Patents

Literature

1178 results about "Alkyl methacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

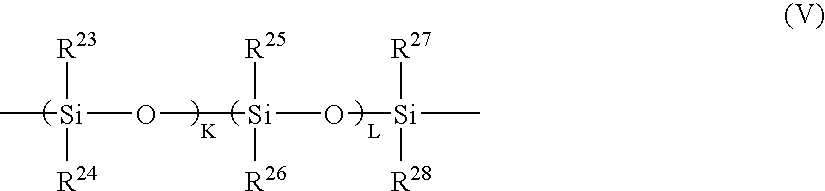

Curable resin composition

The object of the present invention is to provide a novel acrylic-modified silyl-terminated polyether resin composition which is advantageous not only in terms of the availability of raw materials and the ease of synthetic reaction, but also in fast-curing, good storage stability, good weatherability, high adhesiveness, thus promising high potentials of industrial utilization. Further, the object of the present invention is also to develop an environment-friendly curable composition which is a major social consideration. The composition is a curable composition comprising an oxyalkylene polymer (A) containing silyl functional group capable of crosslinking by forming a siloxane bond and a copolymer (B) having a molecular chain comprising alkyl acrylate and / or alkyl methacrylate monomer units and containing silyl functional group capable of crosslinking by forming a siloxane bond, said copolymer (B) having both dialkoxysilyl and trialkoxysilyl groups as said silyl functional group.

Owner:KANEKA CORP

Method for injection moulding moulded bodies consisting of (meth) acrylate copolymers

InactiveUS20040104501A1Reduce contentLittle reabsorptionPharmaceutical non-active ingredientsEndocrine system disorderPolymer scienceMeth-

The invention relates to a process for producing mouldings by injection moulding the steps in the process being a) melting and mixing of a (meth)acrylate copolymer composed of from 85 to 98% by weight of C1-C4-alkyl (meth)acrylates capable of free-radical polymerization and from 15 to 2% by weight of (meth)acrylate monomers having a quaternary ammonium group in the alkyl radical, with from 10 to 25% by weight of a plasticizer, and also from 10 to 50% by weight of a dryers [sic] and / or from 0.1 to 3% by weight of a release agent, and, where appropriate, with other conventional pharmaceutical additives or auxiliaries and / or with an active pharmaceutical ingredient, b) devolatilizing the mixture at temperatures of at least 120° C., thus reducing the content of the low-boiling constituents with a vapour pressure of at least 1.9 bar at 120° C. to not more than 0.5% by weight, and c) injecting the devolatilized mixture at a temperature of from 80 to 160° C. into the mould of an injection moulding system and removing the resultant moulding from the mould.

Owner:ROEHM GMBH & CO KG +1

Pressure sensitive adhesive composition for optical members, pressure sensitive adhesive layer for optical members, pressure sensitive adhesive optical member and image display

InactiveUS20050014879A1Improve adhesionExcellent in re-releasabilityFilm/foil adhesivesElectroluminescent light sourcesPolymer scienceMeth-

The present invention provides a pressure sensitive adhesive composition for optical members, which is excellent in durability, re-releasability and stress relaxation, as well as a pressure sensitive adhesive composition for optical members, which hardly increases adhesion after storage for a long time and does not leave a residual adhesive on glass upon disposal or repair. The pressure sensitive adhesive composition for optical members according to the present invention comprises 100 parts by weight of an acrylic polymer (A) having a weight-average molecular weight of 500,000 or more, containing at least 50 wt % alkyl (meth)acrylate having an alkyl group with 5 or more carbon atoms and 0.2 to 2 wt % unsaturated carboxylic acid as the monomer unit, 0.1 to 4 parts by weight of an acrylic polymer (B) having a weight-average molecular weight of 2,000 to 50,000, containing at least 70 wt % alkyl(meth)acrylate and 1 to 7 wt % unsaturated carboxylic acid as the monomer unit and having a higher carboxylic acid equivalent than that of the acrylic polymer (A), 0.01 to 1 part by weight of a silane coupling agent, and a crosslinking agent.

Owner:NITTO DENKO CORP

Curable liquid resin composition

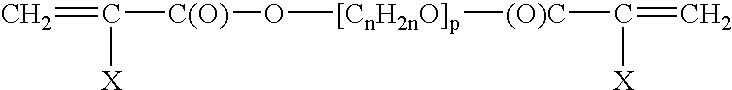

PCT No. PCT / JP97 / 01871 Sec. 371 Date Feb. 3, 1998 Sec. 102(e) Date Feb. 3, 1998 PCT Filed Jun. 2, 1997 PCT Pub. No. WO97 / 46601 PCT Pub. Date Dec. 11, 1997A curable liquid resin composition containing 100 parts by weight of the following (meth)acrylic liquid resin (A) and 1 to 1,000 parts by weight of a (meth)acrylic monomer (B) having an unsaturated double bond in its molecule and having a number average molecular weight of 1,000 or less, the (meth)acrylic liquid resin (A) being a liquid resin which is obtained by polymerizing monomers containing an alkyl (meth)acrylate monomer (a-1-1) of the formula (1),CH2 C(R1)COO-R2(1)wherein R1 is a hydrogen atom or CH3 and R2 is an alkyl group, and / or an alkylene glycol (meth)acrylate monomer (a-1-2) of the formula (2),CH2=C(R1)COO(CnH2nO)mR3(2)wherein R1 is a hydrogen atom or CH3, R3 is an alkyl group or a phenyl group, n is an integer of 1 to 3, and m is an integer of 3 to 25, and other polymerizable vinyl monomer (a-2), an average of molecular weights of all the monomers being 100 to 1,500, the liquid resin having a number average molecular weight of 10,000 to 200,000 and a viscosity of 1 to 10,000 poise (measured at 50 DEG C.), or a modified product of the above liquid resin, the curable liquid resin composition can form a film as a film-forming material or as a resin for an adhesive without using a solvent and give a cured film.

Owner:TOYO INK SC HOLD CO LTD

Pressure-sensitive adhesive for optical films

ActiveUS20090305068A1High viscosityEasy to operateFilm/foil adhesivesSynthetic resin layered productsPolymer scienceHeat resistance

Pressure-sensitive adhesives for optical films exhibit high cohesion, excellent re-workability, adhesion properties, heat resistance and durability without chemical crosslinking.A pressure-sensitive adhesive contains an acrylic triblock copolymer (I) at not less than 60% by mass based on the total mass of all solids contained in the pressure-sensitive adhesive, the acrylic triblock copolymer being represented by the formula A1-B-A2 wherein: A1 and A2 are each independently an alkyl methacrylate polymer block having Tg of not less than 100° C. and B is an acryl acrylate polymer block having Tg of not more than −20° C.; the content of the polymer block B is 50 to 95% by mass; Mw is in the range of 50,000 to 300,000; and the molecular weight distribution is in the range of 1.0 to 1.5. In a preferred embodiment, the acrylic triblock copolymer (I) is a combination of an acrylic triblock copolymer (Ia) having Mw of 50,000 to less than 100,000 and an acrylic triblock copolymer (Ib) having Mw of 100,000 to 300,000, in a mass ratio (Ia):(Ib) of 45:55 to 75:25.

Owner:KURARAY CO LTD

Coated carrier

A composition comprised of a core and thereover a polymer of (1) polystyrene / alkyl methacrylate / dialkylaminoethyl methacrylate, (2) polystyrene / alkyl methacrylate / alkyl hydrogen aminoethyl methacrylate, (3) polystyrene / alkyl acrylate / dialkylaminoethyl methacrylate, or (4) polystyrene / alkyl acrylate / alkyl hydrogen aminoethyl methacrylate.

Owner:XEROX CORP

High-solid hydroxyl fluorine-containing acrylic resin and preparation method thereof

The invention relates to high-solid hydroxyl fluorine-containing acrylic resin and a preparation method thereof. The high-solid hydroxyl fluorine-containing acrylic resin comprises the following components in parts by weight: 10-25 parts of fluorine-containing acrylic ester monomer, 10-30 parts of hydroxyl group-containing acrylic ester monomer, 5-20 parts of methyl acrylic alkyl ester monomer, 5-15 parts of acrylic alkyl ester monomer, 0.3-6 parts of initiator, 0.2-4 parts of chain transfer and 30-50 parts of solvent. According to the hydroxyl fluorine-containing acrylic resin, the solid content reaches up to 75-90 percent, the viscosity is only 900-3,000 mPa.s, the number-average molecular weight is 1,200-6,000, and the molecular weight distribution index is 1.4-2.5; and the resin has the advantages of superior performance, high transparency, no odor of mercaptan, low VOC (Volatile Organic Compound) content, a fluorine carbon group included on a polymer chain and superior corrosion resistance of the resin and can be applied to the fields such as heavy anticorrosive coatings, marine antifouling coatings, aircraft surface coatings, anti-doodling coatings, exterior wall coatings of high weathering resistance and the like.

