Patents

Literature

123 results about "Pavement milling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

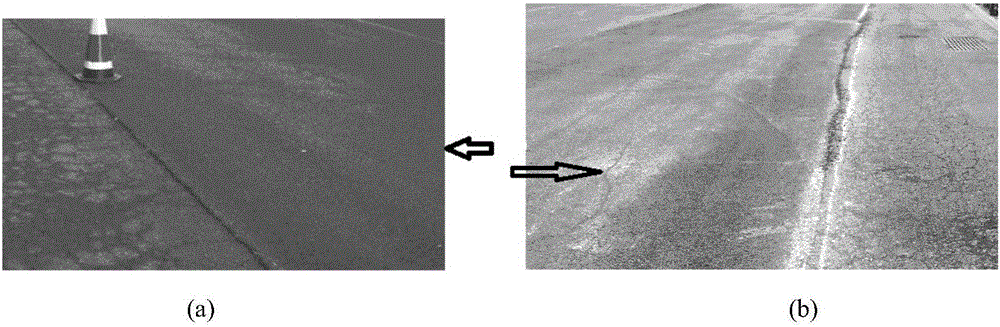

Pavement milling (cold planing, asphalt milling, or profiling) is the process of removing at least part of the surface of a paved area such as a road, bridge, or parking lot. Milling removes anywhere from just enough thickness to level and smooth the surface to a full depth removal. There are a number of different reasons for milling a paved area instead of simply repaving over the existing surface.

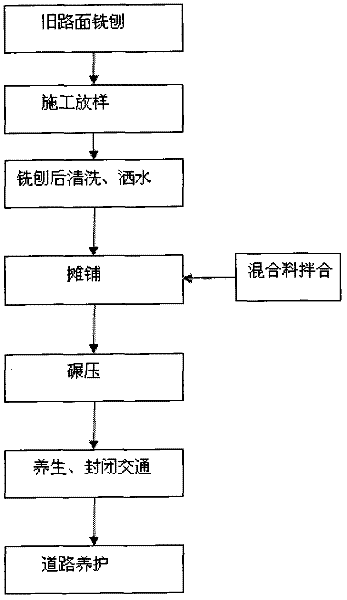

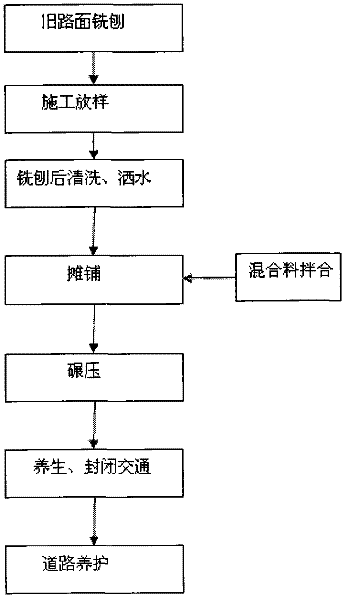

On-site construction method of cold recycling asphalt pavement

InactiveCN102505600AImprove traffic service levelHigh proportion of one-time cold regenerationIn situ pavingsRoads maintainenceEconomic benefitsRoad surface

The invention discloses an on-site construction method of a cold recycling asphalt pavement. The on-site construction method comprises the following process steps: digging out used materials of the asphalt pavement by a pavement milling and planing device; performing continuous circulating crushing and screening on the used materials of the asphalt pavement by a crushing and screening device; placing the crushed and screened used materials of the asphalt pavement into a finished product hopper, mixing emulsified asphalt with water in a proportion of 1: 1, blending with the used materials of the asphalt pavement in the finished product hopper, then adding a mixture of cement and ore powder to form an asphalt mixture; laying the asphalt mixture on a base layer of the pavement in a slow, uniform and continuous way, completing the compaction of a recycling asphalt mixture through three rolling stages, namely initial rolling, re-rolling and final rolling; and standing and curing the rolled base layer of the cold recycling asphalt mixture for 10-14 days. According to the method disclosed by the invention, the proportion of one-time cold recycling is high, the economic benefits are higher, the problem of secondary pollution is avoided, and the method is a green and environment-friendly preparation method.

Owner:JIANGYIN TAIFU ASPHALTUM

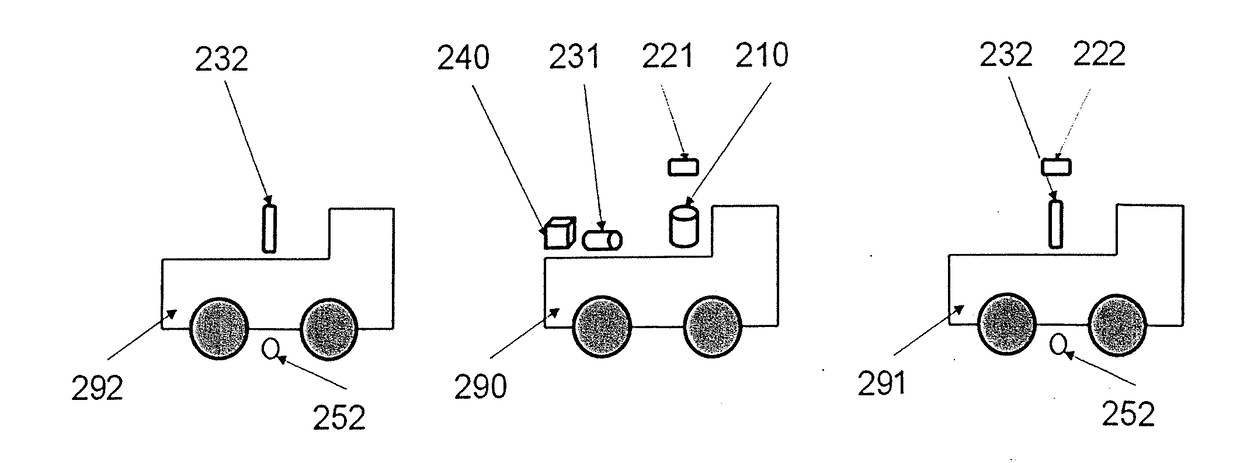

Method of measurement, processing and use of the data of the digital terrain model for objective evaluation of geometric parameters of measured object surfaces of the constructional parts and measuring device for performing the method

ActiveUS20170205534A1Eliminate any disputeAccurately defined and objectively measurable characteristicGeomodellingHeight/levelling measurementHigh elevationTerrain

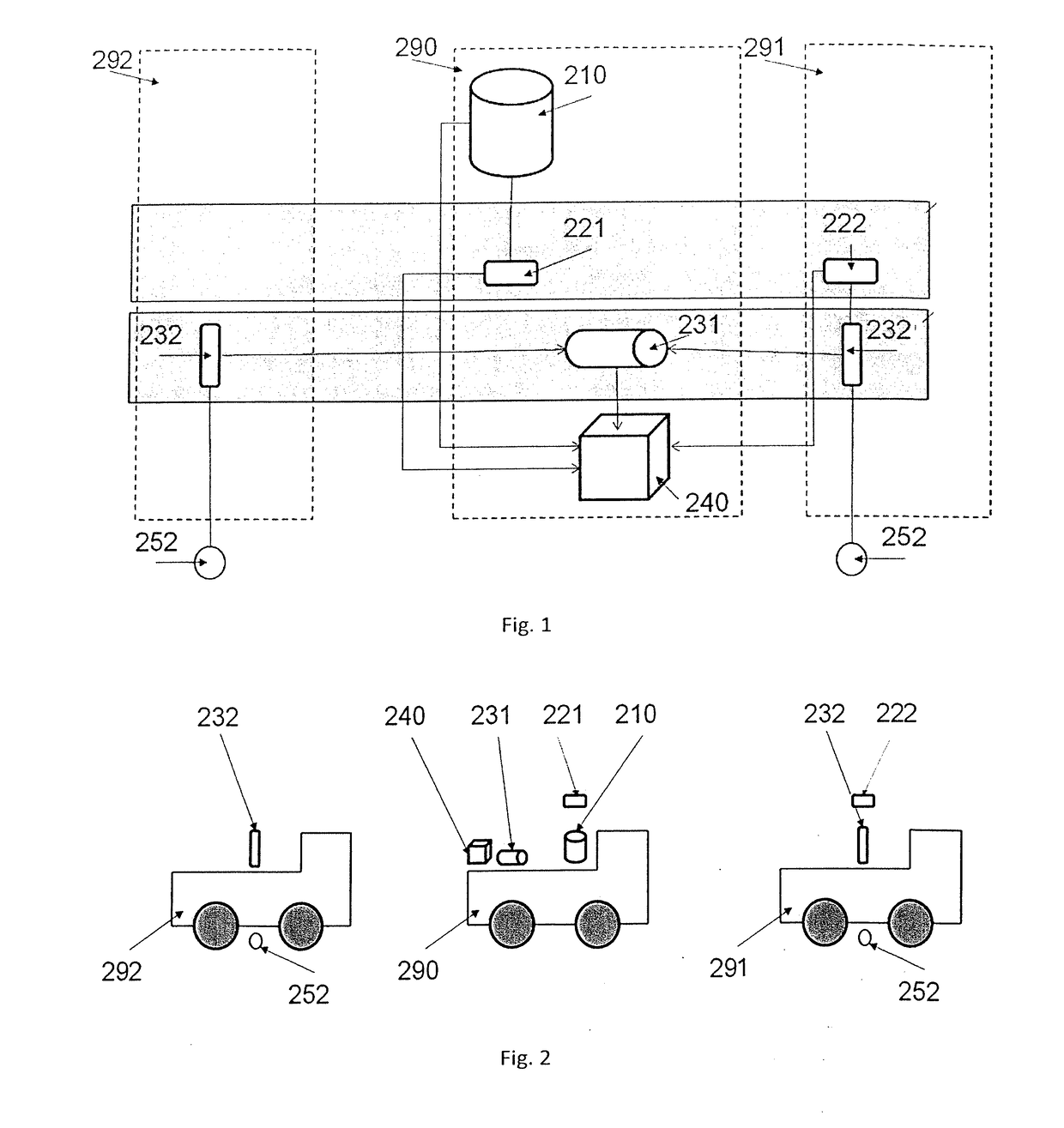

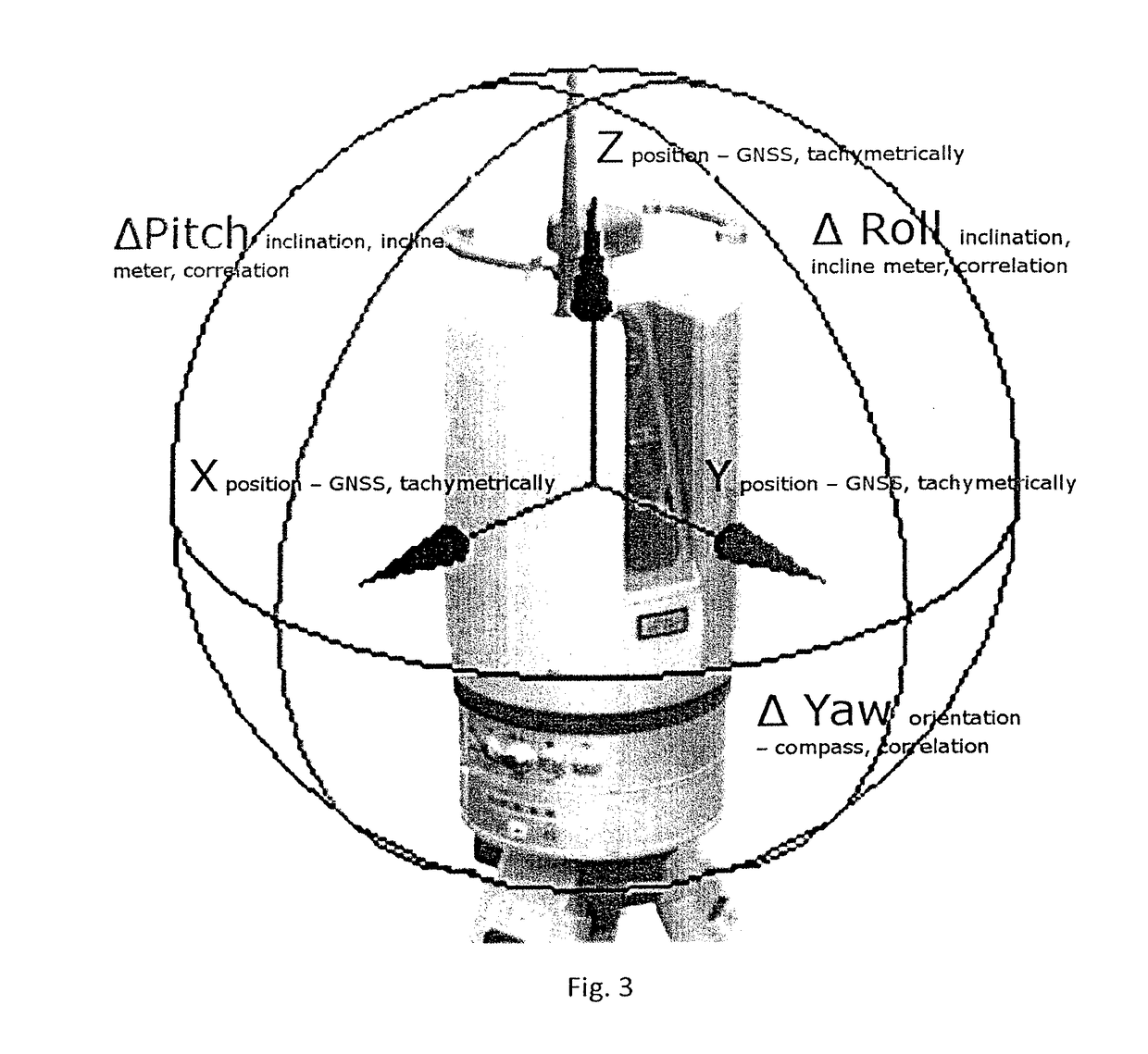

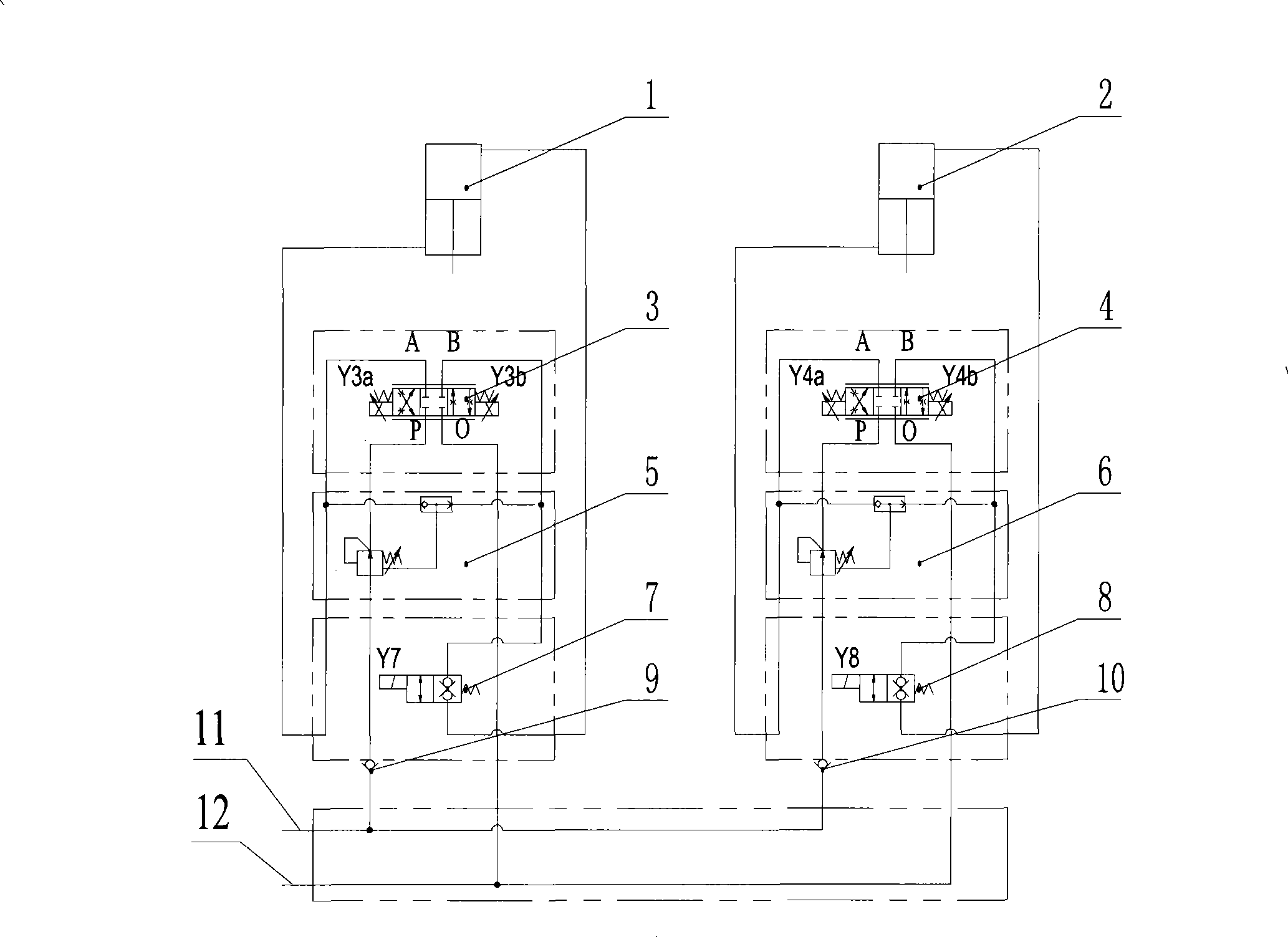

PROBLEM: Efficiently generating digital terrain model (DTM) having high elevation surface accuracy and high point density, and suitable for controlling pavement milling machines during road repairs. SOLUTION: Combination of motorized levelling and Stop-Go mobile laser scanning system, including train of three vehicles, which are at standstill during measurements, and which move in unison in between measurements. Middle vehicle carries laser scanner, elevation sight, and GNSS receiver. Front and rear vehicle each carry levelling rod; front vehicle also carries GNSS receiver. During measurement cycle, laser scanner generates point cloud, while GNSS positions of middle and front vehicles and elevations at the resp. positions of front and rear vehicles are determined. After measurement cycle, vehicle train moves until rear vehicle halts at previous GNSS position of front vehicle, etc. When all measurement cycles are completed, collected data is integrated and transformed into a DTM.

Owner:R O G

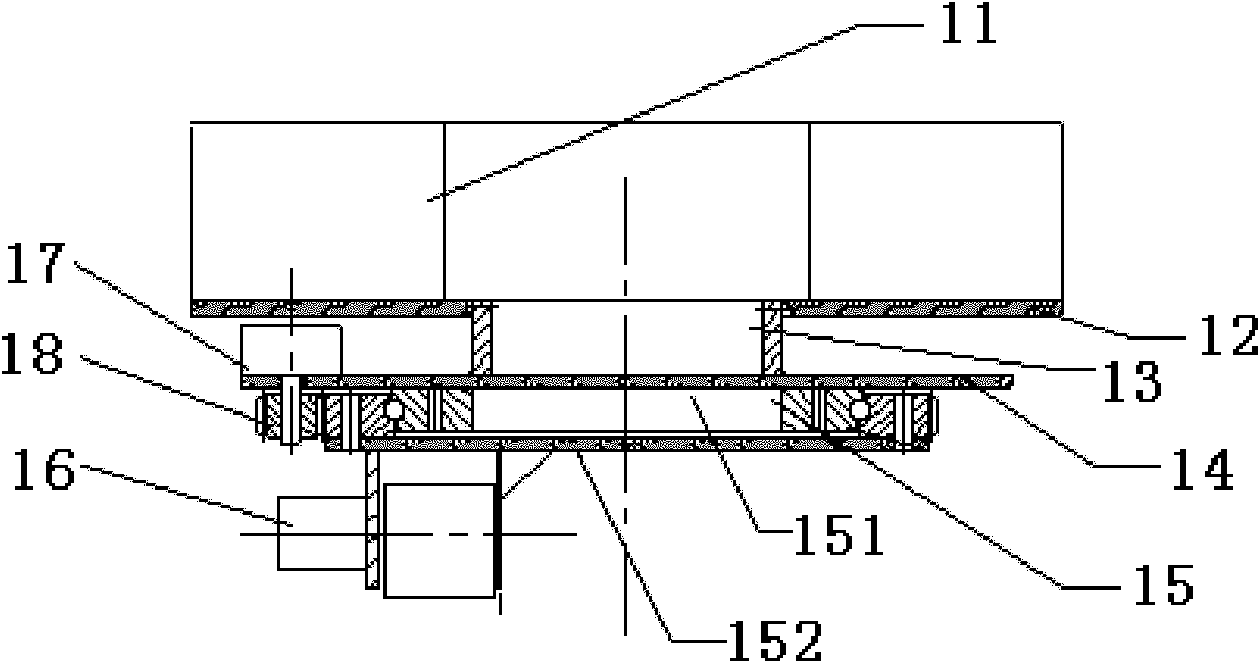

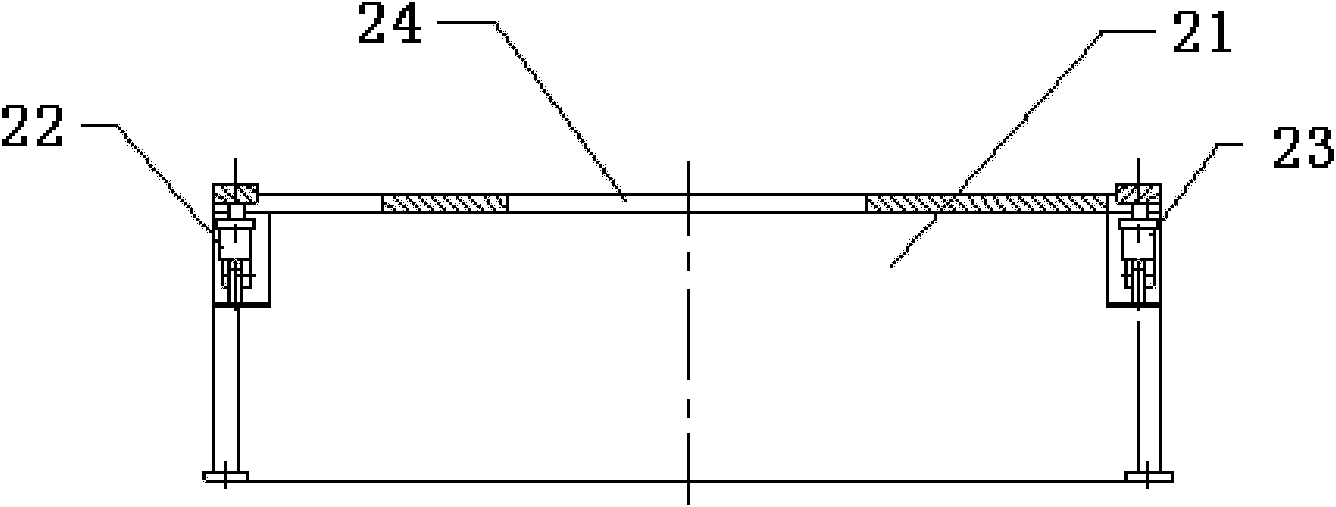

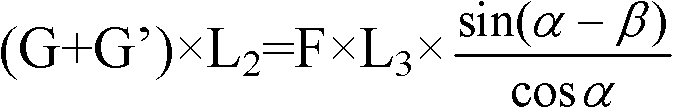

Milling machine outrigger elevator apparatus and pavement milling machine using the same

