Blade for bituminous pavement milling machine and grooving machine

A technology for asphalt pavement and milling machine, which is applied to roads, roads, road repair and other directions, can solve the problems of wasting manpower, large resistance, and shortening the service life of the engine, and achieves the effect of high operation efficiency, reasonable design, and reduced resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

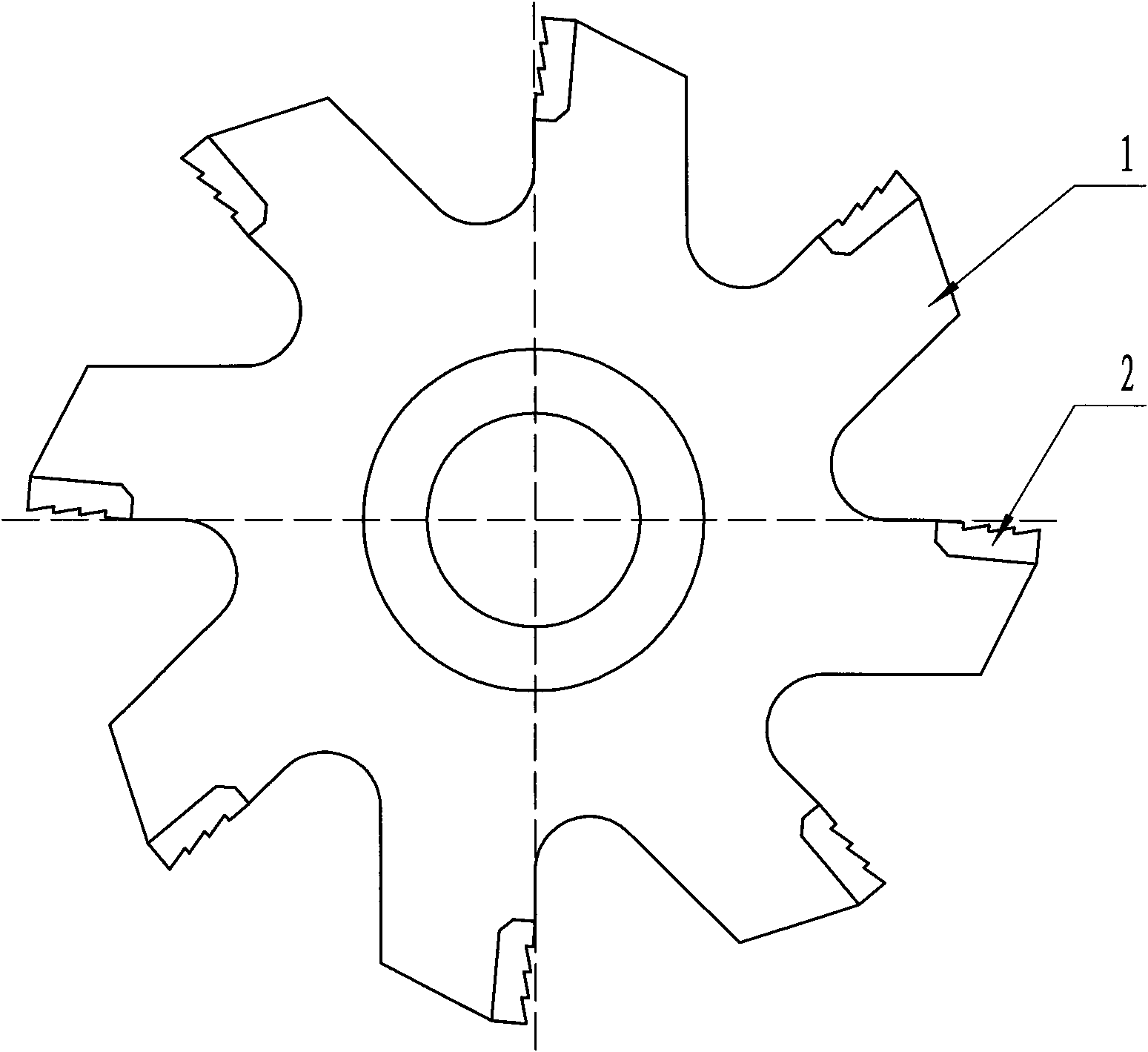

[0016] exist figure 1 , 2 Among them, the blades of the asphalt road milling machine and slotting machine in this embodiment are composed of a cutter body 1 and a cutter head 2 .

[0017] The cutter body 1 of this embodiment has a disc-shaped structure, which is the same as the existing cutter body 1. Eight cutter heads 2 are welded and connected to the front end of the cutter body 1, and the cutter heads 2 are alloy steel materials.

