Patents

Literature

191results about How to "Eliminate adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

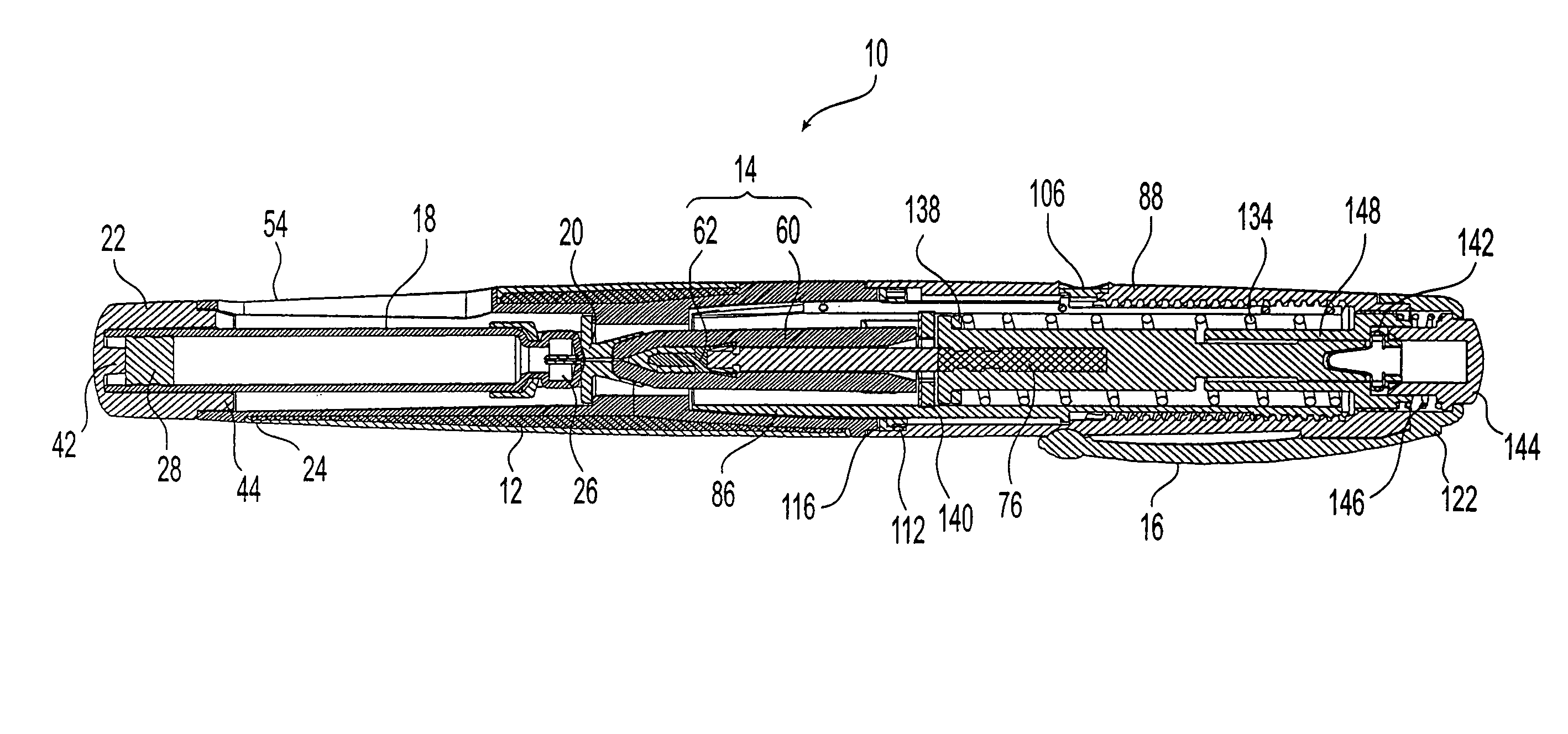

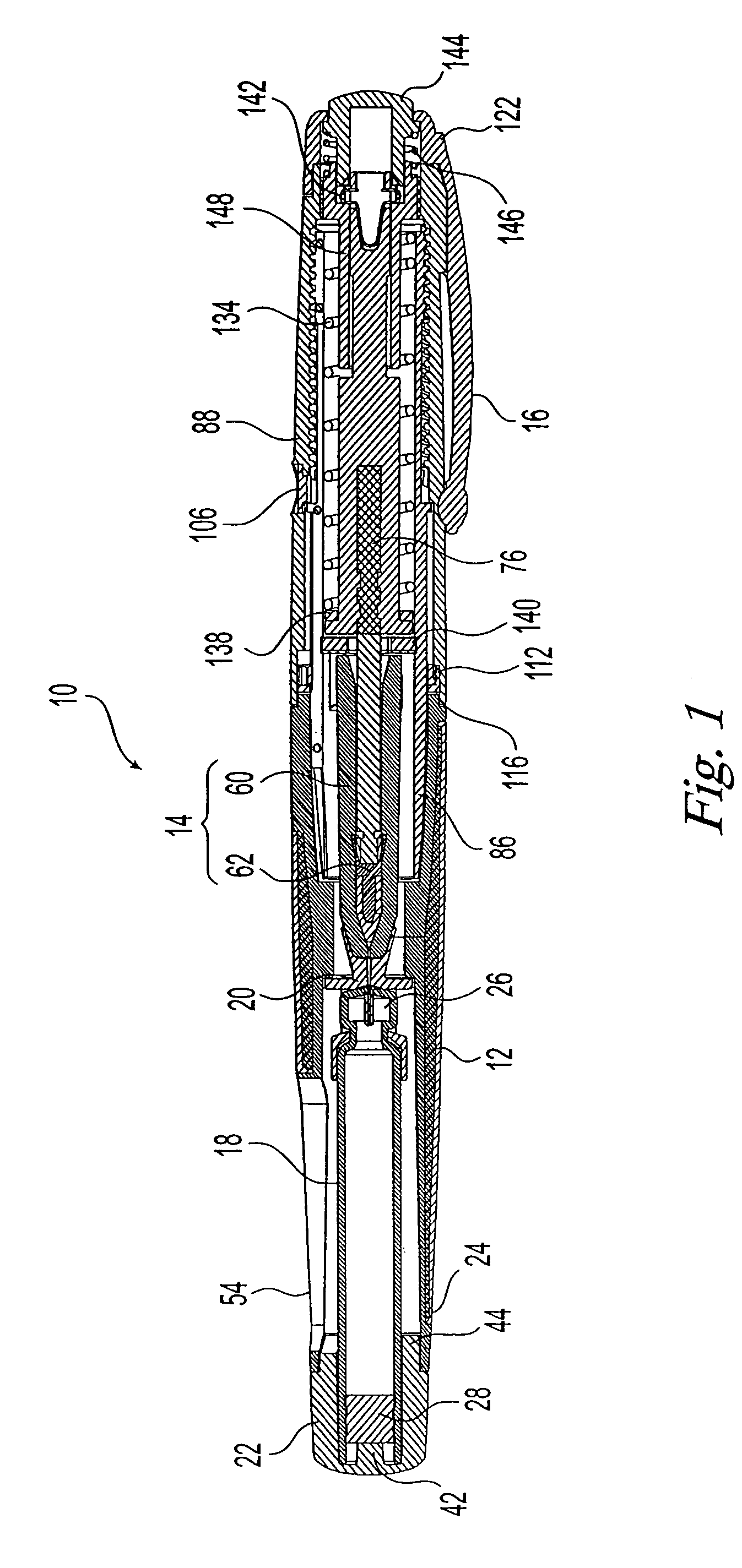

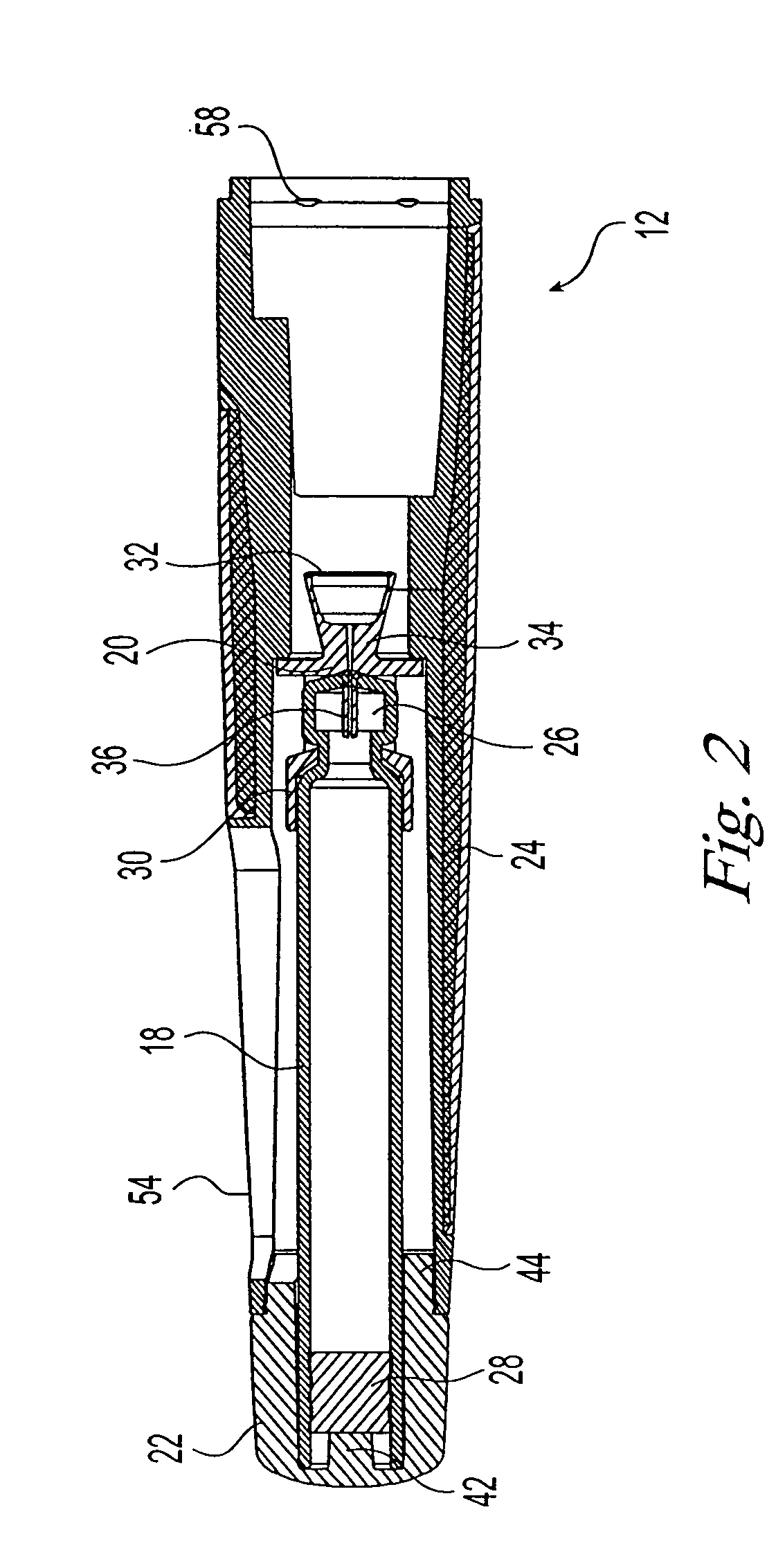

Medical injector and medicament loading system for use therewith

InactiveUS7341575B2Eliminate adhesionImprove accuracyAmpoule syringesJet injection syringesNeedle Free InjectionNeedle free

The present invention discloses a medical injector and medicament loading system for use therewith. The medicament loading system includes cap for a medicament cartridge. The cap has a post for causing movement of the cartridge stopper toward the seal when the cap engages the medicament cartridge to thereby eliminate adhesion between the medicament chamber and the stopper. The medical injector according to the present invention includes the medicament loading system, i.e., a cartridge assembly, a needle free syringe assembly, and a power pack assembly.

Owner:FERRING INT CENT SA

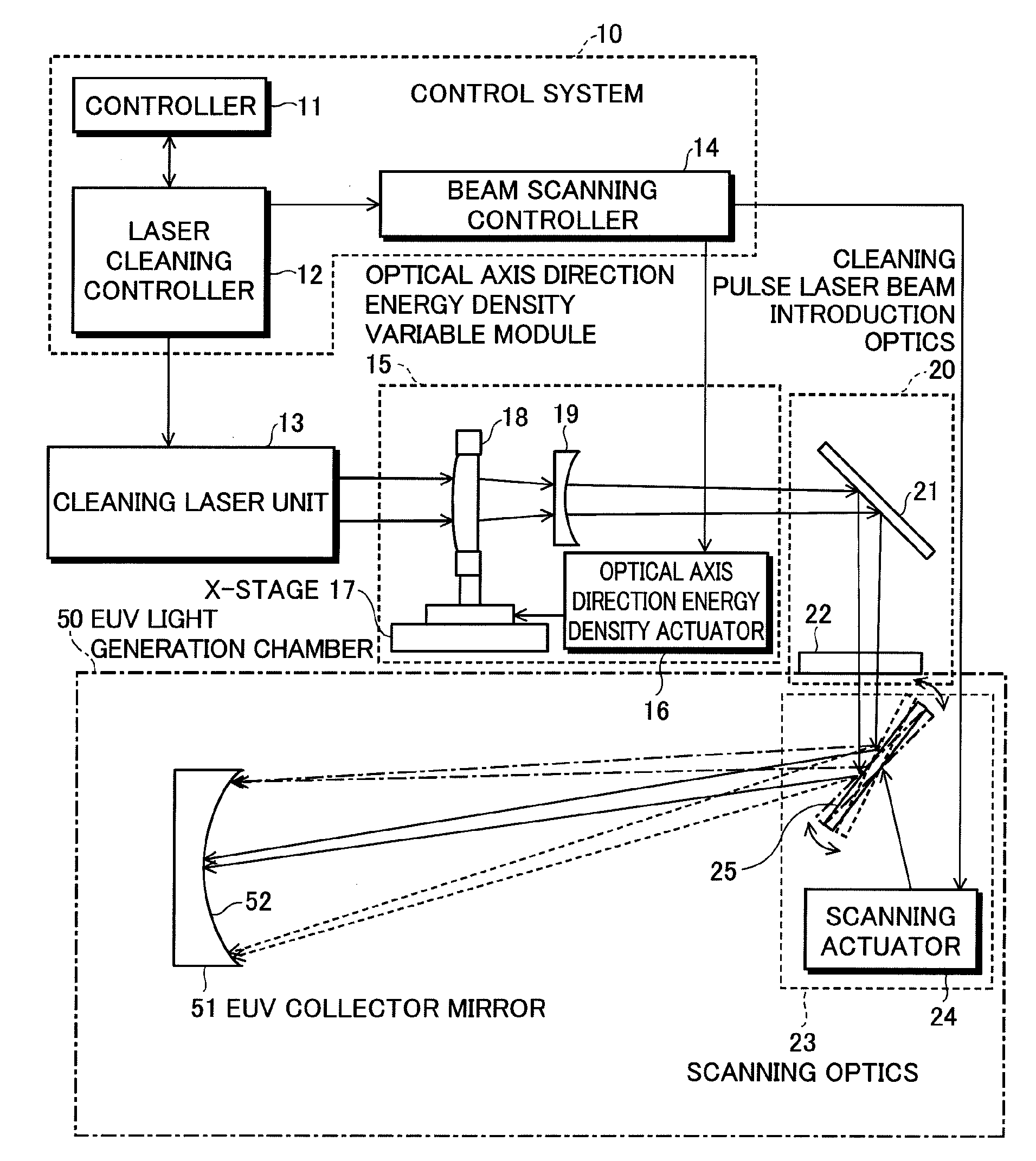

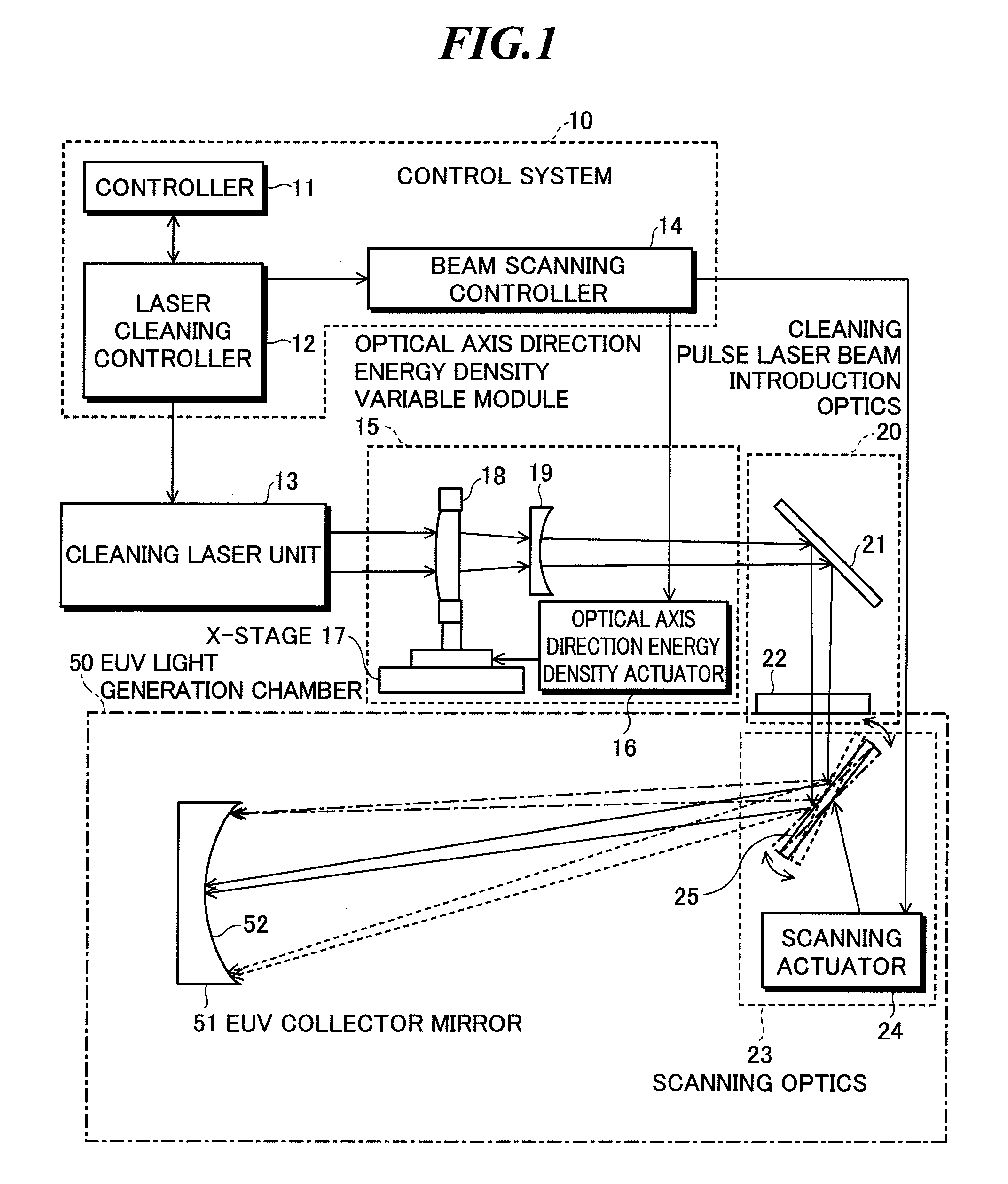

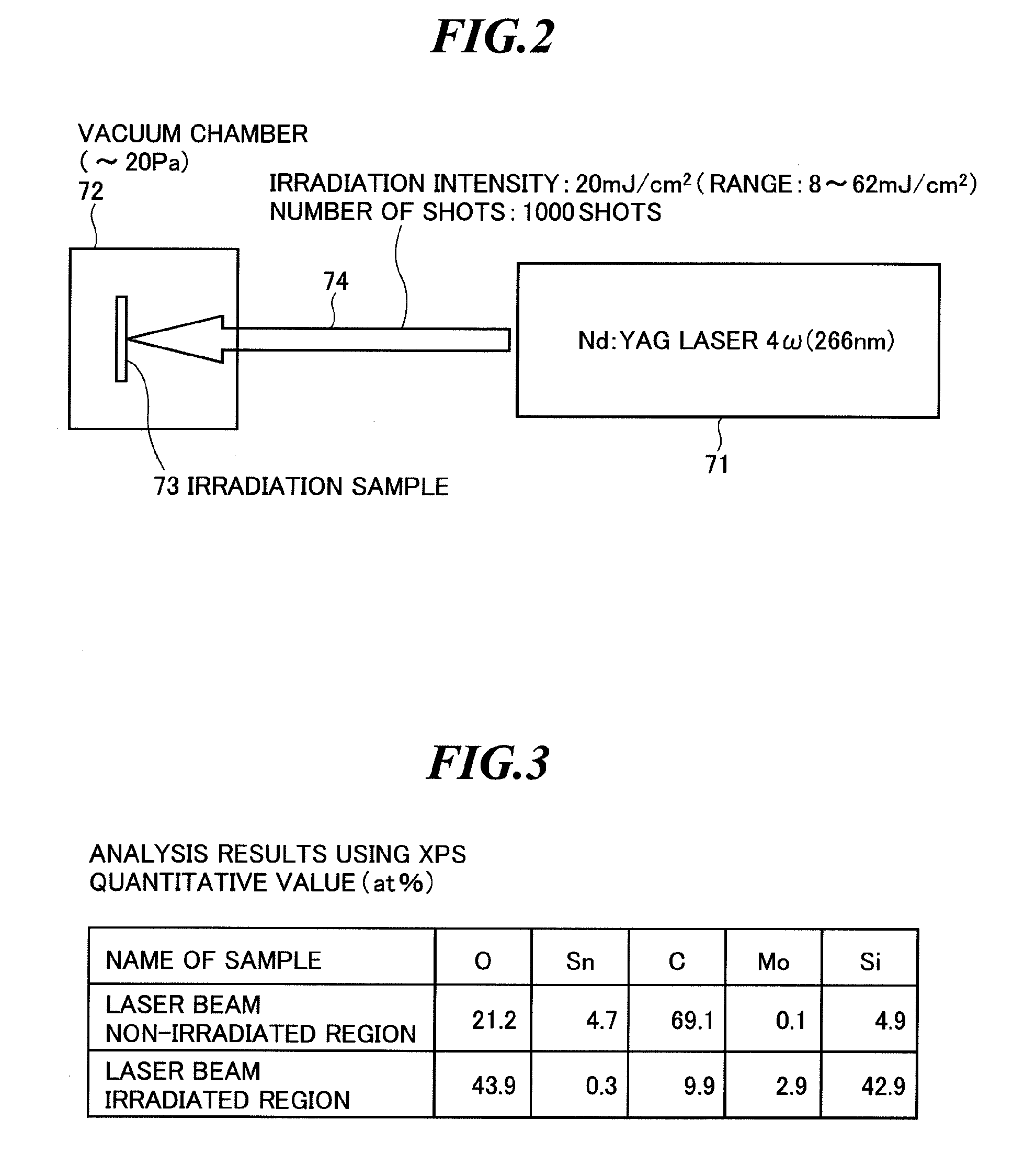

Extreme ultraviolet light source apparatus and cleaning method

InactiveUS20100192973A1Eliminate adhesionEfficient removalSimulator controlPhotomechanical apparatusLight beamPulsed laser beam

An extreme ultraviolet light source apparatus that can eliminate debris adhering to a component such as optical elements provided within a chamber. The extreme ultraviolet light source apparatus includes: a chamber in which extreme ultraviolet light is generated; a target material supply unit for supplying a target material into the chamber; a driver laser unit for irradiating the target material with a driver pulse laser beam to generate plasma; a cleaning laser unit for emitting a cleaning pulse laser beam; and a control unit for controlling an irradiation position of the cleaning pulse laser beam emitted from the cleaning laser unit so as to irradiate a component provided within the chamber with the cleaning pulse laser beam to remove debris adhering to a surface of the component.

