Patents

Literature

240 results about "Wood waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

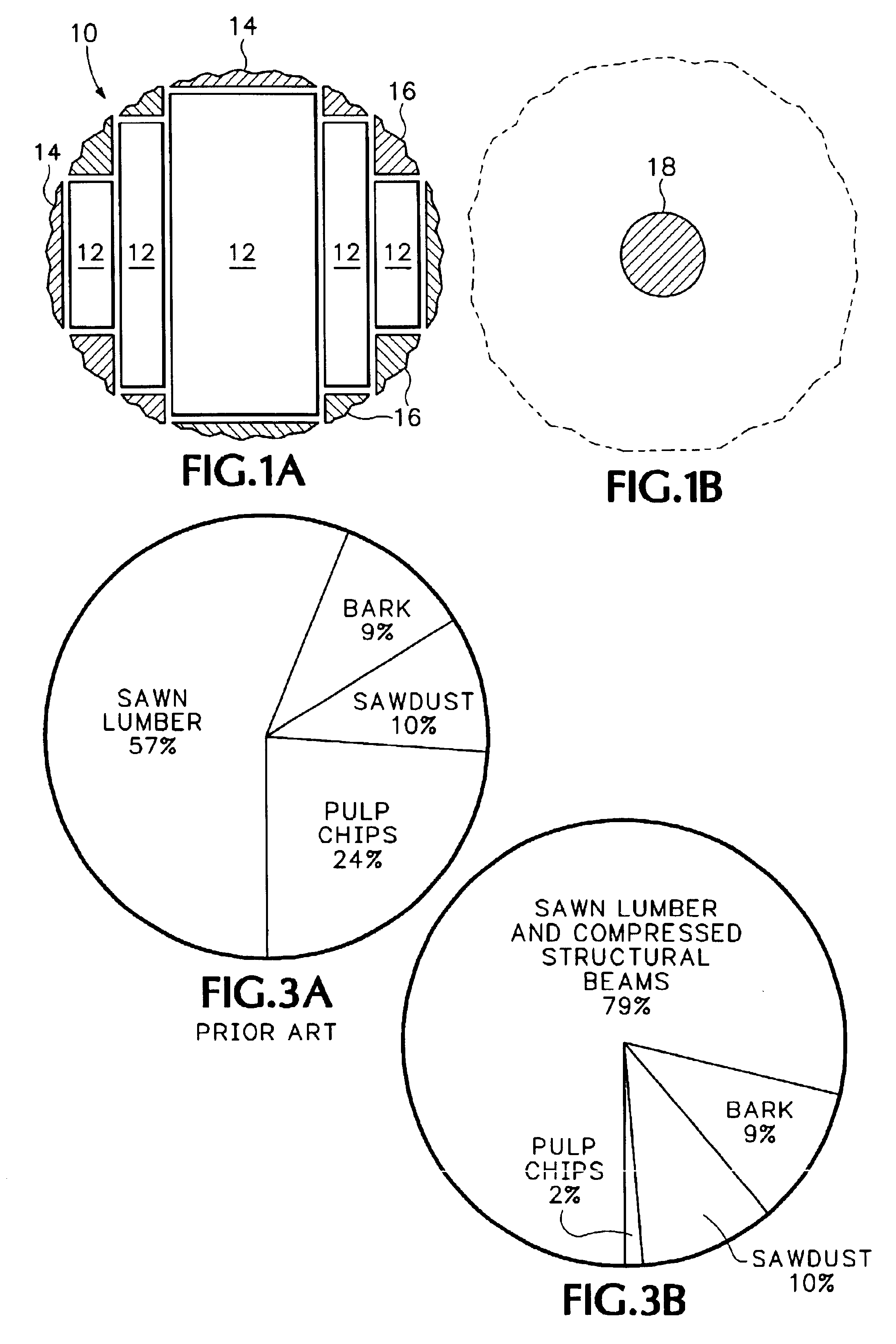

Wood waste is, by far, the largest portion of the waste stream generated from construction and demolition activities.

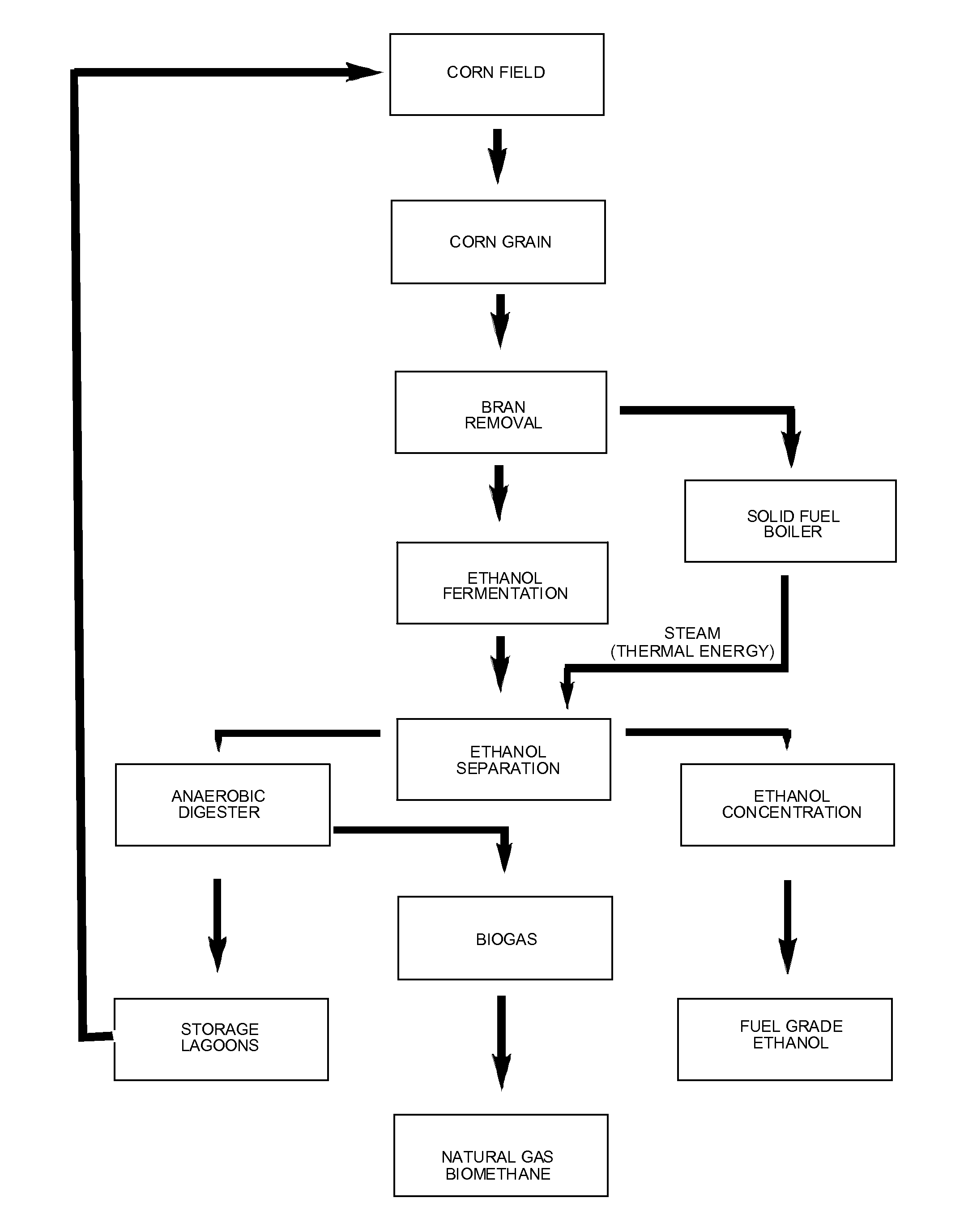

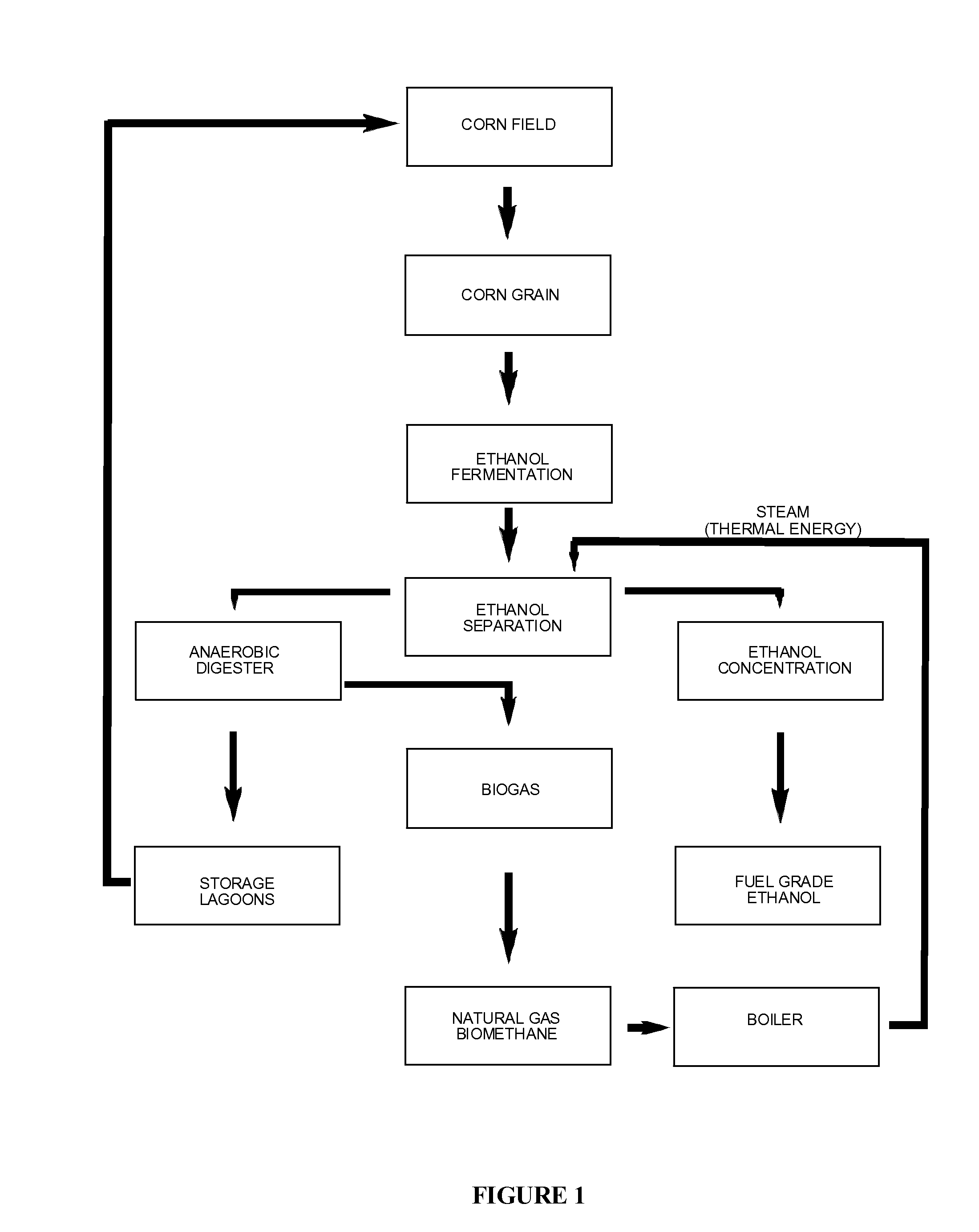

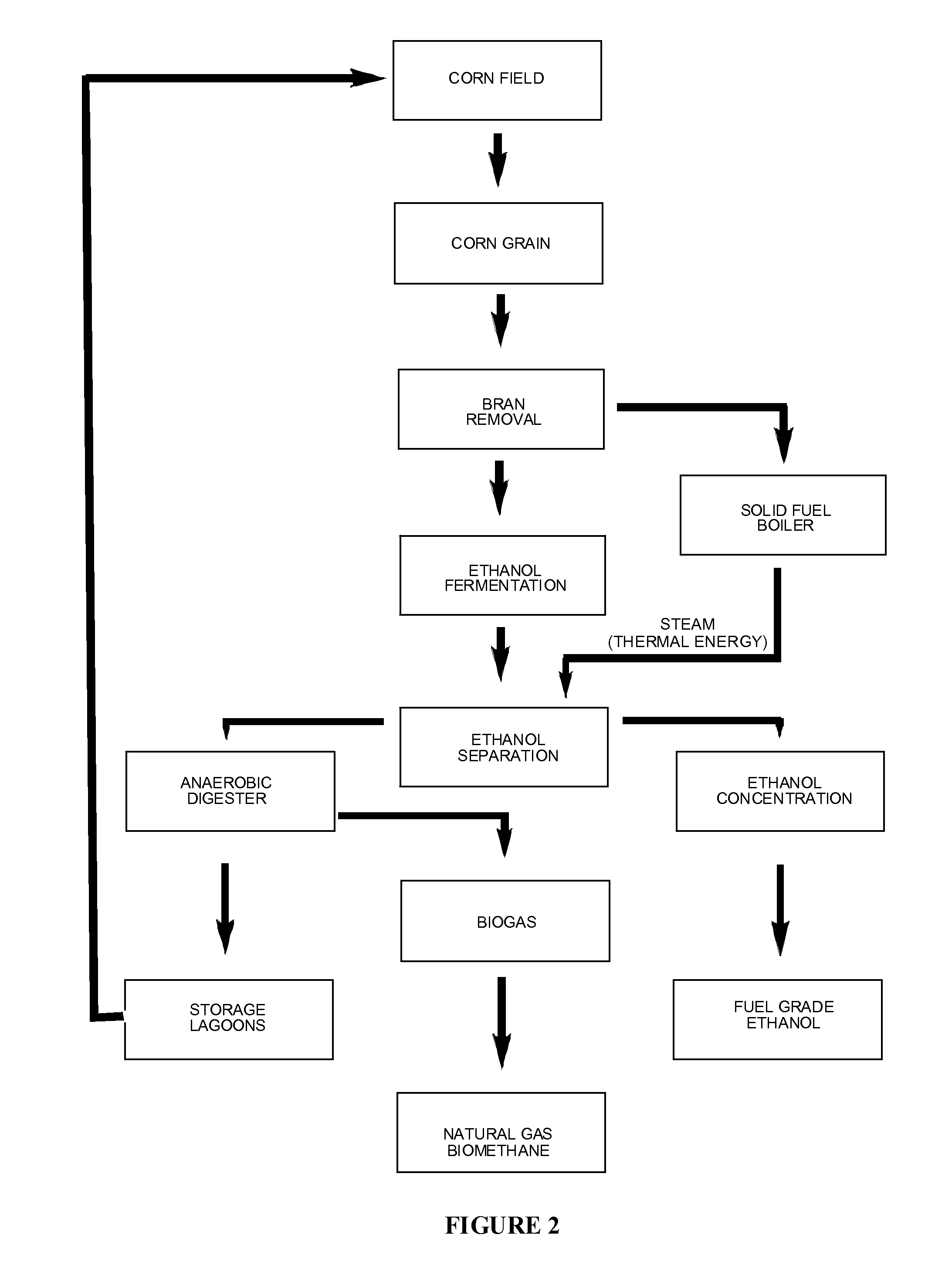

Farm Scale Ethanol Plant

An energy-efficient cycle for the production of ethanol and optionally natural gas from sunlight and biomass comprising first producing or obtaining biomass, for example by planting and harvesting of either an annual or perennial crop or both, and optionally tilling, fertilizing and obtaining wood wastes or paper wastes on-site or from a secondary site, for example, to supplement the on-site production of biomass, or for use as the sole source of biomass. The biomass is then converted to fermentable sugars through enzymatic conversion, acid hydrolysis, thermal cracking, or other processes that reduce cellulosic and hemi-cellulosic compounds to simple sugars. The reduced product is then fermented, producing ethanol in an intermediate beer product followed by recovery of ethanol from the resulting fermentation beer, wherein liquids are concentrated and recovered as fuel grade product. Recovery of ethanol may be by any suitable means including distillation, membrane separation or similar methods, and chromatographic rectification

Owner:6SOLUTIONS

Method for producing environment-friendly particle board through continuous hot pressing of total eucalypt wood leftover material

ActiveCN106363714ASolve insufficient resourcesSave raw materialsLaminationLamination apparatusNational standardParticle board

The invention discloses a method for producing an environment-friendly particle board through continuous hot pressing of a total eucalypt wood leftover material. The method comprises the procedures like chipping, flaking, drying, two-time screening (veneer removing and grit removing), sorting and polishing, mixing glue, hot press molding, aftertreatment, sanding and board selecting. According to the method, the eucalypt wood leftover material is fully utilized, and the wood waste is reduced; the produced particle board reaches the national standard and meets the GB / T4897-2015 requirement in Particle Board and the GB18570-2001 requirement in Indoor Decorating and Refurbishing Materials Limit of Formaldehyde Emission of Wood-based Panels and Finishing Products; melamine impregnated paper can be pasted on the surface of a produced panel; and the particle board is manufactured into high-end desk panels, wardrobe and cabinet panels, partitions, wood floors, ceilings, and other panels.

Owner:广西华晟木业有限公司

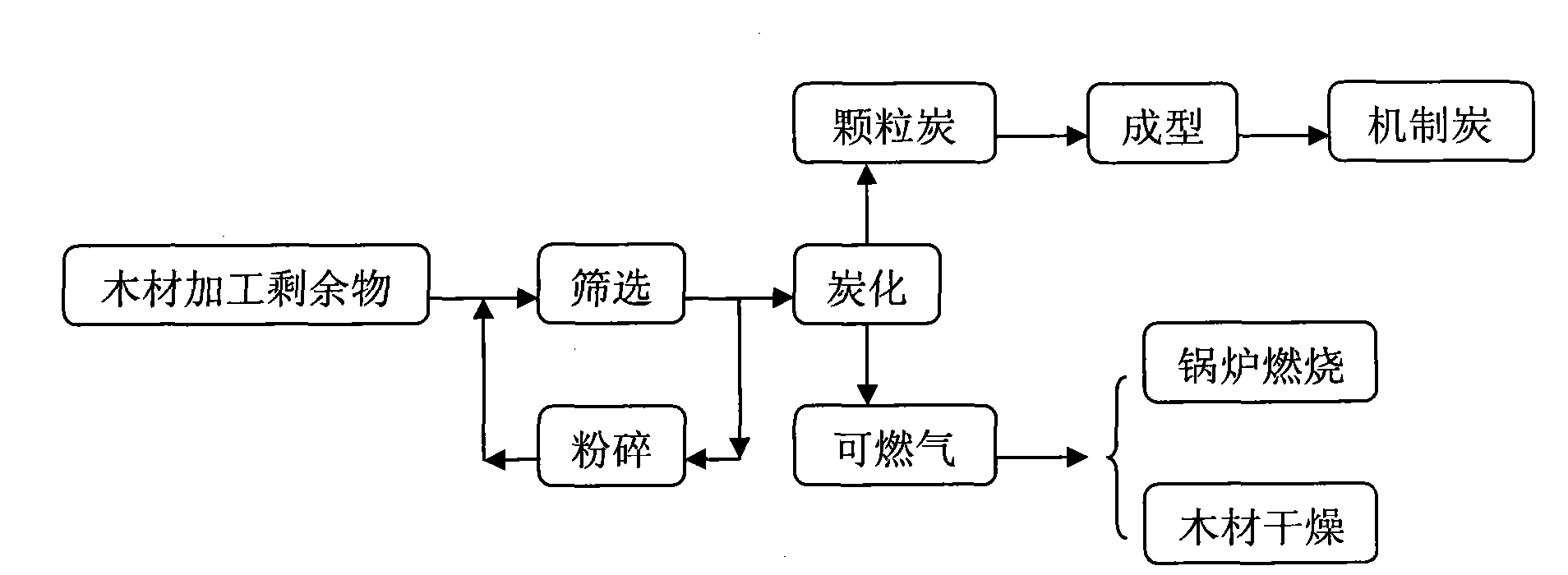

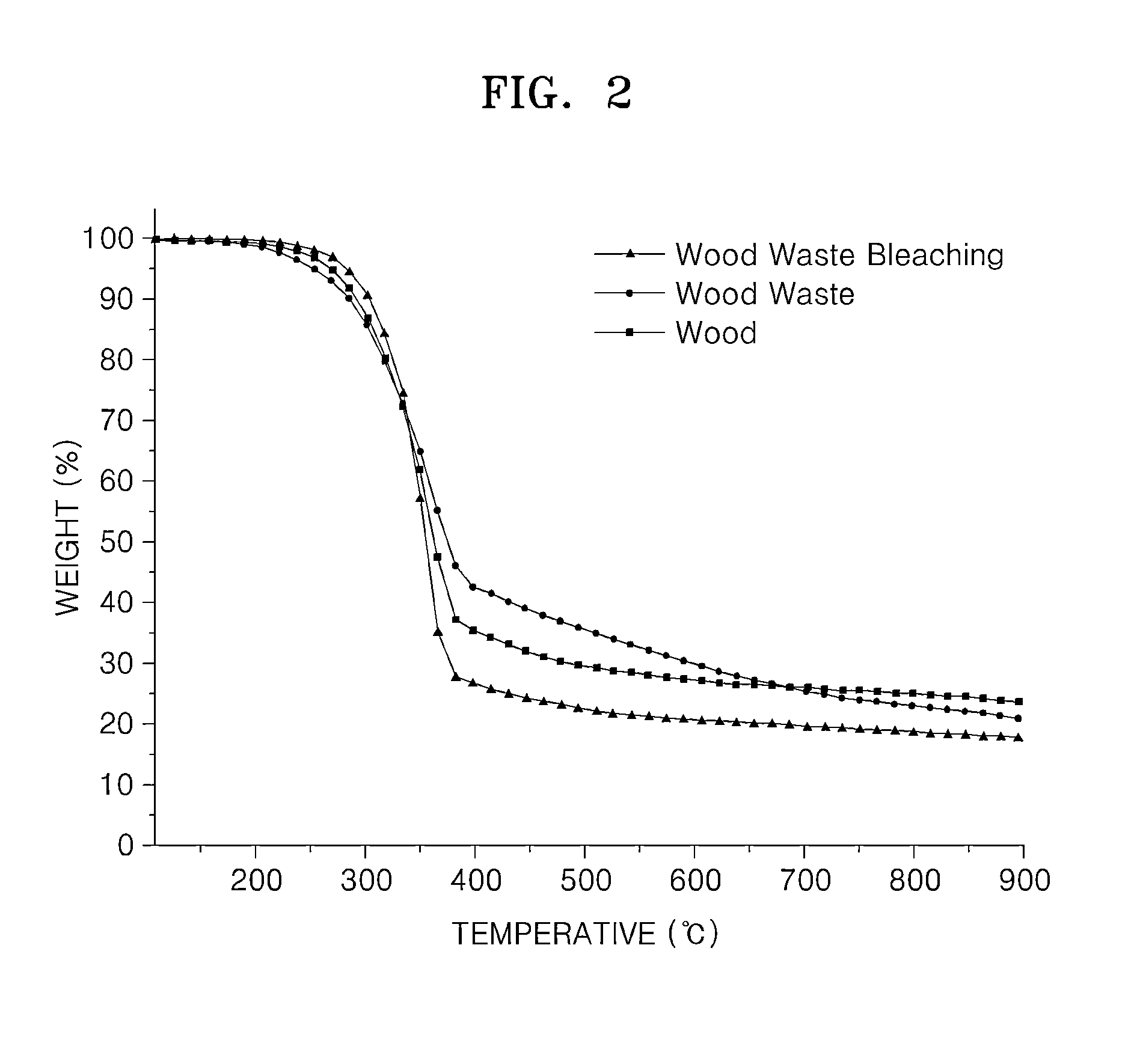

Treatment method of wood processing residues and charcoal prepared thereby

ActiveCN101629083AEasy to prepare and useImprove combustion efficiencyBiofuelsSolid fuelsCompression moldingCarbonization

The invention relates to a treatment method of wood processing residues, a method for preparing machine-made charcoal by utilizing the wood processing residues and the machine-made charcoal prepared by the method. The treatment method of the wood processing residues comprises the steps of carrying out carbonization treatment and obtaining the charcoal and combustible gas, wherein, the carbonization temperature for carbonization treatment is 400-900 DEG C, the time of carbonization treatment is 0.5-4 hours, and air of less than 4m<3> is introduced into each 1kg of the wood processing residues during the process of carbonization treatment. The treatment method can improve the energy utilization rate of the wood processing residues and reduce environmental pollution; the treatment method adopts the way of firstly carrying out the carbonization and then carrying out molding for preparing the charcoal, thereby greatly reducing energy consumption of wood wastes during direct compression molding and carrying out the thorough carbonization; the treatment method does not produce black smoke during ignition, and the performance indicators of the machine-made charcoal are in line with the requirements of standard of first-grade charcoal of national standard GB / T17664-1999.

