiliary nozzle inlet openings (26a, 26b, 26c) are arranged on a second control circuit path (24′) congruent with the first control circuit path about the longitudinal axis (22) in the control surface (27) such that helically rising individual portions (28) of the second food (8) from corresponding auxiliary nozzle outlet openings (30) can be positioned on the inner wall of the cup (29) during the filling process. A main nozzle (31) is provided below the control surface (27) in the valve body within the control circuit paths and auxiliary nozzle inlet openings on the longitudinal axis arranged along the same paths; the feed of said nozzle with the food forming the main component is controlled in the known manner by only one rotary disc valve (13) in the supply line (15) coming from the corresponding dosing device (3).

Owner:AMPACK GMBH

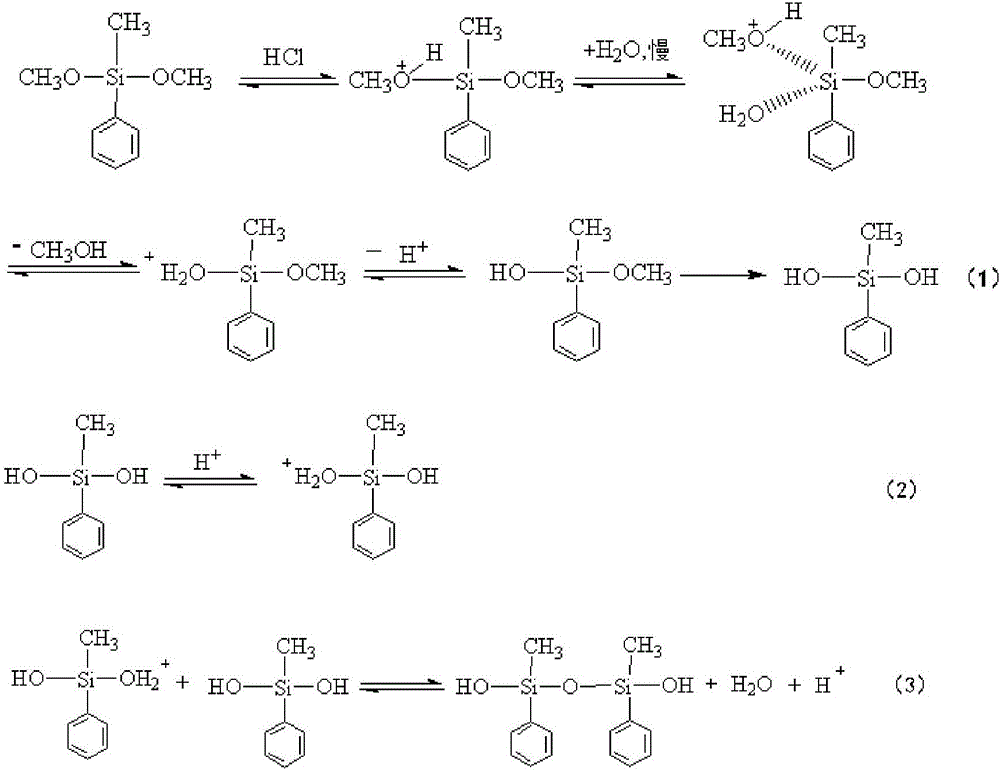

Preparation method of methyl phenyl hydrogen-containing silicone oil for LED packaging adhesive

InactiveCN106478951AAvoid complex processesSingle hydrolysis and condensation processDisiloxaneTetralin

The invention discloses a preparation method of methyl phenyl hydrogen-containing silicone oil for LED packaging adhesive. The method takes methyl phenyl dimethoxy silaneas raw material and hydrochloric acid or acid cationic resin as catalyst, and performs hydrolytic condensation reaction under the heating and stirring condition, and prepares methyl phenyl hydroxyl silicone oil; the prepared methyl phenyl hydrogen-containing silicone oil and tetramethyl tetralin cyclotetrasiloxane (D4H) as raw materials, hexamethyl disiloxane (MM) or hydrogen-containing dual-sealing end (MMH) as the end-capping reagent, and acid cationic resin as the catalyst; the reaction is carried out under the heating and stirring conditions; after finishing the reaction, catalyst is filtered and removed; and then the methyl phenyl hydrogen-containing silicone oil is obtained after depressurizing and distilling the product and removing the low-boiling-point substance. The prepared hydrogen-containing silicone oil is colorless and transparent thick fluid; the light transmittance, refractive index and activated hydrogen content are high, the thermal stability is good; besides, the methyl phenyl hydrogen-containing silicone oil can be used as the LED packaging material.

Owner:SOUTH CHINA UNIV OF TECH

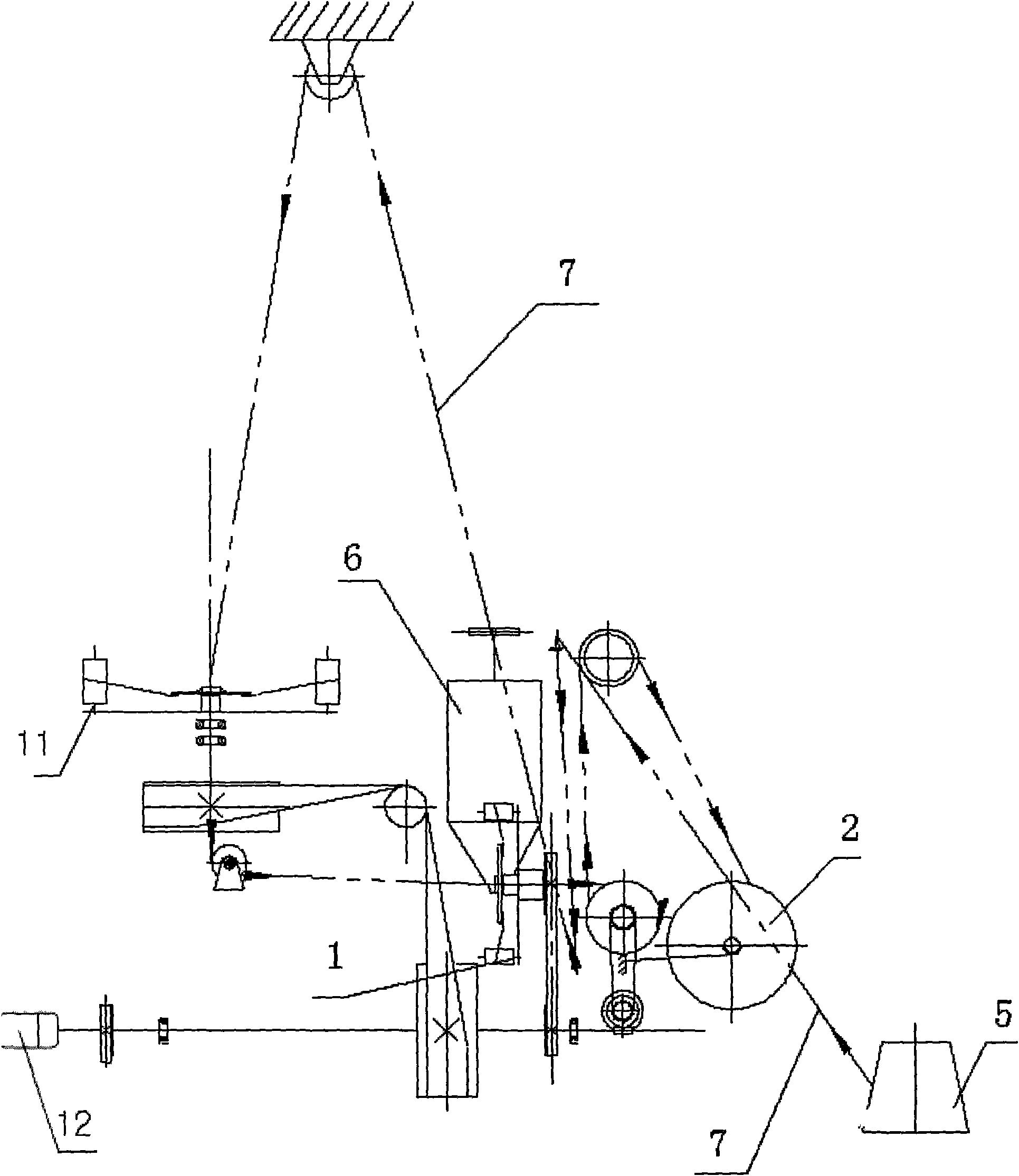

Fireworks safety firing cable and manufacturing method thereof

InactiveCN101619009APut an end to the malpractice scattered in the production siteReduction of more hazardous processesFusesYarnOrganic solvent

The invention discloses a fireworks safety firing cable and a manufacturing method thereof. The fireworks safety firing cable comprises an ignition-composition core and cotton yarn attached with firing cable compositions; and the manufacturing method is mainly characterized by comprising the following steps: adding an appropriate amount of organic solvents into the prior firing cable compositions, and evenly stirring to enable the compositions to be in a thick fluid flurry state; and evenly attaching the fluid slurry onto priming cotton yarn as a firing cable composition core by improving the structure of a priming machine. The invention has the advantages that a plurality of process flows with higher hazards are reduced in the processing process of firing cable compositions, the defect that composition powder is interspersed in production places is avoided in the cotton yarn wrapping process, and the production security is improved qualitatively; the quality of the product is improved, and the phenomena of composition interruption, shortage and leakage are prevented from generating; no dust pollution is generated in production and application, and production personnel are avoided from being injured by occupational diseases, such as silicosis, and the like.