Owner:GIGAPHOTON

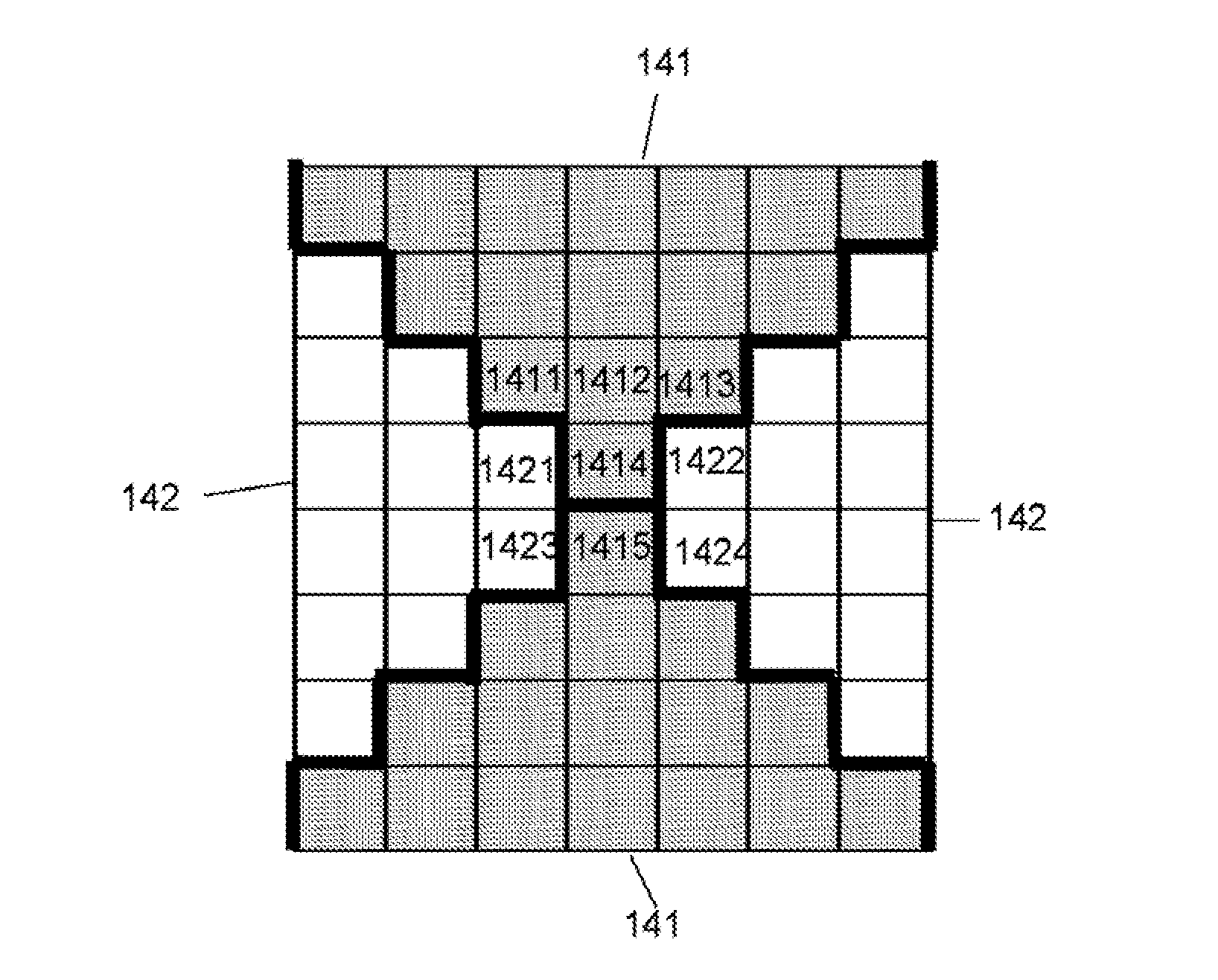

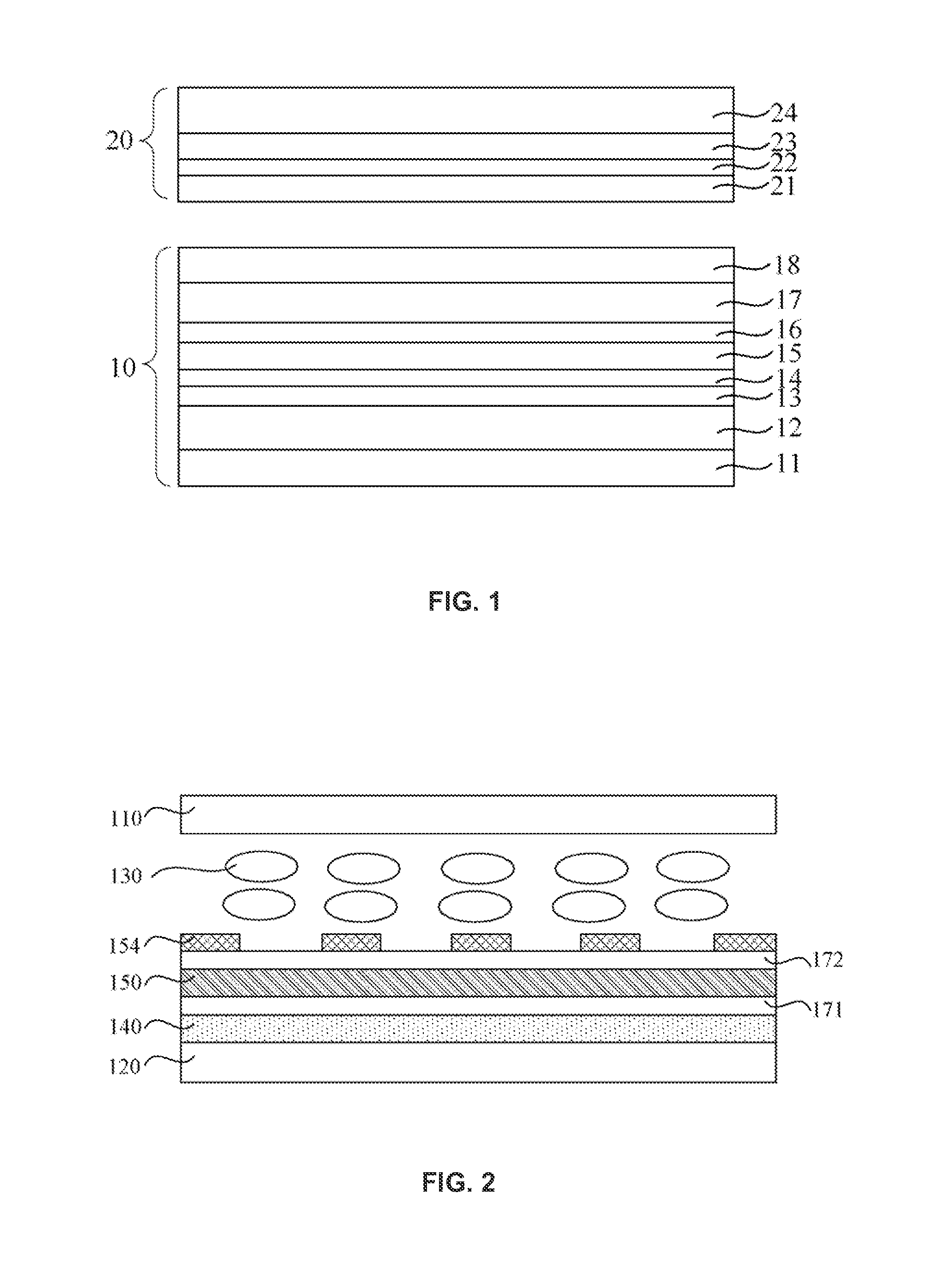

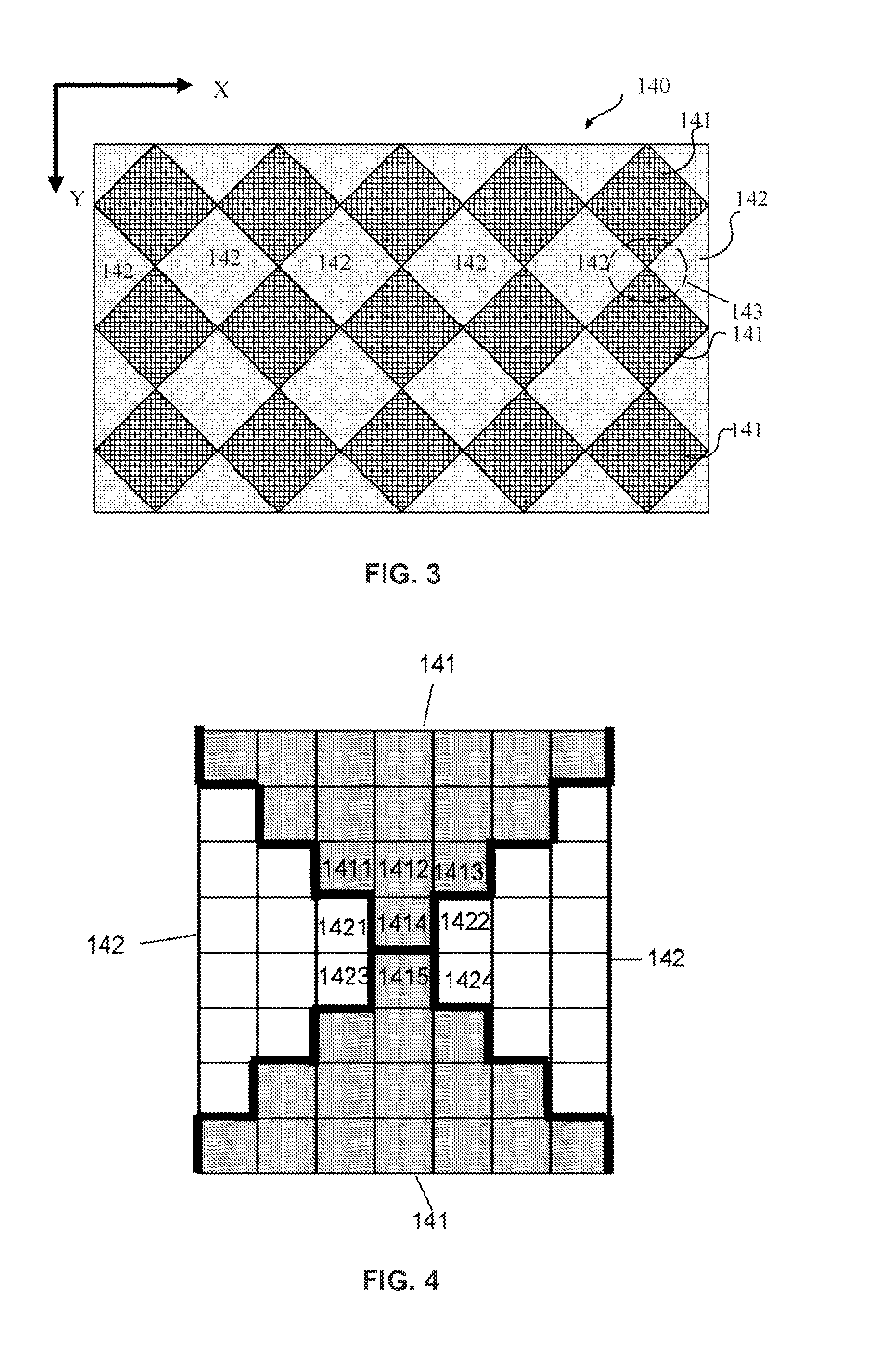

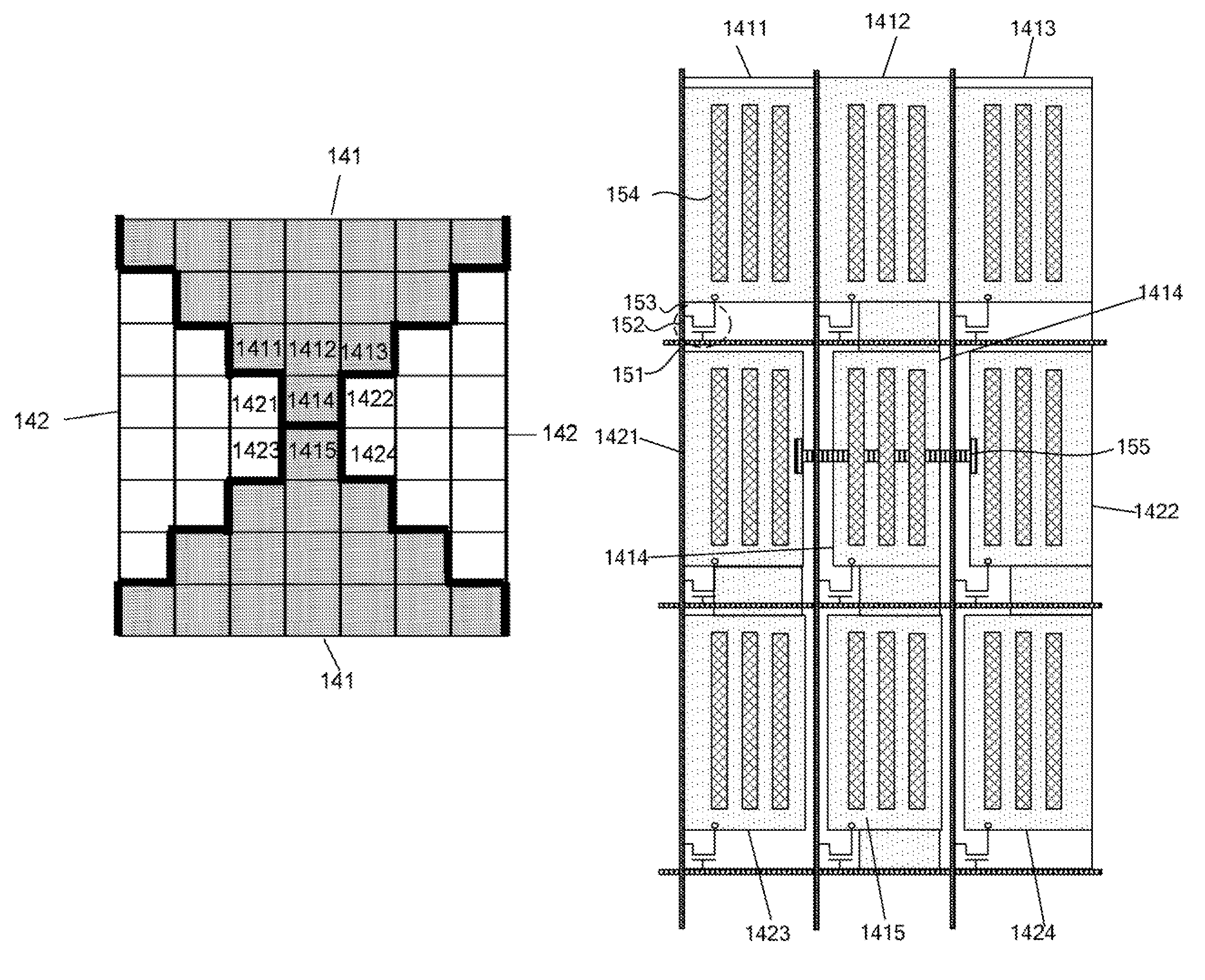

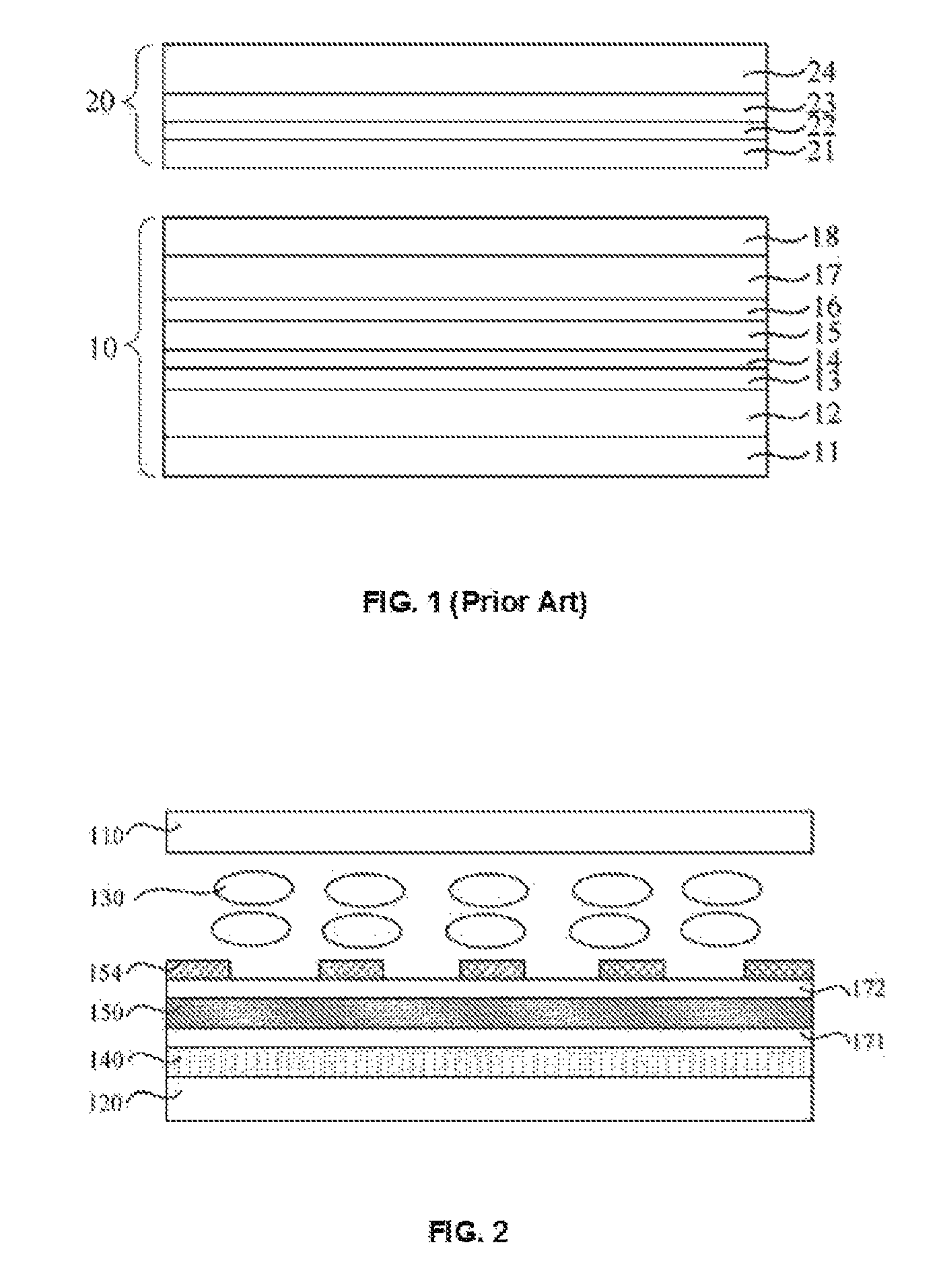

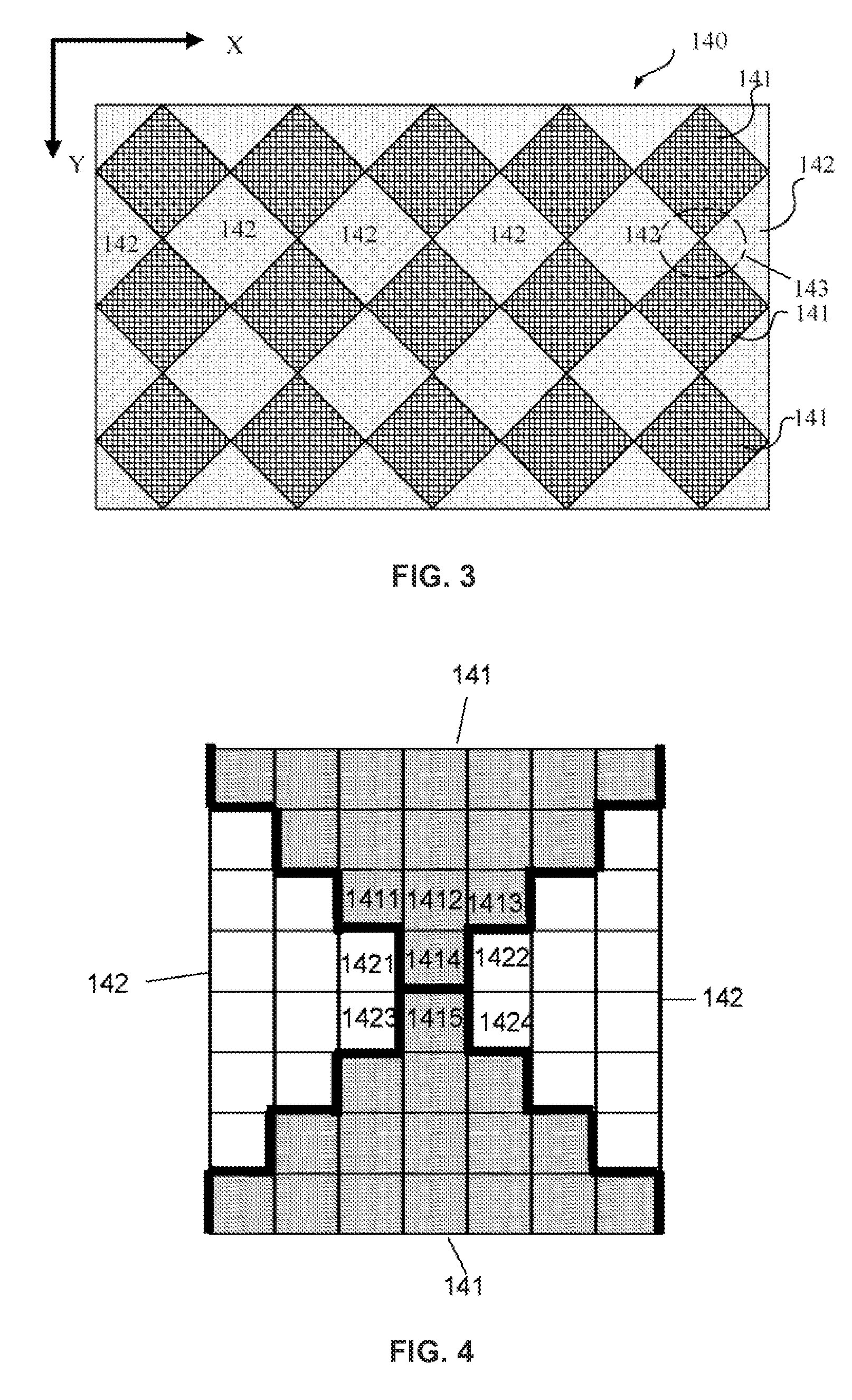

Imbedded touch screen liquid crystal display device and touch drive method thereof

ActiveUS20140333582A1Increasing the thicknessEliminate adhesionNon-linear opticsInput/output processes for data processingLiquid-crystal displayDisplay device

An in-cell touch panel liquid crystal display device is disclosed. The display device includes a first substrate, a second substrate disposed opposite the first substrate, and a liquid crystal layer disposed between the first substrate and the second substrate. The display device also includes a common electrode layer disposed on a side of the second substrate facing the first substrate, where the common electrode layer includes a plurality of first common electrodes and a plurality of second common electrodes both arranged in a matrix. In addition, the first common electrodes and the second common electrodes are configured to detect a touched position on the in-cell touch panel liquid crystal display device.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Chinese medicinal herbs for treating spur and its preparation

InactiveCN1939491AEffective cureEffective penetrationHeavy metal active ingredientsSkeletal disorderMedicinal herbsMedicinal herb

A Chinese medicine for treating osteophyte, rheumatic or rheumatoid arthritis, osteoarthritis, ischias, lumbar intervertebral disc protrusion, periomethritis, etc includes the enterior-applied pills prepared from 46 Chinese-medicinal materials and the exterior-applied ointment prepared from 54 Chinese-medicinal materials.

Owner:夏书桂

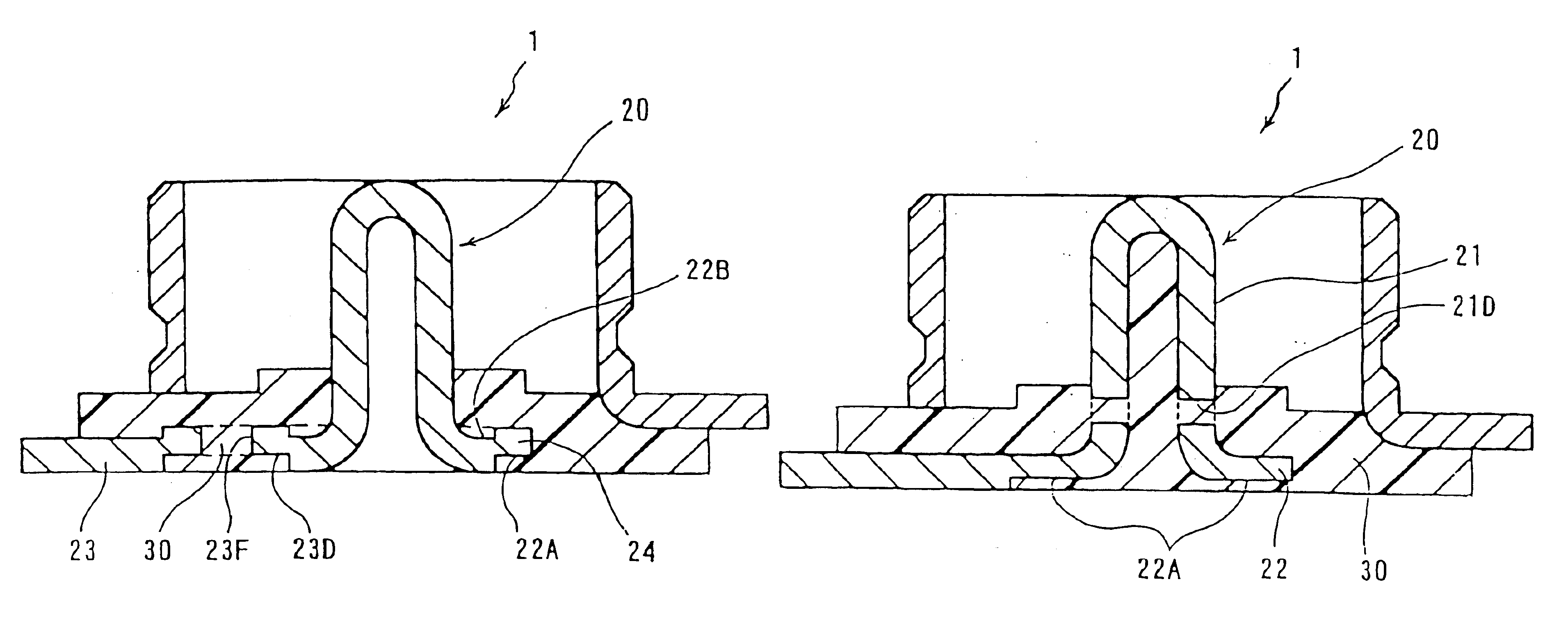

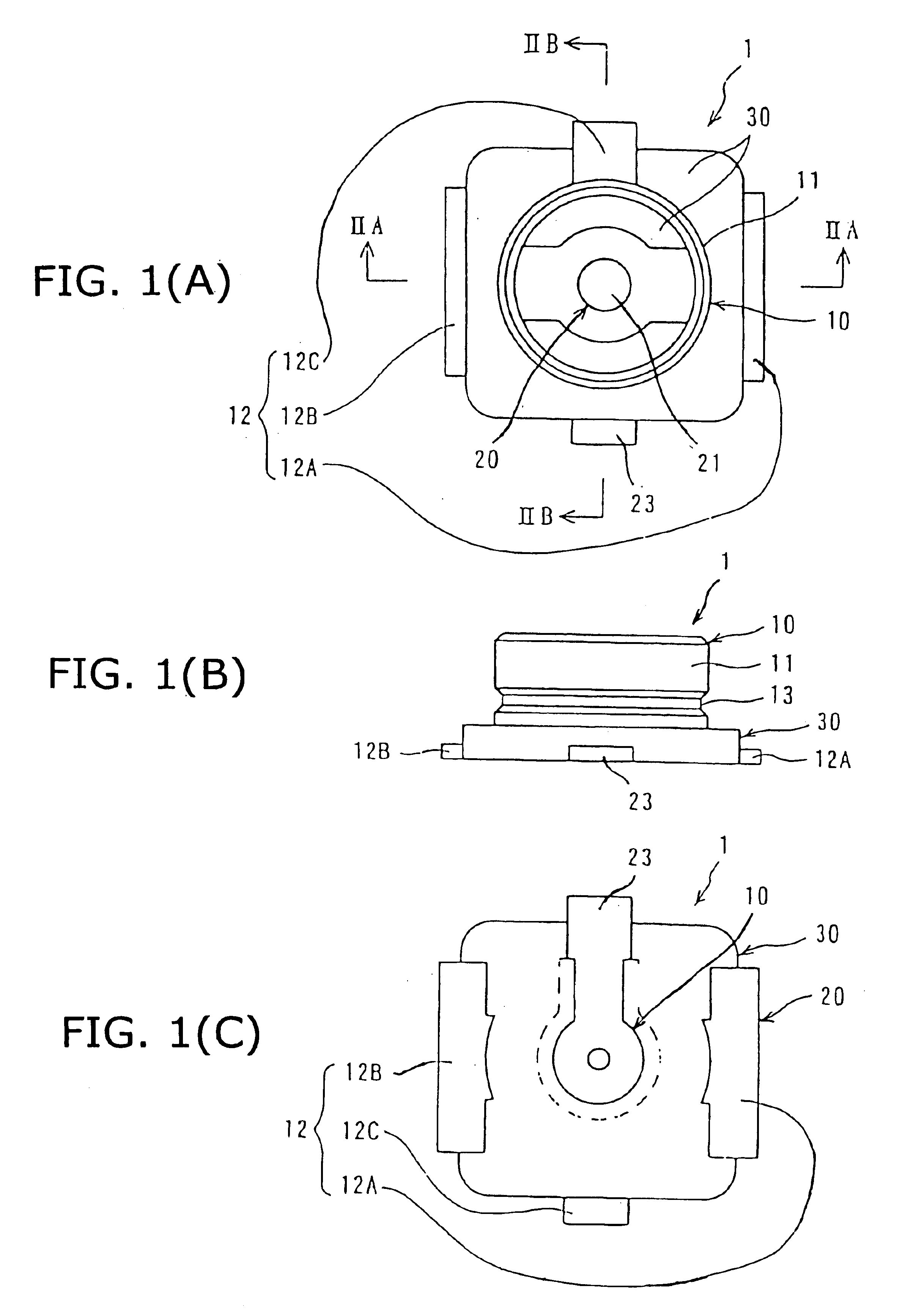

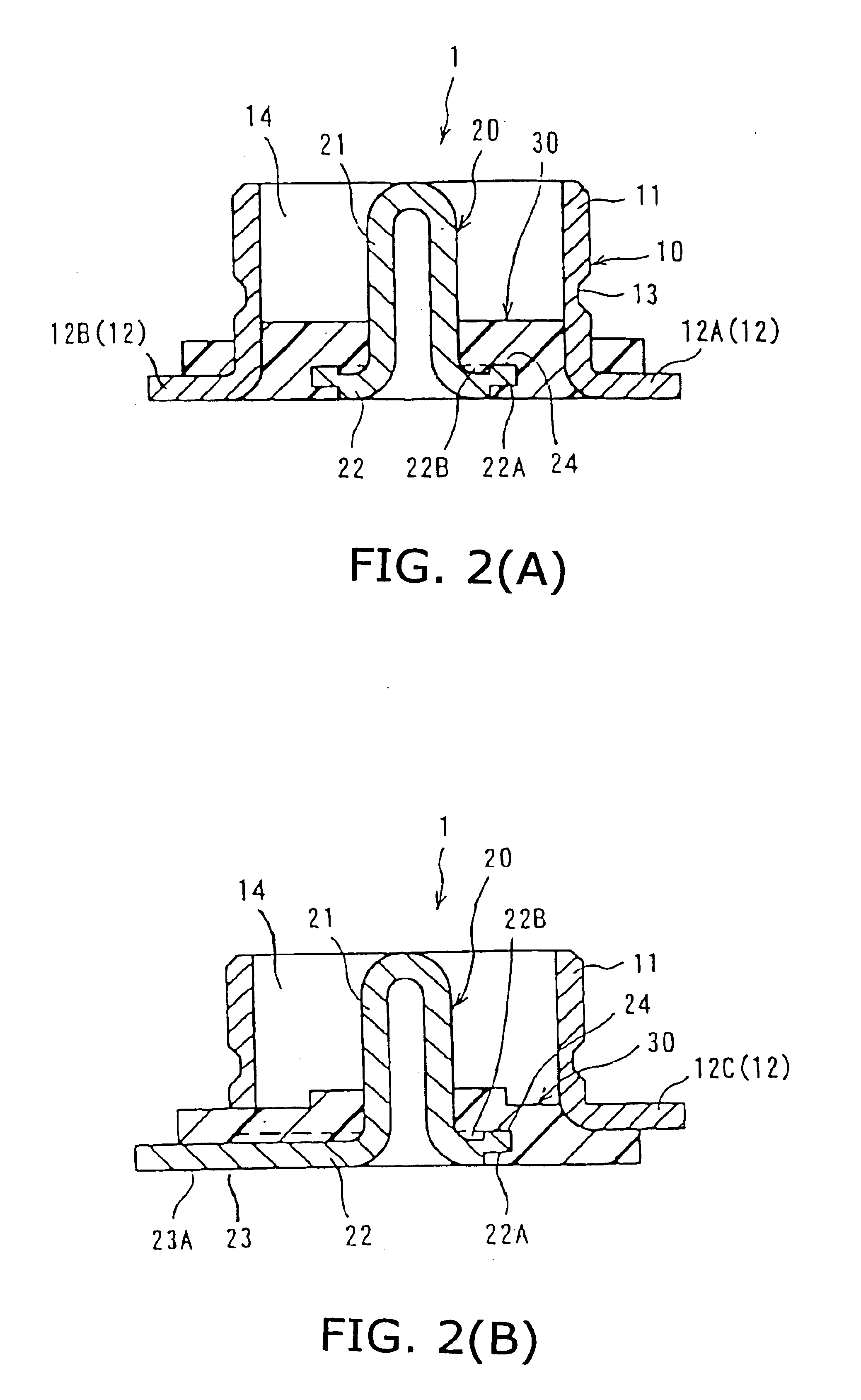

Coaxial electrical connector

InactiveUS6902408B2Avoid displacementIncrease powerLine/current collector detailsTwo pole connectionsElectrical conductorEngineering

A coaxial electrical connector comprises an outer conductor (10) having a tubular section (11); a central conductor (20) having a contact section (21) extending in the axial direction in the tubular section (11); and a dielectric block (30) molded to hold together both the conductors (10, 20). The central conductor (20) has a radial section (22) extending outwardly in the radial direction from the bottom of the contact section (21) and a connection portion (23A) on the bottom face of the radial section (22) for contact with a circuit board. The central conductor 20 has a surface-processed portion so as to form at least one of a raised portion (24) and an indented portion (22A) and is in contact with the dielectric block at the surface-processed portion.

Owner:HIROSE ELECTRIC GROUP

Embedded touch screen liquid crystal display device and touch drive method thereof

ActiveUS9442330B2Increasing the thicknessEliminate adhesionNon-linear opticsInput/output processes for data processingLiquid-crystal displayDisplay device

An in-cell touch panel liquid crystal display device is disclosed. The display device includes a first substrate, a second substrate disposed opposite the first substrate, and a liquid crystal layer disposed between the first substrate and the second substrate. The display device also includes a common electrode layer disposed on a side of the second substrate facing the first substrate, where the common electrode layer includes a plurality of first common electrodes and a plurality of second common electrodes both arranged in a matrix. In addition, the first common electrodes and the second common electrodes are configured to detect a touched position on the in-cell touch panel liquid crystal display device.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Extruded image receiver elements

ActiveUS20100330306A1Enhance adhesionEliminate adhesionDecorative surface effectsSynthetic resin layered productsWaxElectrical and Electronics engineering

An image receiving element is a composite of two or more extruded layers on a support including, in order, an extruded compliant layer, an extruded antistatic tie layer, and an image receiving layer that may also be extruded. The extruded compliant layer is non-voided and comprises from about 10 to about 40 weight % of at least one elastomeric polymer. This image receiving element can be disposed on a support to form a thermal dye transfer receiver element, an electrophotographic image receiver element, or a thermal wax receiver element. Two or more extruded layers can be co-extruded.

