Patents

Literature

72results about How to "Reduce alkali metal content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

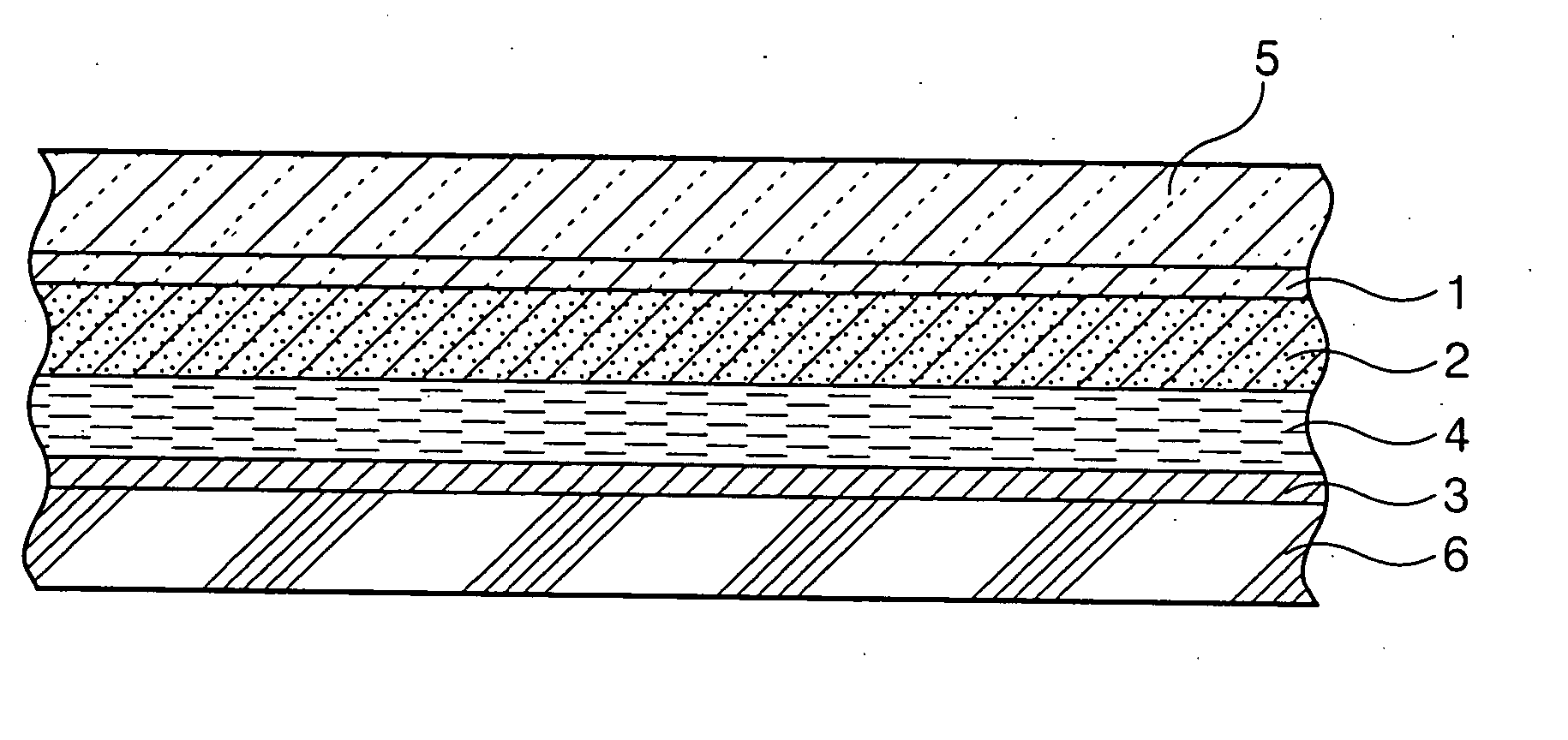

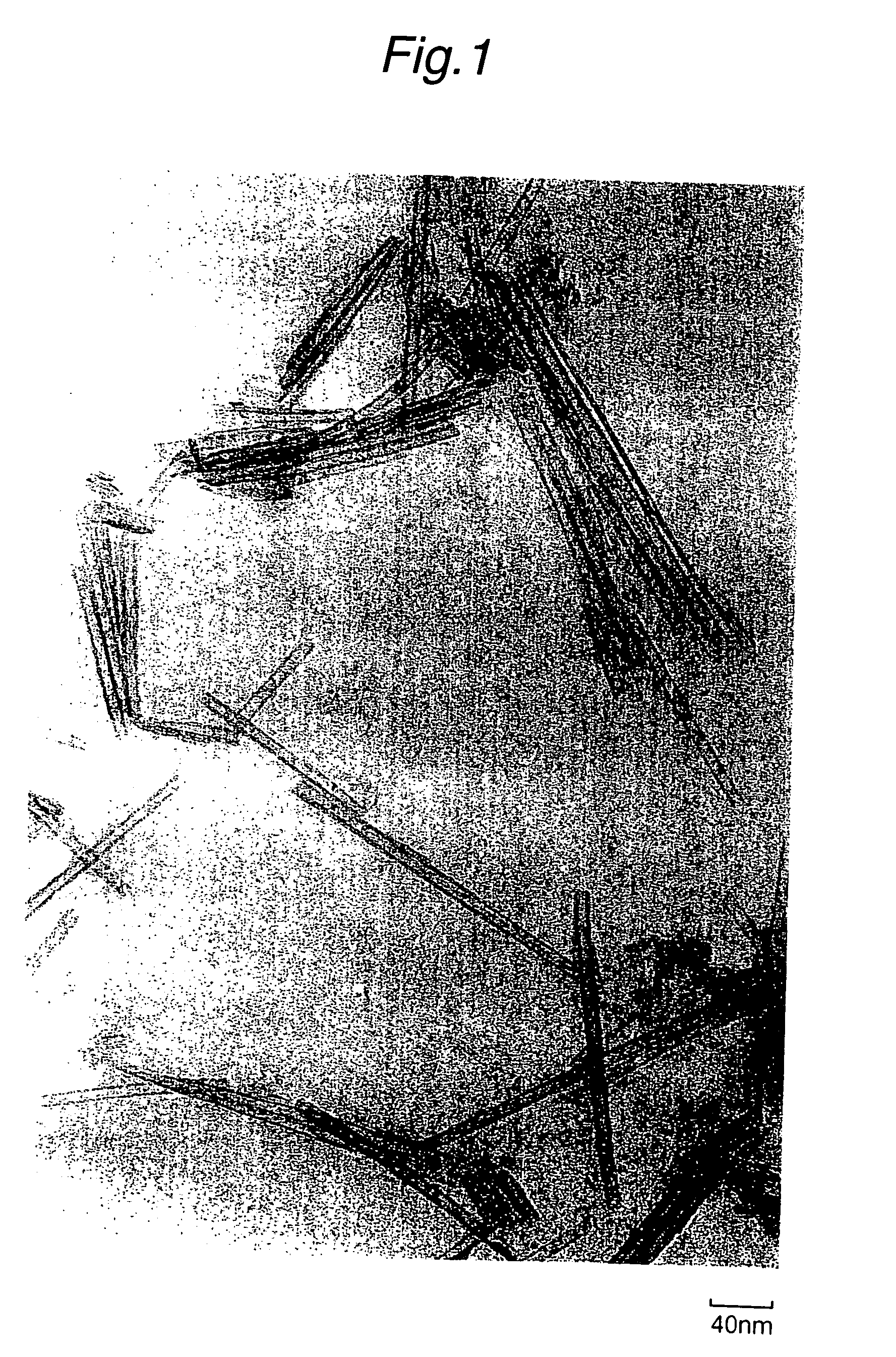

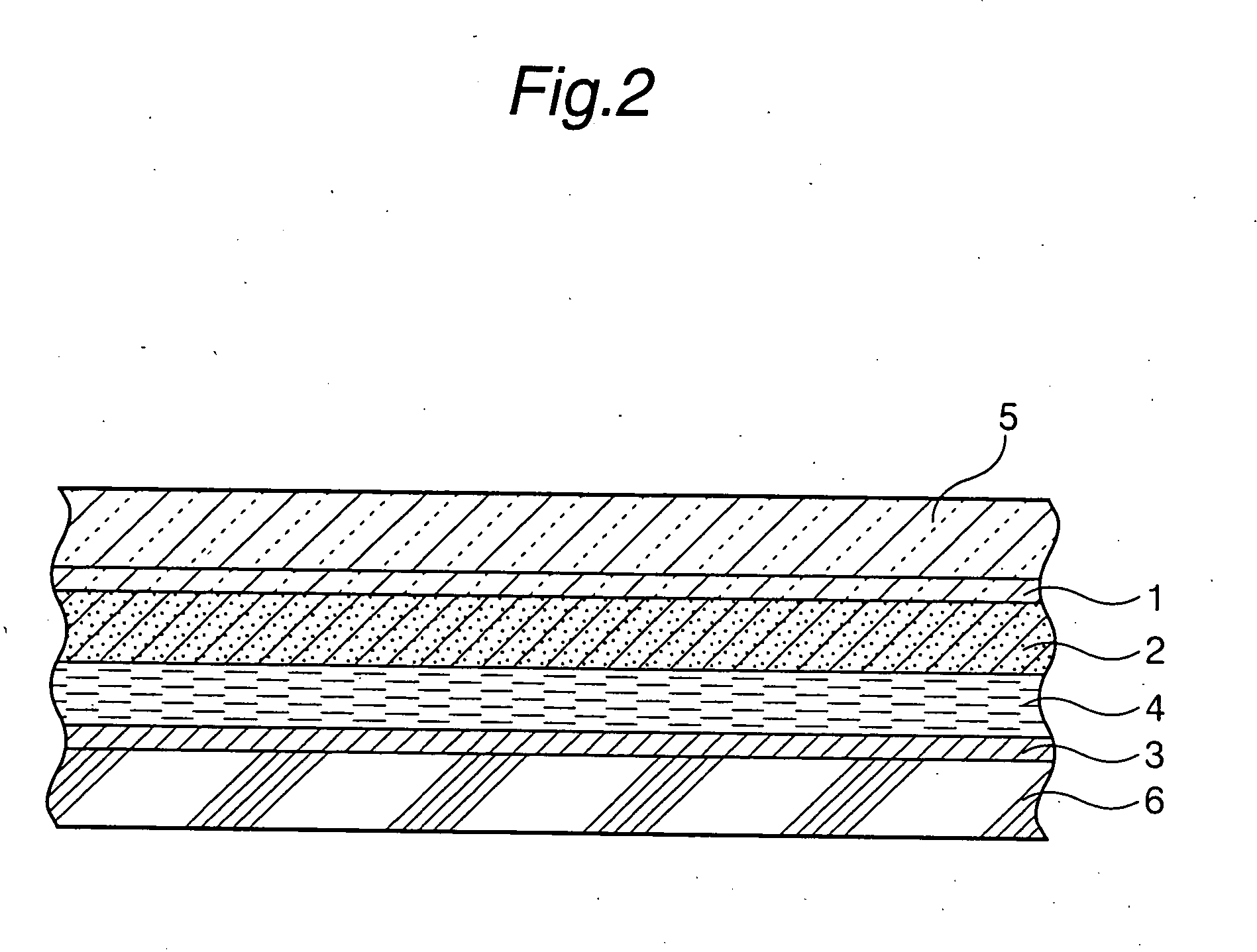

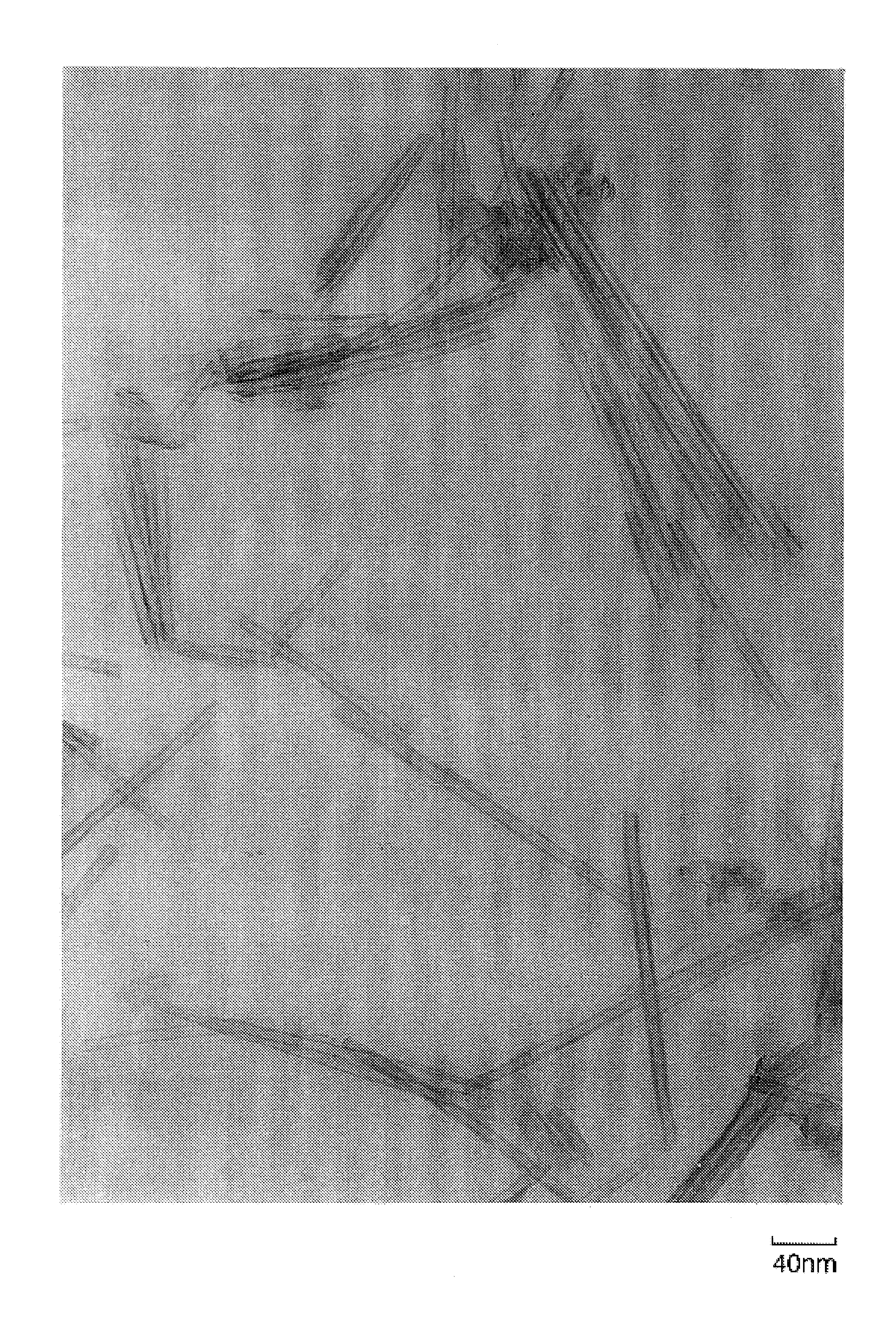

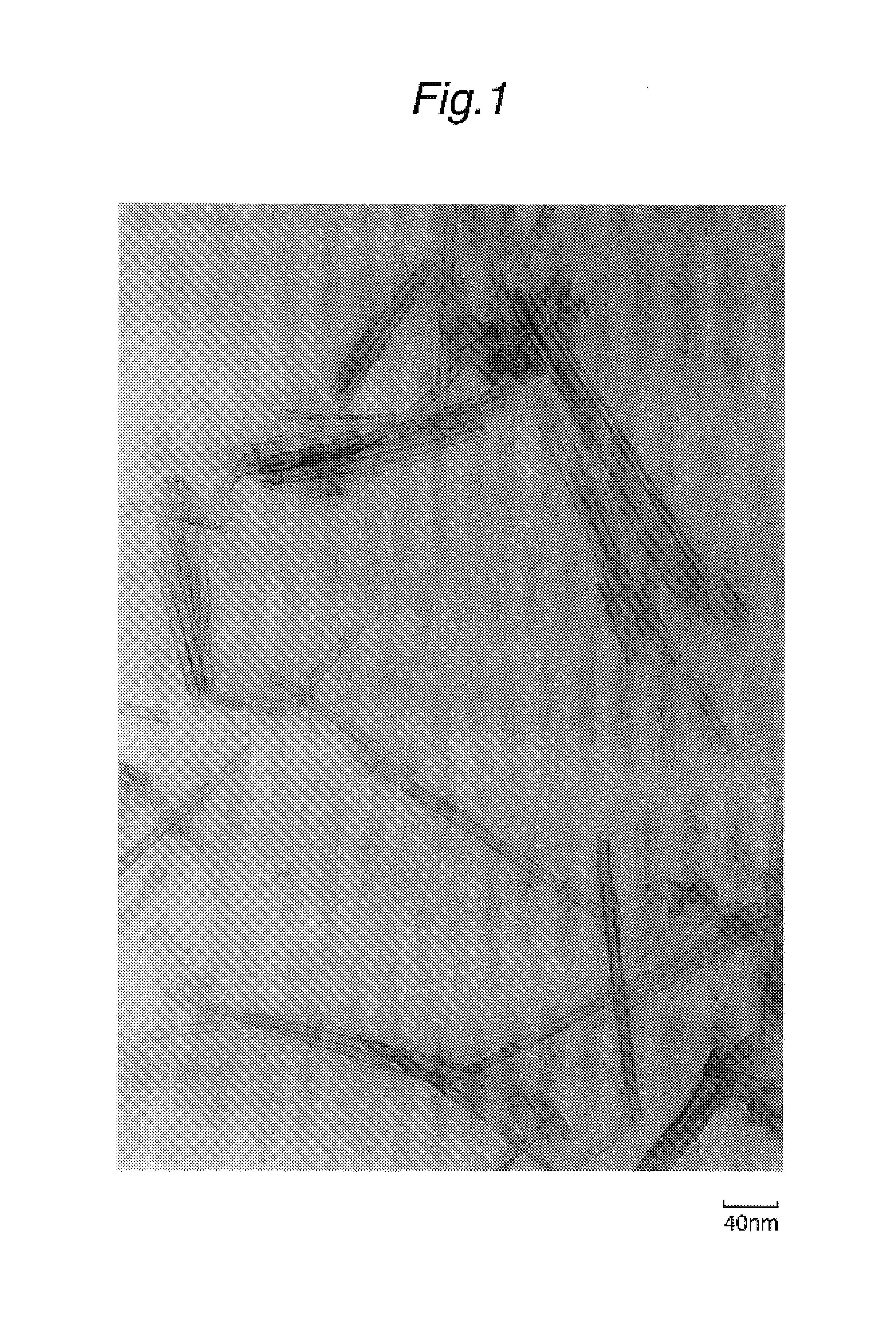

Tubular titanium oxide particles, method for preparing the same, and use of the same

InactiveUS20040265587A1Large specific surface areaImprove detection accuracyMaterial nanotechnologyLight-sensitive devicesReduction treatmentSorbent

The process for preparing tubular titanium oxide particles comprises subjecting a water dispersion sol, which is obtained by dispersing (i) titanium oxide particles and / or (ii) titanium oxide type composite oxide particles comprising titanium oxide and an oxide other than titanium oxide in water, said particles having an average particle diameter of 2 to 100 nm, to hydrothermal treatment in the presence of an alkali metal hydroxide. After the hydrothermal treatment, reduction treatment (including nitriding treatment) may be carried out. The tubular titanium oxide particles obtained in this process are useful as catalysts, catalyst carriers, adsorbents, photocatalysts, decorative materials, optical materials and photoelectric conversion materials. Especially when the particles are used for semiconductor films for photovoltaic cells or photocatalysts, prominently excellent effects are exhibited.

Owner:JGC CATALYSTS & CHEM LTD

Tubular titanium oxide particles and process for preparing same

InactiveUS7431903B2Uniform particle shapeReduce contentMaterial nanotechnologyLight-sensitive devicesReduction treatmentSorbent