Owner:鲁向华

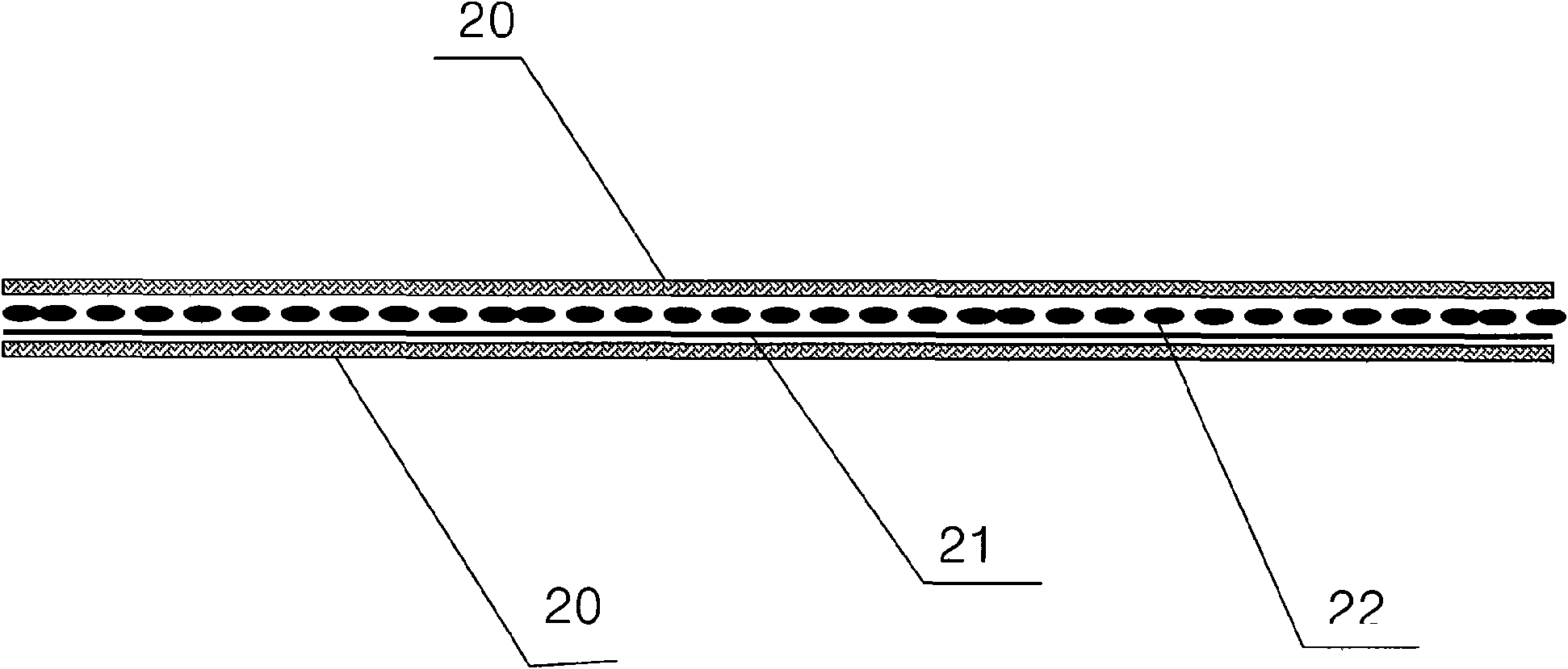

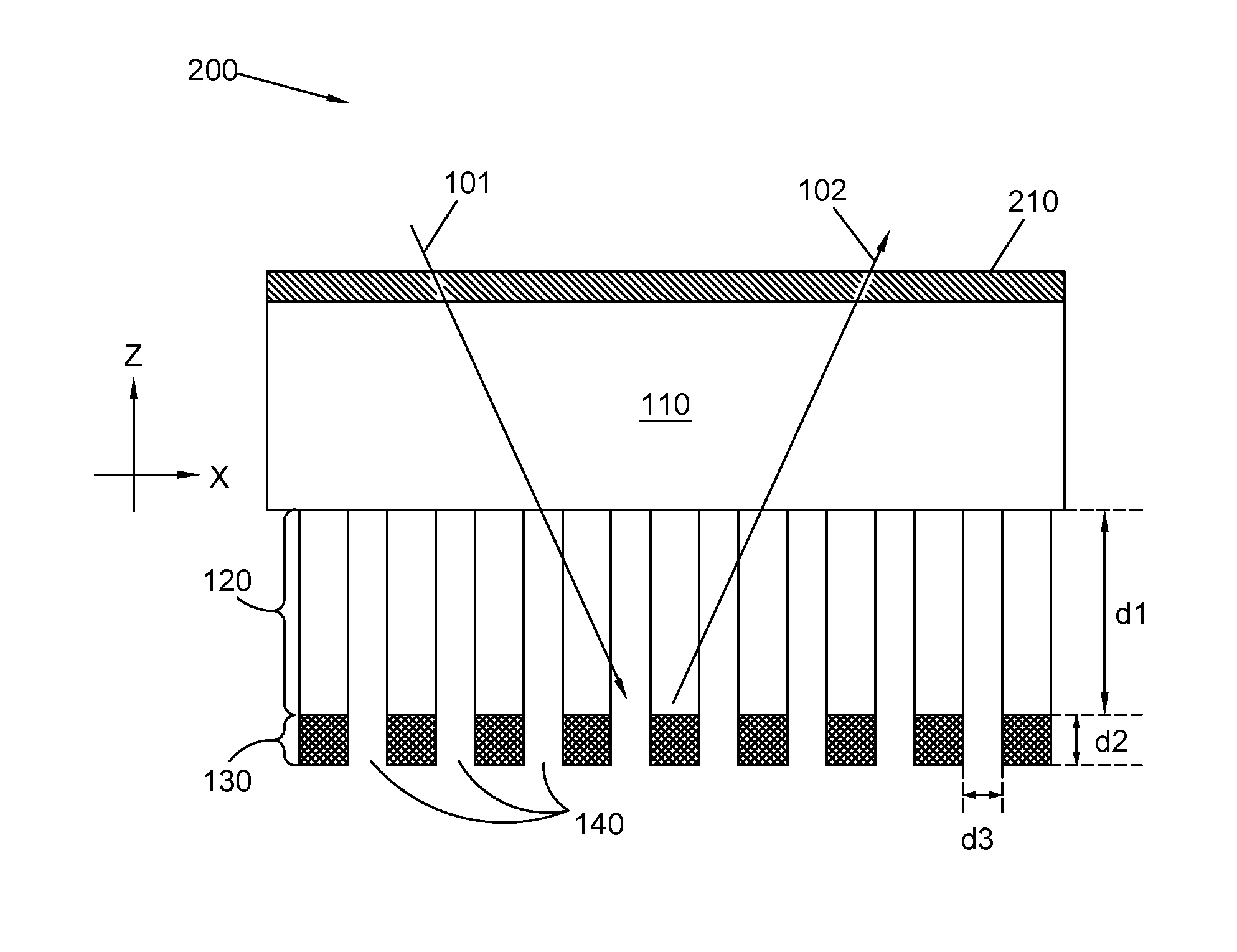

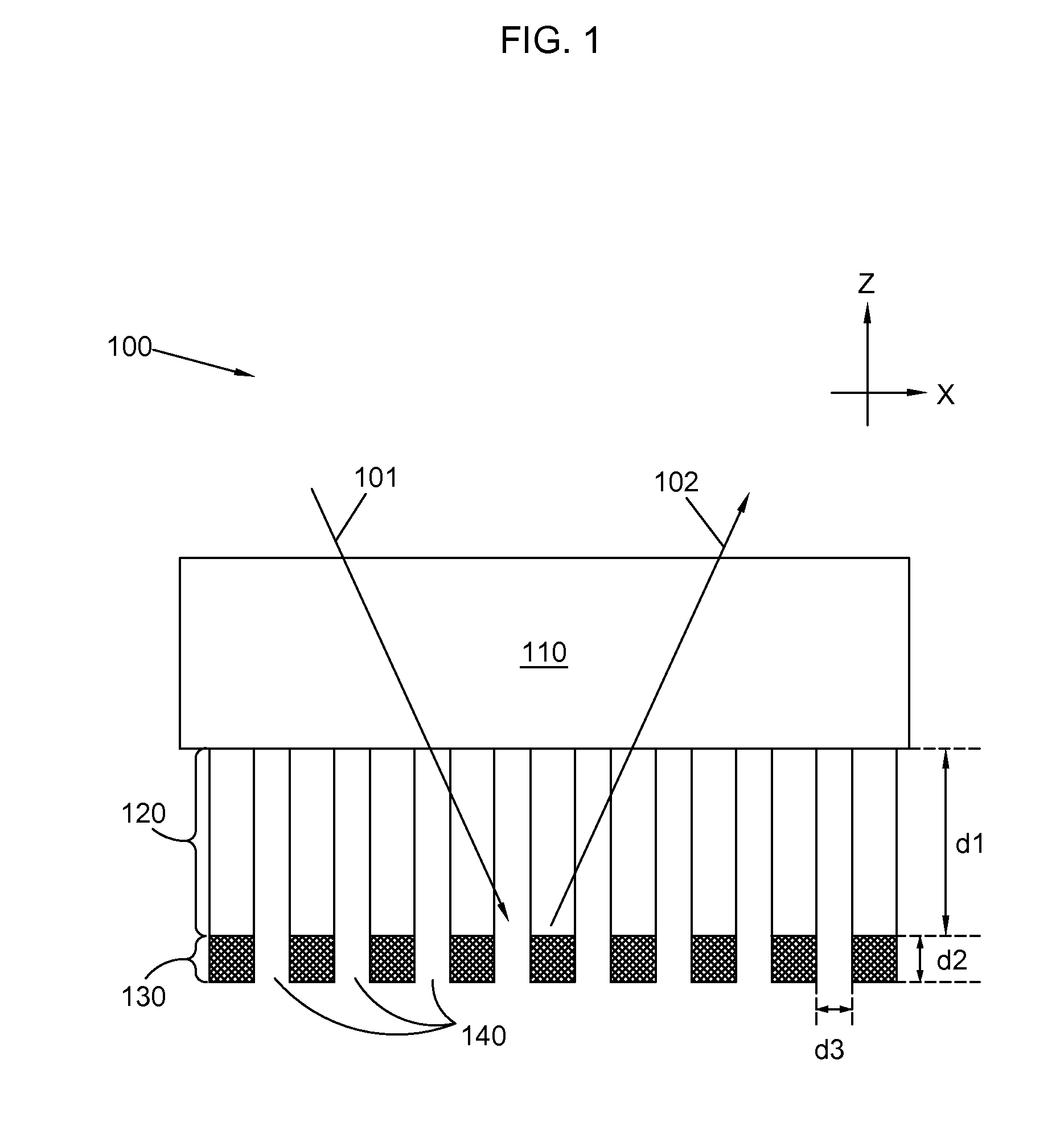

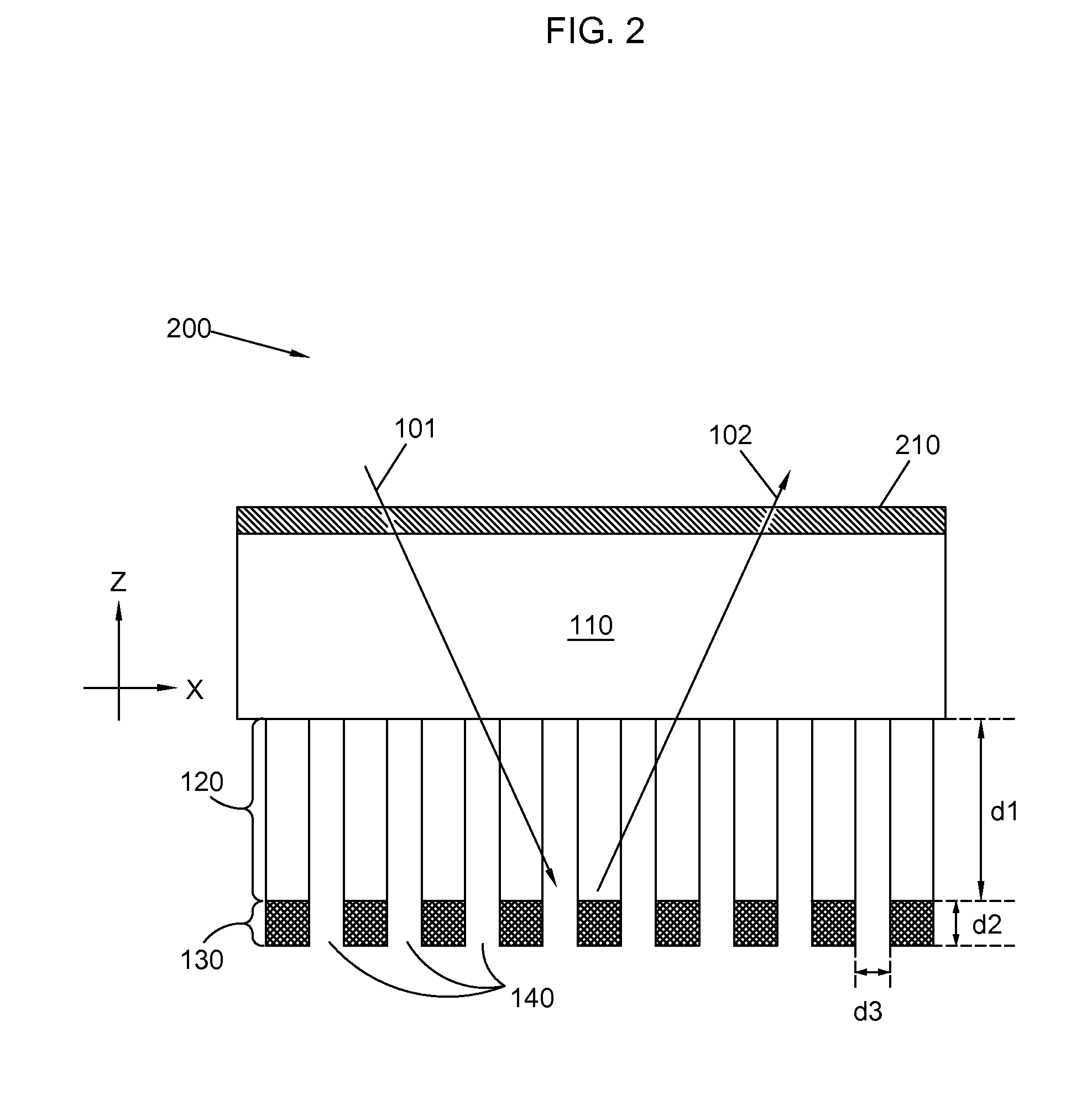

Optically Transparent Films for Measuring Optically Thick Fluids

A multilayered film and a method for performing spectroscopic measurements in a fluid are provided. The multilayered film includes a substrate; a porous layer adjacent to the substrate; and a reflective layer formed on the porous layer, wherein the porous layer selectively allows a component of a fluid to be optically measured when the multilayered film is immersed in the fluid. A sensor for spectroscopic measurements in crude oil samples including a multilayered film as above is also provided. A method of manufacturing a multilayered film for spectroscopic measurements in fluids as above is also provided.

Owner:HALLIBURTON ENERGY SERVICES INC

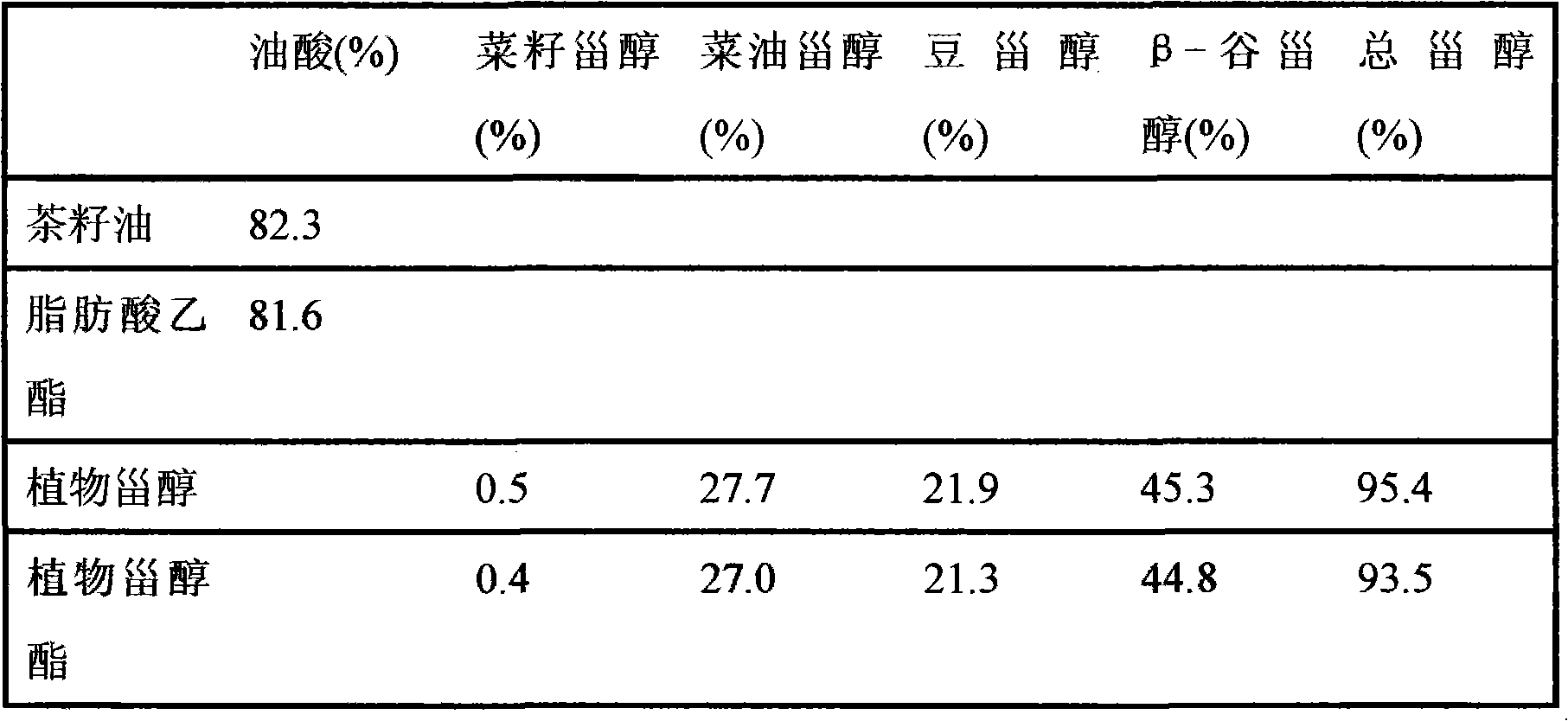

Preparation method of phytosterin ester rich in oleic acid

InactiveCN101538306AHigh yieldNon-corrosiveOrganic-compounds/hydrides/coordination-complexes catalystsSteroidsVegetable oilOrganic solvent

The invention provides a preparation method of phytosterin ester rich in oleic acid, which comprises the following steps: firstly, leading seed fat rich in oletic acid and ethanol to perform alcoholysis reaction under the action of catalyst to obtain fatty acid ethyl ester rich in oleic acid; secondly, leading the fatty acid ethyl ester rich in oleic acid and phytosterin to perform the ester exchange reaction under the action of the catalyst, and removing unreacted ethanol and redundant fatty acid ethyl ester so as to obtain crude phytosterin ester rich in oleic acid; thirdly, obtaining primrose yellow to white thick fluid by decoloring the phytosterin ester, i.e. refined phytosterin ester. The oleic acid content of the seed oil is more than 60 percent; and high-content oleic acid reduces the side reaction and improves the yield of the phytosterin ester. The preparation method does not use deleterious organic solvent and produce deleterious materials during the whole preparation, has lower requirement on reaction condition, and is suitable for industrial mass production of food.

Owner:中粮工科(西安)国际工程有限公司

Device for simultaneously filling at least two foods of different compositions into one container

A device for simultaneously filling at least two foods of different compositions, predominantly in a thick fluid and / or pasty form, into a container, particularly a transparent plastic cup, having a valve head with a nozzle inlet opening and nozzle outlet openings for the food and fed by dosing devices, wherein the controller has a control disc (23) rotatable about a longitudinal axis (22) in the valve head (1) having control openings (25a, 25b, 25c) distributed about said longitudinal axis (22) on a first control circuit path (24), said control openings being alignable during an incremental rotation of the control disc (23) alternating in succession with auxiliary nozzle inlet openings (26a, 26b, 26c) of a stationary control surface (27) of the valve head (1) lying below in a planar manner, wherein auxiliary nozzle inlet openings (26a, 26b, 26c) are arranged on a second control circuit path (24′) congruent with the first control circuit path about the longitudinal axis (22) in the control surface (27) such that helically rising individual portions (28) of the second food (8) from corresponding auxiliary nozzle outlet openings (30) can be positioned on the inner wall of the cup (29) during the filling process. A main nozzle (31) is provided below the control surface (27) in the valve body within the control circuit paths and auxiliary nozzle inlet openings on the longitudinal axis arranged along the same paths; the feed of said nozzle with the food forming the main component is controlled in the known manner by only one rotary disc valve (13) in the supply line (15) coming from the corresponding dosing device (3).

Owner:AMPACK GMBH

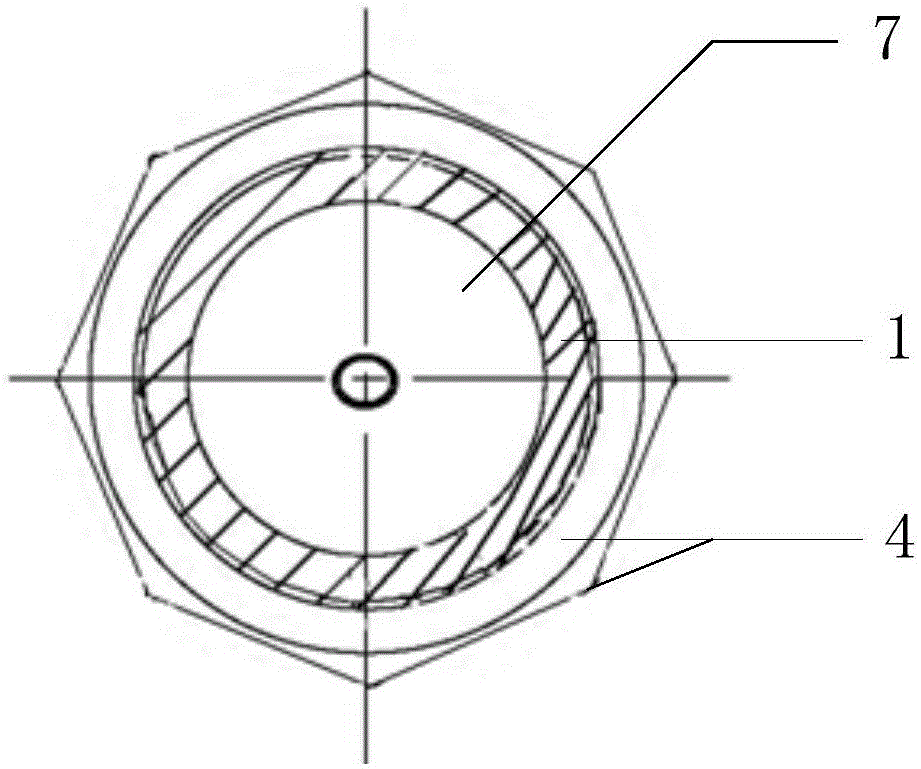

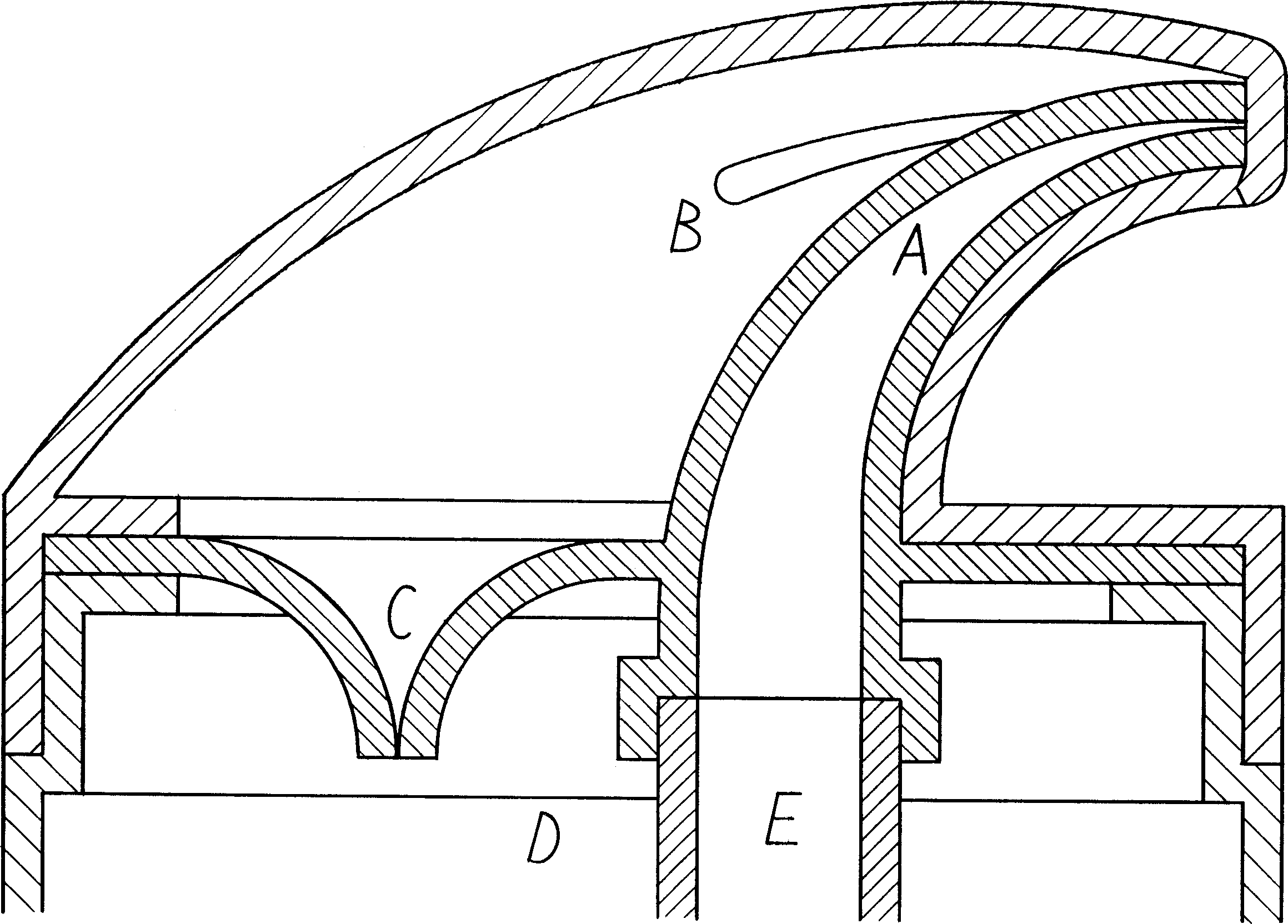

Oil seal

InactiveCN101932859AImprove the lubrication effectReduced slip torqueEngine sealsAtmospheric airEngineering