Owner:KODAK ALARIS INC

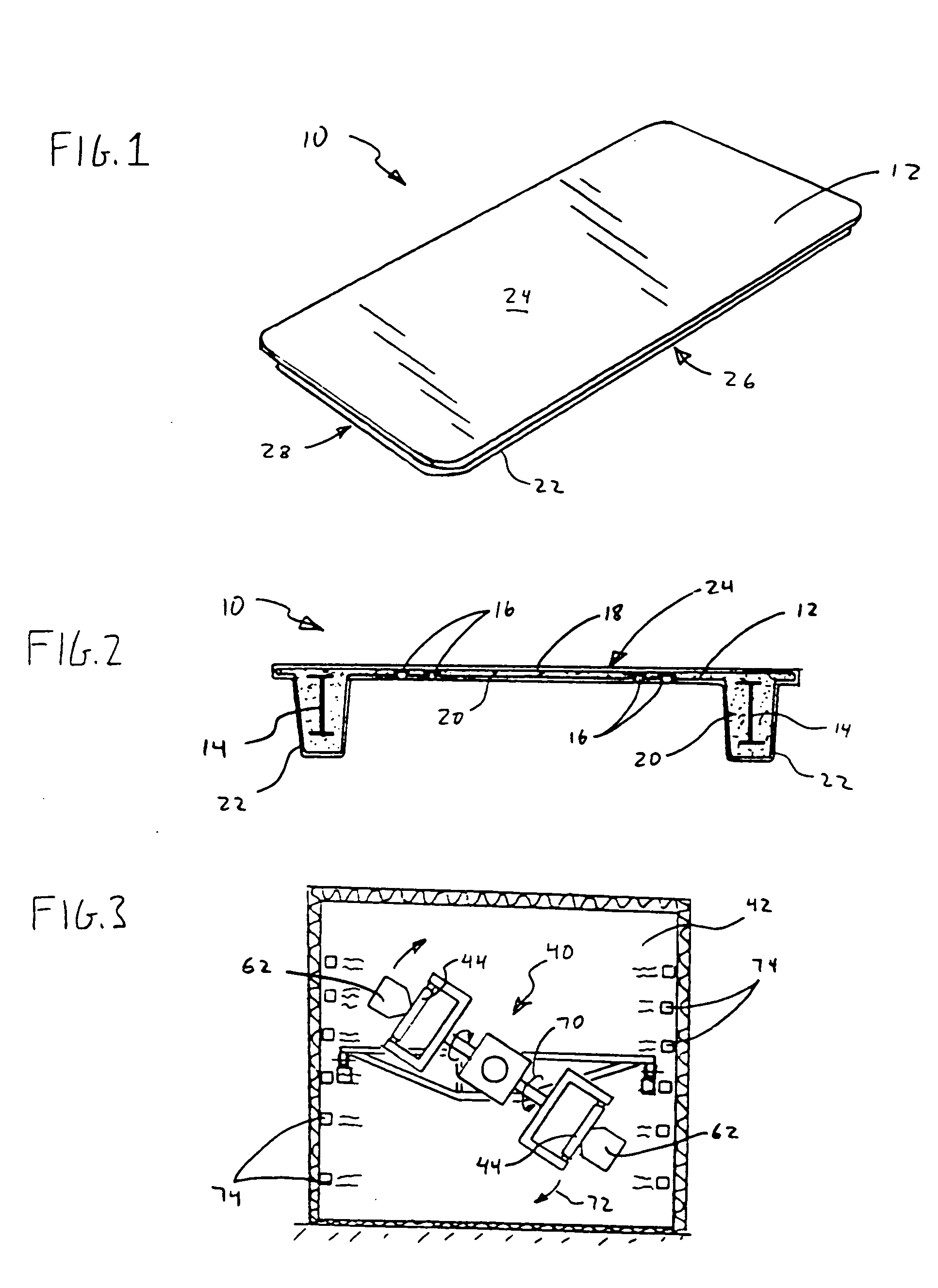

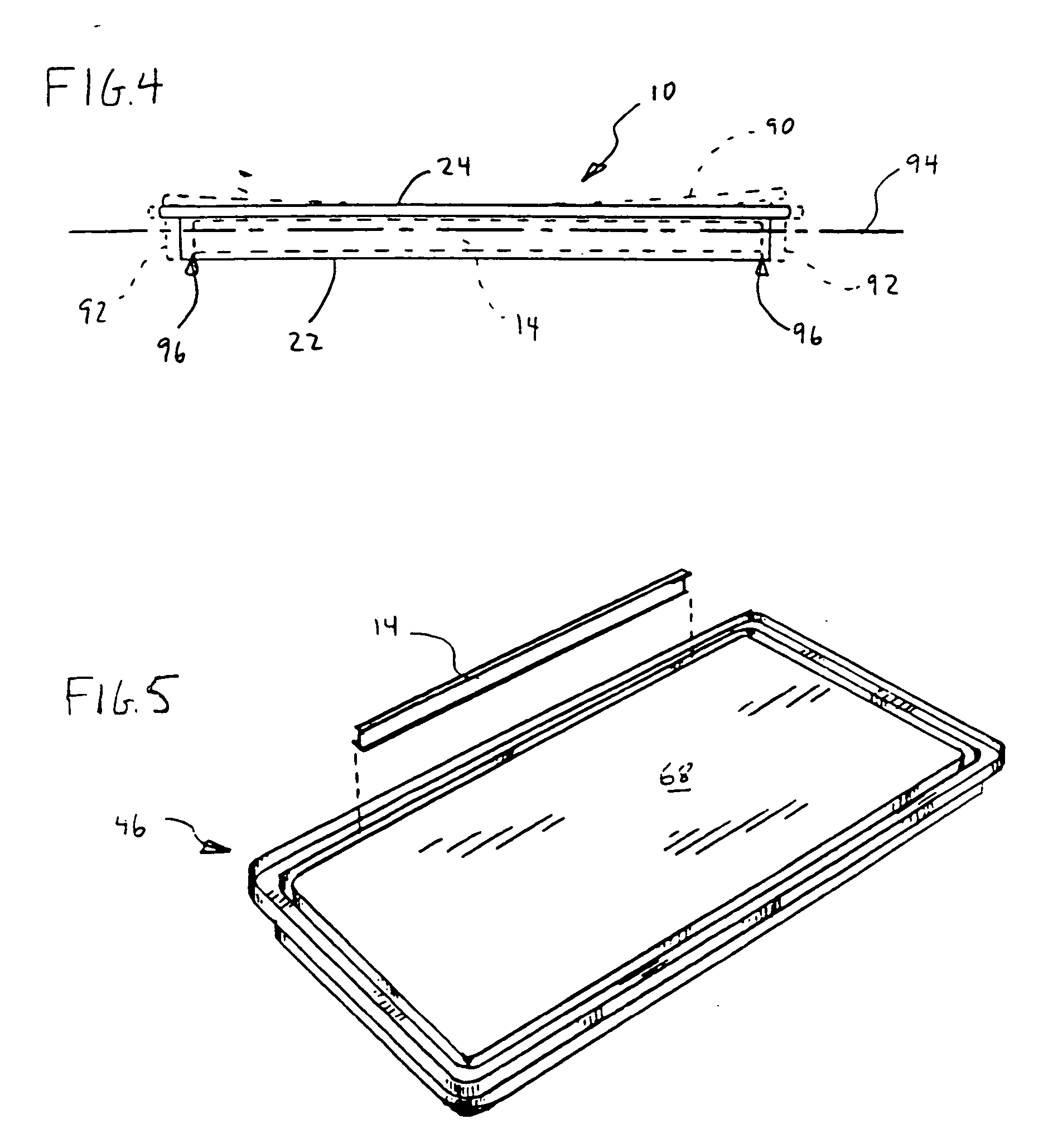

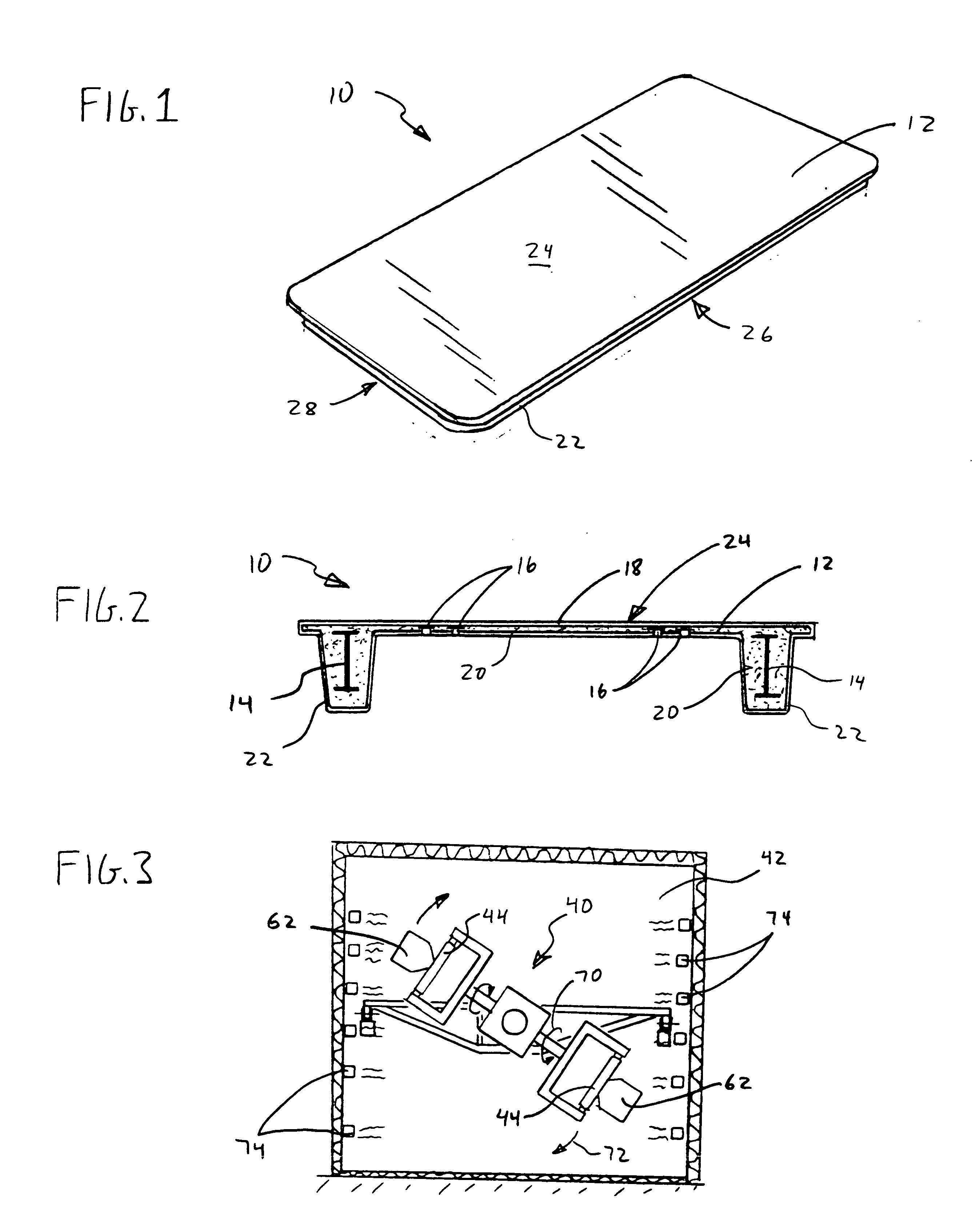

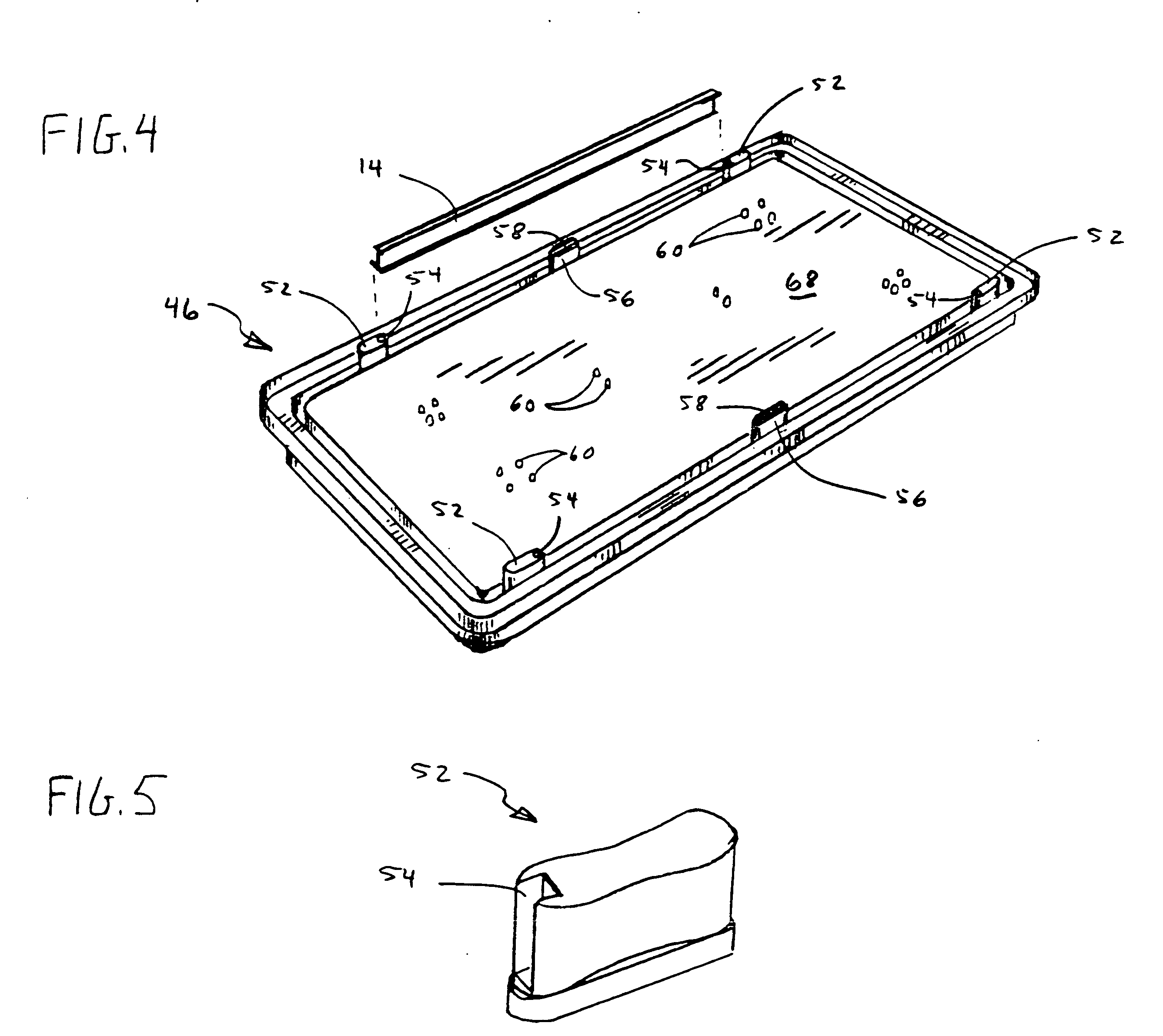

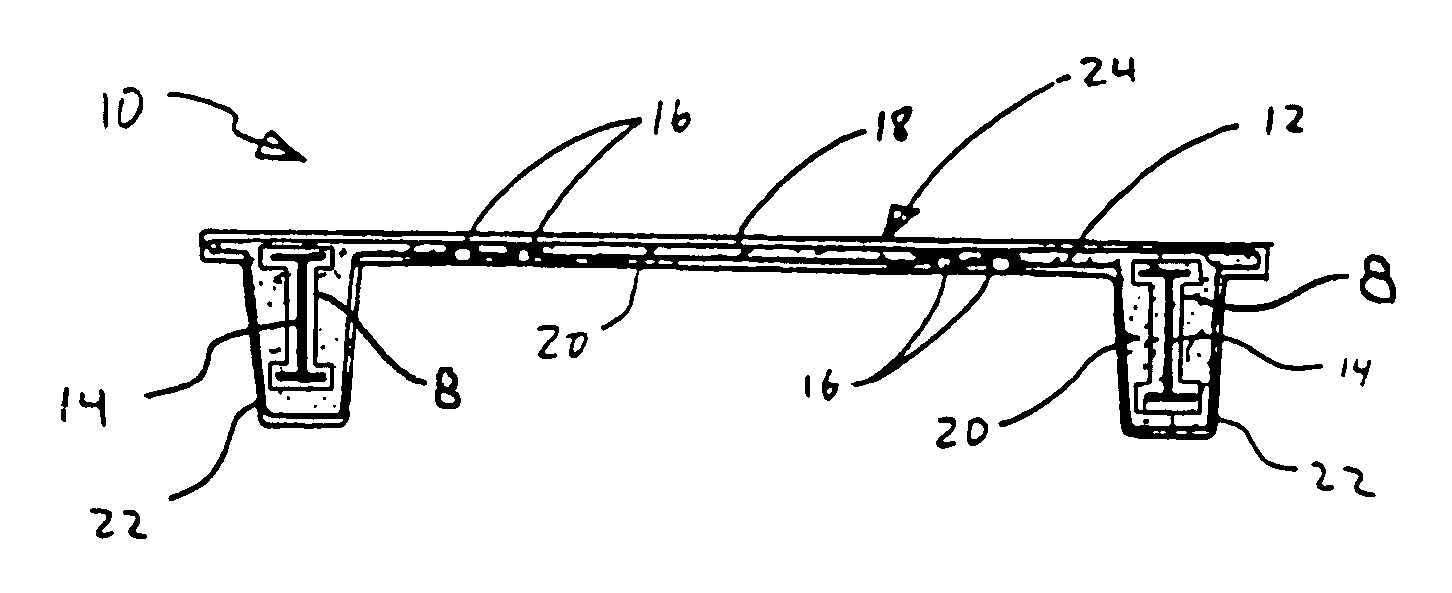

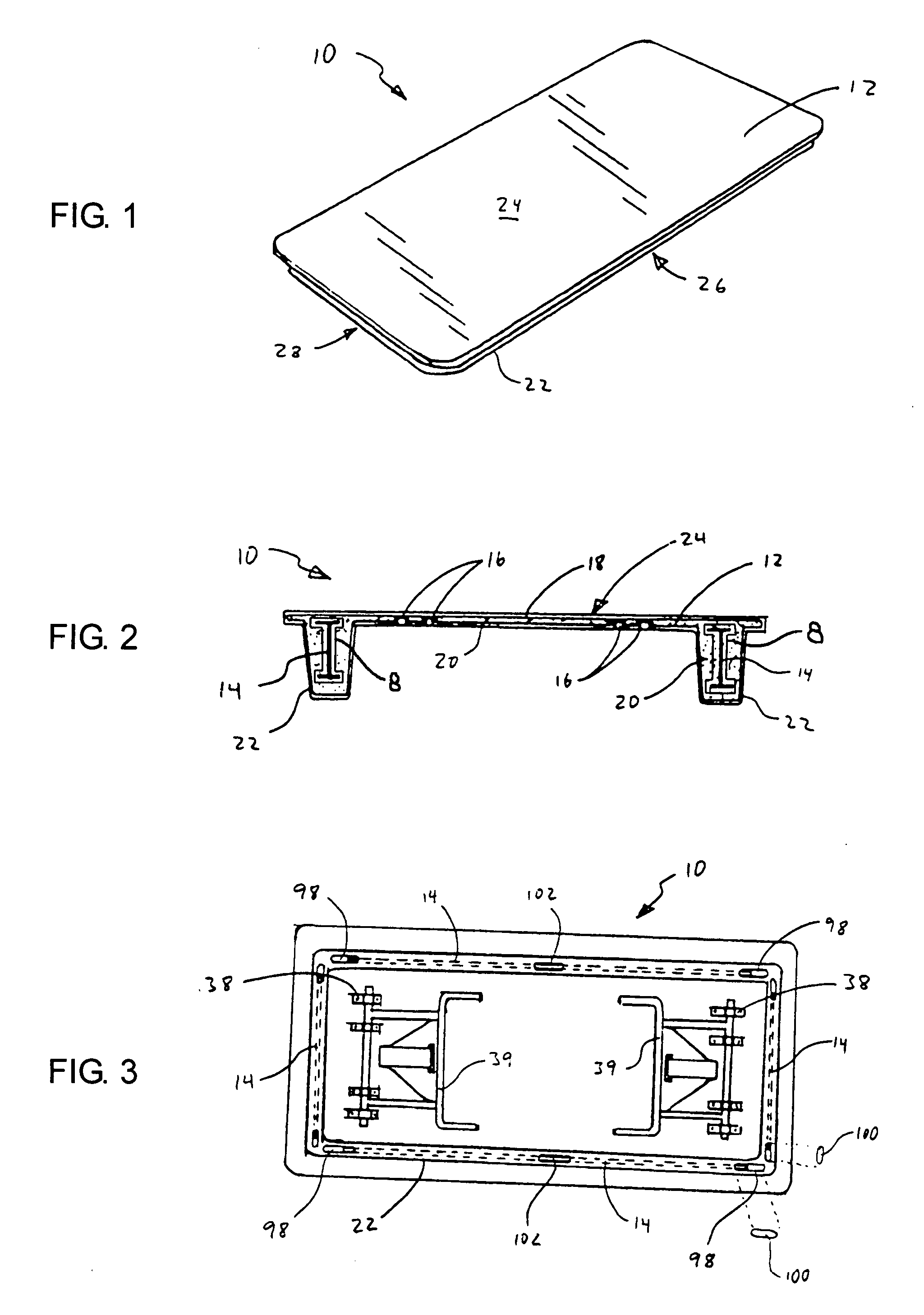

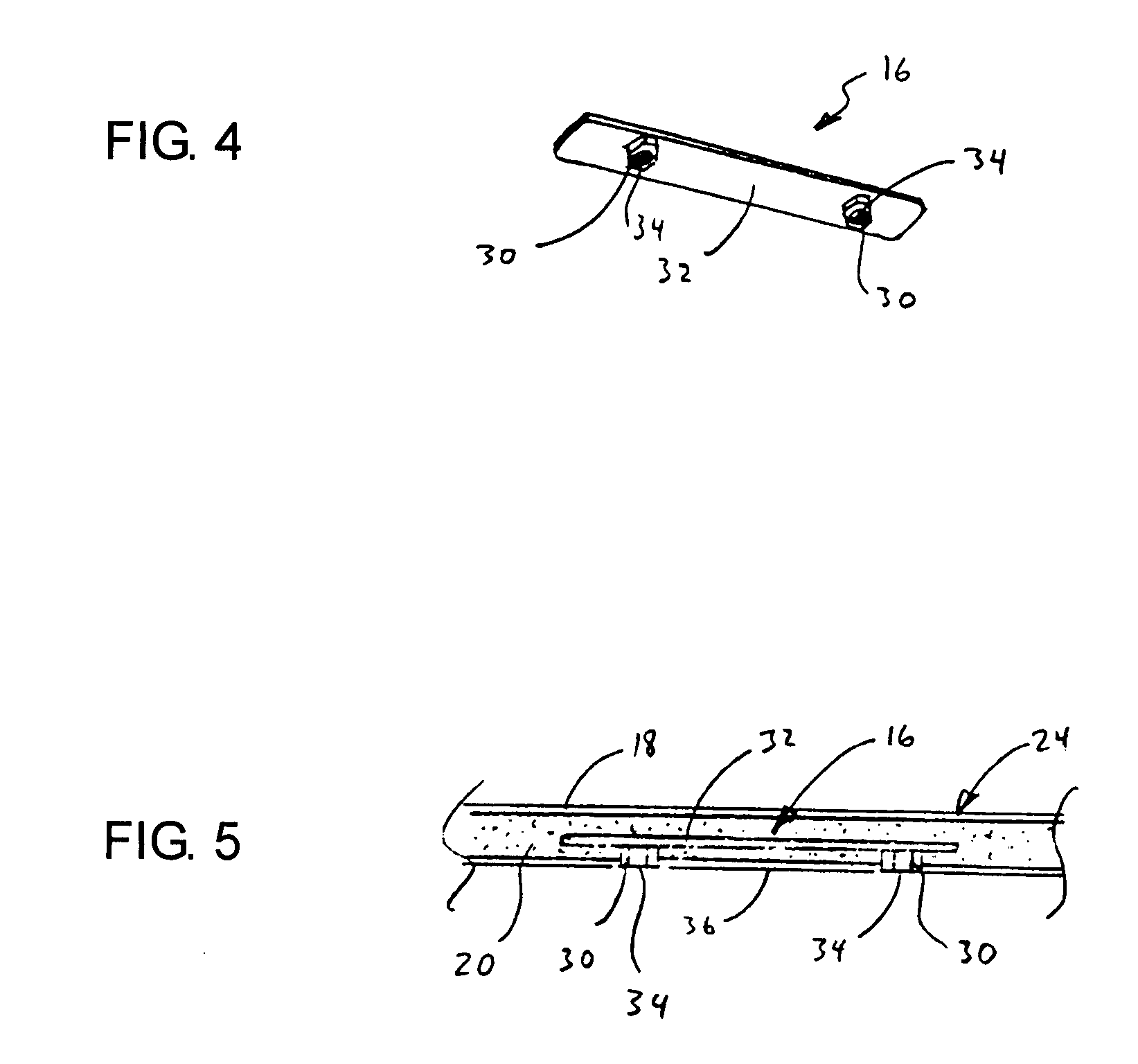

Molded article with adhesion-resistant reinforcing member and method

InactiveUS20050129901A1Control deformationMinimal internal stressLaminationLamination apparatusPolymerShell molding

A molded article includes a rotationally-molded body of polymer material, and a reinforcing member substantially encased within and in direct contact with the polymer material. Both the polymer material and the reinforcing member have their own unique post-molding shrinkage characteristics. The reinforcing member has a surface that substantially eliminates adhesion with the polymer material, so as to enable displacement of the reinforcing member with respect to contacting polymer material, and thereby reduce post-molding deformation of the molded article.

Owner:MITY-LITE

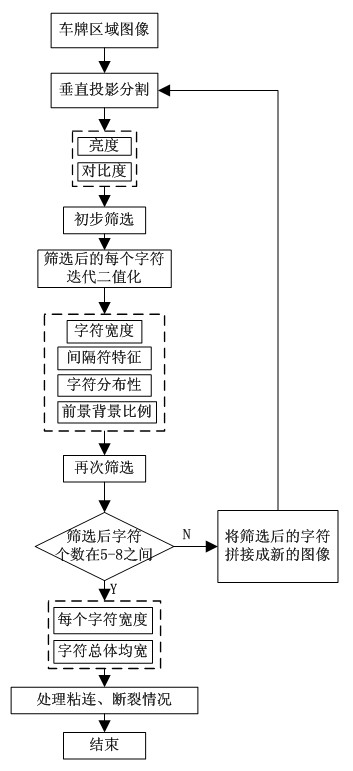

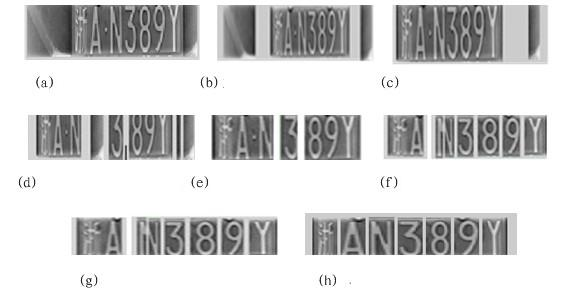

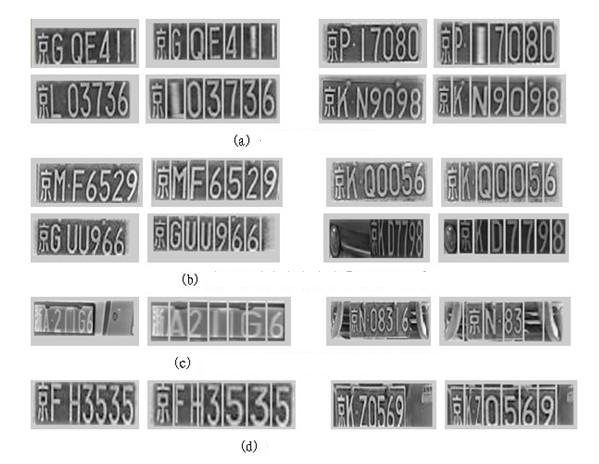

Priori analysis based iterative method for segmenting characters of licence plate

ActiveCN102222226ALow positioning accuracy requirementsReduce adverse effectsCharacter and pattern recognitionAdverse effectPattern recognition

The invention relates to a priori analysis based iterative method for segmenting characters of a licence plate. Method comprises the following steps of: firstly, preprocessing the image of the licence plate, segmenting the preprocessed image of the licence plate by utilizing the vertical projection method, calculating the parameter of each character block, and carrying out preliminary screening according to the parameters; secondly, carrying out binaryzation on the characters processed by preliminary screening by utilizing the threshold value iteration method, calculating the priori knowledgecontained by each character block according to the standard licence plate system, and obtaining the characters processed by secondary screening; and thirdly, calculating the quantity of blocks of thecharacters processed by secondary screening, calculating the width of characters of the licence plate and the mean width of all characters under the condition that set conditions are met, and determining whether ultimate characters can be obtained or not according to the two parameters, or carrying projection again when the set conditions are not met. The method reduces the requirement on positioning accuracy of the licence plate, overcomes the adverse effects due to a complex background, eliminates the common segmentation results of conglutination, breakage and the like of the other methods,and further improves the accuracy of segmentation.

Owner:HANGZHOU DIANZI UNIV

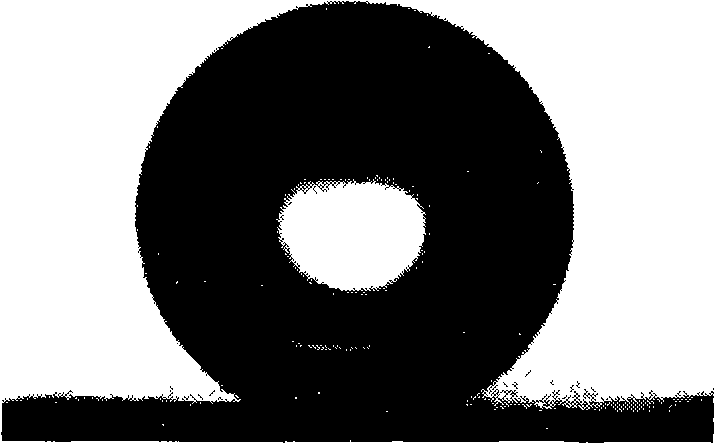

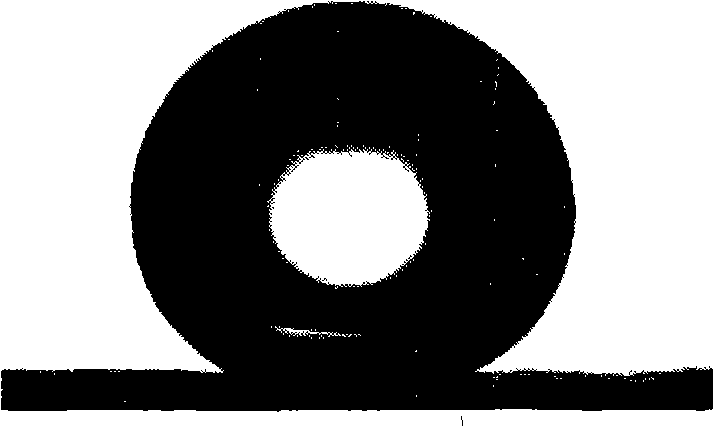

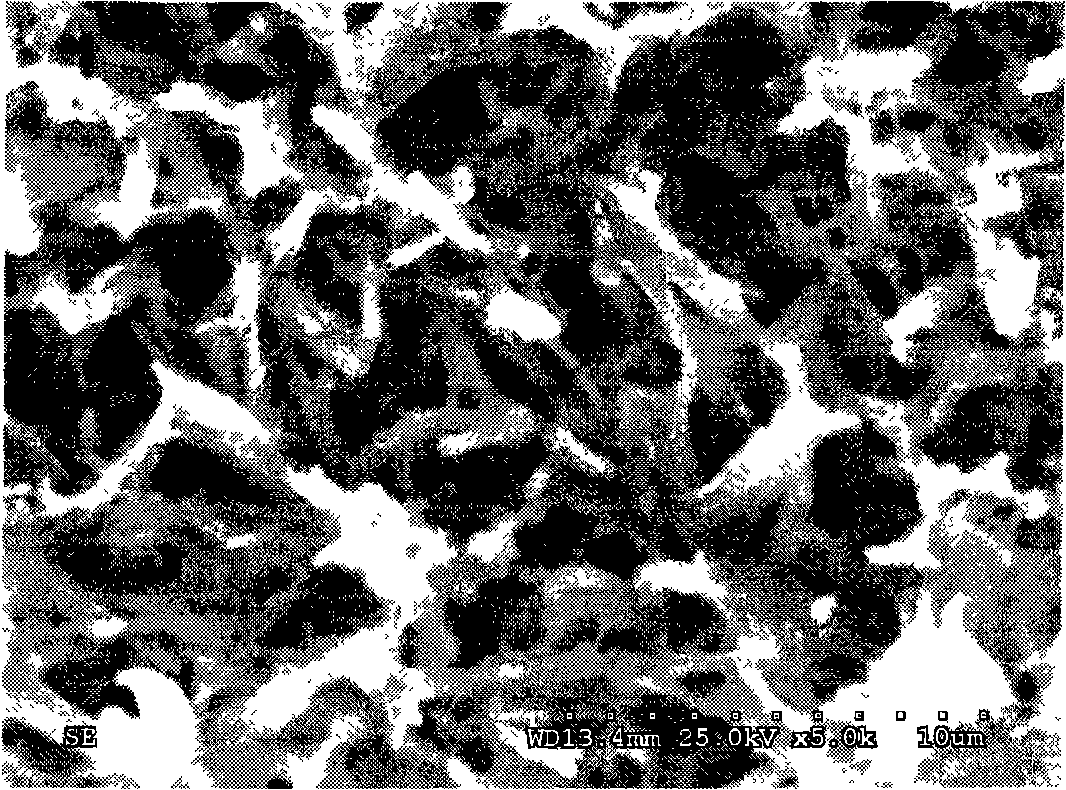

Method for acquiring super-double-thinning property on metallic copper or copper alloy backing material surface

InactiveCN101492815AAvoid corrosionTo achieve the purpose of anticorrosionMetallic material coating processesSurface finishingWork in process