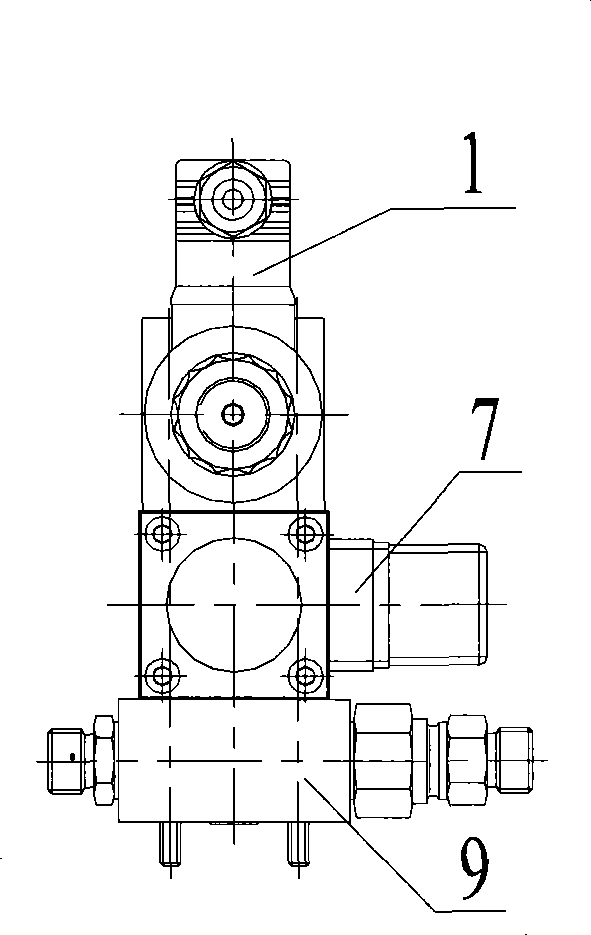

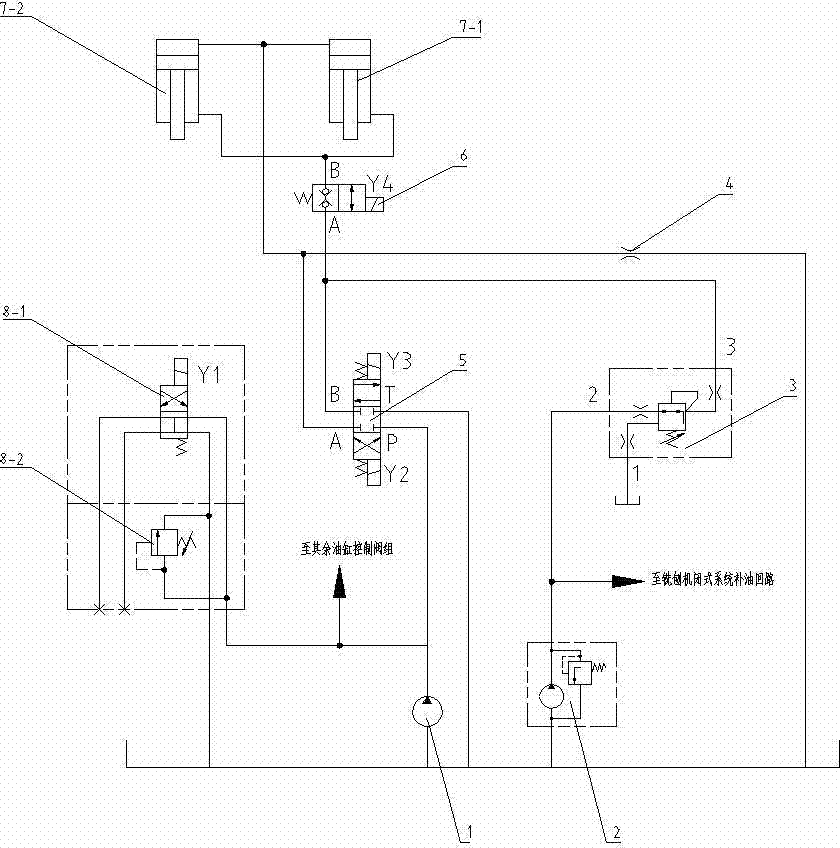

ActiveCN101397770AHigh synchronization accuracyAvoid mutual interferenceRoads maintainenceRoad surfaceProportional valve

The invention discloses a support lifting device of a milling machine, which comprises a left support oil cylinder and a right support oil cylinder. The support lifting device is used for adjusting the heights of a left leg and a right leg by flexible actions of the left support oil cylinder and the right support oil cylinder. The support lifting device also comprises a left proportional and directional valve and a right proportional and directional valve which are communicated with the left support oil cylinder and the right support oil cylinder respectively through oil circuits and used for controlling the speed of the flexible actions of the left support oil cylinder and the right support oil cylinder; and a left pressure compensator and a right pressure compensator, which are also included by the device, and are respectively installed on the oil circuits between the left proportional and directional valve and the left support oil cylinder and between the right proportional and directional valve and the right support oil cylinder and used for stabilizing the pressures of the left support oil cylinder and the right support oil cylinder. The proportional valves can not only reverse the directions, but also can adjust the flow rate, thereby being capable of adjusting the direction and the speed of the flexible actions of the support oil cylinders to realize the infinitely variable control of the lifting speed of the legs with comparatively high synchronous precision; and the pressure compensators can stabilize the pressure of the oil cylinder and eliminate the load difference between the support oil cylinders so as to ensure no interaction in the actions of the two oil cylinders. The invention also discloses a road milling machine using the support lifting device.

