A method for blast furnace injection of biomass hydrothermal charcoal

A biomass and hydrothermal charcoal technology, applied in blast furnaces, biofuels, blast furnace details, etc., can solve the problems of deepening deterioration of ore and coke, adverse effects on normal blast furnace production, and increasing the amount of alkali metals in fuels, so as to improve transportation and efficiency. Effects of injection performance, improvement of comprehensive utilization efficiency, and elimination of blast furnace soda load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

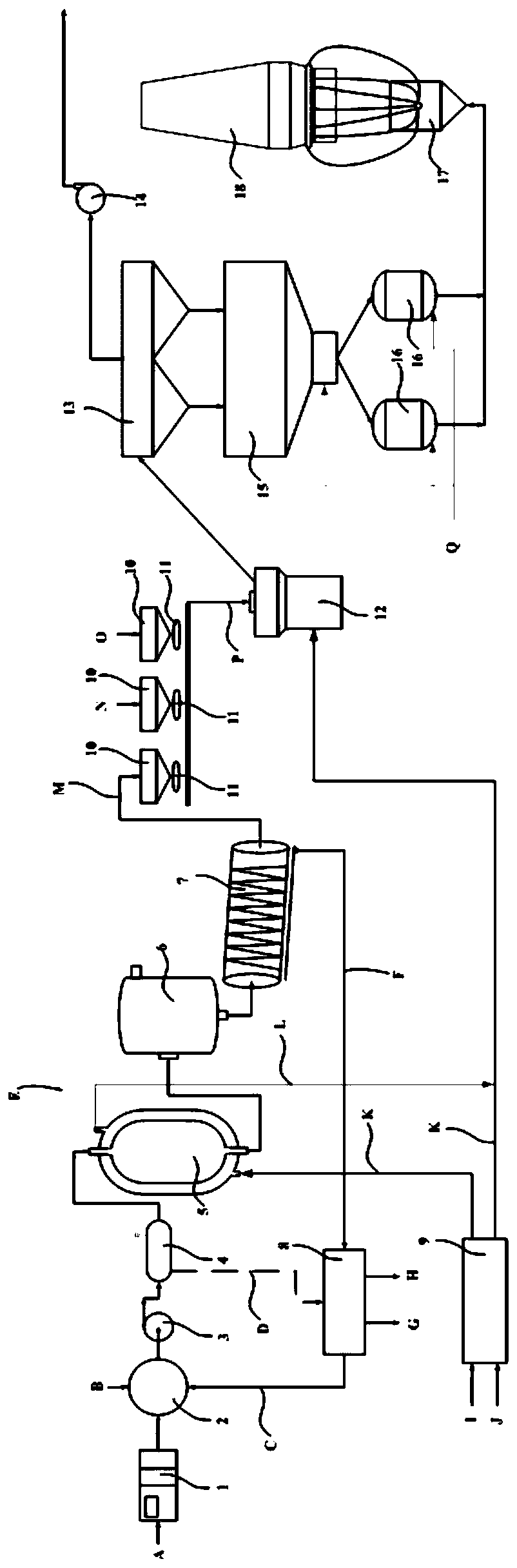

[0053] use figure 1 One embodiment of the present invention will be described. A is biomass raw material, B is coking wastewater, C is desalination circulating water, D is condensed water, E is high-pressure steam from flash tank, F is oil-water mixture, G is biomass tar, H is crude potassium salt, I is Blast furnace gas, J is combustion-supporting air, K is high-temperature waste gas, L is low-temperature waste gas, M is biomass hydrothermal charcoal, N is bituminous coal, O is anthracite, P is a mixture of biomass hydrothermal charcoal and coal, and Q is high-pressure nitrogen . The biomass A is crushed by the pulverizer 1, and the slurry is prepared in the slurry storage tank 2. The pulping water can be one or both of coking wastewater B and desalination circulating water C in an appropriate proportion. The prepared slurry is transported under pressure by the high-pressure slurry pump 3. In order to improve the hydrothermal carbonization efficiency, the slurry is preheate...

Embodiment 2

[0071] usefigure 1 The equipment shown is an experiment of hydrothermal carbonization of biomass, in which waste poplar is used as biomass. The results of industrial analysis and elemental analysis of the biomass used are shown in Table 4.

[0072] Table 4 Industrial analysis and elemental analysis results of waste poplar wood

[0073]

[0074] The waste poplar wood in Table 4 is subjected to carbonization reaction in an autoclave after crushing and pulping, and the carbonization temperature and carbonization time are changed to obtain biomass hydrothermal charcoal. The obtained waste poplar wood hydrothermal charcoal is subjected to industrial analysis, elemental analysis, and calorific value. , Hastelloy grindability index and alkali metal content analysis, the results are shown in Table 5 and 6.

[0075] Table 5 Industrial analysis and elemental analysis of waste poplar wood hydrothermal charcoal

[0076]

[0077] Table 6 Analysis of Hastelloy's grindability index, ...

Embodiment 3

[0083] use figure 1 The shown facility performs experiments on hydrothermal carbonization of biomass using palm shells. The results of industrial analysis and elemental analysis of the biomass used are shown in Table 1.

[0084] Table 7 Results of industrial analysis and elemental analysis of palm shells

[0085]

[0086] After the palm shells in Table 7 are crushed and pulped, the carbonization reaction is carried out in an autoclave, and the carbonization temperature and carbonization time are changed to obtain biomass hydrothermal charcoal. The obtained palm shell hydrothermal charcoal is subjected to industrial analysis, elemental analysis, Calorific value, Hastelloy grindability index and alkali metal content analysis, the results are shown in Tables 8 and 9.

[0087] Table 8 Industrial analysis and elemental analysis of palm shell hydrothermal charcoal

[0088]

[0089] Table 9 Analysis of Hastelloy grindability index, calorific value and alkali metal content of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com