The invention relates to corrosion resistance and self cleaning of a metal surface, in particular to the corrosion resistance and self cleaning realized by obtaining super-amphiphobic property on the surface of copper metal and copper alloy. The method is to clean the copper metal, a copper alloy base material or a base material coated by the copper metal on the surface to be immersed in a perfluorinated aliphatic acid organic solvent with concentration of 0.005-0.05mol / L, thereby obtaining a self-cleaning surface with super-dual hydrophobic property on the surface of the copper metal, the copper alloy base material or the base material coated by the metal copper on the surface. The method has simple operation and low requirement on equipment, is not restricted by the shape of the base material, is also applicable to surface treatment of a finished product and a semi-finished product workpiece, and is easy to realize industrialization. The method can be widely applied to each department of national production and living, such as machinery, shipbuilding, electric power, military, building, kitchenware and the like, and has wide practical value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

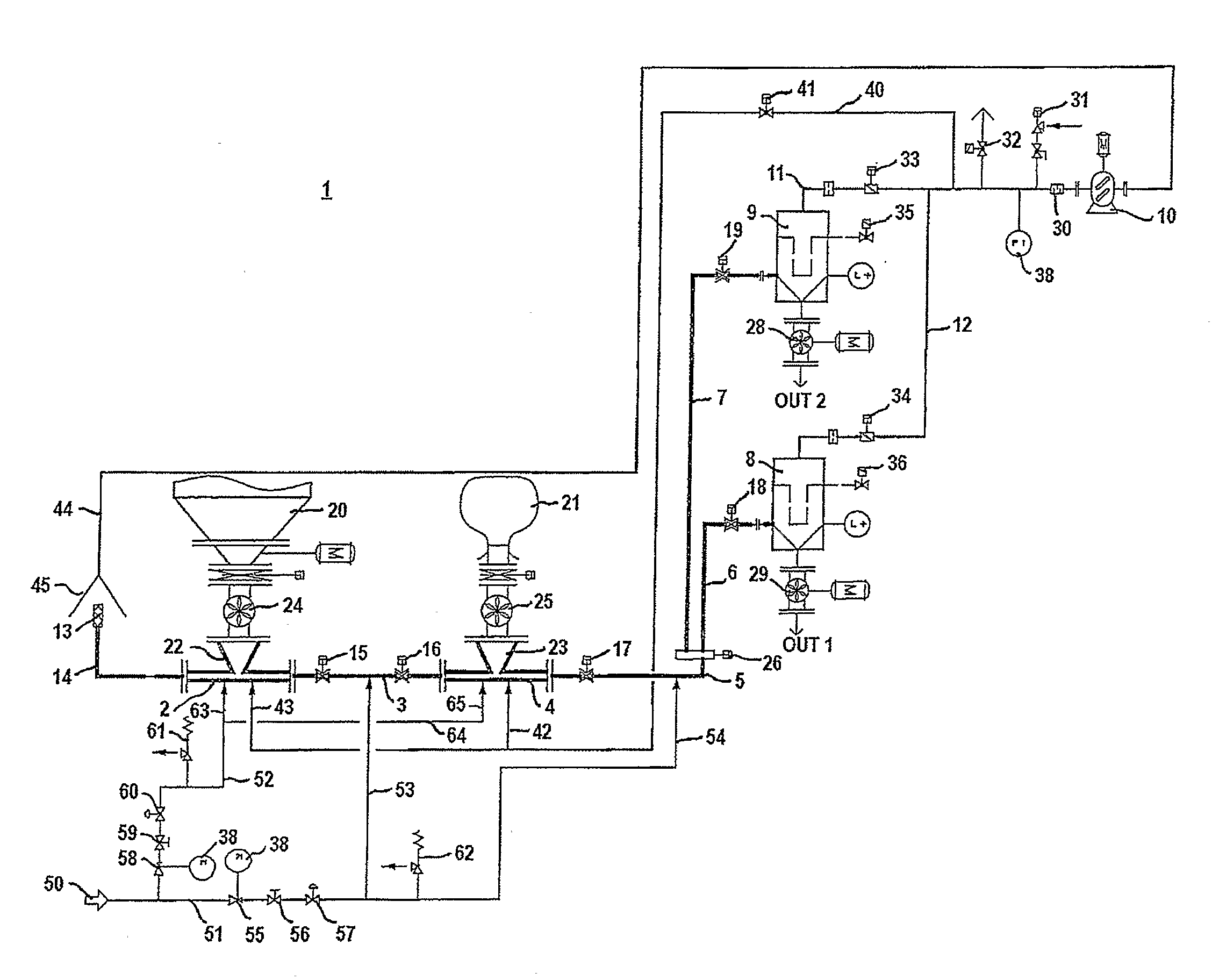

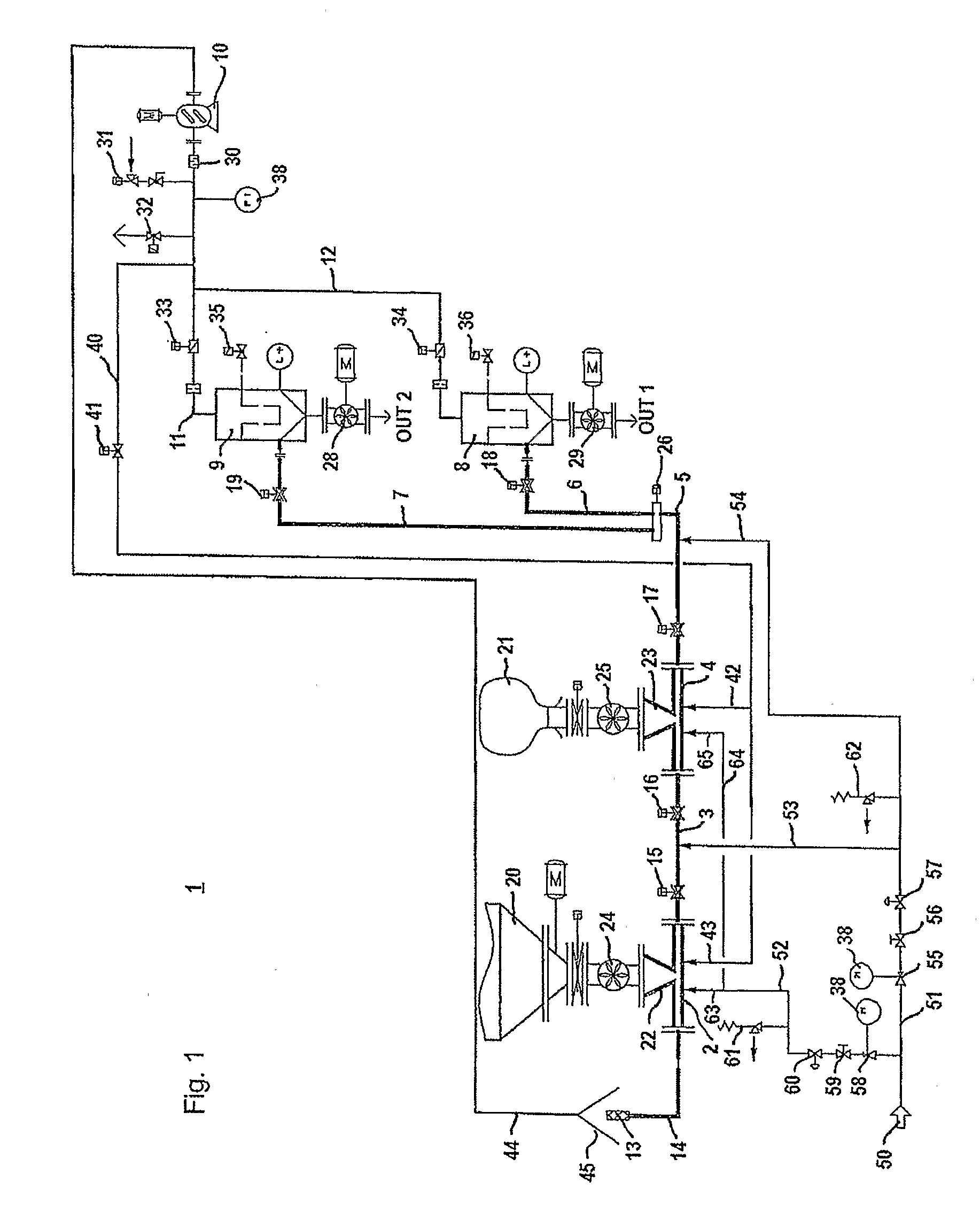

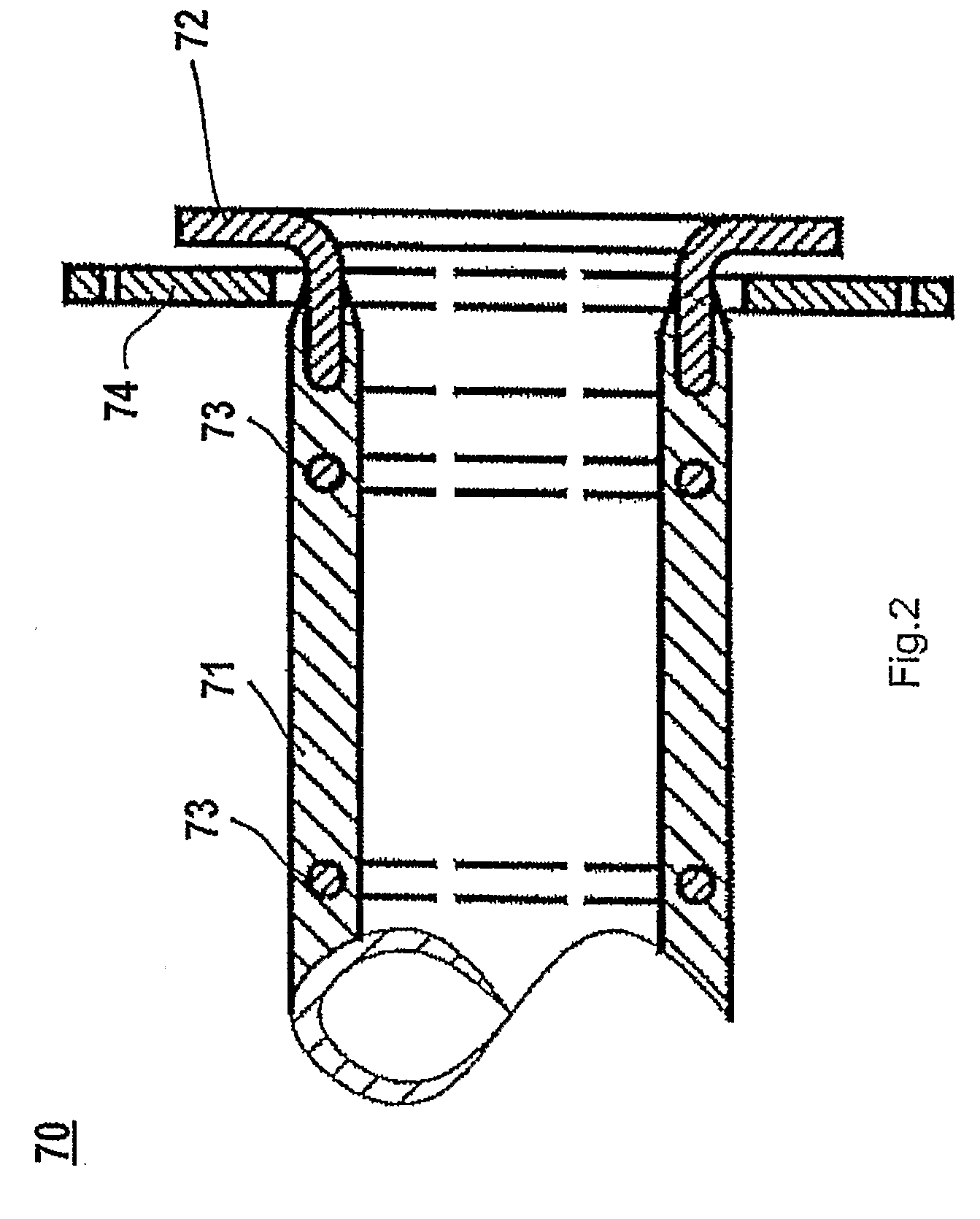

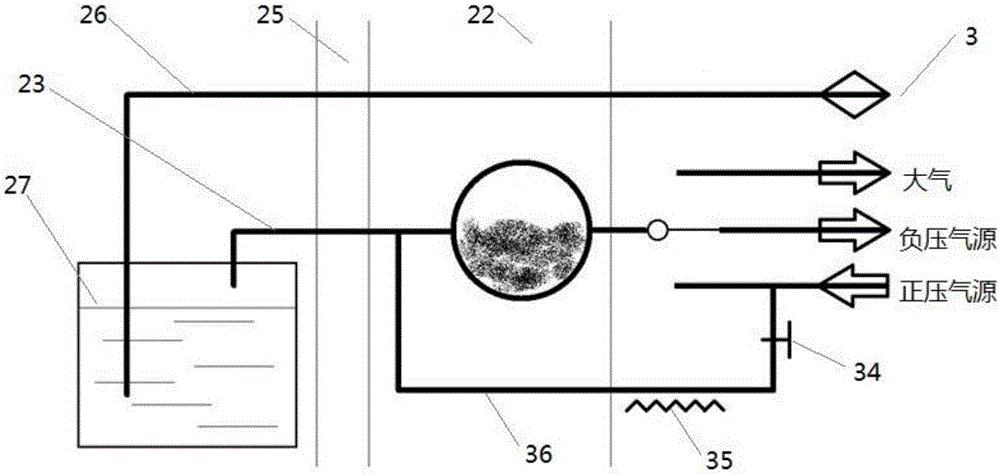

Method and system for vacuum conveying of bulk material and computer program product

InactiveUS20090304461A1Avoid stickingEfficiently prevent adherenceDigital data processing detailsBulk conveyorsEngineeringComputer program

The invention relates to a method for vacuum conveying bulk material in a vacuum conveying system (1) which comprises: a plurality of tubes (2-6) for conveying bulk material, at least some of said tubes having flexible walls (71), a vacuum blower (10) disposed at a first end of said vacuum conveying system (1) for generating a conveying gas flow within said vacuum conveying system (1), a bulk material discharging section (22, 23) for discharging bulk material into said vacuum conveying system (1), and a bulk material receiving section (8, 9) communicating with said vacuum blower (10), for receiving bulk material conveyed by said gas flow from said bulk material discharging section (22, 23). According to the invention, the method comprises the steps of: disconnecting said vacuum blower (10) from said vacuum conveying system (1); and applying pressurized gas to said vacuum conveying system (1) or at least to a subsection thereof for stretching or inflating said flexible walls (71) to thereby reduce adherence of bulk material to said flexible walls (71). Other aspects of the invention relate to a corresponding vacuum conveying system, to a controlling device and a computer program product for controlling the vacuum conveying system in accordance with the above method steps.

Owner:SUN CHEM CORP

Process for producing super-double-thinning surface for metal corrosion protection and oil stain self-cleaning

InactiveCN101492829AImprove stabilityEasy to operateElectrolytic organic material coatingElectrochemical responseElectrochemistry

The invention relates to a method for preparing a super-amphiphobic material, in particular to an electromechanical preparation method of a super-amphiphobic surface with stain self-cleaning effect used for metal corrosion prevention. The method comprises the following steps: a metal or metal alloy base material is washed cleanly to remove stains and pollutants on the surface of the metal or metal alloy base material; perfluorinated aliphatic acid organic electrolytic solution with concentration of 0.001-0.1mol / L is prepared; the clean metal or metal alloy base material and copper metal or copper alloy base material are respectively used as a cathode and an anode to be arranged into the perfluorinated aliphatic acid organic electrolytic solution; 0.5 to 25V voltage is applied between the cathode and the anode for electrochemical reaction; and a perfluorinated aliphatic acid nantokite super-amphiphobic surface layer with stain self-cleaning effect used for metal corrosion prevention is deposited on the surface of the metal or metal alloy base material used as the cathode. The method has the advantages of simple operation and low requirement of equipment, is not limited by substrate shape, is easy for industrialization, and has quite wide practical value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

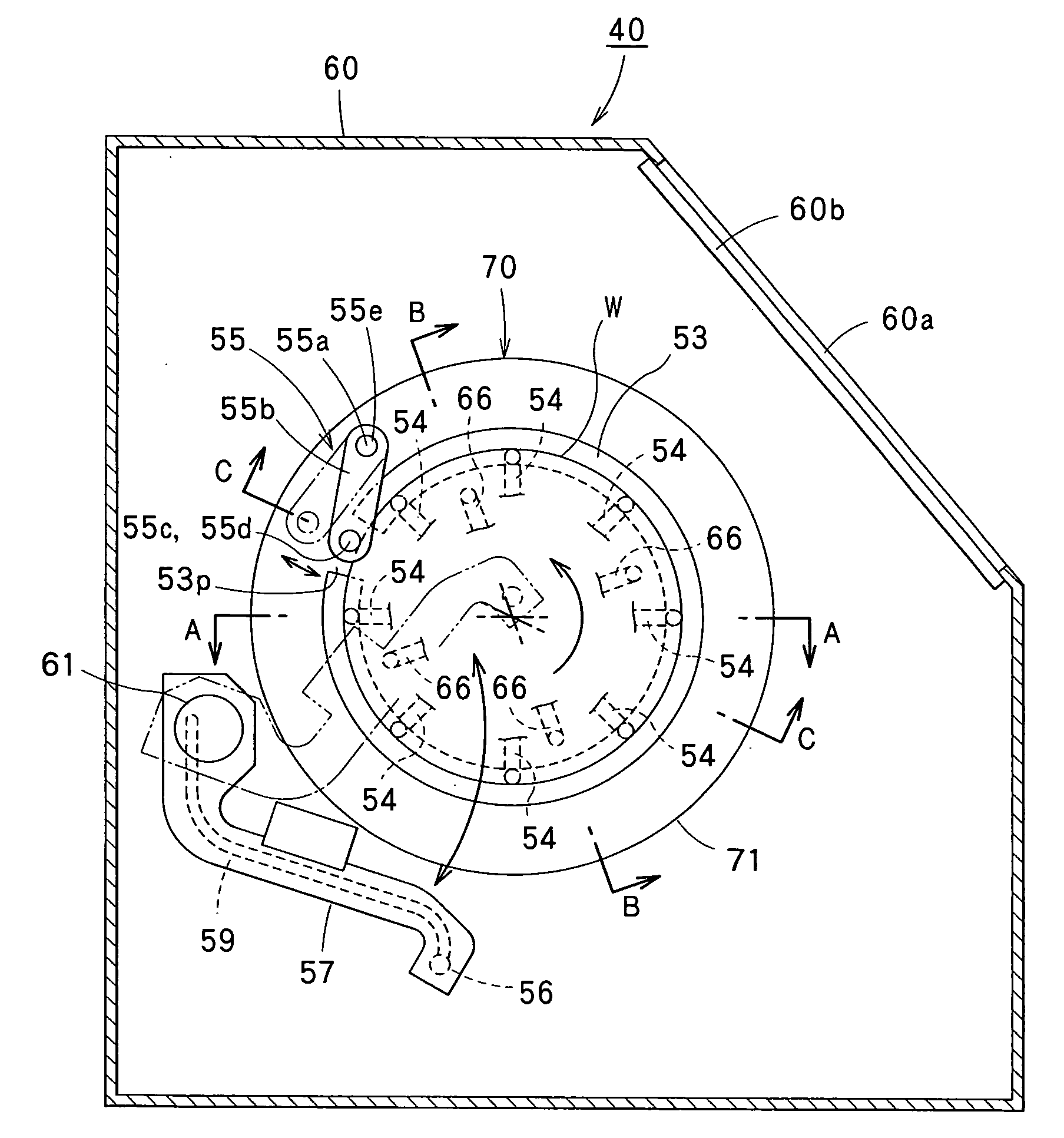

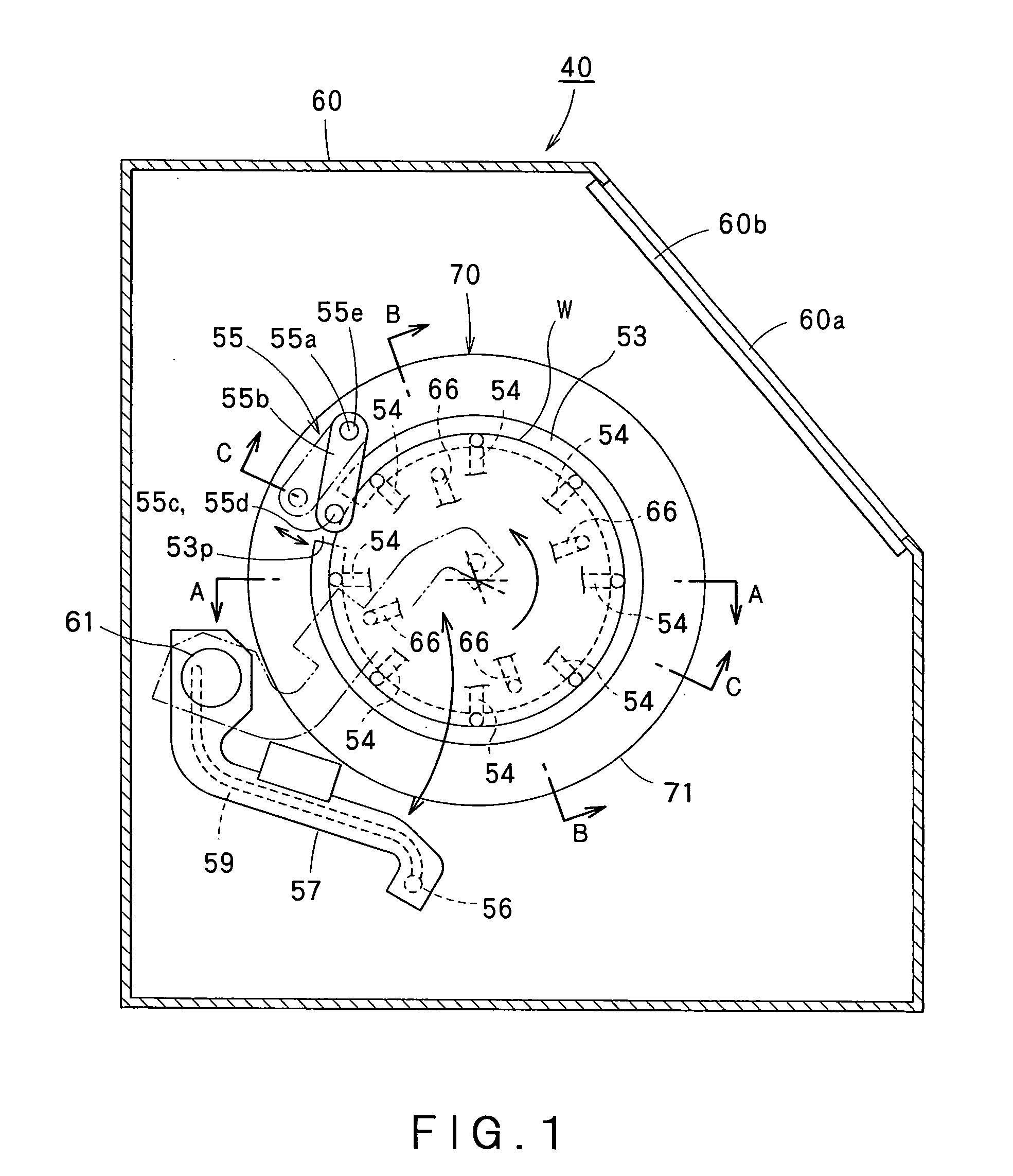

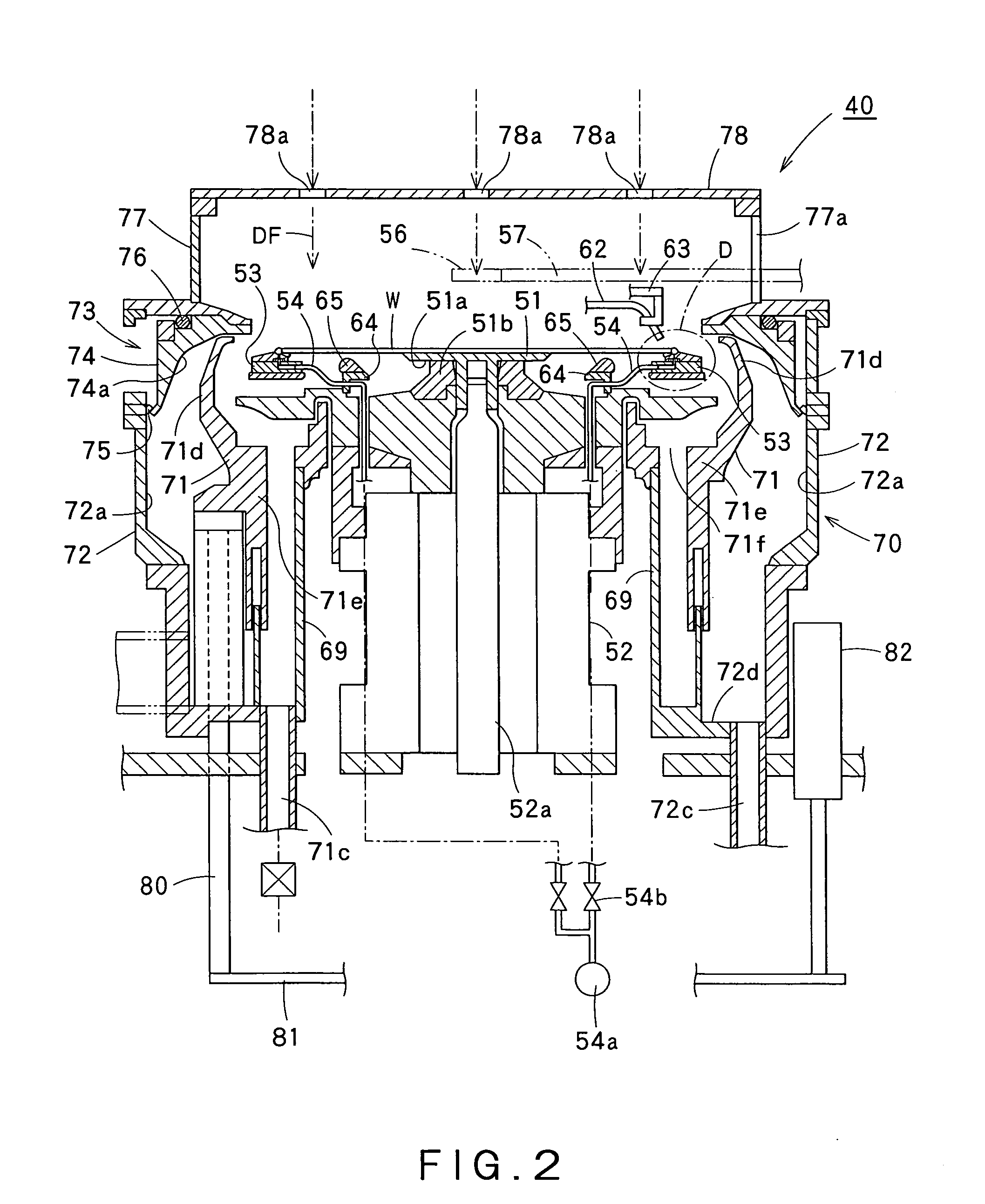

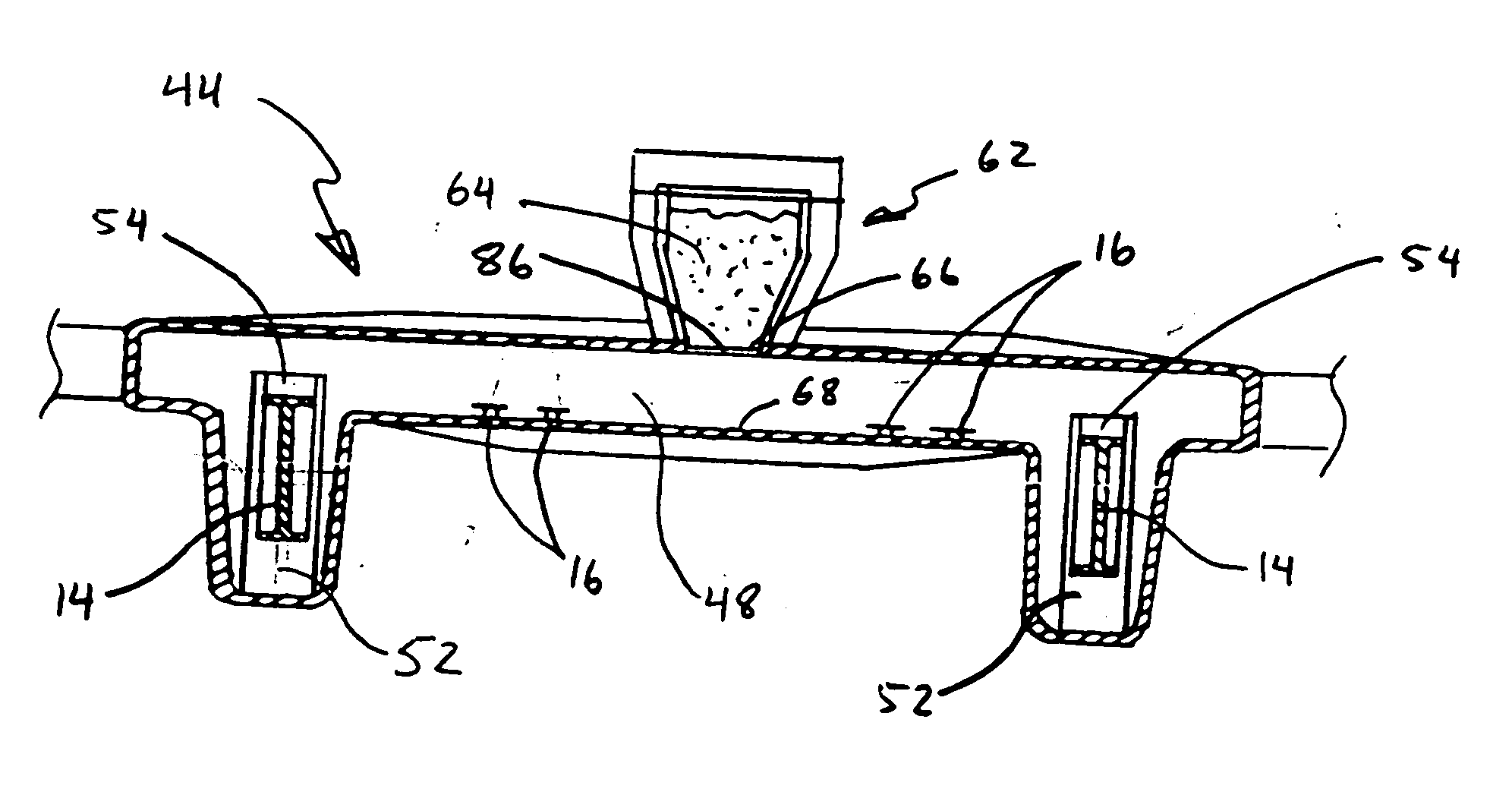

Substrate Cleaning Apparatus, Substrate Cleaning Method, Substrate Processing System, and Storage Medium

InactiveUS20090038641A1Reduce adhesionEliminate adhesionSemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringProcess engineering

A substrate cleaning apparatus 40 includes: a cleaning tank 70; a holding table 51 rotatably disposed in the cleaning tank 70, for holding a substrate to be processed W; and a rotary drive mechanism 52 for rotating the holding table 51. A chemical liquid storing unit 53 is disposed at a part circumferentially outward of the holding table 51, for storing a chemical liquid along a peripheral part of the substrate to be processed W held by the holding table 51, so as to immerse the peripheral part of the substrate to be processed W in the chemical liquid. A chemical liquid supply unit 54 is connected to the chemical liquid storing unit 53, for supplying a chemical liquid to the chemical liquid storing unit 53. Further, there is disposed a brush 55d for brushing the peripheral part of the substrate to be processed held by the holding table 51.