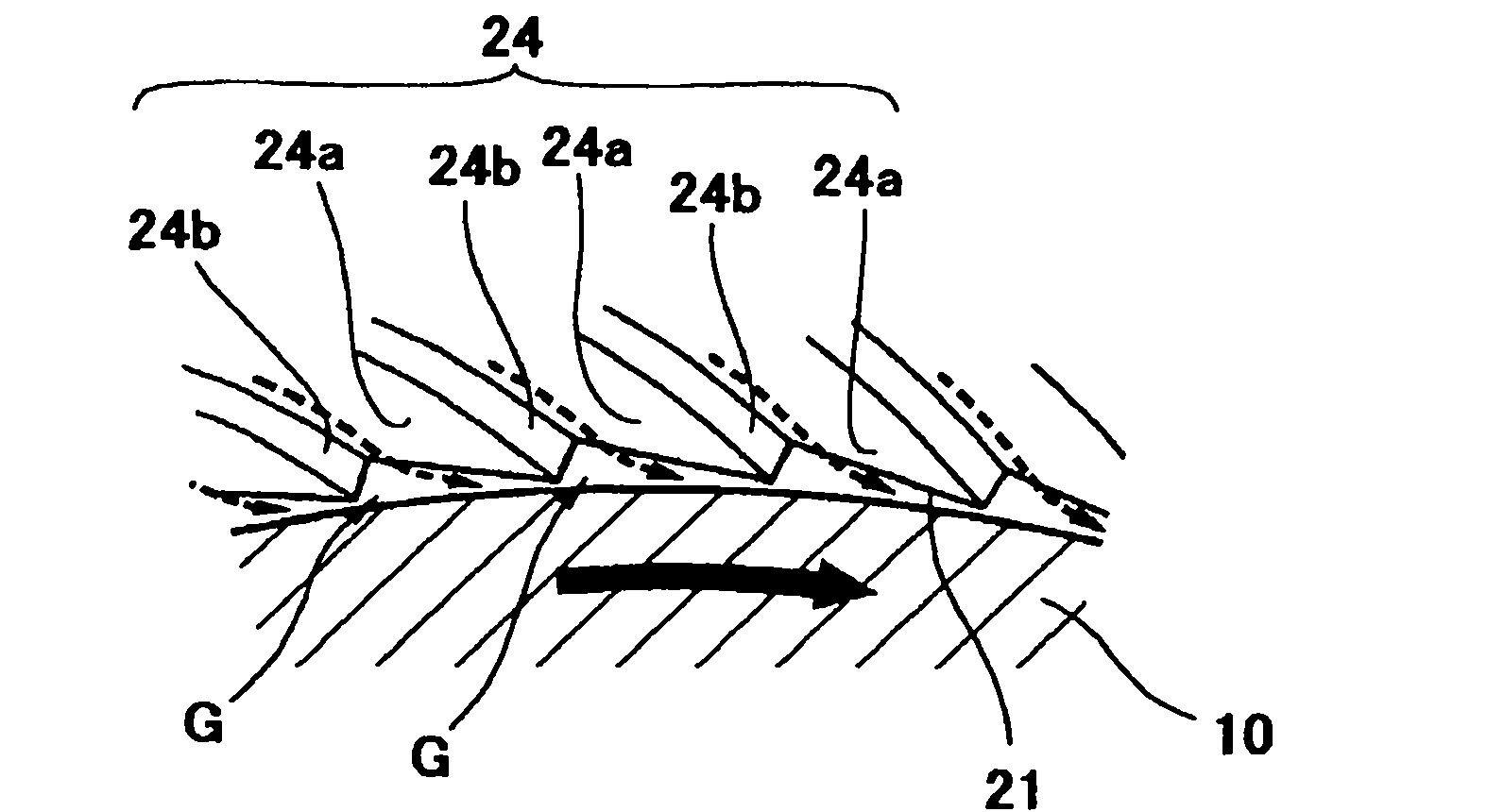

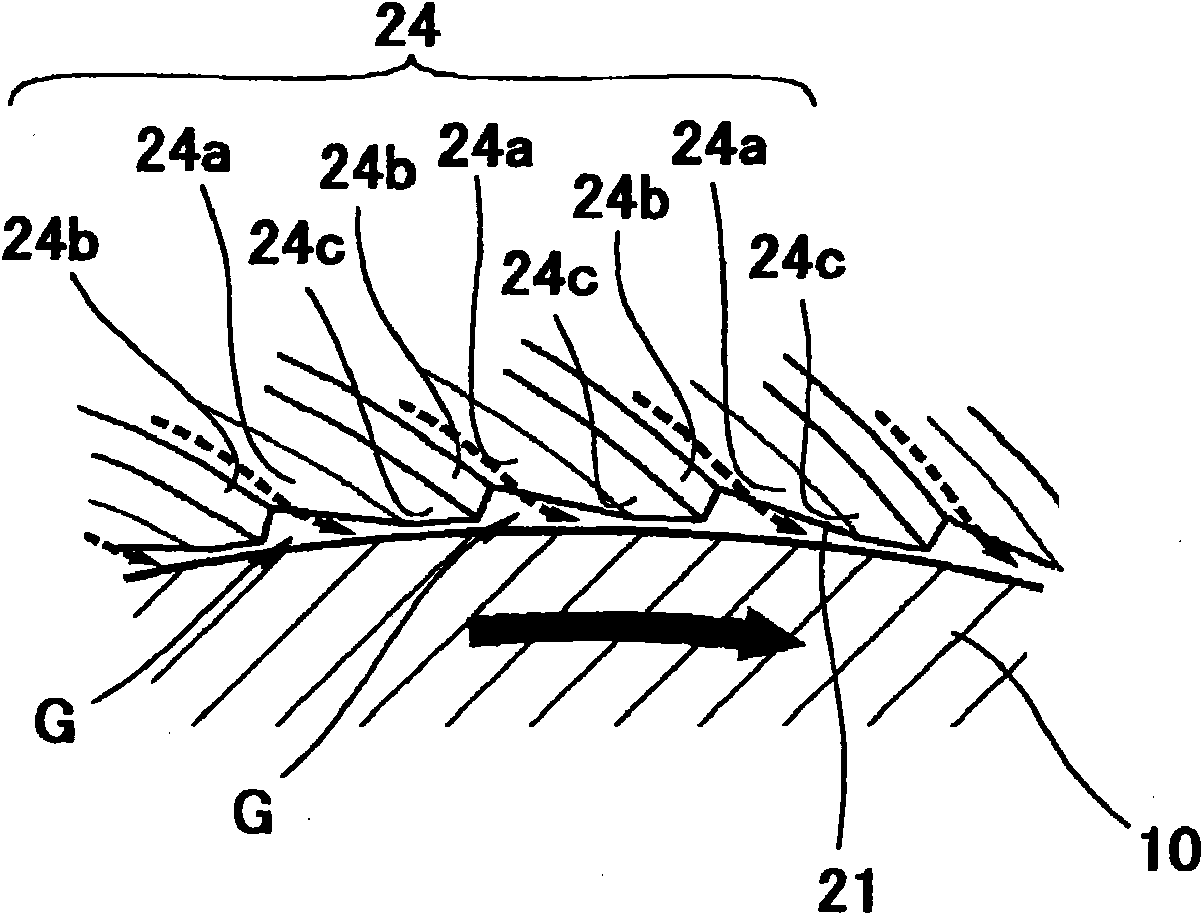

Ridge and groove sections (24) are formed at a predetermined circumferential pitch on at least either of a slide seal surface (21) and an atmosphere-side circular conical surface (23) of a seal lip (2). Each of the ridge and groove sections (24) has a first slope surface (24a) and a second slope surface (24b). The first slope surface (24a) slopes at a gentle gradient toward the rotation direction of a rotation body (10) and in the direction in which the distance between the first slope surface (24a) and the outer peripheral surface of the rotation body (10) decreases. The second slope surface (24b) rises at a steeper gradient than the first slope surface (24a) from the decreased distance portion. As the rotation body (10) rotates, a portion of fluid to be sealed introduced into a gap between the rotation body (10) and the ridge and groove sections (24) enters like a wedge into the gap toward the decreased distance portion to generate dynamic pressure. This forms a thick fluid lubrication film to reduce slide resistance between the seal lip and the outer peripheral surface of the rotation body (10).

Owner:NOK CORP

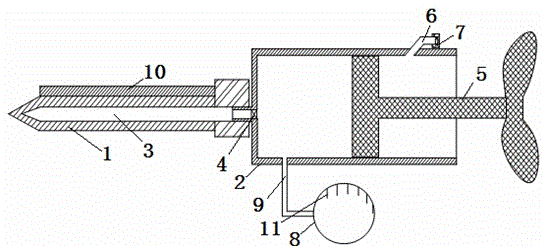

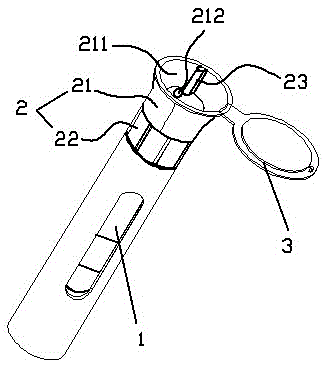

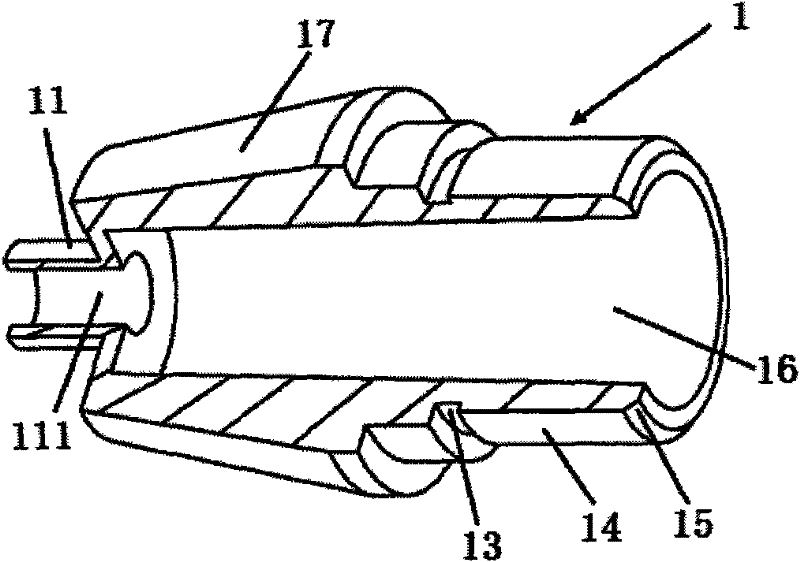

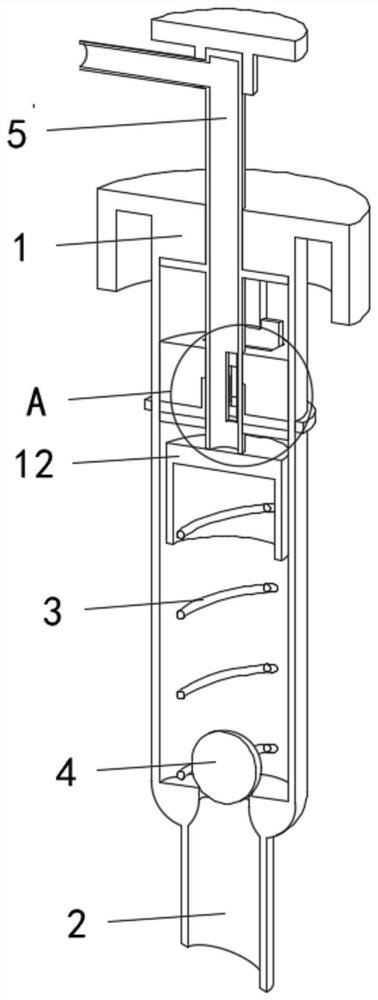

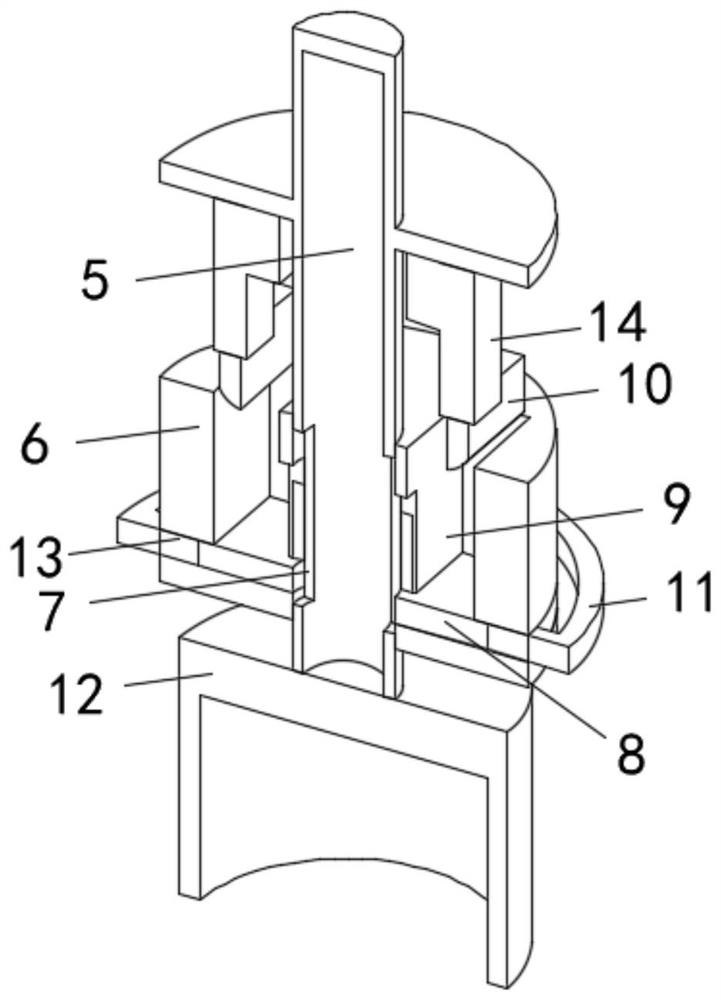

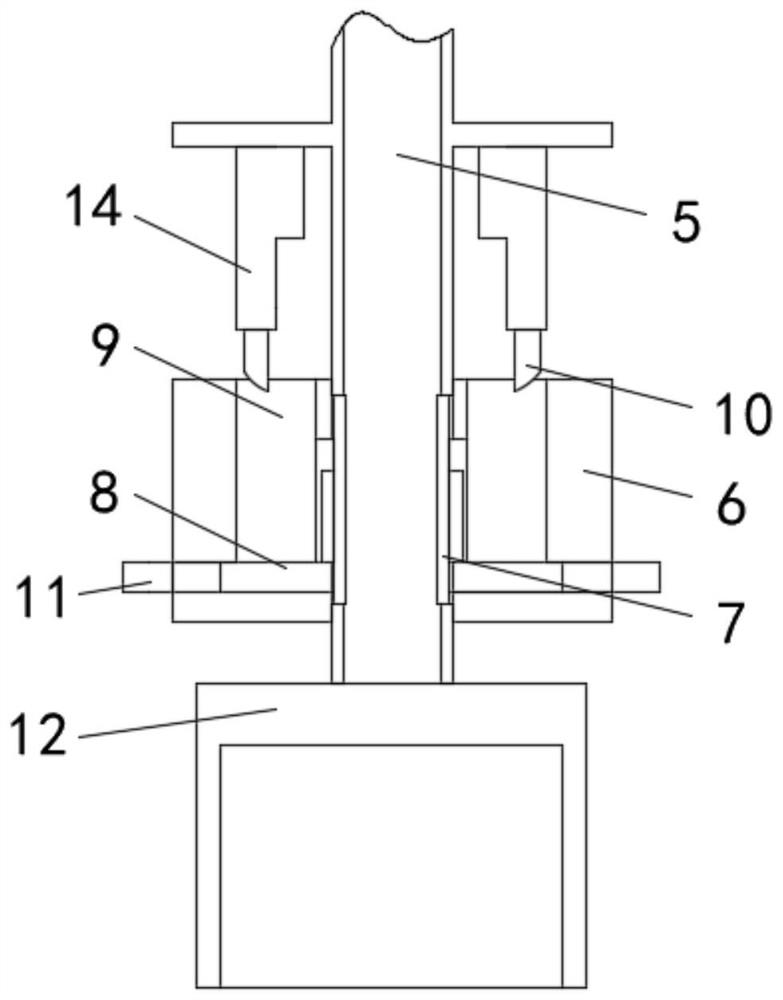

Thyroid puncture device

InactiveCN104665896APrecise volume controlConvenient diagnosis and treatmentSurgical needlesVaccination/ovulation diagnosticsDiseaseCysts fluid

The invention relates to a thyroid puncture device, and belongs to the technical field of medical tool structures. The thyroid puncture device comprises an injector; a needle body in which a needle core is mounted is connected to the front of the injector; an one-way valve is arranged at an inlet of the injector; a pushing handle is arranged in the injector; a negative pressure pipe equipped with a piston is fixedly mounted at one side of the injector, and while a fluid storing bottle is mounted at the other side of the injector. According to the thyroid puncture device, the negative pressure pipe is arranged and can generate sufficient negative pressure to absorb cyst fluid, and the absorbed cyst fluid is enough for diagnosis; the liquid storing bottle is arranged, so that cyst fluid can be extracted at a plurality of times; the cyst fluid can be smoothly extracted in case of thick fluid or solid nodule mass; in addition, scales in the fluid storing bottle are able to accurately control the volume of the fluid extracted, which greatly facilitates the diagnosis and treatment of diseases.

