Patents

Literature

60results about How to "Improve print quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Printing liquids for improved print quality

InactiveUS6022908AImprove print qualityReduce bleedingDuplicating/marking methodsInksColoring agentsAnionic polymers

A set of printing liquids is disclosed comprising a first anionic printing liquid comprising an aqueous vehicle, at least one first colorant, and at least one first anionic polymer; a second anionic printing liquid comprising an aqueous vehicle at least one second colorant, at least one second anionic polymer, and an acid additive having a pKa up to the pKa of the at least first polymer of the first liquid; a third cationic printing liquid comprising an aqueous vehicle, at least one third colorant, at least one third cationic polymer, and a pH in the range from about 2 to about 5; and a fourth anionic printing liquid comprising an aqueous vehicle, at least one fourth anionic dye, and a precipitating agent. More specifically, the present set of printing liquids may find application in ink-jet printing. The set of ink-jet inks provides improved print quality, specifically, reduced bleed; improved edge-acuity, uniform area fills, and color quality; while maximizing lightfastness without sacrificing printing reliability.

Owner:HEWLETT PACKARD DEV CO LP

Ink-jet printing system for improved print quality

InactiveUS6247808B1Improve print qualityReduce bleedingMeasurement apparatus componentsDuplicating/marking methodsInkjet printingColoring agents

An ink-jet printing system is disclosed comprising a set of ink-jet inks comprising a first anionic ink comprising an aqueous vehicle, at least one first colorant, and at least one first anionic polymer; a second anionic ink comprising an aqueous vehicle; at least one second colorant, at least one second anionic polymer, and an acid additive having a pKa up to the pKa of the at least first polymer of the first ink; a third cationic ink comprising an aqueous vehicle, at least one third colorant, at least one third cationic polymer, and a pH in the range from about 2 to about 5; and a fourth anionic ink comprising an aqueous vehicle, at least one fourth anionic dye, and a precipitating agent. The printing system provides improved print quality, specifically, reduced bleed; improved edge-acuity, uniform area fills, and color quality; while maximizing lightfastness without sacrificing printing reliability.

Owner:HEWLETT PACKARD DEV CO LP

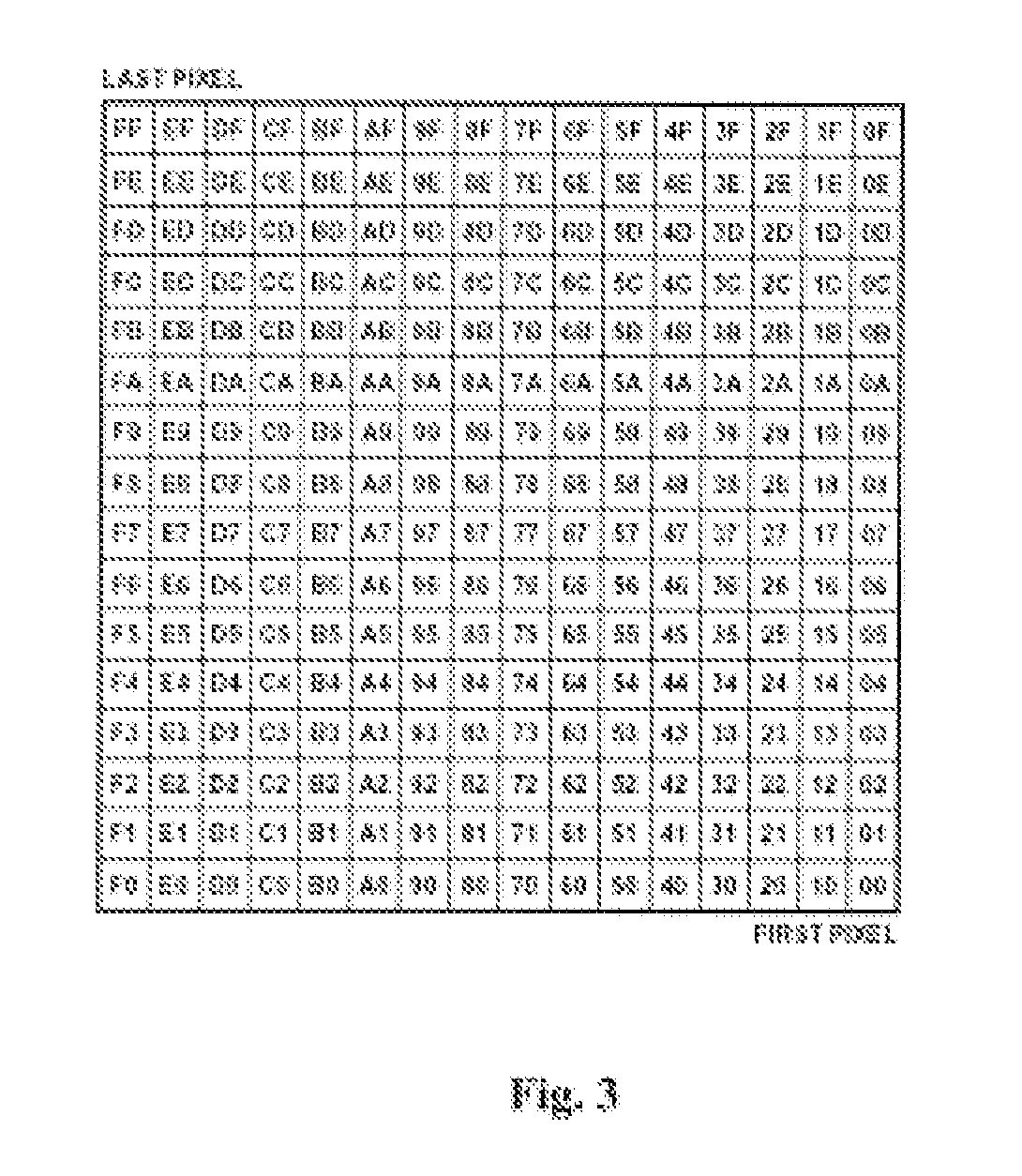

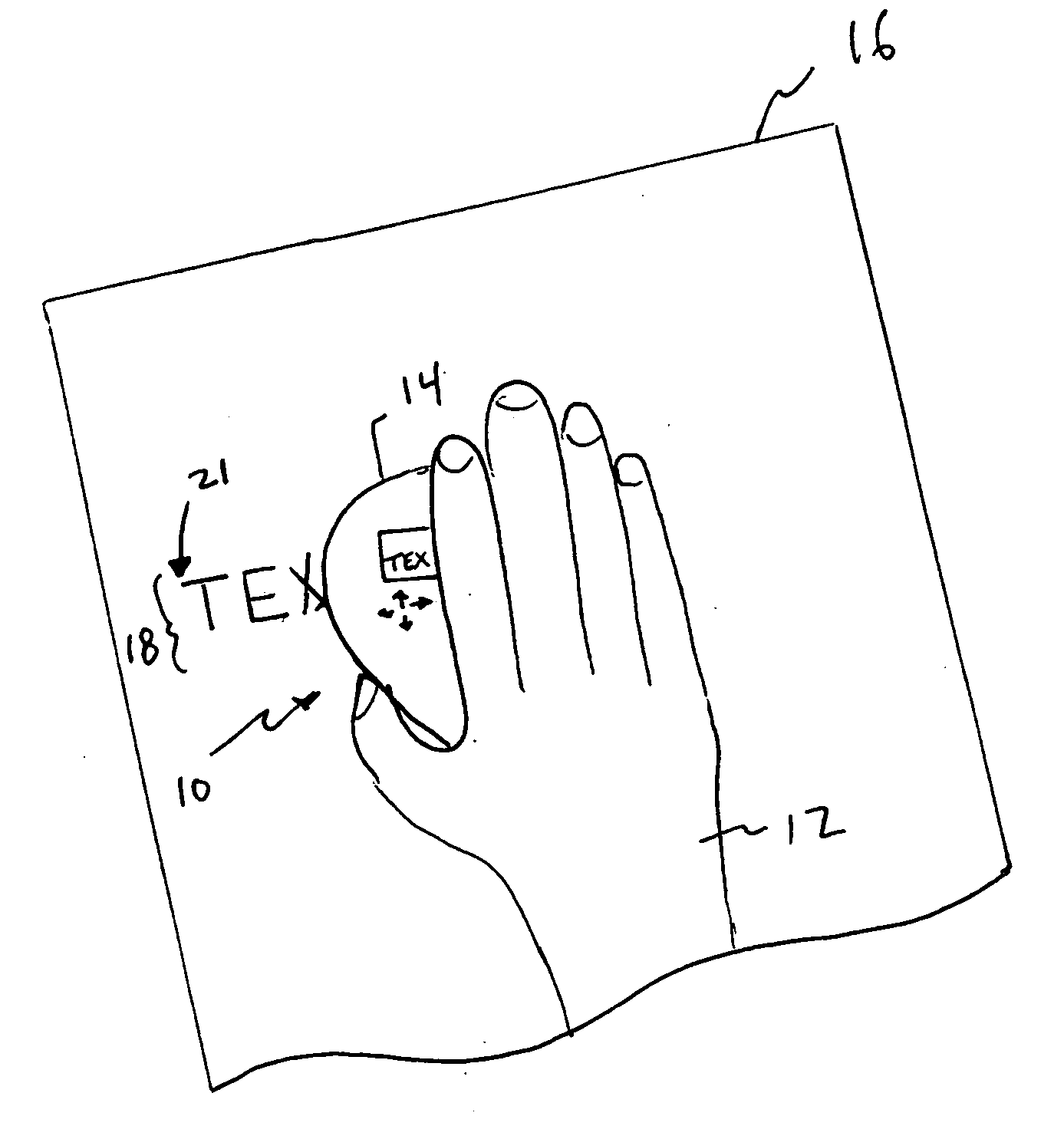

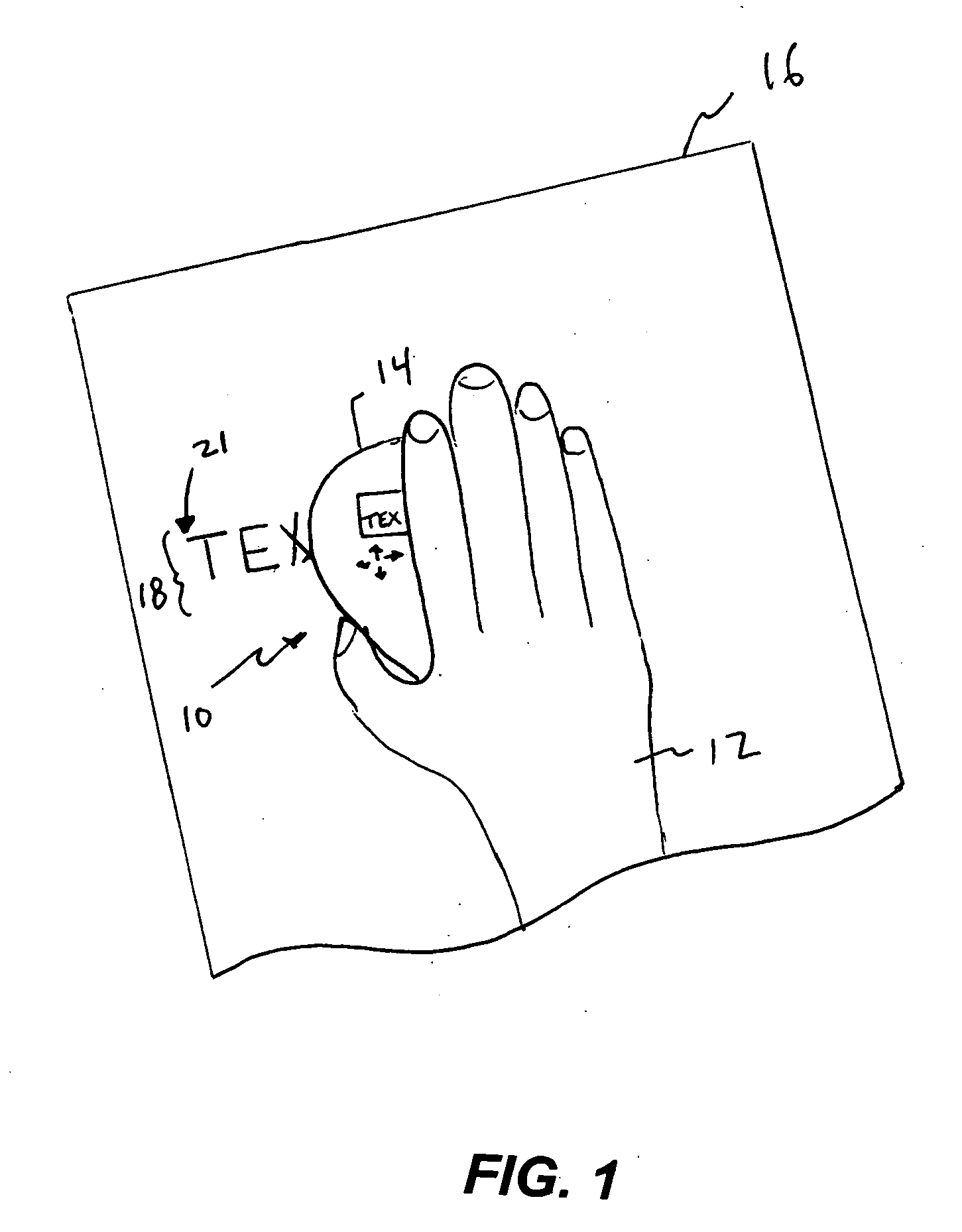

Methods for Improving Print Quality in a Hand-held Printer

InactiveUS20080007762A1Improve print qualityImprove printing qualityDigitally marking record carriersVisual representation by matrix printersHand heldComputer science

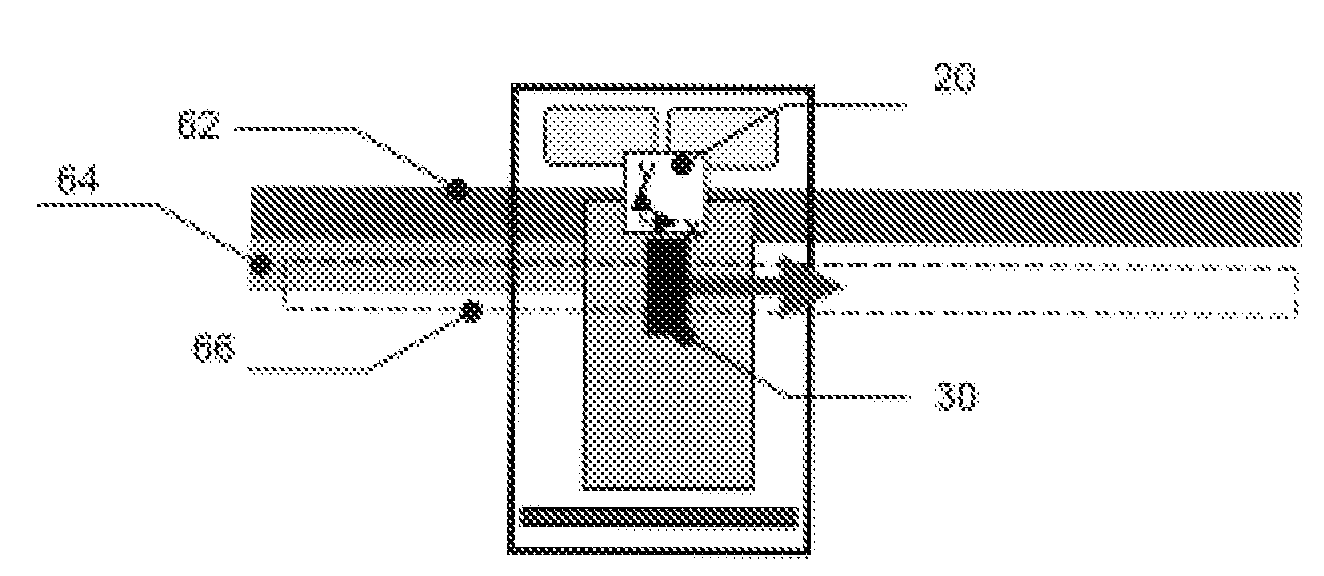

Method for determining enhanced printing functions on a hand-held inkjet printer having one or more optical sensors configured to measure speed and distance across the page. Collecting a first frame of individual pixel data, mapping the first frame of individual pixel data into a pixel map memory, processing the first frame of individual pixel data to perform additional print quality features. These additional features can be categorized in three main categories: 1) sensing non-printing elements, 2) sensing pre-printed elements, and 3) sensing print elements.

Owner:LEXMARK INT INC

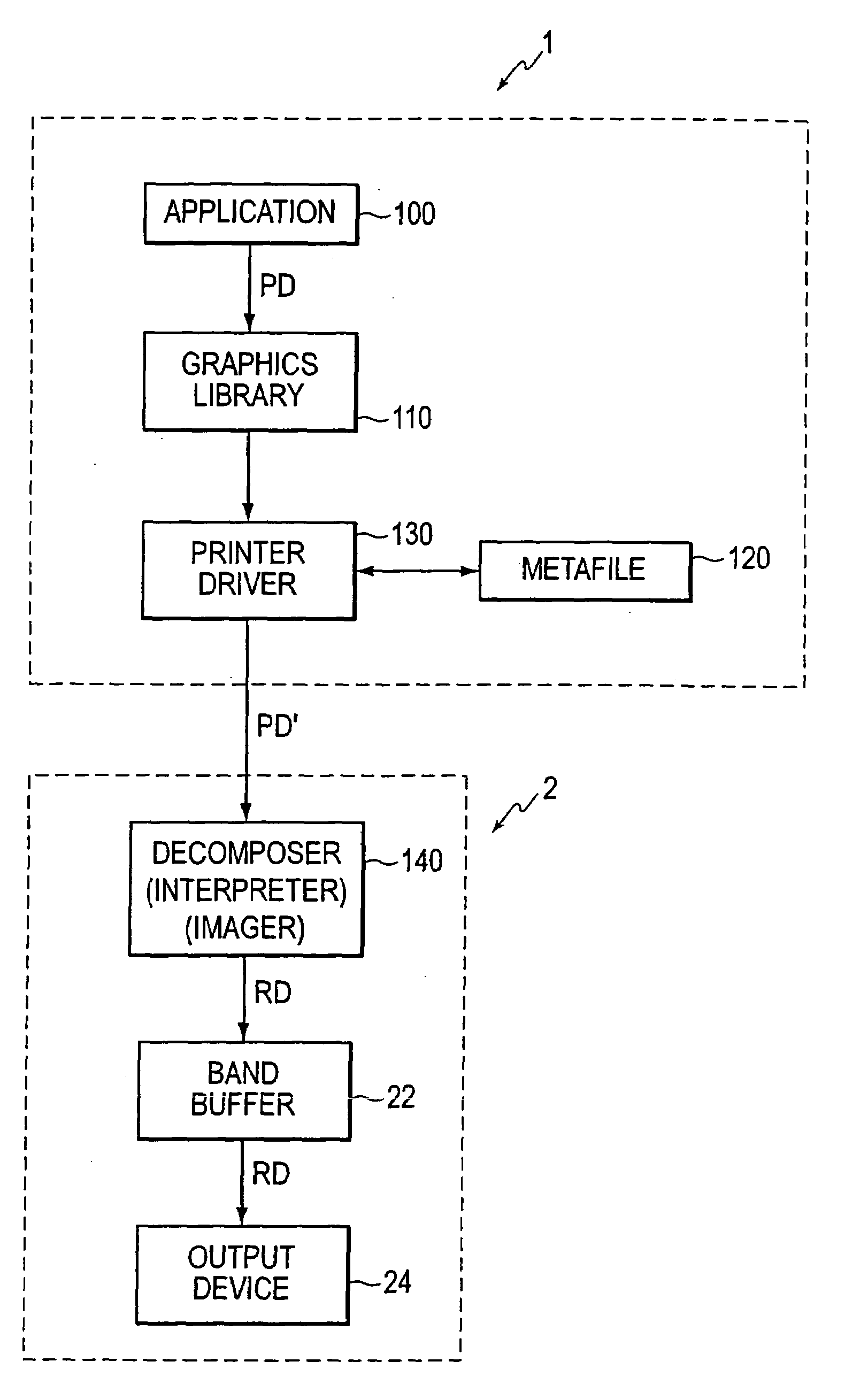

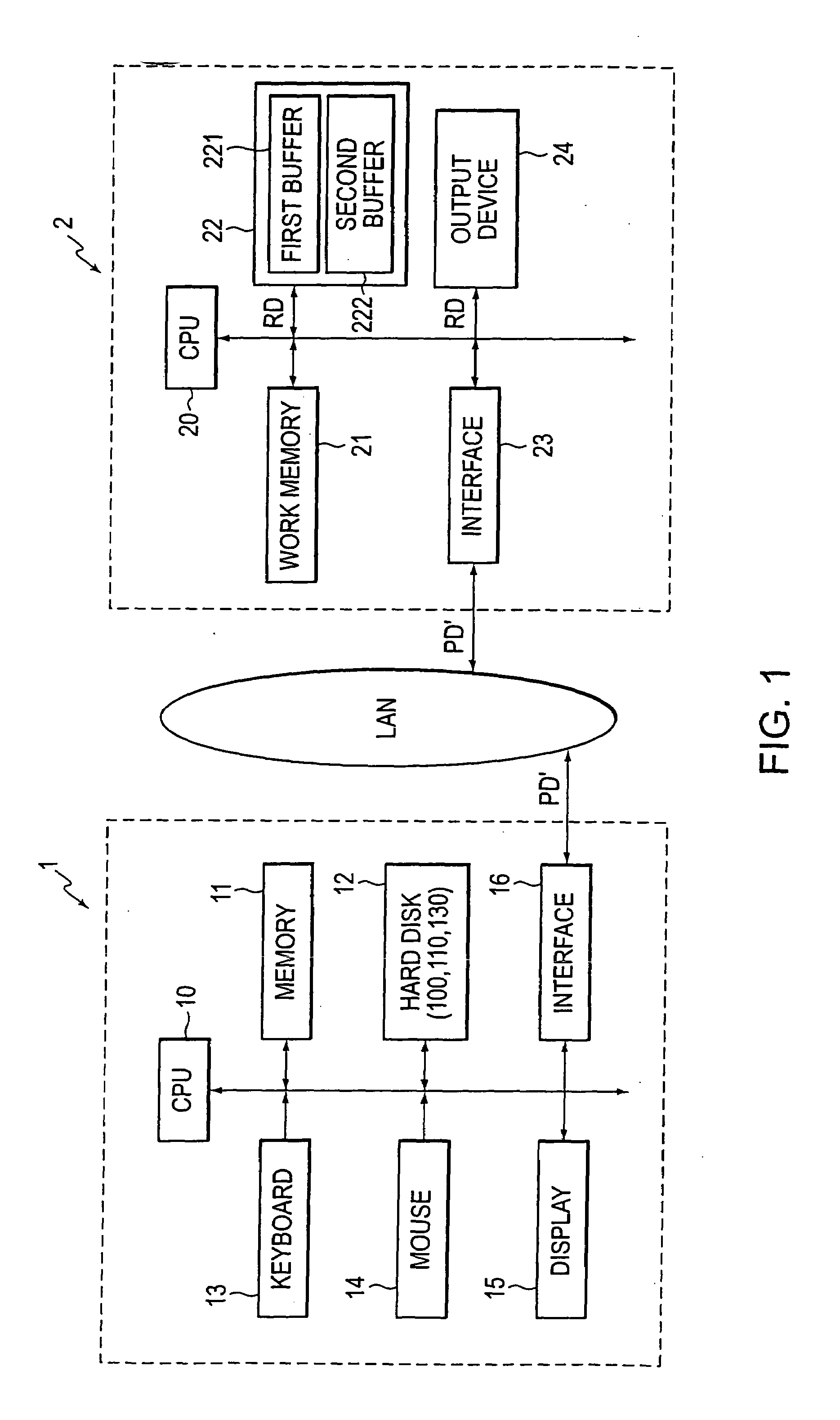

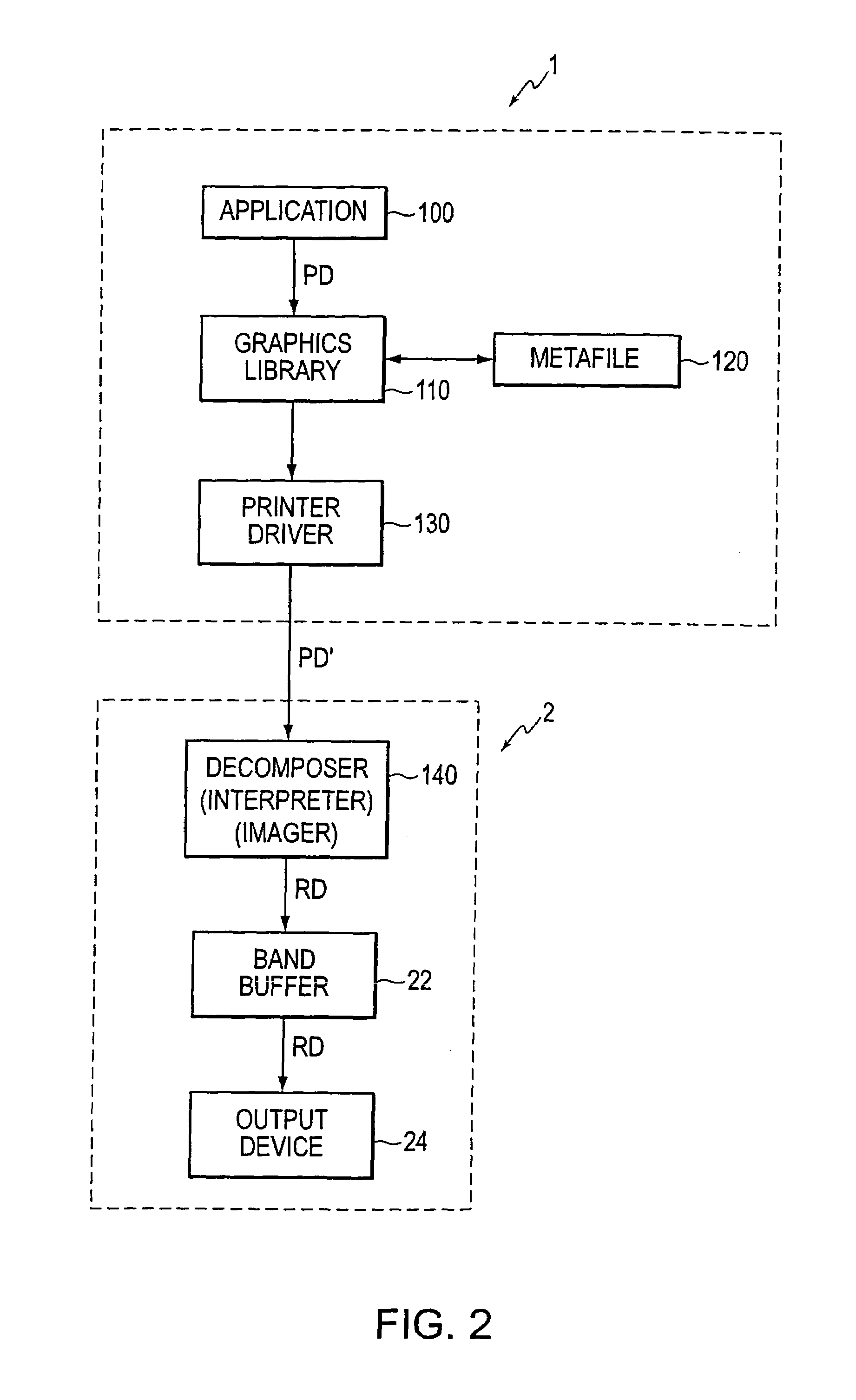

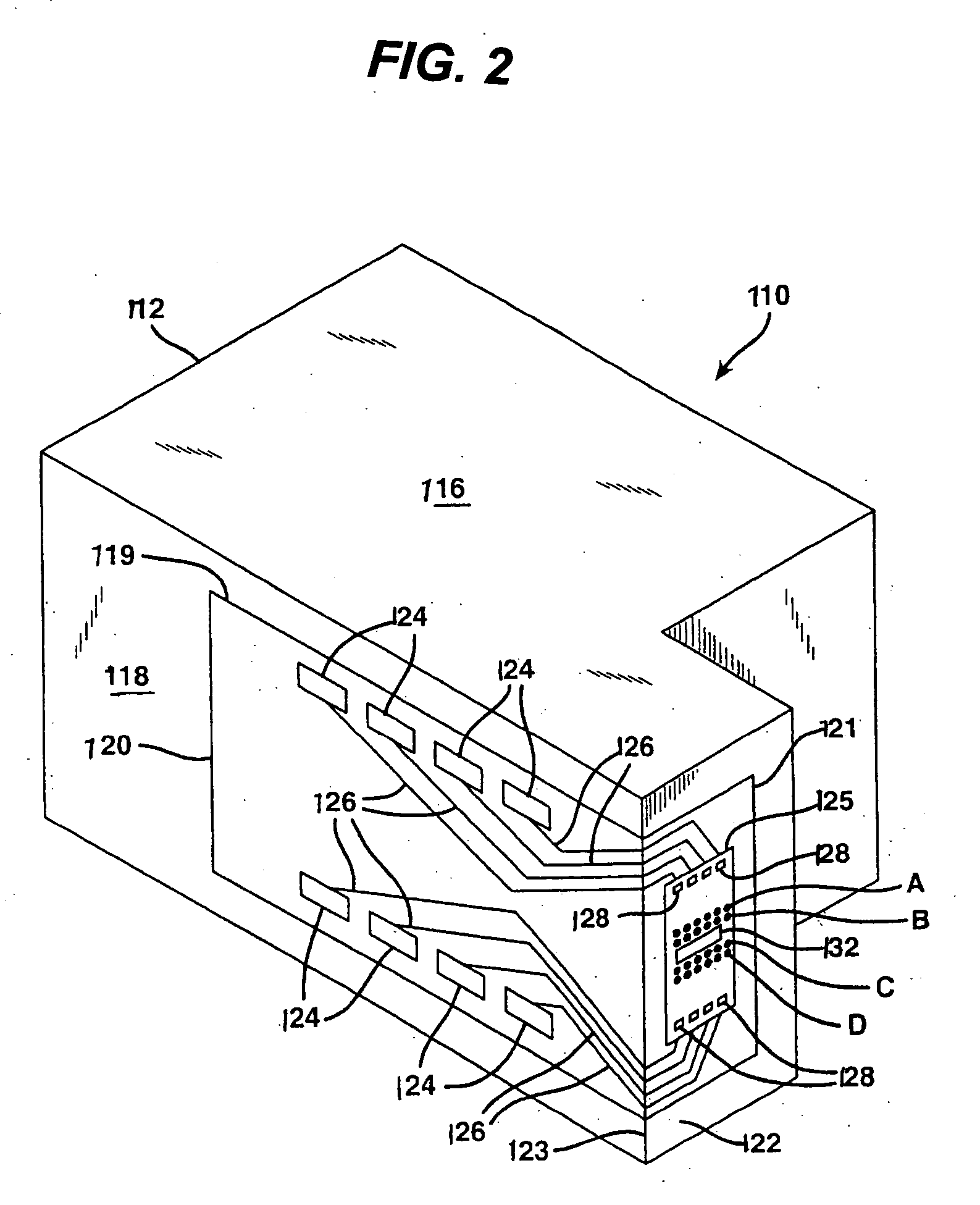

Image processing apparatus, output apparatus, image processing system and image processing method

InactiveUS7103833B1Reduce capacityImprove print qualityDigital computer detailsOther printing apparatusPrint processorPaper sheet

When print data PD generated by applications 100 is supplied to a graphics library 110 in an order of describing objects, the graphics library 110 makes correspond print data PD to objects so as to store print data PD in a metafile 120. After print data for one page has been stored in the metafile 120, the metafile 120 is retrieved. Thus, print data PD is reconstructed for each band. A printer driver 130 converts reconstructed print data PD into the PDL data PD′ so as to transfer the PDL data PD′ to an output apparatus 2. A decomposer 140 does not generate intermediate format data and directly develops the PDL data PD′ in a band buffer 22. An output device 24 reads raster data RD from the band buffer 22 so as to print an image on a paper sheet.