Owner:益阳市科技成果转化服务中心 +1

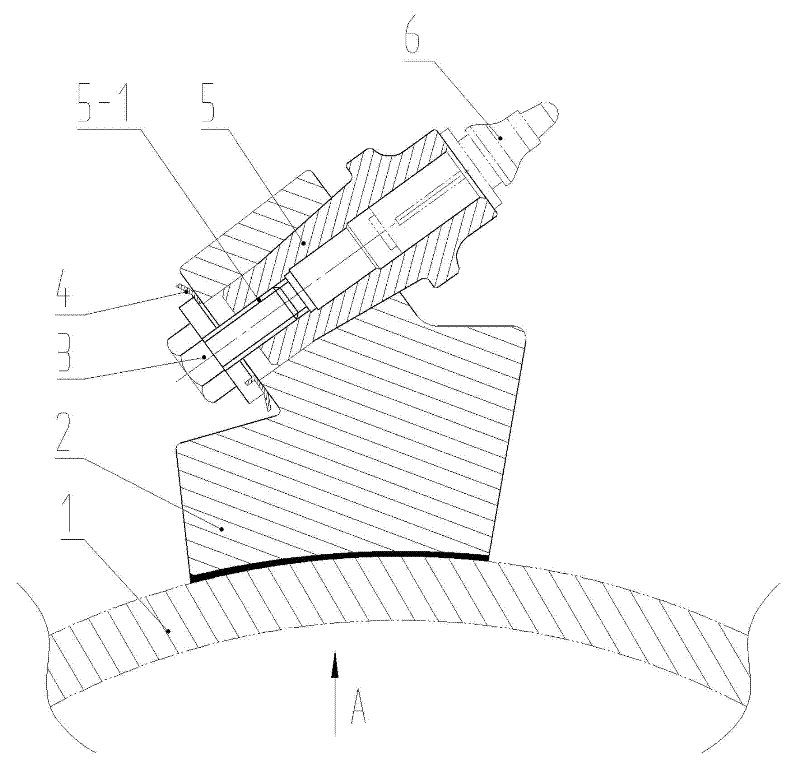

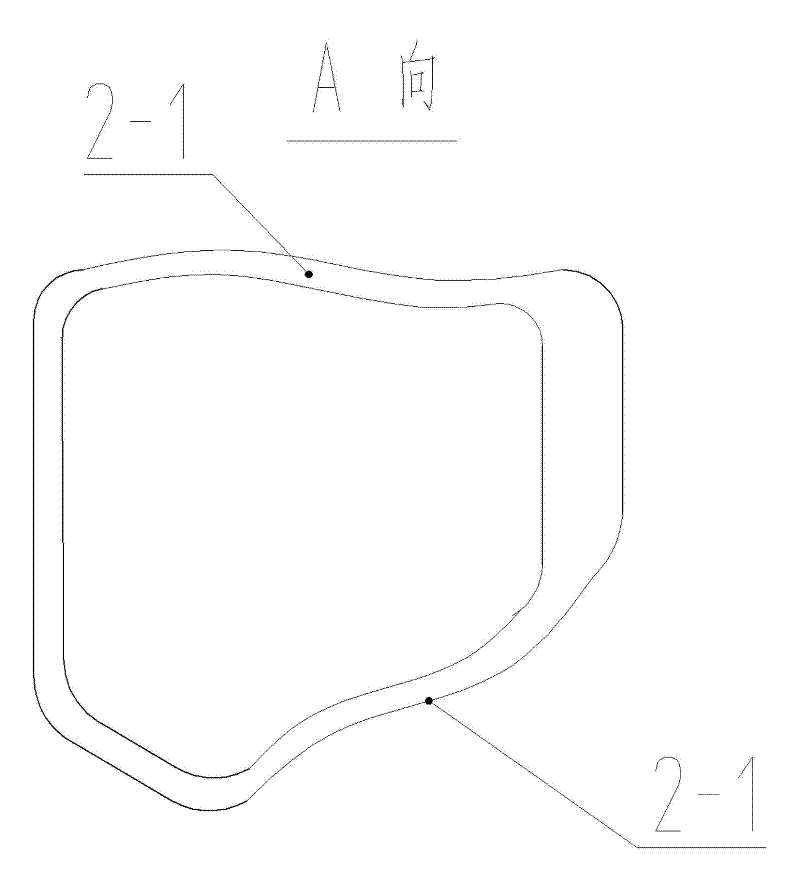

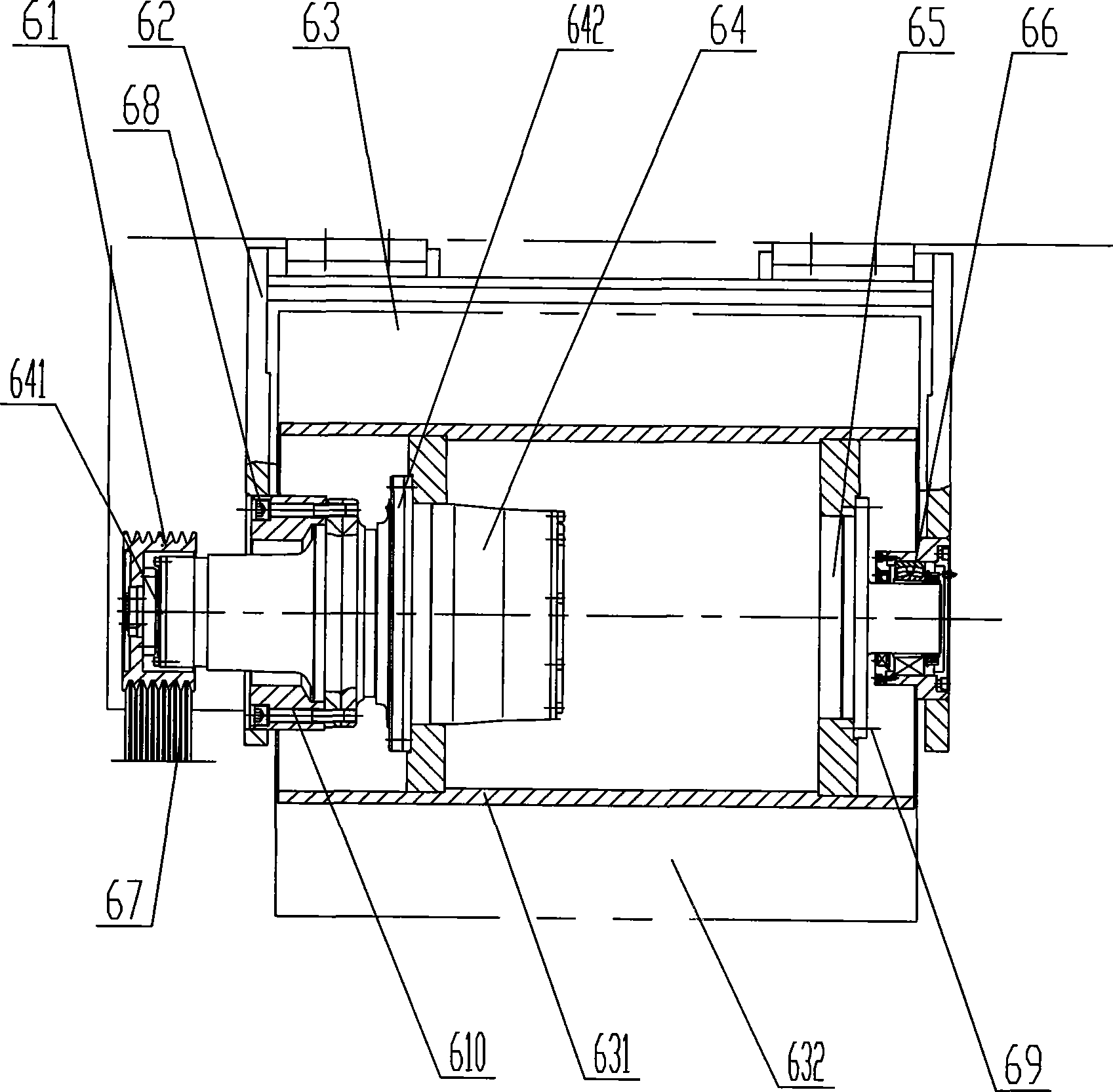

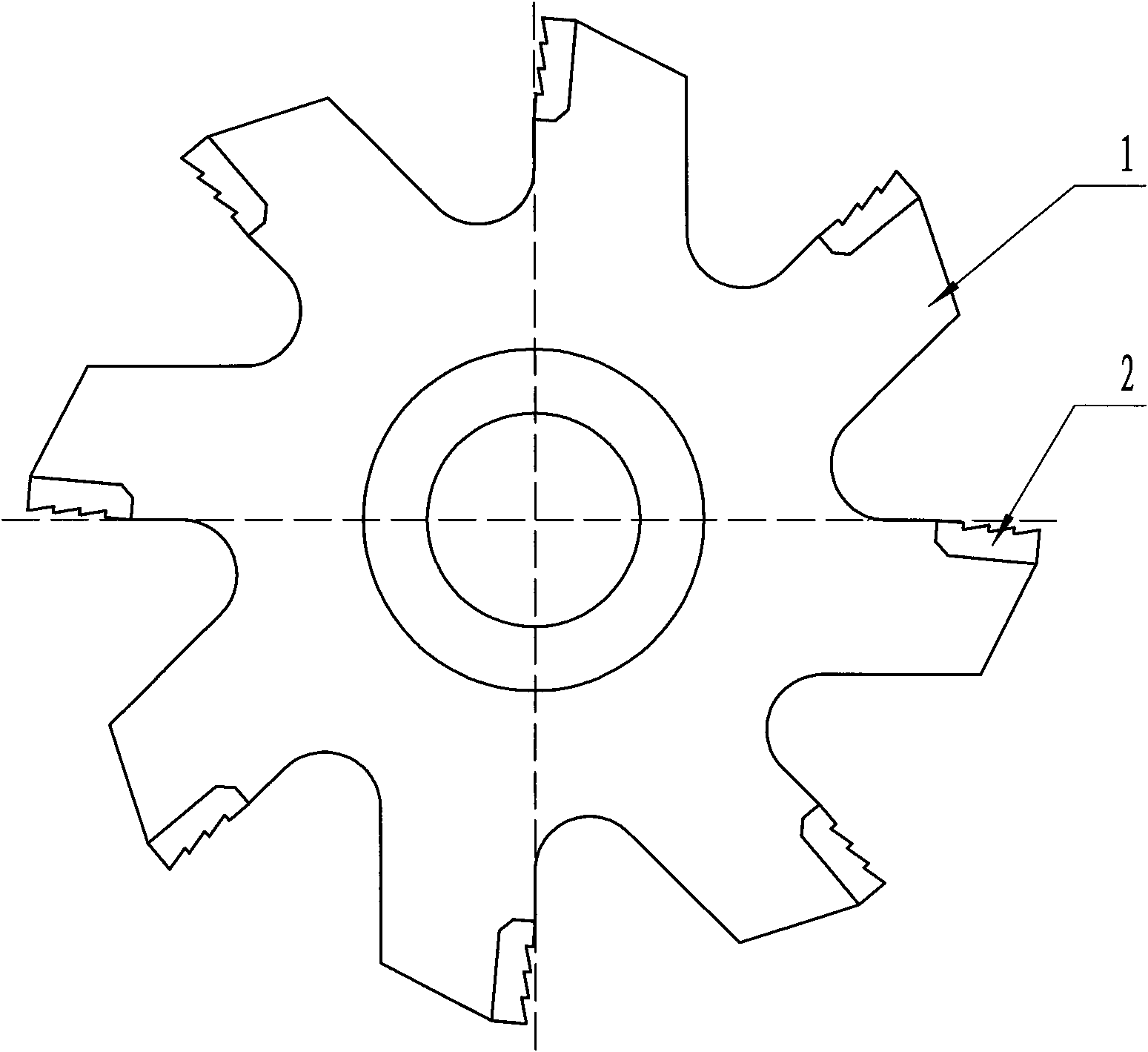

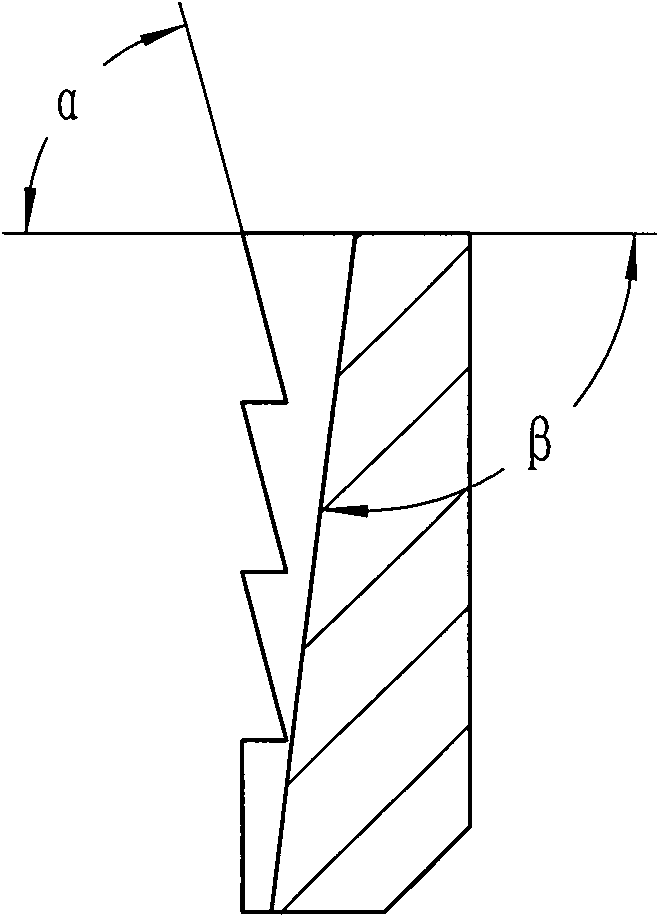

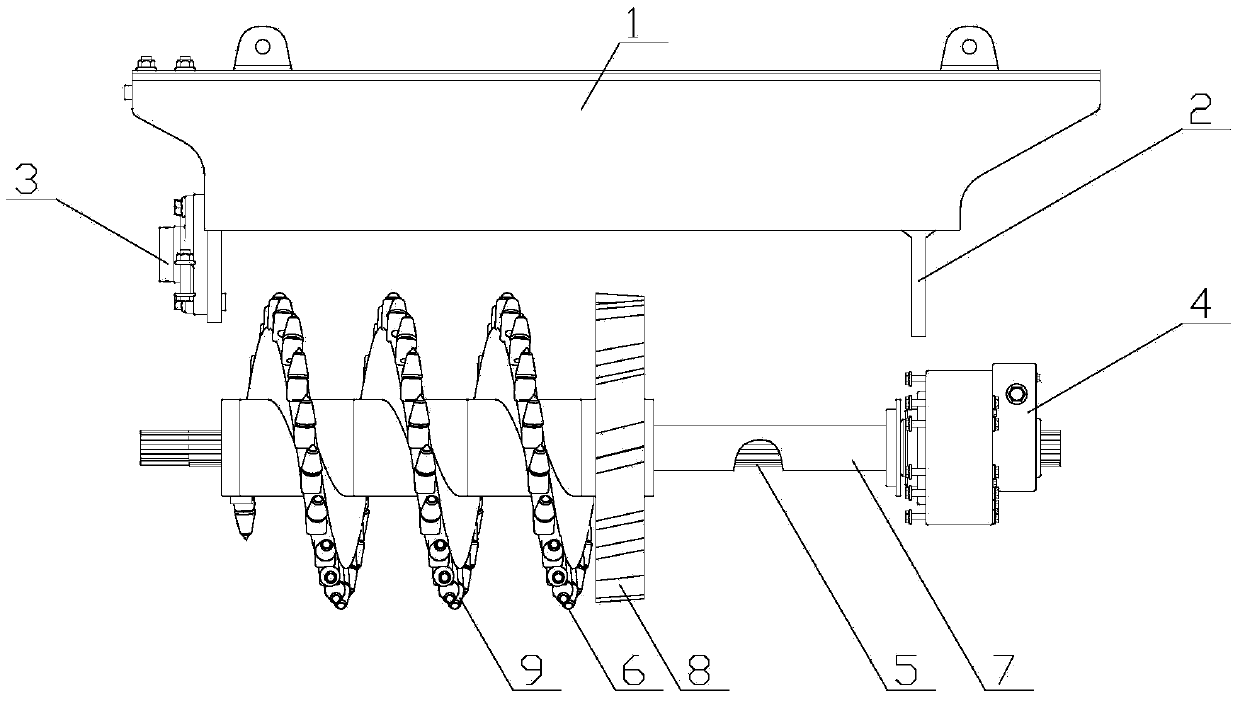

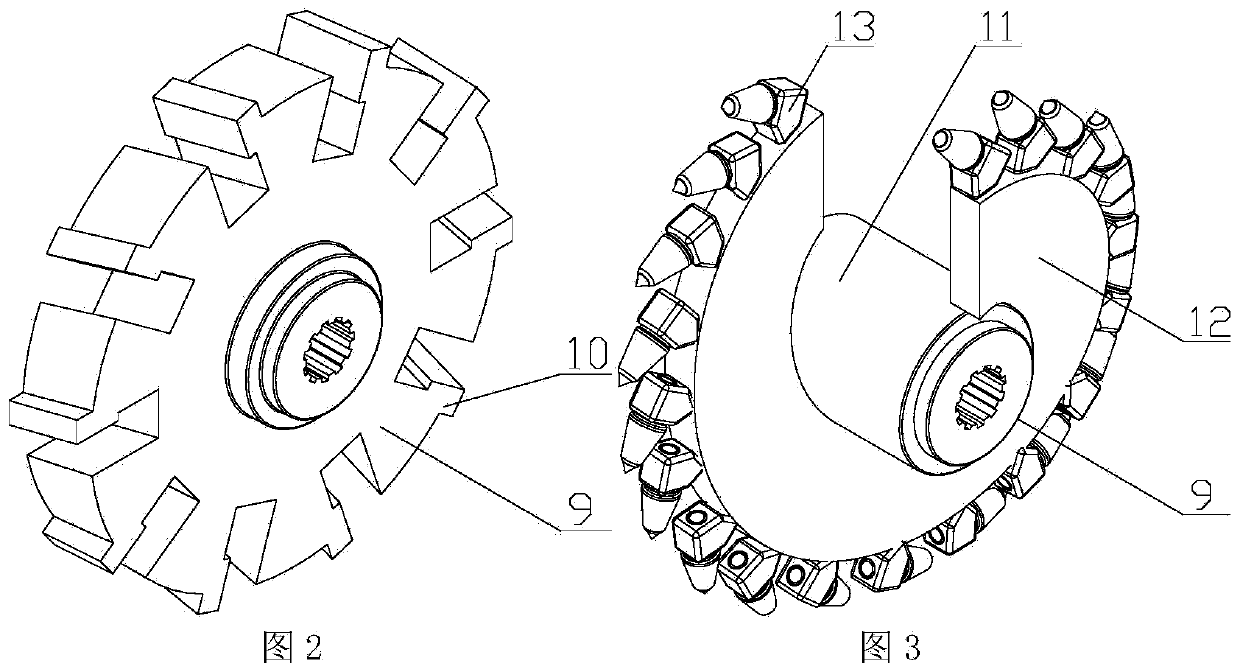

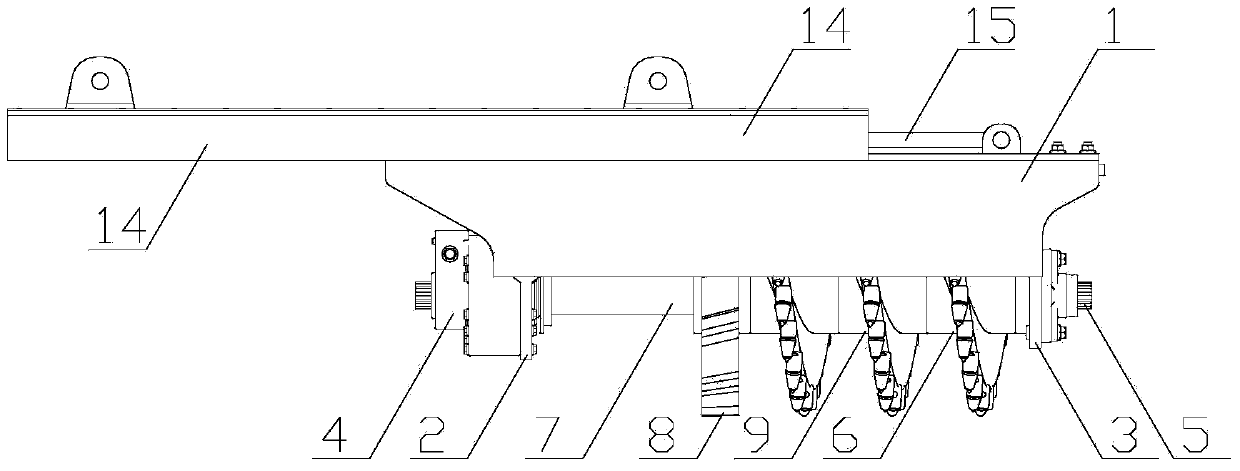

Quick cutter change milling rotor used on a pavement milling machine

The invention discloses a quick cutter change milling rotor used on a pavement milling machine, relating to an engineering machine. The quick cutter change milling rotor comprises a barrel, pedestals, a cutter sheath and a cutter head, wherein the lower part of each pedestal is a pyramid with large upper end and small lower end, the left side face and the right side face of the pyramid are manufactured into spiral faces, the left side faces and the right side faces of a plurality of adjacent pedestal are close to each other to form two groups of auger type spiral blade surface chains with opposite direction of turning, the spiral blade surfaces are flat and smooth and has small resistance, and waste materials are avoided from splashing and falling into troughs after milling. The cutter sheath and the pedestals are connected through conical degree to ensure concentricity and high strength, the cutting edge of the cutter head is maintained on the same spiral line to increase the flatness of the cut pavement, and the service life of the cutter head is prolonged. A threaded hole is arranged at the tail of the cutter sheath, the threaded hole fixes the cutter sheath on the pedestals through lock bolts and lock washers, and unsafe accidents caused by the dropping of the cutter sheath and cutter falling during use are avoided.

Owner:徐州昂拓机械科技有限公司

Low-energy-consumption asphalt concrete pavement hot in-place recycling method

ActiveCN106192700AReduce fuel consumptionGuarantee the construction qualityRoads maintainencePavement maintenanceRoad surface

The invention provides a low-energy-consumption asphalt concrete pavement hot in-place recycling method to solve the problems existing in the pavement heating process of three heating machines in an existing hot in-place recycling technology, and belongs to the technical field of asphalt concrete pavement maintenance. The method includes the steps of pavement sweeping, guide line drawing, pavement heating, pavement milling and planing, regenerant and new asphalt adding, recycled mixture re-stirring and paving, pavement compaction, high-permeability asphalt spraying to seal a recycled pavement and the like. Two heating machines are adopted for heating the pavement in a gradient heating manner, and the phenomenon that the pavement is heated to be too hot under the condition that the temperature of the pavement is high in summer or in South China is avoided; and for a road section aging seriously, after hot recycling construction is finished, the service life of the pavement is prolonged in a high-permeability asphalt spraying manner.

Owner:河北森远路桥工程有限公司

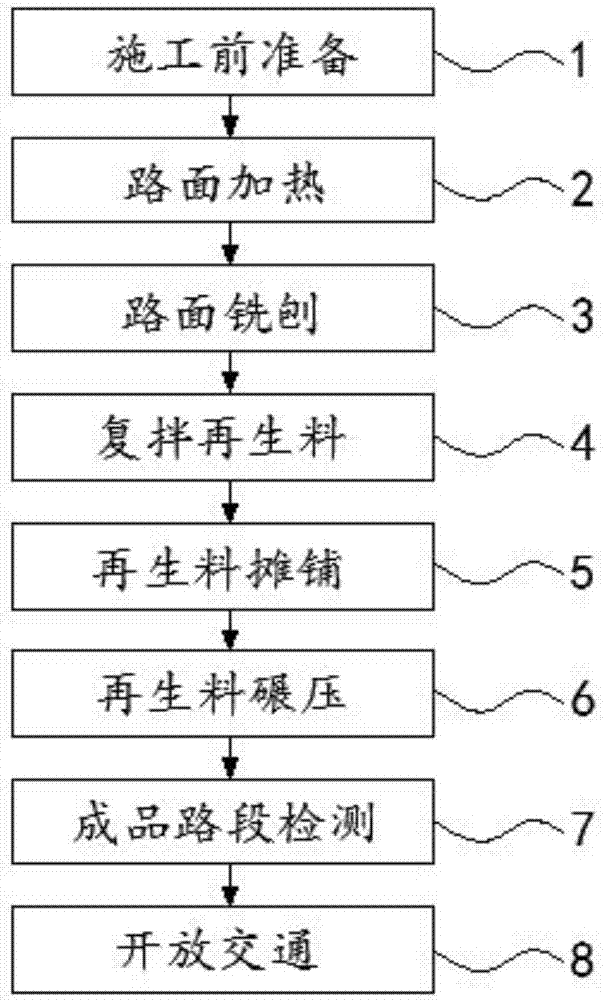

Construction technology of in situ thermal regeneration

InactiveCN107227671AReduce pollutionLow costPaving detailsRoads maintainenceSocial benefitsRoad surface

The invention discloses a construction technology of in situ thermal regeneration. The construction technology comprises the following steps that firstly pre-construction preparation is conducted; then pavement heating is conducted; pavement milling is conducted, and a regenerant and new asphalt are sprayed; reclaimed materials are remixed; paving of the reclaimed materials is conducted; rolling of the reclaimed materials is conducted; then a finished-product road section is detected; and finally traffic is opened. According to the construction technology of in situ thermal regeneration, one-time forming of a new pavement can be achieved, the use ratio of original pavement materials can reach to 100%, and waste is recycled and used; resources are saved, environmental pollution is reduced, and traffic is not closed in the operating process; the economic and social benefits are remarkable, marshalling type combined operation is conducted, the technology of heating, drying and stirring and mixing in the whole process ensures the quality of new and old regenerated mixtures, automated line production of pavement construction is achieved, the maintenance effect is good, and the road condition is good after maintenance is conducted.

Owner:海环科技集团股份有限公司

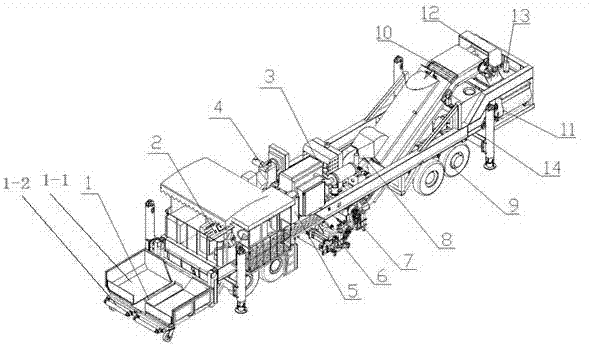

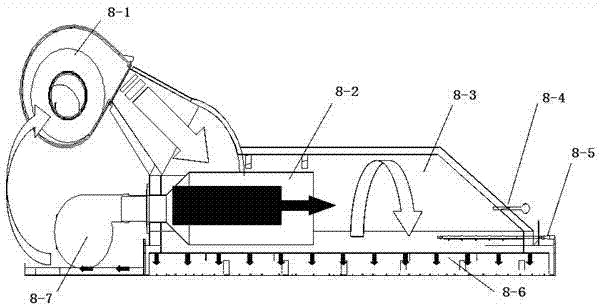

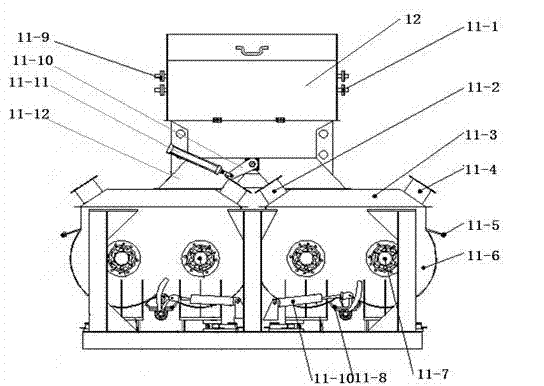

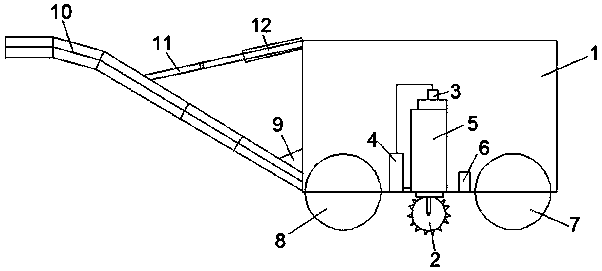

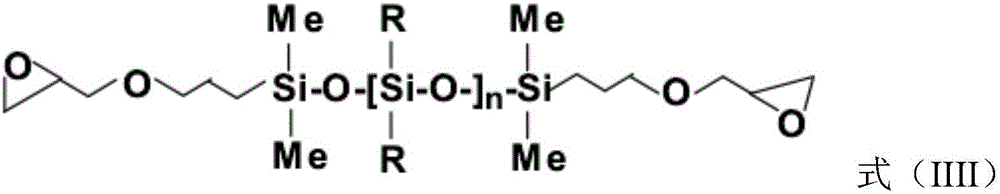

In-place heat regeneration integrated machine for bituminous pavements and control method

ActiveCN104727208AExtend heating timeExtend the mixing timeRoads maintainenceStopped workControl system

The invention provides an in-place heat regeneration integrated machine for bituminous pavements and a control method, wherein the in-place heat regeneration integrated machine for bituminous pavements integrates the functions of pavement milling-planing, bituminous mixture heating, remixing and the like. The regeneration integrated machine comprises a chassis, a milling-planing device, a conveyor, a conveyor heating device, an agitating pan, agitating pan heating devices, and a control system, wherein the conveyor is located behind the milling-planing device, the conveyor heating device is located above the conveyor, the agitating pan heating device is arranged at the top of the agitating pan, and the control system is used for controlling the travelling speed of the chassis, the heating temperature, the mixture metering and the agitating time of the agitating pan. The control method comprises the following steps: starting to accumulate travelling pulses, and if a required travelling distance reaches, switching a material distribution board to the other side; if the material distribution board is overturned, opening an agitating cylinder on the other side, discharging for a period of time, and waiting for the next switching of the material distribution board; and repeating the steps until the machine stops working.

Owner:SHANDONG LUQIAO GROUP

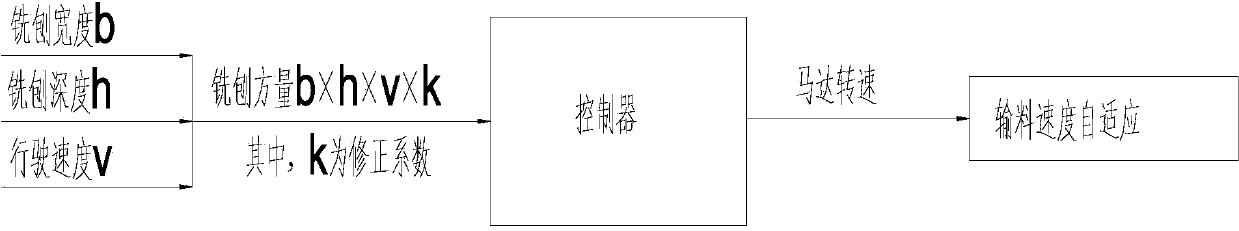

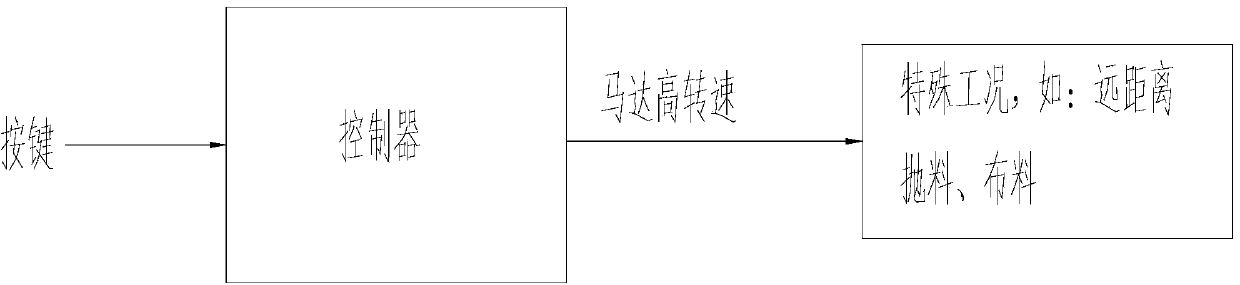

Milling machine and control system thereof

ActiveCN103741575AEasy to operateAccurate calculationRoads maintainenceControl systemControl engineering

The invention provides a control system of a milling machine. The control system is used on the milling machine and comprises a controller and detection devices, wherein the controller is electrically connected with the detection devices; the controller can be used for controlling the running speed of the milling machine; the pavement milling width of the milling machine can be input or selected in the controller; the detection devices comprise a first detection device and a second detection device, wherein the first detection device is used for detecting the milling depth of the milling machine, and the second detection device is used for detecting the running speed of the milling machine; the controller can control the material delivery speed of the milling machine according to the milling material quantity of the milling machine. The control system with the structure can accurately calculate the milling material capacity of the milling machine in real time and can adjust the material delivery speed of the milling machine according to the milling material quantity and enable the delivery speed to be higher when the milling material quantity is larger. On the other side, the invention also provides the milling machine comprising the control system of the milling machine.

Owner:HUNAN SANY ZHONGYI MASCH CO LTD

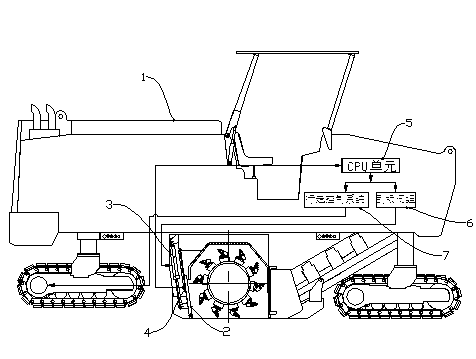

Self-feedback floating scraping system of pavement milling machine

InactiveCN103215883AAppropriate ground pressureGood construction performanceRoads maintainenceTerrainControl system

The invention belongs to the field of pavement engineering machinery, and relates to a self-feedback floating scraping system of a pavement milling machine. The self-feedback floating scraping system comprises a scraping plate and a control system, wherein the scraping plate is arranged on the lower part of a turning body of the pavement milling machine and can lift by being driven by a scraping plate oil cylinder; the control system is used for controlling the lifting of the scraping plate, and comprises a pressure sensor which is arranged on the scraping plate and can detect ground pressure of the scraping plate; the detection signal output end of the pressure sensor is connected to a CPU (Central Processing Unit) capable of processing detection data; and the control instruction output end of the CPU is connected to a scraping plate valve group capable of controlling the action of the scraping plate oil cylinder. The self-feedback floating scraping system disclosed by the invention can keep the appropriate ground pressure all the time for milling in a pulling and scraping operation process by detecting and regulating the ground pressure of the scraping plate in real time, thereby being suitable for the change of pavements with different terrains and improving the construction effect and efficiency.

