Textile negative pressure dust collection and drying device

A drying device and technology for textiles, applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problems of residue, inconvenient drying work, affecting the quality of textiles, etc., to accelerate drying speed and promote absorption. dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

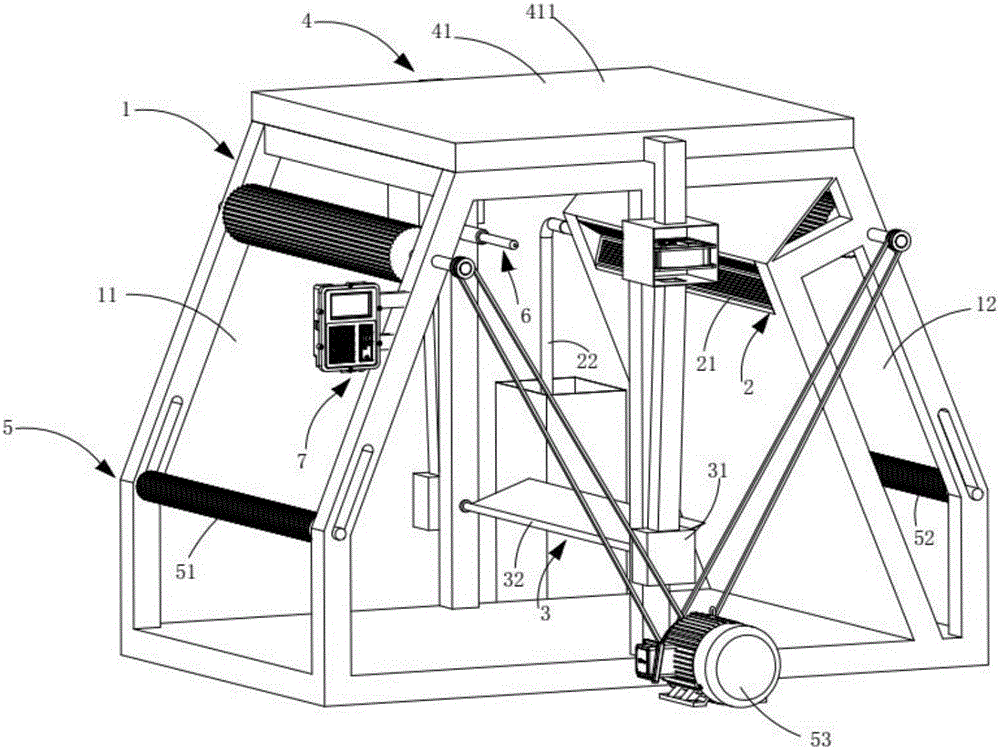

[0032] Such as figure 1 As shown, a negative pressure suction and drying device for textiles is characterized by comprising:

[0033] A box body 1, which includes a drying zone 11 on the left and a dust collection zone 12 on the right; and