Owner:任瑞珍

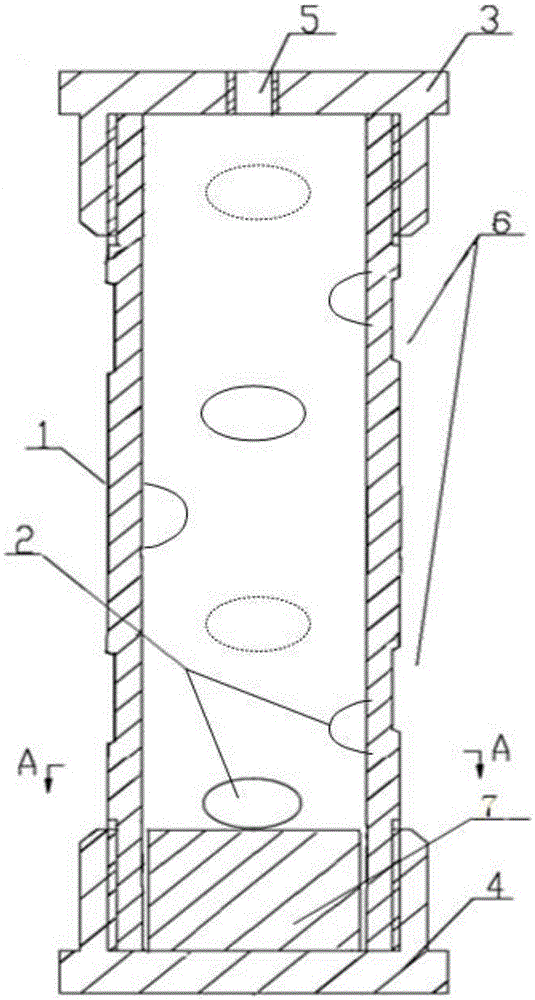

Method for measuring settlement stability of pad fluid or post-pad fluid for well cementation

ActiveCN105043931ASimple structureEasy to disassembleSpecific gravity measurementPressure dataEvaluation system

The invention discloses a method for measuring settlement stability of a pad fluid or a post-pad fluid for well cementation. The method is realized through a device for measuring settlement stability of the pad fluid or the post-pad fluid for well cementation; the settlement stability of the pad fluid or the post-pad fluid, with different density and different standing time, for well cementation is measured; and the measurement of settlement stability of the pad thick fluid or the post-pad thick liquid, with different characteristics, different density and different standing time, under the well for well cementation can be effectively simulated. The device is simple in structure, is convenient for disassembly and cleaning, and can be reused. The device is convenient and efficient to operate, so the construction cost is reduced. Measurement and evaluation system is much closer to the actual engineering. The method is strong in comparability, simple to operate, and wide in application range. The data of single-group settlement stability can be measured and predicted, and a tendency chart of settlement stability can be drawn according to different standing time. Judgment basis of reliable annular pressure data for well cementation is provided, and the method has a wide application prospect.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

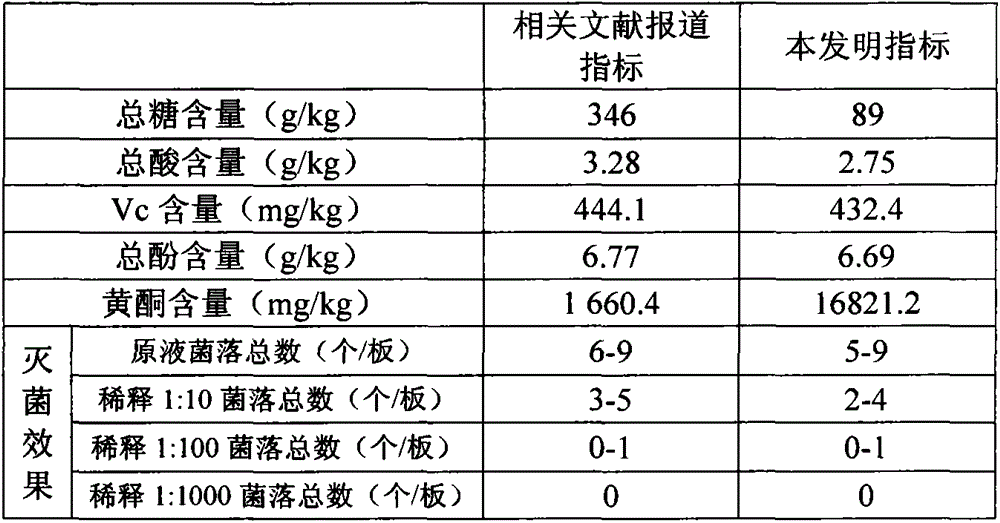

Sweet purple sweet potato wine, purple sweet potato fruit vinegar and brewing method thereof

ActiveCN103966042ASpecial Roasted FlavorMild fermented flavorAlcoholic beverage preparationVinegar preparationPharbitis nilFermentation broth

The invention discloses sweet purple sweet potato wine, purple sweet potato fruit vinegar and a brewing method thereof. The brewing method comprises the steps as follows: taking purple sweet potatoes, and cooking, drying, baking and crushing the purple sweet potatoes to obtain purple sweet potato powder; taking glutinous rice, and baking and crushing the glutinous rice to obtain glutinous rice powder; mixing the purple sweet potato powder with the glutinous rice powder, and adding water into the mixture to obtain a thick liquid; liquefying and saccharifying the thick fluid sequentially to obtain a saccharification liquid, inoculating yeast into the saccharification liquid, and performing semi-closed type alcoholic fermentation; after the alcoholic fermentation, filtering fermentation liquor to obtain wine liquor and fermented mash, and blending the wine liquor to obtain the sweet purple sweet potato wine; performing acetic fermentation on the fermented mash to obtain the purple sweet potato fruit vinegar. The invention further provides the sweet purple sweet potato wine and the purple sweet potato fruit vinegar which are obtained with the brewing method. The prepared purple sweet potato drinks well reserve the purple color of the purple sweet potatoes and are clear and transparent in color and rich in nutrition.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method for preparing walnut sesame milk

The invention relates to a method for preparing walnut sesame milk. The method particularly comprises the following steps of: 1, pretreating raw material; 2, grinding into thick fluid; and 3, blending. In the method, the prepared walnut sesame milk has uniform in color and luster and the unique fragrance of walnuts, is mixed with peanuts and sesames, contains multiple nutrition ingredients and can improve the immunity of human bodies.

Owner:CHENGDU LONGYUAN YILONGDONG SLICED WALNUT FACTORY

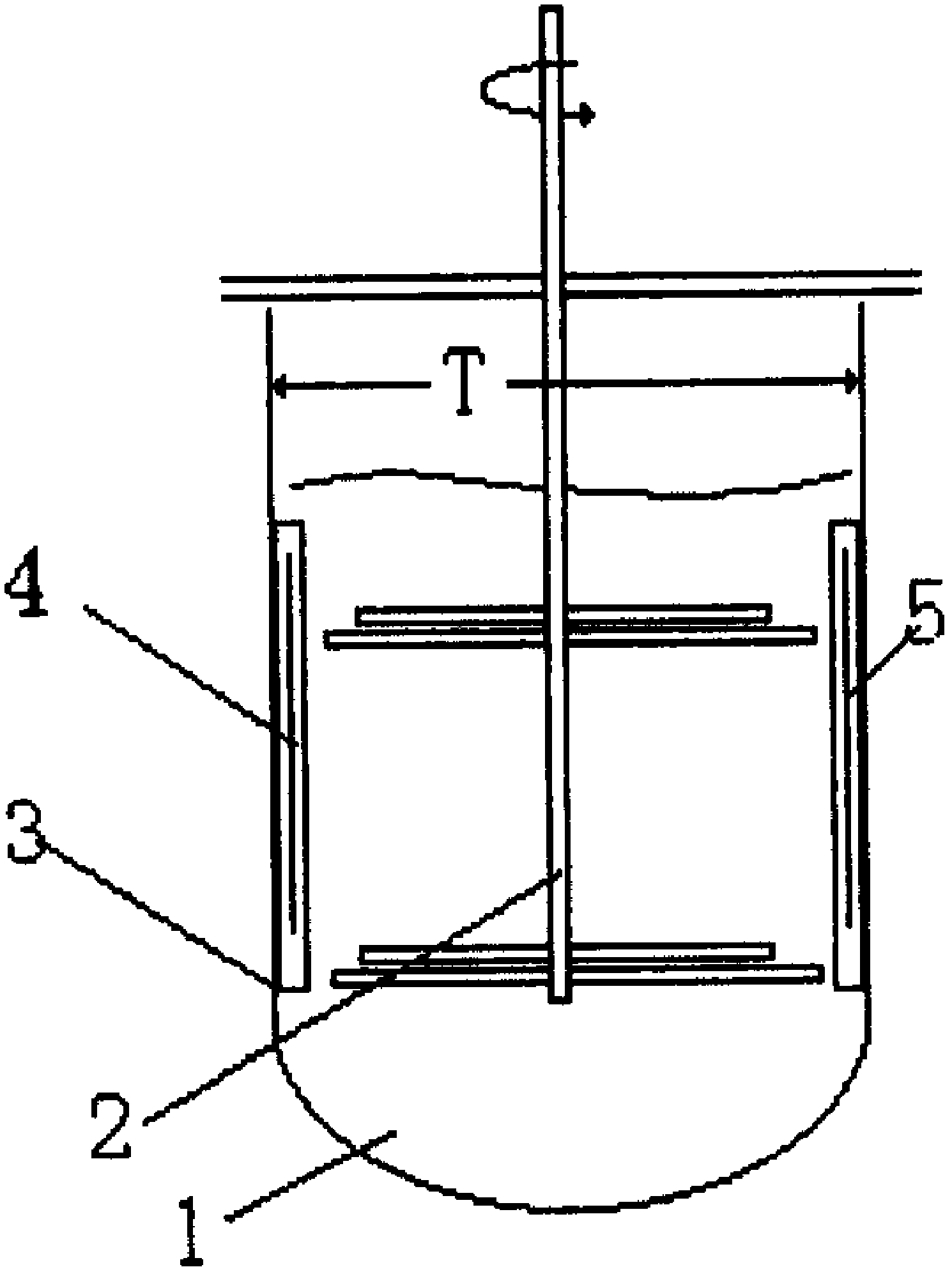

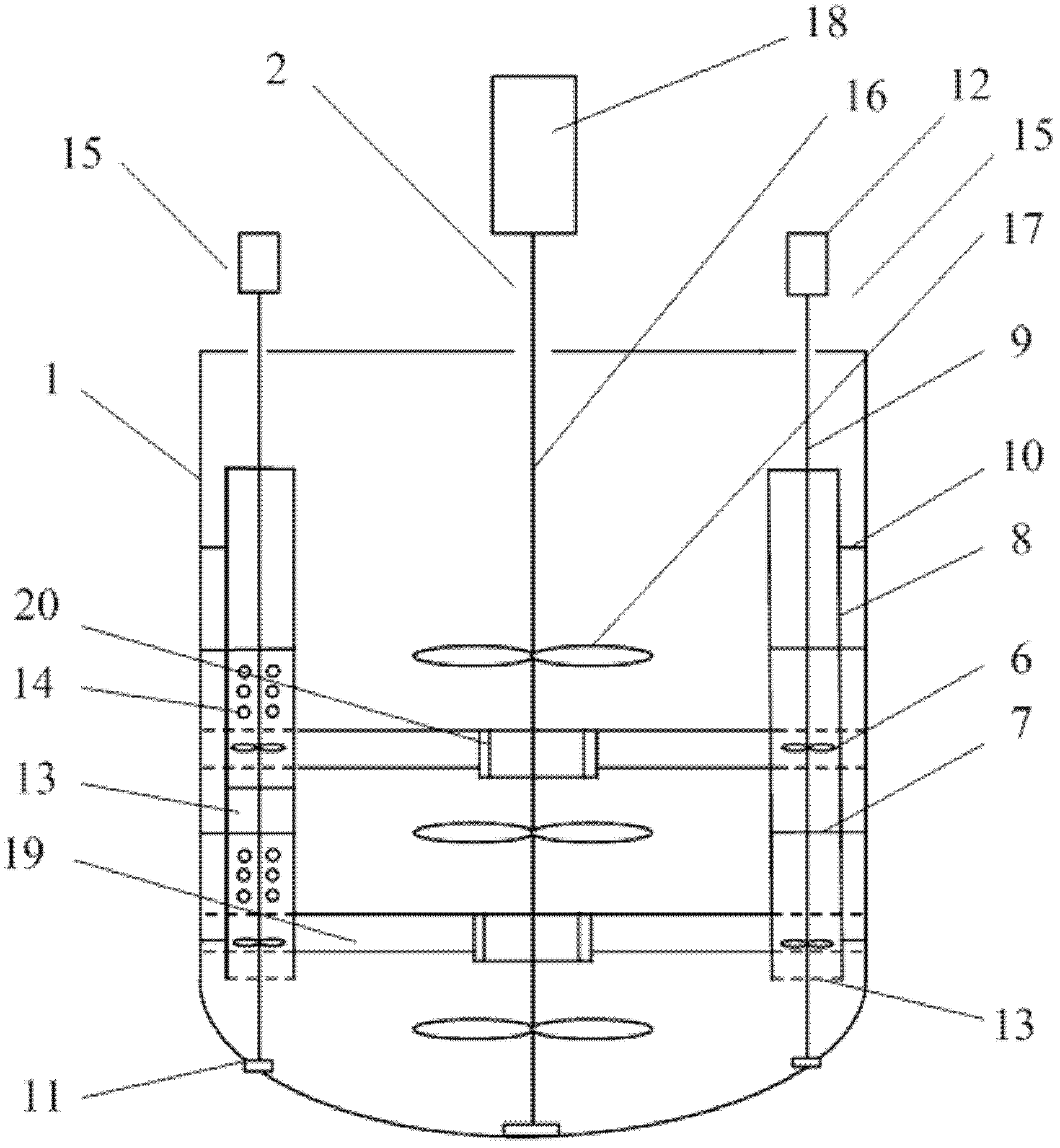

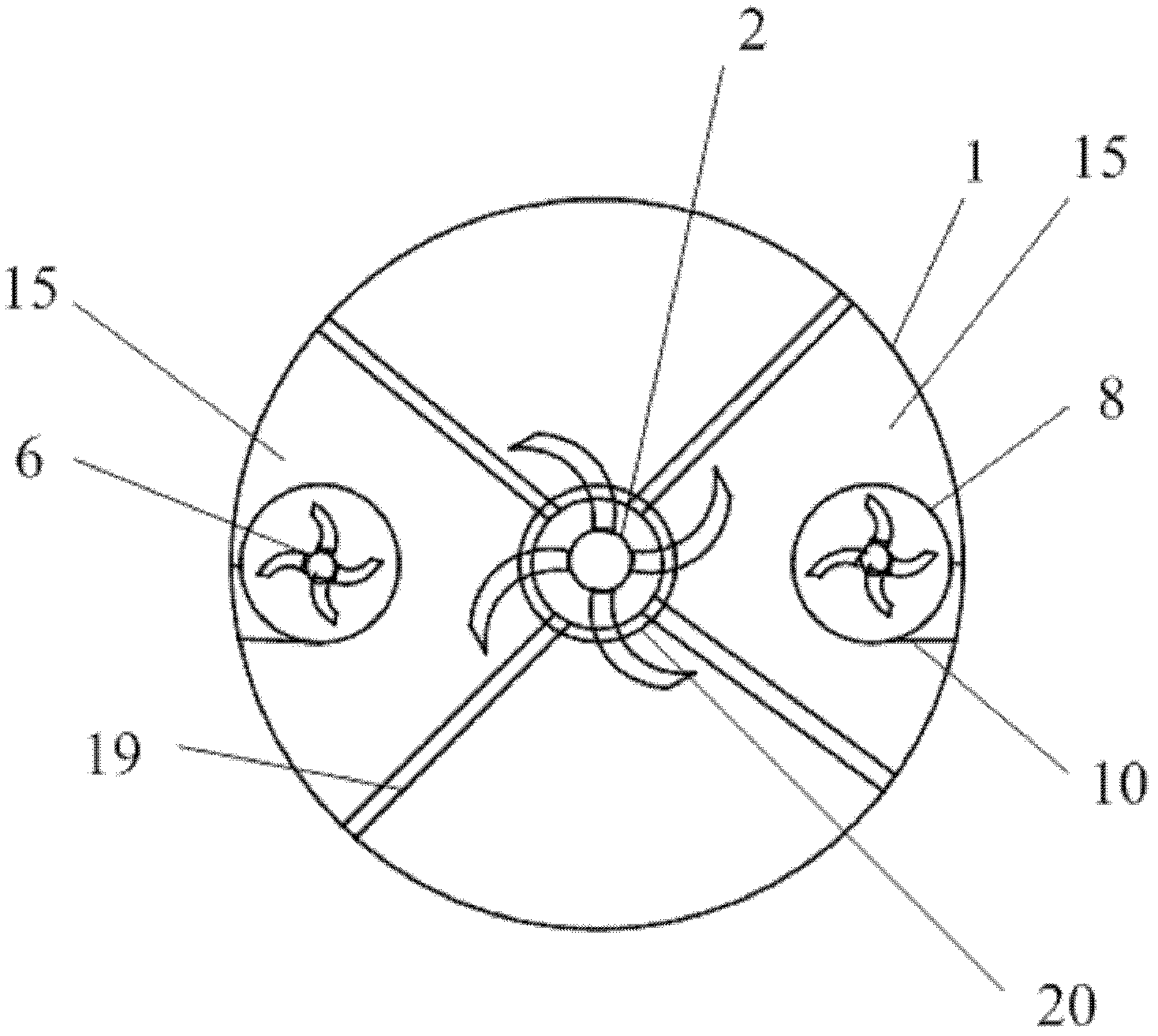

Agitation reactor

ActiveCN103007866AEnhanced turbulence patternsWell mixedRotary stirring mixersChemical/physical/physico-chemical stationary reactorsProcess engineeringSolid particle

