Multifunctional self-positioning broken pavement milling machine

A self-positioning and multi-functional technology, applied in the direction of roads, roads, road repairs, etc., can solve problems such as increasing work costs, and achieve the effects of small footprint, good integration, and high intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

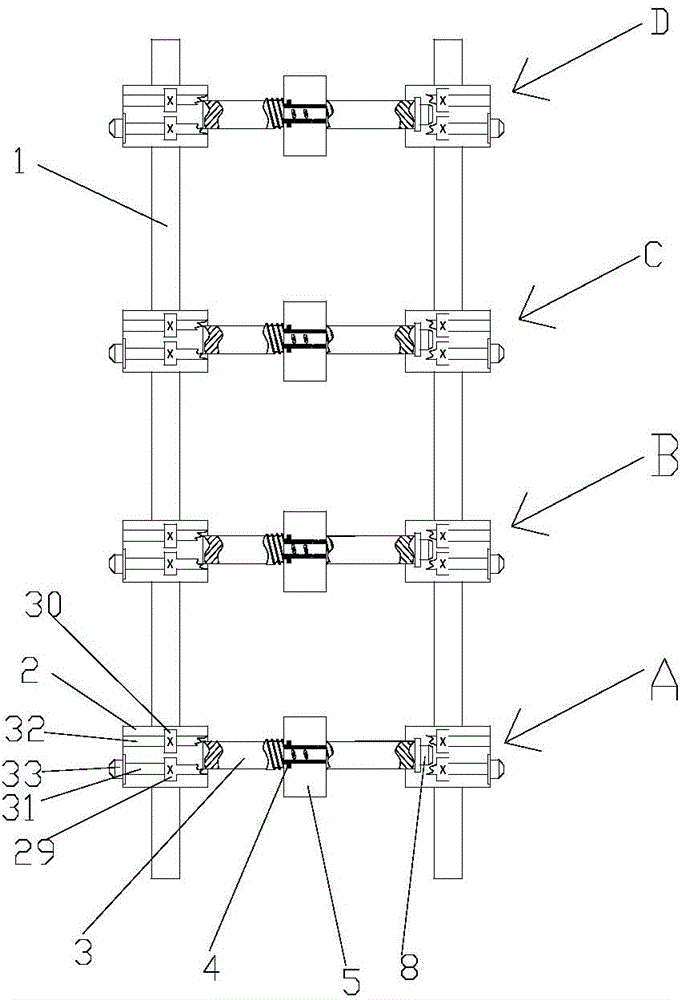

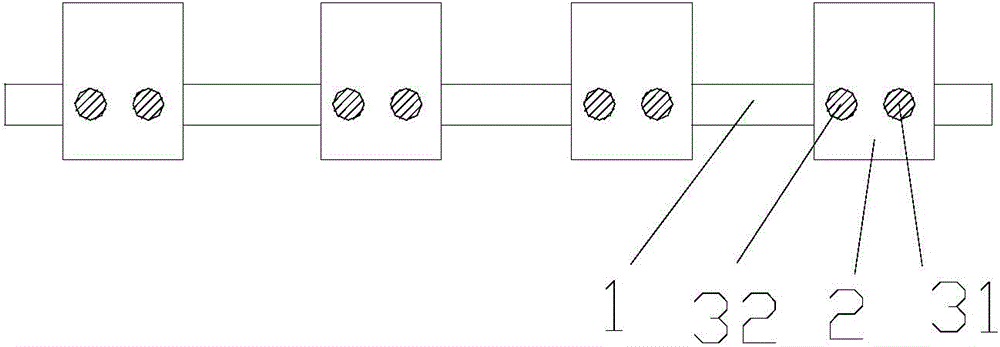

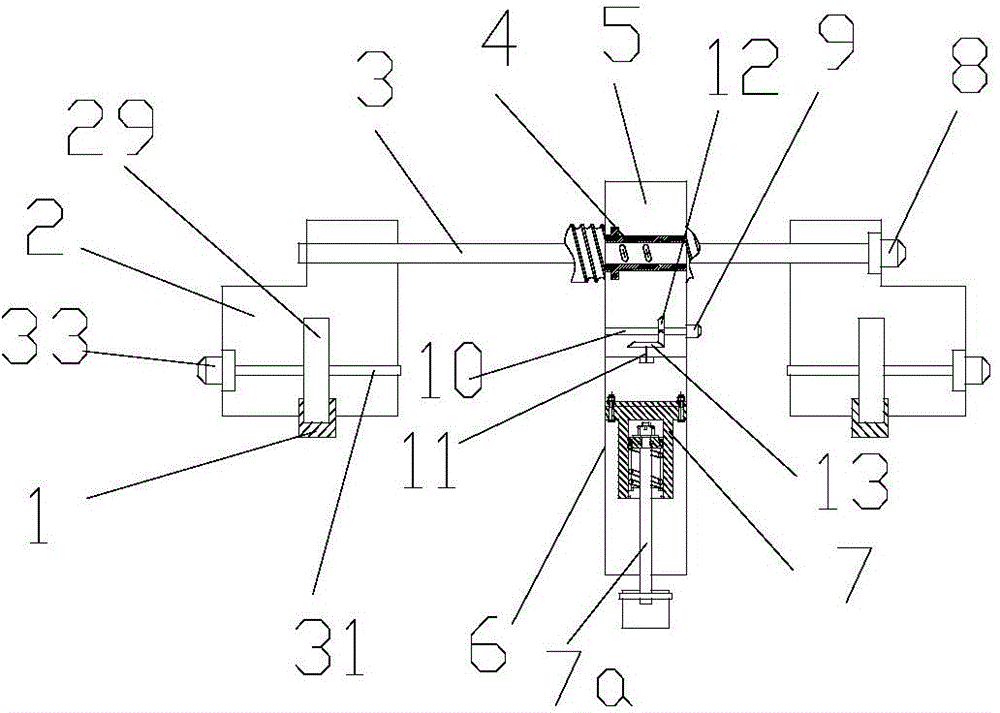

[0029] As shown in the figure: the multifunctional self-positioning damaged road surface milling machine of this embodiment includes a frame 1, a cutting device for cutting the damaged road surface, a hammering device for hammering the cut road surface and a For the milling device for fine milling of the hammered road surface, the cutting device, the hammering device and the milling device are all integrated on the frame 1; figure 1 As shown, the frame 1 includes two guide rails arranged side by side, and the frame 1 itself can be mobile, and can be realized by an existing motorized frame, and a driving mechanism can also be provided additionally;

[0030] It also includes a positioning control system for locating damaged pavement, including:

[0031] The visual sensor is arranged on each of the devices to scan and locate the spatial position of the pit and monitor the working status of each of the devices; the visual sensor is mainly composed of one or two graphic sensors, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com