Owner:BEIJING FORESTRY UNIVERSITY

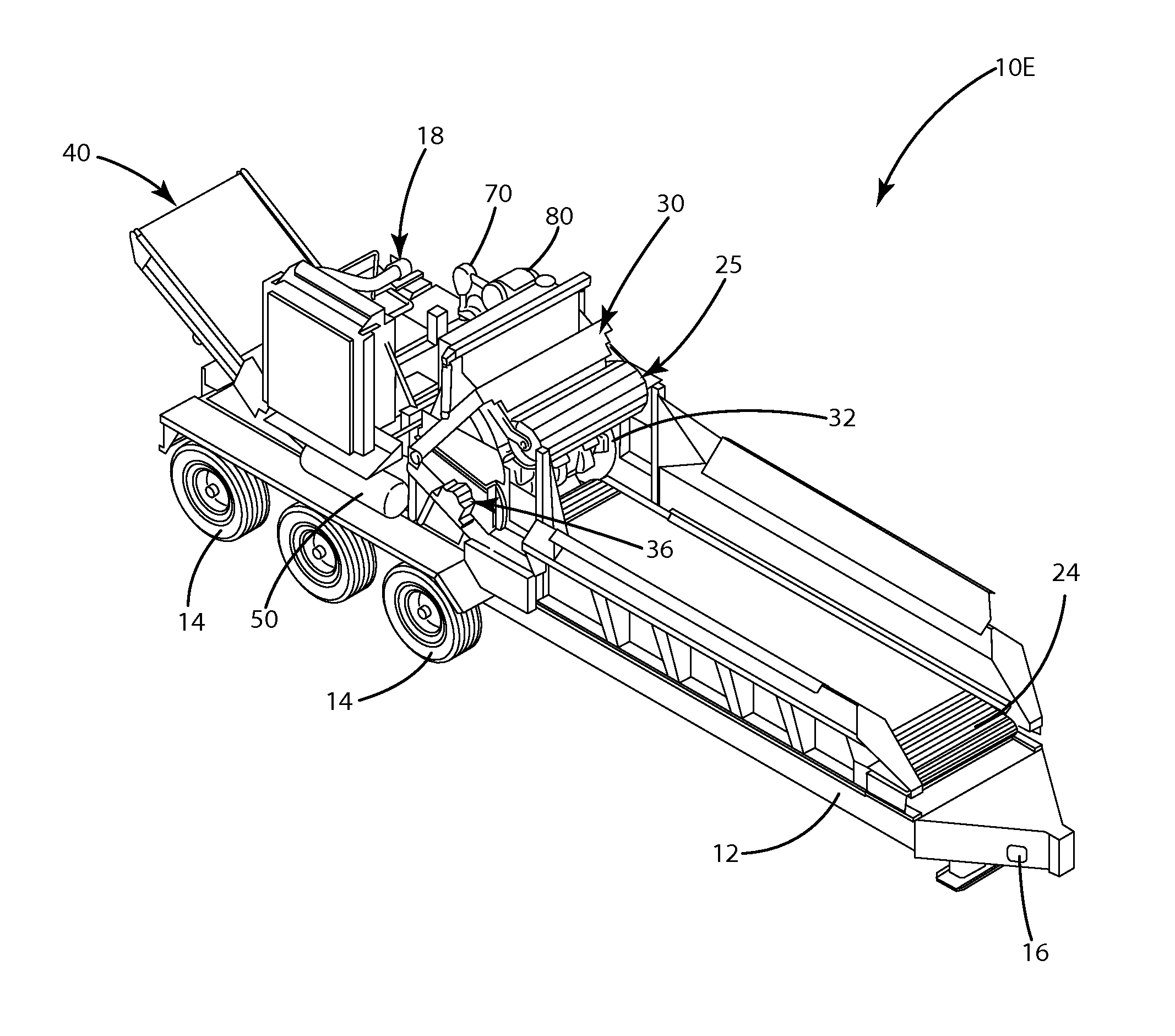

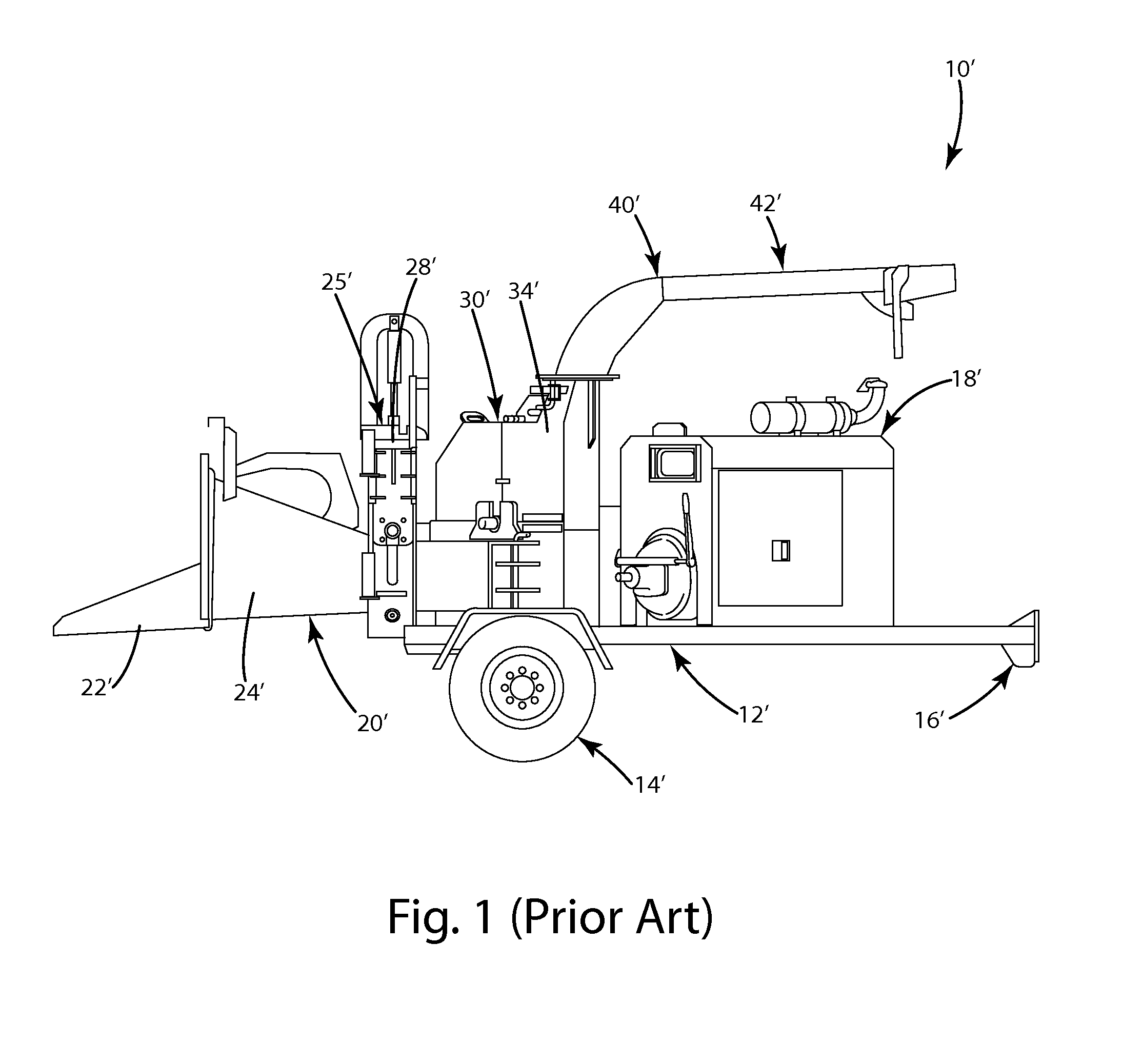

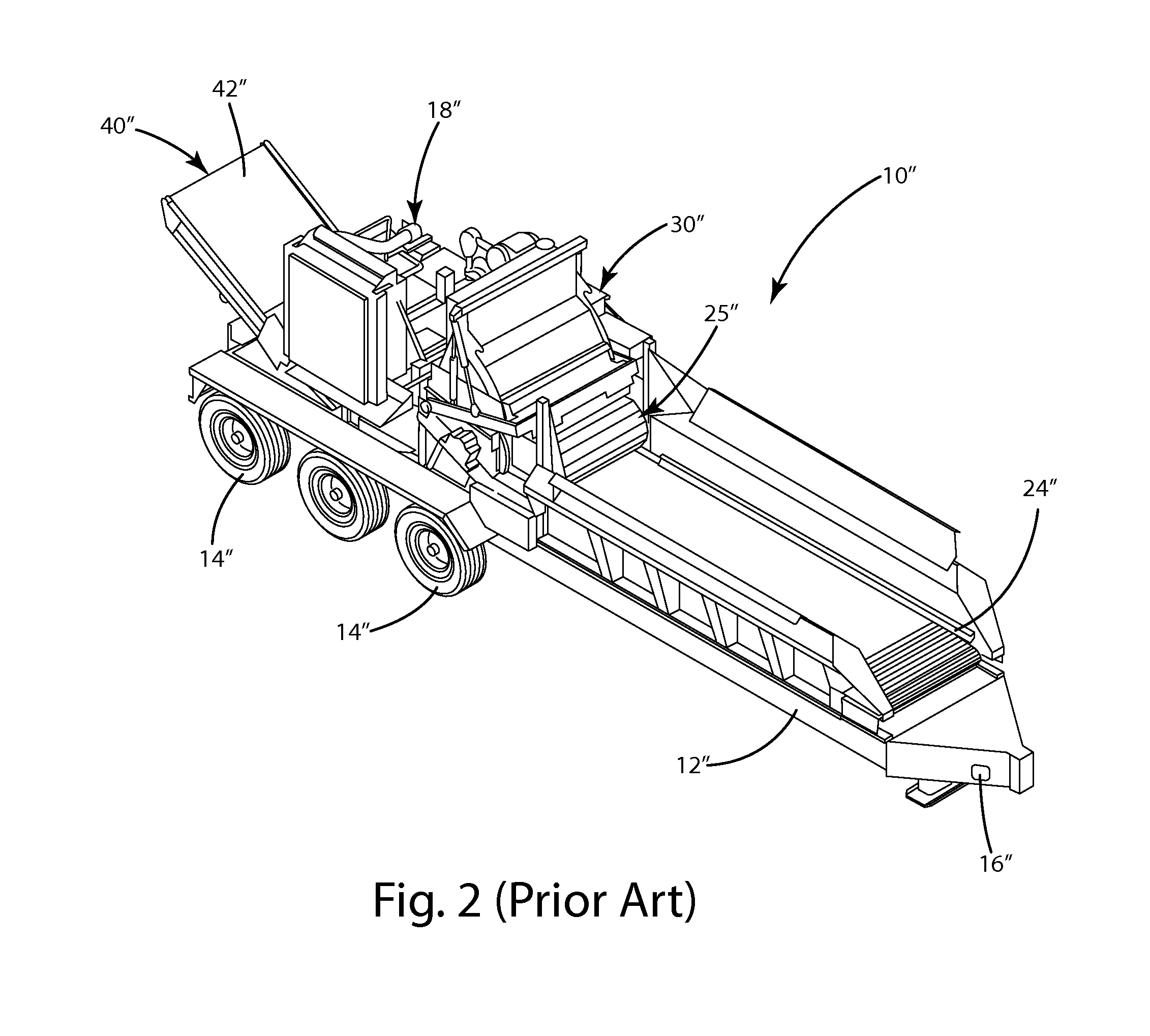

Waste processing system, machine and method thereof

ActiveUS20120234949A1Reduced material requiredMowersPlant waste comminutingWaste processingWood waste

a waste processing machine for reducing wood waste comprises an accumulator operatively connected to the cutting system so as to power the cutting system upon discharge thereof. The accumulator is adapted to receive, store, and release a charge developed from a charging device operatively connected to the accumulator and one or more systems of the waste processing machine.

Owner:BANDIT IND

Manufacturing method for environmental-friendly fire-retardant fiber board

InactiveCN101879739ASolve pollutionSolve problems that endanger human healthWood working apparatusFlat articlesWaxWood waste

The invention relates to an environmental-friendly fire-retardant fiber board and a manufacturing method thereof. In the technical scheme of the invention, forest residues and wood wastes are used as main raw materials to output with wood fiber, filling materials such as lignin ammonium sulphonate, industrial urea and wax emulsion recycled from paper-making waste liquid in raw materials after the raw materials are dried and treated, appropriate amount of ammonium dihydrogen phosphate flame retardant is added, and the processing technology of heat treatment setting under high pressure is adopted to manufacture the middle and high density fiber board with functions of high strength ratio, environment-friendly characteristic, fire retardant property and the like. On one side, the manufacture process solves the practical problem of low resource utilization ratio in spite of rich biomass resources in China. On the other side, the manufacture process abandons the traditional processing method of direct glue sizing, breaking away from depending on formaldehyde adhesives. Therefore, the process is a novel, environmental-friendly technology with functions such as fire retardant property for fiber board manufacture.

Owner:郭明辉 +2

Compound biosorbent capable of greatly improving capability of adsorbing heavy metal by waste biomasses and preparation method thereof

InactiveCN104138748AImplement security controlsReduce concentrationOther chemical processesWater/sewage treatment by sorptionSorbentSolid particle

The invention discloses a compound biosorbent capable of greatly improving the capability of adsorbing heavy metal by waste biomasses and a preparation method thereof. The biosorbent comprises following components: particles made of crops or wood wastes and nano ferric oxide hydrate which is loaded on the surfaces of the particles and is 10-100mg / g based on iron. The preparation method of the sorbent comprises the following preparation steps: enabling a Fe (III) solution with a certain mass concentration to slowly pass through an adsorption column filled with particle-form agricultural wastes and sufficiently contacting the Fe (III) solution with solid particles; then drying the solid particles at the temperature of 40-60 DEG C for 2 hours; adding the solid particles into a Na-NaCl mixed solution to be vibrated for 12-24 hours; filtering solid substances and repeatedly washing by using 0.001M HCl solution and distilled water until the pH value is 6-8; and finally, drying the treated agricultural waste particles at the temperature of 40-60 DEG C for 12-24 hours to obtain a needed material. According to the compound biosorbent, the adsorption capacity can be increased by 2-6 times, the adsorption speed can be increased by 2-5 times and the distribution coefficient of representation adsorption selectivity is increased by 10-50 times.

Owner:HUANGSHAN UNIV

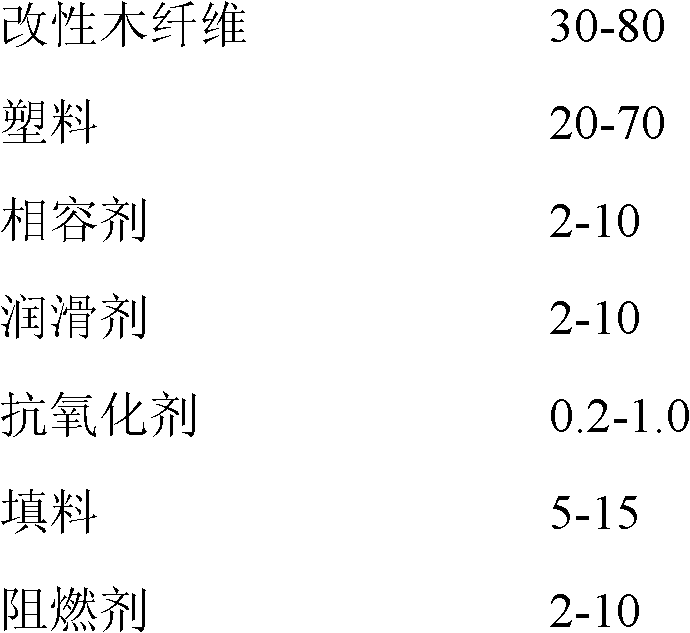

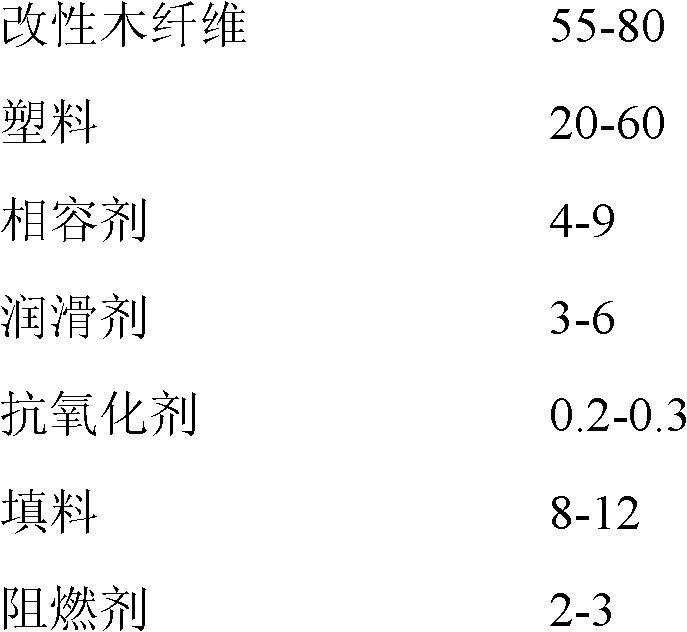

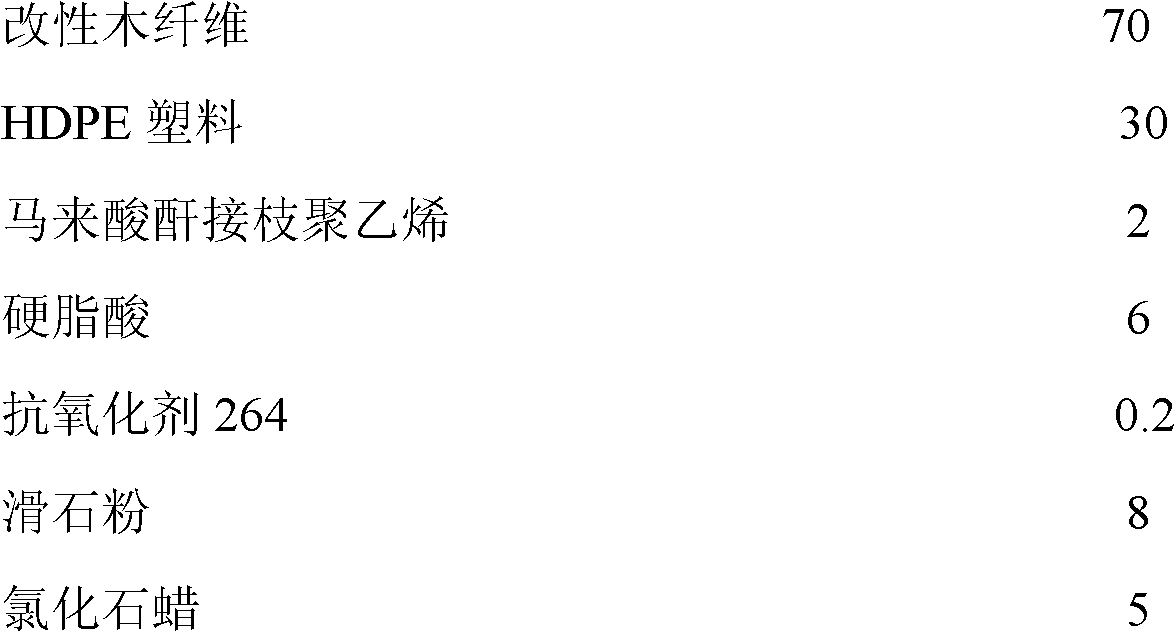

Wood plastic composite and preparation method thereof

InactiveCN102304290AImprove mechanical propertiesReduce consumptionRaw material divisionThermoplasticForest industry

The invention discloses a wood plastic composite and a preparation method thereof. The wood plastic composite comprises the following raw materials according to parts by weight: 30-80 parts of modified wood fiber, 20-70 parts of plastic, 2-10 parts of compatilizer, 2-10 parts of lubricant, 0.2-1.0 part of antioxidant, 5-15 parts of filler and 2-10 parts of fire retardant. 'forestry three waste' wood wastes are prepared onto modified wood fibers with an explosion treatment method, wherein the modified wood fibers are mutually separated, and eh surface of the modified wood fibers is covered with lignin; then the modified wood fiber is compounded with plastic; and the product is extruded to form finished product material. According to the wood plastic composite, the technical problems of poor compatibility of wood fiber and thermoplastic plastics can be solved to realize the purpose of comprehensively utilizing the 'forestry three waste' wood and plastic, the wood can be omitted, and the additional value of the forest residue is increased. The wood plastic composite manufactured with the preparation method has high mechanical property, and strong tensile strength, bending strength and impact strength of composite material, and the industrial production of high-performance products, such as building engineering materials, can be realized.

Owner:BEIJING FORESTRY UNIVERSITY

Shiitake mushroom cultivation material and manufacturing method thereof

InactiveCN104892111AQuality improvementIncrease productionFertilizer mixturesEcological environmentPhosphate

A shiitake mushroom cultivation material and a manufacturing method thereof are provided; the shiitake mushroom cultivation material is prepared from the following raw materials: agricultural crop straws, sawdust, rice bran, a gypsum powder, ammonium carbonate, potassium chloride, urea, calcium superphosphate, potassium dihydrogen phosphate, cottonseed hulls, carbohydrates, and composite probiotics. The water content of the cultivation material is 55%-60%. The cultivation material has the advantages of easily obtained used raw materials, low production cost, simple production process, easy management, and easy popularization; at the same time, the cultivation material is comprehensive in nitrogen, phosphorus and potassium nutrition, cultivated shiitake mushroom is good in quality and high in yield, and the economic benefits are effectively improved. Moreover, a variety of agricultural crop straws and wood waste can be utilized, protection of ecological environments is facilitated, and the cultivation material can be widely developed in urban and rural areas.