Owner:TOKYO ELECTRON LTD

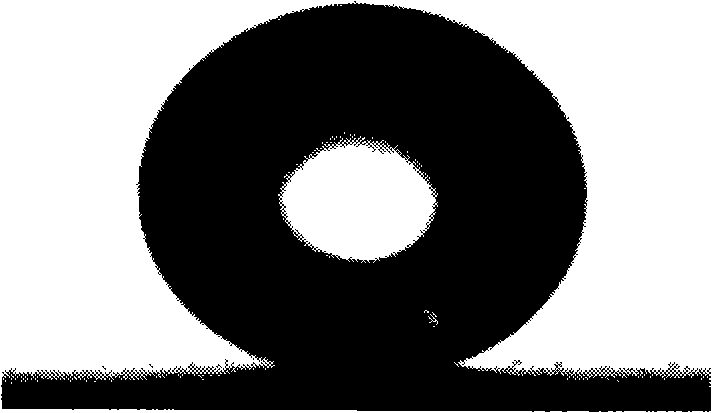

Method for preparing ultra hydrophobic surface on surface of metal copper

InactiveCN101091947ASuperhydrophobicSupersulfuric acidAntifouling/underwater paintsPretreated surfacesAir atmosphereSulfur water

The invention publics a method of preparing super sulfur-water surface on the metal copper surface, especially involves a method that it can prepare super sulfur-water surface, super vitriol surface and super sulfur-alkalescence surface simultaneously. The method puts the metal copper plate in the oversaturation solution full of vitriol copper for 10-15 days,and cleans with the deionized water, and has a air-dry; smearing the ethylene-dimethyl siloxanes on the metal copper plate surface reelingly, and drying 1-2 hours in air atmosphere 100-120deg.c.Then dropping the pure water, the acid or the alkali on the copper sign surface to make a determination of the contact angle which needs to be bigger than 150deg.The invention simultaneously has the super sulfur-water, super vitriol and super sulfur-alkalescence on the copper surface, it may help to prevent the metal copper surface from being polluted and rusted and so on.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

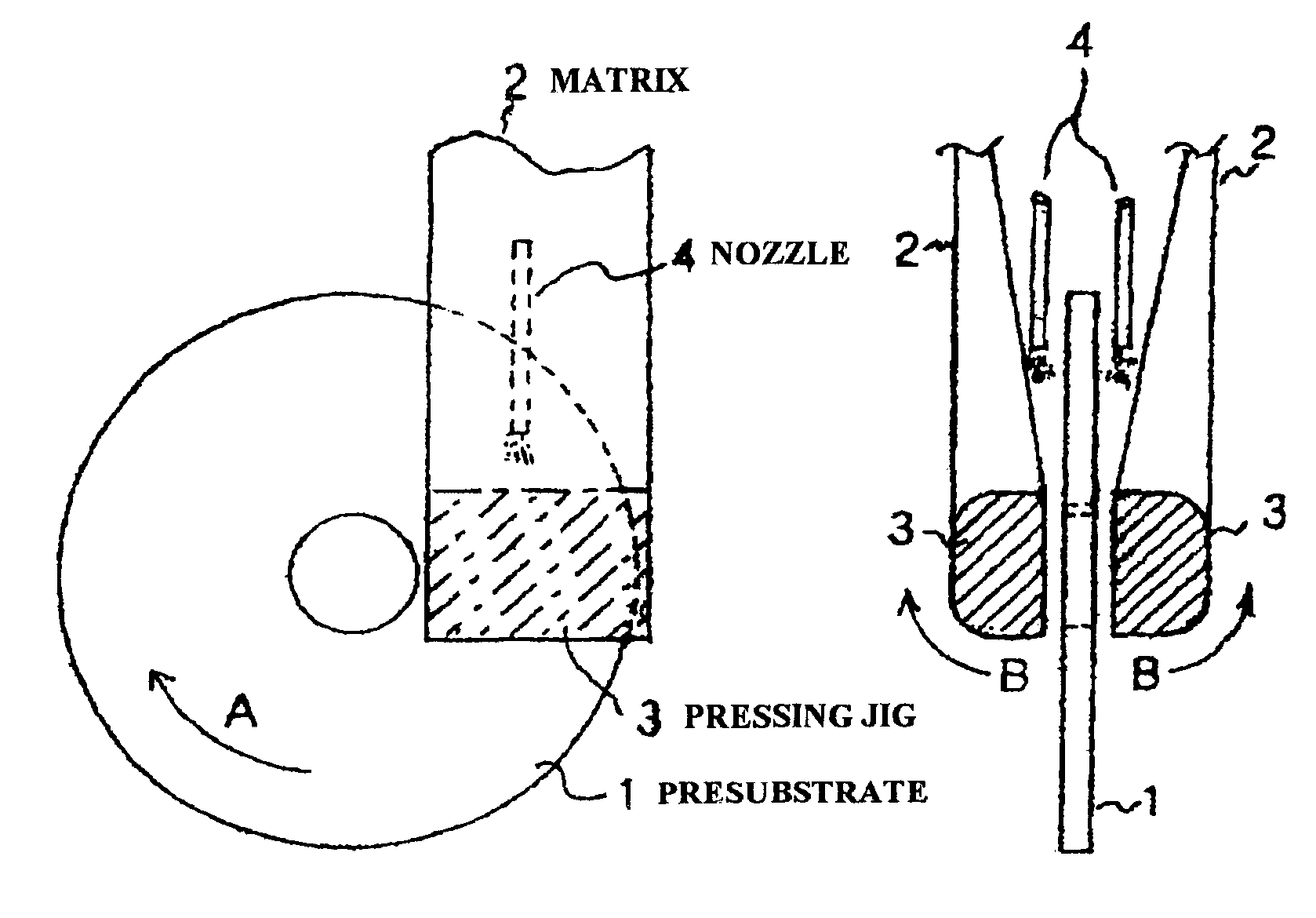

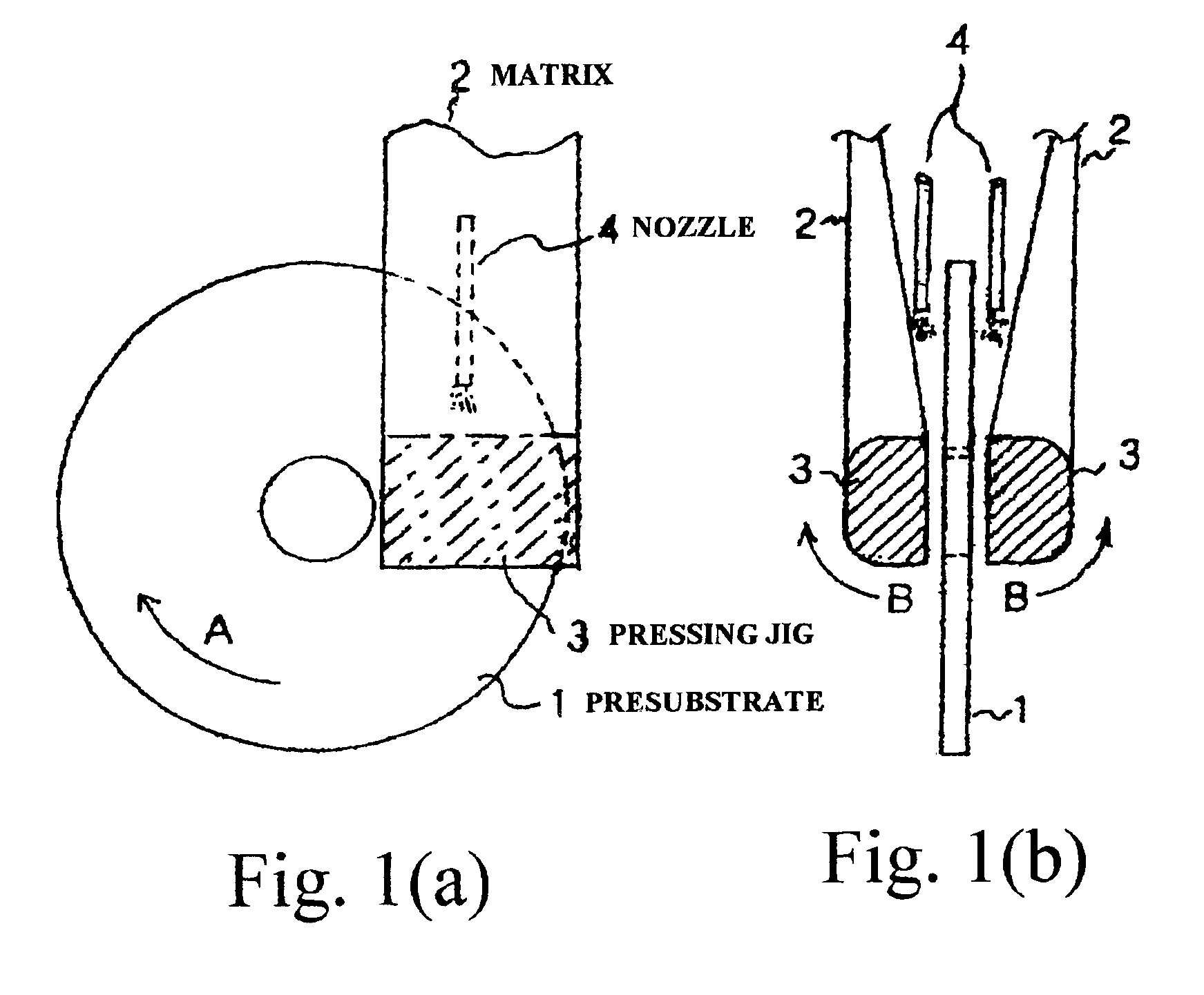

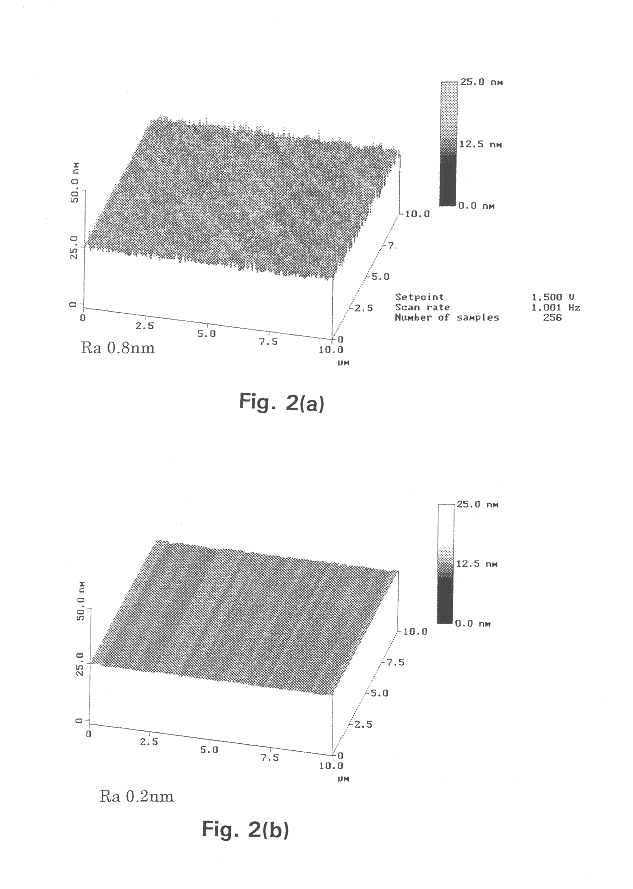

Substrate for magnetic recording medium, manufacturing method thereof, and magnetic recording medium

InactiveUS6632547B2Increased surface roughness accuracyImproved machine characteristicPolishing machinesRevolution surface grinding machinesSingle processContact pressure

A slowly advancing tape-shaped matrix is pressed into contact with a surface of a rapidly rotating non-magnetic substrate for a magnetic recording medium. An abrasive slurry is added to the matrix. The area contact rate between the matrix and the surface, as well as the contact pressure per unit area between the matrix and the surface are regulated to both polish and slightly roughen the surface in a single process. In the case of a glass presubstrate, the glass is chemically strengthened before being surface-treated.< / PTEXT>

Owner:FUJI ELECTRIC CO LTD

Wood counting method based on contour optimization

ActiveCN106023137AEasy post-processingEliminate adhesionImage enhancementImage analysisPattern recognitionEdge operator

The invention discloses a wood counting method based on contour optimization. The method comprises the steps that dimension conversion is carried out on a wood image; a wood target image is extracted from the conversed image through a color model, and edge information in the image is extracted through an edge operator; the extracted wood target image and the edge information are merged to acquire a pre-segmented image; the outline of a candidate target is extracted from the pre-segmented image, and extracted outer contour and inner contour are respectively corroded and expanded for optimization; and the above process is repeated until the number of extracted outer contours is invariant and the inner contour is not present. According to the optimization process, a false target and the adherence of targets are eliminated for the wood candidate target of the pre-segmented image; and the extracted wood target can be directly used for counting. According to the invention, the validity of the method is experimentally verified.

Owner:HUAZHONG UNIV OF SCI & TECH

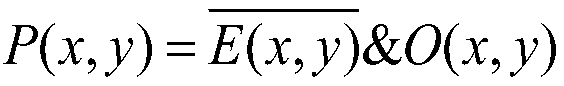

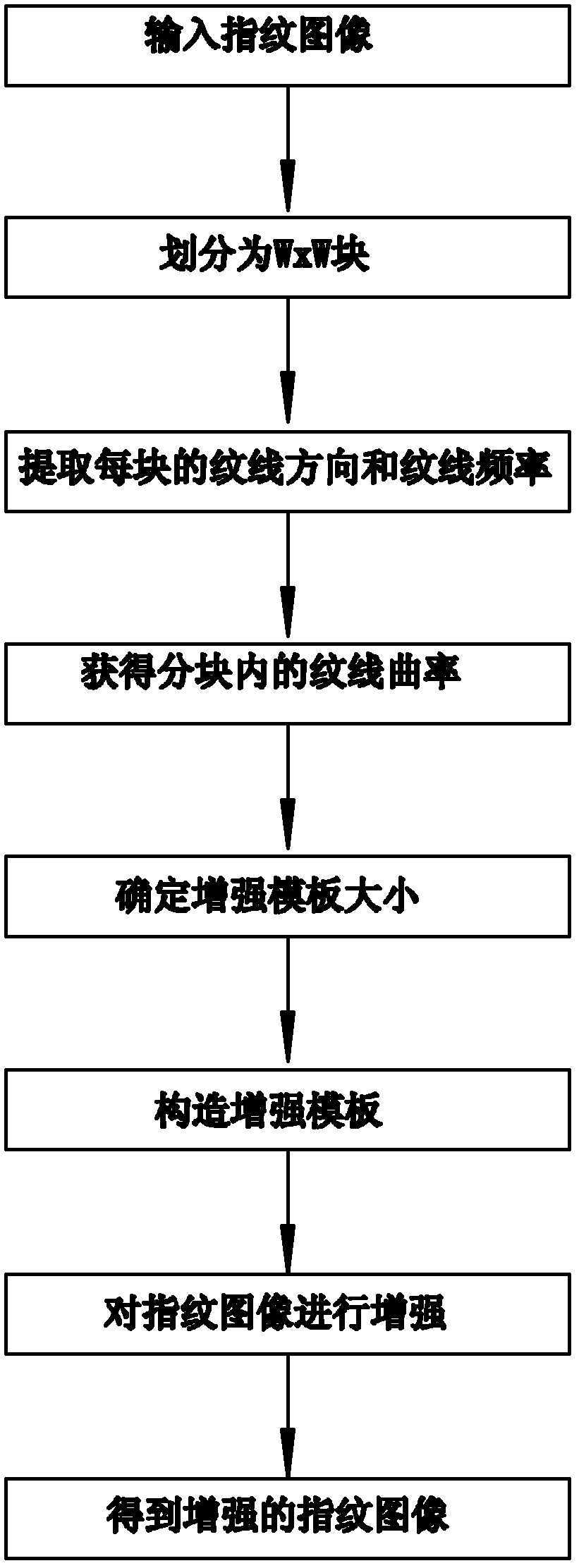

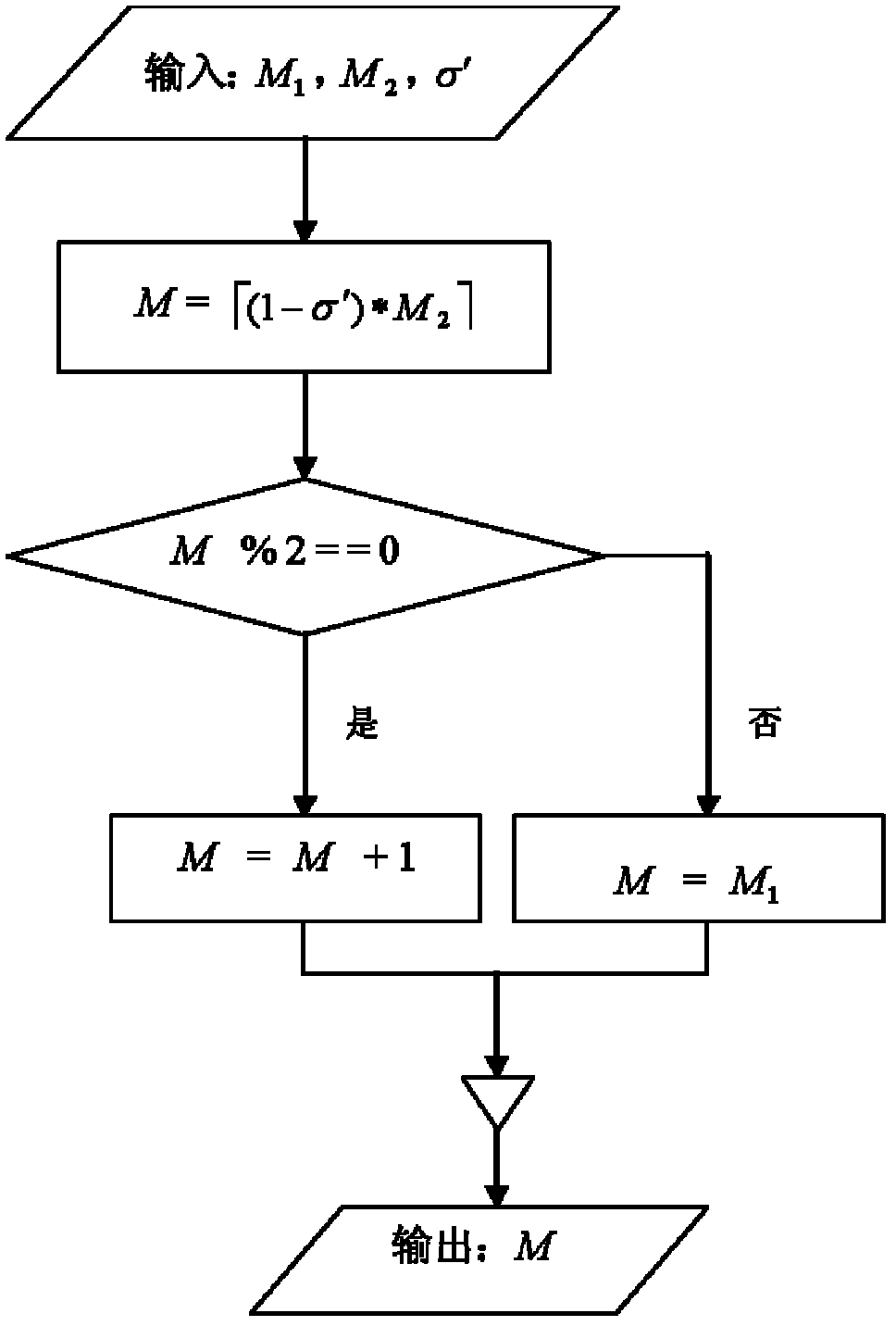

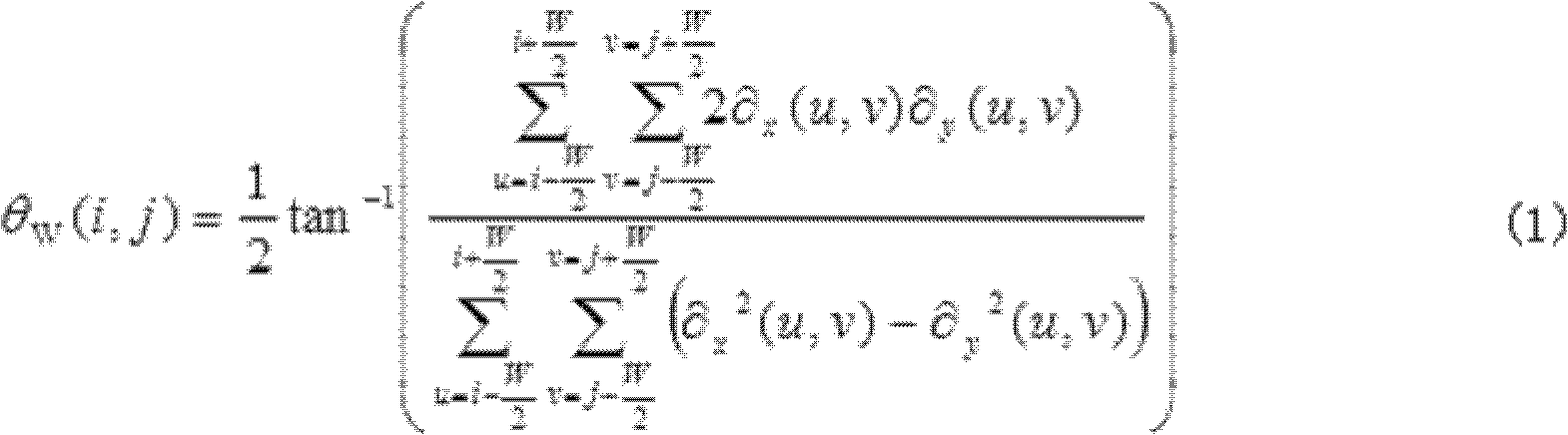

Template size self-adaptable Gabor fingerprint image enhancement method

InactiveCN102254163AQuality improvementAvoid destructionCharacter and pattern recognitionPattern recognitionFingerprint image

The invention discloses a template size self-adaptable Gabor fingerprint image enhancement method, which comprises the following steps of: (1) inputting a fingerprint image, dividing the inputted image I (x, y) into W*W blocks of sub blocks which are not mutually overlapped and extracting a ridge direction and a ridge frequency of each sub block; (2) obtaining a ridge curvature in the sub blocks; (3) determining sizes of enhancement templates; (4) constructing the enhancement templates; and (5) carrying out enhancement on the fingerprint image to obtain an enhanced fingerprint image. The template size self-adaptable Gabor fingerprint image enhancement method disclosed by the invention is used for self-adaptively adjusting sizes of Gabor enhancement templates according to degree of ridge direction change in the sub blocks of the fingerprint image, different enhancement degrees are obtained, so that the definition of fingerprint ridges is enhanced and original ridge structure information is maintained, and the destruction to the fingerprint ridge structure in the traditional Gabor fingerprint image enhancement method is avoided and the quality of the fingerprint image is better improved.