The process for preparing tubular titanium oxide particles comprises subjecting a water dispersion sol, which is obtained by dispersing (i) titanium oxide particles and / or (ii) titanium oxide type composite oxide particles comprising titanium oxide and an oxide other than titanium oxide in water, said particles having an average particle diameter of 2 to 100 nm, to hydrothermal treatment in the presence of an alkali metal hydroxide. After the hydrothermal treatment, reduction treatment (including nitriding treatment) may be carried out. The tubular titanium oxide particles obtained in this process are useful as catalysts, catalyst carriers, adsorbents, photocatalysts, decorative materials, optical materials and photoelectric conversion materials. Especially when the particles are used for semiconductor films for photovoltaic cells or photocatalysts, prominently excellent effects are exhibited.

Owner:JGC CATALYSTS & CHEM LTD

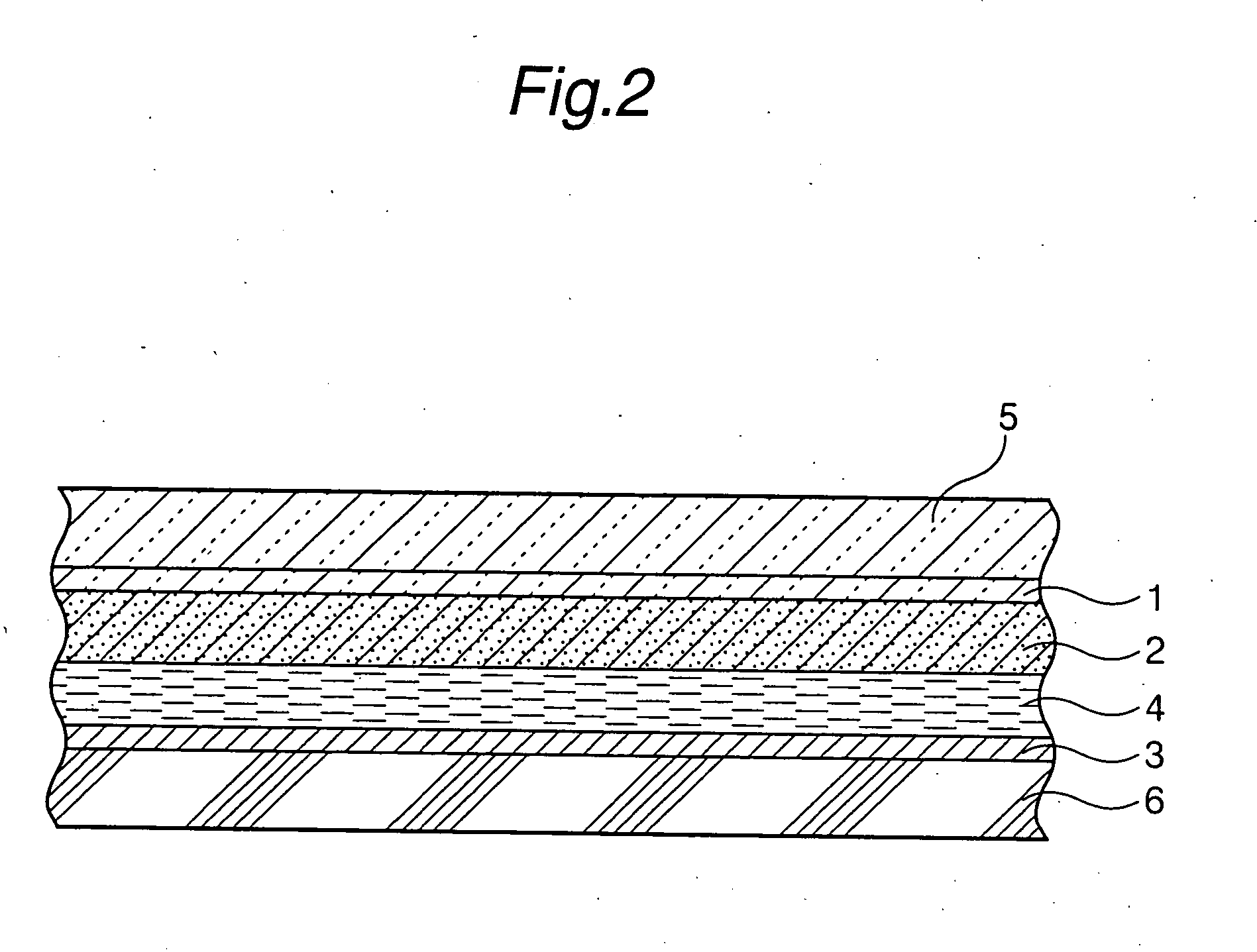

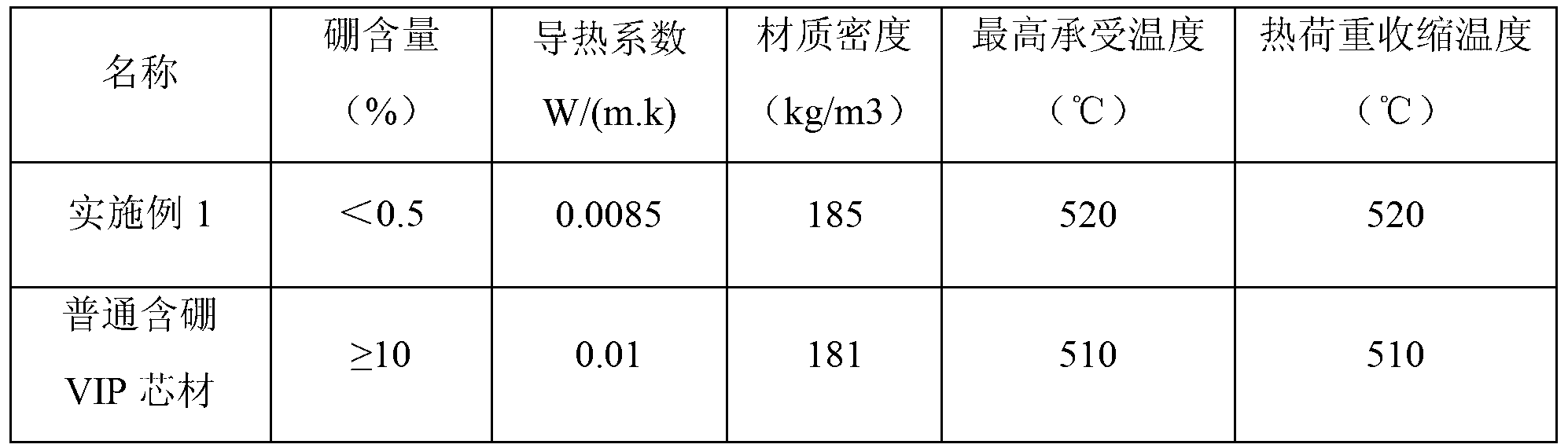

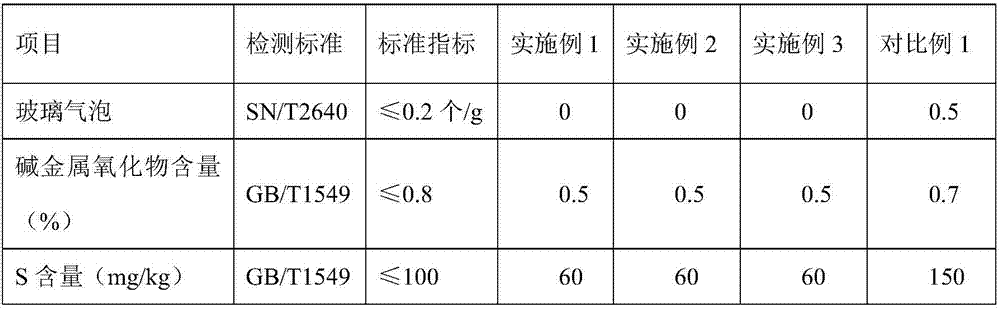

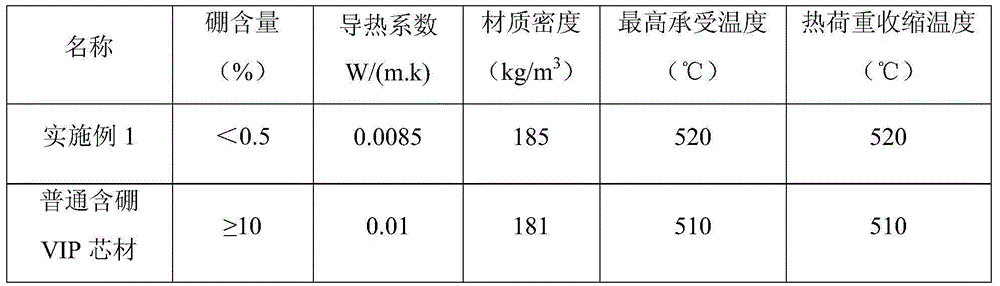

Novel glass fiber vacuum insulation panel core and preparation method

ActiveCN103244793ALower boron contentImprove insulation effectFibreboardThermal insulationAir filtrationGlass fiber

The invention discloses a novel glass fiber vacuum insulation panel core. The vacuum insulation panel core is made of low-boron glass cellucotton which has the boric mass percentage of less than 0.5% and the diameter of 0.5-1.0 micrometer. The invention further discloses a preparation method of the vacuum insulation panel core, which comprises the following steps of: (1) selecting the low-boron glass cellucotton, (2) beating and dispersing the selected low-boron glass cellucotton to obtain slurry, (3) diluting the slurry, (4) deslagging the slurry of Step (3) and preparing wet paper in a wet forming manner, (5) dehydrating the wet paper of Step (4); and (6) drying the wet paper of Step (5). The glass fiber air filtration paper has outstanding comprehensive performances; the preparation process is pollution-free; and the service life is long.