Owner:FUJIFILM BUSINESS INNOVATION CORP

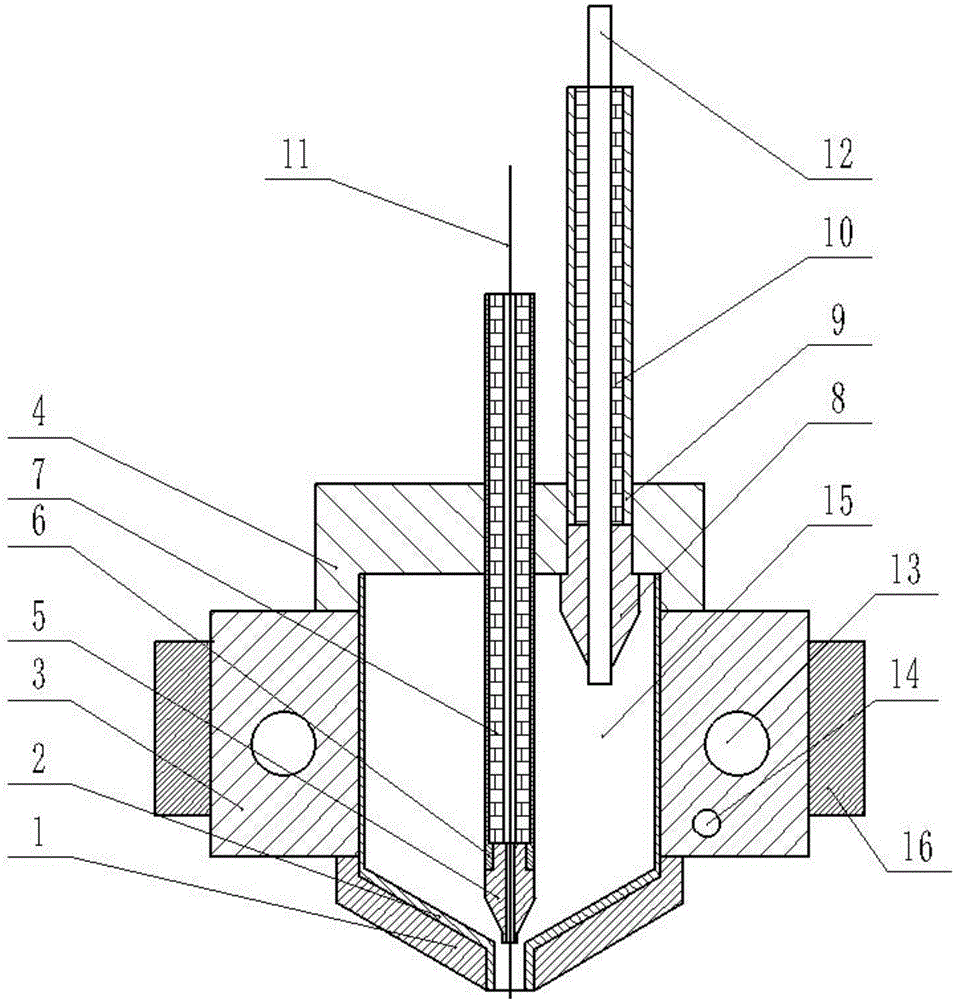

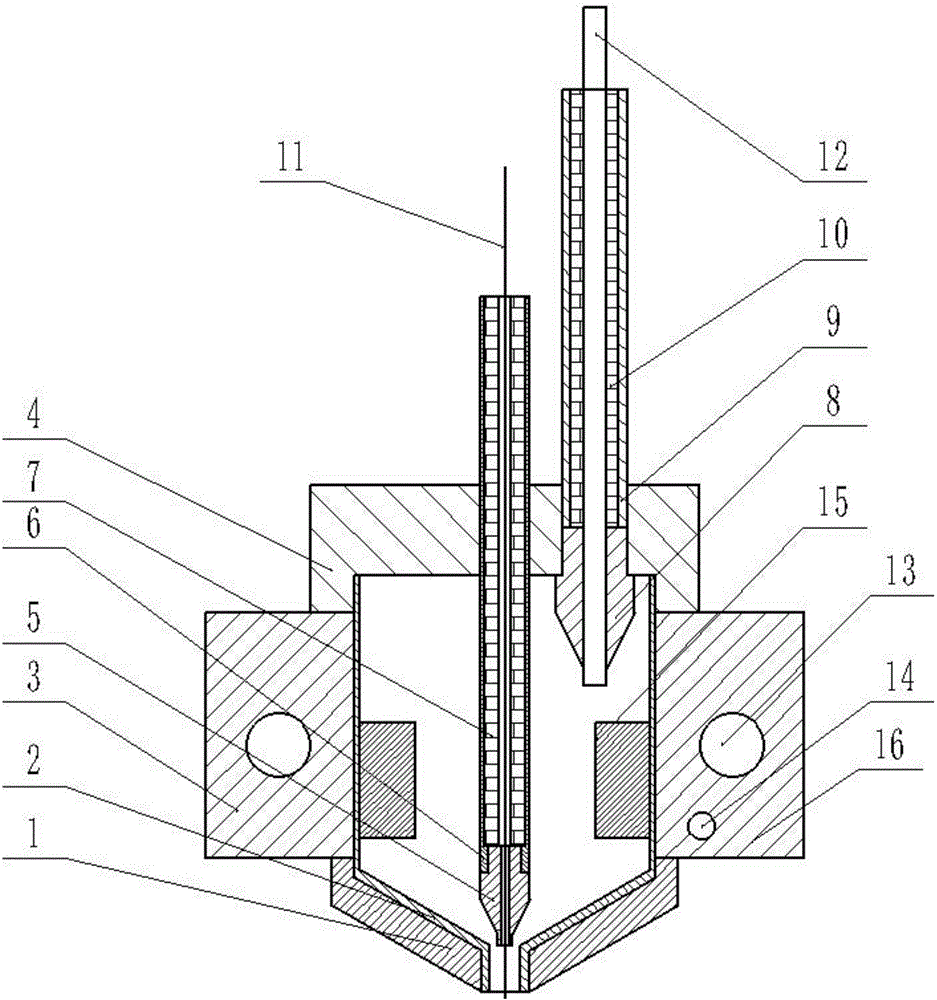

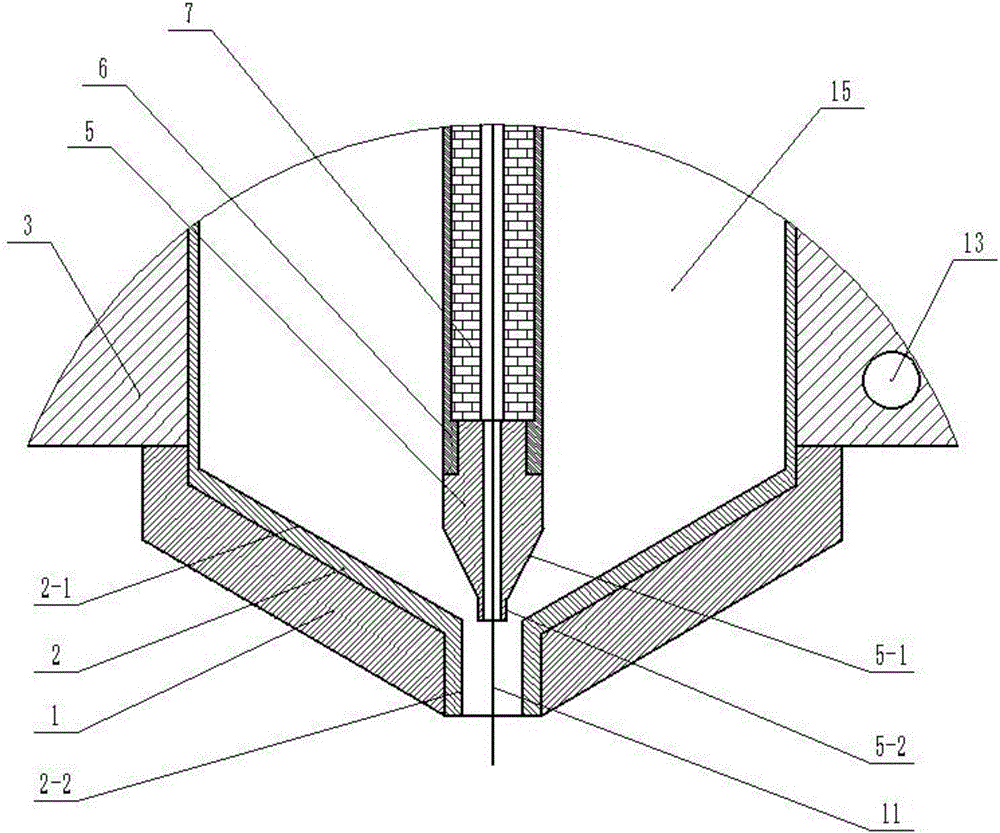

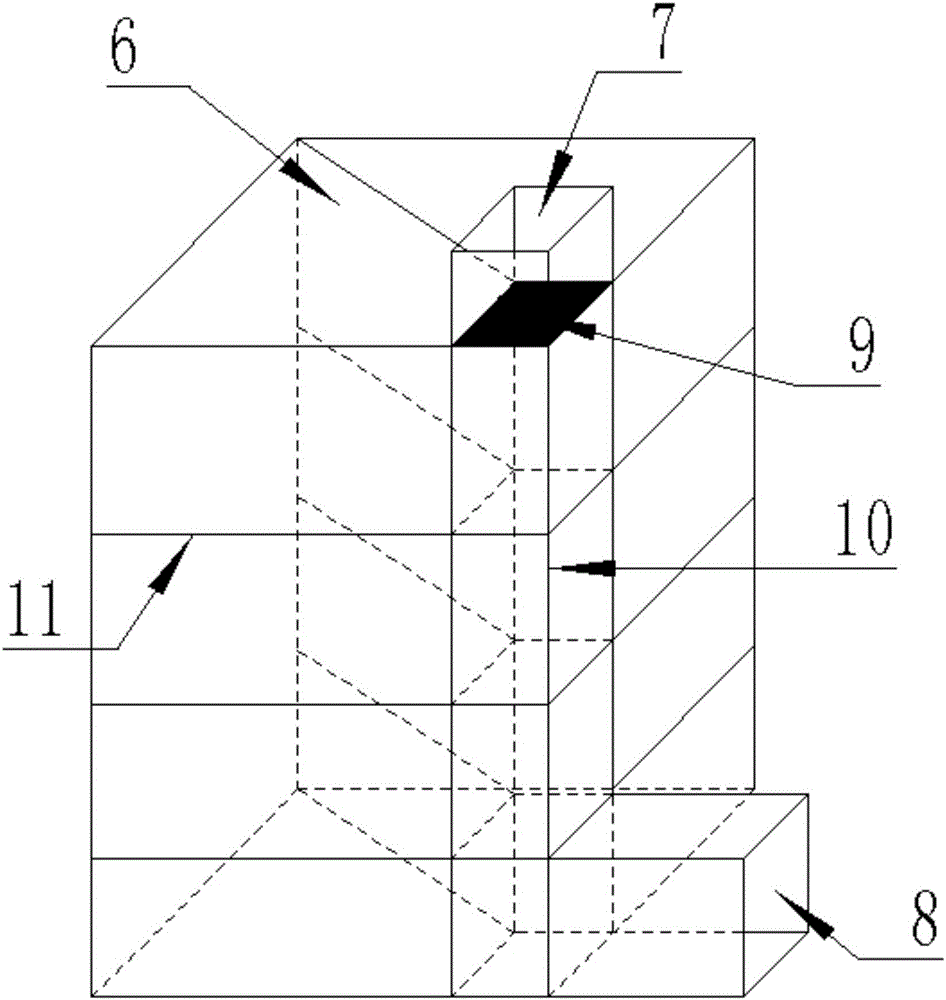

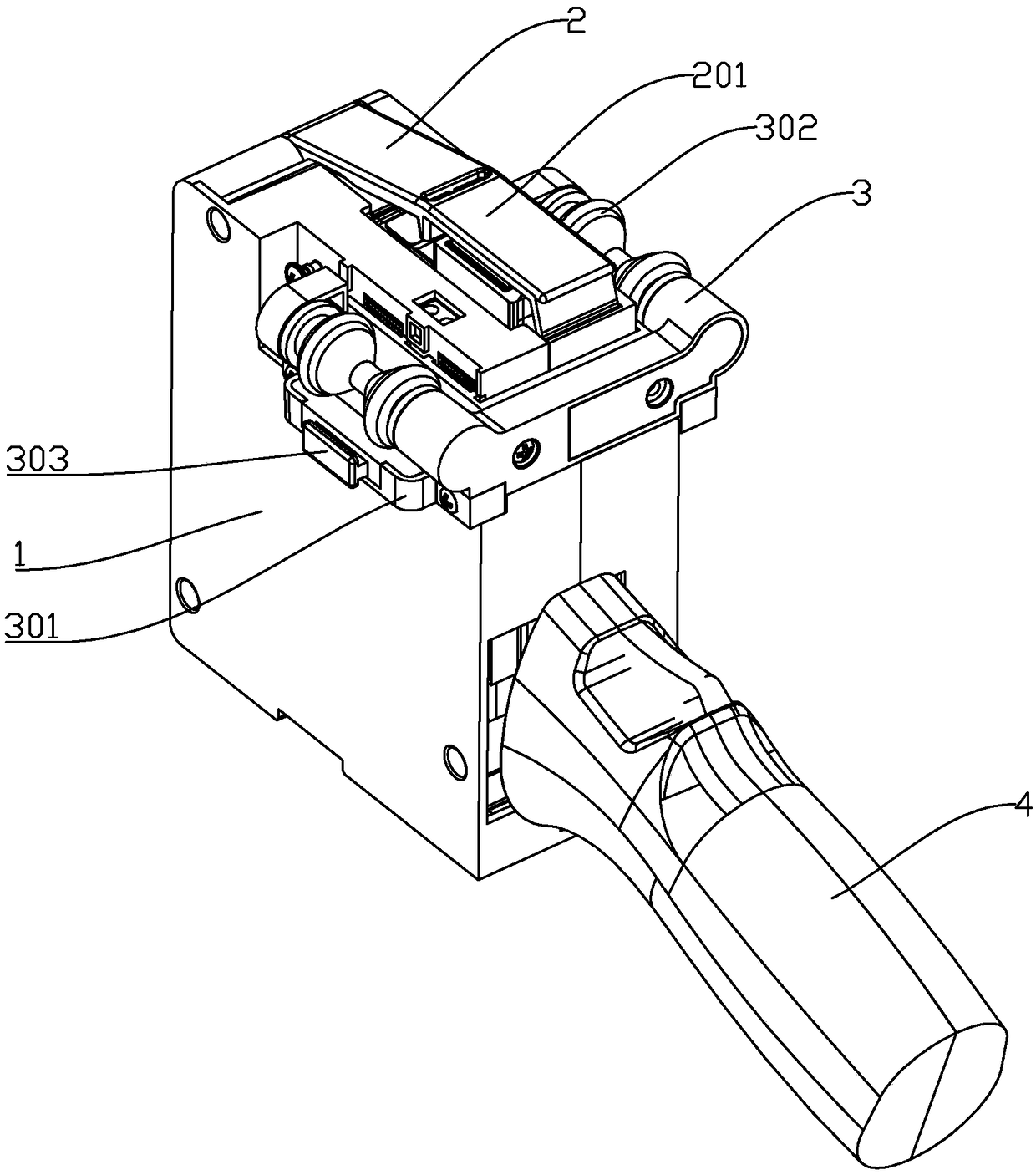

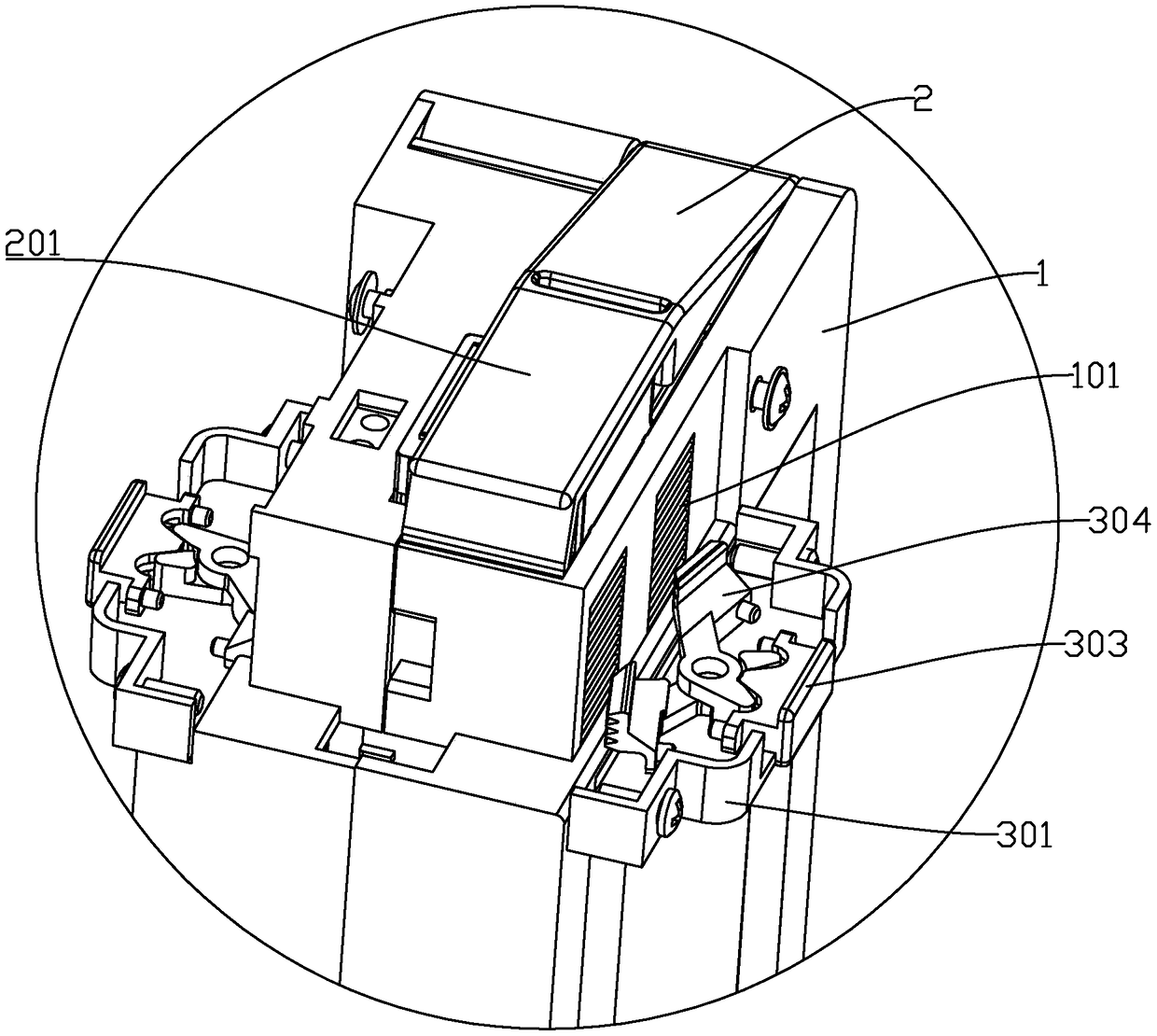

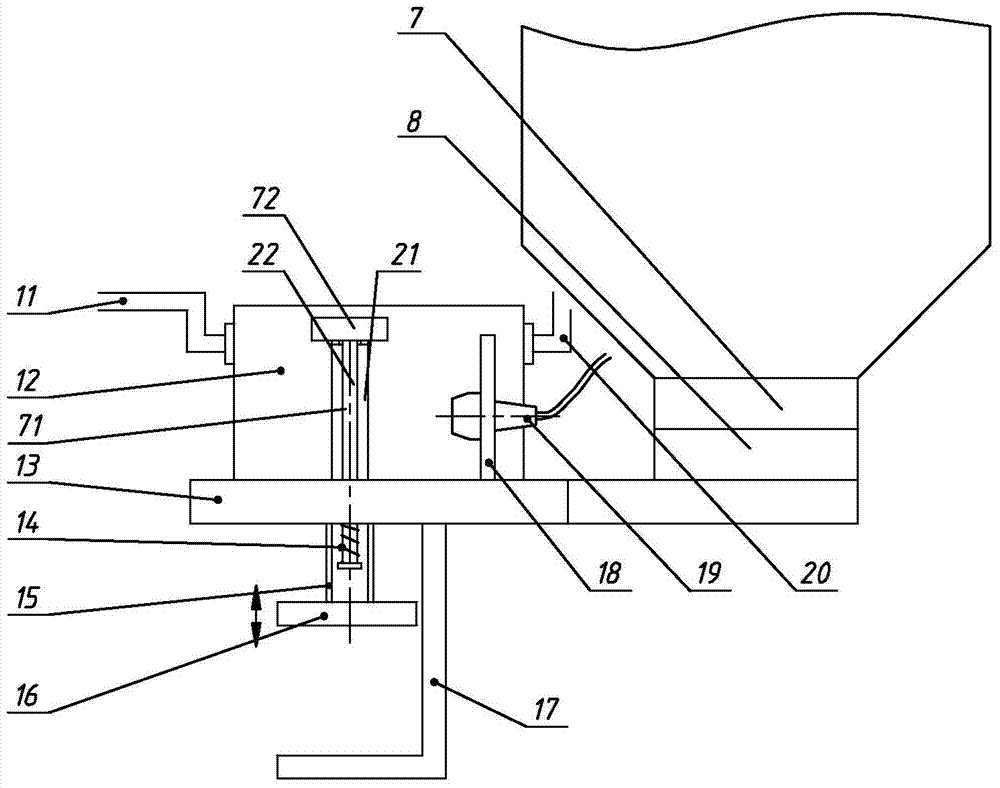

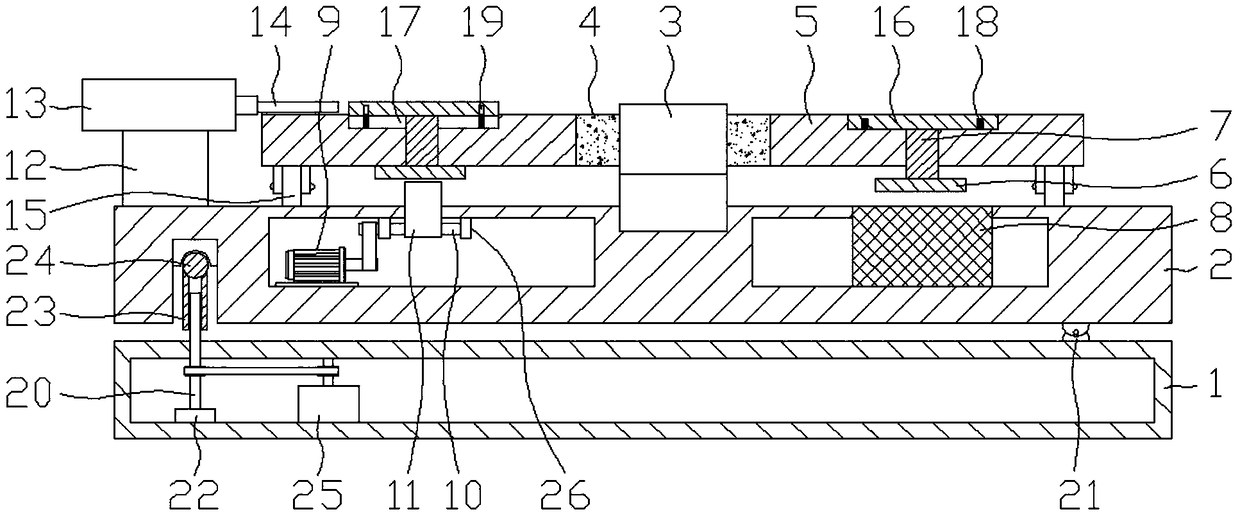

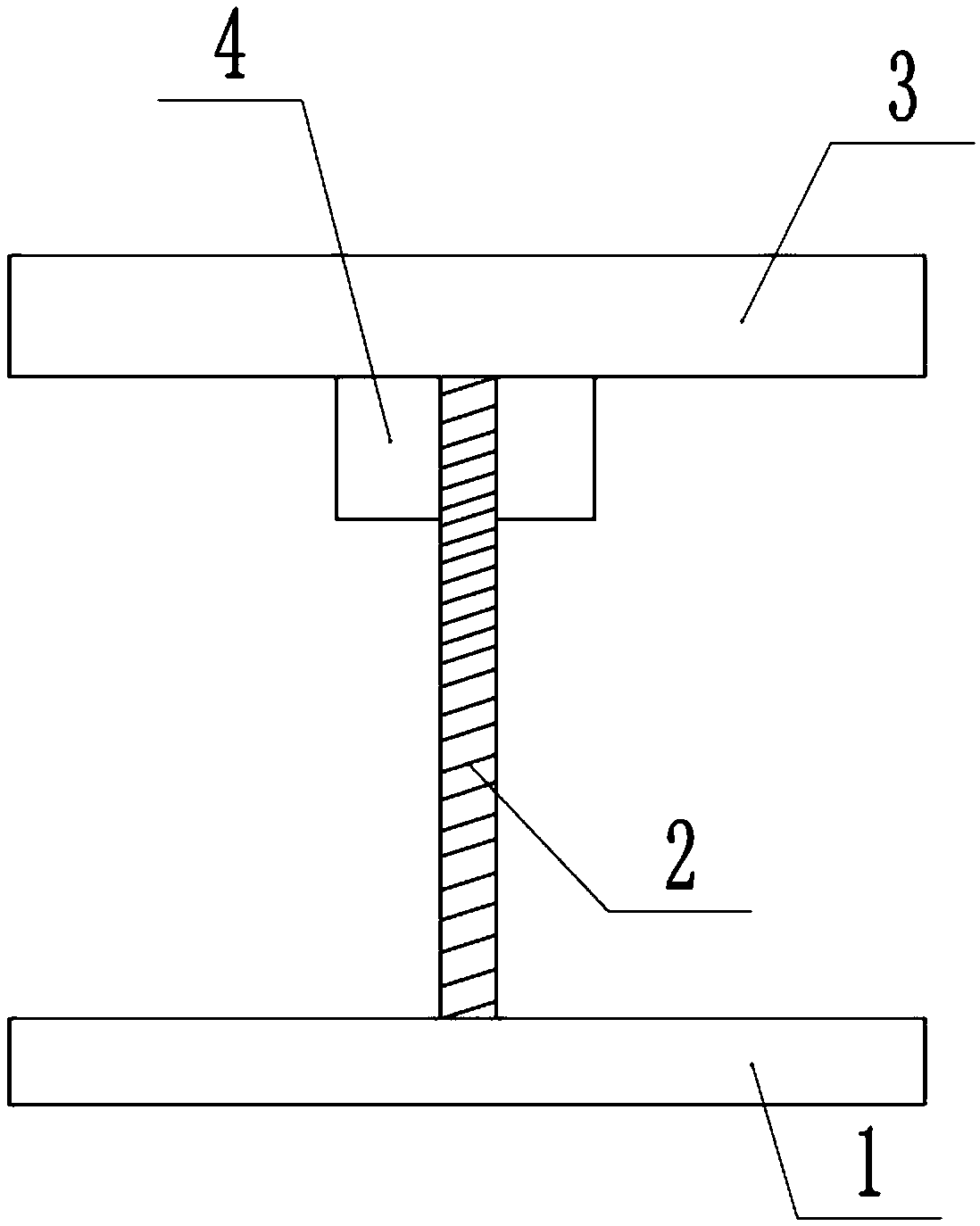

Additive manufacturing sprayer for fiber reinforced composite material based on ultrasonic enhancing

ActiveCN106363905AImprove bonding effectImprove print quality3D object support structuresApplying layer meansUltrasonic generatorPolytetrafluoroethylene

The invention belongs to the field of additive manufacturing and relates to an additive manufacturing sprayer for a fiber reinforced composite material based on ultrasonic enhancing. The additive manufacturing sprayer for the fiber reinforced composite material based on ultrasonic enhancing comprises a sprayer body, an inner cavity, a heat conducting block, a cap, a fiber sprayer body, a fiber throat pipe, a polytetrafluoroethylene pipe I, a resin sprayer body, a resin throat pipe, a polytetrafluoroethylene pipe II, heating rods, temperature sensors and ultrasonic generators, the resin and fiber bonding effect can be improved, sprayer blockage is prevented, and the sprayer body can be conveniently cleaned. The sprayer body is detachably connected to the lower end of the inner cavity and is sleeved with the heat conducting block; the heating rods and the temperature sensors are arranged on the heat conducting block in a nested manner; the upper end of the inner cavity is detachably connected with the cap; the fiber throat pipe and the resin throat pipe are both detachably connected to through holes of the cap; the through hole connected with the resin throat pipe is further detachably connected with the resin sprayer body; the polytetrafluoroethylene pipe I is arranged in the fiber throat pipe in a sleeved manner; the lower end of the fiber throat pipe is detachably connected with the fiber sprayer body; the polytetrafluoroethylene pipe II is arranged in the resin throat pipe in a sleeved manner; and a cavity is formed after the inner cavity is connected with the cap.

