Patents

Literature

113results about How to "Reduce work procedures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

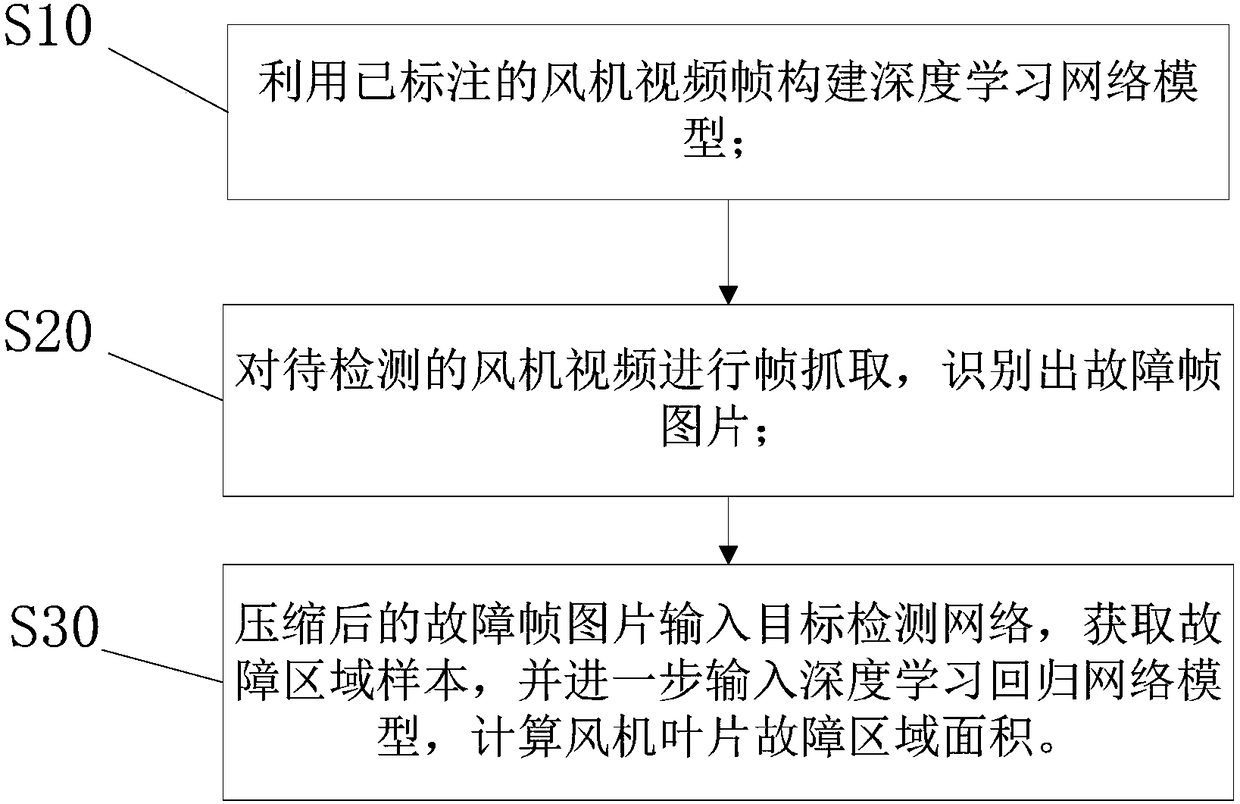

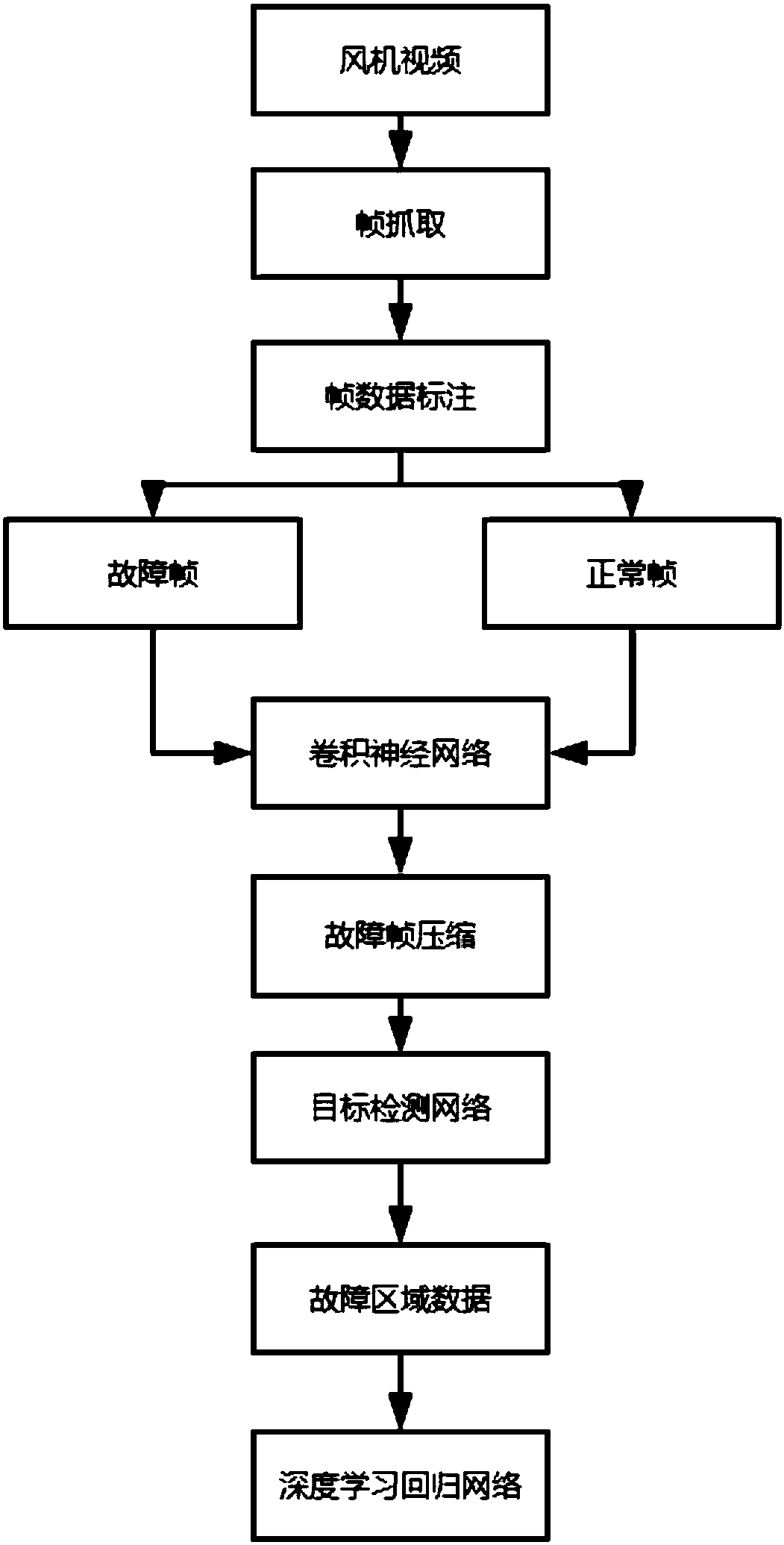

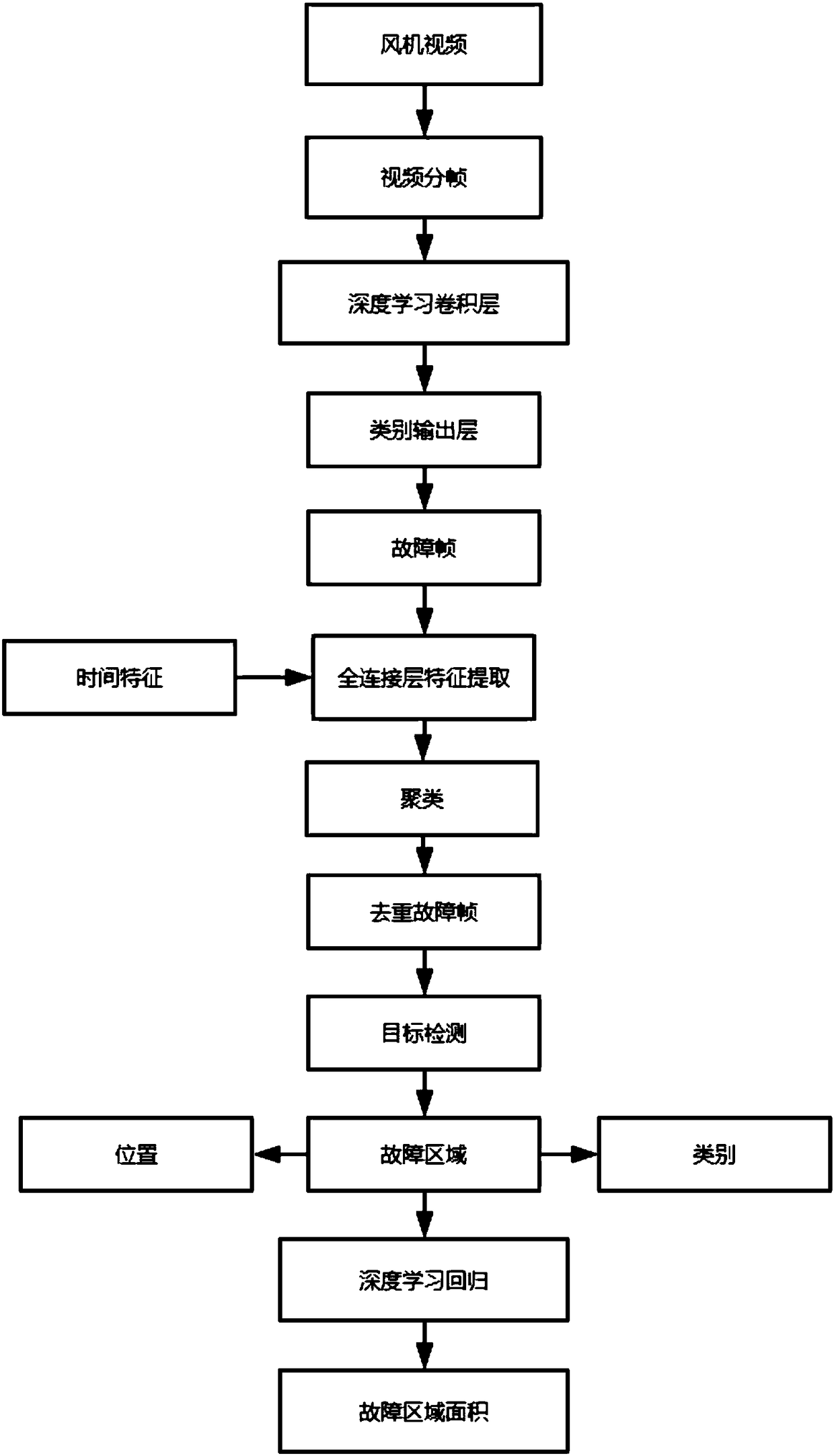

Blower blade fault intelligent identification method based on deep learning

ActiveCN108416294AReduce misjudgmentImprove work efficiencyImage enhancementImage analysisUncrewed vehicleNetwork model

The invention belongs to the application of deep leaning in the technical field of computer vision, and discloses a blower blade fault intelligent identification method based on deep learning. Fault identification and location can be automatically performed on the blower video photographed by the unmanned aerial vehicle so that the labor cost can be saved and the working efficiency can be enhancedfor the work personnel. The method concretely comprises the following steps that: a deep learning network model is constructed by using the marked blower video frame; frame capture is performed on the blower video to be detected so as to identify the fault frame image; and the compressed fault frame image is inputted to the target detection network, and the fault area sample is acquired and further inputted to the deep learning regression network model so as to calculate the area of the blower blade fault area.

Owner:NANJING ILUVATAR COREX TECH CO LTD (DBA ILUVATAR COREX INC NANJING)

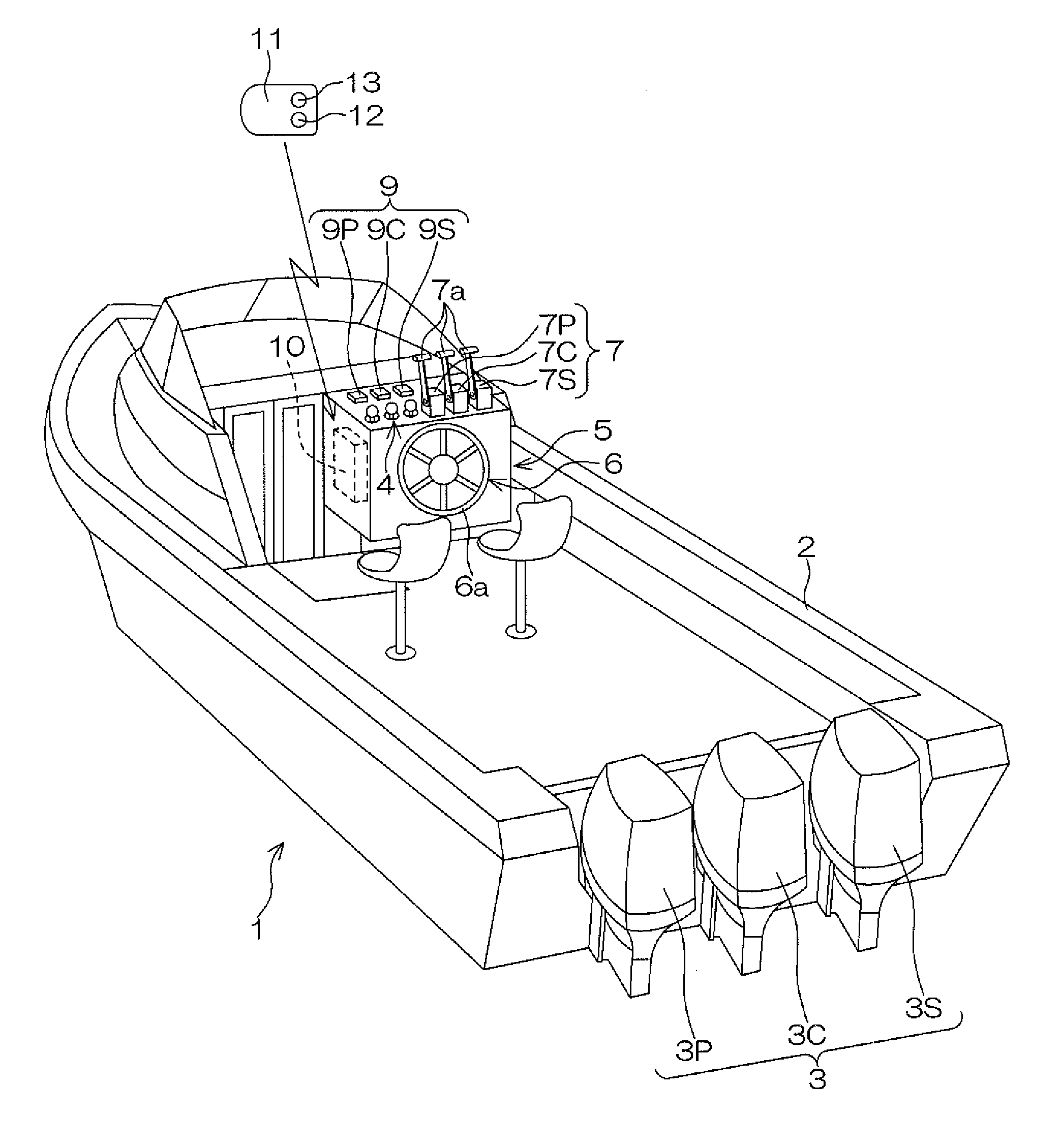

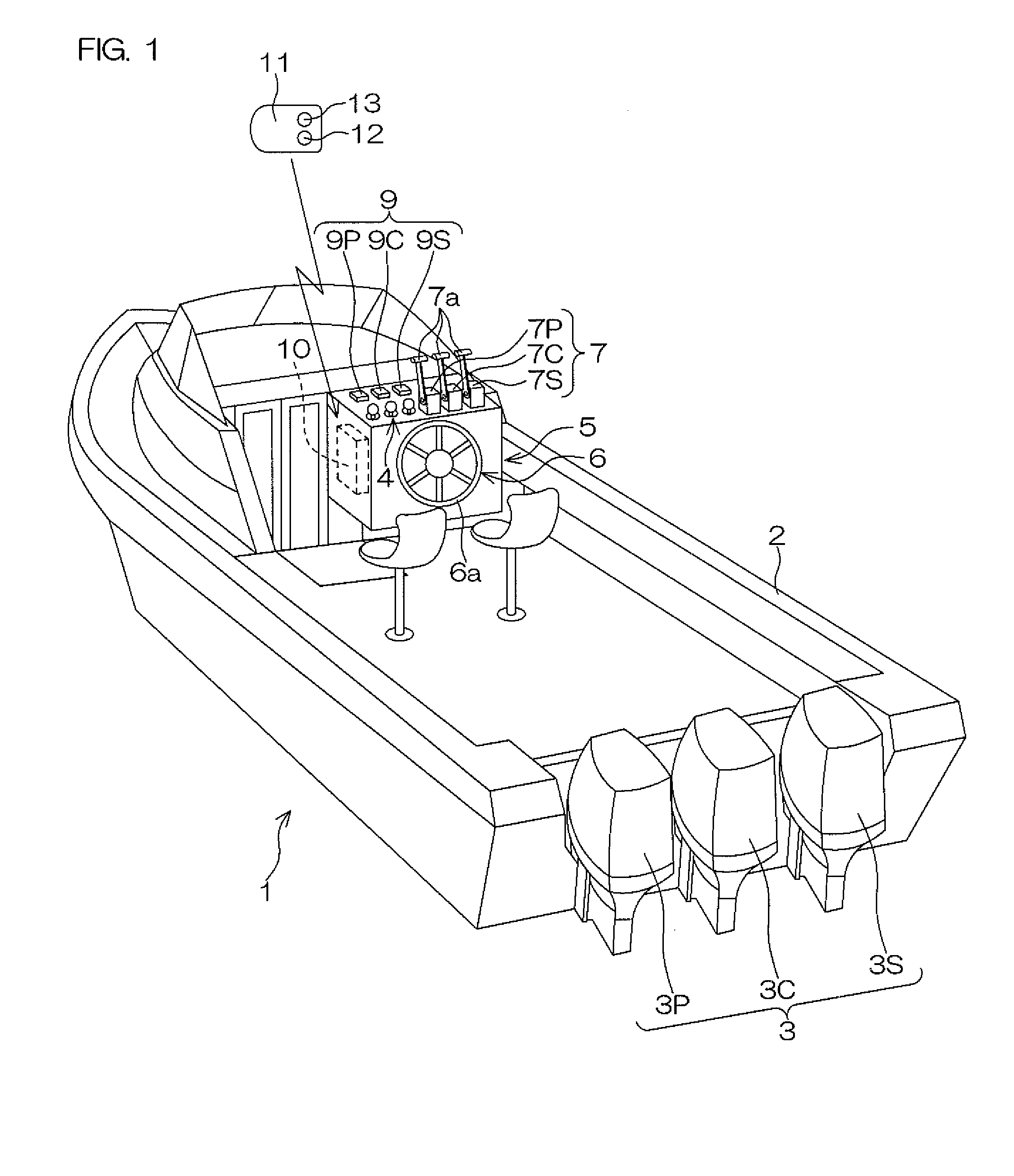

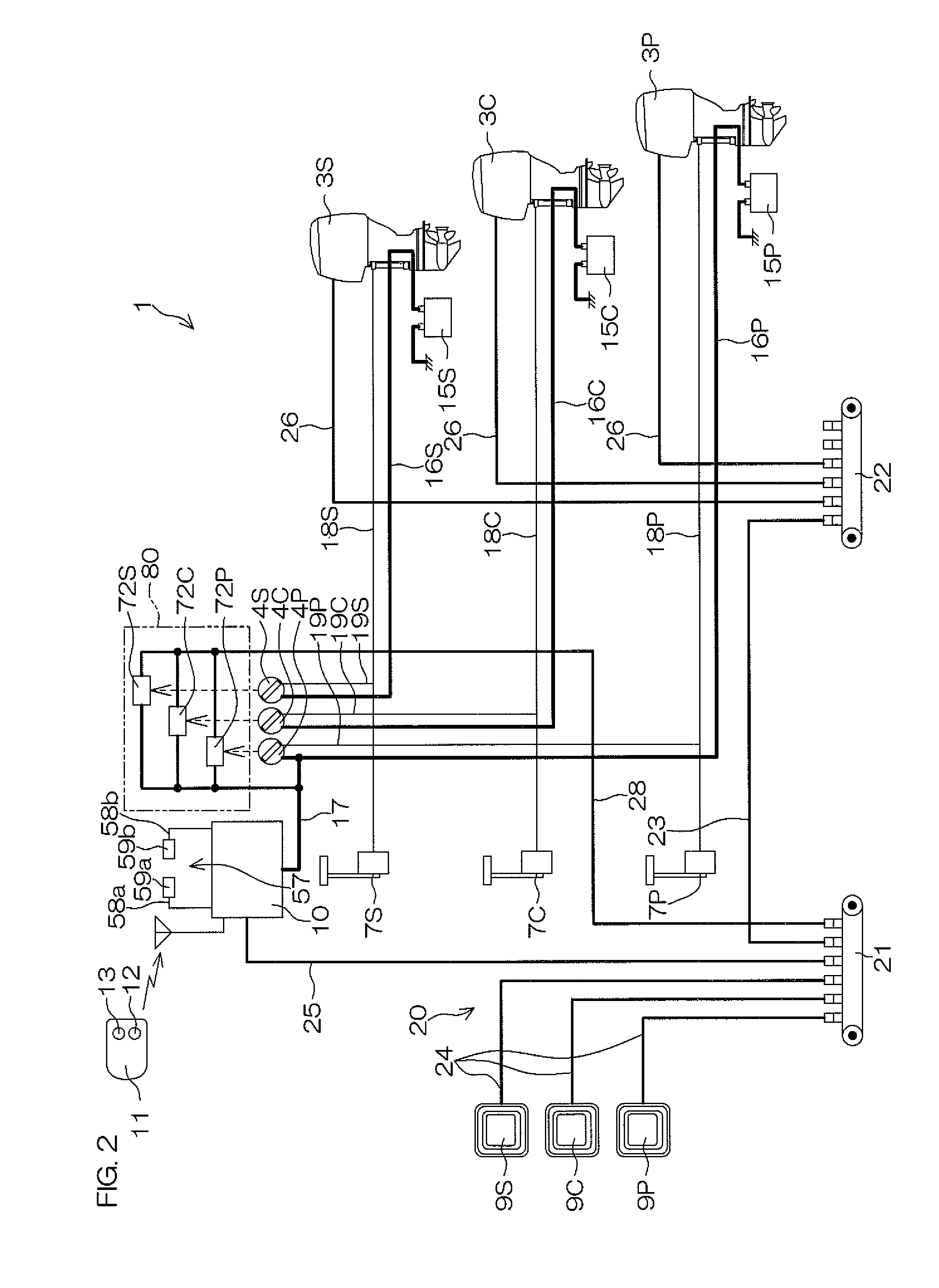

Marine vessel theft deterrent apparatus and marine vessel including the same

ActiveUS20100049386A1Easy to operateUser-friendliness can thus be improvedVehicle testingRegistering/indicating working of vehiclesOperation modeEngineering

A theft deterrent apparatus is used in a marine vessel which includes a propulsion device. The theft deterrent apparatus includes an authentication unit, a fault detection unit arranged to detect a fault of the authentication unit, and an operation control unit arranged to control operation of the propulsion device. When the authentication unit is normal, the operation control unit controls the operation of the propulsion device in accordance with an authentication result of the authentication unit. When a fault has occurred in the authentication unit, the operation control unit controls the operation of the propulsion device without referring to the authentication result of the authentication unit. When the authentication unit is normal, the operation control unit sets an operation mode of the propulsion device to an ordinary operation mode under a condition of success of authentication by the authentication unit and prohibits the operation of the propulsion device if the authentication by the authentication unit does not succeed. When a fault has occurred in the authentication unit, the operation control unit sets the operation mode of the propulsion device to an emergency operation mode in which a predetermined restriction is applied with respect to the ordinary operation mode.