Owner:张计划

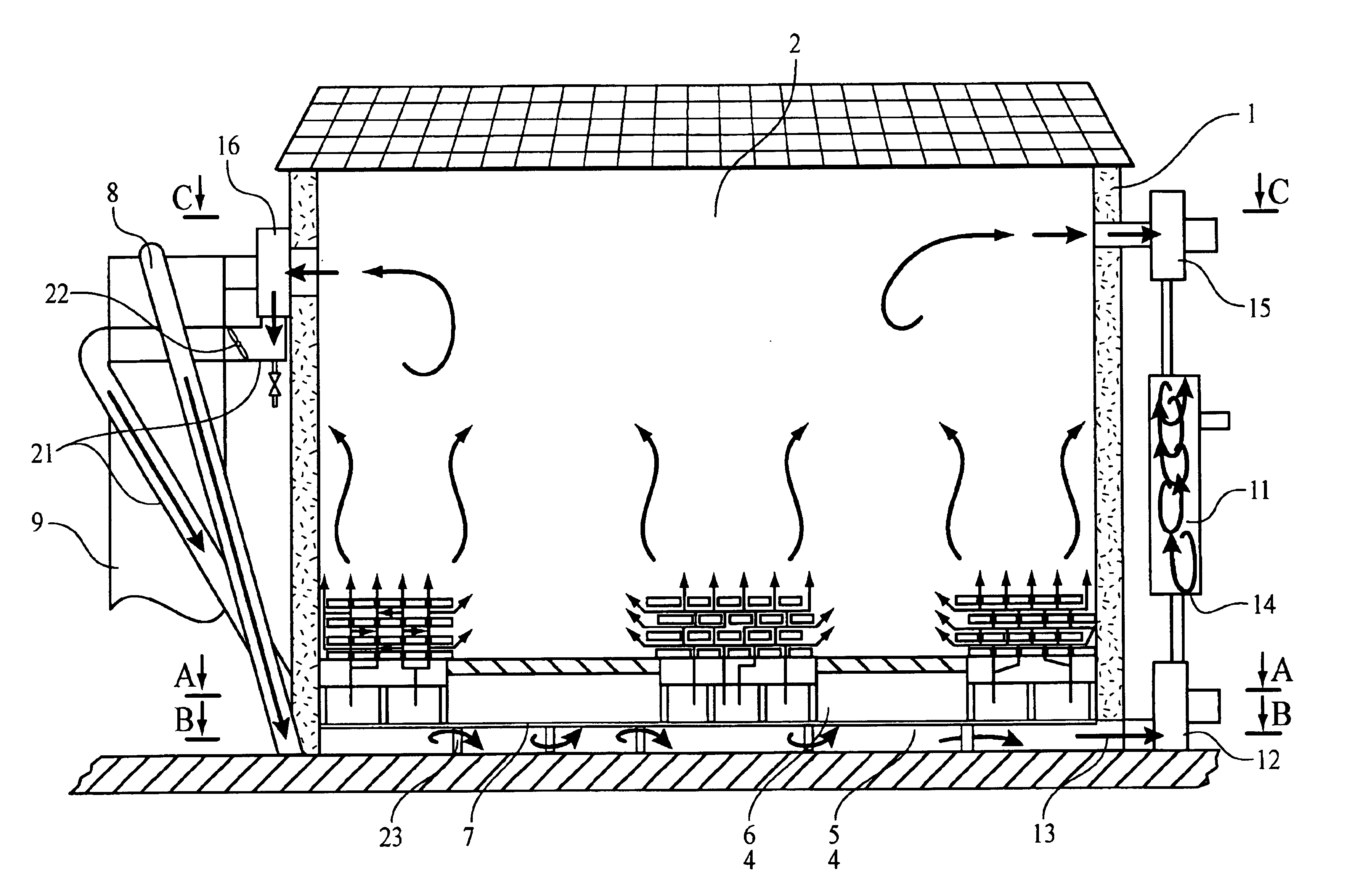

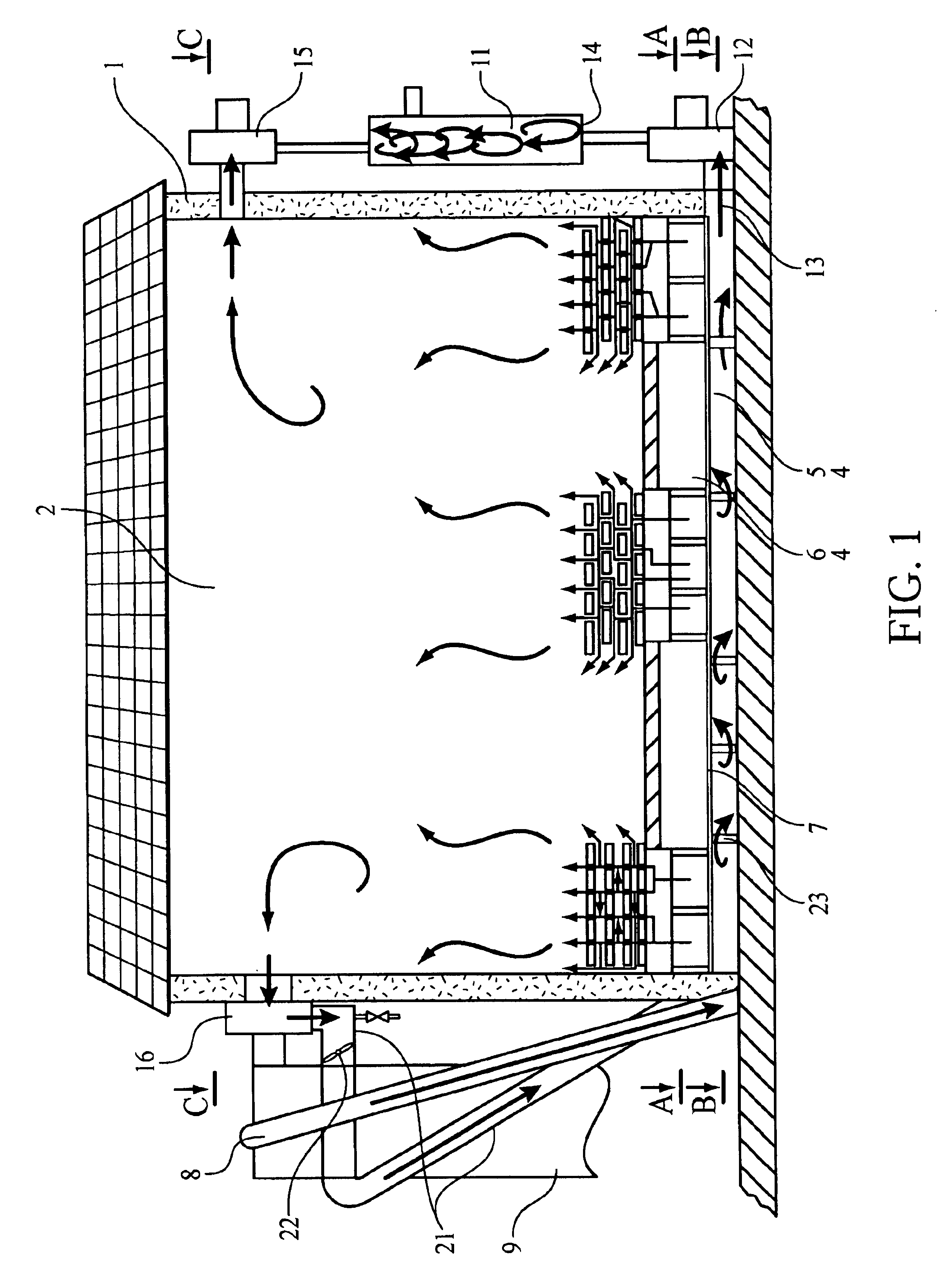

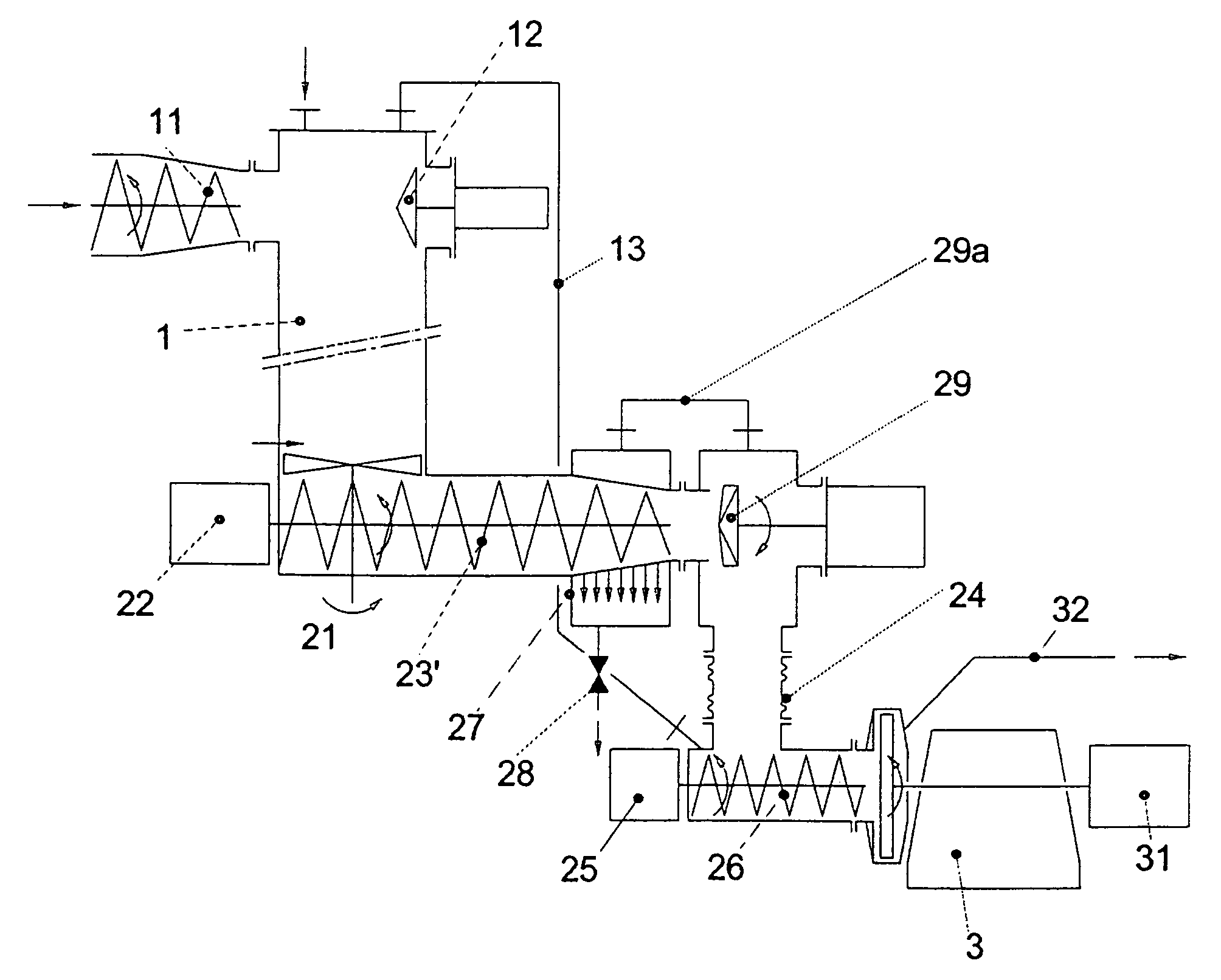

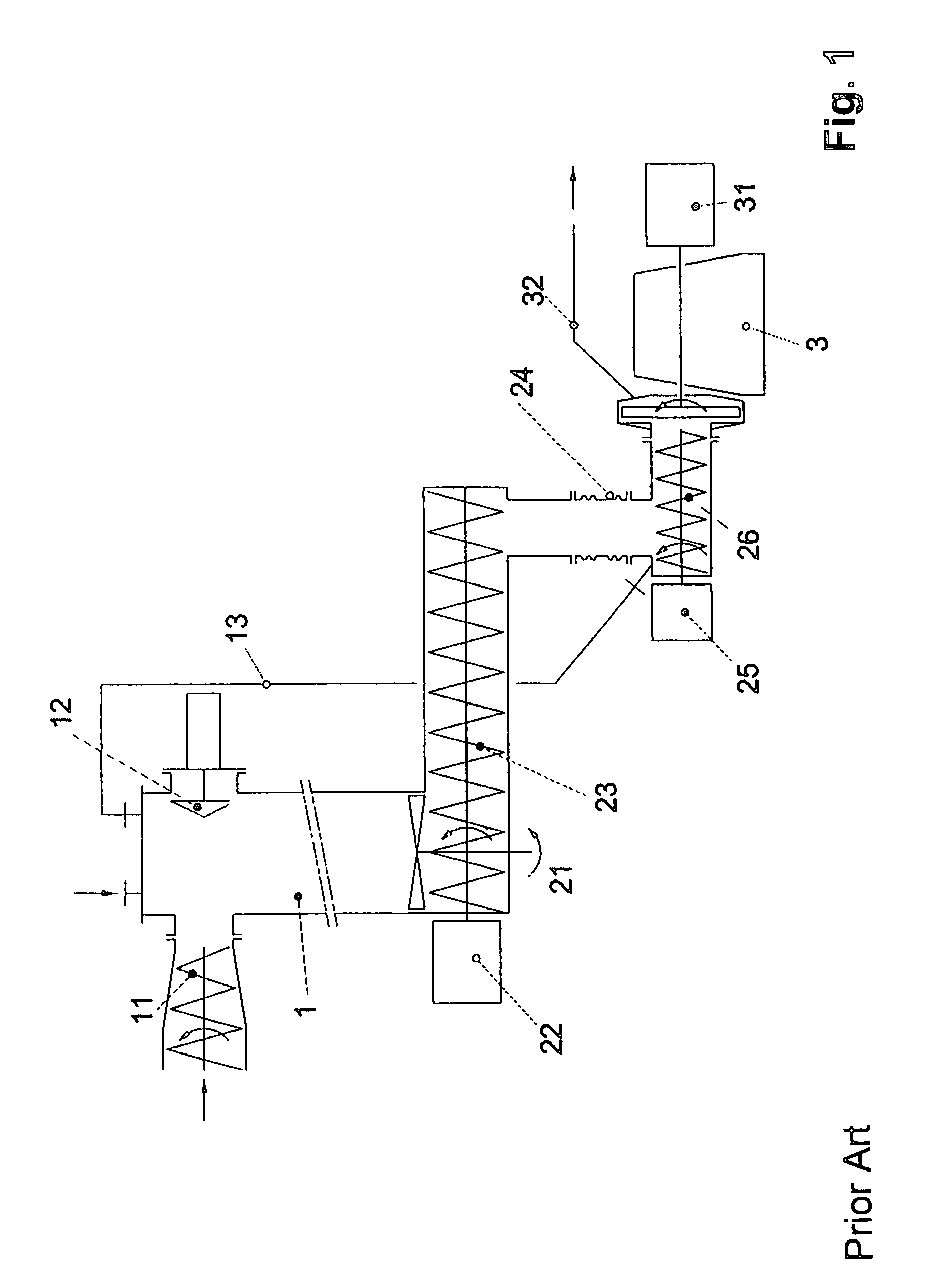

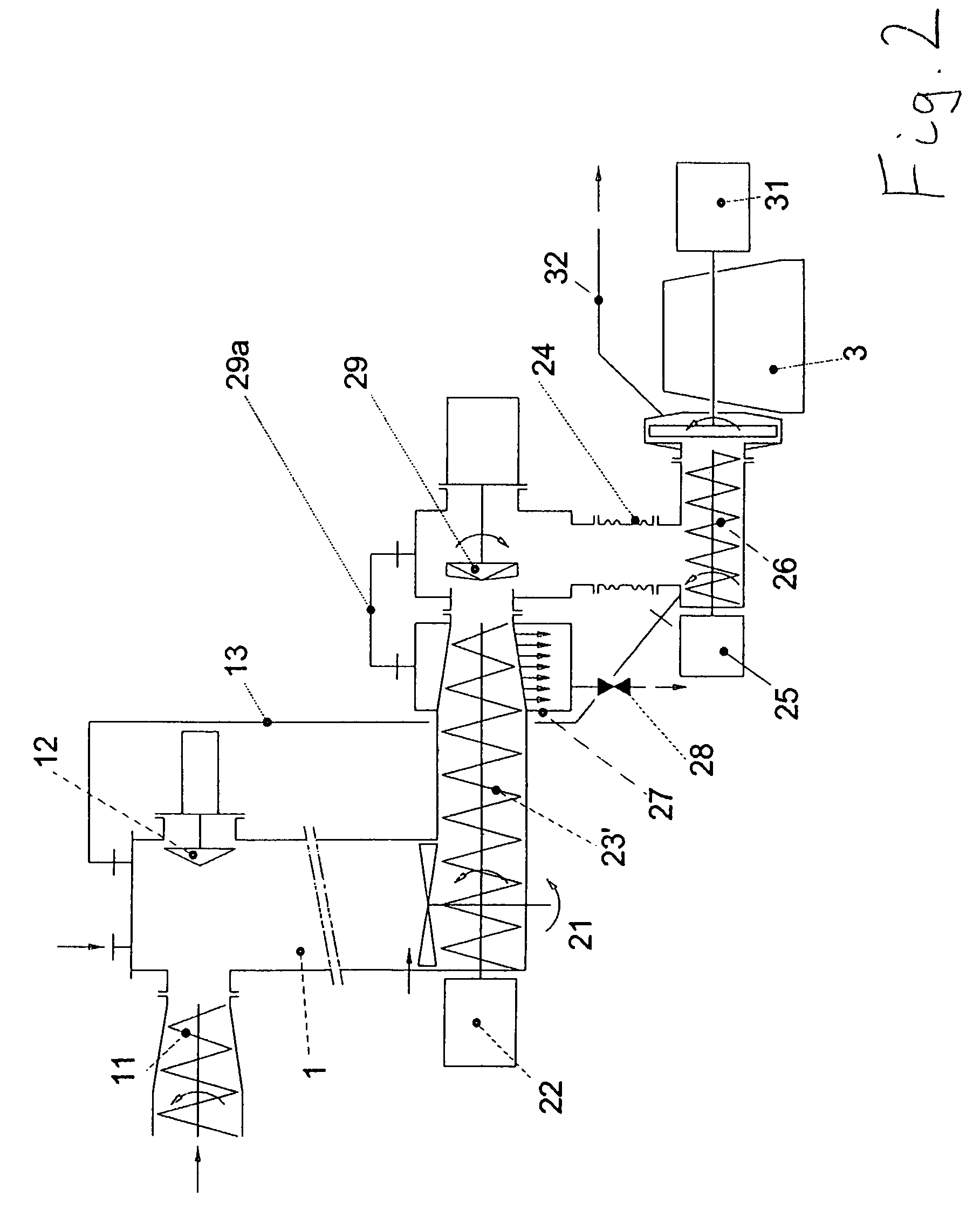

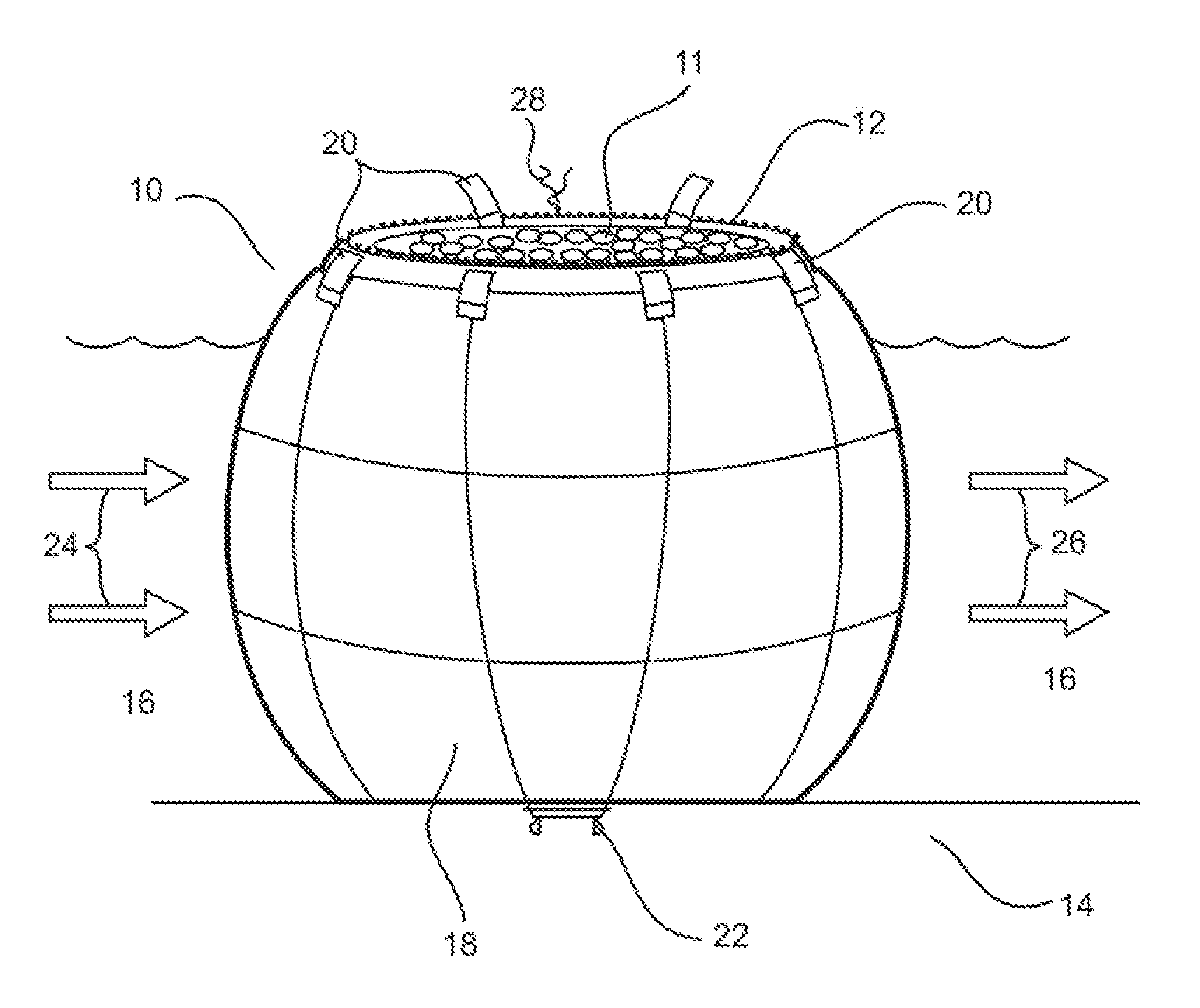

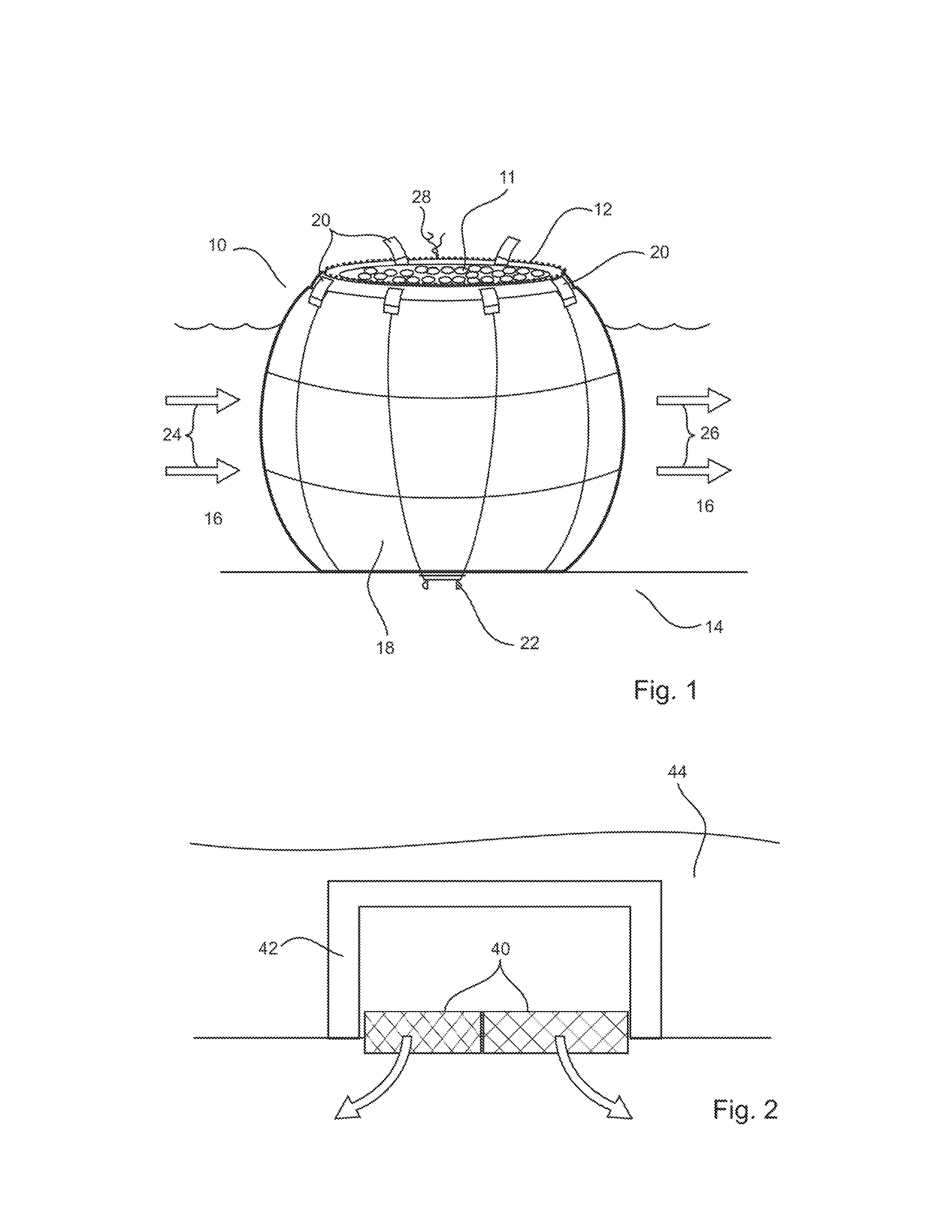

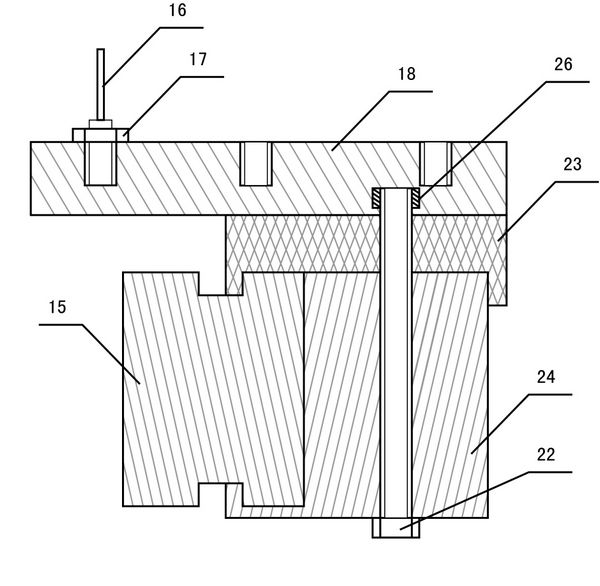

Drying plant and method for drying wood

InactiveUS6725566B1Drying using combination processesDrying solid materials with heatDesiccantProduct gas

The invention relates to drying equipment and can be used in wood and wood treatment industries, etc., whenever parameters and procedures necessary to dry materials such as wood are used. The invention allows the drying process to achieve a higher degree of environmental protection, a larger product output and power saving features on the account of the following design of the plant: the drying chamber (1) which contains the material to be dried includes a bottom (4) which has two cavities (5,6); hot combustion products are injected into one of these cavities (5) from the flue pipe (9) of the furnace (3) which is used to burn wood waste; hot air is supplied into the other cavity (6), whereby said air is heated in pipes which are located in the flue (9), and is used as a drying agent. The hot drying agent is supplied from the cavity (6) in the bottom and circulates through air distribution channels in the lower part of the drying chamber (1) where it passes through the material to be dried and rises in the top portion of the internal open space of the drying chamber (1). From that point, one part of the drying agent is fed into a closed circuit in the flue (9) of the furnace and is heated therein, and the other part of said drying agent is directed into a condensate cleaning unit (11) where it is mixed with furnace gases and purifies these gases by condensation.

