Full-thread fiber resin rod body soil nailing wall and construction method thereof

A fiber-resin, full-thread technology, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve the problems of tunnel slotting construction difficulty, heavy force, soil nail wall easy to rust, short service life, etc., to avoid fire Hidden danger, improve soil nail bearing capacity, easy to cut effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

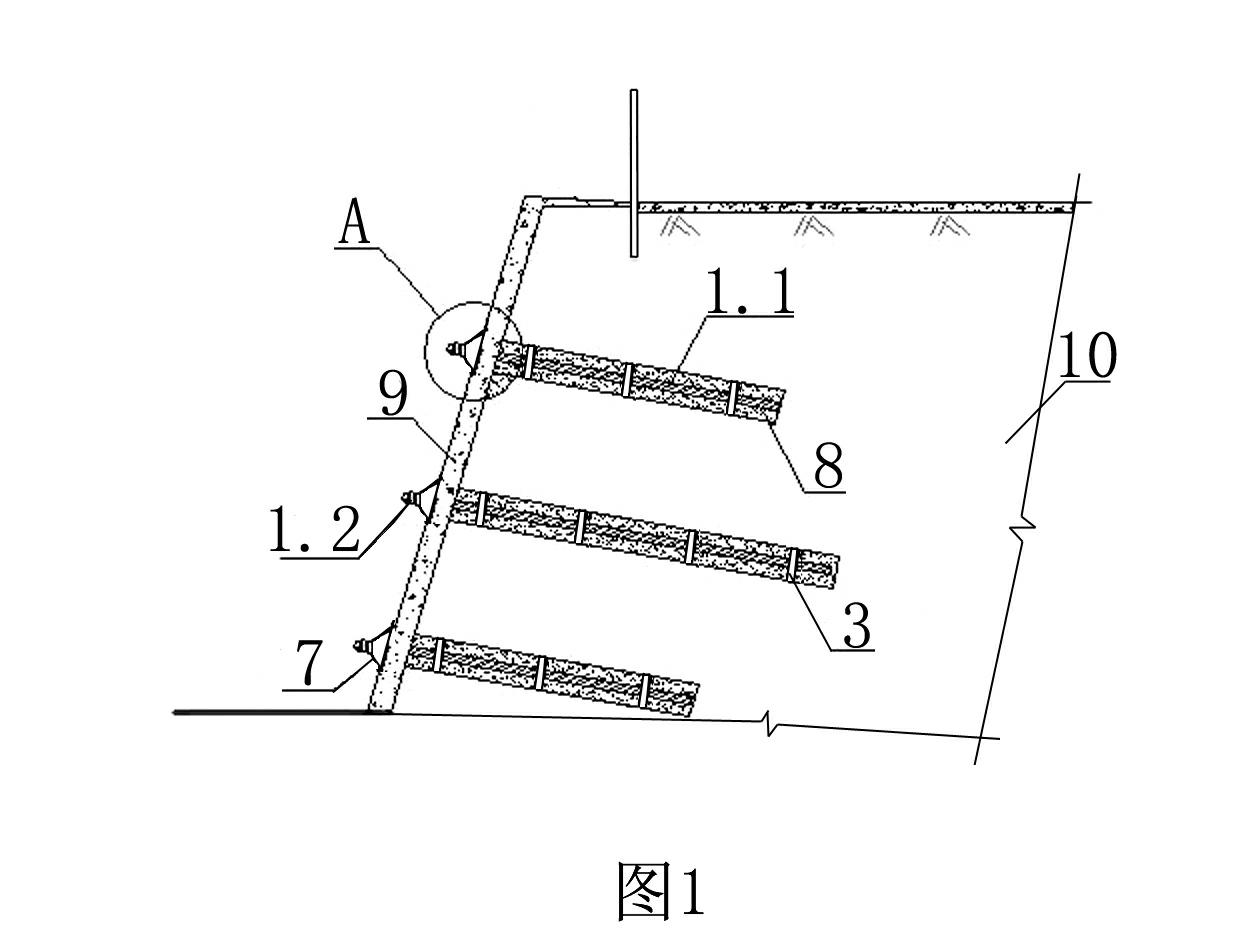

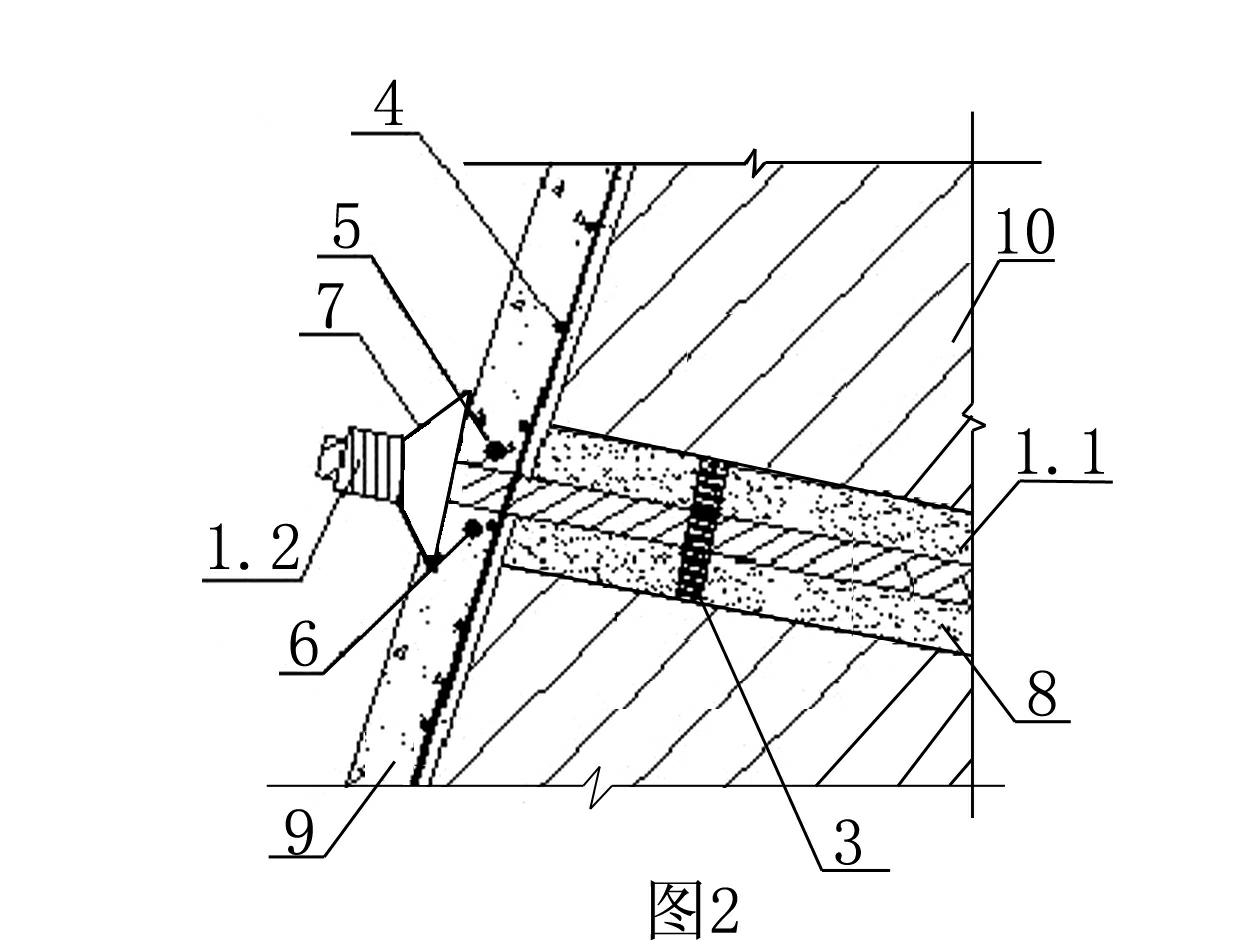