Owner:SHANDONG ZHIHUA INFORMATION TECH

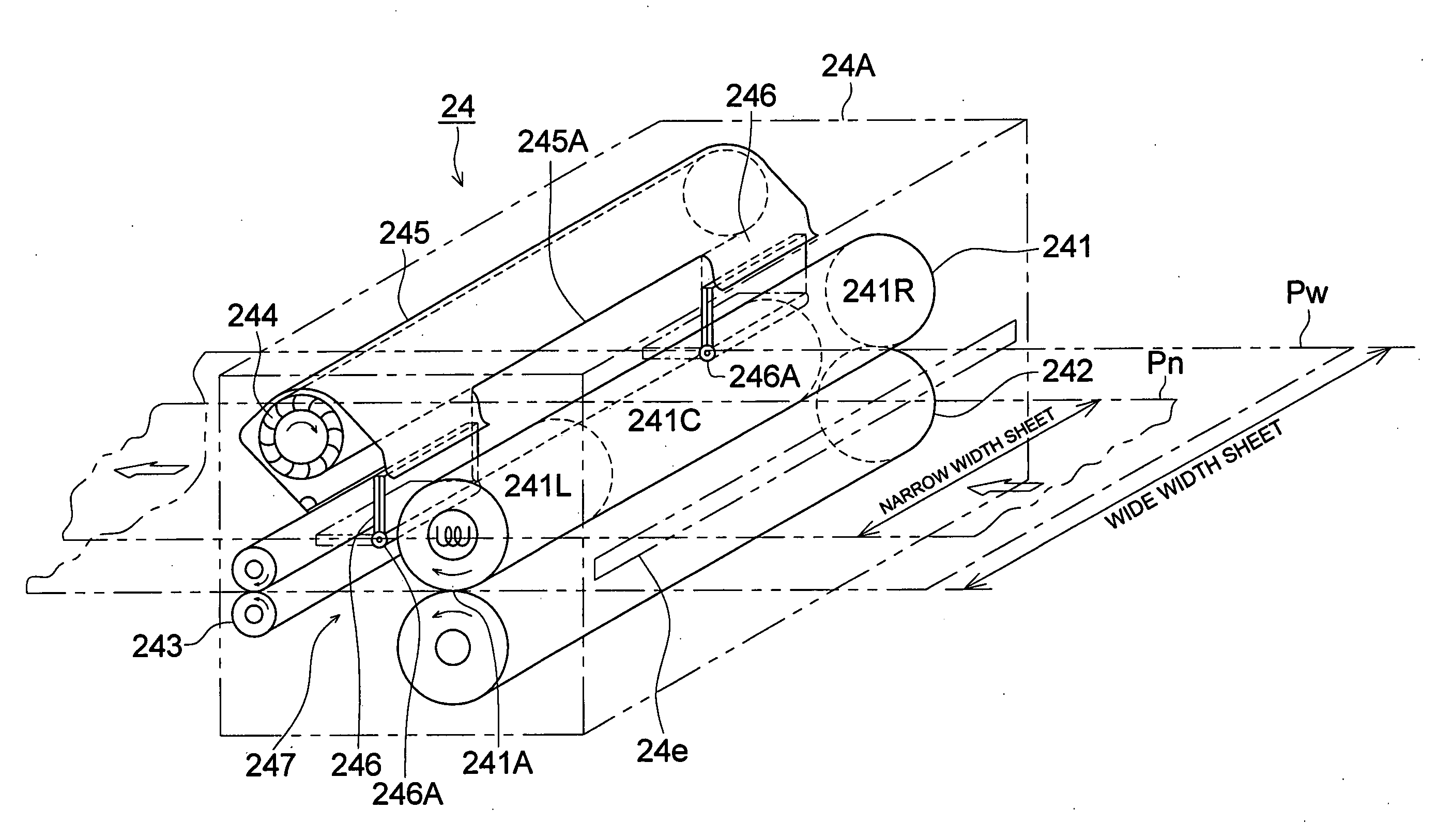

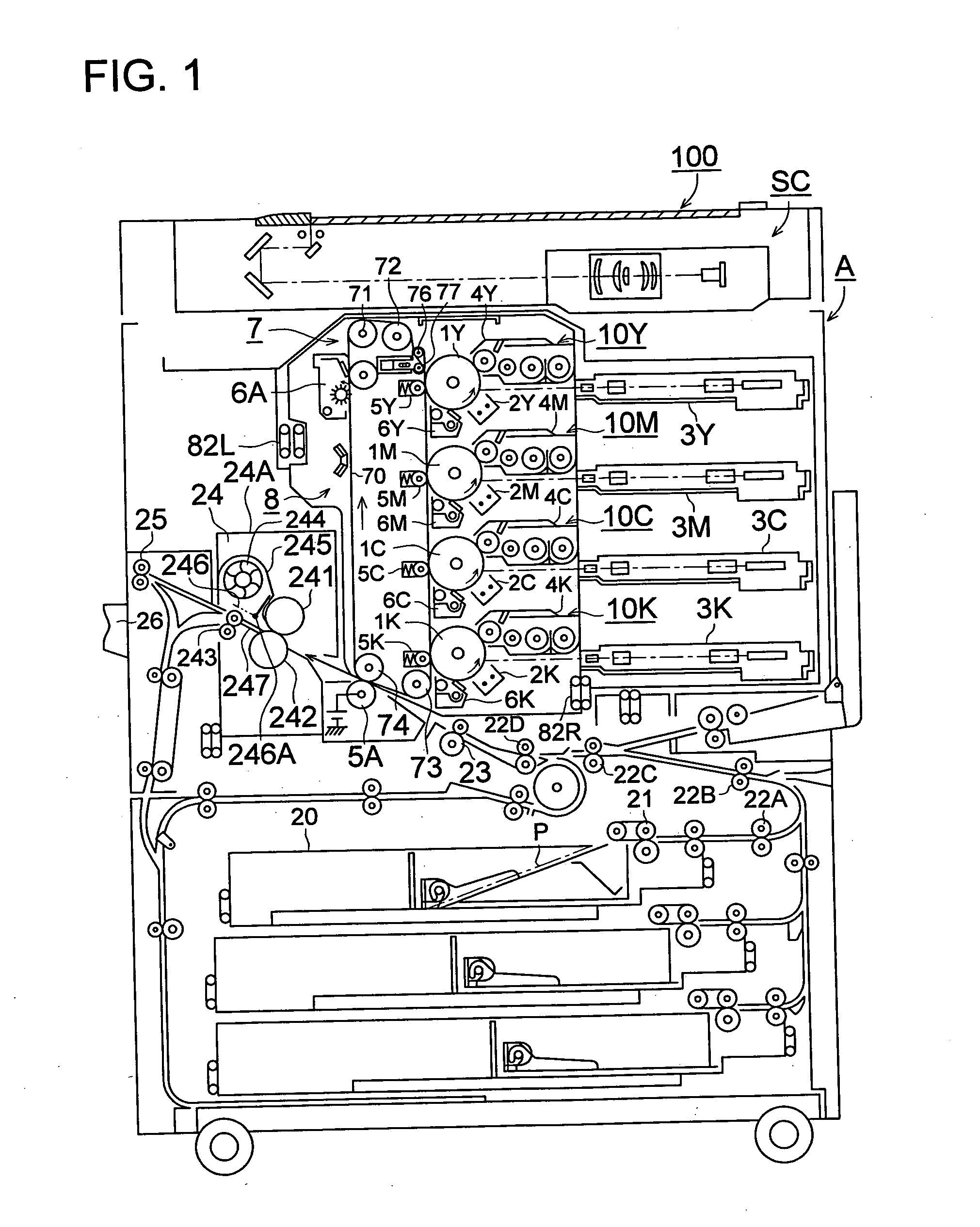

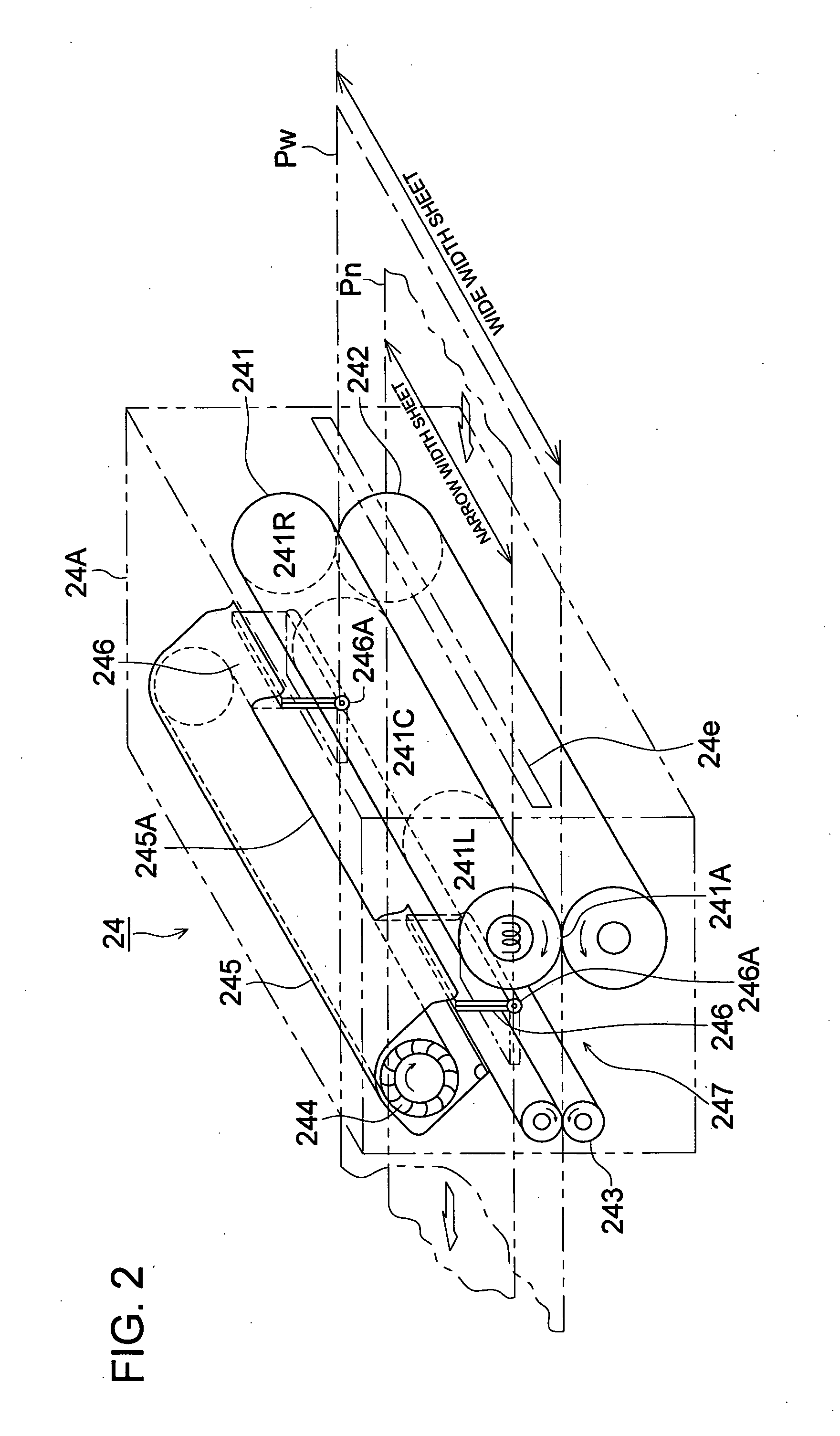

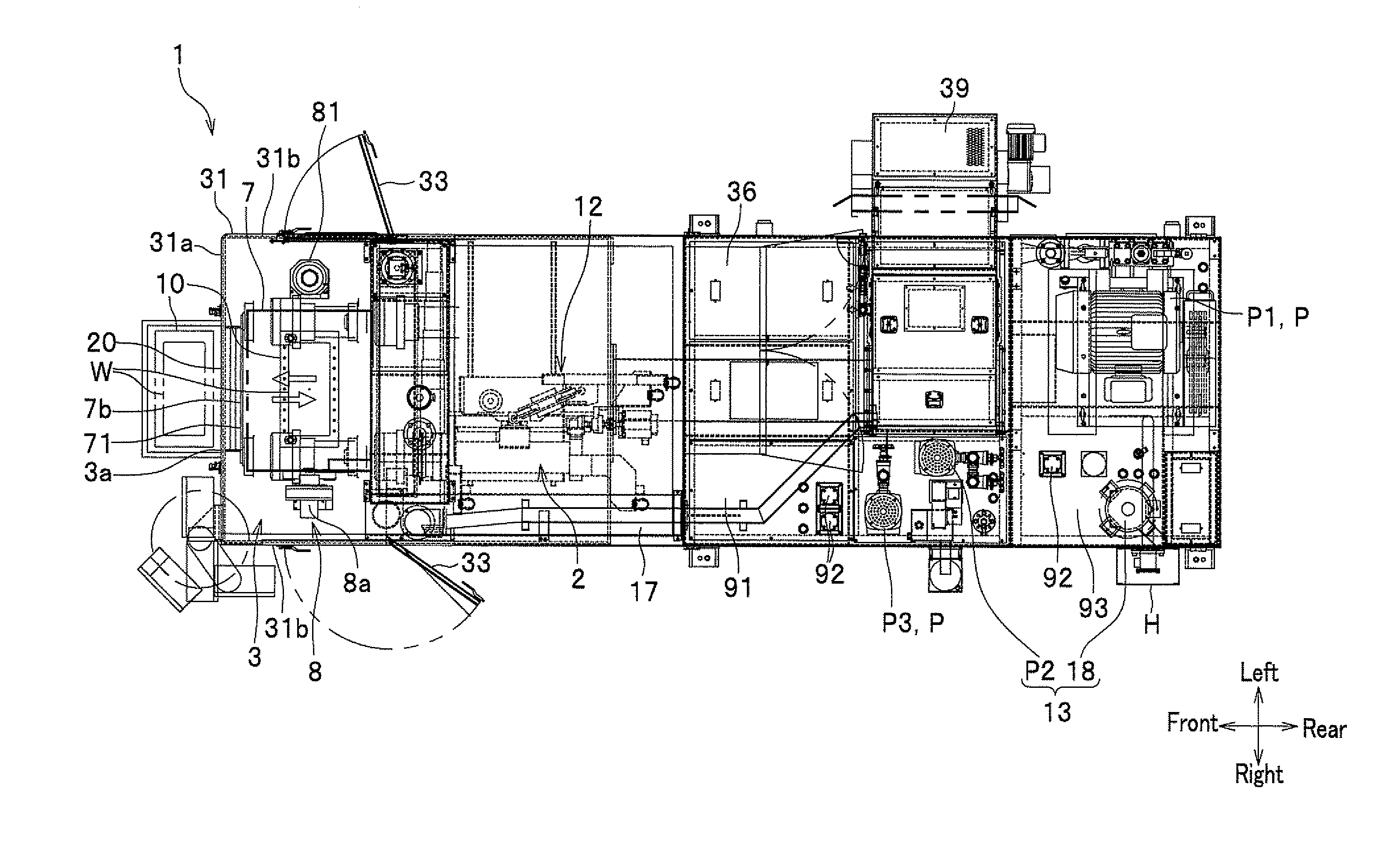

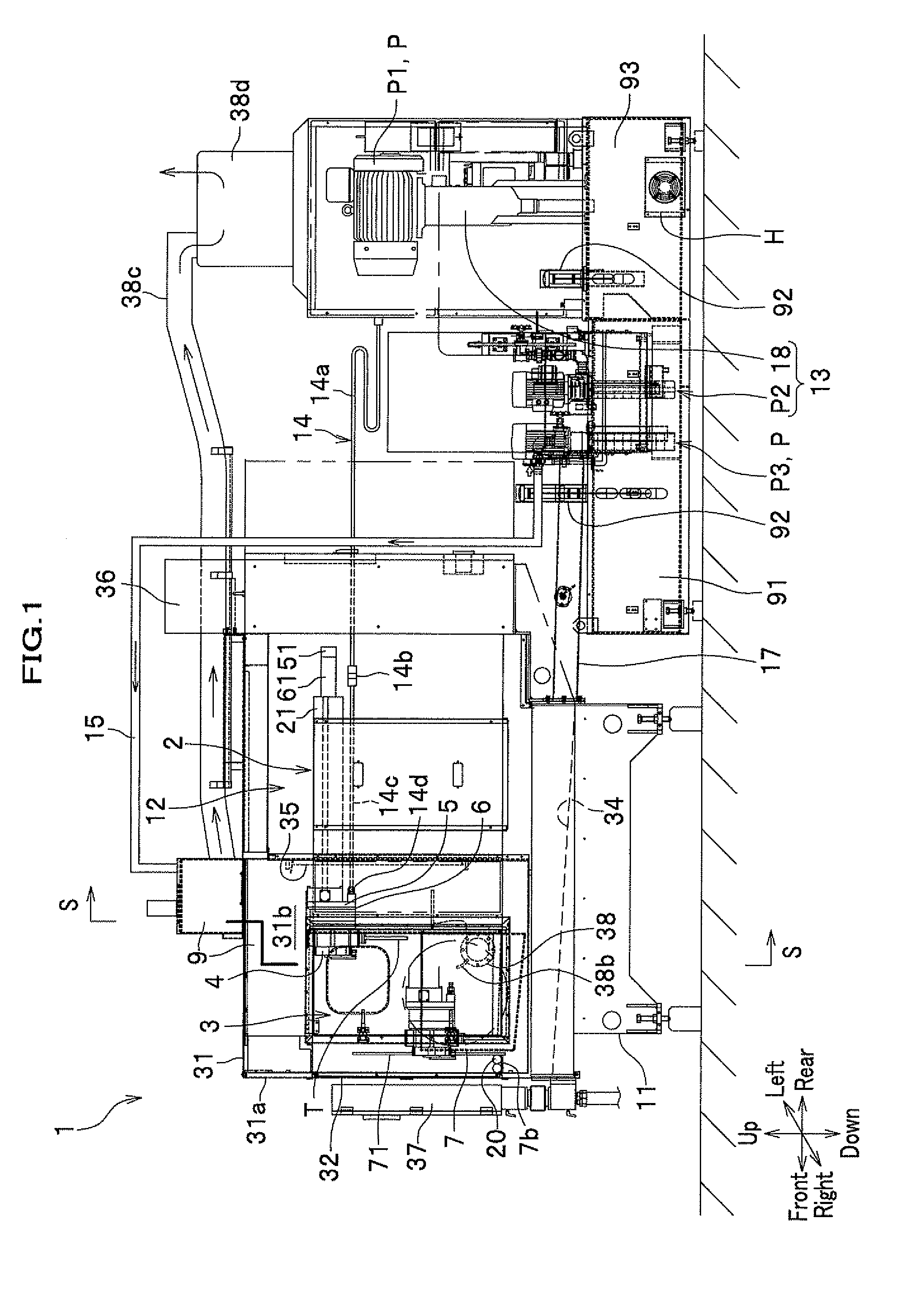

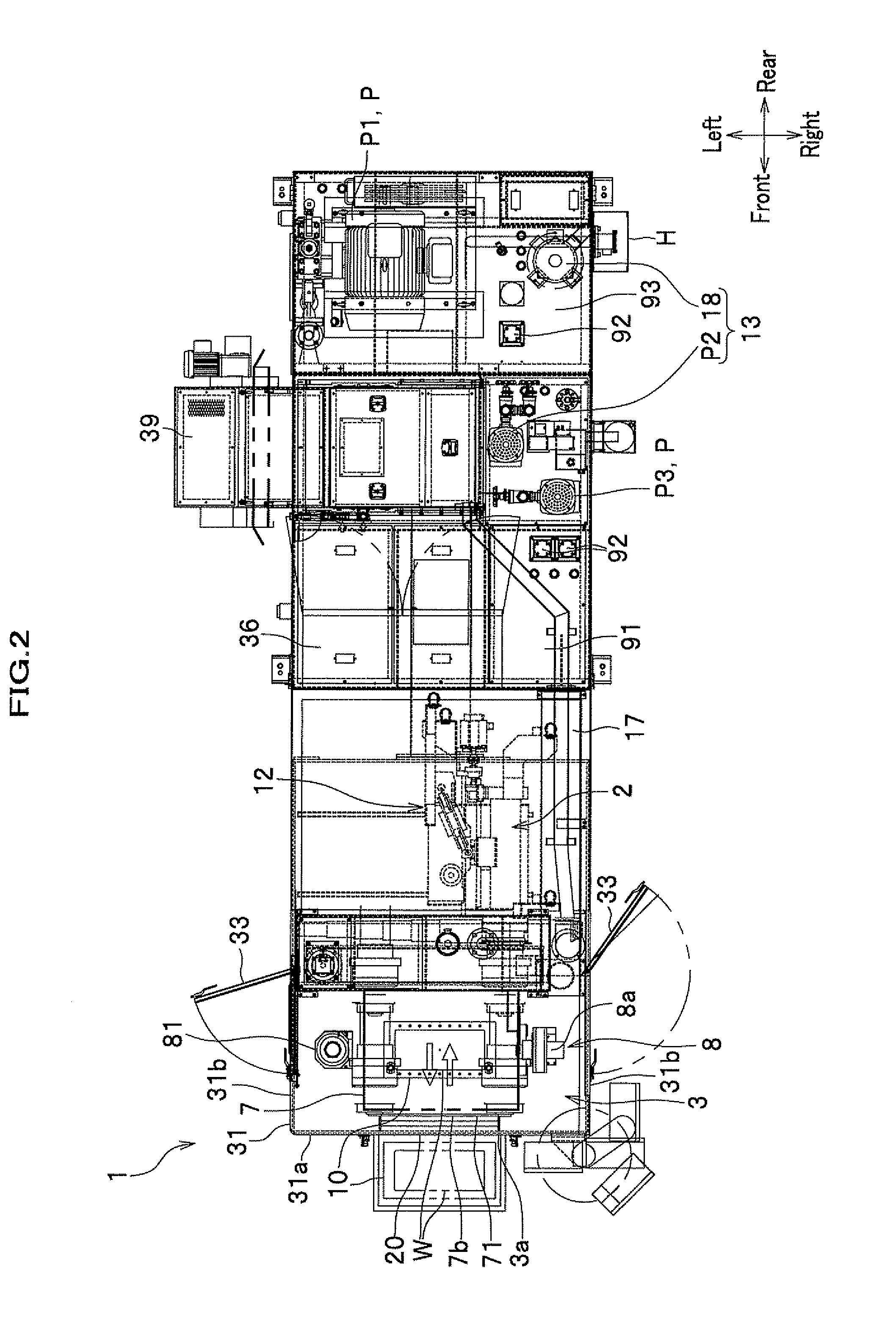

Image forming apparatus

ActiveUS20060140662A1Easy constructionEliminate adhesionElectrographic process apparatusImage formationEngineering

An image forming apparatus provided with a fixing unit, the fixing unit comprising: a fixing member having a heating member therein; a pressing member that presses against the fixing member, wherein an image supporting material carrying a toner image is grasped and conveyed by a nipping portion formed between the fixing member and the pressing member and the toner image is fixed by applying heat and pressure at the nipping portion; an air blowing section provided downstream of the nipping portion on a conveying path of the image supporting material; and an air flow path switching section that switches an air blow of the air blowing section in accordance with a size of the image supporting material for both ends of the conveying path and for both ends of the fixing member.

Owner:KONICA MINOLTA BUSINESS TECH INC

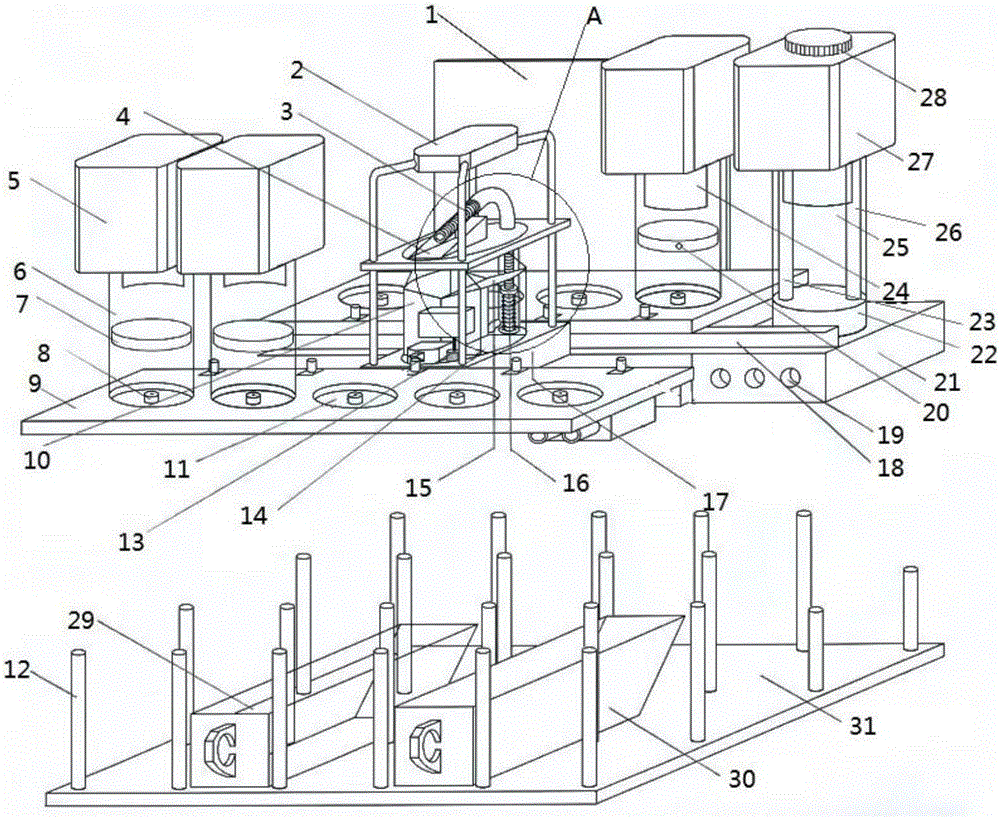

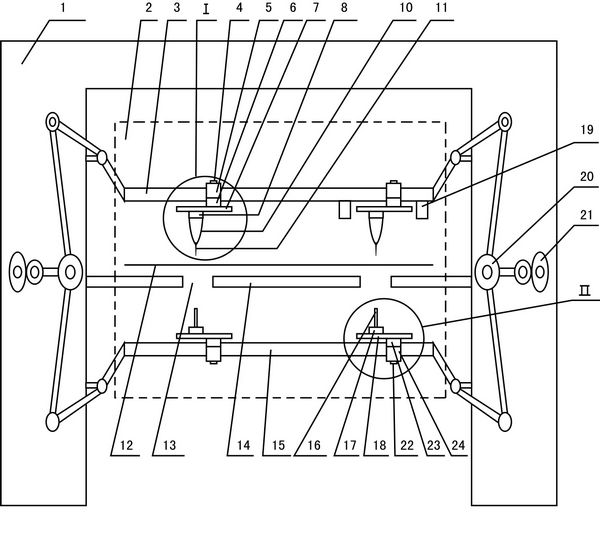

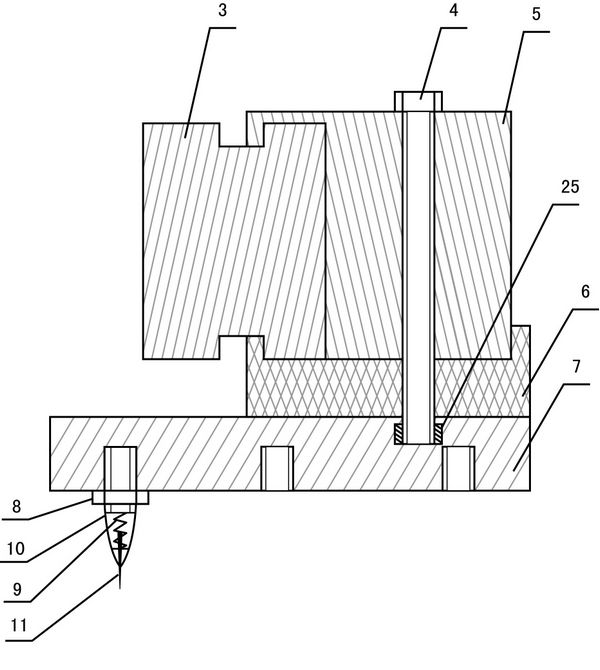

Medicine dispensing device for automatically dispensing tablets

ActiveCN106491253ASimple procedureOverall small sizeCoin-freed apparatus detailsOral administration deviceOral medicineControl system

The invention discloses a medicine dispensing device for automatically dispensing tablets comprising a medicine supply system, a sorting system and a control system; the medicine supply system comprises multiple medicine supply units; the sorting system comprises a negative pressure medicine fetching machine and a visual verification mechanism; the negative pressure medicine fetching machine is provided with a negative pressure suction nozzle which is used for sucking up tablets; the negative pressure suction nozzle sucks single tablet from the medicine supply units; the visual verification mechanism photographs images of tablets and sends the images to the control system; the device also comprises a medicine dispensing buffer region and a medicine discarding buffer region; the medicine dispensing buffer region is used for receiving expected tablets and the medicine discarding buffer region is used for receiving unexpected tablets. The device of the invention uses negative pressure suction principle to guarantee that the object of each suction is a single tablet. The visual verification mechanism photographs images of tablets after the negative pressure suction nozzle successfully sucks tablets, identifies the types, quantity and integrity of tablets. The device greatly simplifies procedures of taking various kinds of medicines for people; the device fills the gap that there is no household automatic oral medicine placing device currently; the device is reliable, simple and efficient, etc.

Owner:马朴存

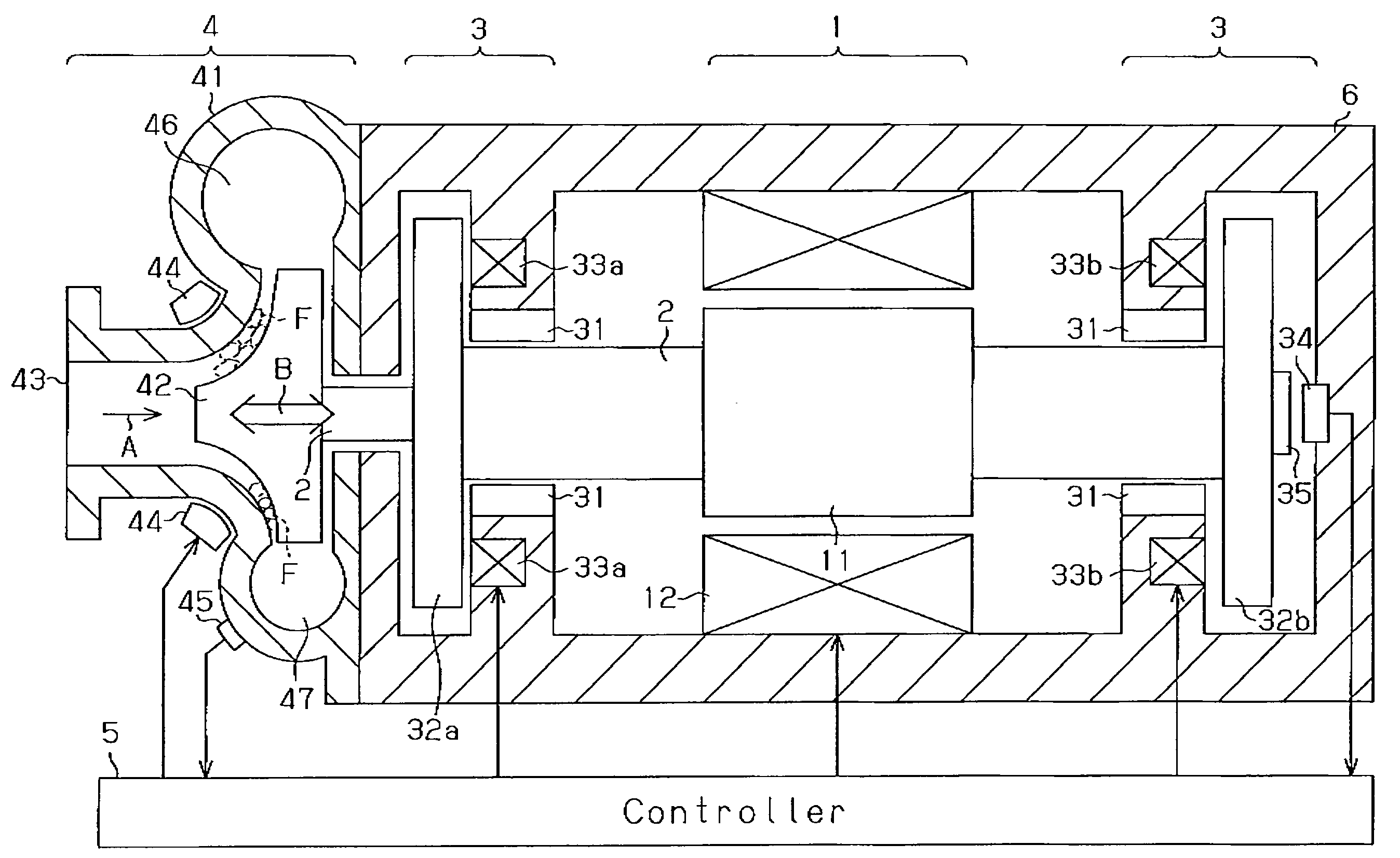

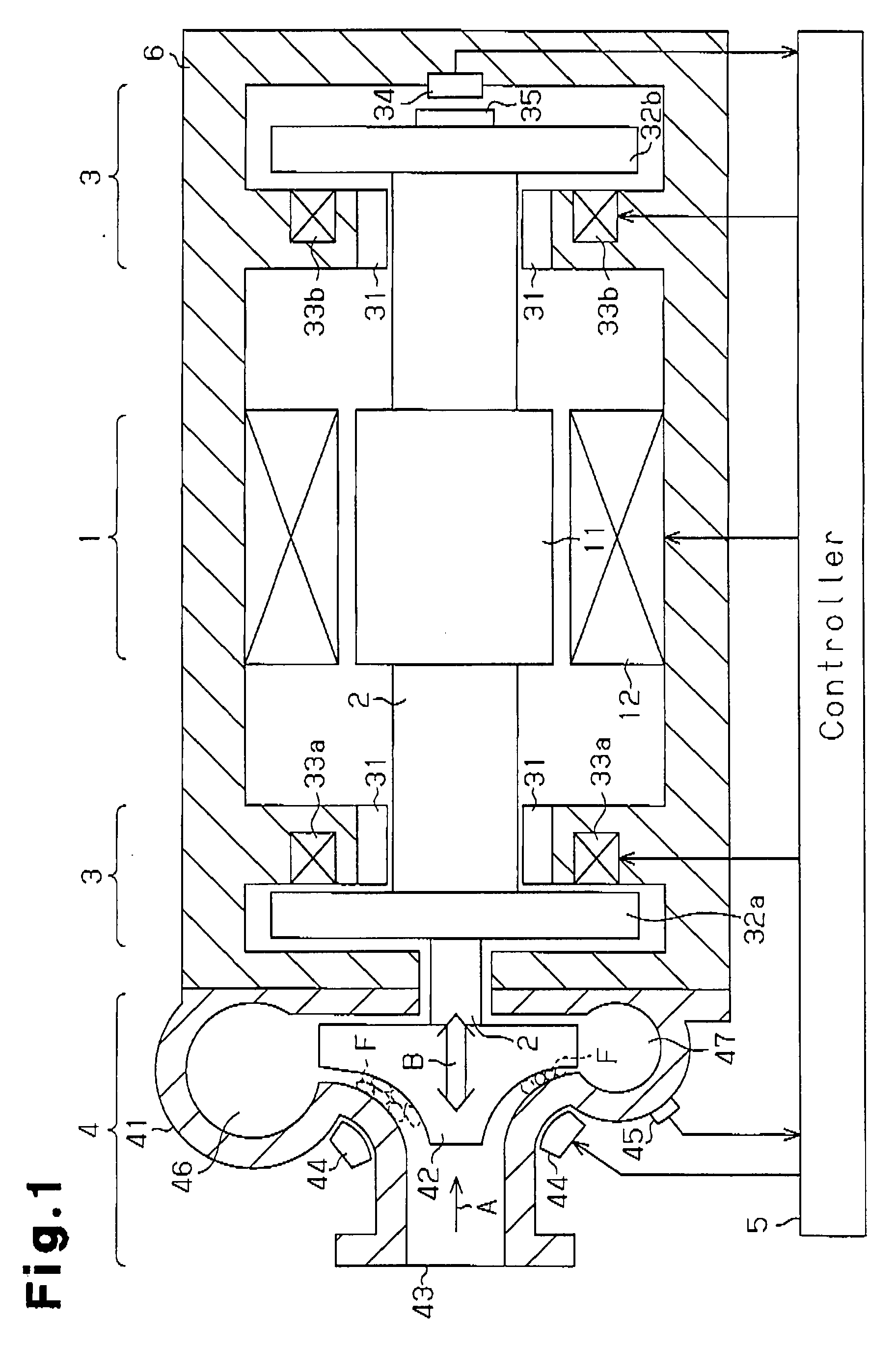

Centrifugal air compressor

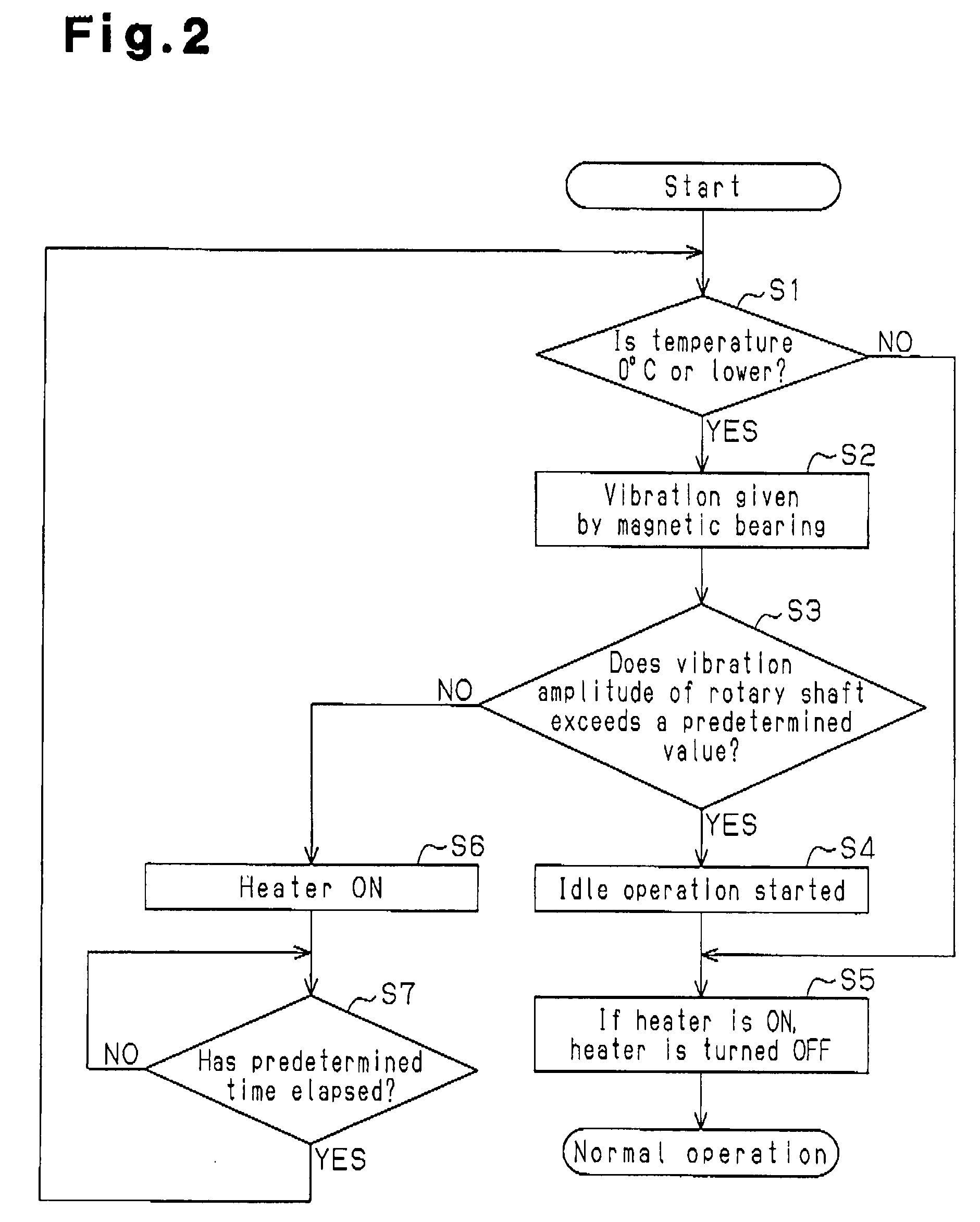

InactiveUS20080292469A1Eliminate adhesionSmooth startPump componentsPump controlVibration amplitudeMagnetic bearing

If the ambient temperature of a pressure volute measured by a temperature sensor exceeds 0° C., a compressor is instantly started at normal operation. If the temperature of the pressure volute measured by the temperature sensor is 0° C. or lower, there is a possibility that a rotary vane may be adhered to the pressure volute due to a congelation. Therefore, vibration along the axial direction is given to the rotary shaft by way of an axial magnetic bearing. If the vibration amplitude of the thus given vibration exceeds a predetermined value, the compressor is started at normal operation after idle operation. On the other hand, if the vibration amplitude is lower than a predetermined value, it is determined that the thus given vibration is unable to eliminate the adhesion of the rotary vane due to the congelation, and the heater is actuated to heat the pressure volute only for a predetermined time. Thereafter, the ambient temperature is detected again, and if the ambient temperature exceeds 0° C., the compressor is started,

Owner:JTEKT CORP

Molded article with foam-encased reinforcing member

InactiveUS20050129921A1Control deformationMinimal internal stressLayered productsConfectioneryPolymer scienceShell molding

A molded article includes a rotationally-molded body of polymer material, formed in a mold, with an elongate reinforcing member, having an end, substantially encased within the body of polymer material during molding thereof. A slip zone, defining a void in the body of polymer material, is formed around the end of the reinforcing member, such that post-molding shrinkage of the polymer material imposes substantially no stress on the end of the reinforcing member.

