Crusher special for brush wood

A technology of crusher and yam, which is used in applications, agricultural machinery and implements, cutting equipment, etc., to achieve the effect of beautifying the environment, making full use of it, and avoiding fire hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The concrete technical scheme of the present invention will be further described below in conjunction with embodiment:

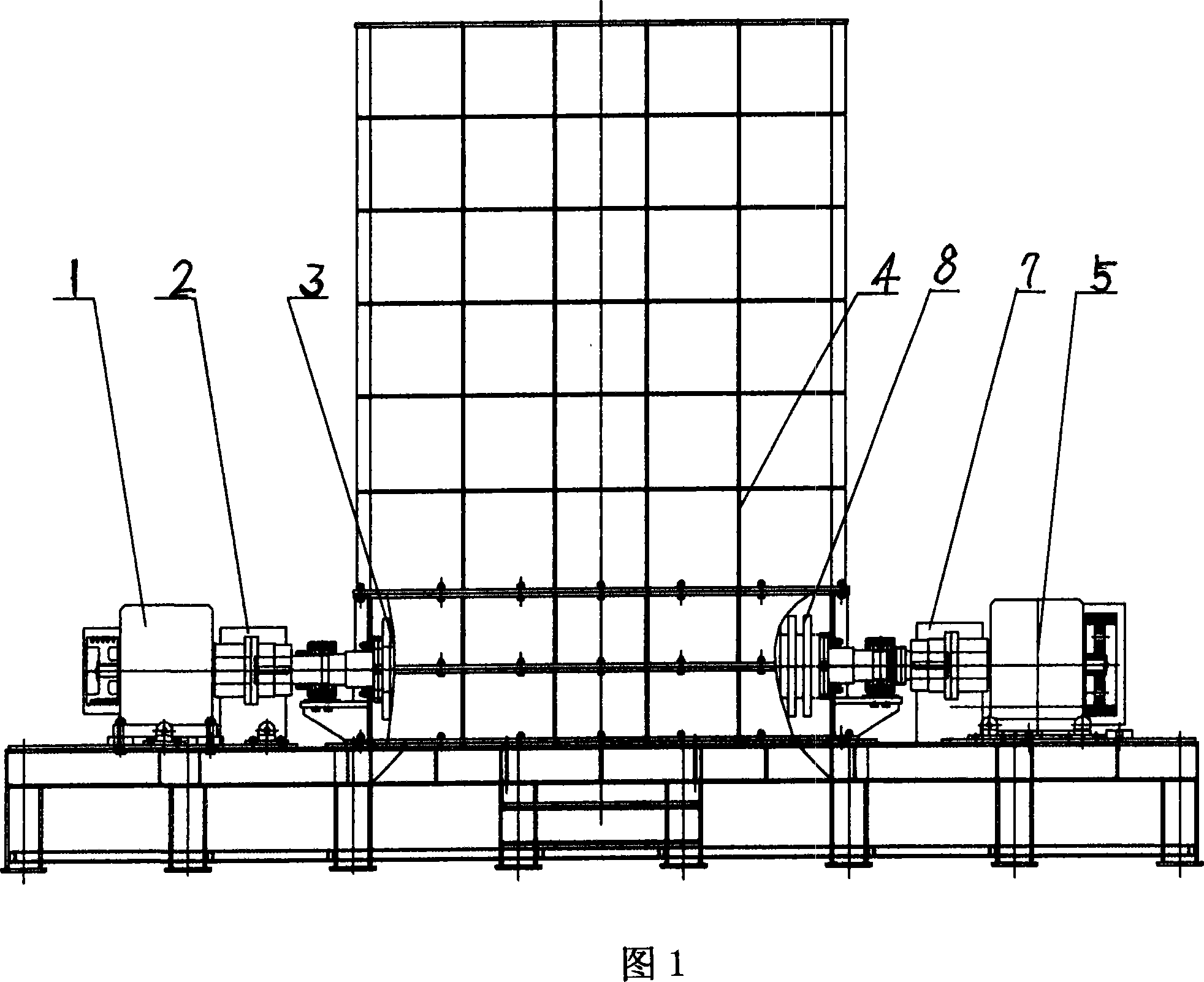

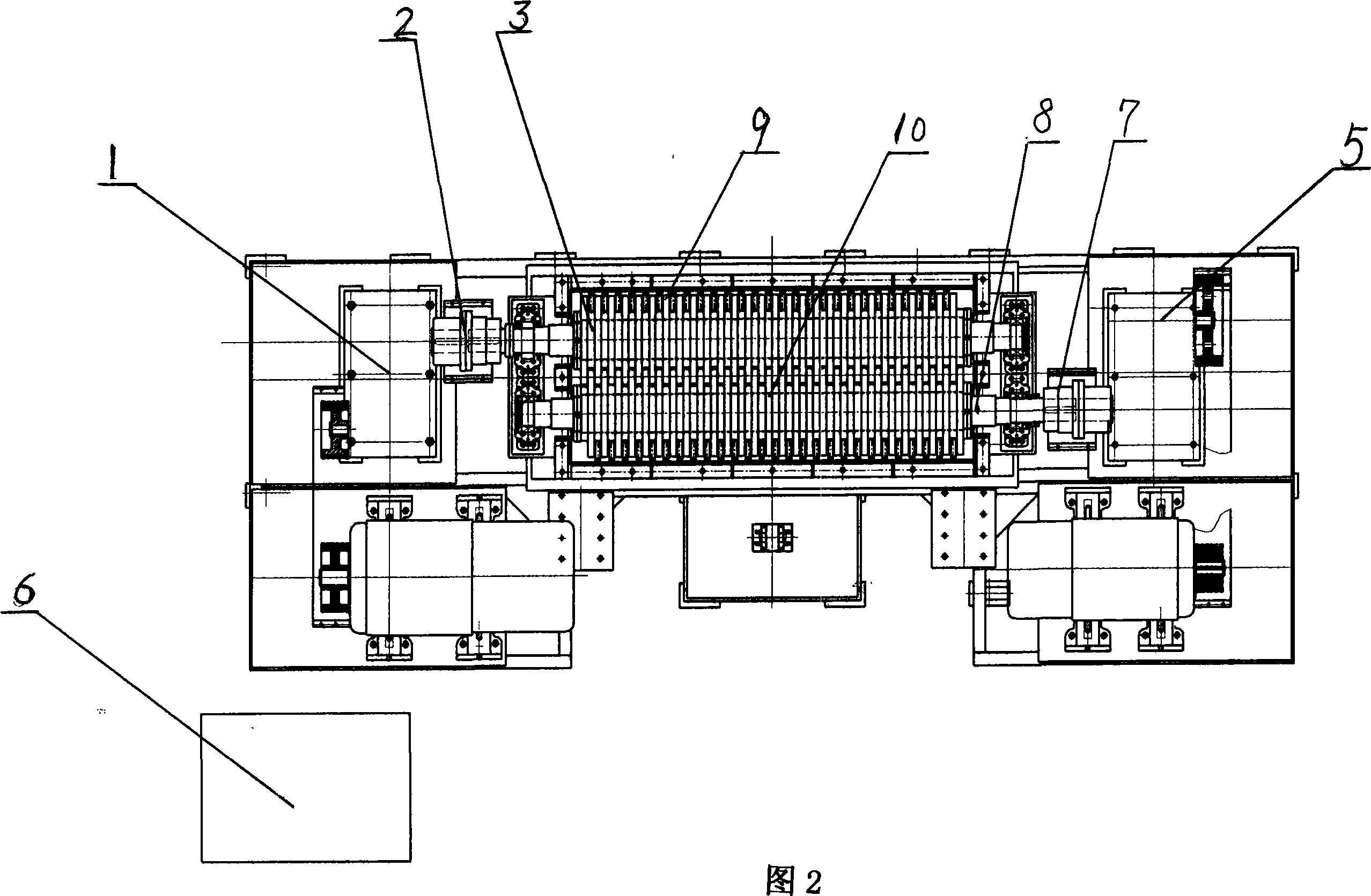

[0014] As shown in Figures 1 to 2, this special crusher for branch materials includes a hopper, a crushing system, a base part, and an electrical control part. The hopper 4 is provided with a presser, and the crushing system is mainly It consists of main drive motor 1, reducer 2, pulley, high-speed toothed roller rotor 3, secondary motor 5, reducer 7, pulley, low-speed toothed roller rotor 8, in which high-speed toothed roller rotor 3 and low-speed toothed roller rotor 8 are parallel Set on one side of the discharge port of the hopper 4, the high-speed toothed roller rotor 3 and the low-speed toothed roller rotor 8 are equipped with linearly arranged knife teeth 9 and 10, and the high-speed toothed roller rotor 3 is connected with the belt pulley and the reducer 2 The main driving motor 1 is connected, and the low-speed toothed roller rotor 8 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com