Patents

Literature

250 results about "Air Pump Assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

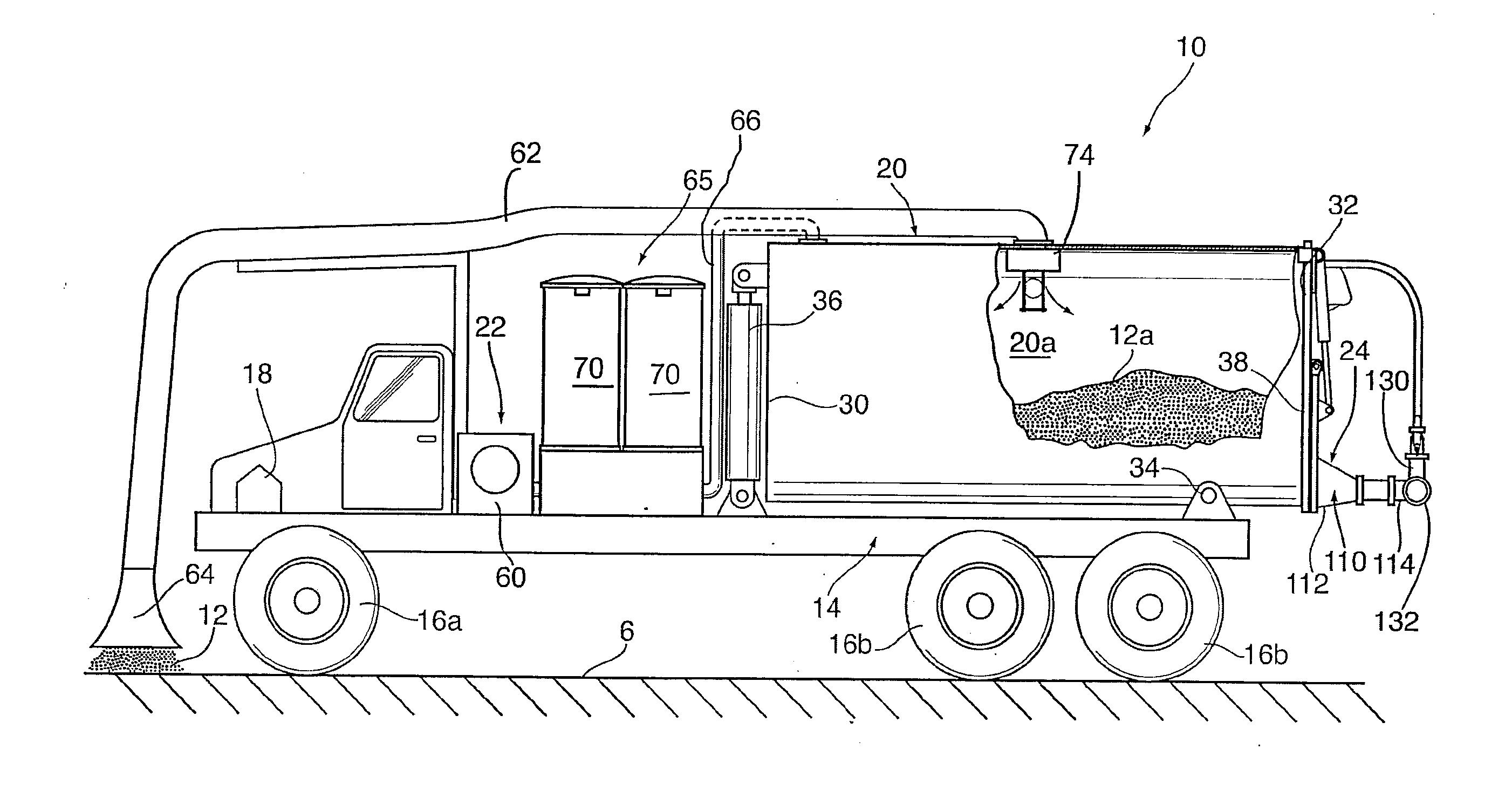

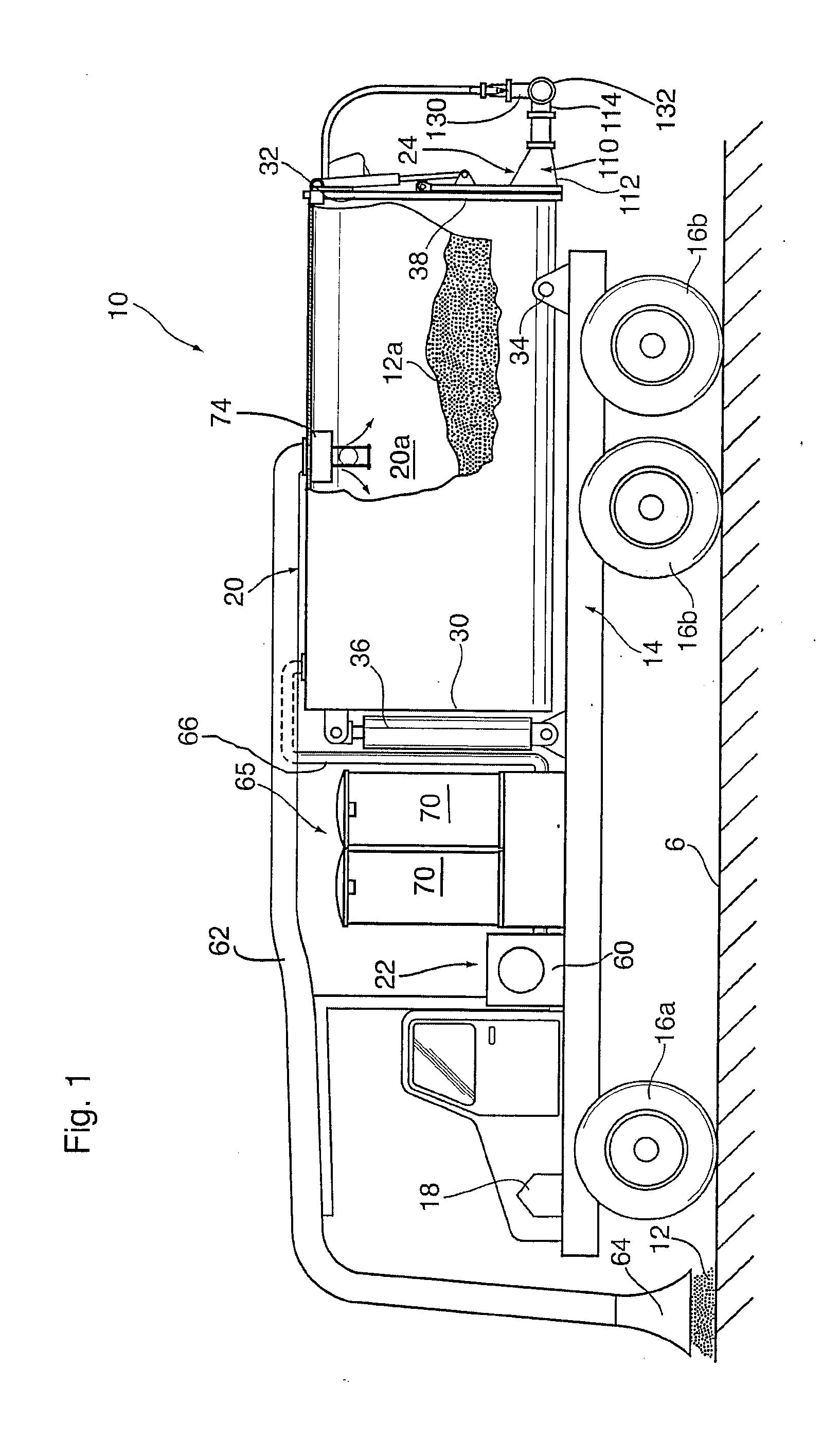

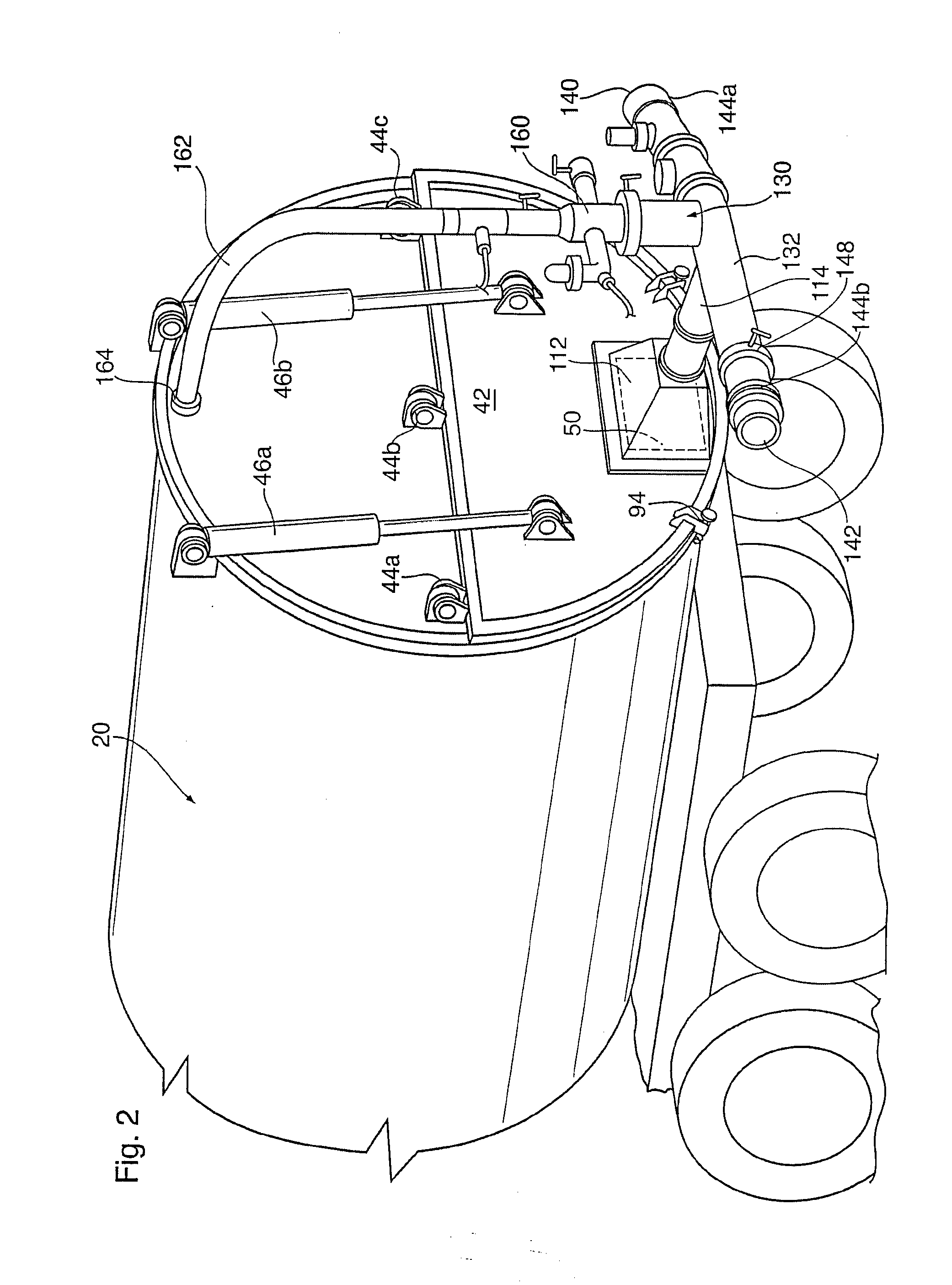

Vacuum Truck With Pneumatic Transfer System

InactiveUS20140017018A1Minimize re-entrainmentMinimize escapeLoading/unloading vehicle arrangmentRoad cleaningPositive pressureTransfer system

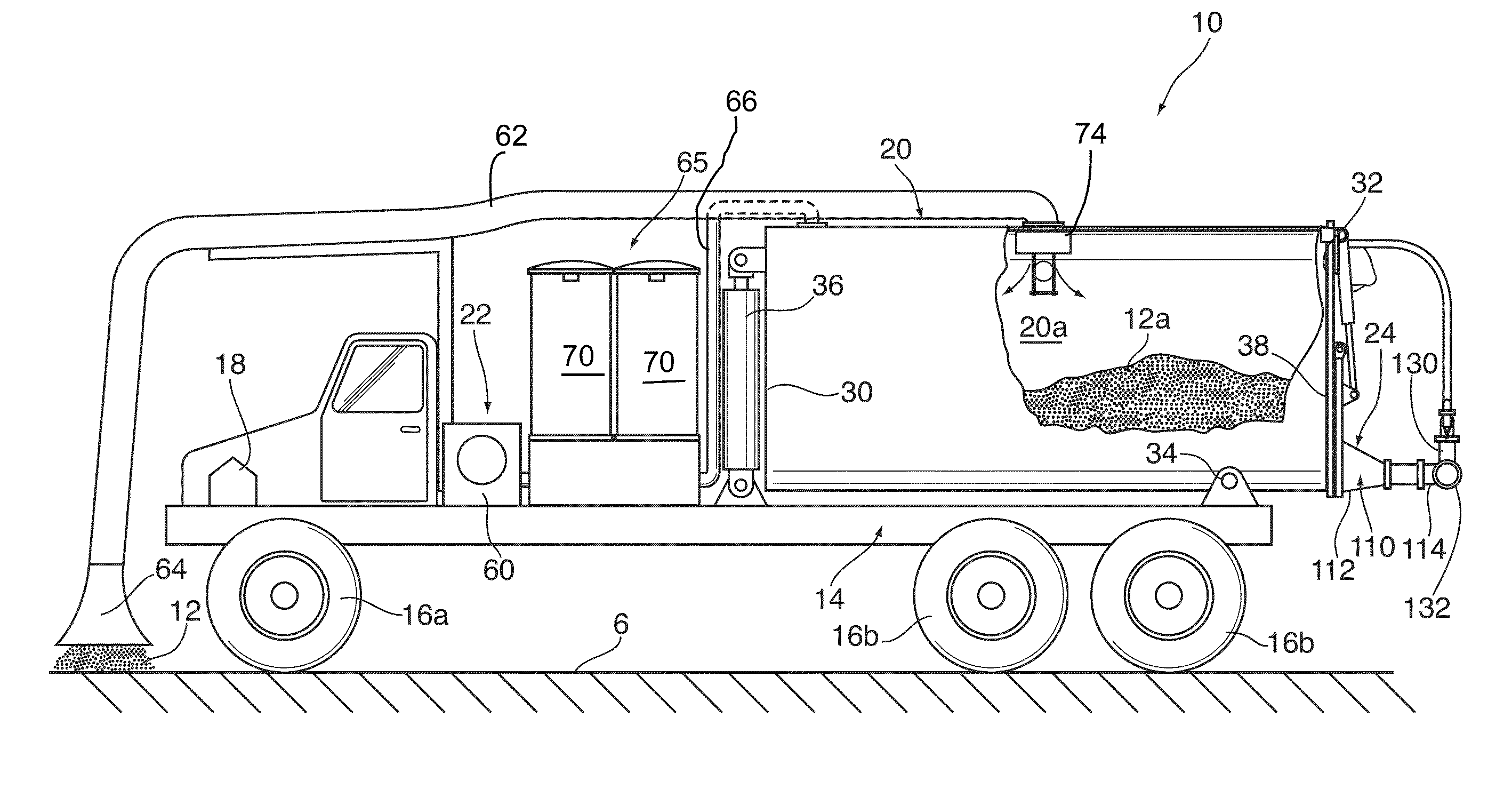

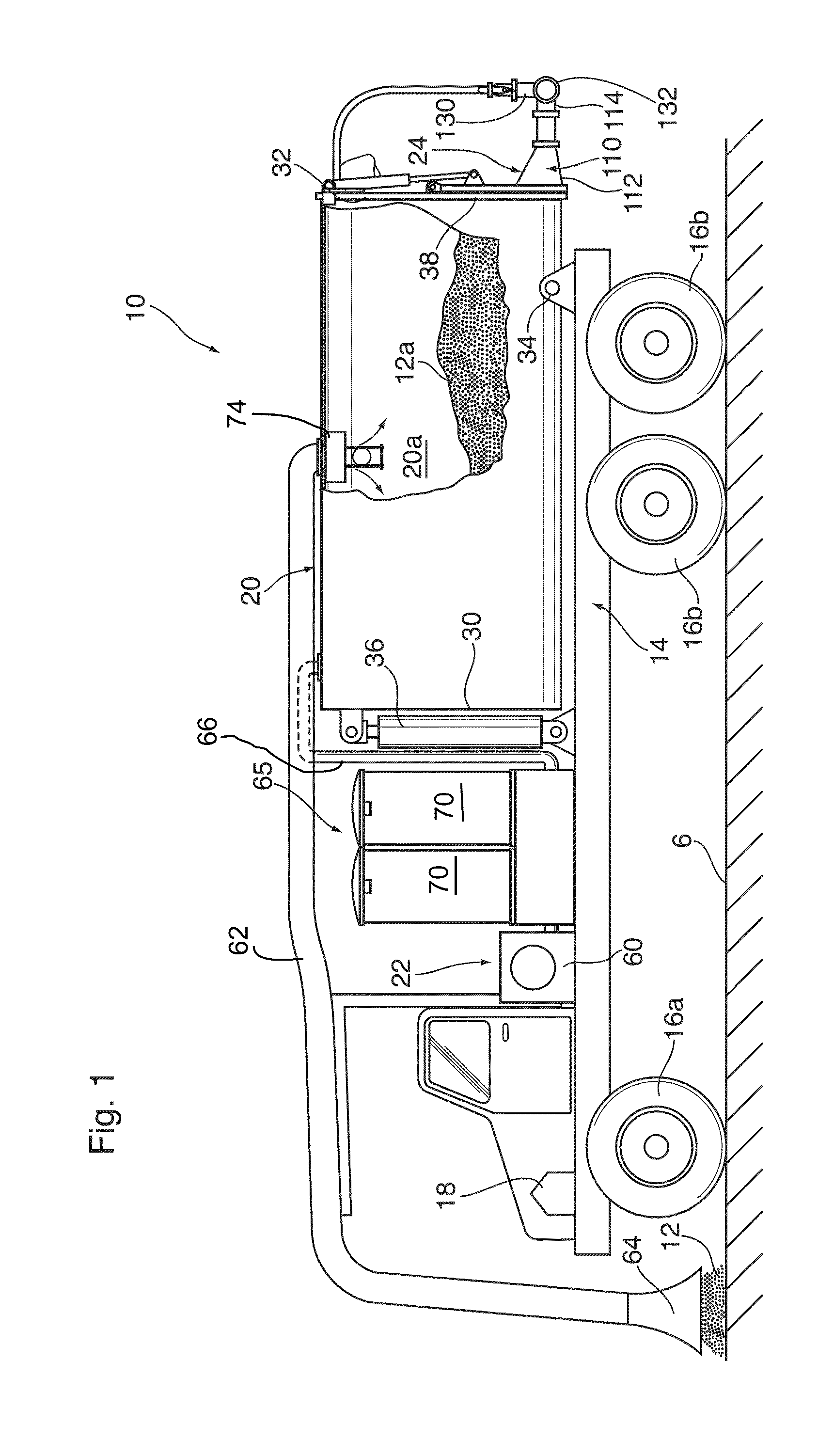

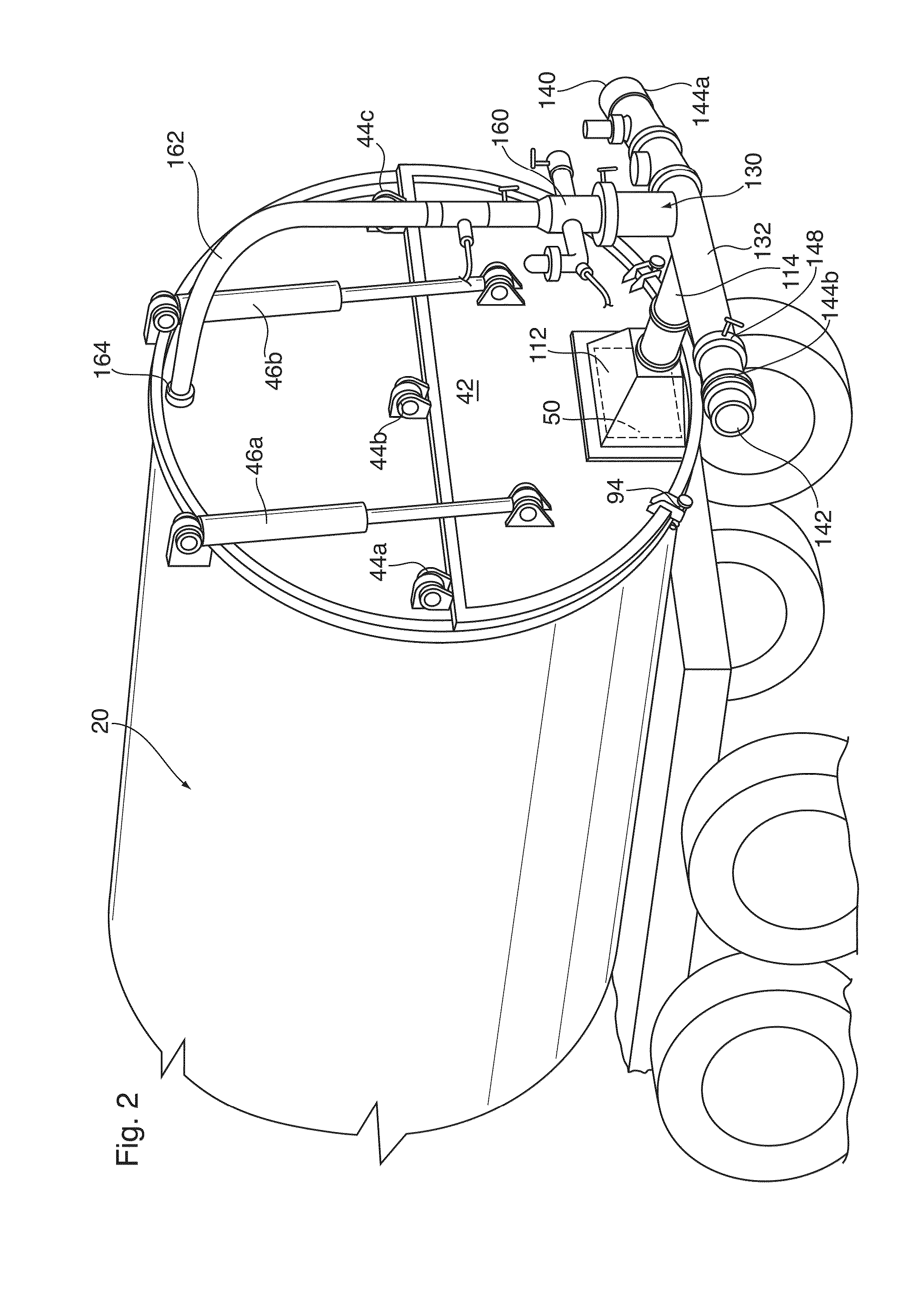

A vacuum truck for the collection and discharge of a waste particulate material which includes a storage tank, waste collection and discharge assemblies and an air pump assembly. The air pump assembly is operable to induce negative and positive pressures within the storage tank. The collection assembly includes a vacuum inlet for fluid flow between the vacuum inlet and the storage tank inlet during air pump operation to induce said negative pressure. The waste discharge assembly includes a discharge conduit for conveying a pressurized fluid flow and entrained collected material from a tank materials outlet to an outlet end while the air pump assembly is operated to induces a positive pressure.

Owner:BM METALS SERVICES

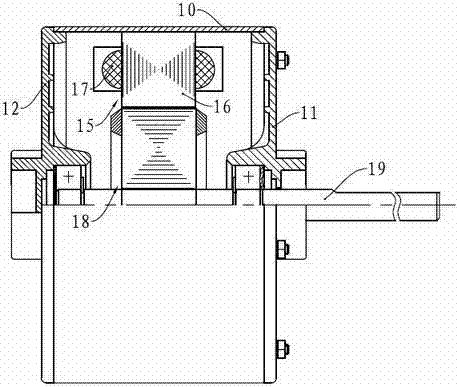

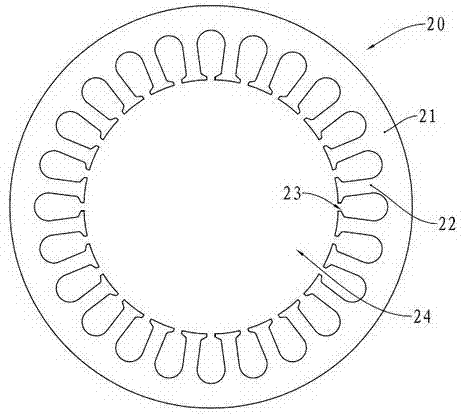

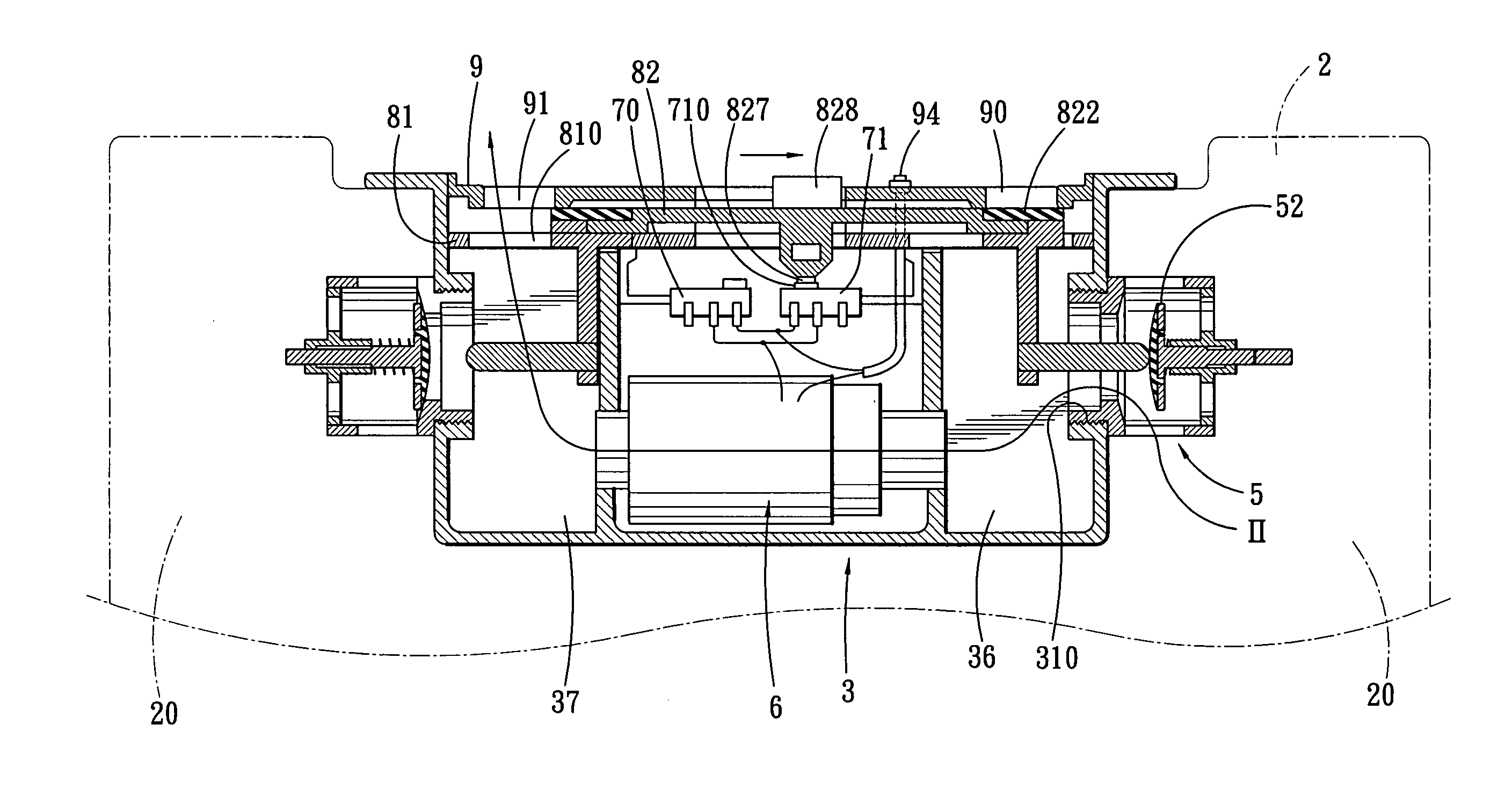

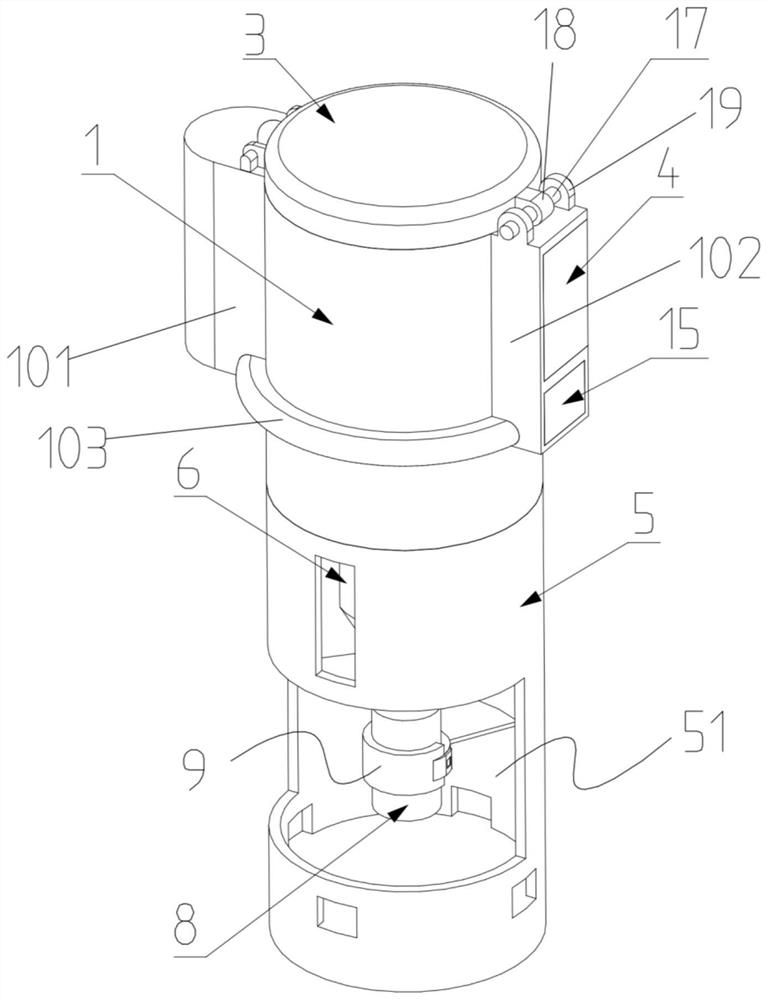

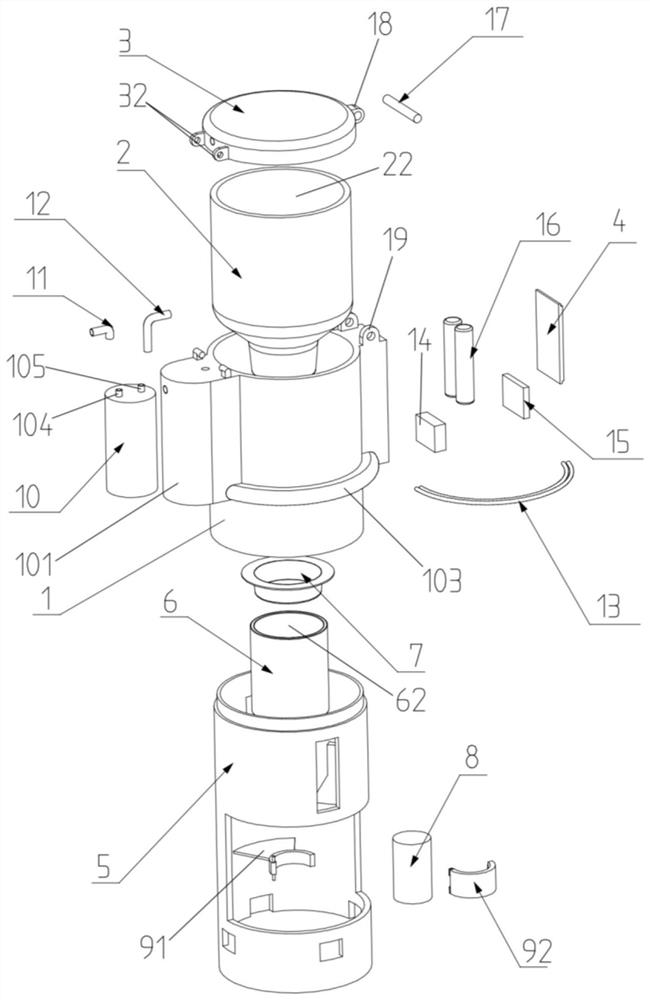

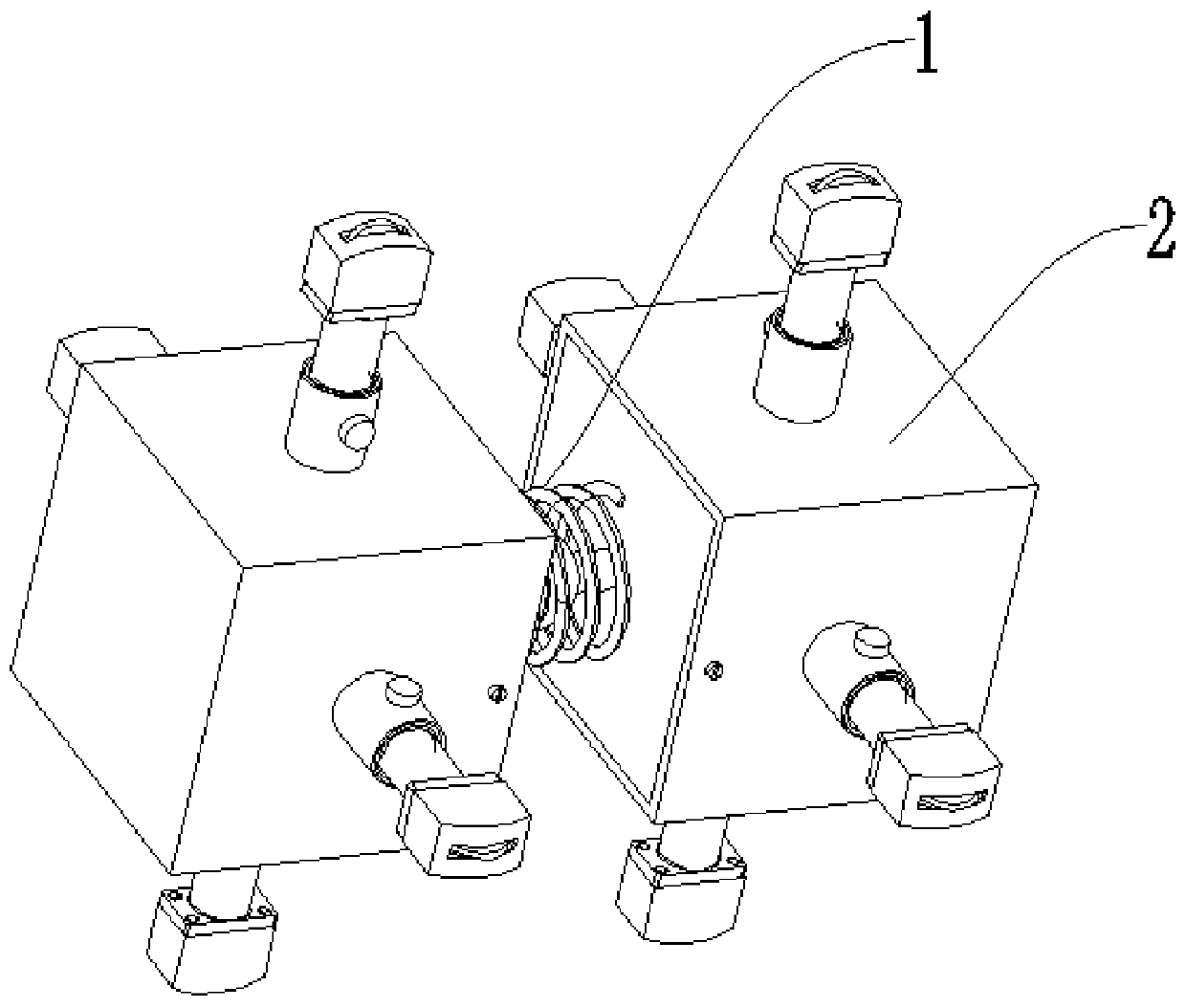

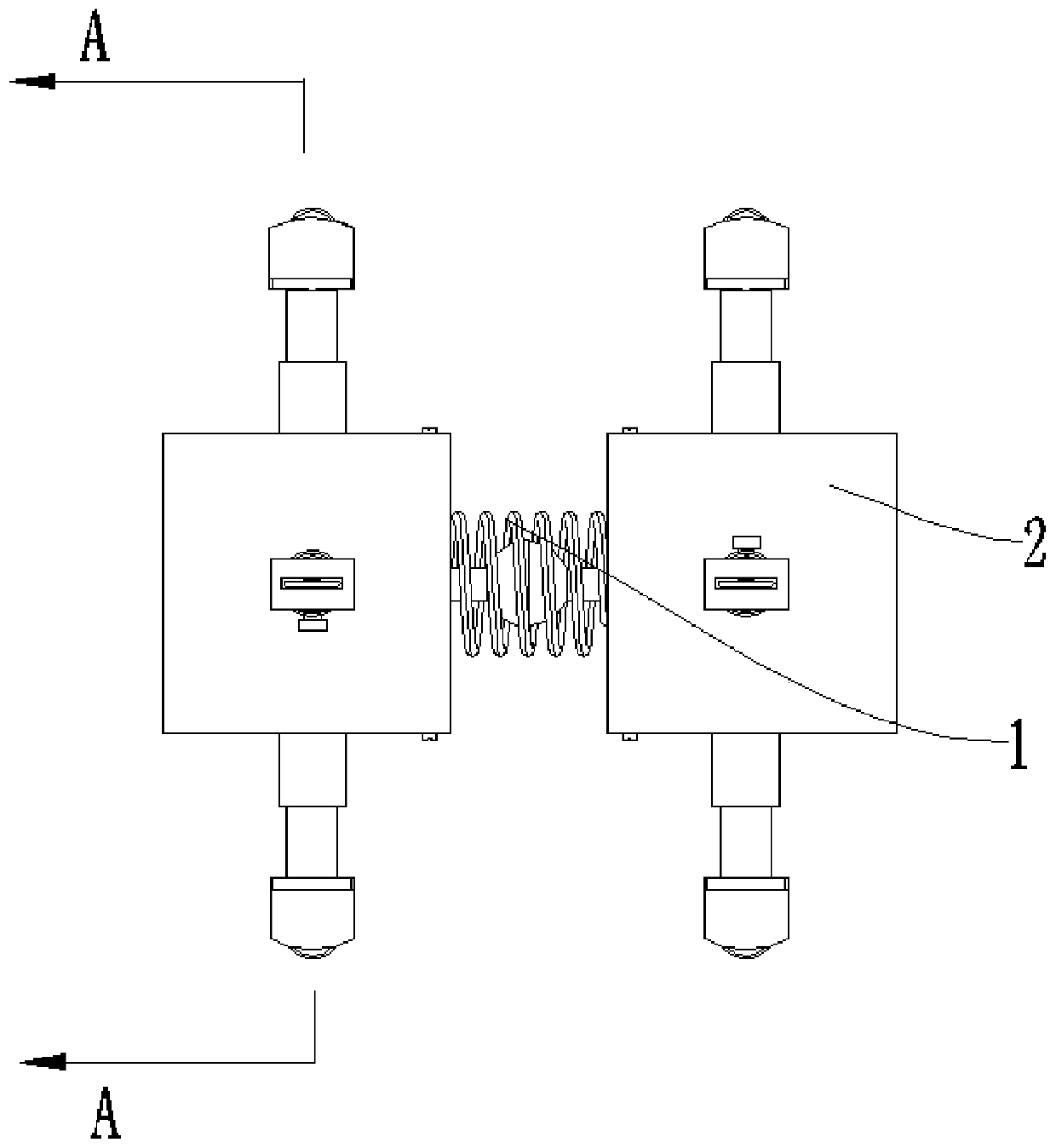

Spherical hinge universal rotary motor, and manufacturing method and operating method thereof

ActiveCN103780041AChange tilt angleAchieving freedom of movementMagnetic circuit rotating partsMagnetic circuit stationary partsJoint componentElectric machine

The invention provides a spherical hinge universal rotary motor, and a manufacturing method and an operating method thereof. The motor comprises a stator body made of a permanent magnet, wherein the permanent magnet is magnetized into a plurality of magnetic poles, the stator body is internally provided with a rotor body, the rotor body is provided with multiple layers of armatures, two adjacent layers of armatures are provided with a spacer layer therebetween, the multiple layers of armatures and the multiple layers of spacer layers are fixedly connected through a bolt, the bolt is connected with a rotor shaft, and the rotor body is of a spherical shape. A first layer of coils is wound on a rotor core of the armature, and the first layer of coils is wound on a rotor core of an armature at the same layer. The invention further provides a manufacturing method and an operating method of the motor. The motor provided by the invention can rotate in various directions, and comprises rotation around a Z-axis and oblique rotation relative to the Z-axis. The spherical hinge universal rotary motor is divided into a type with an air pump assembly mechanism and a type without the air pump assembly mechanism according to the air supply mode, and is widely applied to intelligent bionic robots to act as a joint component.

