One-component waterborne epoxy ester anticorrosive priming paint used for automobile chassis and preparation method of one-component waterborne epoxy ester anticorrosive priming paint

A technology for anti-corrosion primer and automobile chassis, applied in anti-corrosion coatings, coatings, etc., to achieve the effect of low acid value, small particle size of latex particles, and improved water resistance and anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

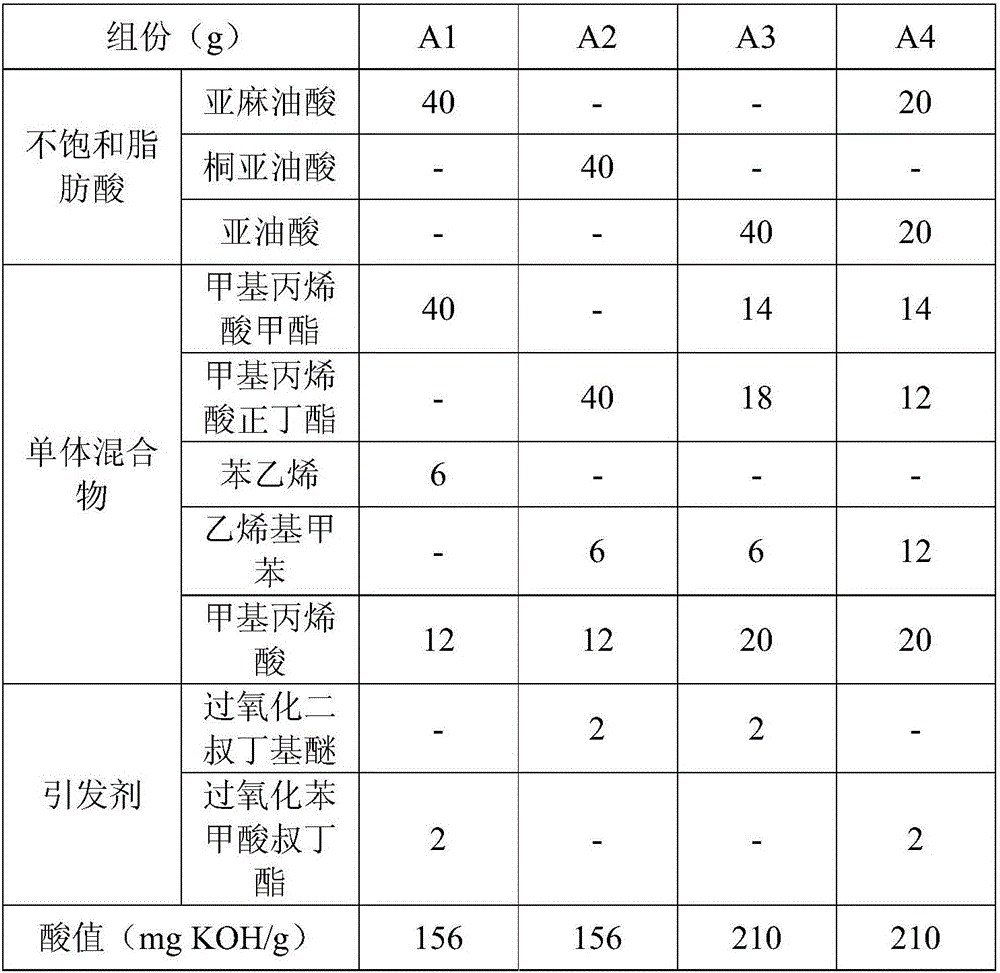

[0076] Example 1. Preparation of acrylic resin

[0077] According to the formula shown in Table 1, the unsaturated fatty acid was put into the reaction flask, and the temperature was gradually raised to 140 ° C ~ 145 ° C under stirring, and the monomer mixture was continuously and uniformly added dropwise for 5 to 8 hours. ℃~145℃ for 3 to 4 hours until the conversion rate is over 98%, as evidenced by the solid content. Acrylic resins A1-A4 were obtained. The formulations and acid values of the acrylic resins A1-A4 are listed in Table 1.

[0078] Table 1 Formula and acid value of acrylic resin A1-A4

[0079]

Embodiment 2

[0080] Example 2, preparation of epoxy ester resin

[0081] According to the formula in Table 2, take 40% to 50% by weight of unsaturated fatty acid and 50% to 60% by weight of epoxy resin to carry out esterification at 190 to 200°C to obtain an acid value of 5 to 10 mg KOH / g epoxy ester resin B1-B4.

[0082] Table 2 Formula and acid value of epoxy ester resin B1-B4

[0083]

[0084]

Embodiment 3

[0085] Example 3. Preparation of water-based epoxy ester resin

[0086] According to the formula in Table 3, the acrylic resins A1-A4 prepared in Example 1 were added to the epoxy ester resins B1-B4 prepared in Example 2, respectively, and the esterification reaction was carried out at 190-200 ° C until the final acid The value is 20-50 mg KOH / g, and finally diluted with the cosolvent ethylene glycol butyl ether until the solid weight percentage is 70-75% to obtain the water-based epoxy ester resin.

[0087] Table 3 Formula and acid value of water-based epoxy ester resin

[0088]

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com