Owner:MITY-LITE

Molded article with foam-encased adhesion-resistant reinforcing member and method

InactiveUS20070275229A1Resistant to deformationMinimal internal stressLayered productsCeramic shaping apparatusPolymerSurface coating

A molded article includes a rotationally-molded body of polymer material, and a reinforcing member substantially encased within and in direct contact with the polymer material. Both the polymer material and the reinforcing member have their own unique post-molding shrinkage characteristics. A slip zone, defining a void in the body of polymer material, is formed around the end of the reinforcing member, such that post-molding shrinkage of the polymer material imposes substantially no stress on the end of the reinforcing member. The reinforcing member has a surface coating that substantially eliminates adhesion with the polymer material, so as to enable displacement of the reinforcing member with respect to contacting polymer material, and thereby reduce post-molding deformation of the molded article.

Owner:MFS

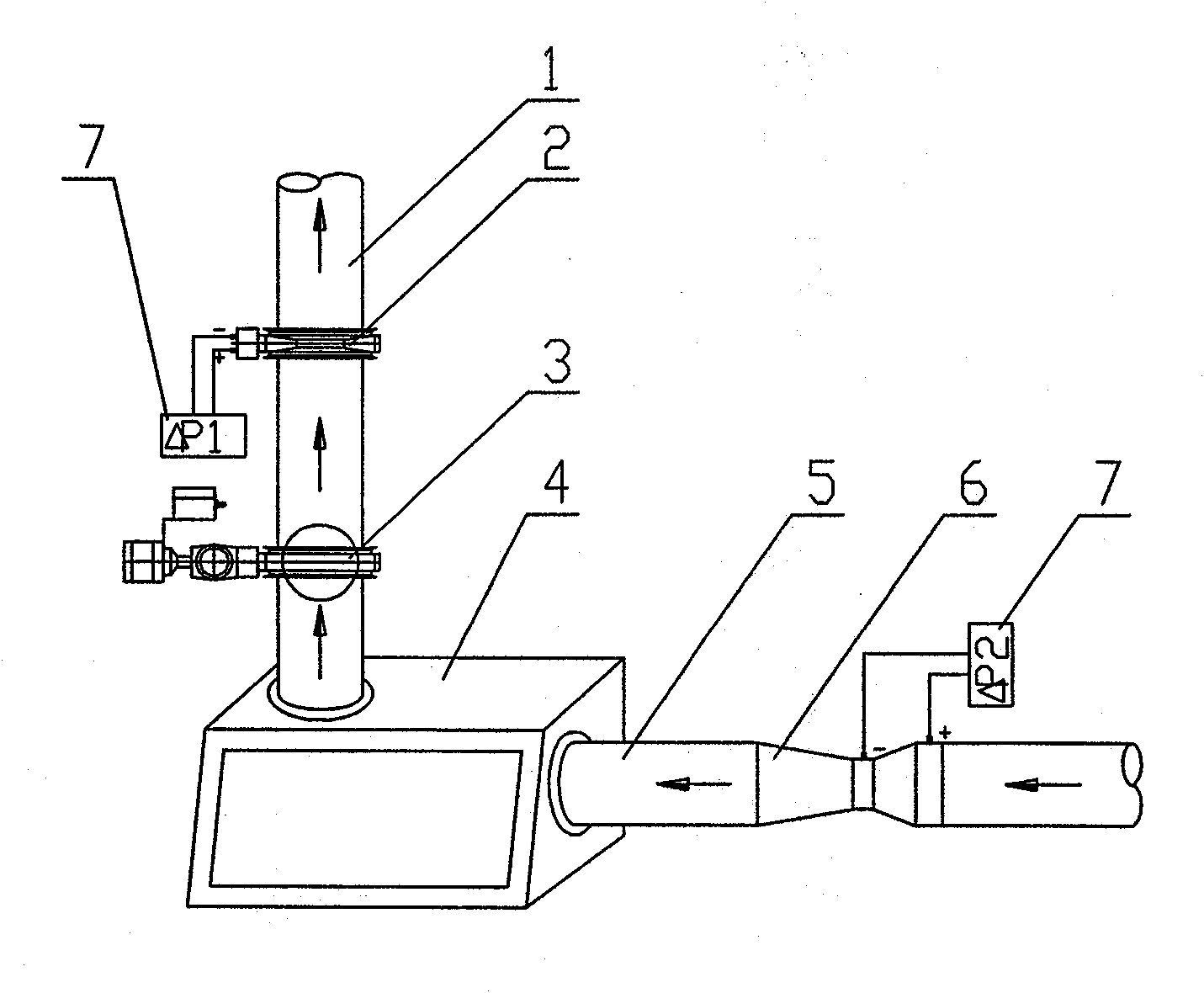

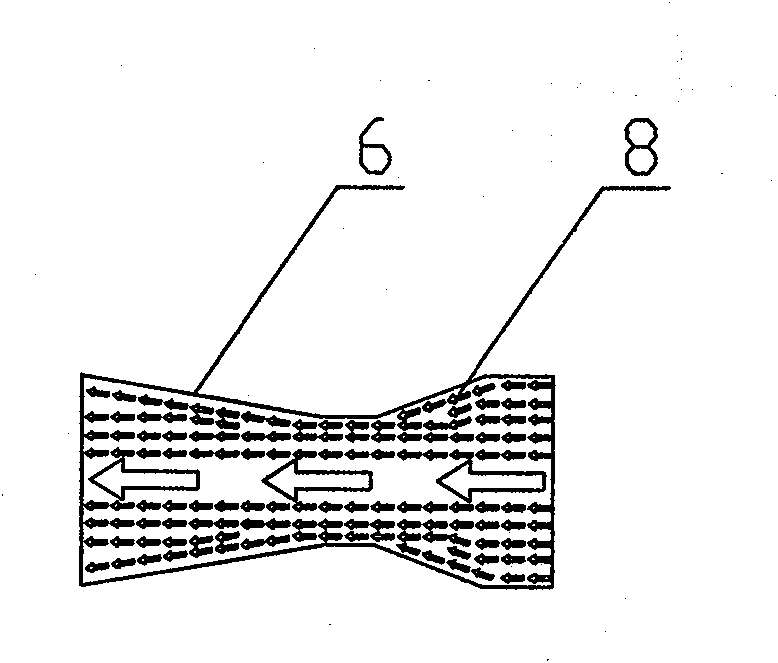

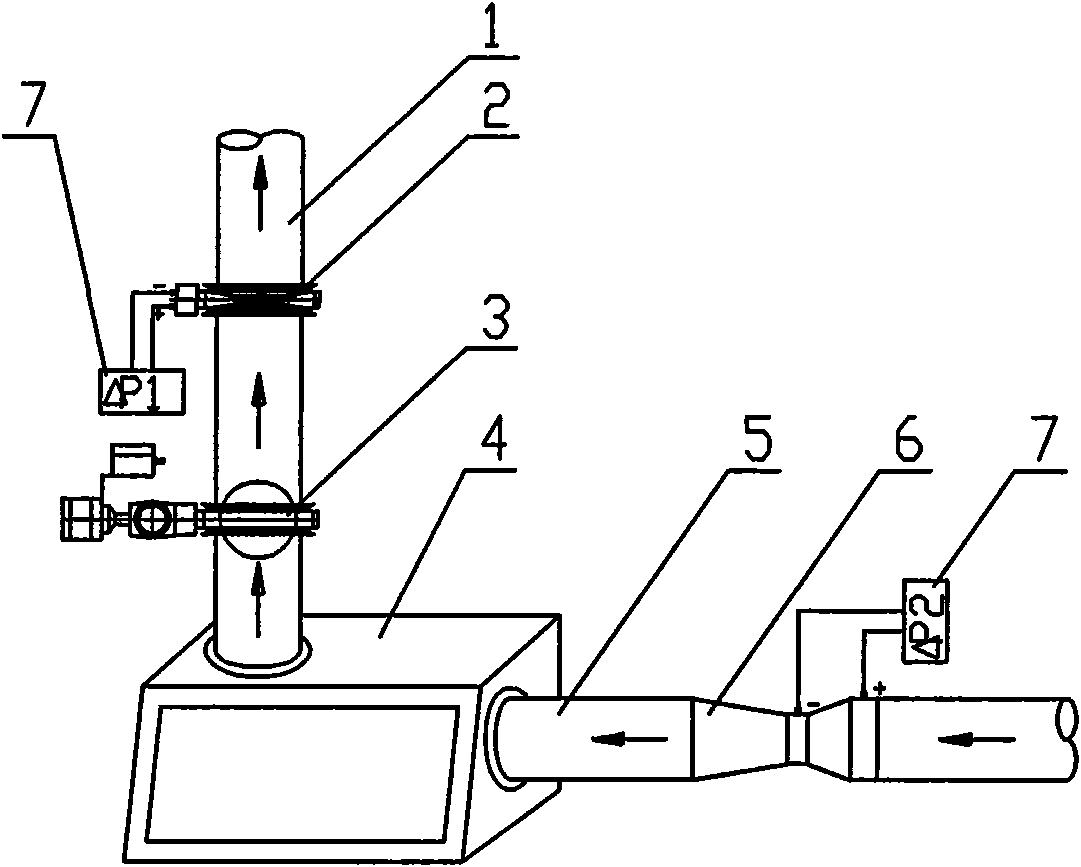

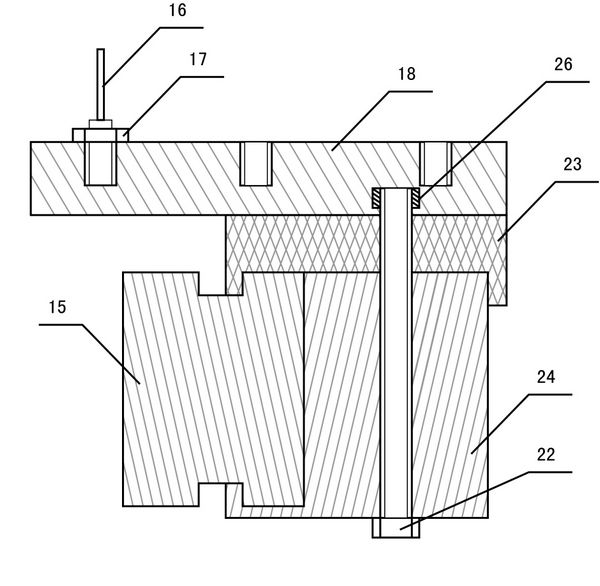

Differential pressure air speed detection and control device

InactiveCN101862035AStop stayingEliminate adhesionCigarette manufactureBulk conveyorsDifferential pressureEngineering

The invention relates to a differential pressure air speed detection and control device, which comprises an air-conveying de-dusting branch pipe, an electric (pneumatic) adjustment butterfly valve, a cut tobacco collecting box of a cigarette making machine, a cut tobacco conveying pipeline and a differential pressure flowmeter, and is characterized by also comprising a split type orifice flowmeter arranged on the air-conveying de-dusting branch pipe, wherein the differential pressure flowmeter is a split type venturi flowmeter and is arranged on the cut tobacco conveying pipeline, and the speed measuring pipe diameter of the venturi flowmeter gradually becomes small and then gradually becomes large. The invention eliminates the phenomena of cut tobacco retention, adhesion and blockage, is more suitable for detection of cut tobacco material flow in the cut tobacco conveying pipeline, and can maintain long-term operation of high-precision detection to ensure the effective operating ratio and reliability of a system.

Owner:扬州市天宝自动化工程有限公司

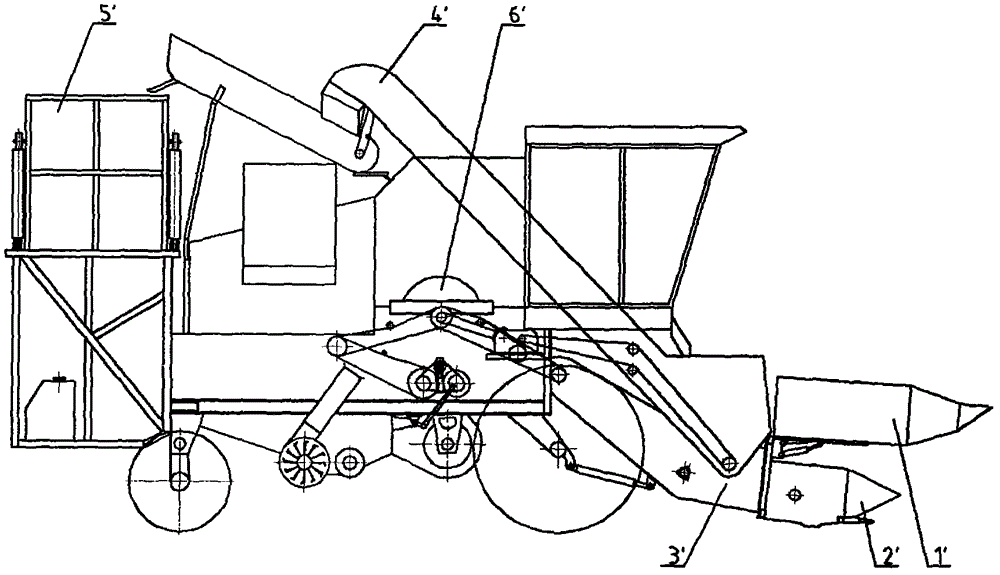

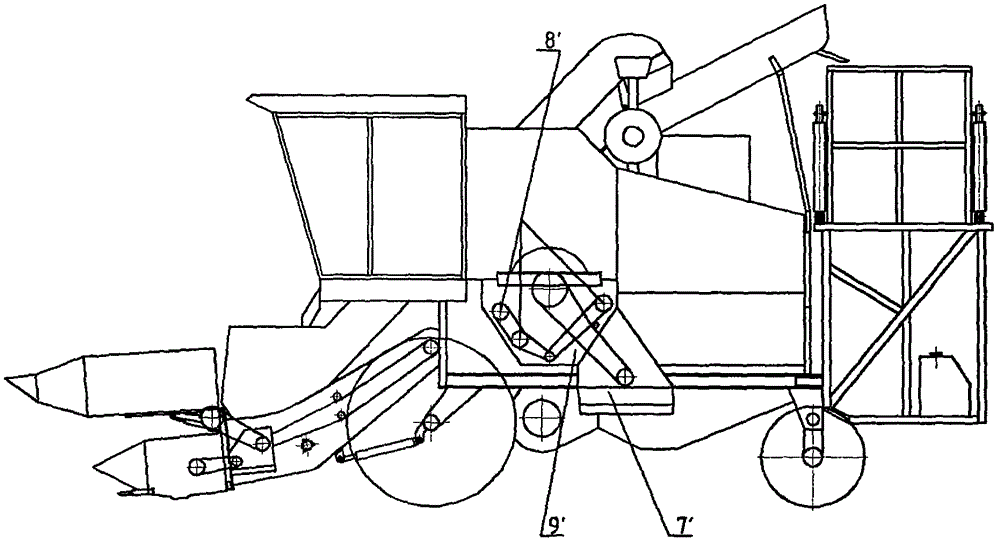

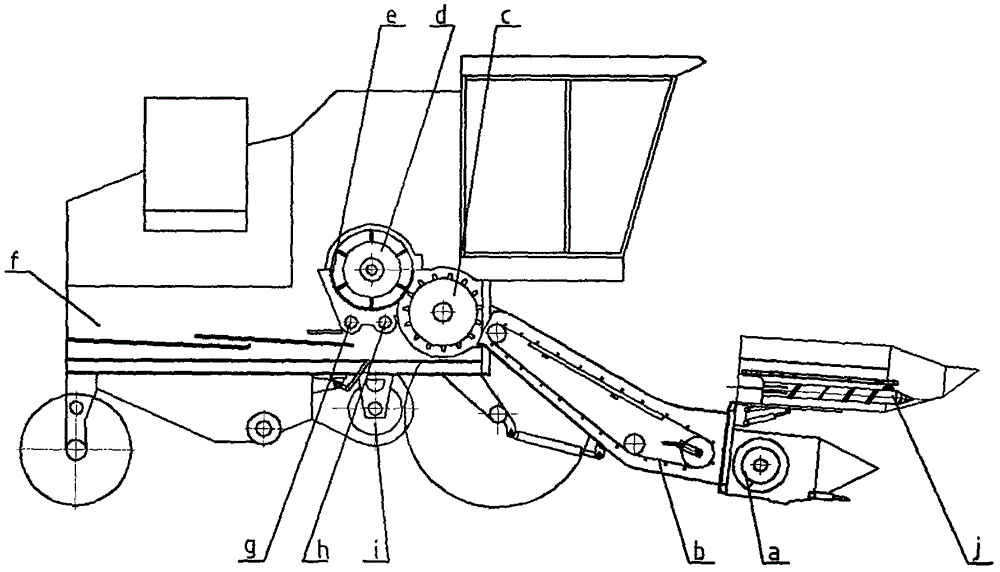

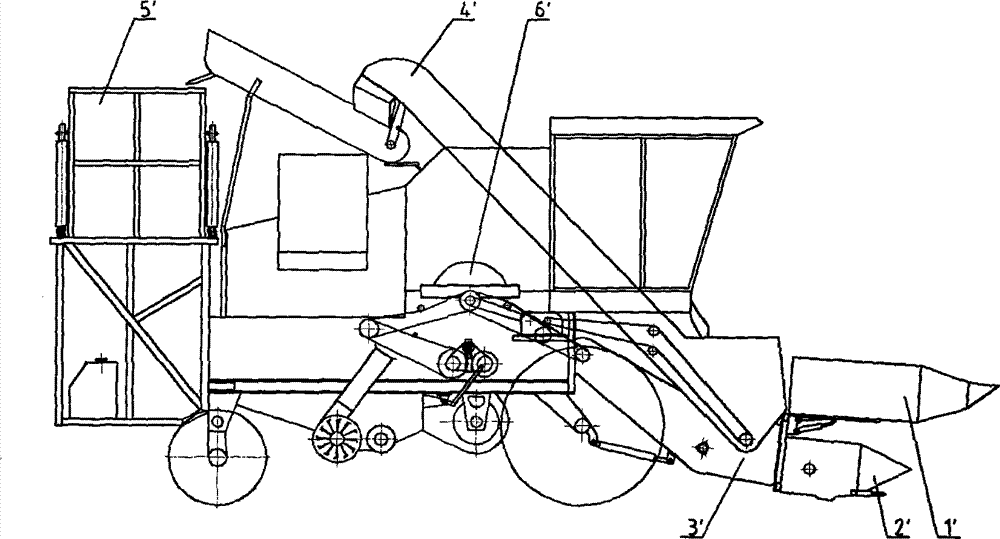

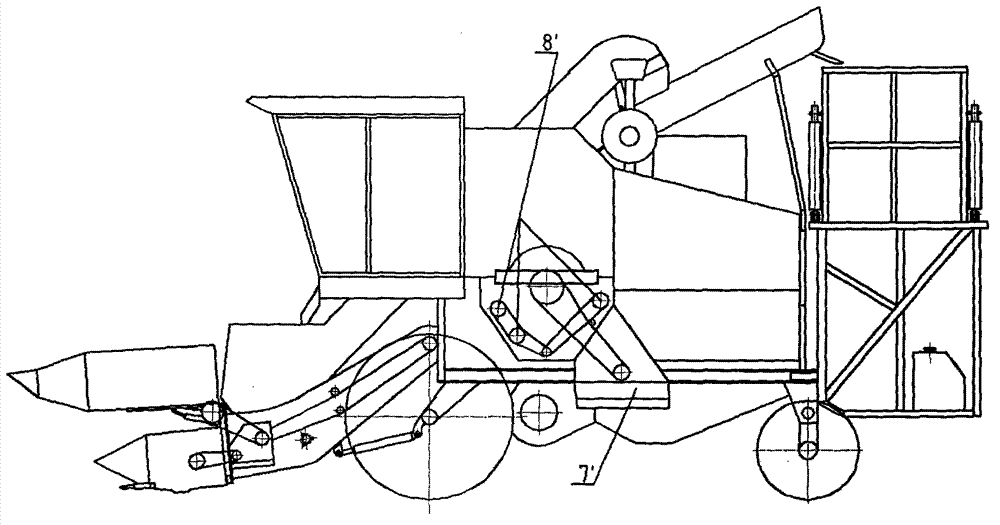

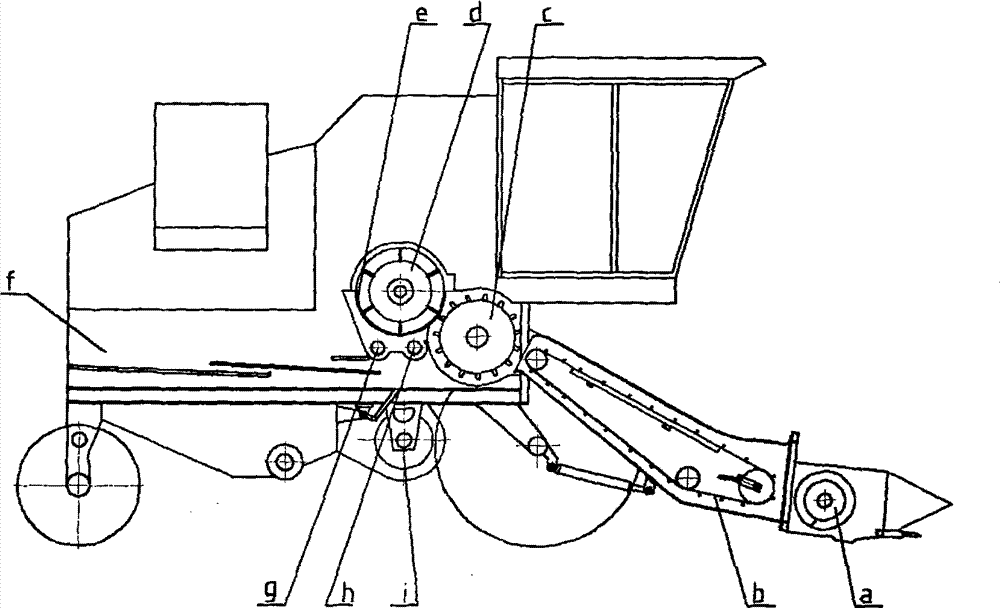

Corn harvesting and stalk separating machine and harvesting method

The invention relates to a corn harvesting and stalk separating machine and a harvesting method. The corn harvesting and stalk separating machine comprises a transmission device, a hydraulic system and a driving operation system of a harvesting machine, a corn stripping header, a stalk collecting header, a stalk conveying device, a corn warehouse and a snapped-corn elevator, wherein the corn stripping header is located in front of the harvesting machine and is used for harvesting corn; the stalk collecting header is used for cutting off and collecting corn stalks; the stalk conveying device is used for conveying the corn stalks; and the corn warehouse is located at the rear of the harvesting machine and is used for holding corncobs. The corn harvesting and stalk separating machine also can be provided with a corn stalk peel and flesh separating device, a stalk peel dispersing device and an anti-blocking mechanism which is used for preventing a griddle from being blocked. While the corn is harvested, corn stalk peel is torn into thin strips through the corn stalk peel and flesh separating device, and leaves and flesh are torn up and are respectively discharged and stored.

Owner:SHANDONG TRALIN PAPER

Turret-type cleaning apparatus

ActiveUS20120080060A1Easy to disassembleEasy to cleanCleaning using toolsCleaning using gasesEngineeringTurret

A turret-type cleaning apparatus for using cleaning liquids, and deburring and cleaning a workpiece includes: cleaning tools for spraying one of the liquids onto the workpiece and deburring and / or cleaning it; a turnable turret head where the tools are attached; a turret drive device connected to the head and for turning the head; a cleaning liquid source for supplying the liquids to first and second cleaning liquid supply flow passages; a first cleaning liquid supply flow passage configured to supply the one of the liquids to the cleaning tool; a second cleaning liquid supply flow passage for supplying the other of the liquids to the bath; a cleaning chamber where the head is arranged; a cleaning bath installed in the chamber; and a drain port openably and closably provided below the bath and for draining the liquids in the bath.

Owner:SUGINO MACHINE

Device and method for separating skin and pulp of straw

The invention relates to an axial flow roller for separating skin and pulp of a straw and a separation device with the axial flow roller and belongs to the field of agricultural machinery. The device for separating the skin and the pulp of the straw comprises the axial flow roller and a screen, the axial flow roller comprises a round supporting disc, rack bars and spike teeth, the rack bars are fixed on the circumference outside the round supporting disc, and the spike teeth are fixed on the rack bars; the screen is arranged below the roller along the length of the axial flow roller, and a gap is reserved between the roller and the screen and forms straw separation space. The device for separating the skin and the pulp of the corn straw can be directly installed on a harvester so that when corn is harvested, simultaneously, the corn straw can be separated into elongated straw outer skin, irregular block pulp and small sheet leaf blades to be discharged, the elongated straw outer skin, the irregular block pulp and the small sheet leaf blades are dried and classified to be used, and utilization values of the straw are improved.