Owner:何国华

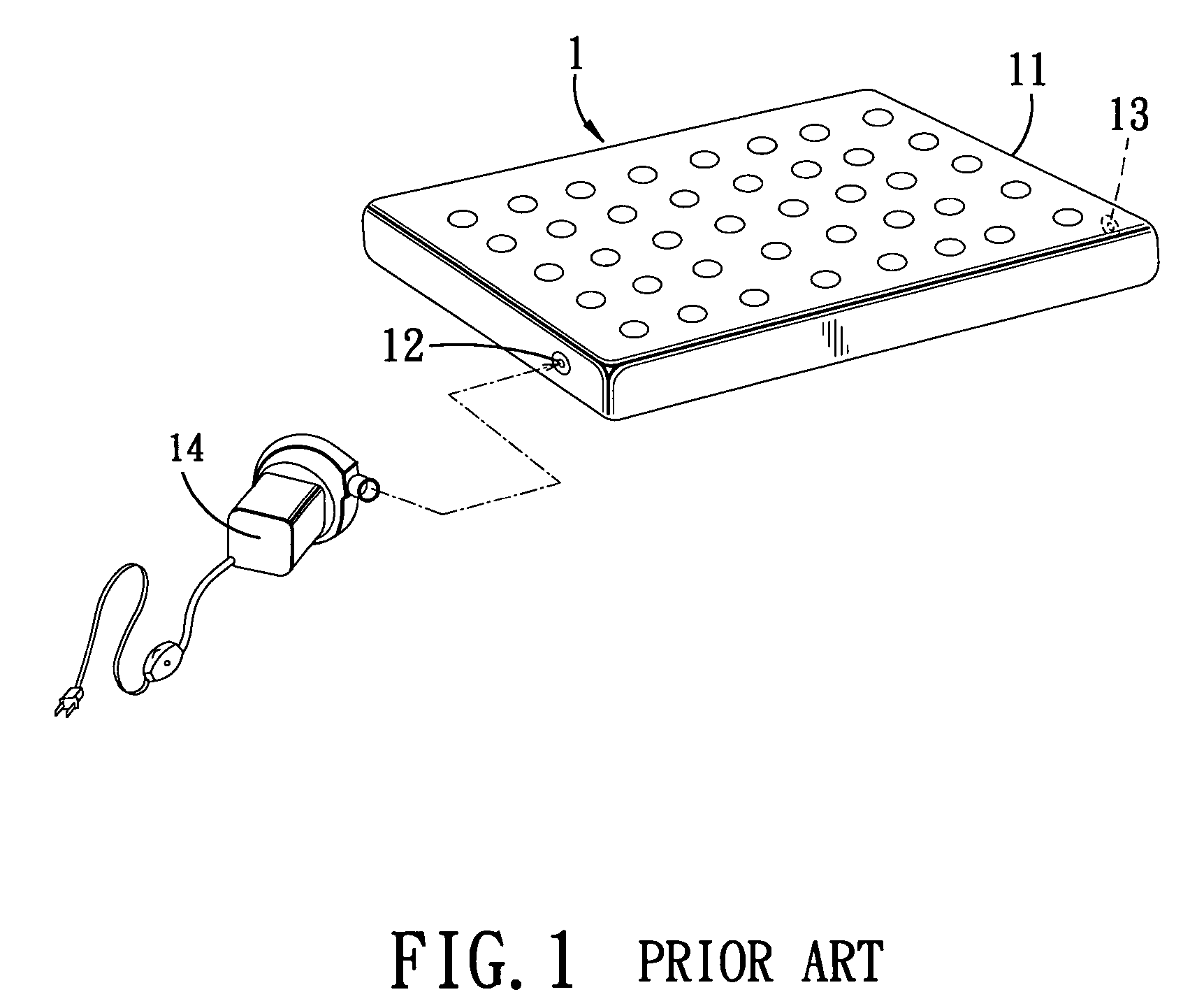

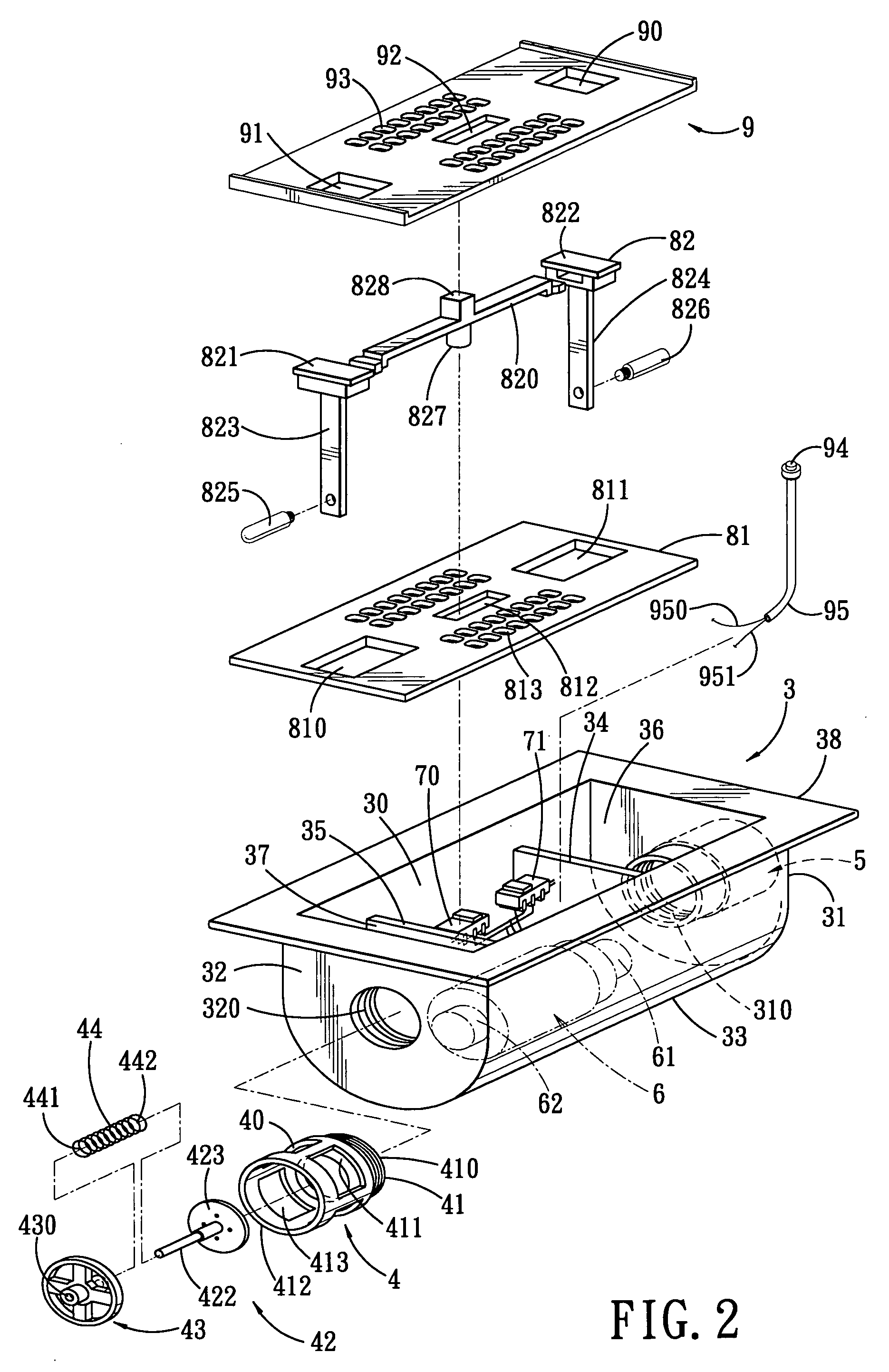

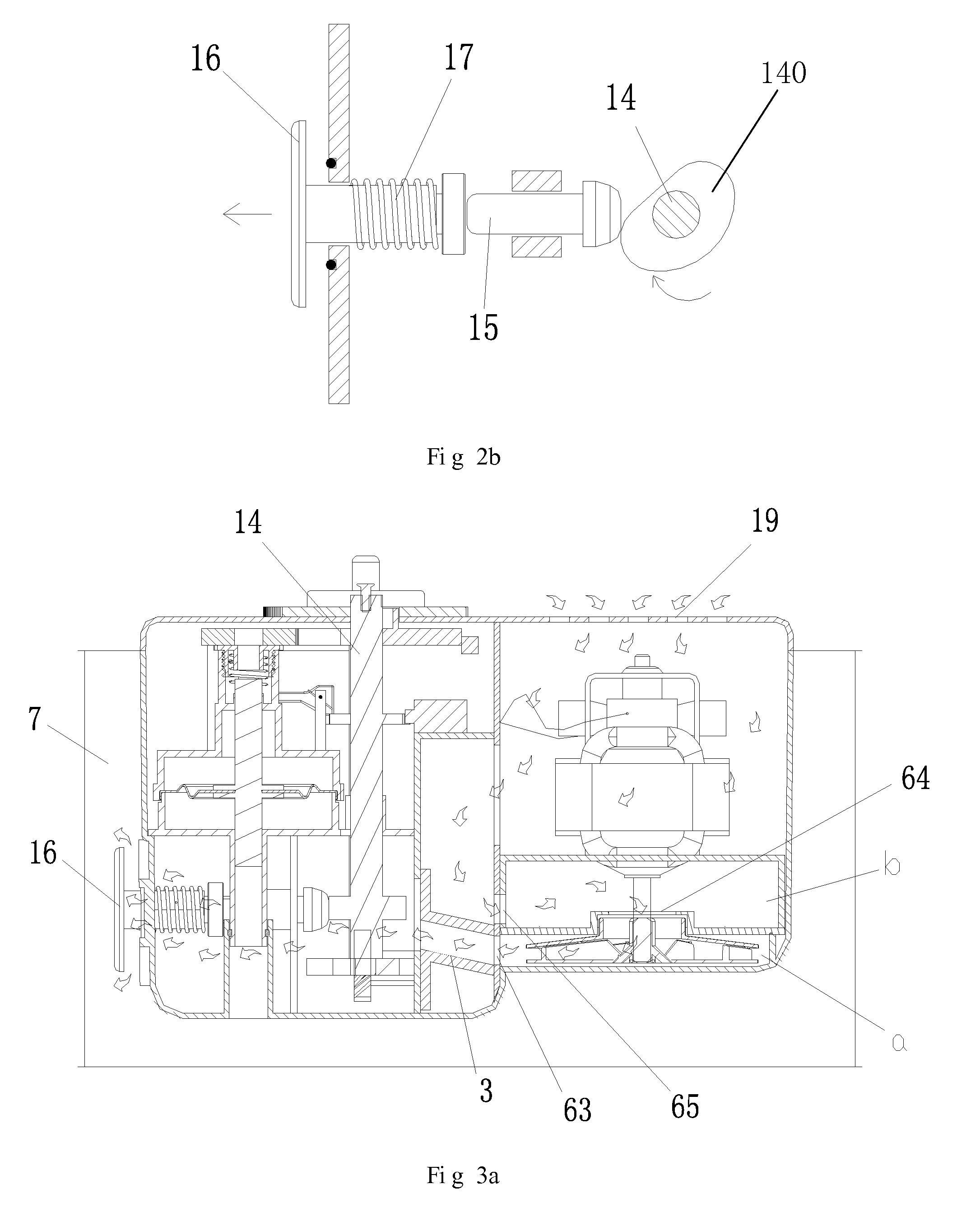

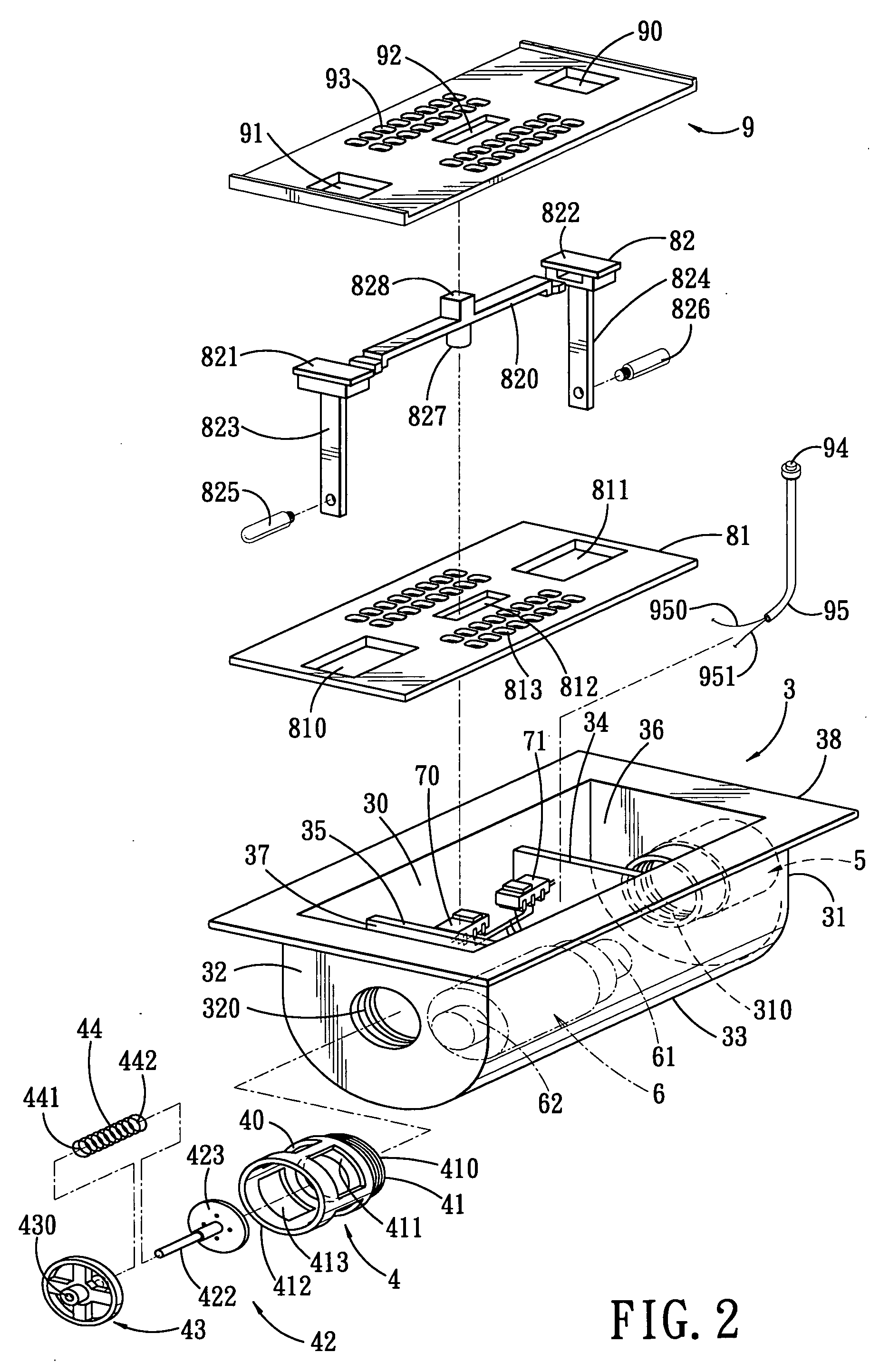

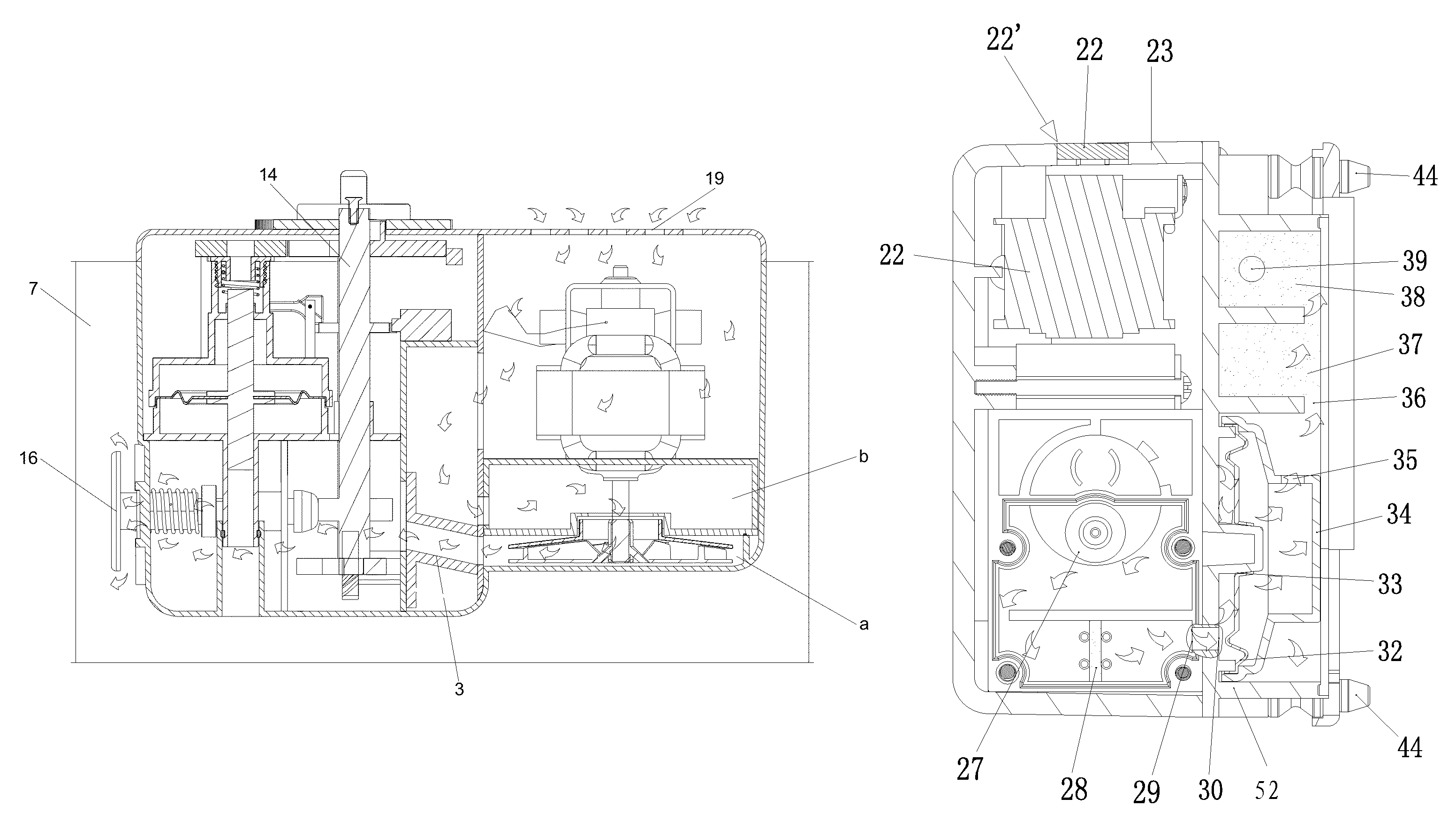

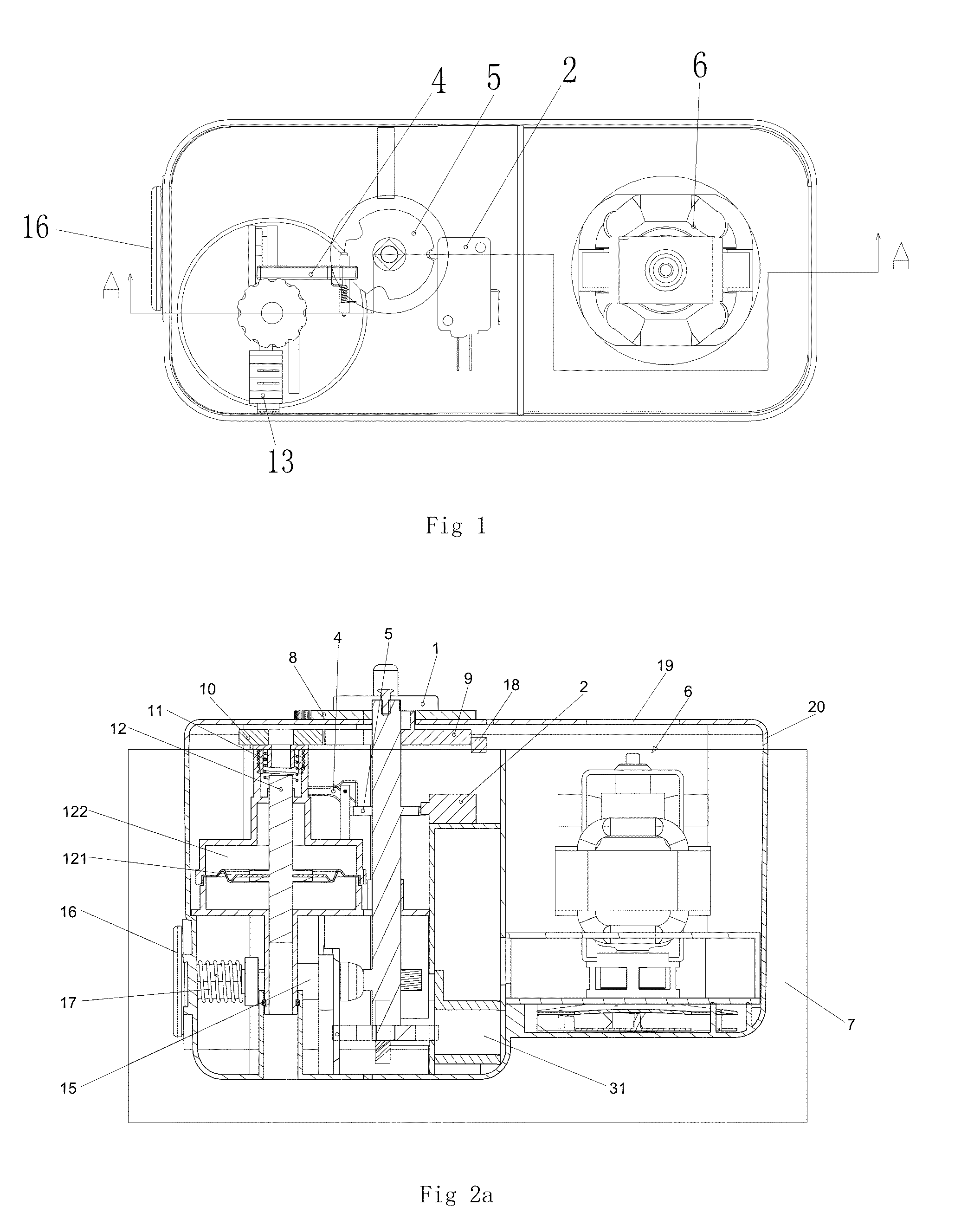

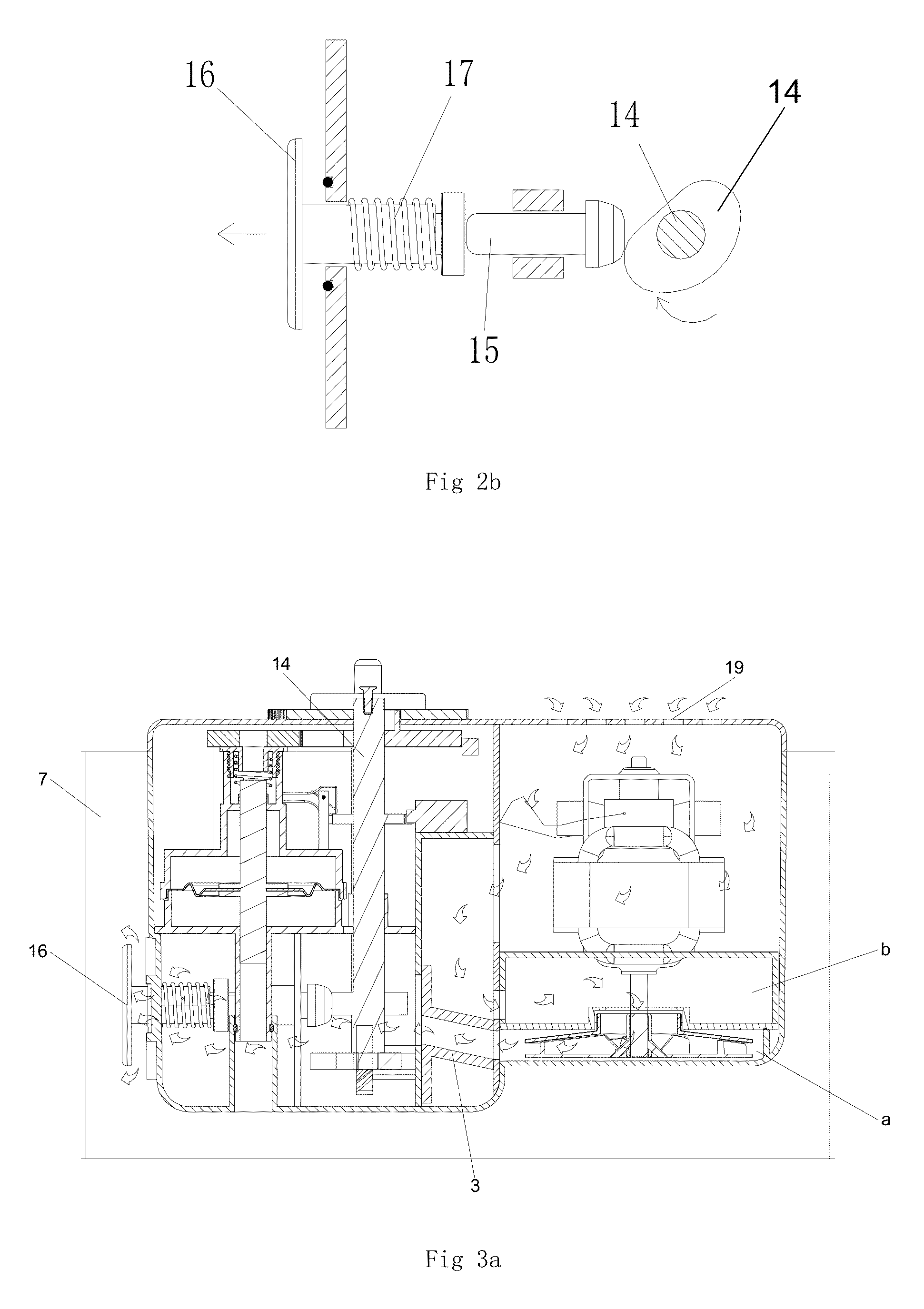

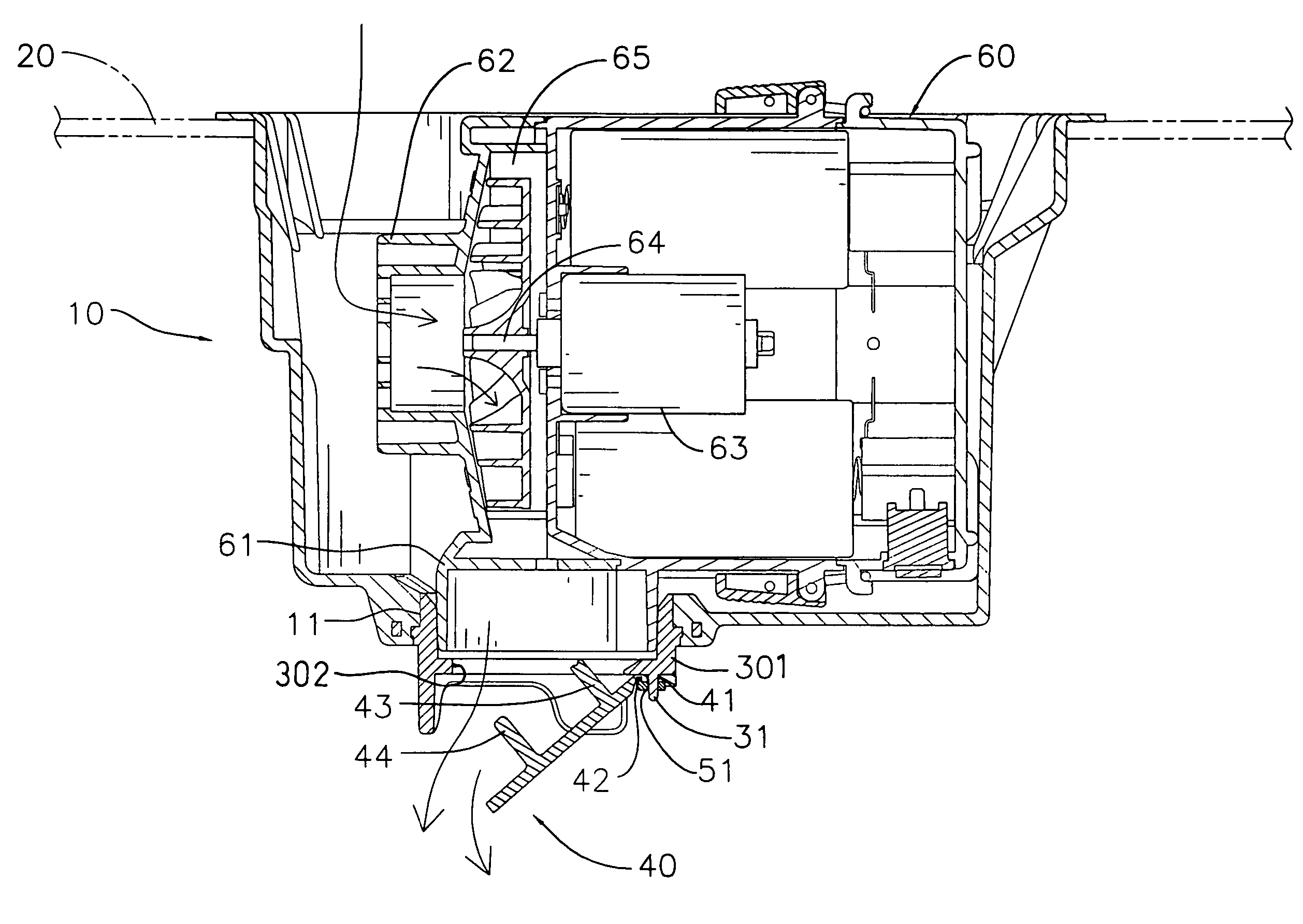

Air pump assembly for inflating and deflating an inflatable article

An air pump assembly is disposed within an inflatable article, and includes a movable member. When the movable member is moved relative to a base to an inflating position, an outflow outlet in the base is closed, and an inflow valve is activated to open an inflow outlet in the base so as to permit air to be sucked into the inflatable article through an inflow inlet and the inflow outlet in the base by an air pump. When the movable member is moved to a deflating position, the inflow inlet is closed, and an outflow valve is activated to open an outflow inlet in the base so as to permit air to be forced out of the inflatable article through the outflow inlet and the outflow outlet.

