Composite fining agent for glass and preparation method thereof

A technology of compound clarifier and glass, applied in the field of glass compound clarifier and its preparation, can solve the problems of low decomposition temperature of carbon powder, reduced use effect, influence of clarifier, etc., and achieves less material loss, excellent energy saving and emission reduction, and clarification good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

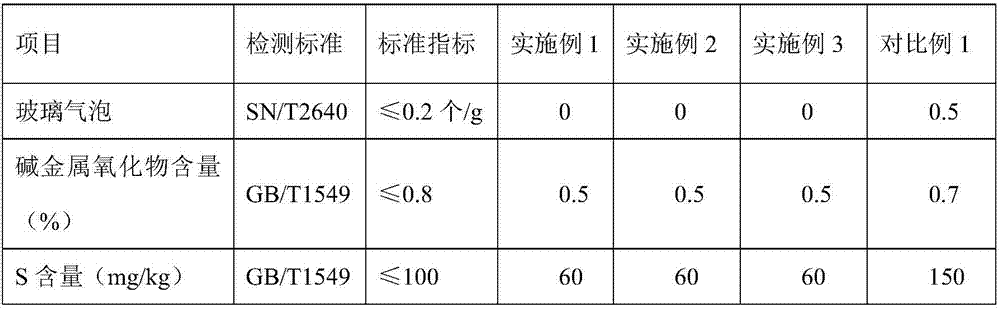

Examples

preparation example Construction

[0020] A preparation method for glass composite clarifying agent, comprising the following steps:

[0021] 1) mixing and stirring cerium oxide or its precursor with calcite to obtain a semi-finished composite clarifier;

[0022] 2) Mixing the semi-finished compound clarifying agent with flux, sodium sulfate and carbon powder to obtain the glass compound clarifying agent.

[0023] Preferably, the mixing in step 2) is pneumatic mixing.

[0024] Preferably, the number of compressed air pulses for step 2) pneumatic mixing is 20-40 times.

[0025] Further, a preparation method of a glass composite clarifier, comprising the following steps:

[0026] 1) adding cerium oxide or its precursor to calcite, stirring evenly, to obtain a semi-finished composite clarifier;

[0027] 2) Add flux, sodium sulfate and carbon powder before use, adjust the amount of flux and redox atmosphere, weigh all the raw materials through the batching system, put them into the pneumatic mixing delivery tank...

Embodiment 1

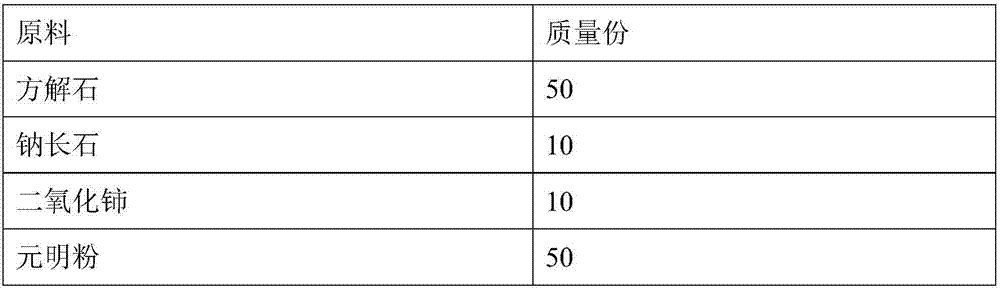

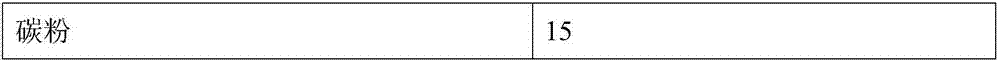

[0030] A kind of composition of the raw material of glass composite clarifier as described in table 1.

[0031] The raw material composition of table 1 embodiment 1 glass composite clarifying agent

[0032] raw material

Embodiment 2

[0034] A kind of composition of the raw material of glass composite clarifier as described in table 2.

[0035] The raw material composition of table 2 embodiment 2 glass composite clarifying agent

[0036] raw material

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com