Owner:ZHENJIANG HUACHEN HUATONG ROAD MASCH CO LTD

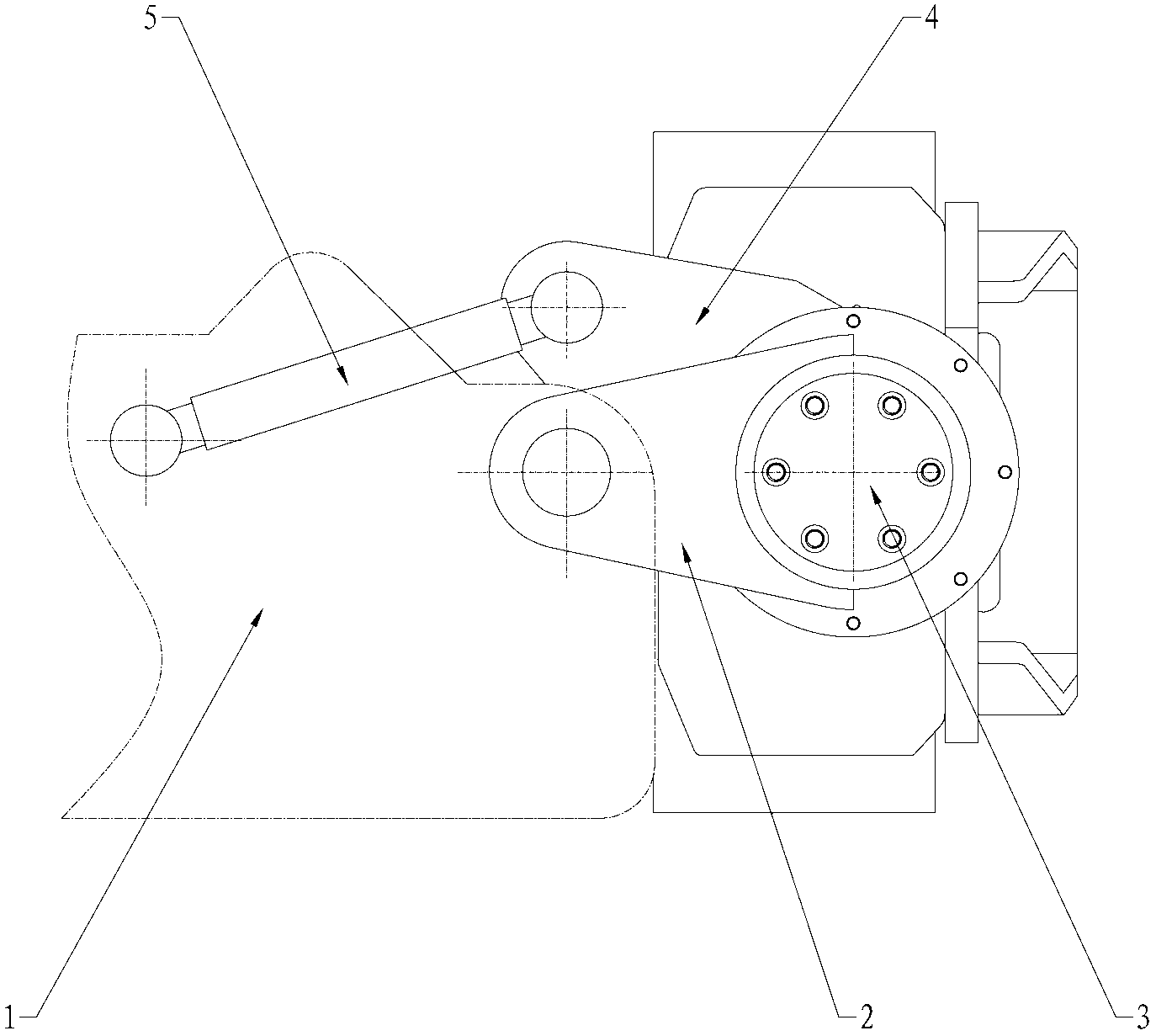

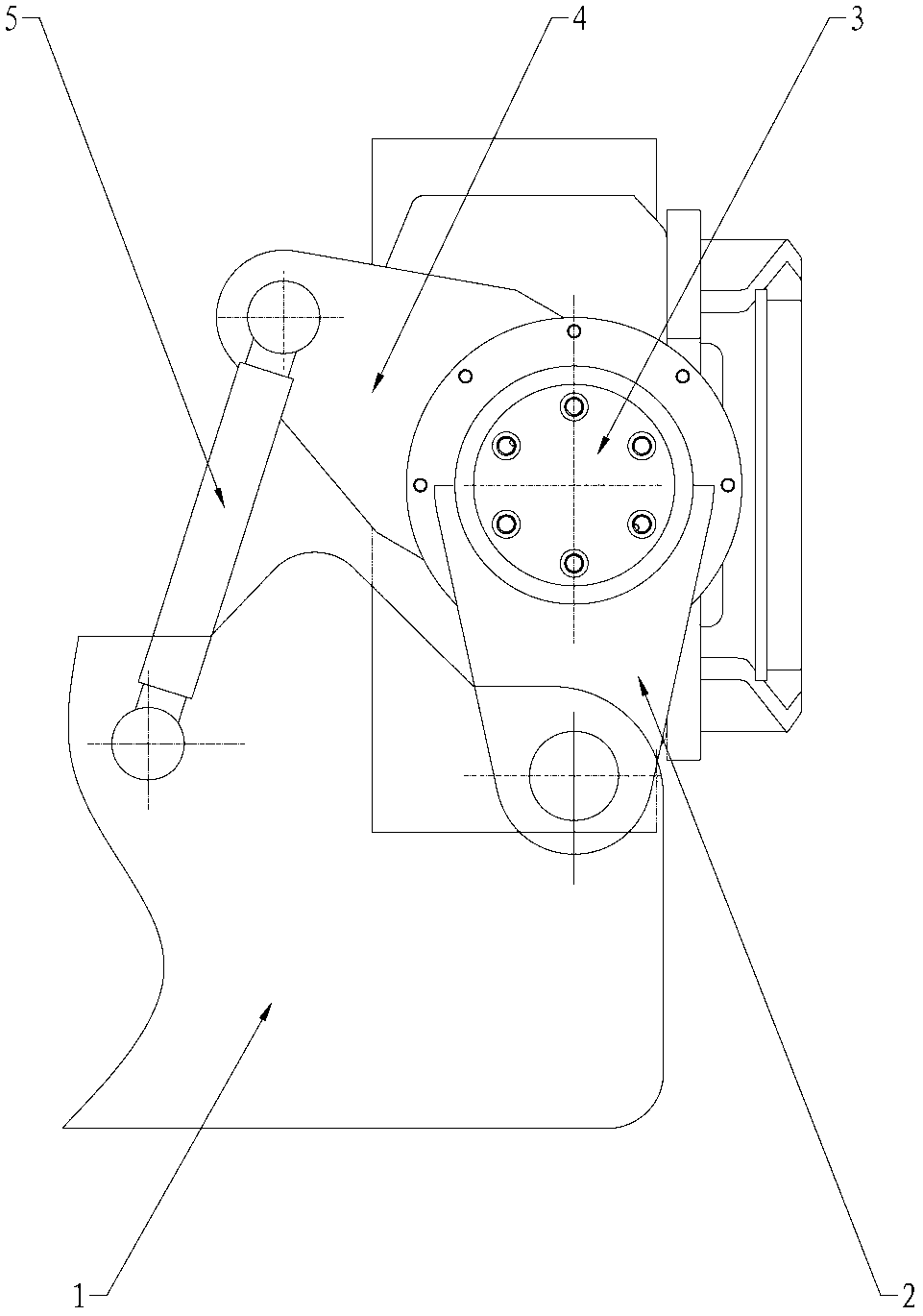

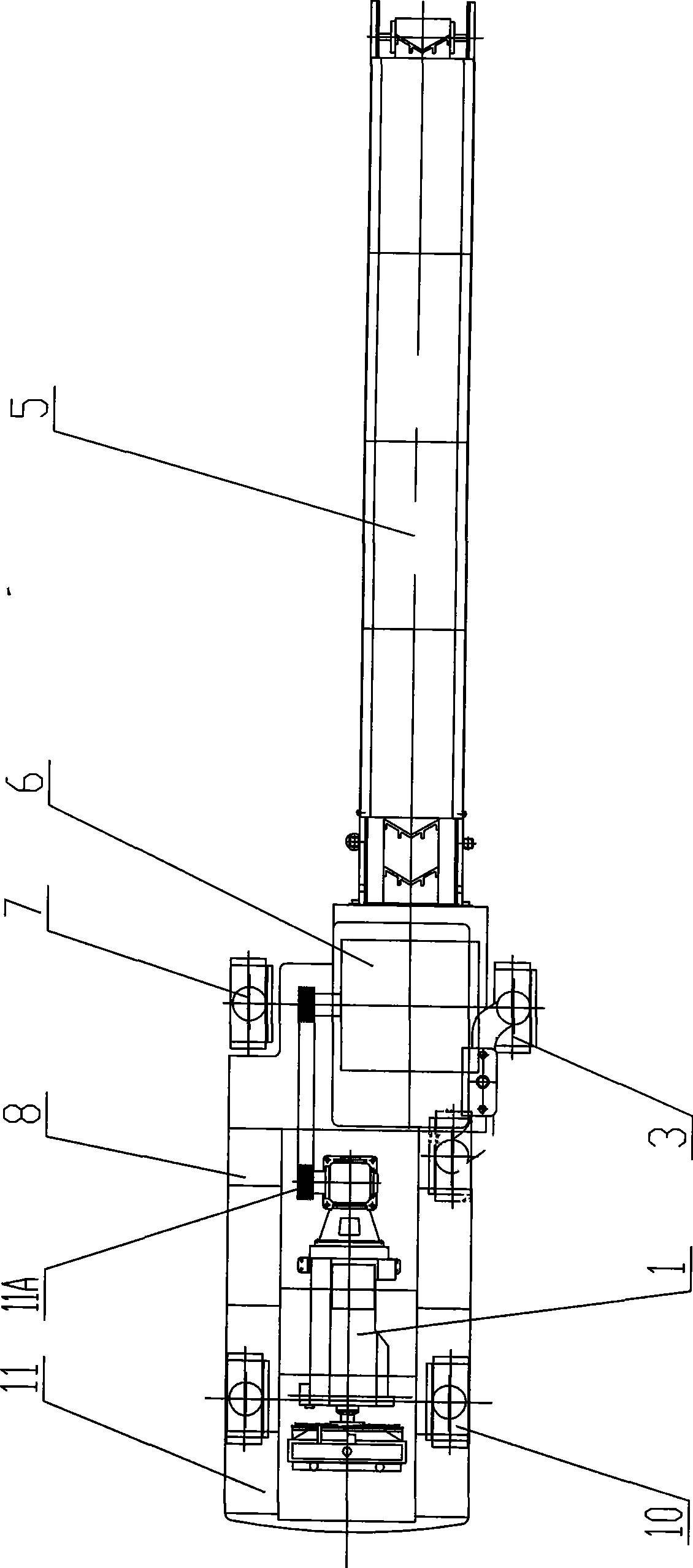

Pavement milling machine and landing leg swinging mechanism thereof

InactiveCN102704385ALarge displacement rangeWon't change directionSteering linkagesRoads maintainencePavement millingHinge point

The invention provides a pavement milling machine and a landing leg swinging mechanism thereof. The landing leg swinging mechanism comprises a double-rocker mechanism consisting of a machine frame, swinging rods, a rotatable sleeve rod, and fixing and connecting rods, wherein the swinging rods and the rotatable sleeve rod are rockers; and the fixing and connecting rods are connecting rods, are rotatably connected with the rotatable sleeve rod by taking landing legs of the pavement milling machine as hinge shafts, and are fixedly connected with the landing legs and are parallel to each other before and after swinging of the double-rocker mechanism. According to the landing leg swinging mechanism, the double-rocker mechanism is adopted, and the landing legs are used as the hinge shafts of the rotatable sleeve rod and the fixing and connecting rods; and due to the adoption of the structure, the fixing and connecting rods are fixedly connected with the landing legs and keep parallel to each before and after swinging, so that the direction of the forward motion of a tire or a tack is not changed, and under the condition that the two kinds of rockers are small in movement range, the landing legs positioned at the hinge points are large in displacement range; and the landing leg swinging mechanism is compact in structure and small in occupied space.

Owner:SANY HEAVY IND CO LTD (CN)

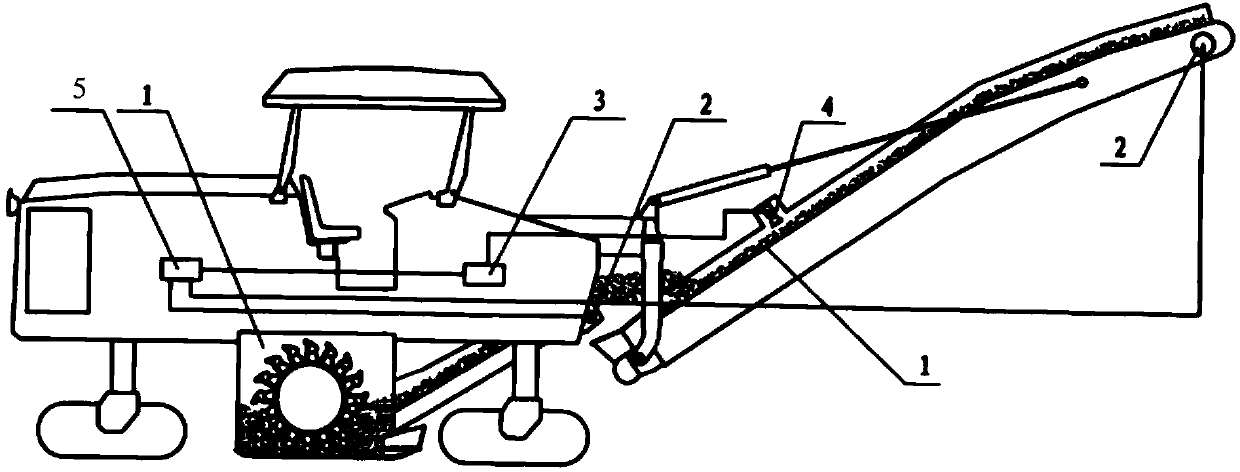

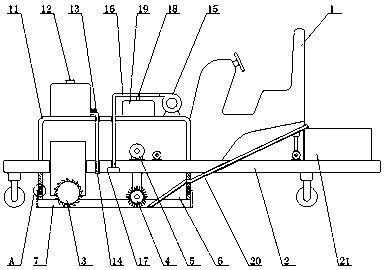

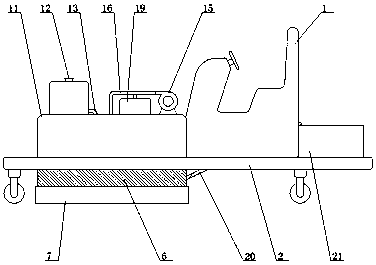

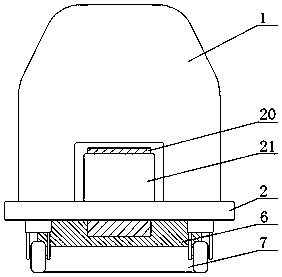

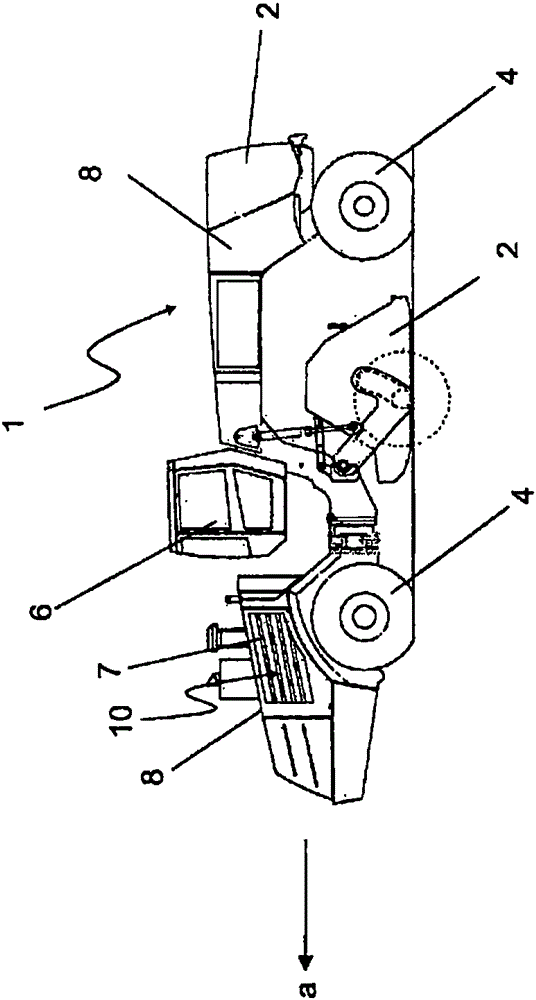

Planing mill for recycling pavement

InactiveCN101509225AImprove work efficiencyReduce labor intensityRoads maintainenceFuel tankEngineering

The invention discloses an anterior recycling pavement milling machine which comprises an engine, a frame, a front wobble wheel, a cab, a single-grade belt conveyer, a working device, a front wheel, a hydraulic oil tank, a water tank, a back steering wheel and a diesel oil tank. The engine is arranged on the frame. Two ends of the frame are supported on the back steering wheel, the front wheel and the front wobble wheel. The hydraulic oil tank and the diesel oil tank are arranged at one side of a machine body. The water tank is arranged under the machine body. The working device is arranged between the front wheel and the front wobble wheel of the machine body. The single-grade belt conveyer is arranged at the front of the working device. The invention changes the back discharge and recycling type of the prior milling machine into anterior discharge and recycling type, a milling tool mills asphalt concrete surface layer adversely to ensure that milled waste material is thrown to a belt of the single-grade belt conveyer from a front discharge opening directly, thereby reducing the material-throwing power loss and the abrasion of the tool. The forward direction of the anterior recycling pavement milling machine is the same as the waste material discharge direction, so that a transporter is not required to back and follow to receive the material, and the work efficiency is improved.

Owner:ZHENJIANG HUACHEN HUATONG ROAD MASCH CO LTD

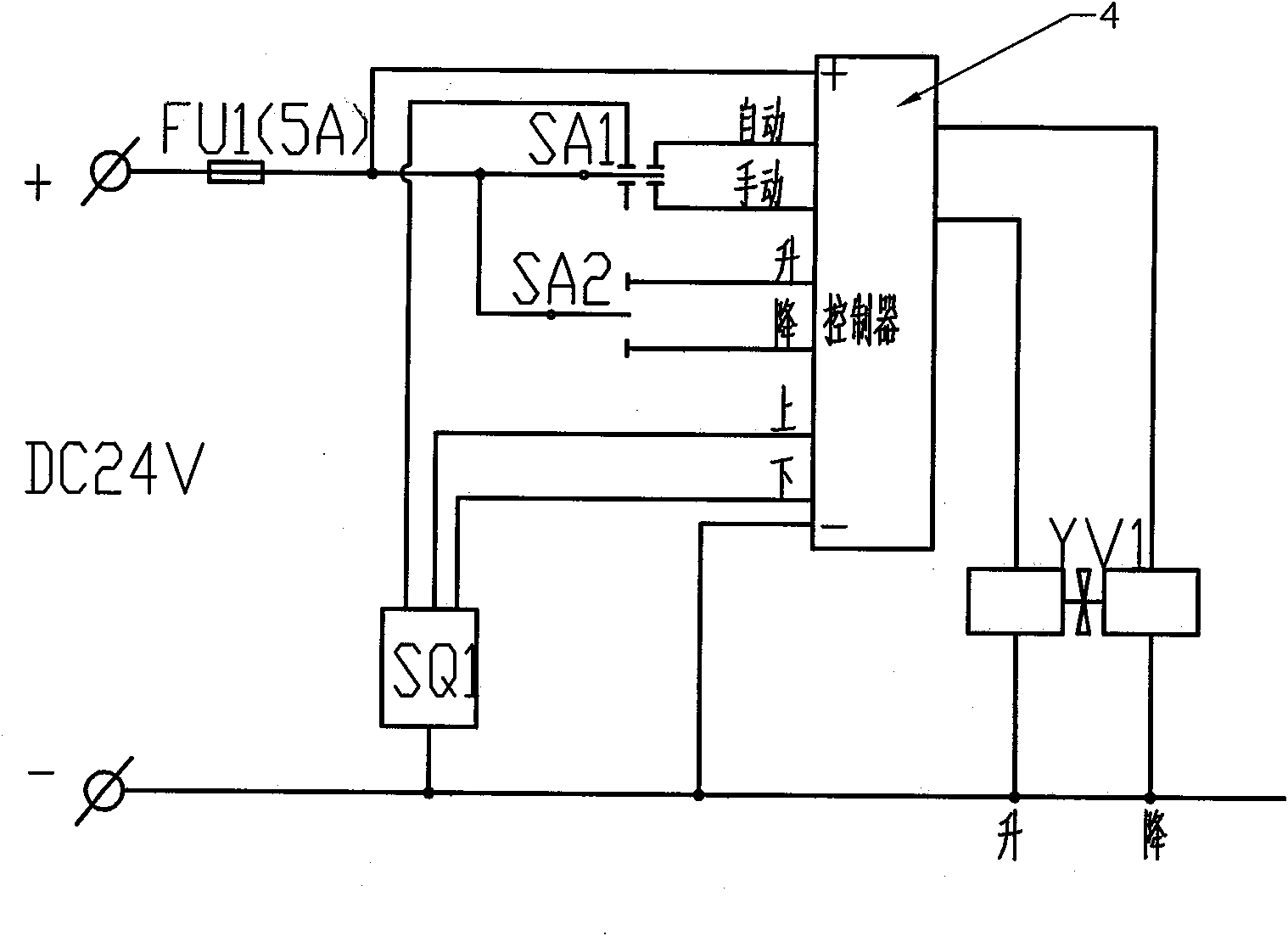

Device for adaptive control of ground clearance of front discharge door of pavement milling machine

InactiveCN101775774AAvoid frictional damageExtended service lifeRoads maintainenceControl without using feedbackAuto regulationHydraulic cylinder

The invention relates to a device for adaptive control of the ground clearance of a front discharge door of a pavement milling machine, which comprises a conveyer bracket connected with the front discharge door of the milling machine, a hydraulic cylinder capable of driving the front discharge door and the conveyer bracket to ascend and descend, and an electromagnetic valve capable of controlling lifting actions of the hydraulic cylinder, wherein the bottom of the conveyer bracket is provided with a position sensor; the device also comprises a controller capable of outputting ascending and descending control commands to the electromagnetic valve; the position sensor can input part of the output ascending or descending control signals to the control signals of the controller; a control signal input part of the controller is also connected with a manual option switch capable of inputting ascending or descending control signals; and the controller is also connected with the position sensor through a state switch. The device can automatically adjust the heights of the front discharge door and a conveyer of the pavement milling machine, and simultaneously has the advantages of high detection accuracy, high use reliability and long service life.

Owner:江苏华通动力重工有限公司(中外合资)

Pavement milling machine with cleaning function

InactiveCN109487671AWith cleaning functionReduce work proceduresDirt cleaningCleaning using toolsPavement maintenancePulp and paper industry

The invention relates to the technical field of pavement maintenance equipment and discloses a pavement milling machine with a cleaning function. The pavement milling machine comprises a body and a rack, wherein a milling component extending to the bottom of the rack is fixedly inserted into the left side of the top of the rack; a rolling brush is rotationally connected to the bottom of the rack and positioned on the right side of the milling component; a motor connected with the rolling brush is fixedly connected to the top of the rack; and a coaming is fixedly connected to the bottom of therack and positioned on the outer side of the milling component and the rolling brush. According to the pavement milling machine with the cleaning function, chippings and dust produced by milling are crowded around by the coaming and a floating plate, the chippings are swept onto a transfer component by the rolling brush and then transferred into a waste tank, air containing lots of dust is dissociated by an exhaust fan, and the dust is filtered in a dust collection box by a filtering net. According to the manner, the pavement milling machine is capable of cleaning and collecting the chippingsand dust during operation, the environment and body health of operators can be protected, the working efficiency is improved, and the machine is convenient to use.

Owner:湖州蓝云建材股份有限公司

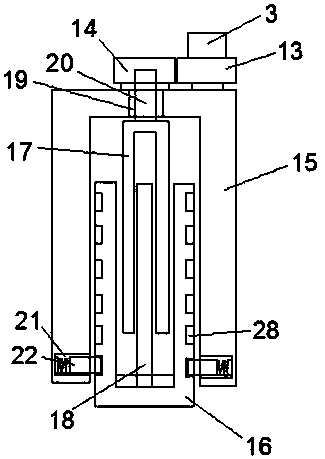

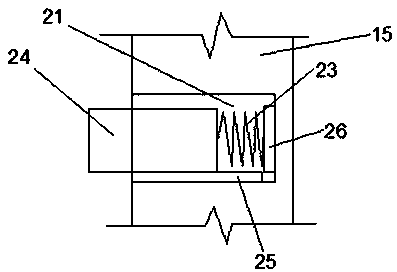

Milling machine capable of adjusting milling depth and using method thereof

ActiveCN107558341ATo achieve the desired effectPrevent rotationRoads maintainenceElectric machineryPulp and paper industry

The invention provides a milling machine capable of adjusting the milling depth. The milling machine comprises a milling machine frame, a milling rotor, an engine, a milling depth control device, a milling depth adjusting device, a walking motor, a front rolling wheel, a rear rolling wheel, a tail door, a recycling belt device, a connecting rod and an oil cylinder. Through the milling depth control device and the milling depth adjusting device of the pavement milling machine, the milling depth of the pavement can be accurately adjusted to achieve the ideal milling effect.