Owner:WU HSIN TSAI

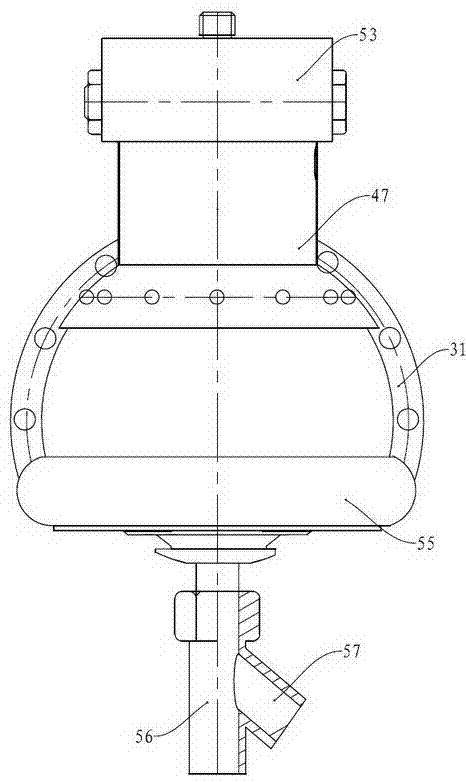

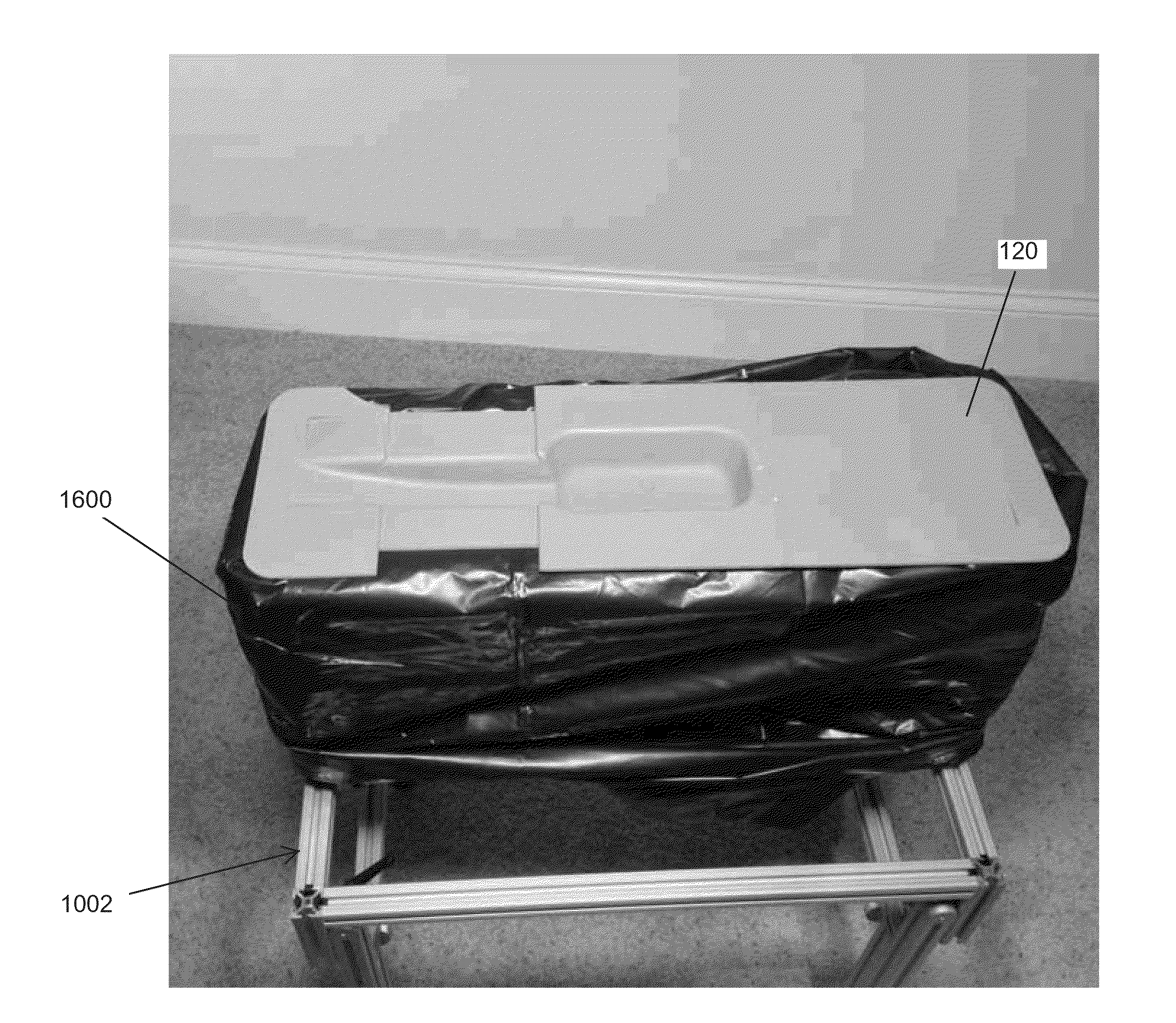

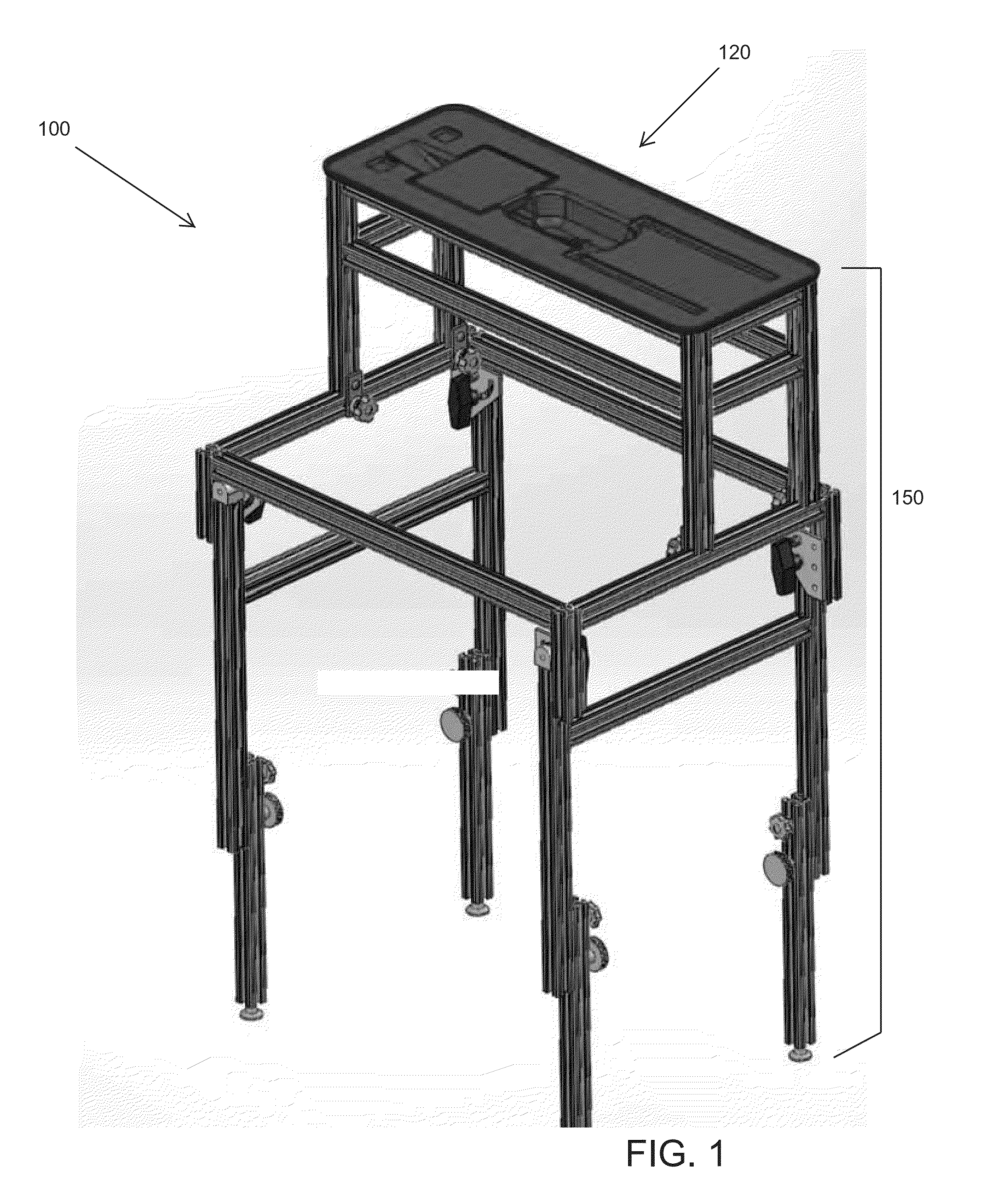

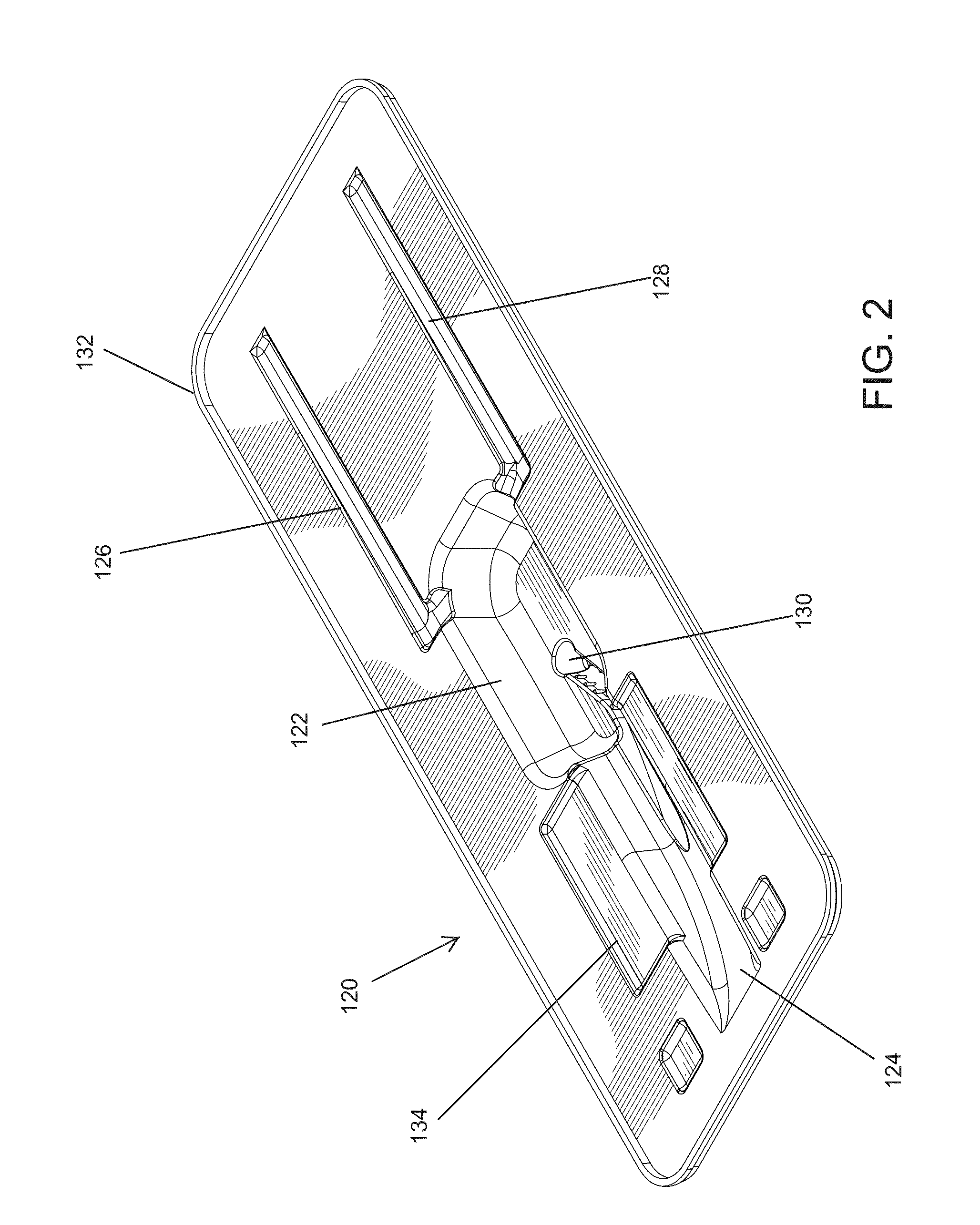

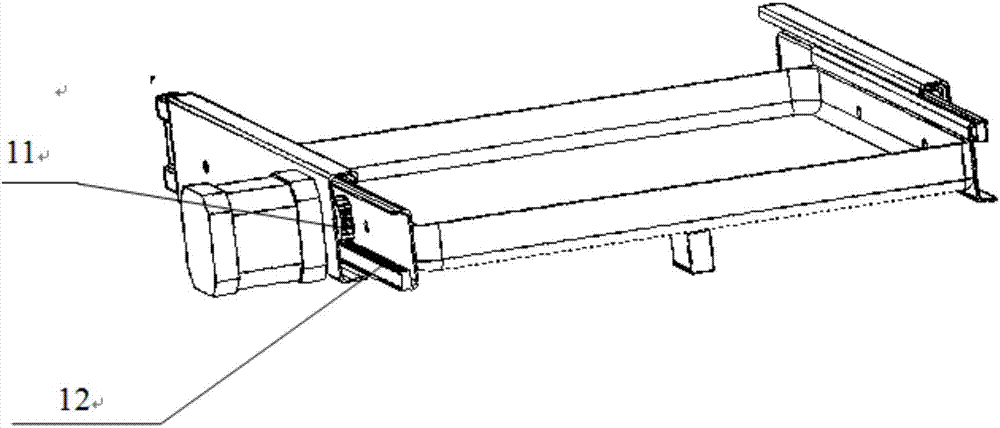

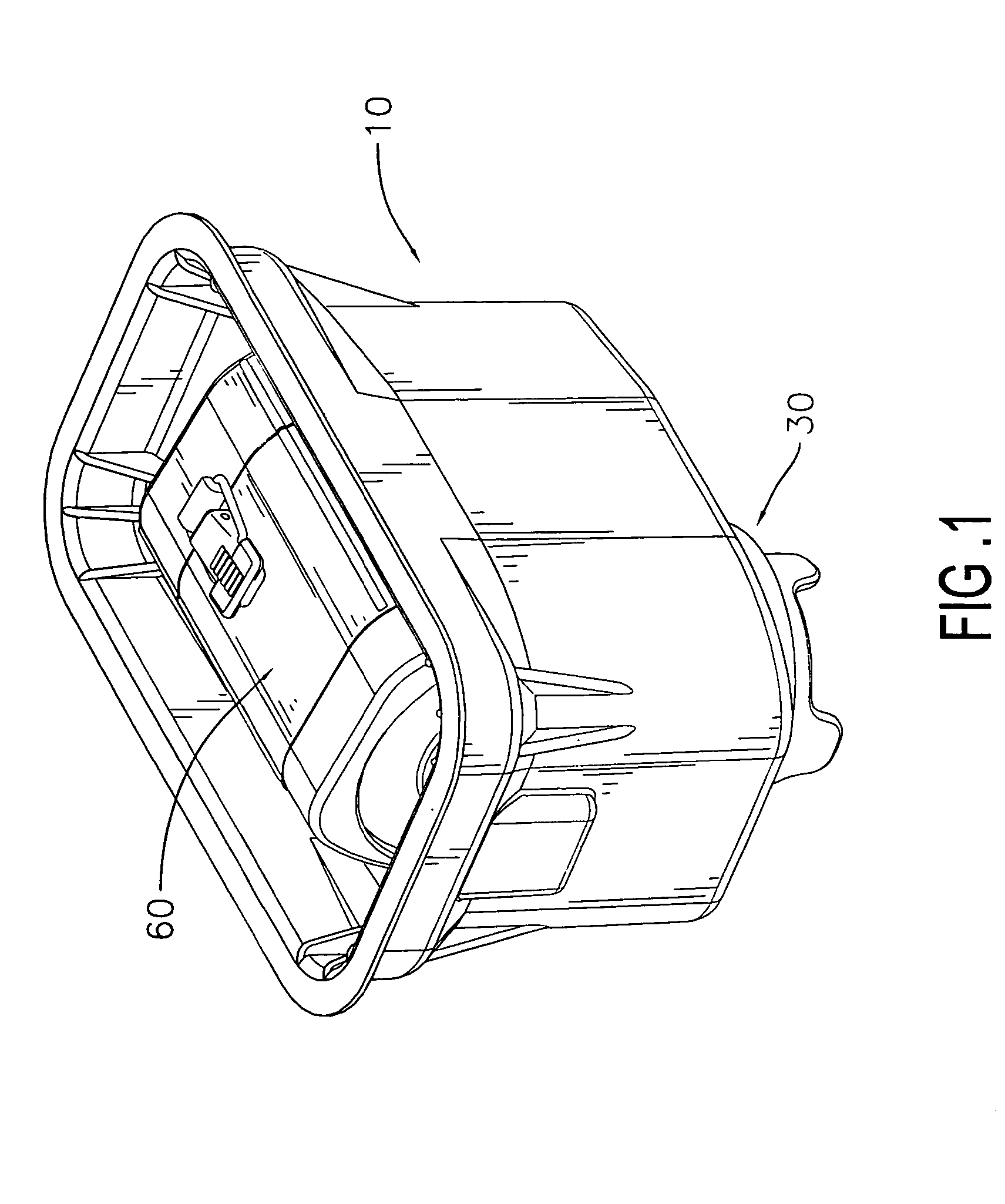

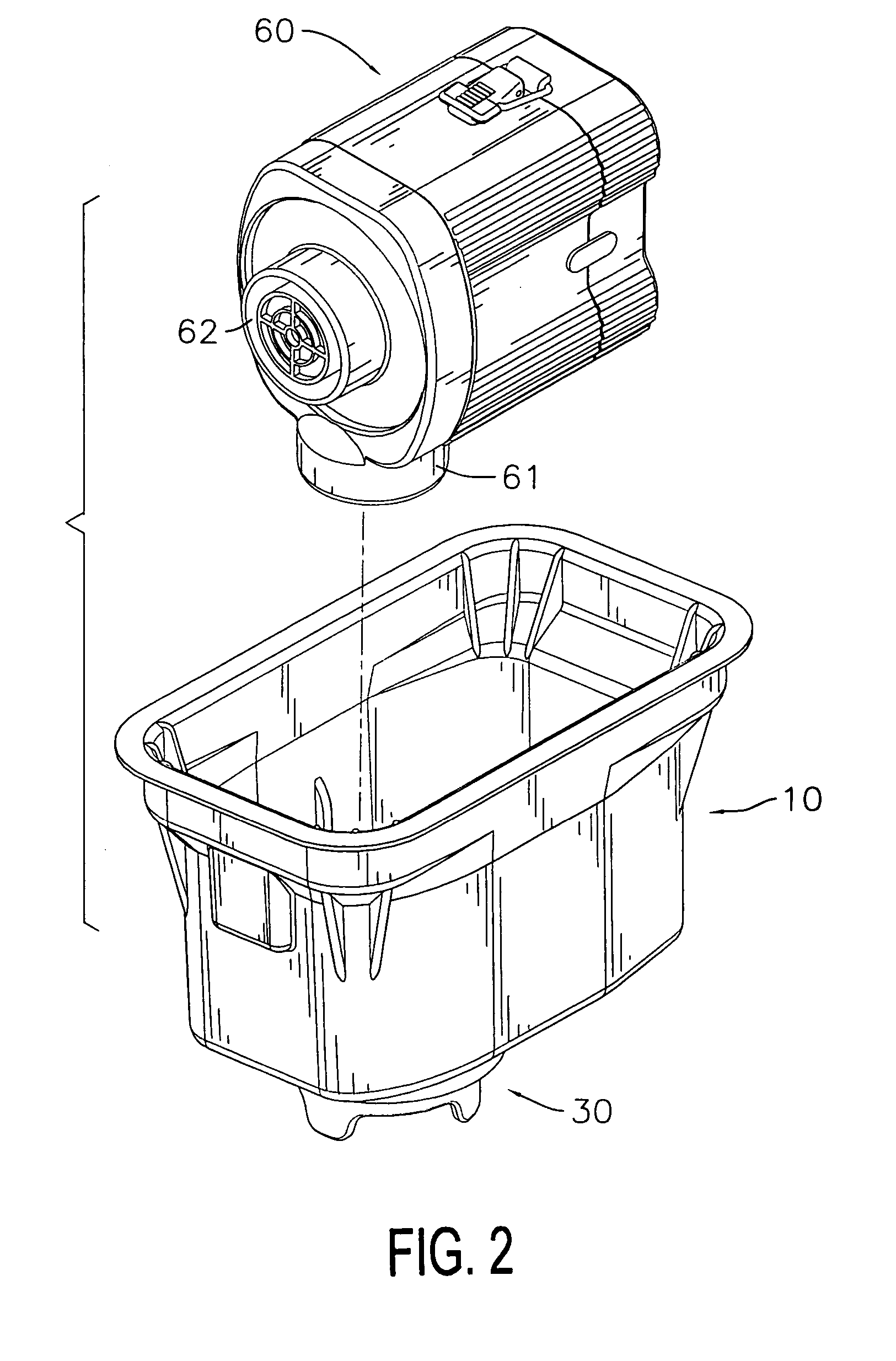

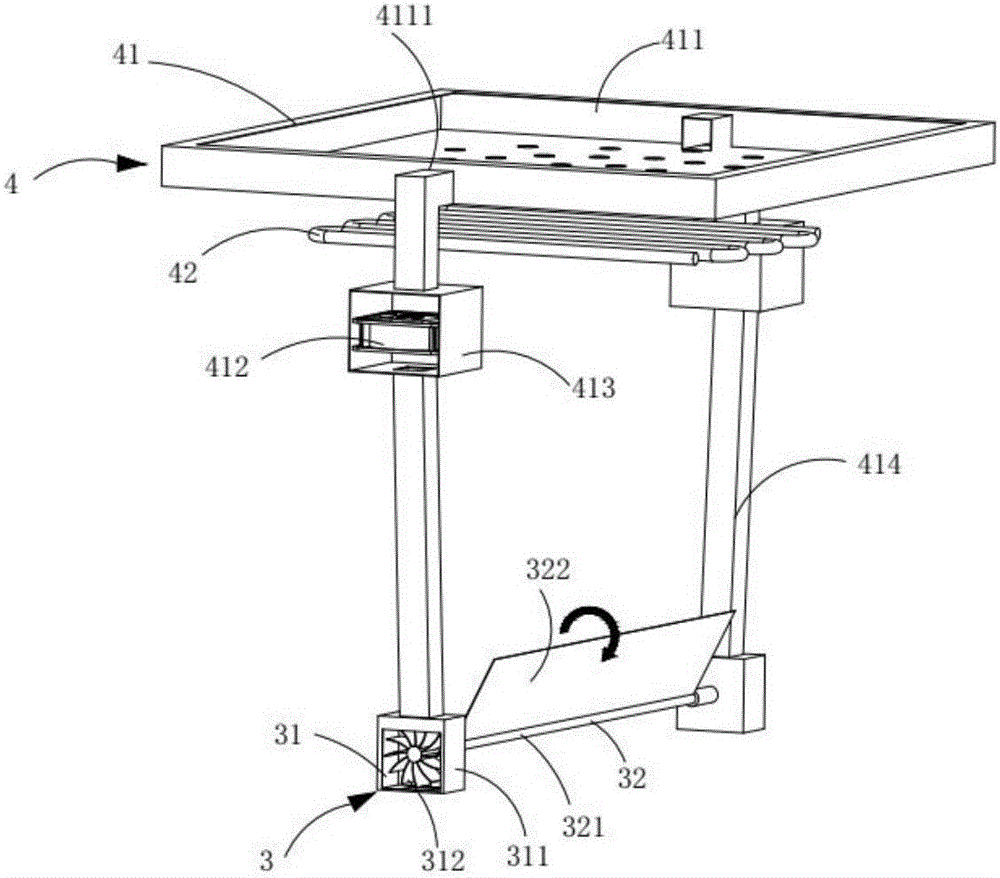

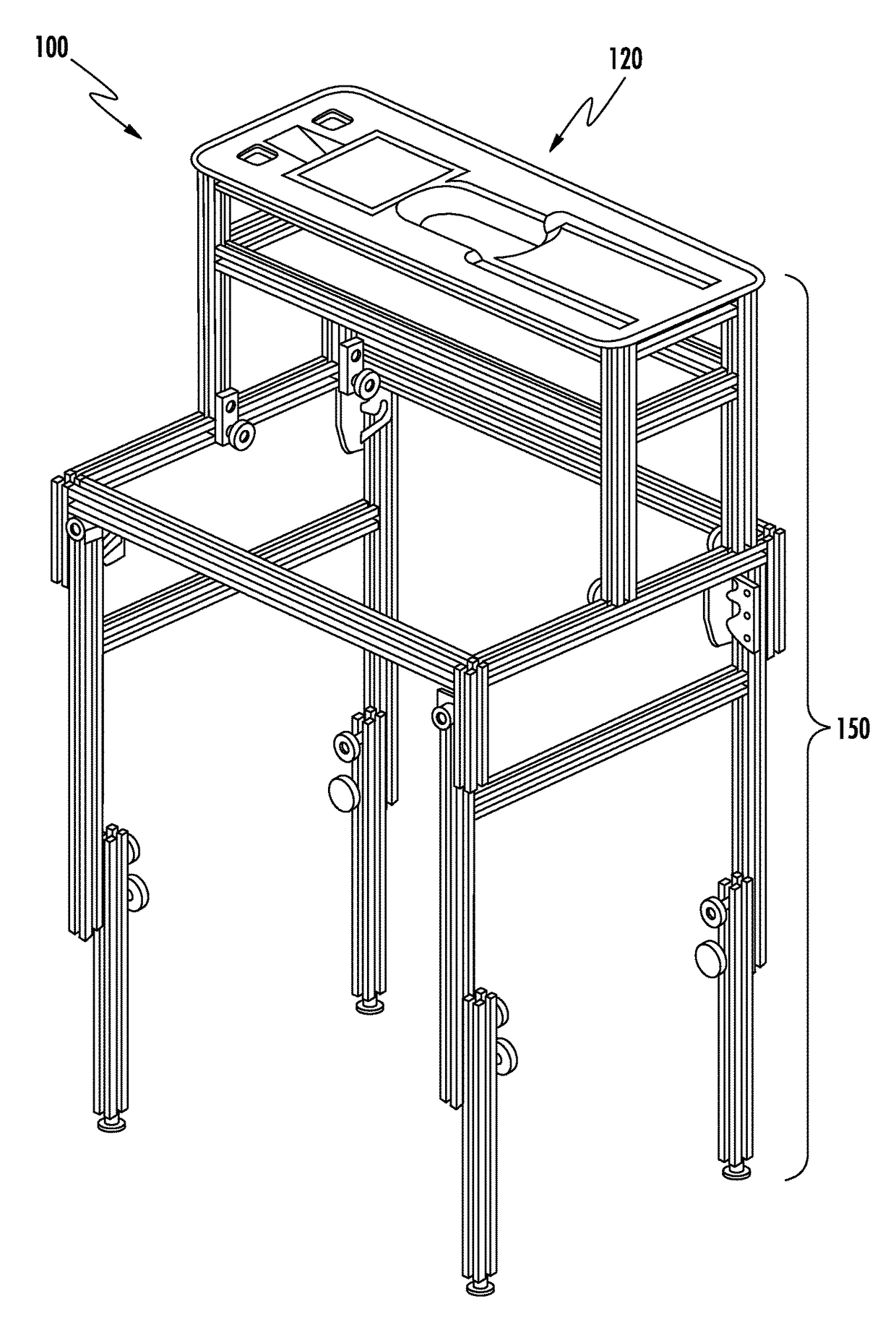

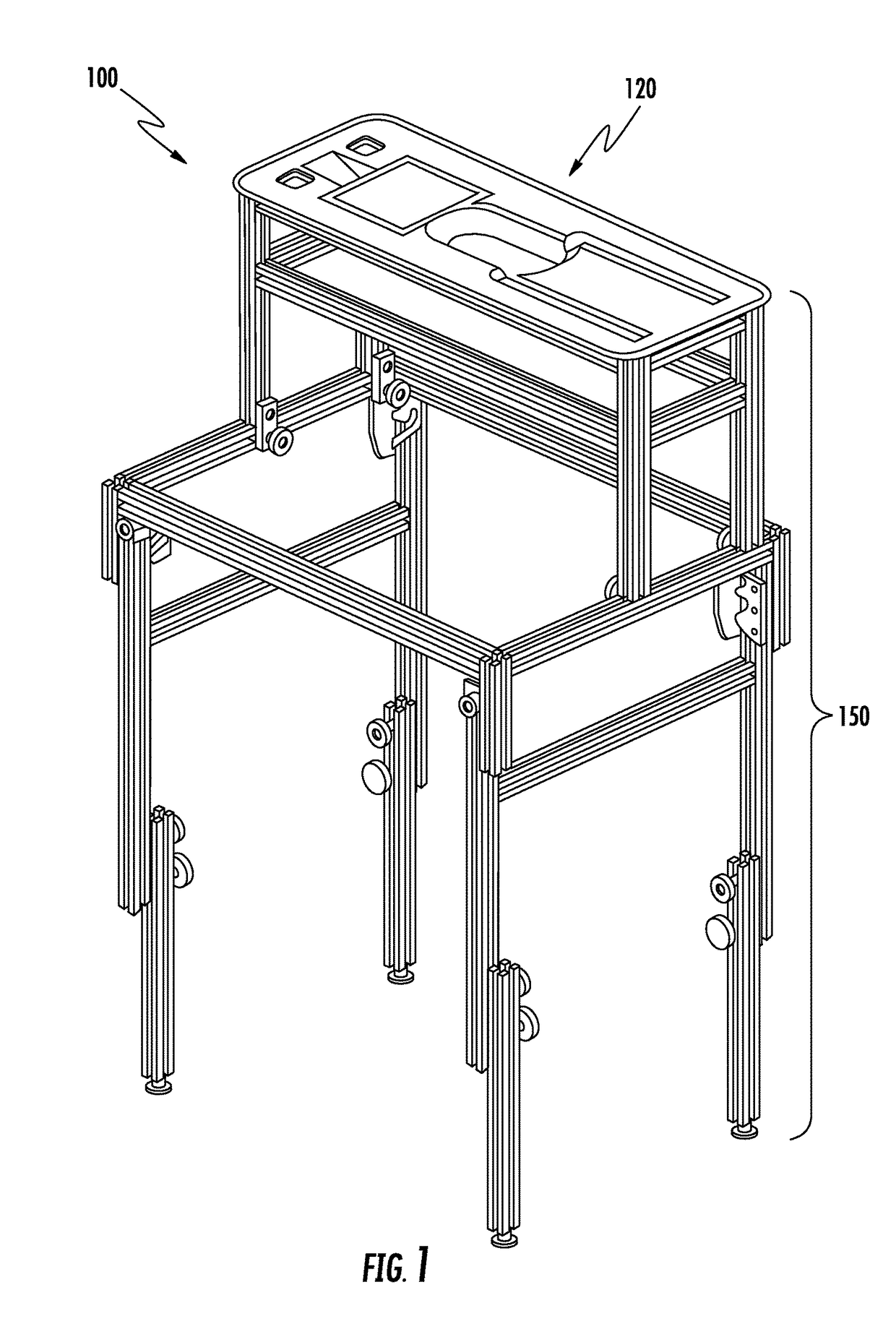

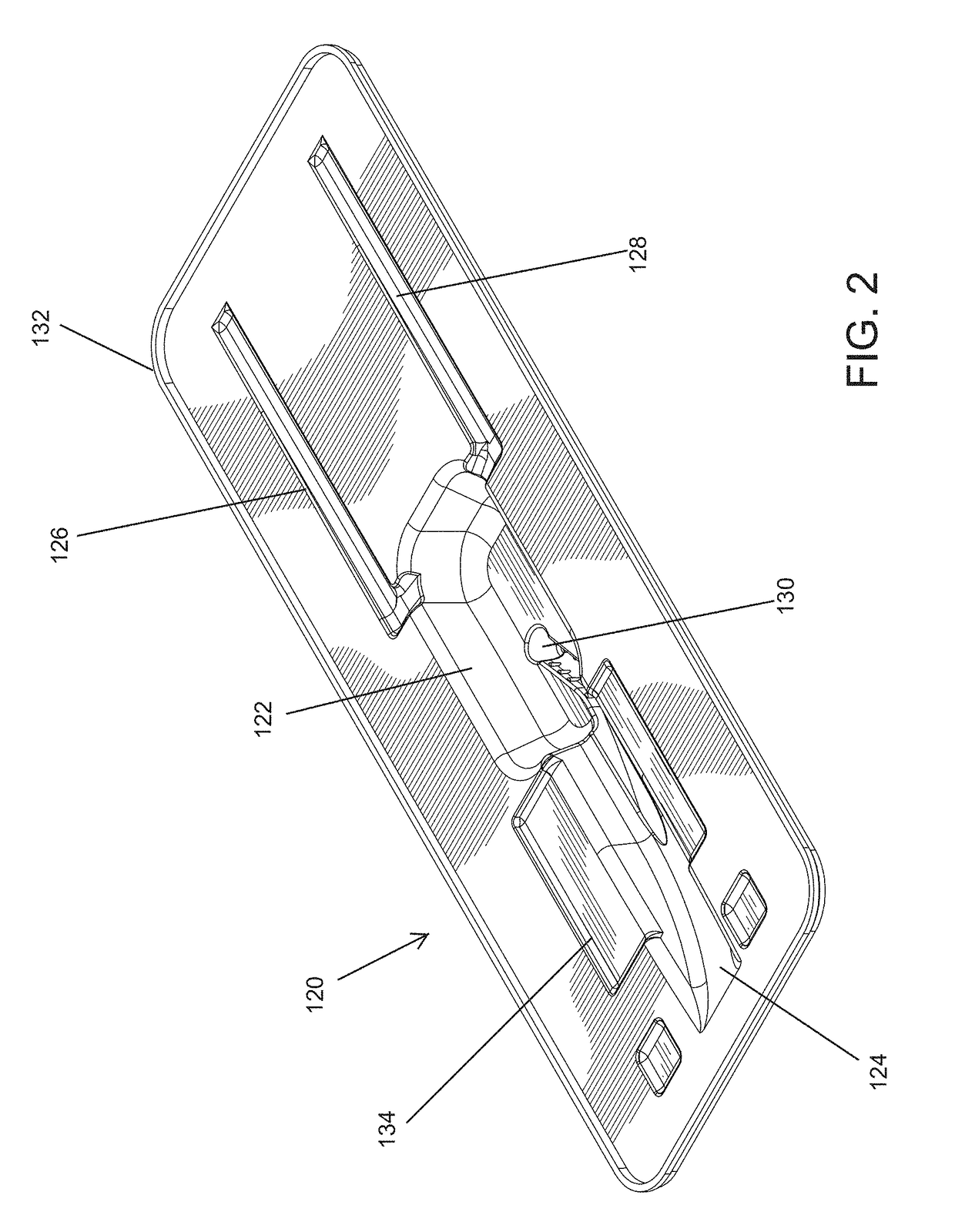

Surgical simulation assembly

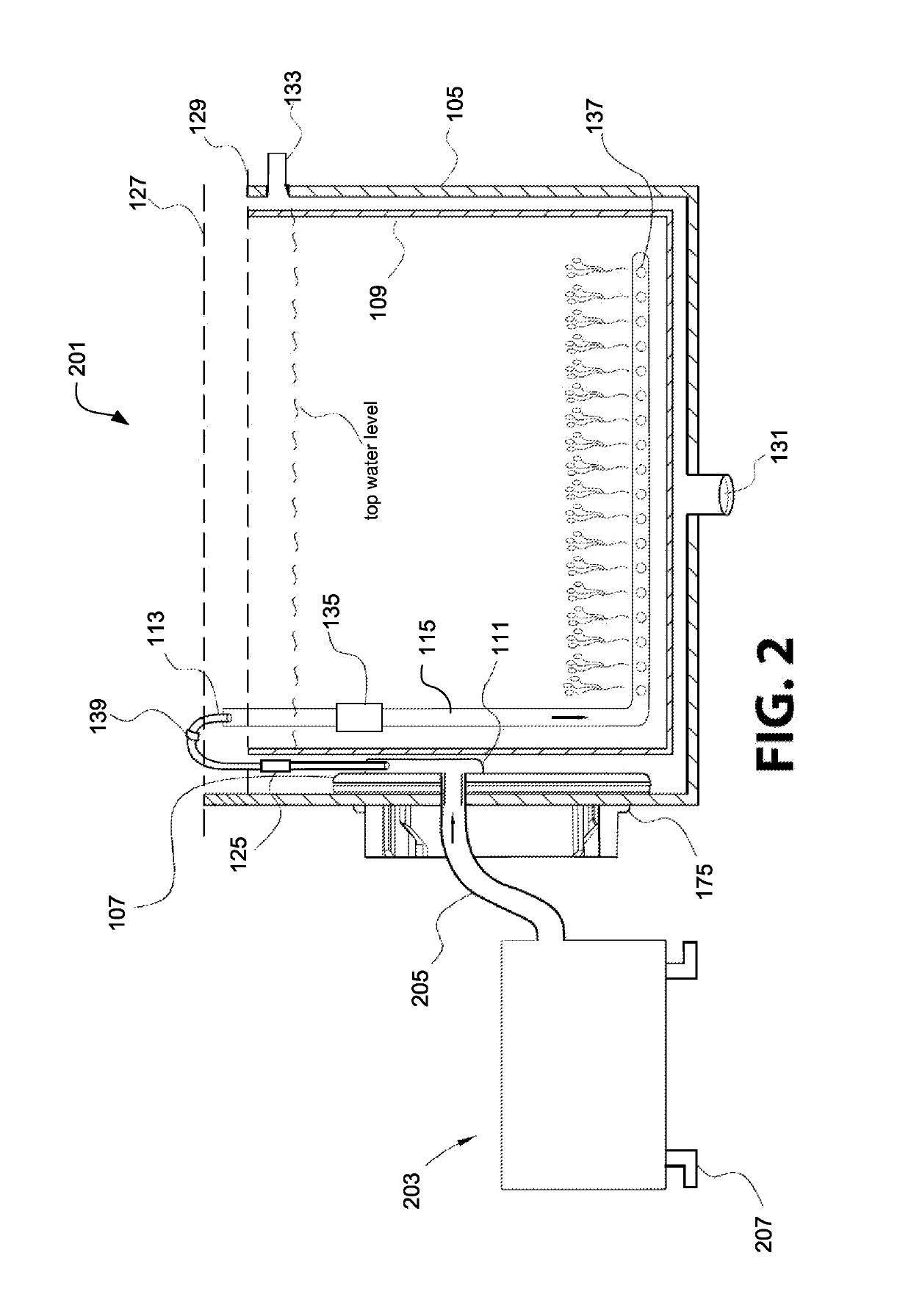

ActiveUS20150024362A1Easy to assembleOperating tablesEducational modelsAnimal OrgansPositive pressure

A surgical simulation assembly is provided for simulating realistic surgery on animal organs or human cadavers. The surgical simulation assembly comprises a generally flat tray having a central indentation for receiving an organ, at least one drainage aperture and at least one indented trough extending from the central indentation for receiving at least one tube. The tray is assembled with a simulator heart and lungs prepped for connection to a variable speed double action air pump assembly that creates both positive pressure and a vacuum on the heart to simulate a beating heart. The tray is supported on a basket having a lower containment portion for containing fluid waste collected during the simulated surgery. The basket is elevated by risers over a base designed to support the assembly.

Owner:INTUITIVE SURGICAL OPERATIONS INC

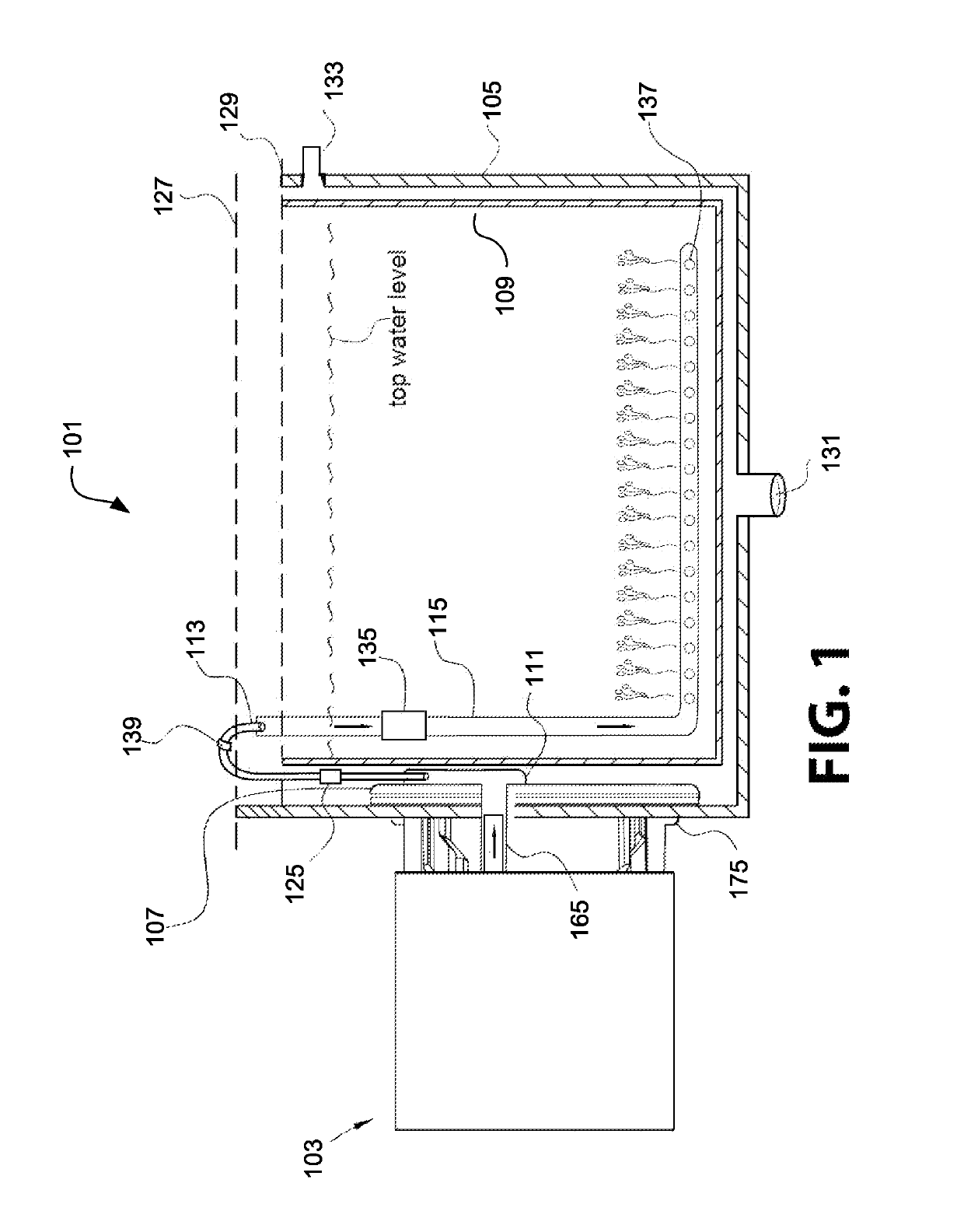

Liquid dispensing apparatus

ActiveUS20070181004A1Increase water flowOptimize volumeOpening closed containersBottle/container closureAir Pump AssemblyBiomedical engineering

A liquid dispensing apparatus for use in a beverage brewing machine, the liquid dispensing apparatus, includes a dispensing chamber, a liquid delivery and venting arrangement in communication with an interior of the dispensing chamber for delivery of liquid thereto and for venting air therefrom, an air pump assembly in communication with the interior of the heating and dispensing chamber for pumping air into the dispensing chamber, a liquid discharge conduit in communication with the interior of the heating and dispensing chamber for discharging liquid therefrom, an end of the discharge conduit located at a predetermined level of the dispensing chamber, and a liquid pump connected to the liquid discharge conduit for pumping liquid out of the heating and dispensing chamber. During liquid dispensing, the liquid delivery and venting arrangement is closed.