Owner:CHINA PETROLEUM & CHEM CORP +1

Pediatric medical sugar and manufacturing method thereof

InactiveCN104126721AEasy to swallowAvoid suffocation hazardsConfectioneryMammal material medical ingredientsYolkBitter gourd

The invention discloses pediatric medical sugar. The pediatric medical sugar is formed by coating a thick fluid obtained by mixing traditional Chinese medicines and various fruit pulps by using a sugar coating including hawthorn fruits and a little of glucose and syrup, and needs to place in an environment with a temperature of 0-3 DEG C in a refrigerator. The medical sugar is coated by edible sugar paper or put in a box with cells and a cover in a manner of putting one medical sugar in each cell. The medicines comprise, by weight, 10-20 parts of chrysanthemum flower, 5-15 parts of loquat leaves, 5-15 parts of honeysuckle flower, 2-8 parts of American ginseng, 6-18 parts of unprocessed rehamnnia root, 7-16 parts of sterculia seeds, 8-10 parts of radix ophiopogonis, 6-10 parts of radix scrophulariae, 7-12 parts of towel gourd, 6-10 parts of yolk powder, 3-12 parts of mint powder, 3-10 parts of bitter gourd, 7-15 parts of bamboo leaves, 6-45 parts of bamboo root, 1-2 parts of snake gall powder and 3-10 parts of licorice root. The medical sugar has high safety, contains no preservative, has a good curative effect, and is popular among children.

Owner:孟娟

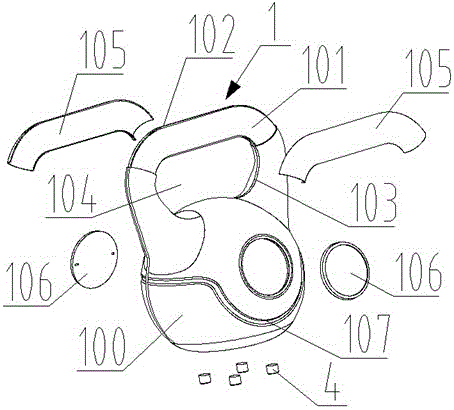

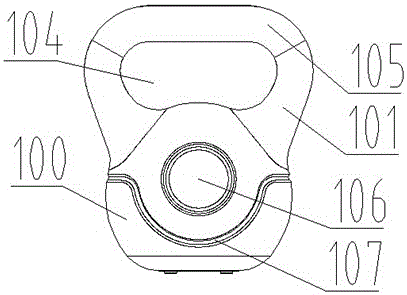

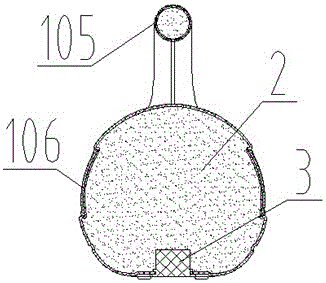

Kettle bell, kettle bell shell and production method of kettle bell

The invention provides a kettle bell, a kettle bell shell and a production method of the kettle bell. The kettle bell comprises a shell and a counter weight filling the inside of the shell, wherein an opening is formed at the bottom of the shell; a cover sealing the opening is arranged at the opening; the counter weight is classified into a liquid-state counter weight and a solid-state counter weight which are poured into the shell through the opening respectively; and the solid-state counter weight and the liquid-state counter weight are mixed and then condensed with the inner wall of the shell and the cover. In the invention, the counter weight of the kettle bell is classified into a liquid-state counter weight and a solid-state counter weight which are poured into the shell of the kettle bell through the opening respectively; the liquid-state counter weight and the solid-state counter weight have relatively high fluidity and are convenient to pour; and compared with existing technology of mixing the two into a thick fluid before pouring, the pouring speed can be at least doubled. Moreover, the liquid-state counter weight and the solid-state counter weight are poured separately, the hard-to-clear mixed solidified object of water and cement is not formed on the outer surface of the kettle bell, and convenience is provided for follow-up cleaning and shaping of the kettle bell.

Owner:南通鑫鑫体育运动用品有限公司

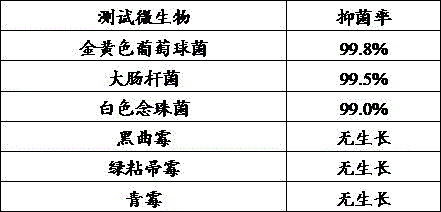

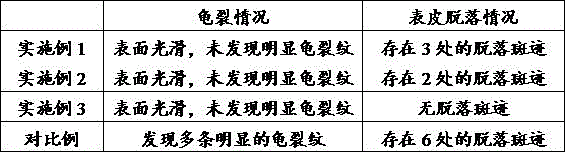

Method for preparing putty powder excellent in cracking resistance

InactiveCN106833088AImprove water resistanceGood gluing propertiesAntifouling/underwater paintsPaints with biocidesMolten stateEpoxy

The invention relates to a method for preparing putty powder excellent in cracking resistance. The putty powder is prepared from, by weight, 20-30 parts of white cement, 10-20 parts of calcium bicarbonate, 25-35 parts of talcum powder, 25-35 parts of ash calcium powder and 2-4 parts of adhesive powder. A preparation method of the adhesive powder includes steps: (1) main agent preparation, to be more specific, taking phenolic resin adhesives as a base material, adjusting a pH value to be neutral, heating to 50-60 DEG C, adding an appropriate amount of epoxy resin, keeping constant-temperature reaction for 5-15min, and cooling to the room temperature; (2) functional agent preparation, to be more specific, uniformly mixing an appropriate amount of propolis powder, water soluble glucan and an antioxidant, heating to 60-70 DEG C to form stable molten-state thick fluid, filtering particle impurities, and keeping for standby application; (3) adhesive powder finished product preparation, to be more specific, well mixing a main agent and a functional agent according to a proper proportion, and performing spray drying to obtain adhesive powder. The putty powder is reasonable in raw material selection and appropriate in compatibility and has advantages of excellent water resistance, bonding performances and antibacterial and anticorrosion performances as compared with existing putty powder.

Owner:WENZHOU CHUYING TECH CO LTD

Antistatic water-soluble latex paint

InactiveCN104650704AHas antistatic effectMeet environmental protection production standardsPolyurea/polyurethane coatingsEmulsion paintsPolyethylene glycolThick fluid

The invention aims to prepare an antistatic water-soluble latex paint which is characterized by being composed of following chemical raw materials: a cationic surfactant dodecyl dimethyl benzene chloride as an antistatic agent, a nonionic surfactant nonylphenol polyoxyethylene ether as an emulsifying agent, high carbonic acid diethanolamide polyoxyethylene ether as an anti-hard water-dispersing agent, a wetting agent high carbonic acid polyethylene glycol ester, a film-forming agent polyurethane, a film-forming agent polyethyl acetate, a nonionic surfactant ethylene glycol polyether as a defoaming agent, acrylic acid silicone oil emulsion as a flatting agent, Cassion as a preservative, ethylene glycol as an anti-freezing agent, hydroxyl cellulose as a thickening agent, calcium carbonate as a whitening agent and pure water. The latex paint has an antistatic effect, is a milky-white thick fluid, is free of generation of foam when being vibrated, is 6-8 in pH, is good in stability, is quite low in human skin irritation and toxin, needs to be stored at an environmental temperature higher than 10 DEG C. The preparation method is free of waste gas, waste water and solid waste and is in conformity with a national environmental production standard.