Owner:SOUTHEAST UNIV

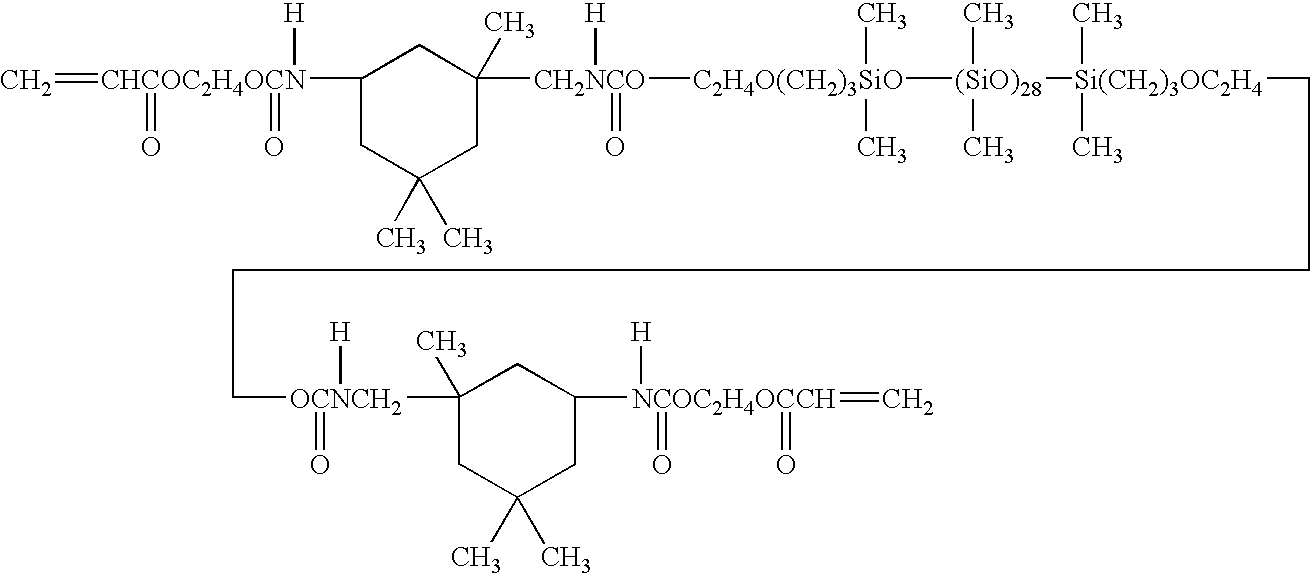

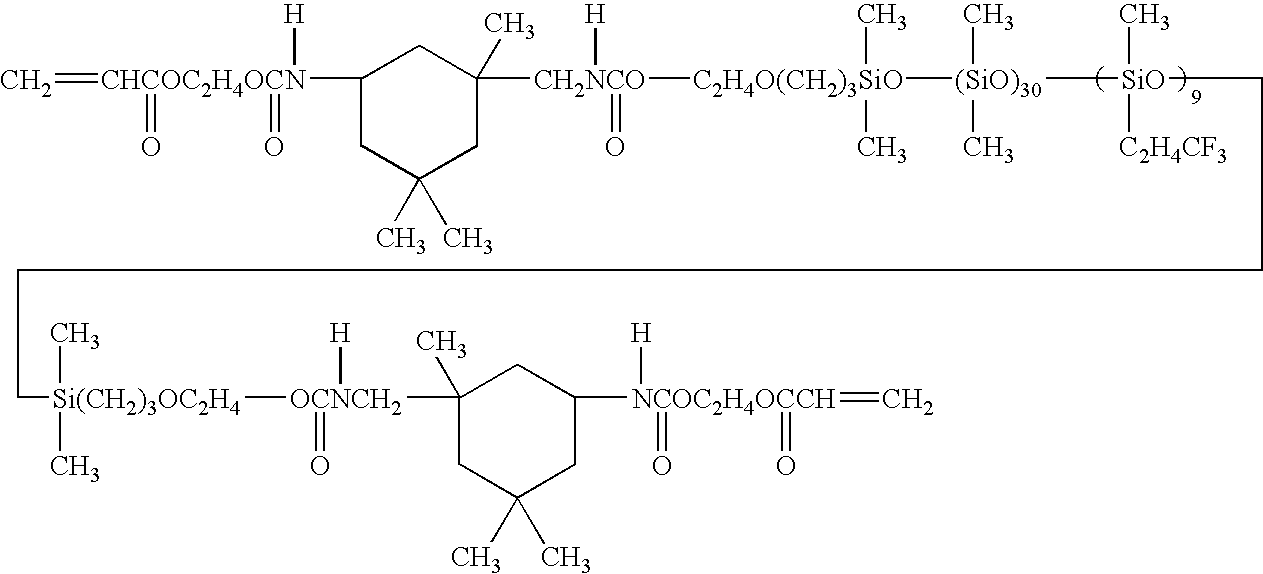

Ocular lens material

InactiveUS20040039077A1High oxygen permeabilityHigh mechanical strengthTissue regenerationProsthesisHydrophilic monomerPolymer science