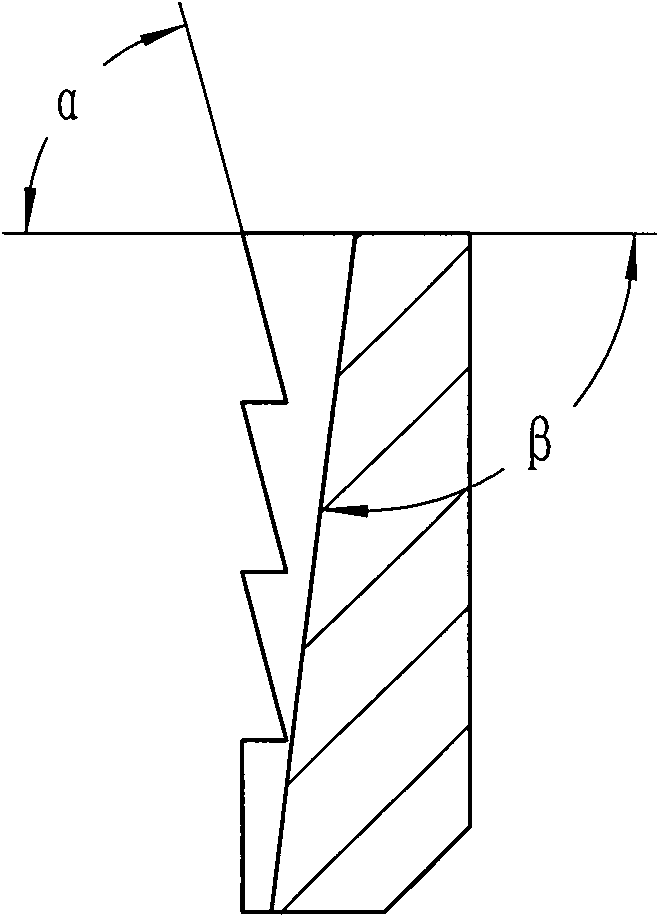

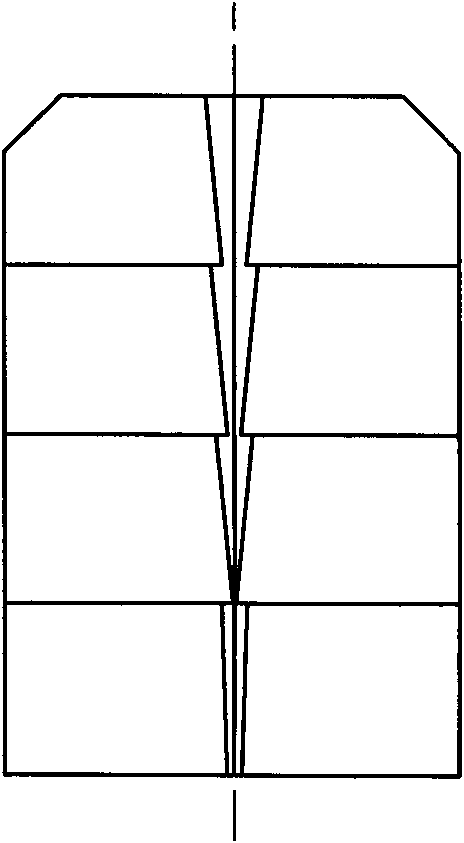

[0018] figure 2 , 3 , 4 shows the structure diagram of the cutter head 2 of this embodiment. exist figure 2 , 3 In 4, the front cutting surface of the cutter head 2 is processed into a zigzag cutting edge arranged in a radial direction and connected as a whole, wherein one tooth at the root is a straight-toothed cutting edge, and the remaining teeth are helical-toothed cutting edges. In this embodiment The front end face of the cutter head 2 is processed with three helical-toothed cutting blades. The specific number of helical-toothed cu...

Embodiment 2

[0020] In this embodiment, the front cutting surface of the cutter head 2 is processed into a zigzag cutting edge arranged in a radial direction, one tooth at the root is a straight-toothed cutting edge, and the remaining three teeth are helical-toothed cutting edges , the cutting angle α of the straight-toothed cutting edge is 90°, and the cutting angle α of the helical-toothed cutting edge is 70°. The center line of the front cutting surface of the cutter head 2 is processed with a middle split edge groove, the middle split edge groove is a V-shaped groove, the angle γ between the two sides of the middle split edge groove is 28°, and the clip between the bottom of the groove and the outer end surface of the cutter head 2 The angle β is 93°. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0022] In this embodiment, the front cutting surface of the cutter head 2 is processed into a zigzag cutting edge arranged in a radial direction, one tooth at the root is a straight-toothed cutting edge, and the remaining three teeth are helical-toothed cutting edges , the cutting angle α of the straight-toothed cutting edge is 90°, and the cutting angle α of the helical-toothed cutting edge is 80°. The center line of the front cutting surface of the cutter head 2 is processed with a middle split edge groove, the middle split edge groove is a V-shaped groove, the angle γ between the two sides of the middle split edge groove is 28°, and the clip between the bottom of the groove and the outer end surface of the cutter head 2 The angle β is 97°. Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com