Owner:1693778 ONTARIO LTD

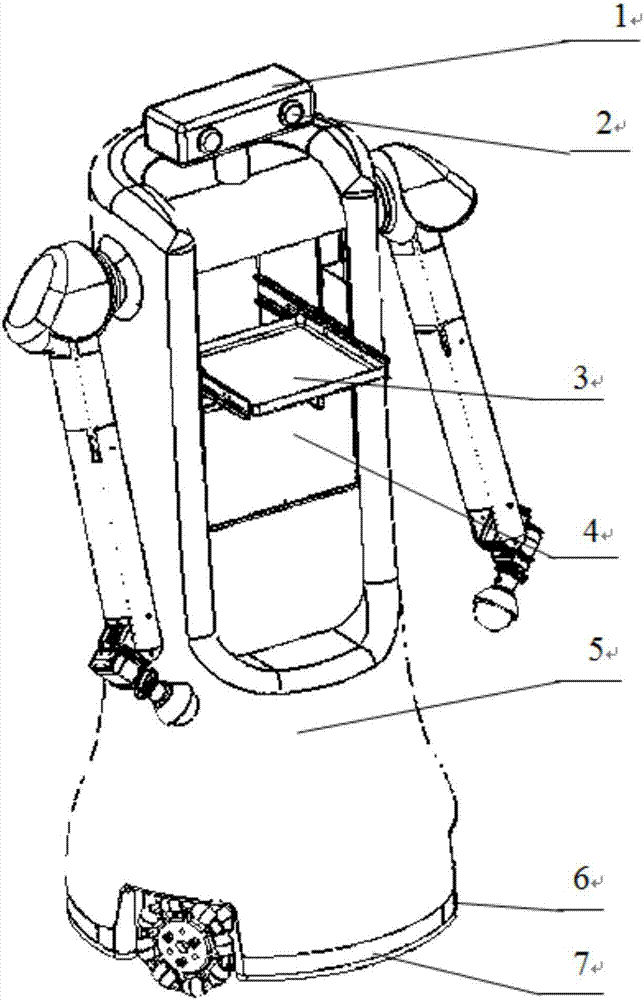

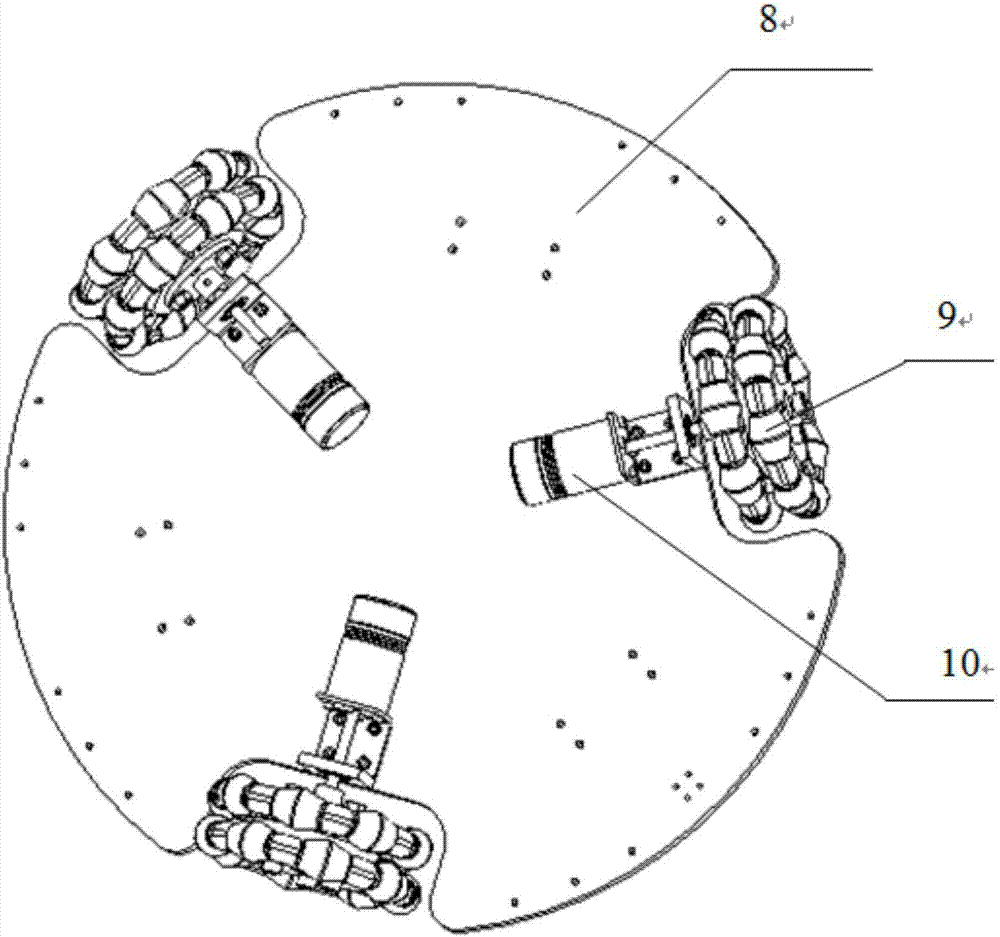

All-direction movable food delivering robot

The invention relates to an all-direction movable food delivering robot. The all-direction movable food delivering robot comprises a bottom plate and further comprises a body, hands, a head and a telescopic tray, all of which are arranged on the bottom plate. The left hand or the right hand comprises an arm and a spherical hand. The left hand and the right hand are integrated with the body into a whole. Each arm is provided with a shoulder joint, an elbow joint and a wrist joint, wherein the lower end of the wrist joint is connected with a joint air pump assembly and the corresponding spherical hand filled with coffee powder. The lower portion of the body is connected with the bottom plate. The bottom plate is provided with three sets of walking universal wheels, a human body sensor inducting the human body, an obstacle avoiding sensor used for achieving obstacle avoiding steering, a storage battery, a charging module and a master controller. An emergency stop device is arranged on the back of the body, the upper end of the body is connected with the head, positioning cameras are arranged in the head, and the telescopic tray is fixed in the body chest. The all-direction movable food delivering robot is simple in structure and low in cost and is applied to the restaurant food delivering service, the problem that the restaurant manual cost is high can be solved, meanwhile, the food can be directly served to a dining table, and people can feel comfortable and sense the technology charm.