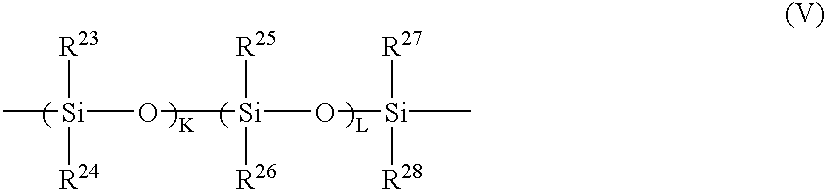

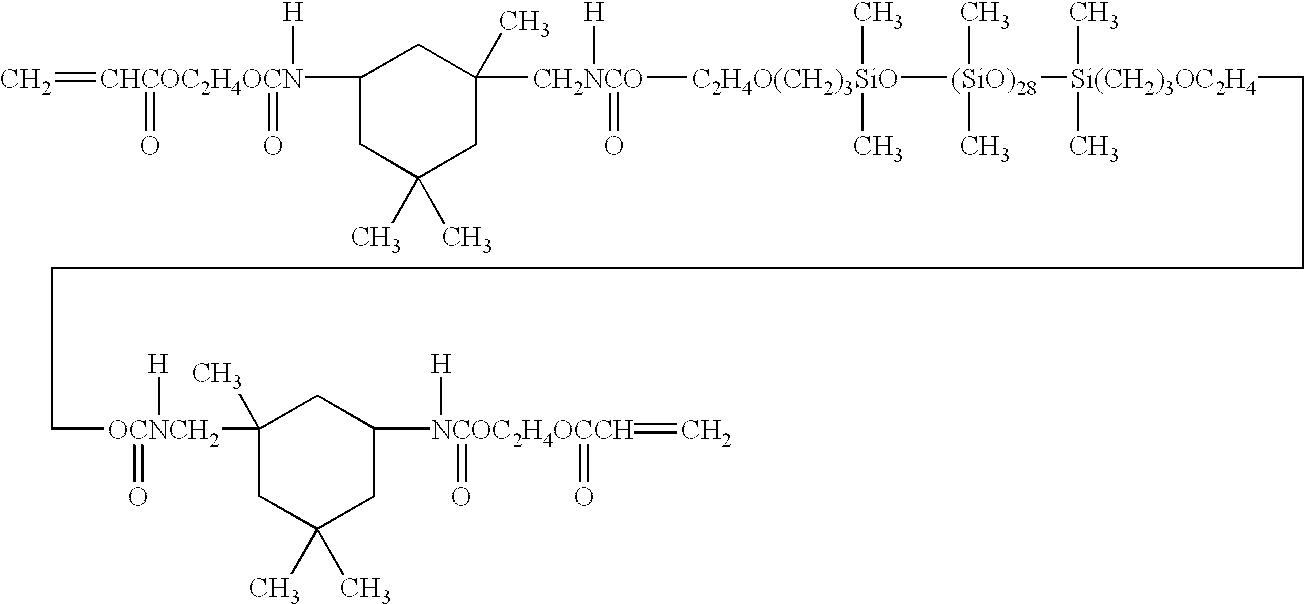

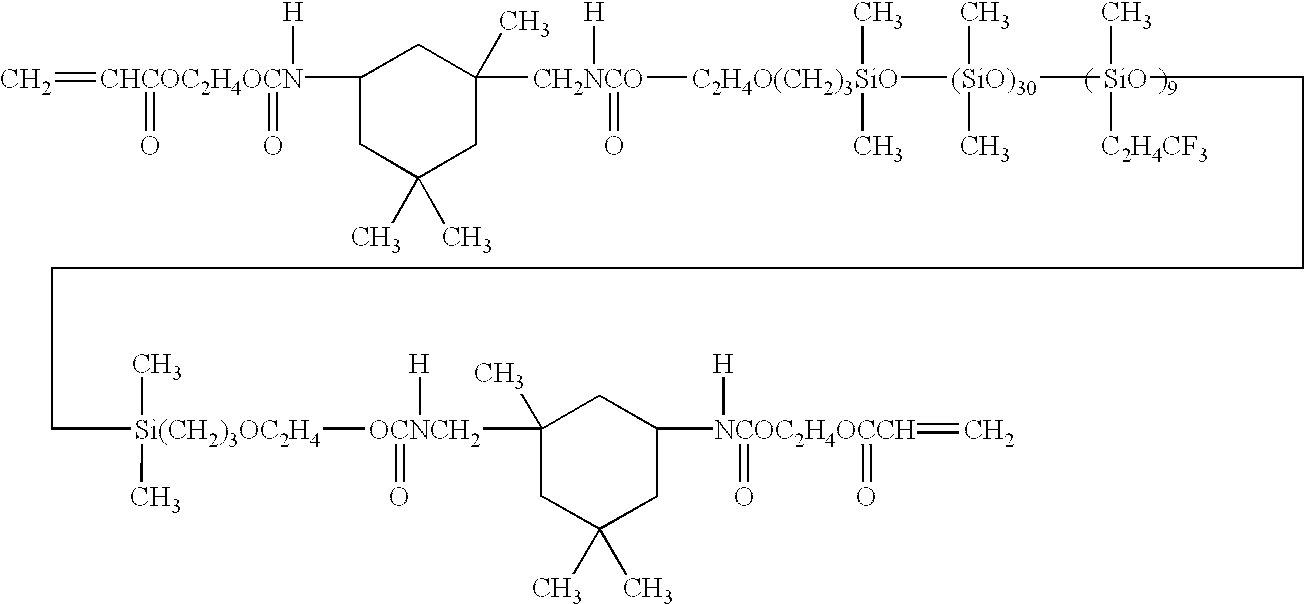

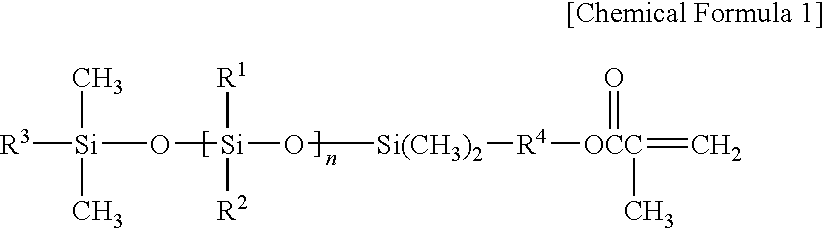

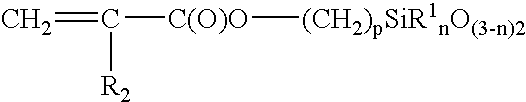

An ocular lens material comprising a copolymer prepared by polymerization with heating of a monomer mixture and / or with irradiating a monomer mixture with ultraviolet ray by means of a molding method, the monomer mixture containing a polysiloxane macromonomer A, a Si-containing alkyl methacrylate B, a hydrophilic monomer C comprising NVP as C-1 and another hydrophilic monomer C-2, another monomer D and a crosslinkable monomer E comprising a crosslinkable monomer E-1 containing at least one group selected from acryloyl group, vinyl group and allyl group, and methacryloyl group, and a crosslinkable monomer E-2 containing at least two methacryloyl groups as main components, wherein (A+B) / C (weight ratio) is 30 / 70 to 70 / 30, A / B is 25 / 75 to 75 / 25, C-1 / C-2 is 50 / 50 to 100 / 0, the amount of D is 0 to 20% by weight in the monomer mixture, which has high oxygen permeability, high mechanical strength, excellent surface wettability and low surface frictional property.

Owner:MENICON CO LTD

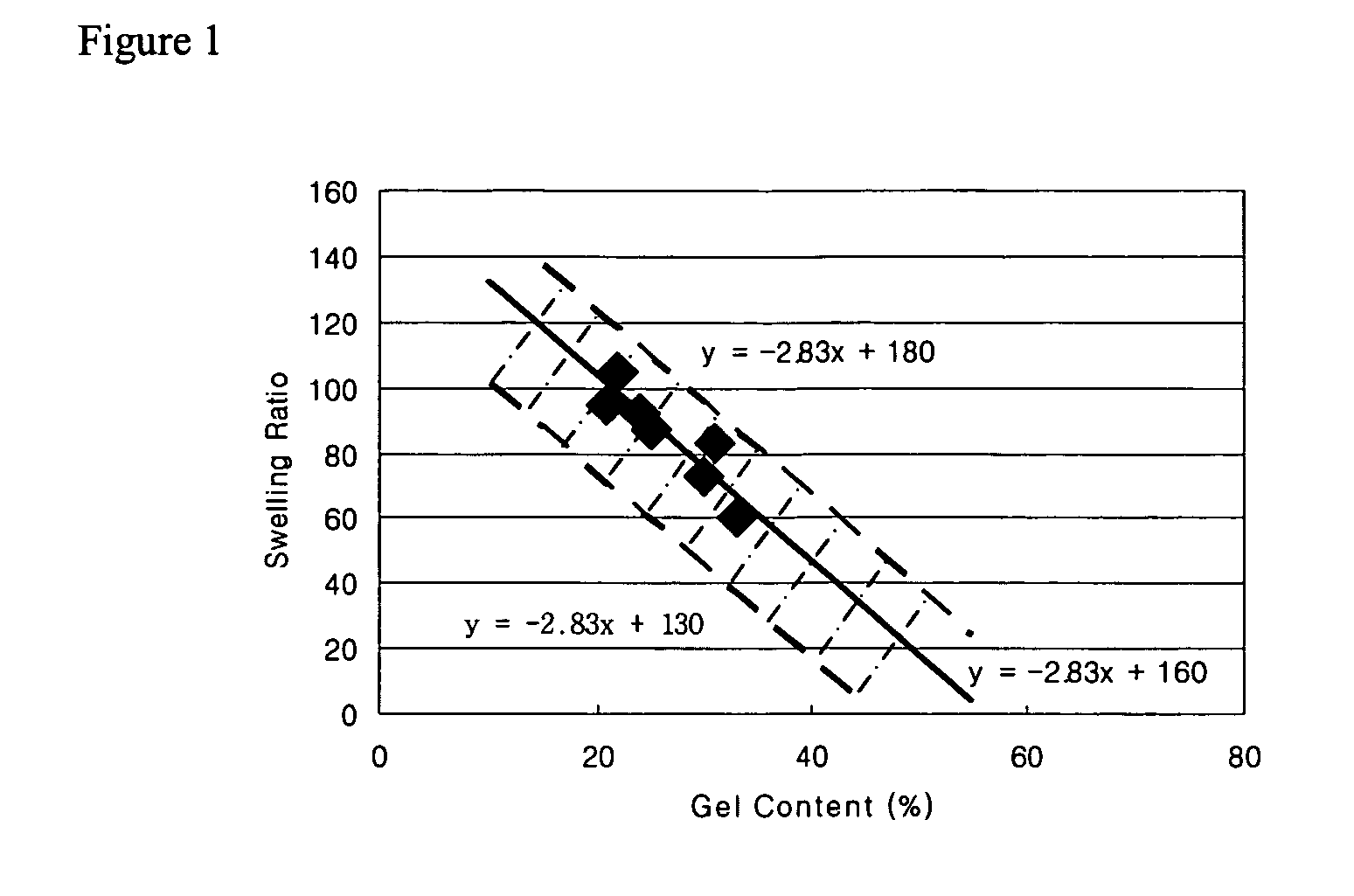

Acrylic pressure-sensitive adhesive composition for polarizing film

ActiveUS20070055006A1Improve light leakagePreventing operability decreaseEster polymer adhesivesEmulsion paintsPolymer scienceSwelling ratio

The present invention relates to an acrylic pressure sensitive adhesive composition comprising (meth)acrylic copolymers including alkyl(meth)acrylic acid ester monomer having 1˜12 carbon atoms of alkyl group, characterized in that the gel content is 10˜55%, the swelling ratio is 30˜110, the weight average molecular weight of sol eluted from the adhesive by ethyl acetate is at least 800,000, the molecular weight distribution is 2.0˜7.0; and a polarizer and a liquid crystal display comprising the above composition show excellent durability under a high temperature and humidity condition, and can improve the light leakage phenomenon and provide excellent operability at the time of manufacturing polarizer by effectively providing high modulus and stress release property.

Owner:SHANJIN OPTOELECTRONICS SUZHOU CO LTD

Blends of ethylene copolymers with high-frequency weldability

InactiveUS20060160952A1Use welding processingWoven fabricsEmulsion paintsMeth-Ethylenevinylacetate copolymer

Disclosed are high frequency-active blends comprising (a) copolymers of ethylene and maleic anhydride or its functional equivalents and (b) ethylene copolymers with polar comonomers such as ethylene / vinyl acetate copolymers, ethylene / alkyl (meth)acrylate copolymers and ethylene / (meth)acrylate / carbon monoxide terpolymers; and films, powders, multilayer structures, and articles prepared therefrom.

Owner:PERFORMANCE MATERIALS NA INC

Liquid composition for making pigment fixed, ink set, method for producing ink jet recorded matter on fabric and ink jet recorded matter on fabric

InactiveUS20090226678A1Improve wear resistanceGood dry-cleanabilityLayered productsDecorative surface effectsHigh resistanceColor intensity

There are provided a liquid composition for making pigment fixed having a high resistance to rubbing and a good dry-cleanability; an ink set including the liquid composition for making pigment fixed and an ink composition excellent in terms of color intensity, discharge stability, and adhesiveness; and a method for producing ink-jet-recorded matter on a fabric having a high resistance to rubbing and good dry-cleanability using the liquid composition for making pigment fixed and the ink composition.The liquid composition for making pigment fixed according to the present invention contains at least a reactant and polymer fine particles synthesized from an alkyl (meth)acrylate and / or cyclic alkyl (meth)acrylate, the glass transition temperature and acid value of the liquid composition being equal to or lower than −10° C. and equal to or lower than 100 mg KOH / g, respectively.

Owner:SEIKO EPSON CORP

Scuff resistant compositions comprising ethylene acid copolymers and polyamides

InactiveUS20050020762A1Improve toughnessHigh transparencyProtective equipmentSynthetic resin layered productsAlkaline earth metalPolyamide

Disclosed are compositions of ethylene acid copolymers and polyamides that are useful for fabricating films, sheets and molded articles for scuff and scratch resistant material and their application as decorative and protective films, comprising (1) from about 30 to about 65 weight % of a polyamide; and (2) from about 70 to about 35 weight % of a copolymer of (a) ethylene; (b) from about 5 weight % to about 15 weight % of an α,β-unsaturated C3-C8 carboxylic acid; (c) from about 0.5 weight % to about 12 weight % of at least one comonomer that is an ethylenically unsaturated dicarboxylic acid; and (d) from 0 weight % to about 30 weight % of monomers selected from alkyl acrylate and alkyl methacrylate, wherein the alkyl groups have from one to twelve carbon atoms; at least partially neutralized by one or more alkali metal, transition metal, or alkaline earth metal cations. Articles prepared from these compositions, such as films, show high toughness, good mechanical properties, excellent scratch and scuff resistance and, most importantly, good optical properties. More particularly, the compositions of ethylene copolymers and polyamides of the present invention can be used as protective coatings or layers on scuff- and scratch-exposed objects.