Owner:台州市黄岩裕盛聚酯模具厂

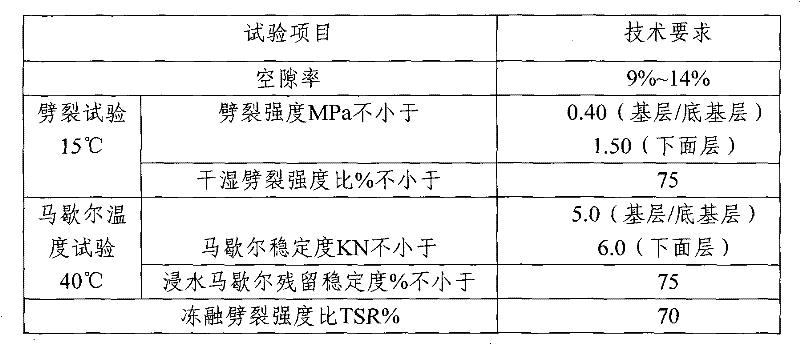

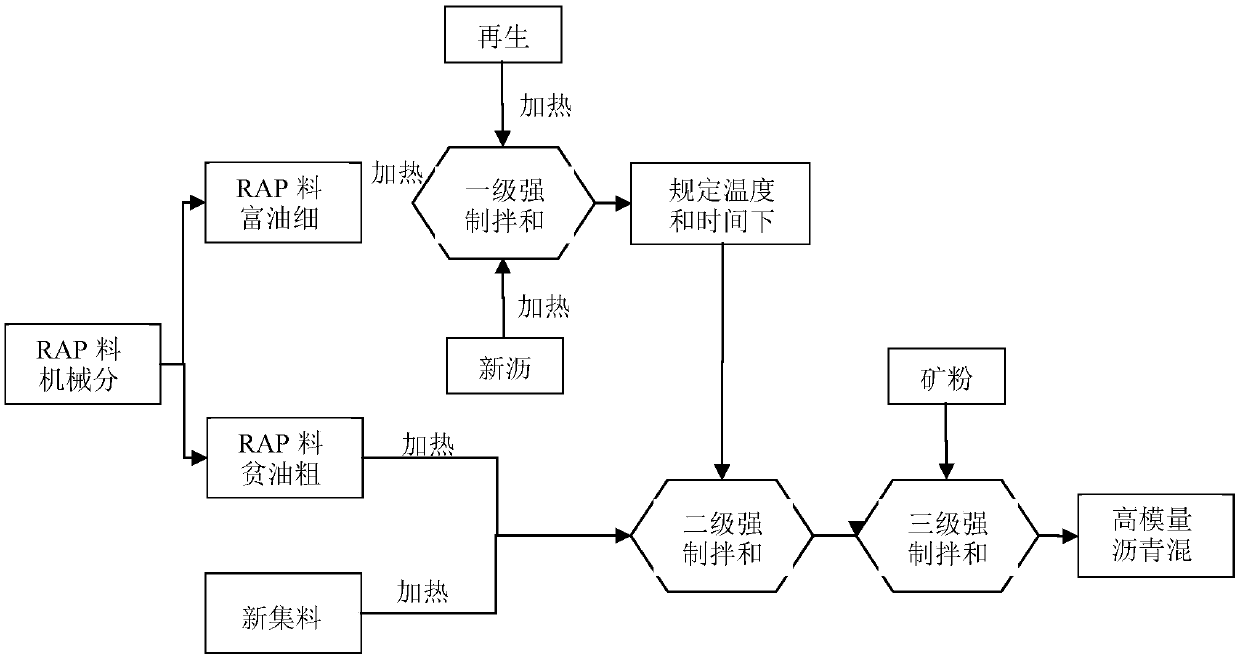

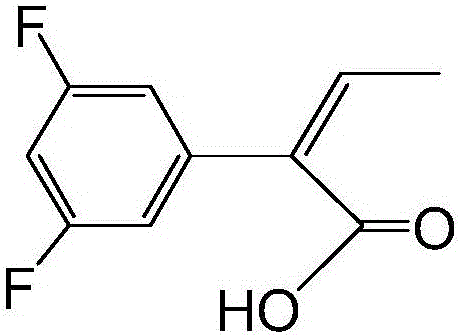

High-modulus asphalt mixture based on old pavement milling material, and preparation method thereof

The present invention discloses a high-modulus asphalt mixture based on an old pavement milling material, and a preparation method thereof, and belongs to the technical field of road engineering, wherein the high-modulus asphalt mixture comprises the following raw materials by mass: 35-75% of the lean oil coarse component (particle size of greater than 4.75 mm) in an old pavement milling material,25-65% of the rich oil fine component (particle size of less than 4.75 mm) in an old pavement milling material, 0.1-2% of a modification regeneration agent, 0-20% of new aggregate, 0-3% of ore powder, and 0-3% of new asphalt. According to the present invention, the high-modulus asphalt mixture prepared through the method has advantages of high modulus, excellent mechanical property, good anti-rutting ability, good durability and good water stability; the 100% recycling of the lean oil coarse aggregate in the old asphalt pavement milling material and the 100% resource utilization of the rich oil fine aggregate are achieved, and the potential value of the old asphalt pavement milling material is completely provided; and the super-long service life, the safe driving and the economy of the pavement are achieved.

Owner:江苏天诺环境工程技术开发有限公司

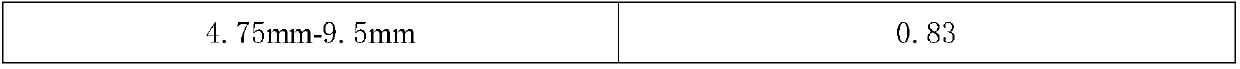

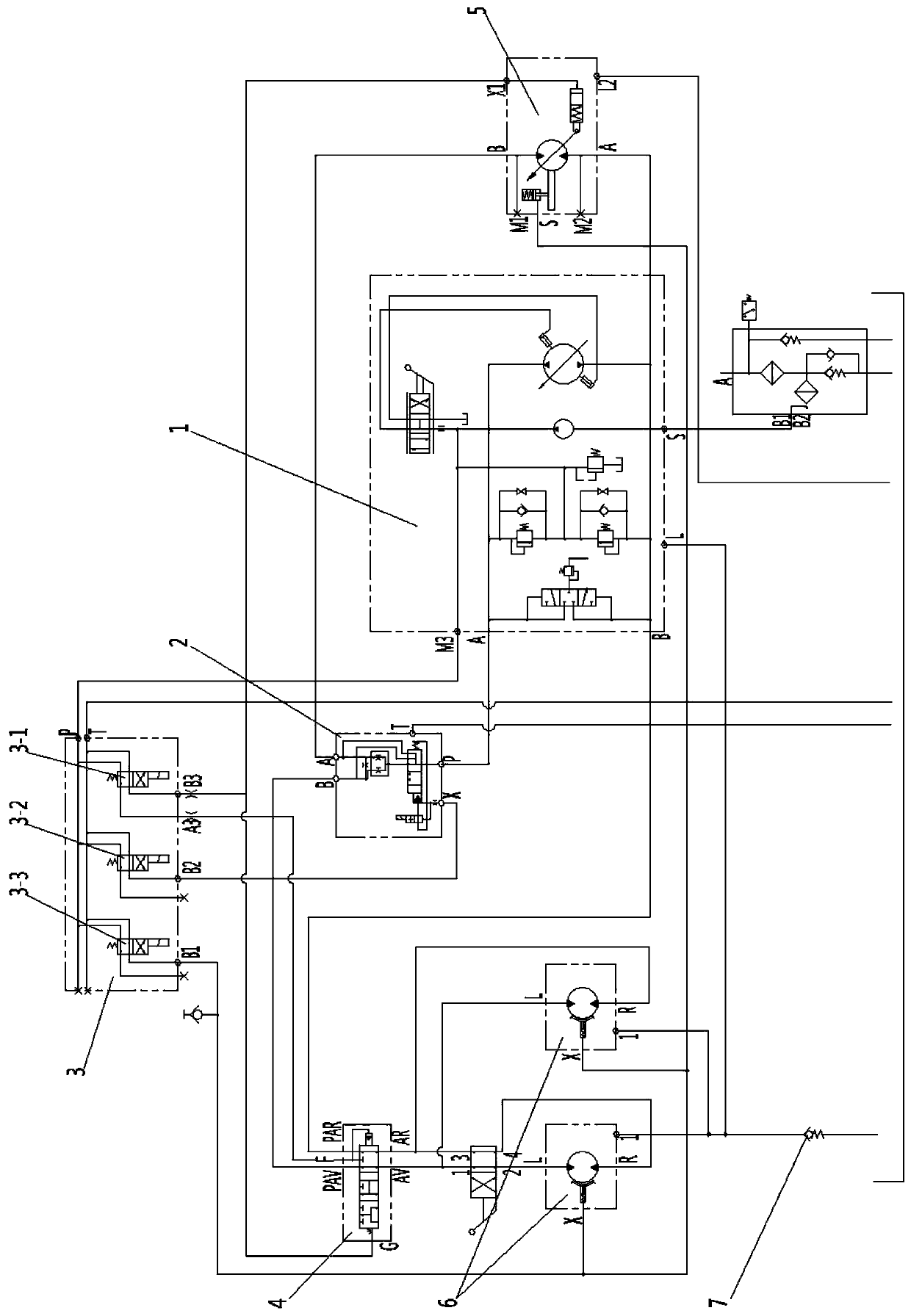

Small-sized pavement milling machine traveling control system

The invention relates to a traveling control system, in particular to a traveling control system which is particularly applicable to a small-sized pavement milling machine, and belongs to the field of an electric-hydraulic control system of a traveling machine. The small-sized pavement milling machine traveling control system comprises a traveling pump, a diverting valve, a control valve blank, a high-speed motor and two low-speed motors, wherein the traveling pump conveys the hydraulic oil respectively to the low-speed motors and the high-speed motor in parallel connection through the diverting valve, and then the hydraulic oil is returned to the traveling pump to form a closed loop. The small-sized pavement milling machine traveling control system is characterized in that by adopting the parallel connection way of the high-speed motor and the two low-speed motors, a rear wheel does not need to be connected with a reducer, so that the axial size of the rear wheel is reduced, the entire design is optimized, the swinging of the rear wheel is not influenced, and the rear wheel is more applicable to the small-sized pavement milling machine; meanwhile, the sufficient driving force also can be guaranteed, and the milling requirement of the milling machine can be met.

Owner:XUZHOU XUGONG ROAD CONSTR MACHINERY

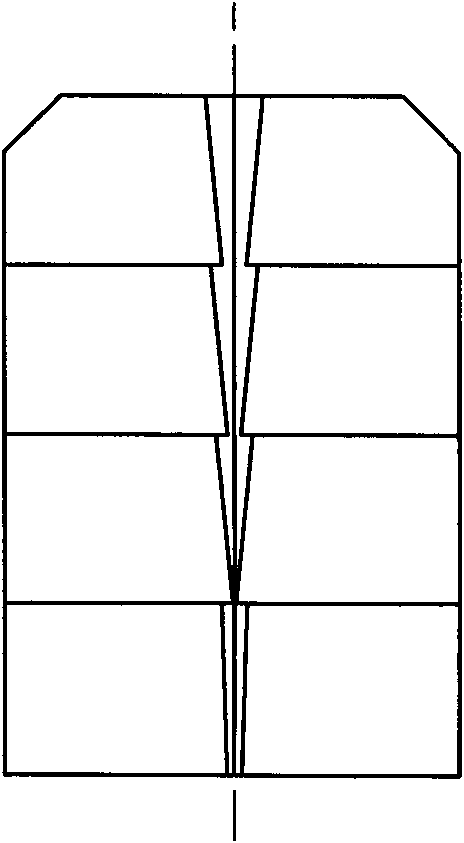

Blade for bituminous pavement milling machine and grooving machine

The invention provides a blade for a bituminous pavement milling machine and a grooving machine. A tool bit is arranged at the front end of a cutter body; 45-degree chamfers are manufactured at the rear end of the root of the tool bit and on both sides of the front end face of the tool bit; the tool bit is that: an integrally connected sawtooth-shaped cutting edge is arranged in the radial direction of the front cutting face of the tool bit; and a cutting edge division groove is formed on the central line of the front cutting face of the tool bit. By using the blade, the cutting edge of the tool bit is very sharp, so the area of the cutting edge is increased and a cutting resistance is reduced; in the process of milling or grooving, even the tip of the first helical-form cutting edge at the head is damaged, the other helical-form cutting edges and straight-tooth cutting edges still have strong cutting forces; and the middle cutting edge division groove allows the cut-down bituminous concrete to be easily drained. The blade for the bituminous pavement milling machine and the grooving machine has a rational design and high working efficiency, can be used for milling and grooving, and can be used on the milling machine.

Owner:HENAN LUDA HIGHWAY TRANSPORTATION TECH CO LTD

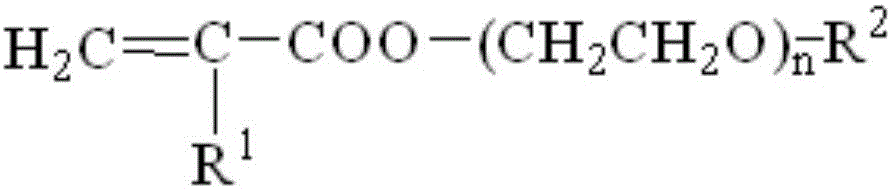

Cold-recycling asphalt mixture

InactiveCN105461258AImprove performanceImprove recycling ratesSolid waste managementAluminium chlorideFiber

The invention discloses a cold-recycling asphalt mixture, which is composed of the following ingredients (by weight): 75-95 parts of a waste asphalt mixture, 1-5 parts of gutter oil, 2-4 parts of diesel oil, 0.3-0.6 part of slaked lime, 0.5-1 part of lignin fiber, 2-3 parts of aluminium chloride, 3-5 parts of fly ash, 0.5-1 part of benzophenone, 0.2-0.3 part of p-toluenesulfonic acid and 0.3-0.6 part of aniline. By the use of a formula-improved cold-recycling mixture, a cold-recycling mixture having improved performance is obtained. A pavement milling material of the in-place cold-recycling mixture has high recycling rate and good construction performance. High-temperature stability and water stability of the in-place cold-recycling pavement are obviously enhanced. The technological flow is simplified. There is no need to consume fuel, and no exhaust gas is discharged. Thus, real cold-recycling of asphalt is realized, and mixture is beneficial to ''energy conservation and emission reduction'' and environmental protection.

Owner:SOUTHEAST UNIV

Pavement milling machine

The invention discloses a pavement milling machine which comprises an upper milling machine body and a lower milling machine body, wherein the upper milling machine body comprises a fixed plate, a hydraulic driving and rotating system is fixed at one end of the fixed plate, a guiding device is arranged at the upper end of the fixed plate, a mechanical rotating system is arranged at the lower end of the fixed plate, a supporting plate is arranged at the upper end of the guiding device, a hydraulic power system is arranged at the upper end of the supporting plate and is matched with the mechanical rotating system through a gear, a hydraulic milling system is matched at the lower end of the mechanical rotating system, the lower milling machine body comprises a support body and a hydraulic lifting device, and the support body is also provided with a guiding hole matched with the guiding device. The pavement milling machine is in a split structure, reduces the complexity of mechanical and hydraulic driving, has a simple structure and low cost, is convenient to install and use, and has a better application prospect in using environments with complex working conditions such as a circular pavement around a milling well cover, a linear pavement of a road shoulder, a slope pavement and the like.