Owner:SKROTSKY VIKTOR GEORGIEVICH +1

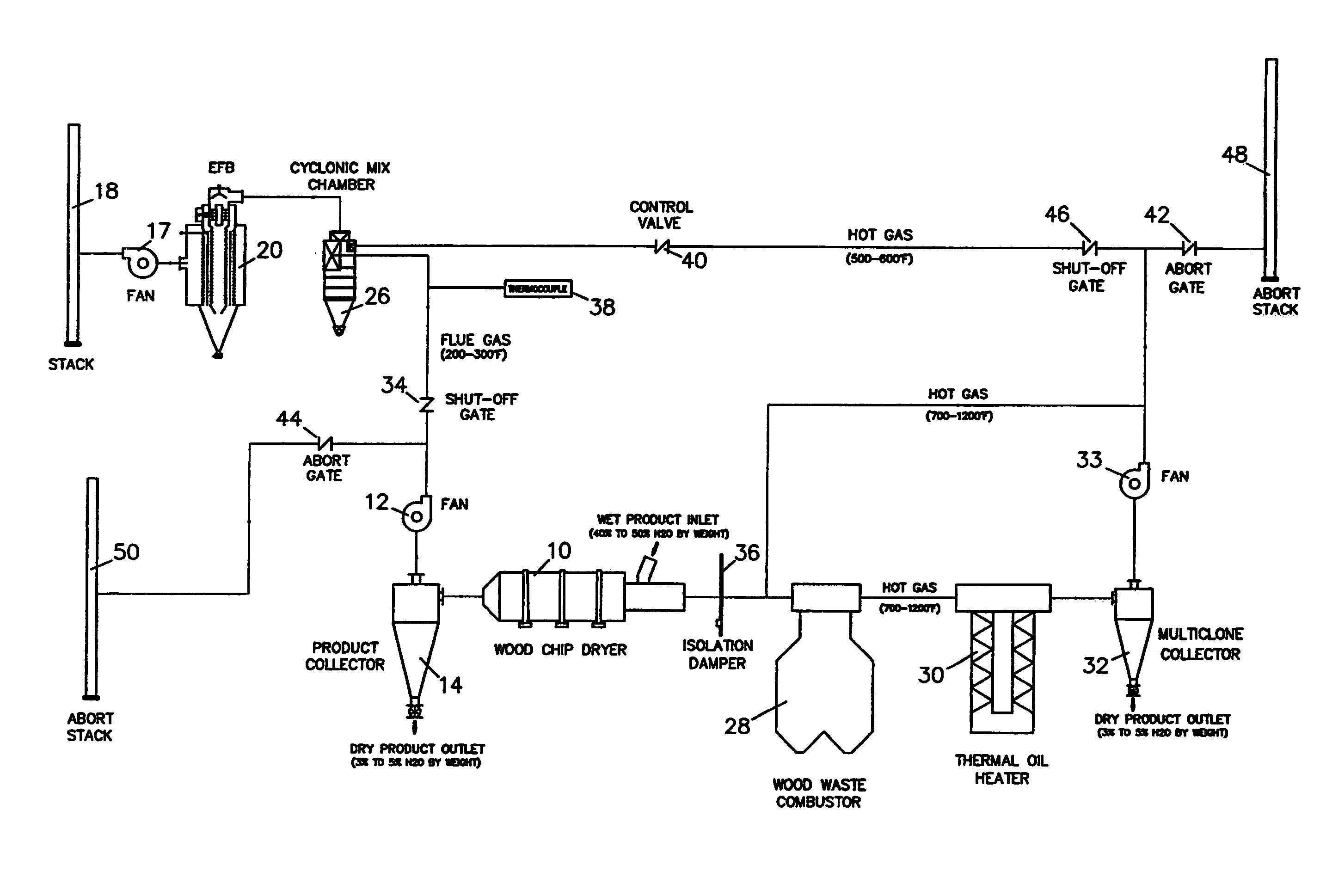

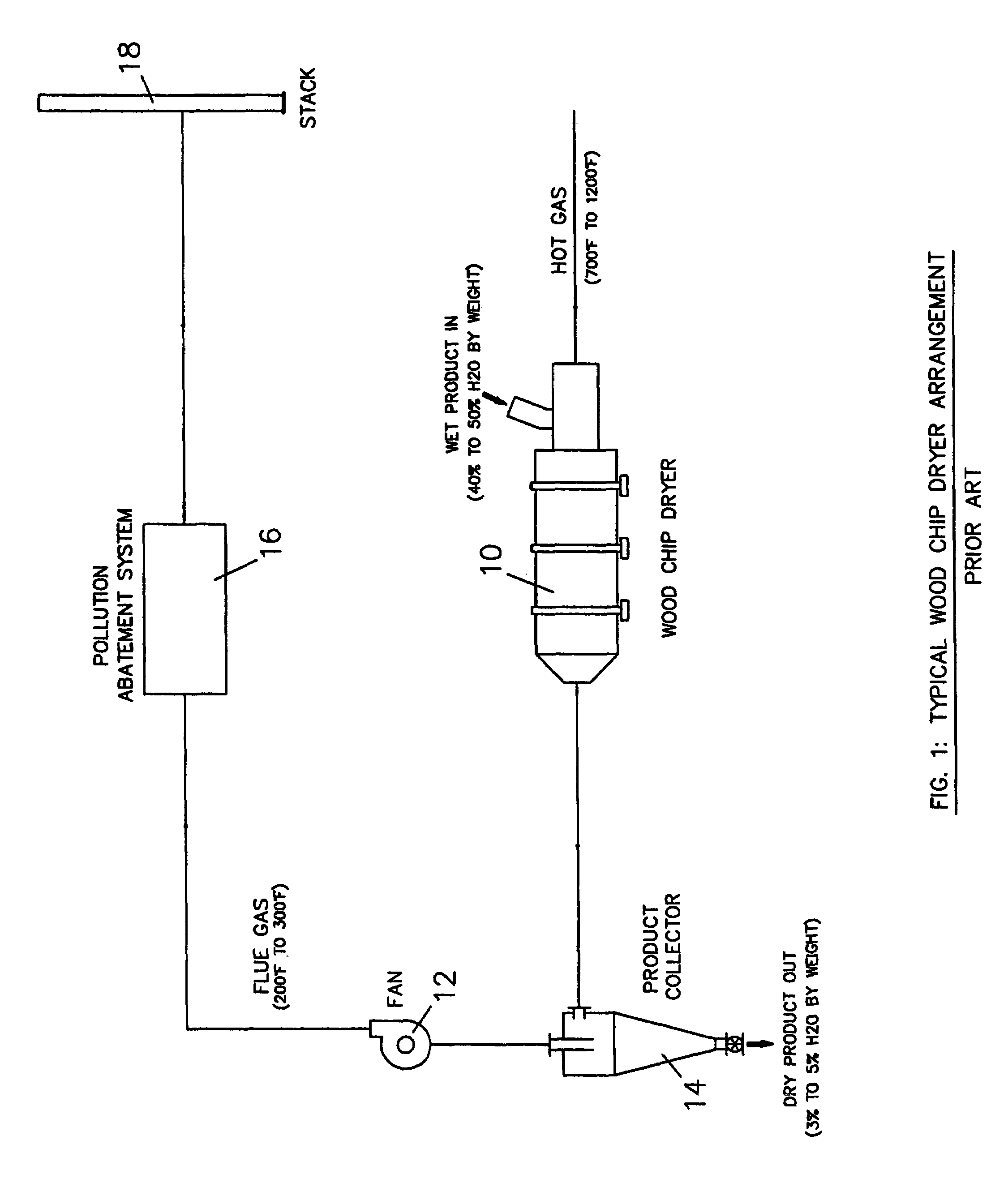

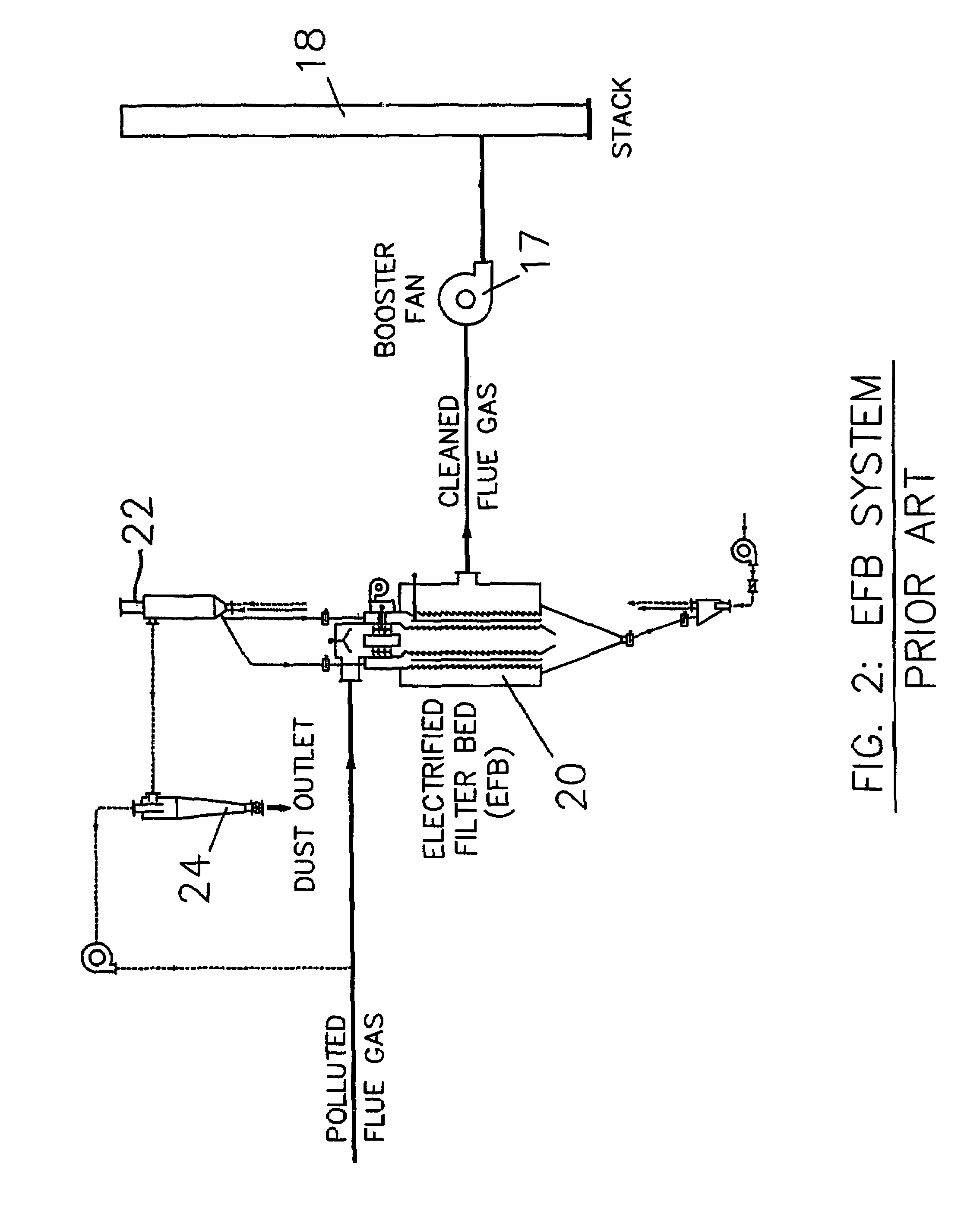

Apparatus and method using an electrified filter bed for removal of pollutants from a flue gas stream

InactiveUS20070214676A1Free of materialRapidly preheatedDrying using combination processesDrying solid materials with heatWhirlwindPollution

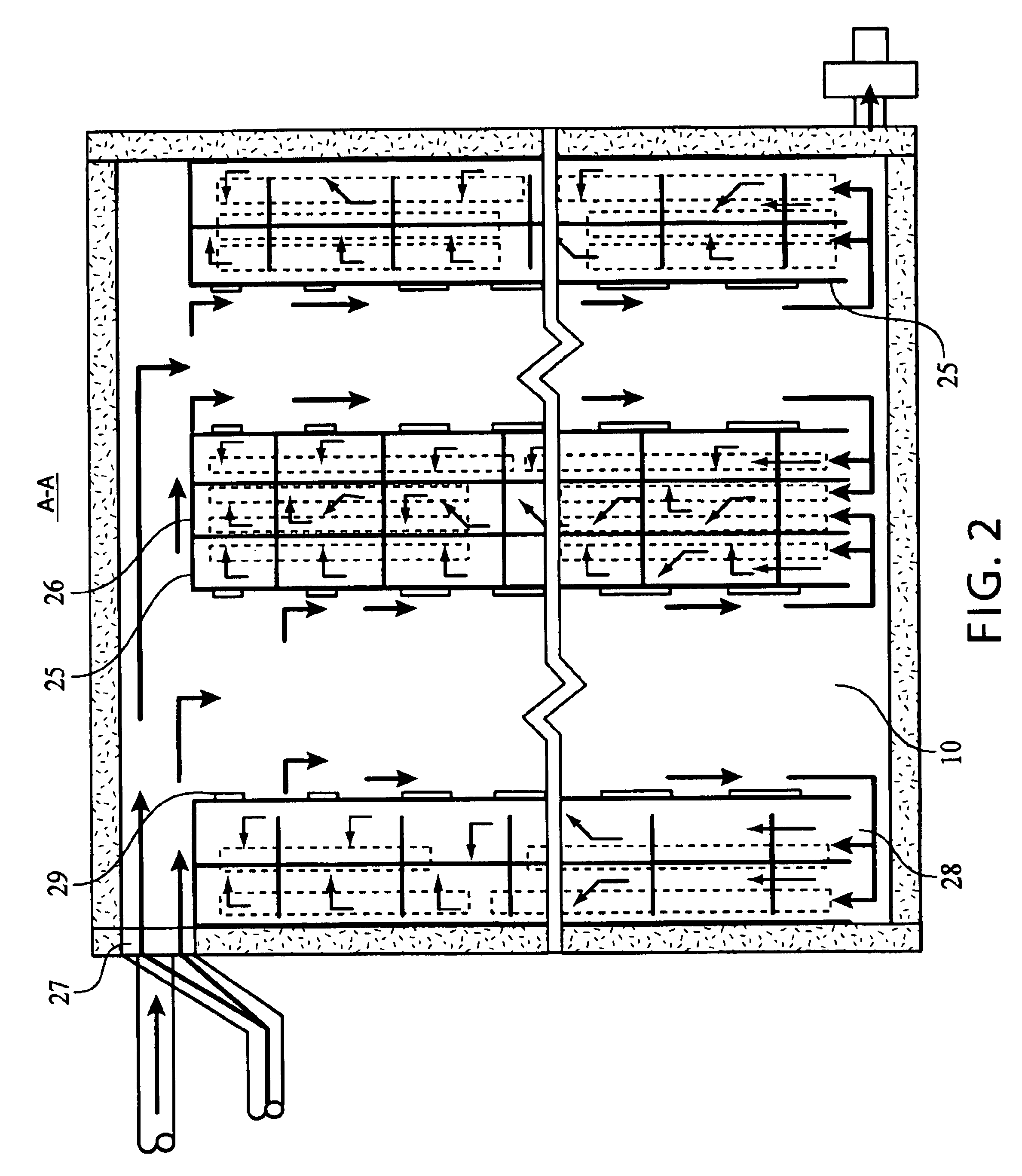

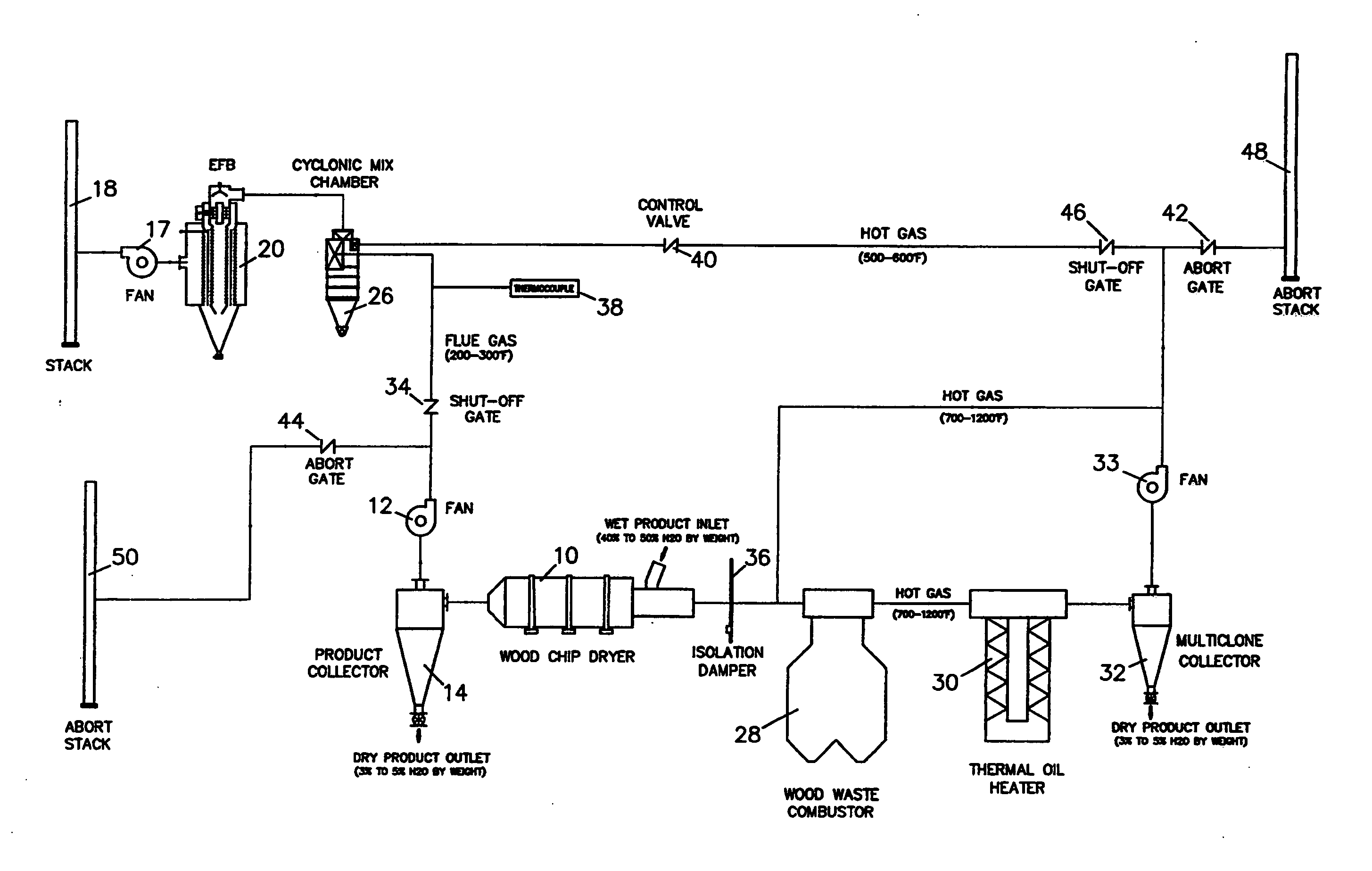

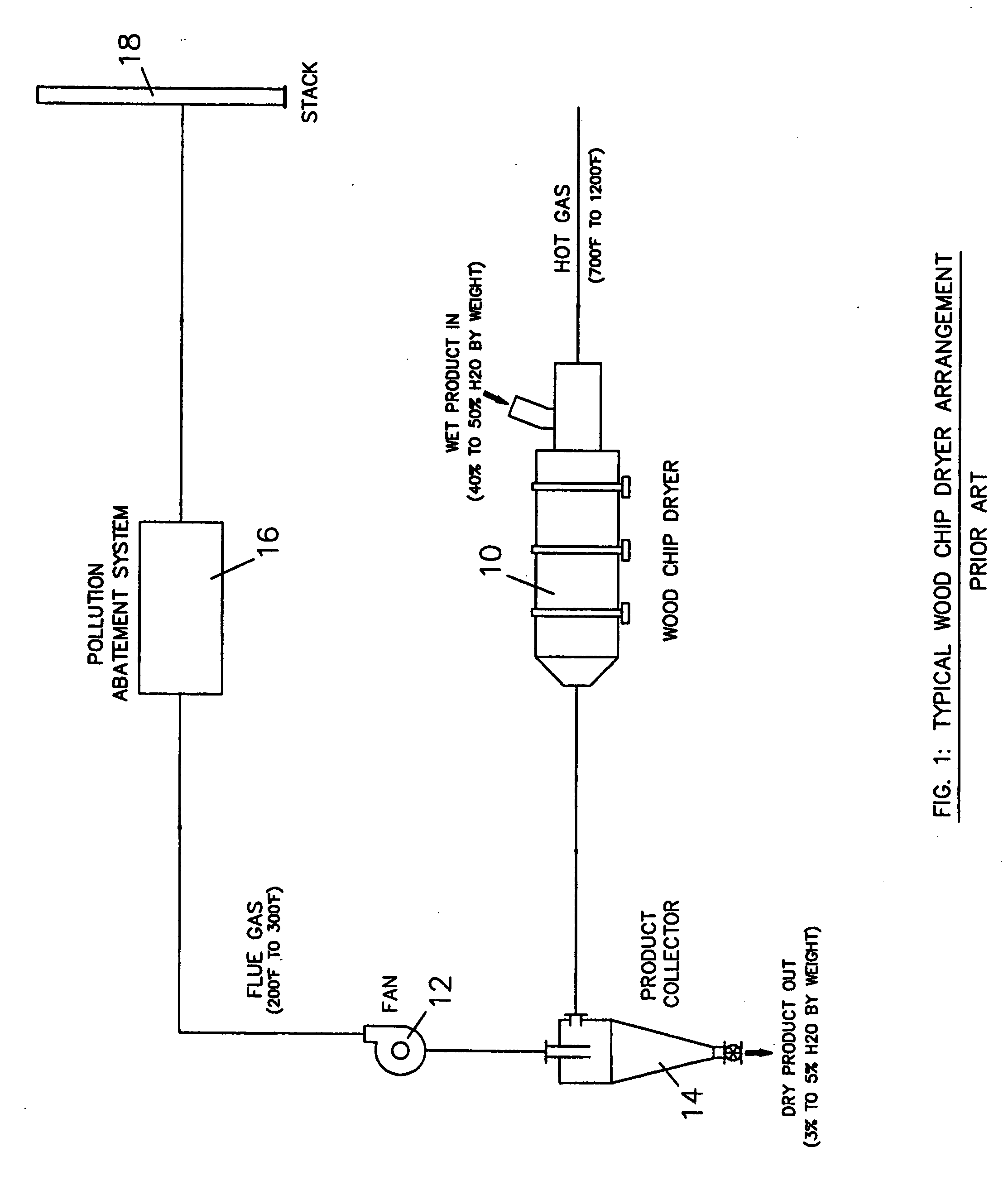

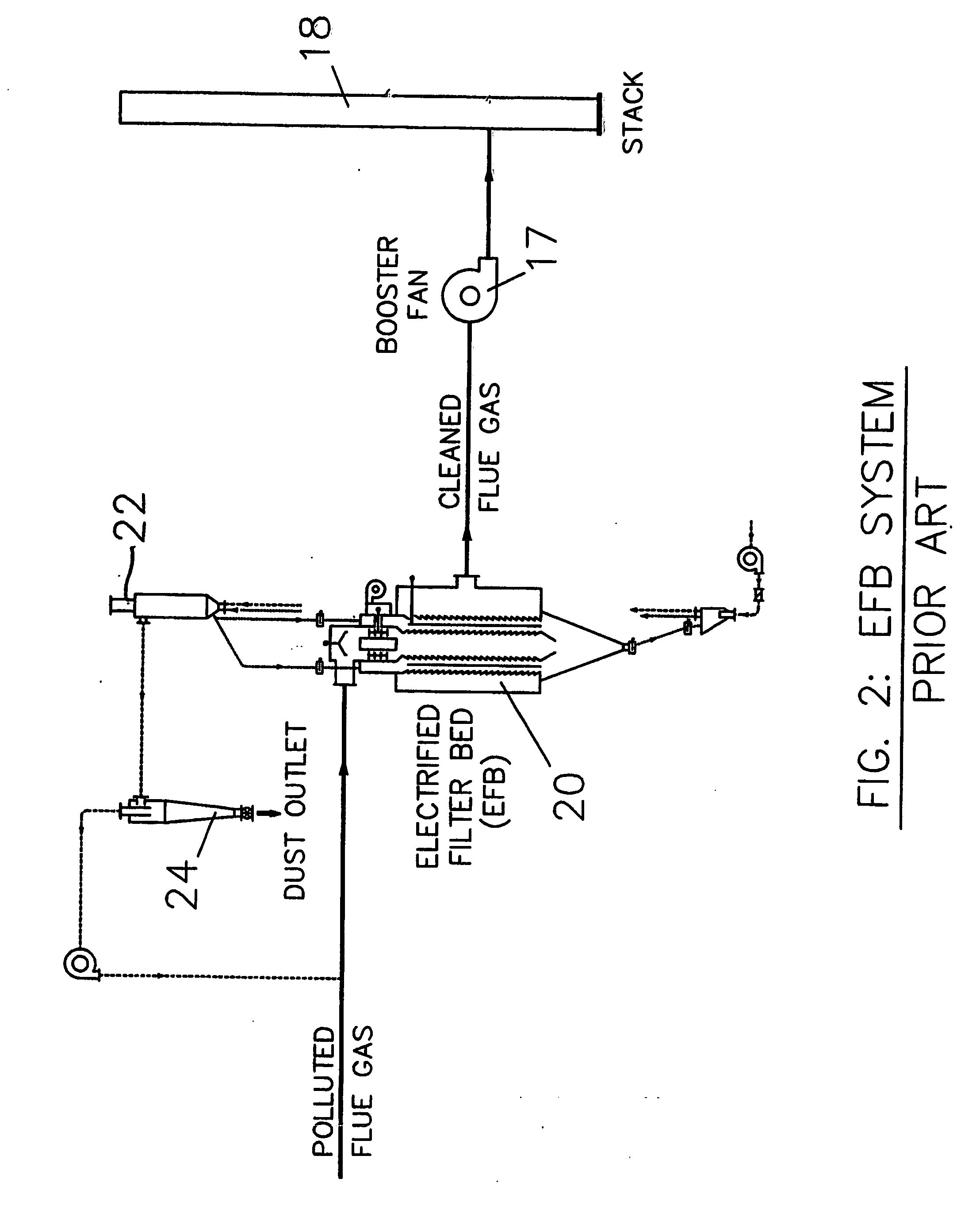

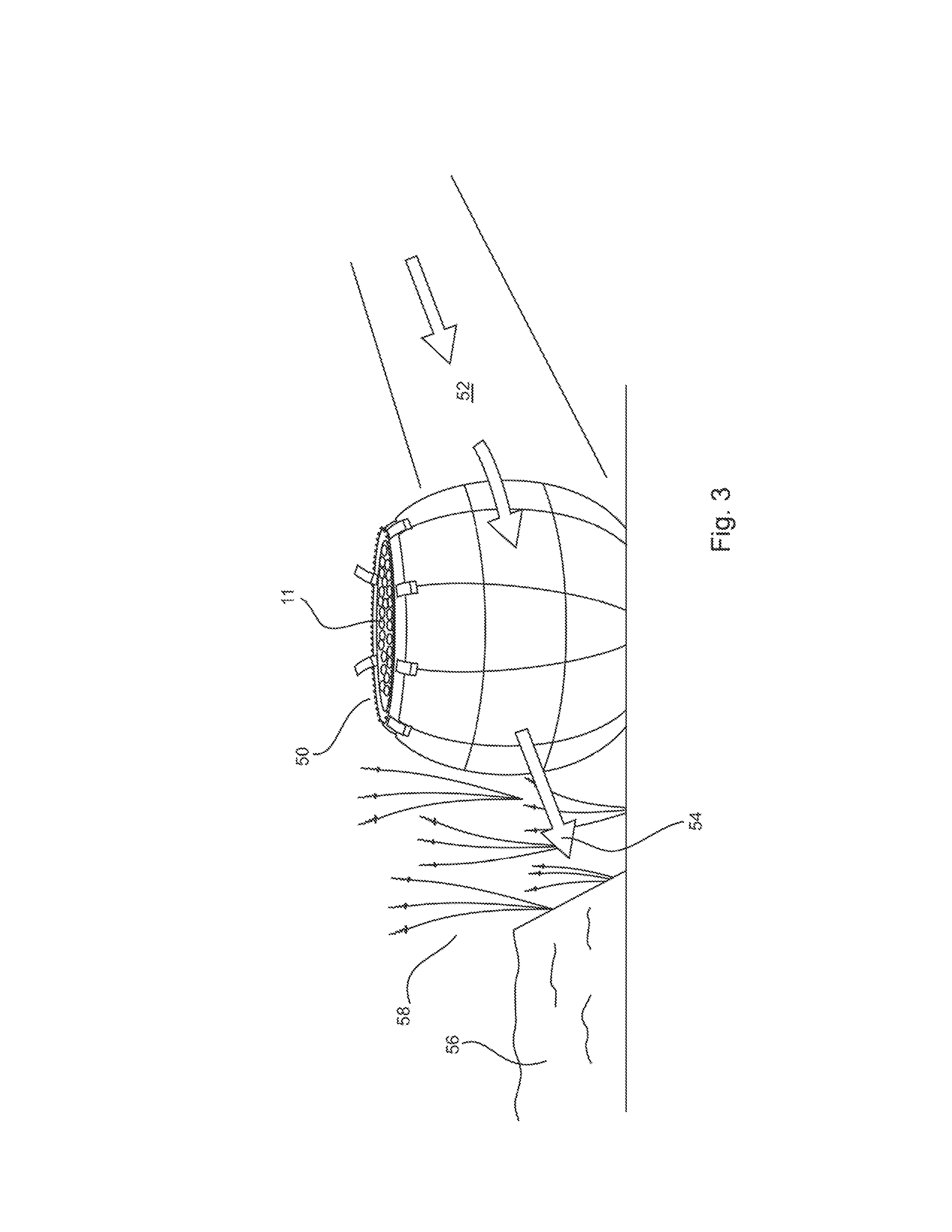

A pollution abatement apparatus comprises an electrified filter bed preceded by a cyclonic mix chamber to remove wood fines and fly ash in a flue gas stream from a wood chip dryer heated by hot gas from an energy system that includes a wood waste combustor. The cyclonic mix chamber has dual inlets, one supplied with flue gas from the dryer and the other supplied with hot gas from the energy system.