Owner:PERFORMANCE MATERIALS NA INC

Curable composition

The present invention provides a curable composition which comprises: Component (A): A polyoxyalkylene polymer containing at least one reactive silyl group at a molecular chain terminus; Component (B): A polymer composed of acrylic acid alkyl ester monomer units and / or methacrylic acid alkyl ester monomer units containing, on the average, at least one reactive silyl group in each molecule; and, Component (C): An ionic surfactant, and which may be suitably used as a sealant for buildings inhibiting dust / dirt adhesion and hardly allowing traces of rain and like stains to leave thereon.

Owner:KANEKA CORP

Adhesive composition, adhesive optical film and image display device

ActiveUS20060188712A1Improve adhesionImprove heat resistanceBlast furnace componentsSynthetic resin layered productsPolymer scienceMeth-

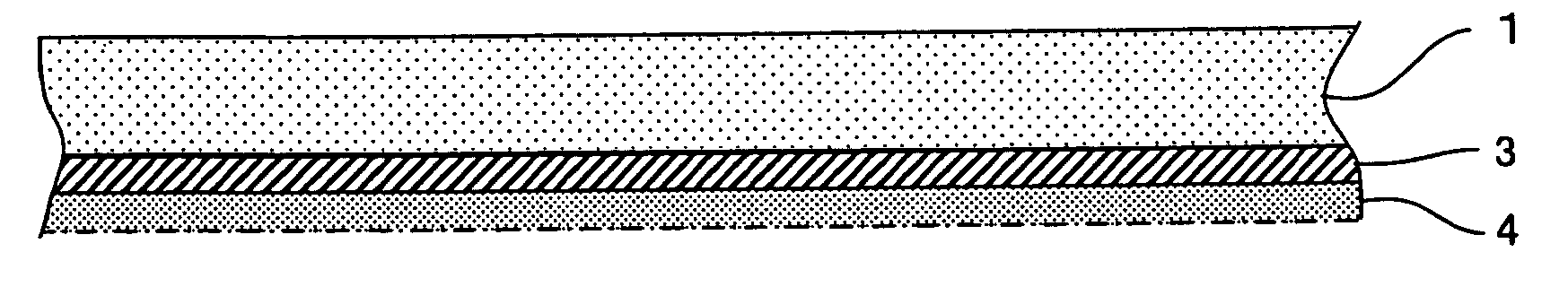

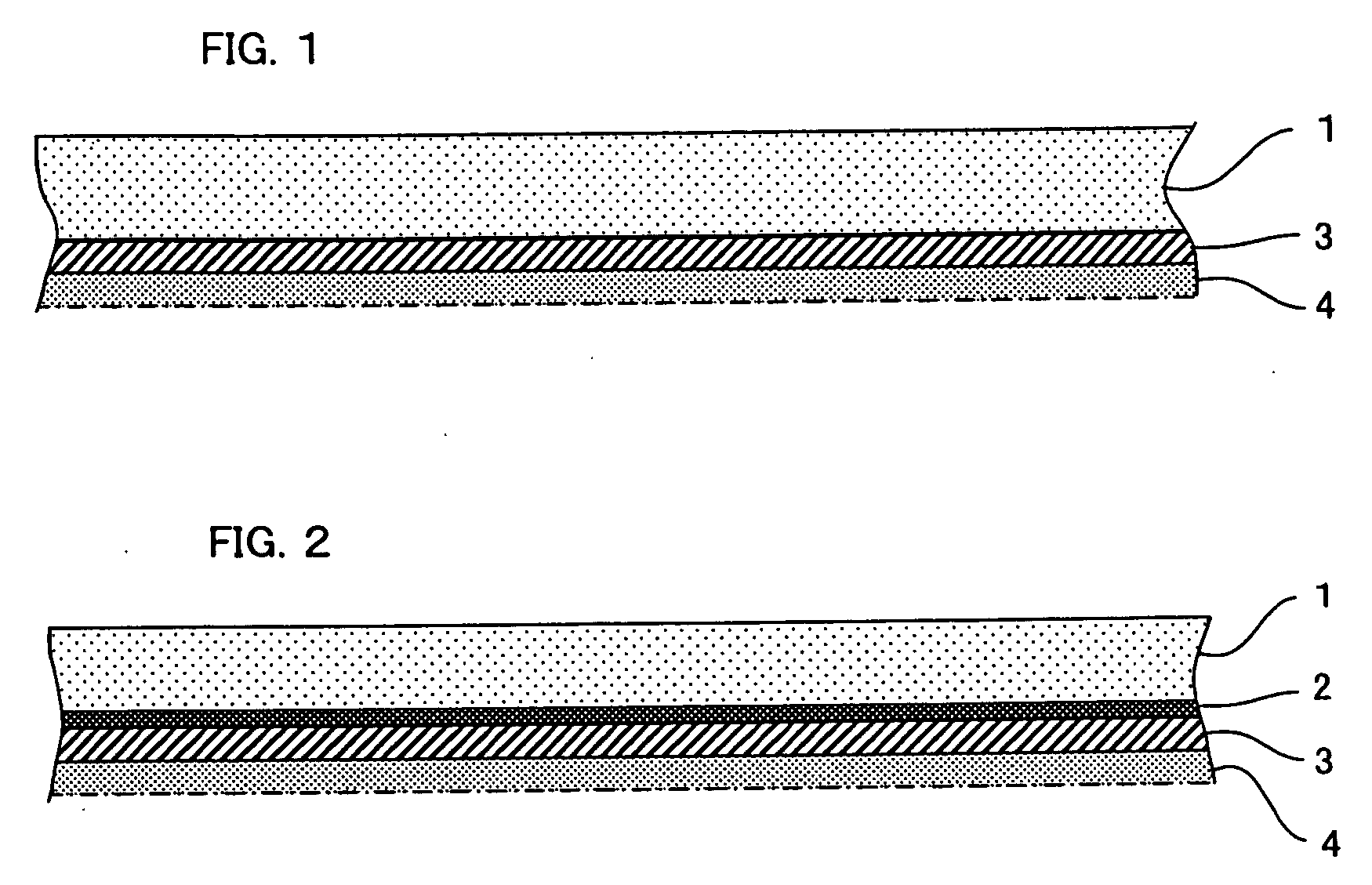

To provide an adhesive composition which shows high adhesion with a glass substrate and has excellent heat resistance, moisture resistance and moist heat resistance, an adhesive optical film comprising an adhesive layer made of the adhesive composition, which shows high adhesion between the adhesive layer and an optical film and effectively suppresses the occurrence of adhesive residue and lack of adhesive and also has excellent heat resistance, moisture resistance and moist heat resistance, and an image display device comprising the adhesive optical film, the adhesive optical film comprises an optical film 1, an adhesive layer 3 made of a water dispersible adhesive composition comprising, as raw monomers, an alkyl(meth)acrylate ester whose alkyl group has 4 to 18 carbon atoms, a carboxyl group-containing vinyl monomer, a phosphoric acid group-containing vinyl monomer, and a copolymerizable vinyl monomer which is optionally copolymerizable with the above monomers, wherein a carboxyl group concentration is from 0.05 to 1.50 mmol / g and a phosphoric acid group concentration is from 0.01 to 0.45 mmol / g in the raw monomers, an under coat layer 2 containing an oxazoline group-containing polymer, and being interposed between the optical film 1 and the adhesive layer 3, and the adhesive optical film is applied onto an image display device.

Owner:NITTO DENKO CORP

Material for ocular lens

InactiveUS20020198280A1Avoid phase separationAvoid preparationTissue regenerationProsthesisHydrophilic monomerUltraviolet

Owner:MENICON CO LTD

Pressure-sensitive adhesive composition, and pressure-sensitive adhesive product and display using the same

InactiveUS20080281047A1High transparencyFine foamAcid polymer adhesivesEster polymer adhesivesPolymer scienceMeth-

The present invention provides a pressure-sensitive adhesive composition comprising an acrylic polymer (a), an acrylic oligomer (b), a silane coupling agent having an amino group, and a cross-linking agent, the acrylic polymer (a) containing, as a main monomer component, at least one of a (meth)acrylic acid alkyl ester containing an alkyl group having a number of carbons of from 4 to 12 and a (meth)acrylic acid alkoxyalkyl ester, and containing 1 to 10 parts by weight of a carboxyl group-containing monomer as a monomer component based on 100 parts by weight of the total monomer components constituting the acrylic polymer (a), the acrylic polymer (a) having a weight-average molecular weight of from 400,000 to 1,500,000; and the acrylic oligomer (b) containing a (meth)acrylic acid ester as a main monomer component, and containing 1 to 10 parts by weight of a carboxyl group-containing monomer as a monomer component based on 100 parts by weight of the total monomer components constituting the acrylic oligomer (b), the acrylic oligomer (b) having a weight-average molecular weight of 3,000 or more but less than 6,000, in which the pressure-sensitive adhesive composition contains 10 to 35 parts by weight of the acrylic oligomer (b) and 0.01 part by weight or more but less than 1.0 part by weight of the silane coupling agent having an amino group, based on 100 parts by weight of the acrylic polymer (a). The pressure-sensitive adhesive composition is excellent in transparency and foaming and separation resistances, does not cause periodical reduction of adhesiveness and dramatically improves adhesion reliability.