Owner:曹振华

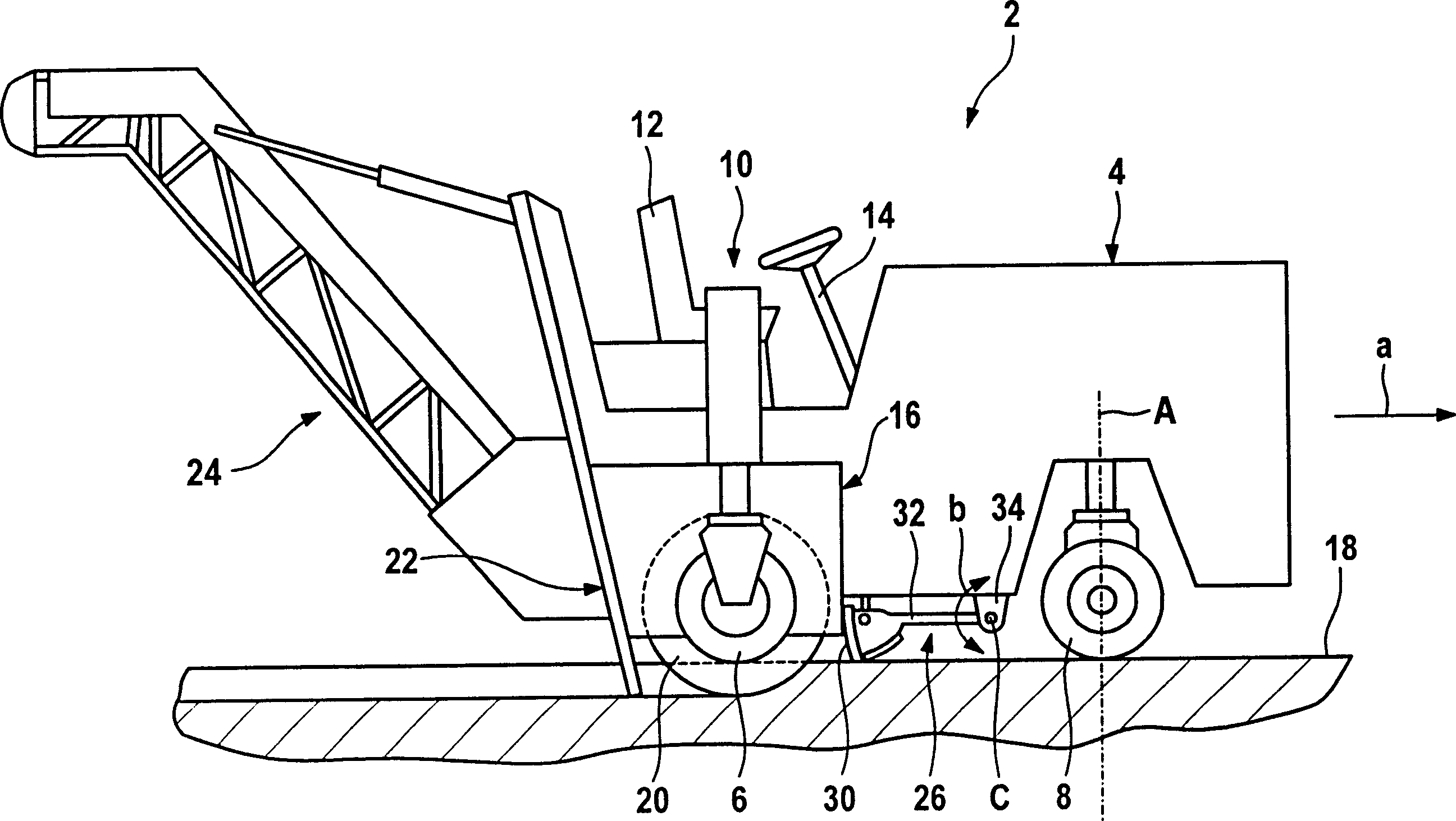

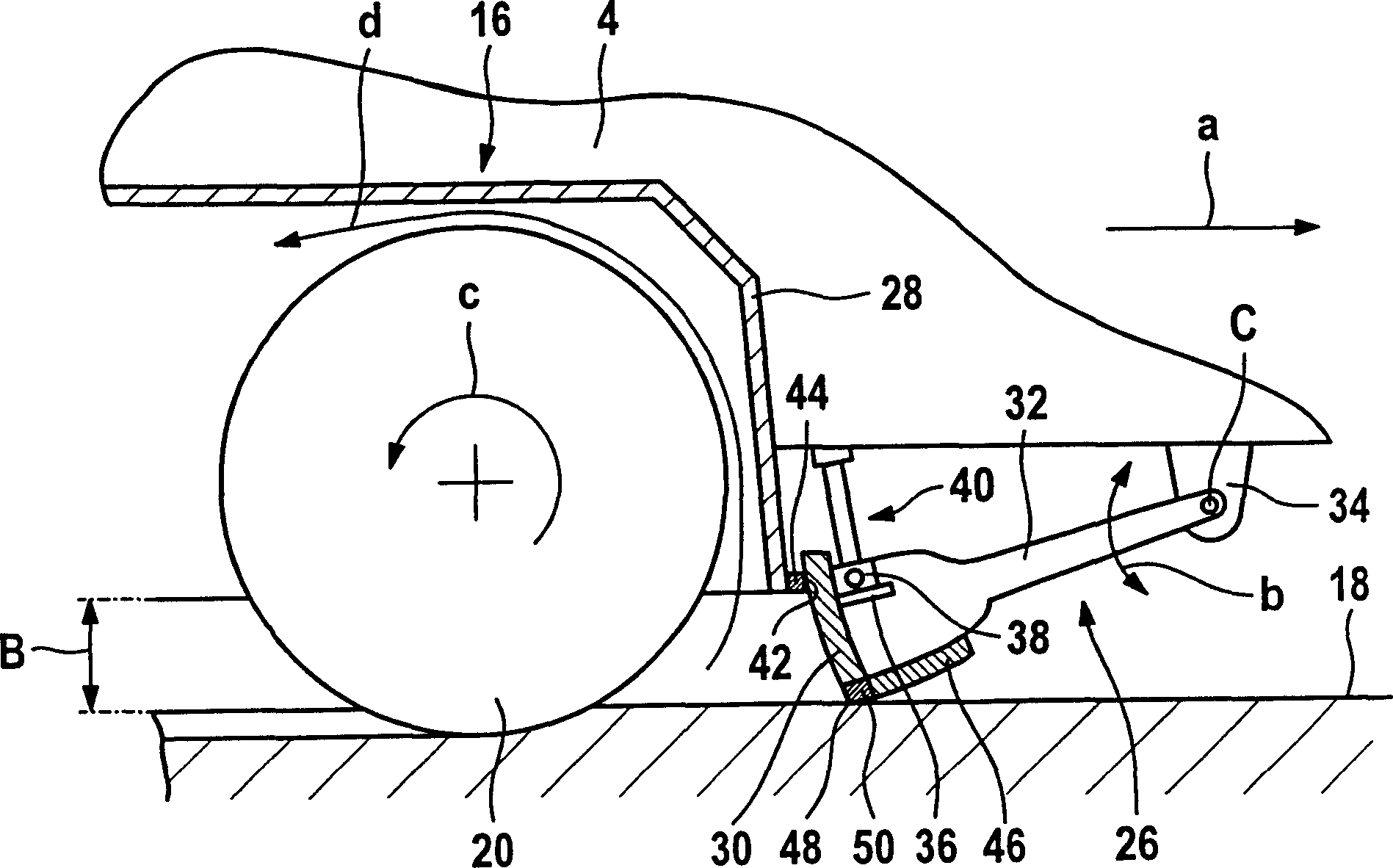

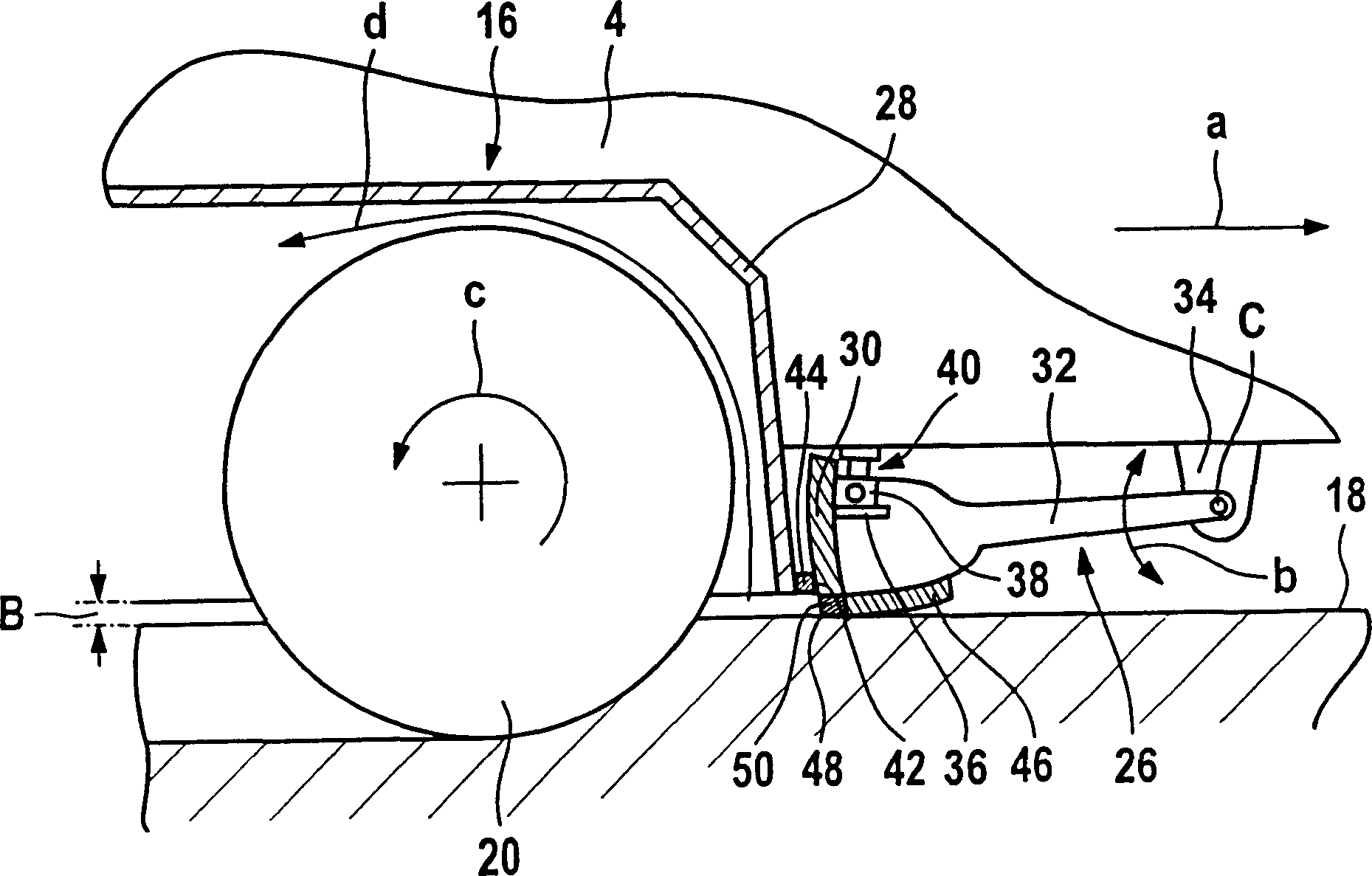

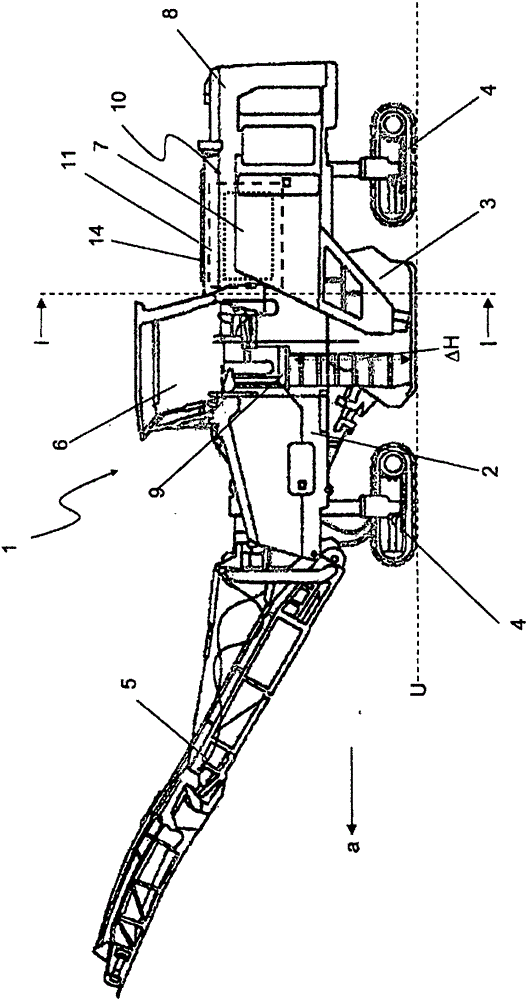

Rear loading road milling machine with height adjustable sealing device

InactiveCN1605683AProjectile preventionEliminate interruptionRoads maintainenceRoad surfaceMechanical engineering

Rear loader road milling machine comprises a milling roller (20) arranged in a roller housing (16) that is open at the bottom. An opening (B) facing the direction of travel (a) between the front part (28) of the roller housing and the road covering (18) can be closed by a height-adjustable sealing unit (26). The height of the sealing unit can be adjusted by pivoting the unit in front of the milling roller about an axis (C) in the direction of travel. Preferred Features: The sealing unit has an impact shield (30) facing the opening.

Owner:WIRTGEN GMBH

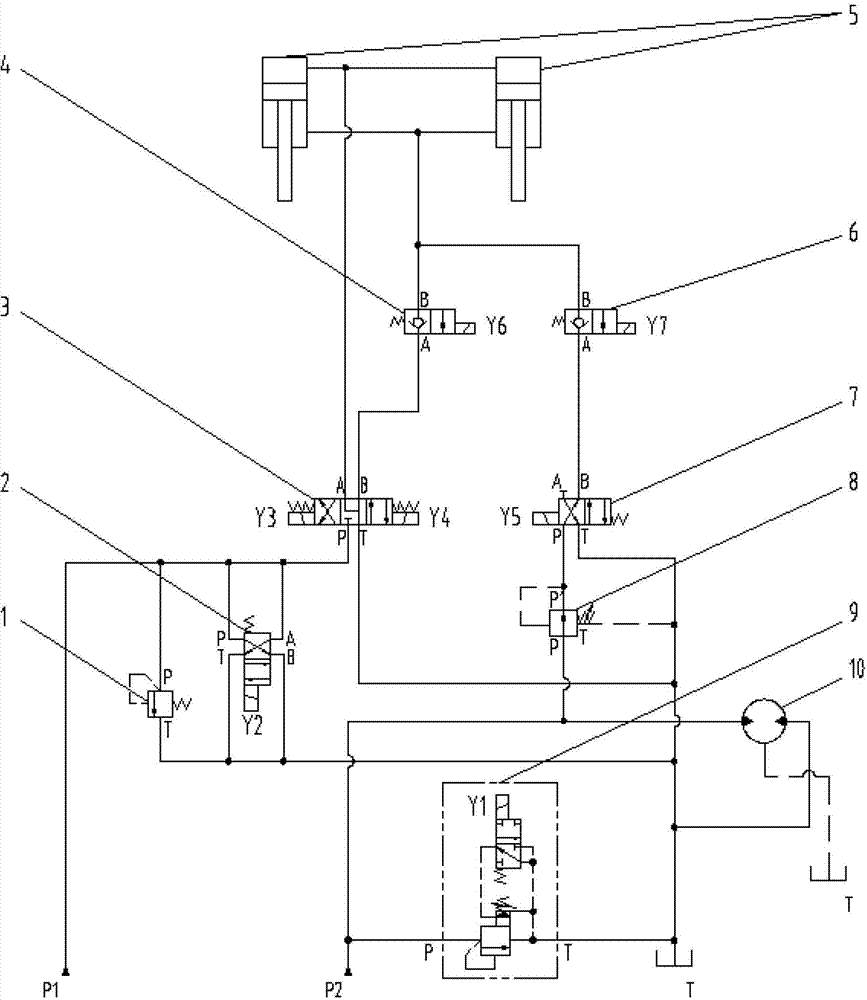

Hydraulic system for controlling tail gate of pavement milling machine

InactiveCN102900014AImprove job qualityReduce ground pressureRoads maintainenceEngineeringRoad surface

The invention provides a hydraulic system for controlling a tail gate of a pavement milling machine. The hydraulic system comprises an overflow valve, an electromagnetic overflow valve, a first two-position four-way electromagnetic reversing valve, a second two-position four-way electromagnetic reversing valve, a first normally-closed two-position two-way electromagnetic reversing ball valve, a second normally-closed two-position two-way electromagnetic reversing ball valve, a three-position four-way electromagnetic reversing valve, a conveying motor of a belt conveyor, a fixed pressure reducing valve and a tail gate lifting oil cylinder. The hydraulic system has the advantages that the technical scheme is adopted, so that the operating quality of the milling machine is improved, the energy consumption is reduced, the performance is reliable, the structure is simple, the cost is cheap, lifting, locking, floating and back pressure functions of the tail gate can be achieved, the whole weight of the tail gate and a conveying device is grounded, pressure oil is fed into a rod cavity of the tail gate lifting oil cylinder to reduce the ground pressing of the tail gate, the ground pressing can be adjusted according to pavement conditions, the construction quality is guaranteed, the energy consumption is effectively reduced, and the operation is convenient.

Owner:天津山河装备开发有限公司

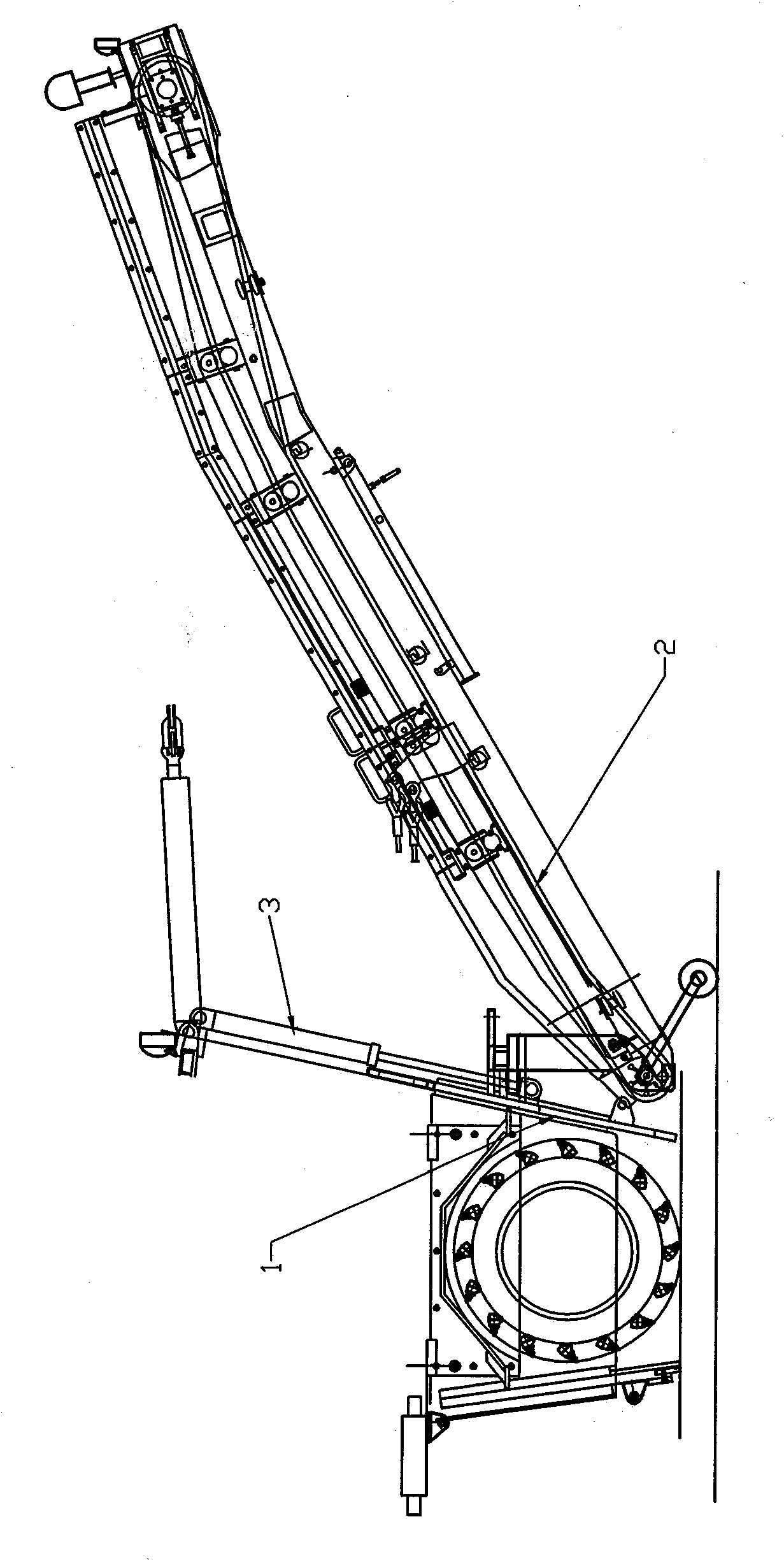

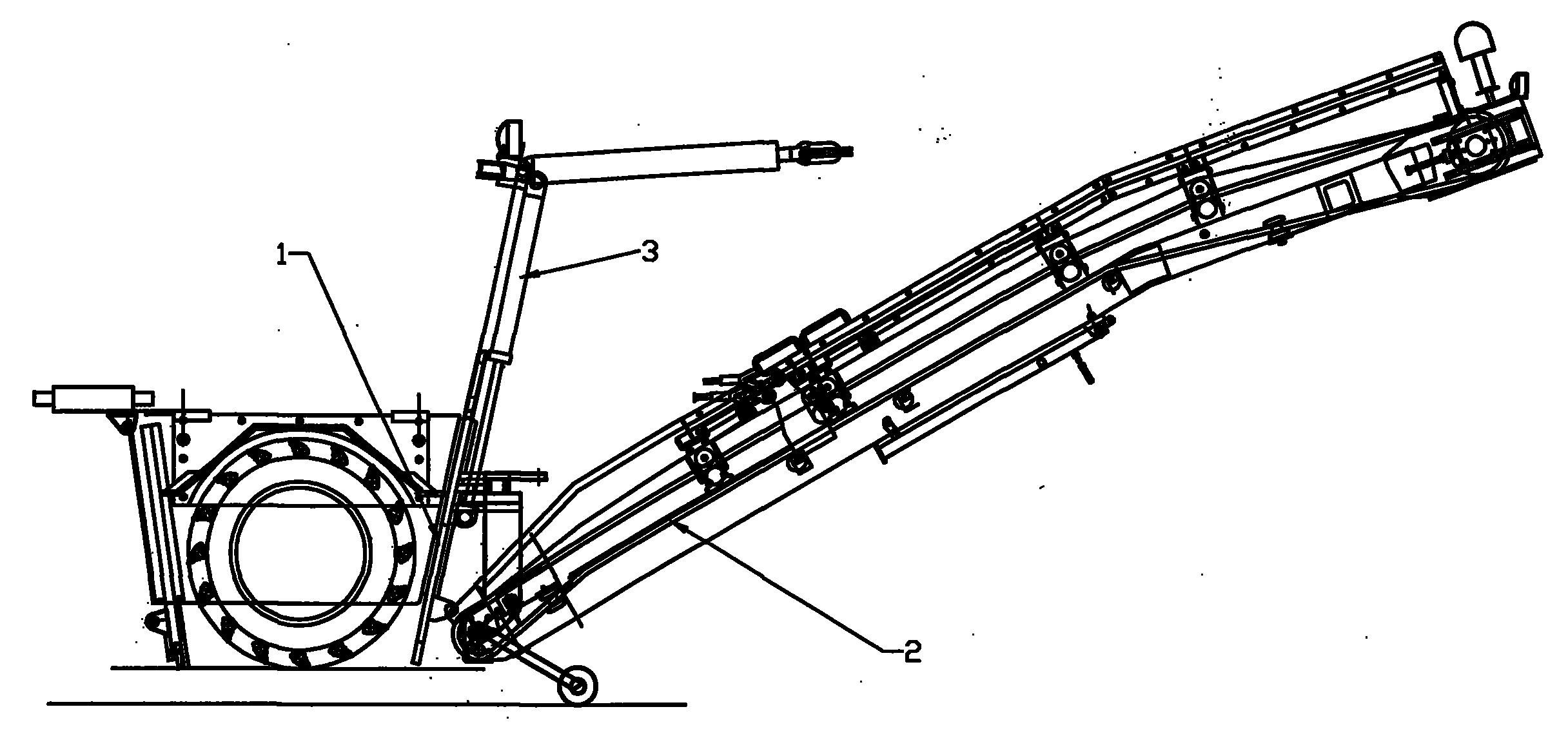

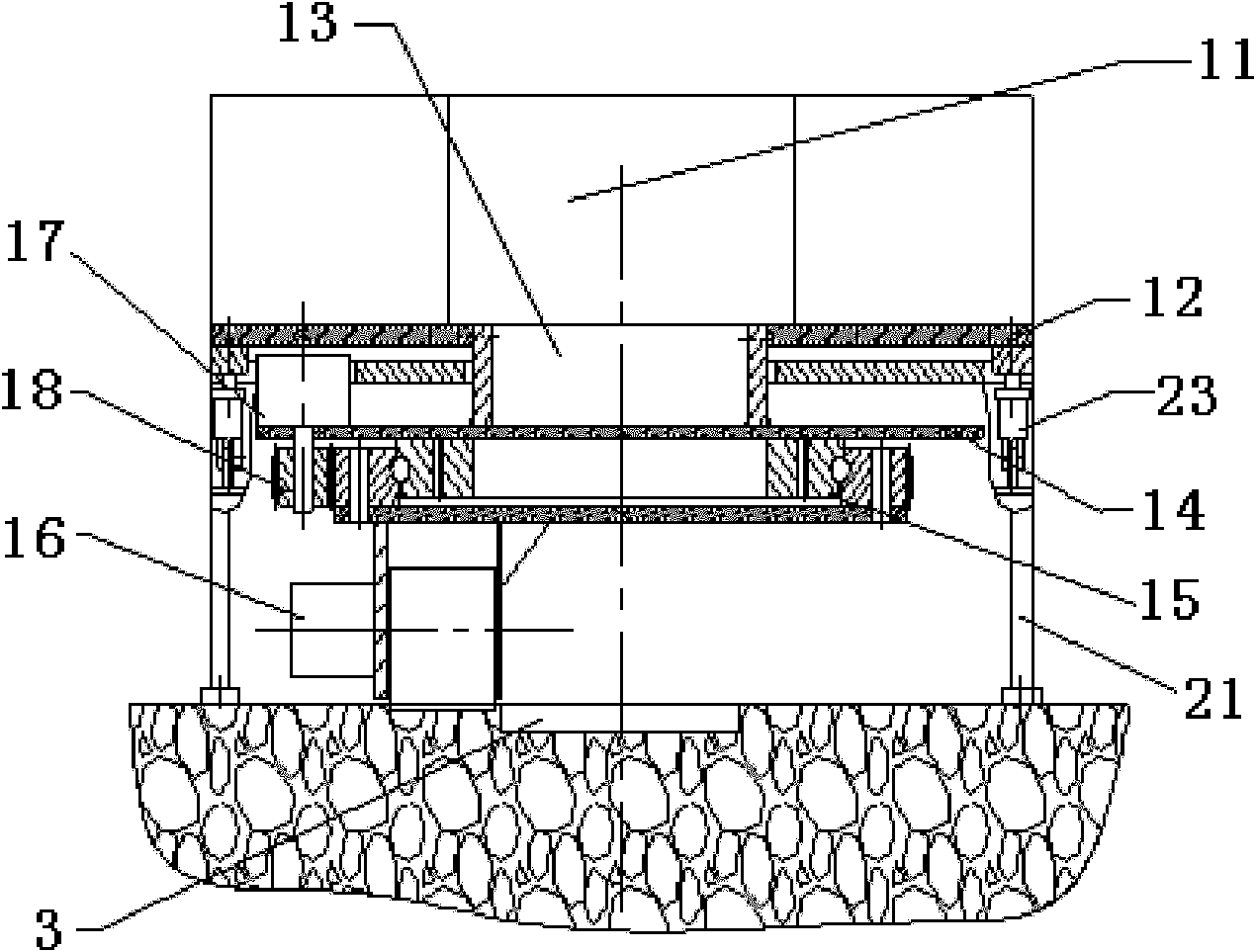

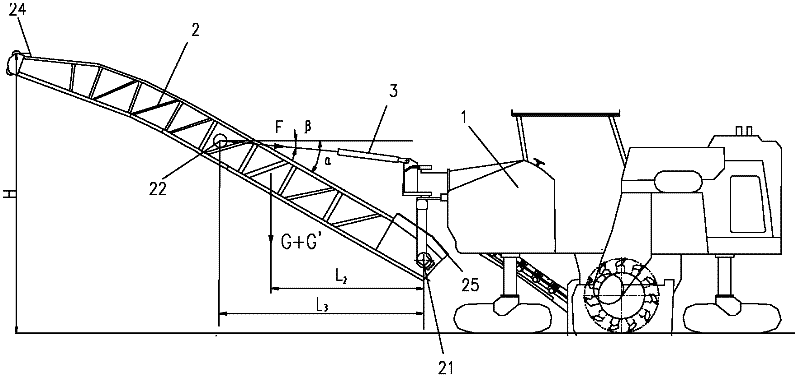

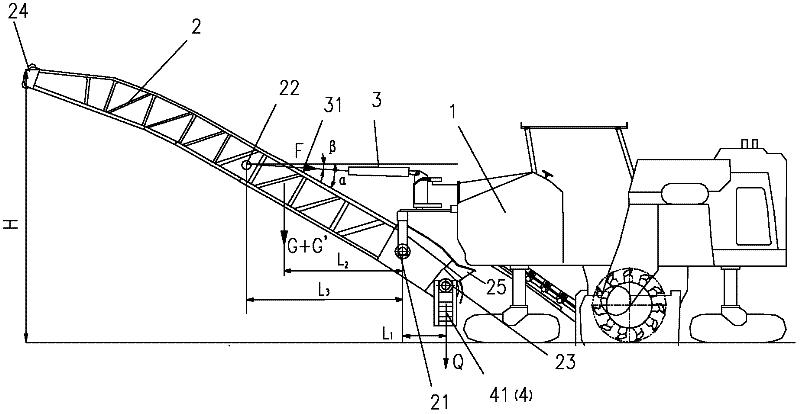

Pavement milling machine

The invention discloses a pavement milling machine, which comprises a frame (1), a material filling belt conveyor (2) and a lifting oil cylinder (3), an input end (25) and an output end (24) which are relatively arranged in the material filling belt conveyor, the material filling belt conveyor is hinged to the frame through a first hinge point (21), one end of the lifting oil cylinder is hinged to the frame, the other end of the lifting oil cylinder is hinge to the material filling belt conveyor through a second hinge point (22), and the second hinge point is positioned over the first hinge point, the first hinge point is positioned between the second hinge point and the input end of the material filling belt conveyor. The first hinge point enables relative movement to the input end upwardly, The own weight of the input end is capable of effectively mitigating the load of the lifting oil cylinder according to the lever principle, so that the pressure of hydraulic oil in the cylinder is reduced, the risks of inner leakage of hydraulic oil and settlement of the oil cylinder can be reduced, thereby the security and reliability of the pavement milling machine are substantially enhanced.

