Diamond milling tooth for pavement longitudinal milling machine

A diamond and milling machine technology, applied in the direction of roads, roads, road repair, etc., can solve the problems of too fast attenuation of anti-skid performance, increase repair cost, delay construction period, etc., to shorten construction period, reduce repair cost, improve The effect of milling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

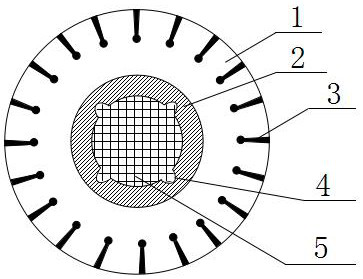

[0021] A diamond milling tooth for a road surface longitudinal milling machine, comprising a wheel shaft 5 and 204 saw blades fixed on the wheel shaft 5 with the same size. The distance between each saw blade is 3mm.

[0022] The saw blade is composed of an inner ring steel sheet 2 and a diamond disc 1, and the outer circular edge of the inner ring steel sheet 2 and the inner circular edge of the diamond disc 1 are bonded by an adhesive.

[0023] The outer diameter of the diamond disc 1 is 300 mm and the thickness is 3 mm; the inner diameter of the inner ring steel sheet is 150 mm and the outer diameter is 200 mm. The outer edge of the diamond disc 1 is provided with grooves I3, and 20 grooves I3 are arranged along the circumference, and each groove I3 is 5mm wide and 40mm deep.

[0024] The wheel shaft 5 is provided with 4 raised lines; the inner circular edge of the inner ring steel sheet 2 is provided with 4 grooves II4 adapted to the raised lines; fixed with the axle.

Embodiment 2

[0026] A diamond milling tooth for a road surface longitudinal milling machine, comprising a wheel shaft 5 and 220 saw blades of the same size fixed on the wheel shaft 5. The distance between each saw blade is 2.5mm.

[0027] The saw blade is composed of an inner ring steel sheet 2 and a diamond disc 1, and the outer circular edge of the inner ring steel sheet 2 and the inner circular edge of the diamond disc 1 are bonded by an adhesive.

[0028] The outer diameter of the diamond disc 1 is 350 mm and the thickness is 2.5 mm; the inner diameter of the inner ring steel sheet is 160 mm and the outer diameter is 220 mm. The outer edge of the diamond disc 1 is provided with grooves I3, and 22 grooves I3 are arranged along the circumference, and each groove I3 is 6mm wide and 45mm deep.

[0029] The wheel shaft 5 is provided with 3 raised lines; the inner circular edge of the inner ring steel sheet 2 is provided with 3 grooves II4 adapted to the raised lines; fixed with the axle. ...

Embodiment 3

[0031] A diamond milling tooth for a road surface longitudinal milling machine, comprising a wheel shaft and a saw blade fixed on the wheel shaft.

[0032] The saw blade has two sizes, both of which are composed of an inner ring steel sheet and a diamond disc.

[0033] The saw blade I has a diameter of 300mm and a thickness of 2.8mm; the saw blade is provided with 20 grooves along the circumference, the groove width is 5mm, and the depth is 45mm; The axle is fixed.

[0034] Saw blade II has a diameter of 330mm and a thickness of 2.8mm; the saw blade is provided with 24 grooves along the circumference, the groove width is 6mm, and the depth is 50mm; fixed.

[0035] The saw blades are arranged in such a way that four small-diameter saw blades I are arranged between every two large-diameter saw blades II, and the distance between the saw blades is 1mm. There are 310 saw blades in total, including 248 saw blades I and 62 saw blades II.

[0036] Compared with the traditional mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com