Owner:NITTO DENKO CORP

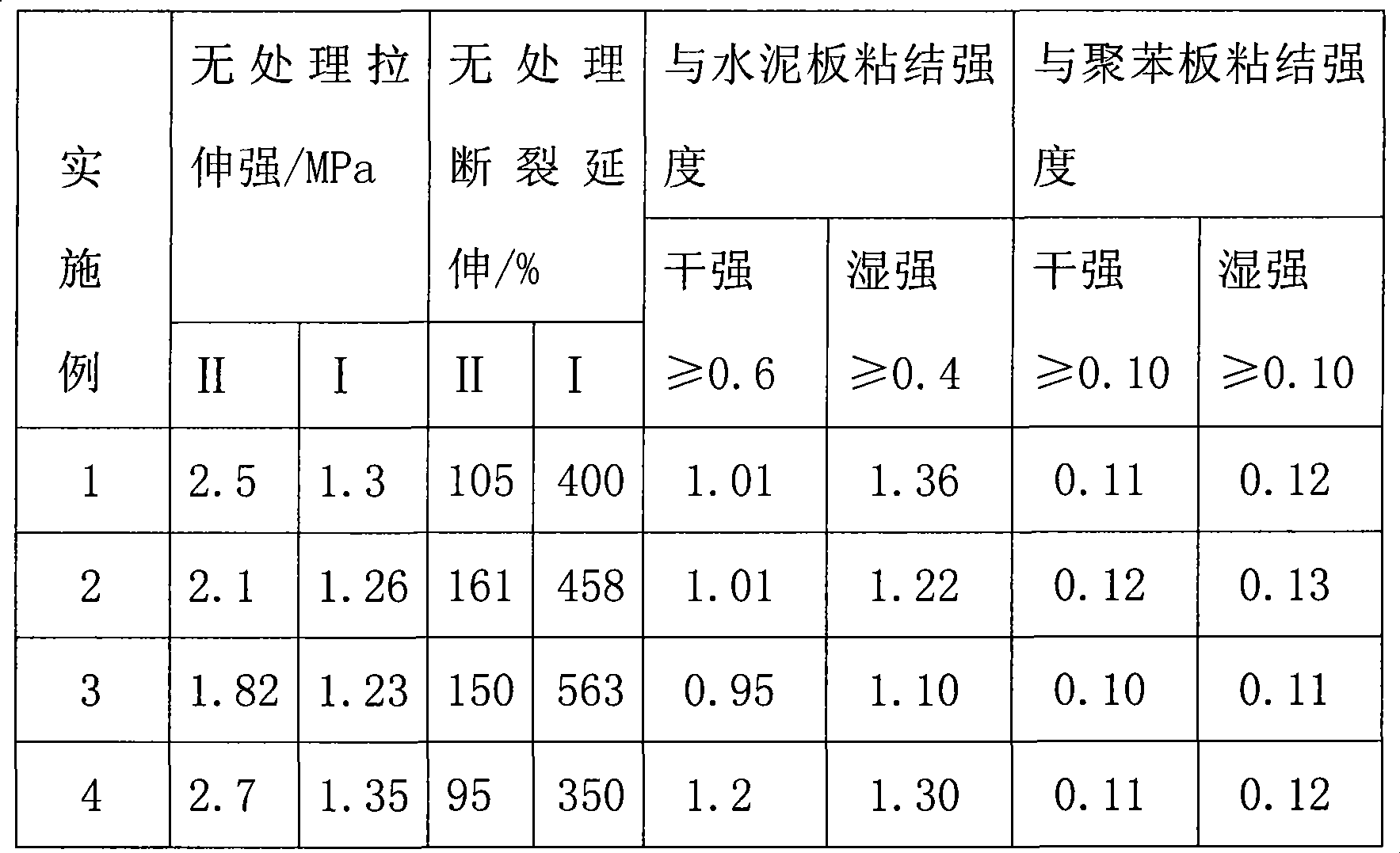

Acrylic acid series nucleocapsid polymer emulsion and re-dispersible emulsion powder, and method for producing thereof

InactiveCN101173021AImprove performanceMeet the redispersion performanceAnticaking agentPolymer chemistry

The invention relates to a crylic acid nucleocapsid polymer emulsion and subdividable emulsion powder and the preparation method thereof. The emulsion is prepared by methacrylic acid alkyl ester, crylic acid alkyl ester, hydroxyalkyl ester, methacrylic acid, N-methylol acrylamide, an emulsifying agent and an initiator through the method of emulsion polymerization. The subdividable emulsion powder is prepared by the crylic acid nucleocapsid polymer emulsion, a protective colloid, and an anticaking agent through the spray method of emulsion. The subdividable emulsion powder of the invention has high fixed content (approximating 100 percent) and can reduce the difficulty of transportation and storage, and can be packed by using paper to reduce the packing cost, moreover, the storage stability is good and the storage period is long, and the subdividable emulsion powder of the invention can not go bad due to the water freezing or volatilization; the invention has the important thing that the subdividable emulsion powder can be rapidly dissolved in water and evenly distributed to repeatedly form the emulsion having the same performance as the primary matrix polymer emulsion, thereby being widely applied to zero VOC dry powder paint, terrace patch mortar, artesian flow flat plateau mortar, wall and floor tile bonding agent, sealed mortar, construction luting powder, plastering material, plastering gypsum, heat insulation and heated board bonding material, concrete interface agent, powder binding agent, powder paint, etc.

