A kind of biomass-based fuel and preparation method thereof

A biomass and fuel technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems that the ash melting property of biomass cannot be improved cheaply and efficiently, the cost of additives can be reduced, and the cost of additives is high, so as to improve burnout or The effect of gasification carbon conversion rate, reduction of operating costs, and improvement of energy density and calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A biomass-based fuel for gasification, using rice straw as biomass raw material, crushing it to a length less than 2.5cm, grinding blast furnace slag into 200-mesh powder, and uniformly mixing rice straw and blast furnace slag at a weight ratio of 100:3 Raw material A.

[0037] The mass percentage of CaO in blast furnace slag is 38.5%, SiO 2 The mass percentage content is 36.8%, A1 2 o 3 The mass percentage of FeO is 10.6%, the mass percentage of MgO is 8.7%, the mass percentage of MnO is 2.7%, the mass percentage of FeO is 1.5%, the mass percentage of CaS is 0.8%, and the balance is impurities.

[0038] Select bituminous coal with a total sulfur content of 0.7% as low-sulfur raw coal, grind steel slag into 200-mesh powder, and uniformly mix low-sulfur bituminous coal and steel slag at a weight ratio of 100:5 to obtain raw material B.

[0039] The mass percentage of CaO in steel slag is 48.7%, SiO 2 The mass percentage content is 11.5%, A1 2 o 3 The mass percentag...

Embodiment 2

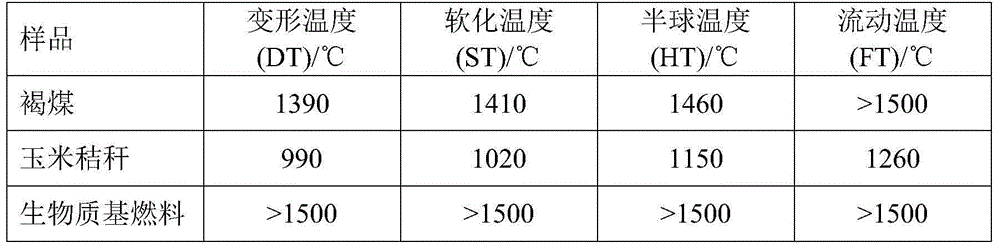

[0045] A biomass-based fuel for gasification, which is obtained by crushing corn stalks to a length of less than 2.5 cm, grinding blast furnace slag into 300-mesh powder, and uniformly mixing corn stalks and blast furnace slag at a weight ratio of 100:8. Raw material A.

[0046] The mass percentage of CaO in blast furnace slag is 35%, SiO 2 The mass percentage content is 32%, A1 2 o 3 The mass percentage of FeO is 6%, the mass percentage of MgO is 4%, the mass percentage of MnO is 2%, the mass percentage of FeO is 1%, and the balance is impurities.

[0047] Select lignite with a total sulfur content of 0.8% as low-sulfur raw coal, grind steel slag and gas slime into 300-mesh powder according to any weight ratio, and uniformly mix lignite, steel slag and gas slime at a weight ratio of 100:10 to obtain raw material B.

[0048] The mass percentage of CaO in steel slag is 45%, SiO 2 The mass percentage content is 10%, A1 2 o 3 The mass percentage content of FeO is 1%, the ma...

Embodiment 3

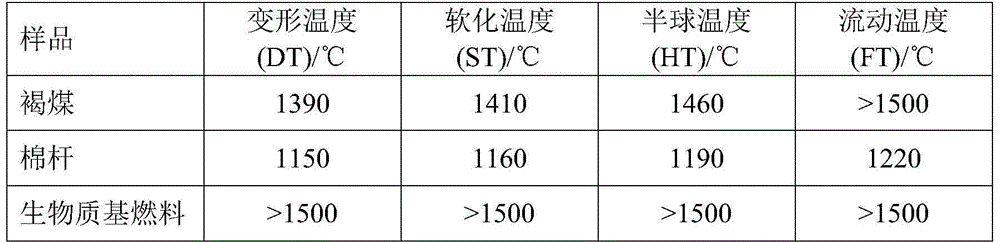

[0055] A biomass-based fuel for gasification, using cotton stalks as biomass raw materials, crushing them to a length less than 2.5 cm, grinding blast furnace slag into 400-mesh powder, and uniformly mixing cotton stalks and blast furnace slag at a weight ratio of 100:5 Raw material A.

[0056] The mass percentage of CaO in blast furnace slag is 44%, SiO 2 The mass percentage content is 32%, A1 2 o 3 The mass percentage of FeO is 10%, the mass percentage of MgO is 4%, the mass percentage of MnO is 2%, the mass percentage of FeO is 5%, the mass percentage of CaS is 1%, and the balance is impurities.

[0057] Select lignite with a total sulfur content of 0.8% as low-sulfur raw coal, grind steel slag and gas slime into 400-mesh powder according to any weight ratio, and mix uniformly according to the mixture weight ratio of lignite, steel slag and gas slime of 100:8 to obtain raw material B.

[0058] The mass percentage of CaO in steel slag is 60%, SiO 2 The mass percentage co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com