Owner:HARBIN INST OF TECH

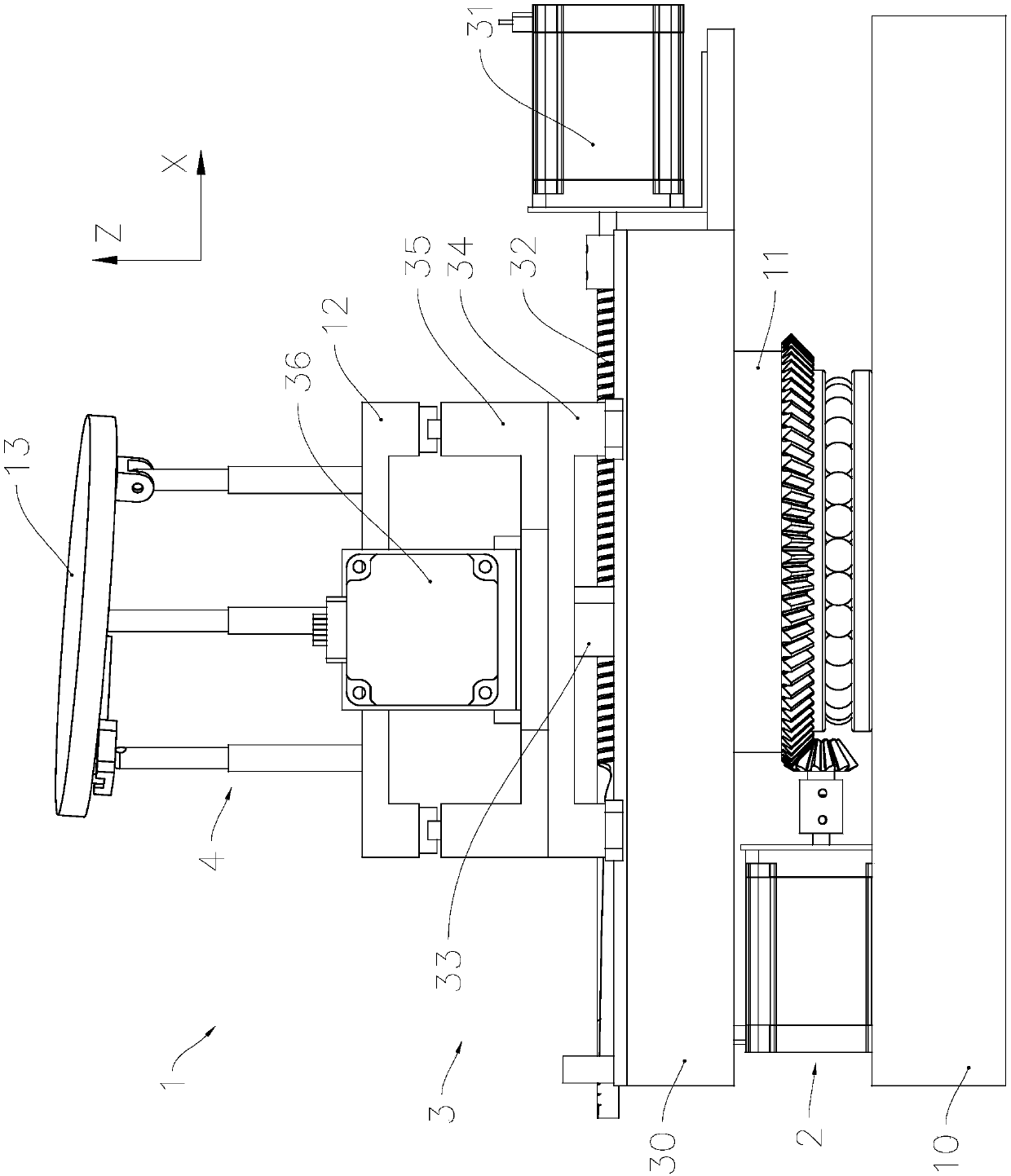

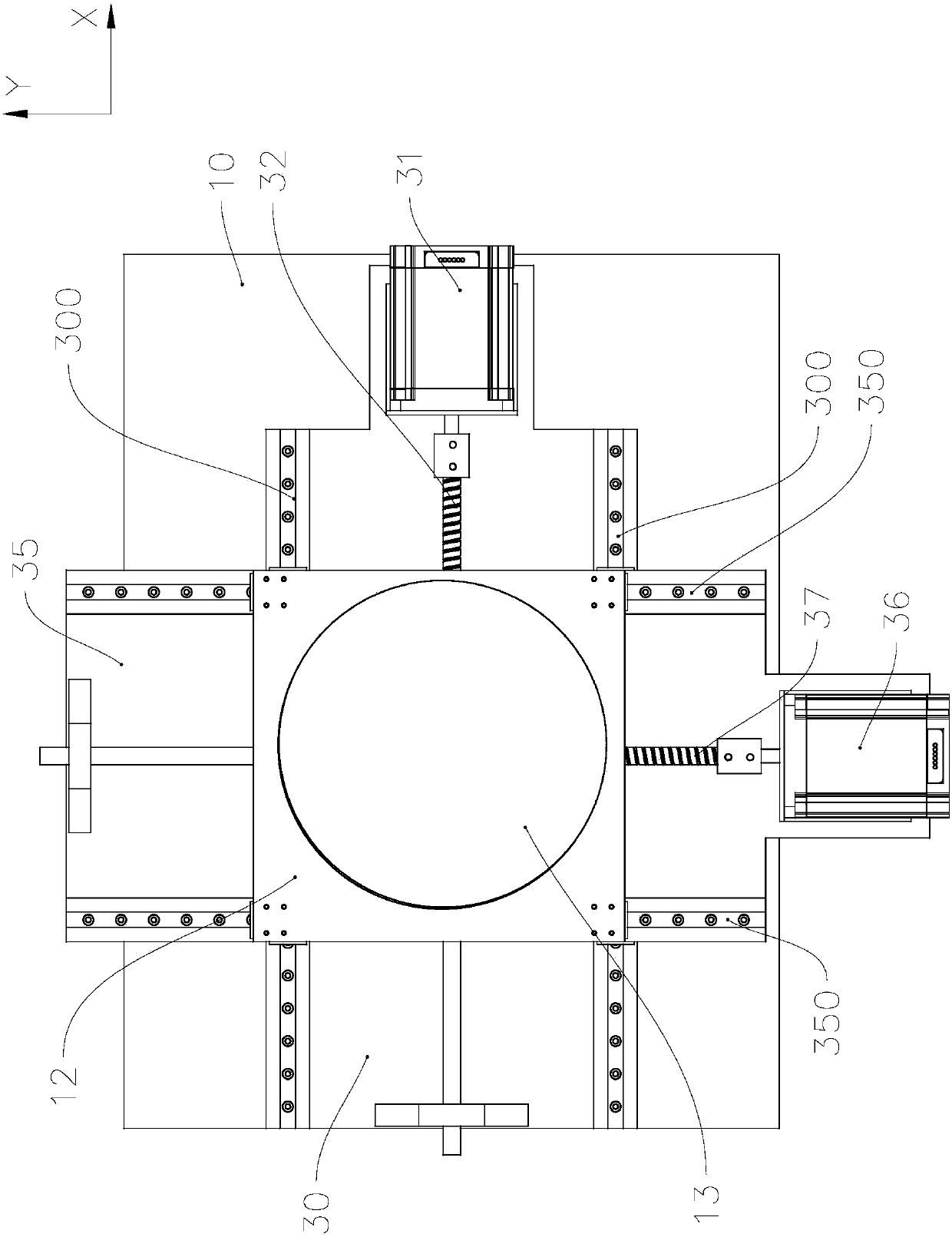

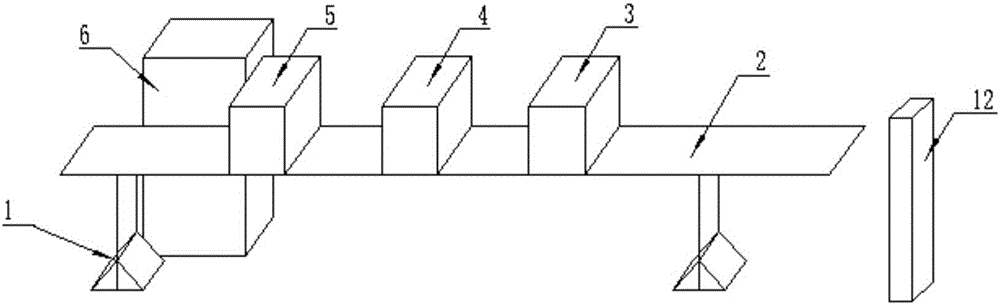

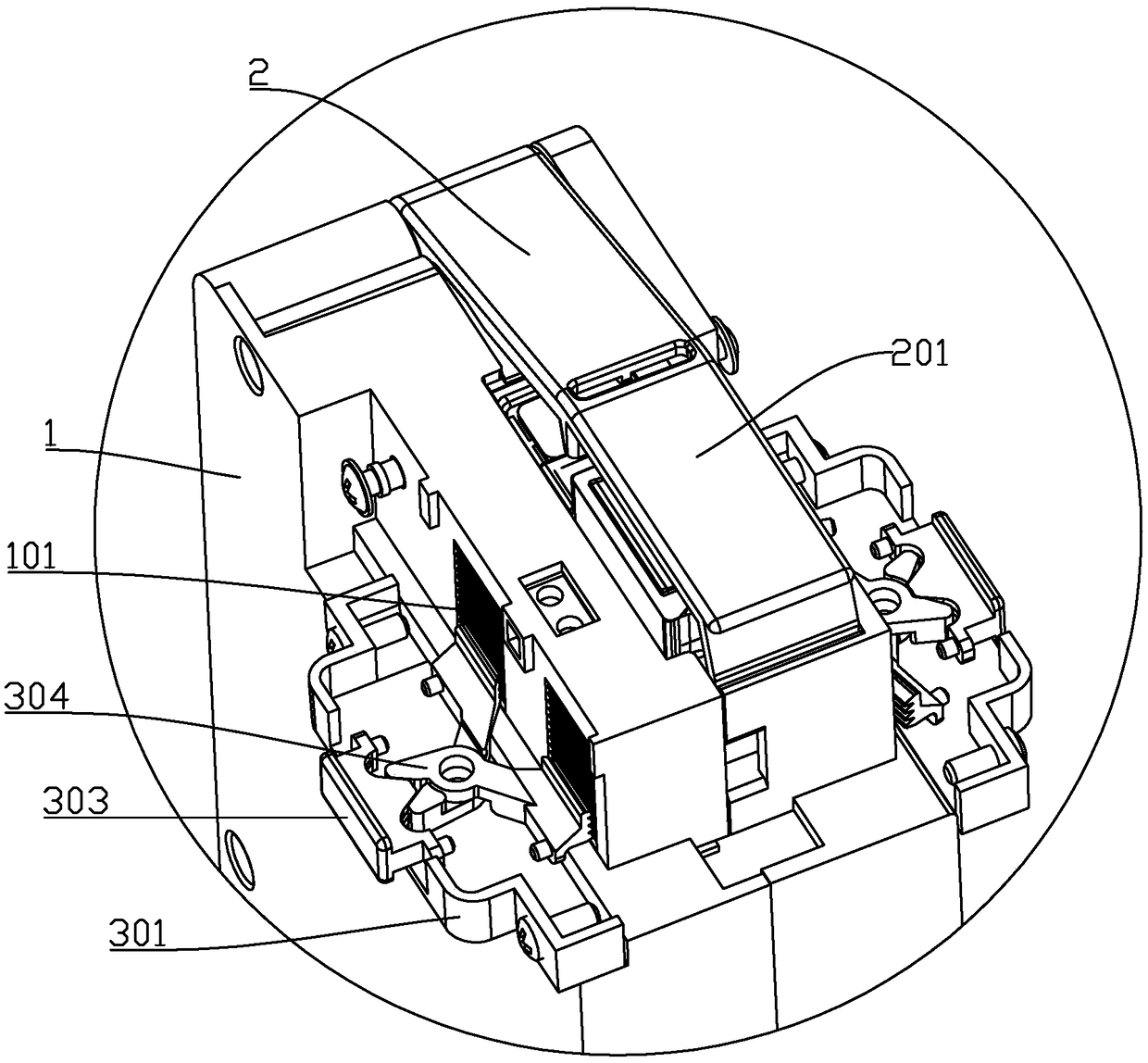

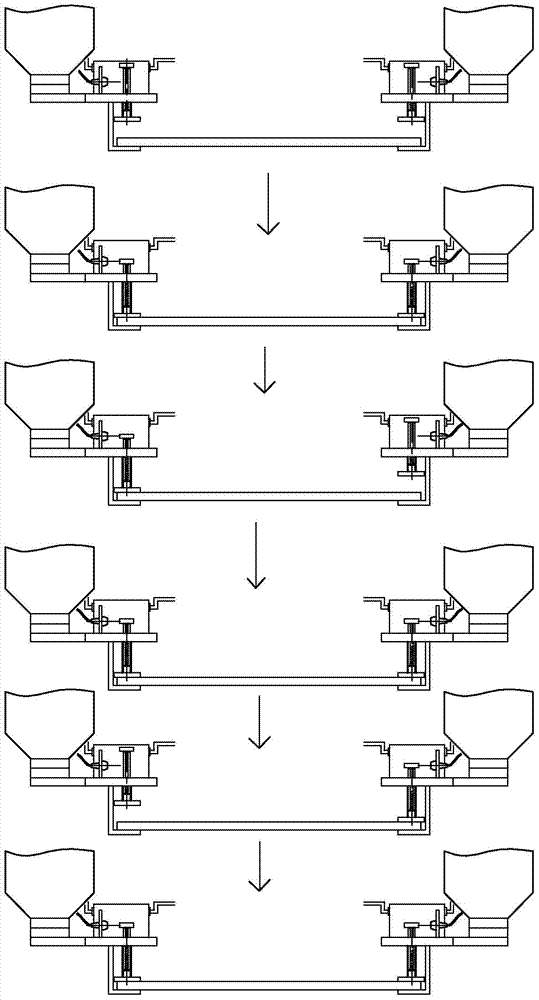

Three-dimensional printing device and printing platform system thereof

ActiveCN107901413AImprove print qualityReduce print volumeManufacturing platforms/substratesManufacturing driving means3D printingRapid prototyping

The invention relates to a three-dimensional printing device and a printing platform system thereof, and belongs to the technical field of rapid forming. The three-dimensional printing device comprises a control unit, a machine frame, a printing head and the printing platform system, wherein the printing head and the printing platform system are installed on the machine frame and controlled by thecontrol unit; the printing platform system comprises a mounting seat, a driving system and a printing platform, and the printing head can do a three-dimensional space movement relative to the mounting seat; the driving system comprises a rotating table arranged on the mounting seat through a rotating shaft, a rotating driver used for driving the rotating table to rotate around the rotating shaft,a sliding table arranged at the rotating table in a manner of being capable of sliding in the transverse direction, and a transverse driver used for driving the sliding table to do two-dimensional plane movement in the transverse direction; and the printing platform is installed on the sliding table through a posture adjusting mechanism used for adjusting the posture of the printing platform. Byarranging the printing platform system in the three-dimensional printing device, the printing quality of a three-dimensional curved piece can be effectively improved, and the three-dimensional printing device and the printing platform system can be widely applied to the field of rapid forming manufacturing.

Owner:ZHEJIANG UNIV

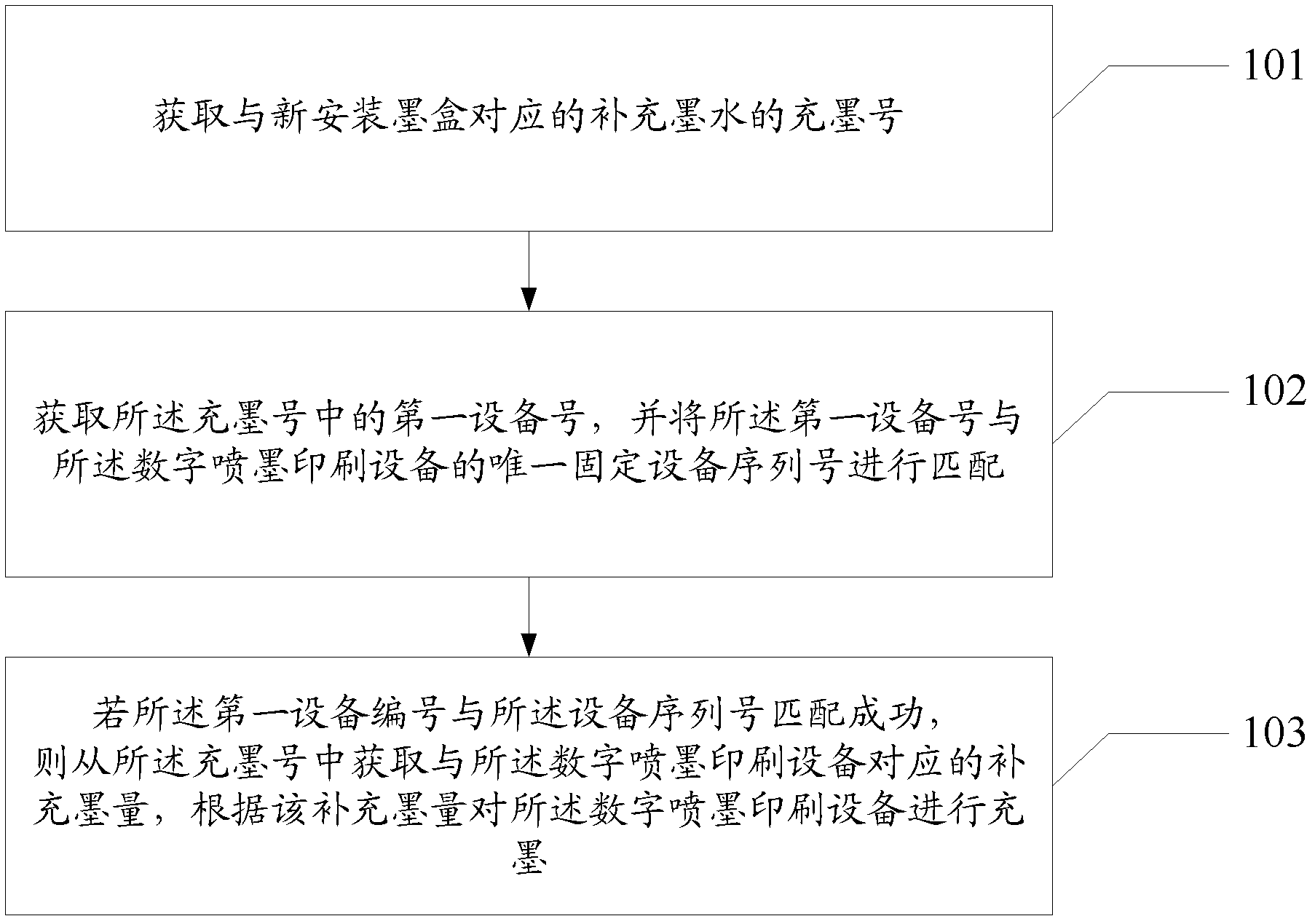

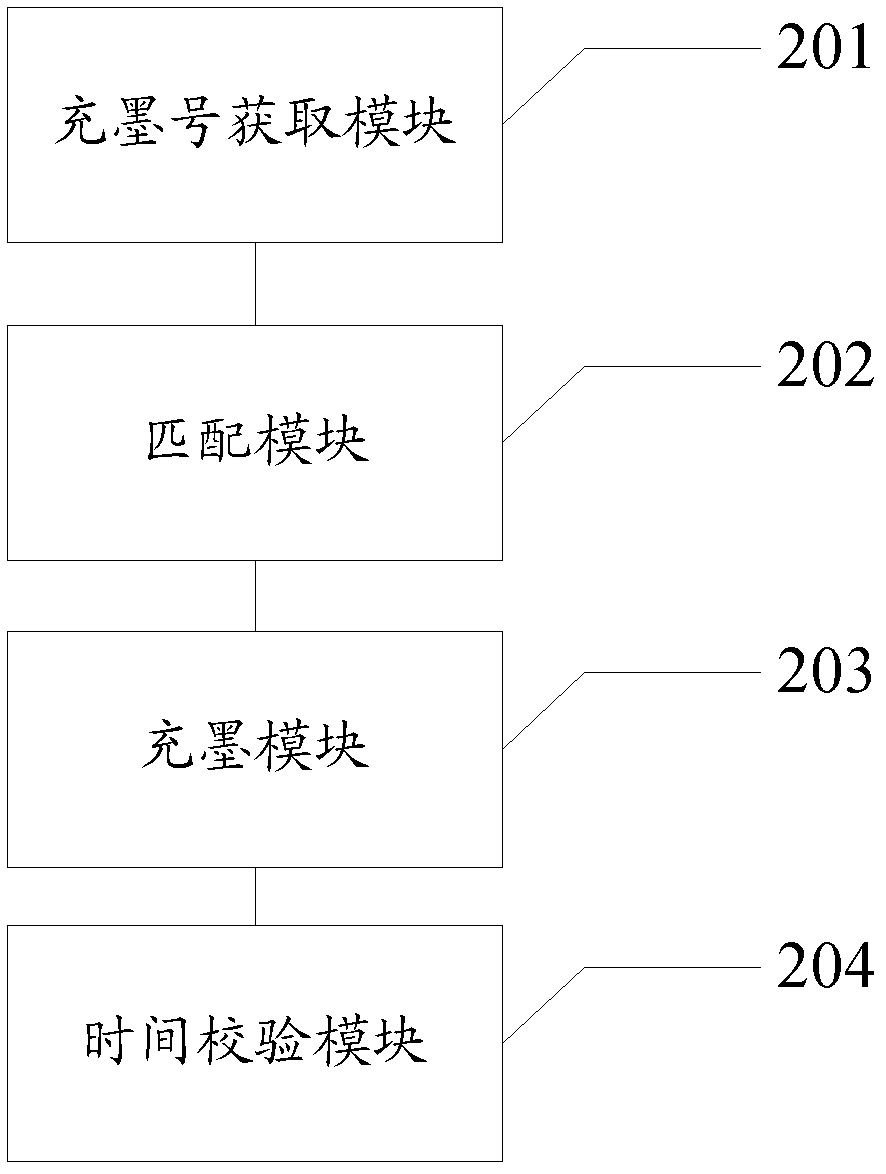

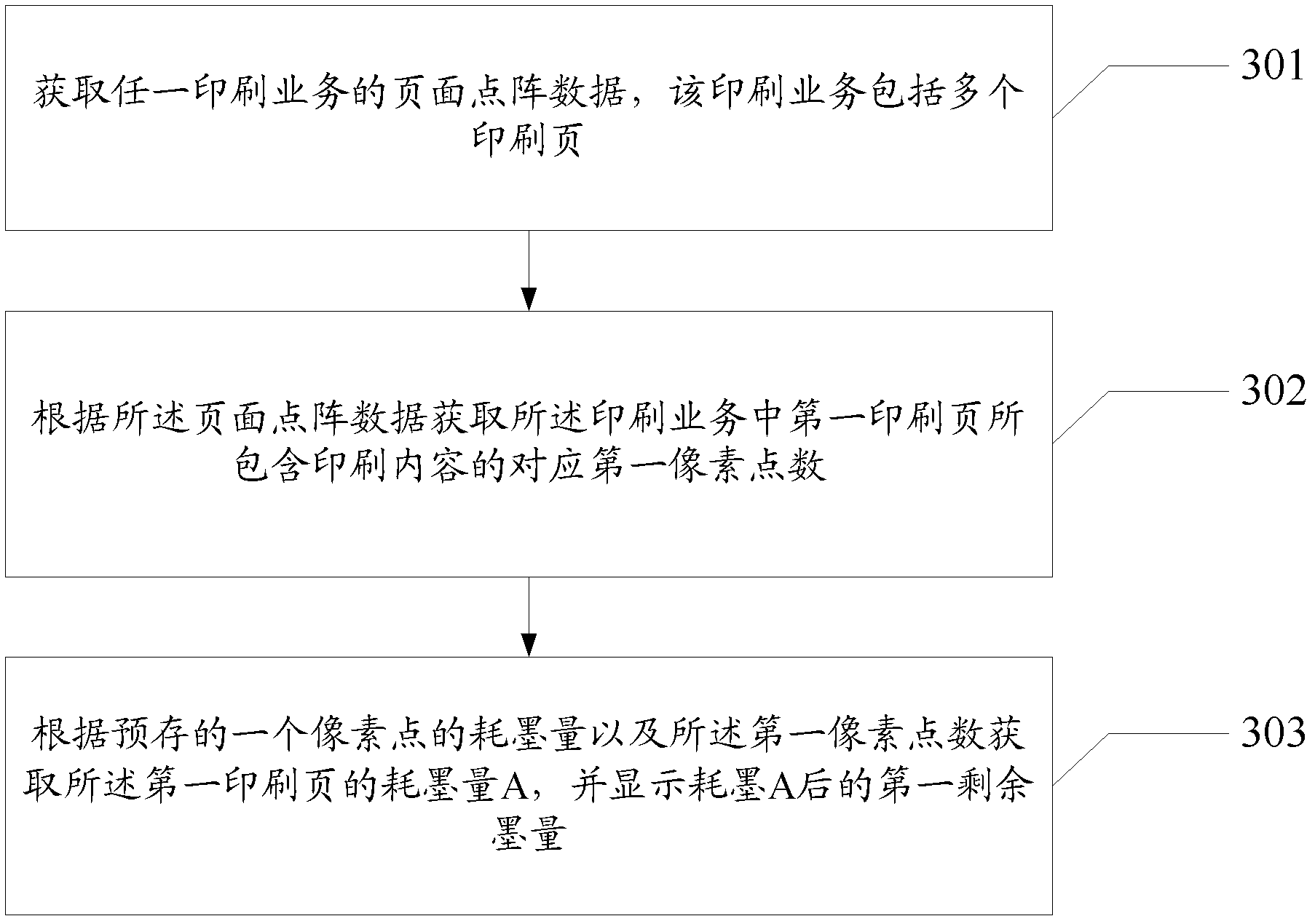

Ink supplement method and ink supplement device of digital ink jet printing equipment

ActiveCN103182852AImprove print qualitySafeguard legitimate rights and interestsPrintingDigital printingDigital ink

The invention provides an ink supplement method and an ink supplement device of digital ink jet printing equipment. The ink supplement method and the ink supplement device of the digital ink jet printing equipment are applied to the field of digital printing. The ink supplement method of the digital ink jet printing equipment comprises the steps of obtaining an ink supplement number corresponding to a newly installed ink box, matching a first equipment number in the ink supplement number with an equipment serial number, obtaining an ink supplement amount corresponding to the digital ink jet printing equipment from the ink supplement number when the first equipment number and the equipment serial number are successfully matched, and carrying out ink supplement on the digital ink jet printing equipment according to the supplement ink amount. The ink supplement method and the ink supplement device of the digital ink jet printing equipment have the advantages of preventing a user from using different printing ink on the same ink jet equipment, effectively protecting the digital ink jet printing equipment, and improving jet printing quality of the digital ink jet printing equipment.

Owner:PEKING UNIV +2

Method and automatic production plant for printing on photovoltaic cells

ActiveUS20190067508A1Improve print qualityReduce breakage rateScreen printersSemiconductor/solid-state device manufacturingMagnetOn board

A method and related automatic production plant are disclosed for the silk-screen printing of inks or conductive pastes on photovoltaic cells or wafers, with an integrated handling system of the LSM moving coils drive type, wherein multiple shuttles with on-board coils act on a rail with permanent magnets in an independent but coordinated way, synchronous and / or asynchronous with respect to each other, to simultaneously perform missions different from each other in such a way as to advantageously carry out the printing operating steps provided by the method. Each shuttle is provided with an equipped tray of the removable type which is specifically configured to carry out the automated processing of the single cell, it also being intended to interact with the plant.

Owner:VISMUNDA

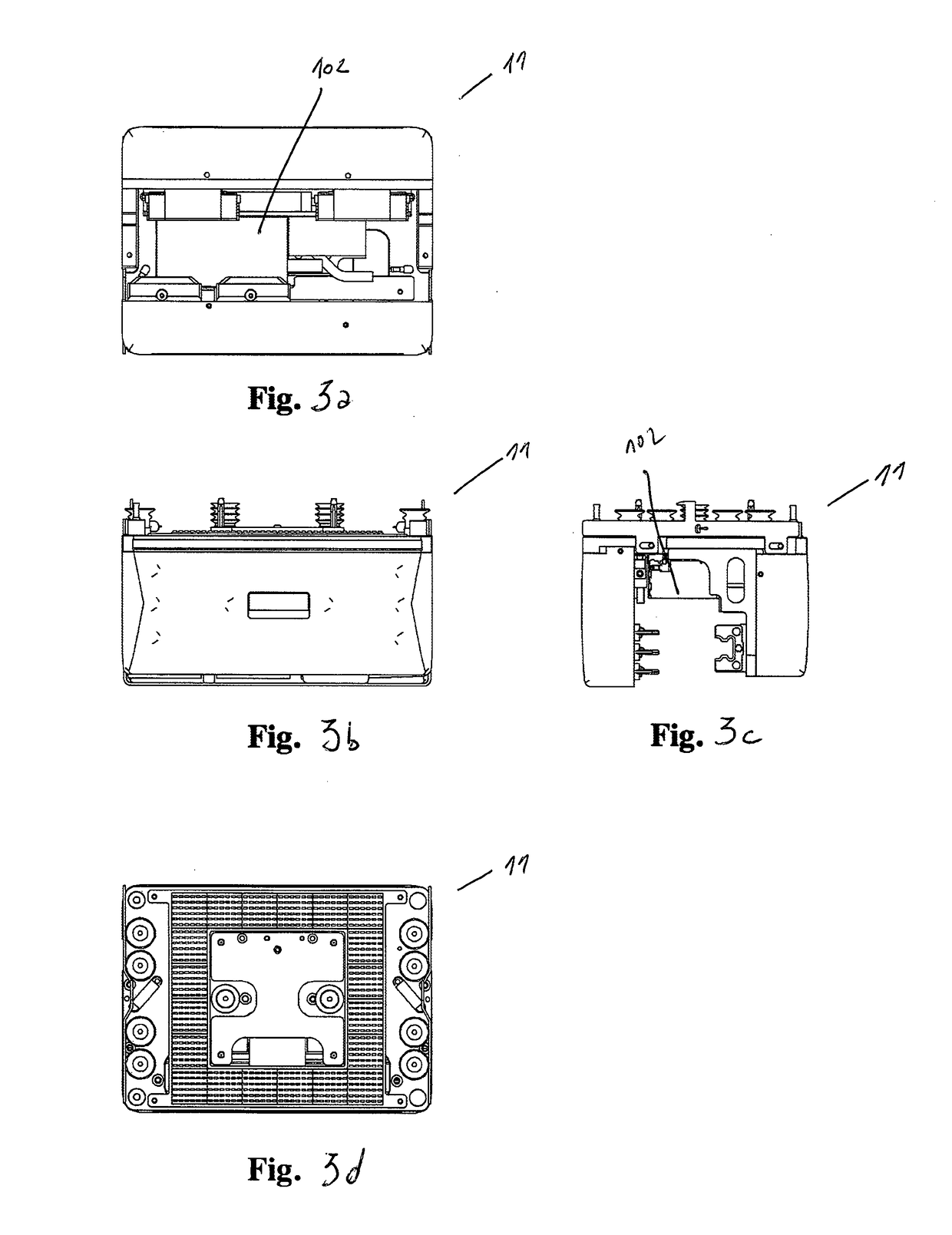

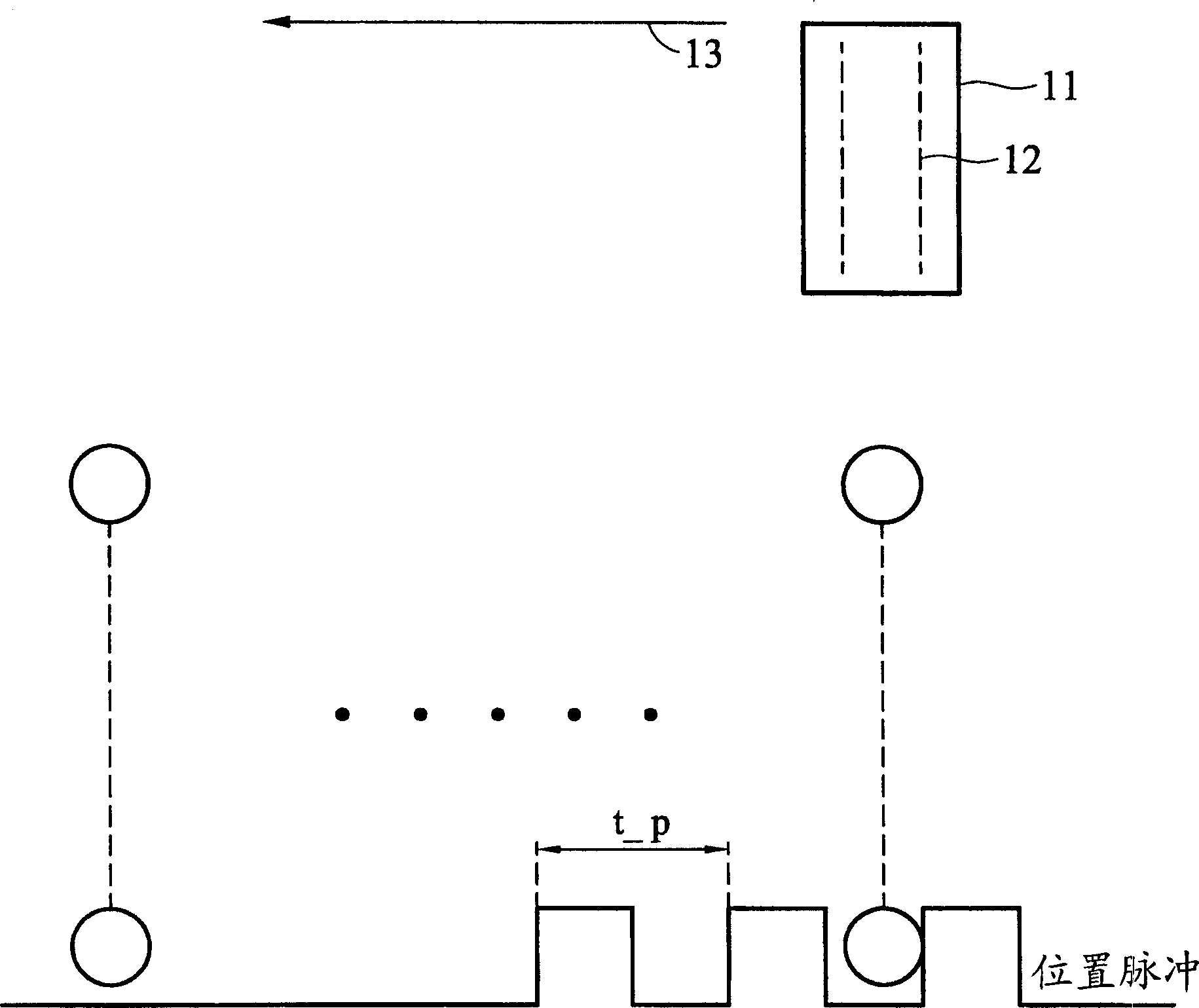

Handheld printer minimizing printing defects

InactiveUS20070263063A1Improve print qualityPrevent fireTypewritersOther printing apparatusHand heldPosition sensor

Methods and apparatus include a handheld printer manipulated back and forth by an operator during use to print an image. An inkjet printhead of the printer has a plurality of fluid firing actuators arranged in a substantial column. A controller communicates with the printhead to identify active actuators given to fire at a particular time during use to print the image. However, to prevent unsightly print quality from occurring during overlapping adjacent print swaths, for example, certain of the identified actuators are prevented from firing. Especially, actuators in the column further from a center of the column fire less frequently than those closer to the center. A position sensor is also used to locate the printhead relative to the image. The controller correlates the position to the printhead and actuators and fires the active actuators or not.