Owner:SHANGHAI UNIV +1

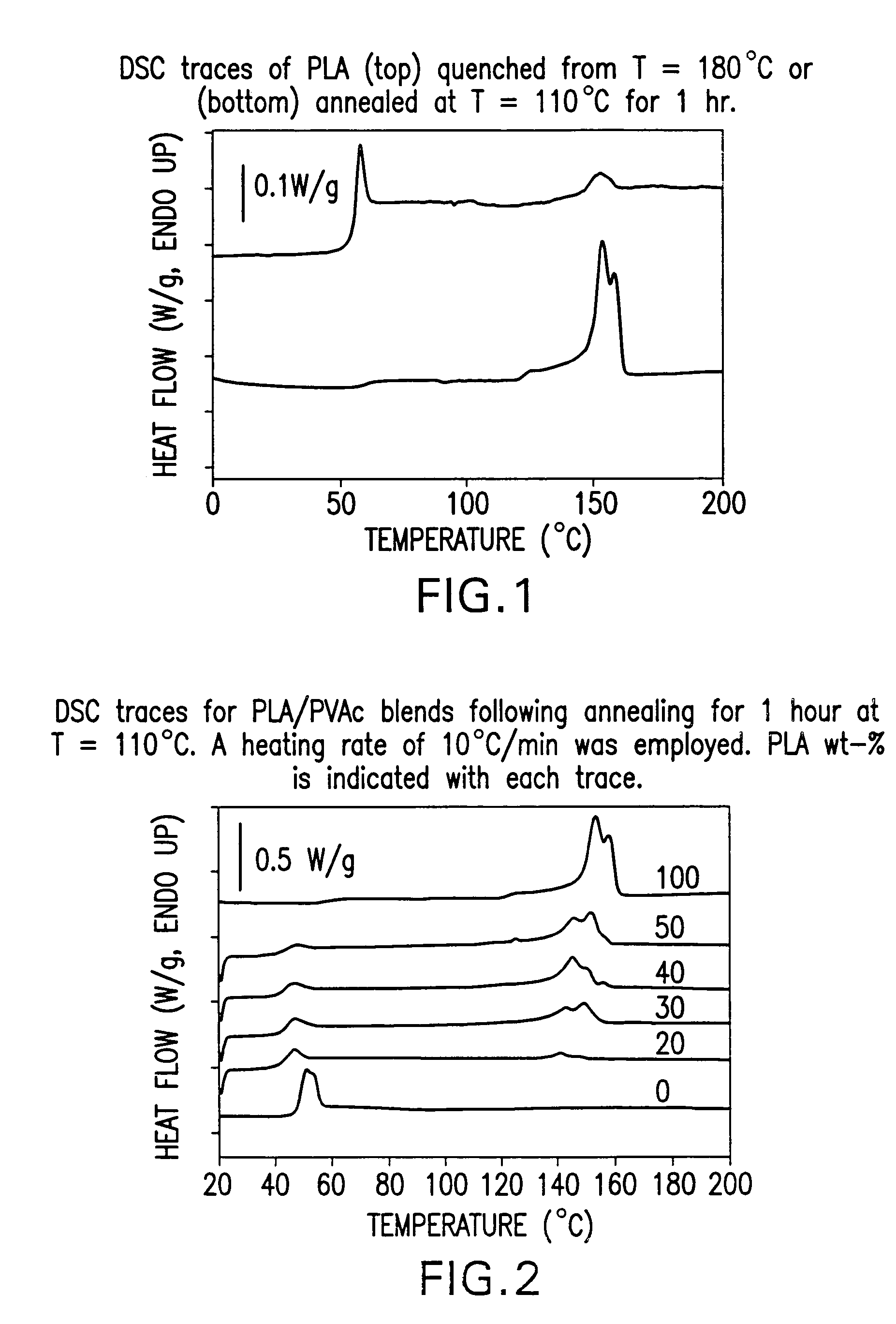

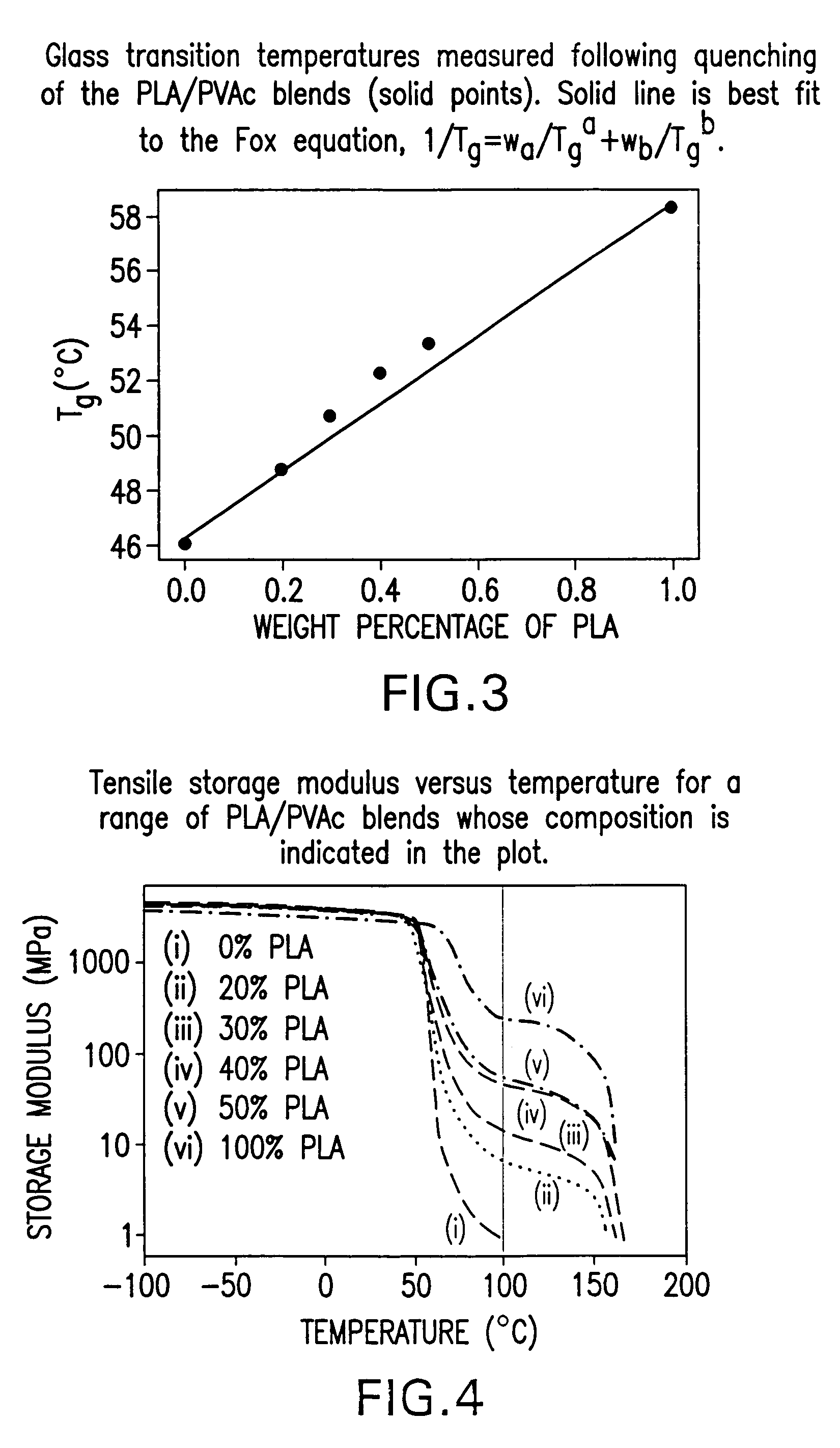

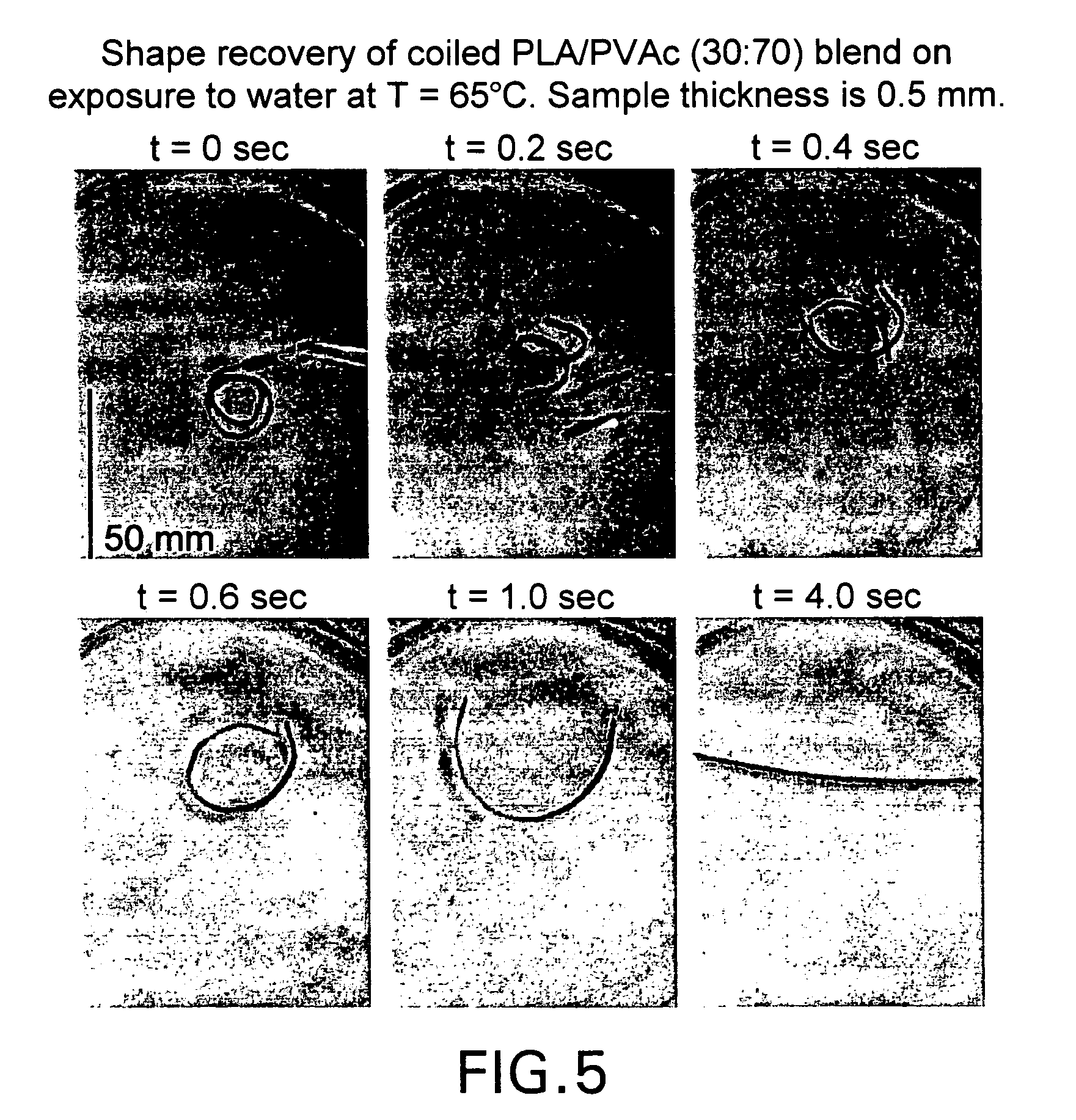

Blends of amorphous and semicrystalline polymers having shape memory properties

InactiveUS7208550B2High modulusDental impression compositionsPoly(methyl methacrylate)Glycol synthesis

Blends of amorphous and semicrystalline polymers having shape memory properties were prepared by blending a crystalline polymer such as poly(vinylidene fluoride), polylactide, poly(hydroxxybutyrate), poly(ethylene glycol) polyethylene, polyethylene-co-vinyl acetate, poly(vinyl chloride), poly(vinylidene chloride) and copolymers of poly(vinylidene chloride) and poly(vinyle chloride) and an amorphous polymer such as poly(vinyl acetate), poly methyl acrylate, poly ethyl acrylate, atactic poly methyl methacrylate, isotactic poly methyl methacrylate, syndiotactic poly methyl methacrylate and other poly alkyl methacrylates. The method for preparing the polymeric materials and applications thereof, for example, as smart medical devices, are also disclosed.

Owner:UNIV OF CONNECTICUT

Multifunctional acrylic ester emulsion

The invention discloses a multifunctional acrylic ester emulsion, which is prepared from deionized water, an initiator, an emulsifier, acrylic acid alkyl ester of C4 to C12, alkyl methacrylate of C4-C12, an aryl unsaturated monomer, an unsaturated monomer of C3 to C4, an acrylamide functional monomer, a silane coupler, and other components which are subjected to mechanical stirring to disperse olefin unsaturated monomers into water, and carry out free radical polymerization under the action of the initiator to obtain the emulsion. The emulsion in thermal insulation mortar has the functions of reinforcing tenacity and strength, remarkably improves the bonding strength of the mortar, increases the compressive strength / rupture strength ratio of hardened mortar, and brings about the stable quality of walling materials, improves construction efficiency and reduces mortar contraction. The emulsion which is applied to polymer cement waterproof paint has good water proofing function with great tensile strength and high extension coefficient.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

High Tg acrylic polymer and epoxy-containing blend therefor as pressure sensitive adhesive

InactiveUS20020185222A1Simple compositionLaminationAdhesive processes with adhesive heatingEpoxyPolymer science

A high Tg acrylic polymer is provided as well as an epoxy-blend thereof for use as a pressure sensitive adhesive. The high Tg acrylic polymer comprises a copolymer of an alkyl (meth)acrylate monomer having a Tg>20° C., a C1-30 (meth)acrylate monomer, an nitrogen-containing polar monomer, and a polymerizable epoxy-containing monomer, with the polymer having a Tg>50° C. When blended with an epoxy resin, the resulting mixture exhibits desirable pressure sensitive adhesive properties and may be thermocured.