Owner:EFB

Method for preparing biological organic fertilizer by utilizing garden plant waste

InactiveCN104003822AImprove the environmentAddressing or Alleviating Acidification ProblemsFertilizer mixturesForest industryDecomposition

The invention relates to a method for preparing a biological organic fertilizer by utilizing garden plant waste, and belongs to the field of forestry biological environment. With the garden plant waste as main raw material, wood waste having higher lignification degree is carbonized, and a powdery carbonized material is obtained; grass waste having lower lignification degree is subjected to high-temperature microbial fermentation decomposition, and a decomposed material is obtained; and then the powdery carbonized material and the decomposed material are mixed in proper proportion, the novel biological organic fertilizer enriched with biochar is prepared, and a new way is provided for resource utilization of the garden plant waste.

Owner:KUNMING UNIV OF SCI & TECH

Nano-reinforced wood-plastic composite and preparation method thereof

The invention discloses a nano-reinforced wood-plastic composite. The nano-reinforced wood-plastic composite comprises the following raw materials in parts by weight: 20-70 parts of modified wood meal, 30-80 parts of polyethylene resin, 2-10 parts of compatilizer, 2-10 parts of lubricating agent, 0.1-1 part of antioxidant, 0.1-1 part of light stabilizer and 0.5-6 parts of nanofiller; and the modified wood meal is obtained by carrying out hydro-thermal treatment on wood wastes. The invention also discloses a preparation method of the nano-reinforcing wood-plastic composite. The preparation method comprises the following steps of: mixing raw materials, and then extruding and pelletizing in an extruder, and finally thermally pressing and forming obtained wood-plastic composite particles. The nano-reinforced wood-plastic composite obtained by the invention is high in bending strength and tensile strength, low in water absorption and moisture content, good in dimensional stability and ageing resistance, long in service life, and capable of replacing wood, and reducing the consumption of timber resources, thereby playing a role in protecting the environment.

