Connection line finished product die-cutting anti-adhesion device of die-cutting machine

A die-cutting machine and connection technology, applied in the field of printing, can solve the problems of impermeable die-cutting, heavy workload, and sticking of knife lines, etc., to overcome manual sticking, improve labor productivity, and die-cutting quality Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

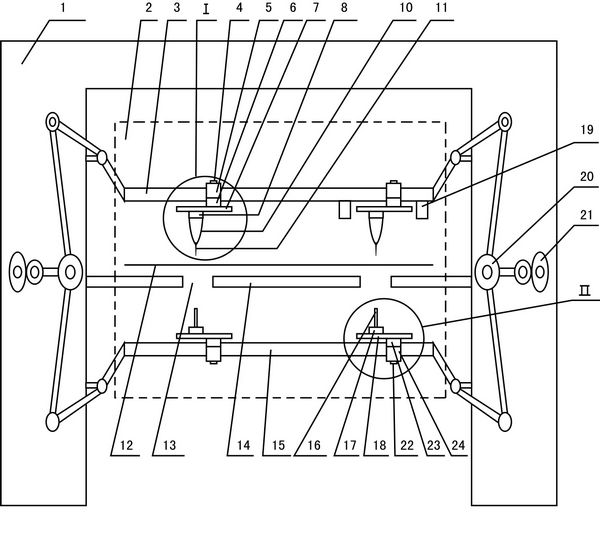

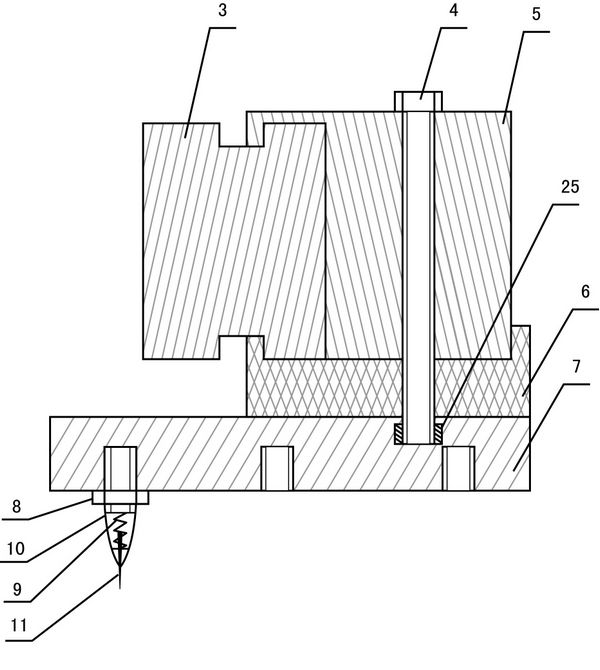

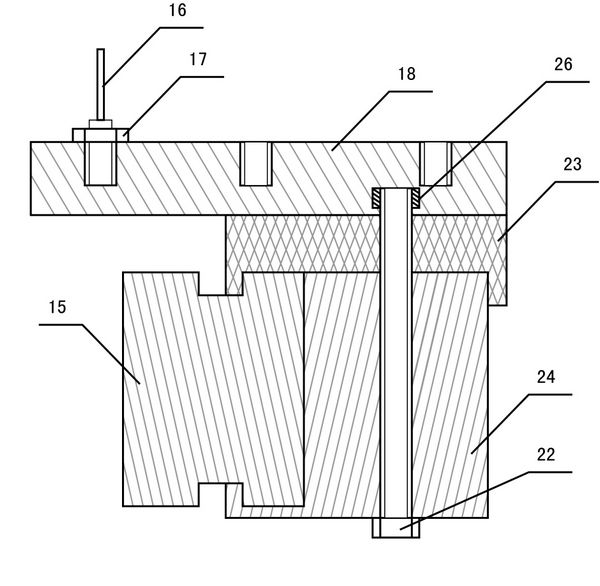

[0012] Such as figure 1 , figure 2 , image 3 As shown, the present invention is added on the subsequent stripping part 2 of the in-line die-cutting product. The frame 1 on both sides of the stripping part 2 of the die-cutting machine is symmetrically equipped with cams 21, and the cams 21 are symmetrically connected to the connecting rods 20 respectively. The upper frame 3 and the lower frame 15 are respectively fixed on the connecting rod 20, and the cam 21 rotates to drive the connecting rod 20 connecting the upper frame 3 and the lower frame 15 to make a splitting movement; On the upper connecting plate 7, the upper connecting plate 7 uses the upper connecting screw 4 to be stuck in the groove of the upper frame 3 through the upper ferrule 6 and the upper clip 5 successively, and the upper nut 25 is embedded in the upper connecting plate 7, and the upper connecting plate 7 There are multiple screw holes, which can be increased arbitrarily according to the number of impo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com