Owner:TIANJIN BOLAIEN TECH DEV

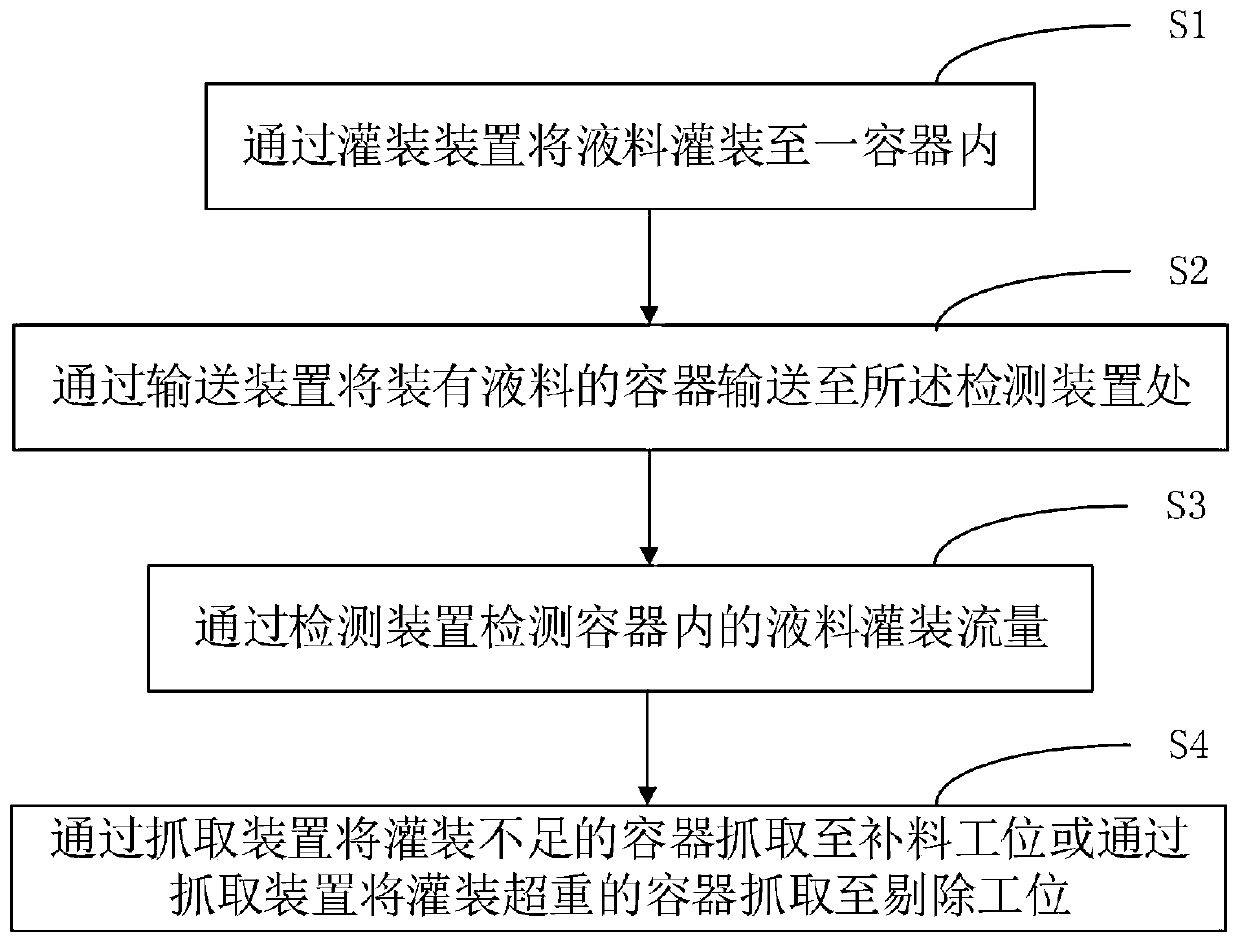

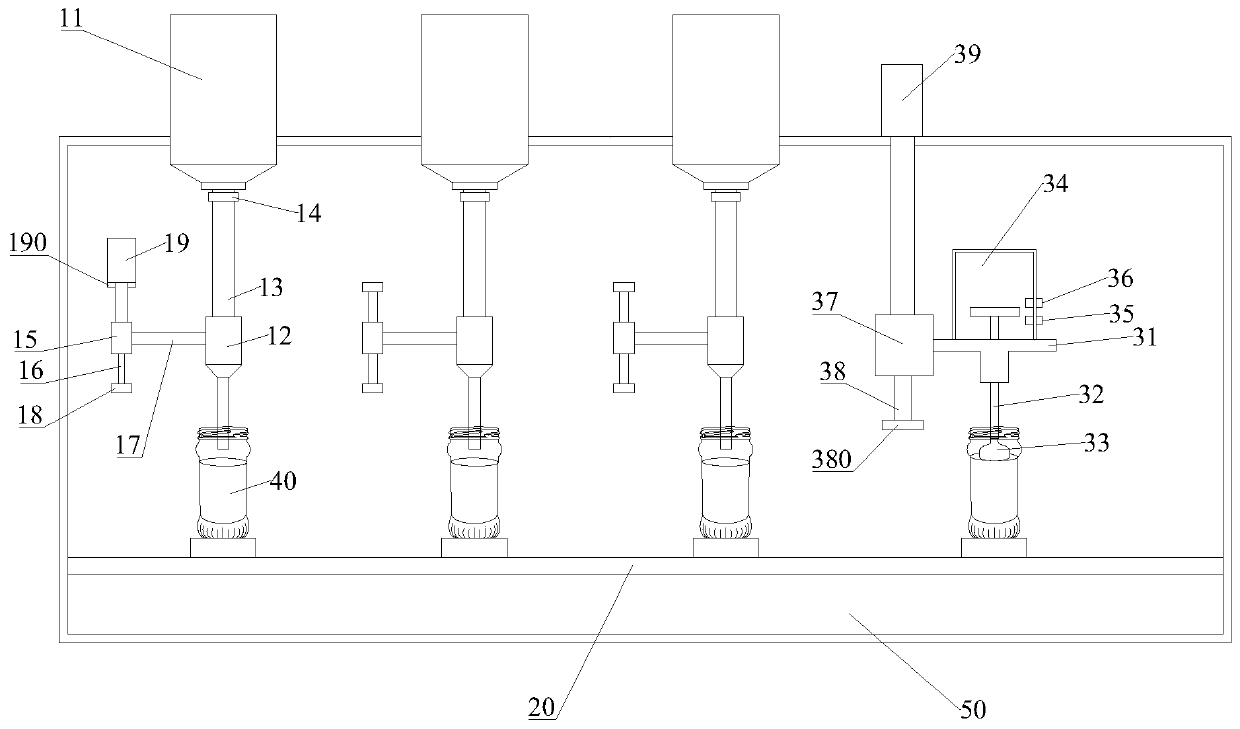

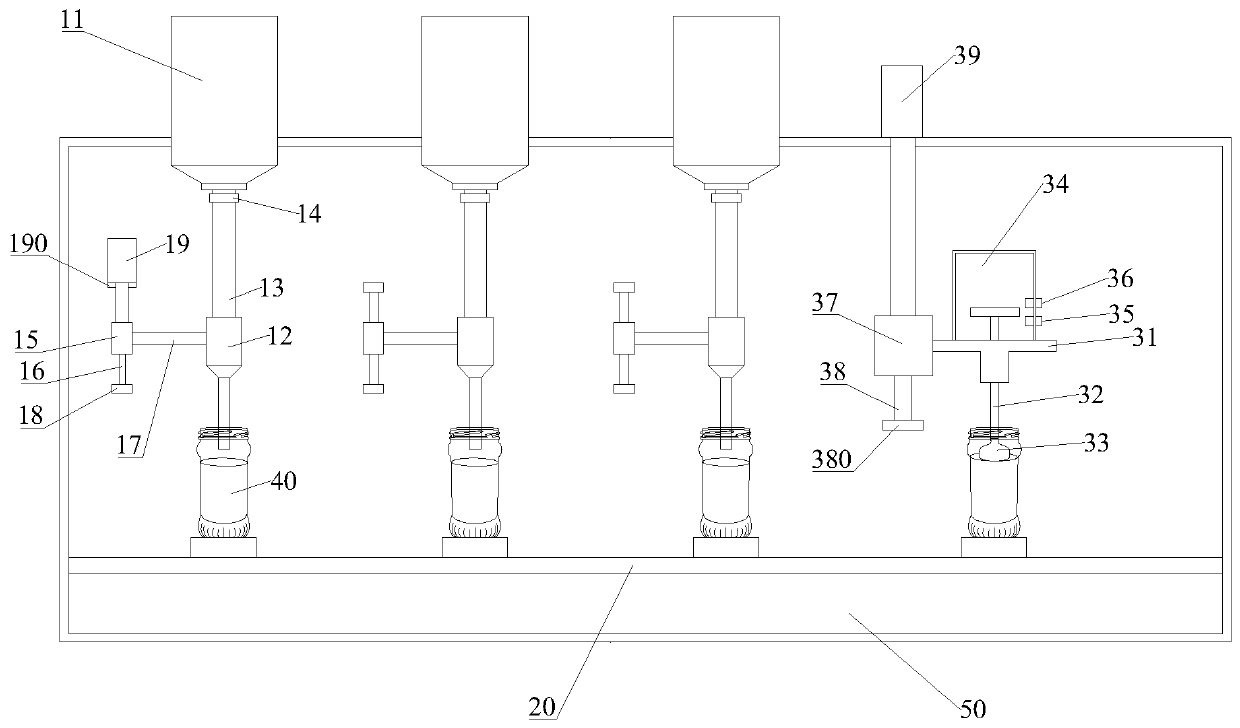

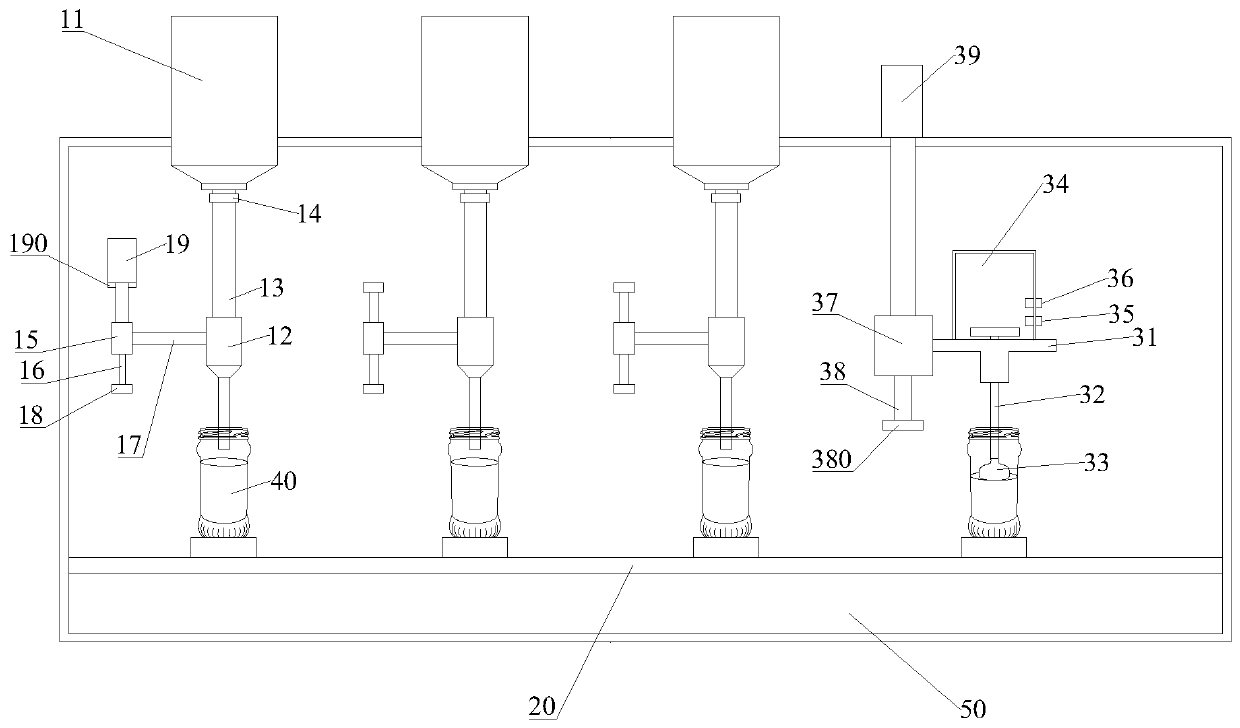

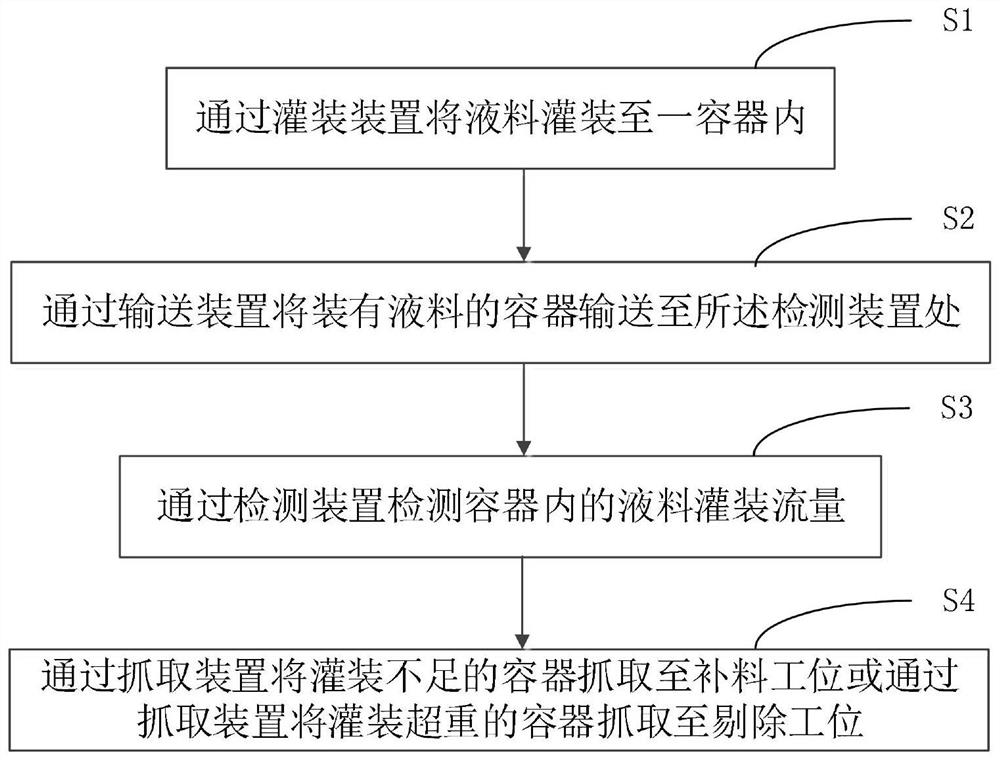

Method for detecting filling flow rate of thick fluid

ActiveCN110759304ARealize monitoringNot affected by viscosityPackaging automatic controlLiquid bottlingThick fluidElectromagnetic valve

The invention relates to the technical field of liquid filling, in particular to a method for detecting filling flow rate of thick fluid. The method comprises the following steps: S1, a container is filled with liquid by a filling device, that is, when the liquid is required for filling, a nozzle driving mechanism is controlled by a control module to drive a nozzle to move downwards, so that the blanking end of the nozzle extends into an opening of the container, an electromagnetic valve is also controlled by the control module to be opened, and the liquid in the tank flows into the nozzle viaa pipe and then flows into the container; S2, the container filled with the liquid is conveyed to a detection device by a conveying device; S3, the filling flow rate of the liquid in the container isdetected by the detection device; S4, a grabbing device grabs the under-filled container to the supplementing station or grabs the over-filled container to the rejecting station. The flow rate of theliquid in the container filled with the liquid can be detected by the filling device, the filling flow rate is monitored, and filling quality is improved.

Owner:HUNAN UNIV OF TECH

Fluid collector

The invention relates to a fluid collector, which comprises a collecting bottle body, a collecting body and a cover body, wherein the collecting body is matched with the collecting bottle body to be used; the cover body is hinged onto the collecting body; the collecting body comprises a collecting part and a connecting part; the upper surface of the collecting part is inwards recessed for forming a collecting surface; a collecting hole is formed in the collecting surface; the collecting hole is matched with a matching hole formed in the surface of the connecting part to form a fluid passage communicated to the inside of the collecting bottle body; the collecting part is provided with a ventilation part; an outlet of the ventilation part is higher than the collecting surface; the collecting part is provided with a ventilation auxiliary hole for communicating the bottle body and the ventilation part; the collecting part and the connecting part can relatively move in the circumferential direction. The fluid collector has the advantages that the fluid collection can be performed by the recessed collecting surface of the collecting part; the balance of air pressure inside the bottle and at the outside can be ensured by the ventilation part isolated from the collecting part; the fluid, particularly thick fluid is enabled to smoothly enter the bottle body; an outlet of the ventilation part is arranged in a way of avoiding the direction rightly aligned with the collecting direction; the fluid can be effectively prevented from entering the ventilation part; the ventilation effect is effectively ensured.

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

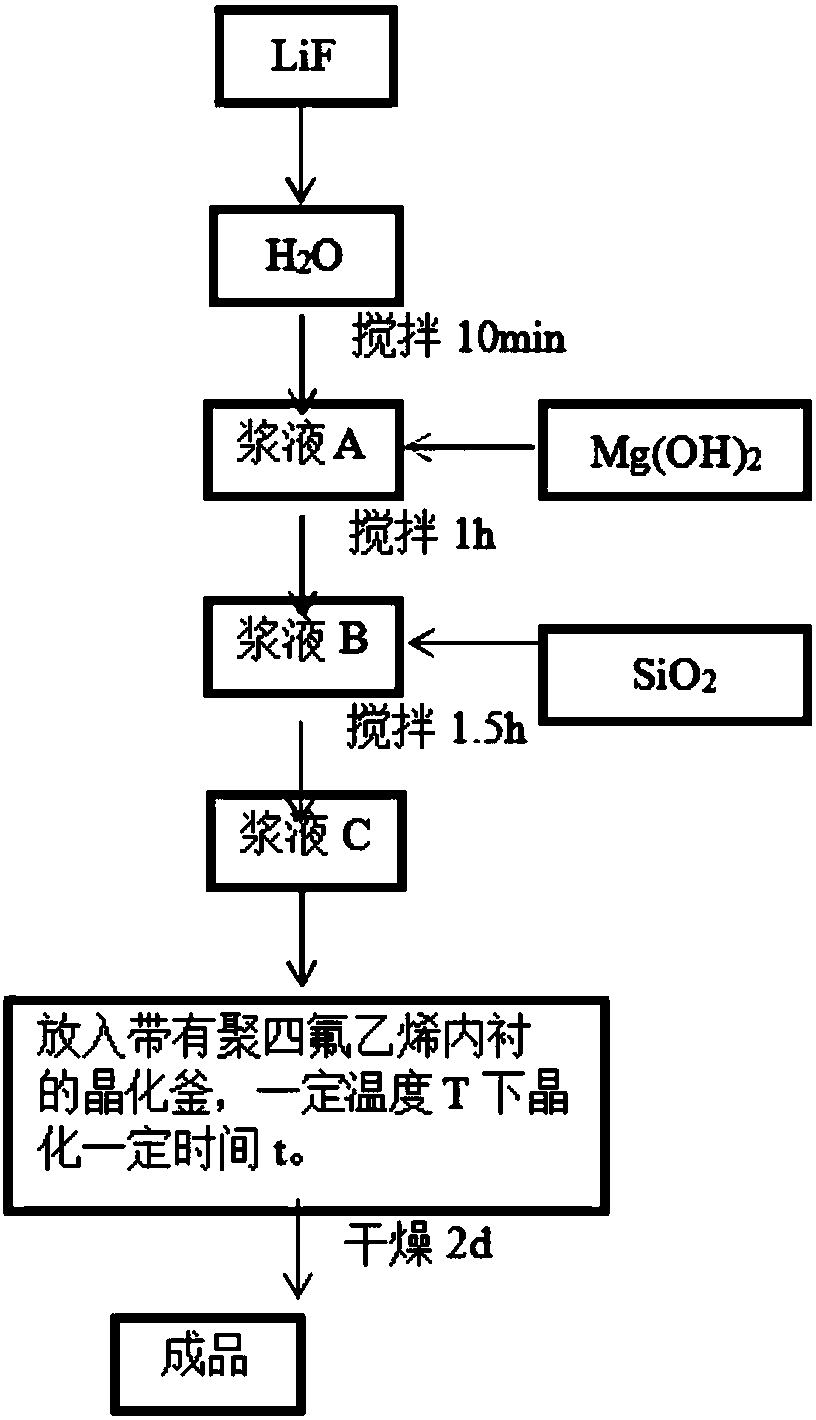

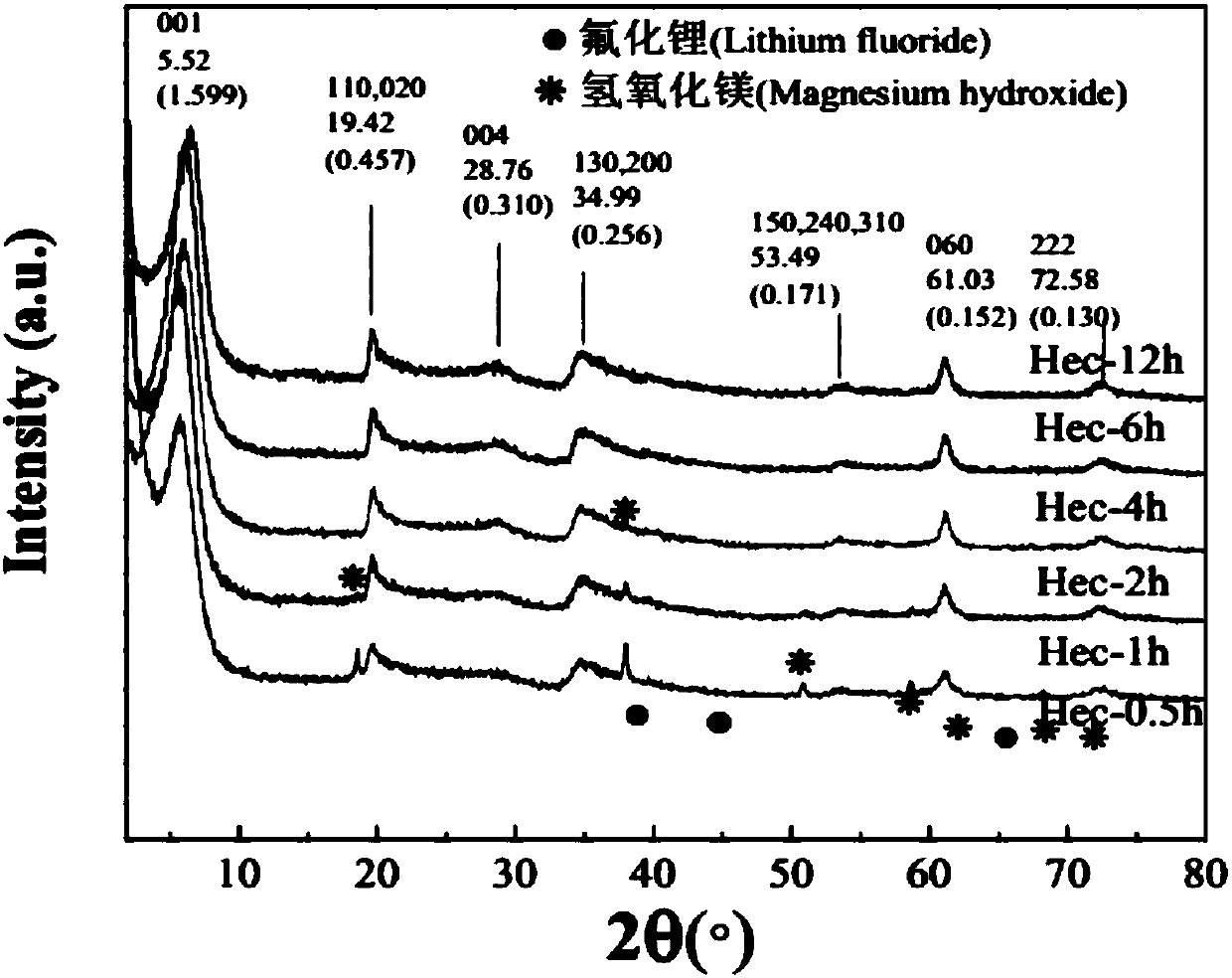

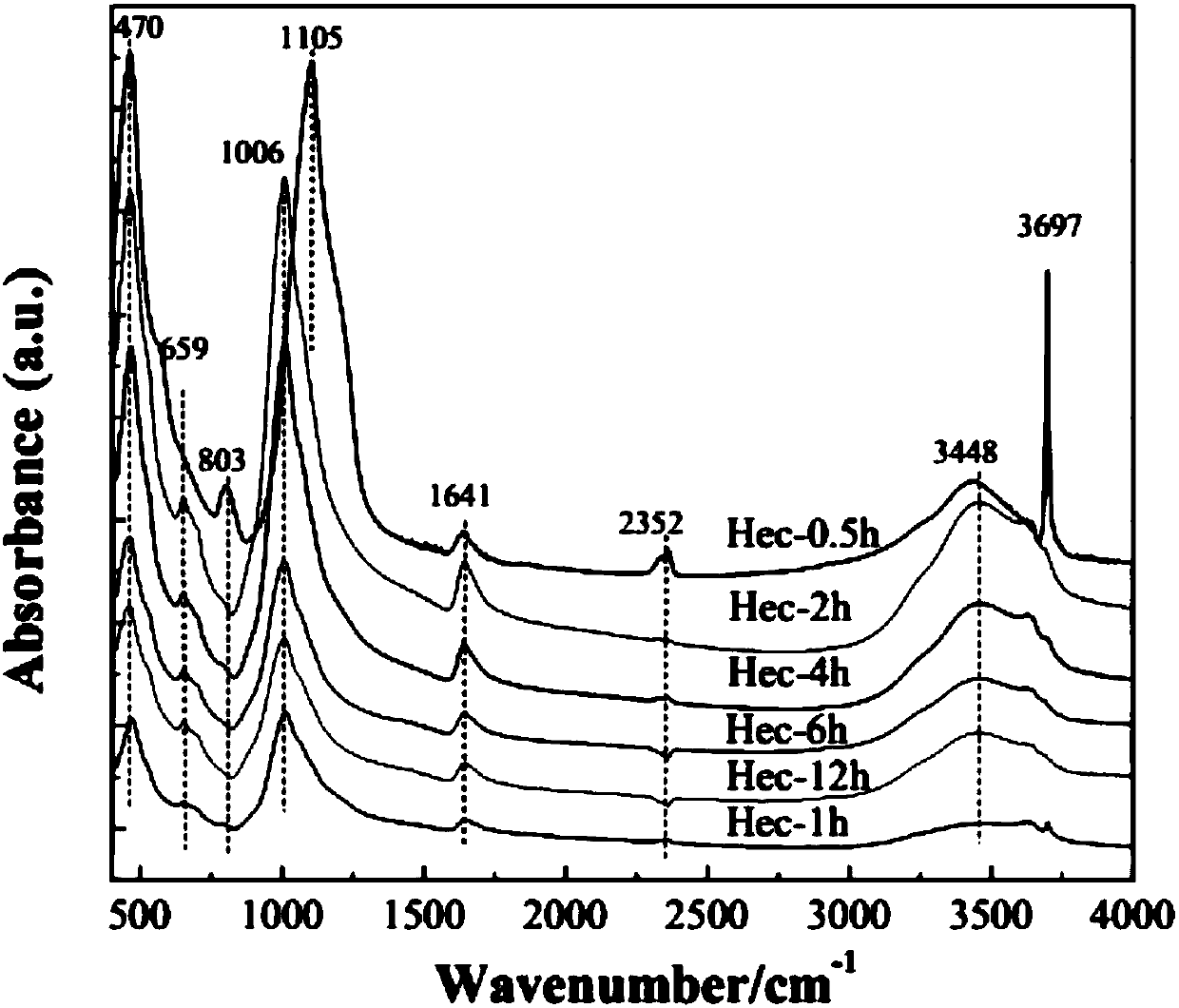

Artificial hectorite and preparation method thereof

The invention discloses artificial hectorite and a preparation method thereof. The preparation method comprises the steps of: stirring deionized water and LiF evenly to obtain thick fluid A, putting Mg(OH)2 in the thick fluid A, performing even stirring to obtain thick fluid B, adding SiO2 into the thick fluid B, and performing even stirring to obtain thick fluid C; performing crystallization on the thick fluid C at 180+ / -10 DEG C, and performing drying to obtain the hectorite. According to the artificial hectorite and the preparation method thereof, an artificial hydrothermal method is adopted, and Mg(OH)2, SiO2 and LiF are used as the raw materials, so that the novel artificial hectorite is obtained; the problems of harsh reaction conditions, high raw material cost and the like in a traditional process are solved, energy saving and emission reduction can be achieved, and the product can be optimized.