Owner:YAMAHA MOTOR CO LTD

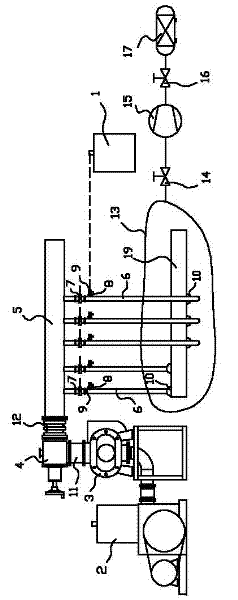

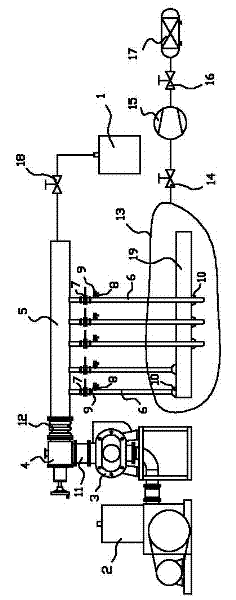

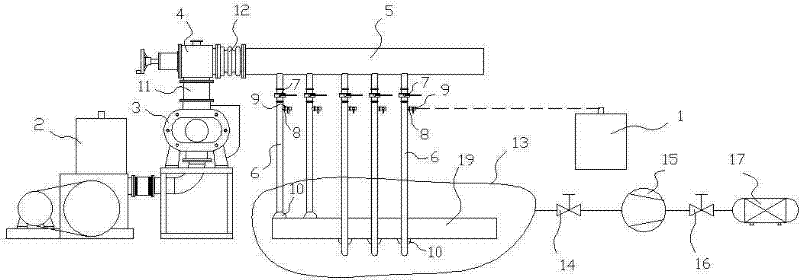

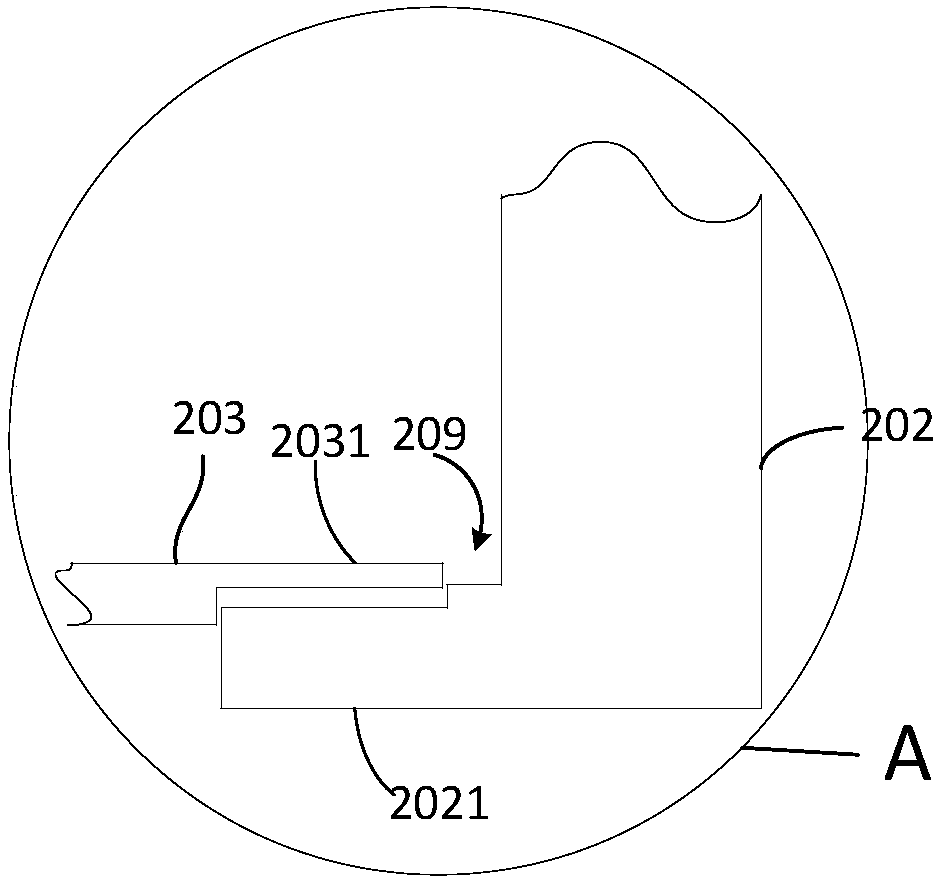

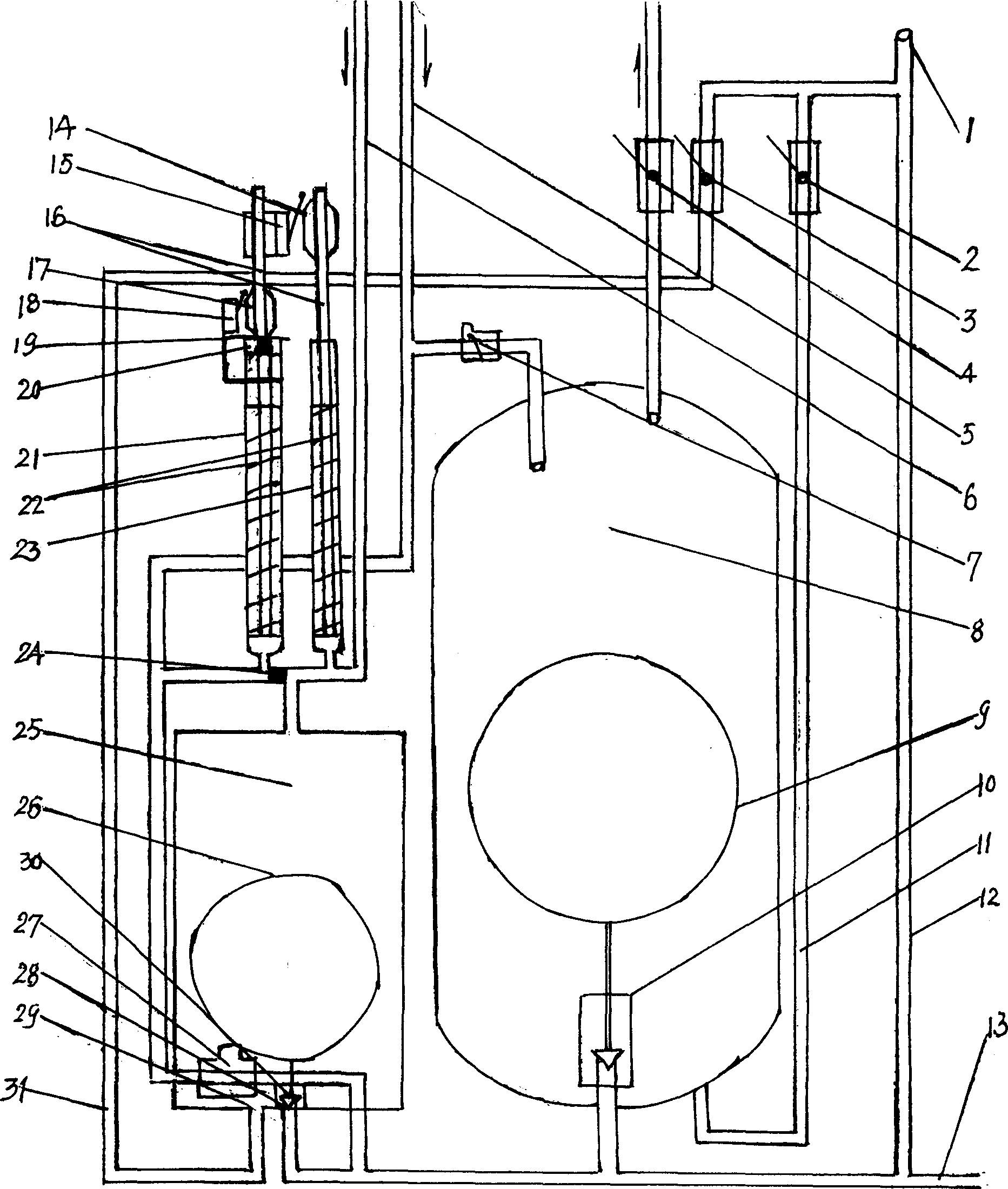

Device for detecting sealing property of multi-cavity container or multiple containers by helium

ActiveCN102564708AReduce work proceduresSave time at workDetection of fluid at leakage pointPhysicsMass spectrometry

The invention discloses a device for detecting the sealing property of a multi-cavity container or multiple containers by helium. The device comprises a helium mass-spectrometer leakage detector, and a vacuum sliding valve pump, a Roots pump, a high vacuum baffle plate valve and a concentrated pipe which are connected with one another sequentially, and a sealing device for sealing the multi-cavity container to be detected or the containers to be detected and filling and releasing helium, and is characterized in that: at least three connection pipelines are arranged on the concentrated pipe; a valve FA for closing and opening each connection pipeline is arranged on each connection pipeline; a port JA detachably connected with the helium mass-spectrometer leakage detector is formed in the connection pipeline below each valve FA; a valve FB for closing and opening each port JA is arranged on each port JA; and the lower end of each connection pipeline is provided with a port JB detachably connected with the inlet of the container to be detected. According to the device, the working procedures can be reduced, the working time is shortened, the work efficiency is improved, and low carbon and environment friendliness are realized; and particularly, when the multi-cavity container is provided with multiple channels, the device has a relatively remarkable effect.