Owner:LEXMARK INT INC

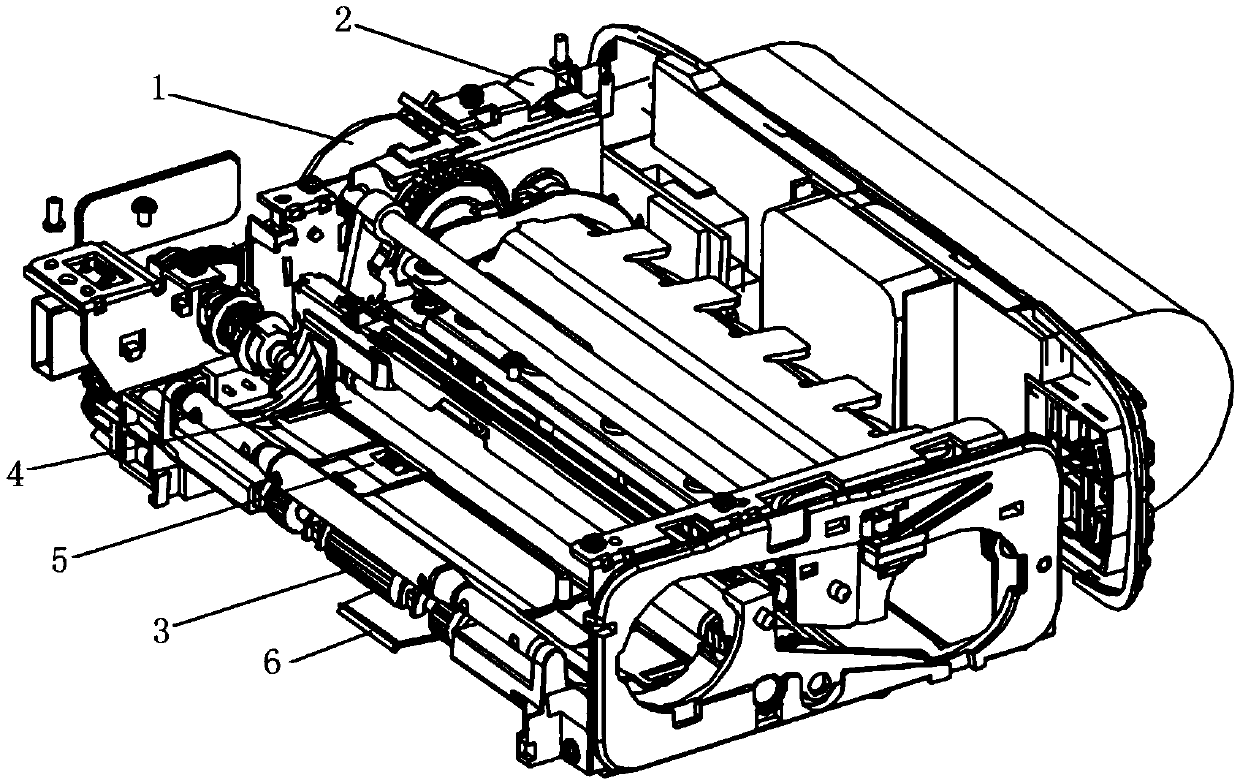

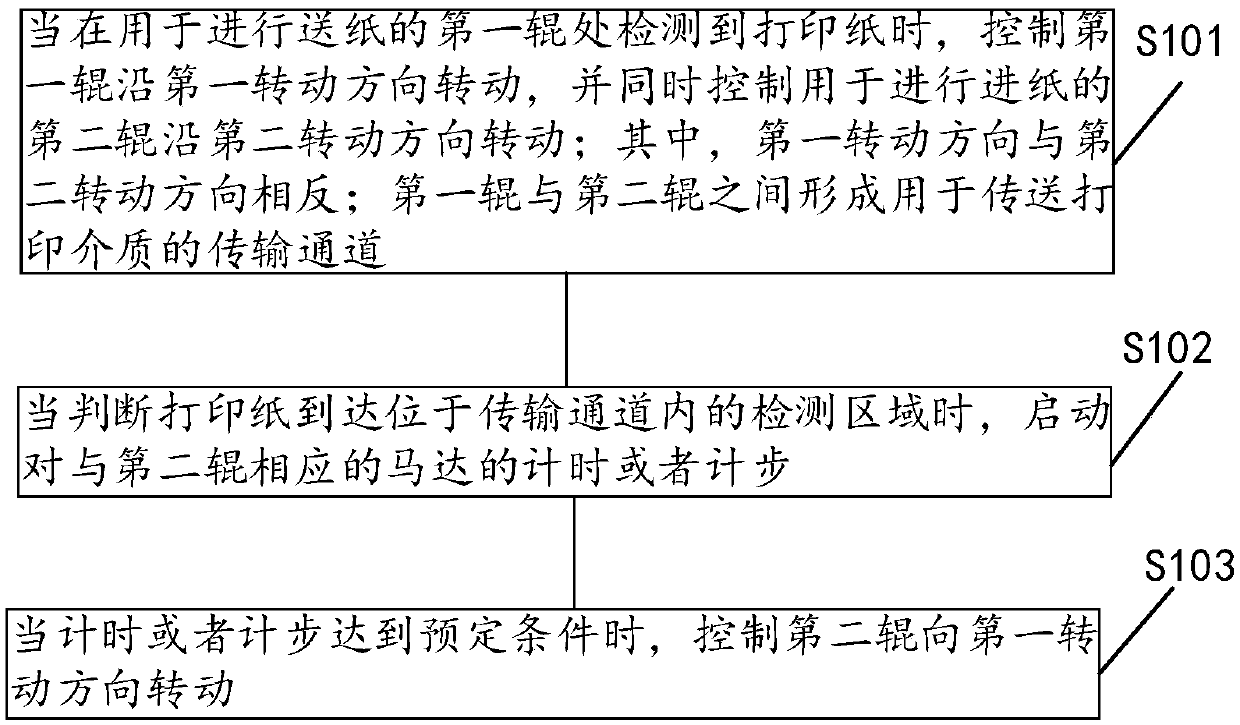

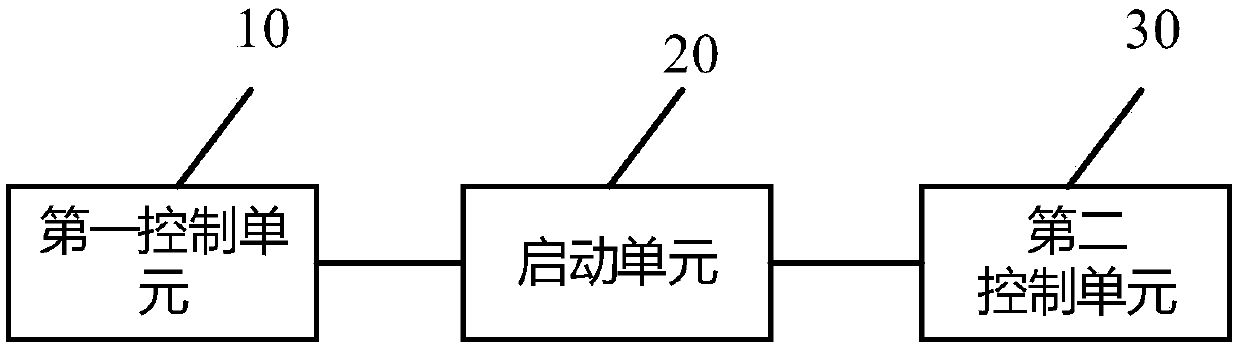

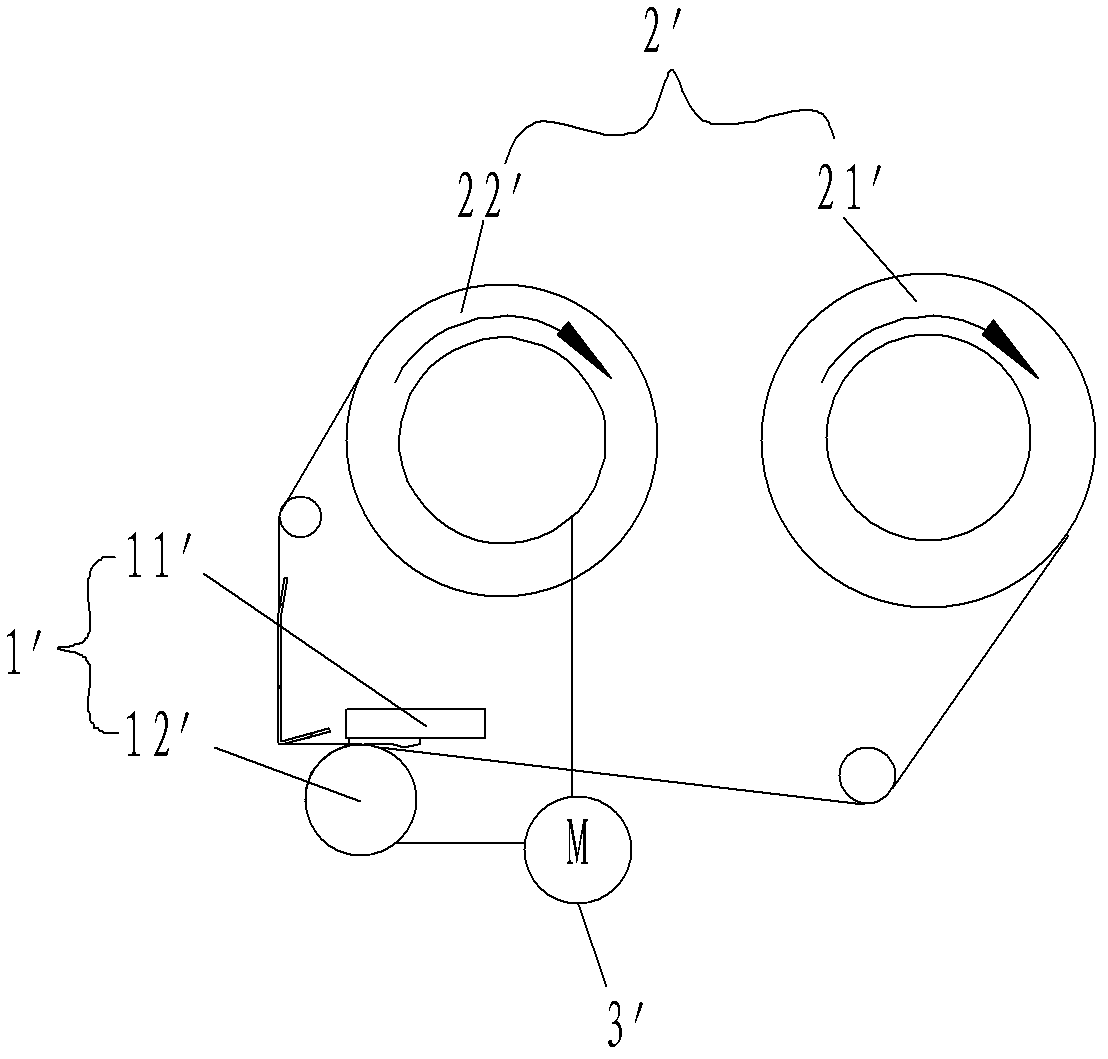

Method and device for correcting tilt printing paper, printer and storage medium

InactiveCN109677965AImprove print qualityAchieving proactive correctionFunction indicatorsOther printing apparatusPaper sheetStep counting

The invention discloses a method and device for correcting tilt printing paper, a printer and a storage medium. The method includes steps of controlling a first roller to rotate along a first rotatingdirection when the printing paper is detected by the first roller for paper delivering, and at the same time, controlling a second roller for paper feeding to rotate along a second rotating direction, specifically, the first rotating direction is opposite to the second rotating direction, and a transmission passage for conveying the printing medium is formed between the first roller and the second roller; when the printing paper is judged to reach the detecting area in the transmission passage, starting a motor corresponding to the second roller for timing or step counting; and when the timing or the step counting reaches the predetermined condition, controlling the second roller to move in the first rotating direction. The tilt printing paper to be printed can be automatically correctedand the printing quality is improved.

Owner:XIAMEN HANIN ELECTRONICS TECH CO LTD

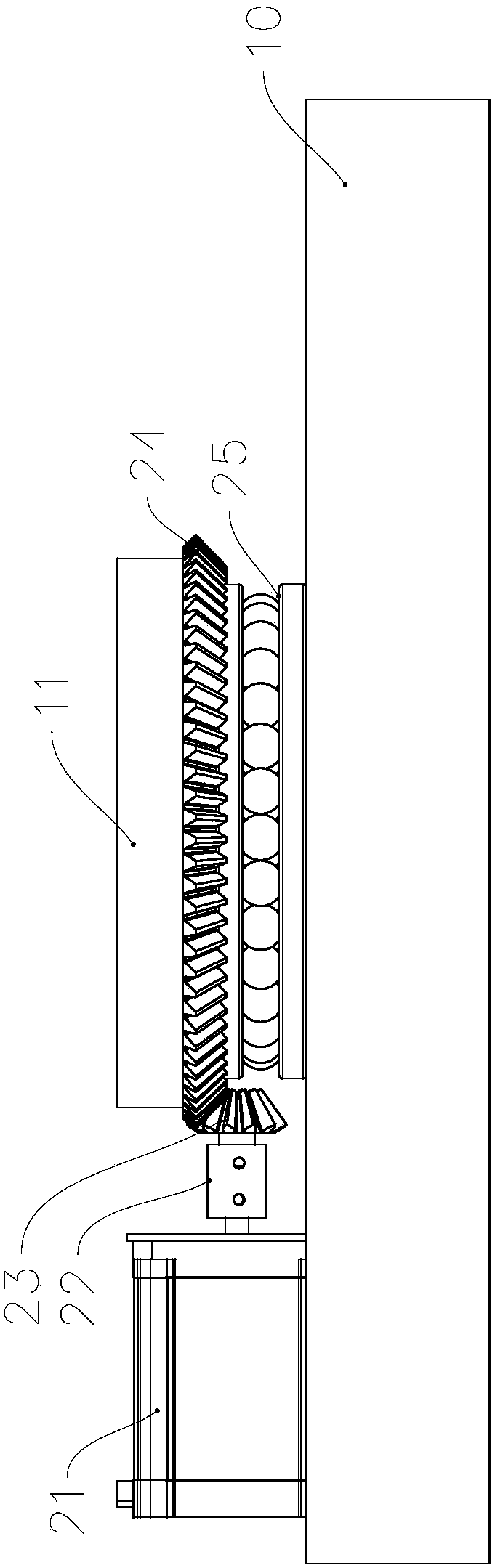

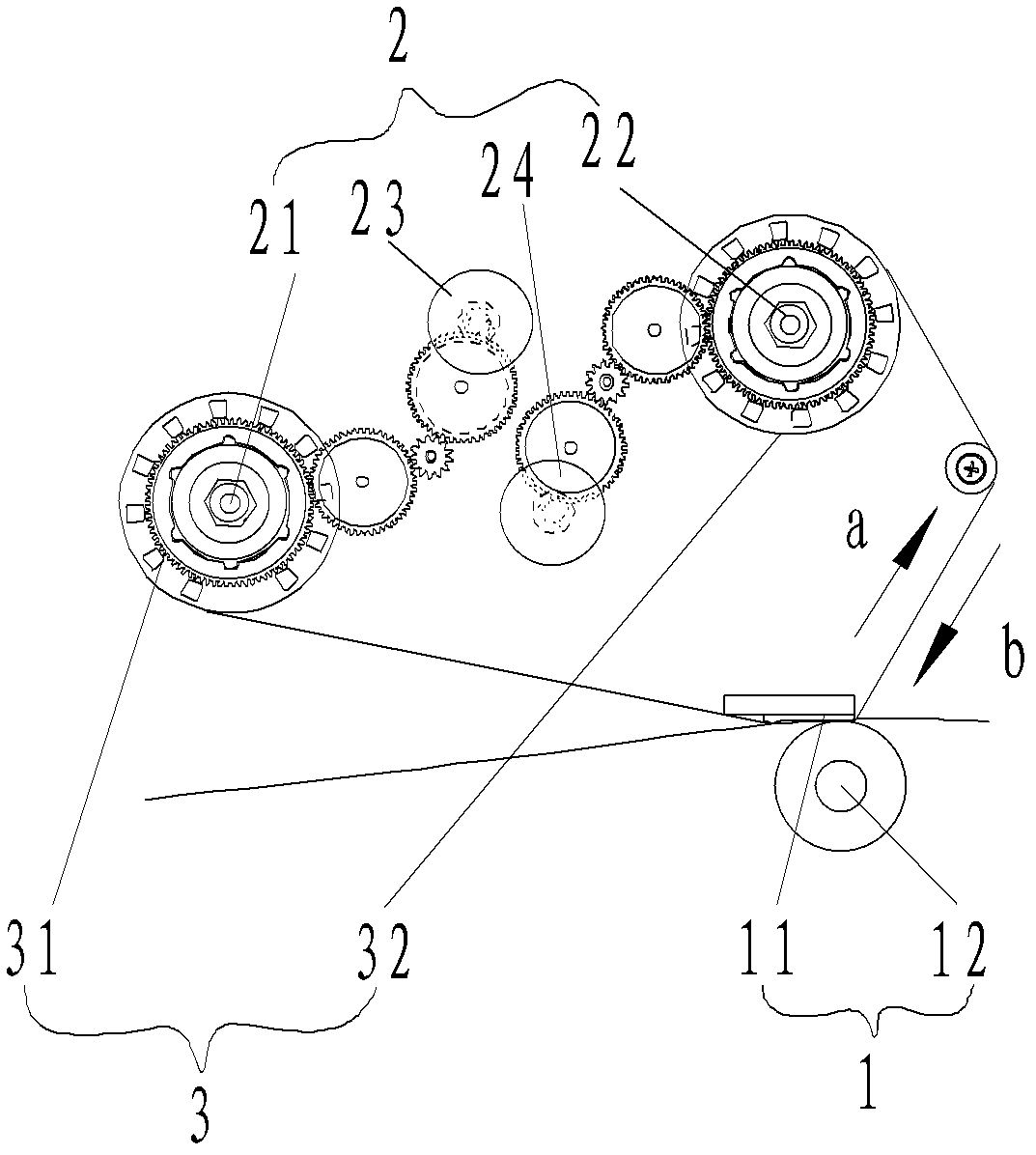

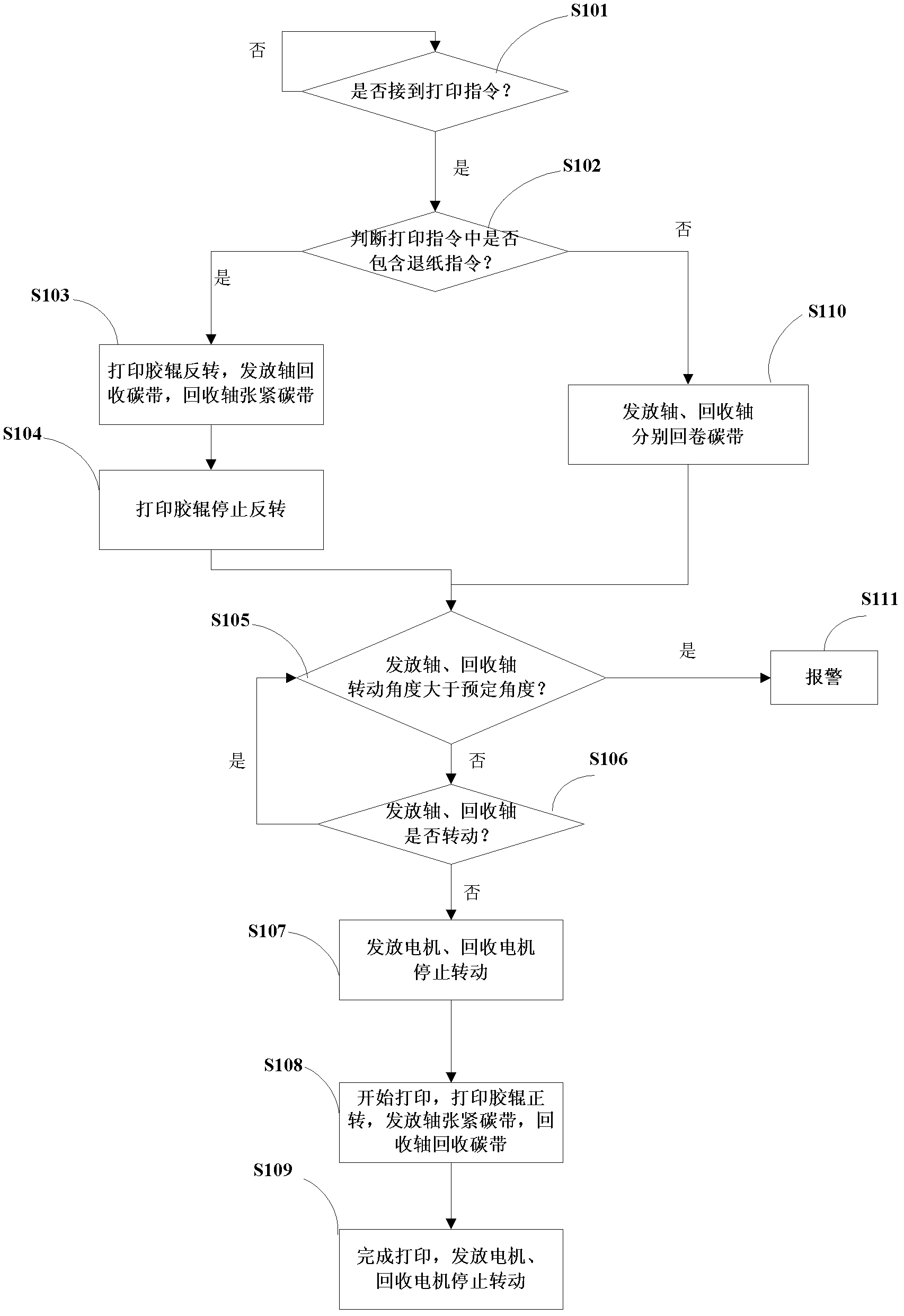

Heat transfer printing printer and control method of heat transfer printing printer

ActiveCN102873990AAvoid ribbon slackImprove print qualityInking apparatusElectricityThermal transfer

The invention discloses a heat transfer printing printer and a control method of the heat transfer printing printer. The heat transfer printing printer comprises a distributing shaft (21) and a recycling shaft (22), wherein the distributing shaft (21) is used for supporting unused thermal transfer ribbons; the recycling shaft (22) is used for rolling back used thermal transfer ribbons; the heat transfer printing printer further comprises a distributing motor (23), a recycling motor (24) and a control mechanism, wherein the distributing motor (23) is in transmission connection with the distributing shaft (21) and is used for driving the rotation of the distributing shaft (21); the recycling motor is in transmission connection with the recycling shaft (22) and is used for driving the rotation of the recycling shaft (22); and the control mechanism is electrically connected with the distributing motor (23) and the recycling motor (24) and is used for respectively controlling the rotation of the distributing motor (23) and the recycling motor (24) before executing an printing operation so that the thermal transfer ribbon are wound on the distributing shaft (21) and the recycling shaft (22). According to the heat transfer printing printer and the control method of the heat transfer printing printer, the relaxation of the thermal transfer ribbons can be avoided, and then the printing quality is improved.

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

Humidification type printing machine

The invention discloses a humidification type printing machine and belongs to the field of printing machines. The printing machine comprises a machine frame and a conveying belt, wherein the conveying belt is mounted on the machine frame; a printed product is arranged on the conveying belt; a printing device, a drying device and a cooling device are arranged in sequence in a moving direction of the conveying belt. The humidification type printing machine further comprises a controller, wherein the printing device, the drying device and a cooling tank are connected with the controller; a water tank is arranged beside the machine frame; a humidification module is arranged in the cooling device and connected with the controller; a water outlet pipeline is arranged at the top of the water tank and connected with the humidification module; a water inlet is formed in the bottom of the water tank. According to the printing machine, the problem of quality influence due to water loss of the printed product is solved; the printing machine has the advantages of capabilities of automatically detecting a humidity value, automatically spraying water and controlling a water spray amount.

Owner:FUYANG FEIYANG PRINTING CO LTD

Toner having Improved Charge Characteristics

ActiveUS20100159378A1Improve print qualityImprove the level ofDevelopersCerium oxideElectrical and Electronics engineering

This invention provides a toner with improved charge and charge stability by suitable addition of extra particulate additives (EPA) such as aluminum cerium oxide and / or cerium zirconium oxide. The additives may be combined with toner in a conical mixer having selected temperature control. The invention also provides toner which may provide reduced print quality defects such as ghosting or residual image and fade-to-color.

Owner:LEXMARK INT INC

Optical information-recording medium and method for producing the same

InactiveUS20080014401A1Improve print qualitySatisfactory solubilityLayered productsPretreated surfacesSolventBoronic acid

A first write-once type recording layer, on which information can be recorded by being irradiated with a laser beam having a wavelength of not more than 450 nm, is provided on a first substrate of a first optical information-recording medium. A dye compound, which contains boron as a constitutive element, is contained in the first write-once type recording layer. Preferred examples of the dye compound include boronic acid. In particular, it is preferable to use a compound having a boroxin moiety formed by condensation of boronic acid. The condensation of boronic acid can be advanced such that a solution, which is prepared by dissolving boronic acid in a solvent, is applied onto the first substrate to form the first write-once type recording layer, and then the first write-once type recording layer is subjected to an annealing treatment.

