T-shaped flow meter

A flowmeter and flow measurement technology, applied in volume measurement, liquid/fluid solid measurement, measurement device and other directions, can solve the problems of reducing measurement accuracy, transmission signal fluctuation, consumption of fluid energy, etc., to achieve stable and reliable operation, easy installation and use , the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

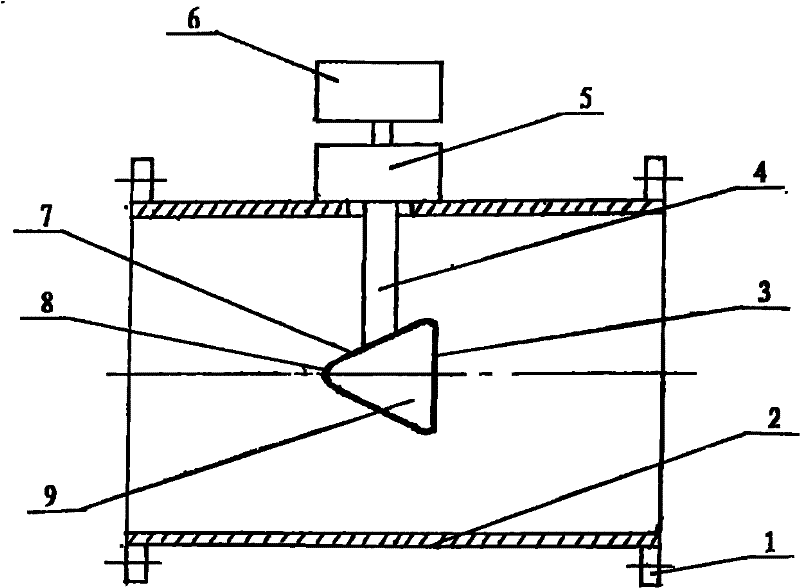

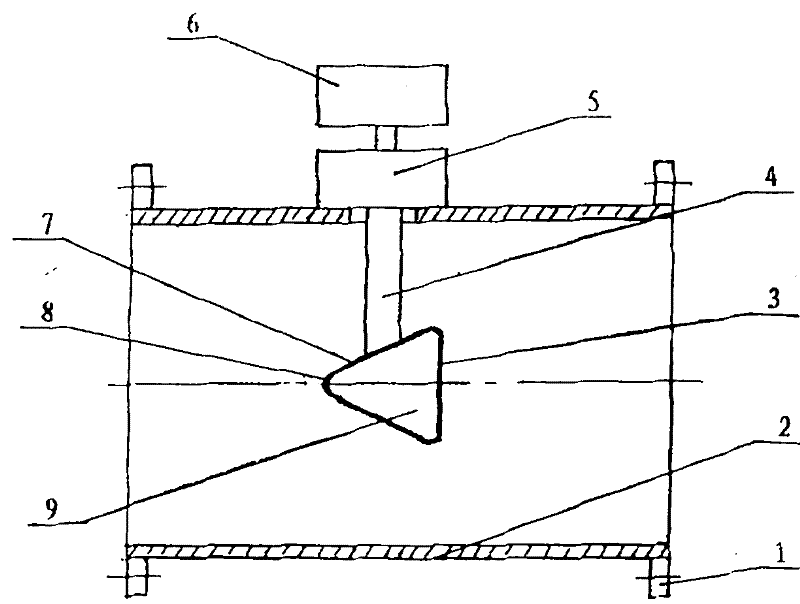

[0011] figure 1 Among them, a T-shaped polyhedron flow measuring element 9 is arranged in the middle of the measuring tube 2 with an inner diameter of 300mm, and the flow measuring element 9 is connected with the conversion unit 5 arranged outside the measuring tube 2 through the force rod 4 connected thereto, and the conversion unit 5 and The computing display unit 6 is connected. And the measuring pipe 2 is connected with the process pipeline flange through the flange 1 connected therewith, which is convenient for on-site installation and disassembly. The upstream surface 3 of the T-shaped polyhedron flow measuring element 9 is a plane with an outer diameter of 100mm, and the downstream surface 7 is a cone, the outer surface of which is a slope, and the cone angle is 60°. The top is a hemisphere 8 that is smoothly connected with the cone and has a radius of 20mm. The flow measuring element 9 is made of plastic sprayed or covered with corrosion-resistant materials; it can a...

Embodiment 2

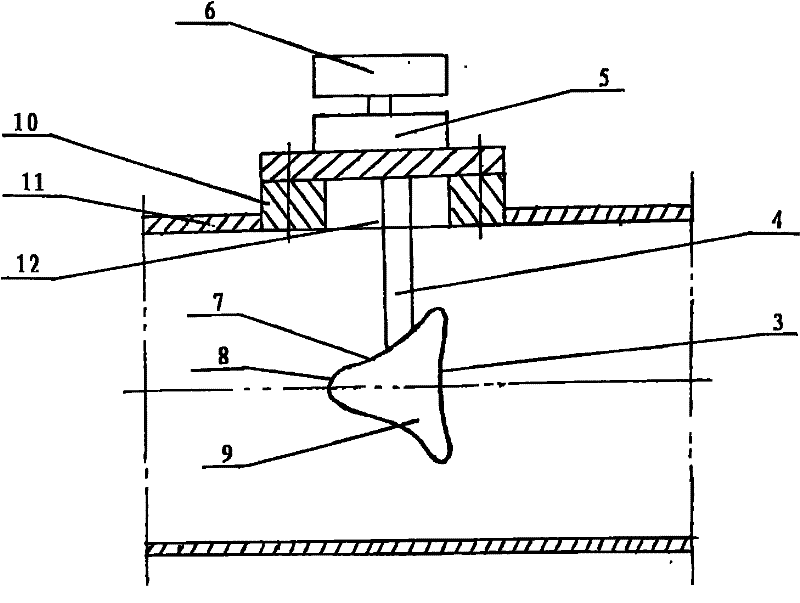

[0014] figure 2 Among them, the upstream surface 3 of the T-shaped polyhedron flow measuring element 9 is a concave arc surface, the downstream surface 7 is a cone, and its outer surface is a concave arc surface, and the top of the downstream surface 7 is smoothly connected with the cone. hemisphere8.

[0015] figure 2 What is shown is a plug-in connection structure between the T-shaped polyhedron flow measuring element 9 and the measuring tube, which is suitable for installation and use during equipment overhaul in existing pipelines. The specific connection method is: the process pipeline 11 is used as the measuring tube of the flowmeter, a rectangular groove is arranged on the pipeline wall of the process pipeline 11 along the pipeline axial direction, and a base 10 is fixedly connected to the pipeline wall at the position of the groove, There is a central hole 12 in the base 10 through which the T-shaped polyhedron flow measuring element 9 can pass. When the T-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com