Owner:宣汉正原微玻纤有限公司

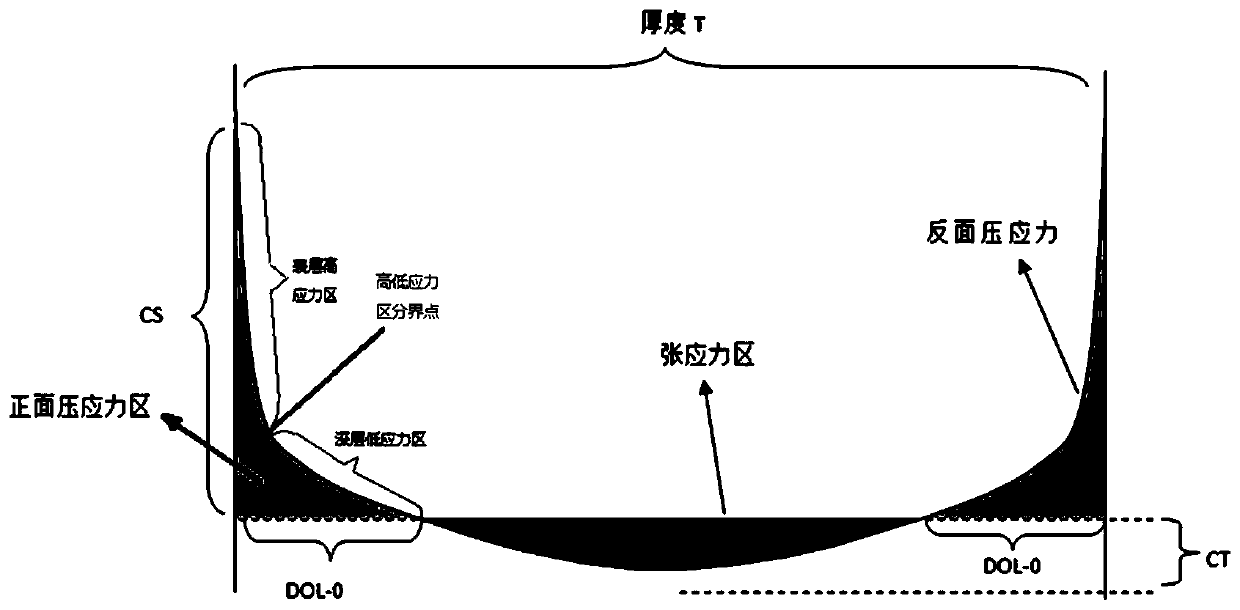

Lithium aluminum silicon glass, lithium aluminum silicon chemically strengthened glass and preparation method and application thereof

The invention discloses lithium aluminum silicon glass, lithium aluminum silicon chemically strengthened glass and a preparation method and application thereof. The molar content of oxide components contained in the lithium aluminum silicon glass satisfies the following relationship: the SiO2 content is at least 66.5 mol%, and the total amount of an alkali metal oxide usable for ion exchange is not more than 14 mol%; (Na2O+Li2O) / (SiO2+Al2O3) is 0.09-0.22; Na2O / Li2O is 0.4-1.2; MgO / SiO2 is 6%-18%; (Na2O+Li2O+0.3*MgO) / Al2O3 is 0.7-1.4; and 0.5%<P2O5+ZnO+SnO2+K2O+ZrO2+TiO2<7%. The lithium aluminum silicon chemically strengthened glass is formed by chemically strengthening the lithium aluminum silicon glass as basic glass.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

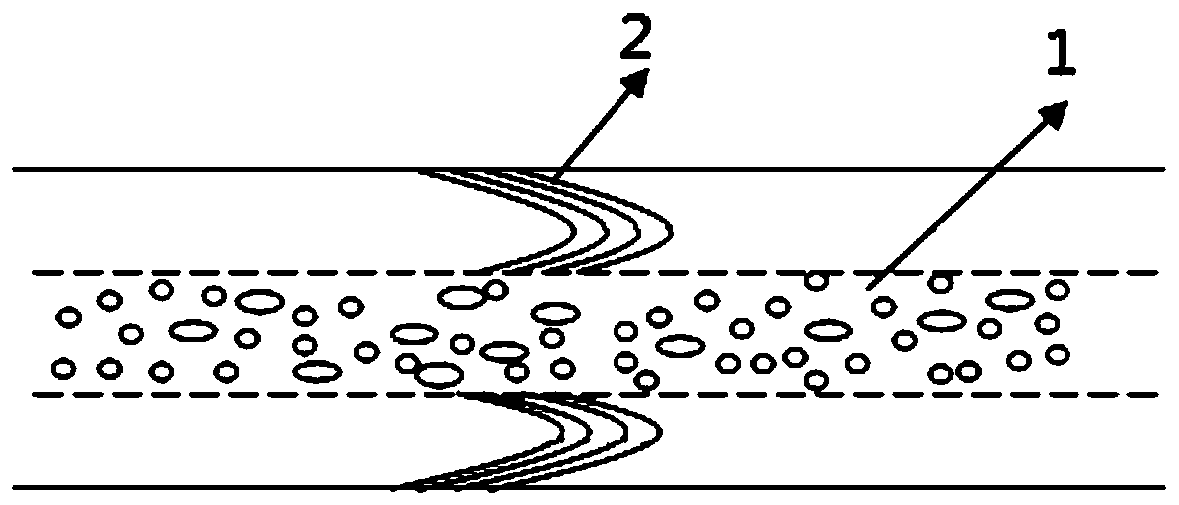

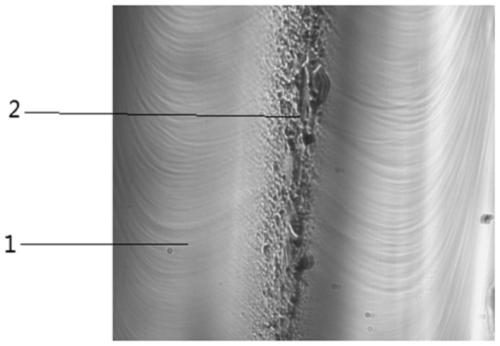

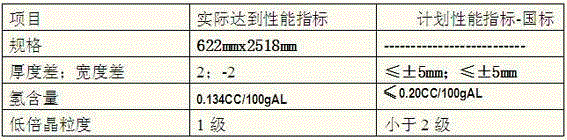

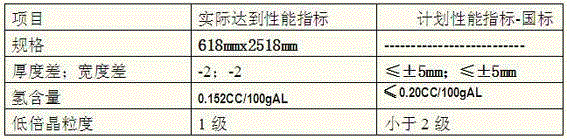

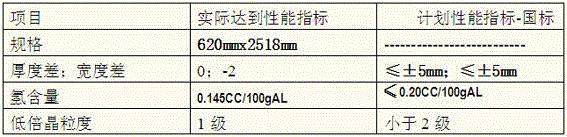

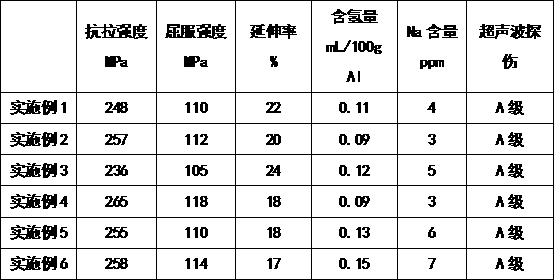

Smelting-casting technique of 6010 aluminum alloy

The invention relates to a 6010 aluminum alloy melting and casting process. This process effectively reduces the non-metallic slag content, hydrogen content and alkali metal content in the melt by controlling the melting temperature, refining in the melt furnace and on-line treatment, and ensures the uniformity of the alloy composition. The ingot casting machine controls the casting speed and water flow during the casting process, avoiding casting cracks and feather crystals, and improving the surface quality of the ingot.

Owner:GUANGXI UNIV

Silica fire resistant castable and preparing method thereof

InactiveCN101550018AGuaranteed StrengthEnsure that the castable has strength after low-temperature bakingRefractoryEconomic benefits

The present invention relates to a silica fire resistant castable and a preparing method thereof. A technical scheme includes steps as follows: mixing quartz grain by weight of 65-75 wt%, rock quartz fine powder by weight of 20-28 wt%, silicon micronized quartz powder by weight of 2-8 wt%, cement by weight of 1-3 wt%, sodium tripolyphosphate by weight of 0.1-0.2 wt% and sodium hexametaphosphate by weight of 0.05-0.1 wt%, than adding water by weight of 5-10 wt% to the mixing material as above, stirring evenly, vibration moulding, drying; then sintering under condition of 590-800 DEG C for preparing the silica fire resistant castable. The method uses the silicon micronized quartz powder as additive agent for adding into the silica fire resistant castable which can increase compactness degree and strength of the products, reduce hard fire working procedure. The silicon micronized quartz powder is used in fire resistant material which can make waste recycling and harmless, and has economic benefit and environmental benefit. The prepared silica fire resistant castable has advantages of better compactness degree, high strength, low cost and environmental-friendly energy-saving.

Owner:WUHAN UNIV OF SCI & TECH +1

Method for manufacturing large-sized 5083 aluminum alloy slab ingot

The invention discloses a method for manufacturing a large-sized 5083 aluminum alloy slab ingot, and relates to the technical field of aluminum alloy manufacturing. The method includes the steps that raw and auxiliary materials are prepared; the temperature of melt in the smelting process is 700-750 DEG C, the temperature of a converter is 740+ / -5 DEG C, the refining temperature is 720-730 DEG C, and refining gas is nitrogen-chlorine mixed gas; standing is conducted for 30 minutes after refining, and the temperature of a maintaining furnace is 705-715 DEG C; Al5Ti0.2B titanium wires are used for conducting grain refinement, and the additive quantity is 0.25%; chlorine-argon mixed gas with the flow being 4-5 m<3> / h is used for conducting on-line degassing; molten aluminum alloy is released into a distributing launder, and an automatic large-sized all-aluminum oil lubrication crystallizer is led in for casting; the casting temperature is 673+ / -5 DEG C, the automatic start filling time is 135 s, and the automatic oil lubrication pulse value is 5; and saw cutting and face milling are carried out. The method solves the problems that the production efficiency is low and the rate of finished products is also low when an existing aluminum alloy slab ingot is used for producing wide aluminum plates.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

Preparation method of ultra-large-specification high-Mg aluminum alloy round ingot

The invention discloses a preparation method of an ultra-large-specification high-Mg aluminum alloy round ingot. The preparation method comprises the following steps of burdening; smelting; preservingheat; carrying out primary refining, and controlling of argon flow; carrying out online degassing refining, and controlling of the rotating speed of a rotor and the argon flow; casting; and carryingout a soaking treatment. According to the method, a hydrogen content and an alkali metal content of the aluminum alloy can be effectively reduced, the probability of cracking of a cast ingot is reduced, and the production percent of pass is improved.

