Milling machine outrigger elevator apparatus and pavement milling machine using the same

A lifting device and milling machine technology, which is applied in the field of road milling machines, can solve the problems that the milling depth cannot be adjusted quickly and accurately, the lifting speed control does not adopt stepless adjustment, and the construction quality of the milling surface does not meet the requirements, etc. , to eliminate the danger of tipping, improve the construction quality, and eliminate the effects of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

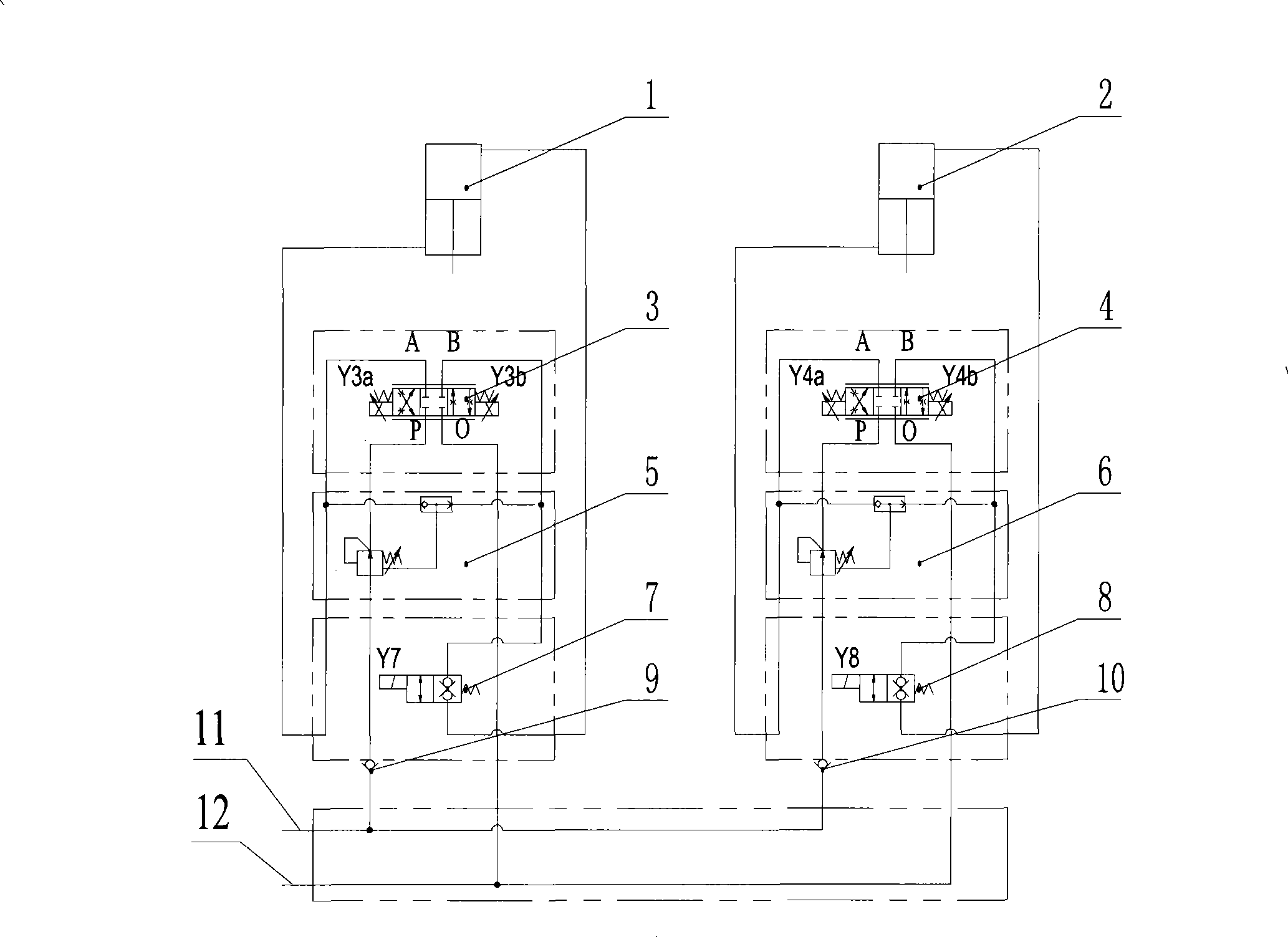

[0023] The basic idea of the present invention is to set left and right proportional reversing valves in the oil circuit where the left and right outrigger oil cylinders are located, so as to control the telescopic action speed of the left and right outrigger oil cylinders and realize the stepless lifting and lowering speed of the outriggers. Adjustment to improve the synchronous lifting accuracy of the outriggers; left and right pressure compensators to stabilize the pressure of the left and right outrigger cylinders to ensure that the actions of the two do not interfere.

[0024] The following will be described in detail in conjunction with the embodiments and accompanying drawings.

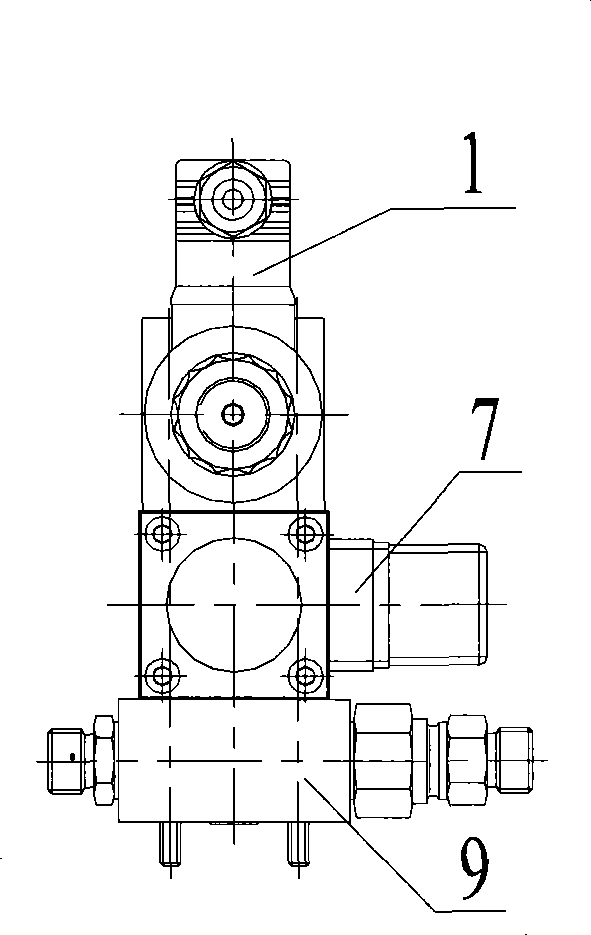

[0025] Please refer to figure 1 , which is a hydraulic schematic diagram of a preferred embodiment of the milling machine leg lifting device of the present invention. figure 1 The leg lifting device of the milling machine shown includes: left outrigger cylinder 1, right outrigger cylinder 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com