Glaucoma drainage tube and preparation method thereof

A drainage tube and glaucoma technology, applied in the field of glaucoma drainage tube and its preparation, can solve the problems of glaucoma drainage tube research and development difficulties, inapplicability to pigmentary glaucoma, failure of glaucoma surgery, etc., to achieve no risk of loss, good treatment of glaucoma, no immunity original effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

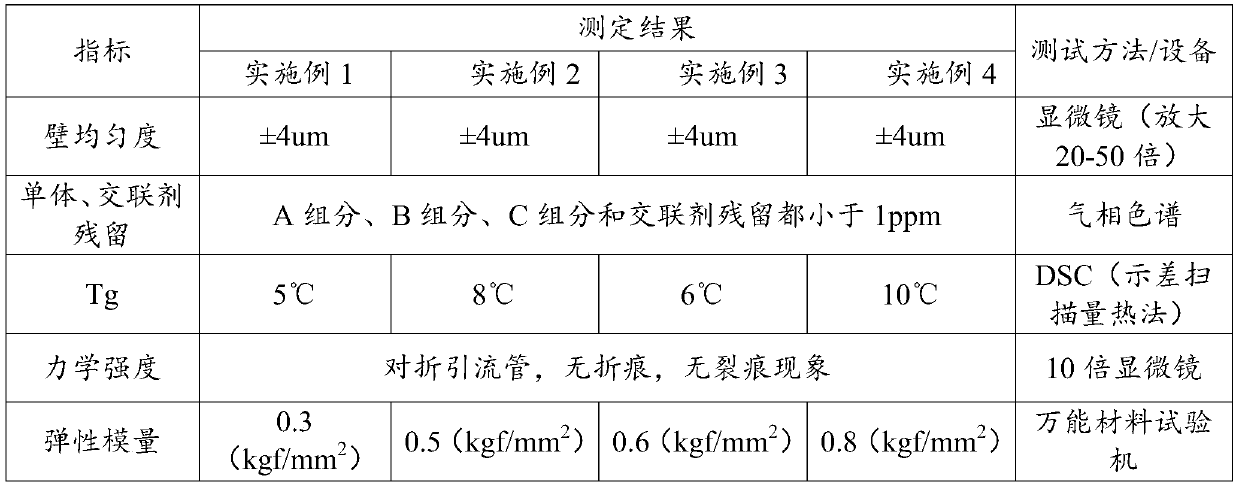

Examples

Embodiment 1

[0042] This embodiment provides a glaucoma drainage tube, the ratio of raw materials is:

[0043] Component A (soft segment monomer): 20wt% of 2-phenylethyl acrylate;

[0044] Component B (hard segment monomer): 20wt% of 2-phenylethyl methacrylate;

[0045] C component (soft segment monomer): ethyl acrylate 55wt%;

[0046] Initiator: bis(4-tert-butylcyclohexyl) peroxydicarbonate 2.6wt%;

[0047] Crosslinking agent: 1,4-butanediol diacrylate 2.4wt%;

[0048] Lifting wire: 316L stainless steel wire with an outer diameter of 45 μm;

[0049] The preparation process is as follows:

[0050] (1) Fully mix the A component, B component, C component and the initiator, react at 40°C for about 2 to 10 hours, wait for the viscosity of the reaction liquid to be 0.5pa.s, quickly cool down to 0°C to stop the reaction , to obtain a prepolymerized sol-gel;

[0051] (2) Add the cross-linking agent to the sol-gel liquid obtained in step (1), mix, and pull it with a 316L stainless steel wire...

Embodiment 2

[0054] This embodiment provides a glaucoma drainage tube, the ratio of raw materials is:

[0055] Component A (soft segment monomer): 25wt% of 2-phenoxyethyl acrylate;

[0056] Component B (hard segment monomer): 20wt% of 2-phenoxyethyl methacrylate;

[0057] Component C (soft segment monomer): 50wt% butyl acrylate;

[0058] Initiator: benzoyl peroxide 2.6wt%;

[0059] Crosslinking agent: 1,4-butanediol dimethacrylate 2.4wt%;

[0060] Lifting wire: 316L stainless steel wire with an outer diameter of 45 μm;

[0061] The preparation process is as follows:

[0062] (1) Fully mix the A component, B component, C component and the initiator, react at 40°C for about 2-10 hours, wait for the viscosity of the mixed liquid to be 1pa.s, quickly cool down to 0°C to stop the reaction, Obtain cross-linked prepolymerized sol-gel;

[0063] (2) Add the cross-linking agent to the sol-gel solution obtained in step (1), mix, and pull with a 316L stainless steel wire with an outer diameter o...

Embodiment 3

[0066] This embodiment provides a glaucoma drainage tube, the ratio of raw materials is:

[0067] Component A (soft segment monomer): 30wt% of 2-phenylethyl acrylate;

[0068] Component B (hard segment monomer): 35wt% of 2-phenylethyl methacrylate;

[0069] C component (soft segment monomer): ethyl acrylate 30wt%;

[0070] Initiator: bis(4-tert-butylcyclohexyl) peroxydicarbonate 2.6wt%;

[0071] Crosslinking agent: 1,4-butanediol diacrylate 2.4wt%;

[0072] Lifting wire: 316L stainless steel wire with an outer diameter of 45 μm;

[0073] The preparation process is as follows:

[0074] (1) Fully mix the A component, B component, C component and the initiator, react at 40°C for about 2 to 10 hours, wait for the viscosity of the mixed liquid to be 2pa.s, quickly cool down to 0°C to stop the reaction, Obtain cross-linked prepolymerized sol-gel;

[0075] (2) Add the cross-linking agent to the sol-gel liquid obtained in step (1), mix, and pull it with a 316L stainless steel wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com