Owner:南京工业大学连云港工业技术研究院

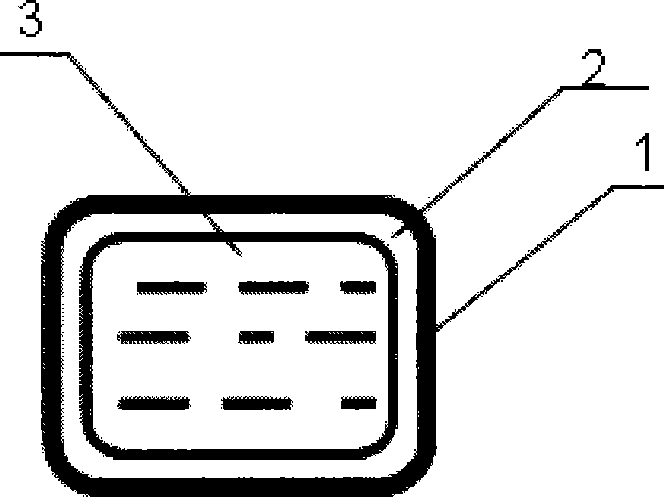

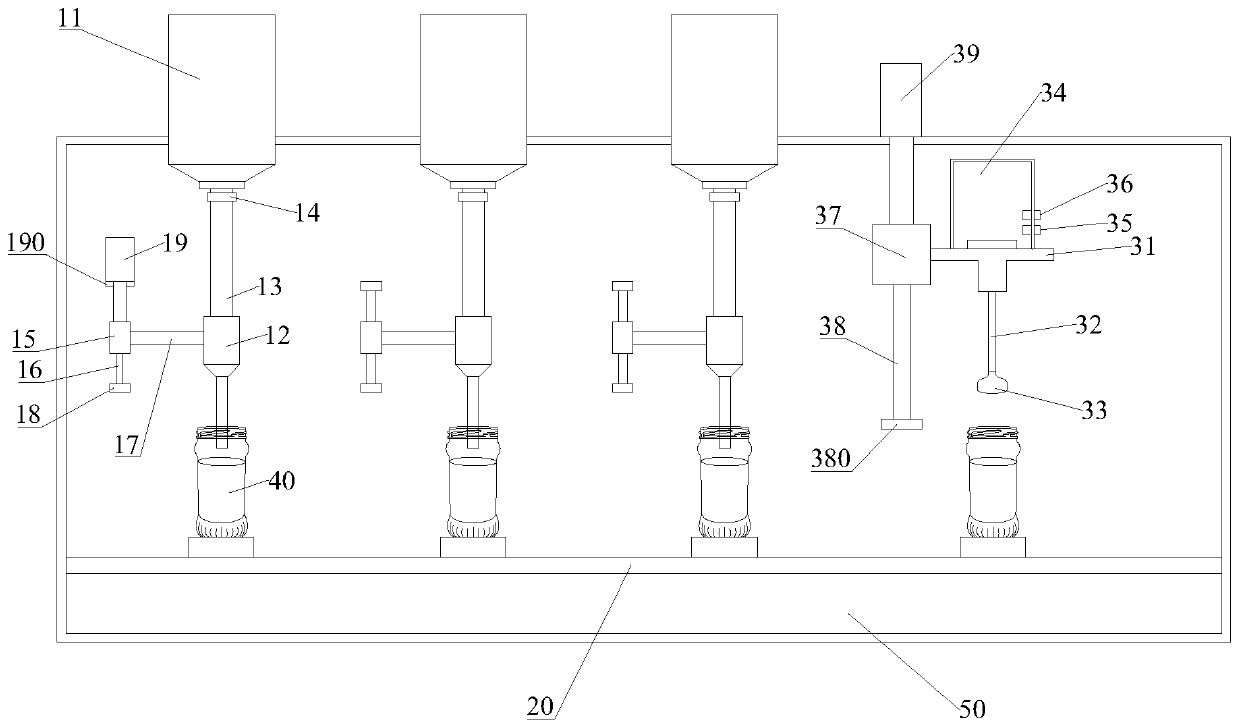

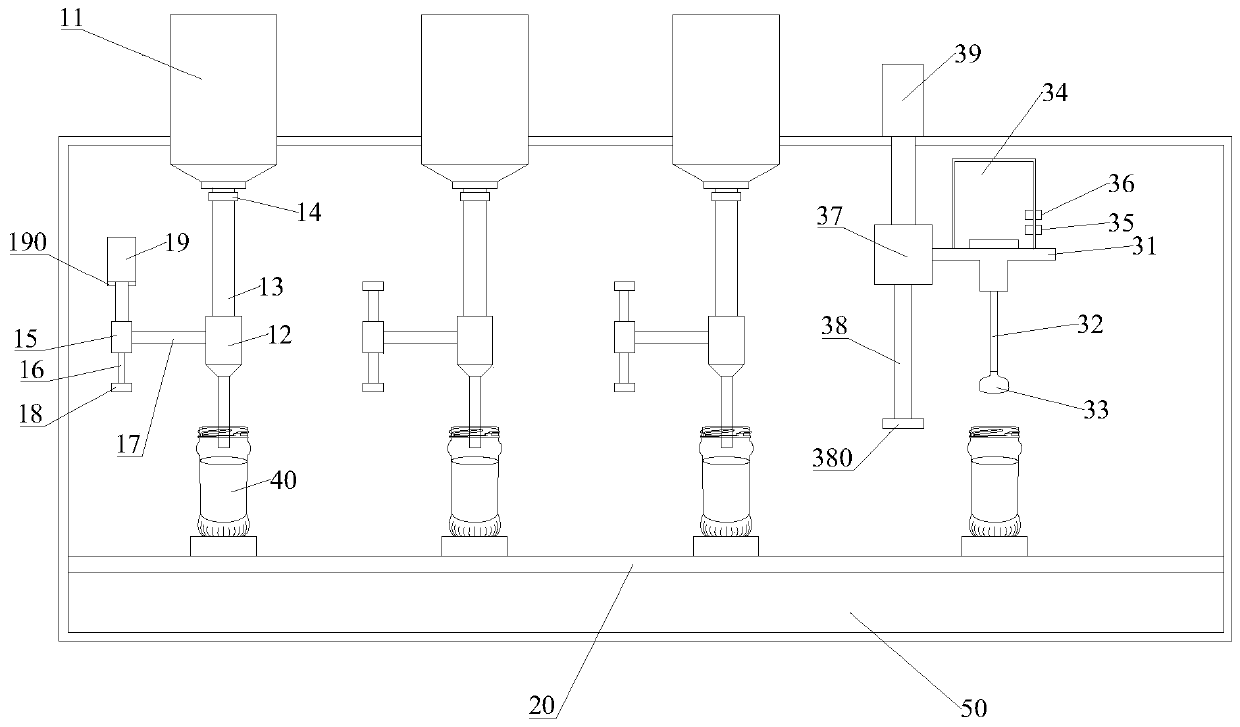

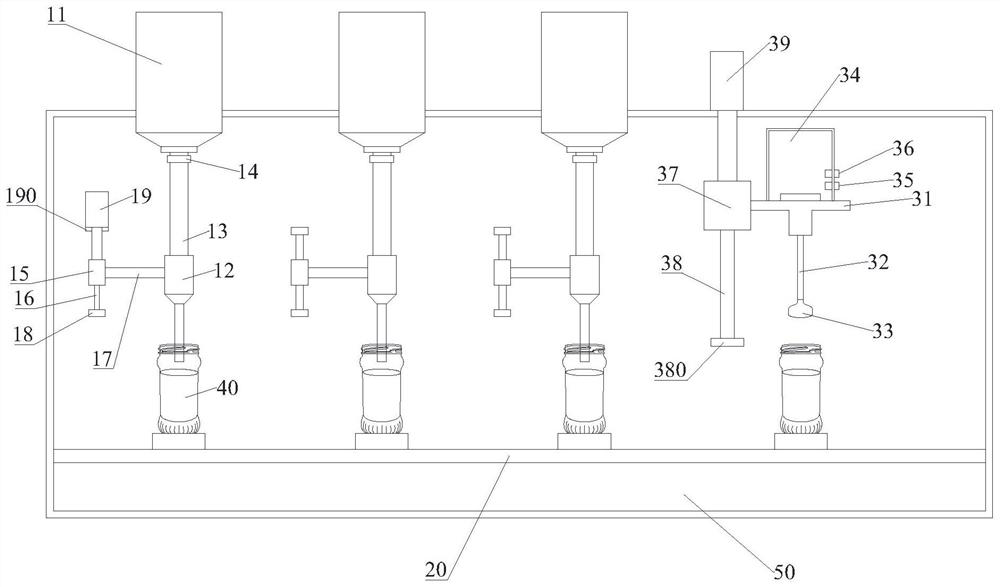

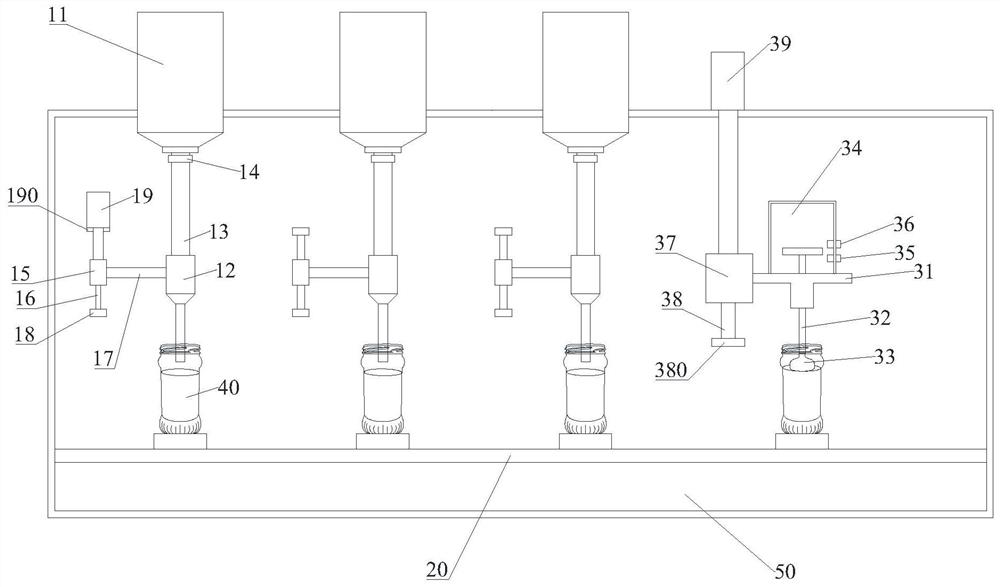

Thick fluid filling system

PendingCN110655028ANot affected by viscosityRealize monitoringLiquid bottlingMechanical engineeringThick fluid

The invention relates to the technical field of liquid material filling, in particular to a thick fluid filling system which includes a control module, a filling device, a conveying device and a detection device. The filling device, the conveying device and the detection device are controlled by the control module, wherein the filling device is suitable for filling a liquid material into a container; the conveying device is suitable for conveying the container containing the liquid material to the detecting device; and the detecting device is suitable for detecting the liquid material fillingflow rate in the container. The thick fluid filling system can detect the liquid material flow rate in the container filled with the liquid material through the filling device through the detection device, monitoring of the filling flow rate is realized, and the filling quality is improved; meanwhile, a flow rate detection mechanism used by the thick fluid filling system is not affected by the consistency of the liquid material, and the detection accuracy of the liquid level of the liquid material is high.

Owner:HUNAN UNIV OF TECH

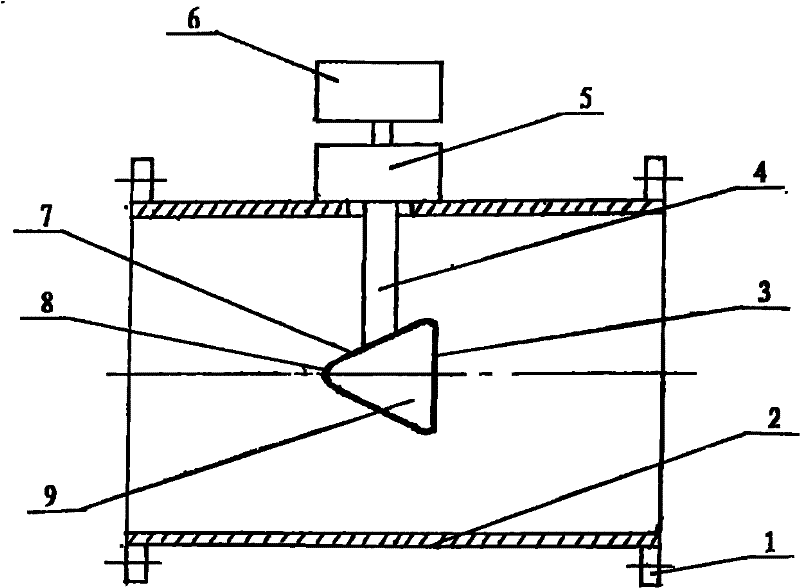

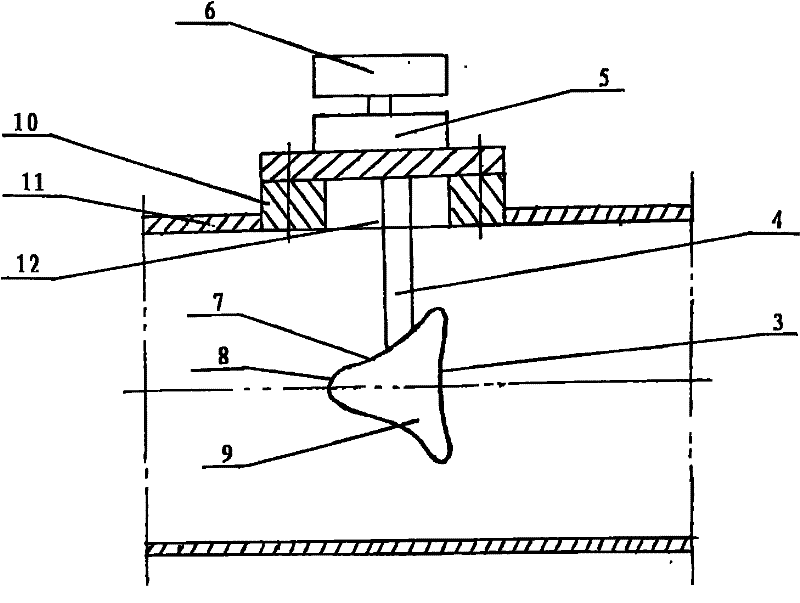

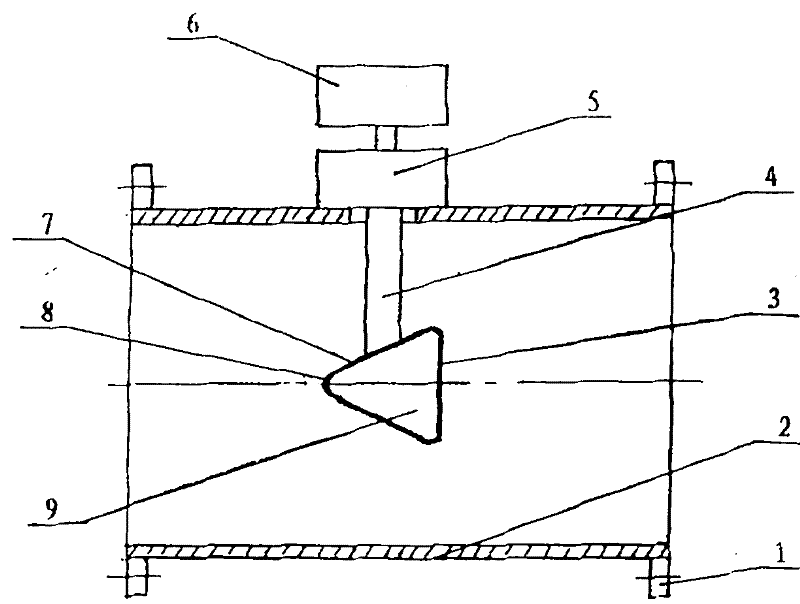

T-shaped flow meter

InactiveCN101806603BAvoid jitterSave energyVolume meteringVolume/mass flow by dynamic fluid flow effectDouble phaseEngineering

Owner:林福成 +1

A method for detecting the filling flow rate of thick fluid

ActiveCN110759304BRealize monitoringNot affected by viscosityPackaging automatic controlLiquid bottlingSolenoid valveEngineering

The present invention relates to the technical field of liquid material filling, in particular to a thick fluid filling flow detection method, comprising: step S1, filling the liquid material into a container through a filling device, that is, when the liquid material needs to be filled, Control the material nozzle driving mechanism through the control module to drive the material nozzle to move downward, so that the feeding end of the material nozzle extends into the container mouth; and control the solenoid valve to open through the control module, so that the liquid material in the material tank flows into the material nozzle through the material pipe and then flow into the container; step S2, transport the container containing the liquid material to the detection device through the conveying device; step S3, detect the filling flow rate of the liquid material in the container through the detection device; and step S4, by grasping The picking device grabs the underfilled container to the filling station or grabs the overfilled container to the rejecting station through the grabbing device. The invention can detect the flow rate of the liquid material in the container filled with the liquid material by the filling device, realize the monitoring of the filling flow rate and improve the filling quality.