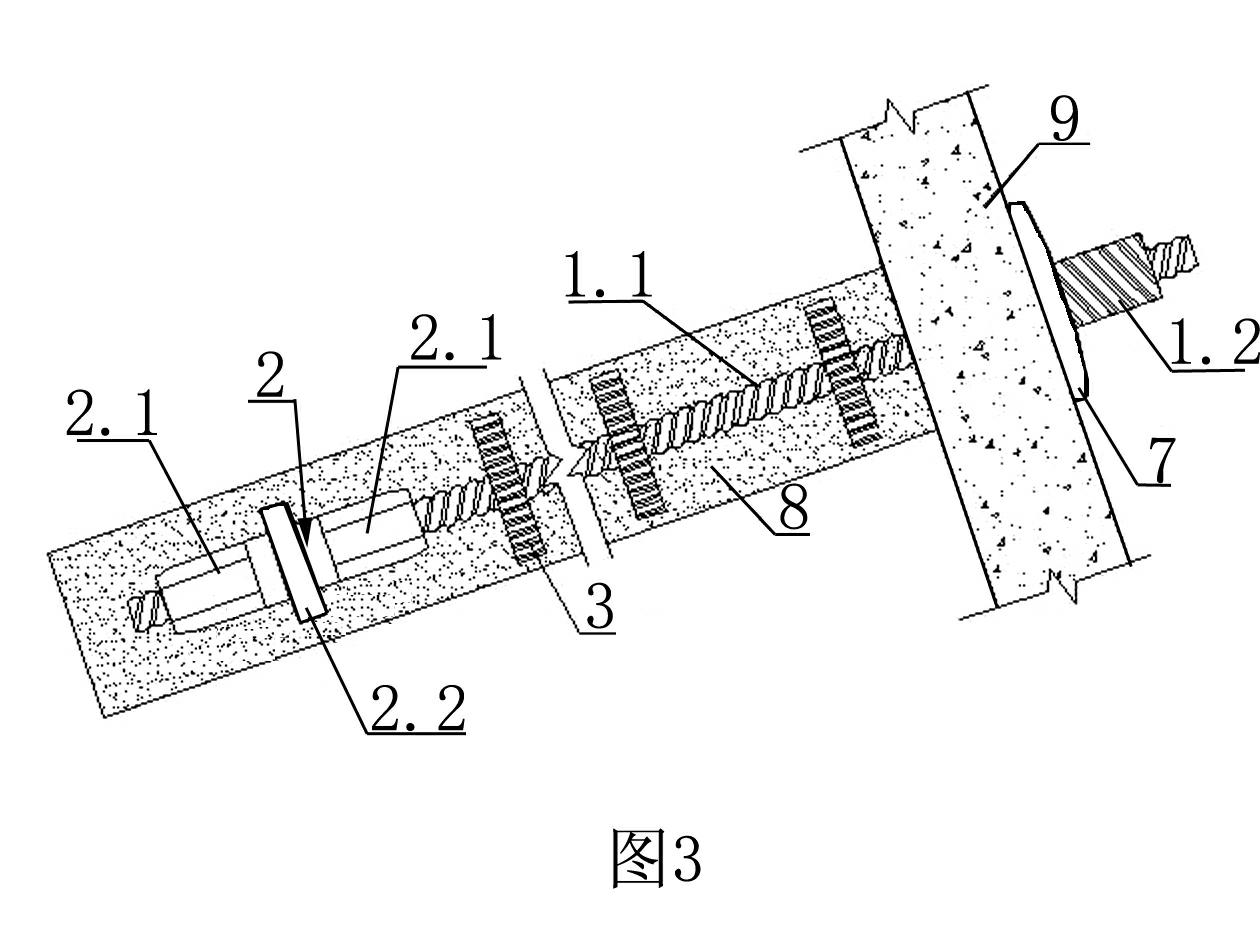

[0036] Examples see figure 1 , figure 2 with Figure 4 As shown, a full-thread fiber resin rod body soil nail wall includes a slope soil body 10, a concrete surface layer 9 and a soil nail 1 formed by spraying concrete slurry, and the soil nail 1 includes a rod body, a backing plate and a tightening nut , the rod body is inserted into the slope soil body 10, the hole between it and the slope soil body 10 is injected with the rod peripheral slurry 8, the outer end of the rod body is tightened by a nut to fix the backing plate, the pad The plate pad is between the tightening nut and the concrete surface layer 9, and the outer surface of the slope soil 10 is laid with a steel mesh 4, and the concrete surface layer 10 wraps the steel mesh 4, and it is characterized in that: the rod body is fully threaded Fiber resin rod body 1.1, which is located in the upper part of the inner section of the concrete surface layer 9, is provided with auxiliary reinforcing ribs 5, and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com