Owner:FUJIFILM CORP

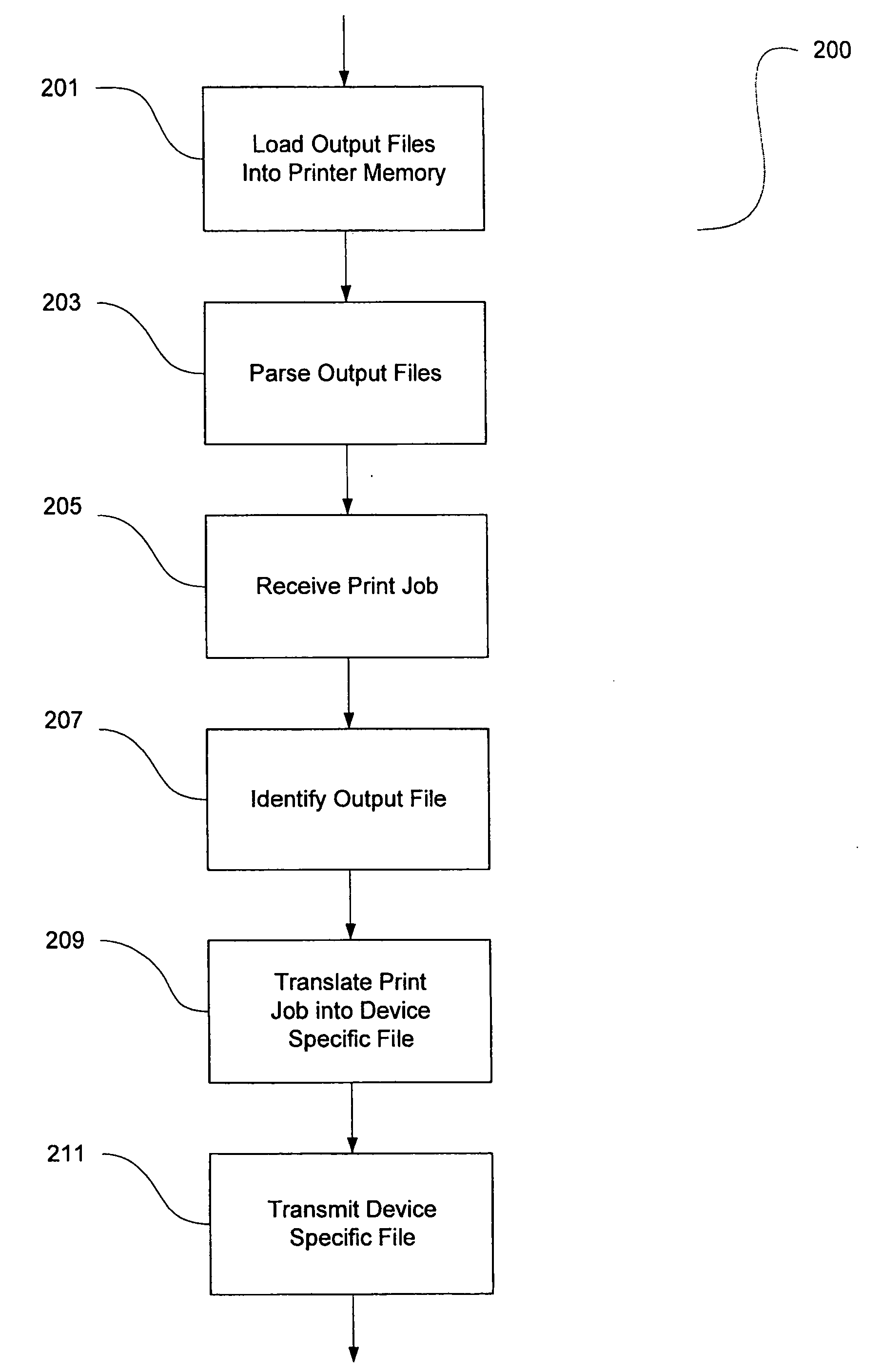

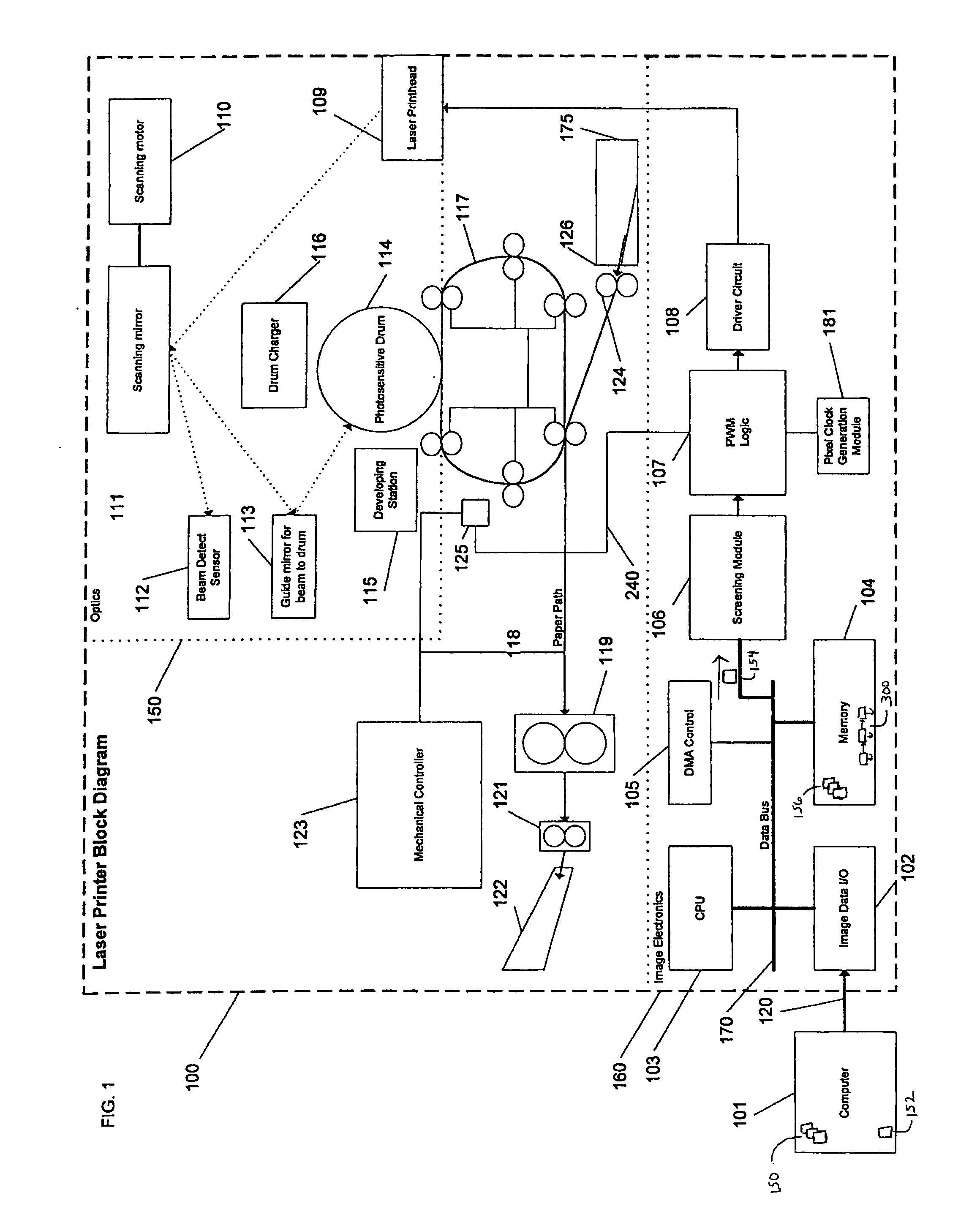

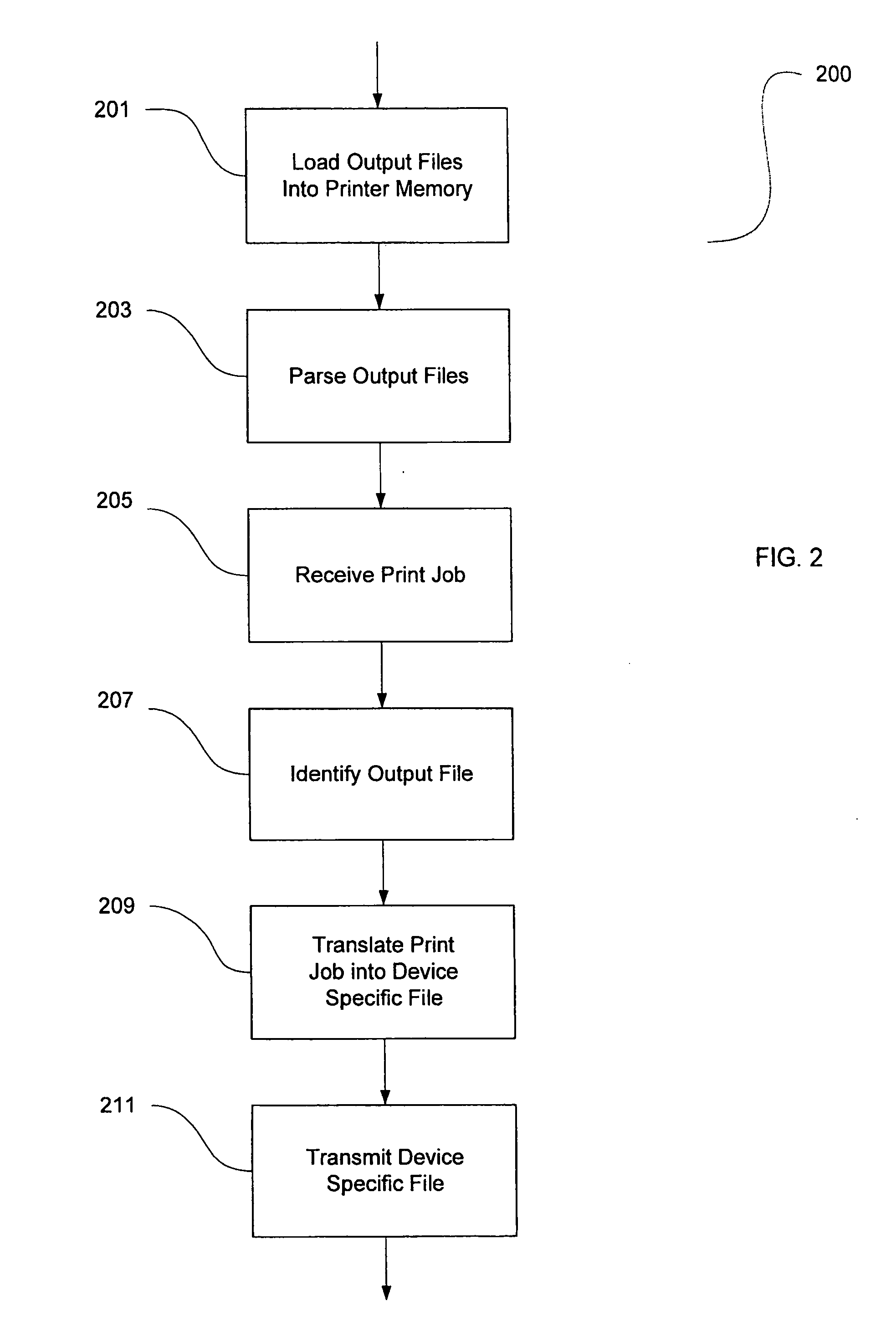

Systems and methods for loading an output profile

InactiveUS20090086272A1Improve print qualityVisual presentation using printersInput/output processes for data processingSystem usageData file

Systems in accordance with the presently claimed invention use parameters to choose the correct output file for translating the color values in a print job into device specific values in an output data file that may be used for printing. A data structure, such as a linked list of parameters, may be used to identify the correct output file to be used by the printer to form the correct device specific data file. The color values for each pixel in the device specific data file may allow a printed document to exhibit high color quality.

Owner:KONICA MINOLTA LAB U S A INC

Adjustable printing device

PendingCN109397888AAvoid contact with occludersImprove print qualityTypewritersOther printing apparatusControl circuit

The present invention discloses an adjustable printing device. The adjustable printing device comprises a body, the body is internally provided with a control circuit board and an ink box storing ink,the lower end of the body is provided with a printing head electrically connected with the control circuit board, and an ink outlet is arranged at the ink box corresponding to the printing head. Roller modules are symmetrically arranged at two sides of the printing head of the body, the roller modules are installed on the body through a regulation mechanism and can regulate the installation height through the regulation mechanism to achieve regulation of a distance from the working surface of the printing head. The roller modules can regulate the distance extruded out of the printing workingend through the regulation mechanism and can return to the side of the body through regulation of the regulation mechanism so as to fit different surfaces to be printed and meet the printing demands of different printing articles, and when the surface to be printed is small and there is a shielding object around, the roller modules can be returned to and located at the side of the body so as to prevent the roller modules from butting against the shielding object, effectively improve the printing quality and widen the application range.

Owner:ZHONGSHAN SANZANG ELECTRONICS TECH

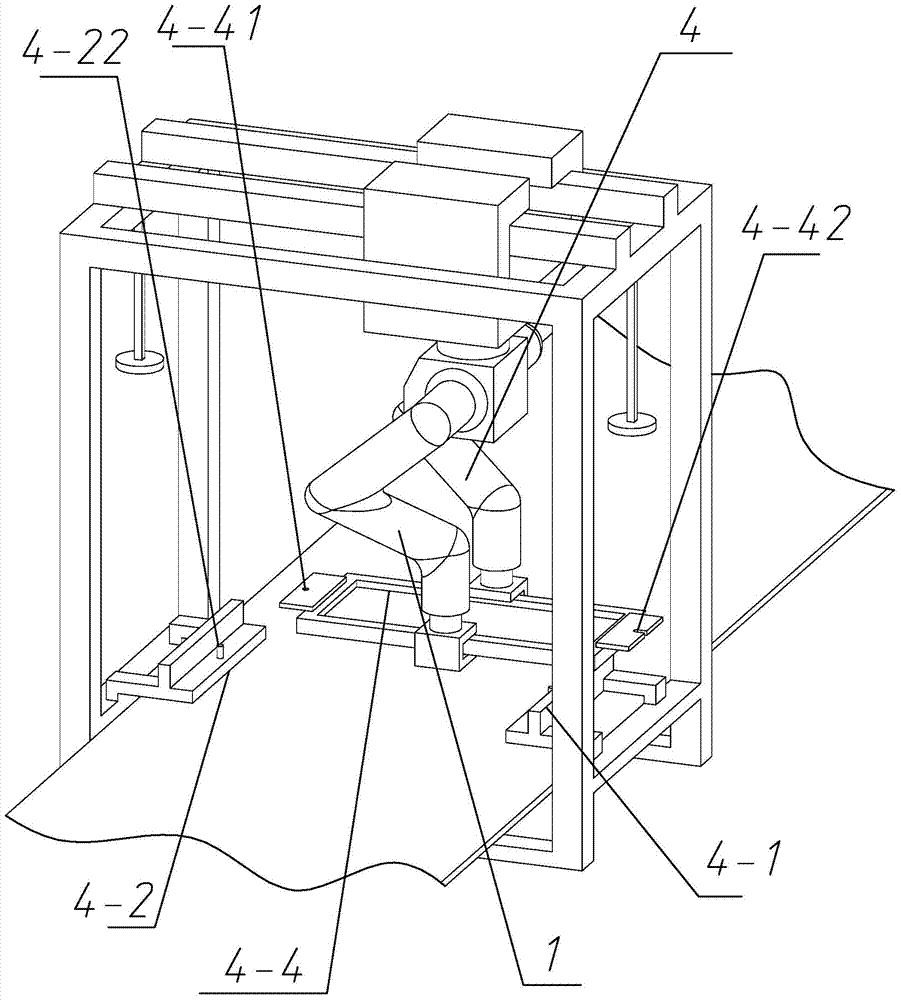

Robot printing sample-making system

The invention provides an intelligent printing sample-making system which comprises a machine frame. A pneumatic screen supporting frame, a frame and flat screen printing guide belt rollers provided with a flat screen printing guide belt are arranged at the two ends of the machine frame, a transverse moving guide rail provided with a robot is arranged at the upper portion of the frame, the robot is provided with a left mechanical arm and a right mechanical arm, a screen clamping device, a size container clamping device and a scraper clamping device are arranged in the frame, the left mechanical arm and the right mechanical arm of the robot are provided with a left automatic hand changing device main disc and a right automatic hand changing device main disc respectively, and the machine frame is further provided with a screen placing position judging device based on a CCD camera. The robot printing sample-making system accurately controls movement of the mechanical arms and different clamping devices, is matched with other auxiliary systems and mechanisms, smartly achieves different functions, and achieves standard, automatic and intelligent printing.

Owner:SHAOXING COUNTY RUIQUN TEXTILE MACHINERY TECH

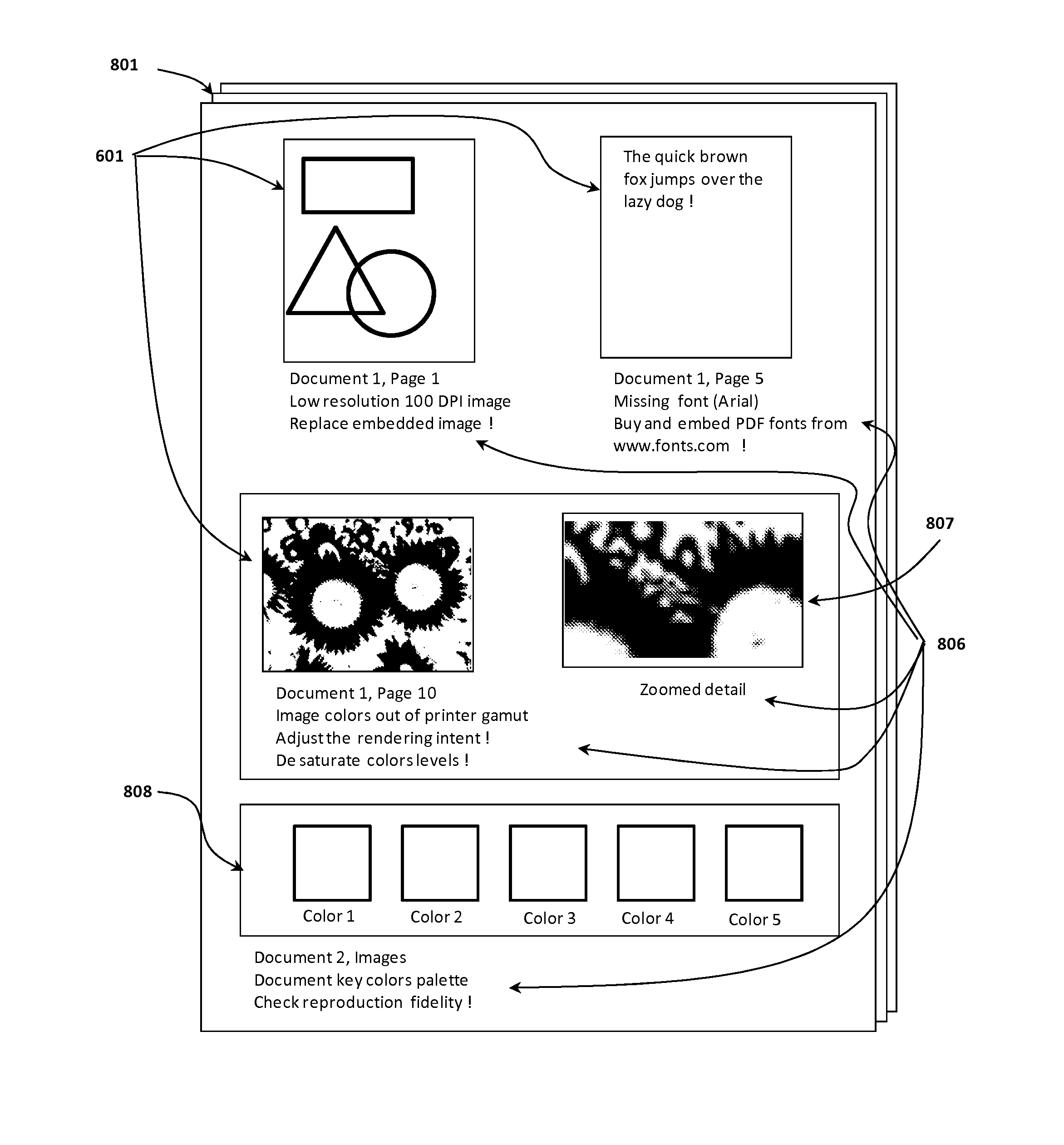

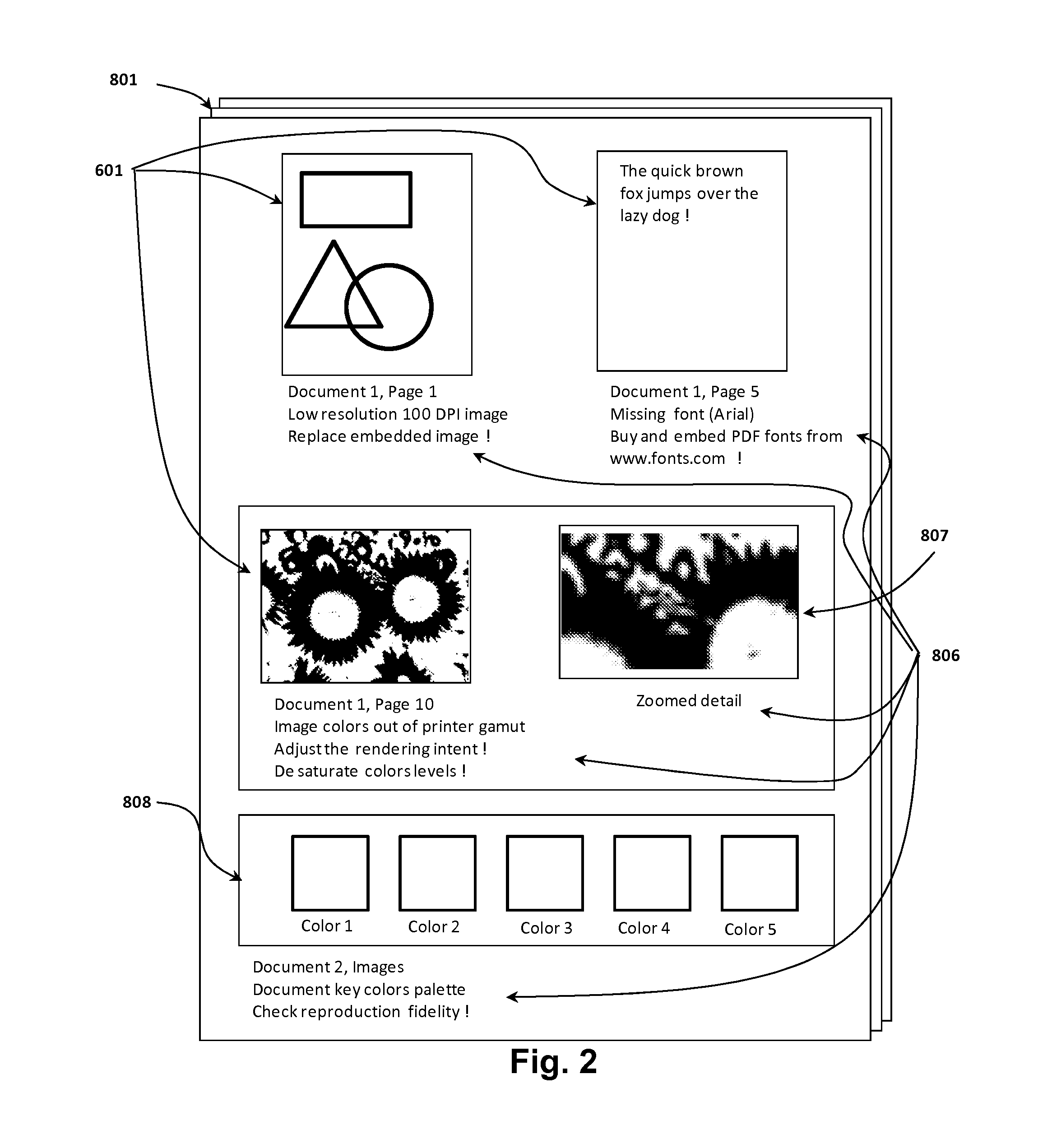

Method for generating a proof of a print job comprising a document to be printed with parameters and system therewith

InactiveUS20160070995A1Improve print qualityEasy and fastVisual presentation using printersDigital output to print unitsPaper documentDocument preparation

Owner:OCE TECH

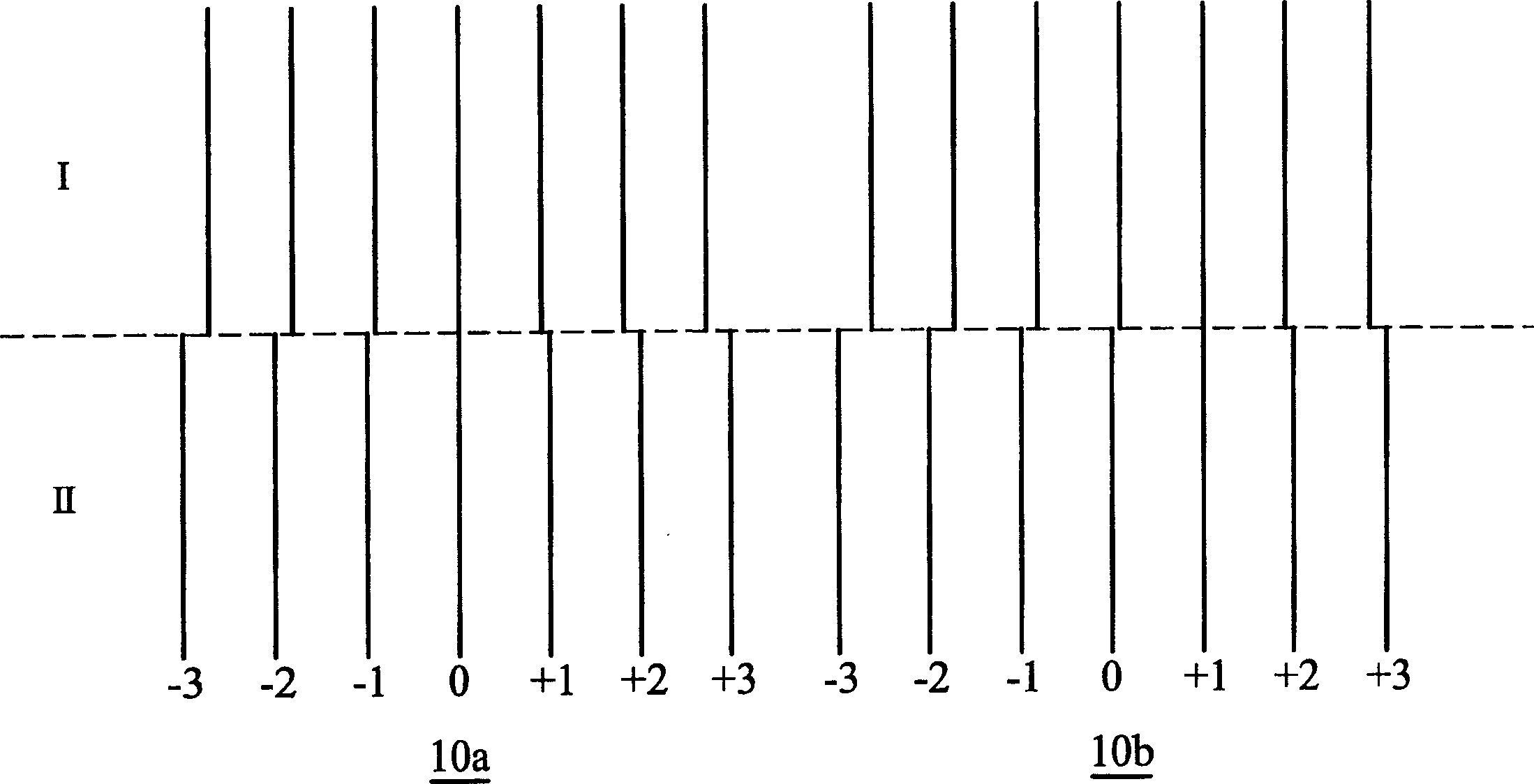

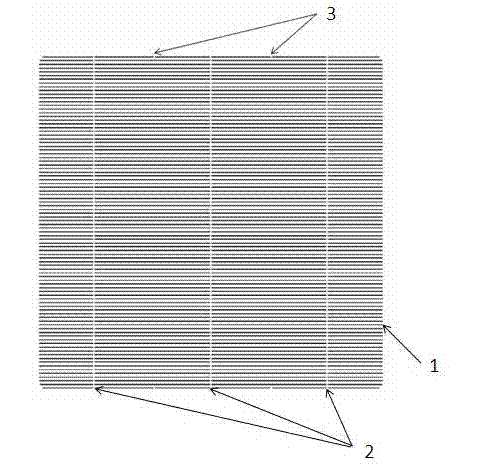

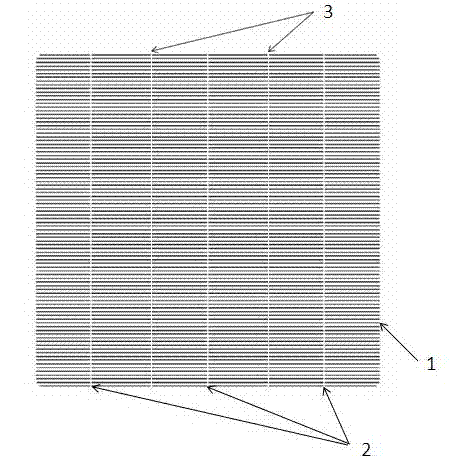

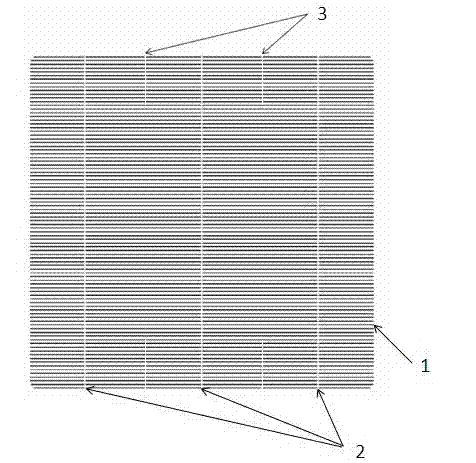

Printing correction unit and method for ink gun

InactiveCN1796124AImprove print skewImprove print qualityOther printing apparatusCorrection methodData shipping

The present invention relates to an ink gun printing correction device and its printing correction method. Said method includes the following steps: detecting skew direction of said ink gun, receiving several line data, every line data is correspondent to jet nozzles of every line on said ink gun from top to bottom, dividing every said line data into N zones from top to bottom, printing and correcting continuous N line data in said line data and transferring the corrected line data to ink gun to print said corrected line data.

Owner:IND TECH RES INST

Forming platform for 3D printer

ActiveCN109228309AImprove efficiencyImprove print qualityManufacturing platforms/substrates3D object support structuresDrive motorMagnet

The invention discloses a forming platform for a 3D printer. The forming platform comprises a base, wherein a platform is arranged at the upper end of the base, a rotary disc is arranged at the middlepart of the platform, connecting rods are symmetrically arranged at the side ends of the rotary disc, and the outer side ends of the connecting rods are connected with a carrier stage; a supporting seat is arranged under the carrier stage, ejecting needles are arranged at the upper end of the supporting seat at intervals, the upper ends of the ejecting needles penetrate into and extend out of theplatform; a magnet is arranged at one side in the platform, a driving motor is arranged at the other side in the platform and is in drive connection with a rotary shaft the rotary shaft is arranged in the platform and is eccentrically provided with a jacking wheel which can extend out the platform and contacts with the supporting seat; a vertical column is arranged at the upper end of the platform and at one side of the carrier stage, and is provided with a cylinder; a piston rod of the cylinder is connected with a horizontally-arranged fork frame. The invention aims at providing the formingplatform for the 3D printer, and products can be quickly taken down from the platform.

Owner:保靖锐恩电子有限责任公司

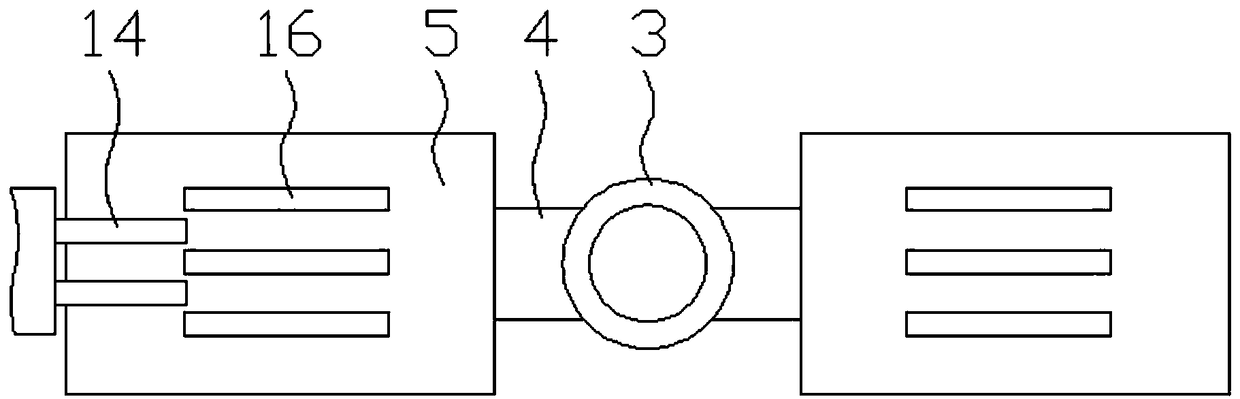

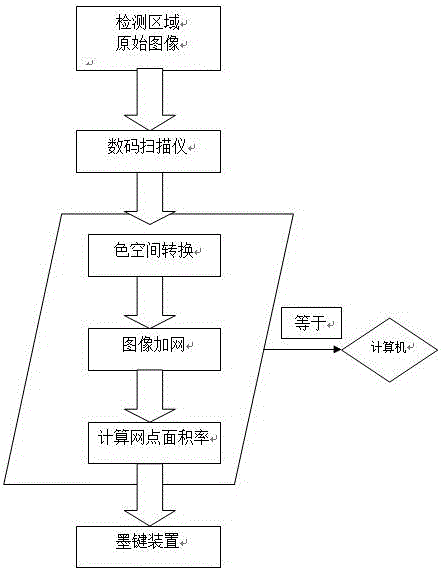

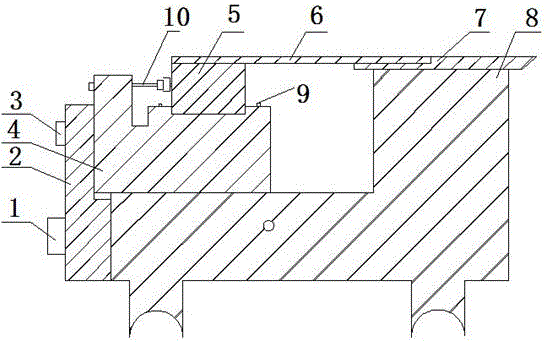

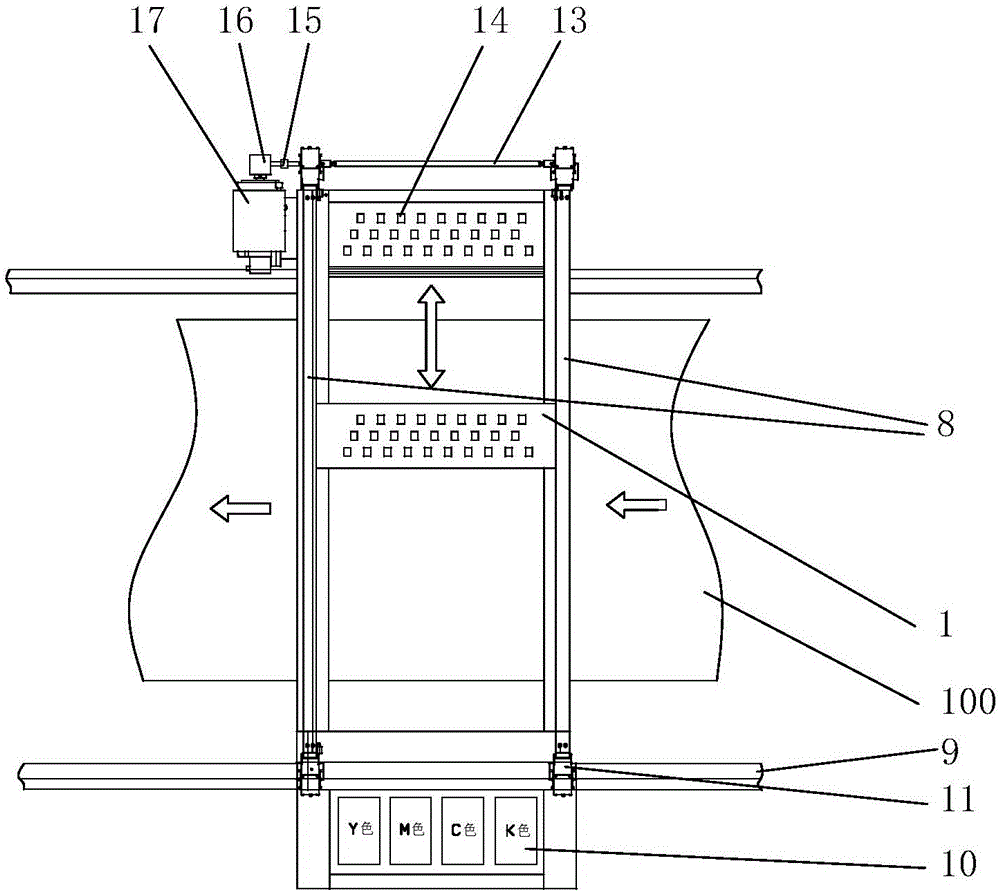

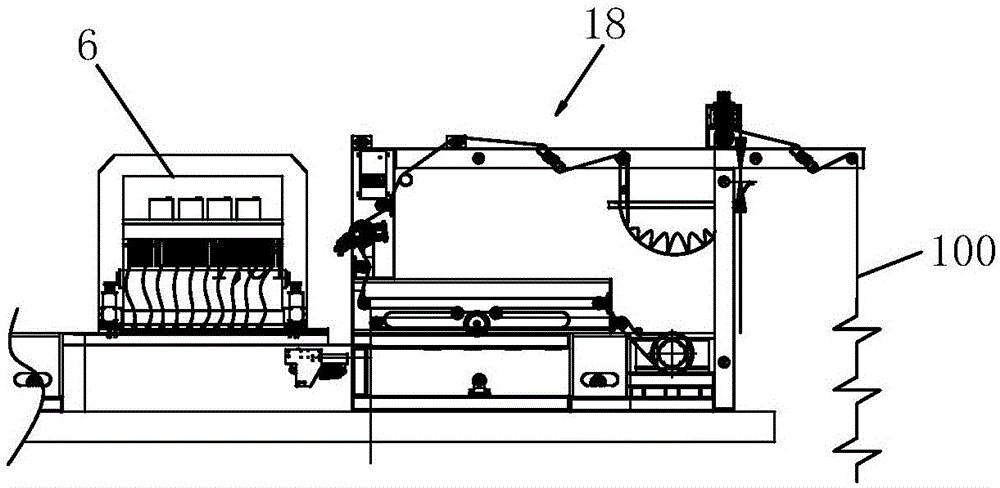

Intelligent ink supply device and method for printing press

ActiveCN106113936AReduce Ink Supply ErrorsImprove print qualityPrinting press partsEngineeringElectrical and Electronics engineering

The invention relates to an intelligent ink supply device and method for a printing press and belongs to the technical field of printing. The intelligent ink supply device comprises a digital scanner, a computer and an ink key device. The digital scanner is used for obtaining a digital image from a printing original, the computer is used for analyzing and processing the digital image and sending out an instruction to control the step rate of a motor, and the ink key device is made to intelligently supply ink. According to the intelligent ink supply device and method for the printing press, by means of intelligent ink supply, ink supply errors are reduced, and the quality of printed matter is improved to a certain degree. When the intelligent ink key device is used for printing products, operation is easy, operators can directly operate the intelligent ink key device, the labor intensity of operators is relieved, printing cost is lowered, and printing work efficiency is improved.