Owner:HANGZHOU ZHONGTAI CRYOGENIC TECHNOLOGY CORPORATION

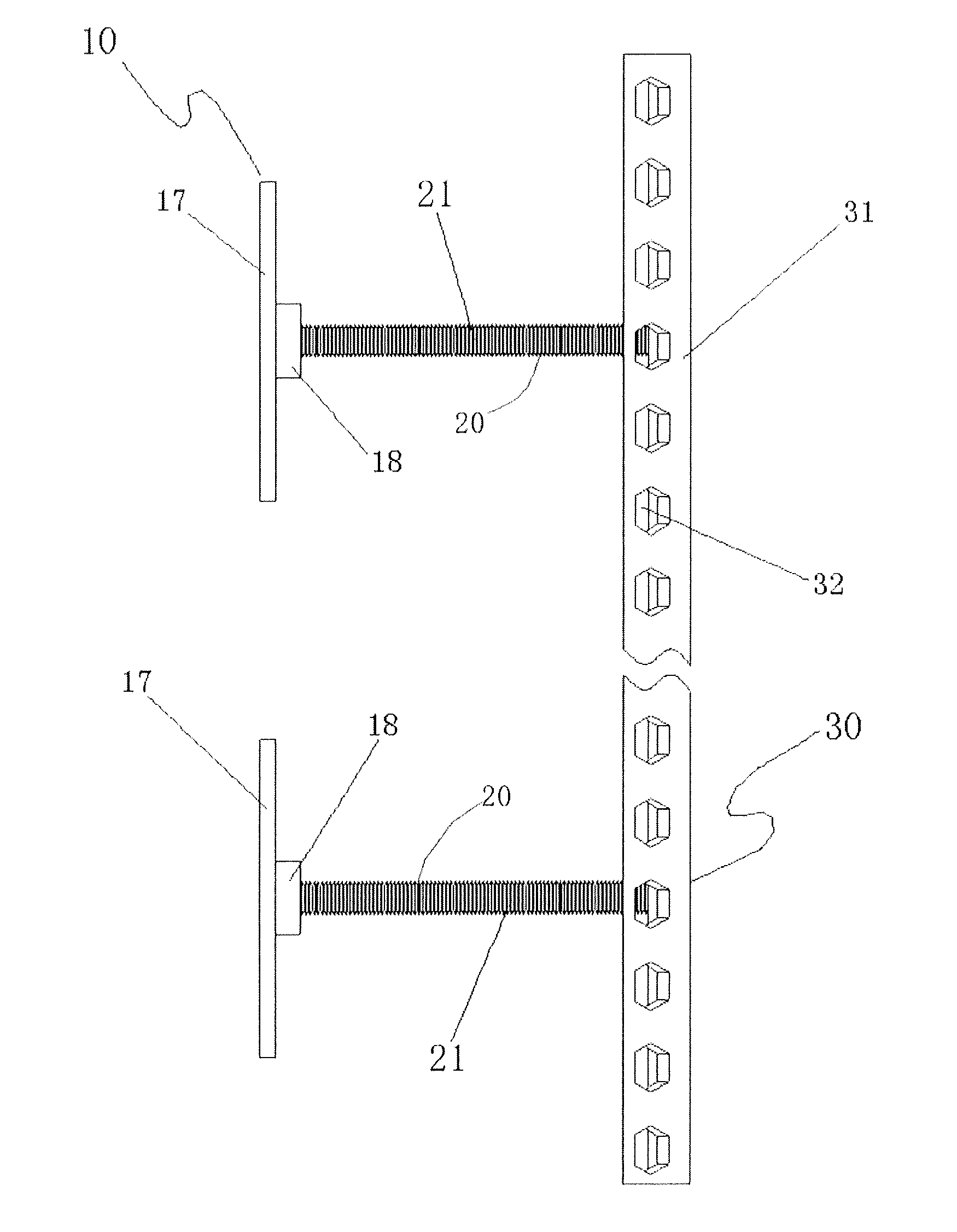

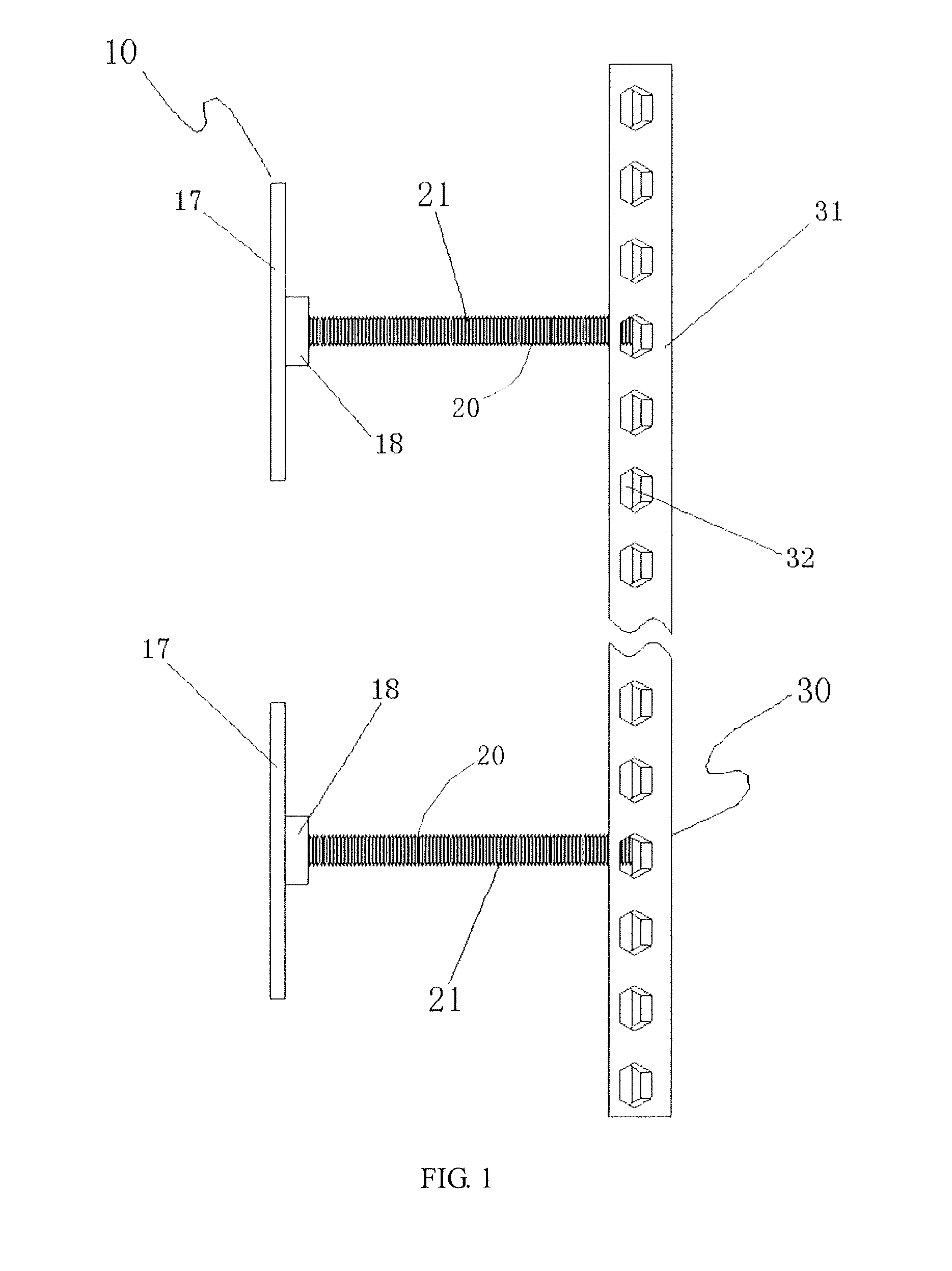

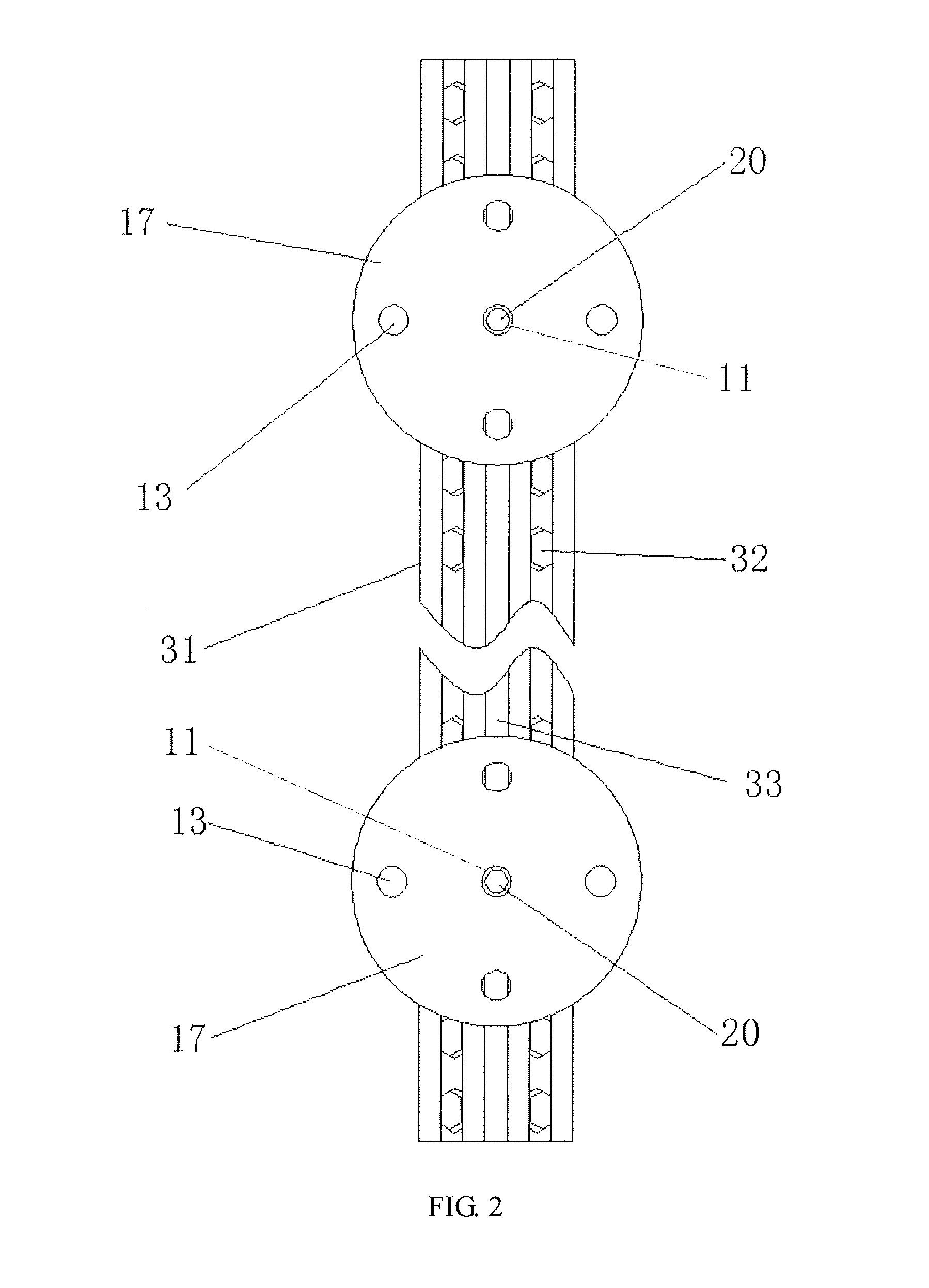

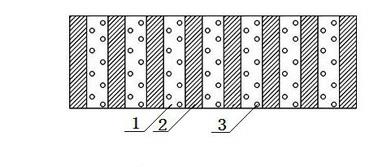

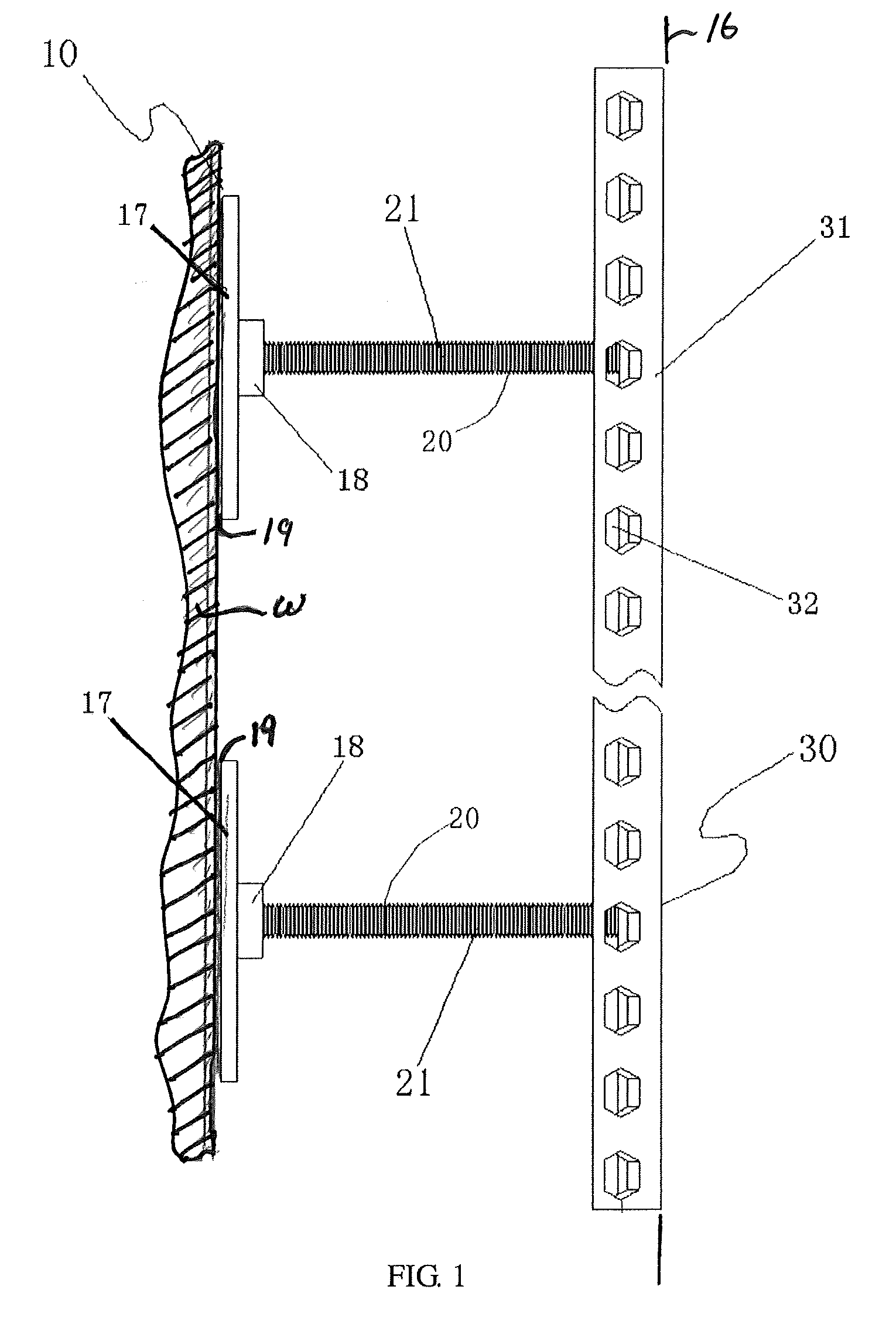

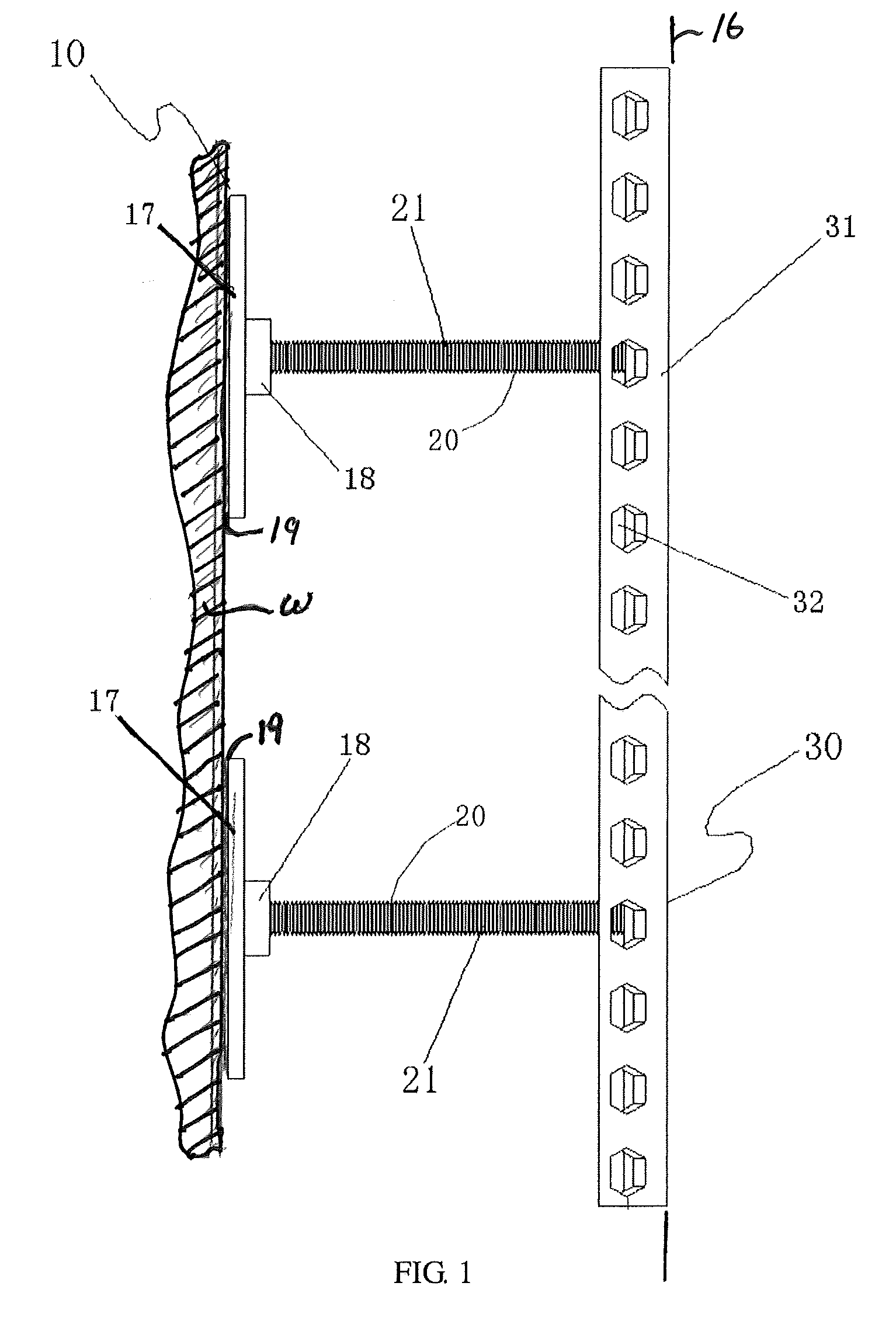

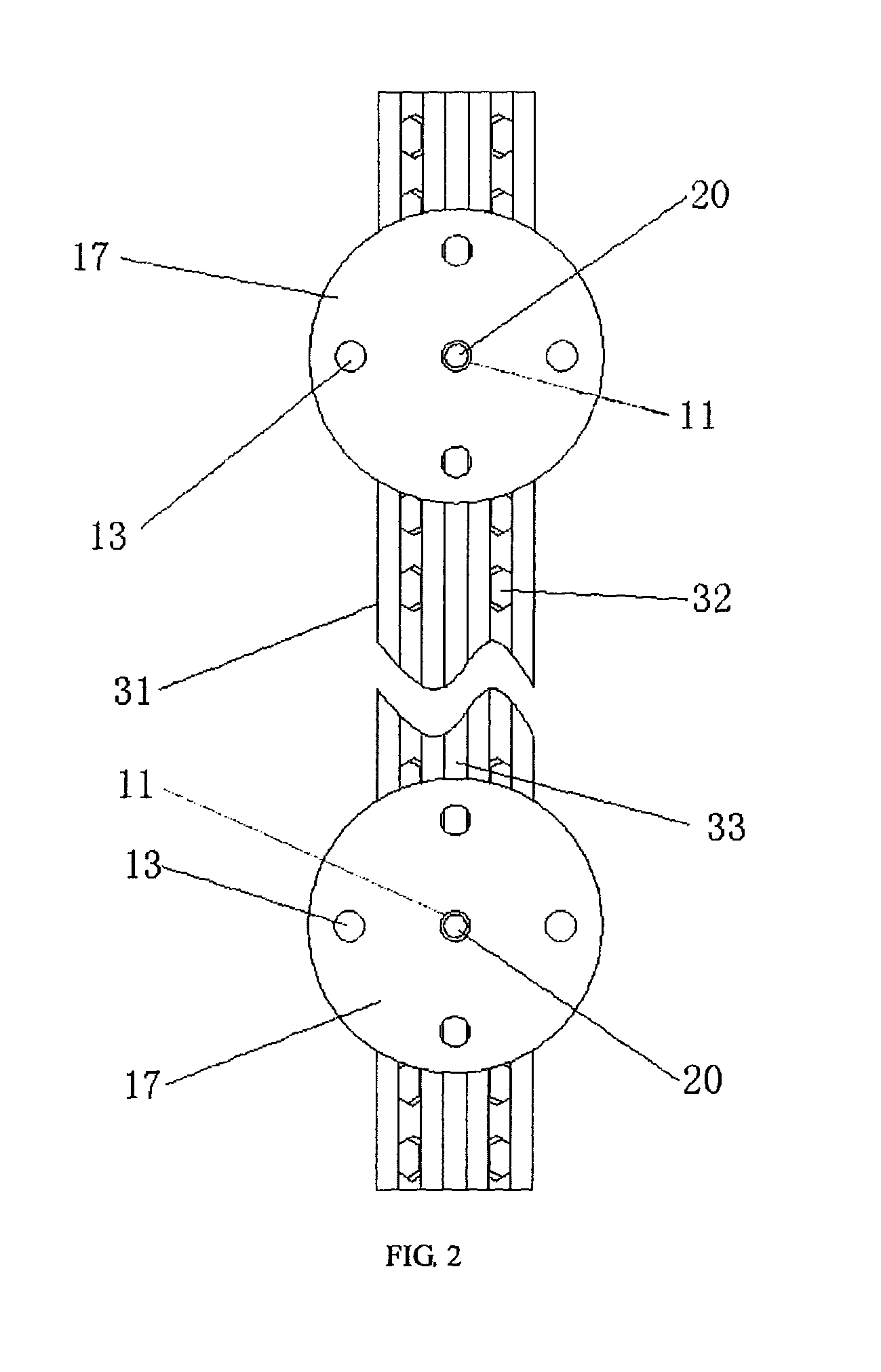

Method for plastering construction in architectural decoration

ActiveUS20150059284A1Improve efficiencyImprove construction qualityCovering/liningsBuilding repairsStructural engineeringBuilding construction

A method for plastering construction in architectural decoration comprises the following steps: (1) base treatment; (2) performing construction positioning paying-off according to the required plastering height, and longitudinally installing screeding templates along a wall surface subjected to the base treatment in Step (1) according to the paying-off height, a lateral space between adjacent screeding templates being 1.3 to 1.8 meters; (3) plastering; and (4) laying aside the wall surface subjected to the plastering for 12 to 24 hours till plastering mortar on the wall surface is in a half-dried compact hardened state, and using teeth of a saw blade for grinding the mortar along the two adjacent screeding templates through a ruler till the mortar is even. The method can improve the construction efficiency and guarantee the construction quality.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

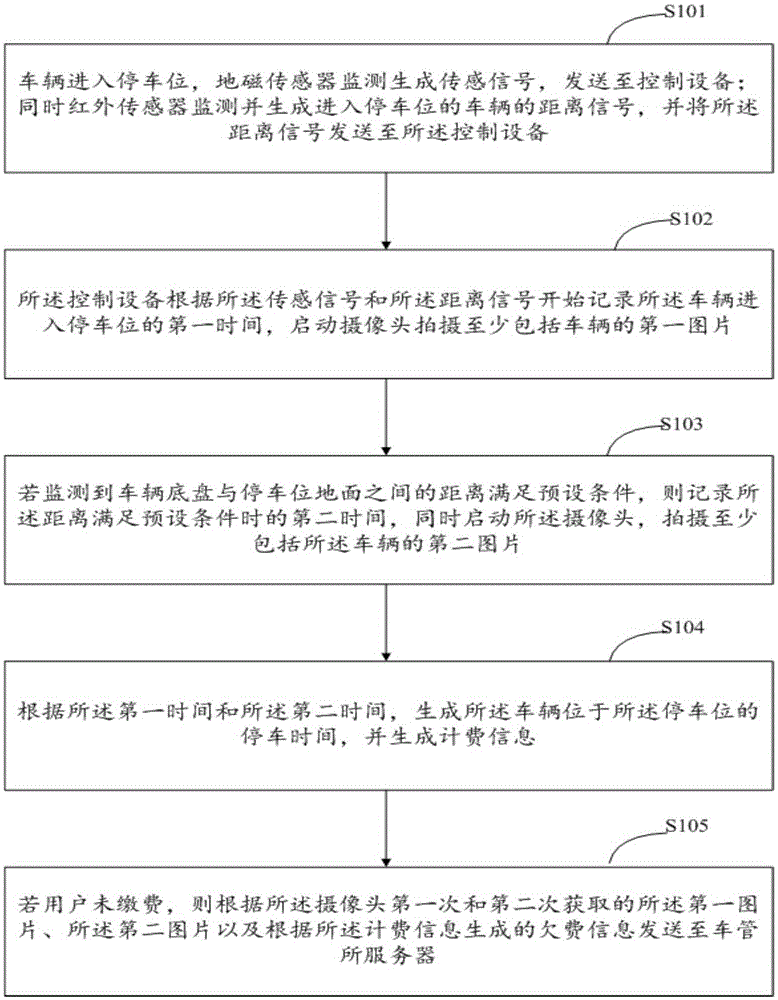

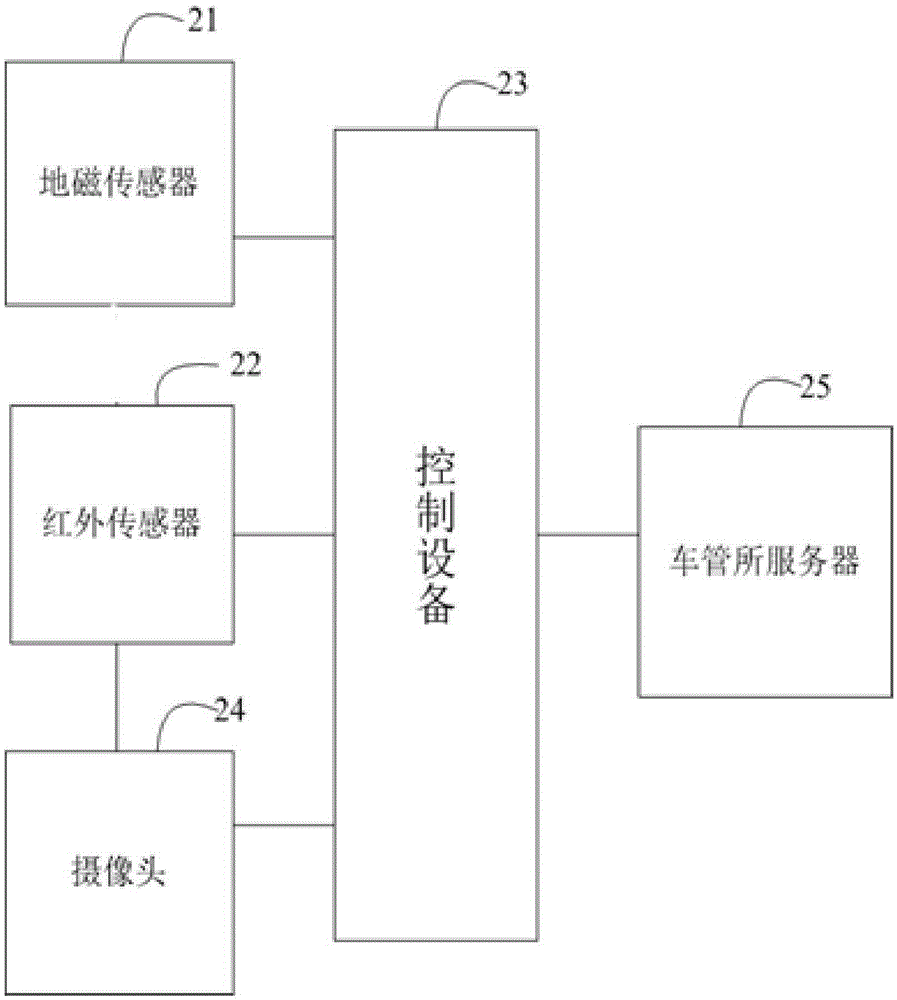

Parking space arrearage management method and system

InactiveCN105321351AGuaranteed accuracyAccurate Accurate AccuracyTicket-issuing apparatusRoad vehicles traffic controlThe InternetParking space

The invention provides a parking space arrearage management method and system, belonging to the internet of things field. The system concretely comprises a geomagnetic sensor, an infrared sensor and a camera. According to the invention, the distance between a vehicle chassis and a parking space ground is monitored in real time to determine whether a vehicle is located in the parking space; and vehicle information is obtained through pictures shot by the camera, and vehicle arrearage information is timely sent to a vehicle administration office, thereby timely providing basis for the annual test of the vehicle administration office.

Owner:徐承柬

Soybean production wholly mechanized matched cultivation method

InactiveCN102119618ASuitable soil environmentHigh activitySeed and root treatmentHorticultureLoss rateFarm machine

The invention relates to a soybean production wholly mechanized matched cultivation method by organically combining an agricultural machine measure and an agronomic measure. The soybean production wholly mechanized matched cultivation method comprises the following steps of: fine soil preparation, seed treatment, precision sowing, mechanical compaction, mechanical medicament weeding and mechanical harvesting, wherein a rational arable layer is provided for soybean production and a suitable soil environment is created through deep tillage; through the treatment of a plasma seed treater, the germination rate and the germination energy of soybean seeds are improved, and seed activity is improved so as to lay the foundation for obtaining full stand of seedlings by one-time sowing. By the soybean production wholly mechanized matched cultivation method, timely sowing is ensured, and high-quality seeds are saved; weeds are effectively controlled, working procedures are reduced, and working hours are saved; and harvesting is in time, and by the agronomic measure, the loss rate of soybean harvesting is reduced, and labor intensity is reduced.

Owner:马振亚

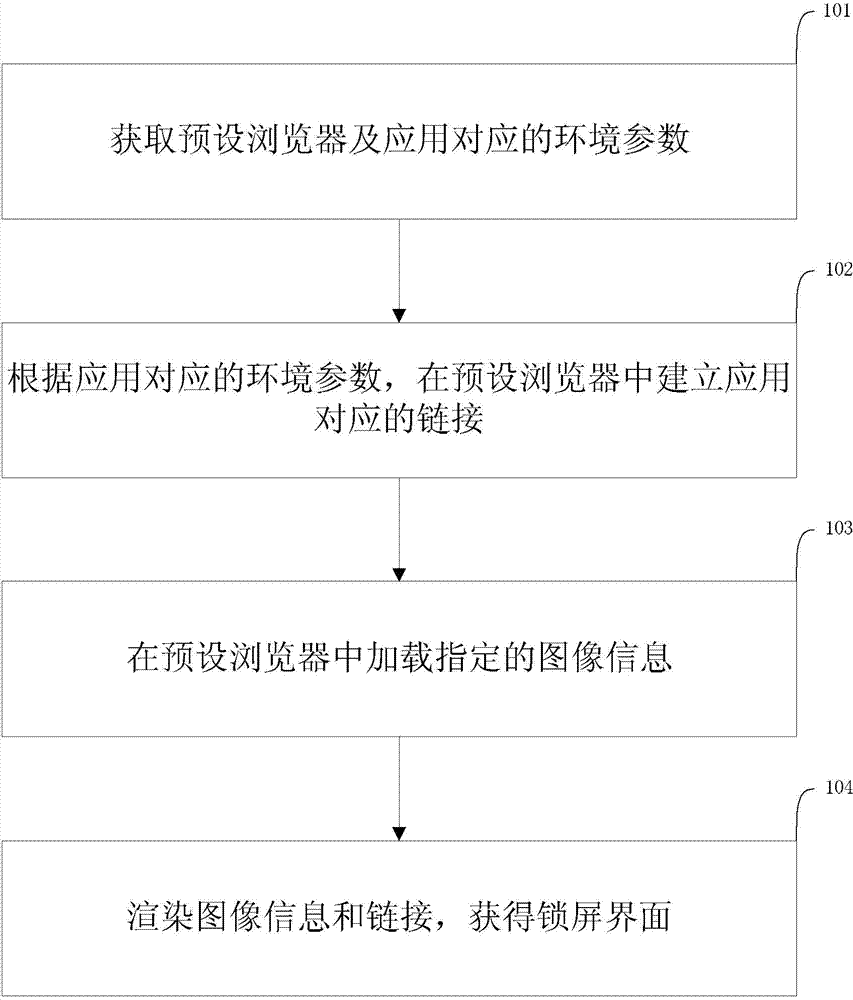

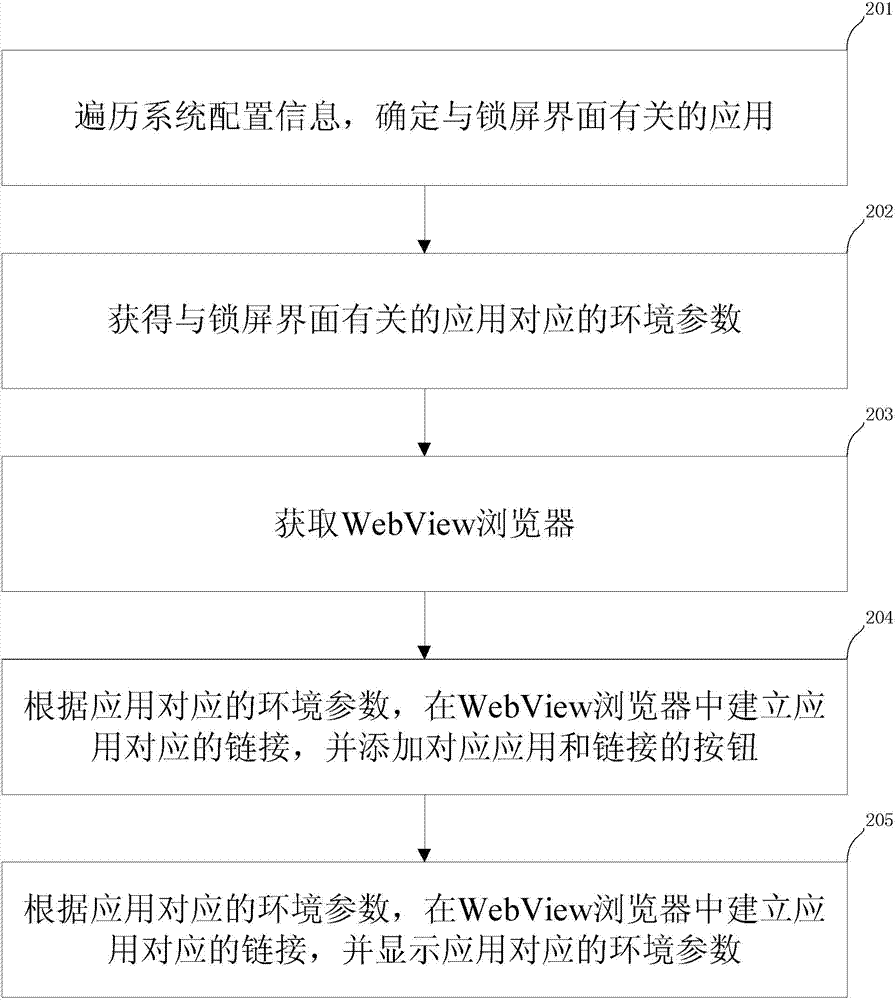

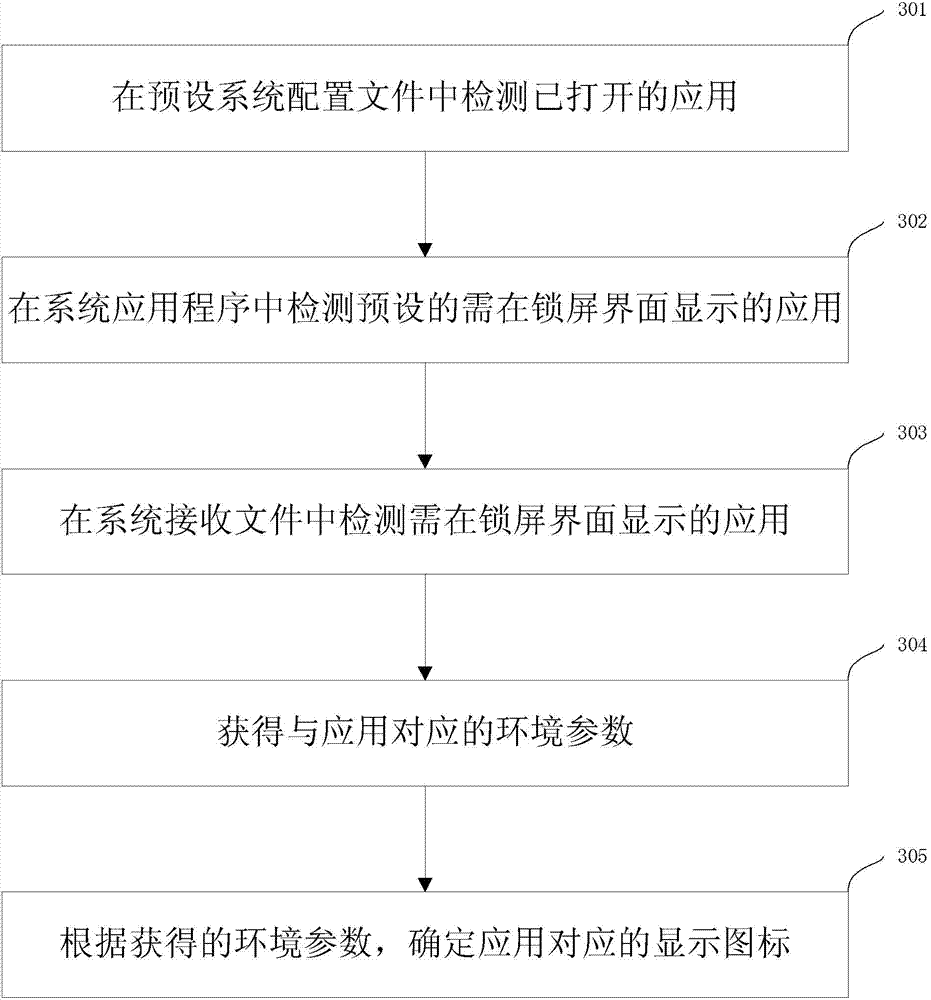

Method and device for manufacturing screen locking interface and terminal device

ActiveCN103677944AReduce work proceduresLow costProgram loading/initiatingTerminal equipmentEmbedded system