Owner:广西南南铝加工有限公司

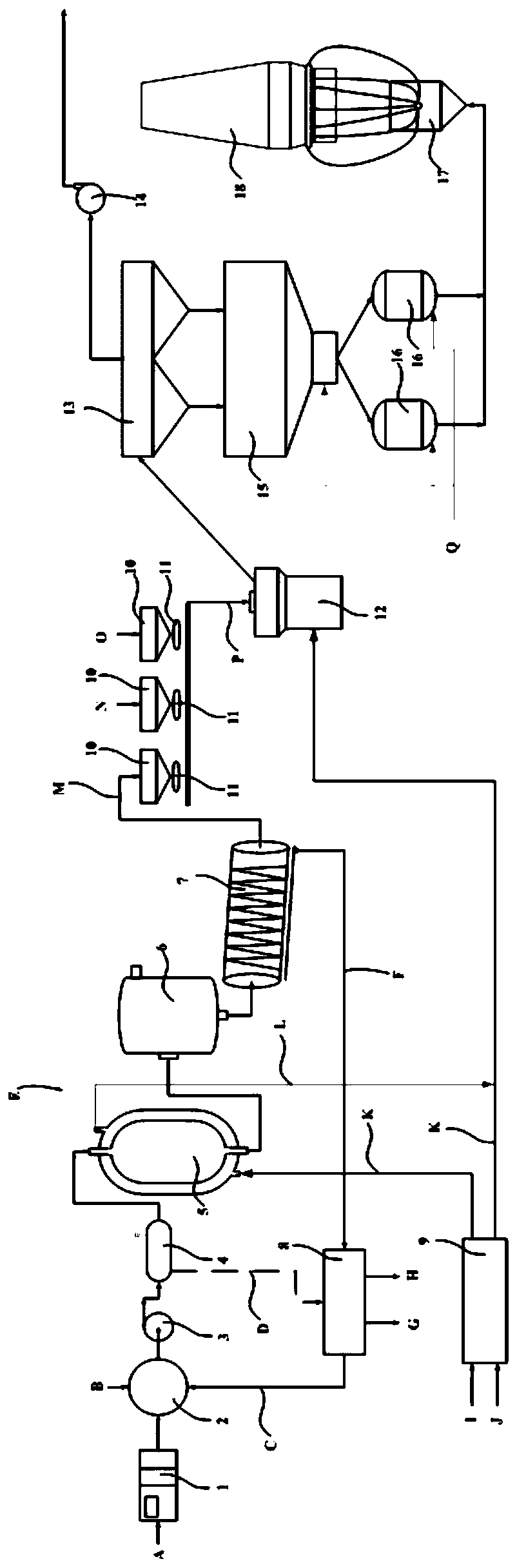

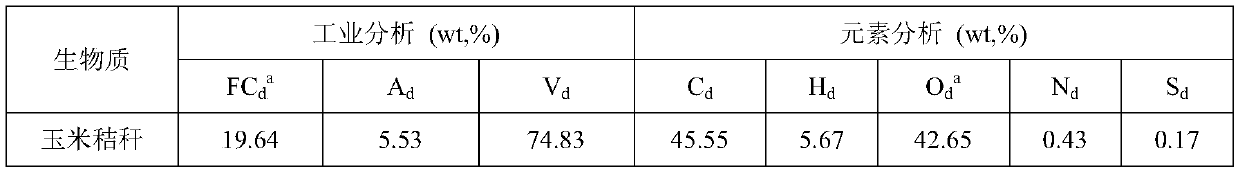

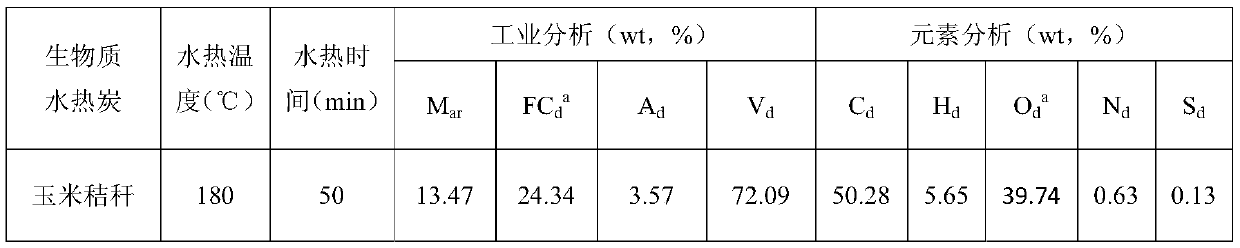

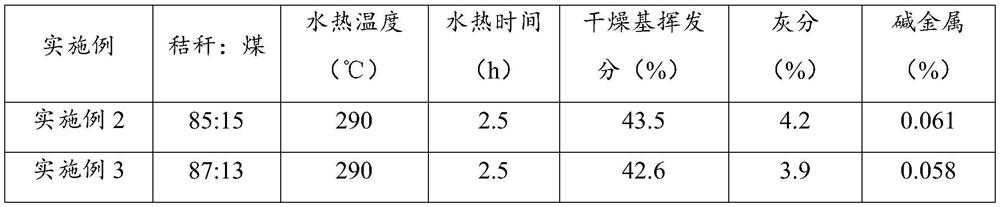

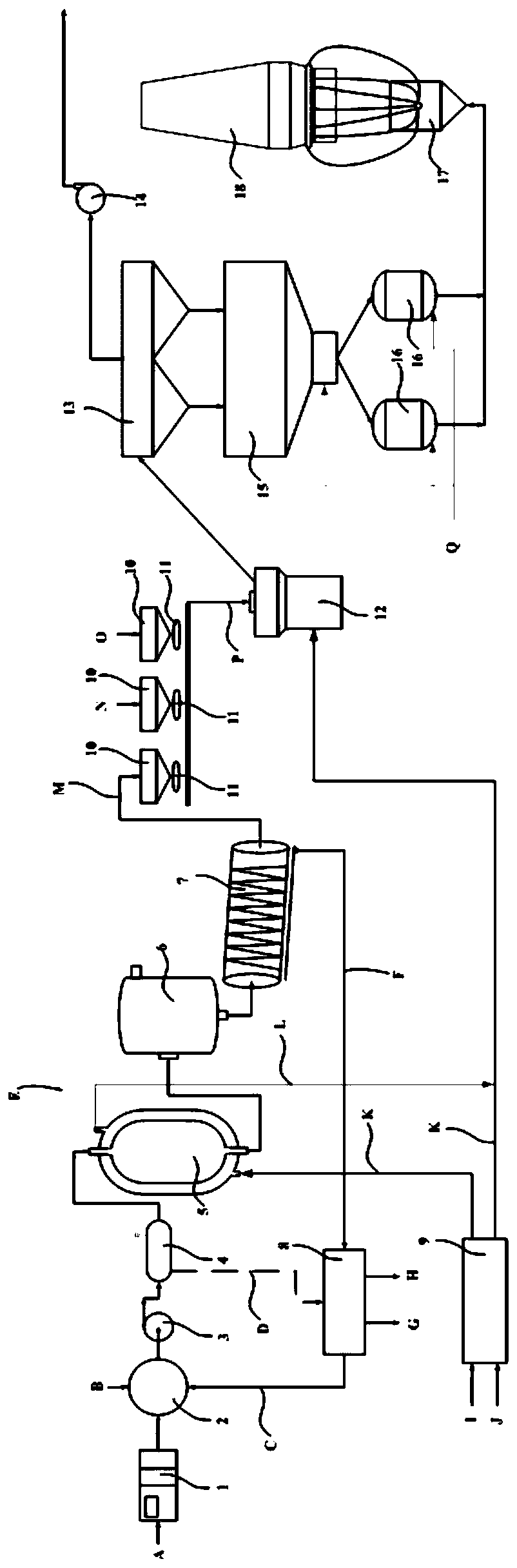

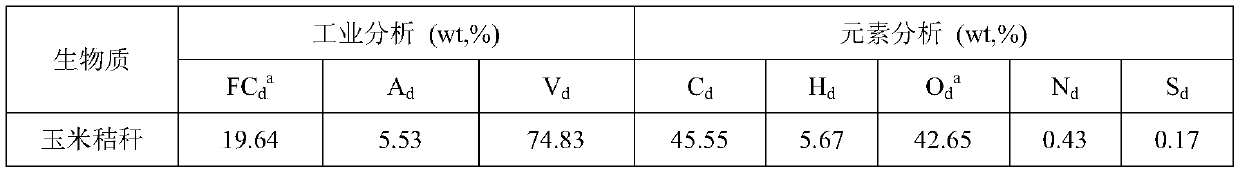

Method for carrying out blast furnace blowing on biomass hydrothermal carbon

ActiveCN110218826AImprove milling performanceEasy to transportBiofuelsSolid fuelsMetallurgyWaste rubber

The invention belongs to the technical field of blast furnace ironmaking, and particularly discloses a method for carrying out blast furnace blowing on biomass hydrothermal carbon. The method solves the problem that an optimal utilization method of biomass resources in blast furnace blowing process. The method can also be used for heat treatment of waste plastics, waste rubbers and other municipalcombustible solid waste water to prepare the hydrothermal carbon and the method can be efficiently applied to determination of a blast furnace blowing scheme. Under the condition that the influencesof biomass hydrothermal carbonization treatment, biomass hydrothermal carbon powder preparing, conveying and blowing on blast furnace smelting key process parameters are considered, the optimal utilization method for carrying out blast furnace blowing on biomass hydrothermal carbon is formed. According to the method, the system is analyzed by aiming at different biomass hydrothermal carbon, important assessment index of the blast furnace smelting downstream behavior is adopted, and the safe and efficient blast furnace blowing on the biomass hydrothermal carbon is realized, so that the comprehensive utilization efficiency of biomass resources is improved, and the emission of CO2 produced by the ironmaking is reduced.