Owner:HUBEI UNIV OF TECH

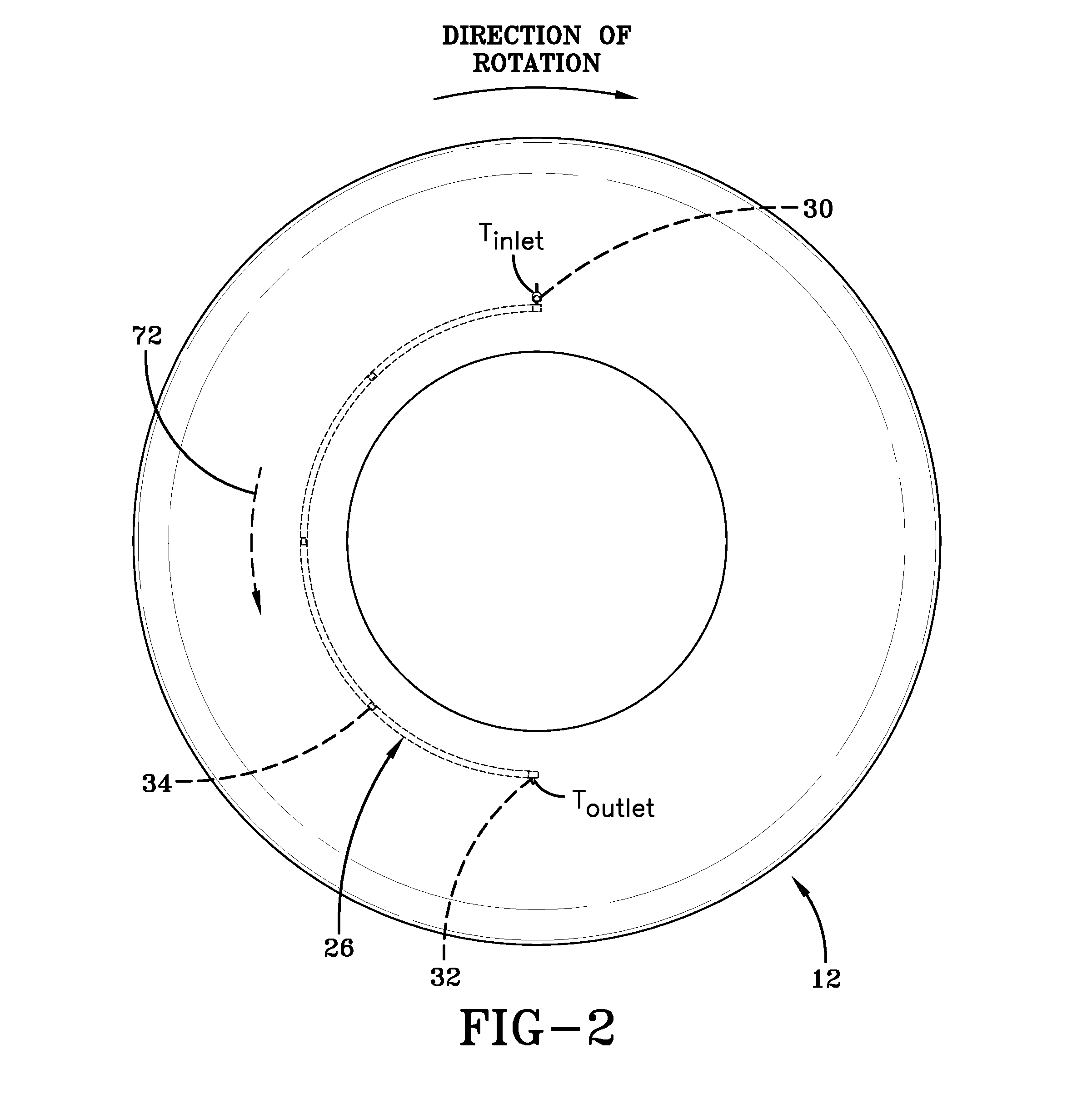

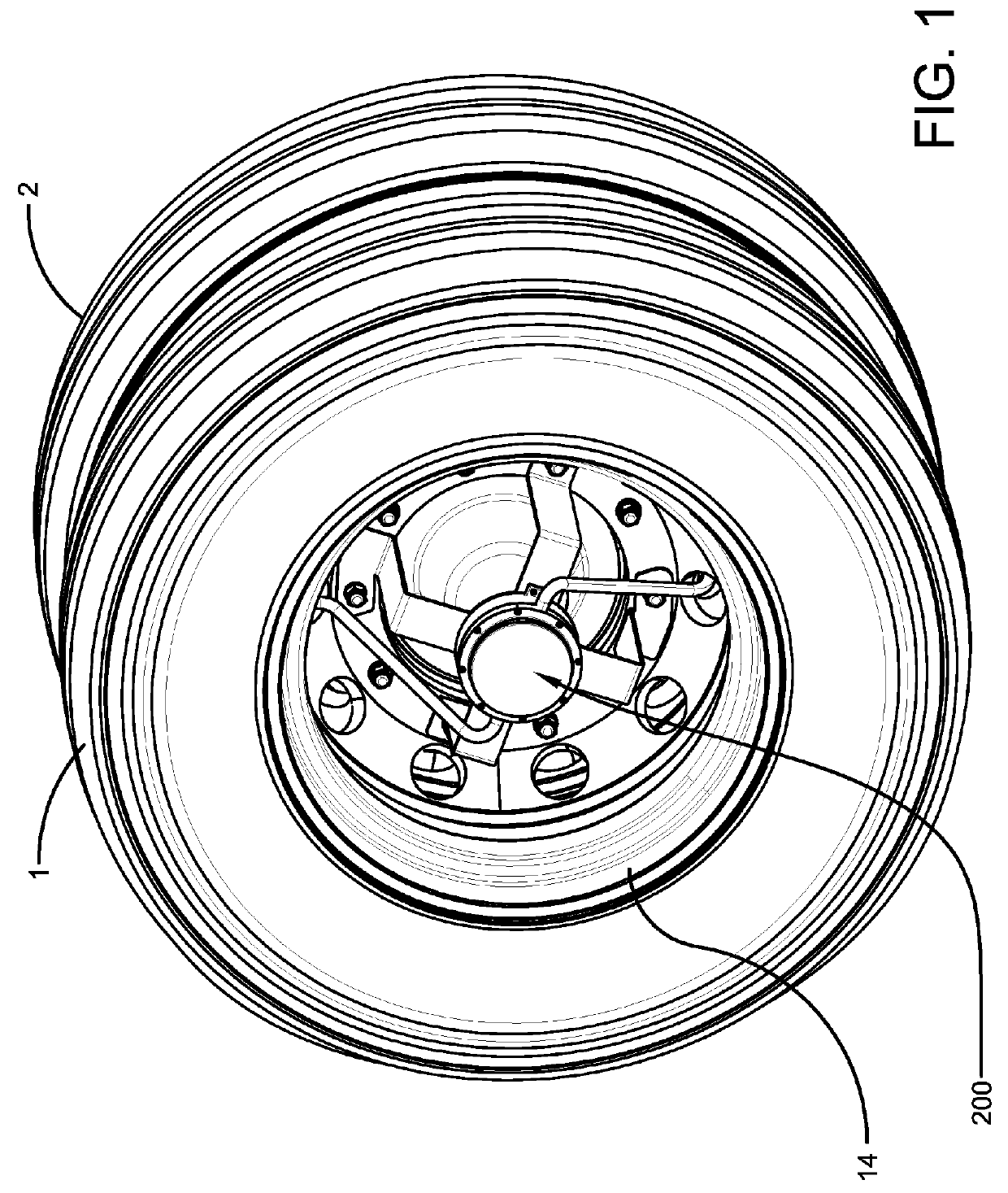

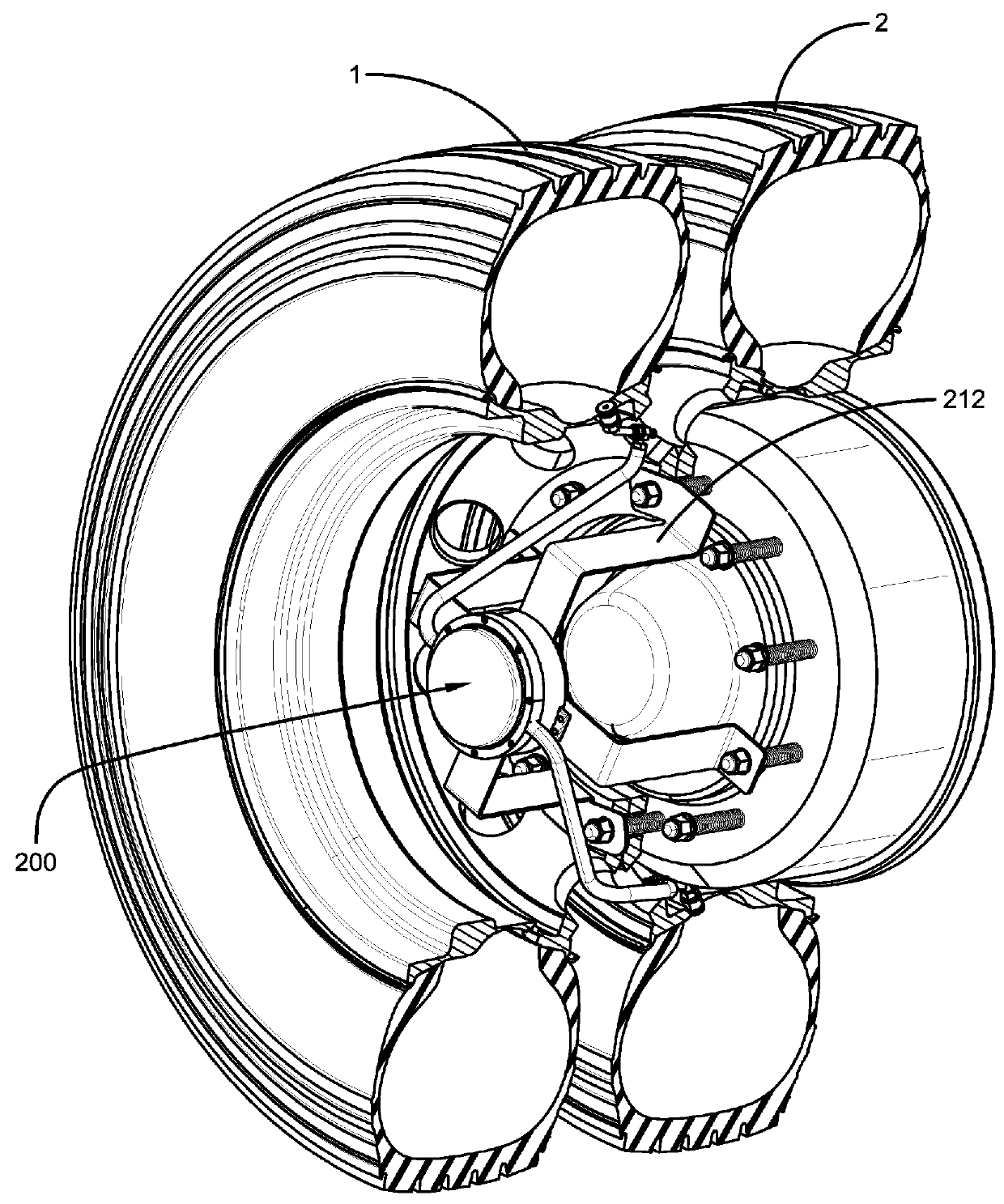

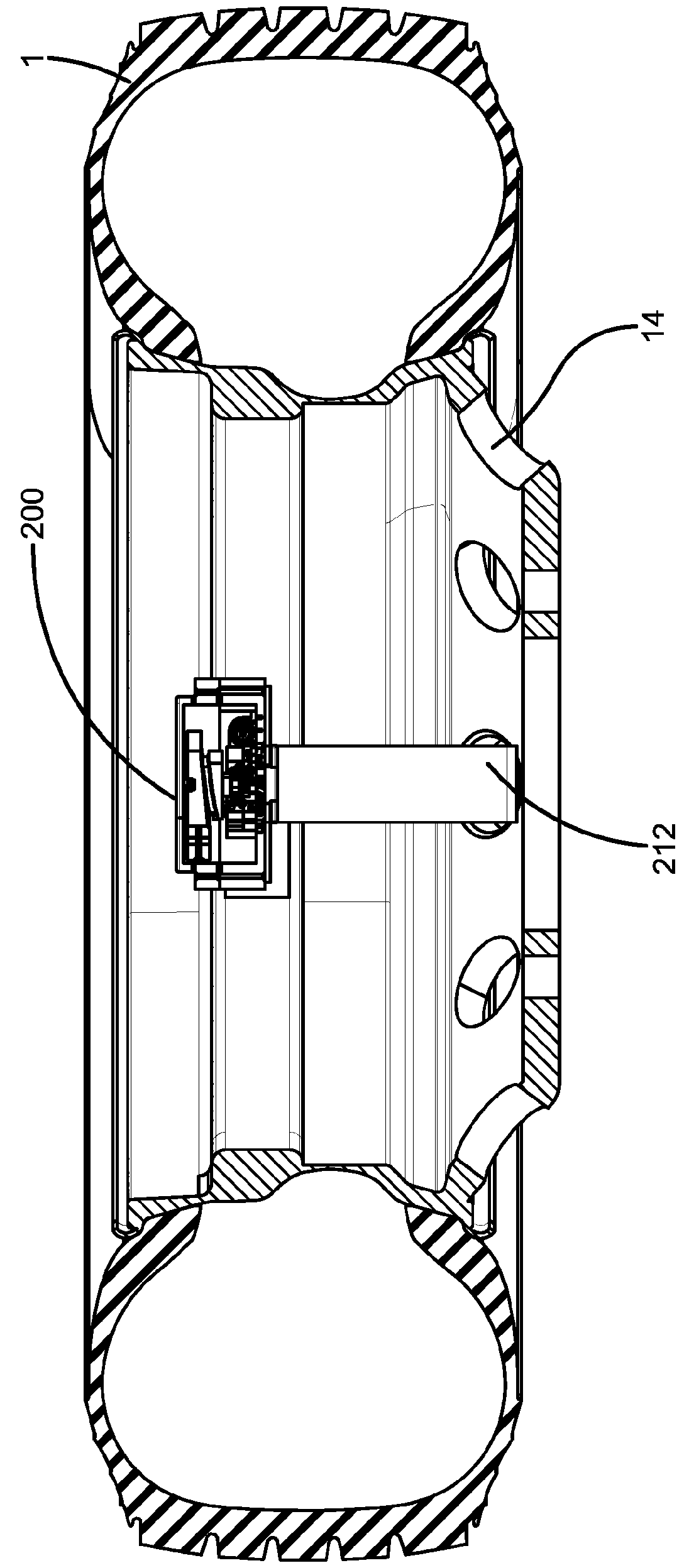

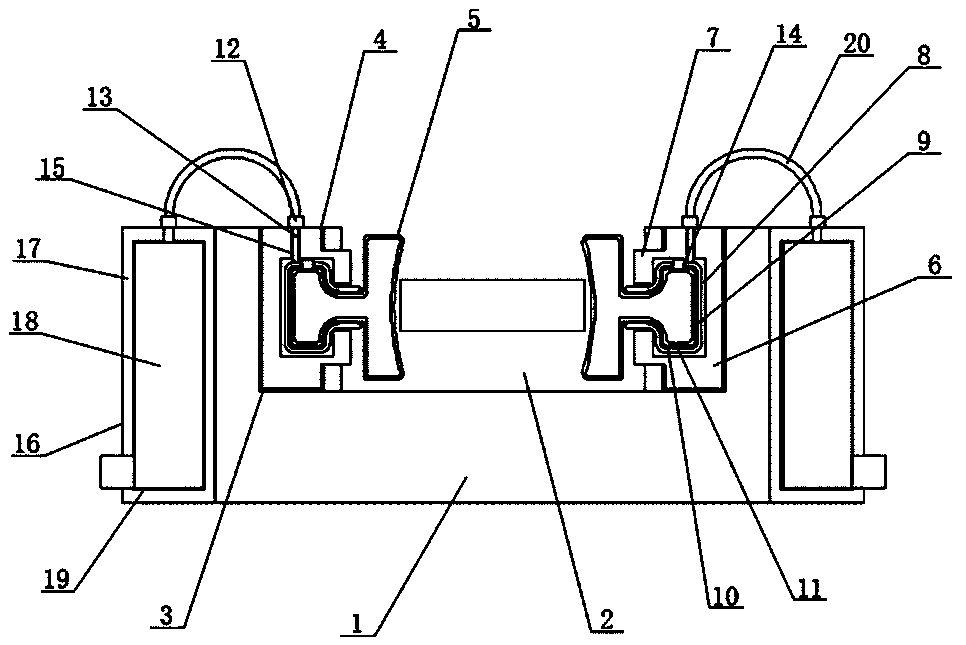

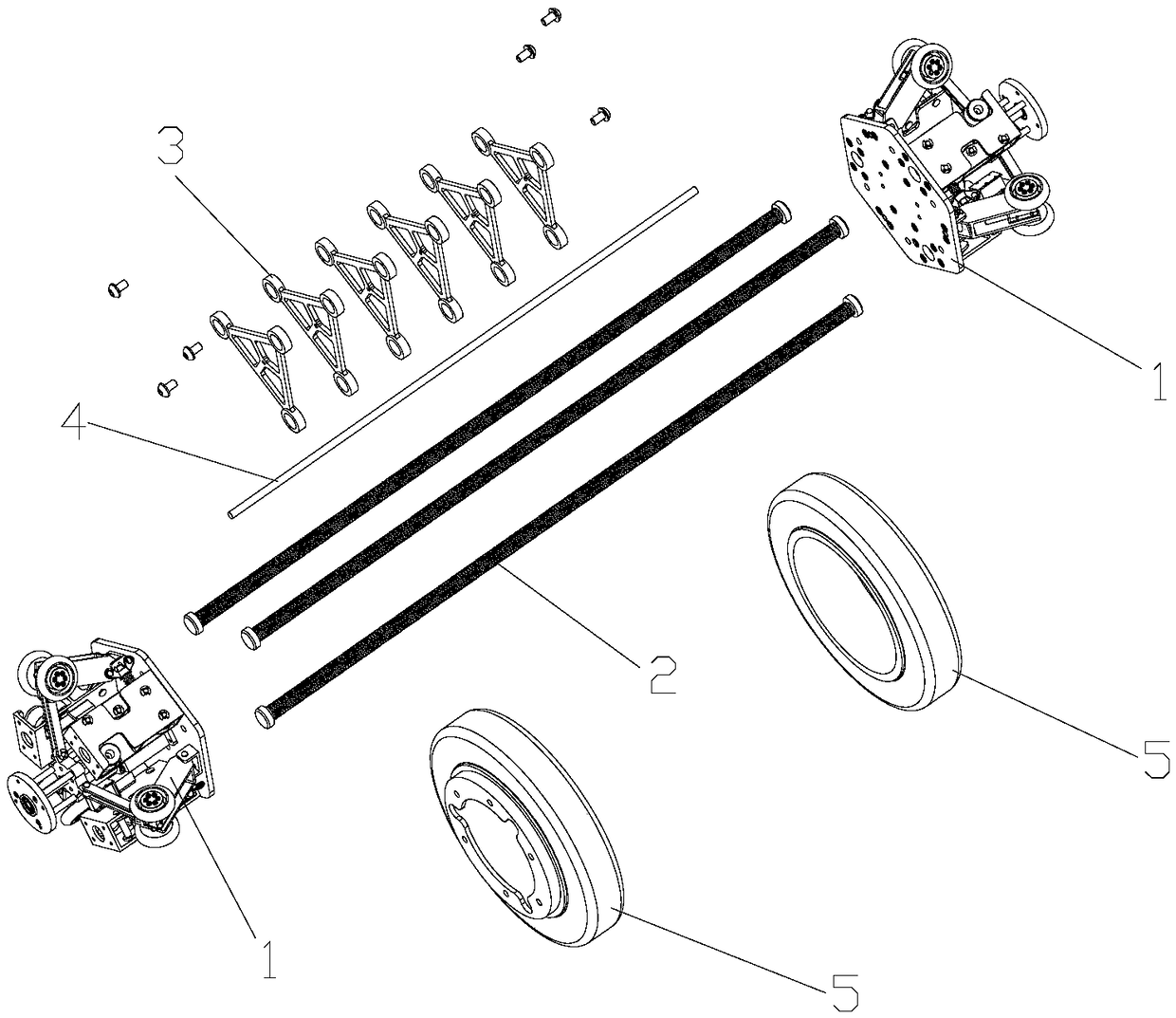

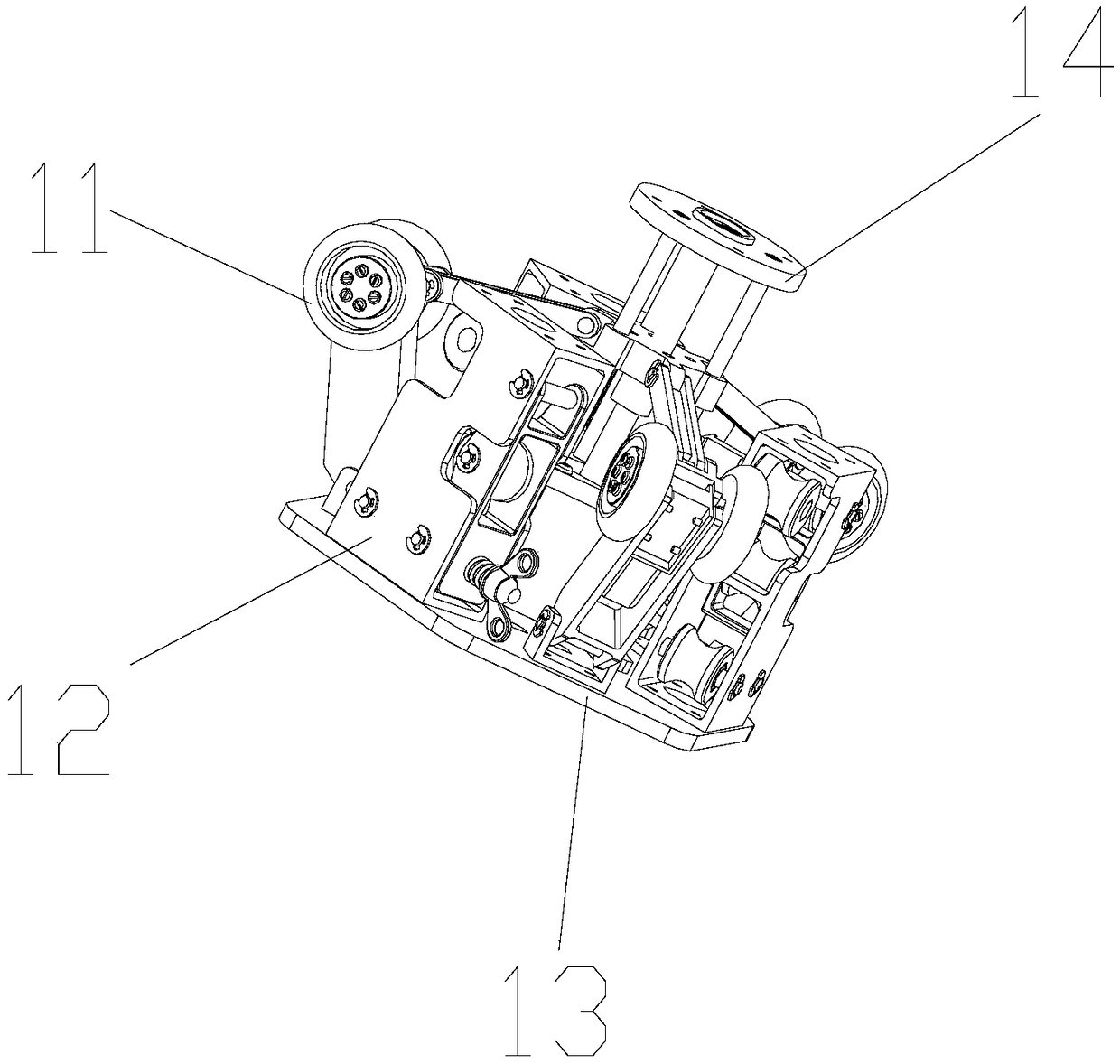

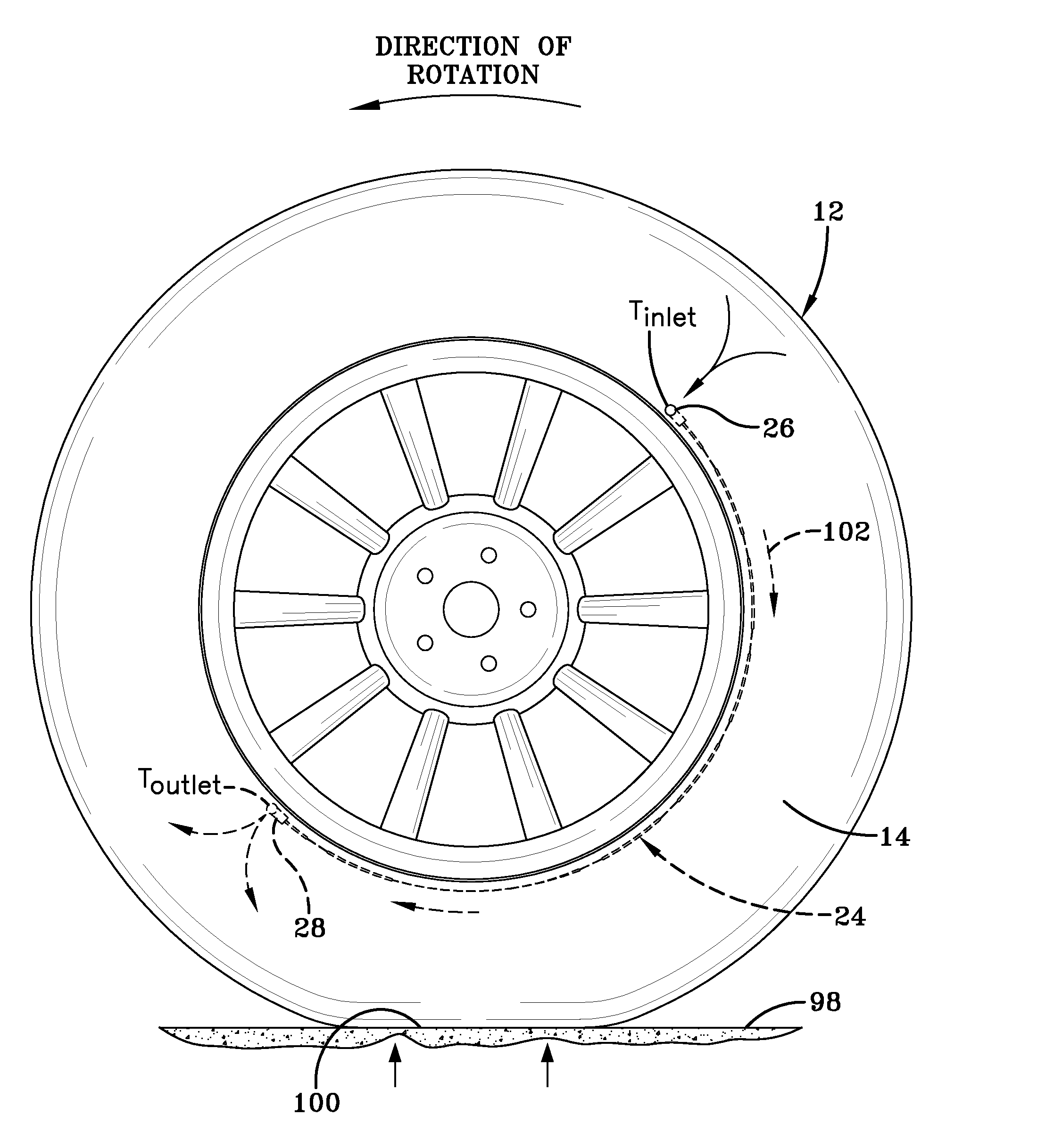

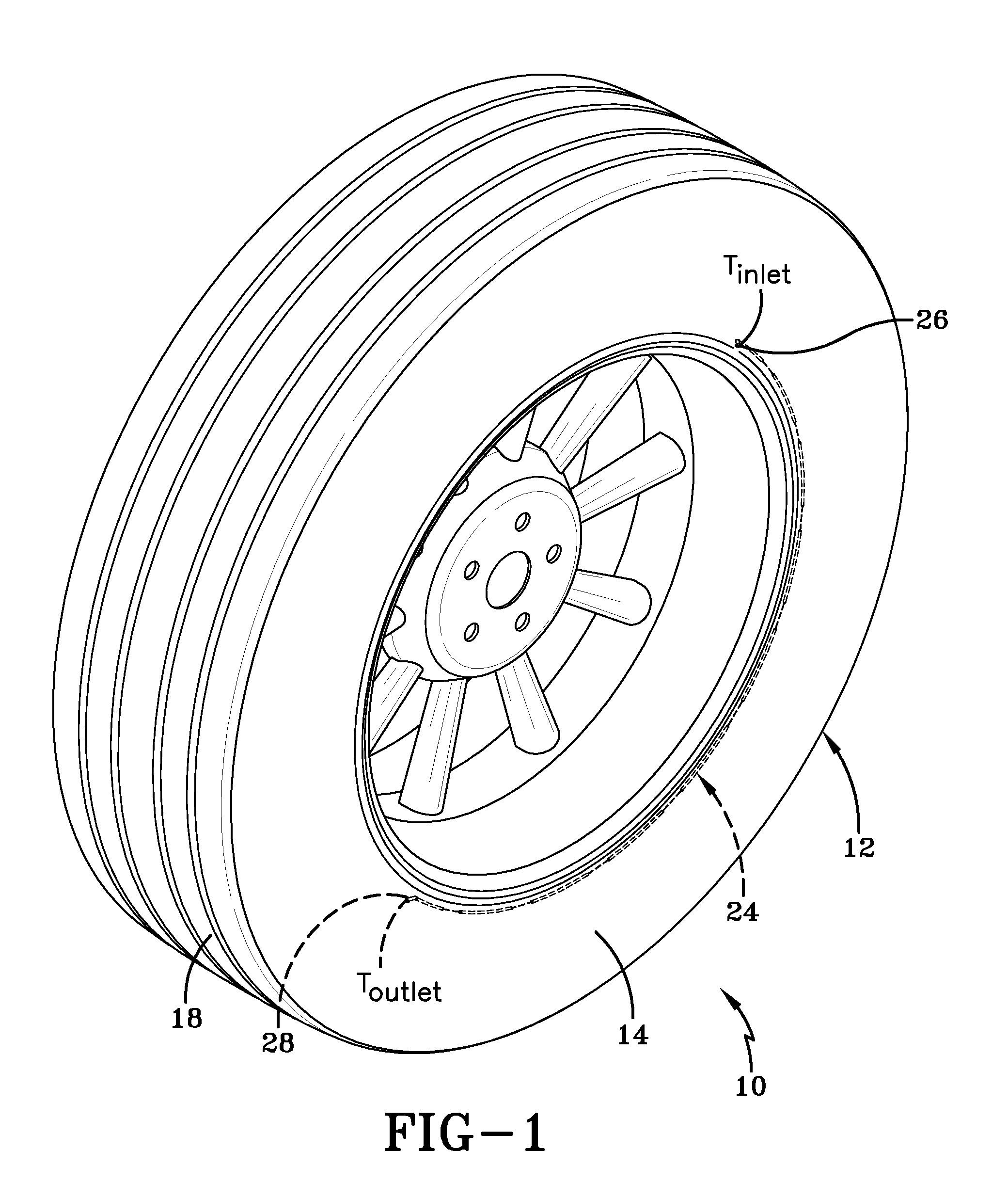

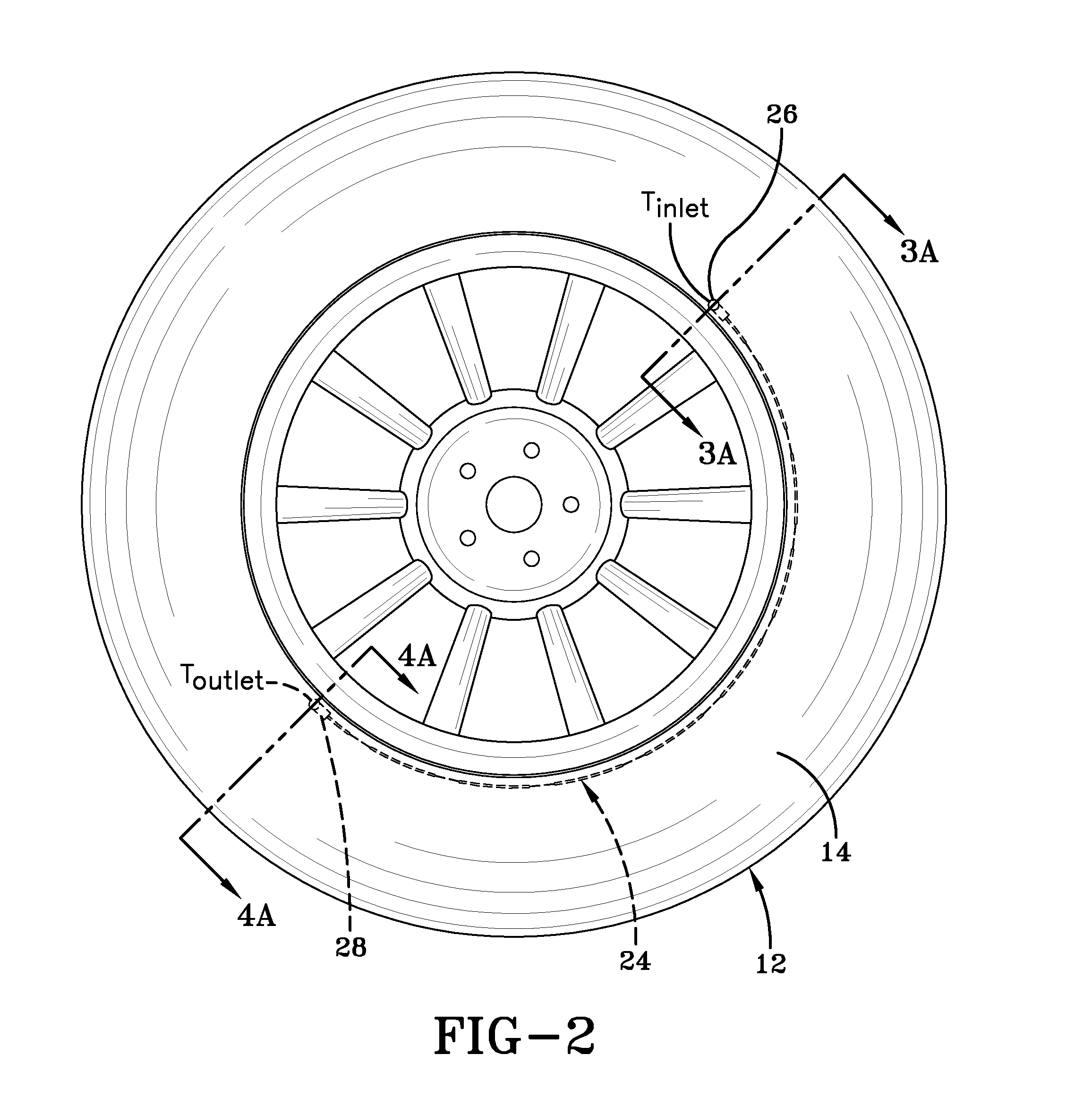

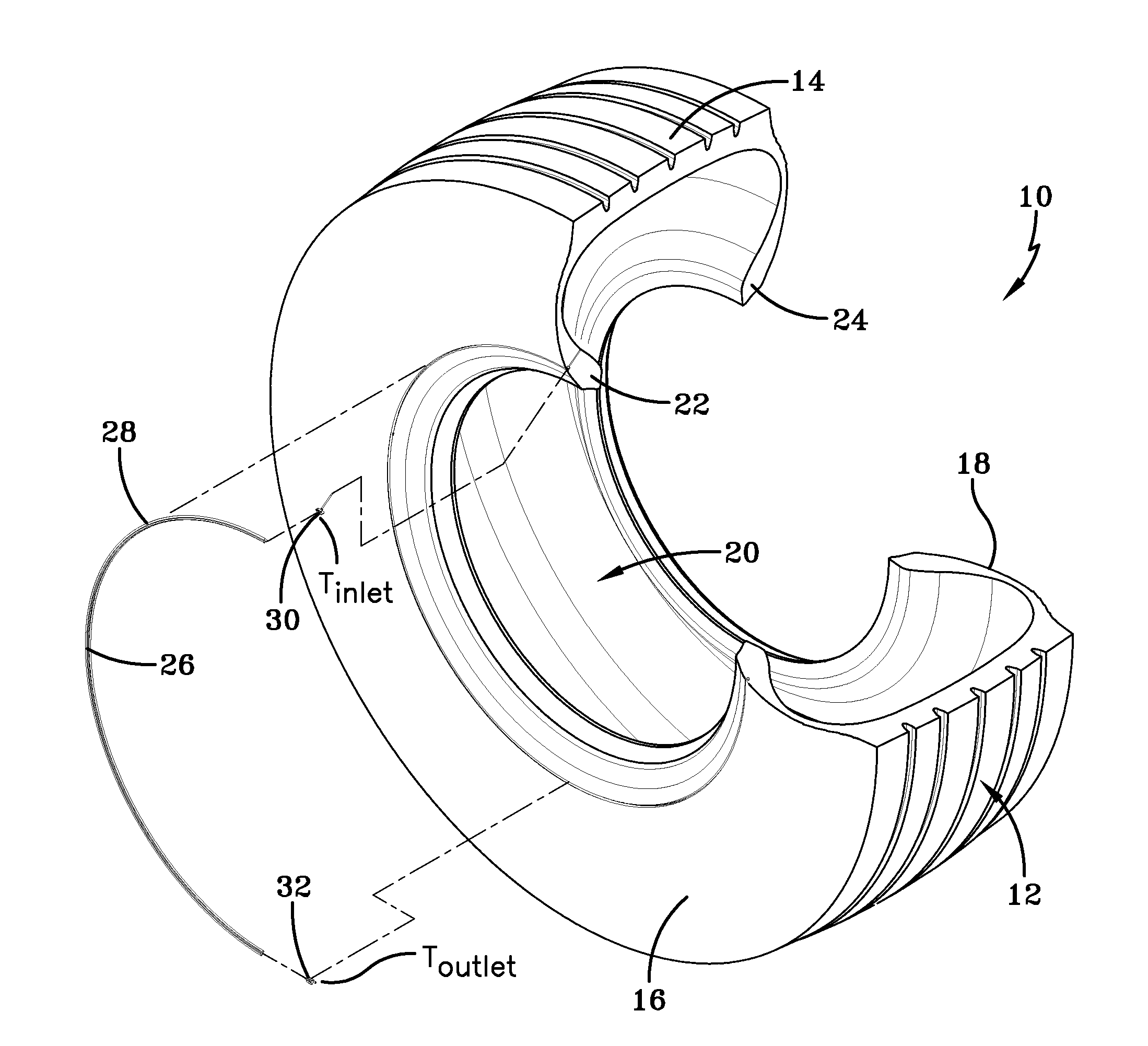

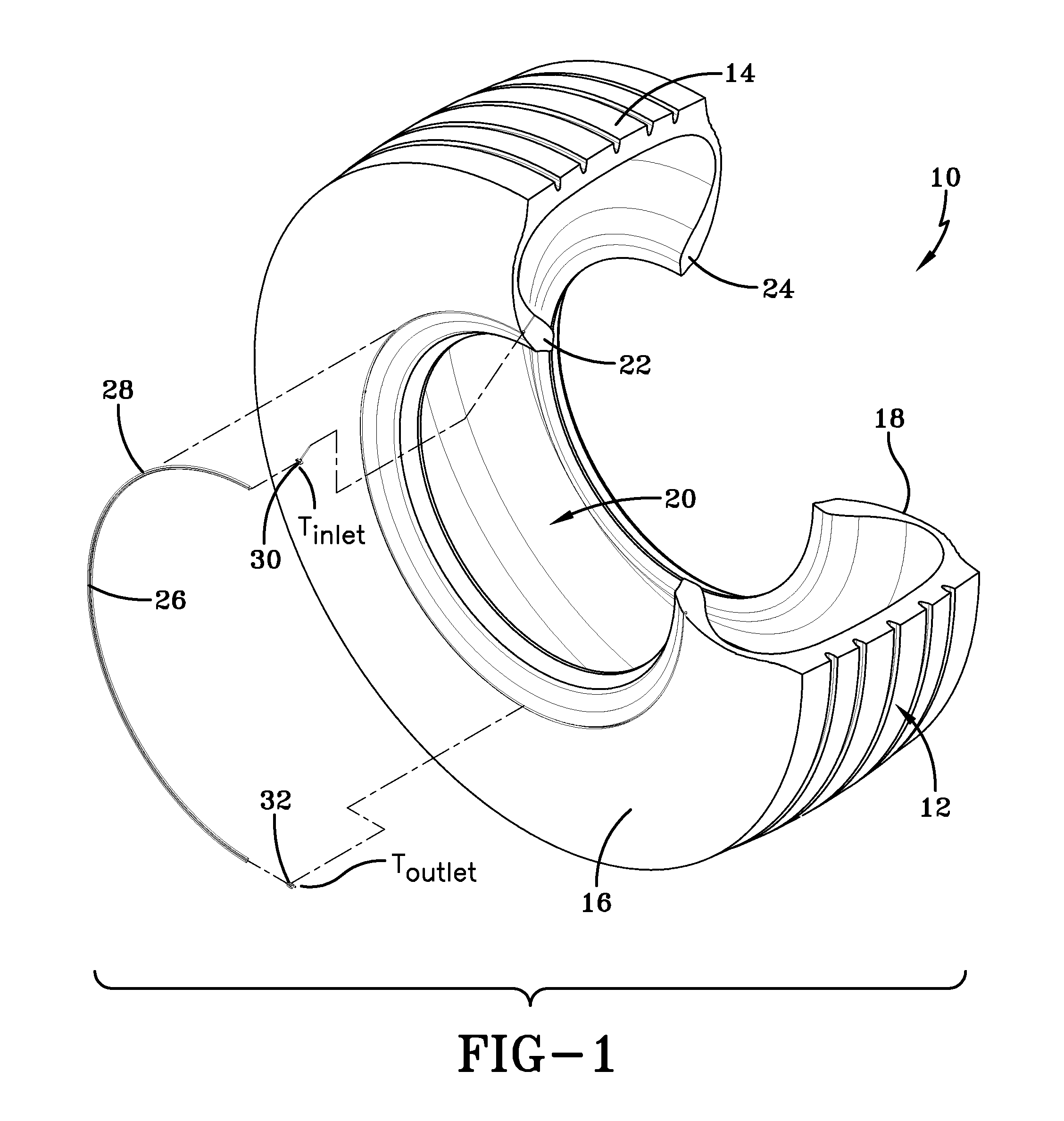

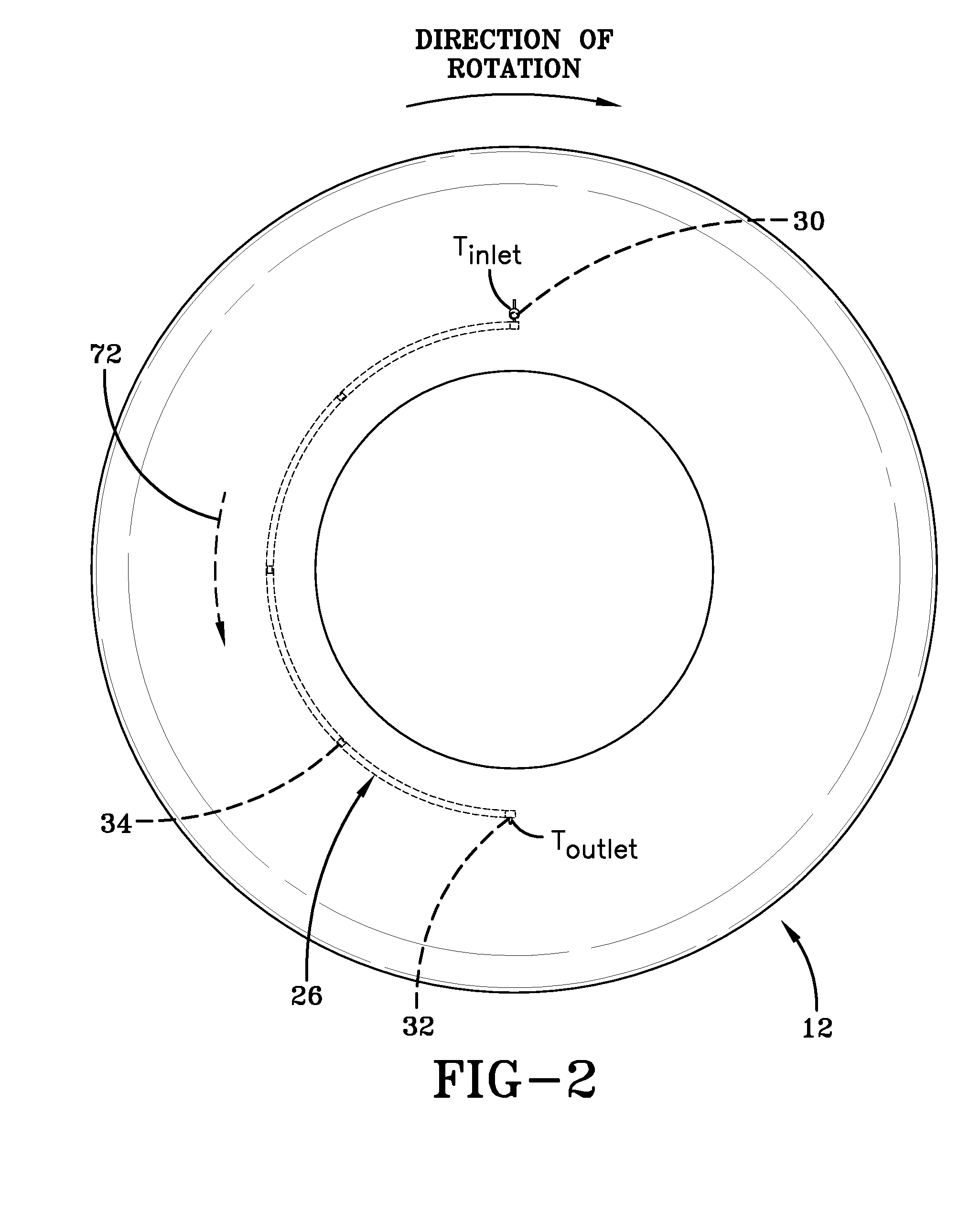

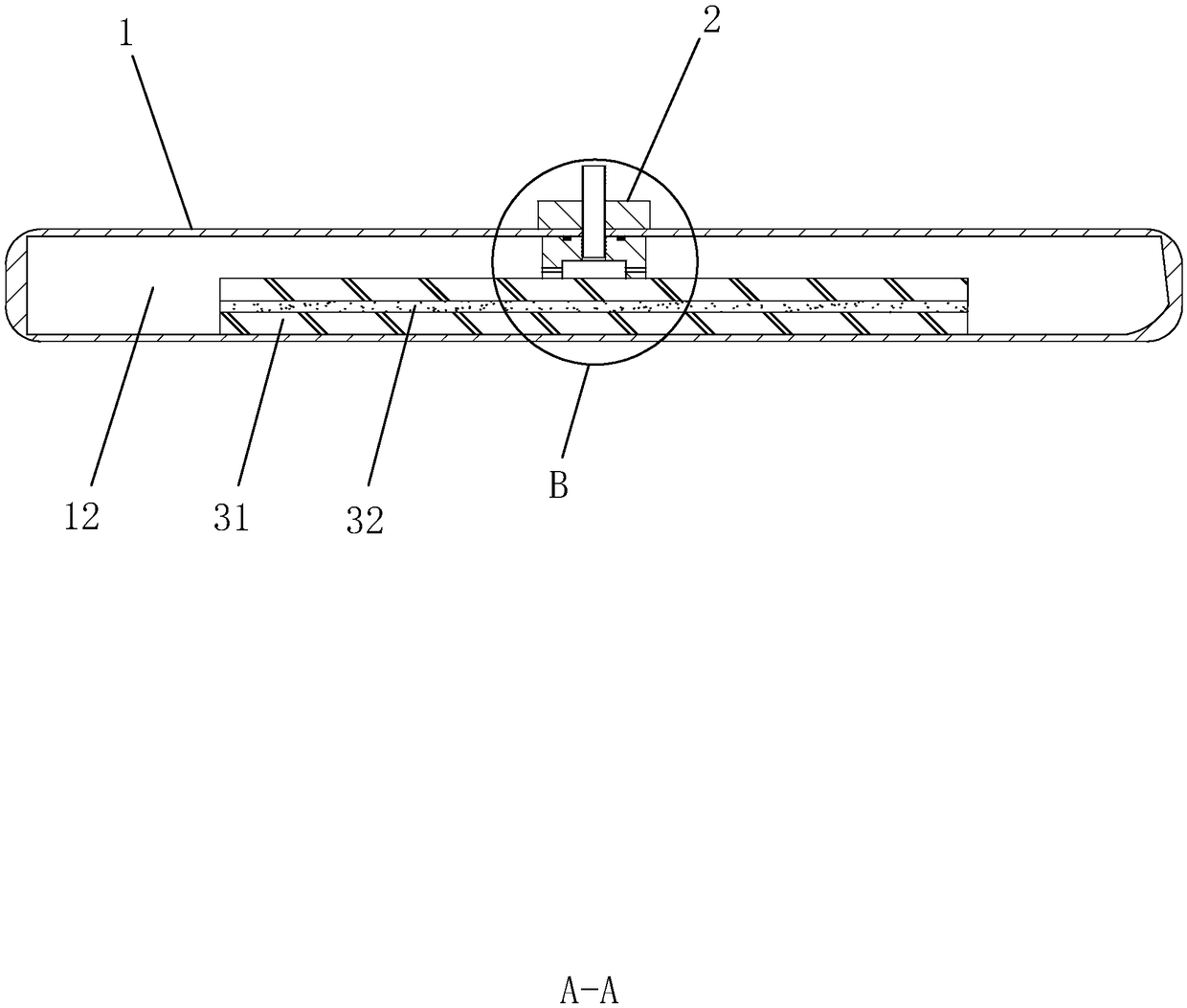

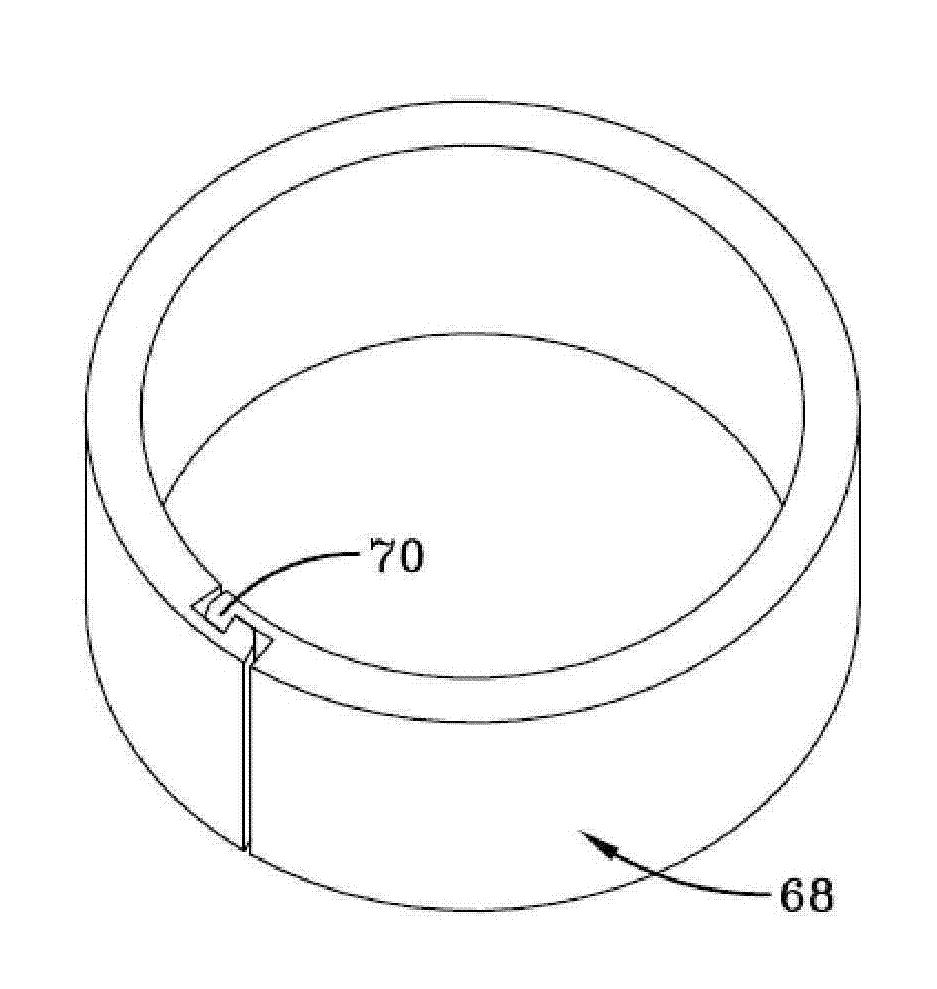

Vein pump assembly for air maintenance tire

InactiveUS20140110029A1Great tractionTyre measurementsTyre-inflating valvesCheck valveAir Pump Assembly

An air maintenance tire and air pump assembly is provided including a tire and an elongate tubular air passageway enclosed within a flexing region of a tire sidewall. A plurality of check valve devices are spaced apart and positioned along the air passageway into multiple air passageway segments. A check valve membrane opens to allow pressurized air to directionally pass through the check valve device from an upstream passageway segment to a downstream passageway segment and closes to prevent air from passing in an opposite direction through the check valve from the downstream segment to the upstream segment.

Owner:BENEDICT ROBERT LEON +4

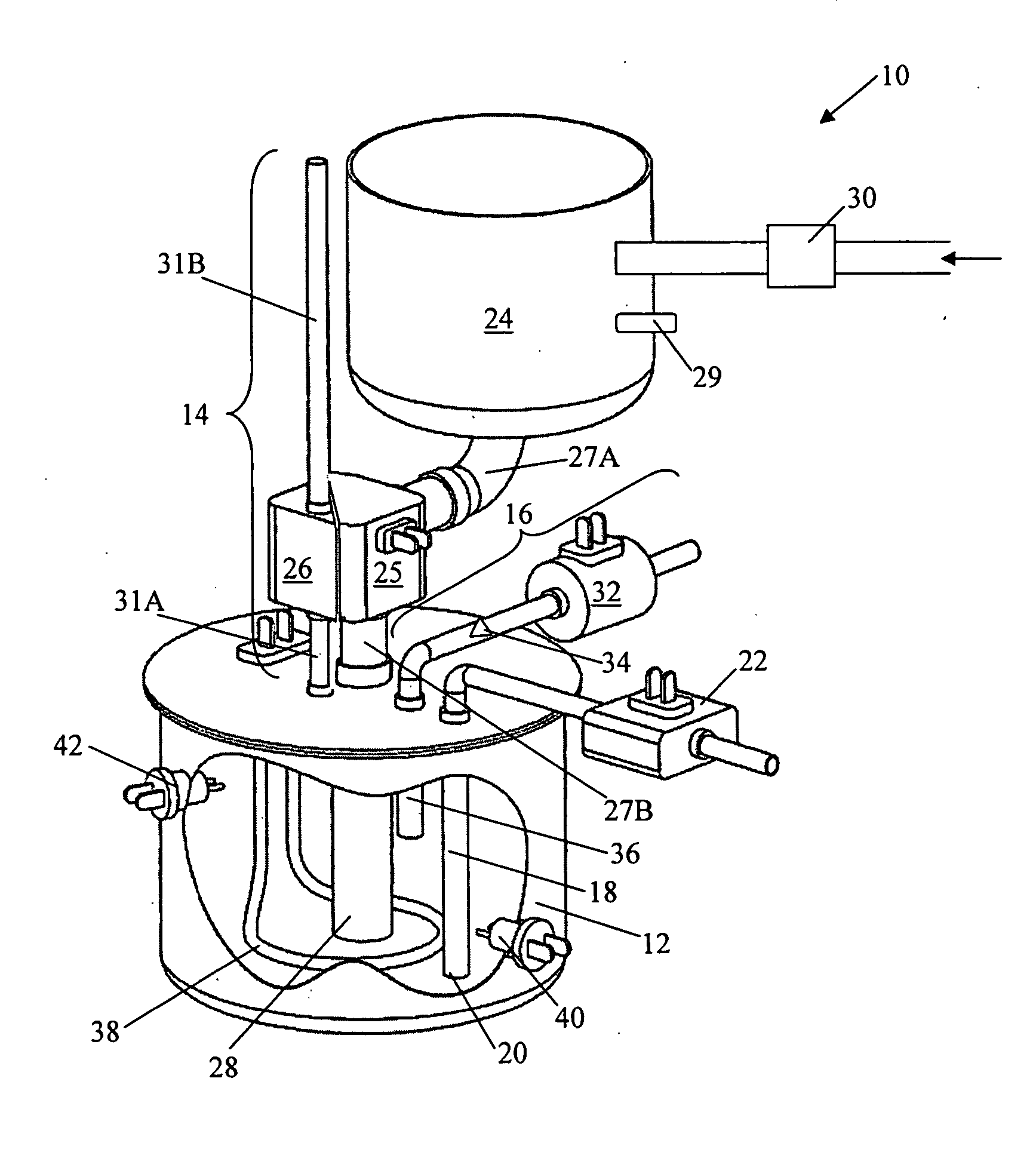

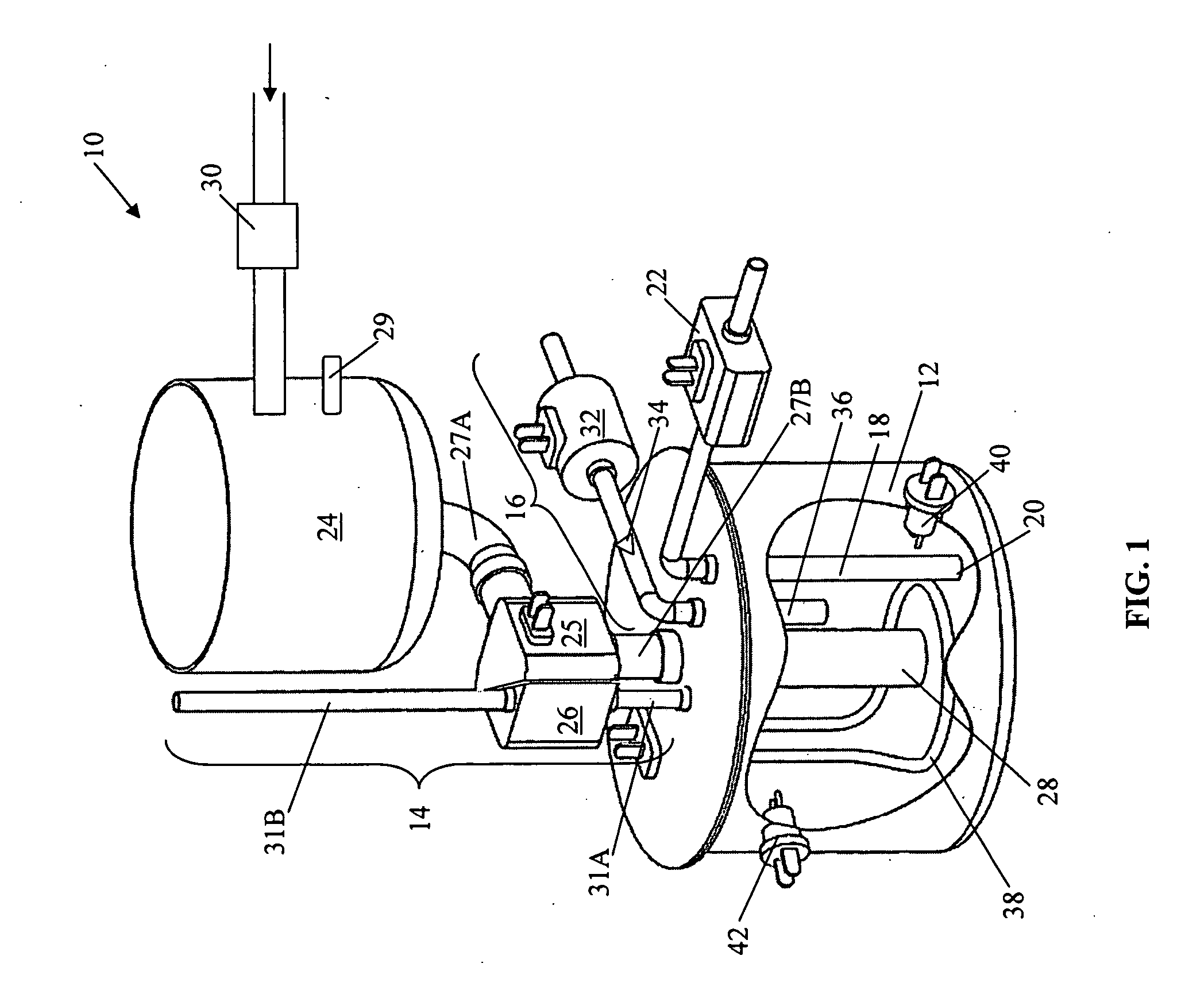

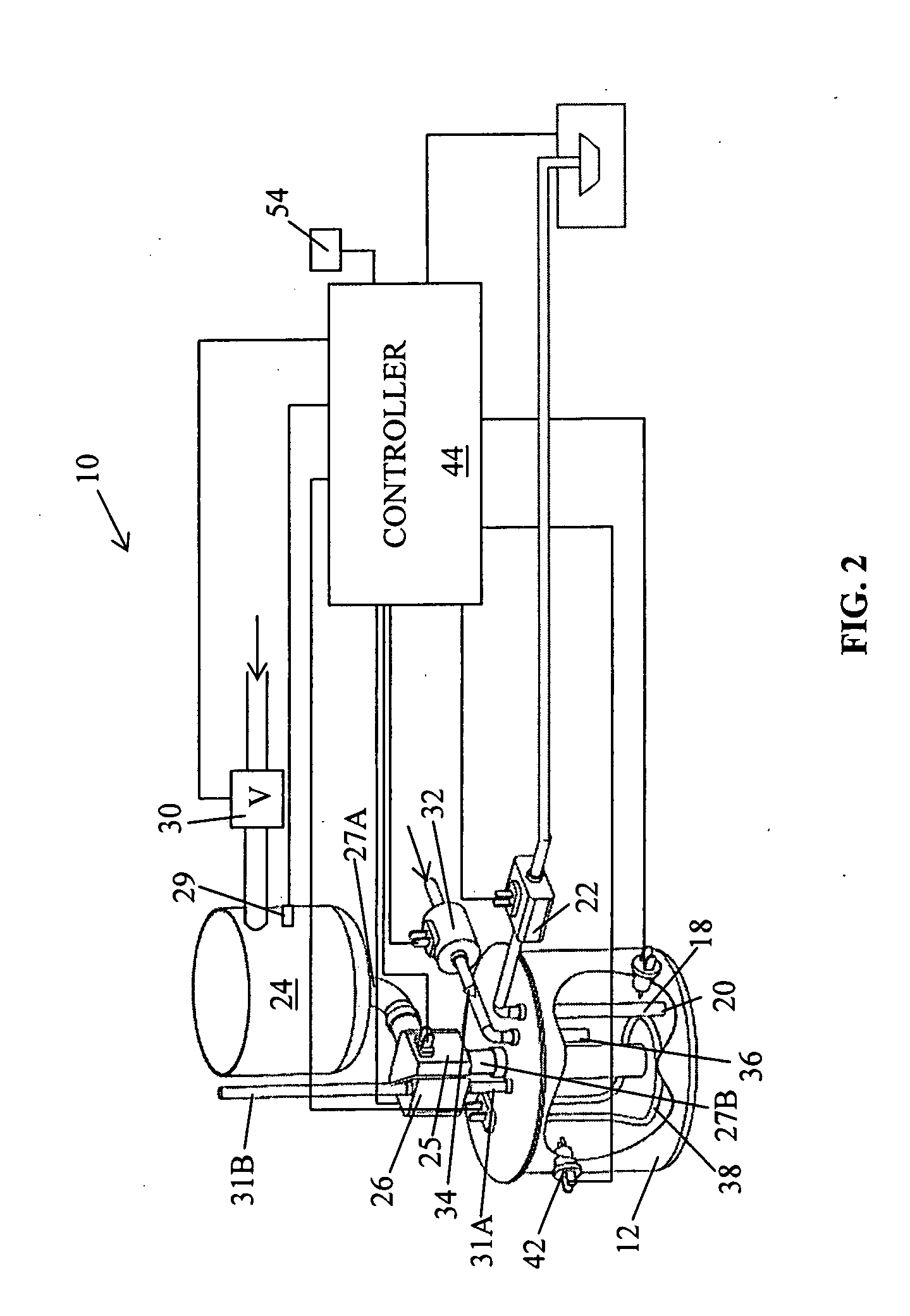

Portable Materials Storage Tank for Use With Vacuum Truck Pneumatic Transfer System

InactiveUS20140010603A1Minimize re-entrainmentMinimize escapeLoading/unloading vehicle arrangmentTransportation itemsTransfer systemPositive pressure

A portable storage tank for use with a vacuum truck for the collection and discharge of a waste particulate material which includes a storage tank, waste collection and discharge assemblies and an air pump assembly. The air pump assembly is operable to induce negative and positive pressures within the storage tank. The collection assembly includes a vacuum inlet for fluid flow between the vacuum inlet and the storage tank inlet during air pump operation to induce said negative pressure. The waste discharge assembly includes a discharge conduit for conveying a pressurized fluid flow and entrained collected material from a tank materials outlet to an outlet end while the air pump assembly is operated to induce a positive pressure.

Owner:BM METALS SERVICES

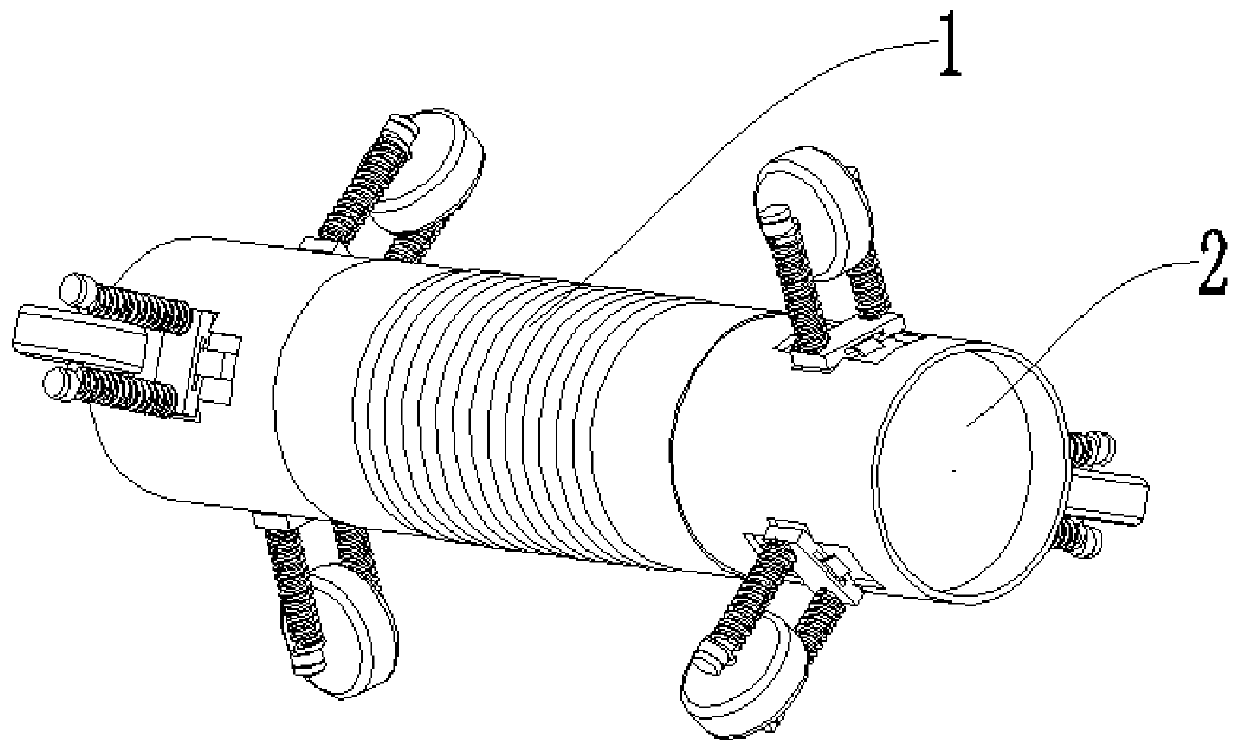

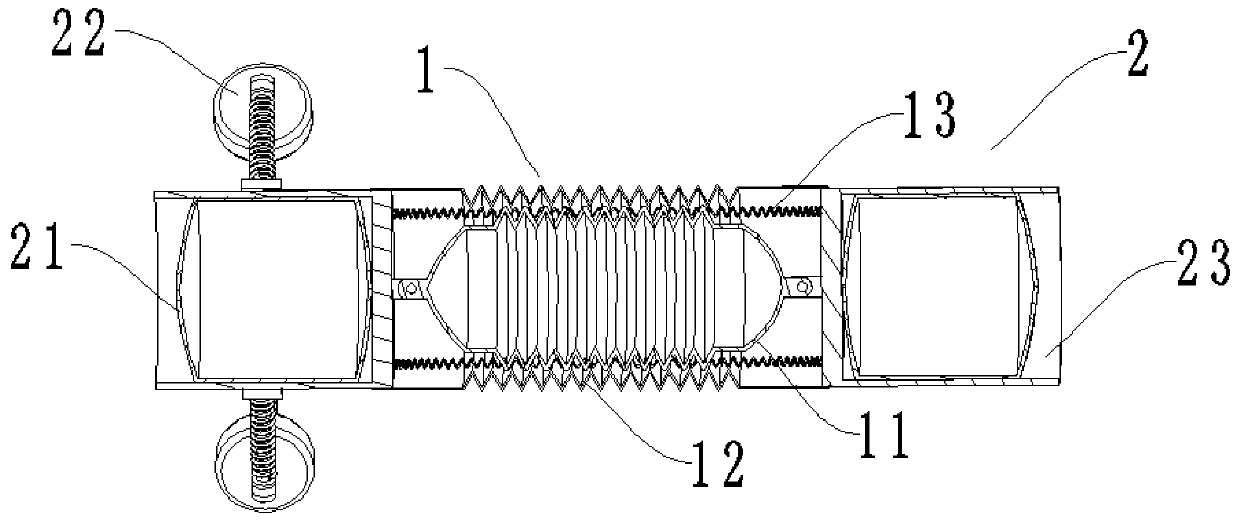

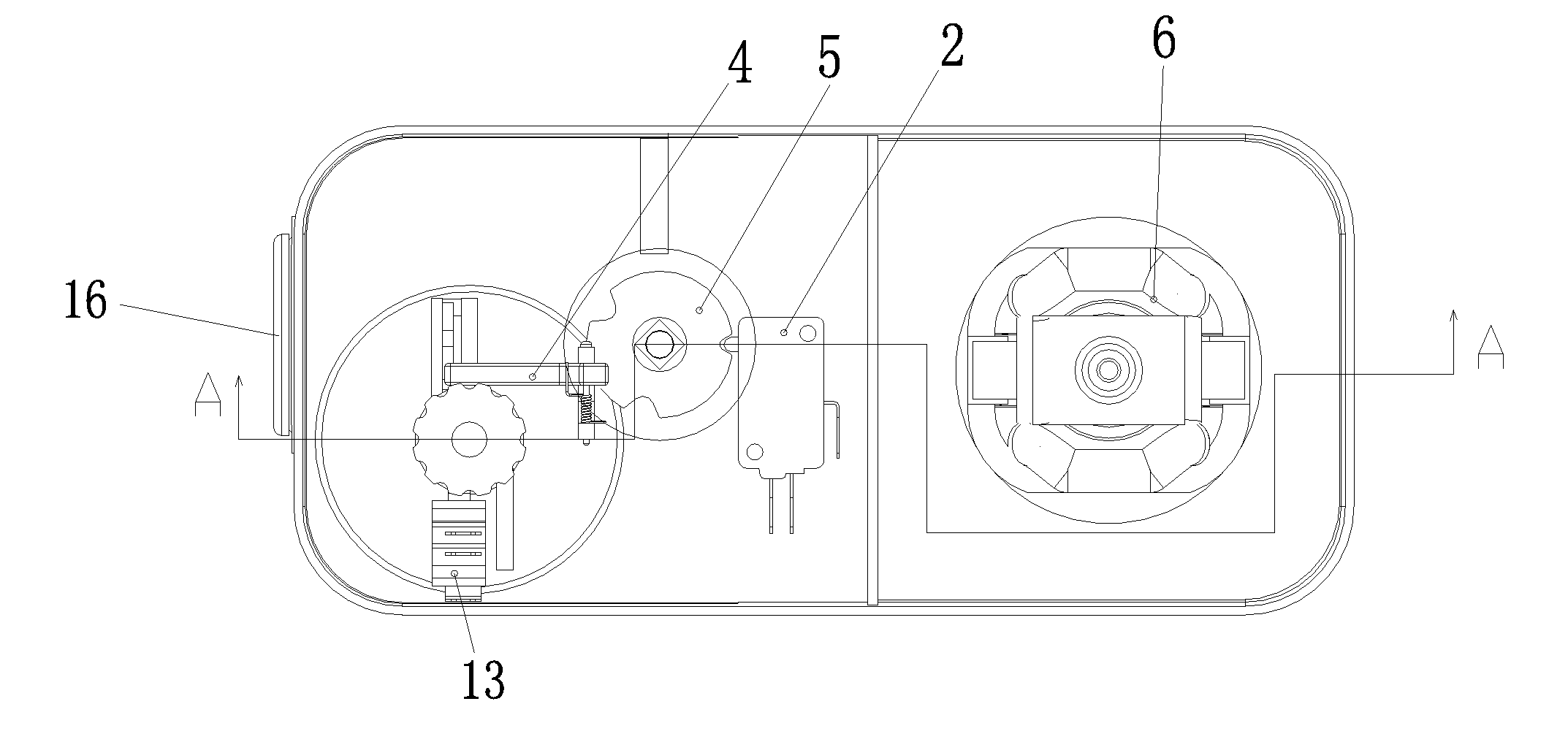

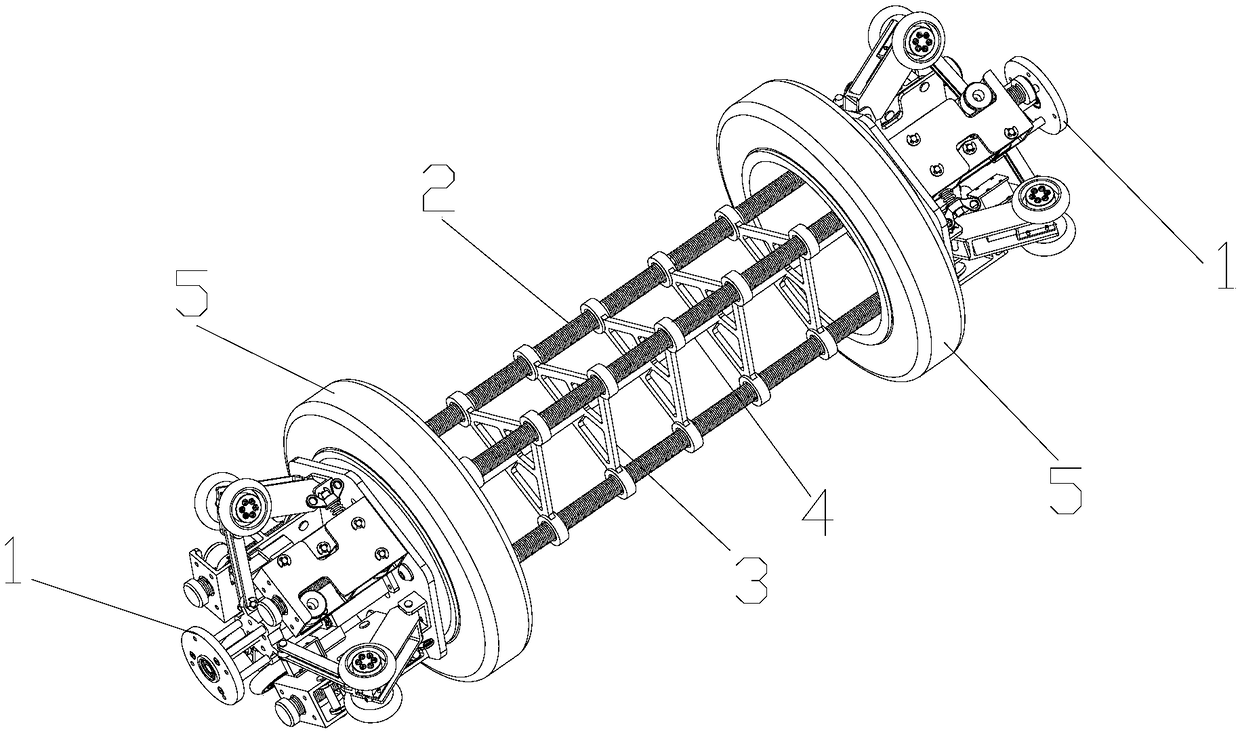

Bionic peristaltic type pipeline inner crawler and crawling method thereof

The invention provides a bionic peristaltic type pipeline inner crawler and a crawling method thereof, and relates to the technical field of bionic robots. The bionic peristaltic type pipeline inner crawler comprises a propelling part and at least two foot parts, each foot part comprises a foot air bag, a plurality of wheel sets arranged along the circumferential direction of the corresponding foot air bag, and a first air pump assembly for controlling the corresponding foot air bag to extend and contract in the radial direction of a pipeline so that the foot part and the inner wall of the pipeline can be fixed or separated, and the propelling part is connected between the two foot parts, and comprises a middle shaft air bag and a second air pump assembly, wherein the second air pump assembly is used for controlling the middle shaft air bag to extend and contract in the axial direction of the pipeline. According to the bionic peristaltic type pipeline inner crawler and the crawling method thereof, the air pump assemblies are used for orderly inflating and deflating the foot parts and the propelling part, so that creeping of the crawler in the pipeline can be realized, and the goodstability and economical efficiency are achieved.