Owner:KUNMING UNIV OF SCI & TECH

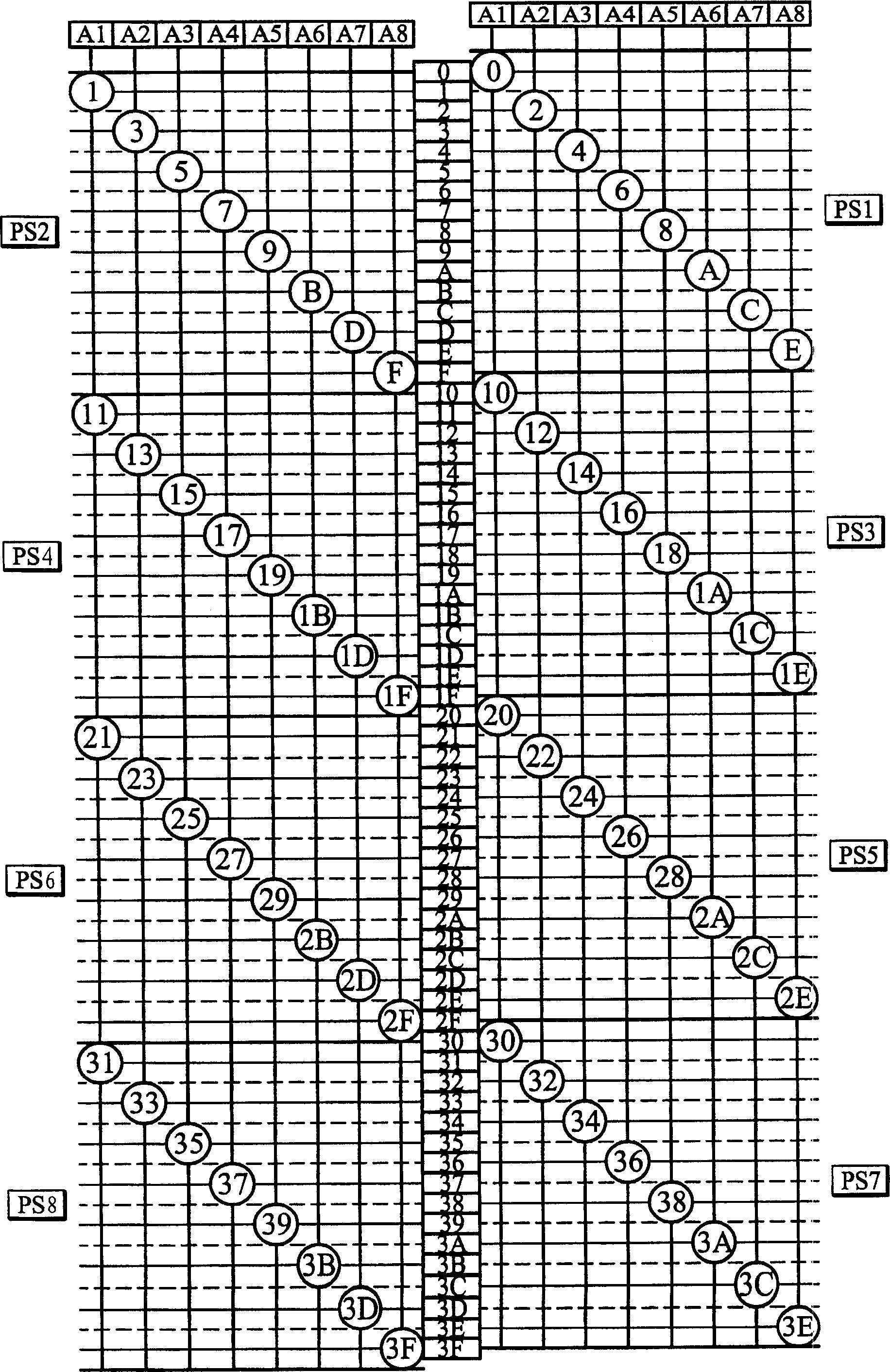

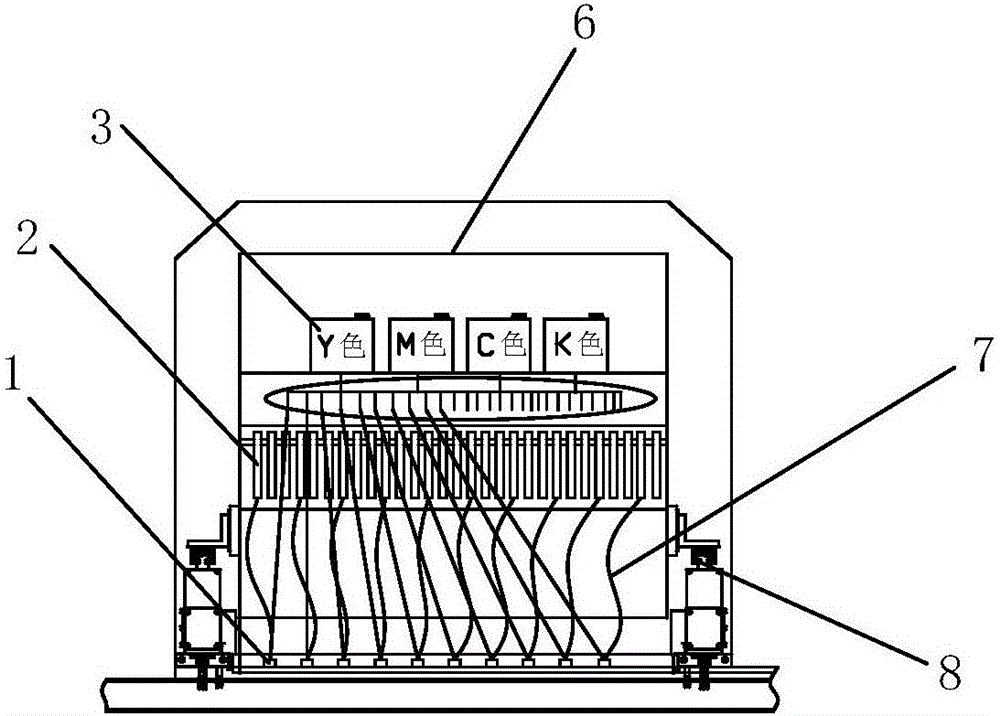

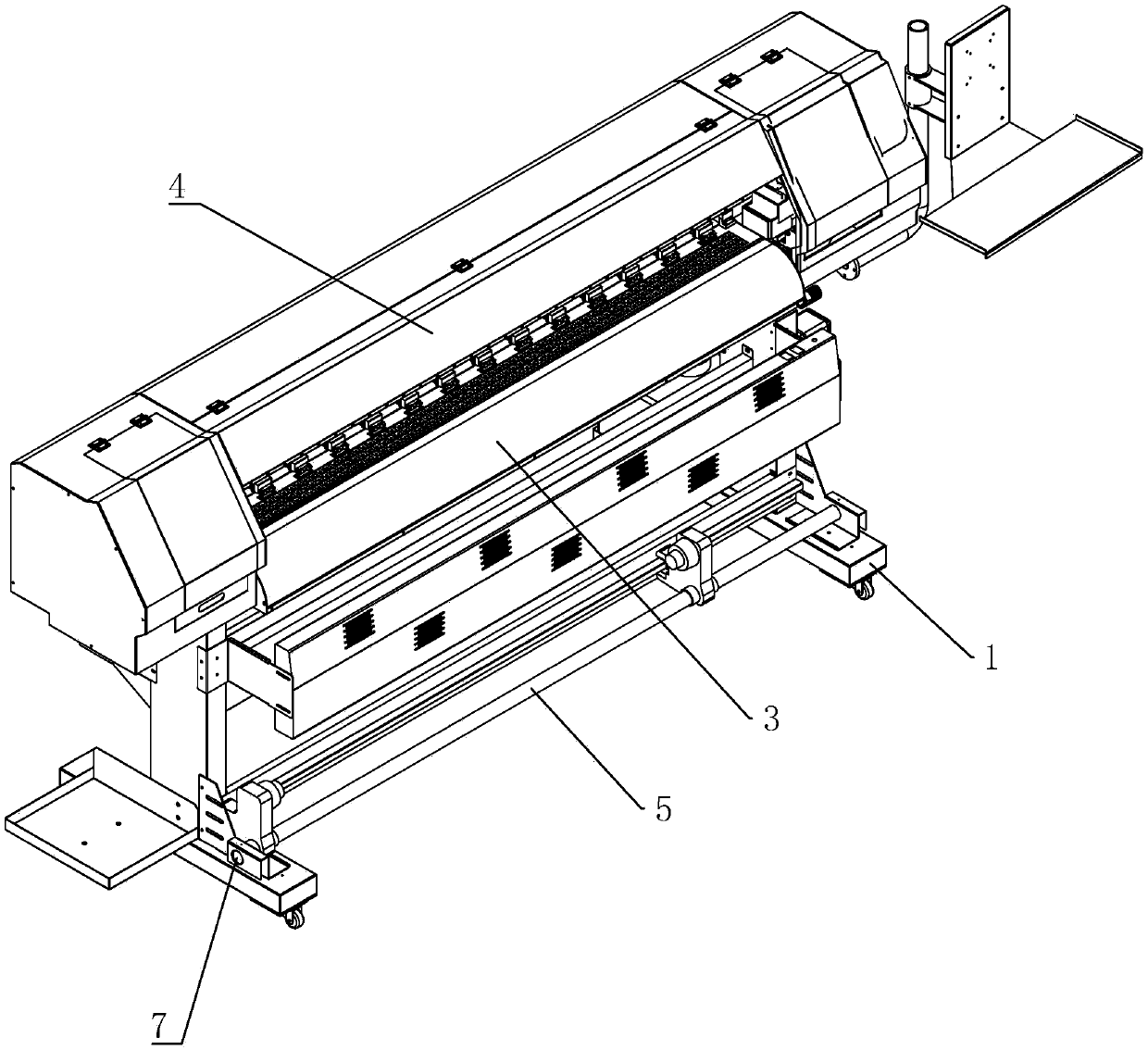

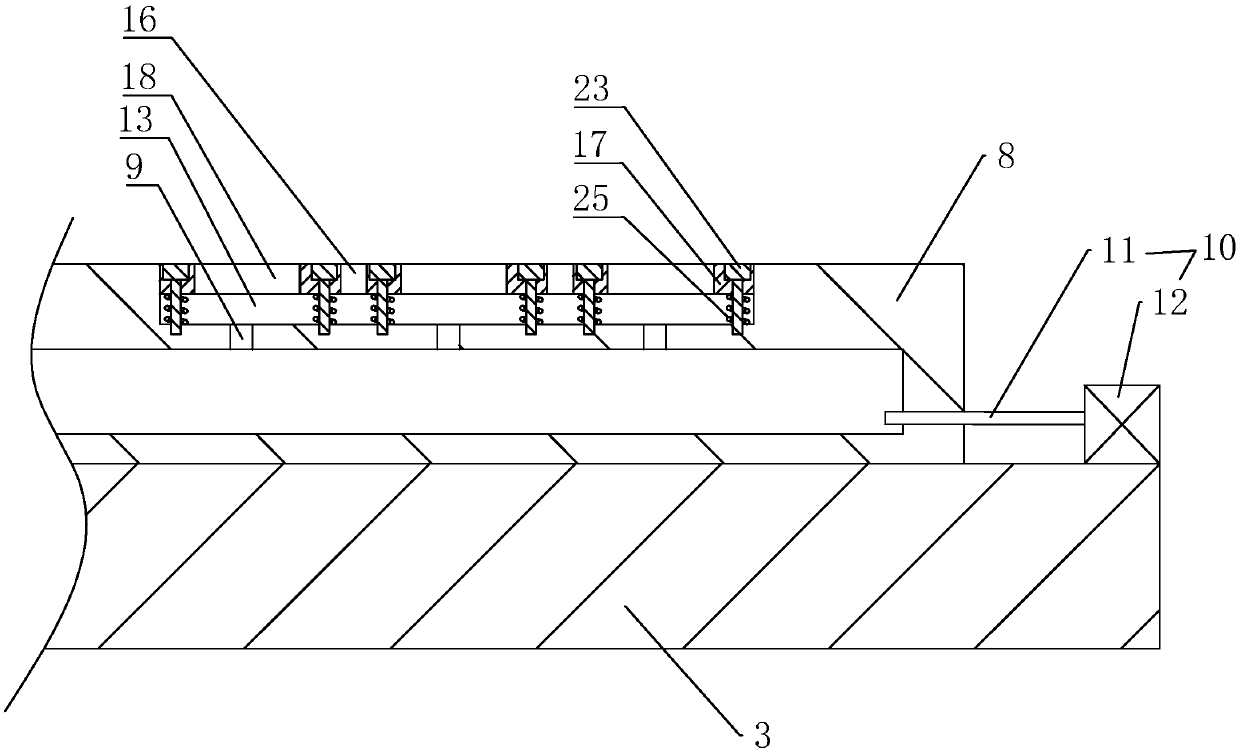

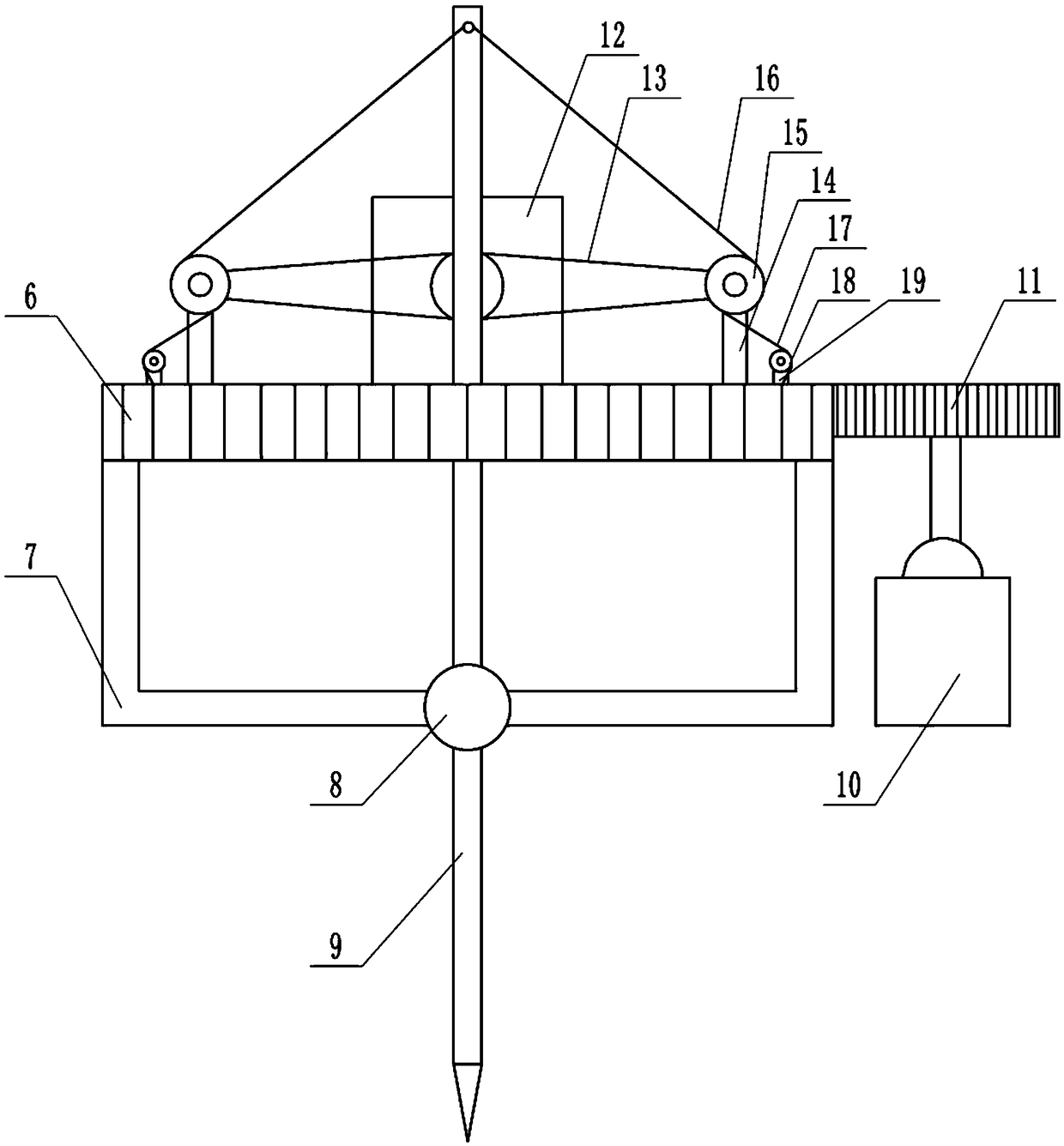

Digital inkjet printing device of conventional flat screen printing machine

The invention discloses a digital inkjet printing device of a conventional flat screen printing machine. A spray head servo motor rotates to drive a connecting rod, a connecting rod gear, a chain and a pinion to rotate, and finally drives a scanning type integrated transferring trolley to move to and fro along the width direction of greige cloth; two pairs of position sensors in an optical grating read head collect the accurate displacement signals of the scanning type integrated transferring trolley, and sends the accurate displacement signals of the scanning type integrated transferring trolley to a controller; the controller sends inkjet printing information to a spray head board card through a cable wire to control a multi-spray-head group to work; a positive-pressure air supply in an ink line system delivers various colors of ink in a primary ink box to a secondary ink box; the various colors of ink is sprayed on the greige cloth through the multi-spray-head group controlled by the spray head board card; and a guide belt servo motor accurately controls a printing guide belt to move, and finally drives the greige cloth to move. The digital inkjet printing device of the conventional flat screen printing machine is also provided with an ink stack moisture preserving device and ink scraping knife leathers, so as to maintain spray heads. The digital inkjet printing device of the conventional flat screen printing machine has the beneficial effects of being reasonable in structure, modifying a conventional printing machine, improving printing quality and being green and environment-friendly.

Owner:浙江东山广信数码印花设备有限公司

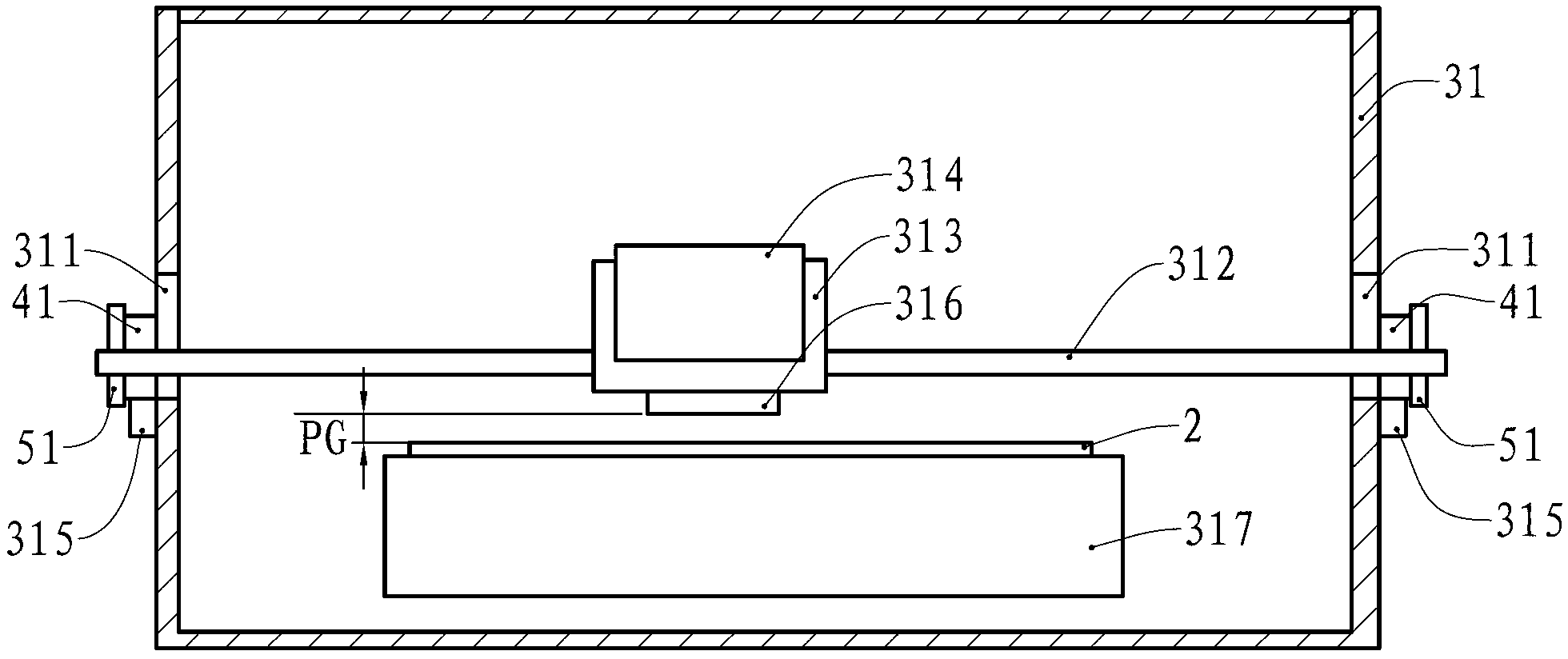

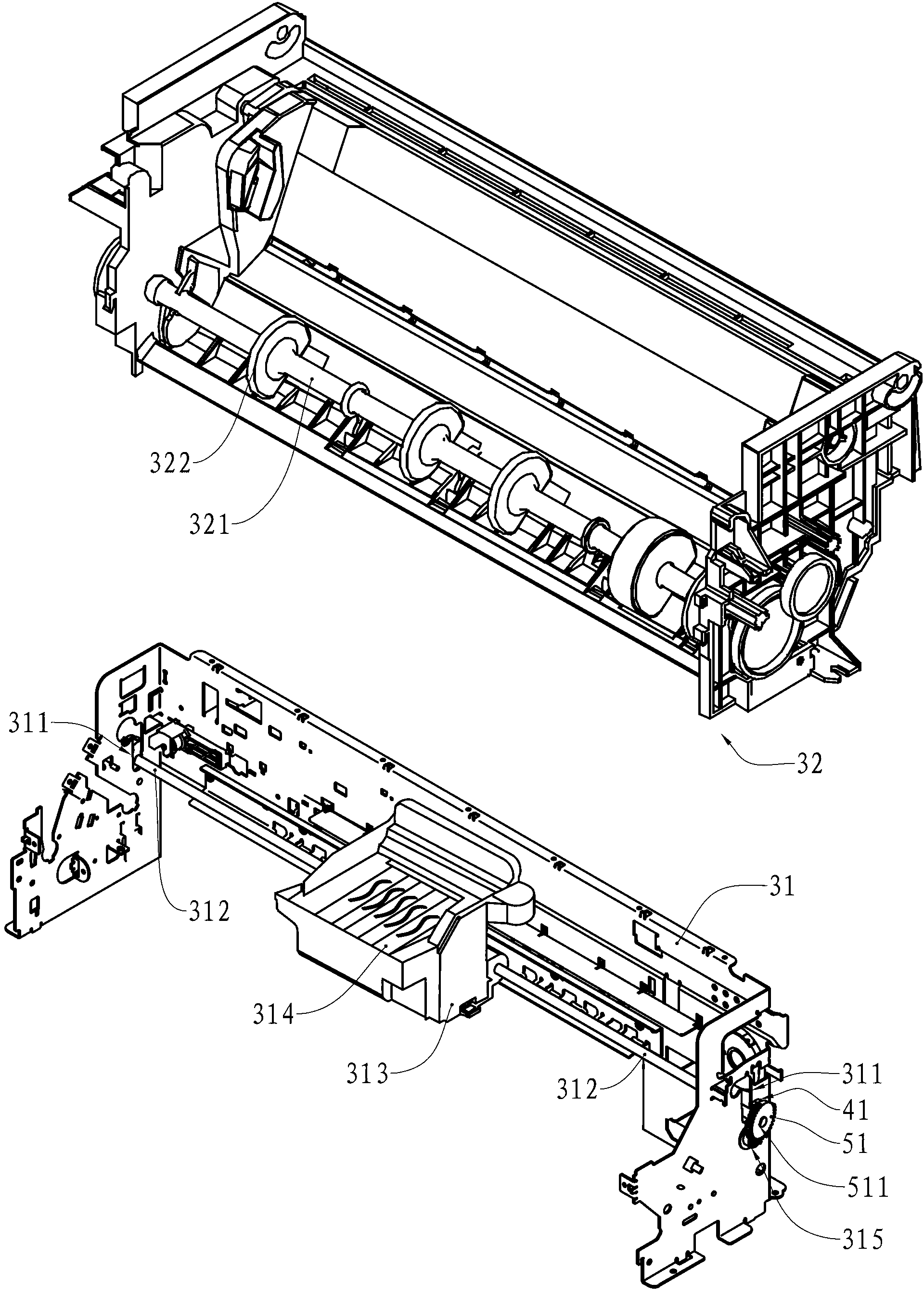

Gap adjusting device, ink-jet printer and modification method thereo

The invention provides a gap adjusting device, an ink-jet printer and a modification method of the ink-jet printer. The gap adjusting device comprises a guide rod, a cam and a gear are arranged on the end portions of the guide rod, a first shaft hole is formed in the middle portion of the cam, the end portion of the guide rod penetrates through the first shaft hole, the gear is arranged outside the cam, a second shaft hole is formed in the middle portion of the gear, and the end portion of the guide rod penetrates through the second shaft hole. The maximum distance between the outer edge of the cam and the center of the first shaft hole is larger than the radius of the root circle of the gear. The ink-jet printer is provided with the gap adjusting device. According to the modification method of the ink-jet printer, the cam is replaced to be arranged in the ink-jet printer. Adjusting of an imaging gap is achieved, an adjustable range is enlarged, and imaging can be smoothly carried out on flexible recording media and rigid recording media large in thickness.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