Owner:UNIV OF SCI & TECH BEIJING

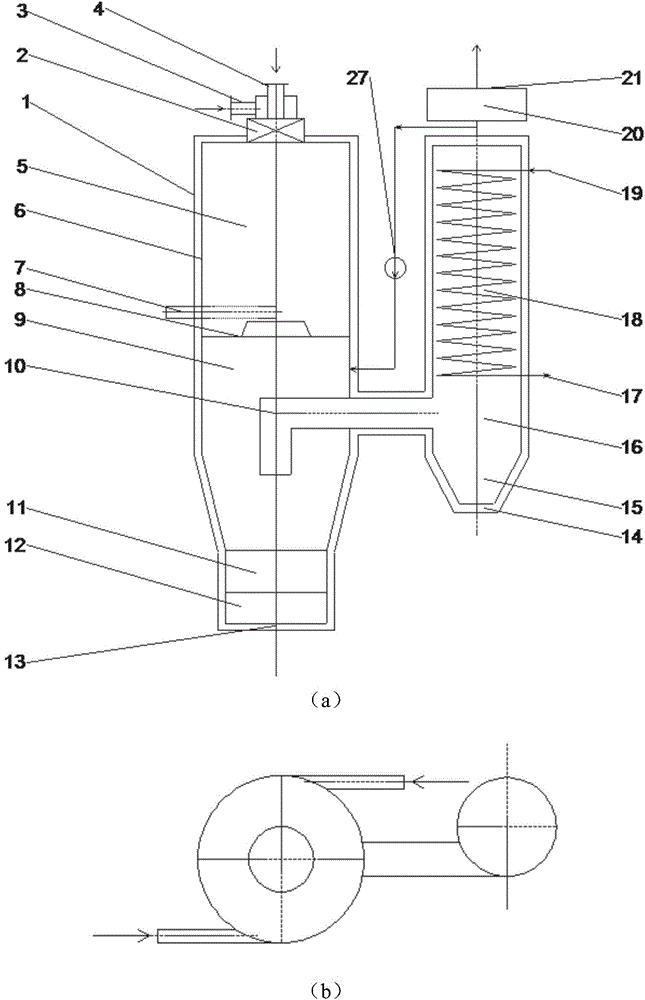

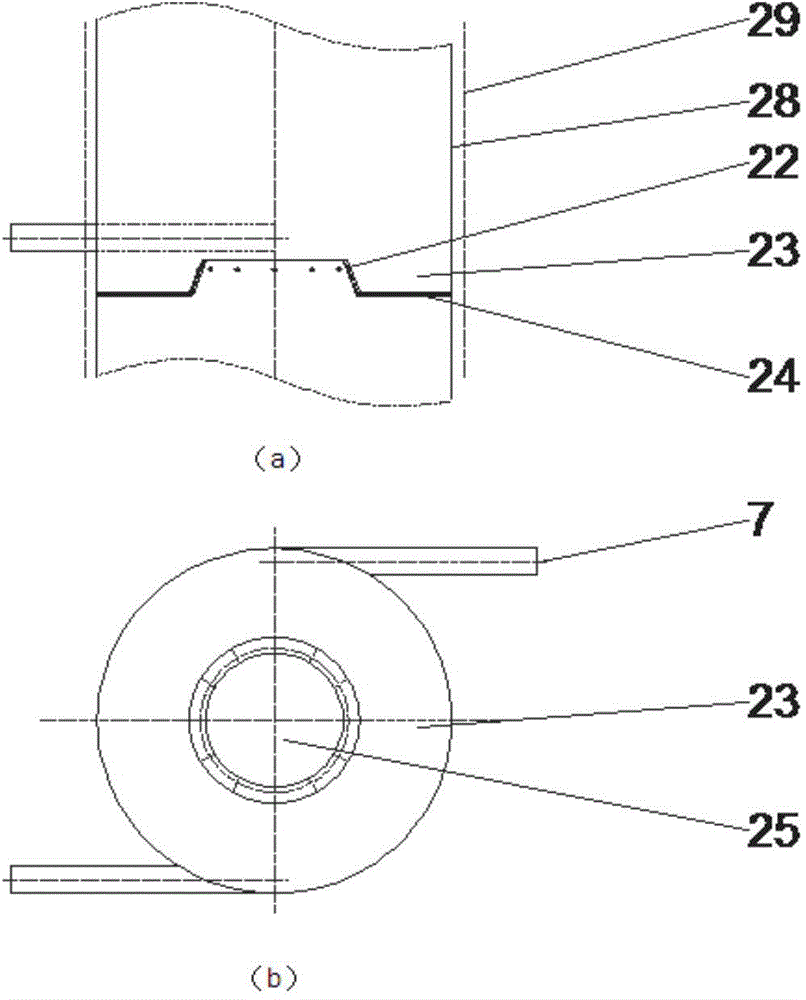

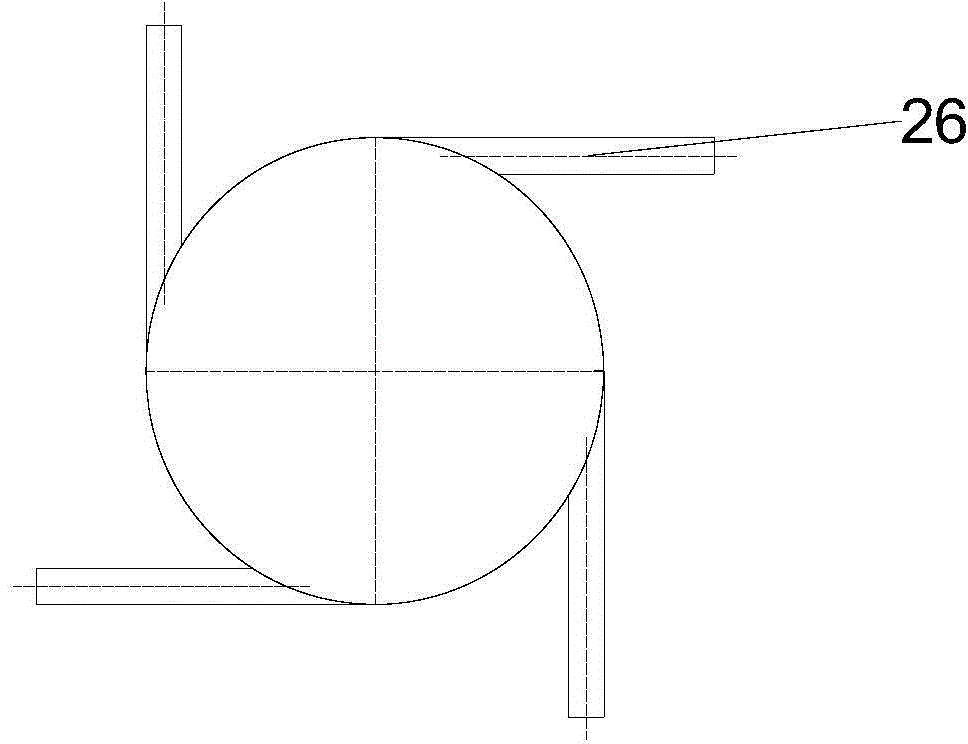

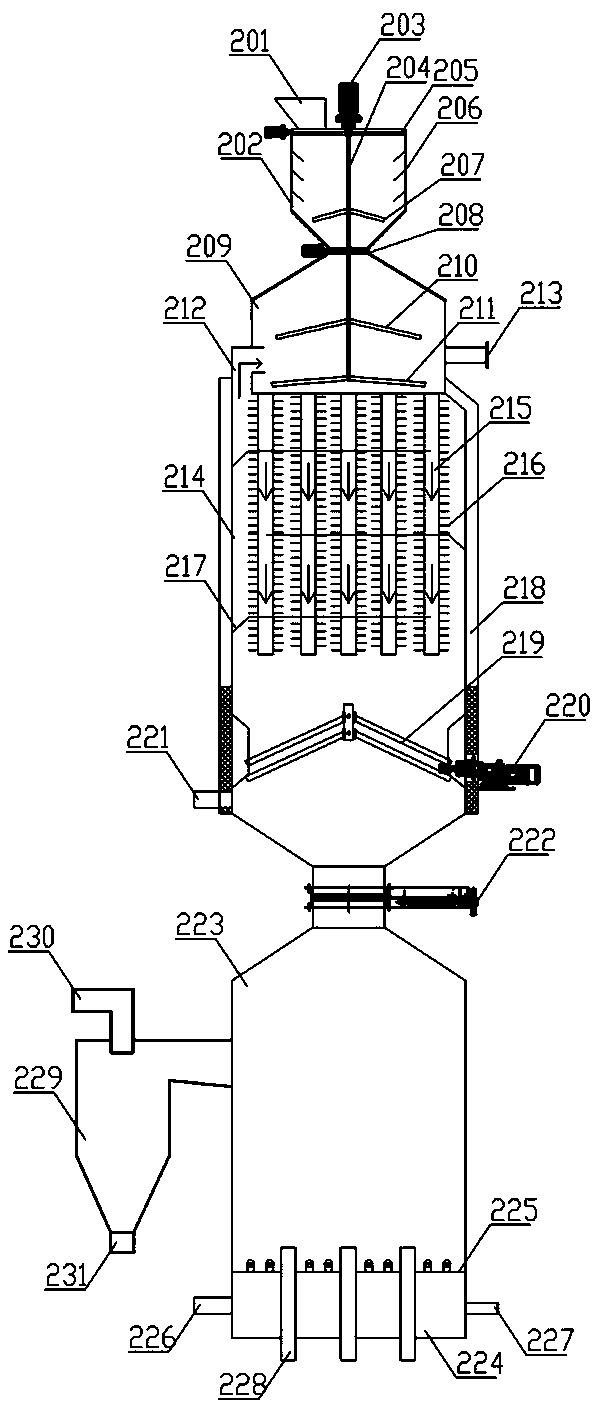

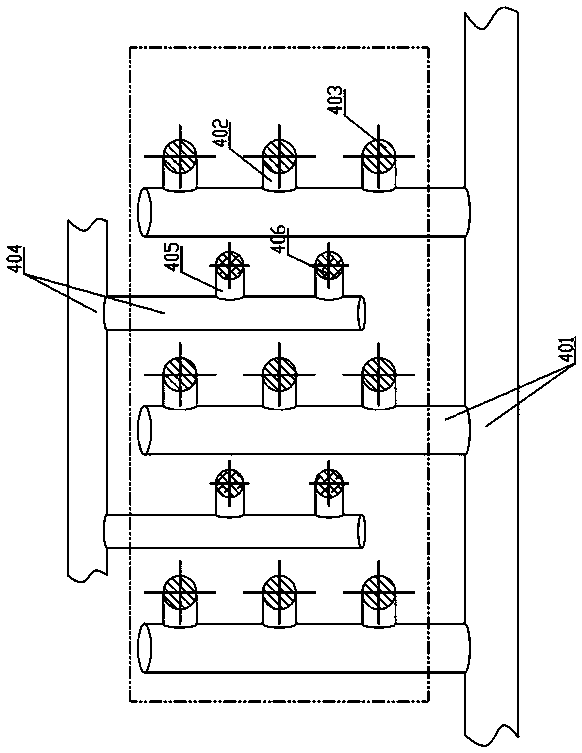

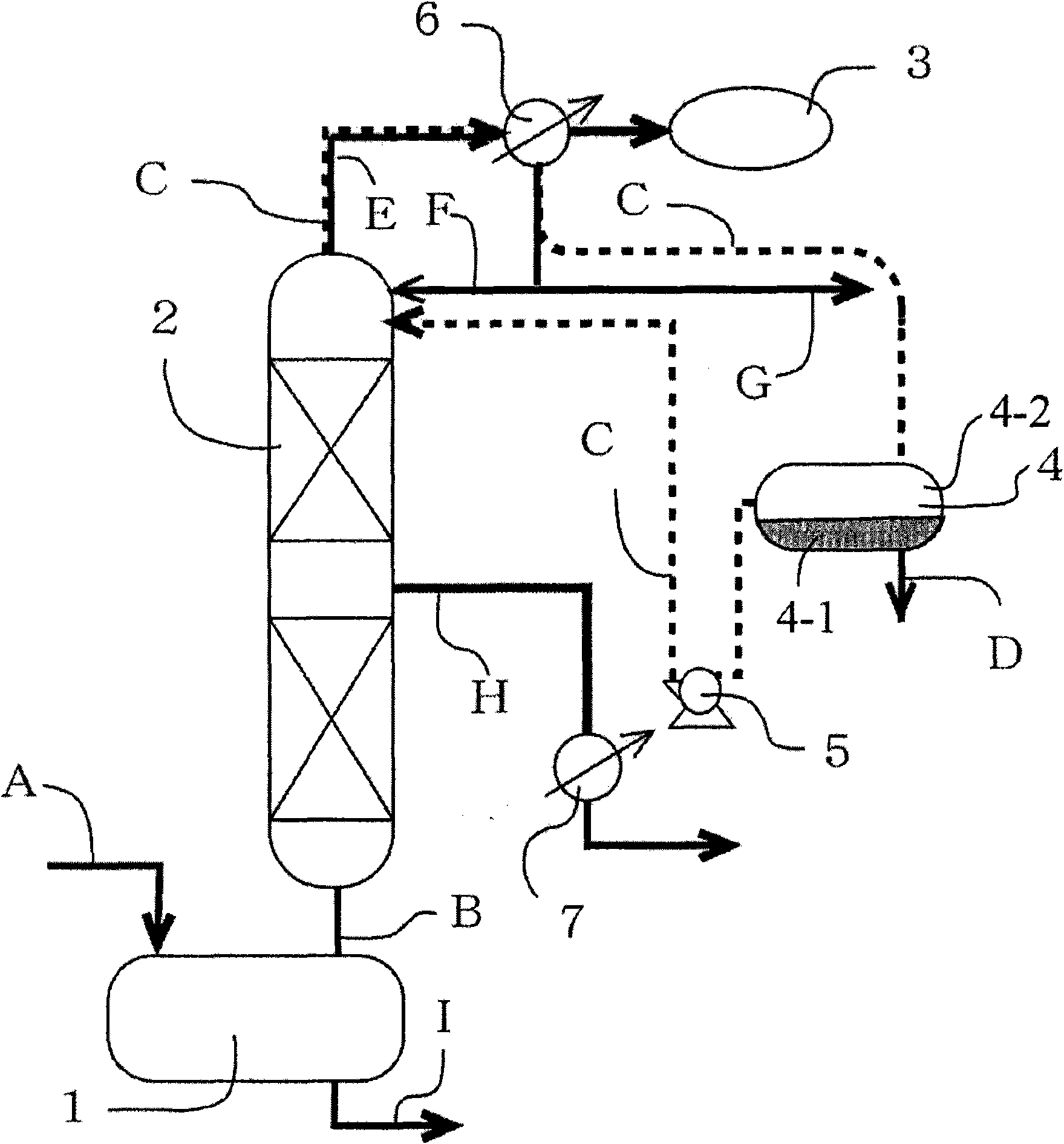

Coal gasifier for slag granulation and coal gas preparation process

ActiveCN104593085AReduce oxygen concentrationReduce the temperatureCombined combustion mitigationGranular/pulverulent flues gasificationCoal waterSlag

The invention discloses a coal gasifier for slag granulation and a coal gas preparation process. The coal gasifier is mainly composed of a pressure-bearing housing, a slag film gasification device, an annular chamber structure slag basin, a quenching chamber, a conduit, a convection cooling section and the like. The process comprises the following steps: with pulverized dry coal or coal water slurry as a raw material, feeding the raw material to a gasification chamber to burn and gasify together with a gasifying agent from a vortex gasification burner; enabling formed liquid slag to collide with the wall surface of the gasification chamber under the vortex action, and flowing from bottom to top under the action of gravity; feeding to the slag basin of the annular chamber structure, carrying out further gasification reaction together with oxygen fed from the upper part of the slag basin, and discharging from a slag discharge hole; feeding coal gas main airflow to the quenching chamber together with liquid drops, cooling to a specific temperature, and then conveying to the convection cooling section to further lower temperature through the conduit; finally removing dust, purifying and then outputting. The liquid slag drops penetrating through the slag basin are cooled to form solid particles and are collected by a dry slag collector; and the heat is recovered by a slag cooler.

Owner:XI AN JIAOTONG UNIV +1

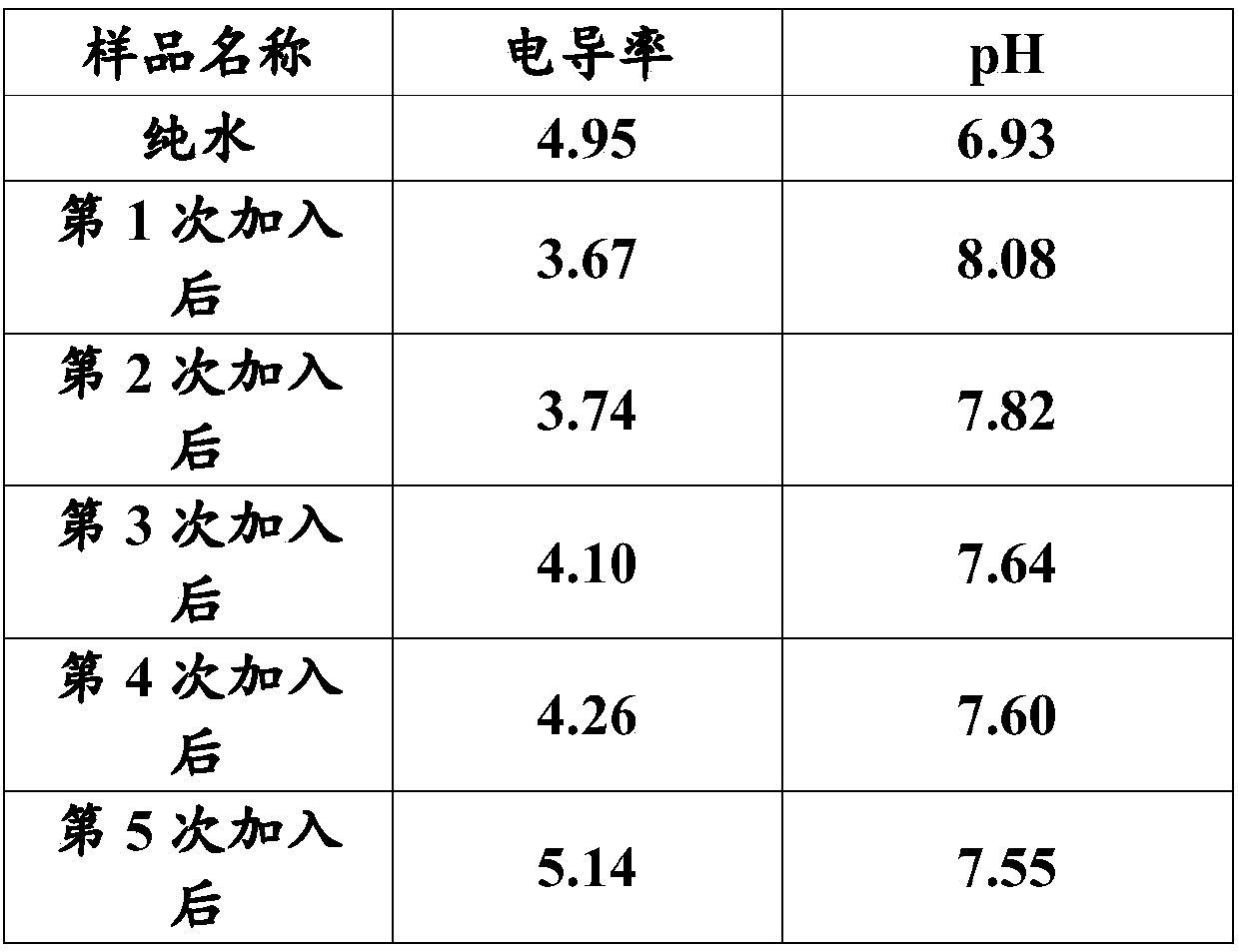

Intermittent sodium removal and purification method for high-sodium coal

The invention discloses an intermittent sodium removal and purification method for high-sodium coal. According to the method, the temperature and pressure intensity in a reaction vessel are changed multiple times, so that high-sodium coal is compressed and expanded multiple times in the purification vessel under the action of violent change of the temperature and pressure, the structural balance of the raw coal is destroyed repeatedly, sodium and other alkali metals in the surfaces and capillary bores of the high-sodium coal can quickly migrate and be dissolved, and a large amount of elements (such as alkali metals, including sodium, potassium, mercury and sulfur) and ashes migrate or are dissolved in a water-based washing solution, thereby achieving the purpose of upgrading and purifying the raw coal.

Owner:上海机易电站设备有限公司

Binder for electric double layer capacitor electrode

ActiveUS7914704B2Reduce alkali metal contentEasy to controlElectrolytic capacitorsHybrid capacitor electrodesPolymer scienceMeth-

A binder for an electric double layer capacitor electrode, which includes a copolymer (A) including monomer units derived from at least one compound (a) represented by the following general formula (1): CH2═CR1—COOR2 (1) wherein R1 represents a hydrogen atom or a methyl group, and R2 represents an alkyl group or a cycloalkyl group, the glass transition temperature obtained by homopolymerizing the compound (a) being less than 0° C., and monomer units derived from at least one compound (b) selected from acrylic acid alkyl esters, methacrylic acid alkyl esters, aromatic vinyl compounds, and α,β-unsaturated nitrile compounds, the glass transition temperature obtained by homopolymerizing the compound (b) being 0° C. or higher, wherein the total content of the monomer units derived from the compound (a) and those derived from the compound (b) is 90% or more by weight per 100% of the whole copolymer (A), and the glass transition temperature of the copolymer (A) is 10° C. or lower, which binder is excellent in smoothness, crack resistance and binding properties.

Owner:ZEON CORP

Method for removing sodium in Sinkiang high-sodium coal

InactiveCN103540381AHigh calorific valueReduce alkali metal contentSolid fuelsCoal waterProcess engineering

The invention relates to a method for removing sodium in Sinkiang high-sodium coal. The method for removing the sodium in the Sinkiang high-sodium coal comprises the following steps: crushing high-sodium raw coal into crushed raw coal in a certain size; washing the crushed raw coal by adopting a high temperature washing solution at a first temperature and a certain pressure to obtain mixed liquor, and stabilizing for a certain time; stirring the mixed liquor for a period of time to obtain a high temperature stirred liquid; cooling the high temperature stirred liquid to a second temperature to obtain a low temperature stirred liquid; carrying out coal water separation on the low temperature stirred liquid to obtain waste liquor and upgraded coal; drying the upgraded coal to obtain low-sodium low-oxygen coal. By virtue of the sodium removing and oxygen removing processes, alkali metal content and oxygen content in the high-sodium raw coal are finally reduced, quality and utilization rate of high-sodium coal are improved, and content of sodium alkali metal volatilized in a combustion process of the high-sodium coal is greatly reduced, so that contamination, scorification and dust stratification caused by combustion of the high-sodium coal are well controlled, heat release during combustion of coal is not influenced, and the treated high-sodium raw coal can be utilized more widely.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