Owner:ZHEJIANG UNIV

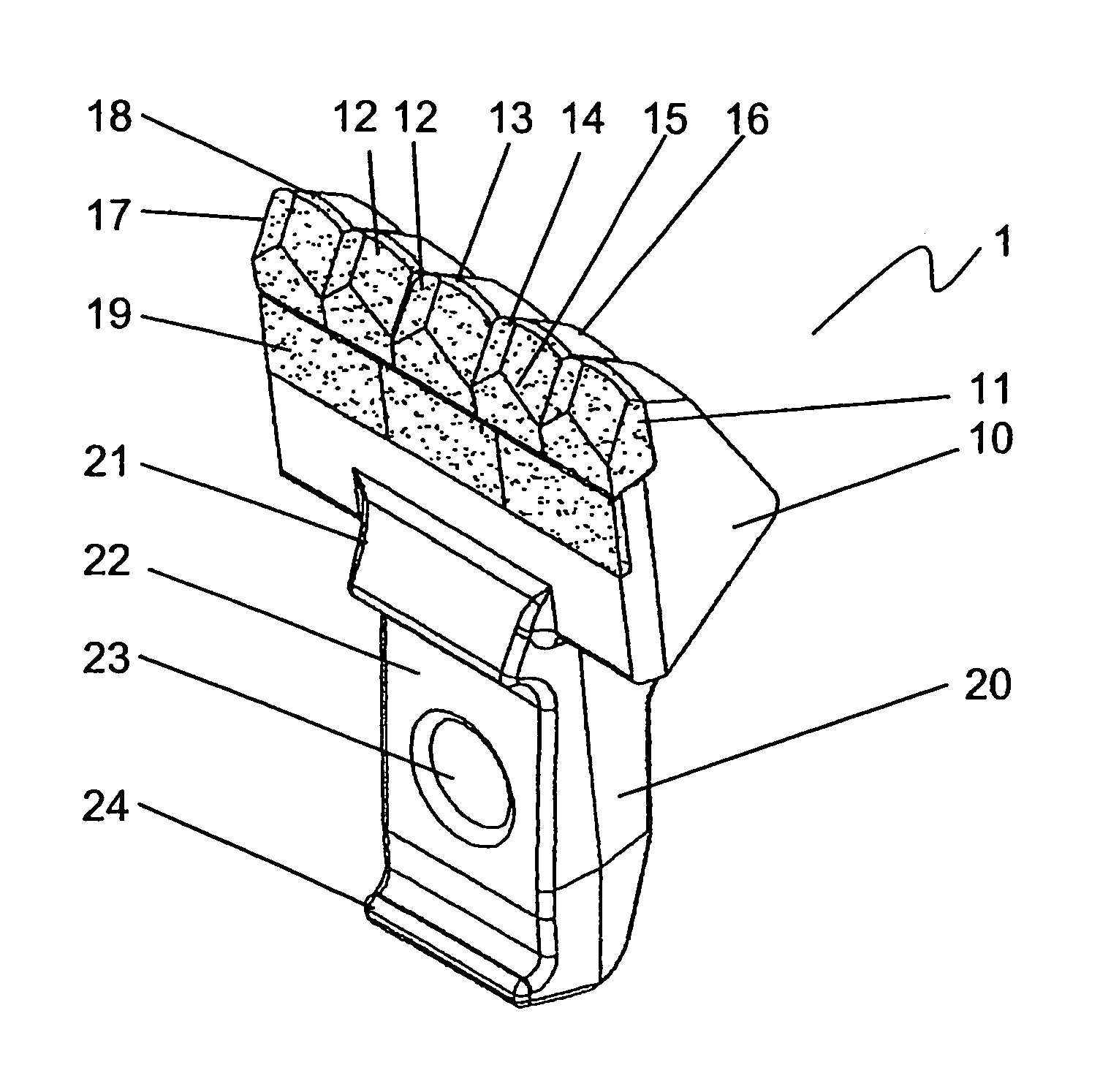

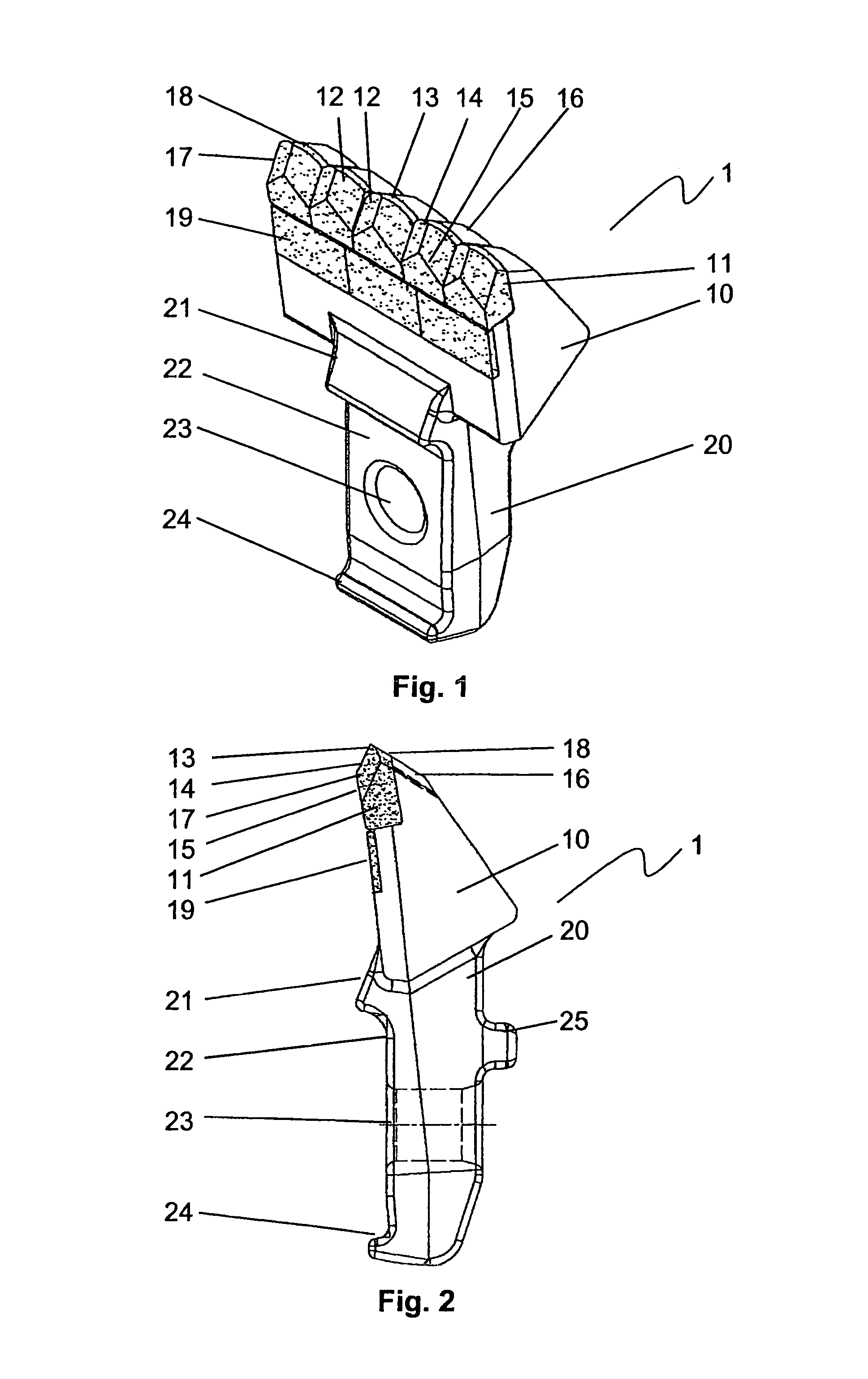

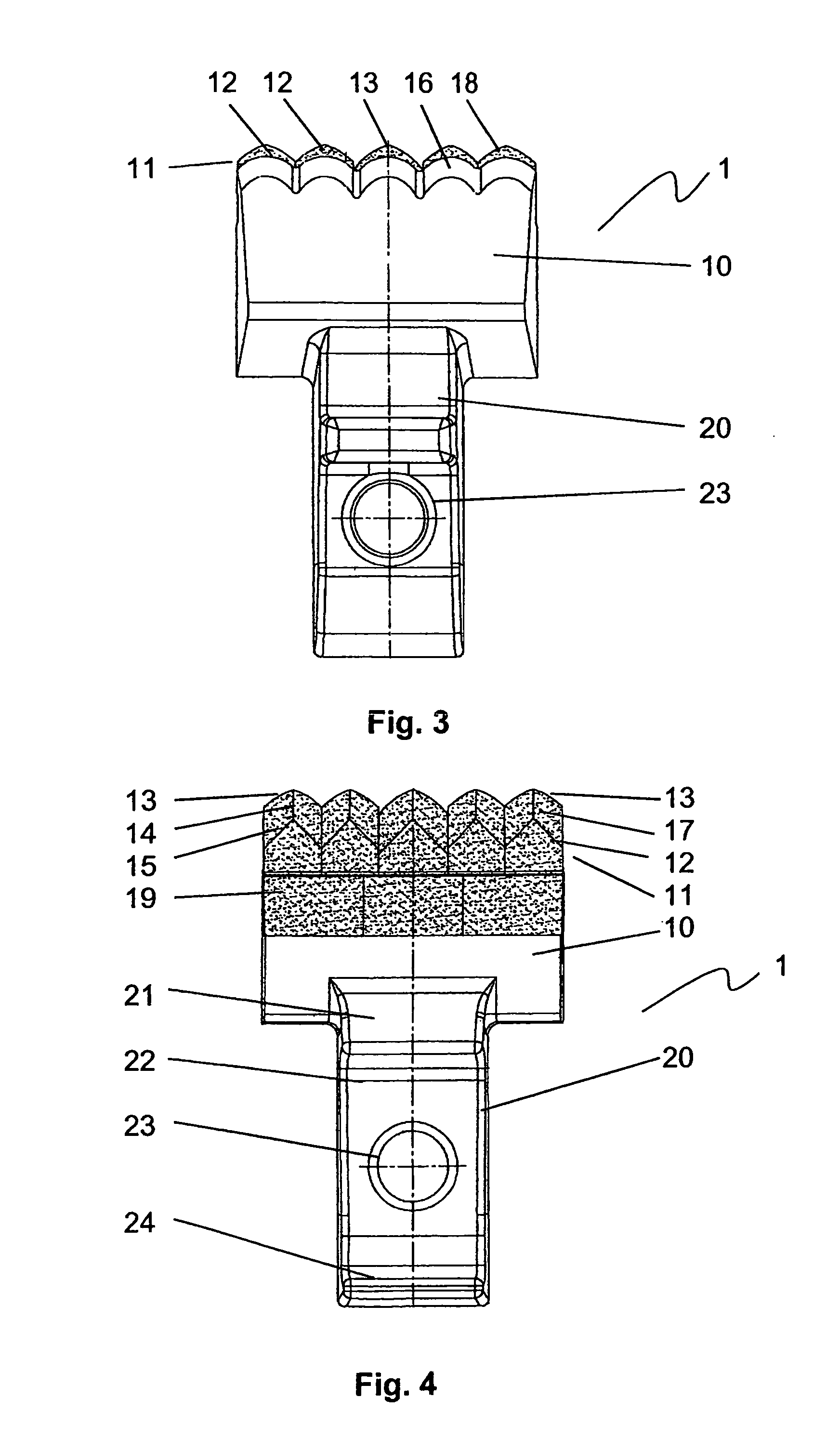

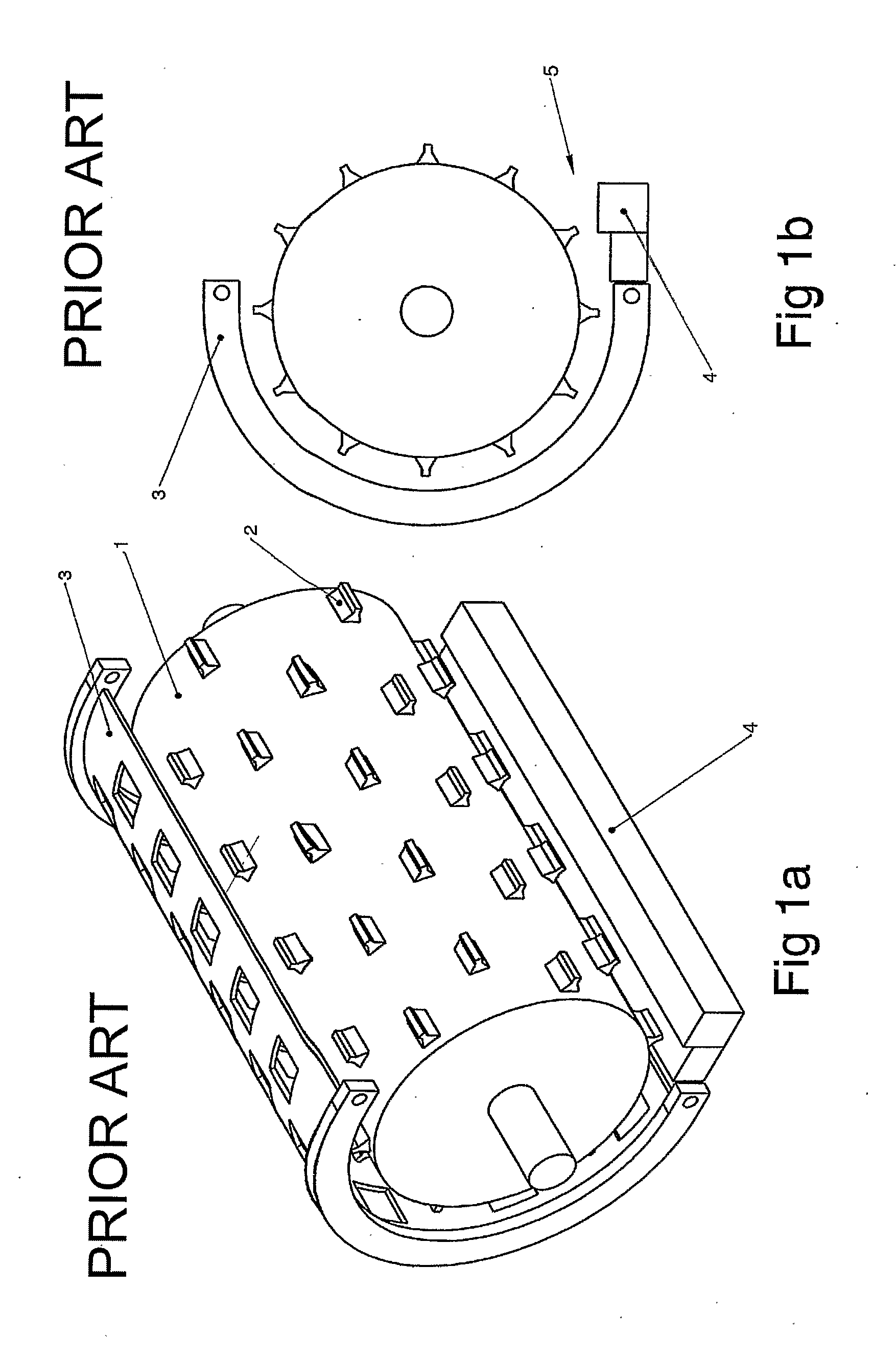

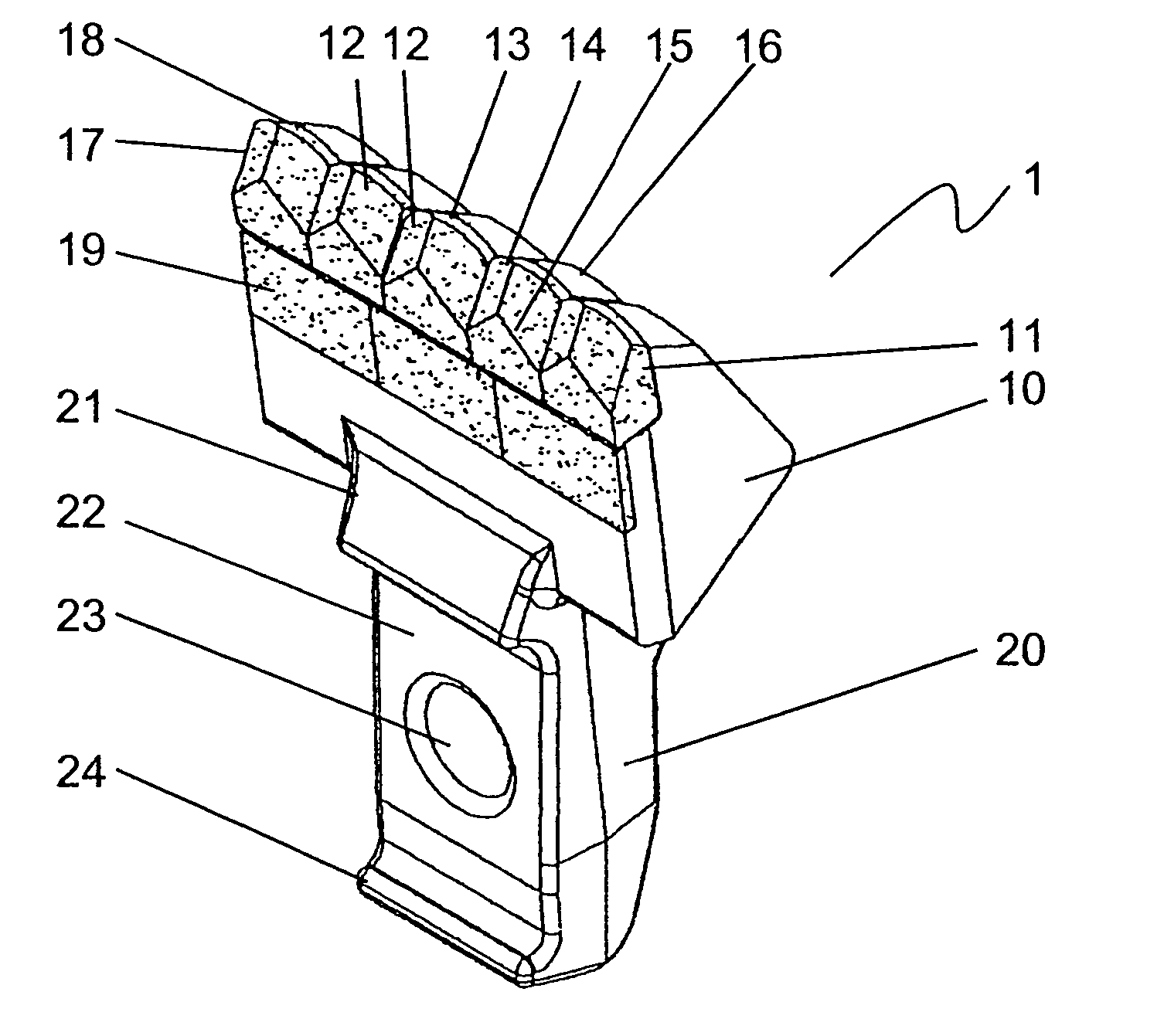

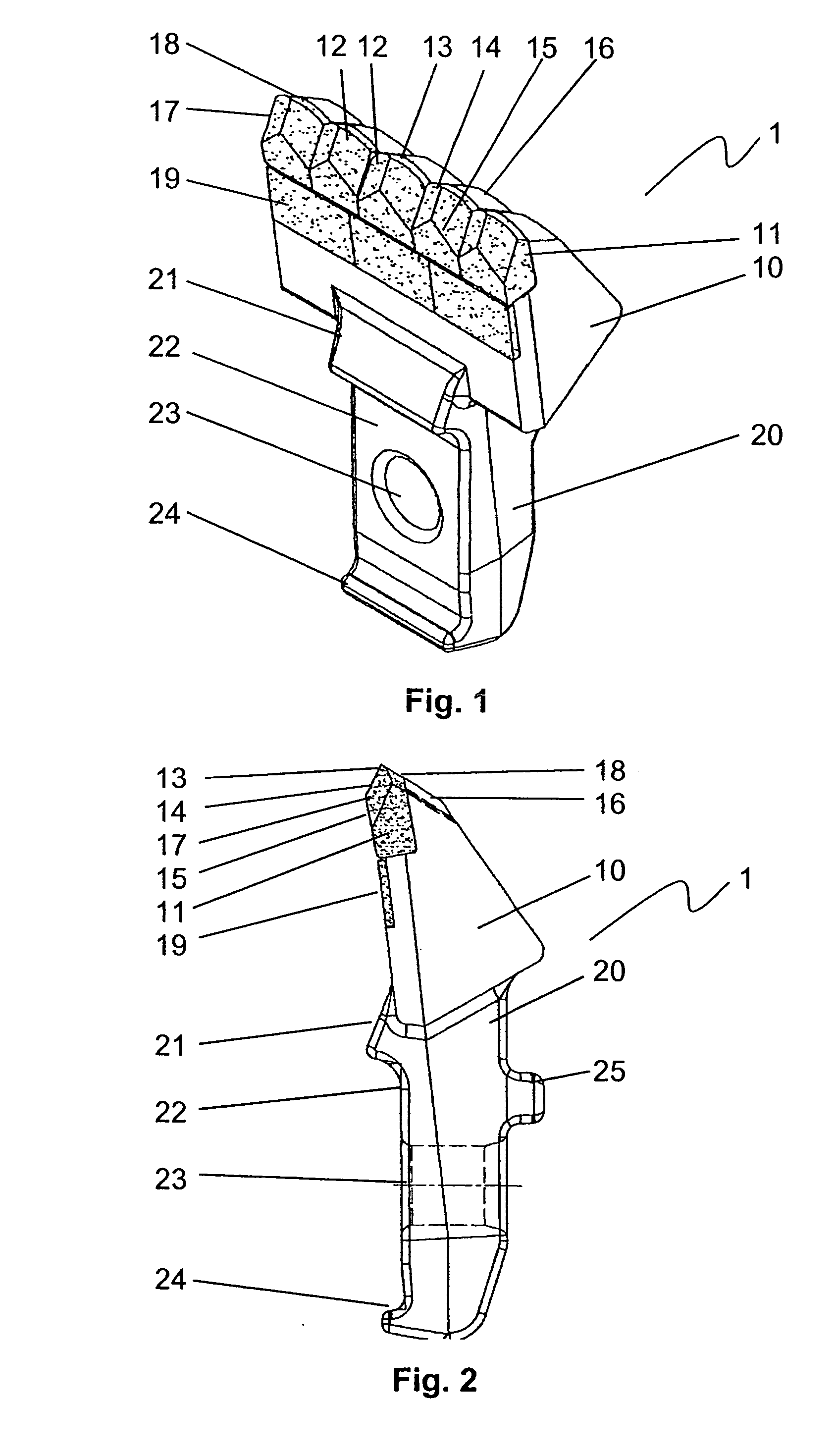

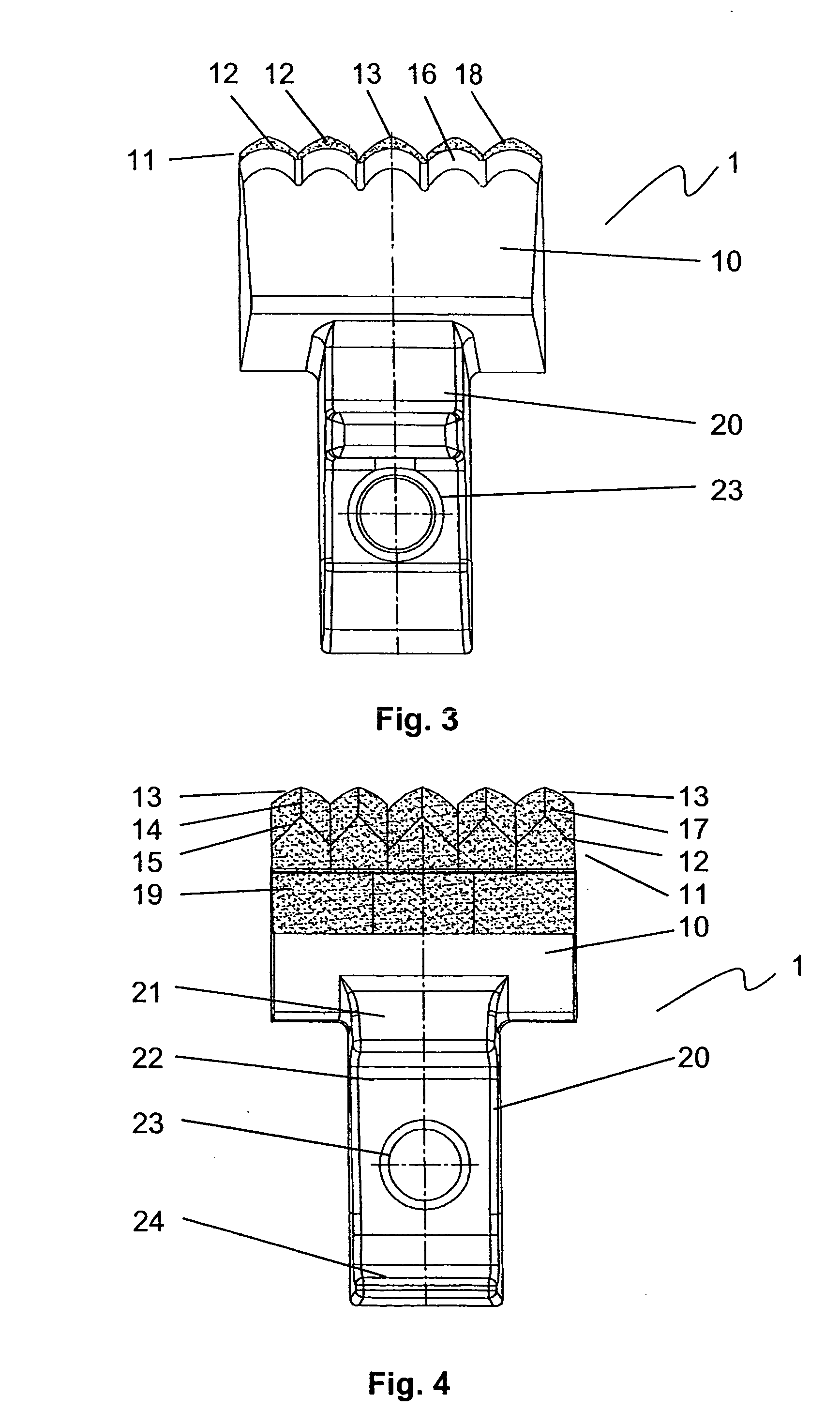

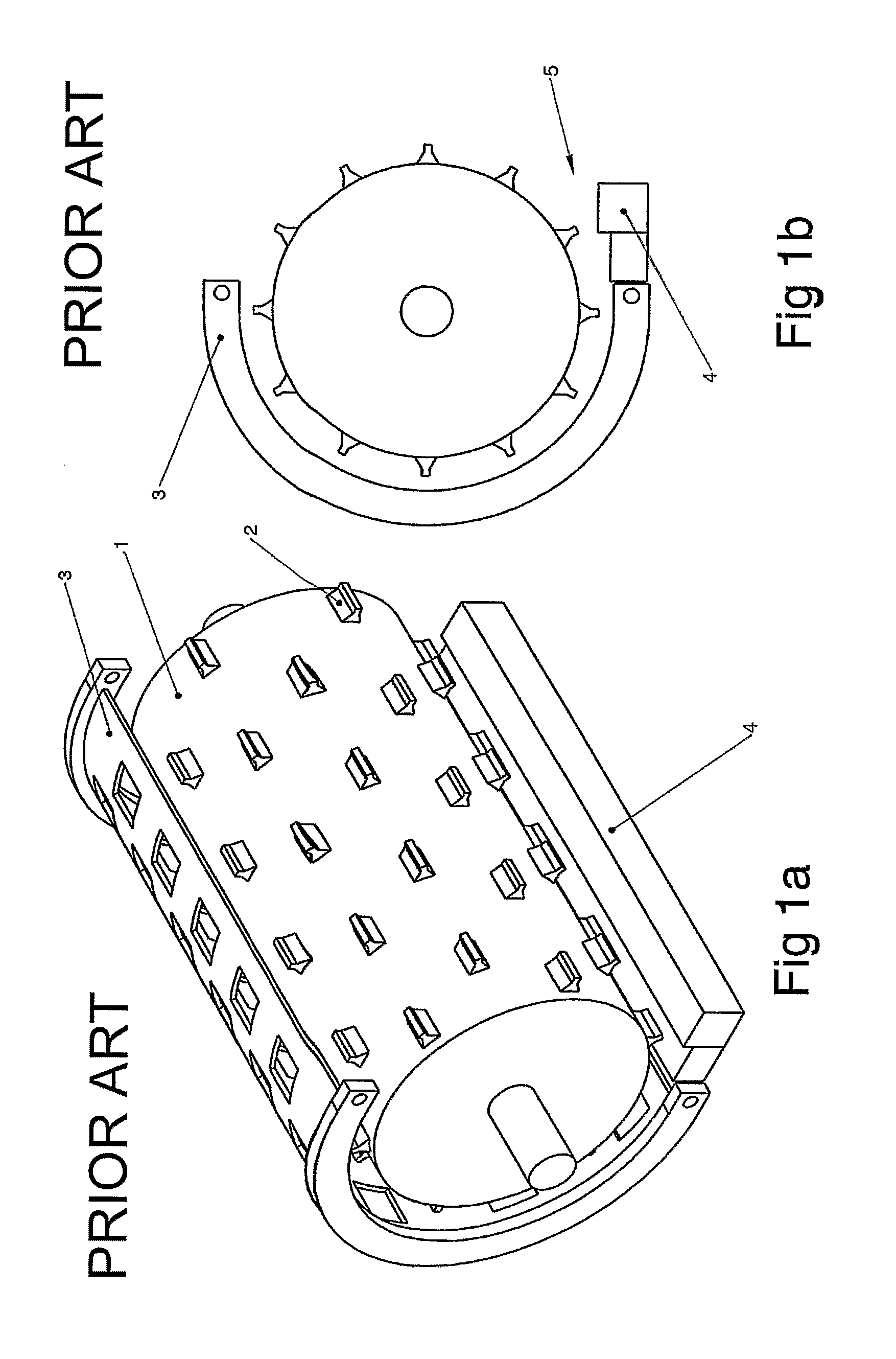

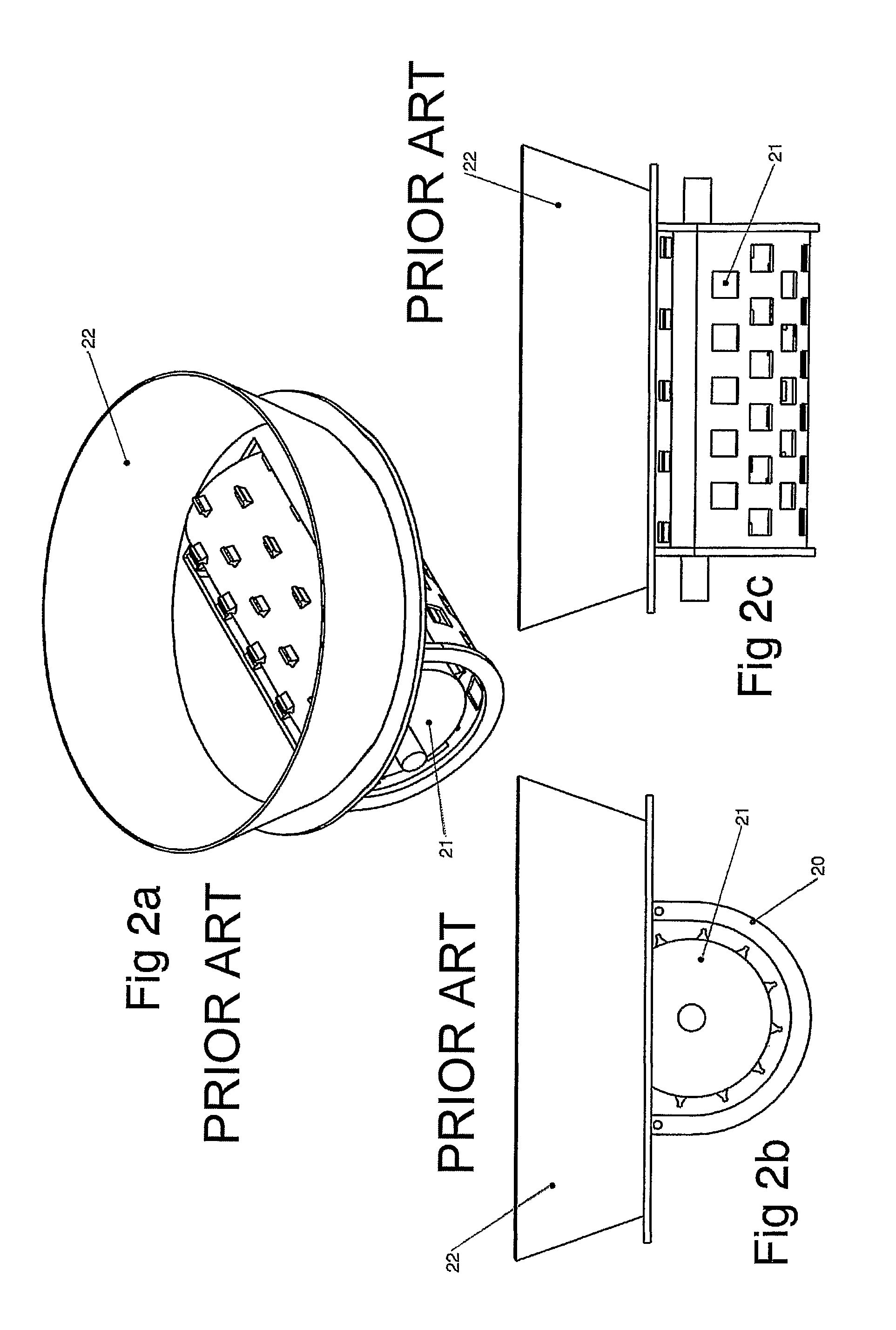

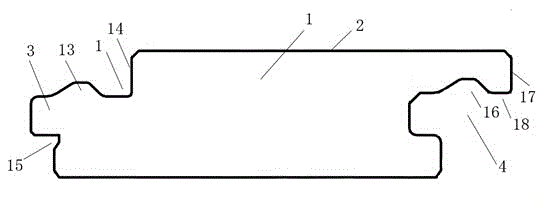

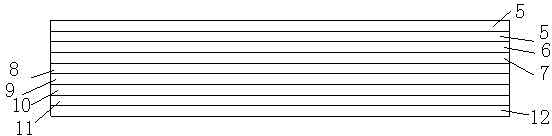

Exchangeable beater

A percussion tool for comminuting materials, in particular wood waste materials, having a beater head and a shank, wherein a cutting insert with an upper cutting edge extending transversely with respect to the cutting direction is fastened on the beater head. If the cutting insert has at least one first cutting element and at least one second cutting element, and if a free space in the shape of the upper cutting edge is arranged on the beater head in the cutting direction behind the cutting insert, then the cutting elements are thus supported over a greatest possible surface and are connected with the beater head. It is thus possible to transfer greater forces into the beater head without it being broken off.

Owner:BETEK BERGBAU UND HARTMETALLTECHN KARL HEINZ SIMON

Apparatus and method using an electrified filter bed for removal of pollutants from a flue gas stream

InactiveUS7318288B2Free of materialRapidly preheatedDrying using combination processesDrying solid materials with heatWhirlwindPollution

Owner:EFB

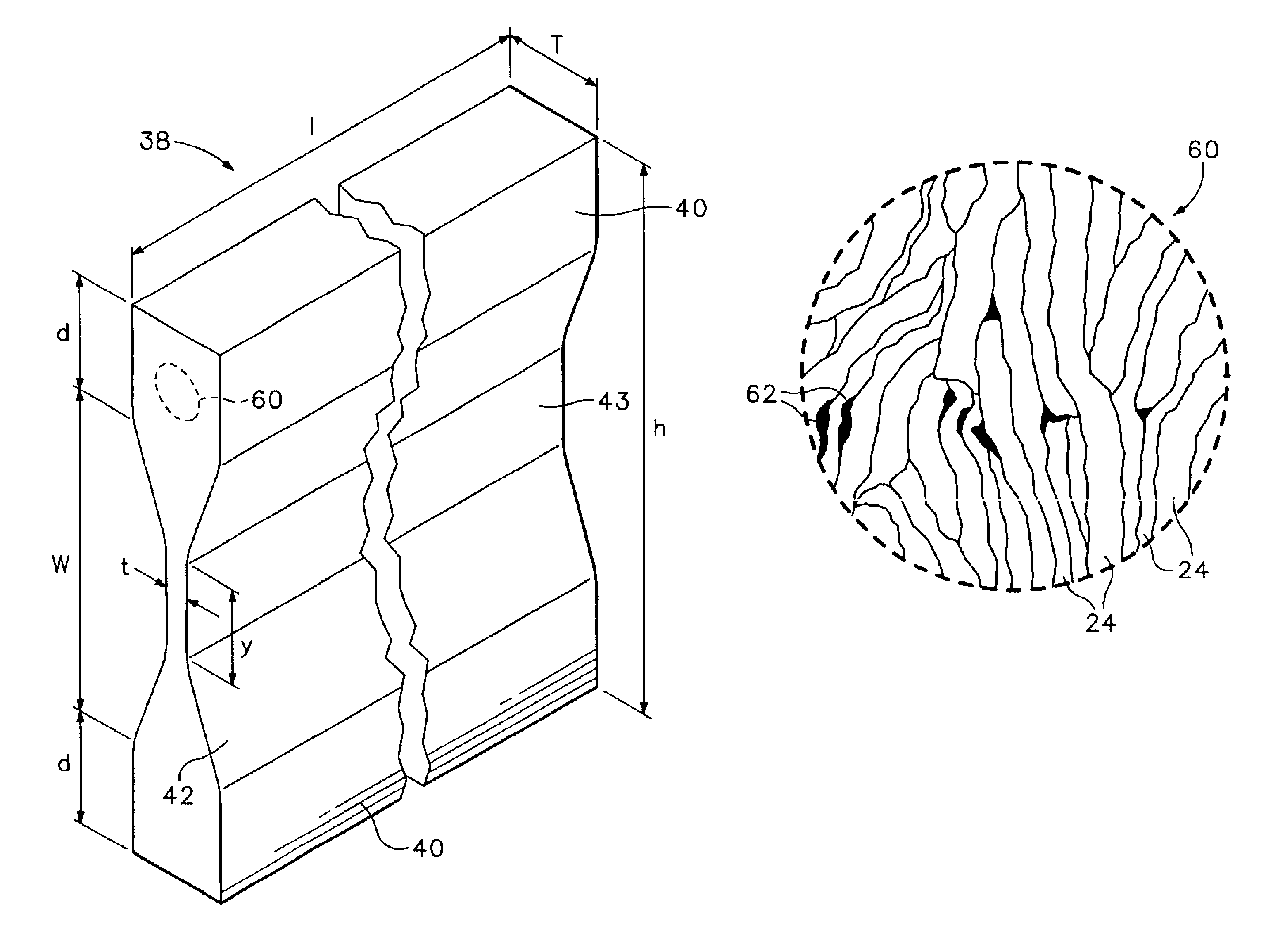

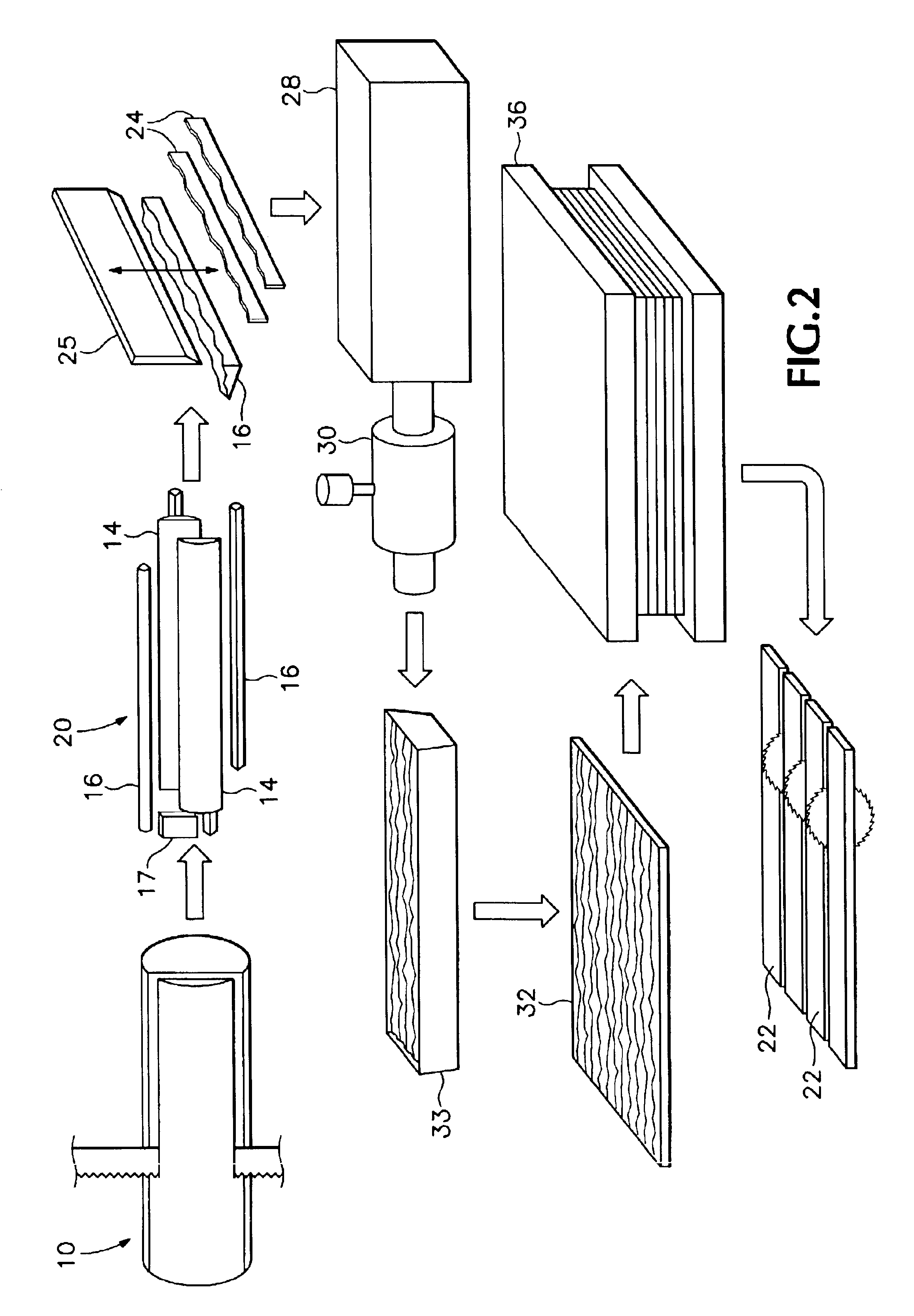

Compressed wood waste structural I-beam

Owner:USNRKOCKUMS CANCAR +2

Process and device for discharging lignocellulose raw materials from a digester and conveying the raw material to a refiner

InactiveUS7314538B2EliminateReduce moisture contentPulp liquor regenerationDigestersCelluloseMaterials science

A process for refining lignocellulose raw materials, especially wood chips, saw dust, annual plants or wood waste, includes dewatering the lignocellulose raw materials discharged from a digester, extracting condensate produced during dewatering, and refining the dewatered lignocellulose raw materials in a refiner.