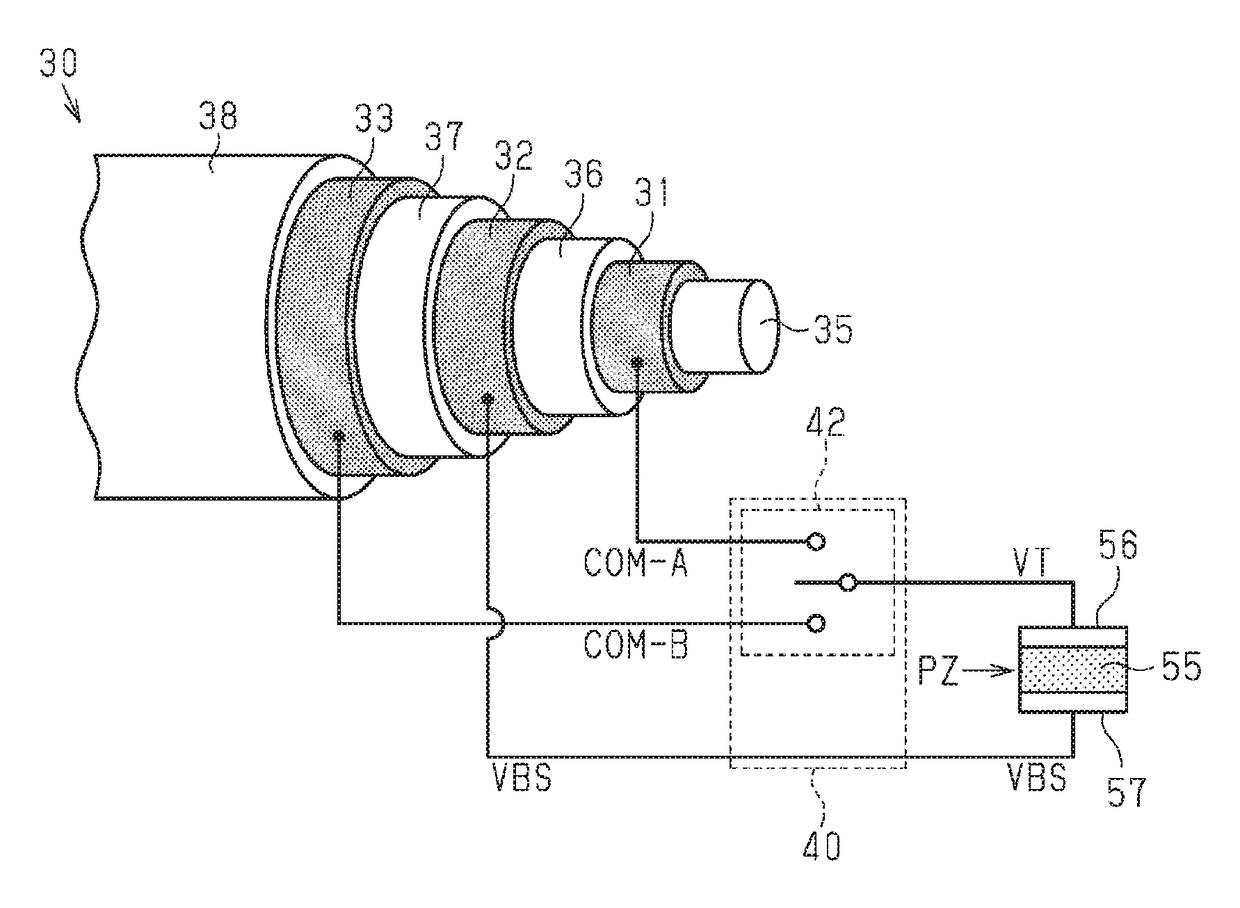

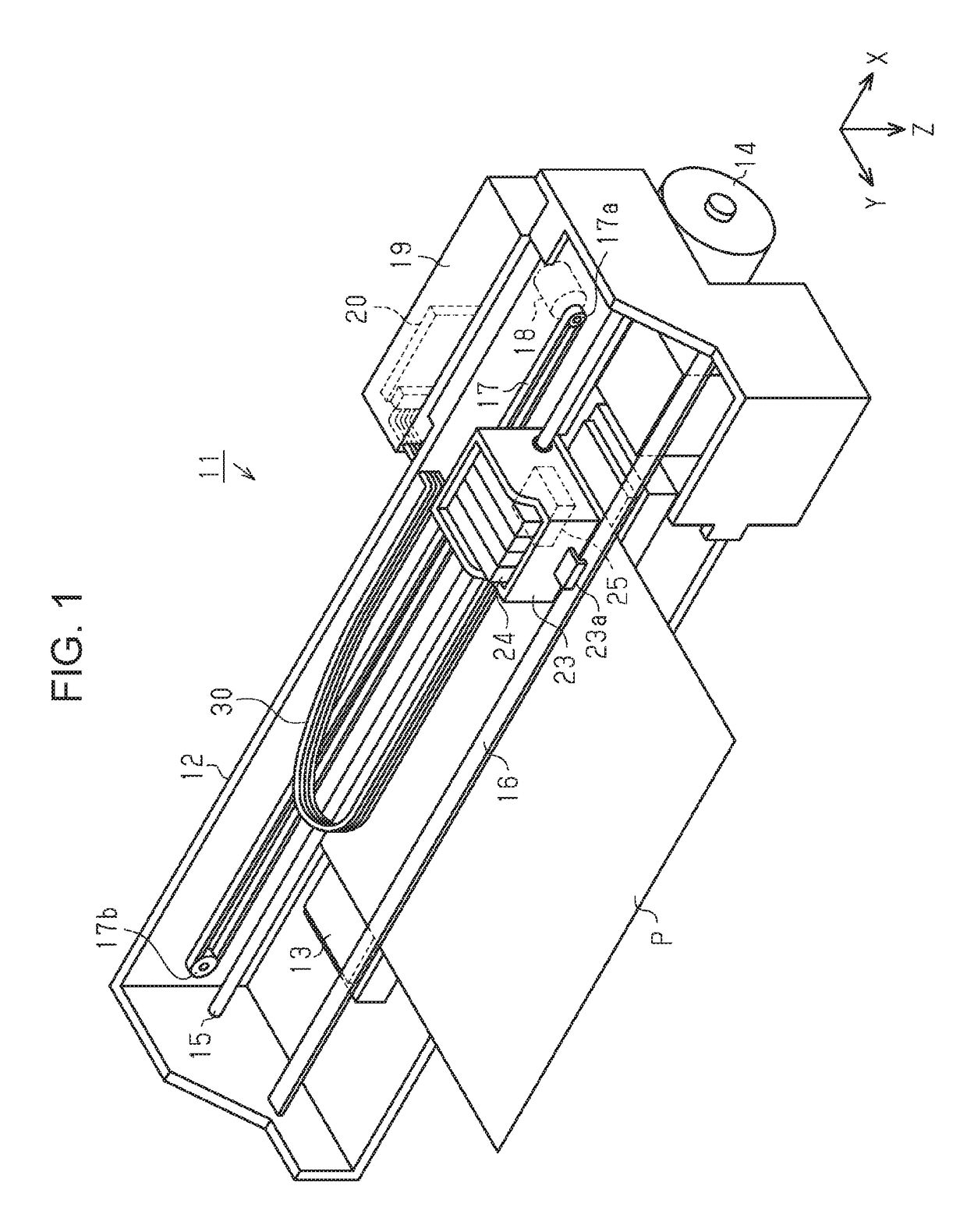

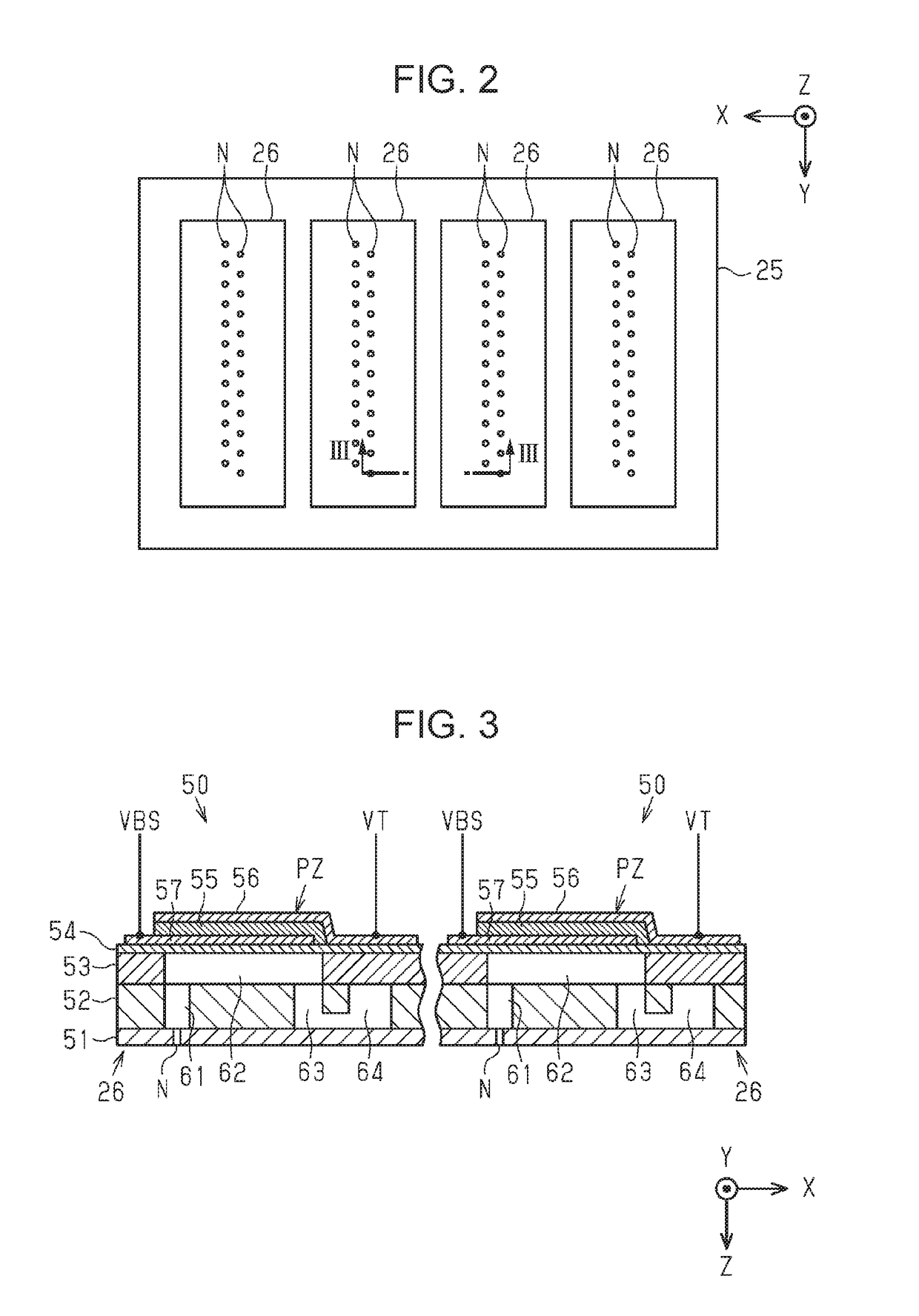

Printing apparatus and transmission cable

A printing apparatus including a voltage signal generation circuit configured to generate a plurality of voltage signals including a first voltage signal and a second voltage signal; and at least one transmission cable configured to transmit the plurality of voltage signals, the transmission cable including a first tubular conductor including a hollow core and configured to transmit the first voltage signal, a second tubular conductor disposed over an outer circumference of the first tubular conductor with a first insulator between the outer circumference of the first tubular conductor and an inner circumference of the second tubular conductor and being in a constant-voltage applied state, and a third tubular conductor disposed over an outer circumference of the second tubular conductor with a second insulator between the outer circumference of the second tubular conductor and an inner circumference of the third tubular conductor and configured to transmit the second voltage signal.