Owner:XIAMEN UNIV OF TECH

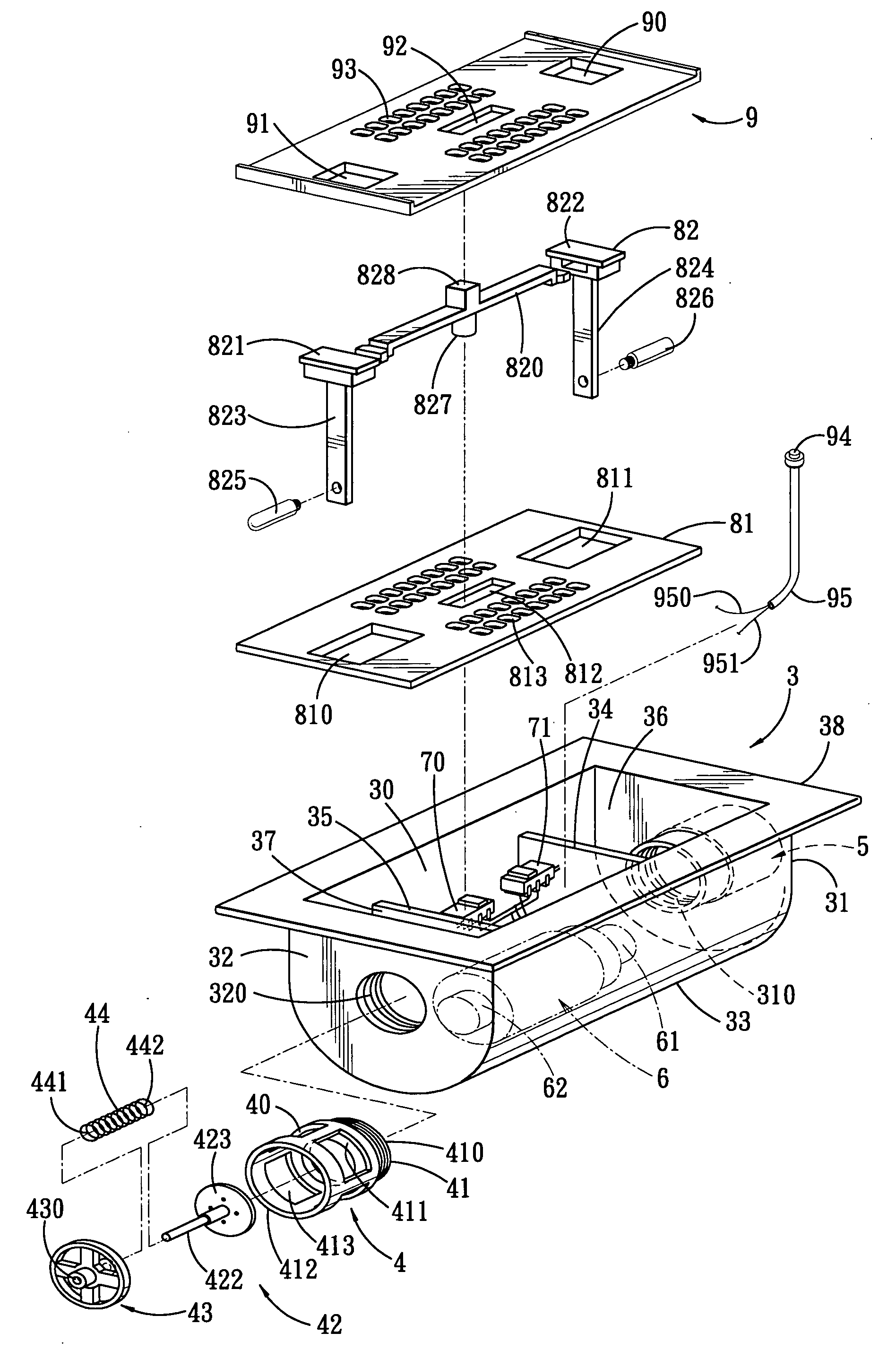

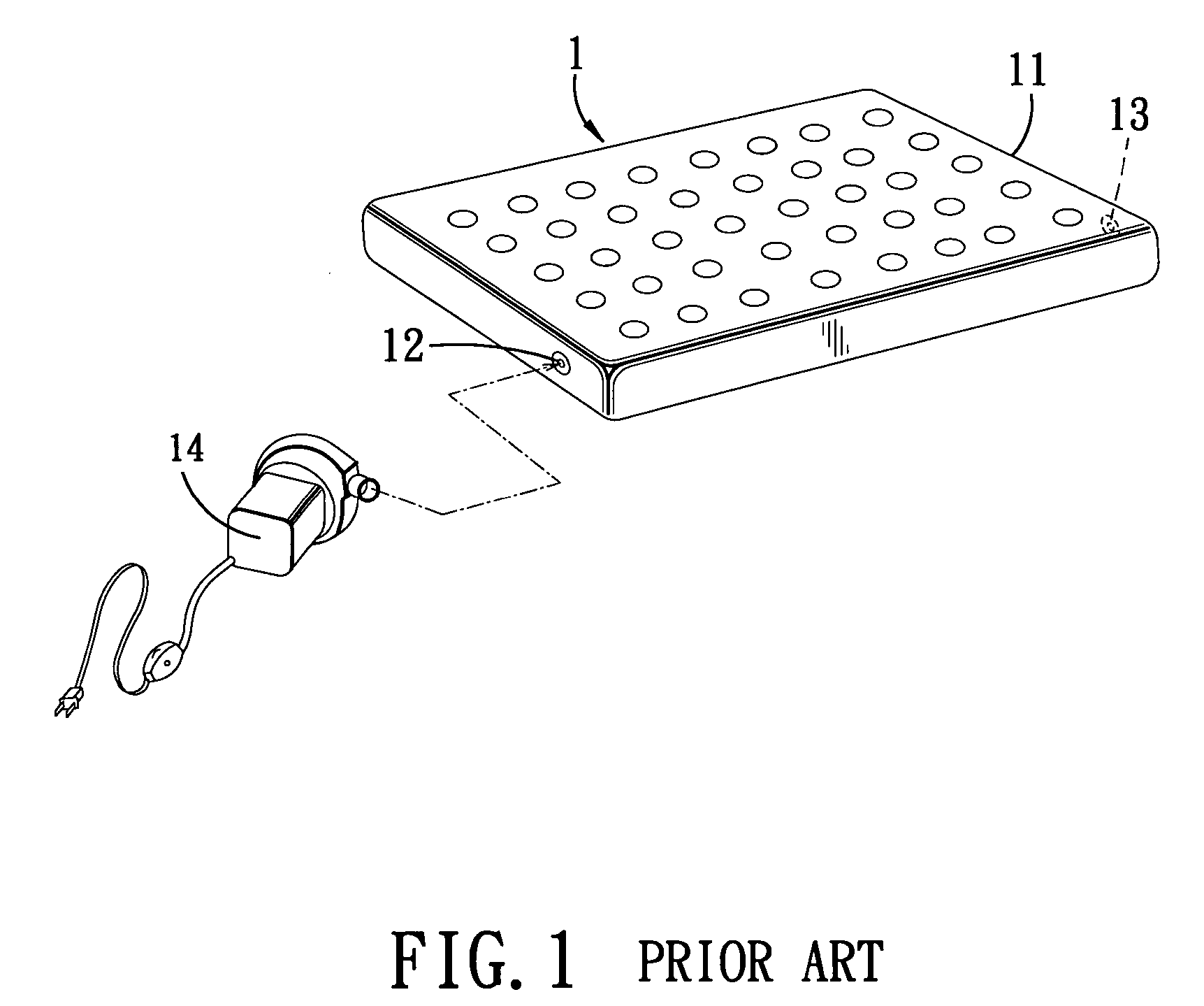

Inflating module for use with an inflatable object

ActiveUS20110284108A1Operating means/releasing devices for valvesPositive displacement pump componentsEngineeringAtmospheric pressure

An inflating module adapted to an inflatable object includes an air pump assembly selectively operable to deflate and inflate the inflatable object and a supplemental air pressure providing device automatically activated to provide supplemental air pressure to the inflatable object when the air pressure of the inflatable object is down and below a predetermined level so as to maintain air pressure of the inflatable object in a predetermined range.

Owner:TEAM WORLDWIDE

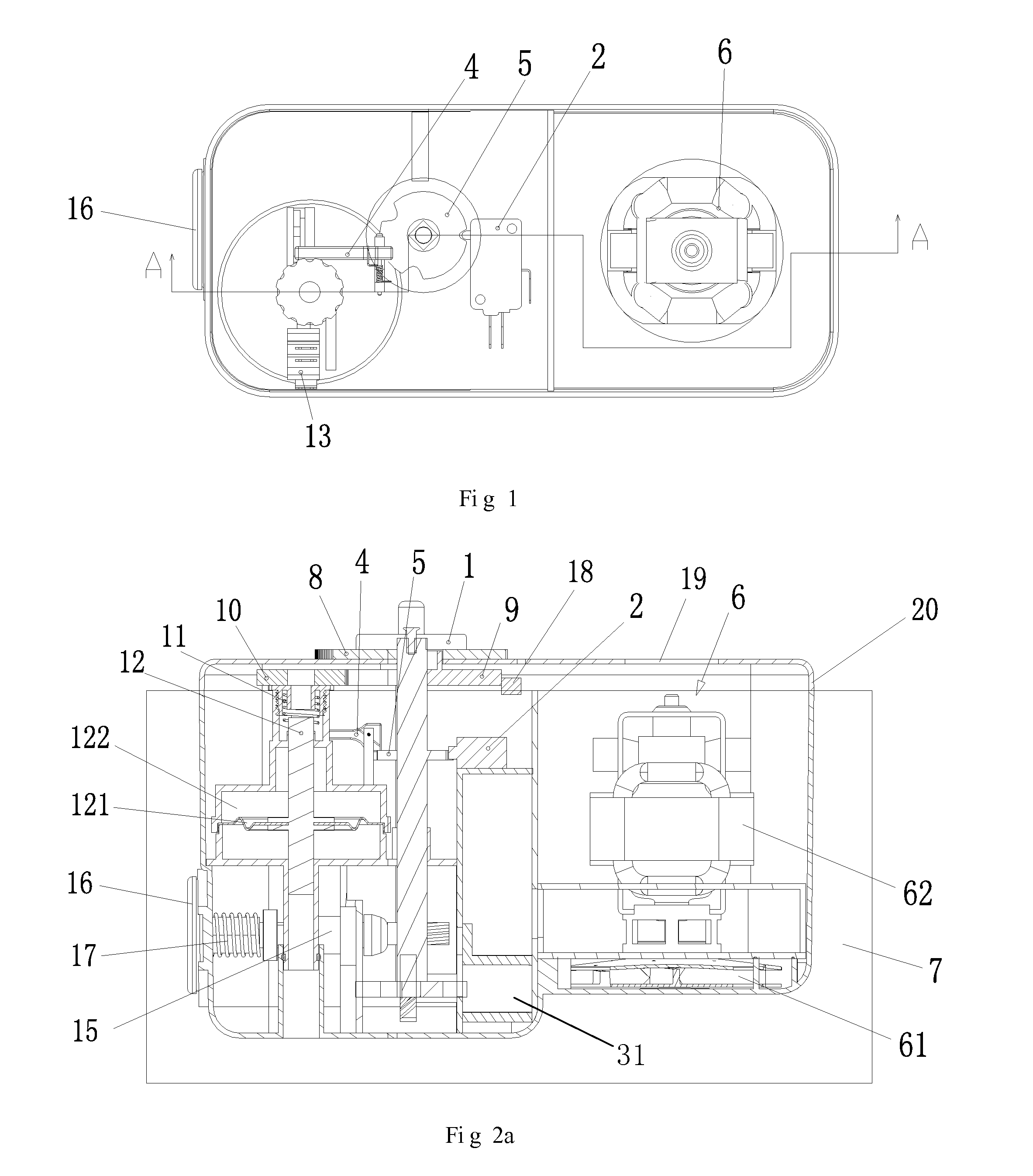

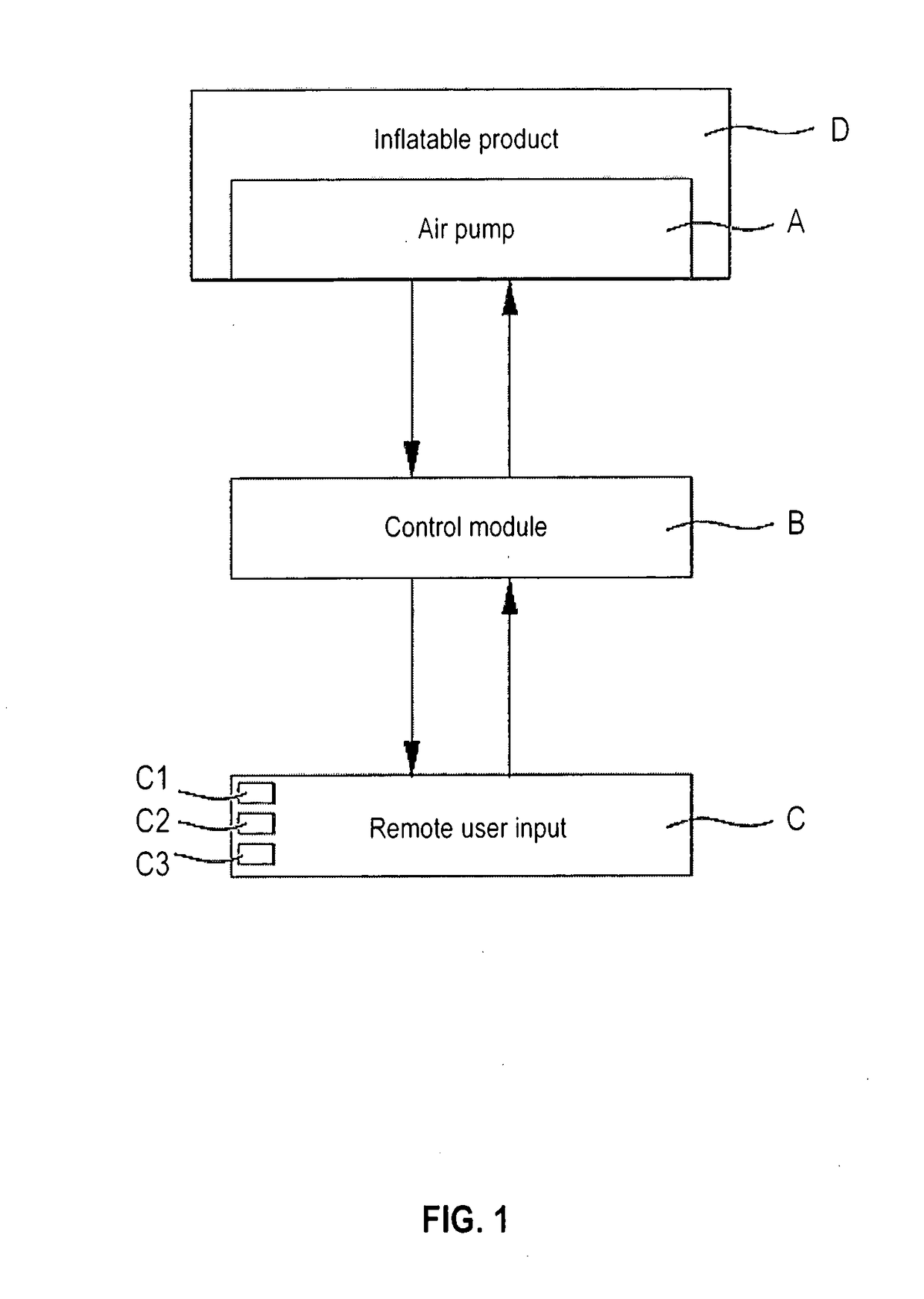

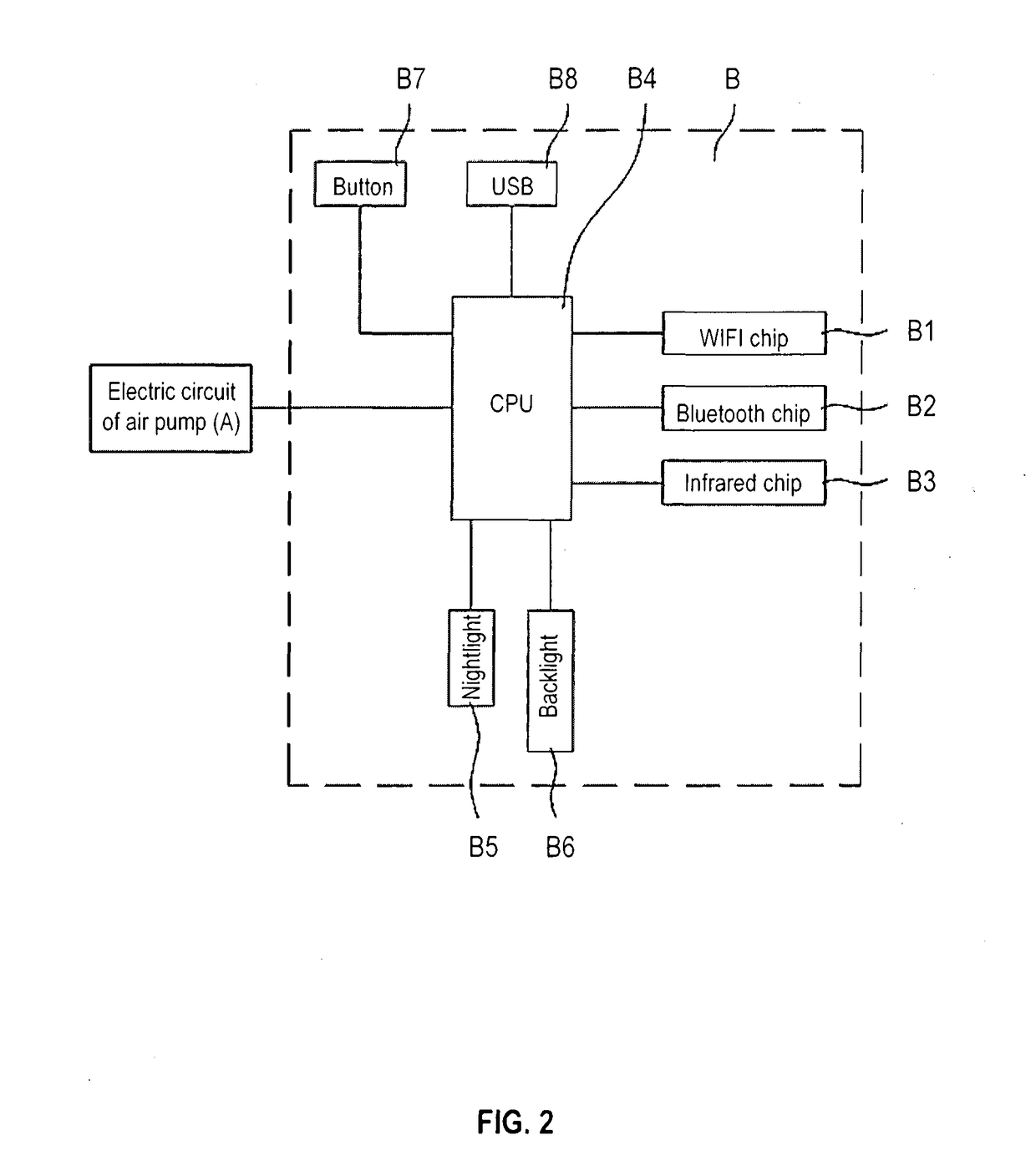

Multifunctional air pump

ActiveUS20180335042A1Keep the pressurePump componentsEfficient regulation technologiesUser inputEngineering

A multifunctional air pump is disclosed including an air pump assembly, a control module, and a remote user input for inflating and deflating an inflatable product. The air pump may be operated remotely for convenience. The air pump may also operate automatically to maintain the pressure of the inflatable product.

Owner:INTEX MARKETING

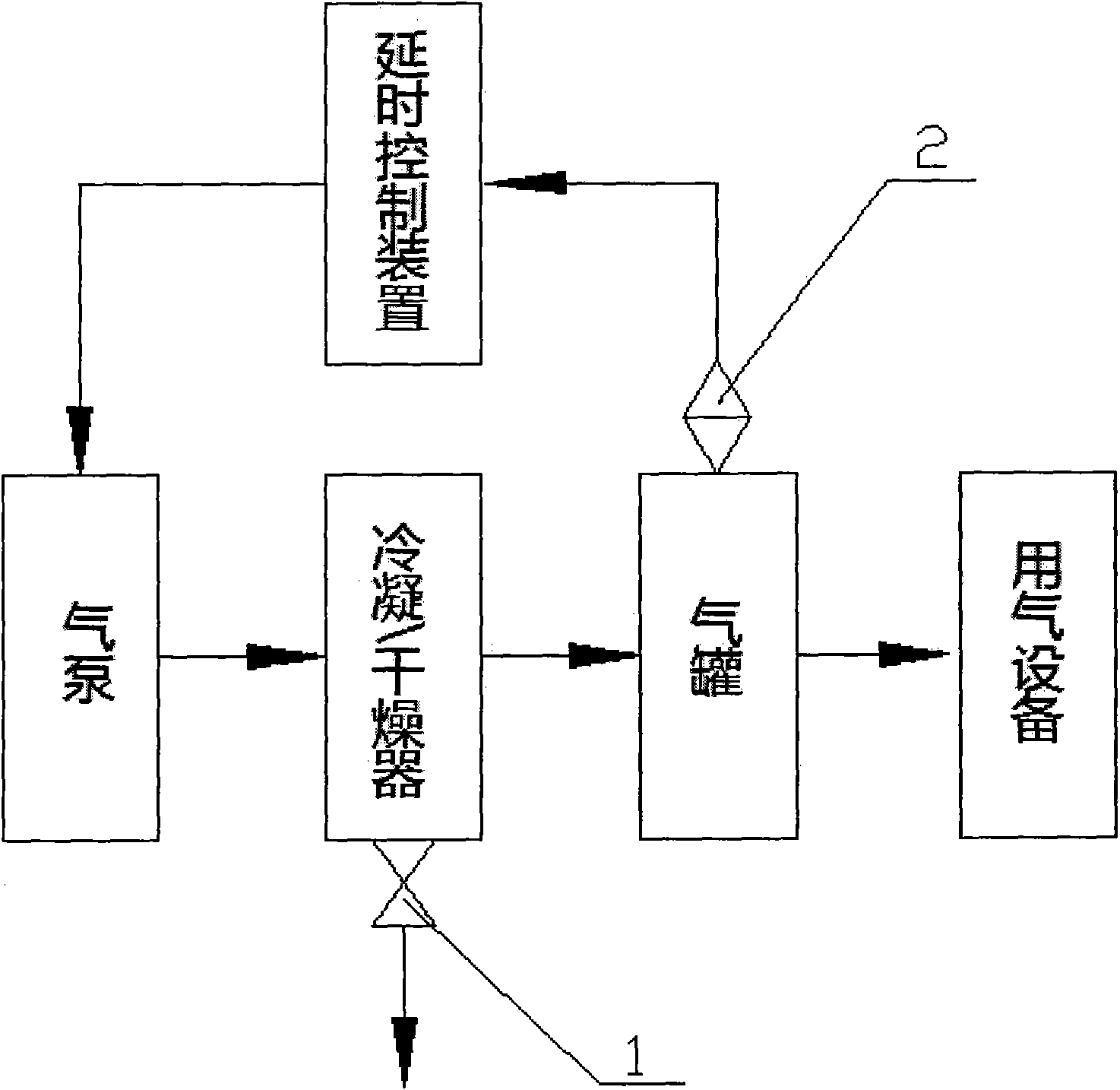

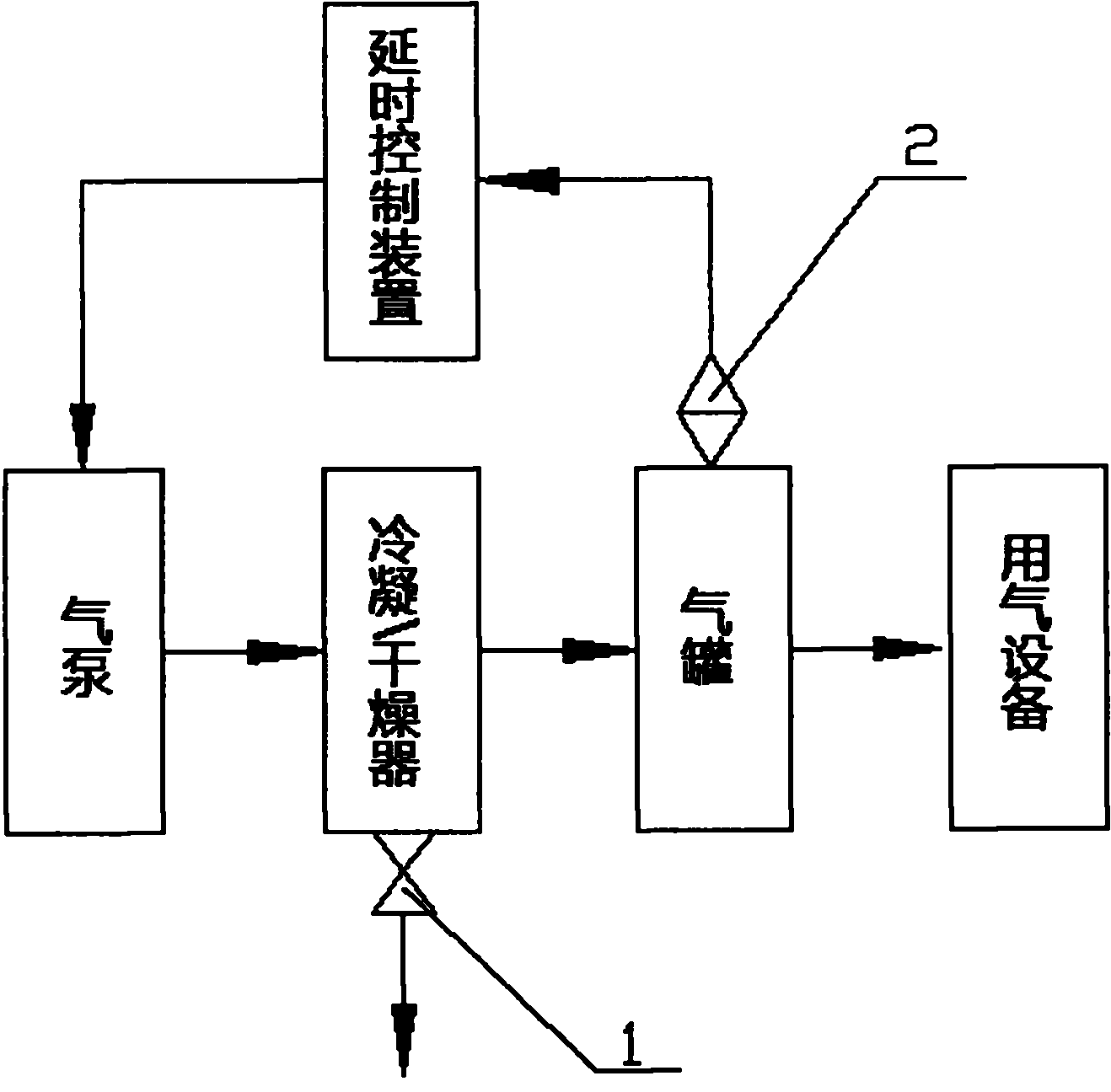

Electric air pump control method and system for vehicle

InactiveCN101929455AReduce workloadReduce consumptionPump controlPositive-displacement liquid enginesTime delaysControl system

The invention discloses an electric air pump control method for a vehicle and a control system adopting the method. The system comprises an air pump assembly, a pressure sensor and a time delay control device, wherein the time delay control device is connected with the pressure sensor and the air pump assembly through a wiring harness respectively, compares a pressure value P which is acquired in an air path by the pressure sensor with a set pressure value P0, and controls the operation of the air pump. The electric air pump control method comprises the following steps that: (1) when the pressure value P is smaller than the set pressure value P0, the time delay control device controls the air pump to start up; and (2) when the pressure value P is more than or equal to the set pressure value P0, the time delay control device stops the air pump after delayed time t. A pressure regulating valve and a pressure relay are not arranged in the traditional air path of the vehicle, the on / off and the water and sewage emission of the air pump are controlled by the time delay control device through a pressure sensor signal, and the method and the system have the advantages of simpleness and capacities of saving energy of the air pump, reducing the workload of the air pump and improving the working stability of a compressed air system.

Owner:安徽星凯龙客车有限公司

Air maintenance pump assembly

A pumping assembly for maintaining a pneumatic tires inflation pressure is described. The pumping assembly includes at least one double chamber pump connected to a cam. The cam is connected to a gravity mass to maintain the cam in a stationary position. The pump has a roller for engaging the cam and producing the pumping action as the tire rim rotates. The assembly is preferably mounted in a reservoir wherein the reservoir is in fluid communication with one or more tire cavities. The system requires no alteration to the tire and pumps the air directly into the valve stem. The pumps are configured to provide an amplication effect because of the way they are configured, and thus do not need high compression ratios.

Owner:THE GOODYEAR TIRE & RUBBER CO

Abrasion-resisting type carbon sliding plate clamping assembly

PendingCN107902402AMulti-event spaceAvoid wear and tearConveyorsConveyor partsClassical mechanicsSlide plate

The invention relates to the field of carbon sliding plates, in particular to an abrasion-resisting type carbon sliding plate clamping assembly. By means of the abrasion-resisting type carbon slidingplate clamping assembly, air pump assemblies composed of installation shells and air pump devices are arranged on the two sides of an installation base body, elastic buffering air bags in positioningsliding blocks and installation cavities in installation parts are inflated, and therefore the sides, located in clamping grooves, of the elastic buffering air bags are expanded, and therefore carbonsliding plates in the clamping grooves are extruded. The carbon sliding plates are clamped and fixed. Due to the fact that abrasion-resisting parts are arranged at the positions, located at the outerportions of the elastic buffering air bags, in the installation cavities and arc chamfers are adopted for avoiding abrasion, pipeline connecting pieces are arranged on the surfaces of the positioningsliding blocks, pipeline limiting through holes and through holes are formed in the positioning sliding blocks, and first flexible pipelines are adopted for being connected with the elastic soft air bags, more moving space can be achieved in the air bags, and position adjustment is facilitated.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