Owner:ANDRITZ AG

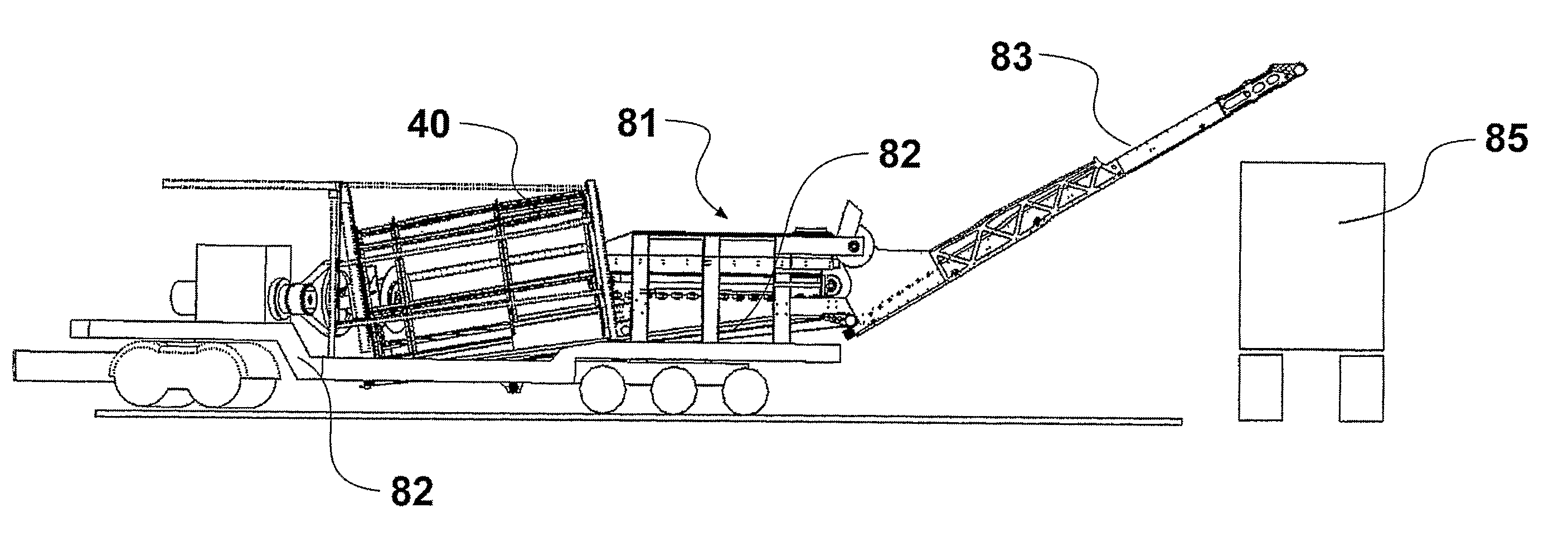

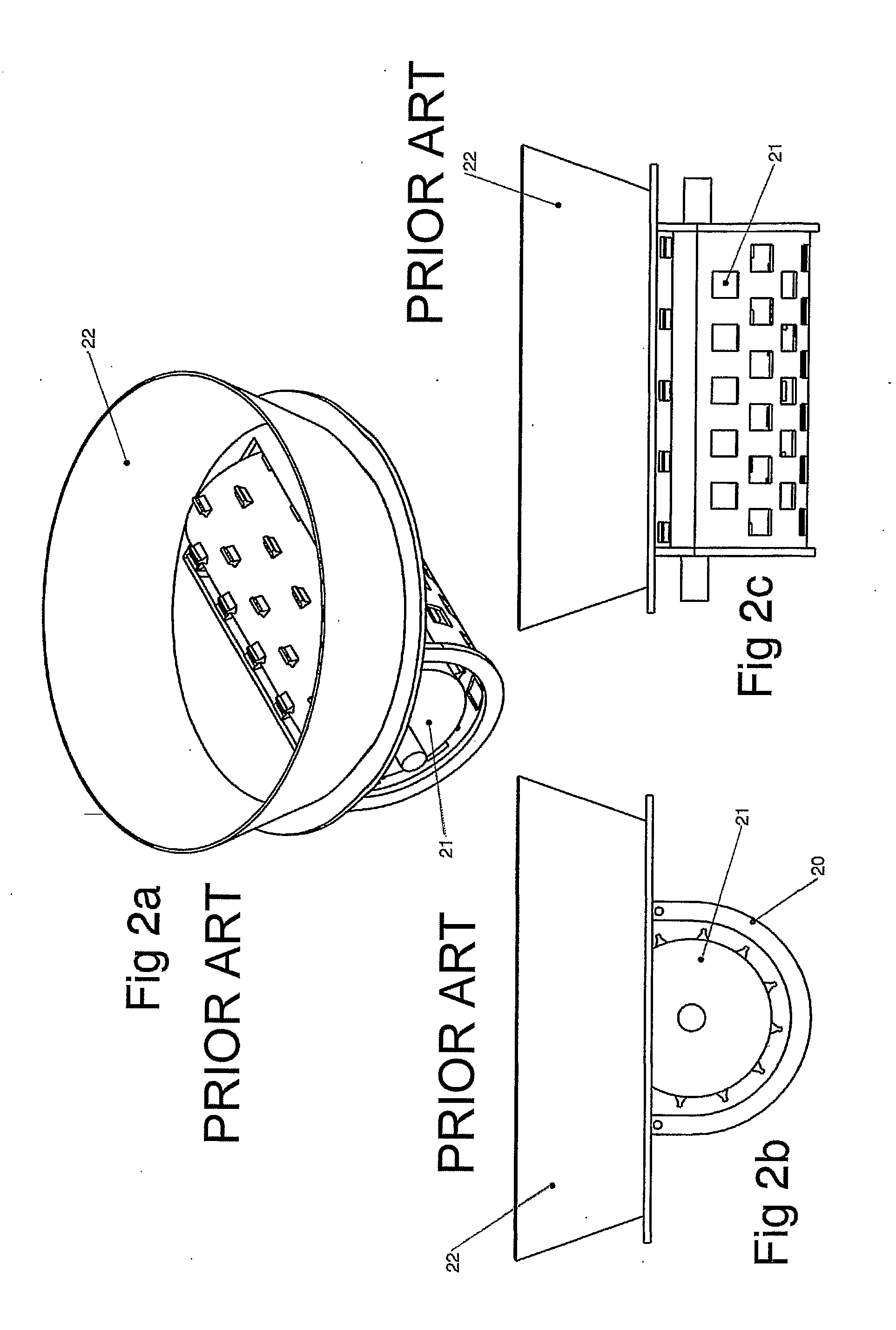

Wood Hogging Apparatus

InactiveUS20080099592A1Increase the sectionSmall sizeWood working apparatusCocoaForeign matterAsphalt

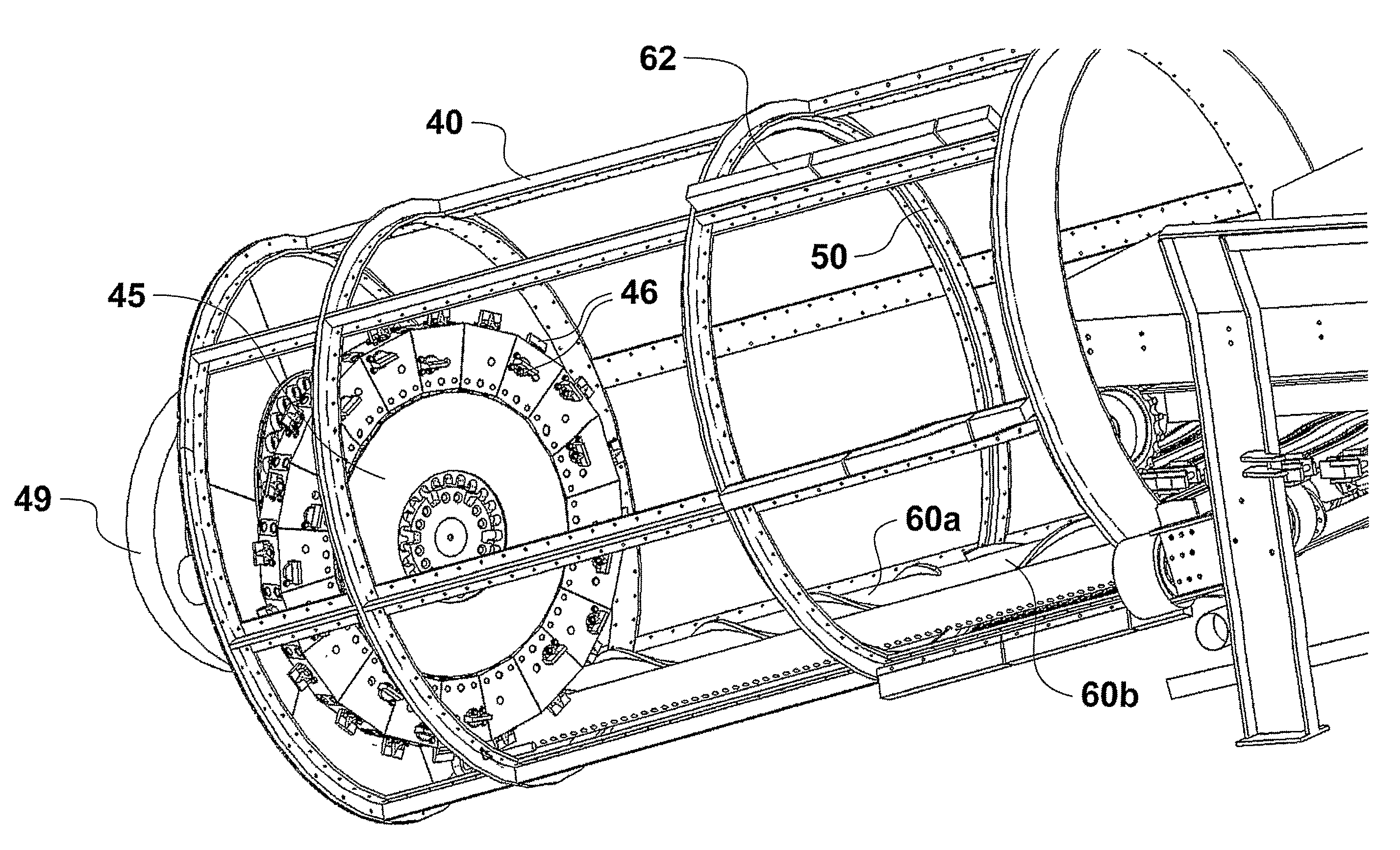

A hogging, sometimes known as reducing, apparatus for reducing wood waste into hog fuel, though some embodiments may also be used for reducing other materials including demolition timber, demolition masonry, mild steel scrap (thin sections), soft metal scrap, recycled cans, recycled glass, recycled plastic, soft rocks, occasionally hard rocks, recycled roading and asphalt, old tyres, and certain green garden waste. The apparatus includes a drum (40) inclined to the horizontal and into which raw material can be fed at its upper end. Rotation of the drum (40) assists driving raw material towards reducing elements (45) positioned at an angle near its (40) lower end. Screening apertures (41) allow sufficiently comminuted material to pass therethrough for removal. Optional features include internal agitators (60) for improving processing and screening, assisted drying of raw material by motor exhaust (71), and initial pre-screening of foreign material.

Owner:SHARP RODNEY WARWICK

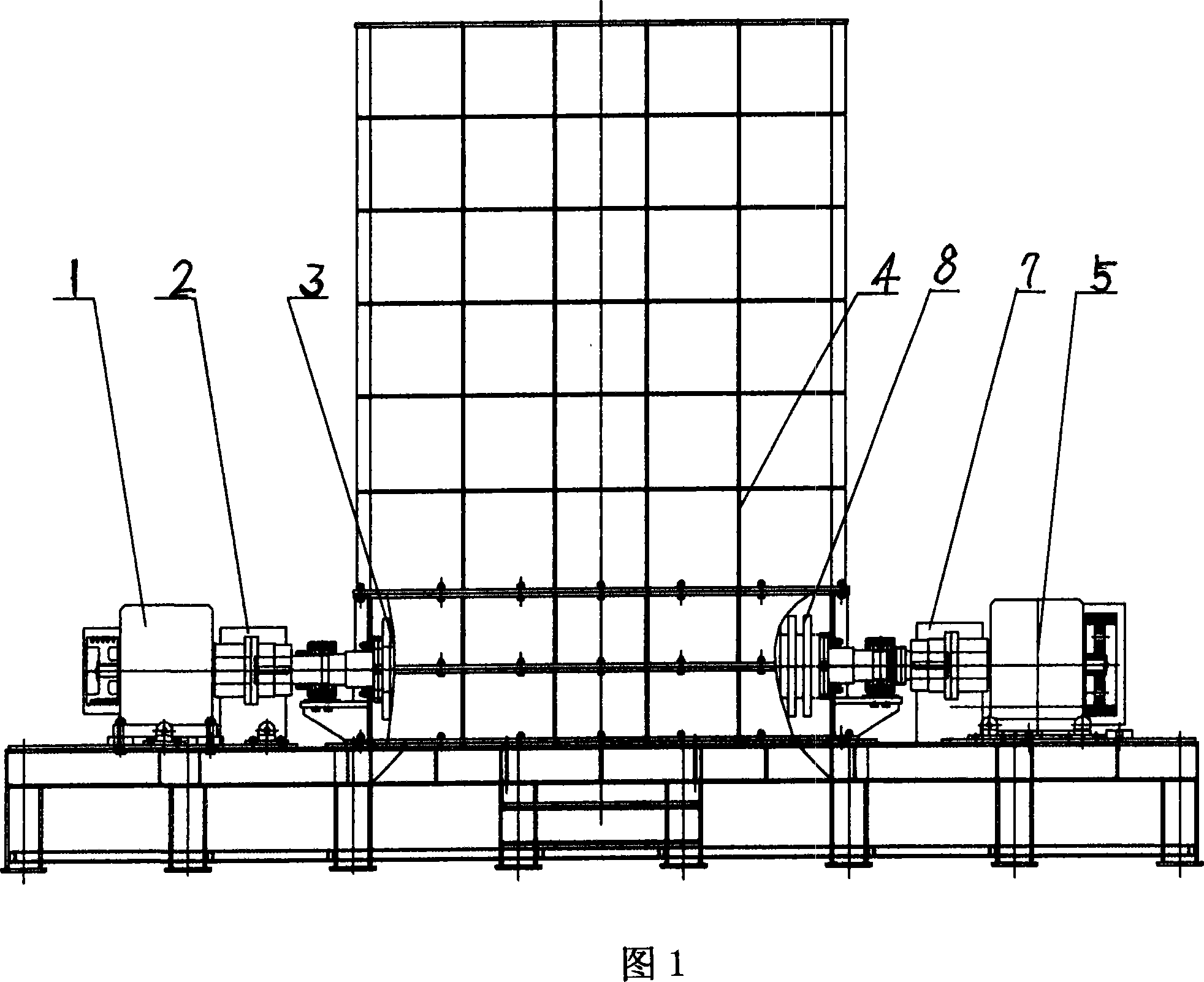

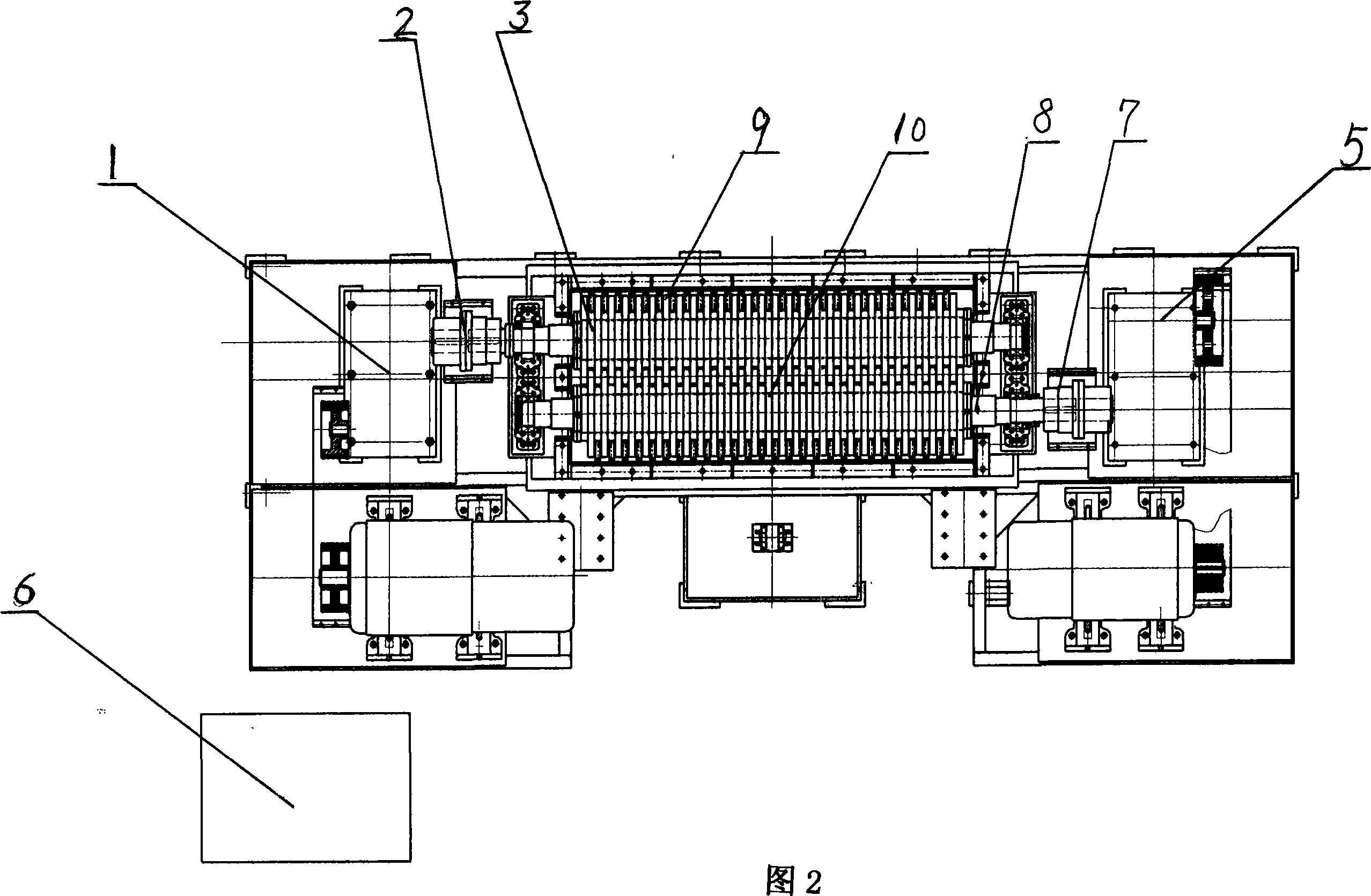

Crusher special for brush wood

InactiveCN101185910ASolving pile-up handling problemsFire Hazard PreventionCuttersGrain treatmentsLow speedElectrical control

A crusher specially used for crotch comprises a feeding hopper, a crushing system, a base part and an electrical control part, which is characterized in that the feeding hopper is internally provided with a material pressing device and the crushing system mainly consists of a main driving electrical motor and a secondary driving electrical motor, a decelerator, a pulley, a high speed teeth roller rotor and a low speed teeth roller rotor, wherein, the high speed teeth roller rotor and the low speed teeth roller rotor are arranged in parallel at one side of the material outlet of the feeding hopper, are provided with blade teeth that are in linear arrangement, and rotate relatively. The invention specifically crushes the crotches, roots and other organic waste biological materials of salix gordejevii and sea buckthorns that are cleaned because of the update planting of sand resistant forests and after being crushed, the products can be taken as burning coal material to substitute coal in thermal power generation, which can not only exploit the specific energy resources in sand resistant project, but can also solve the problem of wood waste disposal. The invention saves coal consumption in power generation and promotes local power development, and is characterized by the advantages of reasonable structure, relative rotation of double roller in different speeds, high crushing efficiency and low energy consumption.

Owner:SHENYANG HENGXING MACHINERY

Method of preparing carbon fiber from wood waste including adhesive

ActiveUS20150078983A1Improve performanceSolid waste disposalMonocomponent cellulose artificial filamentCarbon fibersAdhesive

Provided is a method of preparing cellulose fiber and carbon fiber by recycling industrial wood waste, wherein the carbon fiber is prepared by preparing high purity cellulose pulp by using, as a raw material, wood waste generated by manufacturers of pulp, furniture and other industrial products from wood and by eliminating resin and lignin impregnated in the wood waste through pulping and bleaching of the raw material, by preparing cellulose fiber by directly dissolving the prepared pulp in a cellulose solvent, and then by performing stabilizing and carbonizing with the cellulose fiber as a precursor.

Owner:KOREA INST OF SCI & TECH

Raw material treatment method for injection molding grade micro-foaming wood-plastic composite material

The invention relates to a raw material treatment method for an injection molding grade micro-foaming wood-plastic composite material, which comprises the following steps: pulverizing bamboo and wood waste into 40-200 meshes, then screening to obtain powder having different finenesses, and blending the coarse and fine powder with bamboo and wood powder according to a certain ratio; under a nitrogen gas protective atmosphere, performing heat treatment on the blended bamboo and wood powder at 160-280 DEG C for 0.5-12 hours; under the condition of stirring at a high speed of 300-2800r / min, uniformly mixing the modified bamboo and wood powder with adsorbent, plastic, coupling agent, foaming agent, foaming promoter, pigment, compatilizer, lubricant, plasticizer and enhanced filler to prepare a mixture; and extruding and granulating the mixture through an extruder, thus obtaining the injection molding grade micro-foaming wood-plastic composite material. The wood-plastic composite material has the characteristics of high surface gloss, high strength and toughness, low cost and the like, and is suitable for various injection molding products of which the molding shape is relatively complex.

Owner:江西省大余章源竹木制品有限公司

Exchangeable beater

InactiveUS20060226270A1Accelerated decayIncrease the number ofCocoaGrain treatmentsEngineeringKnife blades

A percussion tool for comminuting materials, in particular wood waste materials, having a beater head and a shank, wherein a cutting insert with an upper cutting edge extending transversely with respect to the cutting direction is fastened on the beater head. If the cutting insert has at least one first cutting element and at least one second cutting element, and if a free space in the shape of the upper cutting edge is arranged on the beater head in the cutting direction behind the cutting insert, then the cutting elements are thus supported over a greatest possible surface and are connected with the beater head. It is thus possible to transfer greater forces into the beater head without it being broken off.