Owner:SEIKO EPSON CORP

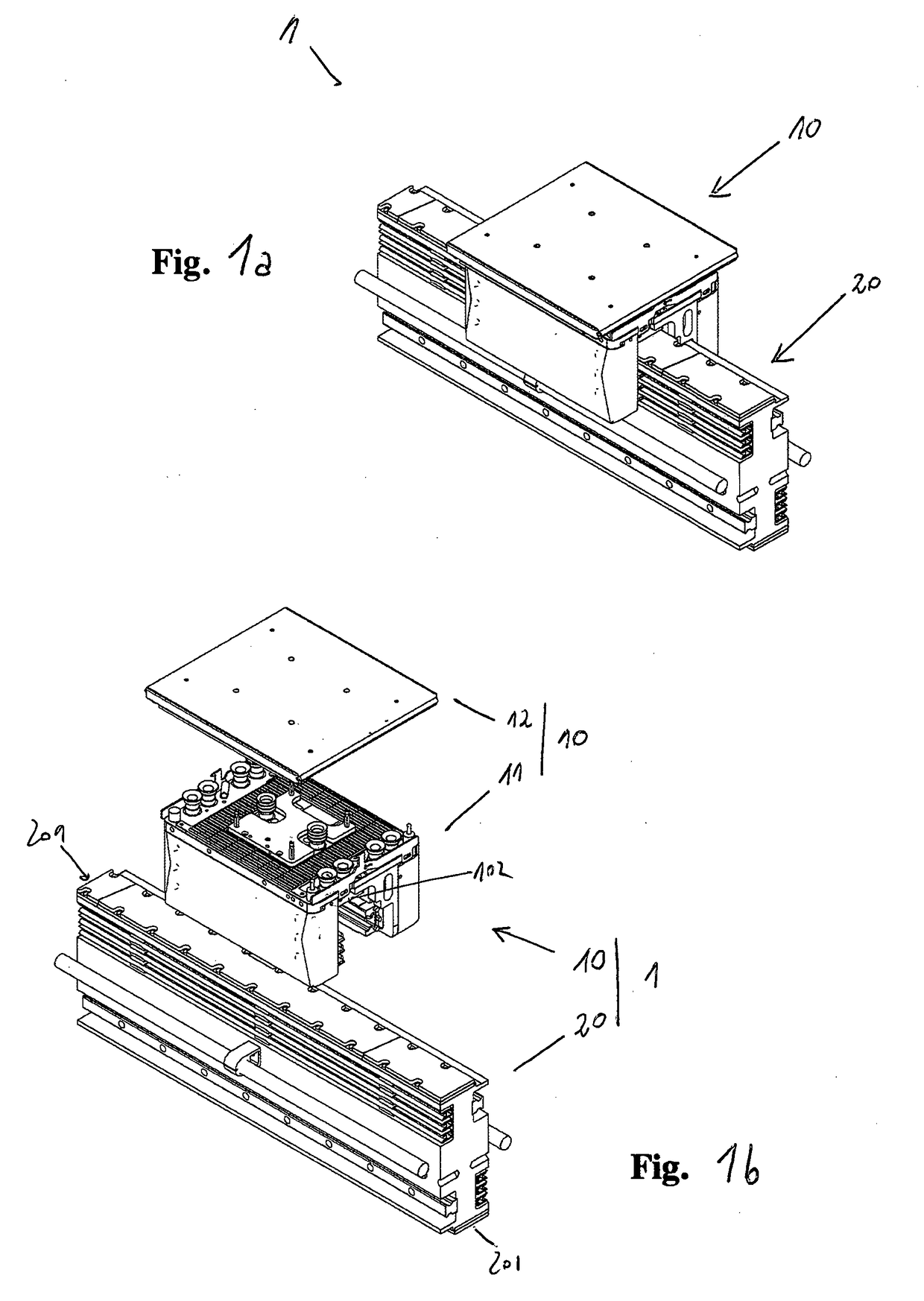

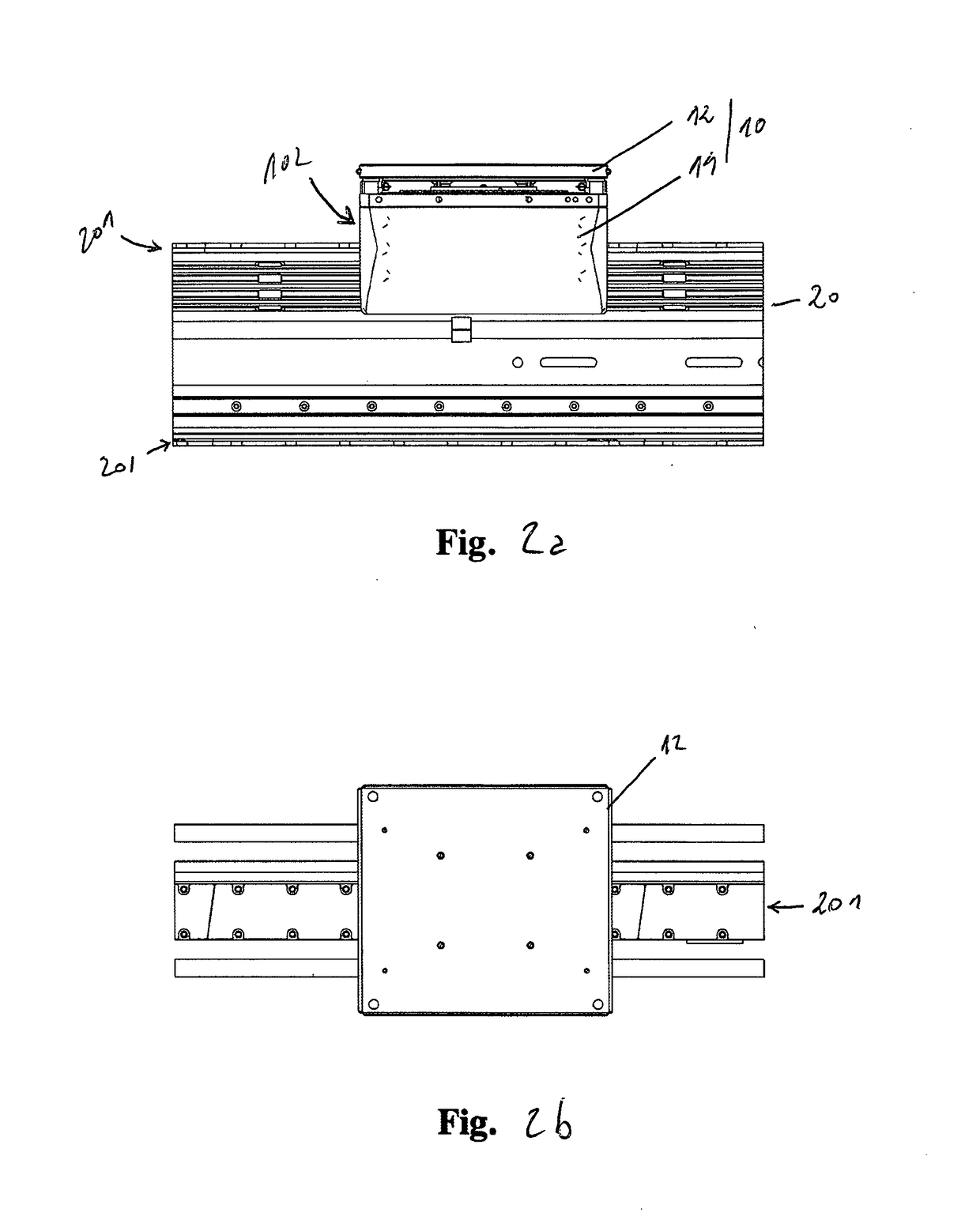

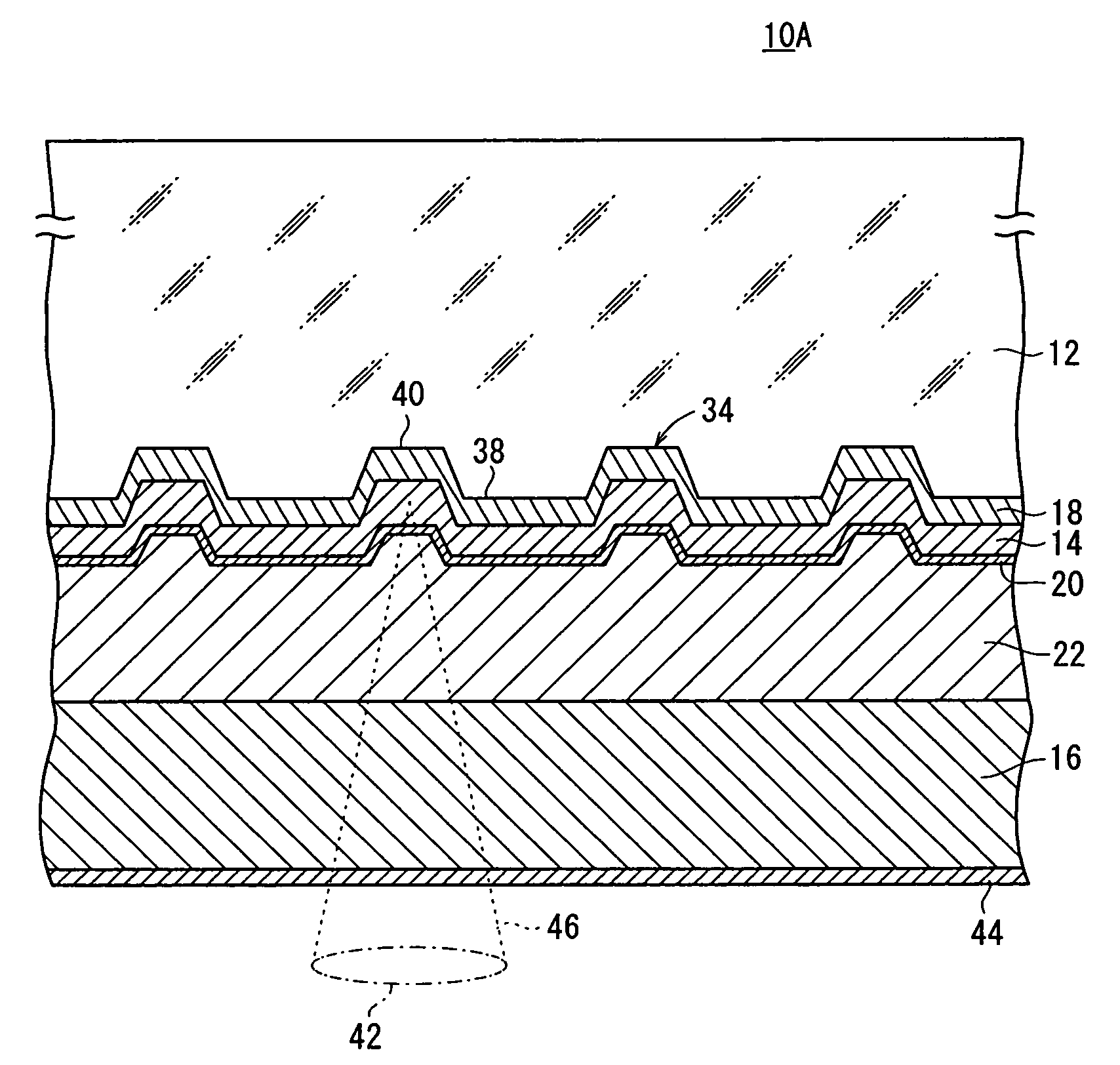

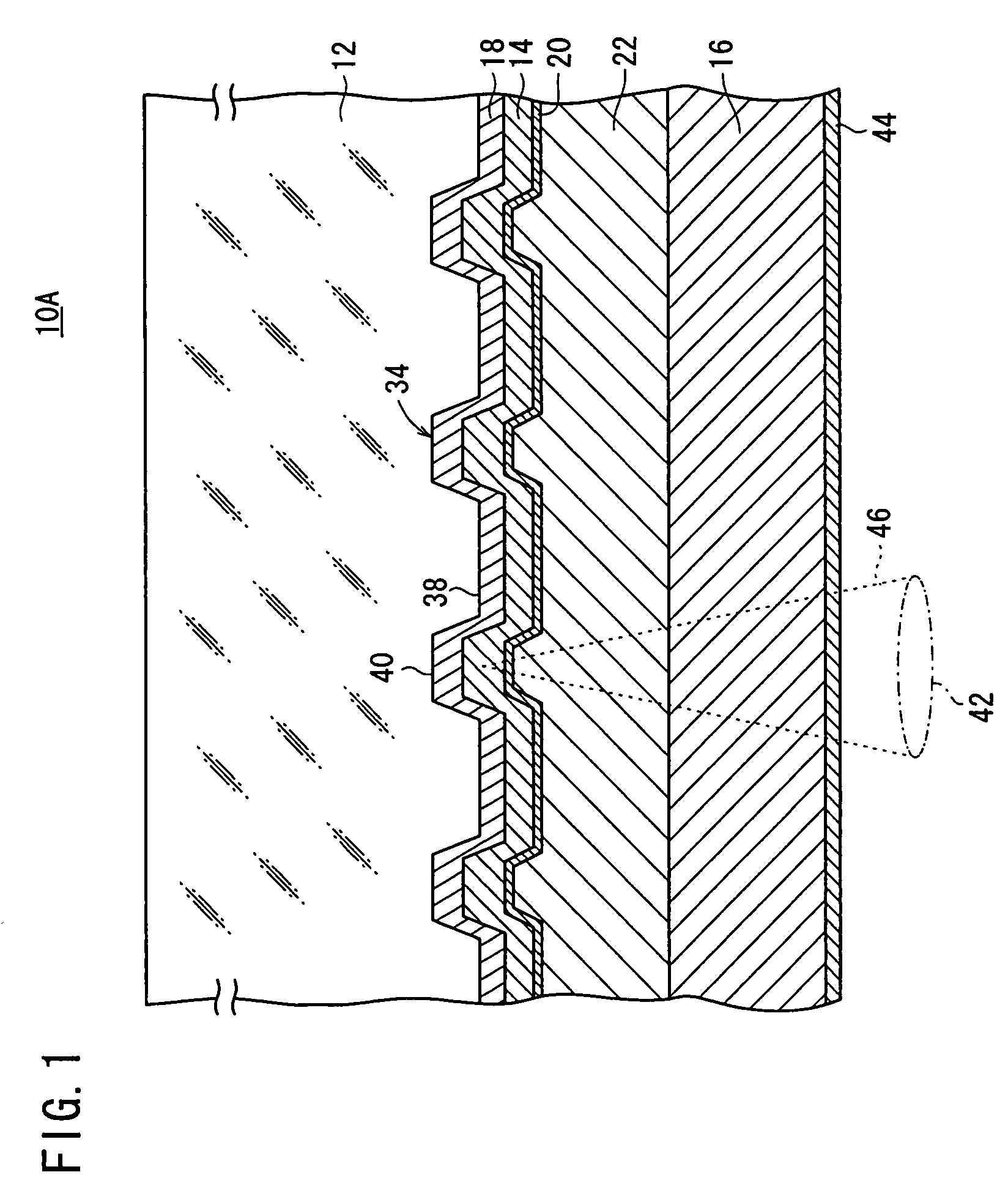

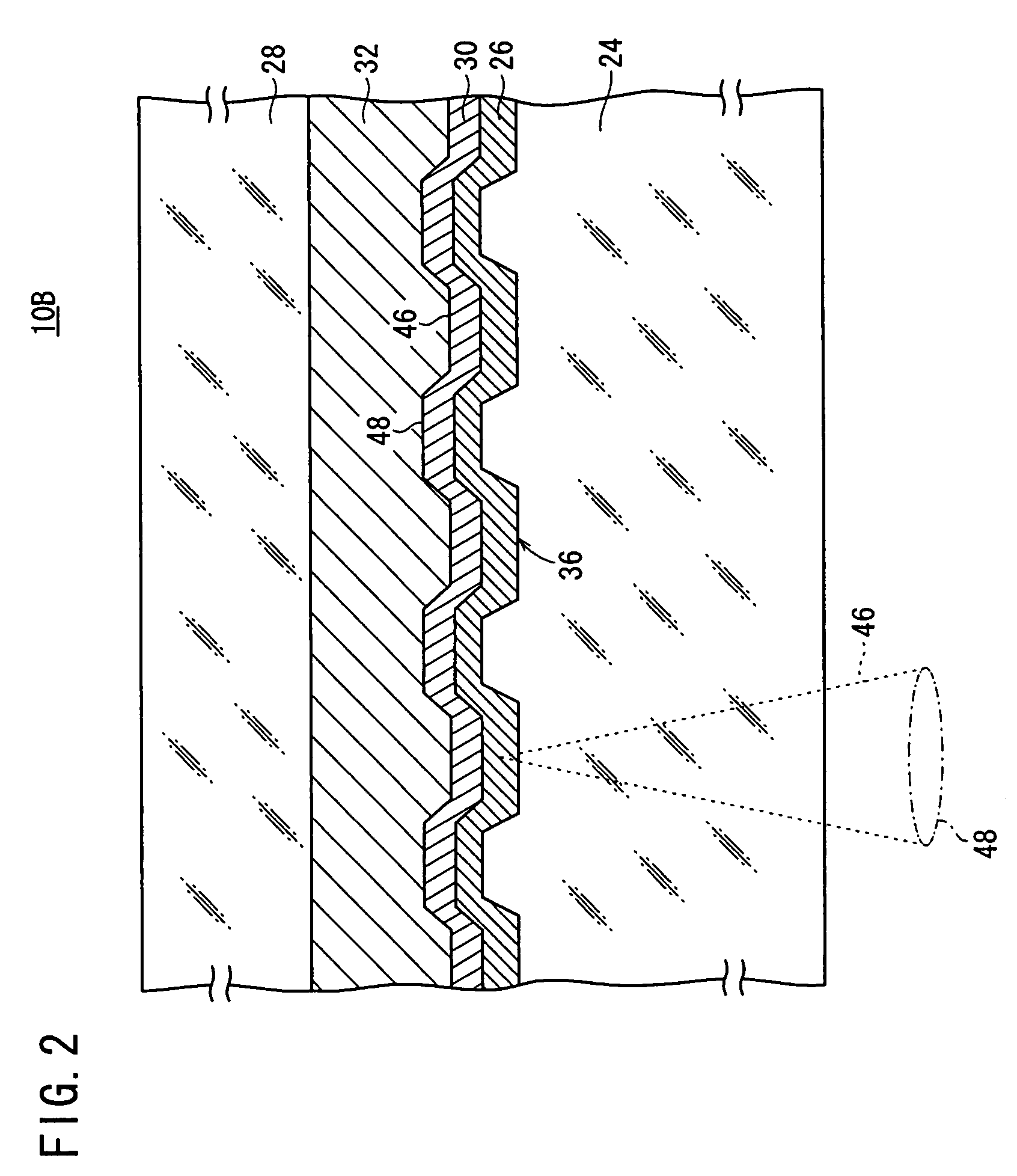

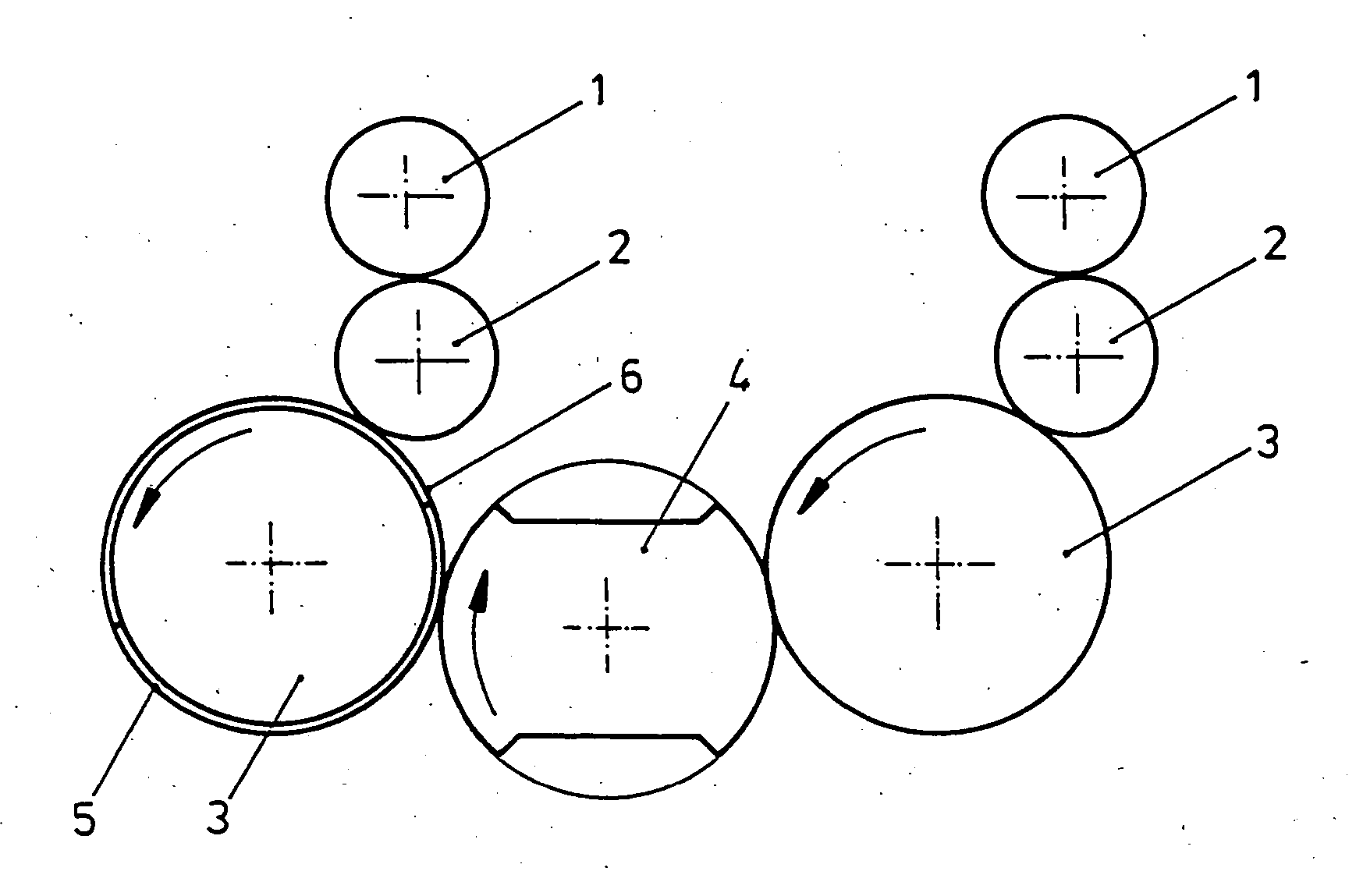

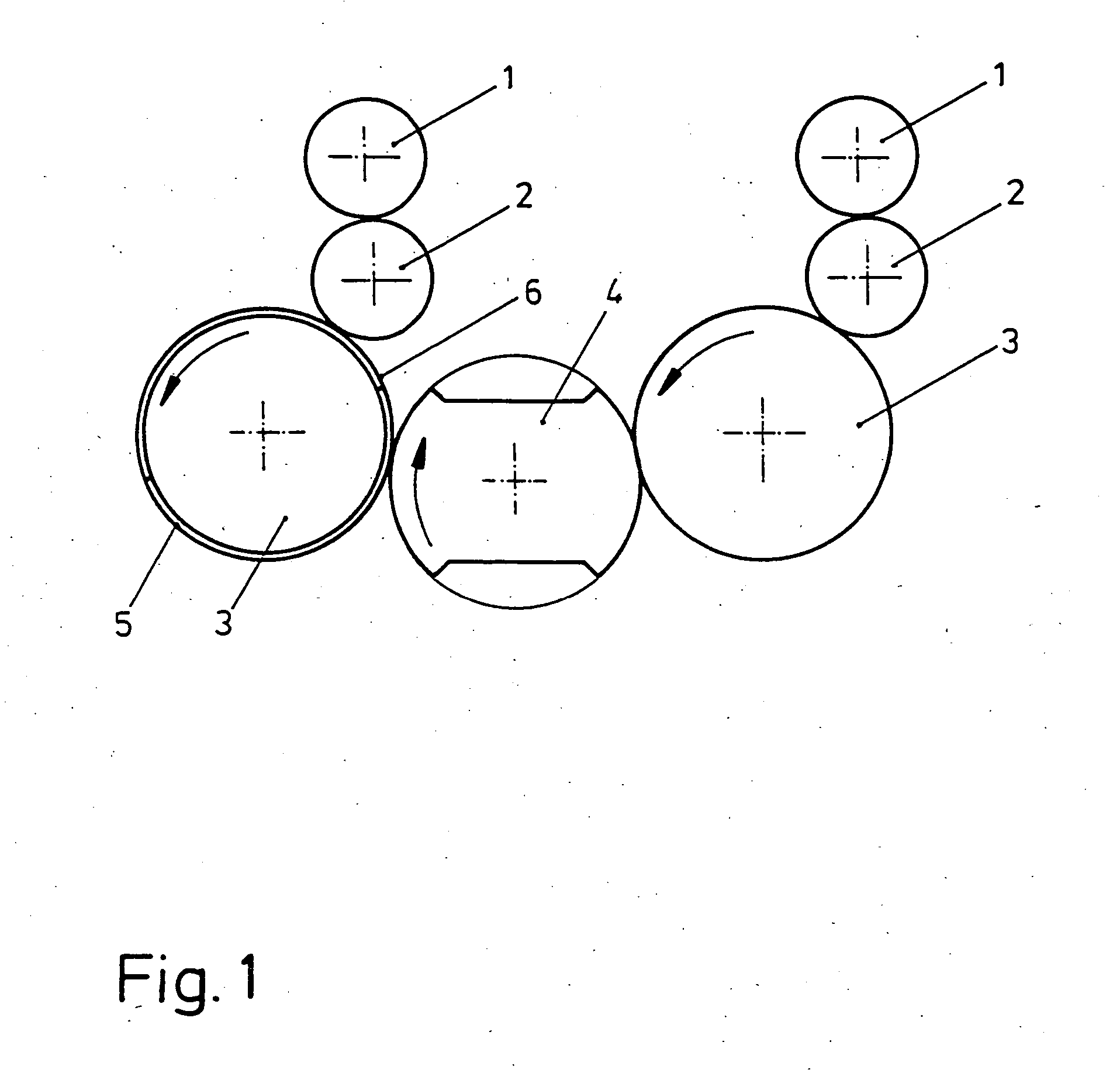

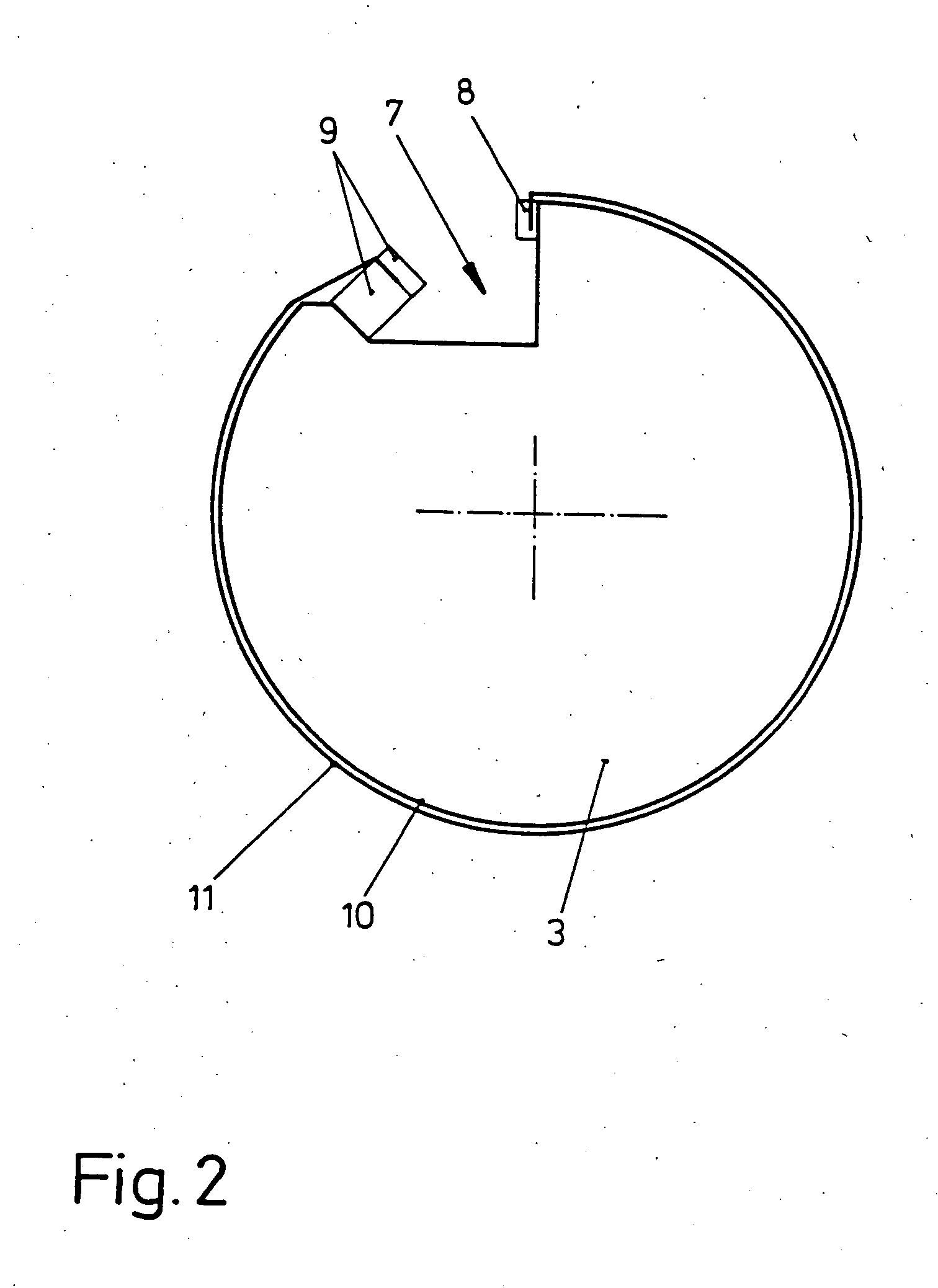

Packing for a sheet-guiding cylinder in a processing machine

InactiveUS20060169155A1Improve print qualityReduce releaseCylinder pressesLayered productsLayered structureEngineering

A printing and / or varnishing machine having a plurality of sheet-guiding cylinders in which at least one of the cylinders has an outer detachable packing which has enhanced ink repellent characteristics and which significantly reduces wear. The packing has a layered structure which includes a flexible backing material 12, the underside of which is assigned to the base body of the sheet-guiding cylinder 3, a coating 13 of molybdenum or tungsten carbide / cobalt which is adhesively applied to the upper side of the backing material 12, and a sealing layer 14 of a material made from the group of polysiloxanes which is adhesively applied to the upper side of the coating 13. The side of the packings 5, 6 which faces the material to be printed has a surface profile consisting of cones 18 with rounded tips 16 for reduced sheet contact.

Owner:COATEC GES FUR OBERFLACHENVEREDELUNG +1

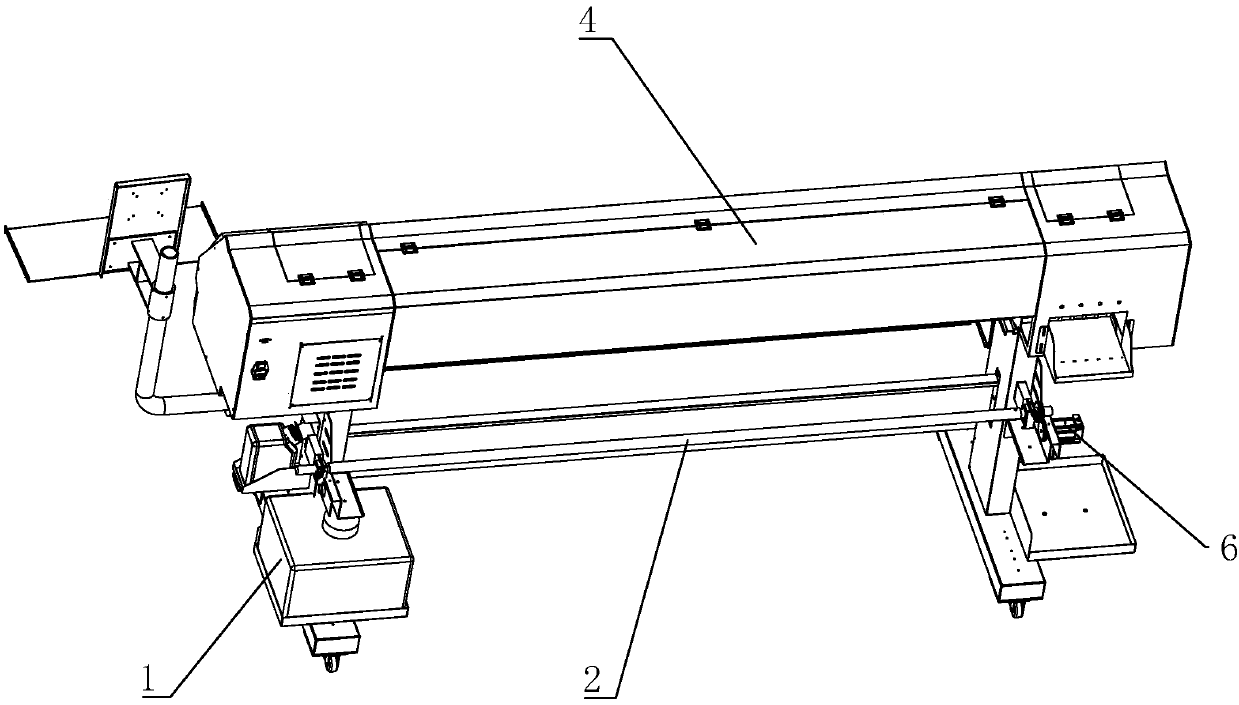

Drawing machine

ActiveCN109605943AIncrease the adsorption areaImprove print qualityPrintingWebs handlingElectric machineryAir Pump Assembly

The invention discloses a drawing machine. The drawing machine comprises a machine frame, an unwinding roller, a printing platform, a printing assembly, a winding roller and a second driving motor used for driving the winding roller to rotate, the printing platform is provided with a hollow bottom plate, the bottom plate is provided with suction holes communicated with an inner cavity of the bottom plate, an air pumping assembly used for pumping air in the bottom plate is arranged on one side of the printing platform, a containing groove is formed in the bottom plate, a diffusion plate is embedded in the containing groove, the upper end face of the diffusion plate and the upper end face of the printing platform are located on the same plane, a plurality of diffusion grooves are formed in the diffusion plate, the diffusion grooves and the suction holes are in matrix distribution, each diffusion groove corresponds to one suction hole, the sectional area of the diffusion grooves is largerthan the sectional area of the suction holes, and the suction holes are located in the diffusion grooves. Through the arrangement of the diffusion grooves, the contact area of the printing medium under the suction force is increased when the air suction assembly is vacuumized, so that the printing medium is kept in a flat state, the phenomenon that the printing medium is wrinkled and the like dueto the adsorption of a multi-point small area is avoided.

Owner:杭州御澜科技有限公司

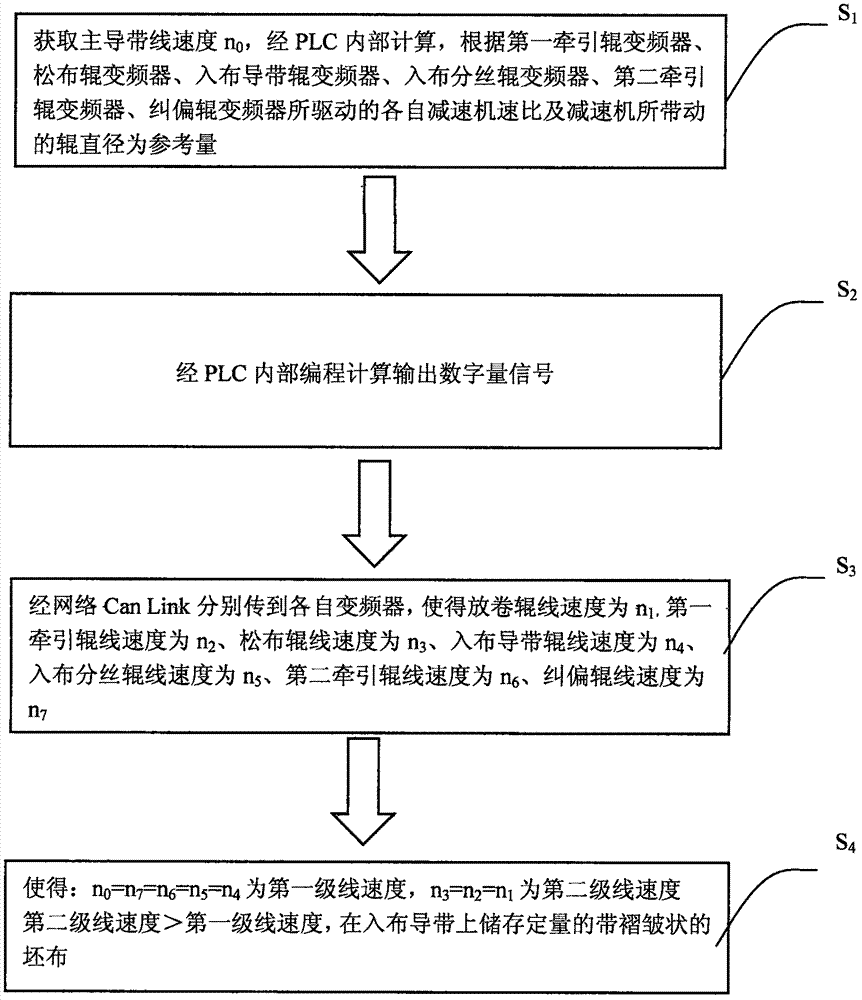

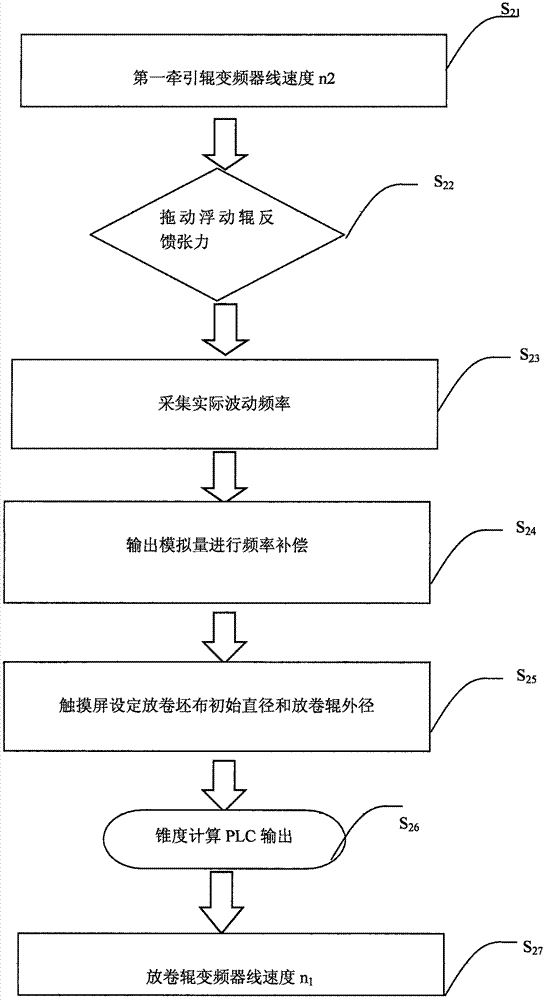

Cloth feeding method for continuous type high-speed textile digital printing machine

PendingCN106985553AImprove print qualityReduce defective rateOther printing apparatusDigital printingDigital textile printing

The invention discloses a method for feeding a continuous high-speed textile digital printing machine. The method belongs to the technical field of textile printing. The invention solves the problem that the existing continuous high-speed textile digital printing machine cannot continuously store quantitative The wrinkled gray cloth causes the gray cloth to be unstable due to tension, and the quality of the pattern after inkjet printing is dried and heated. The Fangming method includes: with the dominant band linear velocity n 0 As the benchmark reference quantity, through PLC internal calculation, it is obtained that the frequency converter of the first traction roller, the frequency converter of the loose cloth roller, the frequency converter of the cloth guide roller, the frequency converter of the cloth feeding roller, the frequency converter of the second traction roller, and the correction rod The linear speed of the corresponding roller driven by the frequency converter ensures that a certain amount of wrinkled gray cloth is stored on the cloth feeding guide belt, and at the same time solves the problem of the torque reduction of the unwinding roller due to the large inertia, reduces the problem of cloth feeding accumulation, and improves Improve the printing quality of the digital printing machine and reduce the loss of gray fabric.

Owner:温泉

Printer

ActiveCN109130179AImprove print qualityEasy to adjustManufacturing platforms/substratesManufacturing driving meansElectrical and Electronics engineeringConductor Coil

The invention relates to the technical field of printing equipment, in particular to a printer. The printer comprises a rack, the rack comprises a base and a vertical moving mechanism, the vertical moving mechanism is provided with a first transverse moving mechanism, the first transverse moving mechanism is provided with a second transverse moving mechanism, and the second transverse moving mechanism comprises two rope rollers, a fixing shelf, a printing rod and a first motor used for driving the two rope rollers to rotate; first pull ropes wind the two rope rollers, the winding directions ofthe two first pull ropes on the rope rollers are opposite respectively, the middle of the printing rod is spherically hinged to the fixing shelf, a printing head is arranged at one end of the printing rod, and the ends, away from the rope rollers, of the two first pull ropes are both fixed to the end, away from the printing head, of the printing rod. According to the printer, inclination of the printing head is achieved, and the side face of the product can be printed.

Owner:仁怀市云侠网络科技有限公司

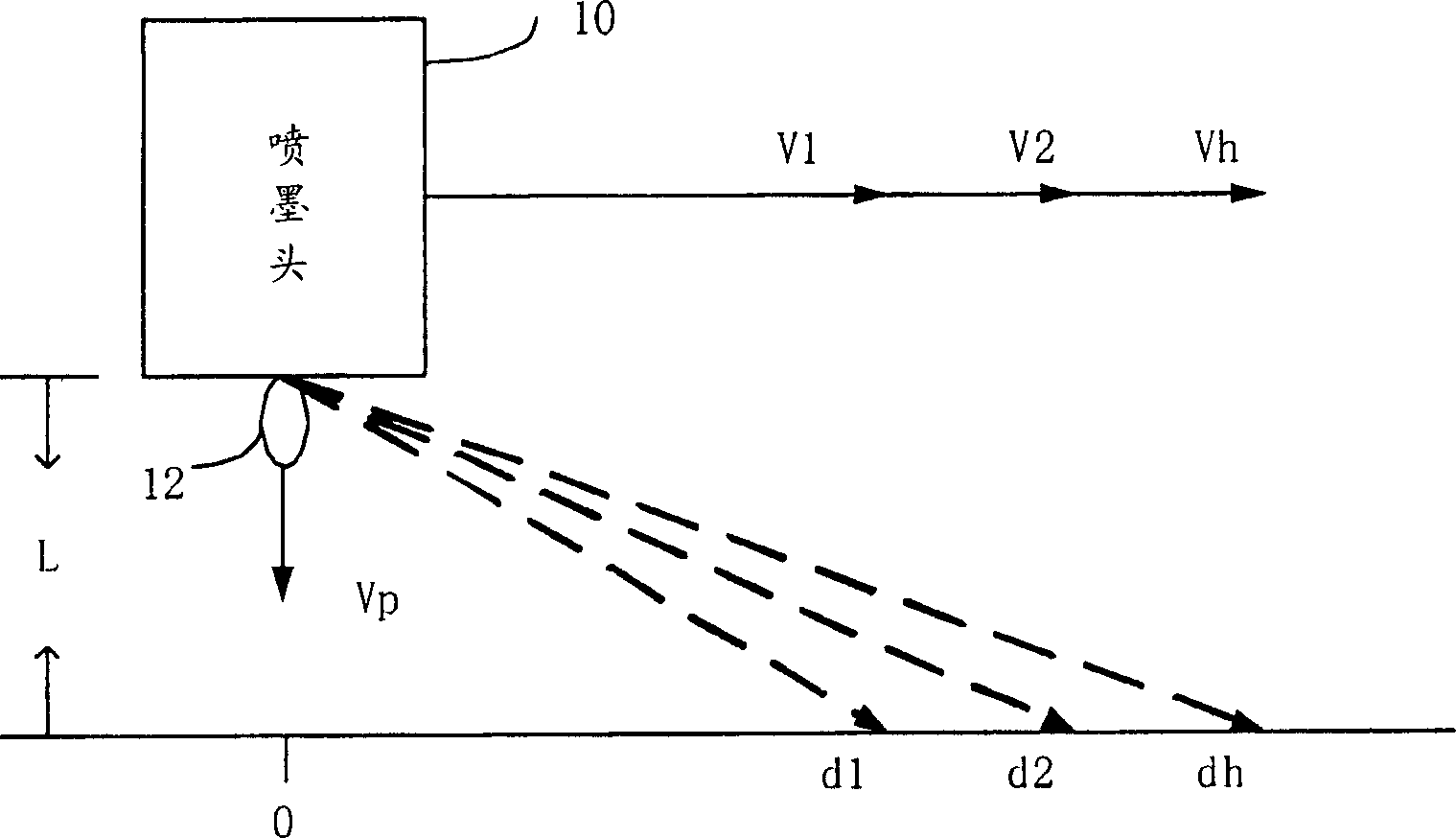

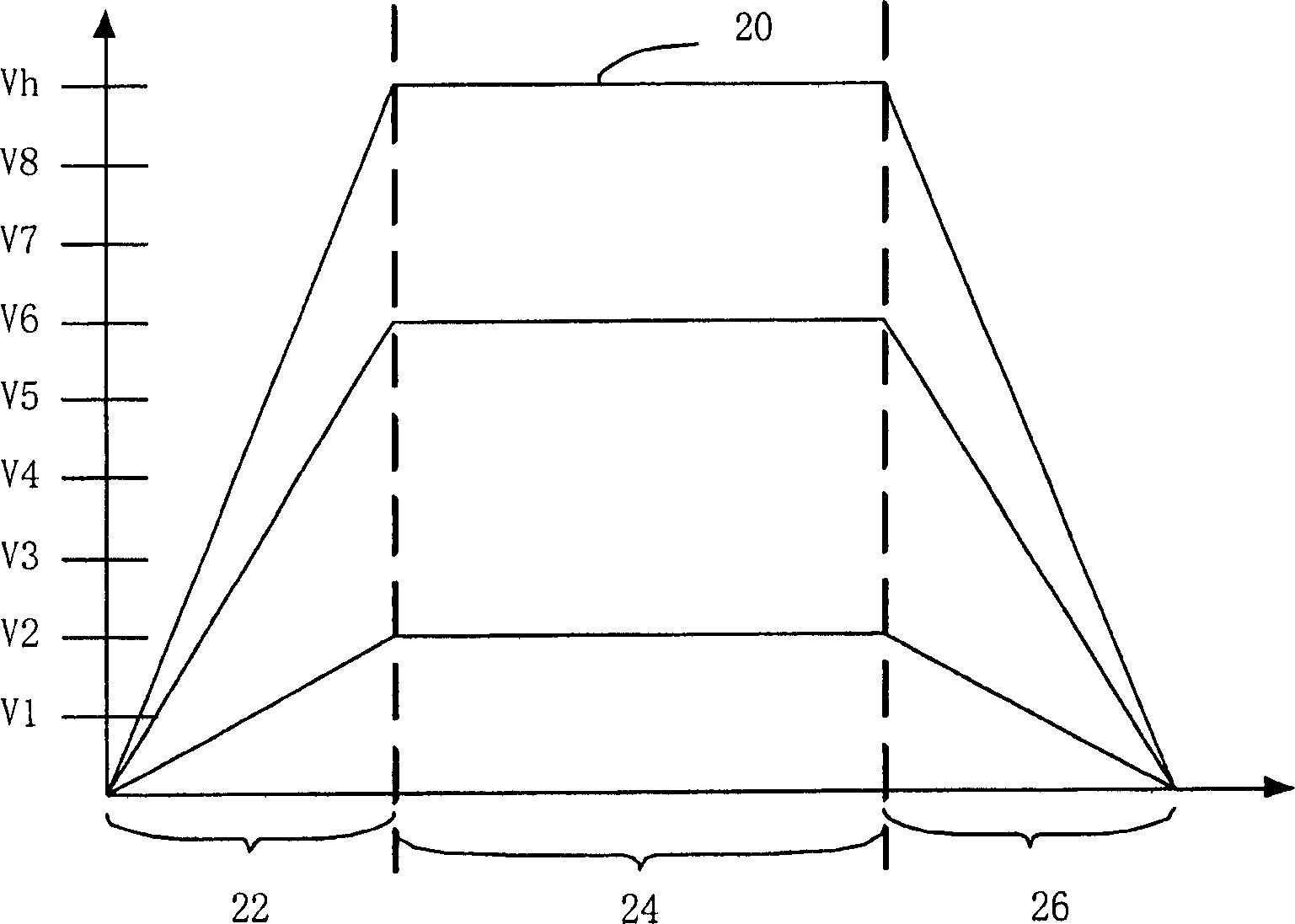

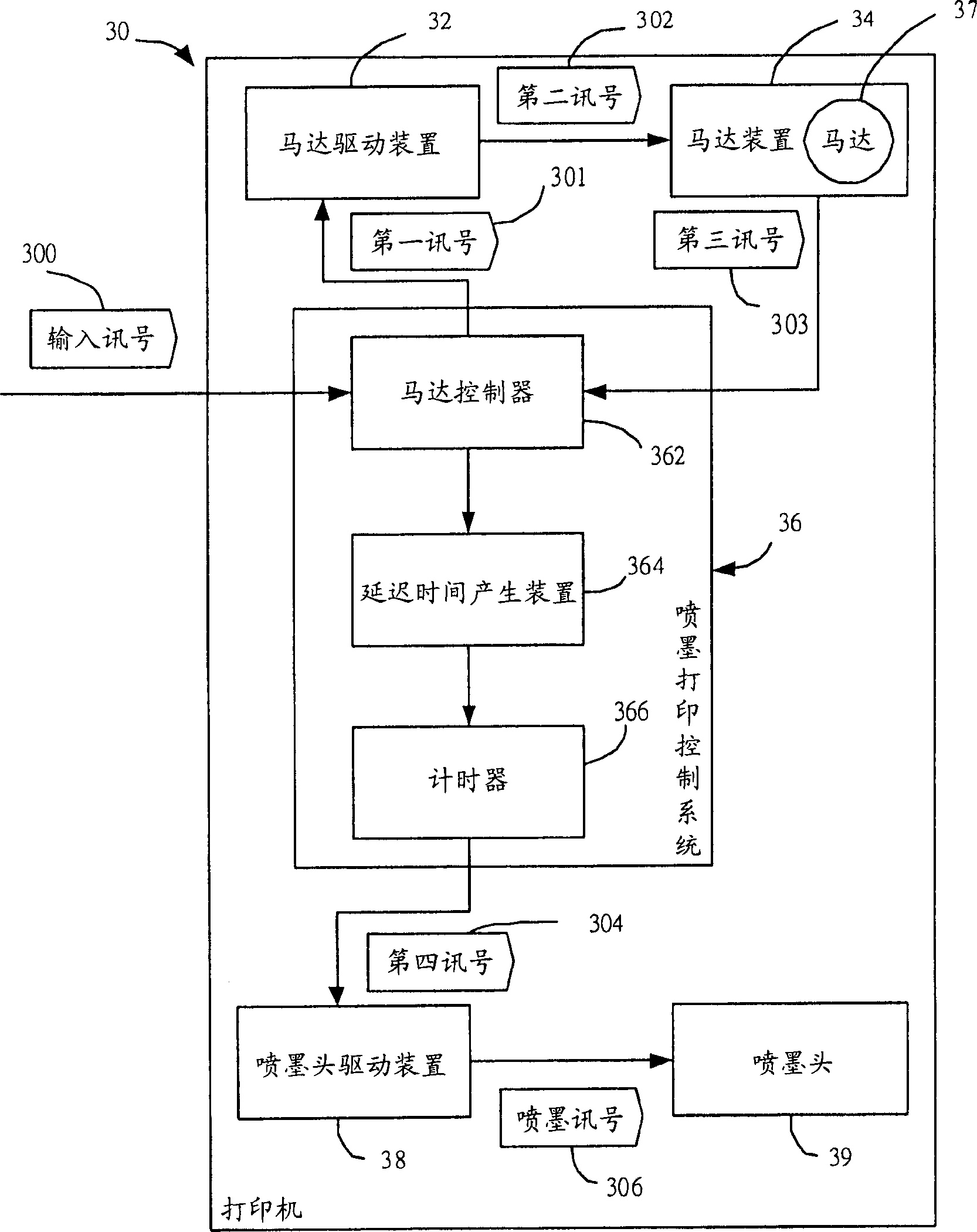

Device and method for controlling ink jet printing time

The invention provides an ink-jet print control system to control a ink-jet head. Said invention comprises a motor controller, a delay-time generator connected to say motor controller; and a timer connected to say delay-time generator. Wherein, the motor controller is used to calculate the moving speed when ink-jet head reaches the ink-jet position; the delay-time generator can generate a delay time according to said moving speed; and the timer can calculate a ink-jet time after the ink-jet head reaches said ink-jet position and output a ink-jet signal to control said ink-jet head when the ink-jet time equals the delay time.

Owner:BENQ CORP

Electroforming screen printing plate grid line for solar battery

InactiveCN103022167AAvoid boldImprove print qualitySemiconductor devicesBreaking pointElectrical and Electronics engineering

The invention discloses an electroforming screen printing plate grid line for a solar battery. Breaking points are arranged on fine grids in the middle of the positions of two main grids of a graph. According to the electroforming screen printing plate grid line for the solar battery, the problem that the printing of the grid line at the farthest edge of electroforming screen printing plate printing is easily slightly rough; and a design of arranging the breaking points on the fine grid lines is adopted so that the condition that the printing of the grid lines at the edges is rough can be avoided, the printing quality is improved and the battery efficiency is not influenced.

Owner:ALTUSVIA ENERGY TAICANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com