Owner:XIAOMI INC

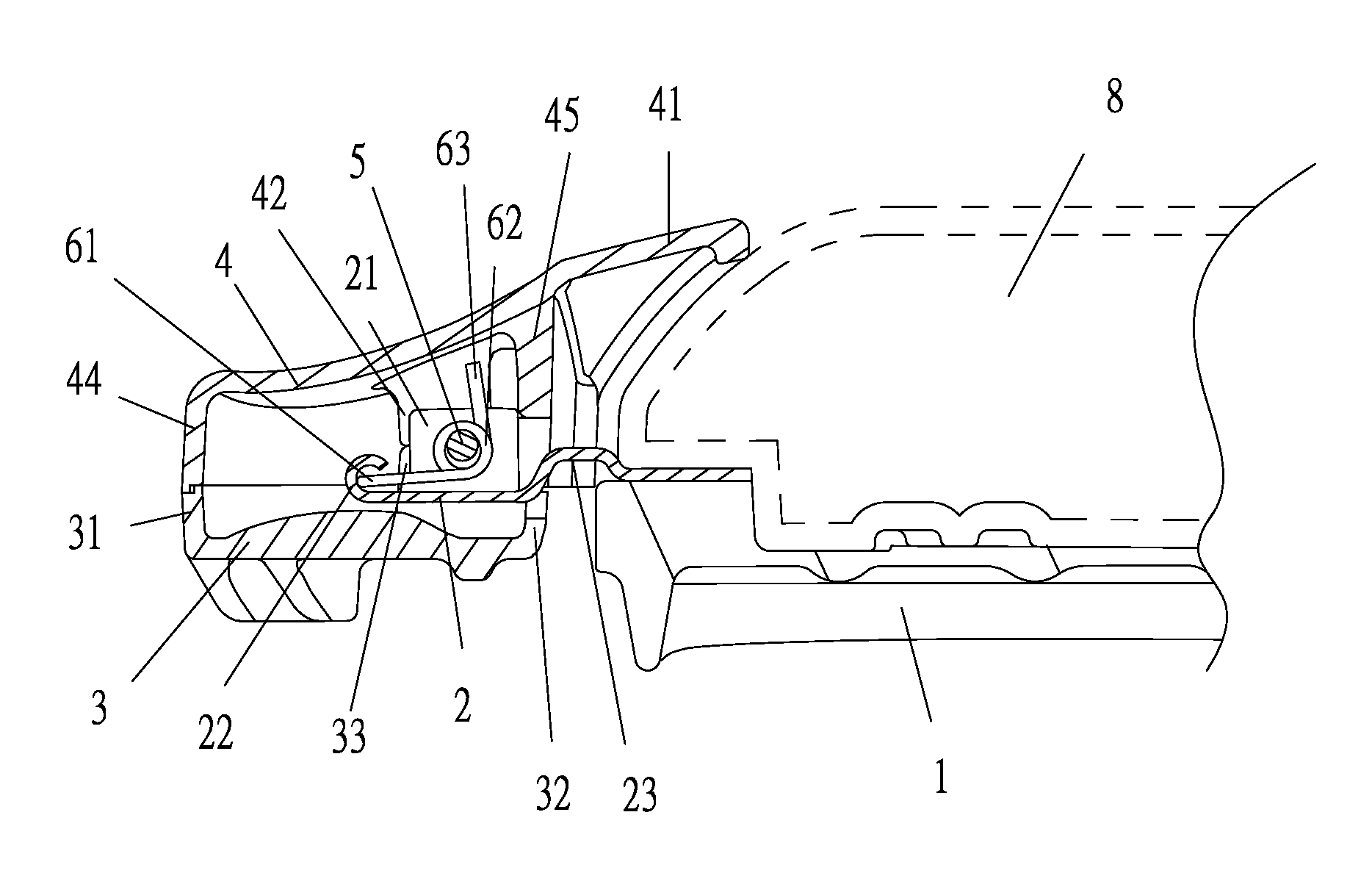

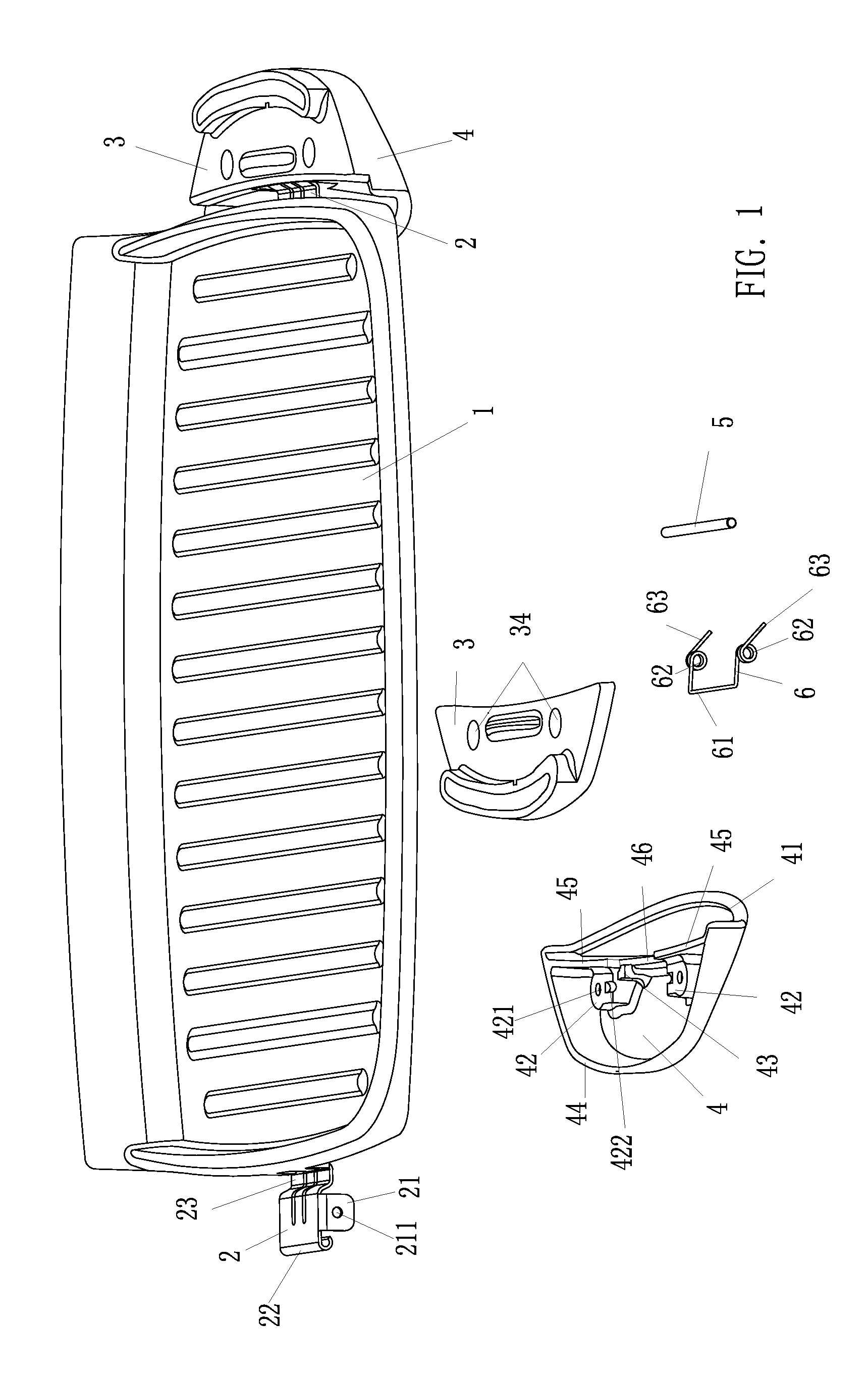

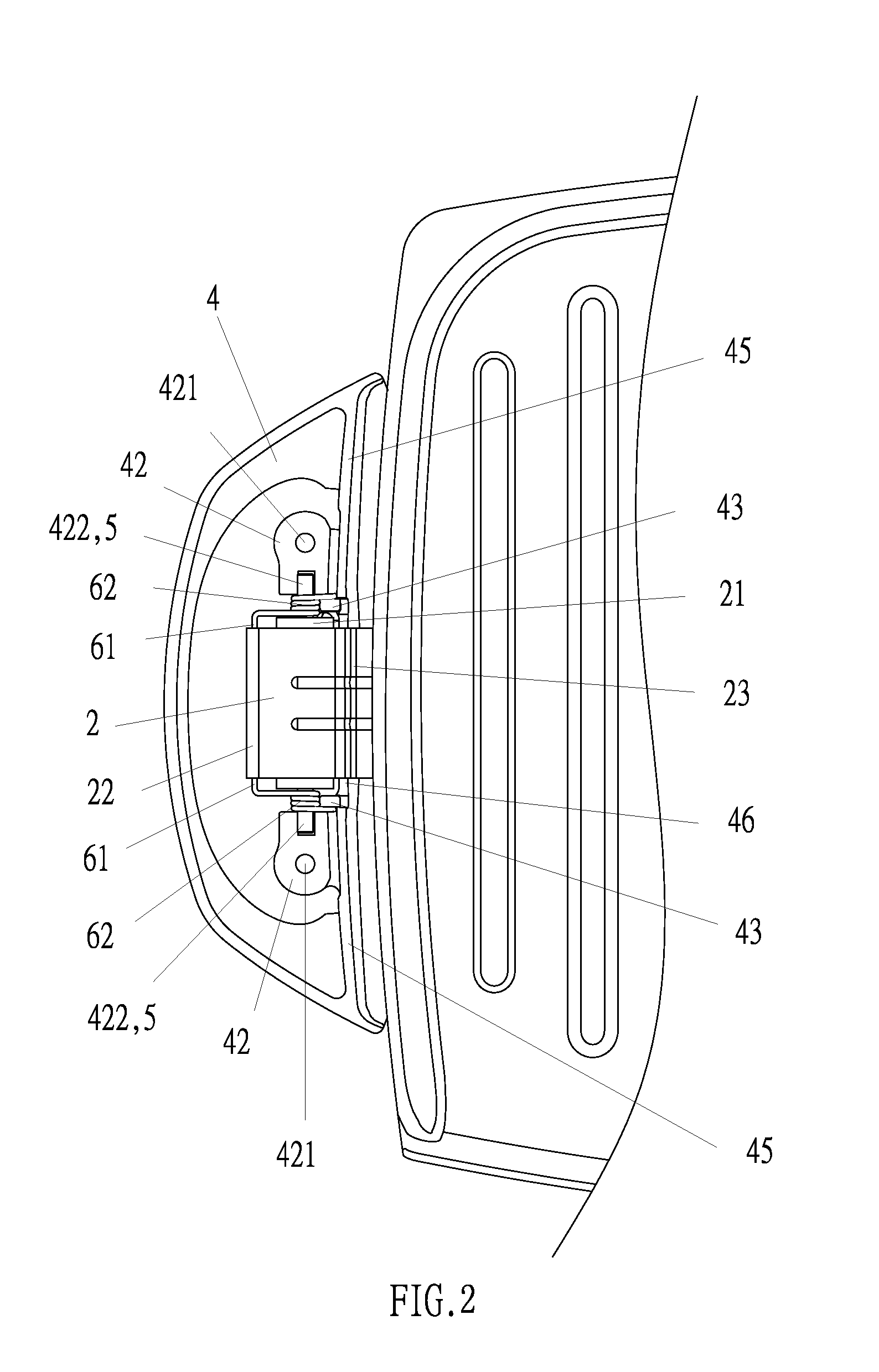

Handle for Baking Device

InactiveUS20090236352A1Reduce work proceduresGood lookingCooking-vessel lids/coversSealingEngineeringTongue part

A bakeware handle comprises a raised part fixedly connected to one side of the bakeware and extending outwards, and the raised ear has a short shaft; a main body of bakeware handle whose tongue part extends to the bakeware being pin jointed with the short shaft; at least a torsional spring covering the short shaft; one end of the torsional spring is set against the raised ear and the other end of the torsional spring is set against the main body of bakeware handle. In the immovable state of the main body of bakeware handle, the tongue part of the main body of bakeware handle is locked at the same edge of the shell that disposed on the bakeware of the electrical baking device. The bakeware is locked at the shell by the pretightening force of the torsional spring. When the main body of bakeware handle is turned relative to the short shaft, the torsional spring is compressed, and the tongue part of the main body of bakeware handle gets separated from the same edge of the shell that disposed on the bakeware of the electrical baking device, and the bakeware is taken away form the shell of the electrical baking device.

Owner:TSANN KUEN CHINA ENTERPRISE

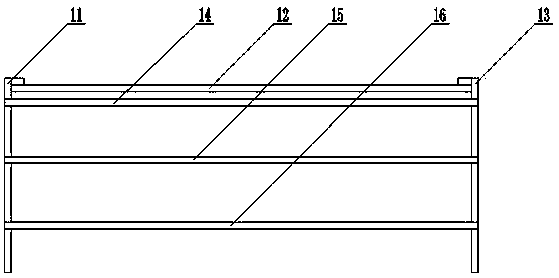

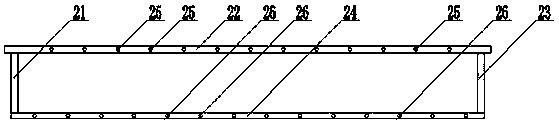

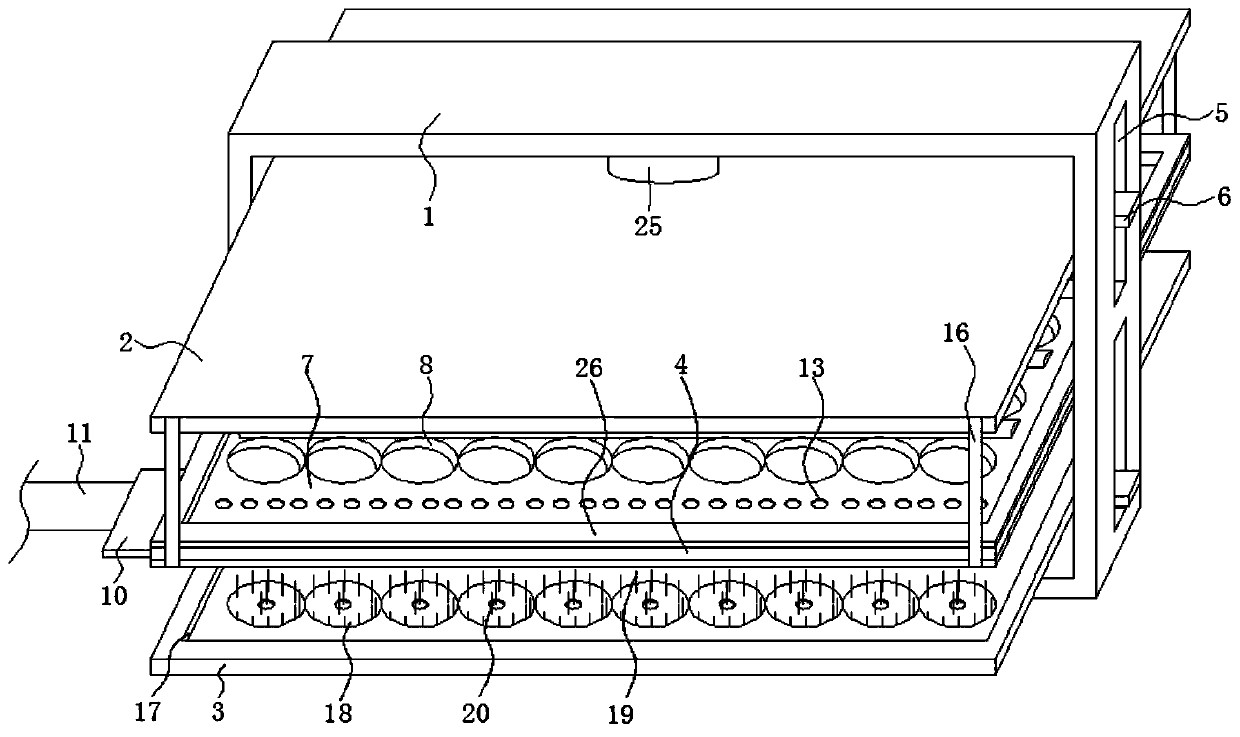

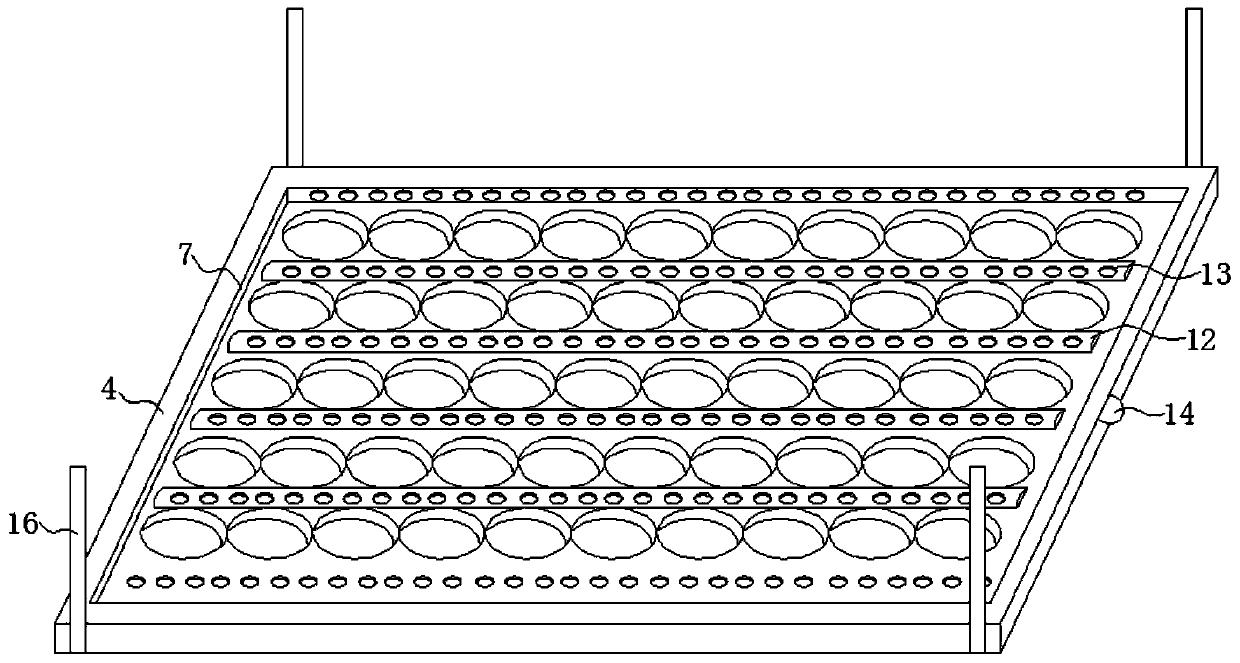

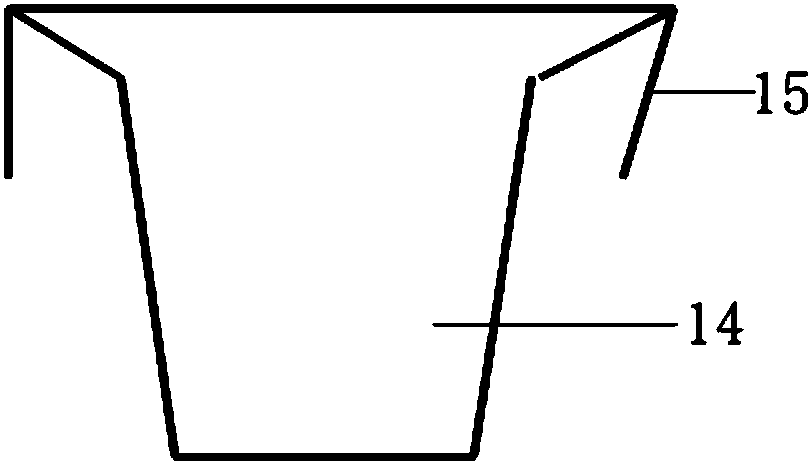

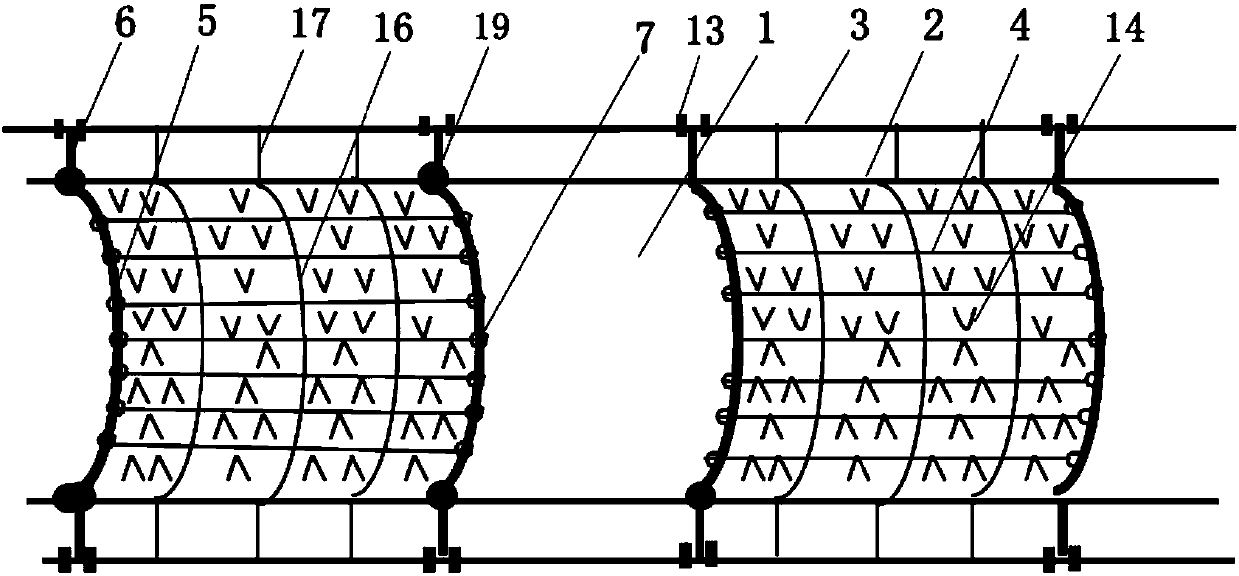

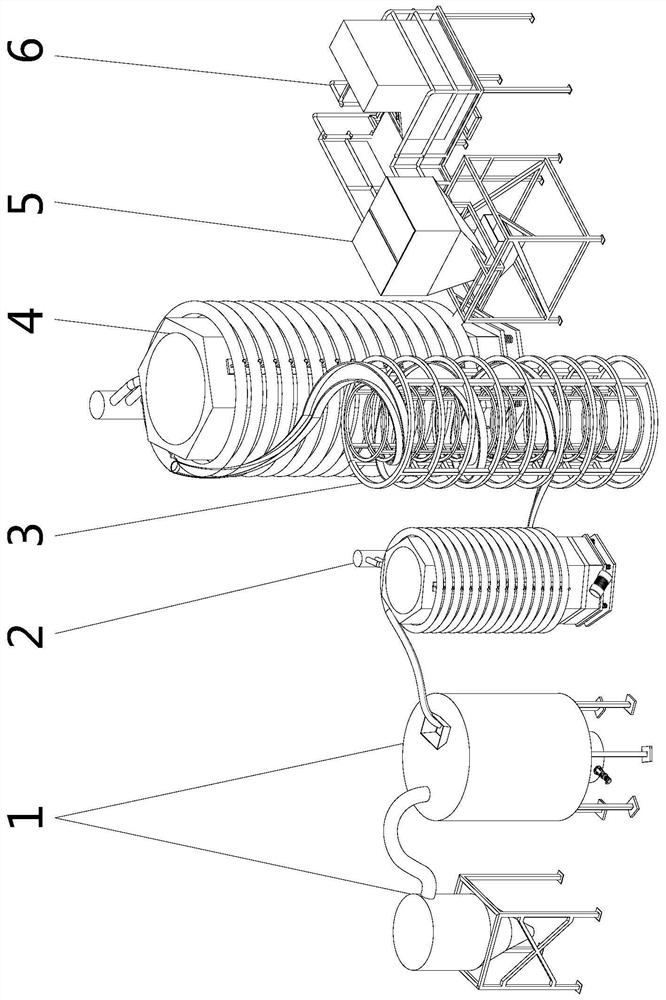

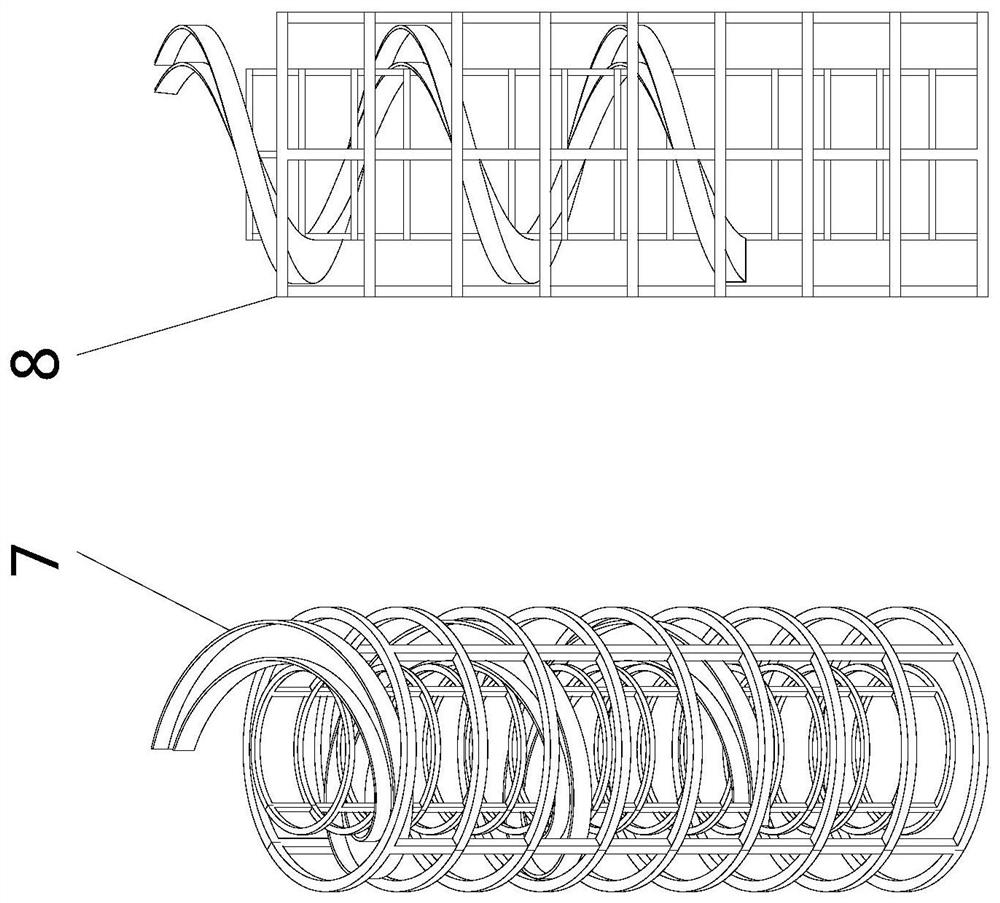

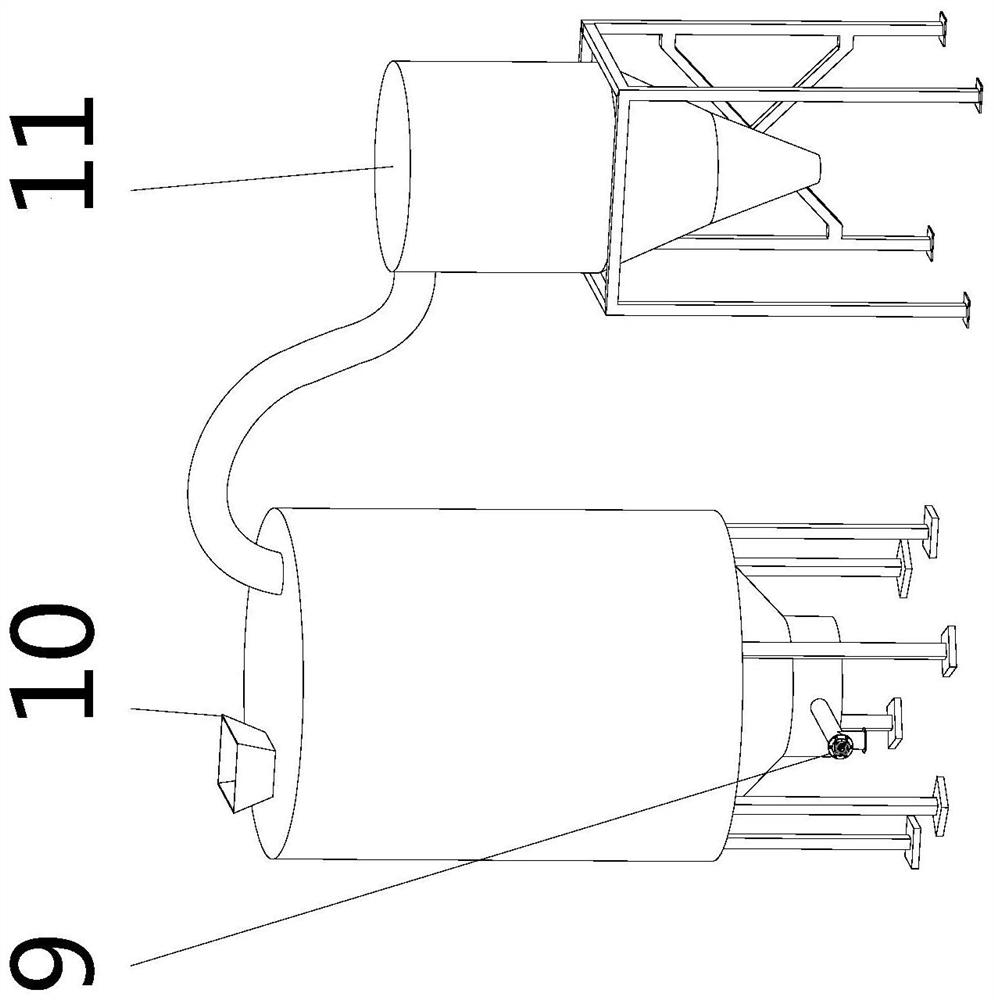

Tobacco separating needle-threading tobacco loading suspension device

The invention belongs to the technical field of tobacco harvesting and curing, and relates to a tobacco separating needle-threading tobacco loading suspension device. The device comprises a tobacco loading basket and a tobacco fixing suspension frame matched with the tobacco loading basket; the tobacco loading basket is provided with a basket frame with a certain depth; a support rod is arranged at the back face of the basket frame; the tobacco fixing suspension frame comprises an upper cross rod provided with an upper line tobacco threading needles vertical to the back face of the basket frame; the effective length of the upper line tobacco threading needles is not smaller than the depth of the basket frame. According to the tobacco separating needle-threading tobacco loading suspension device adopting the structure, the curing capacity can be increased on the basis of not changing the existing curing room structure, without changing the existing curing room process conditions and under the condition of not increasing the operation difficulty of suspension rods, the worker number and curing cost are reduced, the damage and pollution of the tobaccos are reduced in the harvesting and transportation process, the probability of directly contacting the tobacco is reduced, the tobaccos in different batches are prevented from being miss-loaded and miss-cured, the tobacco quality is improved, and great popularization and application values are realized.