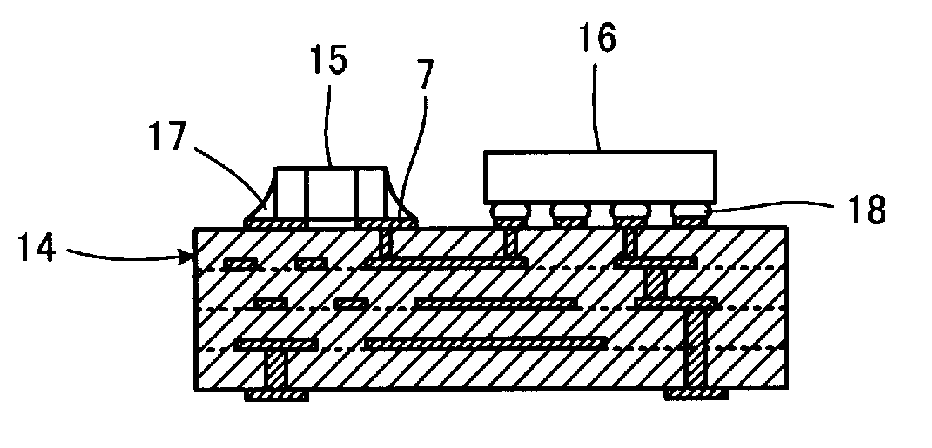

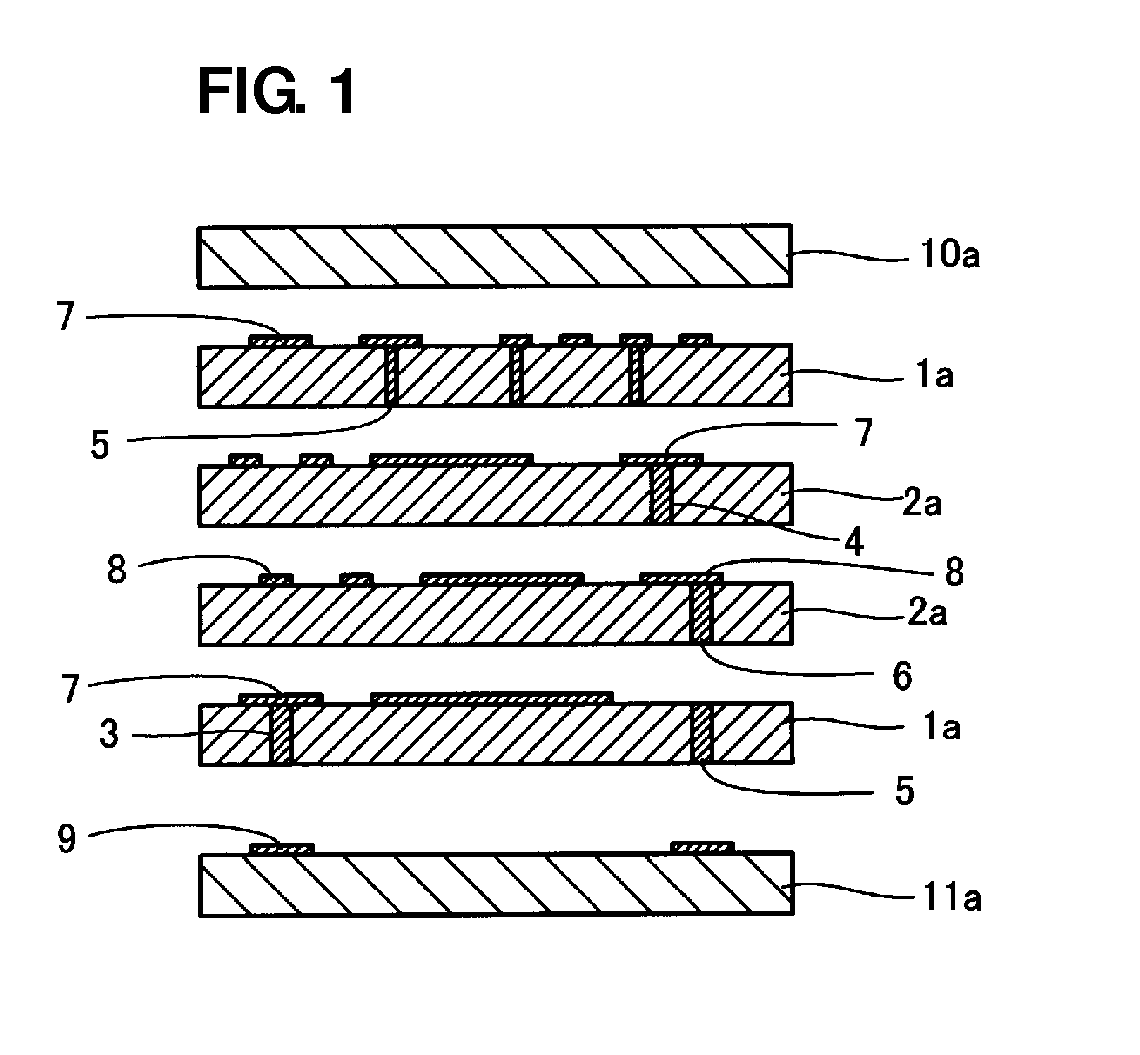

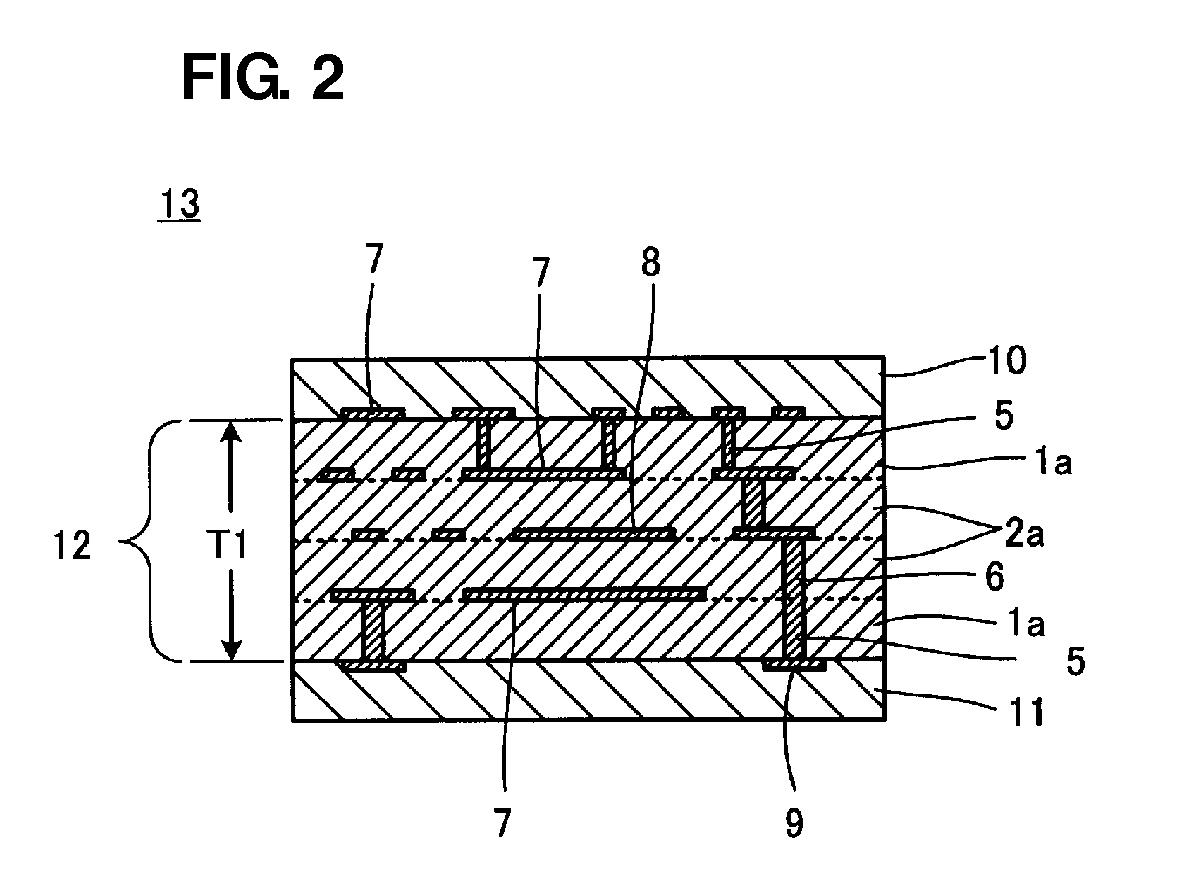

Laminated ceramic electronic component and method for manufacturing the same

InactiveUS20110036622A1Easy to spreadHigh softening pointSolid-state devicesCeramic layered productsSurface layerElectrical conductor

In a method for manufacturing a laminated ceramic electronic component, in order to form a green ceramic laminate to be fired, first ceramic green layers which include first conductor patterns including Ag as a main component and which include a first ceramic material including a first glass component are disposed in surface layer portions. Second ceramic green layers which include second conductor patterns including Ag as a main component, which include a second ceramic material containing a second glass component, and which include a composition in which Ag diffuses than more easily in the first ceramic green layer during firing are disposed in inner layer portions. The green ceramic laminate is fired to produce a multilayer ceramic substrate.

Owner:MURATA MFG CO LTD

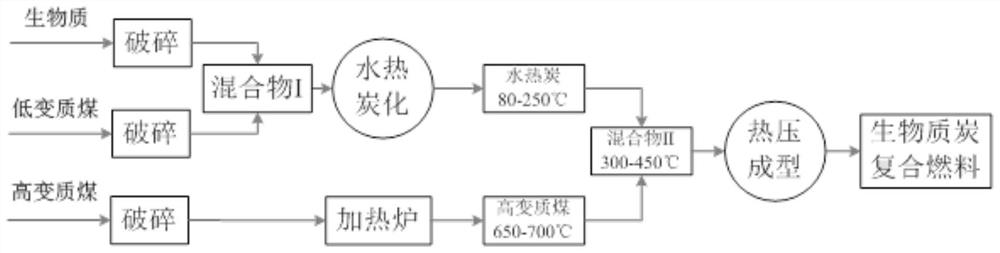

Preparation method of biomass charcoal composite fuel for blast furnace injection

The invention provides a preparation method of a biomass charcoal composite fuel for blast furnace injection, which comprises the following steps: mixing crushed biomass raw materials and low metamorphic coal, carrying out hydrothermal carbonization treatment, then mixing with preheated high metamorphic coal, carrying out heat preservation, and finally carrying out hot pressing treatment. According to the method, the yield of biomass hydrothermal carbonization is increased by utilizing mineral substances in the low-rank coal, and meanwhile, ash, volatile components and water in the low-rank coal can be partially removed, so that the caking property is improved. And then the mixture is mixed with the preheated high-metamorphic coal, so that the ignition point of the mixture can be improved, the explosiveness of the mixture is reduced, and the ash fusion point of the composite fuel can be further improved by utilizing the characteristic of high ash fusion point of the high-metamorphic coal. The biomass charcoal composite fuel can completely replace fossil fuel to be used for blast furnace injection, the emission amount of carbon dioxide and pollutants in the ironmaking production process is reduced, and in addition, the fuel formed through hot pressing has the advantages of being large in volume density and high in compressive strength and is suitable for long-distance transportation and long-term storage.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Silk printing impact-resistant glass ink and preparation method thereof

The invention belongs to the technical field of ink, and particularly relates to silk printing impact-resistant glass ink which comprises, by weight, 60-70% of glass powder, 30-40% of pigment and 20-40% of varnish, wherein the glass powder is composed of, by weight, 40-60% of PbO, 20-35% of SiO2, 5-15% of B2O3, 0-10% of ZnO, 0-5% of TiO2, 0-5% of Al2O3, 0-5% of ZrO2, 0-5% of Li2O, 0-5% of K2O, 0-5% of CdO, 0-5% of V2O5 and 0-5% of P2O5. The silk printing impact-resistant glass ink has excellent impact resistance, low expansion coefficient and high safety and resistance to acid and alkali and is simple in preparation process, easy-to-get in equipment and easy in industrial mass production.

Owner:黄山市晶特美新材料有限公司

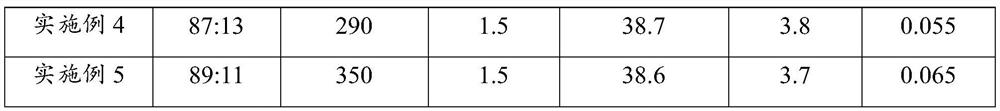

Method for treating iron-containing red mud through coal-based shaft furnace technology

InactiveCN107739819AAdvanced and reliable production technologyProduct quality is stableShaft furnaceCoalOxide

The invention provides a coal-based shaft furnace process for treating iron-containing red mud. Through the coal-based shaft furnace direct reduction process, effective and large-scale comprehensive recycling of iron-containing red mud can be realized, and the production process is advanced and reliable, It can achieve large-scale production, stable product quality, low production cost, high production efficiency and good environmental protection; the metallization rate of the produced sponge iron is ≥90%, and the content of impurities and alkali metals is relatively low, which can be used as electric furnace steelmaking Raw materials, partial replacement of blast furnace oxidized pellets, converter coolant and raw materials for magnetic separation process, etc.

Owner:WUHAN COSRED SCI & TECH LTD

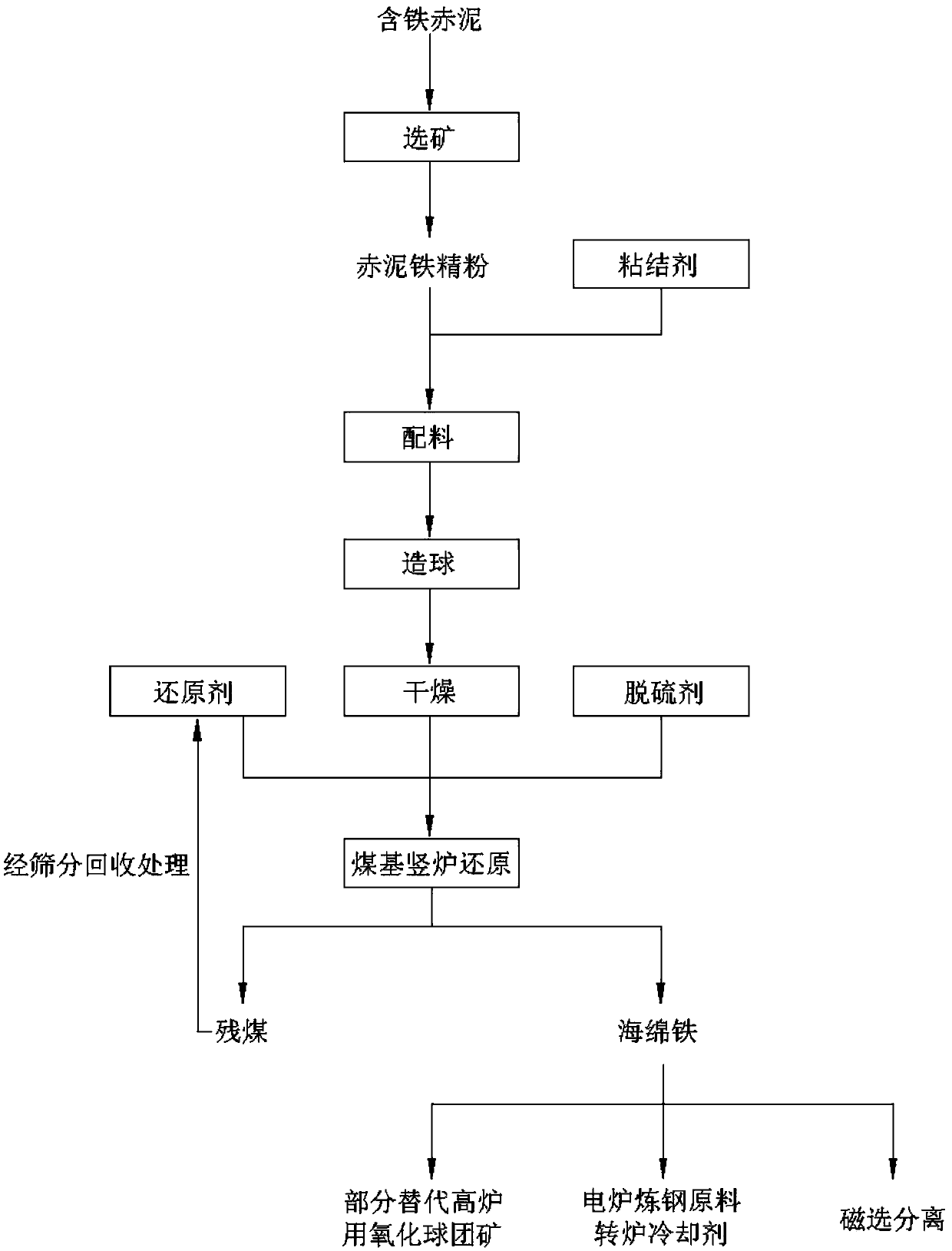

Method for preparing bio-oil by catalytically degrading lignin

ActiveCN107557048AReduce alkali metal contentHigh activityLiquid hydrocarbon mixture productionBio-feedstockSolventOxygen

The invention discloses a method for preparing bio-oil by catalytically degrading lignin. After lignin, serving as a raw material, is treated with acid, with isopropanol as a solvent, Ru / C as a catalyst, oxygen as a carrier gas and a high-pressure reaction kettle with a heating agitator as a reactor, the bio-oil is prepared by degradation, and lignin first undergoes acid soaking pretreatment. Since the alkali metal content of straw lignin is relatively high, the activity of the catalyst can be decreased; since the method first carries out acid pickling pretreatment on the lignin, the alkali metal content in the lignin can be greatly decreased, and thereby the activity of the catalyst is increased. Moreover, since the method disclosed by the invention adopts the isopropanol as the solvent,the price is low, and the impact on the environment is minor as well. The technological method greatly increases the yield of bio-oil, and the yield of produced oil reaches 72 percent; furthermore, the quality of the prepared bio-oil is high as well, and the C content of bio-oil reaches 69 percent; the selectivity of phenolic compound in oil can also be increased, and the selectivity of the phenolic compound in th oil reaches 53 percent.