Owner:BETEK BERGBAU UND HARTMETALLTECHN KARL HEINZ SIMON

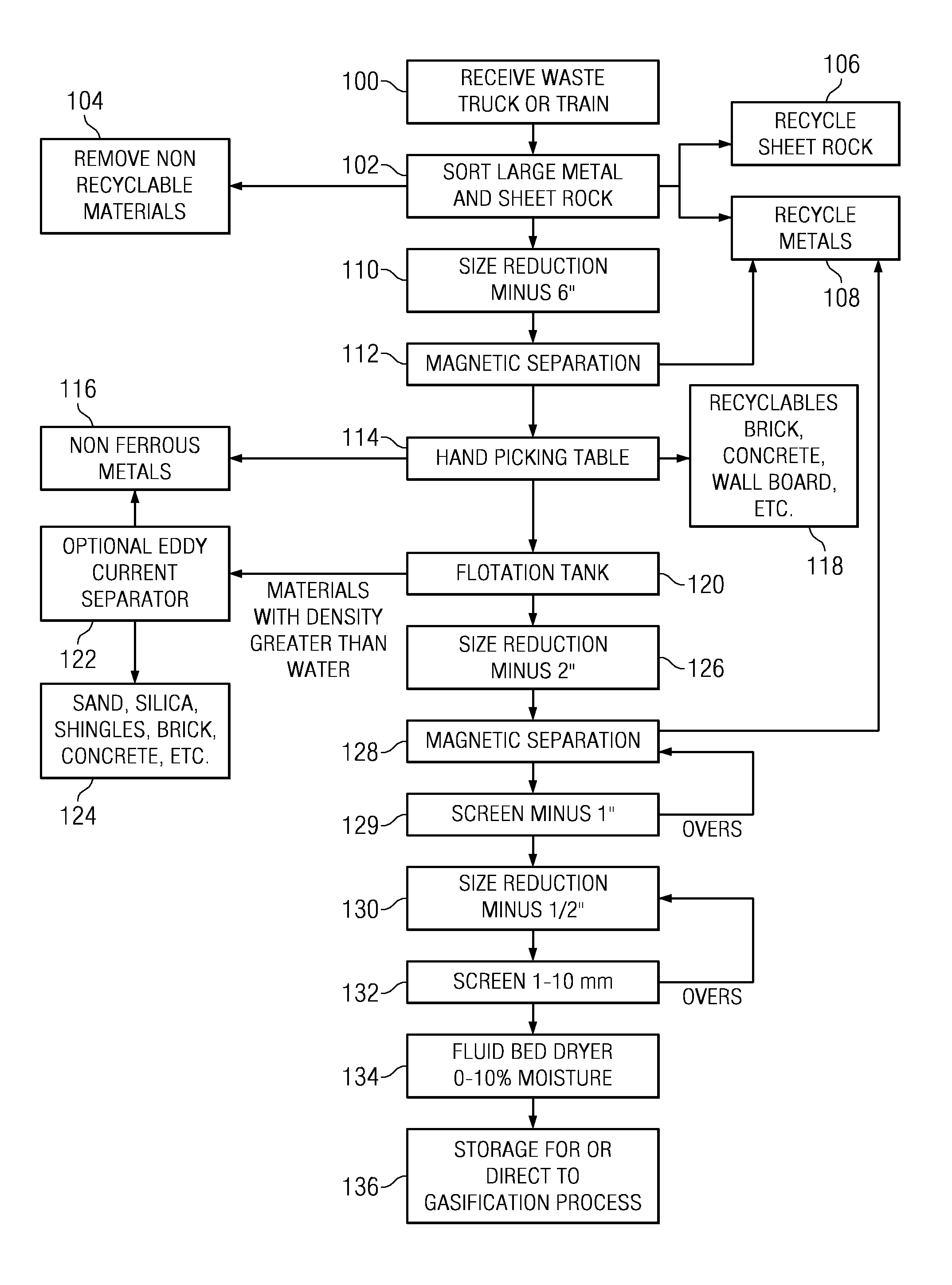

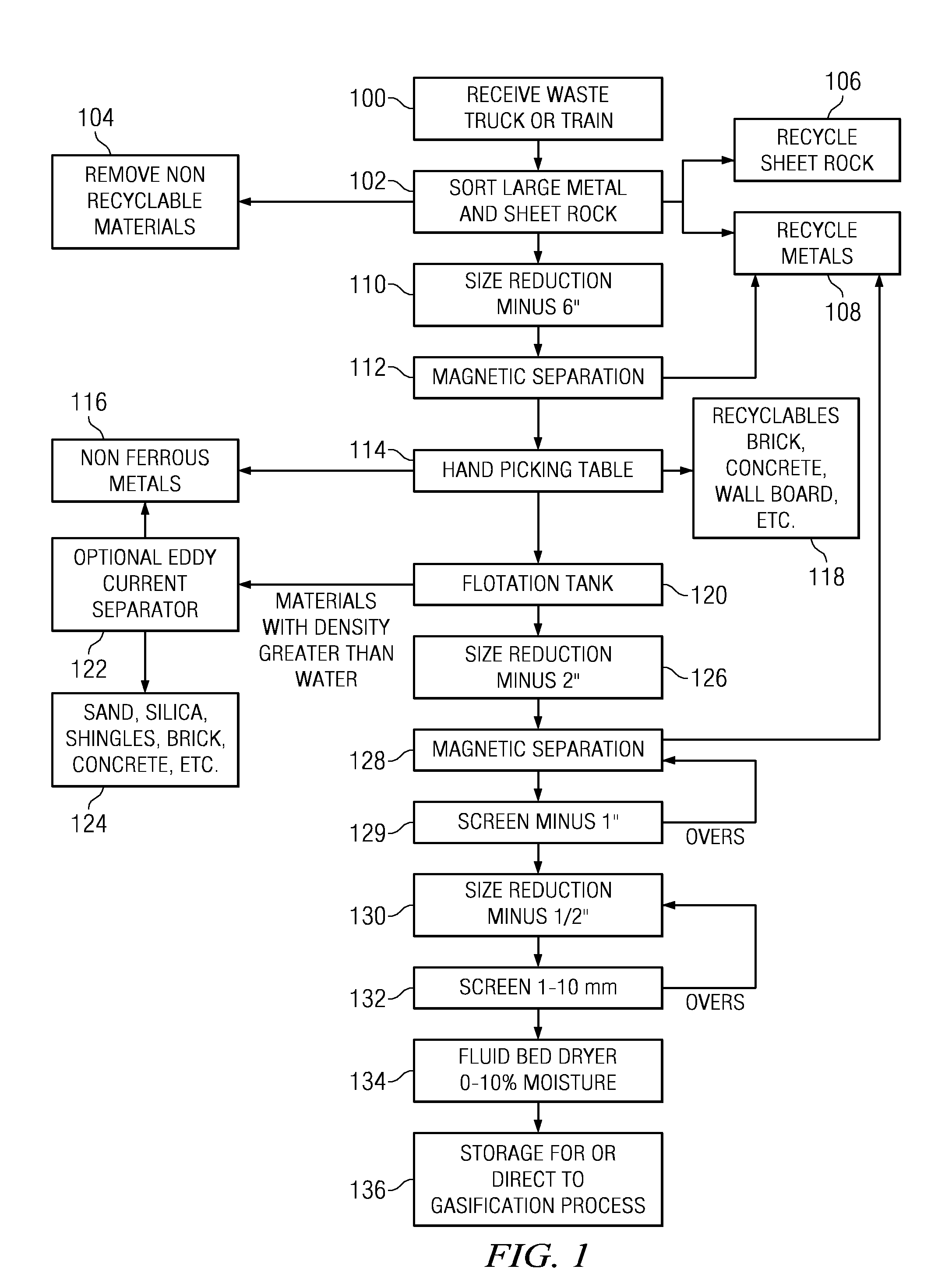

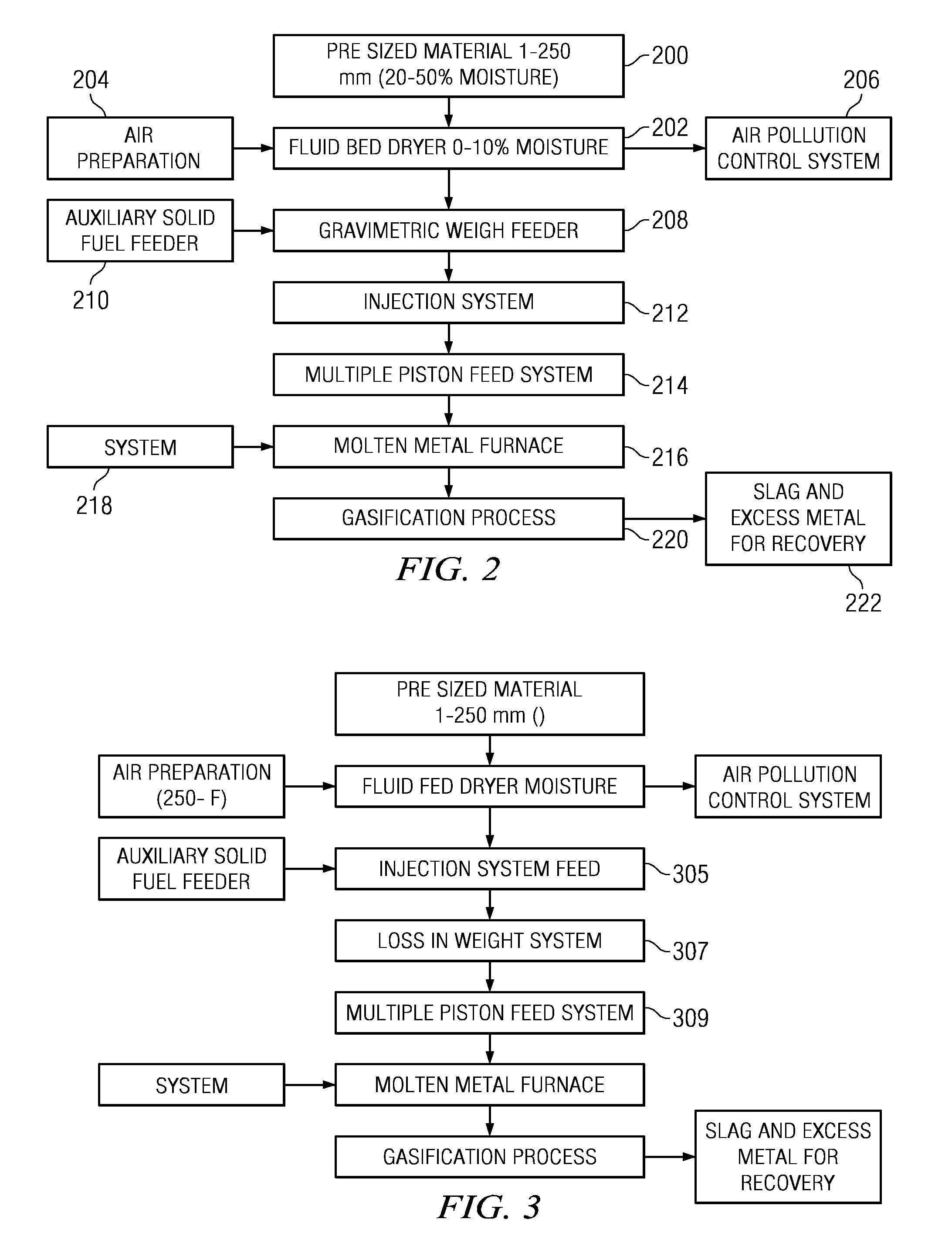

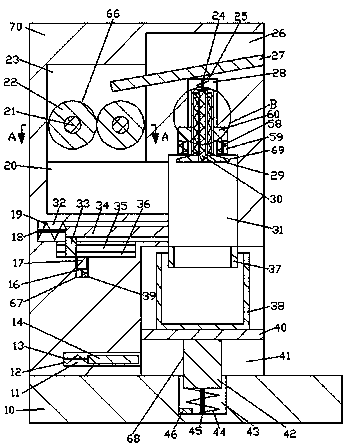

Construction & demolition debris (C&D) materials processing

InactiveUS20090188844A1Constant energy outputConstruction waste recoveryBiofuelsEnvironmental engineeringMaterials processing

A method of processing construction and demolition (C&D) debris at a location includes a set of processing steps. The method begins upon receipt of bulk C&D debris at the location. The bulk C&D debris is sorted into at least a first portion for further processing, and a second portion that is set aside. The first portion is then processed into a substantially homogenous wood waste material having particles of a given size by the unordered steps of shredding, screening, metals separation and flotation. The substantially homogenous wood waste material is then dried so that the particles have moisture content within a desired range. The wood waste material particles are then delivered into a molten metal bath at a submerged depth for gasification. Preferably, the process operates in a continuous or partially-continuous manner within a given facility, or within co-located facilities.

Owner:ZE-GEN

Process for machining antiquing floors by using low-grade boards

InactiveCN107116656AIncrease sales valueConsistent colorBelt grinding machinesCoating impregnationMaterial defectEngineering

The invention relates to a process for machining antiquing floors by using low-grade boards. The process comprises the following steps: low-grade board blanks are machined as plain plates; the surface polishing and the defect port rounding are performed on material defects by using an angle grinding piece, a steel wire disc and a grinding wheel in sequence; then, putty is coated in cracks to fill and level up the cracks; the plain plates are machined by adopting more than two antiquing treatment processes of scraping, wire drawing, dimpling, dull knife machining, relief machining, carbon combustion machining and chemical change machining; and natural oil or wax oil is brushed on the surfaces of the plain plates for airing to obtain finished products. The process uses the boards with such material defects as dead knots, bark pockets, insect holes, mineral lines and cracks and discarded by the industry as raw materials to prevent the wood wastes, finishes natural material defects, and fills the putty to form an artistic effect; and the antiquing treatment process is used for forming the natural antiquing effect on the surfaces of the floors to improve the floor sale additional value.

Owner:湖北燕加隆木制品有限公司

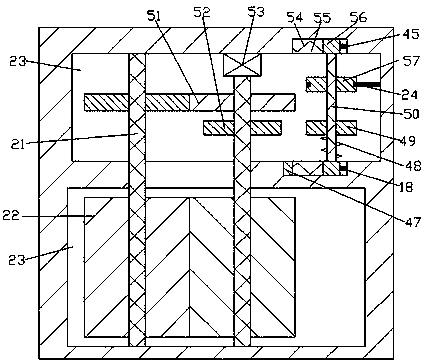

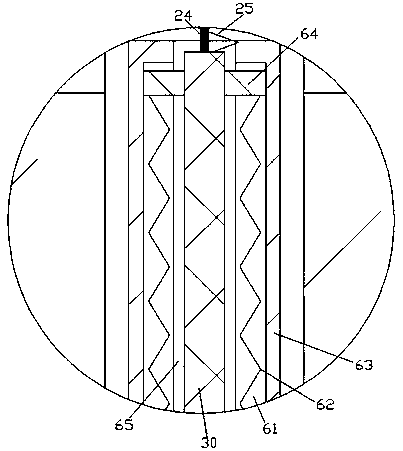

Waste wood treatment and packaging device wood processing plant

ActiveCN110723323AAvoid explosionSimple structureSolid materialGrain treatmentsAgricultural engineeringWaste material

The invention discloses a waste wood treatment and packaging device for a wood processing plant. The waste wood treatment and packaging device comprises a base, wherein a bagging box is fixed in the upper end of the base; a bagging cavity with a rightward opening is formed in the base; a supporting mechanism used for judging the bagging weight is arranged in the bagging cavity; an ejection cavityused for preventing continuous discharging after bagging is completed is formed in the left end wall of the bagging cavity; a falling cavity with a downward opening is formed in the upper end wall ofthe bagging cavity; and a compaction mechanism capable of carrying out compaction operation on bagged waste is arranged in the upper end wall of the falling cavity. The waste wood treatment and packaging device is simple in structure and convenient to operate, the blocky wood waste is crushed, and crushed materials in a loading bag are compacted in a mechanical mode, so that the bagging amount isincreased, quantitative bagging can be automatically completed, and the situation that the packaging bag is burst due to excessive bagging is prevented.

Owner:徐州江之源木制品有限公司

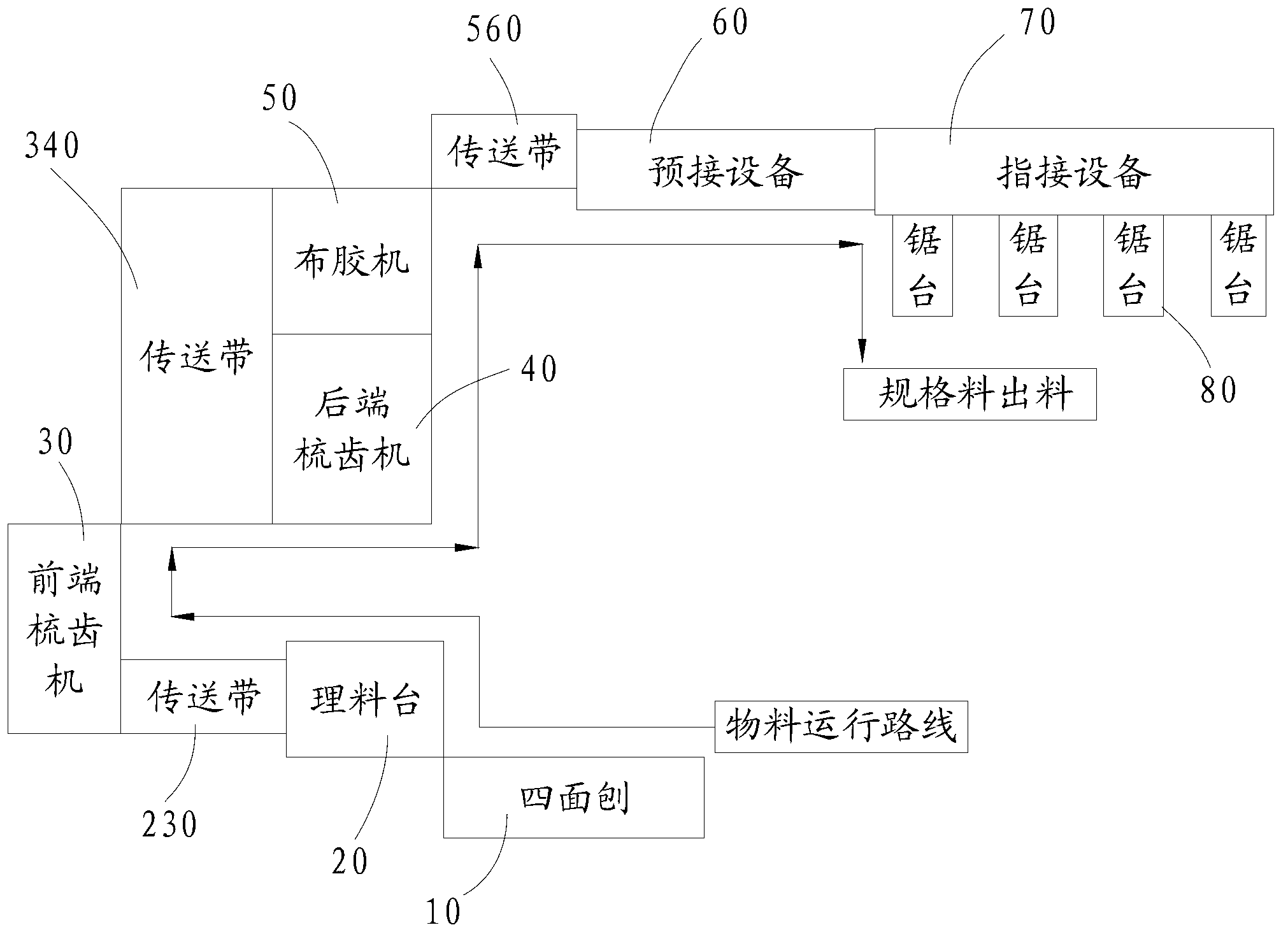

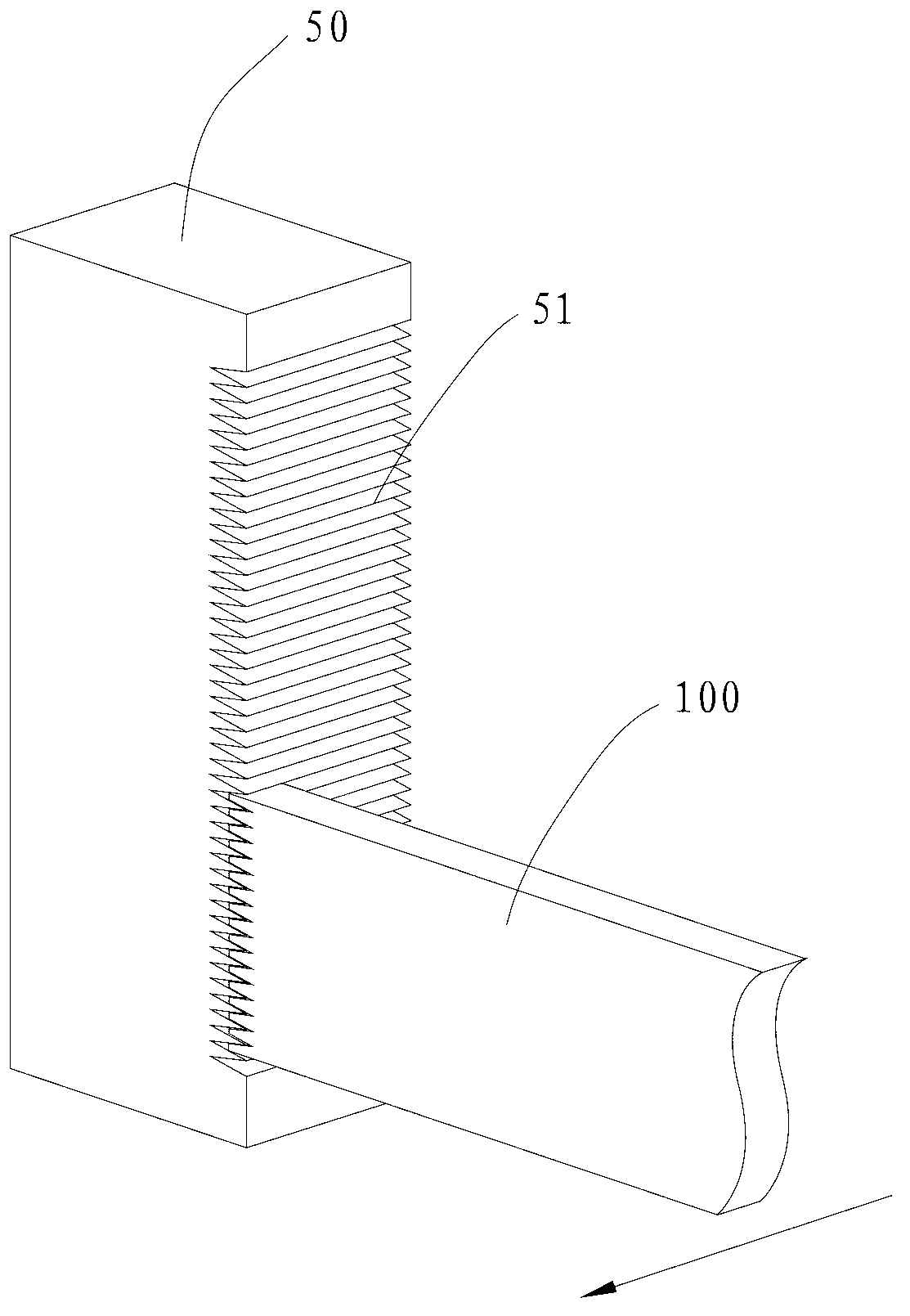

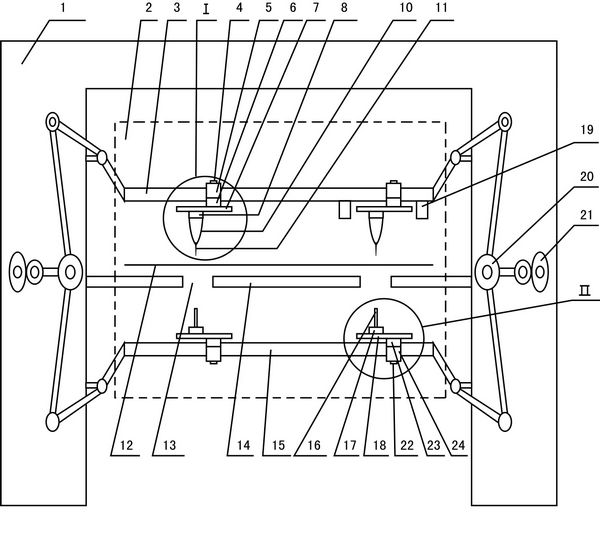

Wood finger joint system and method

ActiveCN102794796AGuaranteed flatnessReduce wasteWood veneer joiningAdhesive application devicesFinger jointPulp and paper industry

The invention discloses a wood finger joint system and method. The wood finger joint system comprises a matcher, an arrangement platform, a front-end comb machine, a rear-end comb machine, a glue spreader, pre-joint equipment and finger joint equipment which are sequentially arranged and connected, wherein the arrangement platform, the front-end comb machine, the rear-end comb machine, the glue spreader, the pre-joint equipment and the finger joint equipment are connected through a conveying device; and the wood is conveyed by the conveying device to pass through all the equipment in sequence. According to the wood finger joint system and method provided by the invention, automatic finger joint processing of wood is realized by use of the reasonable combination and arrangement of multiple sets of equipment, the processing accuracy and the consistency are high, and the production efficiency is improved; and moreover, due to the full-automatic glue spreading mode, the glue spreading is uniform, better finger joint strength is realized, and the length of the finger joint can be properly reduced so as to reduce wood waste.

Owner:FUJIAN DUS WOOD IND

Capture, Control or Removal of Nutrient Laden Effluent, Run-Off or Agricultural, Industrial, Commercial or Domestic Waste Flow

InactiveUS20130174622A1Reduce decreaseSmall surface areaIon-exchanger regenerationLoose filtering material filtersParticulatesPrill

A treatment medium has a particulate natural substrate saturated, suffused and / or coated with hydrous iron oxide. The particulate substrate can be wood based, such as wood chips, bark, sawdust, wood waste or other plant material (such as straw, lucerne, hay, coconut husk or other bulk particulate plant material). The hydrous iron oxide is provided in aqueous suspension form. The substrate may be tumbled in aqueous hydrous iron suspension to achieve saturation / coating. The resulting hydrous iron oxide bearing medium is either placed loose directly into the target treatment site or contained in bags 18 before placing into the target site.

Owner:LONG TOM

Wood hogging apparatus

InactiveUS7712691B2Small sizeAccelerated dryingWood working apparatusCocoaForeign matterWood machining

Owner:SHARP RODNEY WARWICK

Production technology of wood fiber bundle floor and product

The invention discloses a production technology of a wood fiber bundle floor and a product. The production technology comprises the following steps: rolling and compacting wood into strip fiber bundles; mixing the fiber bundles with an adhesive; placing the obtained mixture in a die; and finally obtaining the finished product through hot pressing. By adopting the production technology, the wood waste is reduced maximally during the production process of the floor, the wood is saved and the better economic benefit is obtained for enterprises; and the obtained wood floor has the advantages of good static bending strength, good modulus of elasticity, excellent water resistance, excellent dimensional stability and excellent thickness swelling rate of water absorption.

Owner:JIUSHENG WOOD

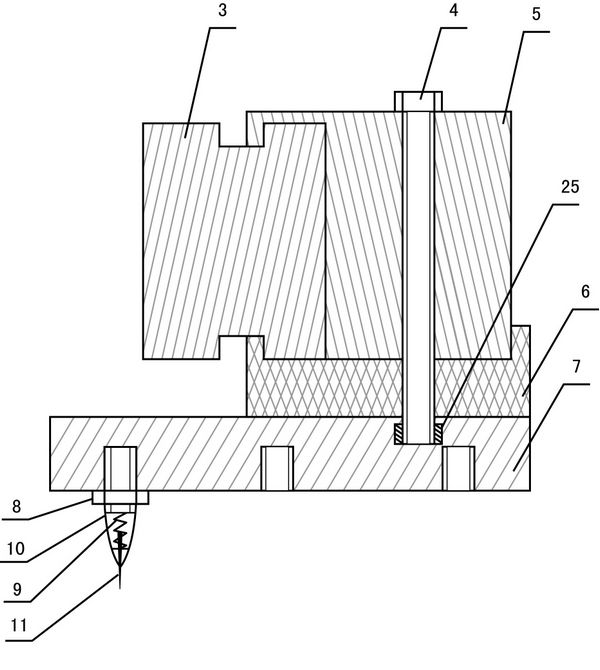

Connection line finished product die-cutting anti-adhesion device of die-cutting machine

ActiveCN102039694AOvercoming the Insufficiency of Manual Handling of AdhesionAvoid Quality AccidentsContainer making machineryPulp and paper industryPaper sheet

The invention discloses a connection line finished product die-cutting anti-adhesion device of a die-cutting machine, which is used for performing subsequent separation on a die-cutting finished product of a cigarette-brand small box. Cams connected to a connecting rod are symmetrically arranged on machine frames on two sides of a waste removing part of the die-cutting machine; an upper frame and a lower frame are fixed on the connecting rod respectively; a sponge strip is adhered to the upper frame, and the upper frame is provided with an upper thimble mounting seat; an upper thimble with a spring is arranged in the upper thimble mounting seat; the lower frame is provided with a lower thimble mounting seat; a lower thimble is arranged in the lower thimble mounting seat; and a wood waste removing plate with holes is fixed on the machine frame, and is arranged between the upper frame and the lower frame. When the cigarette-brand small box after die cutting passes through the waste removing plate with the holes, a machine runs to drive the upper frame to move downwards, the sponge strip presses paper sheets, the upper thimble ejects an easy-adhesion part of a finished product downwards, the lower frame moves upwards at the same time, and the lower thimble ejects the easy-adhesion part of the finished product upwards, so the paper sheets on two sides of a die line are separated under the action of different forces. The connection line finished product die-cutting anti-adhesion device of the die-cutting machine can effectively realize automation of adhesion processing to ensure that the parts which cannot be cut through by die cutting are separated automatically, thereby putting an end to quality accidents caused by machine jamming in the process of packaging finished product cigarettes.

Owner:襄阳金飞环彩色包装有限公司

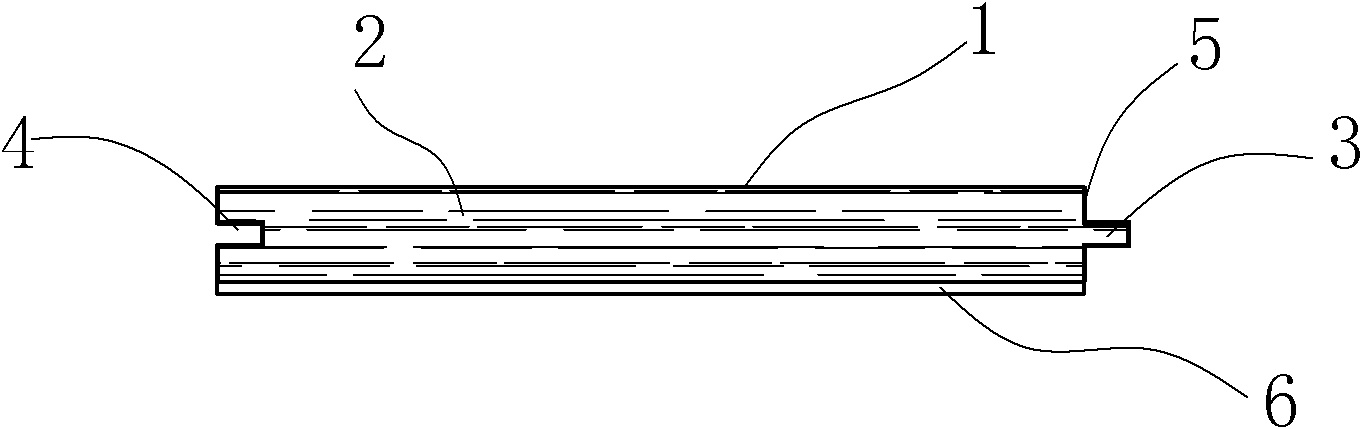

Restructured wooden floor and preparation method thereof

InactiveCN104929344AHigh viscosityHigh compressive strengthWood working apparatusAldehyde/ketone condensation polymer adhesivesFiberEconomic benefits

The invention discloses a restructured wooden floor. The restructured wooden floor comprises a restructured wooden core plate (1) formed by bonding and pressing fiber rods, a paint layer (2) is arranged on the surface of the restructured wooden core plate, and the side face of the restructured wooden core plate is provided with a side tenon (3) and a side groove (4). By means of the restructured wooden floor, the wood waste can be reduced effectively, the wood resources can be saved, and meanwhile the great economic benefit is achieved. In addition, by means of the restructured wooden floor, the viscosity and transparency of the wooden floor can be effectively improved, and the connection strength between the floors can be improved.

Owner:JIUSHENG WOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com