Owner:中国烟草总公司重庆市公司丰都分公司

Static-state-drying-based food processing device for Chinese date processing

The invention provides a static-state-drying-based food processing device for Chinese date processing, and relates to the field of food processing. The food processing device comprises a supporting frame, an upper plywood is arranged inside the supporting frame, a lower plywood is arranged inside the supporting frame, a middle plate is arranged inside the supporting frame, and a supporting slide groove is formed in the surface of the supporting frame; supporting slide rods are fixedly connected to the side face of the upper plywood and the side face of the lower plywood, the surfaces of the supporting slide rods are slidably connected with the inner wall of the supporting slide groove, and a drying groove is formed in the surface of the middle plate. According to the static-state-drying-based food processing device for Chinese date processing, Chinese dates are uniformly distributed, steam uniformly rises, the processing device is suspended in a narrow space to support the Chinese dates and prevent the Chinese dates from being damaged, the steam utilization rate is high, and the source and energy are saved; meanwhile, the efficiency of drying the Chinese dates is high, and the problem that a common drying device for Chinese date processing easily causes damage to different forms of the Chinese dates, and the efficiency of processing the Chinese dates is influenced to a certainextent is effectively solved.

Owner:XUZHOU UNIV OF TECH

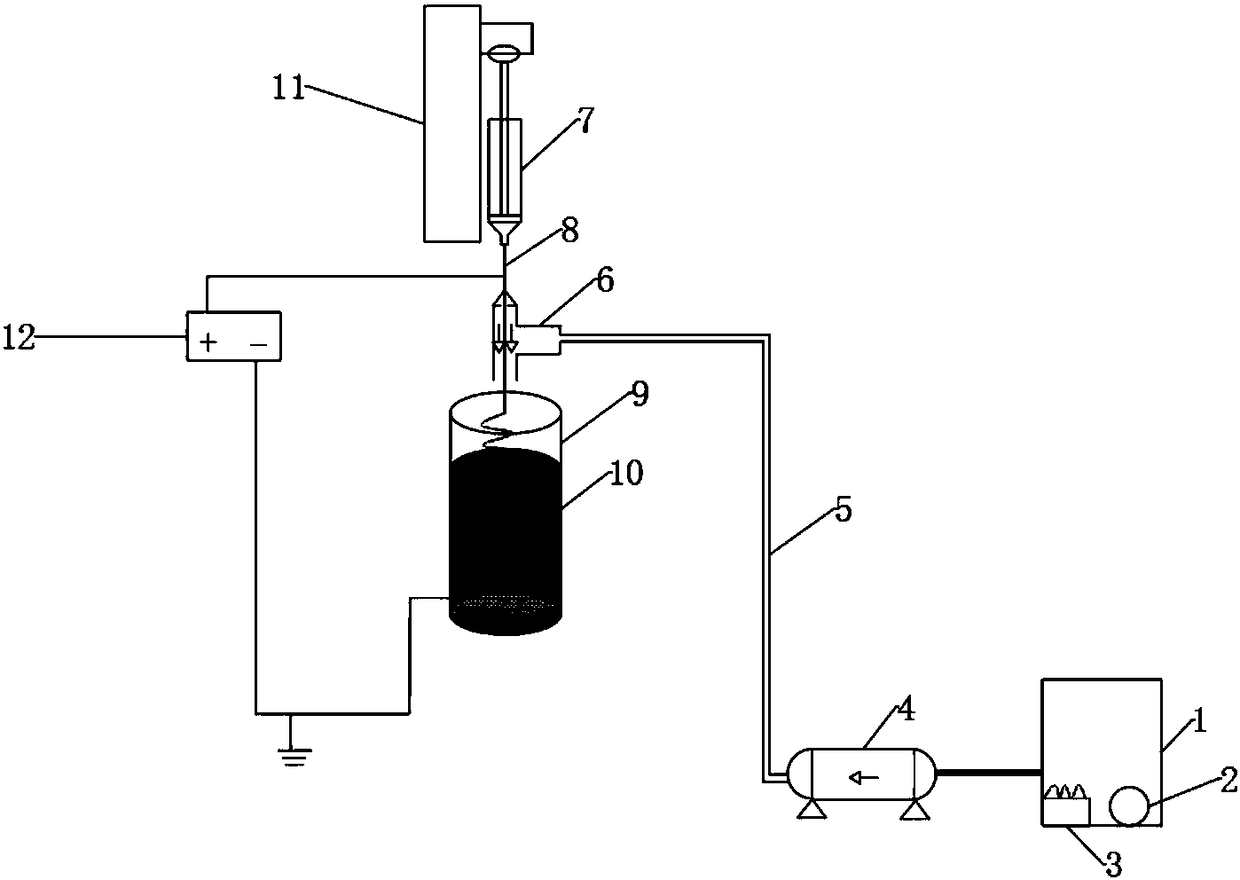

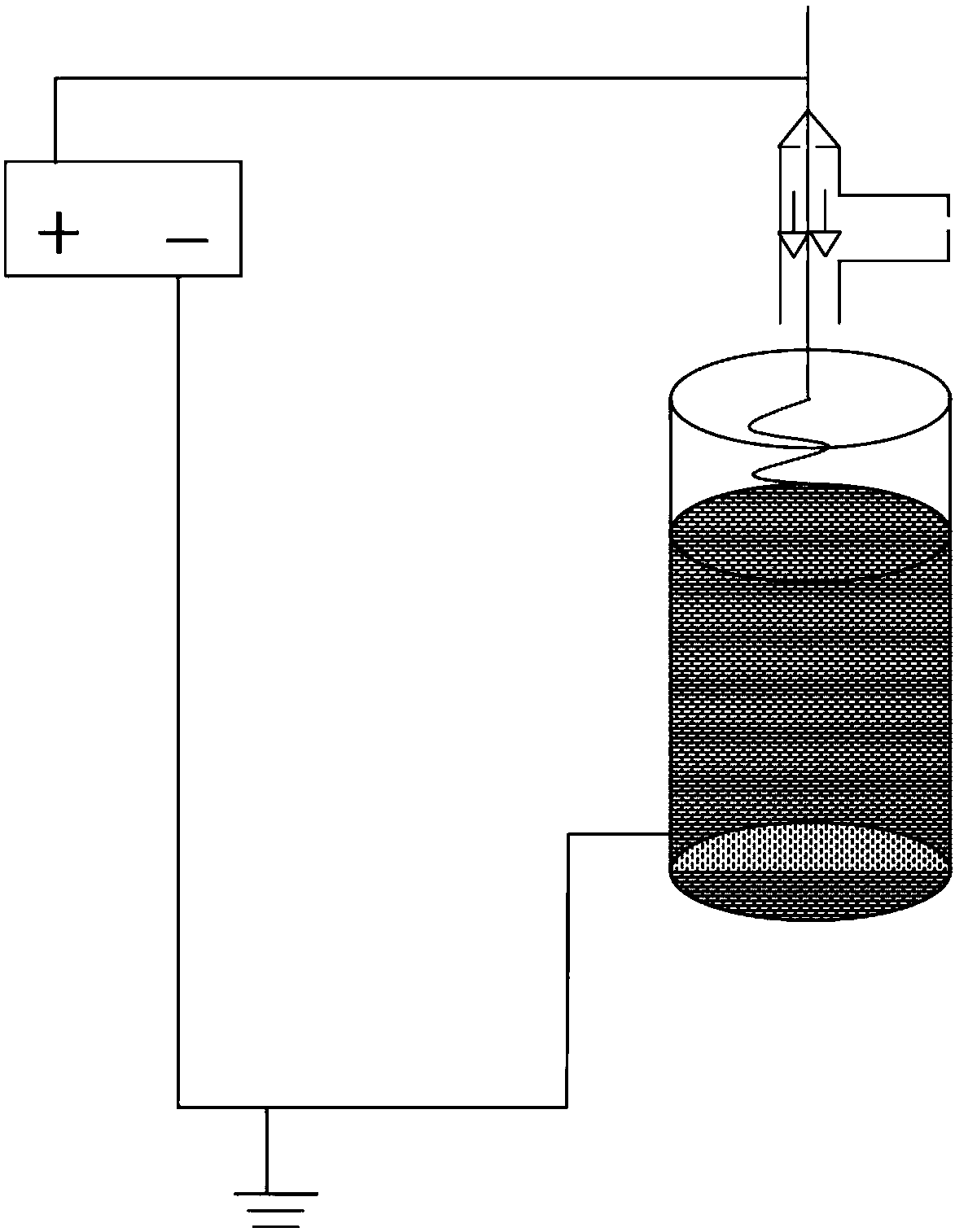

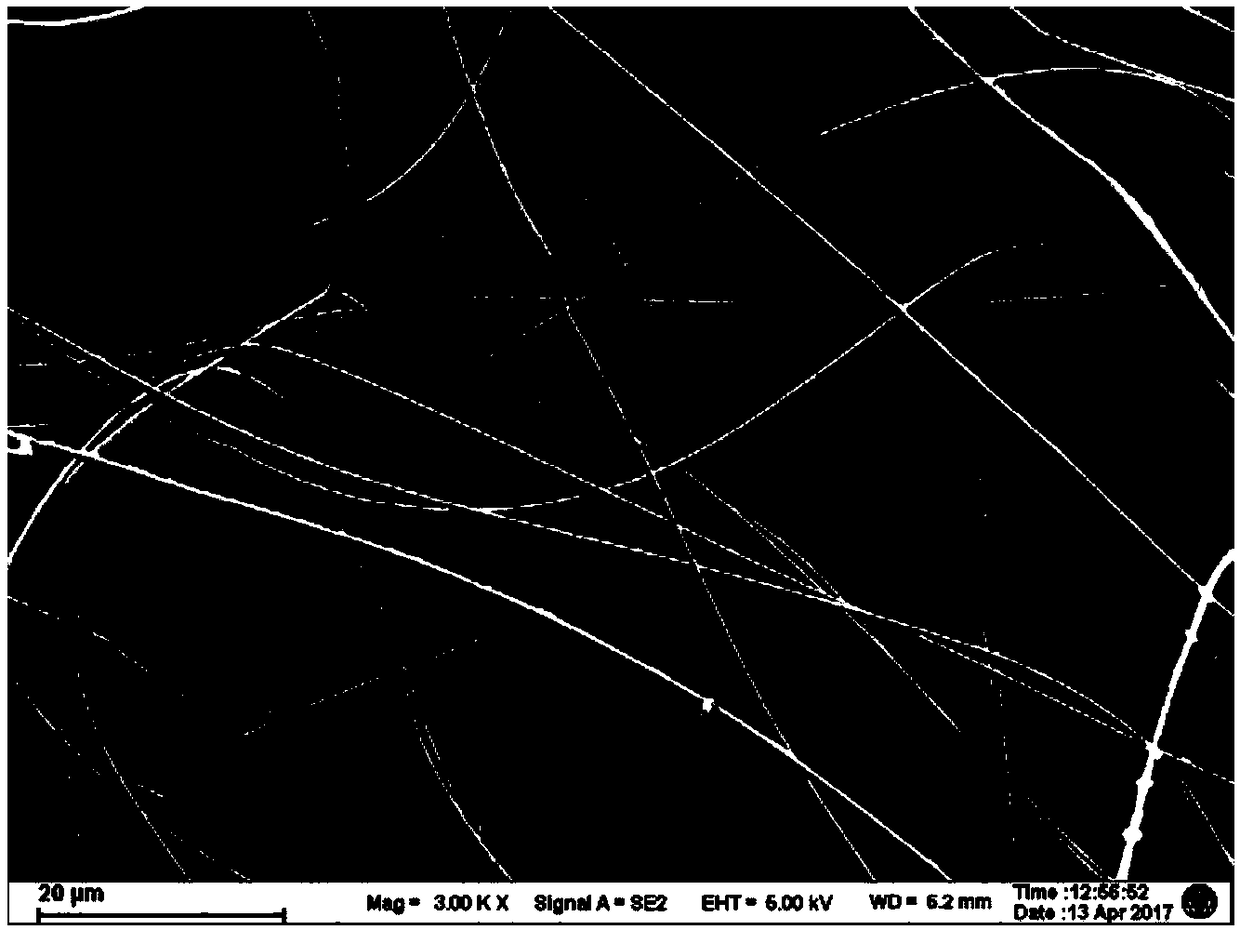

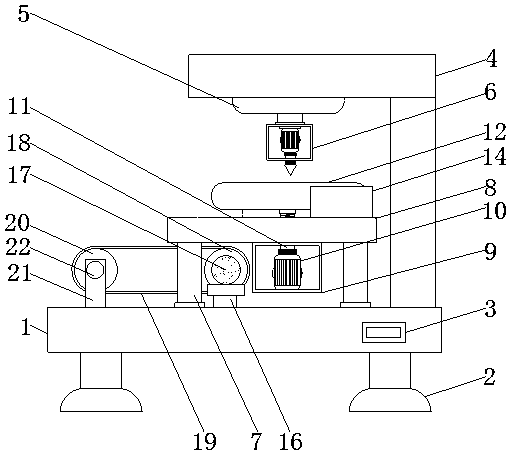

Electrostatic spinning device for preparation of fluffy-state nanofibers and method for preparation of fluffy-state nanofibers

InactiveCN108950700ALow costPrevent double compressionElectro-spinningMonocomponent synthetic polymer artificial filamentFiberPorosity

The invention discloses an electrostatic spinning device for preparation of fluffy-state nanofibers and a method for preparation of fluffy-state nanofibers. The electrostatic spinning device comprisesan air supply device, an injection device and a fluffy-state fiber collection device. The air supply device is connected onto an air guide device through an air guide pipe. A stainless steel needle head of the injection device penetrates through the air guide device and extends above a receiving device. The method for preparation of fluffy-state nanofibers comprises the following steps: solutionpreparation; substrate preparation; preparation of fluffy nanofibers. The production process of the fluffy-state nanofibers comprises the following steps: performing pre-spinning in the environment without sheath gas; introducing sheath gas after a silk film appears; stopping spinning when fluffy-state fibers ascends to the top nearby in order to acquire fluffy-state nanofibers. The device is simple in technique, low in cost and higher in fluffy degree. The high porosity is used as a support of tissue engineering so that a cell-scaffold complex body is formed in vitro.

Owner:NANJING UNIV OF SCI & TECH

A method for promoting ripening and collecting seedlings of seaweed shell filaments

ActiveCN103931482BQuality improvementReduce seedling costCultivating equipmentsSeaweed cultivationSporePorphyra

The invention aims at providing a porphyra haitanensis shell conchocelis ripening and seedling collecting method. The method comprises the following steps: (1) cultivating shell conchocelis before ripening, (2) ripening shell conchocelis, (3) synchronously diffusing conchospore and (4) collecting the conchospore. The porphyra haitanensis shell conchocelis ripening and seedling collecting method is simple to operate, shortens the transportation process, and can produce the spatfall porphyra haitanensis with good quality. Therefore, the production mode of improving synchronous diffusion of the porphyra haitanensis conchospore becomes an approach of relieving seedling cultivation and seedling collection of the porphyra haitanensis with good quality and reducing seedling cultivation cost. The porphyra haitanensis shell conchocelis ripening and seedling collecting method is simple and practicable and good in effect. Compared with the traditional technology, labor strength is reduced, working procedures are reduced, the quality of the porphyra haitanensis spore is good, and production efficiency is obvious.

Owner:NINGBO UNIV

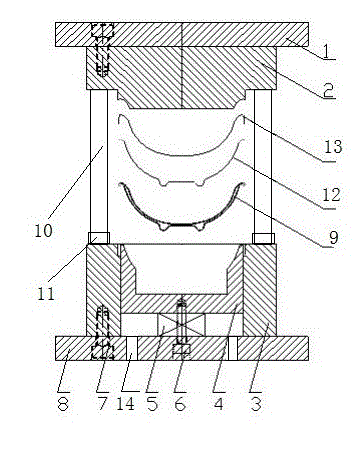

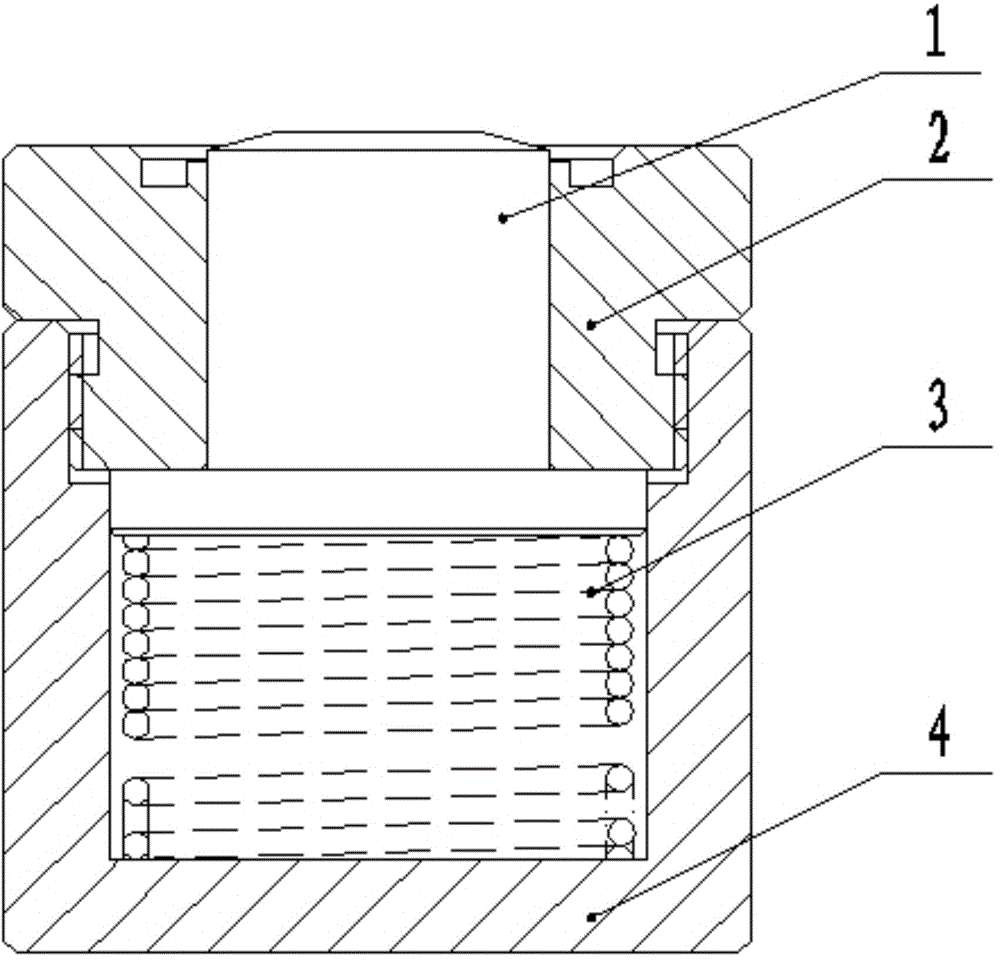

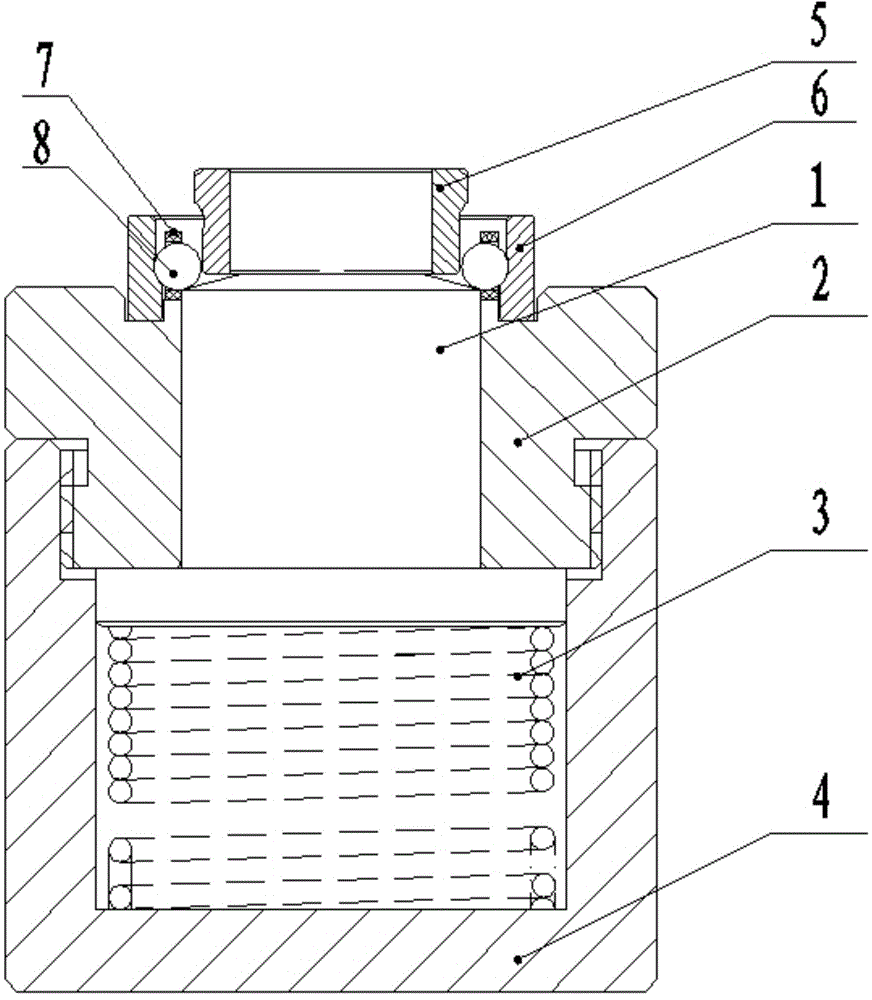

Precise composite mold

InactiveCN105618577AImprove practicalityExquisite appearanceShaping toolsEmbossing decorationsRubber ringTextile printer

The invention discloses a precise composite mold. The precise composite mold comprises an upper mold, a lower mold and a printing bowl mold; the upper mold includes an upper fixed plate and a mold core which are fixedly connected together, wherein the mold core is convex, and the edge of the mold core is set as a concave curved surface; the lower mold includes a mold ring, a pressing positioning block, a pressing spring, a bolt, a screw and a lower fixed plate, wherein the mold ring is fixed on the lower fixed plate through the screw; the pressing positioning block is arranged in the mold ring, and is movably connected with the lower fixed plate through the bolt; the pressing spring is mounted on a bolt section between the bottom of the pressing positioning block and the lower fixed plate; the printing bowl mold is arranged in the pressing positioning block; the upper mold and the lower mold are connected through a guide piece; and a rubber ring is arranged on the guide piece. The precise composite mold directly finishes impressing and combination, reduces working procedures of combination after impressing, guarantees excellent structural strength, can embody a relief pattern more fully, is delicate in appearance, effectively improves the working efficiency, and saves the production cost.