Owner:HUNAN UNIV OF TECH

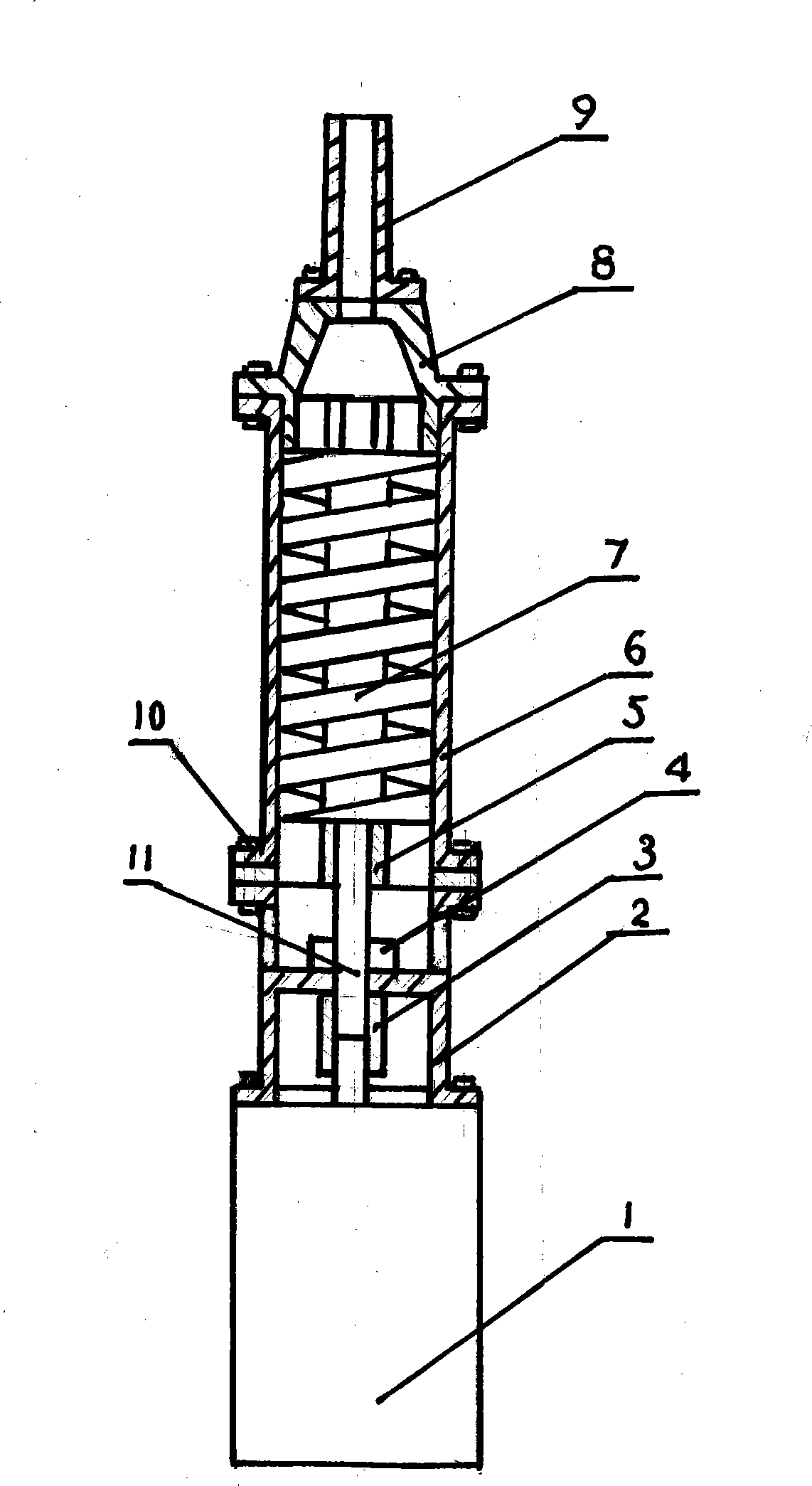

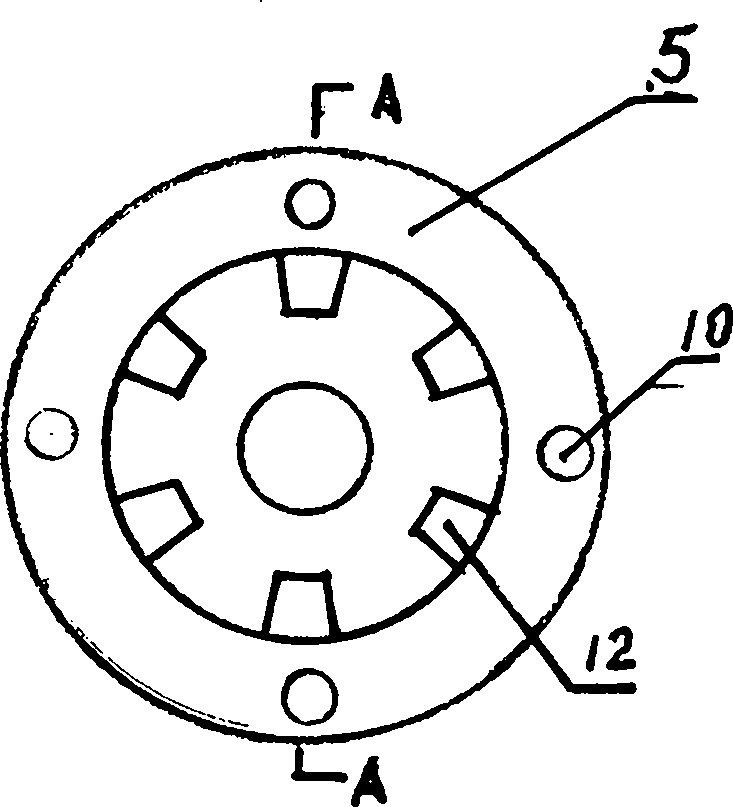

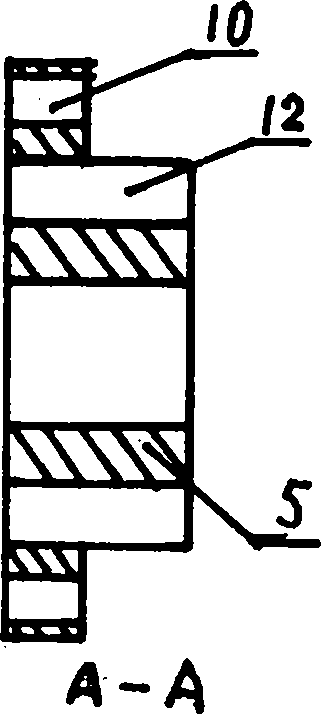

Single-rod multi-head transecting spiral submersible pump

InactiveCN102374175BPull out forcefullyStrong discharge pressurePump installationsAxial flow pumpsCouplingThrust bearing

The invention belongs to a pump, and in particular relates to a single-rod multi-head transecting spiral submersible pump. The single-rod multi-head transecting spiral submersible pump consists of a submersible motor, a motor bracket, a coupling, a suction and drainage disk, a thrust bearing, a multi-head spiral rotor, a shell, a gathering and delivering section, a discharge pipe and bolts, wherein the submersible motor is connected with the suction and drainage disk through the motor bracket and the coupling; the thrust bearing is arranged on a main shaft; the multi-head spiral rotor is machined on the main shaft; the tooth end face of the multi-head spiral rotor is matched with the rotary sliding surface of the suction and drainage disk; the shell is connected with the suction and drainage disk through the bolts; and the upper end of the shell is connected with the gathering and delivering section and the discharge pipe. The single-rod multi-head transecting spiral submersible pump has the advantages of strong discharge pressure, a few structural moving components, long service life and low cost, is particularly suitable for thick fluid media and long-distance transmission, and has the characteristics of energy conservation and high efficiency.

Owner:石增辉

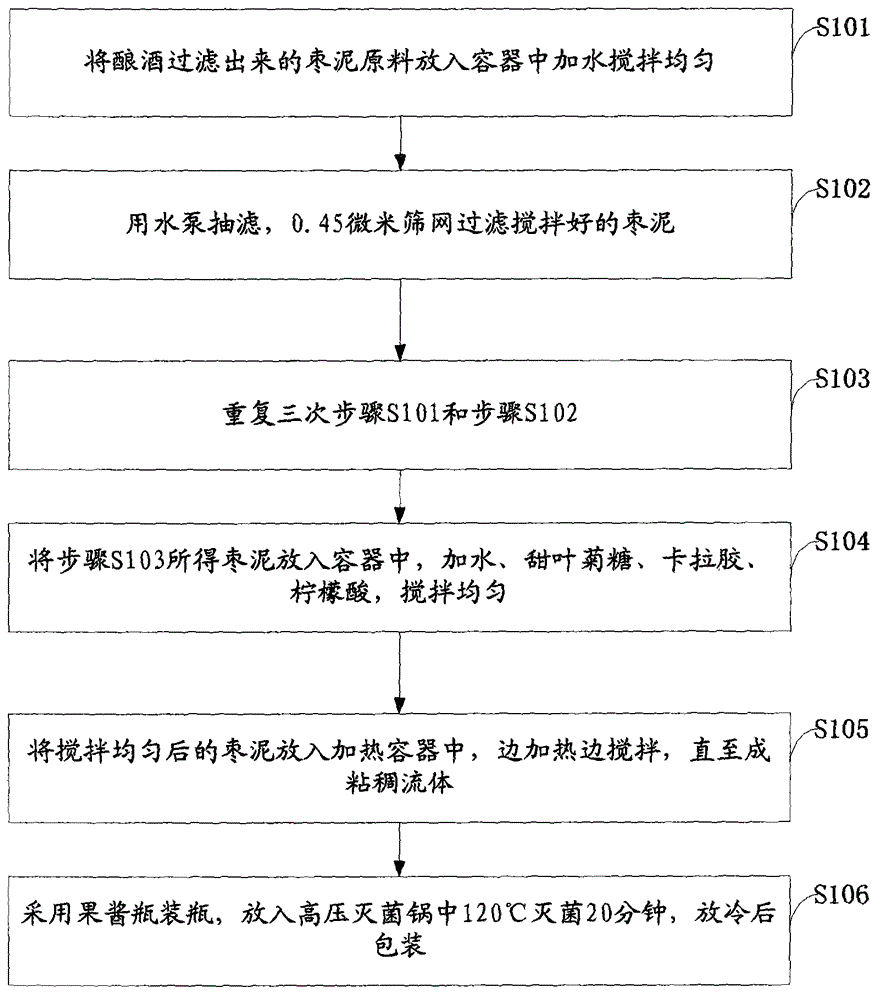

Low-sugar date jam production method

The invention discloses a low-sugar date jam production method comprising the following steps: (1) filling a container with a date paste raw material obtained through filtration of liquor brewing, and adding water to the date paste and stirring the date paste uniformly; (2) performing suction filtration with a water pump, and sieving the filtered and stirred date paste through a 0.45 [mu]m screen; (3) repeatedly doing the step (1) and the step (2) for three times; (4) placing the date paste in the step (3) into the container, adding water, stevioside, carrageenan and citric acid and stirring uniformly the mixture; (5) placing the stirred date paste mixture into a heating container, and heating and stirring the date paste mixture until a thick fluid is formed; and (6) performing high-pressure sterilization. In the invention, the date paste obtained from liquor brewing with dates is employed as the raw material, wherein no preservative is added and the stevioside is employed as a natural sweetening agent, so that the date jam is high in sweetness and is low in calorie, and is suitable for people requiring low-sugar diet. The sour and astringent taste can be eliminated through the washing and filtering process. By means of addition of a proper amount of citric acid, sweet and sour ratio can be regulated so that the date jam is more delicious.

Owner:FUYANG CITY ACADEMY OF AGRI SCI

Three-color wire cable jacket extrusion mold

InactiveCN101635191BEasy to identifyGood symmetryConductor/cable markingInsulating conductors/cablesEngineeringThick fluid

The invention relates to a wire cable jacket extrusion mold, in particular to a three-color wire cable extrusion mold, comprising a mold core unit (1), a first mold cover unit (2) and a mold sleeve unit (3). The three-color cable jacket extrusion mold is characterized by further comprising a second mold cover unit (4), a plurality of flow guiding rods (6) and a fluid director (5); and the axes ofa color distribution hole (34) and the axes of the first mold cover unit (2) form an included angle larger than 5 DEG and less than 175 DEG. The three-color wire cable extrusion mold solves the problem in one-step extrusion of three color marks at one pipeline or the out surface of one wire cable. The invention is easy to install and adjust and coincides with the principle of thick fluid hydromechanics better; and with even distribution of color strips, produced optical cables, cables and pipelines are more attractive.

Owner:SURFACE ENGINEERING RESEARCH CENTER OF NINGBO

Pump head pressing thick liquid backflow mechanism

InactiveCN112027338ALiquid residueWill not remainClosuresSingle-unit apparatusChemical productsPump head

The invention relates to the technical field of daily chemical products, and discloses a pump head pressing thick liquid backflow mechanism. The thick liquid backflow mechanism comprises a shell, a liquid suction pipe is fixedly connected to the lower end of the shell, a spring is fixedly connected to the lower surface of an inner cavity of the shell, and a valve ball located in the middle of thespring is movably placed in the middle of the lower end of the inner cavity of the shell. According to the thick liquid backflow mechanism, through additionally arranging the liquid backflow mechanism, when thick liquid is extruded, a filling block moves downwards, the liquid in an adjusting cavity flows into a liquid conveying pipe through a liquid passing groove and is discharged outwards, whena pump head is released, the pump head automatically resets under the action of the spring, the filling block moves upwards, and a negative pressure cavity is formed in the adjusting cavity; and due to the fact that the liquid passing groove is separated from the middle of the inner cavity of the shell under the staggered condition, the adjusting cavity sucks fluid in an inner cavity of the liquidconveying pipe for negative-pressure filling, part of thick fluid at the extrusion end of the liquid conveying pipe can be sucked inwards, and no liquid remains at the extrusion end of the liquid conveying pipe after extrusion is completed.

Owner:周勇

Antistatic indoor wall decorative coating

InactiveCN104650662APrevent or block attachmentHas antistatic effectCoatingsGlycerolCarvacryl acetate

The invention aims to provide an antistatic indoor wall decorative coating which is composed of following chemical raw materials: 1-2% of a cationic surfactant alkyltrimethyl ammonium chloride as an antistatic agent, 2-4% of a nonionic surfactant high-carbon alcohol diethanolamide as an emulsifying agent, 0.5-1% of a nonionic surfactant glycerol polyether as a defoaming agent, 0.5-1% of caisson as a preservative, 4-6% of glycol as an anti-freezing agent, 1-3% of a styrene-acrylate copolymer as a film-forming binding agent, 2-4% of a vinyl acetate polymer as a film-forming binding agent, 15-25% of titanium dioxide powder as a whitening agent, 15-25% of talcum powder as a whitening agent and 40-60% of pure water. In the antistatic agent alkyltrimethyl ammonium chloride, the number of carbon in alkyl is 16-18. The antistatic indoor wall decorative coating has an antistatic effect and can prevent or stop dust to adsorb on the surface of the internal wall coating. The antistatic indoor wall decorative coating is milky-white thick fluid in appearance, is water-soluble, is free of foam when being vibrated, is 1.5-2.0H in hardness, is 6-8 in pH, is very low in stimulation on human skin and is very low in toxin.

Owner:TIANJIN BOLAIEN TECH DEV

Hand pump type thick liquid packaging bottle

Disclosed is a hand-extrusion pumping magma packing bottle, belonging to the field of packing container. The liquid in the bottle can be tapped off with a single hand and without inverting the bottle. And no liquid flows out when the bottleneck is re-closed. The bottleneck is equipped with parallel elastic leading-out air pressure valve and the elastic leading-in air pressure valve, which form a pump operated by hand, the pump leading the liquid in bottle out continuously.

Owner:刘强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com