Process for producing super-double-thinning surface for metal corrosion protection and oil stain self-cleaning

A super-amphiphobic surface and metal anti-corrosion technology, which is applied in the direction of electrolytic organic material coating, etc., can solve the problems of not functioning normally, metal materials are easily corroded, and affect the service life of materials, so as to achieve easy industrialization, excellent stability, Anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Use an ultrasonic cleaner to clean the metal copper sheet sample for the test. The cleaning steps are: put the copper substrate in acetone, deionized water, and ethanol in turn and clean it with ultrasonic waves for 5 minutes each to remove the grease and other pollution on the surface. substance;

[0027] 2. Use the treated copper sheet as the anode and cathode of the electrochemical reaction respectively, and put in a concentration of 0.05mol / L perfluorinated fatty acid (CF 3 (CF 2 ) 10 COOH) in the acetone solution, apply a DC voltage of 5V between the anode and the cathode;

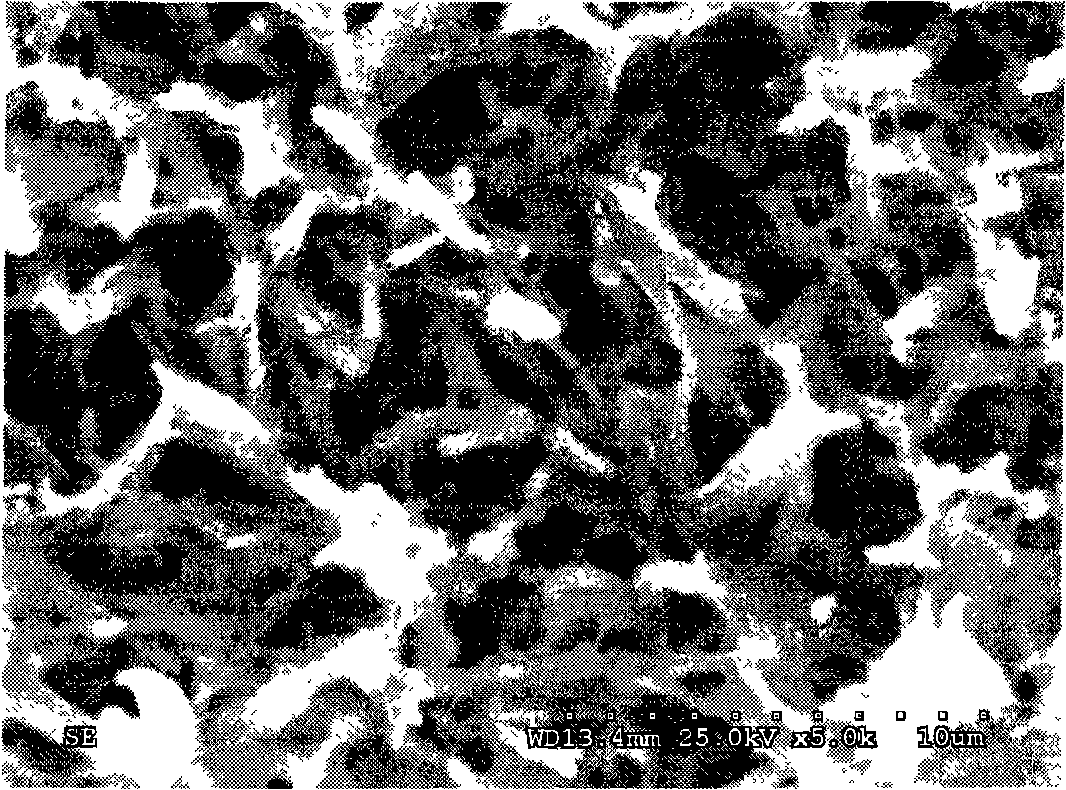

[0028] 3. After 1 hour, take out the cathode copper sheet, rinse it with ethanol and deionized water, and dry it in the atmosphere to obtain the perfluorinated fatty acid copper salt attached to the surface of the cathode copper sheet to obtain a super-amphiphobic surface layer;

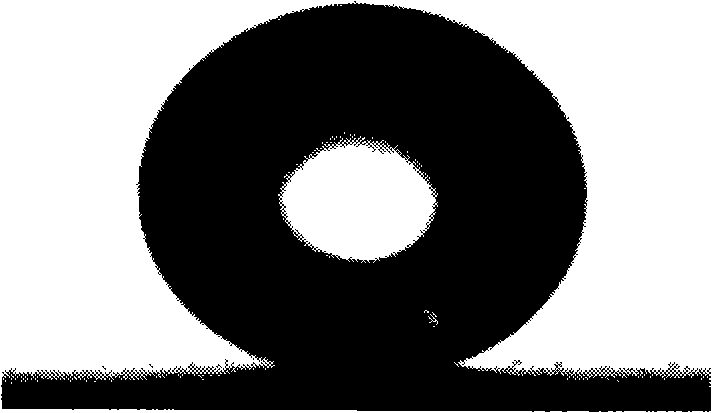

[0029]4. After testing with a contact angle measuring instrument (German Dataphysics OCA20 Contact Angle syst...

Embodiment 2

[0031] 1. Use an ultrasonic cleaner to clean the metal copper and iron samples for the test. The cleaning steps are: put the metal copper and iron substrates into acetone, deionized water, and ethanol in turn and clean them with ultrasonic waves for 5 minutes each to remove Grease and other contaminants on the surface;

[0032] 2. Use the treated metal copper and iron substrates as the anode and cathode of the electrochemical reaction respectively and put 0.05mol / L perfluorinated fatty acid (CF 3 (CF 2 ) 8 COOH) in the ethanol solution, apply a DC voltage of 2V between the anode and the cathode;

[0033] After 3.2 hours, take out the cathode iron sheet, rinse it with ethanol and deionized water, and dry it in the atmosphere to obtain the perfluoro fatty acid copper salt attached to the surface of the cathode iron sheet to obtain a super amphiphobic surface layer;

[0034] 4. After testing by the contact angle measuring instrument, the test results are: the contact angle of ...

Embodiment 3

[0036] 1. The metal copper and aluminum sheet samples used in the cleaning test of the acoustic wave cleaning instrument are as follows: put the copper substrate and the aluminum sheet in acetone, deionized water, and ethanol in turn and clean them with ultrasonic waves for 5 minutes each to remove the surface. grease and other pollutants;

[0037] 2. The treated metal copper and aluminum substrates are respectively used as the anode and cathode of the electrochemical reaction and put into the 0.02mol / L perfluorinated fatty acid (CF 3 (CF 2 ) 12 COOH) in the ethanol solution, apply a DC voltage of 4V between the anode and the cathode;

[0038] After 3.2 hours, take out the cathode aluminum sheet, rinse it with ethanol and deionized water, and dry it in the atmosphere to obtain the perfluoro fatty acid copper salt attached to the surface of the cathode aluminum sheet to obtain a super amphiphobic surface layer;

[0039] 4. After testing by the contact angle measuring instrum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com