Owner:QINGDAO XINYIFA IND & TRADE

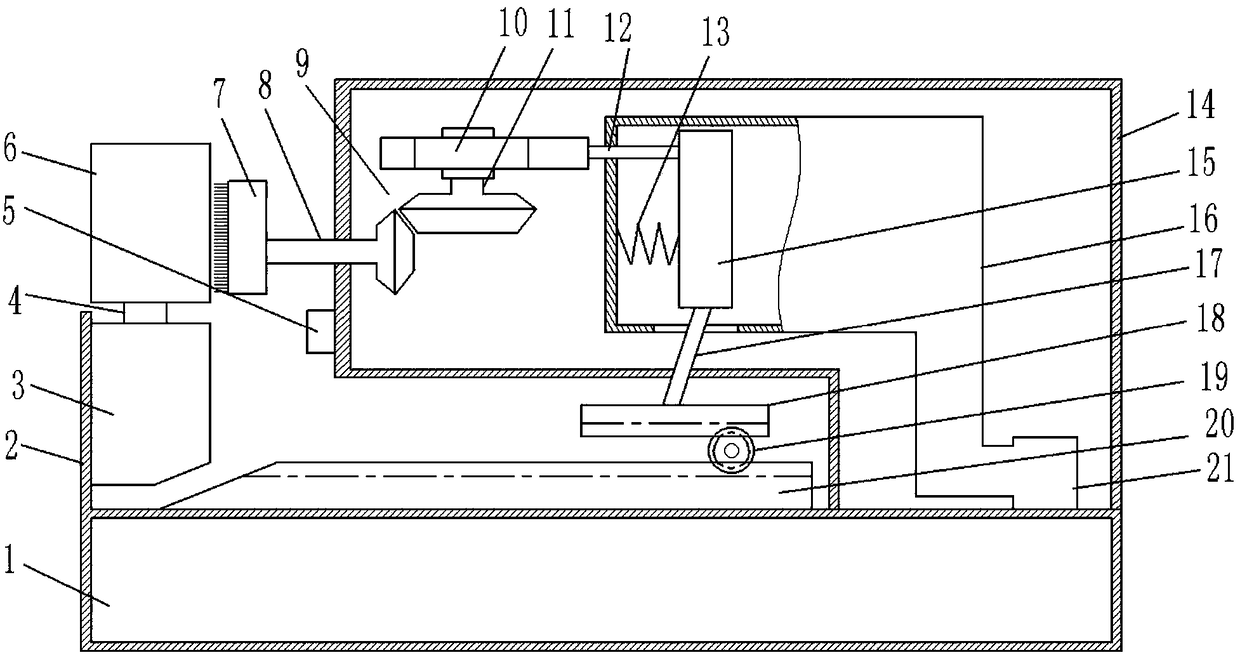

Painting device

ActiveCN108480158AEfficient dust removalComprehensive dust removalSpraying apparatusPretreated surfacesMechanical engineeringPiston

The invention relates to the field of painting decoration equipment, and discloses a painting device. The painting device comprises a supporting frame and a base, a painting opening is formed in the front end of the supporting frame, an electric air pump, an air conveying pipe and a brush rod are arranged in the supporting frame, the electric air pump comprises an air inlet and an air outlet, oneend of the air conveying pipe is connected with the air outlet of the electric air pump, a piston is arranged in the air conveying pipe, a transmission mechanism is arranged between one end of the brush rod and the piston, a brush head is arranged at the other end of the brush rod, a first rack, a first gear, a second rack and a fixing part capable of clamping a workpiece are further included, thepiston is provided with a swing rod, an opening is formed in the air conveying pipe, the swing rod penetrates the opening and is connected with the first rack, the first rack and the second rack areengaged with the first gear, a first wedge face is arranged at one end of the second rack, and the lower end of the fixing part is provided with a second wedge face matched with the second rack. According to the scheme, a workpiece can move up and down while the brush head rotates for dust removal, and the comprehensive thorough dust removal effect on the workpiece surface can be achieved.

Owner:宁波隆锐机械制造有限公司

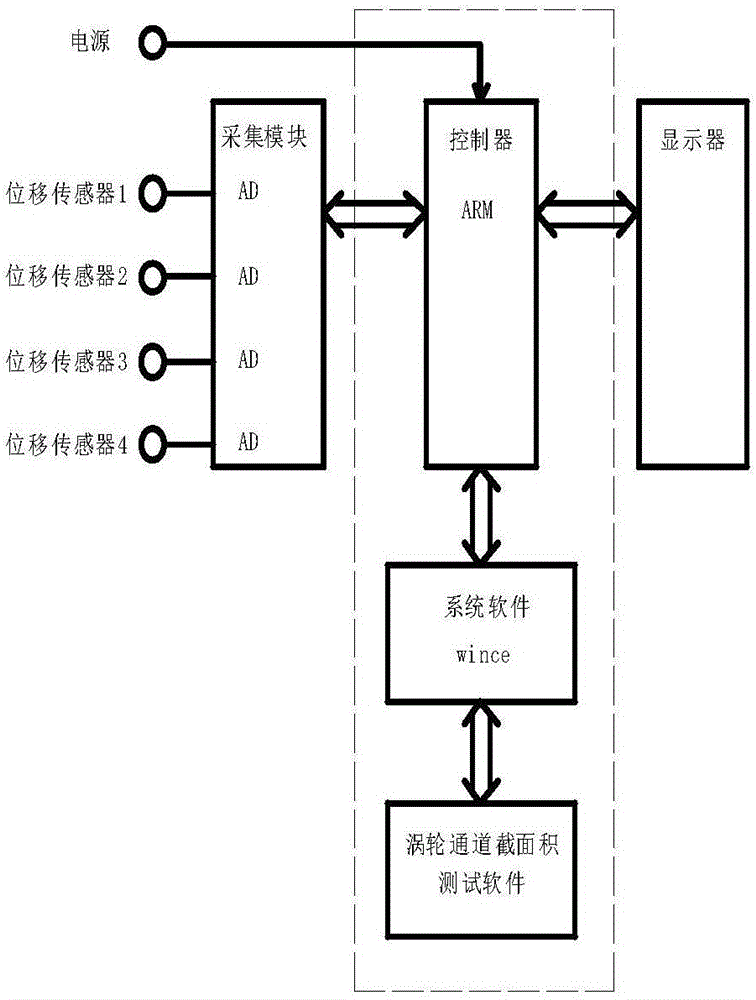

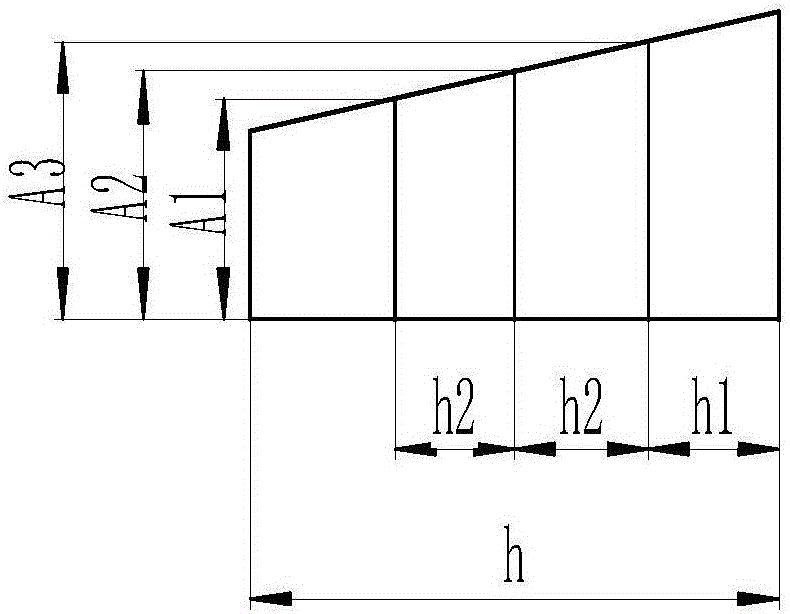

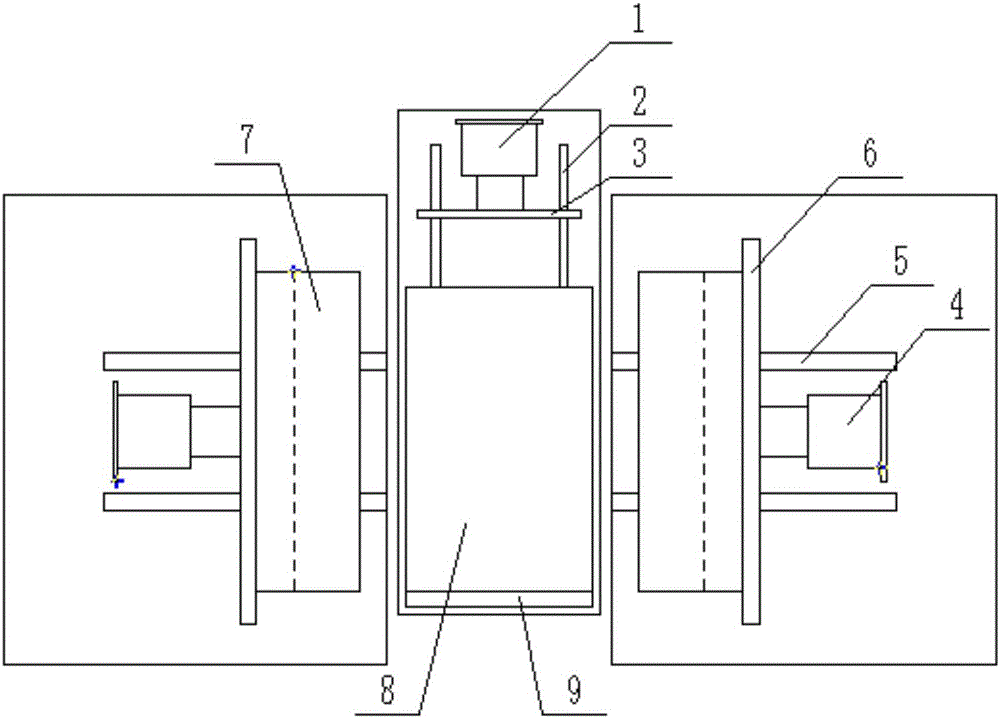

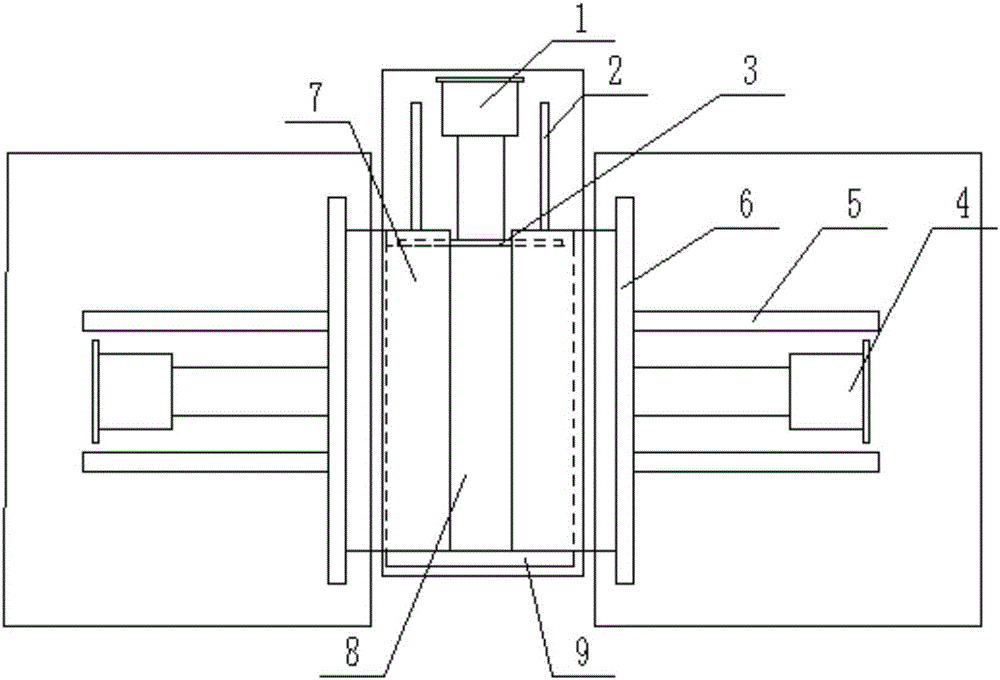

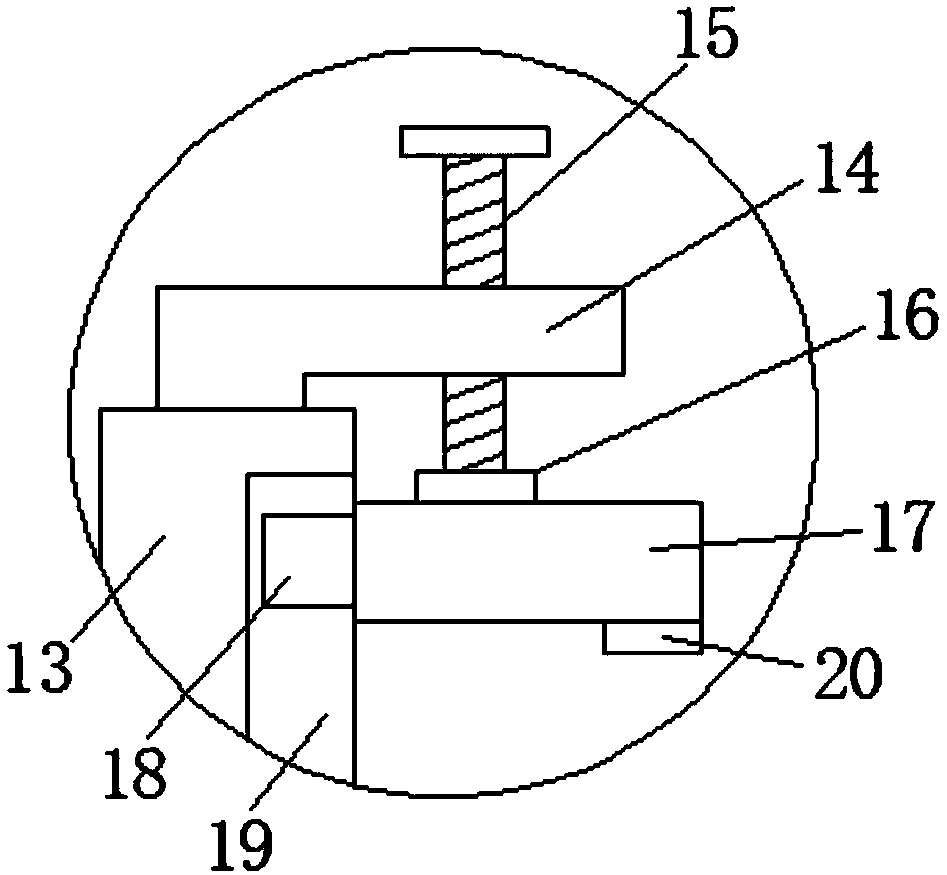

Turbine guider channel area measuring instrument

ActiveCN105043335APrecise positioningAccurate and reliable measurement resultsMeasurement devicesControl theorySingle chip

The invention relates to a turbine guider channel area measuring instrument. The turbine guider channel area measuring instrument comprises measuring units; the measuring unit includes a measuring portion, a displacement sensor and a pressing portion, wherein the displacement sensor is arranged above the tail end of the measuring portion, the pressing portion is arranged below the tail end of the measuring portion, the pressing portion drives the measuring portion to move, and the measuring portion drives the displacement sensor to move. According to the turbine guider channel area measuring instrument of the invention, the lengths of four corresponding sides of each channel are measured, and the lengths are introduced into an area computational formula; area computation can be carried out based on single-chip microcomputer programming, so that the cross-sectional area of each channel can be computed; and the cross-sectional areas of all the channels are added together, and the sum of the cross-sectional areas of all the channels is the total area of the channel of a turbine guider.

Owner:成都国营锦江机器厂

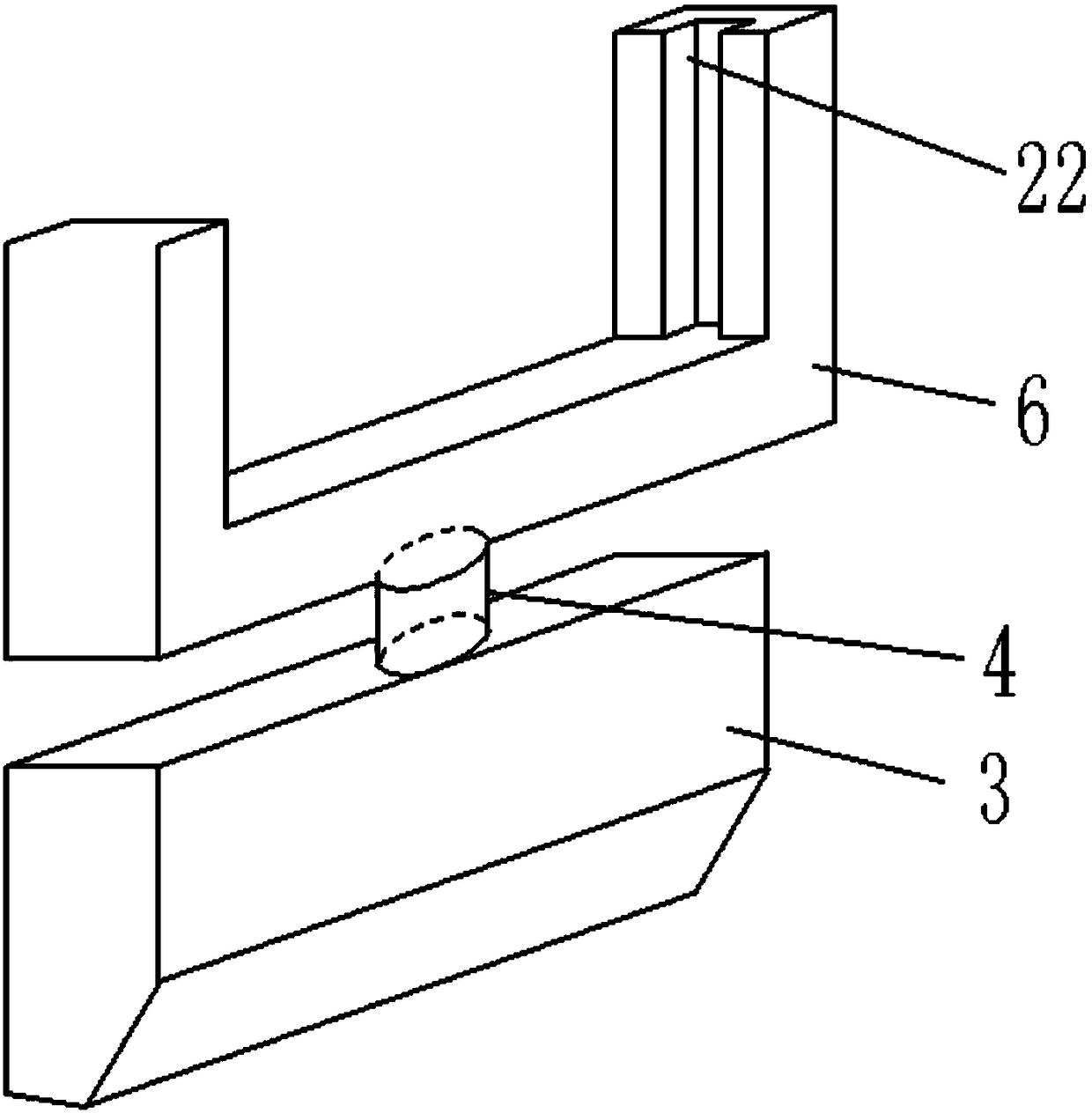

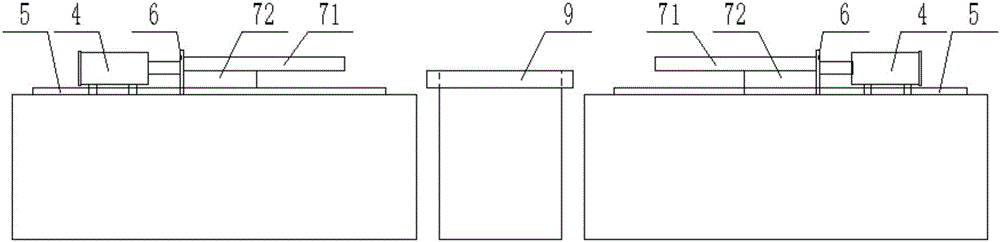

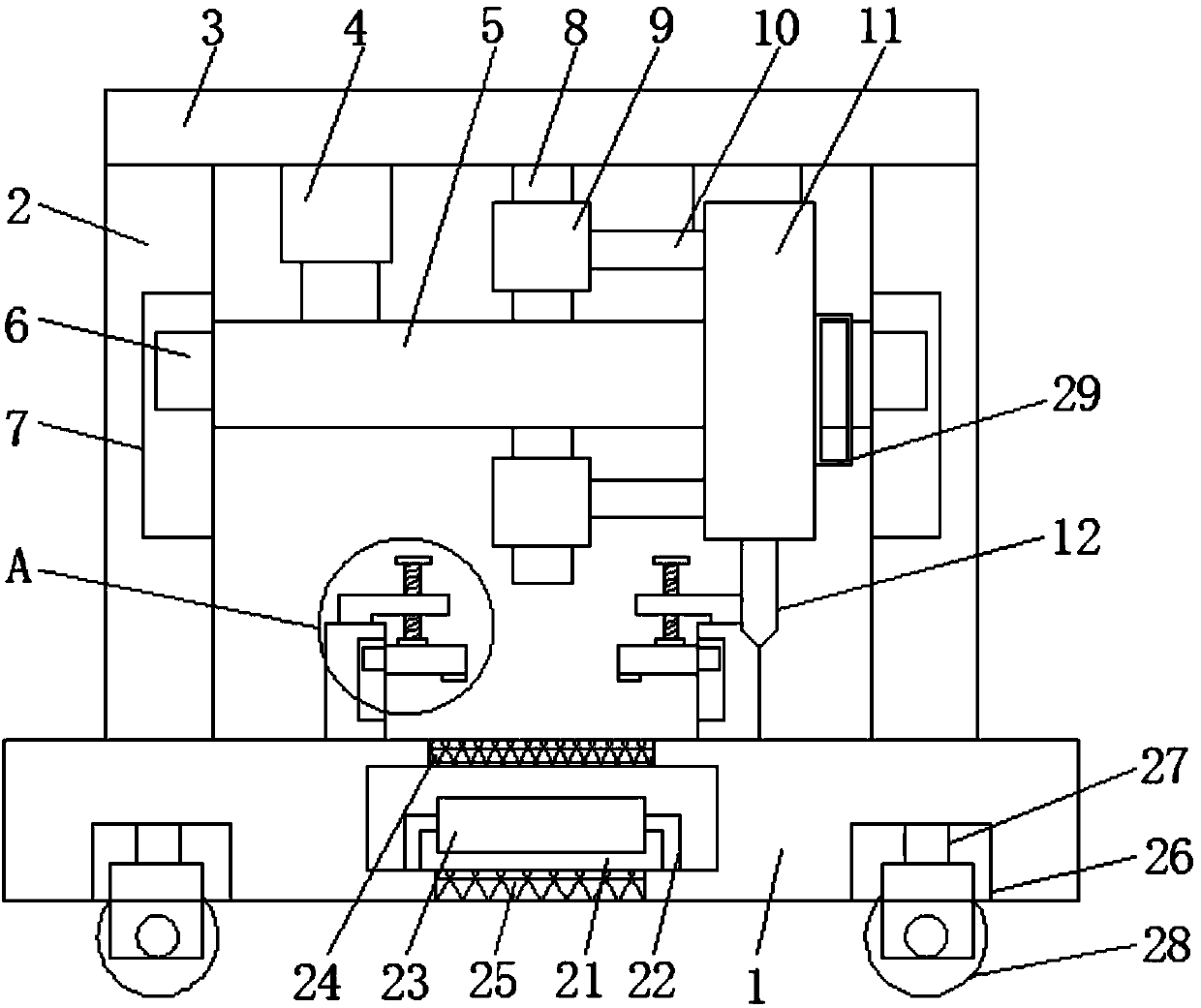

Automatic assembling device for automobile air conditioner radiator

InactiveCN106584074AMeet flatness adjustmentReduce work proceduresVehicle componentsMetal working apparatusHeat sinkEngineering

The invention discloses an automatic assembling device for an automobile air conditioner radiator. The automobile assembling device comprises a first hydraulic cylinder, first rails, a first baffle, second hydraulic cylinders, second rails, second baffles and a work platform. The second hydraulic cylinders, the second rails and the second baffles are evenly and symmetrically distributed on the two sides of the work platform. A clamping connecting unit is fixed to the front section of each second baffle. Each clamping connecting unit comprises a pressing plate and a clamping connecting groove, wherein the length of the pressing plate is larger than that of the clamping connecting groove, and the pressing plate is in movable connection with the clamping connecting groove. A positioning plate is fixed to the side, away from the first hydraulic cylinder, of the work platform. According to the automatic assembling device, a stable positioning and calibrating device is provided, clamping plates can be placed in the clamping connecting grooves in advance, the process of secondary placement is omitted on the basis of ensuring that cooling fins are positioned, flatness adjustment of the cooling fins and cooling strips can also be completed through the pressing plates while pressing and fixing are conducted, the manual process is omitted, and the work efficiency and the production quality are improved.