Owner:ZOOMLION HEAVY IND CO LTD

Novel production method of concrete

The invention provides a novel production method of concrete. The concrete is produced by mixing, by weight, 40-70 parts of road milling waste, 10-20 parts of aggregates prepared from construction waste, 5-15 parts of fly ash, 15-30 parts of cement, 0.02-0.2 part of admixture and 10-50 parts of water, wherein the milling waste is graded aggregates prepared from bituminous concrete pavement milling waste. By means of the novel production method of the concrete, pavement milling materials, the construction waste and waste steel dregs can be fully recycled, and the concrete meeting needs is obtained at low production cost.

Owner:北京联绿技术集团有限公司

Hydraulic system for floating of scraper of pavement milling machine

ActiveCN104500485AAchieve improvementAchieve lockingServomotor componentsServomotorsFuel tankEngineering

The invention discloses a hydraulic system for the floating of a scraper of a pavement milling machine. The hydraulic system comprises a scraper oil cylinder with a piston rod which is vertically arranged downwards, wherein the piston rod of the scraper oil cylinder is connected with the scraper which is horizontally arranged; two oil paths are led from an upper cavity of the scraper oil cylinder, one path is communicated with a first oil port (A) of a three-position four-way electromagnetic reversing valve (5), and the other path is communicated with an oil tank through a throttling valve (4); a lower cavity of the scraper oil cavity is divided into two paths after passing through a two-position two-way electromagnetic valve (6), one path is communicated with a second oil port (B) of the three-position four-way electromagnetic reversing valve (5), and the other is communicated with an oil outlet of a three-way pressure reducing valve (3); an oil inlet (P) of the three-position three-way electromagnetic reversing valve (5) is communicated with the oil tank through an auxiliary pump (1), and an oil outlet(T) of the three-position three-way electromagnetic reversing valve (5) is communicated with the oil tank; an oil inlet of the three-way pressure reducing valve (3) is communicated withthe oil tank through an oil supplementing pump (2). The hydraulic system for the floating of the scraper of the pavement milling machine is simple in structure, safe and reliable.

Owner:柳工无锡路面机械有限公司

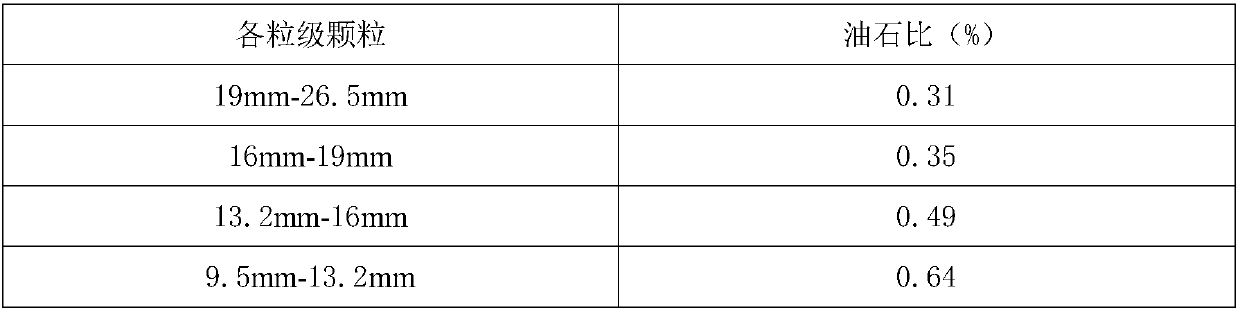

Emulsified asphalt cold in-place recycling mixture as well as grading method and application thereof

The invention provides a grading method of an emulsified asphalt cold in-place recycling mixture. The emulsified asphalt cold in-place recycling mixture is prepared from emulsified asphalt, an old pavement milling material, aggregate, cement and water; a new aggregate doping amount is determined according to the thickness of a cold recycling structure and a old pavement milling thickness; meanwhile, the grading of the emulsified asphalt, coarse aggregate, fine aggregate, the cement and the water in novel aggregate is controlled, so that the emulsified asphalt cold in-place recycling mixture provided by the invention has good pavement performance. Meanwhile, the invention provides the emulsified asphalt cold in-place recycling mixture obtained by the grading method and application of the emulsified asphalt cold in-place recycling mixture to old pavement repairing and modification.

Owner:CHANGAN UNIV

Pavement milling apparatus

A disclosed pavement milling apparatus comprises a milling-apparatus main support; one side of the bottom of the main support is provided with a motor fixing plate, and the other side of the bottom of the main support is flexible provided with a cutter adjusting clamping plate; a driving motor is arranged on the motor fixing plate; the output shaft of the driving motor is coaxially fixedly provided with a spline shaft; the top of the spline shaft penetrates the cutter adjusting clamping plate; and the spline shaft is sleeved by milling cutter wheels and a limit casing pipe. The pavement milling apparatus has the advantages that milling apparatuses with different width can be obtained through combination according to user demands, cutter wheels are easy and convenient to replace, the dumping direction and the direction for cutting edges of a reference layer are selectable, cut reference-layer edges are tidy, and because two employed cutter wheels have different structures and are used to specifically process pavement, the cutting resistance is reduced and milling and ditching operations are steady.

Owner:SHANDONG VANSE MECHANICAL TECH CO LTD

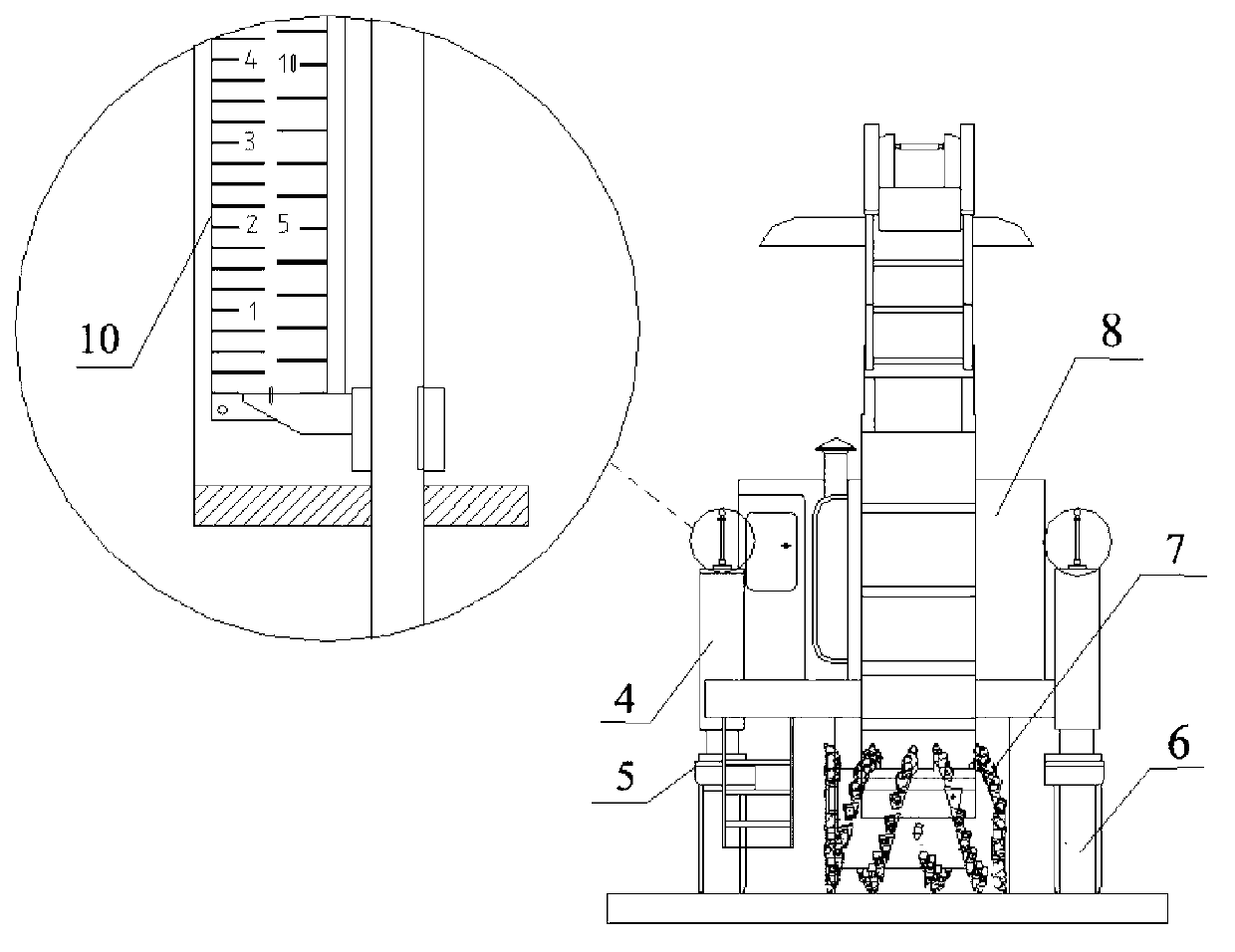

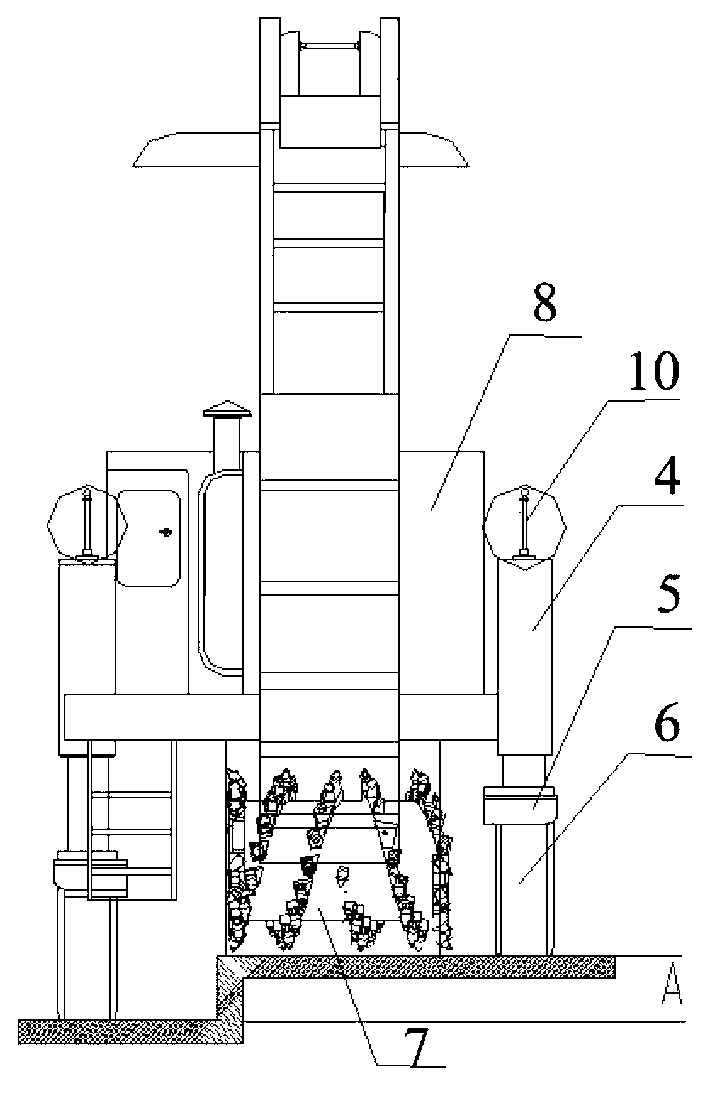

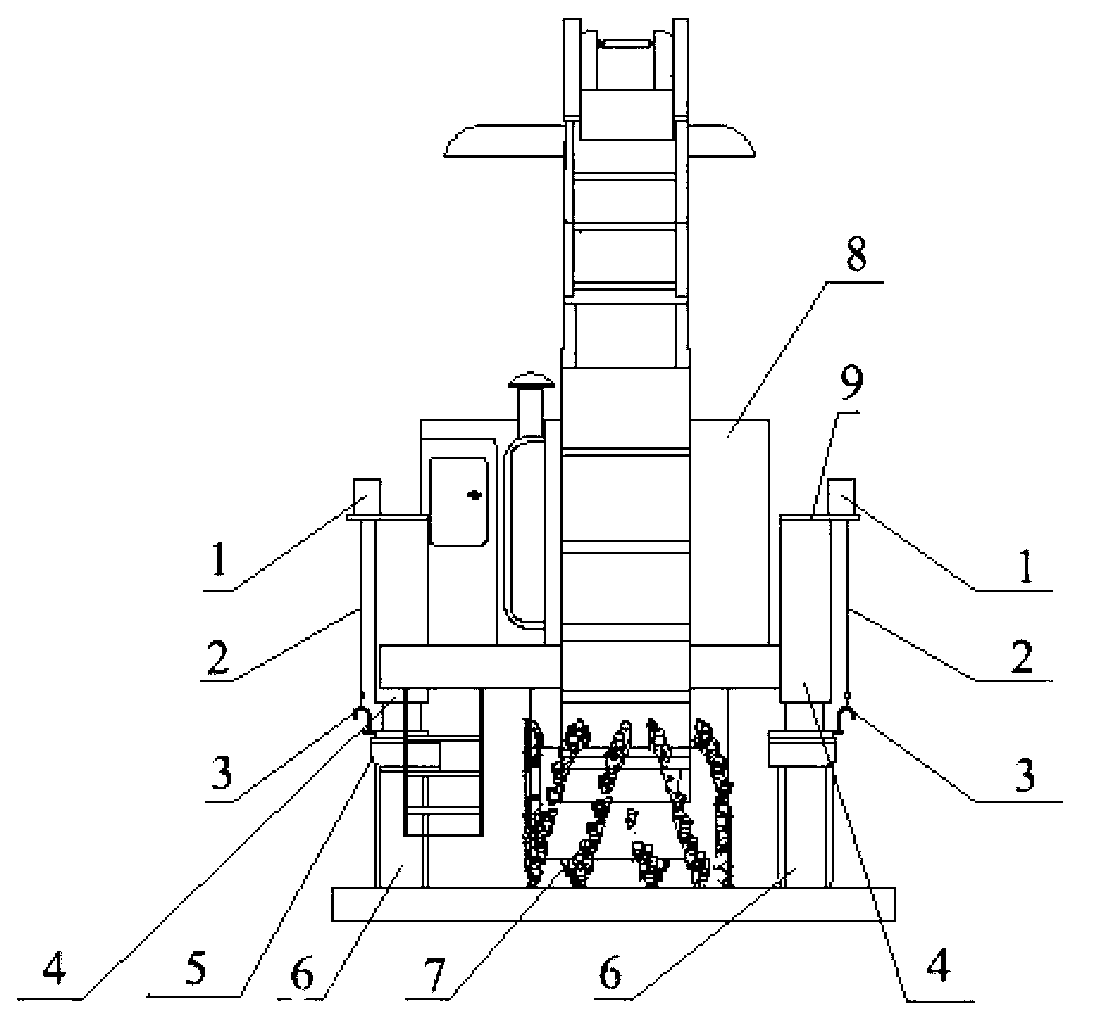

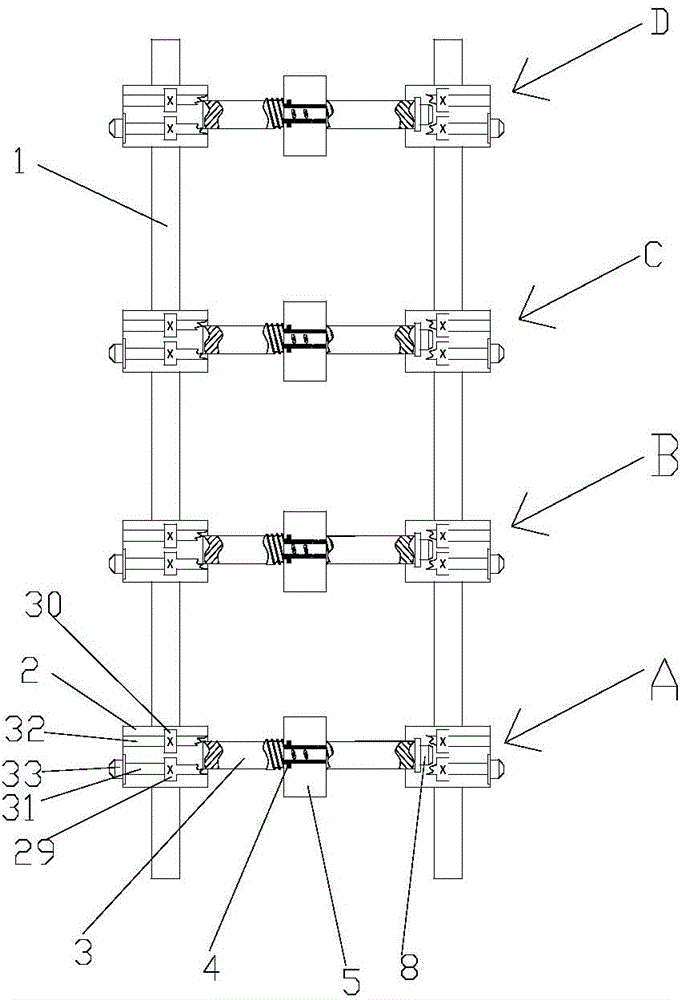

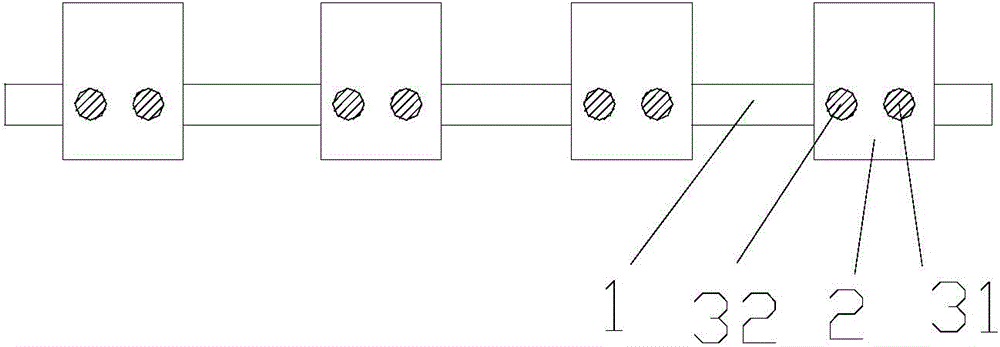

Pavement milling machine and operating method thereof

The invention discloses a pavement milling machine and an operating method of the pavement milling machine. The pavement milling machine comprises a milling depth displaying and leveling device, support oil cylinders (4), wheel installing frames (5), a machine frame (8) and milling drums (7) arranged below the machine frame (8), wherein the wheel installing frames (5) are used for supporting the machine frame (8) through the support oil cylinders (4); the milling depth displaying and leveling device comprises a depth simulating controller (1) and coiled ropes (2), wherein the coiled ropes (2) are coiled in the depth simulating controller (1), and extends outside and fixedly connected to the wheel installing frames (5); and the depth simulating controller (1) is used for detecting and displaying the variable of the extending length of the coiled ropes (2), and is arranged on the machine frame (8) so as to move along with the lifting of the milling drums (7). With the adoption of the pavement milling machine, the mechanical milling depth displaying and leveling device can be manually adjusted or zeroed; and the pavement milling machine is conveniently operated, and specifically the pavement milling machine is convenient for an operator to mill through a plurality of cutters, therefore, higher milling precision can be obtained, and high smoothness can be ensured.

Owner:ZOOMLION HEAVY IND CO LTD

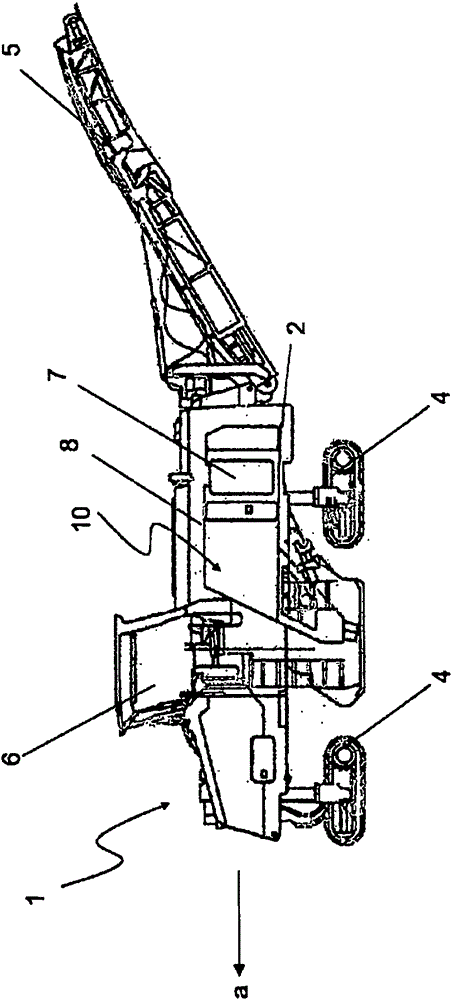

Self-propelled ground milling machine with integrated maintenance platform

InactiveCN105274932AEasy to operateMake sure to enterSuperstructure subunitsSteps arrangementRoad surfaceSurface mining

The present invention relates to a self-propelled ground milling machine with an integrated maintenance platform, comprising a drive engine arranged in an engine compartment and an engine compartment enclosure which covers the engine compartment at least partly to the sides and to the top. A part of the engine compartment enclosure is a cover which is adjustable between a covering position and a maintenance position. At the same time, a maintenance platform is provided which is movable between a stowage position and a maintenance position. When the maintenance platform is in the maintenance position, an operator standing on the floor surface of the maintenance platform can carry out maintenance work in the engine compartment of the self-propelled ground milling machine. The self-propelled ground milling machine preferably is a road milling machine, more particularly a large milling machine, a surface miner, a stabilizer or a recycler.