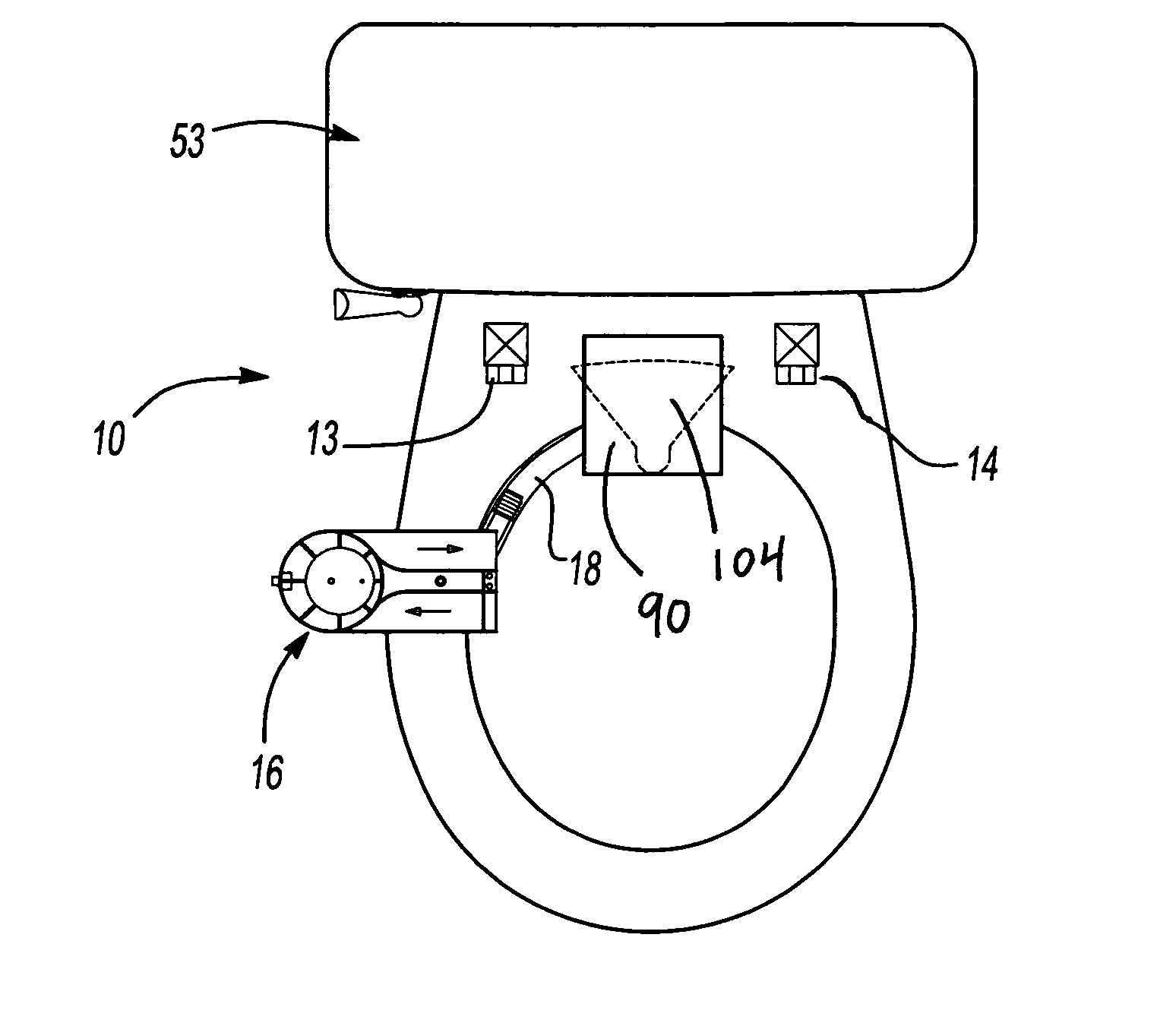

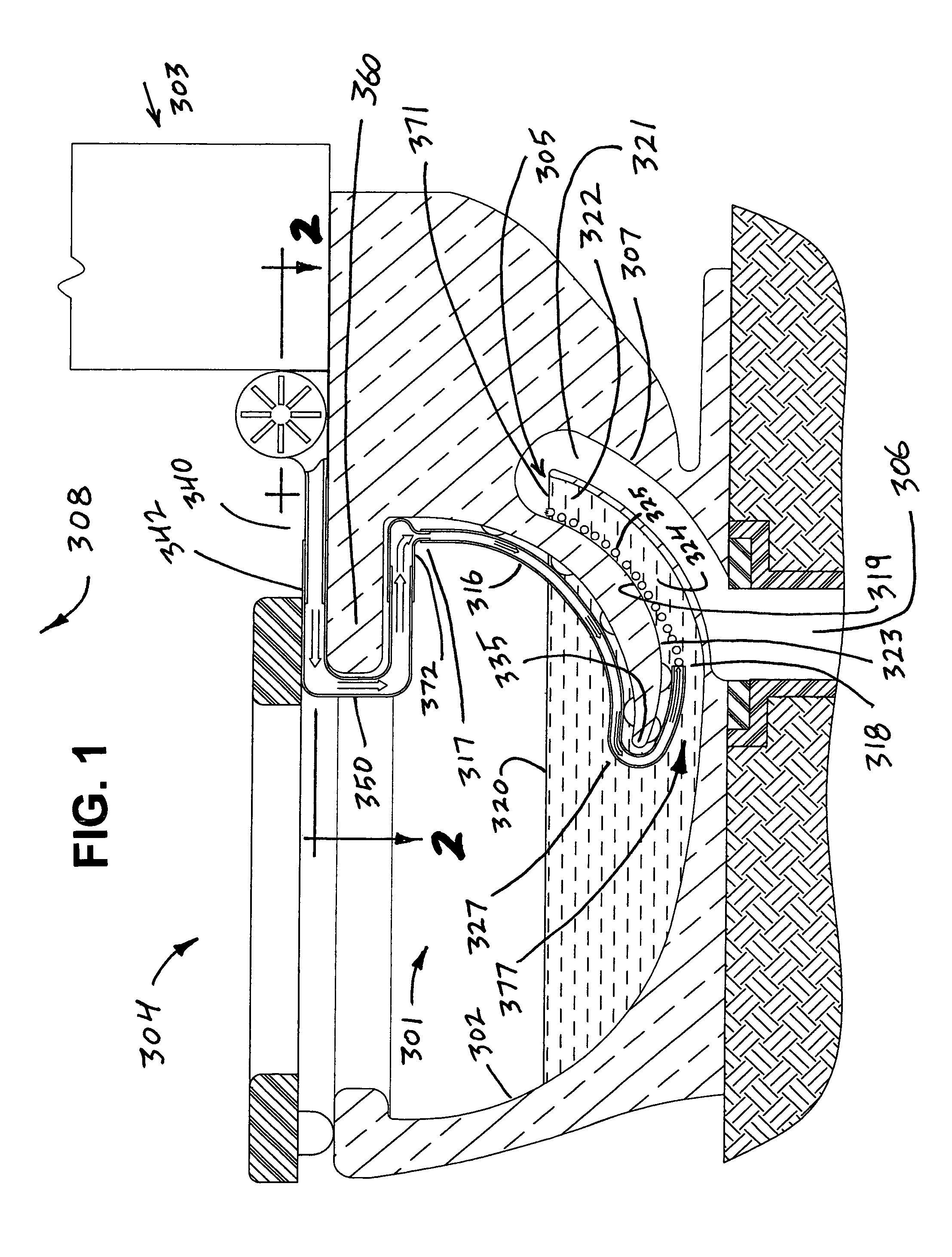

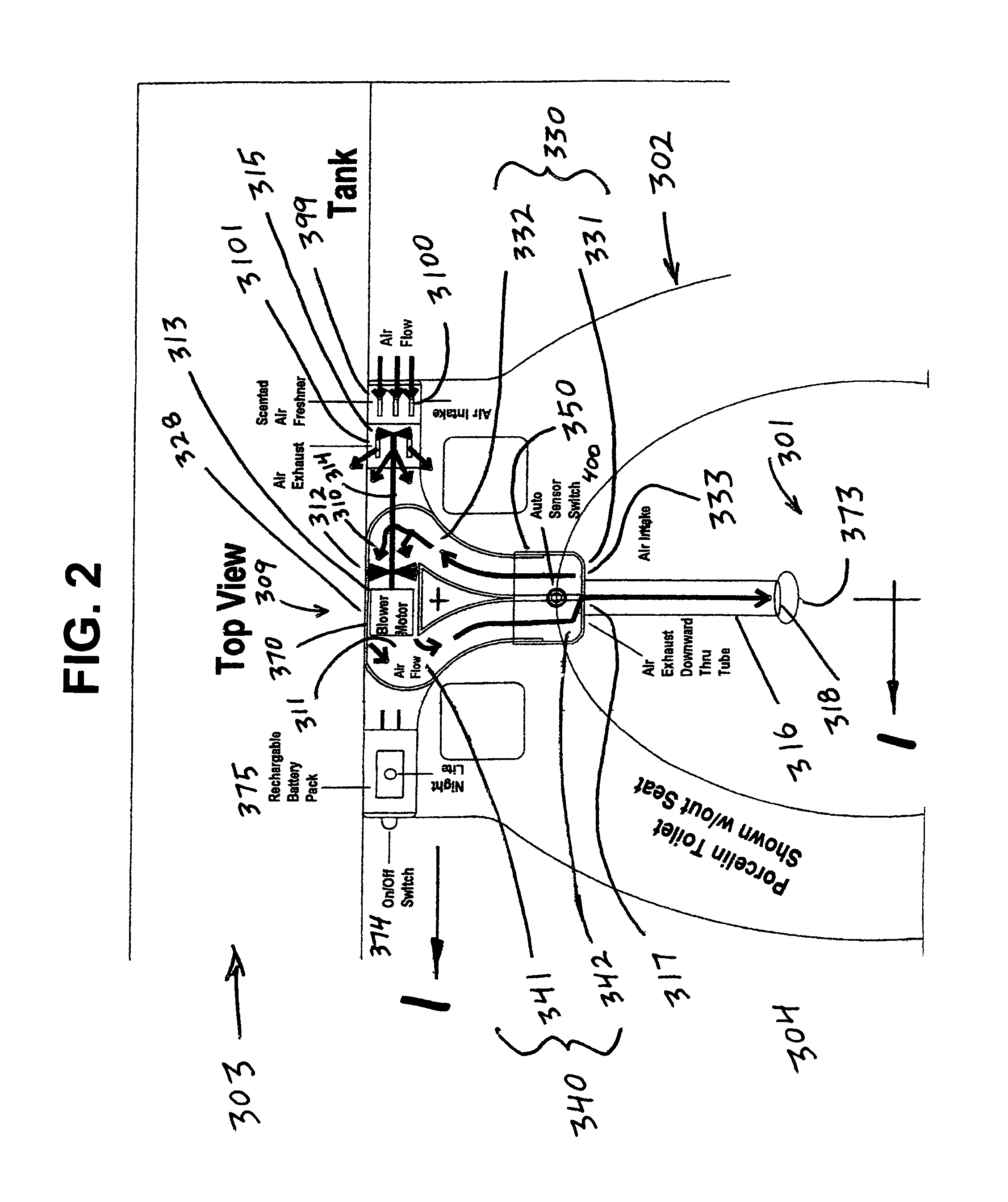

Toilet ventilation device

One embodiment of a device for transporting odor-containing air from a region including an interior airspace of a toilet bowl to a drain line that connects a water seal-type drain of the toilet bowl to a septic system comprises: an exhaust tube having an inlet and an outlet, wherein the inlet is in fluid communication with the region, the water seal-type drain having a drain ceiling at least partly below the normal standing water level of the toilet bowl, wherein the outlet is substantially between the surface of the water seal and the portion of the drain ceiling furthest below the normal standing water level of the toilet bowl.Another embodiment of such a device comprises: an air pump assembly having an air intake and an air exhaust, wherein the air intake is in fluid communication with the region, an exhaust tube assembly including an inlet, and a connecting channel, wherein the connecting channel is in fluid communication with the air exhaust and the inlet.

Owner:SHUMAKER JAMES J

Pipeline robot

The invention belongs to the technical field of robots, and particularly relates to a pipeline robot which comprises two drive modules, two air bags, an air pump assembly and at least two soft shafts.The at least two soft shafts are arranged between the two drive modules; two ends of the soft shafts are arranged in the corresponding drive modules; the drive modules can move along the axial directions of the soft shafts; the air bags have two states, namely, an inflating state and a deflating state; when the two air bags are at the inflating state at the same time, the pipeline robot can be fixed into a pipeline; when the two air bags are at the deflating state at the same time, the pipeline robot can move in the pipeline through a driving assembly; and when the two air bags inflate and deflate alternatively, by cooperating with the pumping of the soft shafts in a wire feeding assembly, the pipeline robot can wriggle in the pipeline. By changing the states of the air bags, the state and the movement mode of the pipeline robot can be changed, so that the pipeline robot can better adapt to a complicated environment in the pipeline.

Owner:THE CHINESE UNIV OF HONG KONG SHENZHEN

Air pump assembly for inflating and deflating an inflatable article

An air pump assembly is disposed within an inflatable article, and includes a movable member. When the movable member is moved relative to a base to an inflating position, an outflow outlet in the base is closed, and an inflow valve is activated to open an inflow outlet in the base so as to permit air to be sucked into the inflatable article through an inflow inlet and the inflow outlet in the base by an air pump. When the movable member is moved to a deflating position, the inflow inlet is closed, and an outflow valve is activated to open an outflow inlet in the base so as to permit air to be forced out of the inflatable article through the outflow inlet and the outflow outlet.

Owner:WU HSIN TSAI

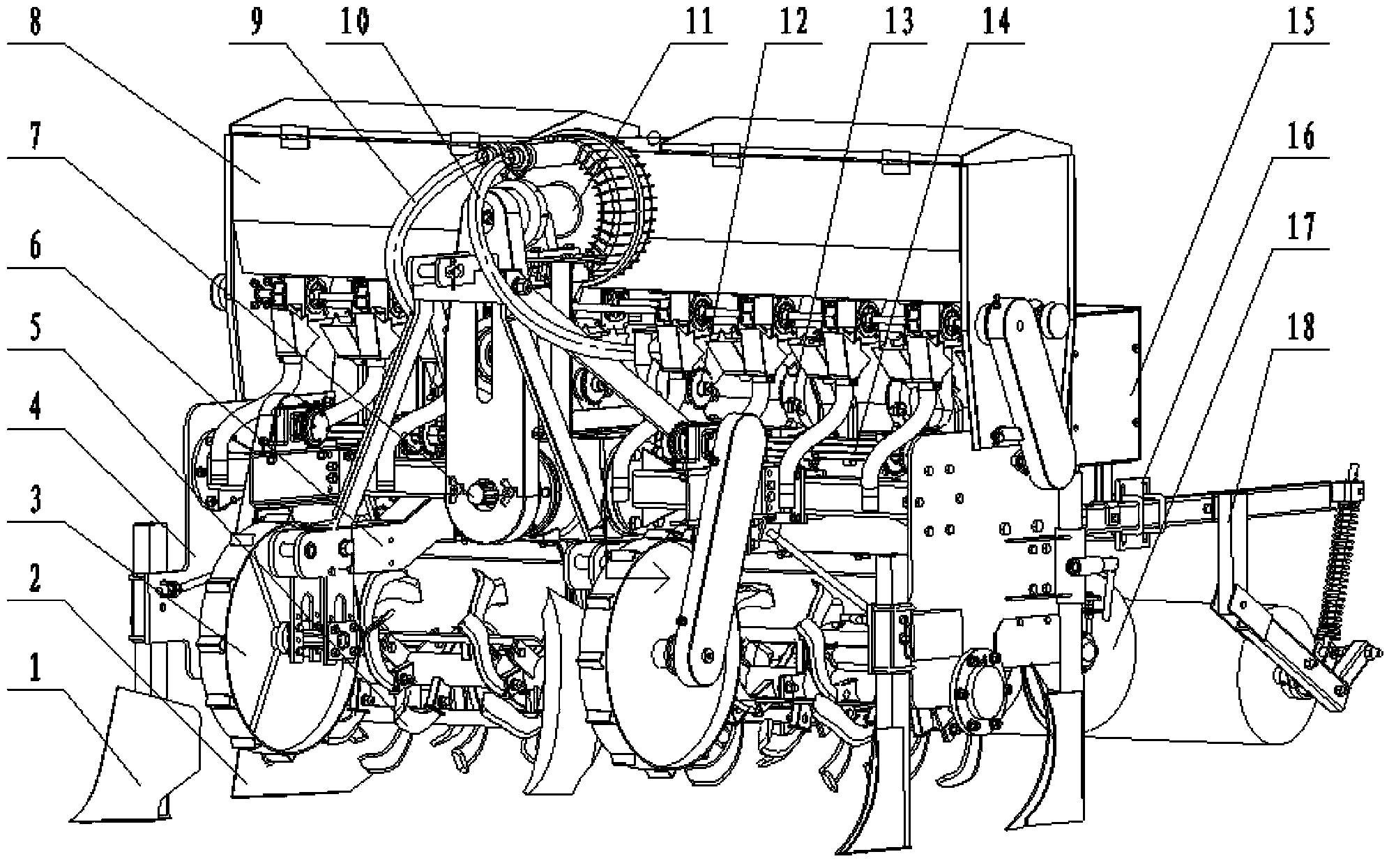

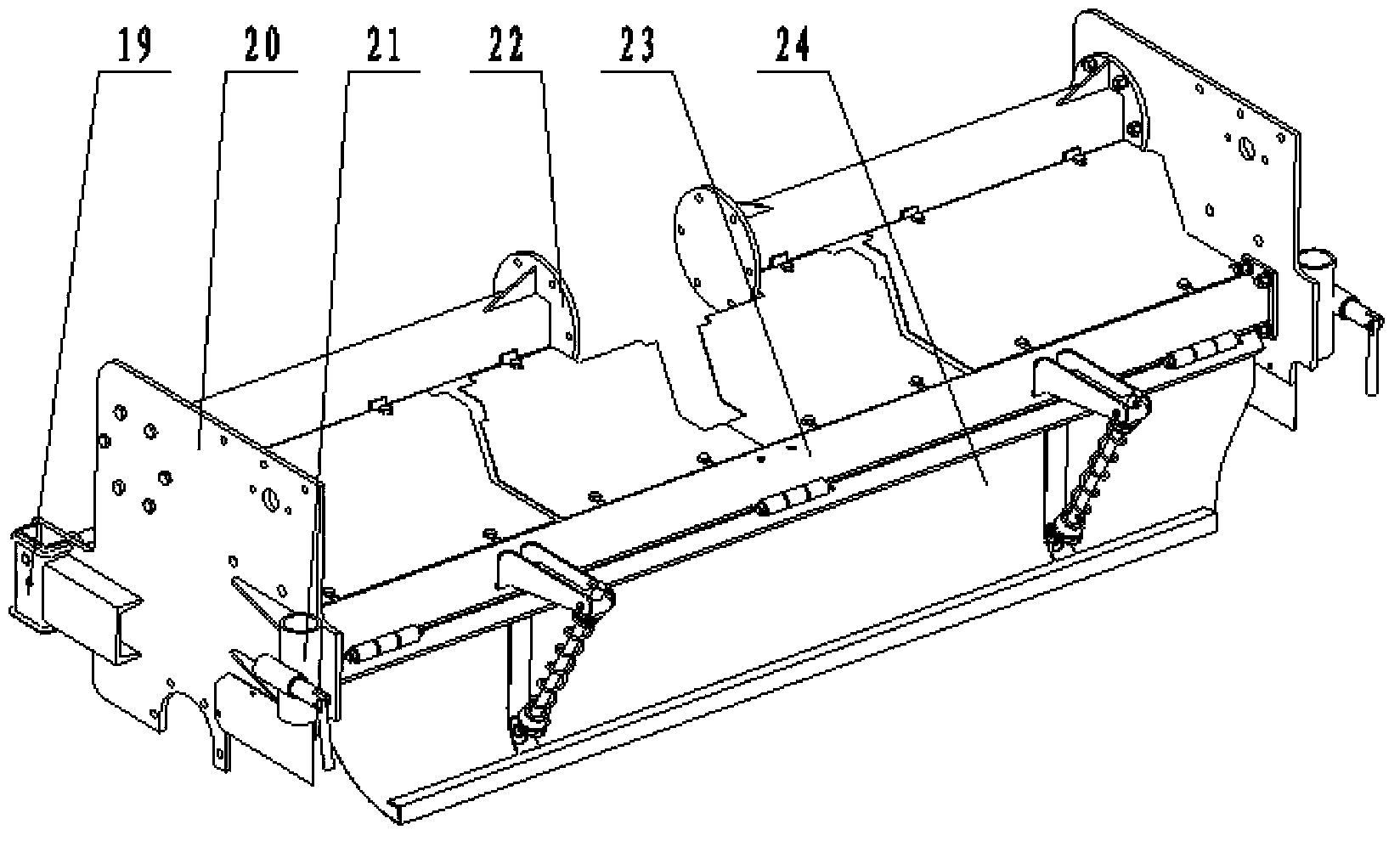

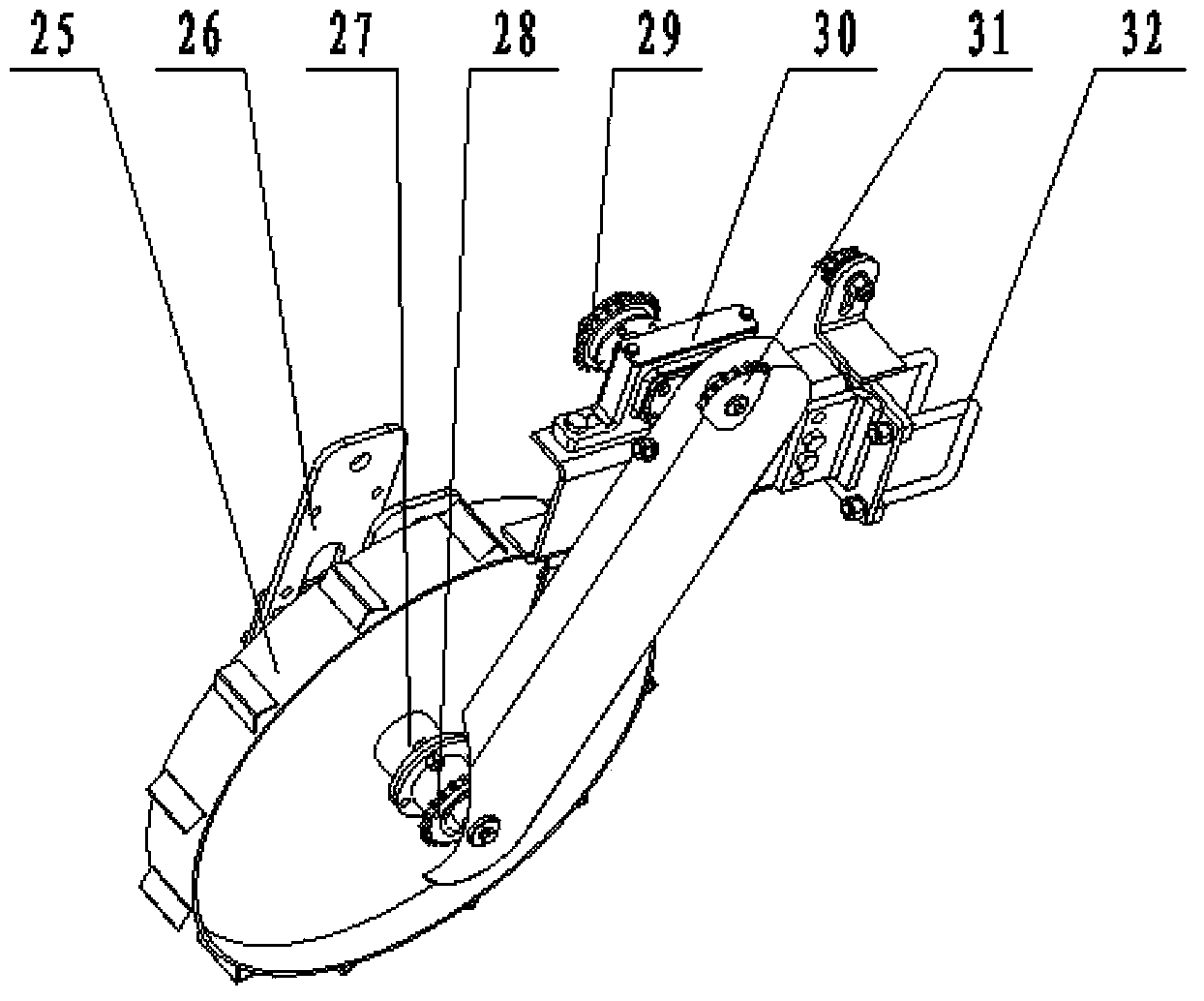

Rape and wheat all-purpose seeder

InactiveCN103416124AReduce labor costsImprove product qualitySpadesPloughsPositive pressureAgricultural engineering

The invention discloses a rape and wheat all-purpose seeder and belongs to the technical field of seeders in agricultural machinery. The rape and wheat all-purpose seeder is characterized by comprising front furrow plough combination, rear furrow plough combination, a land wheel assembly, main frame combination, rotary tillage roller combination, suspension bracket combination, a central gearbox assembly, a fertilizer box assembly, a negative pressure main pipe, a positive pressure main pipe, an air pump assembly, a right seeder unit assembly, a left seeder unit assembly, middle transition shaft combination, auxiliary frame combination, double-disc opener fixing beam combination, a double-disc opener and pressing roller combination. The seeder has multiple functions of completing multiple processes of rotary tillage, stubble cleaning, ditching, effective fertilizing, seeding, pressing, and the like in one-step operation. The seeder is widely applicable to dry land operation and can be satisfactory to rice stubble field planting agronomic requirements. The rape and wheat all-purpose seeder is convenient to use, reliable in performance, high in work efficiency and capable of realizing fine-quantity seeding of the rape and direct seeding of crops such as the wheat.

Owner:HUAZHONG AGRI UNIV

Inflating module for use with an inflatable object

An inflating module adapted to an inflatable object includes an air pump assembly selectively operable to deflate and inflate the inflatable object and a supplemental air pressure providing device automatically activated to provide supplemental air pressure to the inflatable object when the air pressure of the inflatable object is down and below a predetermined level so as to maintain air pressure of the inflatable object in a predetermined range.

Owner:TEAM WORLDWIDE

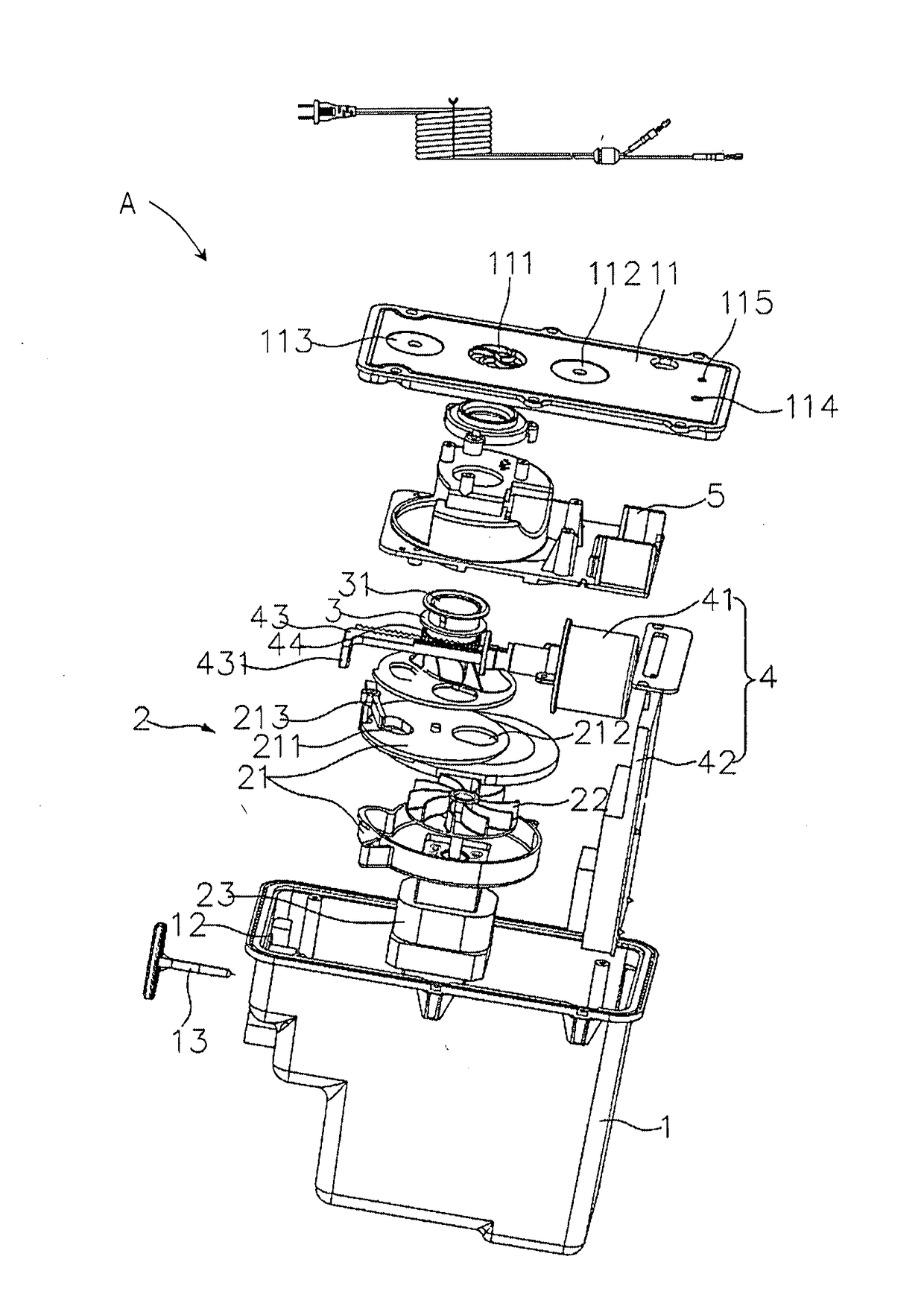

Bidirectional air pump assembly for inflatable objects

ActiveUS6955529B2Shorten the timeProtection worksPositive displacement pump componentsFluid mattressesEngineeringAir Pump Assembly

A bidirectional air pump assembly includes a pump mounting case, a valve and an air pump. The pump mounting case is mounted in an inflatable object and has a valve mounting hole. The valve is held in the valve mounting hole and includes an adapter with a valve port and a valve disk. The valve disk is attached to the adapter and has a disk body and at least one disk stop protruding from the disk body. The air pump is detachably mounted in the pump mounting case and connects to the valve port. Therefore, the air pump draws air out of the inflatable body through the valve port and a gap caused by the at least one disk stop abutting the air pump, which keeps the disk body from completely closing the valve port.

Owner:HO LEE +1

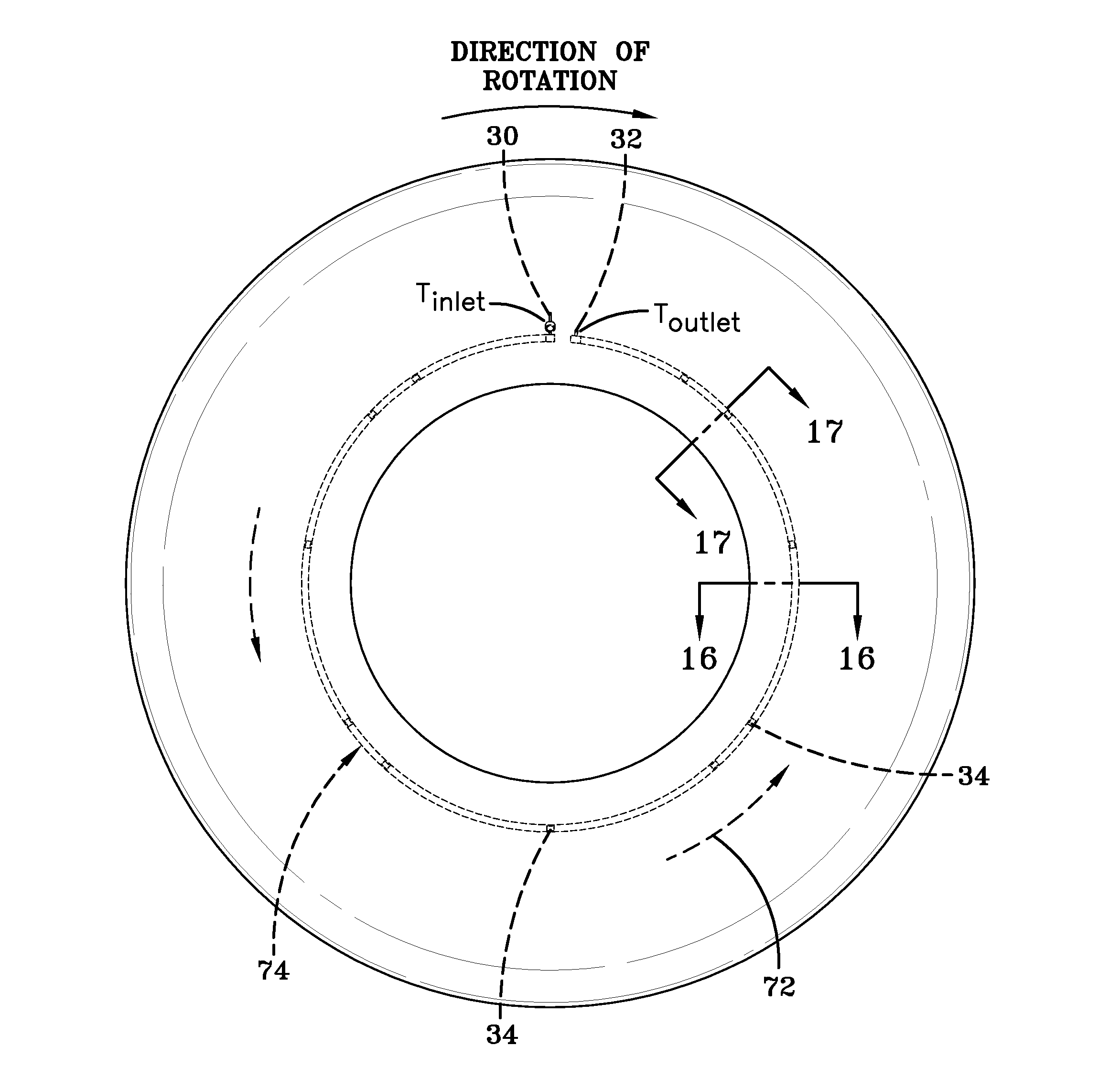

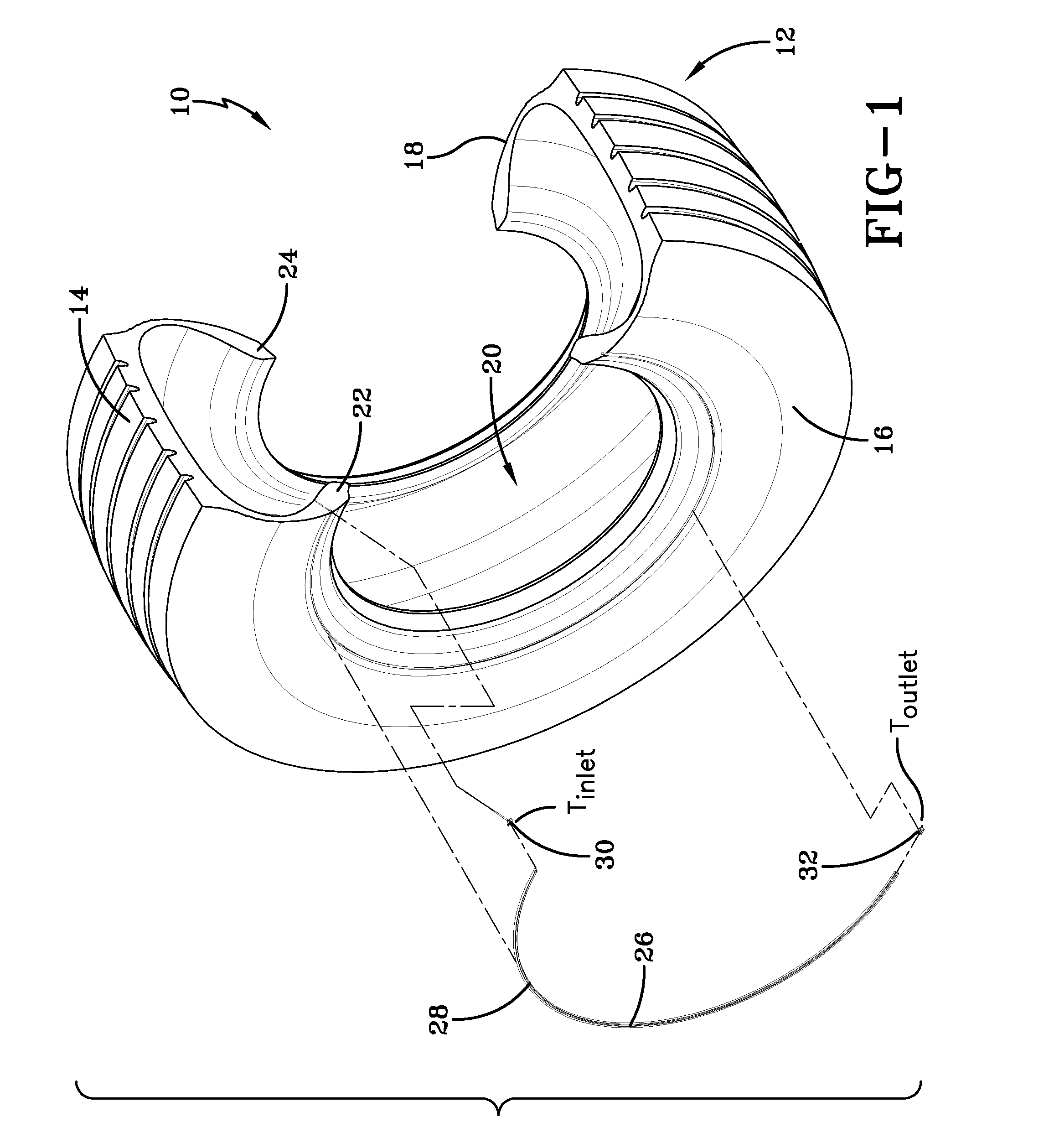

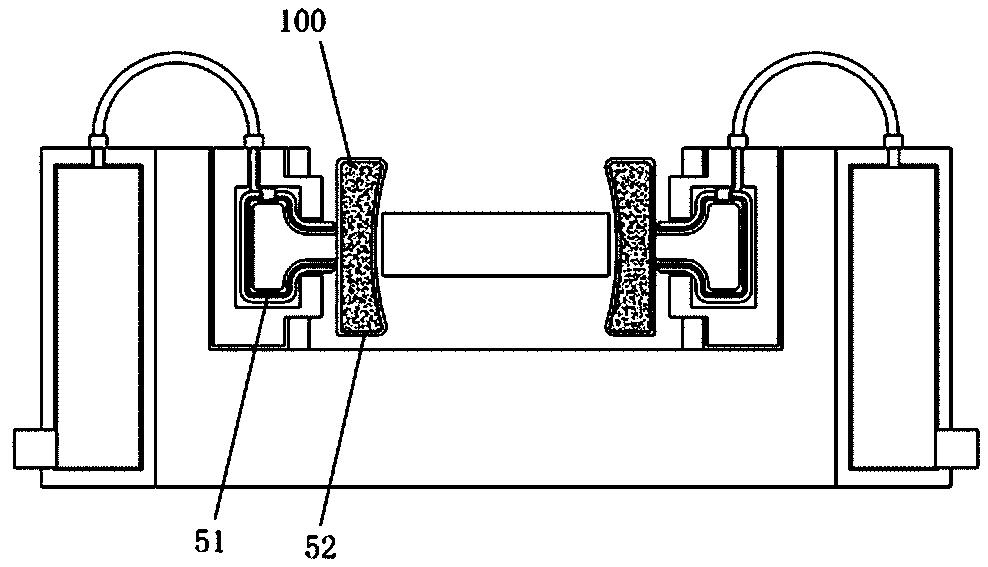

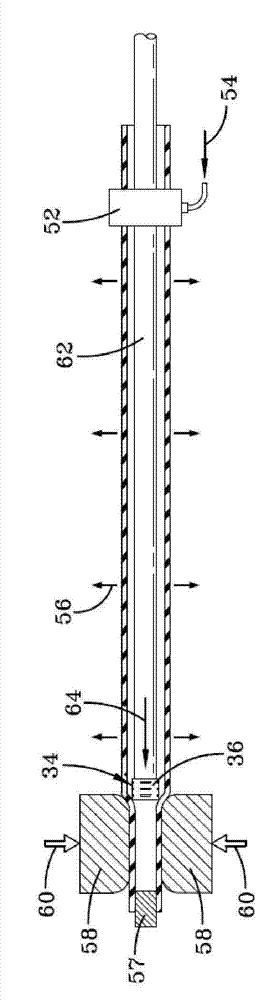

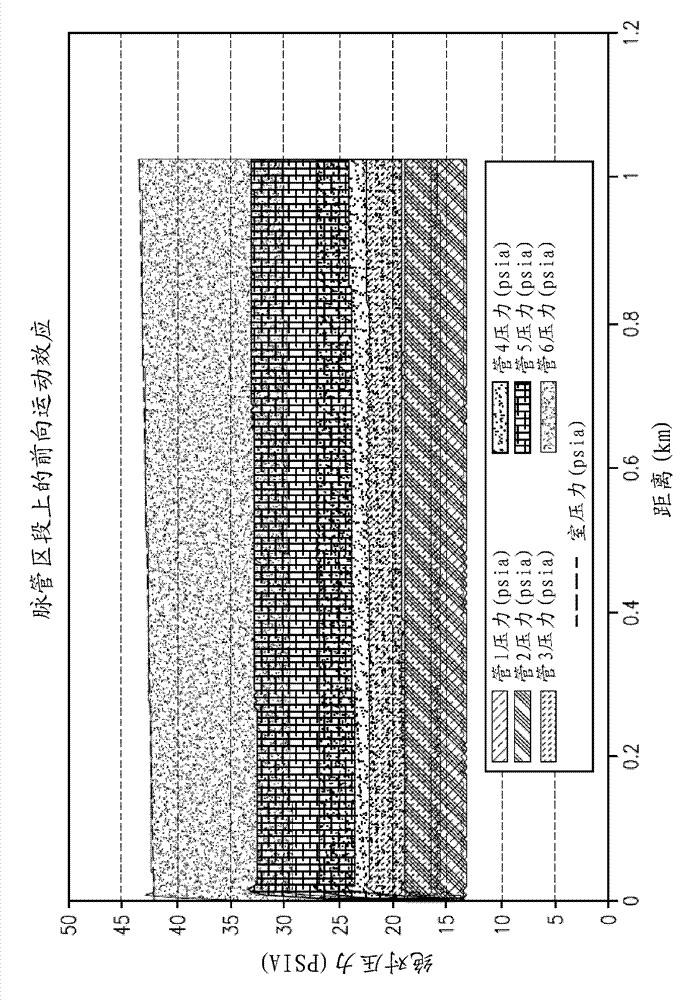

Distributed cavity air pumping assembly and method for a tire

A tire assembly and method includes one or more elongate air passageway formed within a tire component, such as a tire sidewall. The air passageway is configured as a series or string of elongate cavities, adjacent cavities connected end to end by an elongate connecting channel. The connecting channel is dimensioned having a channel diametric size smaller than a cavity diametric size. Positioned within the tire component, the air passageway sequentially collapses segment by segment as each of the cavities pass sequentially over a rolling tire footprint. Air is pumped by the sequential air passageway collapse with the smaller dimensioned connecting channel(s) acting as valve components to directionally keep the pumped air moving between an air passageway air inlet and an air passageway air outlet and from there into the tire cavity.

Owner:THE GOODYEAR TIRE & RUBBER CO

Vein pump assembly for air maintenance tire

An air maintenance tire and air pump assembly is provided including a tire and an elongate tubular air passageway enclosed within a flexing region of a tire sidewall. A plurality of check valve devices are spaced apart and positioned along the air passageway into multiple air passageway segments. A check valve membrane opens to allow pressurized air to directionally pass through the check valve device from an upstream passageway segment to a downstream passageway segment and closes to prevent air from passing in an opposite direction through the check valve from the downstream segment to the upstream segment.