Owner:QINGDAO HAIZHIYUAN INTELLIGENT TECH

Method for plastering construction in architectural decoration

ActiveUS9255413B2Improve efficiencyImprove construction qualitySunshadesCovering/liningsBuilding constructionArchitectural engineering

A method for plastering construction in architectural decoration comprises the following steps: (1) base treatment; (2) applying mortar on the wall surface according to the required plastering depth, and longitudinally installing screeding templates along a wall surface subjected to the base treatment in Step (1) according to the plastering depth, a lateral space between adjacent screeding templates being 1.3 to 1.8 meters; (3) plastering; and (4) laying aside the wall surface subjected to the plastering for 12 to 24 hours till plastering mortar on the wall surface is in a half-dried compact hardened state, and using teeth of a saw blade for grinding the mortar along the two adjacent screeding templates through a ruler till the mortar is even. The method can improve the construction efficiency and guarantee the construction quality.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

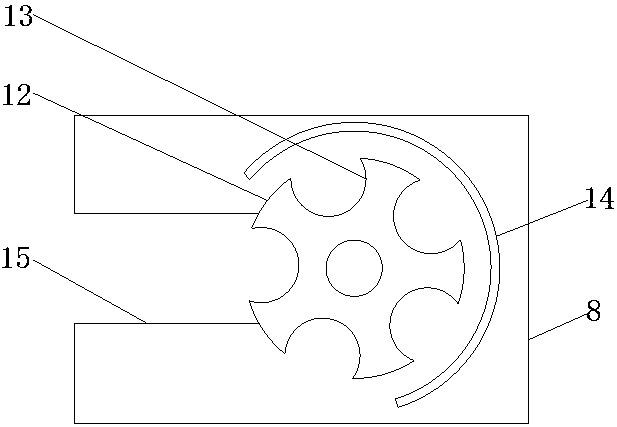

Turn-plate type sample-sending device of testing machine

ActiveCN101995482AReduce work proceduresImprove work efficiencyMaterial analysisMicrocomputer controlWork program

The invention relates to corollary equipment of a testing machine, in particular to a turn-plate type sample-sending device of a testing machine, which comprises a machine base, a guardrail bracket and a transmission device, wherein the guardrail bracket is arranged at the periphery of the machine base and used for dividing the working range of the testing machine; and the transmission device is arranged on a turn-plate of the machine base and used for providing power. When the turn-plate type sample-sending device of the testing machine is tested, the manual control or the microcomputer control can be optionally selected for charging materials automatically, thereby omitting the work procedure of placing a sample by an operator in person, enhancing the working efficiency, effectively shortening the testing time, reducing the danger of sending the sample and locating by labor; meanwhile because the guardrail bracket is provided, the potential safety hazard in operation is avoided and the purpose of realizing efficient and safe tests is achieved.

Owner:SHANGHAI HUALONG TEST INSTR

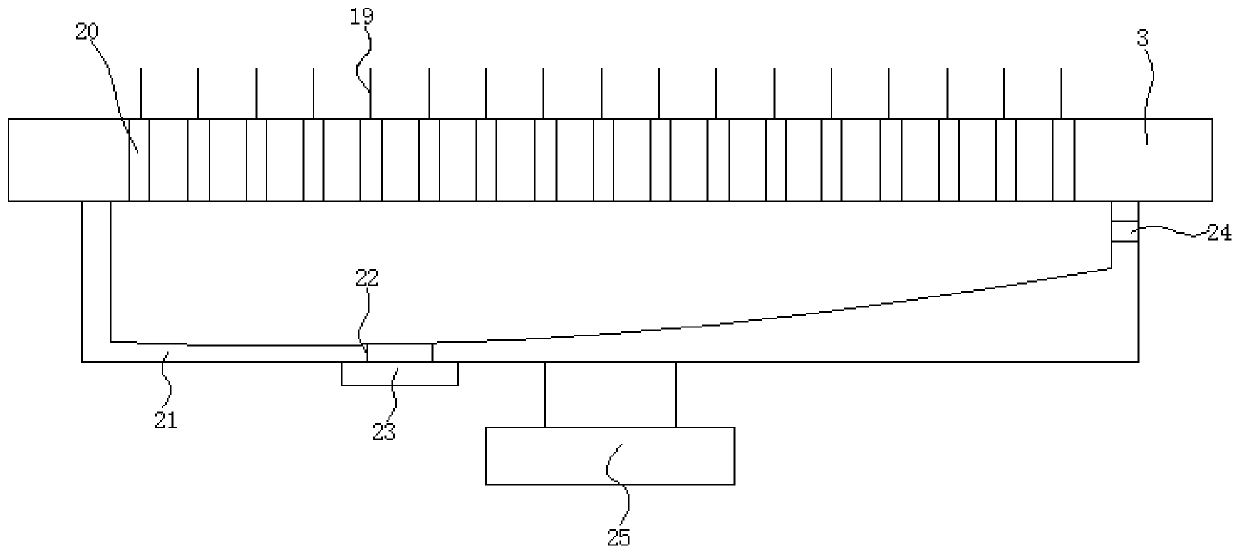

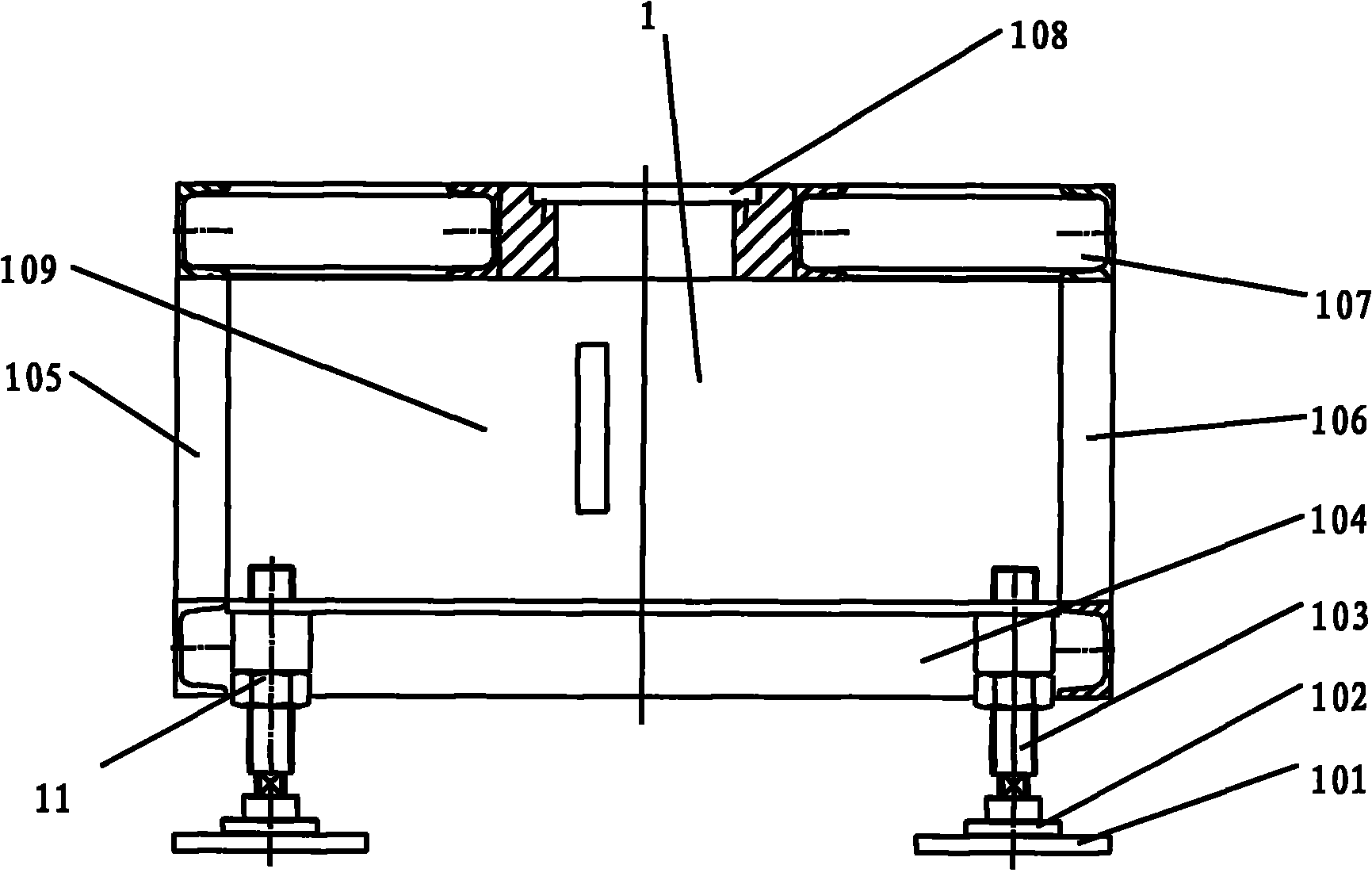

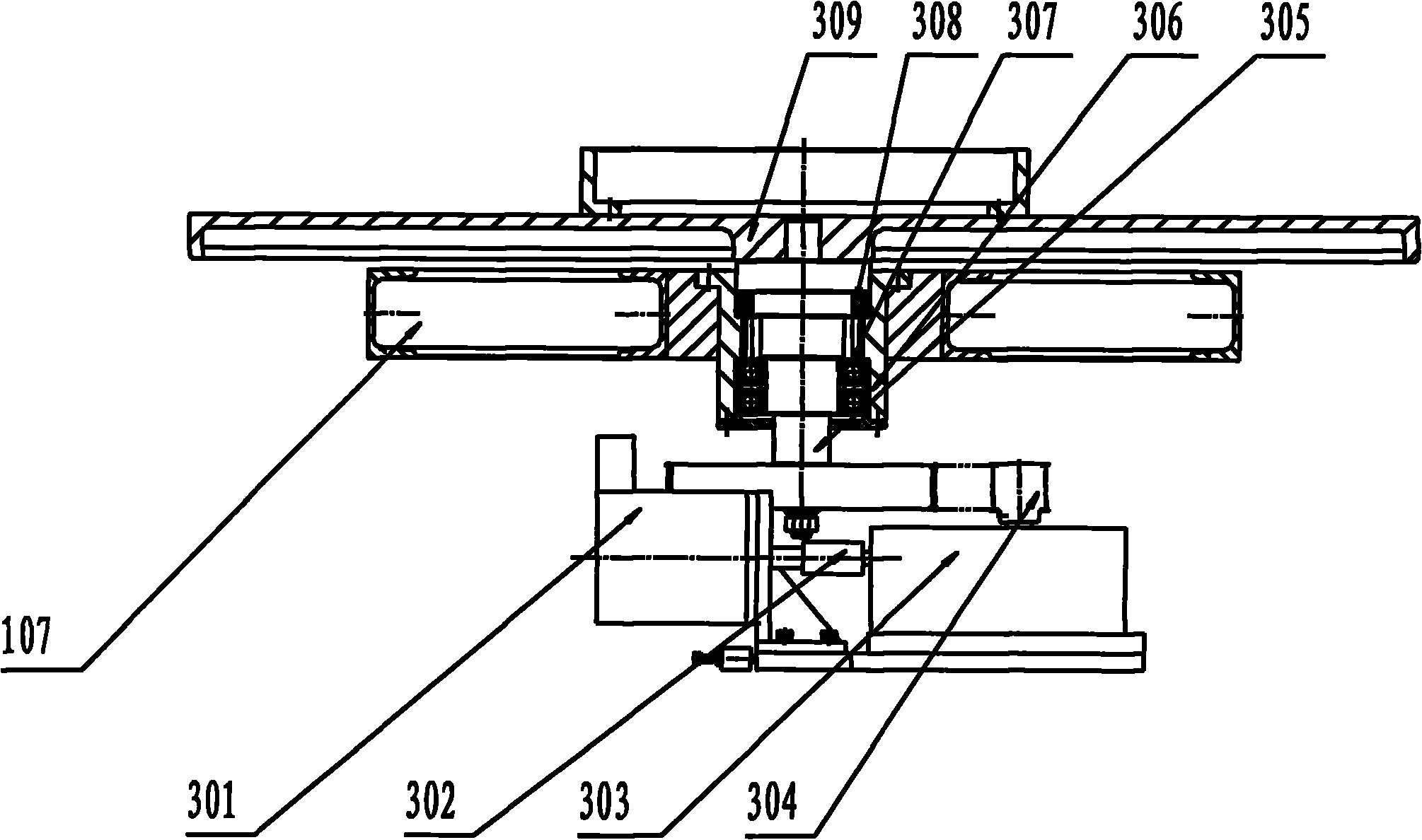

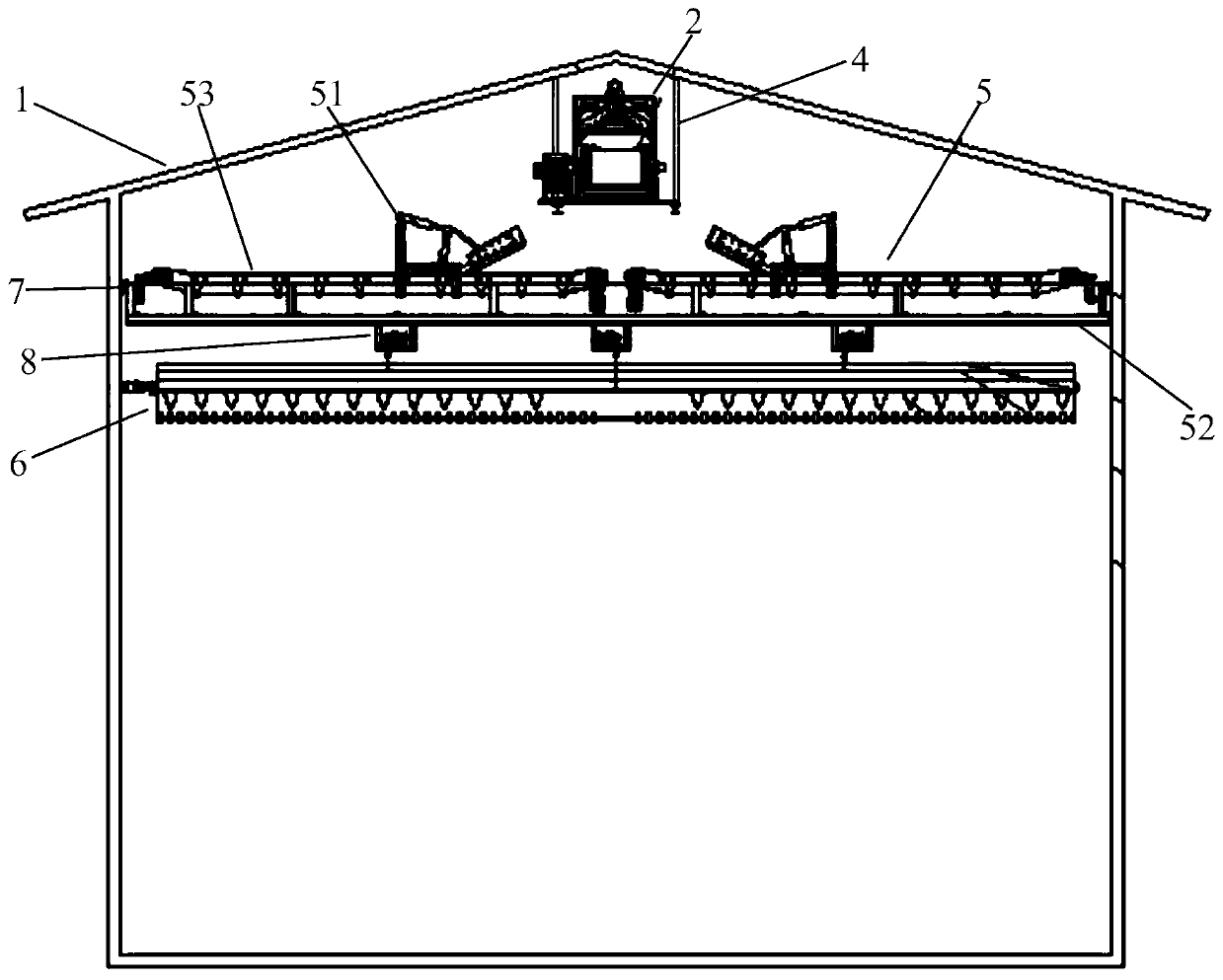

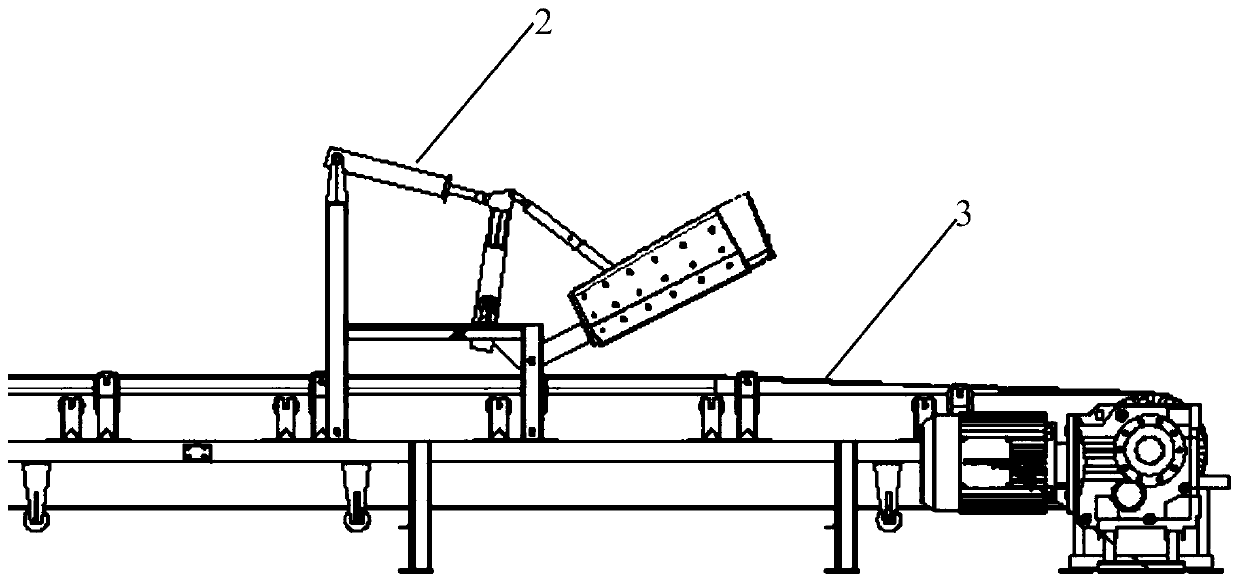

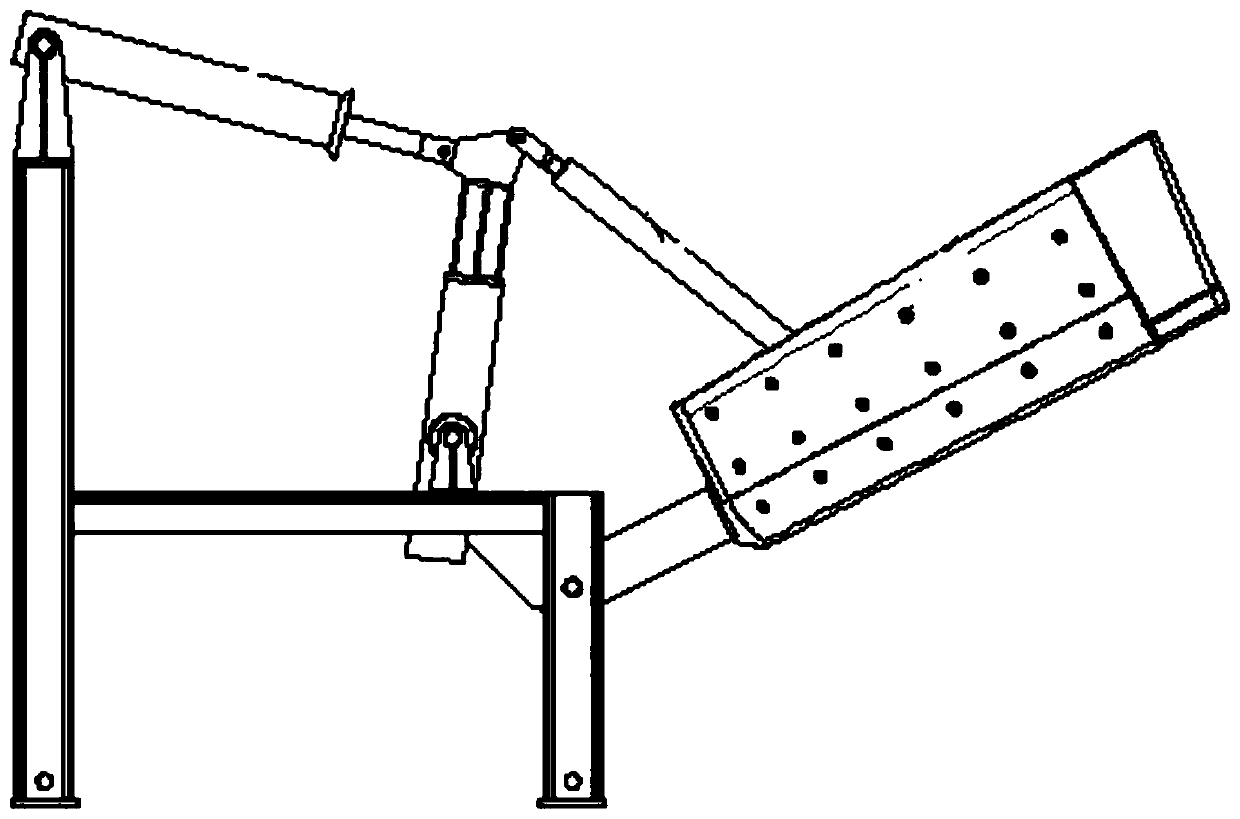

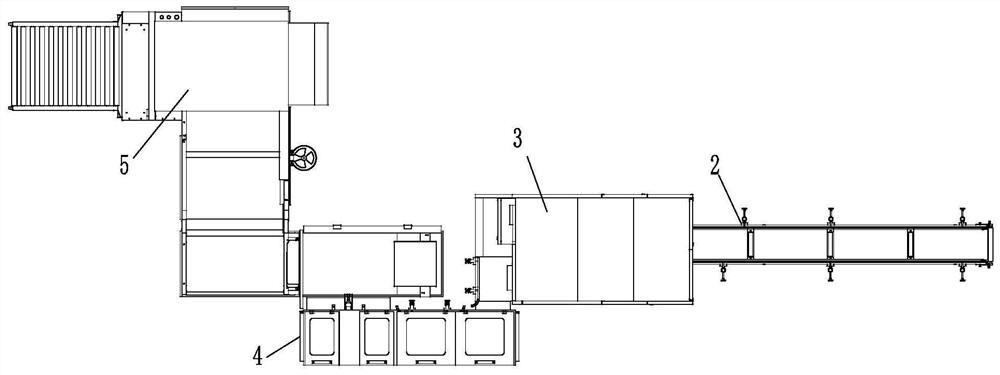

Intelligent granary bulk grain granary entry and grain surface flattening integrated device

PendingCN110255216AReduce labor intensityReasonable structural designConveyorsLoading/unloadingAgricultural engineeringGrain distribution

The invention discloses an intelligent granary bulk grain granary entry and grain surface flattening integrated device. The device comprises a grain distribution trolley, a first belt conveyer, a machine frame, an intelligent traveling device, a grain surface flattening device and second rails. The first belt conveyer is installed on the machine frame. First rails are installed on the two sides of the first belt conveyer. The grain distribution trolley is installed on the first rails. The second rails are installed on the two sides of a granary, and is located below the first belt conveyer. The intelligent traveling device is installed on the second rails and comprises a traveling grain unloading trolley, a traveling machine frame and a second belt conveyer. The traveling machine frame is installed on the second rails. The second belt conveyer is installed on the traveling machine frame. Third rails are installed on the two sides of the second belt conveyer. The traveling grain unloading trolley is installed on the third rails. The grain surface flattening device is installed at the bottom of the traveling machine frame through a lifting device. With the intelligent granary bulk grain granary entry and grain surface flattening integrated device, grain can be evenly distributed at the bottom of the granary without being piled up, the labor intensity of workers can be effectively reduced, and the granary entry efficiency of grain is improved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Device for reducing urban riverway spray burst and using method thereof

PendingCN107777776ADoes not affect functionEasy to moveWater contaminantsBiological treatment apparatusSocial benefitsRiver routing

The invention discloses a device for reducing urban riverway spray burst. The device comprises riverway fixing rods which are symmetrically arranged along a riverway, wherein roadbed fixing rods are arranged in parallel on the outer sides of the riverway fixing rods; a plurality of cultivation units are mounted on the riverway fixing rods; the cultivation units comprise cultivation net curtains and riverway slide bars I perpendicular to the riverway fixing rods; the left and right sides of the cultivation net curtains are connected with the riverway slide bars I; the front and rear ends of theriverway slide bars I are connected with roadbed slide bars I, so that the cultivation units are moved from the left to right along the riverway; a plurality of flowerpots are arranged on the cultivation net curtains; and a plurality of small holes are formed in the bottoms of the flowerpots. The device disclosed by the invention is long in use duration, high in control efficiency and obvious ineconomic and ecological benefits, has excellent social benefits and accords with a mainstream development direction of the ecological model.

