Method for acquiring super-double-thinning property on metallic copper or copper alloy backing material surface

A technology of substrate surface, metal copper, applied in the direction of metal material coating process, etc., can solve the problems of easy corrosion, can not function normally, affect the service life of materials, etc., to avoid corrosion, excellent thermal stability and chemical stability , the effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Use an ultrasonic cleaner to clean the metal copper substrate. The cleaning steps are: put the copper substrate in acetone, deionized water, and ethanol in order to clean it with ultrasonic waves for 5 minutes each to remove the grease and other pollutants on the surface;

[0023] 2. Put the treated copper substrate into the concentration of 0.02mol / L perfluorinated acid (CF 3 (CF 2 ) 8 COOH) soaking in methanol solution;

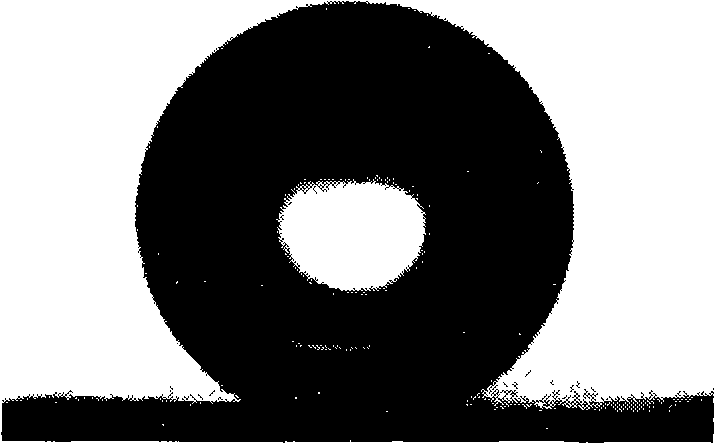

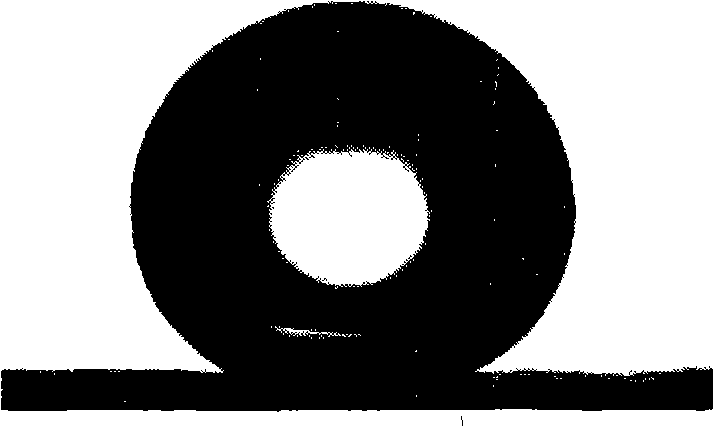

[0024] 3. After 12 days, take out the copper substrate, rinse it with ethanol and deionized water, and dry it with nitrogen, and finally obtain a film composed of perfluorinated fatty acid copper salt microspheres with a diameter of 2 to 4 microns on the surface of the copper substrate. A superamphiphobic surface is obtained on the surface of the copper substrate. The result is asfigure 1 shown.

Embodiment 2

[0026] 1. Use an ultrasonic cleaner to clean the metal copper substrate. The cleaning steps are: put the metal copper substrate in acetone, deionized water, and ethanol in sequence, and use ultrasonic cleaning for 5 minutes each to remove the grease and other pollutants on the surface;

[0027] 2. Put the treated metal copper substrate into the concentration of 0.01mol / L octacarbon perfluoroacid (CF 3 (CF 2 ) 6 COOH) soaked in acetone solution;

[0028] 3. After 16 days, take out the metal copper substrate, rinse it with ethanol and deionized water, and dry it in the atmosphere, and finally obtain a film composed of perfluorinated fatty acid copper salt microspheres with a diameter of 2 to 4 microns on the surface of the copper substrate , the superamphiphobic surface can be obtained on the surface of metal copper substrate.

Embodiment 3

[0030] 1. Use an ultrasonic cleaner to clean the copper-zinc alloy substrate. The cleaning steps are: put the copper-zinc alloy substrate in acetone, deionized water, and ethanol in sequence and clean it with ultrasonic waves for 5 minutes each to remove the grease and other pollution on the surface. substance;

[0031] 2. Put the treated copper-zinc alloy substrate into the concentration of 0.04mol / L dodecyl perfluoroacid (CF 3 (CF 2 ) 8 COOH) soaked in dichloromethane solution;

[0032] 3. After 18 days, take out the copper-zinc alloy substrate, rinse it with ethanol and deionized water, and dry it in the atmosphere, and finally obtain perfluorinated fatty acid copper salt microspheres with a diameter of 2 to 4 microns on the surface of the copper-zinc alloy substrate The composed film can obtain a super-amphiphobic surface on the surface of the copper-zinc alloy substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com