Ink supplement method and ink supplement device of digital ink jet printing equipment

A printing equipment and digital inkjet technology, which is applied in the field of ink filling method and device for setting inkjet printing equipment, can solve the problem of not being able to know the ink volume of the user, and achieve the effect of maintaining legitimate rights and interests and improving the quality of inkjet printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the technical field to which the present application belongs to understand the invention more clearly, the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

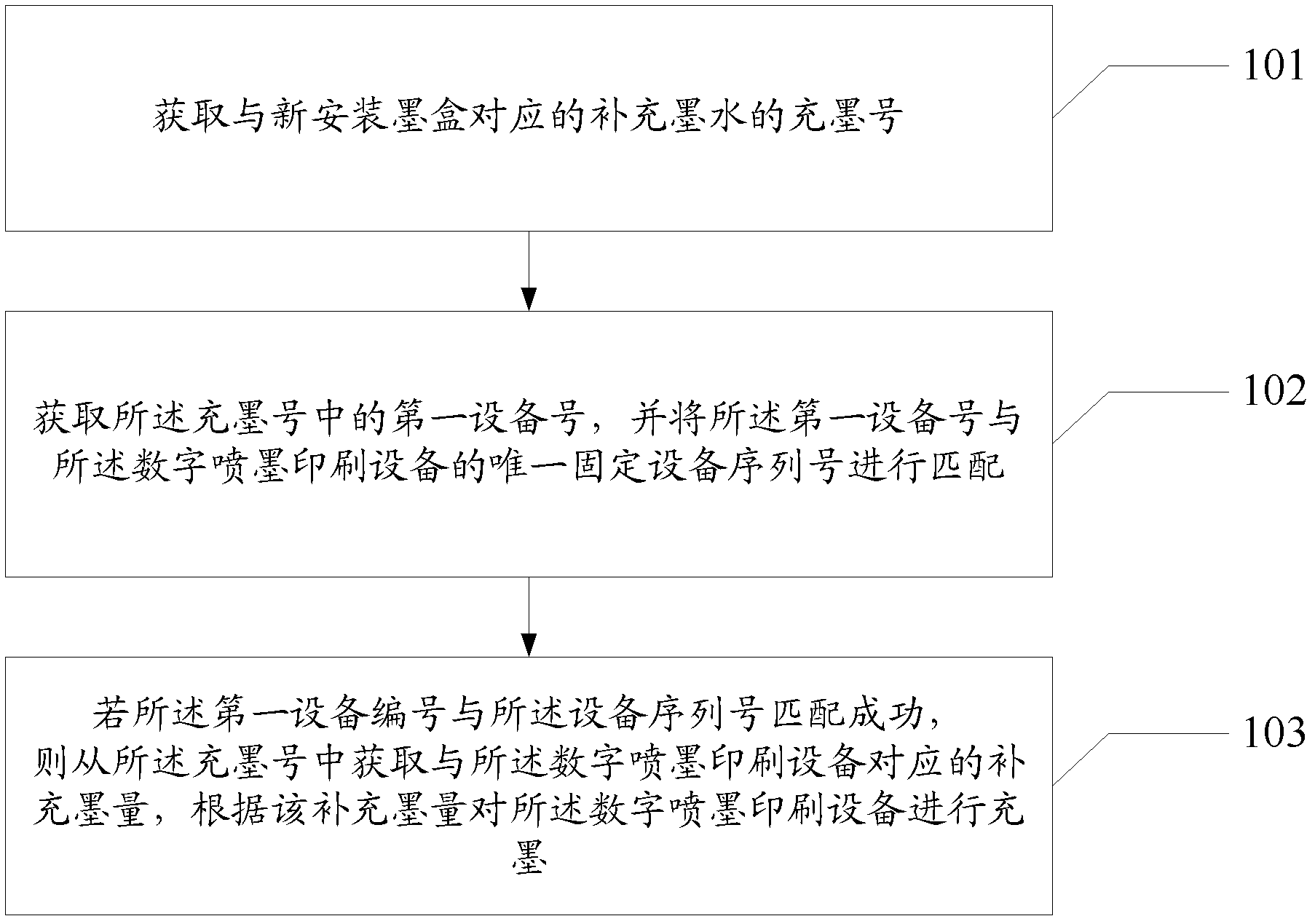

[0024] figure 1 Shown is a schematic diagram of an ink filling method for a digital inkjet printing device of the present invention, specifically including:

[0025] Step 101, acquire the ink filling number of the supplementary ink corresponding to the newly installed ink cartridge.

[0026] In order for the user to purchase an ink cartridge corresponding to the device for ink filling in the future, the user will obtain a unique and fixed device serial number representing the digital inkjet printing device after purchasing the digital inkjet printing device.

[0027] In addition, there is an ink filling number corresponding to the newly installed ink cartridge of the digital inkj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com