Owner:SHANDONG TRALIN PAPER

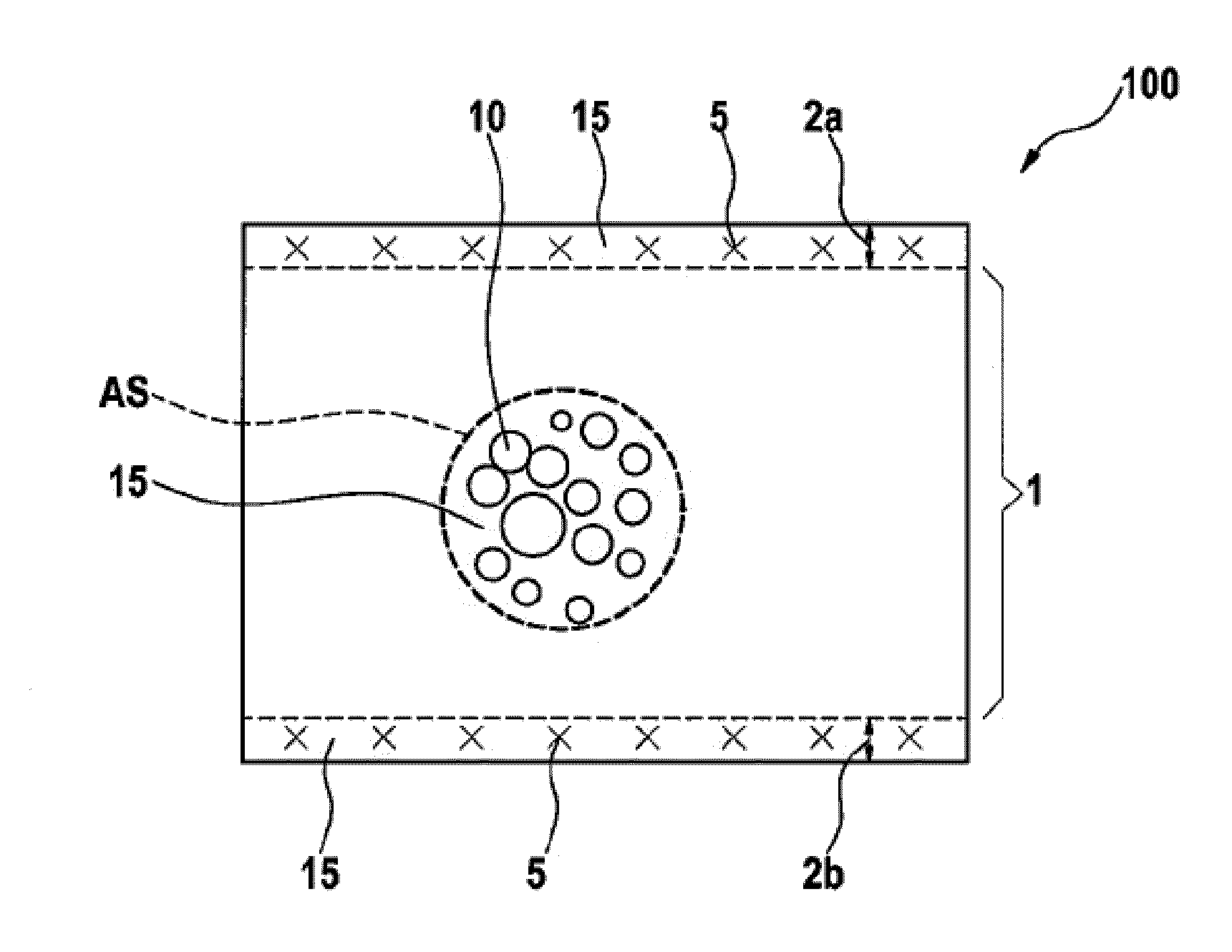

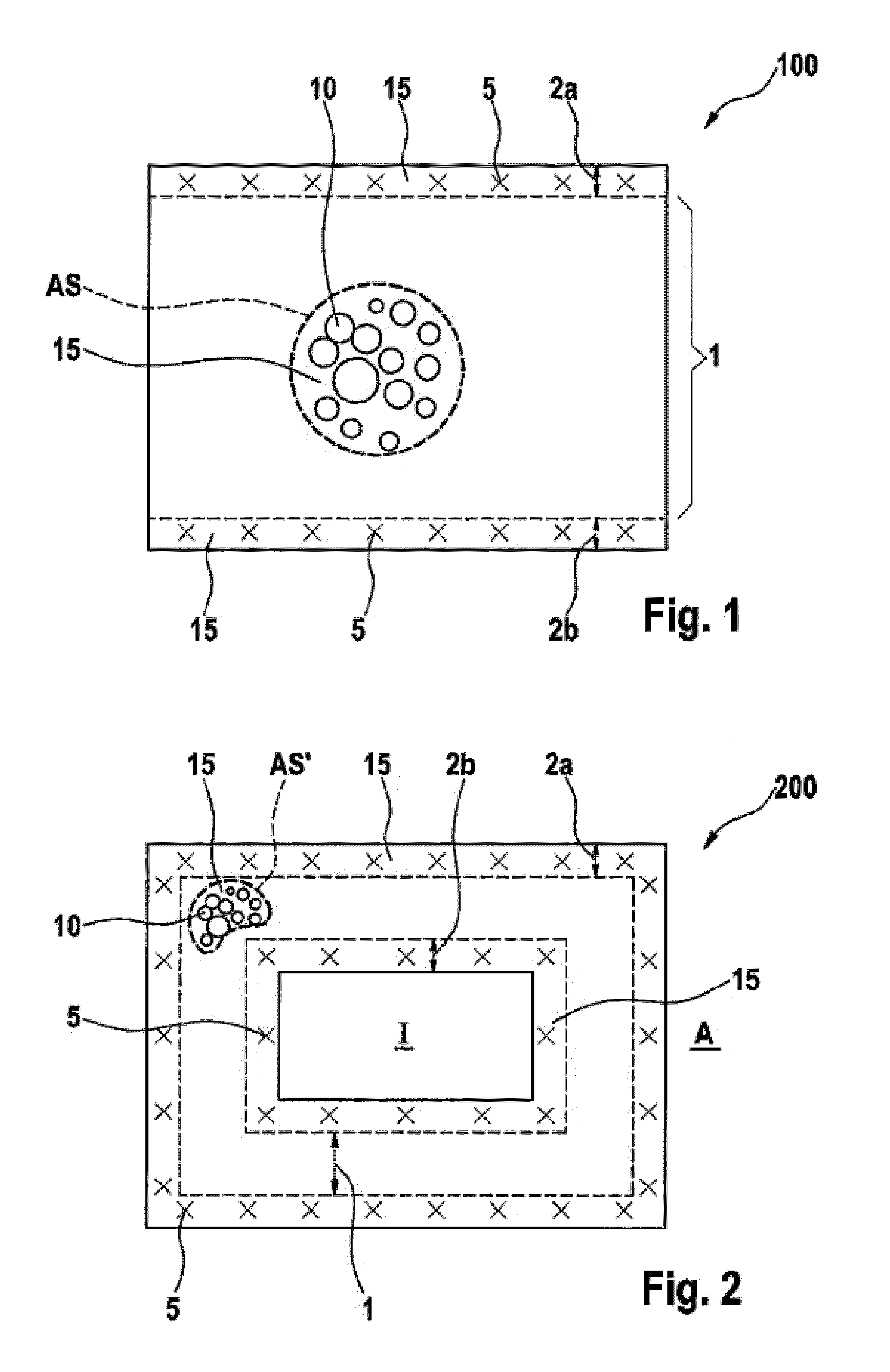

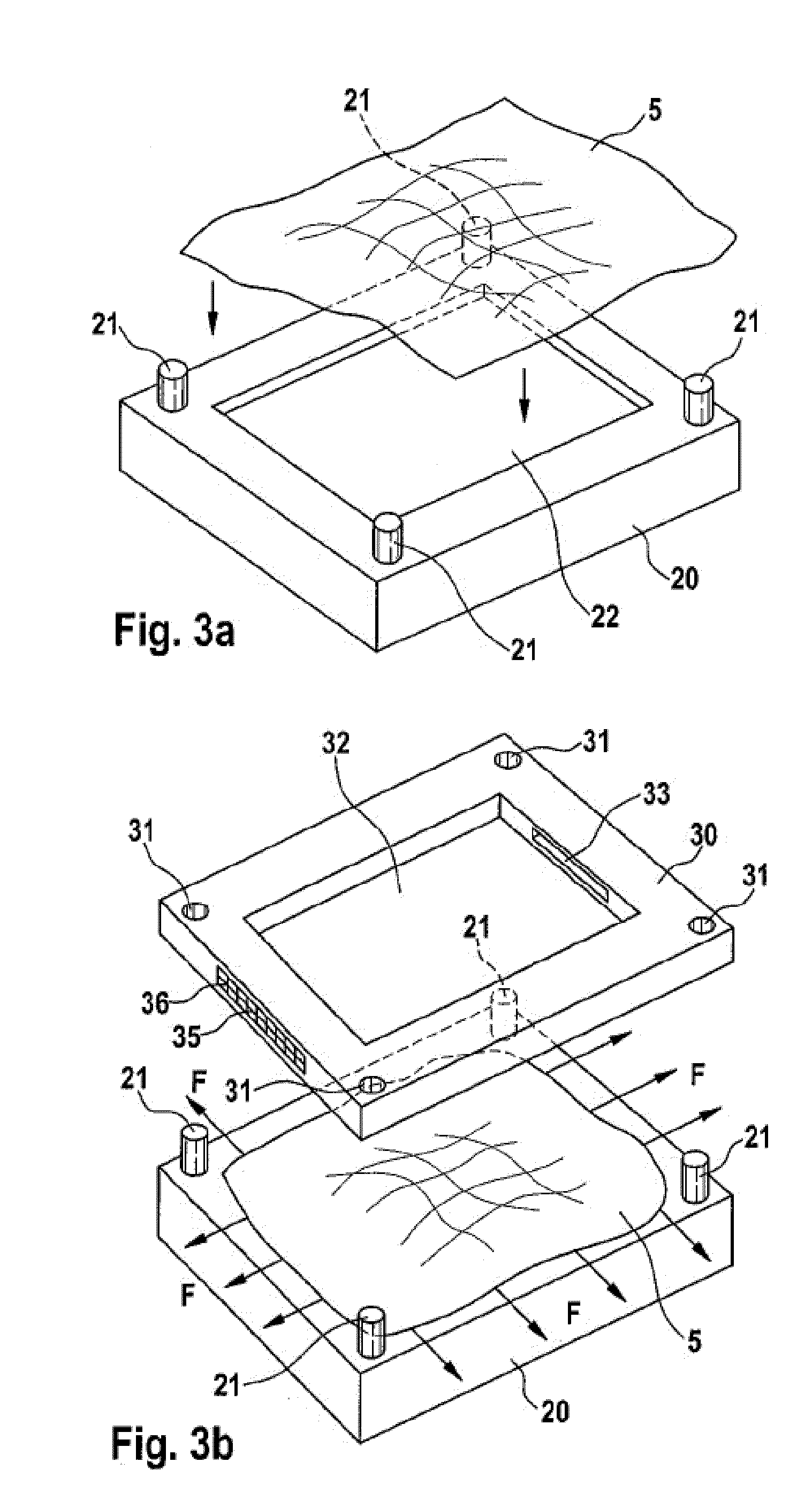

Lightweight moulded piece and corresponding production method

InactiveUS20100140839A1Increase loadHigh force loadSynthetic resin layered productsSolid ballsFiberFilling materials

The present invention provides a lightweight moulded part and a corresponding production method. The lightweight moulded part comprises a core region (1) made of a lightweight composite material (10, 15) which comprises a matrix material (15) and at least one filler material (10); at least one surface or near-surface cover layer region (2a, 2b) which comprises at least one layer of fibre material (5) and the matrix material (15); the layer (or layers) of fibre material (5) of the cover layer region (2a, 2b) being integrated into the matrix material (15) of the core region (1).

Owner:FACHHOCHSCHULE LANDSHUT

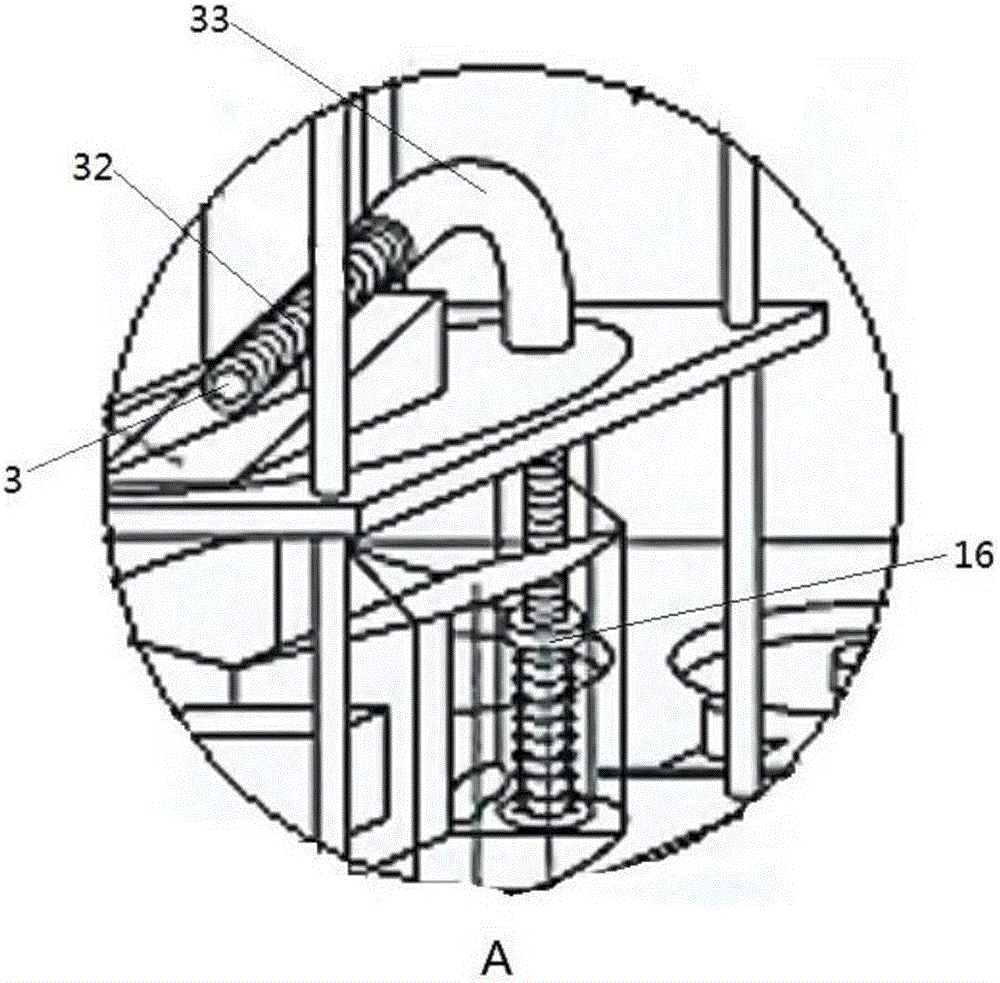

Connection line finished product die-cutting anti-adhesion device of die-cutting machine

ActiveCN102039694AOvercoming the Insufficiency of Manual Handling of AdhesionAvoid Quality AccidentsContainer making machineryPulp and paper industryPaper sheet

The invention discloses a connection line finished product die-cutting anti-adhesion device of a die-cutting machine, which is used for performing subsequent separation on a die-cutting finished product of a cigarette-brand small box. Cams connected to a connecting rod are symmetrically arranged on machine frames on two sides of a waste removing part of the die-cutting machine; an upper frame and a lower frame are fixed on the connecting rod respectively; a sponge strip is adhered to the upper frame, and the upper frame is provided with an upper thimble mounting seat; an upper thimble with a spring is arranged in the upper thimble mounting seat; the lower frame is provided with a lower thimble mounting seat; a lower thimble is arranged in the lower thimble mounting seat; and a wood waste removing plate with holes is fixed on the machine frame, and is arranged between the upper frame and the lower frame. When the cigarette-brand small box after die cutting passes through the waste removing plate with the holes, a machine runs to drive the upper frame to move downwards, the sponge strip presses paper sheets, the upper thimble ejects an easy-adhesion part of a finished product downwards, the lower frame moves upwards at the same time, and the lower thimble ejects the easy-adhesion part of the finished product upwards, so the paper sheets on two sides of a die line are separated under the action of different forces. The connection line finished product die-cutting anti-adhesion device of the die-cutting machine can effectively realize automation of adhesion processing to ensure that the parts which cannot be cut through by die cutting are separated automatically, thereby putting an end to quality accidents caused by machine jamming in the process of packaging finished product cigarettes.

Owner:襄阳金飞环彩色包装有限公司

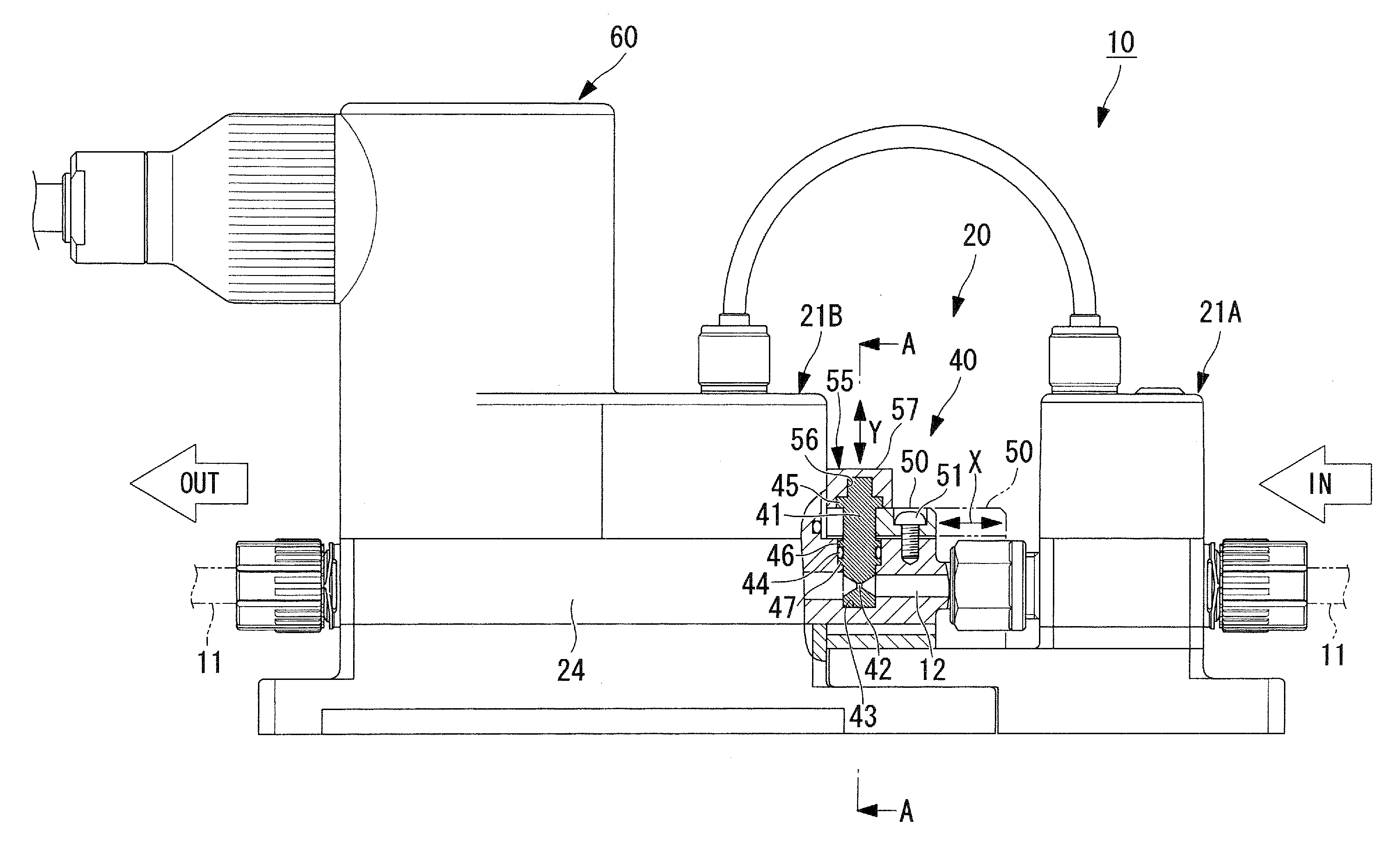

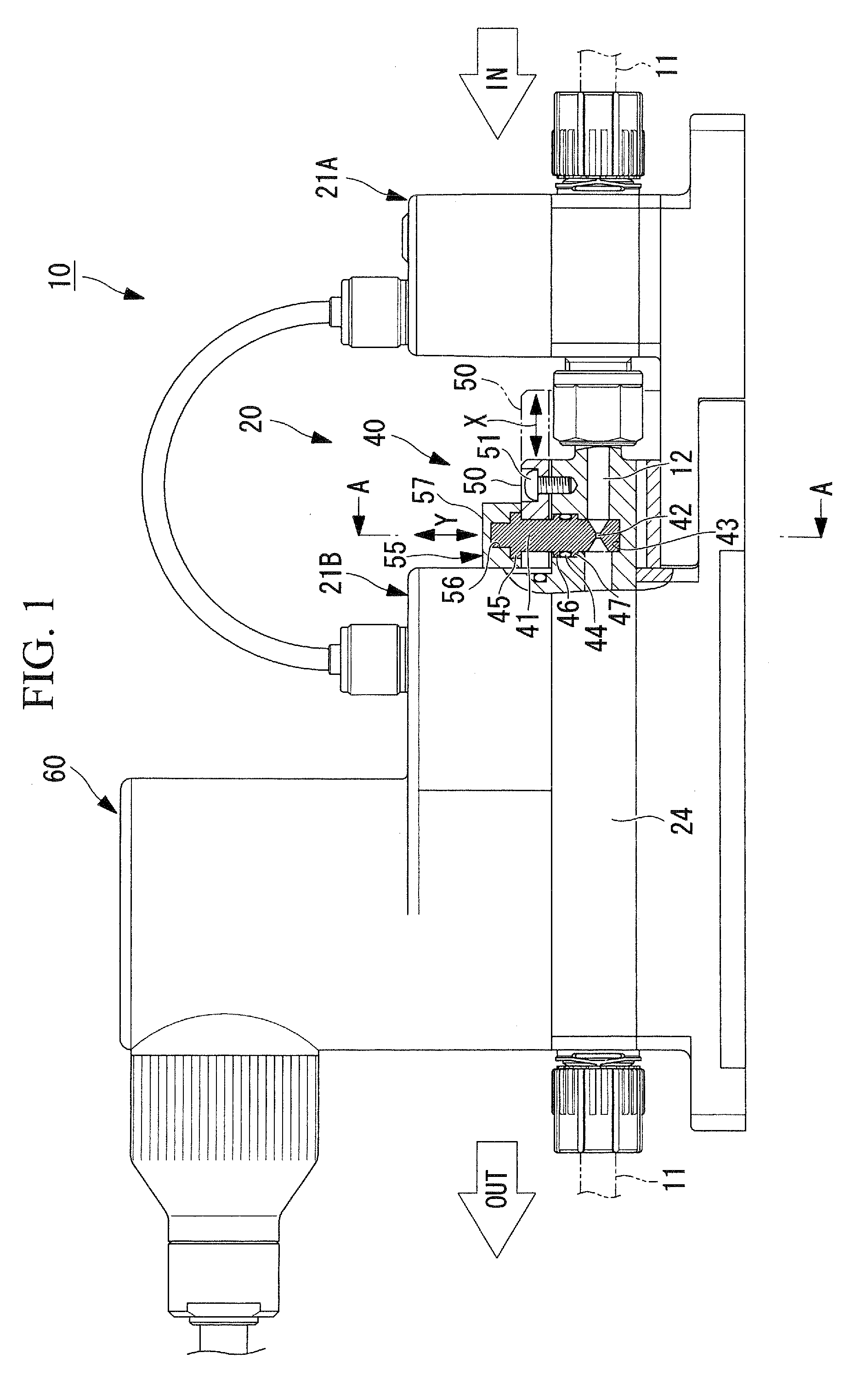

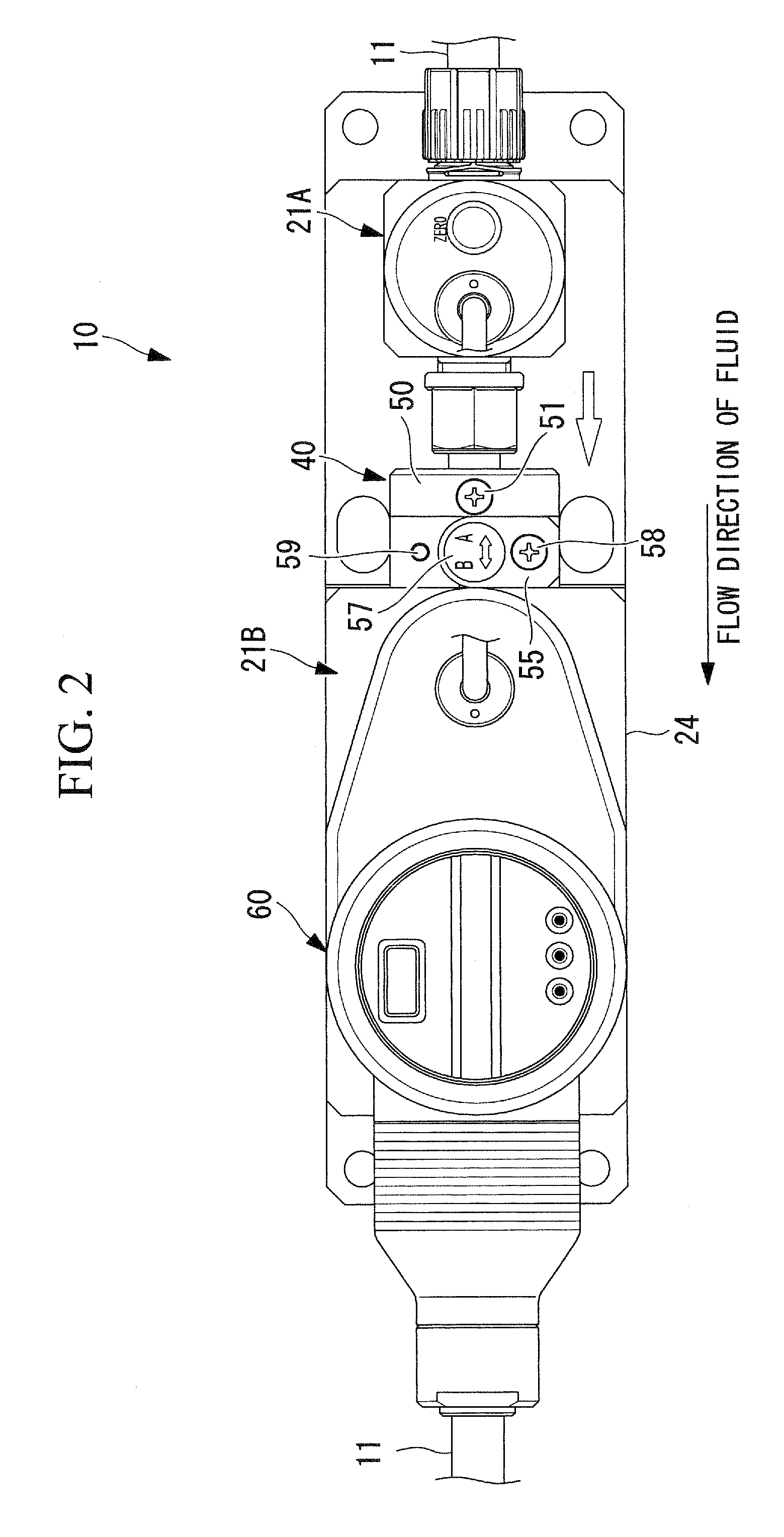

Differential-pressure flow meter and flow-rate controller

ActiveUS20100005904A1Easy to eliminateEliminate adhesionOperating means/releasing devices for valvesVolume meteringDifferential pressureEngineering

A differential-pressure flow meter is capable of easily eliminating adhesion to an orifice of an extraneous material. The differential-pressure flow meter includes: a pair of pressure sensors provided on a straight pipe part of a main fluid channel; an orifice unit interposed between the pair of pressure sensors; a columnar orifice body provided on the main fluid channel to be detachable in a direction orthogonal to a flow direction of a fluid in the main fluid channel; and an orifice hole penetrating the orifice body in the flow direction of the fluid, wherein the orifice body is rotatable at a prescribed installation position to reverse an upstream side and a downstream side with respect to the orifice hole, and flow rate measurement is performed by converting into a flow rate a difference in pressure that is obtained from two pressure values sensed respectively by the pair of pressure sensors.

Owner:SURPASS IND

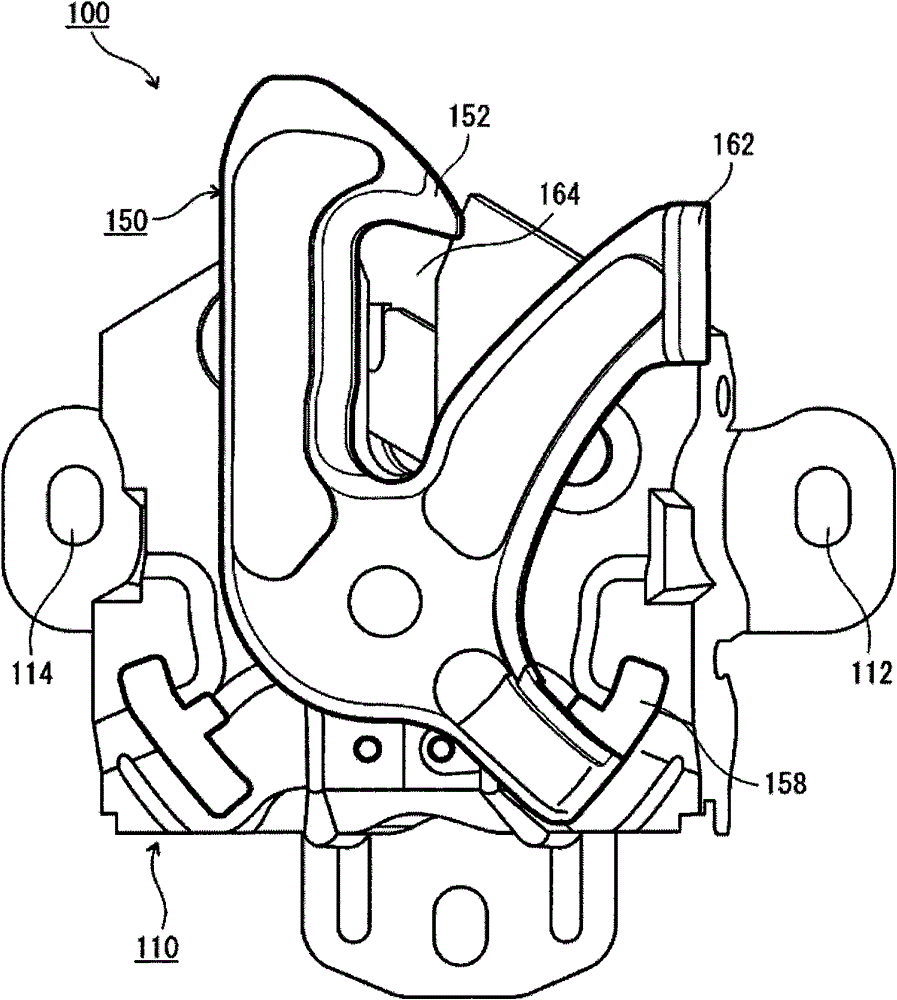

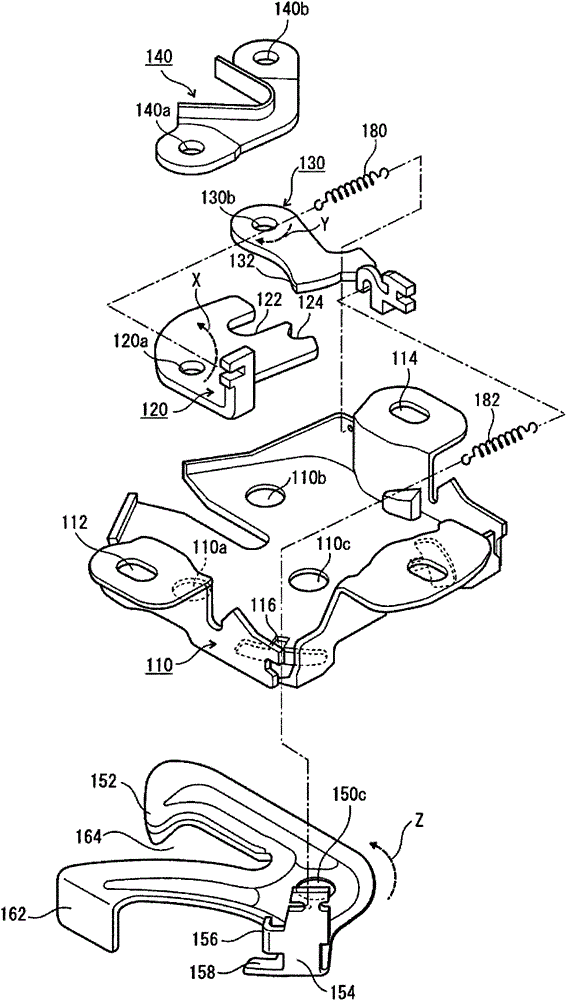

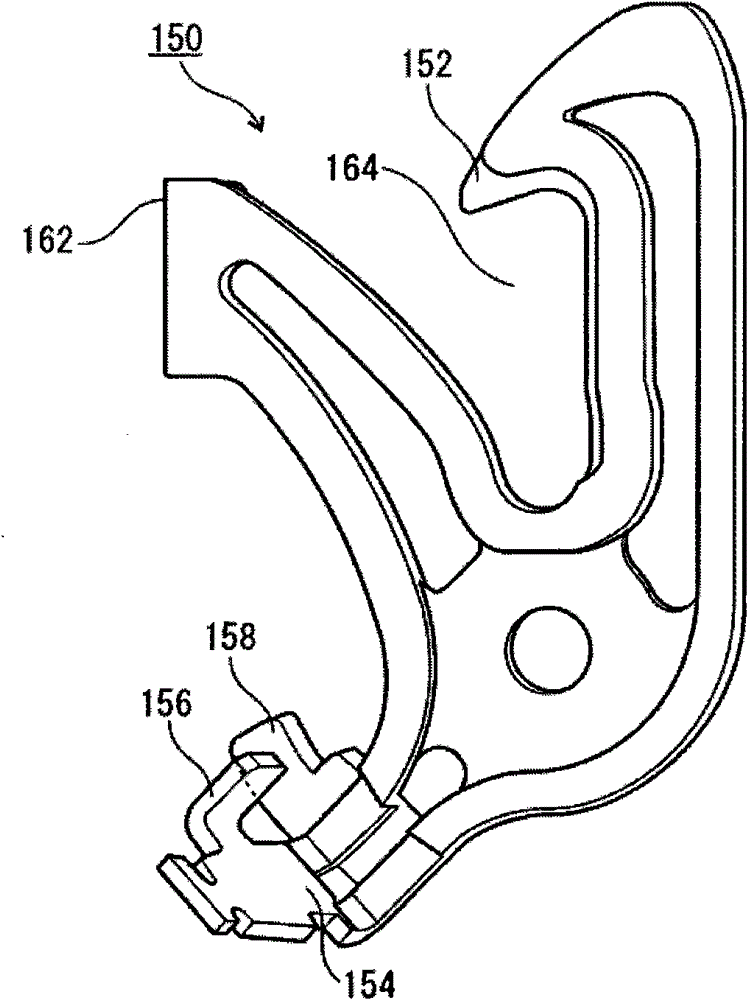

Locking device for vehicle

InactiveCN102864991AEliminate adhesionNo loss of durabilityElectrical locking circuitsEngineeringCantilever

The present invention provides a locking device for a vehicle, which can eliminate the adhesion caused by freezing between a movable contact and a fixed contact under the condition of not causing durableness decrease or cost increase. According to the present invention, the locking device is configured to comprise a first locking hook (120), a second hook (130), an auxiliary rod (150) and a switch, wherein the switch can detect locking according to the contact between the movable contact (thin rod 174) and the fixed contact (172), the movable contact is an elastically-deformable metal thin sheet supported in a cantilever state, the auxiliary rod (150) is provided with a projection (156), when firing pins are separated, the projection (156) rotates in a direction opposite to an offset direction and runs into the opening end side of the movable contact, and the movable contact and the fixed contact (172) are separated.

Owner:SUZUKI MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com