Owner:BOMAG

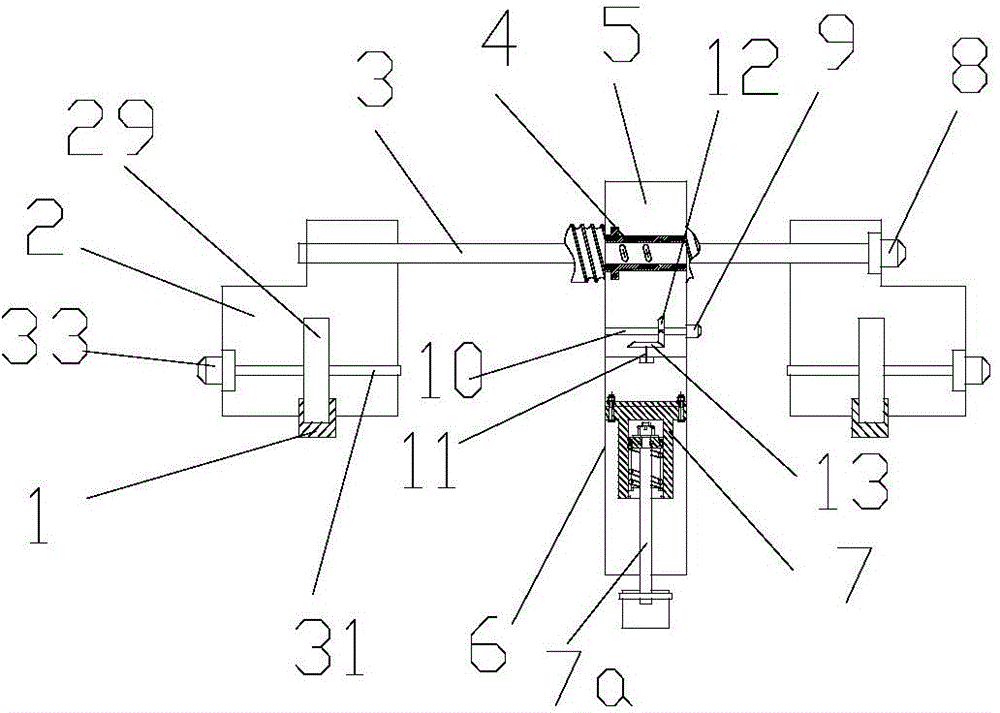

Multifunctional self-positioning broken pavement milling machine

InactiveCN104389260AReduce maintenance costsCompact structureRoads maintainenceRoad surfaceVision sensor

The invention discloses a multifunctional self-positioning broken pavement milling machine. The multifunctional self-positioning broken pavement milling machine comprises a machine frame, a cutting device, a hammering device, a milling device and a positioning control system, wherein the cutting device, the hammering device and the milling device are arranged on the machine frame in an integration manner; the positioning control system is used for positioning a broken pavement and comprises vision sensors, displacement sensors and a central controller. When the multifunctional self-positioning broken pavement milling machine is used, the vision sensors which are mounted on all the devices are used for scanning back and forth by virtue of a computer control technology, the positions of irregular pits needing to be processed in the pavement are recorded, the irregular pits are self-positioned and are processed into regular pits which can be filled with asphalt according to the feedback information of each sensor, and the machine has the advantages of high intelligence, quickness, high maneuverability, high efficiency and reliability.

Owner:CHONGQING JIAOTONG UNIVERSITY

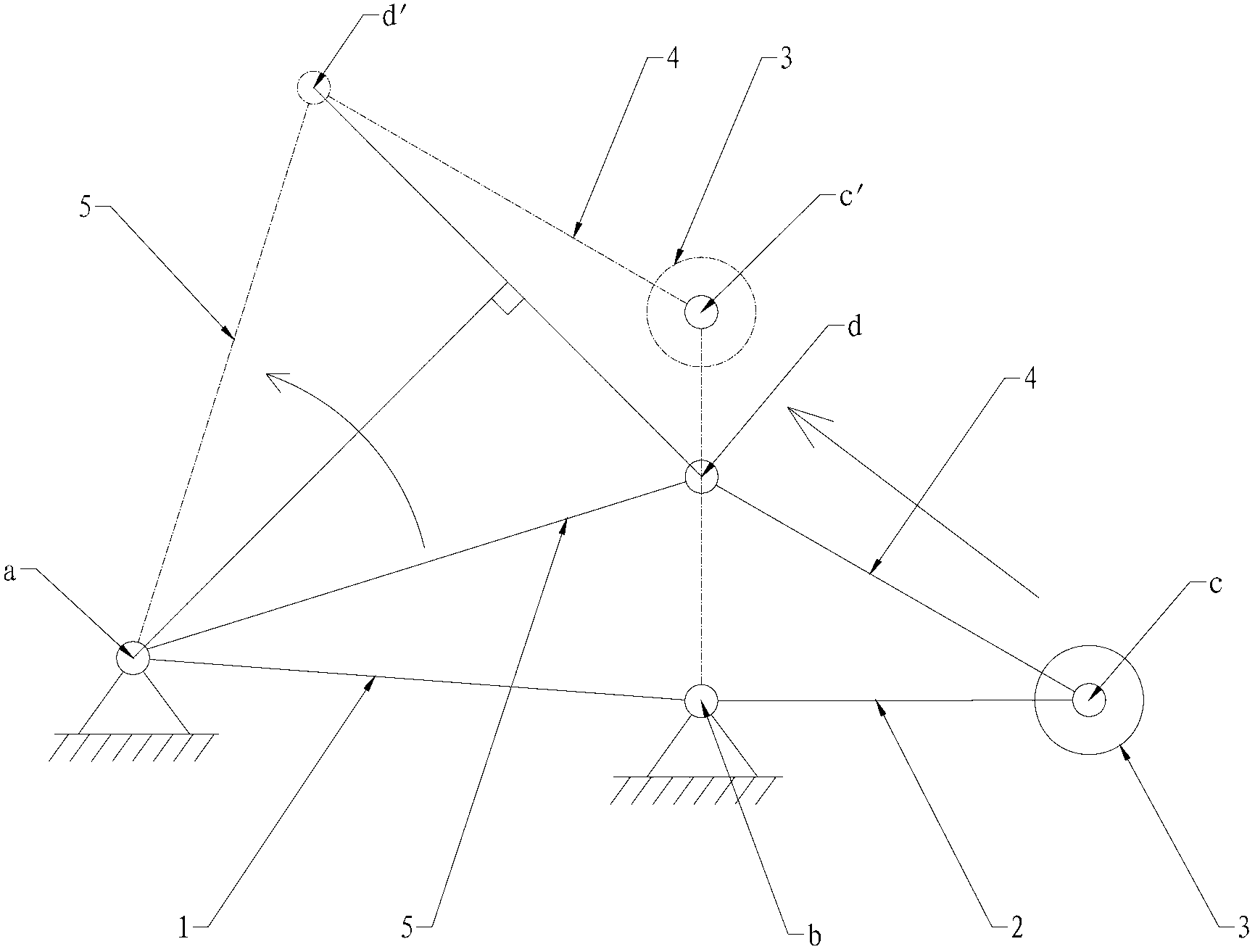

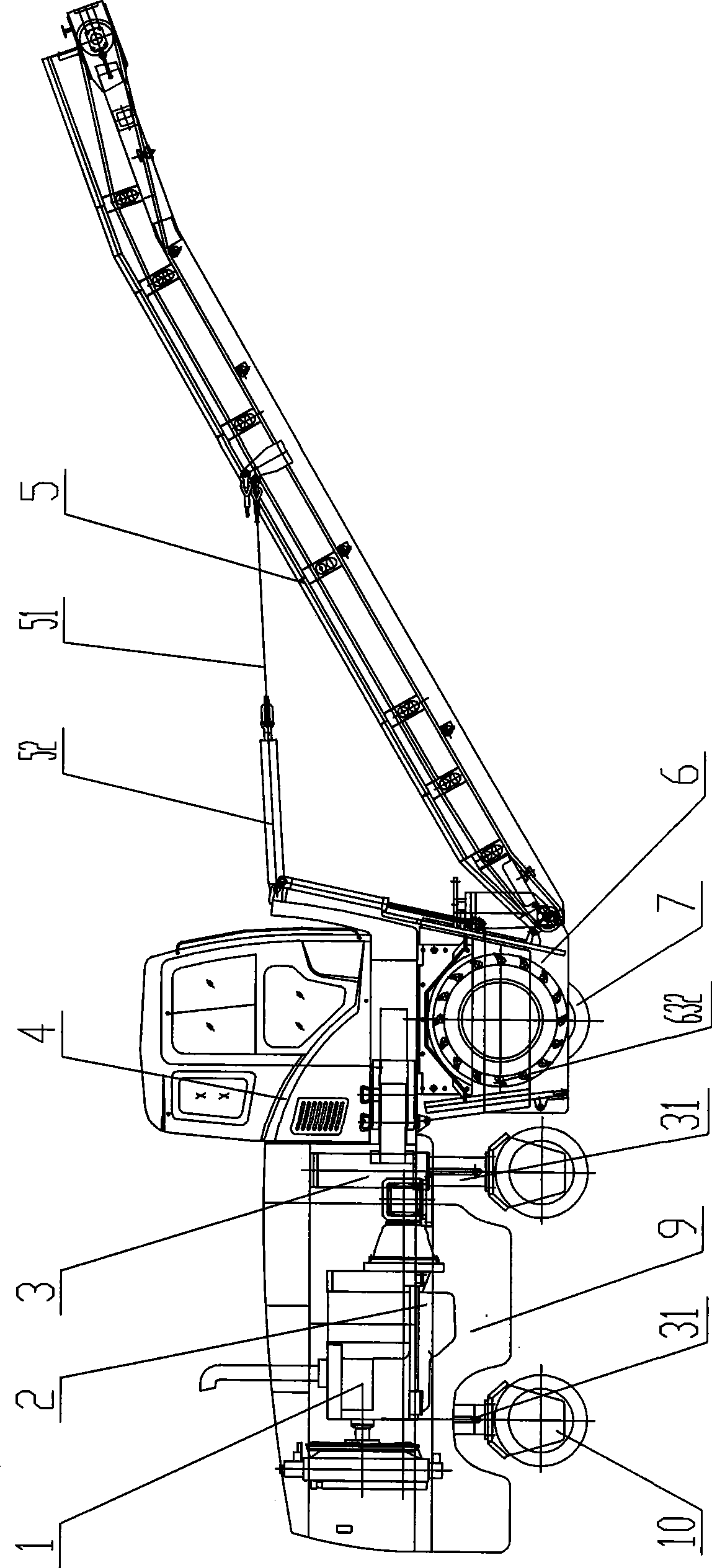

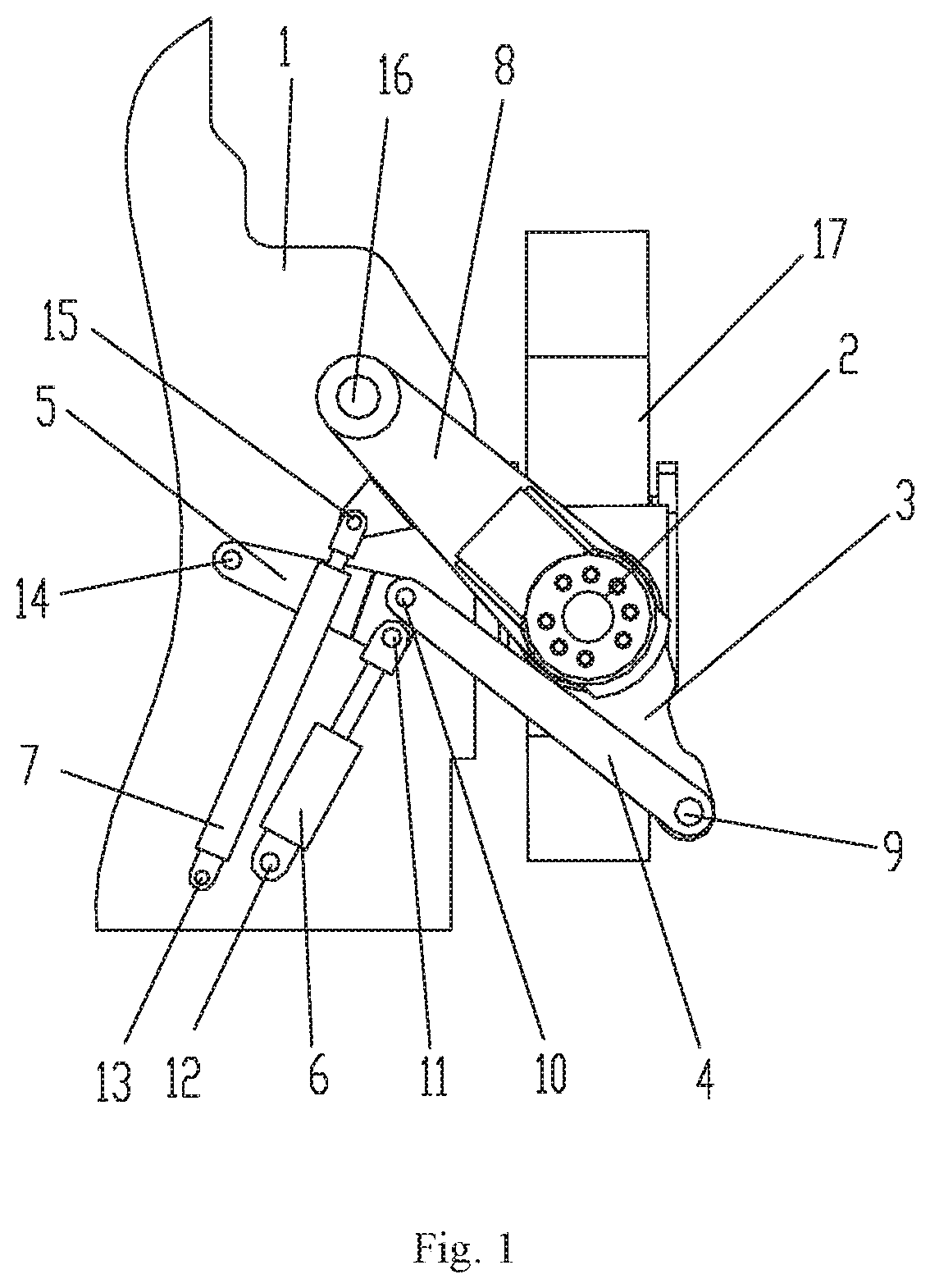

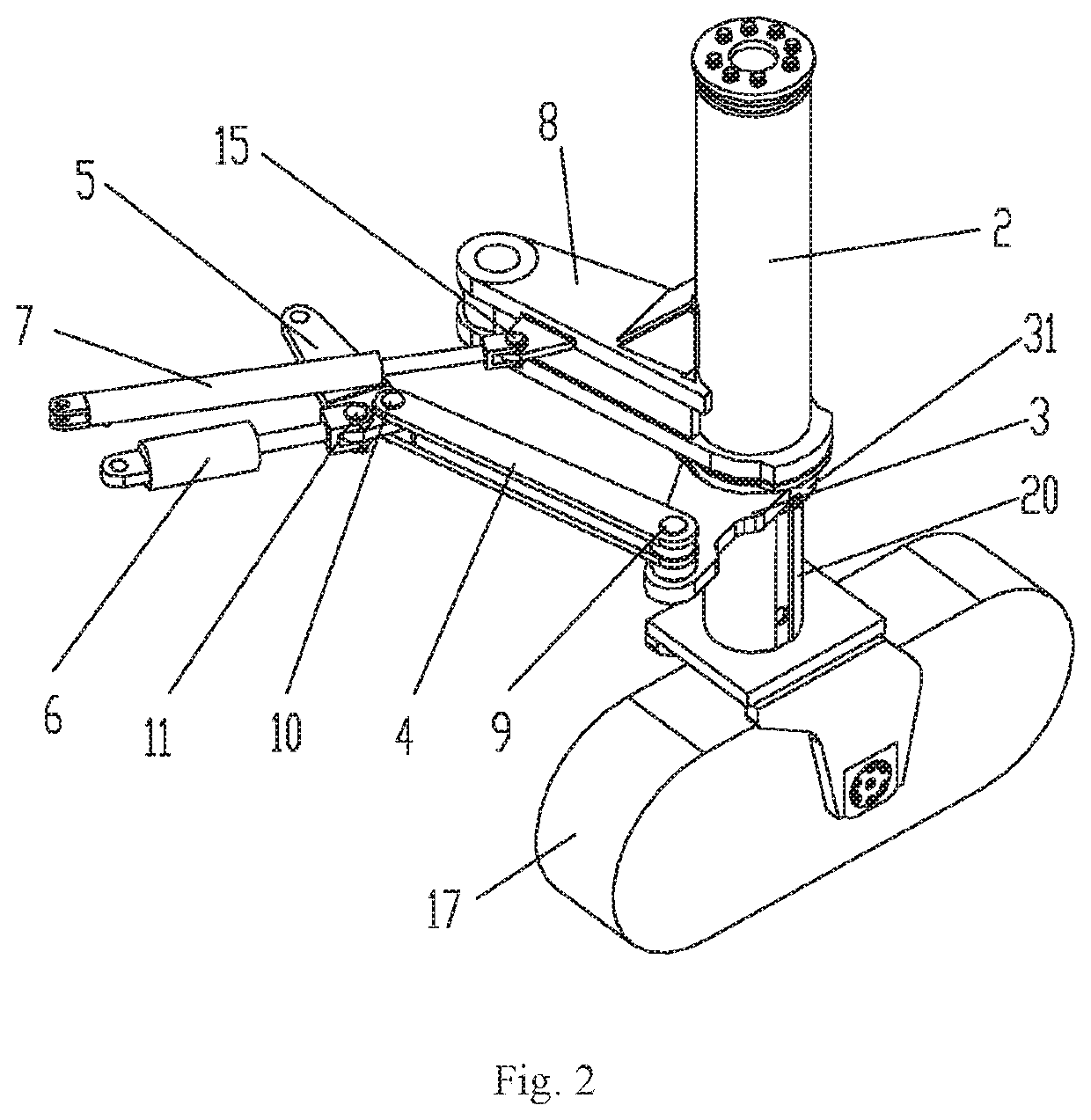

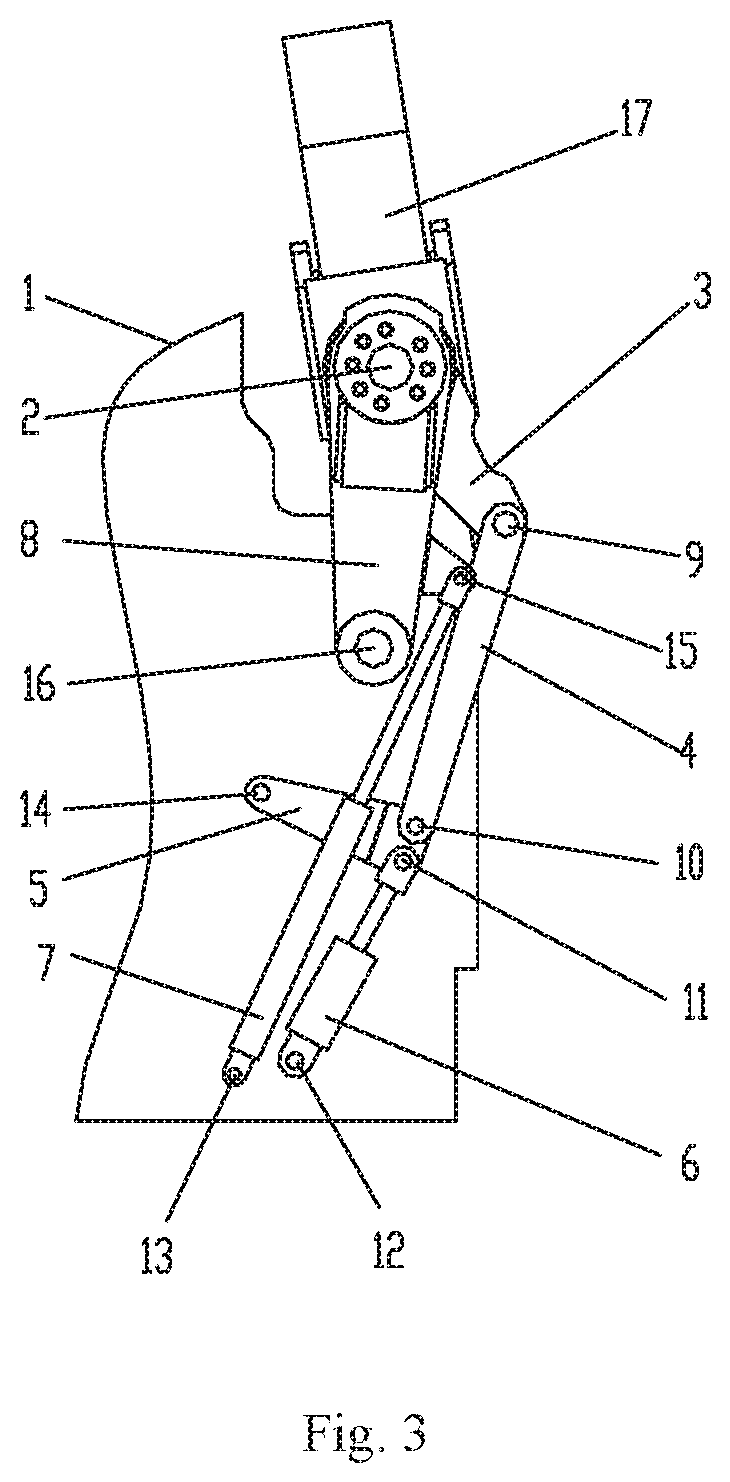

Mechanism for swinging and steering support leg for pavement milling machine

ActiveUS10710631B2Low costEasy to operate and controlResilient suspensionsRoads maintainenceStructural engineeringControl theory

A mechanism for swinging and steering a support leg for a pavement milling machine is provided having a milling machine frame, a swing rod, a steering rod, a first guiding rod and a second guiding rod, the support leg includes a support leg exterior sleeve and a interior sleeve, the support leg exterior sleeve is sleeved onto the support leg interior sleeve, the support leg interior sleeve rotates relative to the exterior sleeve; one end of the swing rod is hinged to the milling machine frame, and the other end is fixedly connected to the exterior sleeve; one end of the second guiding rod is hinged to the milling machine frame, the other end is hinged to one end of the first guiding rod, the other end of the first guiding rod is hinged to one end of the steering rod, and the other end of the steering rod is connected to the support leg interior sleeve.

Owner:DYNAPAC CHINA COMPACTION & PAVING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com