Owner:THE GOODYEAR TIRE & RUBBER CO

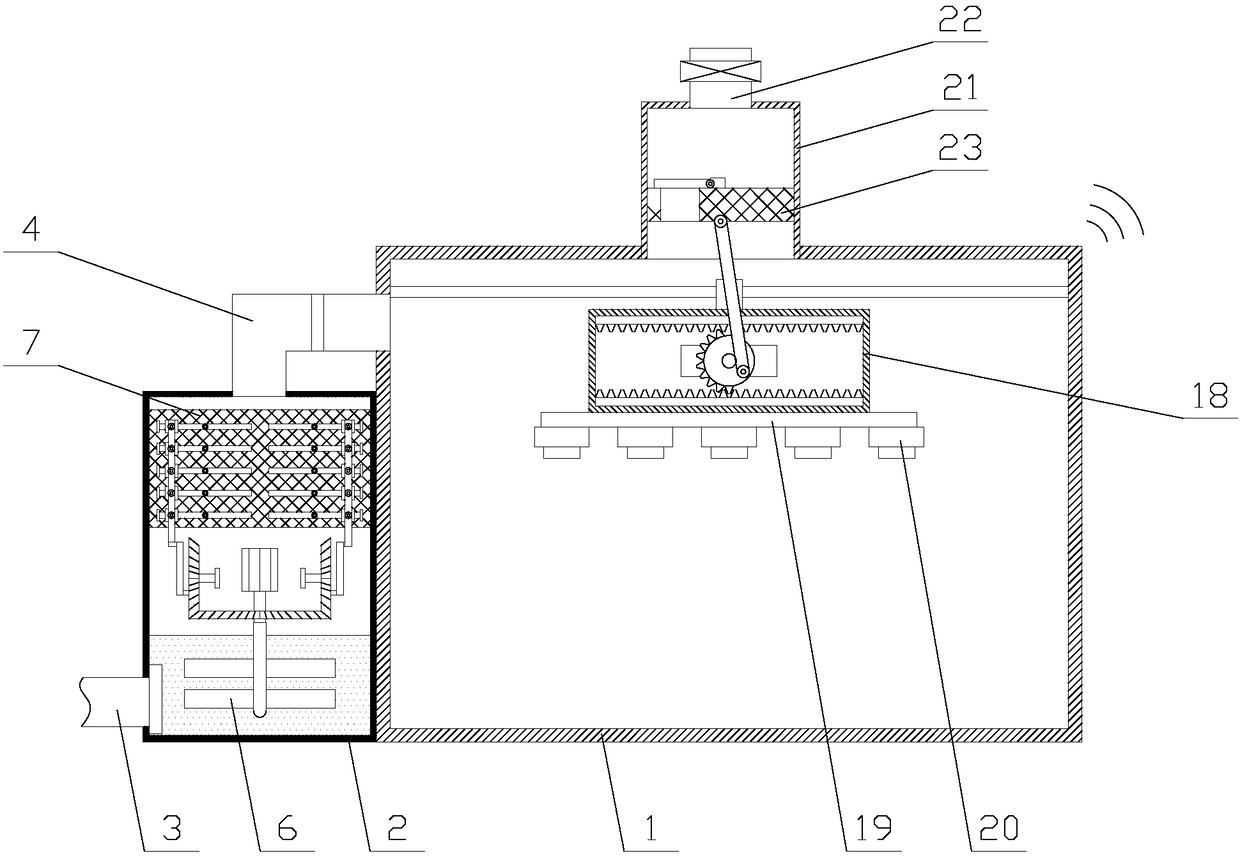

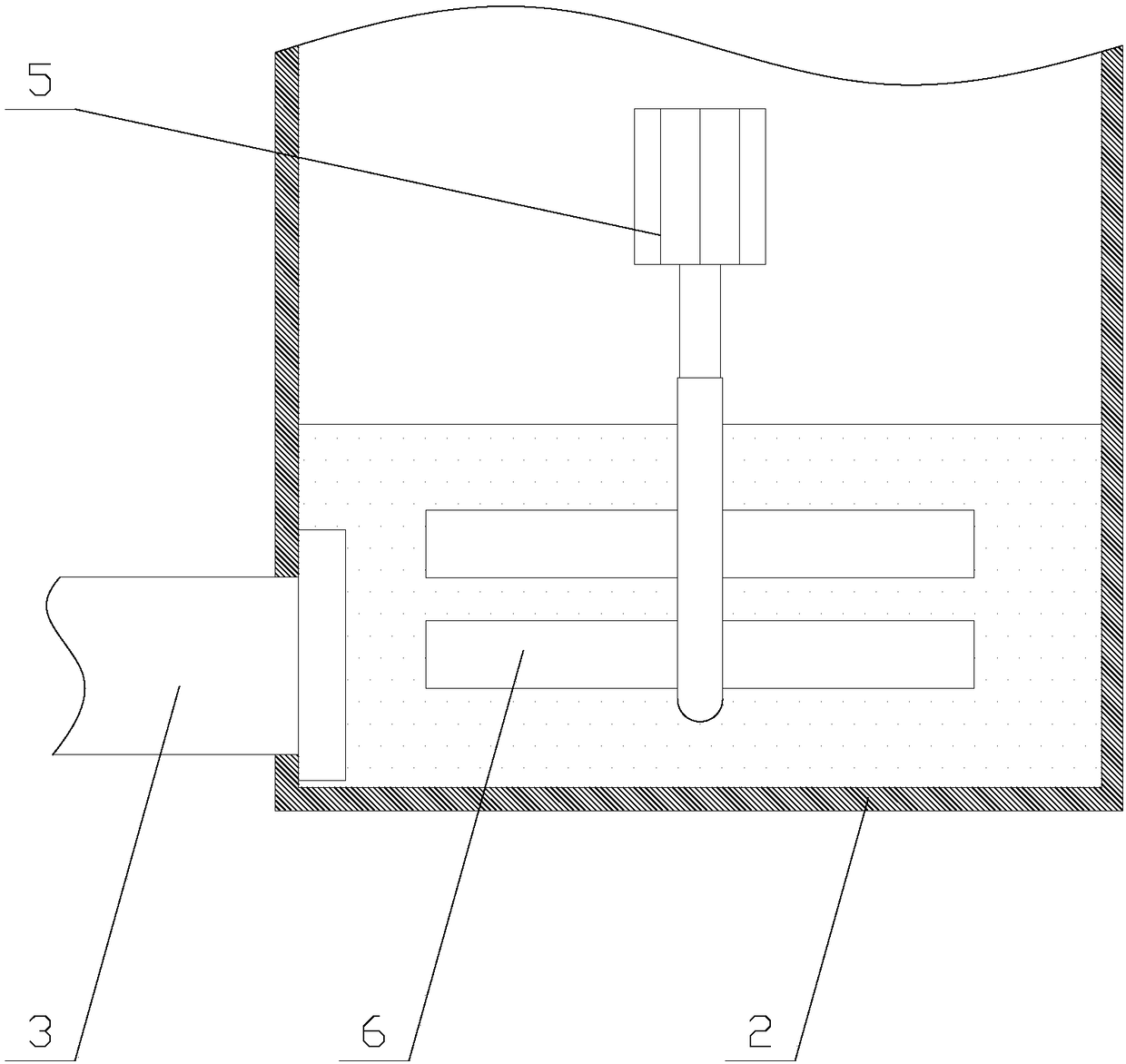

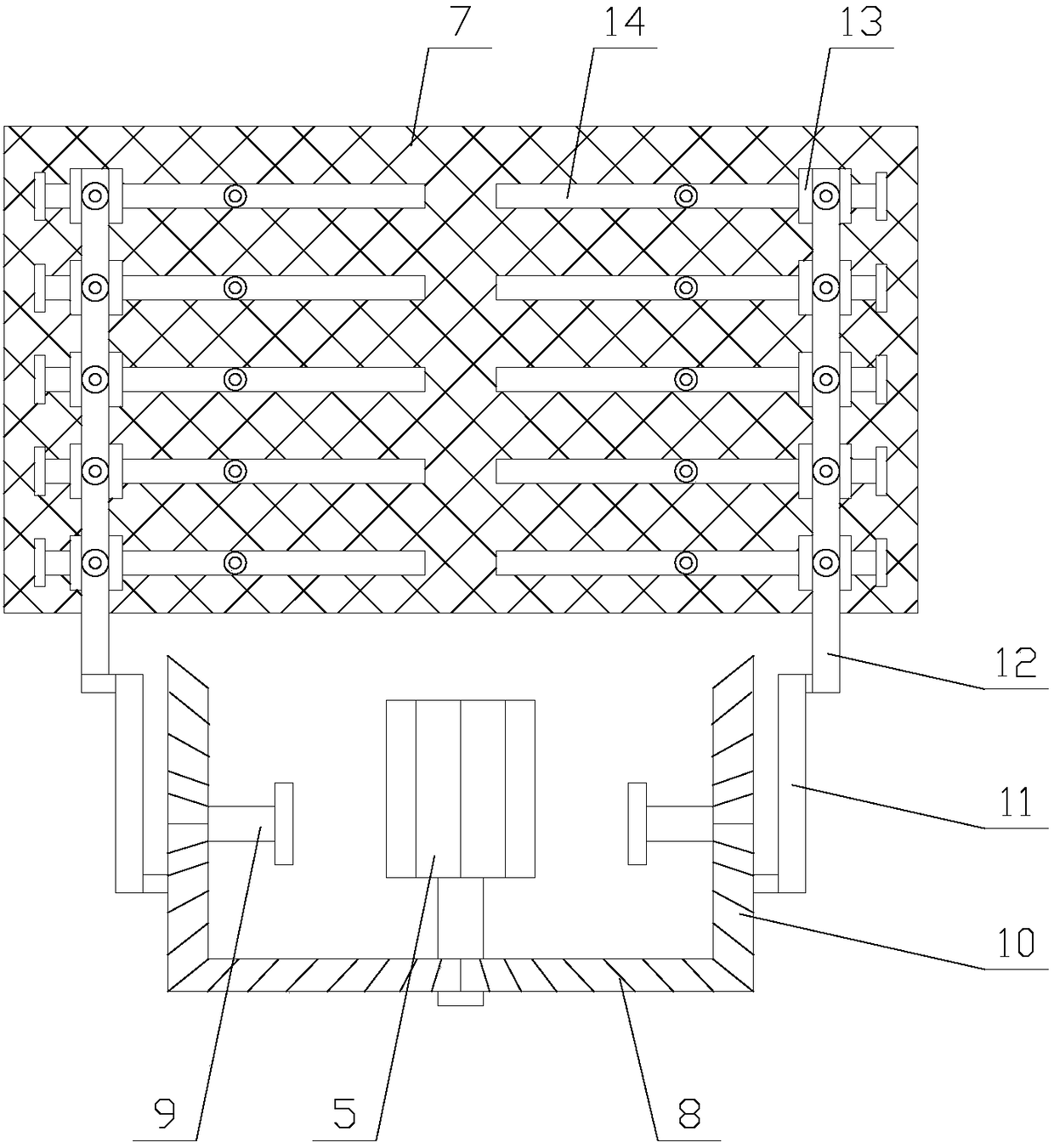

Drying device for production of automobile spare parts

InactiveCN108413758AImprove practicalityImprove reliabilityDrying gas arrangementsFire rescueAir Pump AssemblySpare part

The invention relates to a drying device for production of automobile spare parts. The drying device comprises a main body, and further comprises a purifying mechanism and a fire extinguishing mechanism, wherein the purifying mechanism comprises a purifying chamber, a dust removing assembly and a drying assembly, and the fire extinguishing mechanism comprises a spray assembly and an air pumping assembly. According to the drying device for the production of the automobile spare parts, air can be dedusted and heated by the purifying mechanism, compared with an existing drying device, the situation that dust in the air being sucked on the surfaces of the spare parts affects subsequent surface treatment of some precision spare parts can be avoided, the role of preheating the air is achieved, and the drying device is more energy saving and environmentally friendlier; self-igniting spare parts can be extinguished through the fire extinguishing mechanism, and harmful gases in the main body can be removed; and compared with the existing device, the fire extinguishing effect is better, harm caused by the harmful gases to a human body is reduced, the drying device is safer and more reliable,and the practicability and reliability of the drying device are greatly improved.

Owner:泉州德化宇胜技术咨询有限公司

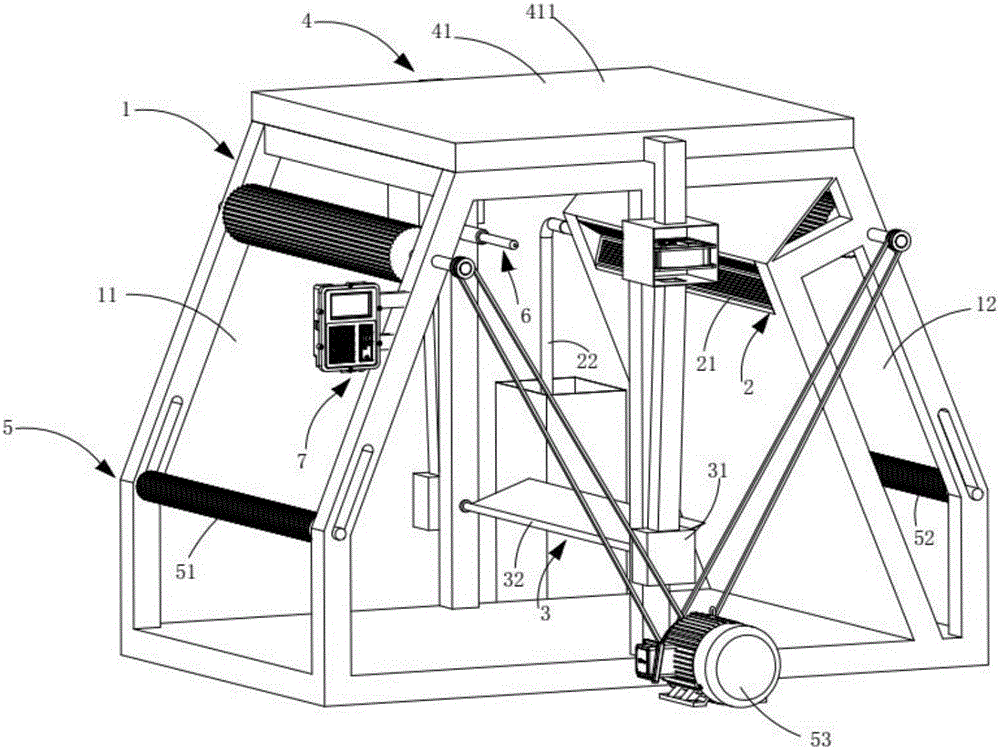

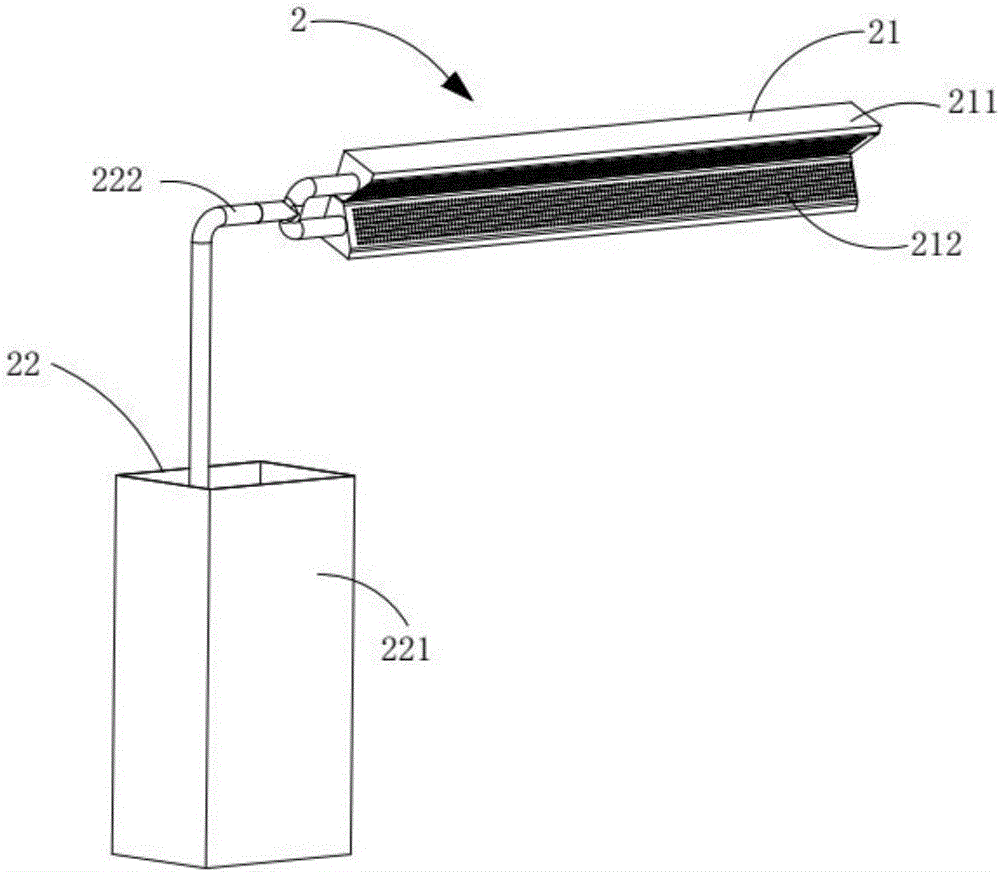

Textile negative pressure dust collection and drying device

ActiveCN106705611ASpeed up the outflowIncrease vacuumDrying gas arrangementsDrying machines with progressive movementsEngineeringAir Pump Assembly

The invention discloses a textile negative pressure dust collection and drying device which comprises a negative pressure dust collection mechanism and a rotating and swing mechanism and furthermore comprises a drying mechanism; the negative pressure dust collection mechanism is arranged on a dust collection area and comprises a dust collection assembly and a dust gathering assembly; the rotating and swing mechanism is located at the front end of the dust collection mechanism and comprises a rotating assembly and a swing assembly; and the drying mechanism comprises an air pumping assembly arranged at the upper end of a drying area and a heating element located under the air pumping assembly. A textile is input into the drying area to be dried, in the drying process, the swing assembly swings all the time, and drying of the textile is accelerated while impurities on the textile fall off in the swing process through swing of the dried textile; and in addition, air flow formed in the swing process of the swing assembly flows to the dust collection mechanism, the dust collection mechanism is beneficial to absorption treatment of the impurities in a box body through air negative pressure formed both inside and outside the device, and thus quality of the textile is improved.

Owner:安徽舜发服装有限公司

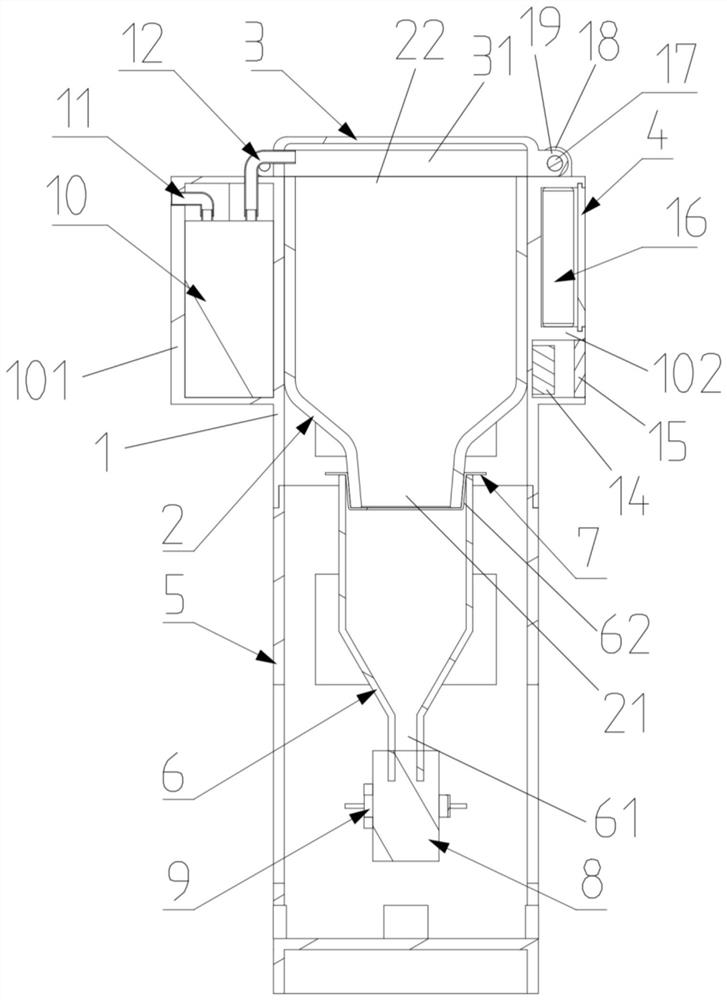

Portable water pollutant enrichment device

PendingCN111999161AReasonable structure layoutReduce volumePreparing sample for investigationEnvironmental engineeringBottle

The invention discloses a portable water pollutant enrichment device which comprises a lower shell, a column clamp connected with the inner wall surface of the lower shell, an extraction column whichcan be clamped and fixed in the lower shell by the column clamp, an upper shell detachably connected with the lower shell, an air pump assembly used for forming a high-pressure environment in the upper shell through air inflation, a control assembly used for controlling the operation of the air pump assembly; a sample storage bottle which is hollow in the interior, and separably arranged in the upper shell; and an enrichment bottle which is hollow in the interior and separably arranged in the lower shell. Part of the sample storage bottle is arranged in the enrichment bottle in a sleeved mode / the whole sample storage bottle is located over the enrichment bottle. The enrichment device is reasonable in structural layout, small in size, convenient to operate, convenient to carry outdoors andcapable of effectively avoiding the problem of enrichment failure caused by drying of the extraction column.

Owner:YANGTZE RIVER FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

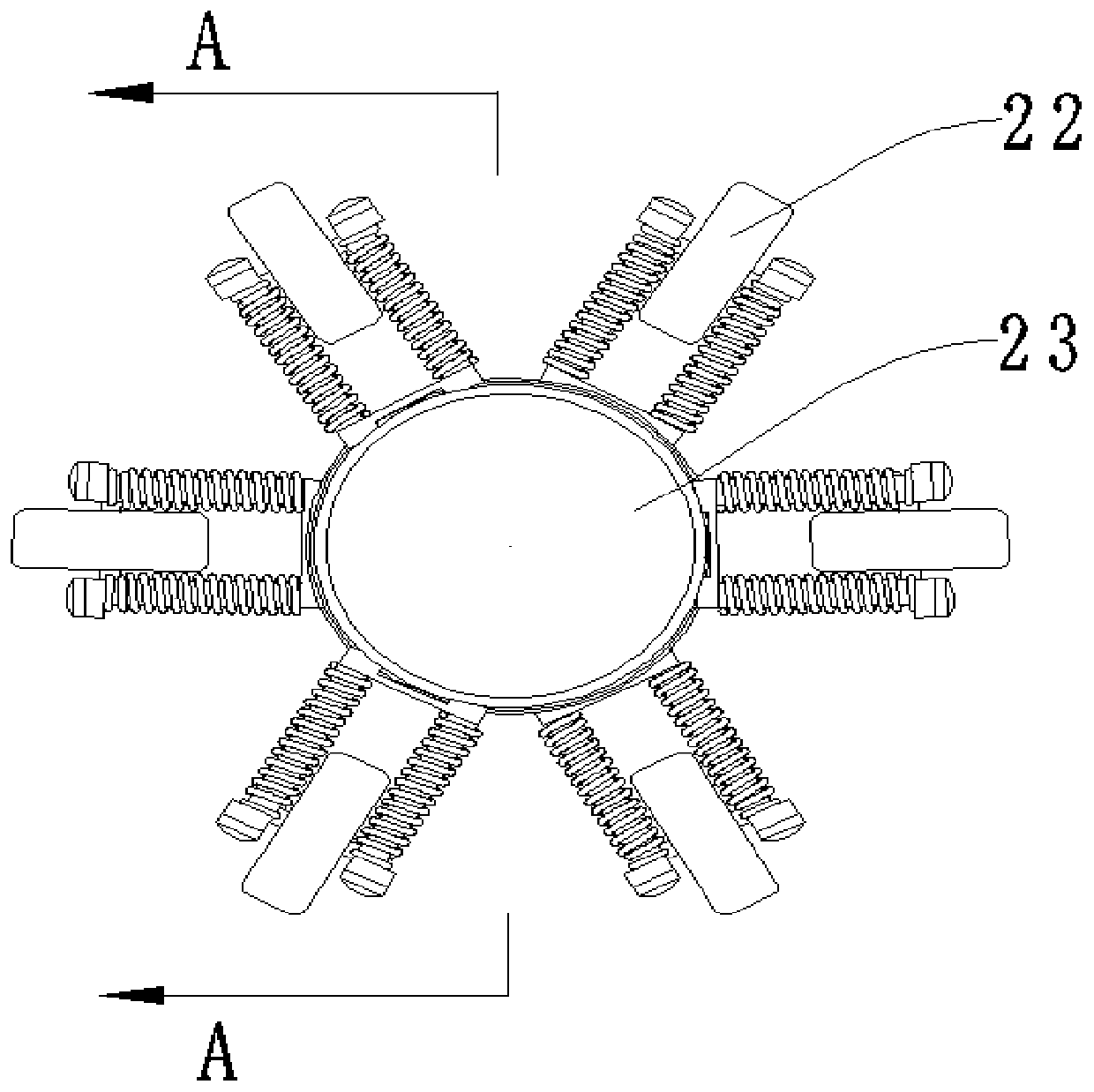

Peristaltic intra-pipeline crawling device and control method thereof

PendingCN109945013AFlexible operationAvoid out-of-control phenomena such as stuckPigs/molesEngineeringAirbag

The invention provides a peristaltic intra-pipeline crawling device and a control method thereof. The device comprises a push part and at least two foot parts. Each foot part comprises a spherical airbag, an air pump assembly and multiple supporting rods arranged around the spherical airbag in the radial direction of a pipeline. The supporting rods comprise rod bodies and rollers connected with the rod bodies, and part of the rollers are arranged in the rod bodies. The air pump assemblies are used for controlling the spherical airbags to stretch and shrink to the periphery, so that the supporting rods make contact with or are separated from the inner wall of the pipeline, and the foot parts and the inner wall of the pipeline are fixed or loosened. The push part comprises an elastic assembly and a spherical hinge connecting part, wherein the elastic assembly is connected between the two foot parts. The spherical hinge connecting part is used for connecting the two spherical airbags, thespherical airbags stretch and shrink to drive the spherical hinge connecting part to move, and the elastic assembly is stretched so that peristaltic crawling can be achieved. By the adoption of an airbag drive manner, part of the rollers are arranged in the rod bodies, and therefore the stability in the operating process of the crawling device is improved.

Owner:XIAMEN UNIV OF TECH

Surgical simulation assembly

A surgical simulation assembly is provided for simulating realistic surgery on animal organs or human cadavers. The surgical simulation assembly comprises a generally flat tray having a central indentation for receiving an organ, at least one drainage aperture and at least one indented trough extending from the central indentation for receiving at least one tube. The tray is assembled with a simulator heart and lungs prepped for connection to a variable speed double action air pump assembly that creates both positive pressure and a vacuum on the heart to simulate a beating heart. The tray is supported on a basket having a lower containment portion for containing fluid waste collected during the simulated surgery. The basket is elevated by risers over a base designed to support the assembly.

Owner:INTUITIVE SURGICAL OPERATIONS INC

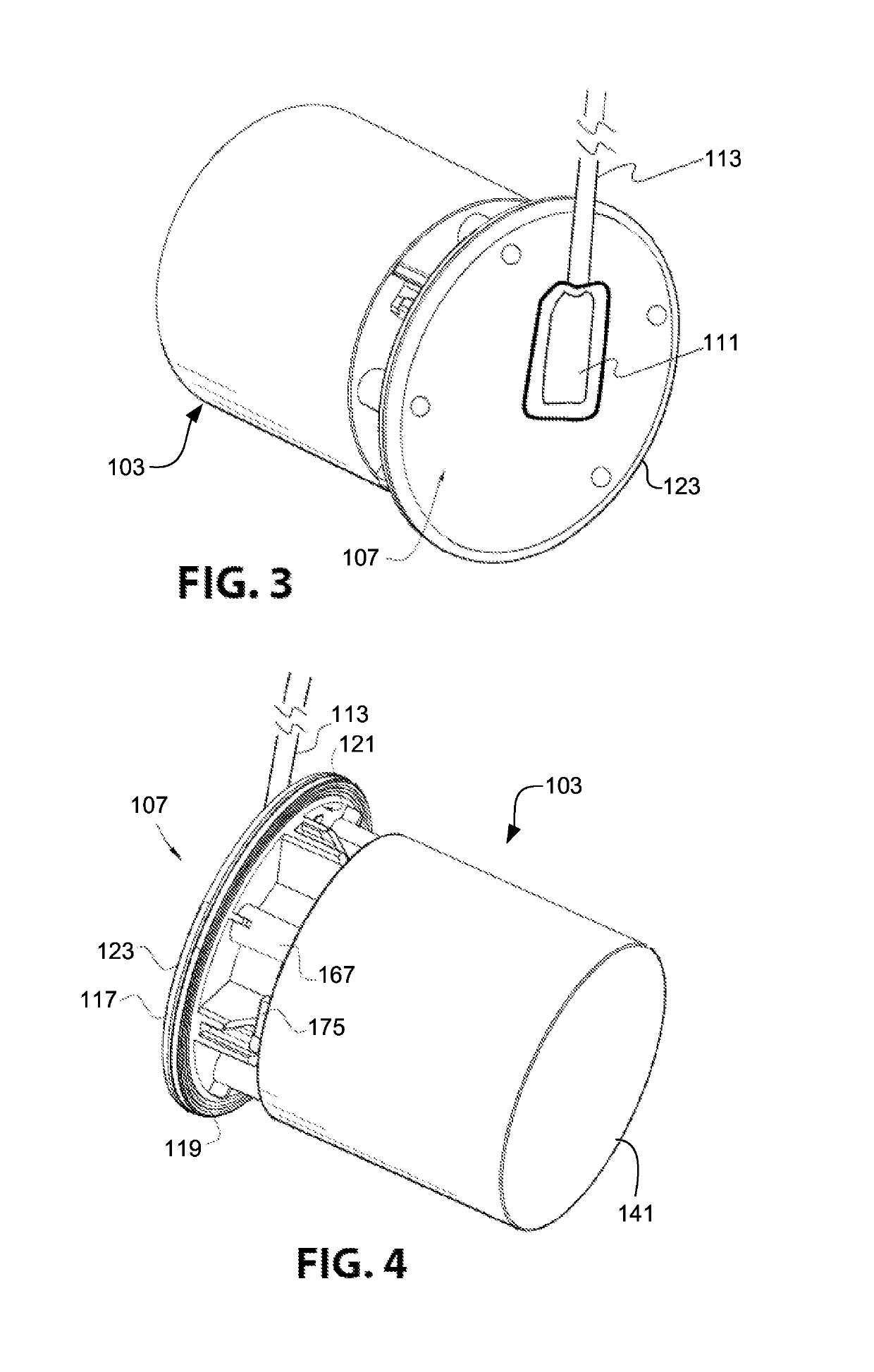

Air massage device for pedicure spa and method

An air pump for dispensing air massage therapy to a basin is provided. It may be used and with a disposal liner. The air pump includes a motor, an air generator, a mounting housing member, a gasket or seal, and an air nozzle. The air pump assembly includes the air pump and the air dispenser. The air pump preferably also includes a printed circuit board (PCB), a PCB cover, an LED light, an infrared light, and a contactless fluid sensor. The present invention is also directed to a pump apparatus that includes an air pump as described, a power source, and / or a control apparatus.

Owner:LURACO INC

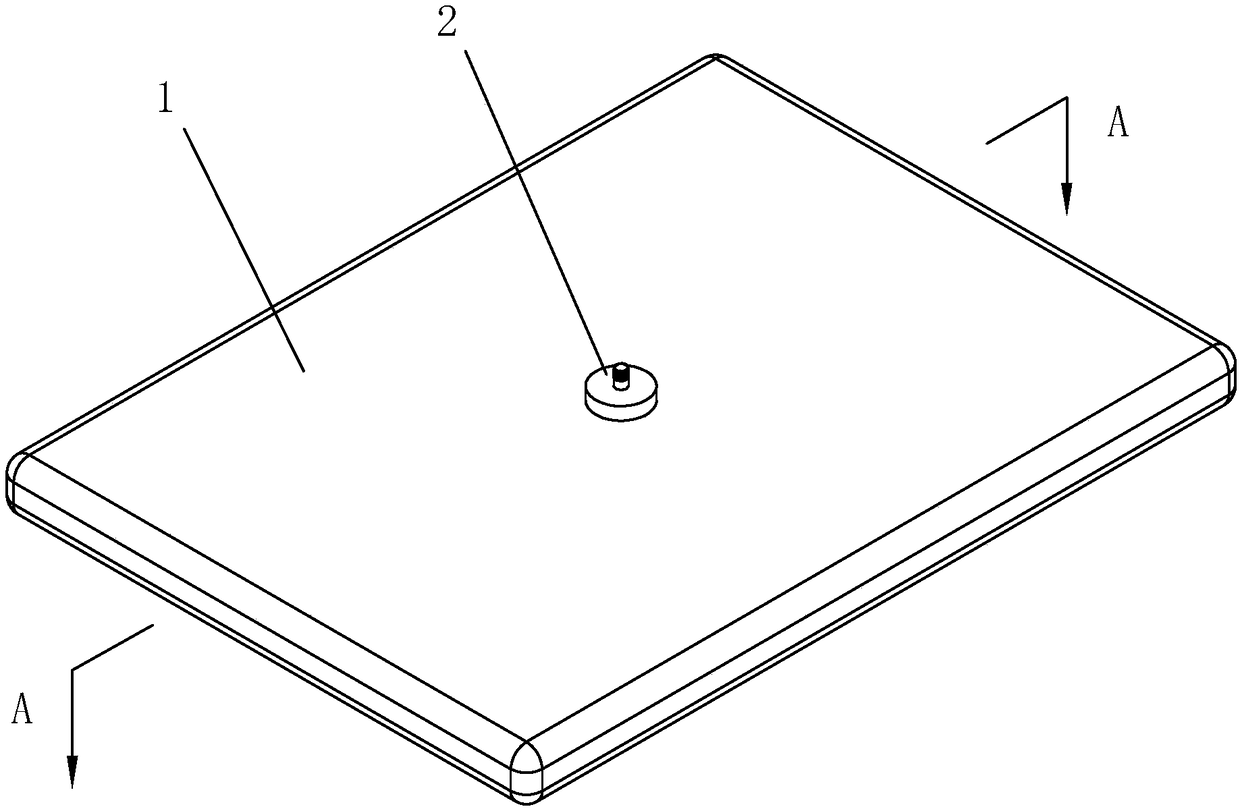

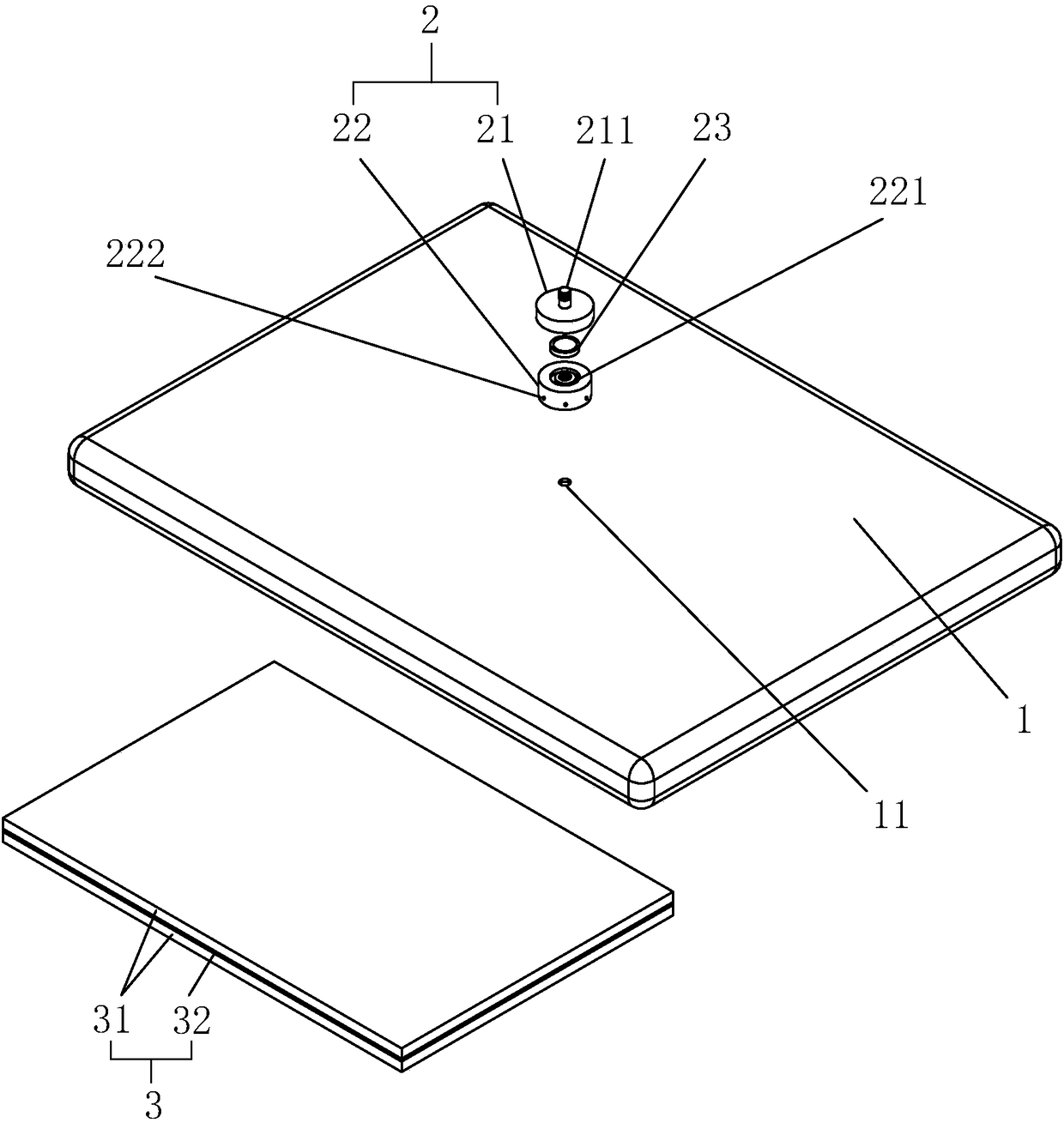

Air pumping device and preparation method of laminated glass

InactiveCN108099347AIncrease the number of layersMeet various needsLamination ancillary operationsLaminationVacuum pumpingSheet film

The invention discloses an air pumping device and a preparation method of laminated glass. The technical scheme is characterized in that the air pumping device comprises a plastic bag, wherein at least one side of the plastic bag is open, a through hole is formed in one surface of the plastic bag, and an air pumping assembly communicated with the inner side and the outer side of the plastic bag isfixed at the through hole; at least two prefabricated glass plates and one film are aligned, laminated and placed in the plastic bag of the air pumping device, and the open edge of the plastic bag issealed; S2, vacuum pumping is performed on the glass plates and the film by the air pumping device for 10-30 min; S3, the air pumping device and glass plates and the film which are placed in the airpumping device are pressurized to 1.2-1.3 MPa at 120-130 DEG C for 30-90 min; S4, the glass plates and the film are discharged out of a furnace after being cooled and pressurized to the normal temperature and normal pressure state, the plastic bag of the air pumping device is taken down, and a finished laminated glass product is obtained. The problem that bubbles are produced easily in existing laminated glass production is solved.

Owner:赋腾河北节能科技有限责任公司

Vein pump assembly for air maintenance tire

The invention relates to a vein pump assembly for an air maintenance tire, specifically to an air maintenance tire and air pump assembly including a tire and an elongate tubular air passageway enclosed within a flexing region of a tire sidewall. A plurality of check valve devices are spaced apart and positioned along the air passageway into multiple air passageway segments. A check valve membrane opens to allow pressurized air to directionally pass through the check valve device from an upstream passageway segment to a downstream passageway segment and closes to prevent air from passing in an opposite direction through the check valve from the downstream segment to the upstream segment.

Owner:THE GOODYEAR TIRE & RUBBER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com