Owner:NANJING FORESTRY UNIV

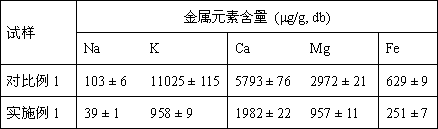

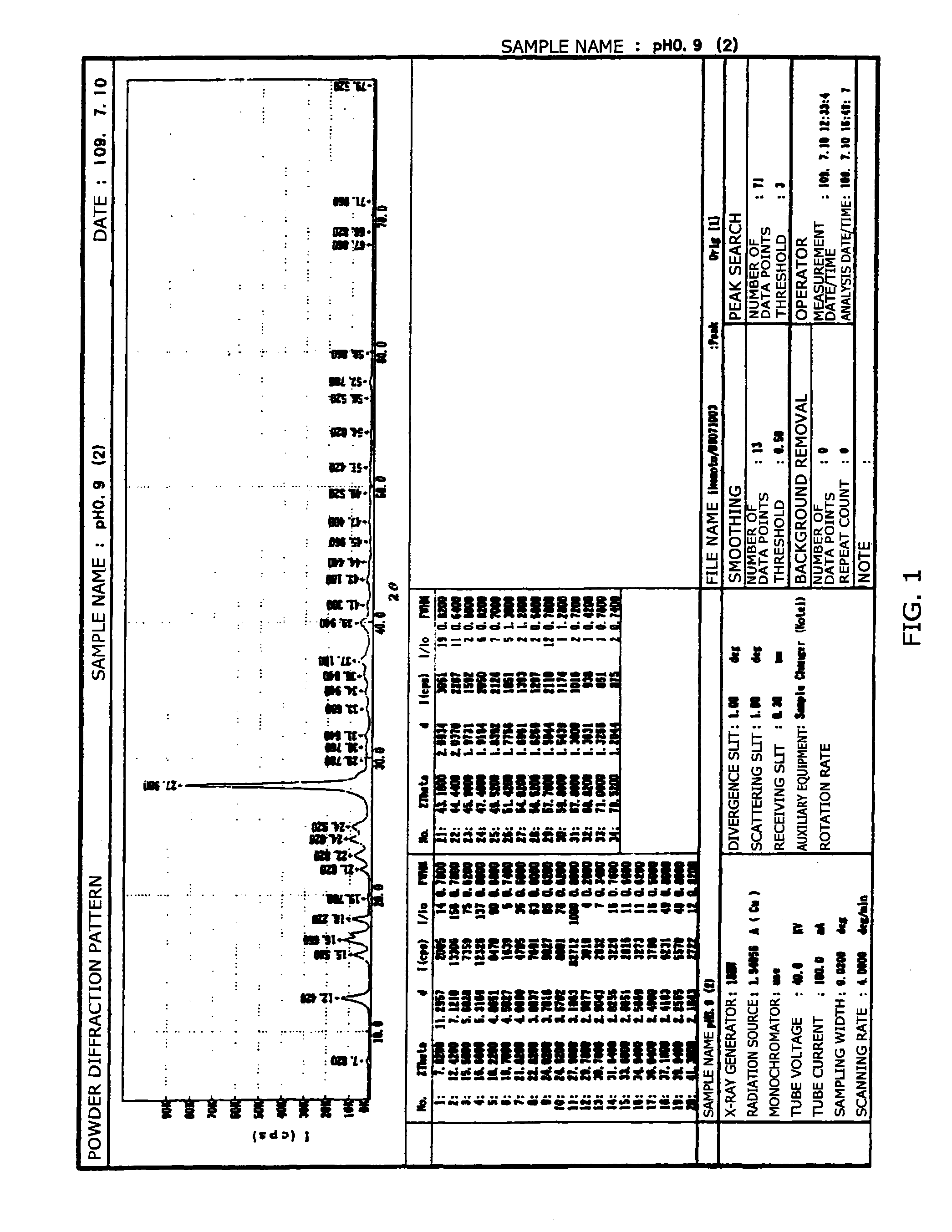

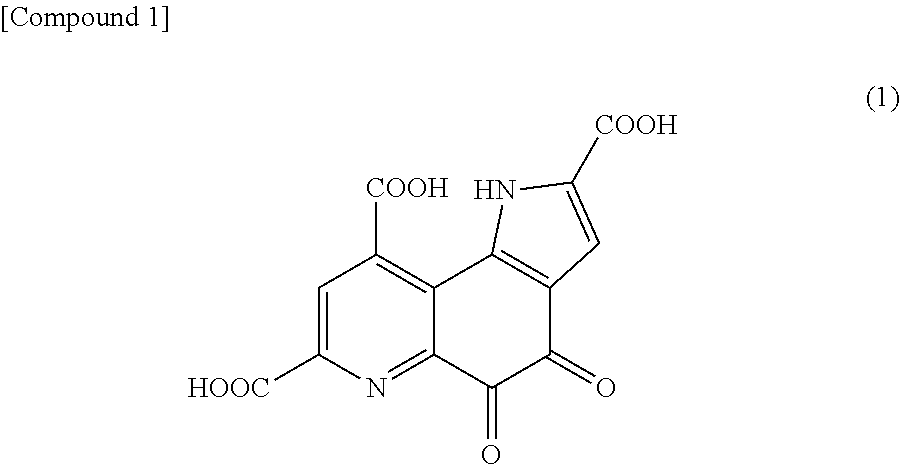

Pyrroloquinoline quinone in free form

InactiveUS20120226045A1High purityReduce alkali metal contentOrganic chemistryOrganic solventFree form

An object of the present invention is to provide a method for conveniently producing pyrroloquinoline quinone in the free form without any organic solvent or ion-exchange resin and highly-pure crystals thereof. According to the present invention, there is provided a production method of pyrroloquinoline quinone in the free form and highly-pure crystals thereof, wherein the production method comprises preparing a solution having a pH of 1.5 or less by dissolving an alkali metal salt of pyrroloquinoline quinone to obtain a precipitate.

Owner:MITSUBISHI GAS CHEM CO INC

A method for blast furnace injection of biomass hydrothermal charcoal

ActiveCN110218826BImprove milling performanceEasy to transportBiofuelsSolid fuelsWaste rubberBlast furnace smelting

The invention belongs to the technical field of blast furnace ironmaking, and particularly discloses a method for carrying out blast furnace blowing on biomass hydrothermal carbon. The method solves the problem that an optimal utilization method of biomass resources in blast furnace blowing process. The method can also be used for heat treatment of waste plastics, waste rubbers and other municipalcombustible solid waste water to prepare the hydrothermal carbon and the method can be efficiently applied to determination of a blast furnace blowing scheme. Under the condition that the influencesof biomass hydrothermal carbonization treatment, biomass hydrothermal carbon powder preparing, conveying and blowing on blast furnace smelting key process parameters are considered, the optimal utilization method for carrying out blast furnace blowing on biomass hydrothermal carbon is formed. According to the method, the system is analyzed by aiming at different biomass hydrothermal carbon, important assessment index of the blast furnace smelting downstream behavior is adopted, and the safe and efficient blast furnace blowing on the biomass hydrothermal carbon is realized, so that the comprehensive utilization efficiency of biomass resources is improved, and the emission of CO2 produced by the ironmaking is reduced.

Owner:UNIV OF SCI & TECH BEIJING

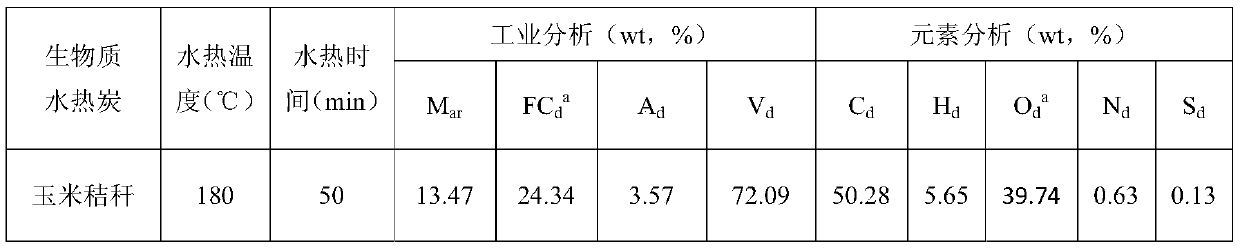

Biomass circulating fluidized bed direct-fired boiler and system coupling same with gasifier for power generation and coproduction of activated carbon

PendingCN109735371AUniform temperature fieldIncrease temperatureCombustible gas productionBiological activationCorrosion

The invention discloses a biomass circulating fluidized bed direct-fired boiler and a system coupling the same with a gasifier for power generation and coproduction of activated carbon. The system comprises a gasifying and activating device, the biomass circulating fluidized bed direct-fired boiler and a steam turbine generator set, and the gasifying and activating device comprises a gasifying system and an activating system; a biomass raw material is fed into the gasifying system to generate cracked combustible gas and biomass charcoal, and the cracked combustible gas is fed into the biomasscirculating fluidized bed direct-fired boiler through fuel gas burning equipment and fed into a fluidized air chamber through a fuel gas nozzle for pre-burning to heat the biomass material; the biomass charcoal generated by the gasifying system through gasifying is fed into the activating system for activation to generate activated carbon to be sent out. The system can relieve the problem that existing biomass circulating fluidized bed direct-fired boilers are prone to bed material sintering and heated face ash accumulation and corrosion and the problem that the biomass raw material is low inenergy effective utilization rate, can effectively improve economic benefit of biomass power plants and is suitable for the biomass circulating fluidized bed direct-fired boiler.

Owner:ZHEJIANG UNIV +1

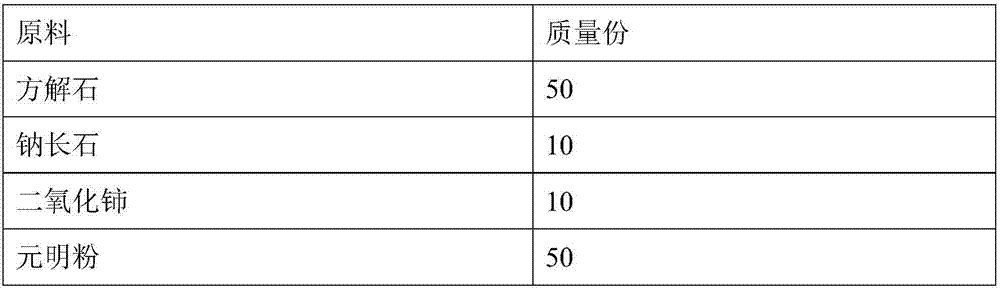

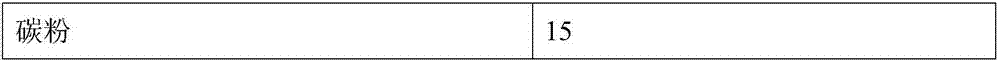

Composite fining agent for glass and preparation method thereof

The invention discloses a composite fining agent for glass and a preparation method thereof. The fining agent for glass comprises the following components: calcite, a fluxing agent, cerium oxide or a precursor thereof, anhydrous sodium sulfate and carbon powder. The invention also discloses a preparation method of the composite fining agent for glass. The composite fining agent for glass has the characteristics of high cleanliness, no toxicity, wide applicable temperature range, low loss, high stability and favorable fining effects.

Owner:GUANGZHOU ZHONGXIN CENTURY FIBERGLASS

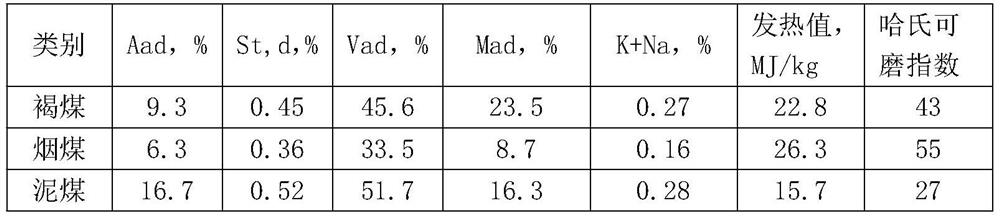

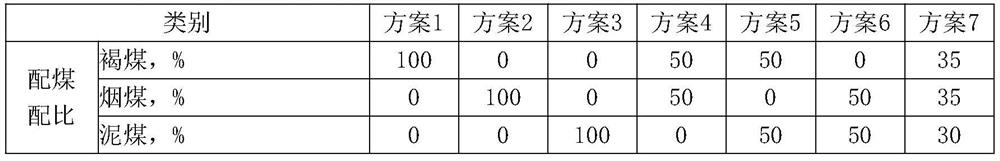

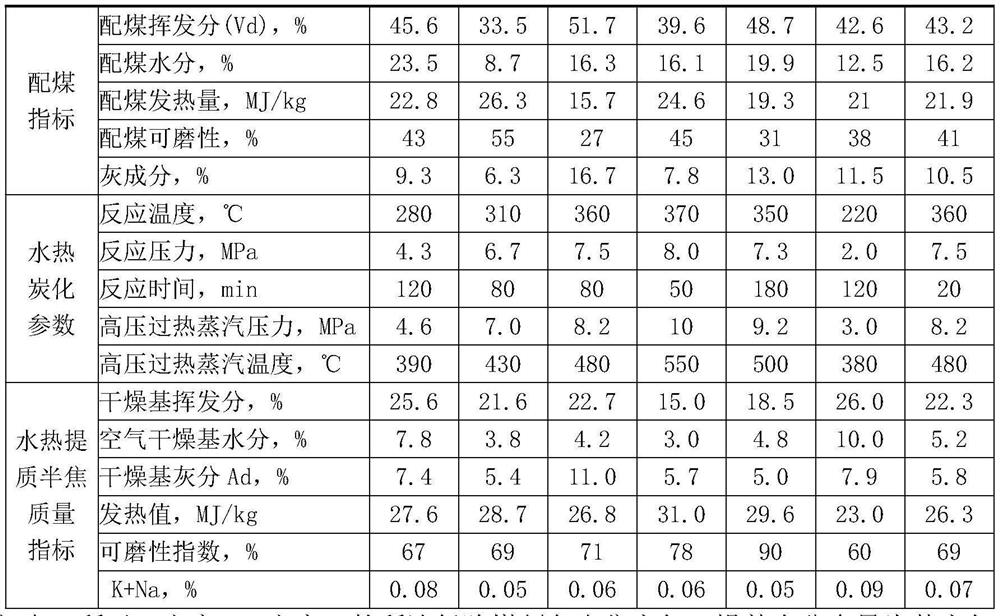

Method for preparing semicoke from low-rank coal

PendingCN114181725ALow volatile contentReduce moistureSpecial form destructive distillationPhysical chemistryCoke

The invention discloses a method for preparing semi-coke from low-rank coal, and mainly solves the technical problems that the existing semi-coke prepared from the low-rank coal is poor in grindability, high in volatile component content, high in moisture content, low in fixed carbon content and exothermic value and incapable of meeting blast furnace injection. According to the technical scheme, the method for preparing the semi-coke from the low-rank coal comprises the following steps: 1) pre-crushing the low-rank coal, namely pre-crushing the low-rank coal to ensure that the coal with the particle size of less than 3mm accounts for 75-80% of the total mass of the low-rank coal; 2) carrying out hydrothermal carbonization treatment on the low-rank coal to obtain a hydrothermal carbonization solution; (3) carrying out separation treatment on the hydrothermal carbonization liquid, and carrying out solid-liquid separation on the hydrothermal carbonization liquid to separate out a solid, namely hydrothermal carbon; and 4) hydrothermal carbon drying treatment: drying the hydrothermal carbon to obtain the finished product semicoke. The method disclosed by the invention is low in production cost and low in pollutant emission in the production process, and the produced semi-coke has the characteristics of low moisture and ash content, high fixed carbon and exothermic value and good grindability.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Process for preparation of esters solvent

InactiveCN101514157AAvoid mixingReduce alkali metal contentOrganic compound preparationCarboxylic acid esters preparationAlcoholBoiling point

The present invention provides high boiling point esters solvent with low content of sodium and acid and high-efficiency industry method for preparing the same. The esters solvent can be used in electronic material field with requirement of high-purity quality. Process for preparation of esters solvent is, at the presence of acid catalyst, putting the esterification reaction stock solution got from esterification of alcohol and acid into distilling tower and distilling to get esters solvent, wherein, the reaction stock solution used for distil purifying without neutralization treatment, and after removing low boiling point ingredients by distillation, distilling off the esters solvent via sidetrack distillate pipe disposed in central part of the distilling tower.