Owner:ADHESIVES RES

Moisture resistant hair styling composition containing two copolymers

The compositions of the present invention relate to improved aqueous or aqueous-alcoholic hair styling compositions comprising a combination of two copolymers. The first copolymer is a copolymer of (a1) acidic vinyl monomers, e.g., acrylic or methacrylic acid, with (a2) hydrophobic nonionic vinyl monomers, e.g., acrylic or methacrylic acid esters, with (a3) a first associative monomer and (a4) at least one other monomer which can be a second associative monomer different from the first associative monomer or a semihydrophobic monomer. The associative monomers having (i) an ethylenically unsaturated end group, (ii) a hydrophilic midsection and (iii) a hydrophobic or semi-hydrophobic end group. The second copolymer is a copolymer of (b1) C3 to C8 monoethylenically unsaturated monocarboxylic acid monomers, (b2) acrylic or methacrylic acid alkyl esters, and (b3) acrylic or methacrylic acid hydroxyalkyl esters. Preferred product forms are gels, additionally containing a gel forming agent. The compositions can be used for increasing the humidity resistance, moisture resistance or sweat resistance of a hair style.

Owner:THE PROCTER & GAMBLE COMPANY

Binder For Electric Double Layer Capacitor Electrode

ActiveUS20080011986A1Reduce alkali metal contentEasy to controlElectrolytic capacitorsHybrid capacitor electrodesVitrificationHydrogen atom

A binder for an electric double layer capacitor electrode, which includes a copolymer (A) including monomer units derived from at least one compound (a) represented by the following general formula (1):CH2═CR1—COOR2 (1)wherein R1 represents a hydrogen atom or a methyl group, and R2 represents an alkyl group or a cycloalkyl group, the glass transition temperature obtained by homopolymerizing the compound (a) being less than 0° C., and monomer units derived from at least one compound (b) selected from acrylic acid alkyl esters, methacrylic acid alkyl esters, aromatic vinyl compounds, and α,β-unsaturated nitrile compounds, the glass transition temperature obtained by homopolymerizing the compound (b) being 0° C. or higher, wherein the total content of the monomer units derived from the compound (a) and those derived from the compound (b) is 90% or more by weight per 100% of the whole copolymer (A), and the glass transition temperature of the copolymer (A) is 10° C. or lower, which binder is excellent in smoothness, crack resistance and binding properties.

Owner:ZEON CORP

Adhesive antimicrobial and/or reparative dentin stimulating dental compositions and methods for forming and using such compositions

InactiveUS6071528AEffective and reliable sealEffective and reliable sealingPowder deliveryBiocideAntibiotic YBond strength

Adhesive antimicrobial dental compositions and methods for forming and using compositions are disclosed. The compositions are primarily useful as pulp caps and dentin liners. The composition includes an alkyl methacrylate having an oxyphosphorus group, a polymerization initiator and an antimicrobial agent. The antimicrobial agent can be organohalogens, antibiotics, alkali metal hydroxides, alkaline earth metal oxides and alkaline earth metal hydroxides. The compositions have high dentin tensile bond strength, are stable as a single component or package system, can be polymerized in situ, prevent ingress by microorganisms into an area of a tooth treated with the compositions and can be syringe delivered.

Owner:ULTRADENT PROD INC

Pigment dispersant

A pigment dispersant is disclosed comprising a tri-block copolymer having a first block comprising a glycidyl(meth)acrylate reacted with a napthoic acid, a second block comprising (meth)acrylic acid alkyl esters, and a third block comprising (meth)acrylic acid alkyl esters, wherein said third block is different from said second block. The dispersant is suited for use in a nanoparticulate dispersion comprising pigment particles having an average primary particle size of less than 100 nm.

Owner:PPG IND OHIO INC

Optical pressure-sensitive adhesive, pressure-sensitive adhesive attached optical film, and image display

ActiveUS20090104445A1Suppress display unevennessSuppress unevennessLayered productsFilm/foil adhesivesMeth-Display device

An object of the invention is to provide an optical pressure-sensitive adhesive that is for use in pressure-sensitive adhesive attached optical films and so on, includes an acrylic copolymer and is less likely to cause display unevenness in the peripheral portion of a display screen. An optical pressure-sensitive adhesive, comprising: an acrylic copolymer containing alkyl (meth)acrylate (a1) and N-(2-hydroxyethyl)(meth)acrylamide (a2) as a monomer unit.

Owner:NITTO DENKO CORP

Resin composition and heat-resistant adhesive

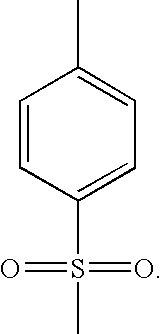

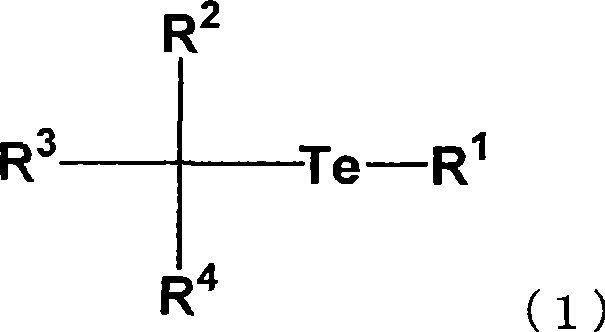

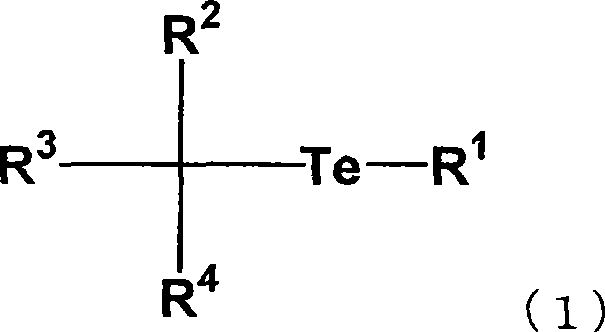

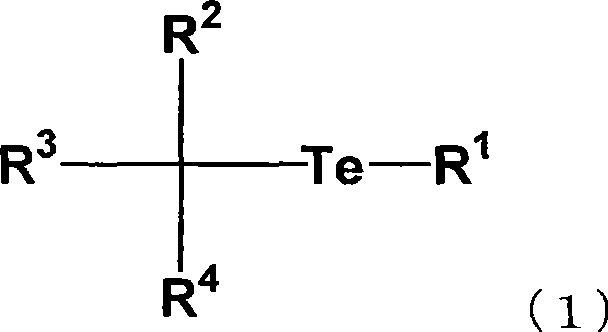

Disclosed is a resin composition which is characterized in that the metal content in the composition is not more than 1000 ppm. The resin composition contains a copolymer which is obtained by copolymerizing 80-99.9 parts by weight of a vinyl monomer mainly containing a (meth)acrylic acid alkyl ester and 0.1-20 parts by weight of a vinyl monomer having a reactive functional group by living radical polymerization, while using, as a polymerization initiator, one of the following: (a) an organic tellurium compound represented by the formula (1) below; (b) a mixture of an organic tellurium compound represented by the formula (1) below and an azo polymerization initiator; (c) a mixture of an organic tellurium compound represented by the formula (1) below and an organic ditellurium compound represented by the formula (2) below; and (d) a mixture of an organic tellurium compound represented by the formula (1) below, an azo polymerization initiator and an organic ditellurium compound represented by the formula (2) below. (In the formula, R<1> represents a C1-C8 alkyl group, an aryl group, a substituted aryl group or an aromatic heterocyclic group; R<2> and R<3> respectively represent a hydrogen atom or a C1-C8 alkyl group; and R<4> represents an aryl group, a substituted aryl group, an aromatic heterocyclic group, an acyl group, an amide group, an oxycarbonyl group or a cyano group.) (R<1>Te)2 (2) (In the formula, R<1> is as defined above).

Owner:OTSUKA CHEM CO LTD

Hot melt adhesive composition

A hot melt adhesive composition comprising: (a) a functional copolymer obtained from copolymerization of ethylene and a comonomer selected from maleic anhydride, citraconic anhydride, itaconic anhydride, tetrahydrophthalic anhydride, maleic acid, citraconic acid, itaconic acid, fumaric acid, tetrahydrophthalic acid, the corresponding salts, monoesters and diesters of these acids, and mixtures of any of these, wherein the functional copolymer is present in an amount from about 5 to about 95 weight % of the combined total amount of (a) and (b); and (b) at least one ethylene copolymer obtained from copolymerization of ethylene with a polar monomer wherein said polar comonomer is present in the copolymer in an amount of from 8 to 40 weight %, wherein said ethylene copolymer is selected from the group consisting of ethylene / vinyl acetate copolymers, ethylene / alkyl (meth)acrylate copolymers and ethylene / alkyl (meth)acrylate / carbon monoxide terpolymers, in an amount from about 5 to about 95 weight % of the combined total amount of (a) and (b); wherein the composition has a melt index of 100 grams / 10 minutes or higher. Articles comprising and process using the hot melt adhesive are also disclosed.

Owner:DOW GLOBAL TECH LLC

Acrylic pressure-sensitive adhesive composition, acrylic pressure-sensitive adhesive sheet, and methods for bonding the sheet to automotive coating

InactiveUS20100101723A1High bonding strengthMaintain good propertiesImpression capsFilm/foil adhesivesPolymer scienceMeth-

Disclosed is an acrylic pressure-sensitive adhesive composition that gives a pressure-sensitive adhesive layer exhibiting superior adhesiveness even to coatings, which are likely to cause low adhesion due to bleeding typically of a surface conditioner, without requiring, for example, washing process.The acrylic pressure-sensitive adhesive composition contains a vinyl monomer or a partial polymer thereof (a); and a (meth)acrylate co-oligomer (b), in which the vinyl monomer contains, as a main component, an alkyl(meth)acrylate monomer (a1) having an alkyl group with 2 to 14 carbon atoms, and the (meth)acrylate co-oligomer (b) has a weight-average molecular weight of from 1000 to 30000 and contains, as monomer components, 96 to 99.5 percent by weight of an alkyl(meth)acrylate (b1) and 0.1 to 4 percent by weight of a (meth)acryloyl group-containing silicone oil (b2).