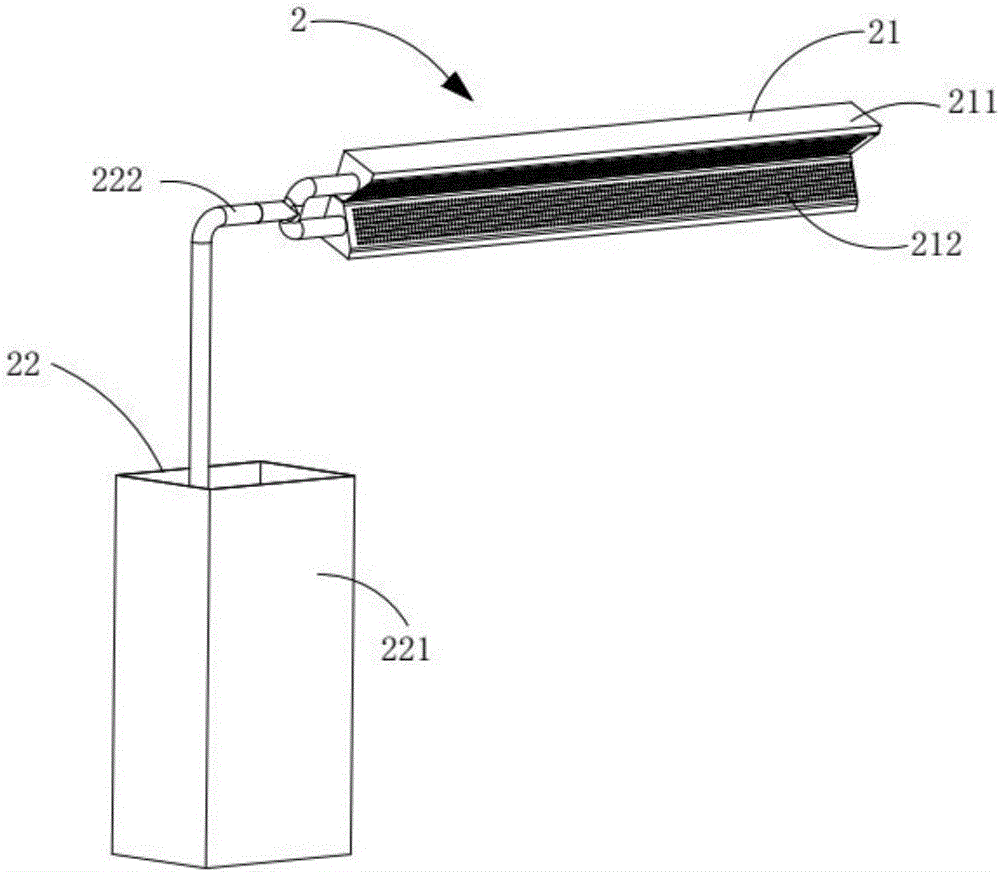

[0034] The negative pressure dust collection mechanism 2, which is arranged on the dust collection area 12, includes a dust collection assembly 21 and a dust collection assembly 22, and the dust collection assembly 22 communicates with the dust collection assembly 21;

[0035] A rotating and swinging mechanism 3, which is located at the front end of the dust suction mechanism 2, and is fixedly arranged on the drying area 11, and includes a rotating assembly 31 and a swinging assembly 32, the rotating assembly 31 works to drive the swinging assembly 32;

[0036] The drying mechanism 4 includes a ventilation assembly 41 arranged at the upper end of the drying zone 11 and a heating element 42 located directly below the ventilation assembly 41.

[0037]...

Embodiment approach

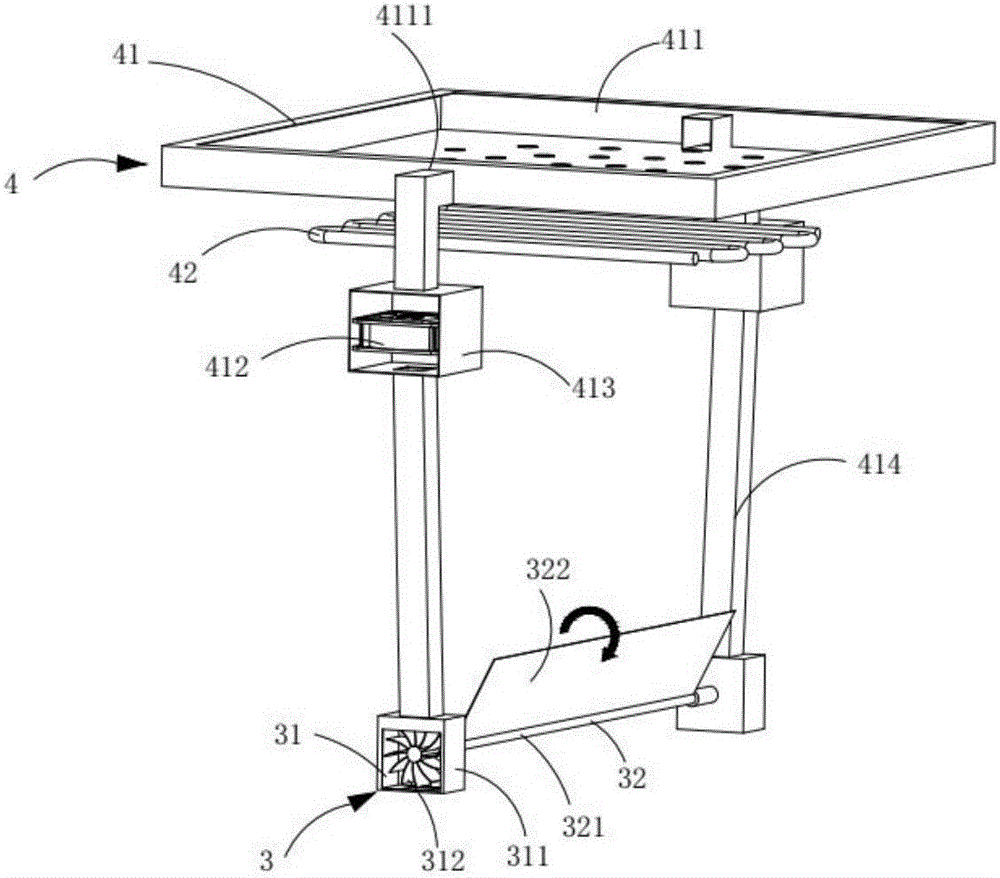

[0053] As a preferred embodiment, the exhaust assembly 41 includes:

[0054] A wind box 411, the wind box 411 is fixed at the upper end of the drying area 11, and the heating element 42 is arranged directly below the wind box 411; and

[0055] A plurality of fan cases 412, the fan case 412 is located at the upper end of the fan box 311, fixed symmetrically at the two ends of the drying area 11, and a fan 413 is horizontally disposed inside; and

[0056] The air duct 414 passes through the air box 412, one end of which is connected to the air box 411, and the other end is connected to the fan box 311.

[0057] It should be noted that the implementation of the ventilation assembly is not limited to the manner in the present invention. The fan 413 in the fan box 412 works to extract dry air outside the device. The air forms an airflow from the fan box 311 into the air duct 414. During the entry process, the fan wheel 312 is driven to rotate, and the fan wheel 312 drives the swing shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com