Owner:DAICEL CHEM IND LTD

Method for the Production of Fire Resistant Glazings

ActiveUS20140360652A1Reduce moistureReduce alkali metal contentGlass/slag layered productsWing framesSilicon dioxideWater content

Owner:PILKINGTON GRP LTD

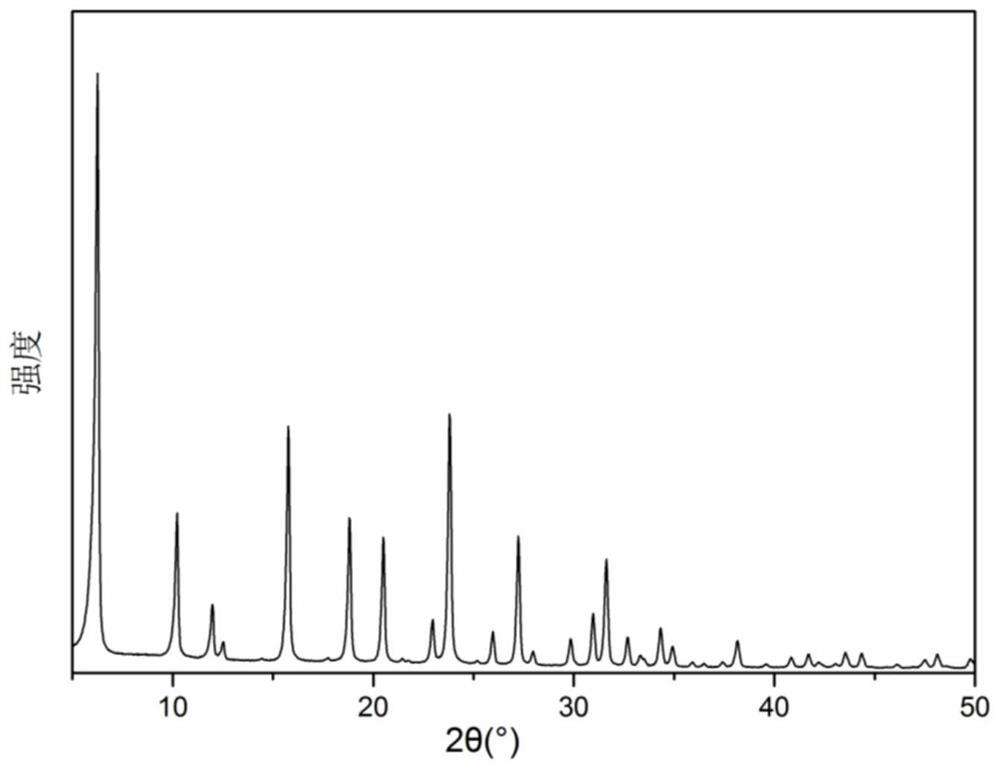

Fluorine-containing high-silicon Y molecular sieve and preparation method thereof

ActiveCN111825103AAchieve synthesisFast crystallization rateCatalyst carriersMolecular sieve catalystsMolecular sieveIon exchange

The invention discloses a fluorine-containing high-silicon Y molecular sieve and a preparation method thereof, and belongs to the field of molecular sieve synthesis. The anhydrous chemical compositionof the fluorine-containing high-silicon Y molecular sieve is hF.kM.mR1. NR2. (SixAly) O2, and the silica-alumina ratio of the fluorine-containing high-silicon Y molecular sieve is 25-100. The methodcomprises the following steps: a) mixing raw materials containing an aluminum source, a silicon source, an alkali metal source, a fluorine source, an organic template agent R2 and water to obtain initial gel, then adding a guiding agent or a silicon-aluminum molecular sieve seed crystal, and stirring to obtain synthetic gel; b) dewatering the synthetic gel to obtain a dry powder mixture; and c) crystallizing the dry powder mixture. According to the method disclosed by the invention, the fluorine-containing high silicon Y molecular sieve has characteristics of high silica-alumina ratio, low alkali metal content and easy ion exchange, and the preparation method has characteristics of rapid crystallization rate, simple process, and easy large-scale industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Spherical super-capacitor activated carbon, and preparation method and application thereof

InactiveCN110723735AGood spherical profileReduce alkali metal contentCarbon compoundsHybrid capacitor electrodesActivated carbonSupercapacitor

The invention belongs to the technical field of electrode material preparation, and in particular relates to spherical super-capacitor activated carbon, and a preparation method and application thereof. The specific surface area B of the spherical super-capacitor activated carbon is 1500-4000 m<2> / g. The invention also provides the preparation method of the spherical super-capacitor activated carbon. The preparation method comprises the following steps: 1) carbonizing a spherical polymer; 2) pre-activating the product obtained in the step 1); and 3) mixing the product obtained by pre-activation in the step 2) with an alkaline compound, and carrying out activation. According to the preparation method provided by the invention, the super-capacitor activated carbon can be prepared at good yield and low cost, and the obtained activated carbon has a good spherical profile and a low metal content, so that the prepared spherical activated carbon can be used as an electrode material of super-capacitors.

Owner:SHENZHEN GLOBAL GREENLAND NEW MATERIALS CO LTD

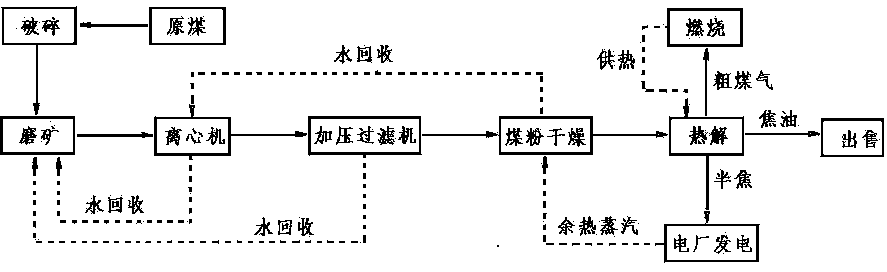

Burning power generation utilization method of high-sodium-content coal

ActiveCN103952164AReduce alkali metal contentReduce contentSolid fuelsSpecial form destructive distillationHigh sodiumSlag

The invention relates to a burning power generation utilization method of high-sodium-content coal, aiming at solving the problem that no method with simple process and low processing cost is provided for processing high-sodium-content coal at present. The raw high-sodium-content coal is characterized in that a dry-ash-free volatile component (Vadf %) accounts for 30 to 50% in content; coal ash comprises 2.0 to 18.0% of basic metal Na2O in content, 0.5 to 9.5% of K2O in content, 6.0 to 42.0% of CaO in content, 1.5 to 15.0% of MgO in content, and 4.0 to 18.0% of Fe2O3 in content. The method comprises the following steps: A, crushing the raw coal, and grinding by a wet method; B, mechanically dehydrating pulverized coal; C, drying pulverized coal; D, thermally decomposing coal; E, burning sodium-free coal to generate power. The method is simple in process, low in processing cost and high in utilization rate of coal resource, and can effectively ease the problems that a boiler is easily polluted and slag bonding is generated in the direct burning utilization of the high-sodium-content coal.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

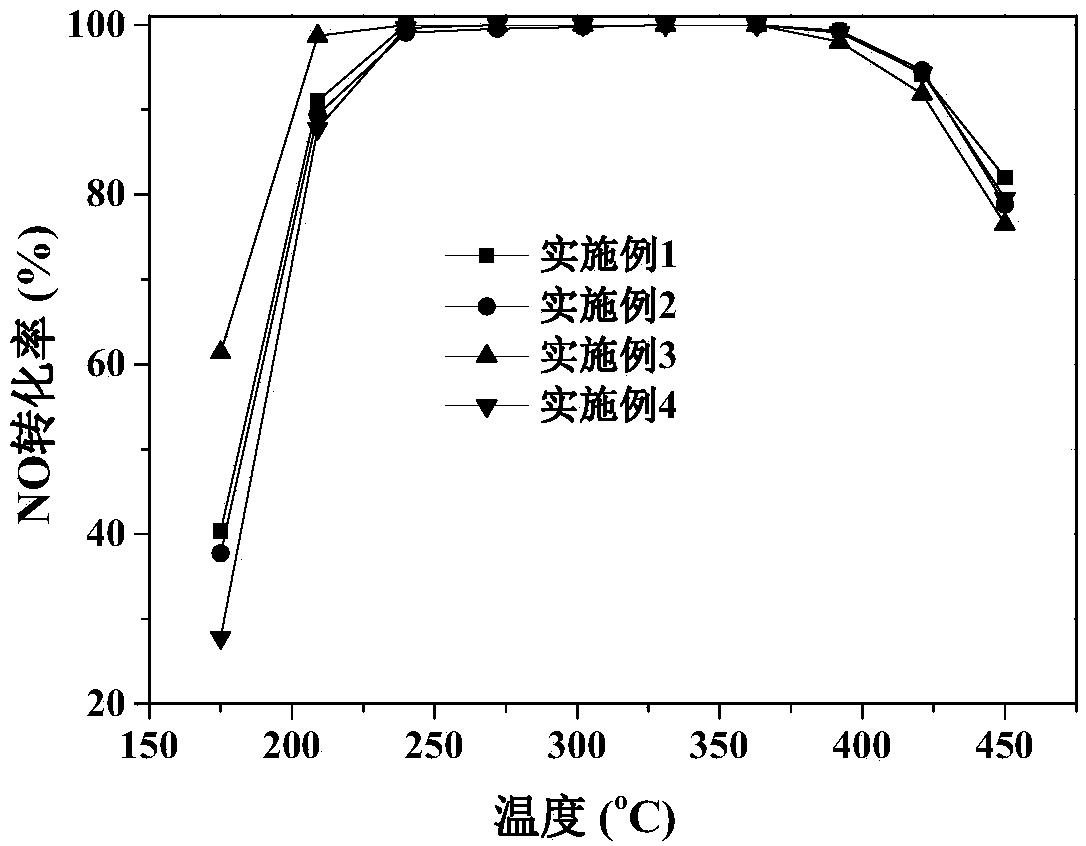

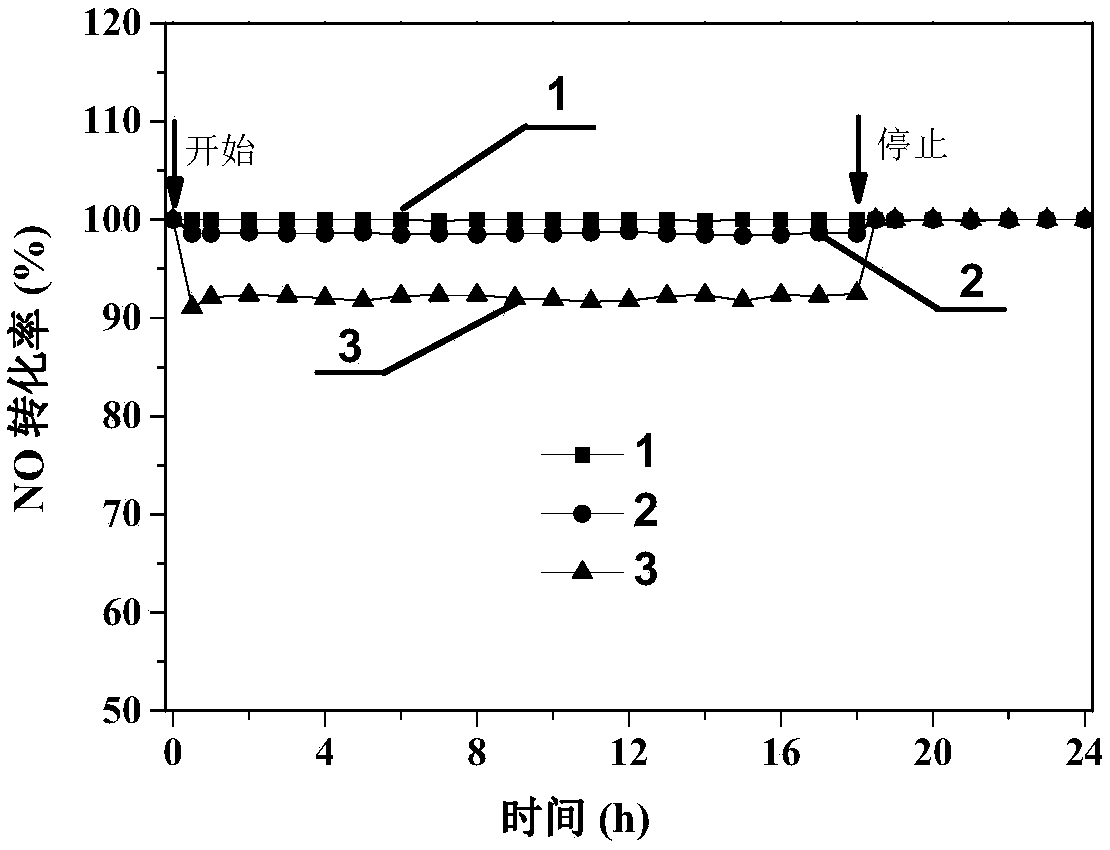

Preparation method for composite denitration catalyst with layered structure

ActiveCN108097235AIncrease surface areaHigh pore volumeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumComposite oxide

The invention relates to a preparation method for a composite denitration catalyst with a layered structure. The catalyst is prepared with organic modified layered clay, cerium salt and molybdate as precursors through adsorption, impregnation, extrusion molding, drying and calcination, wherein the mol ratio of molybdenum to cerium in the catalyst is (0.10-0.25): 1; and the total mass of cerium andmolybdenum metal elements accounts for 35 to 50% of the mass of the catalyst. The catalyst has large surface area; composite oxide nanoparticles are uniformly dispersed in the layered structure of the clay; the catalyst used as a flue gas denitration catalyst shows high denitration efficiency and wide temperature window; meanwhile, the catalyst has high stability, water resistance and sulfur poisoning resistance. In addition, the organic modified layered clay can effectively reduce alkali metal in the clay and improves the denitration performance of the catalyst. The clay used in the composite material has extensive sources, cheap price, low cost and environmental friendliness.

Owner:NANJING UNIV OF TECH

Novel glass fiber vacuum insulation panel core material and preparation method thereof

ActiveCN103244793BLower boron contentImprove insulation effectFibreboardThermal insulationAir filtrationGlass fiber

The invention discloses a novel glass fiber vacuum insulation panel core. The vacuum insulation panel core is made of low-boron glass cellucotton which has the boric mass percentage of less than 0.5% and the diameter of 0.5-1.0 micrometer. The invention further discloses a preparation method of the vacuum insulation panel core, which comprises the following steps of: (1) selecting the low-boron glass cellucotton, (2) beating and dispersing the selected low-boron glass cellucotton to obtain slurry, (3) diluting the slurry, (4) deslagging the slurry of Step (3) and preparing wet paper in a wet forming manner, (5) dehydrating the wet paper of Step (4); and (6) drying the wet paper of Step (5). The glass fiber air filtration paper has outstanding comprehensive performances; the preparation process is pollution-free; and the service life is long.

Owner:宣汉正原微玻纤有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com