Owner:NITTO DENKO CORP

Aqeous inkjet recording ink

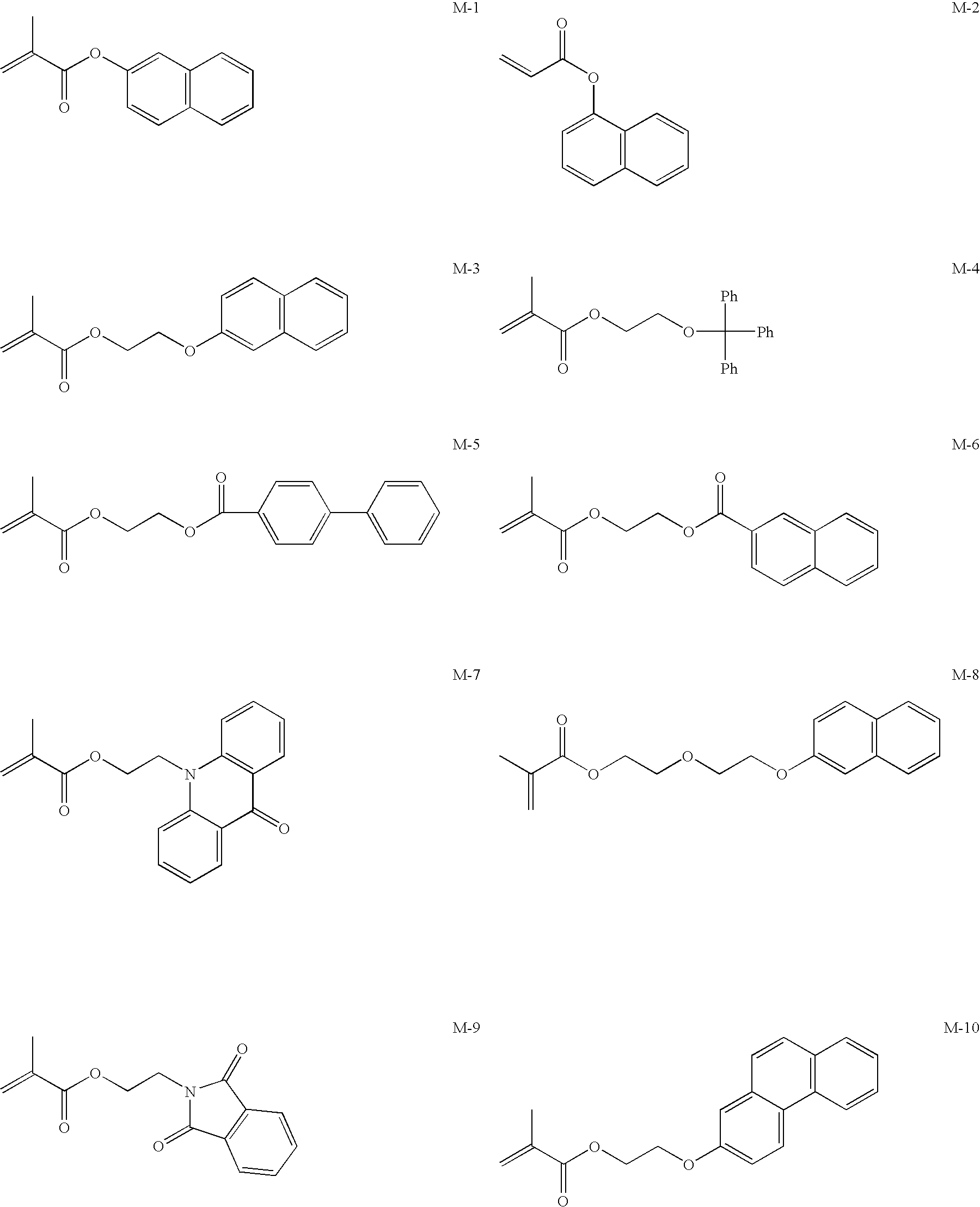

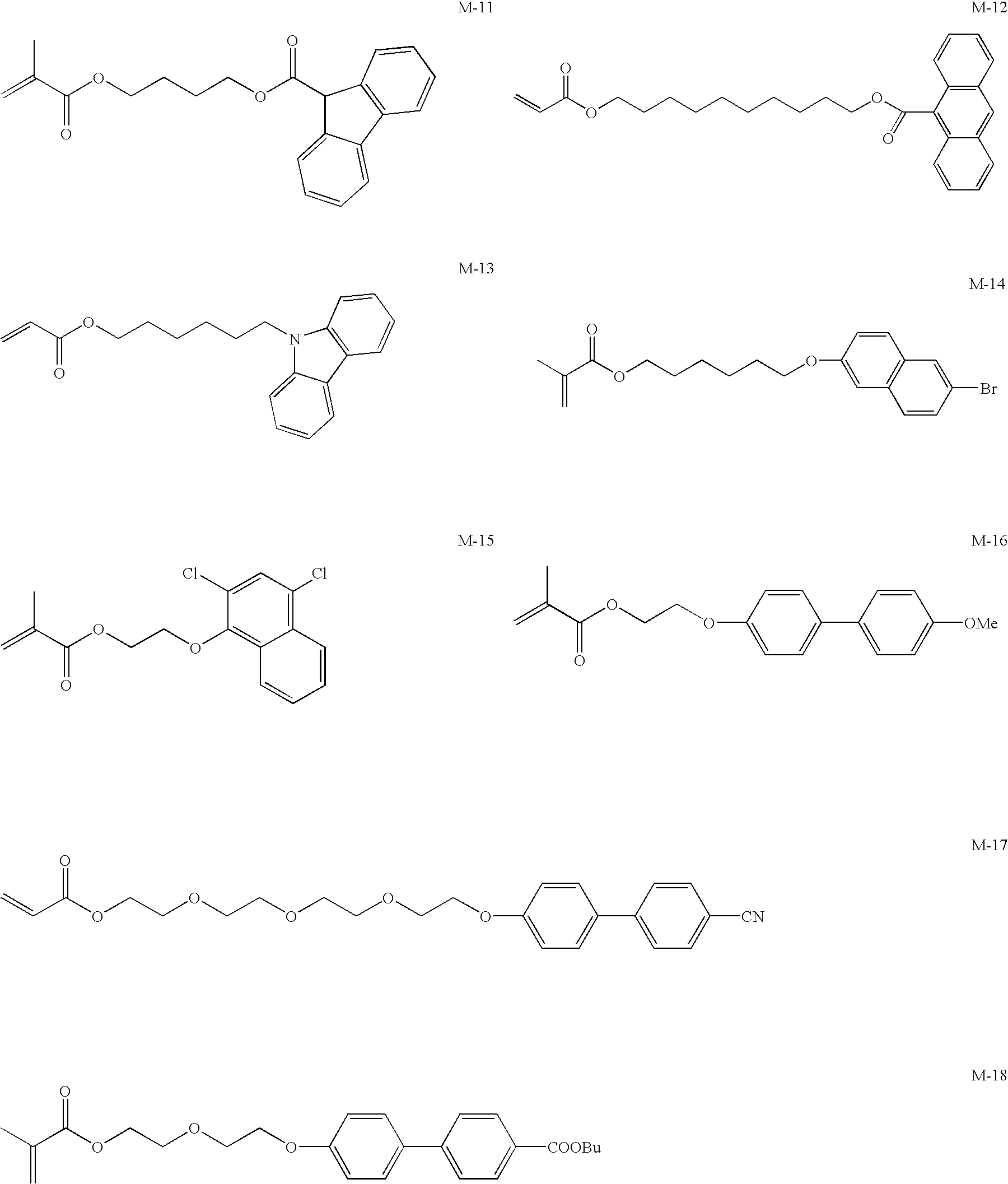

An aqueous inkjet recording ink including at least a resin (A), a pigment (B) dispersed with the resin (A), a resin emulsion (C), and an aqueous liquid medium (D), wherein the resin (A) includes hydrophobic structural units (a) and hydrophilic structural units (b), the hydrophobic structural units (a) include a hydrophobic structural unit (a1) in an amount of 40% by mass or more of the resin (A), the hydrophobic structural unit (a1) having an aromatic ring indirectly linked to an atom for forming the main chain of the resin (A), and a hydrophobic structural unit (a2) in an amount of 15% by mass or more of the resin (A), the hydrophobic structural unit (a2) being derived from a C1 to C4 alkyl acrylate or methacrylate, the hydrophilic structural units (b) include a structural unit (b1) derived from an acrylic acid or a methacrylic acid, and the content of the hydrophilic structural units (b) is 15% by mass or less in the resin (A).

Owner:FUJIFILM CORP

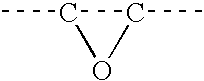

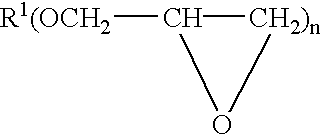

Impact modifier combination for polymers

An improved impact modifier for polymers, such as PBT and blends thereof; is disclosed. The impact modifier is a blend of (A) a core / shell additive having a core based on alkyl acrylate, on a polyorganosiloxane rubber or a blend thereof and a shell based on poly(alkyl methacrylate), or on a styrene-acrylonitrile copolymer grafted onto the core; and (B) a linear copolymer which contains from 50 to 85 parts of units derived from ethylene, from 5 to 40 parts of units derived from (meth)acrylic esters, and from 2 to 10 parts of a copolymerizable monomer containing an epoxy group. The impact strength provided by the impact modifier blend is unexpectedly higher than the impact strength provided by each individual component of the blend.

Owner:ARKEMA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com