Owner:NINGBO UNIV

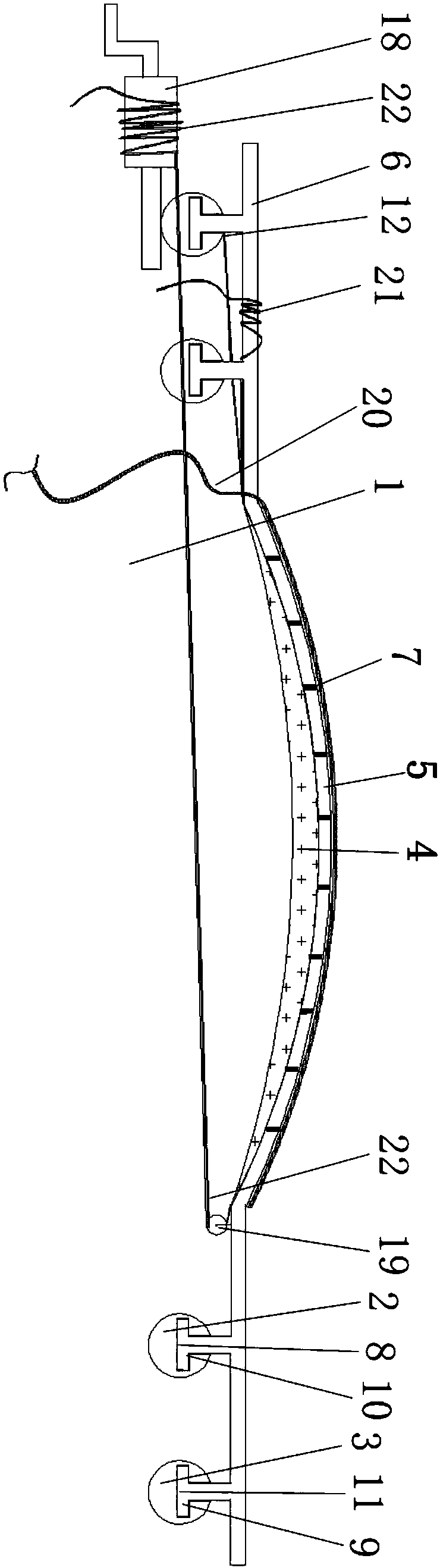

Vertical vibration conveying and drying integrated device

PendingCN111912212AReduce consumptionReduce wearDrying gas arrangementsDrying solid materialsVertical vibrationVertical plane

The invention relates to the technical field of material transportation, in particular to a vertical vibration conveying and drying integrated device. The device comprises a feeding structure, a discharging structure, a material conveying structure and a heater. The material conveying structure comprises two or more vertical conveying pipelines and a driver, and every two adjacent vertical conveying pipelines are connected in series in the material conveying direction. The vertical conveying pipelines are driven by the driver to do horizontal plane circular motion and vertical plane up-and-down vertical motion. A feeding hole at the lower part of the material conveying structure is communicated with the feeding structure, and a discharging hole at the upper part of the material conveying structure is communicated with the discharging structure. The heater is used for heating the materials in the vertical conveying pipelines. By means of the structure of the vertical conveying pipelinesand the heater, after-production drying can be achieved while grains are vibrated and vertically conveyed, the labor intensity of workers can be effectively reduced, the grain conveying and drying efficiency is improved, the investment cost of a grain conveying and drying system is reduced, a traditional grain conveying and drying mode is changed, and rapid grain conveying is guaranteed.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

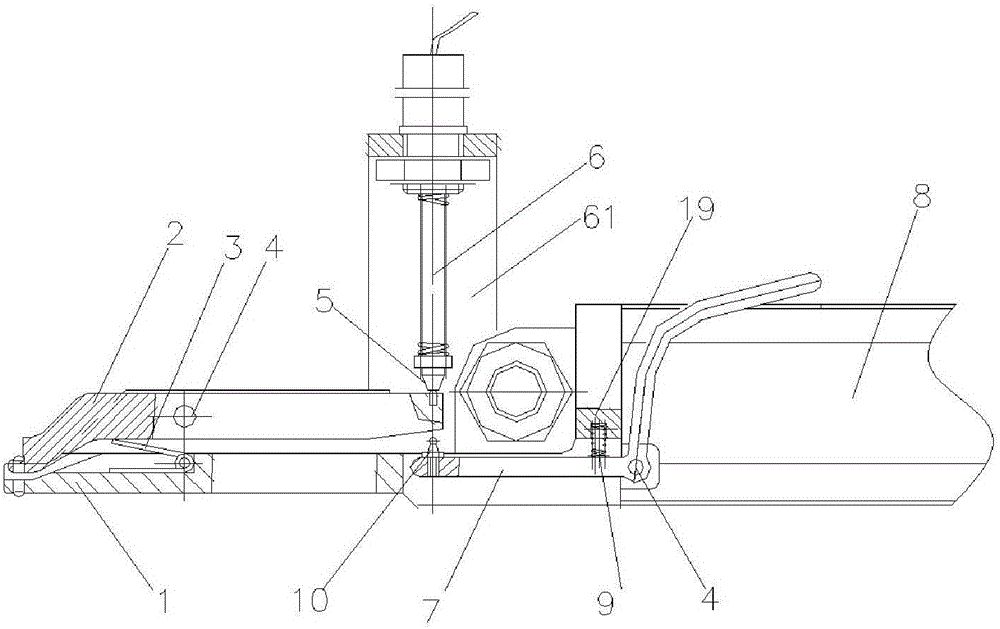

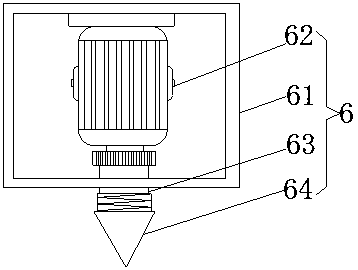

Welding device for multifunctional valve machining

InactiveCN107825032AEasy to fixAvoid shaking situationsWelding/cutting auxillary devicesAuxillary welding devicesThreaded rodIndustrial engineering

The invention relates to the technical field of valve processing, and discloses a welding device for multifunctional valve processing, which includes a support seat, the top of the support seat is fixedly connected with a support frame, the top of the support frame is fixedly connected with a top plate, and the bottom of the top plate is connected with an electric pusher. One end of the rod is fixedly connected, the other end of the electric push rod is fixedly connected with the top of the lifting plate, one side of the lifting plate is fixedly connected with the first slider, and one end of the first slider is inserted into the first chute and connected with the first chute internal sliding connections. The welding device for multifunctional valve processing, through the setting of the fixing plate, the supporting plate, the threaded rod, the bearing, the fixing plate, the second slider, the second chute and the rubber fixing pad, the valve can be welded better. Fixing solves the problem that the existing valve welding device cannot fix the valve during welding, thereby avoiding the shaking of the valve during welding, so that the quality of valve welding can be better.

Owner:郑邓飞

Evaporation coating device

ActiveCN107805782AEasy to replaceHeating evenlyVacuum evaporation coatingSolid-state devicesCrucibleEvaporation

The invention relates to an evaporation coating device which comprises a crucible main body, a side surface heating device and a bottom heating device, wherein the side surface heating device is arranged around the crucible main body, and the bottom heating device is arranged under the crucible main body. The bottom heating device can move up and down in the height direction of the side surface heating device and support the crucible main body to rise to a position which is higher than the side surface heating device. According to the evaporation coating device, by means of the arrangement ofthe heating device on the bottom of the crucible main body, the crucible main body is made to be capable of moving up and down, the maintenance efficiency is improved, the maintenance time is shortened, and unnecessary procedures are reduced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

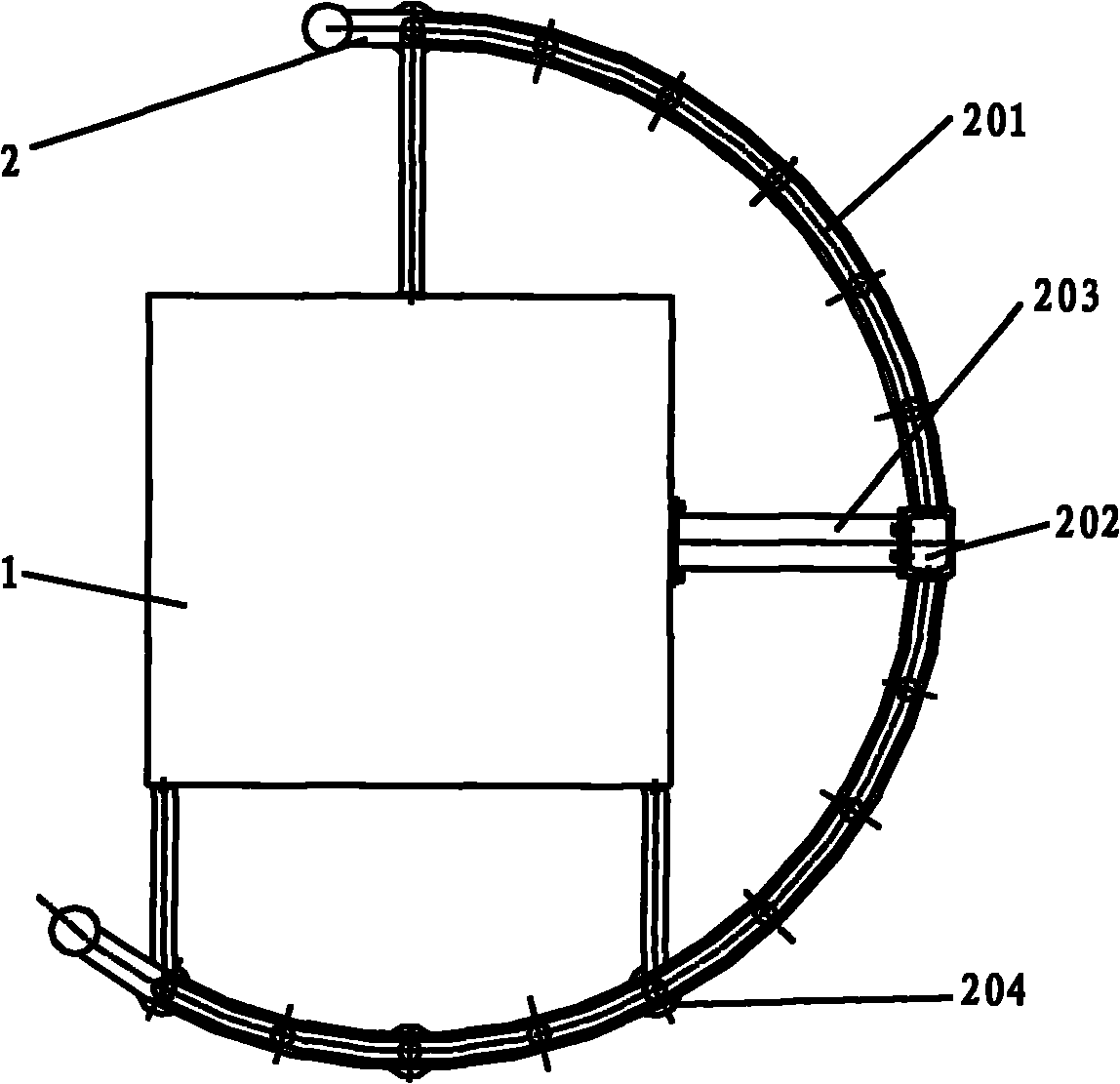

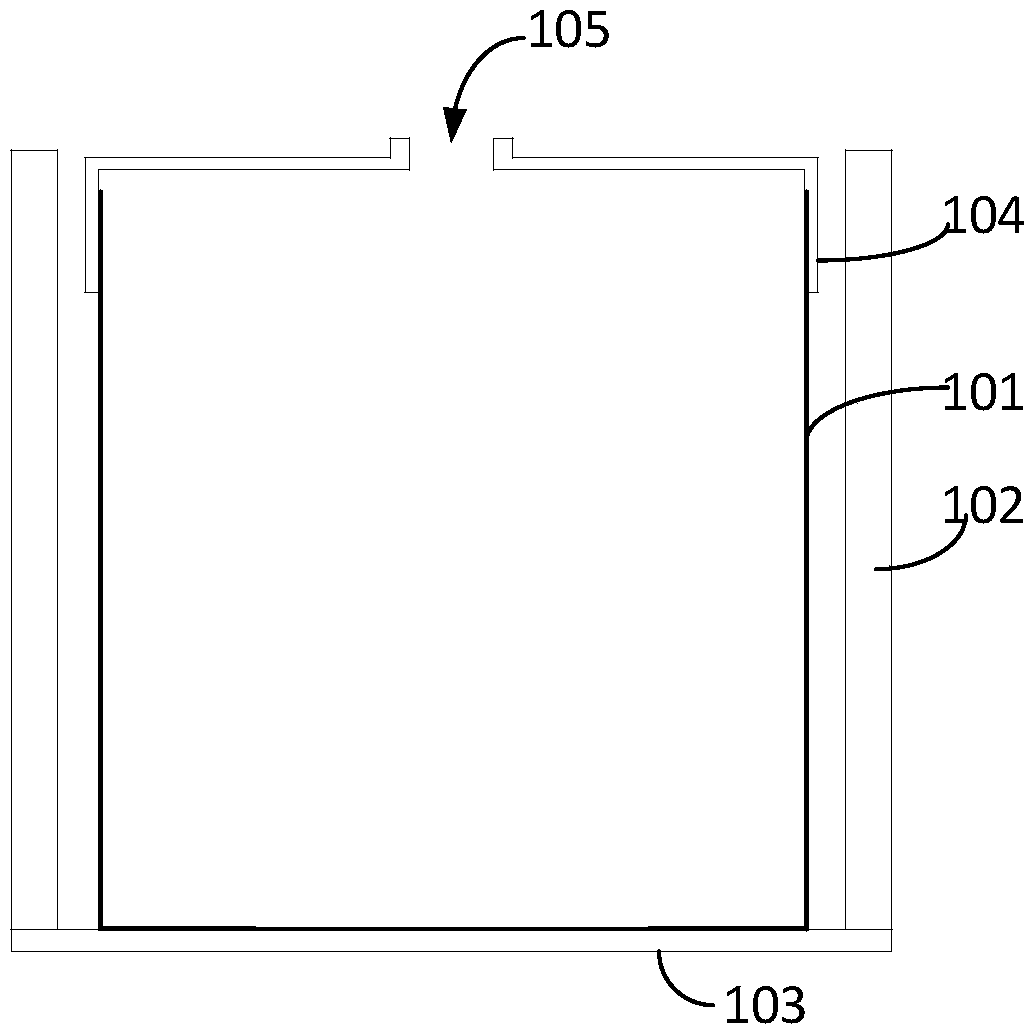

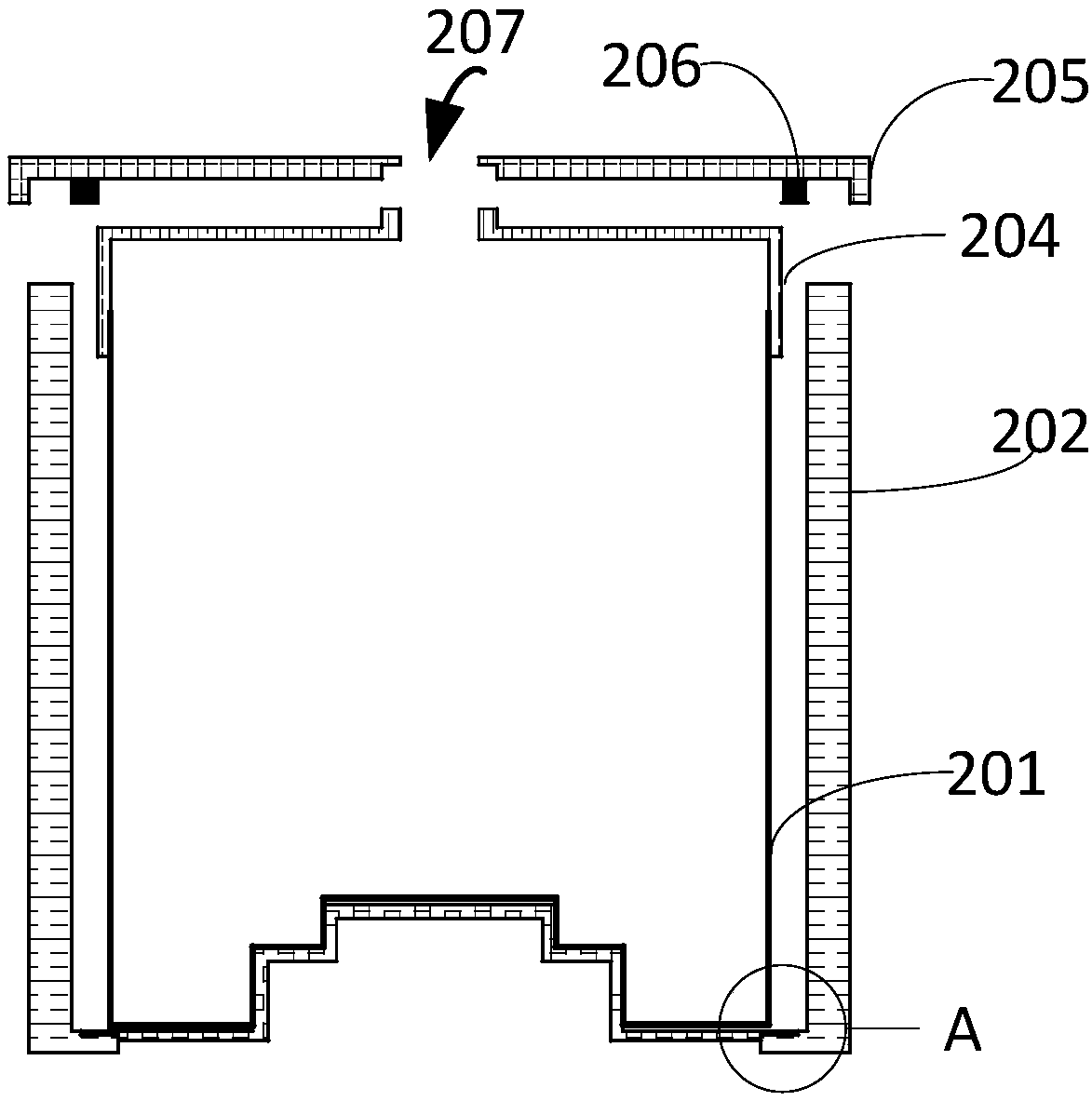

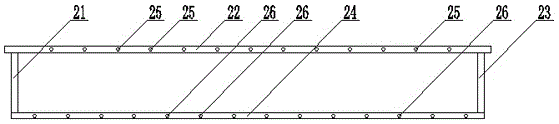

A Tobacco Leaf Separated Type Threading Needle and Loading Tobacco Suspension Device

The invention belongs to the technical field of tobacco harvesting and curing, and relates to a tobacco separating needle-threading tobacco loading suspension device. The device comprises a tobacco loading basket and a tobacco fixing suspension frame matched with the tobacco loading basket; the tobacco loading basket is provided with a basket frame with a certain depth; a support rod is arranged at the back face of the basket frame; the tobacco fixing suspension frame comprises an upper cross rod provided with an upper line tobacco threading needles vertical to the back face of the basket frame; the effective length of the upper line tobacco threading needles is not smaller than the depth of the basket frame. According to the tobacco separating needle-threading tobacco loading suspension device adopting the structure, the curing capacity can be increased on the basis of not changing the existing curing room structure, without changing the existing curing room process conditions and under the condition of not increasing the operation difficulty of suspension rods, the worker number and curing cost are reduced, the damage and pollution of the tobaccos are reduced in the harvesting and transportation process, the probability of directly contacting the tobacco is reduced, the tobaccos in different batches are prevented from being miss-loaded and miss-cured, the tobacco quality is improved, and great popularization and application values are realized.

Owner:中国烟草总公司重庆市公司丰都分公司

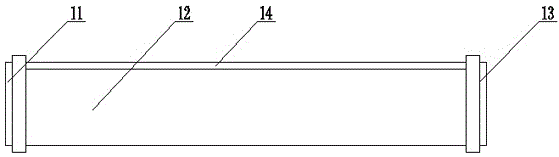

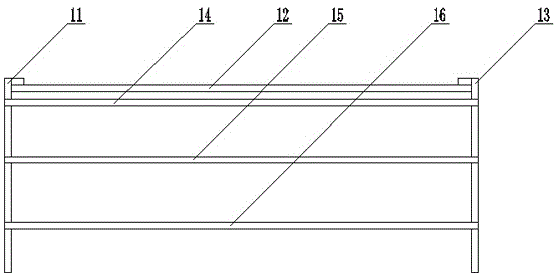

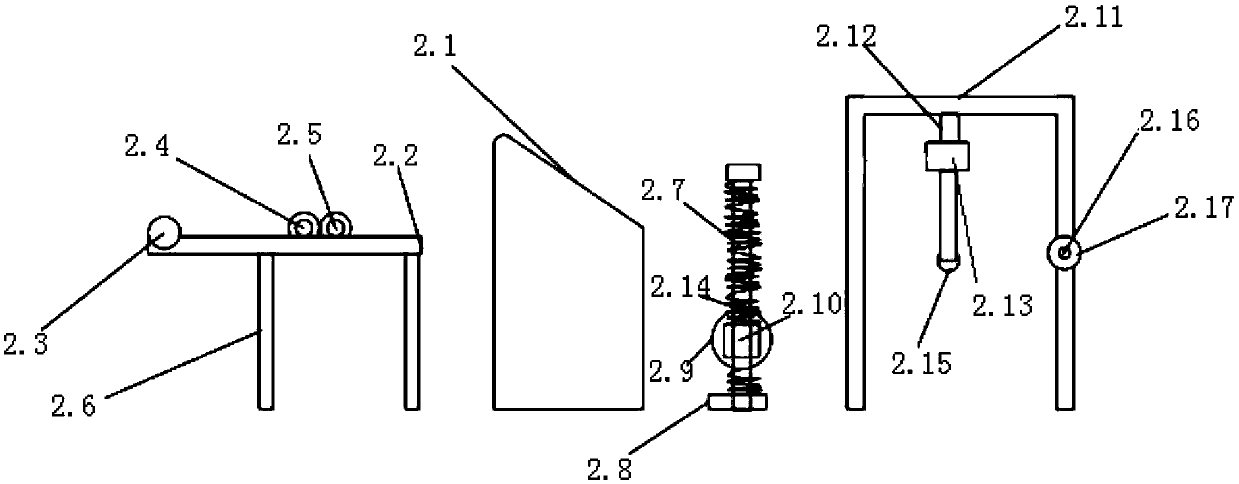

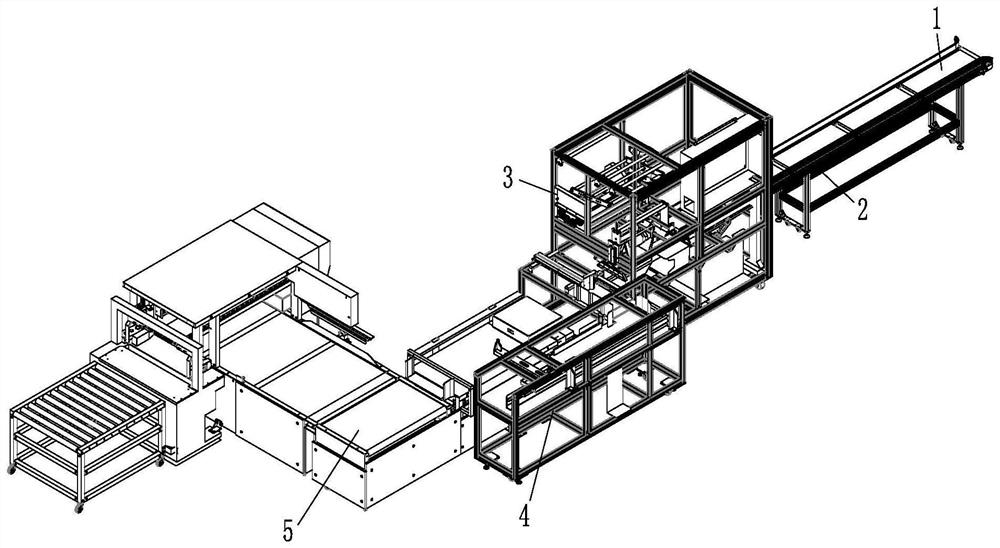

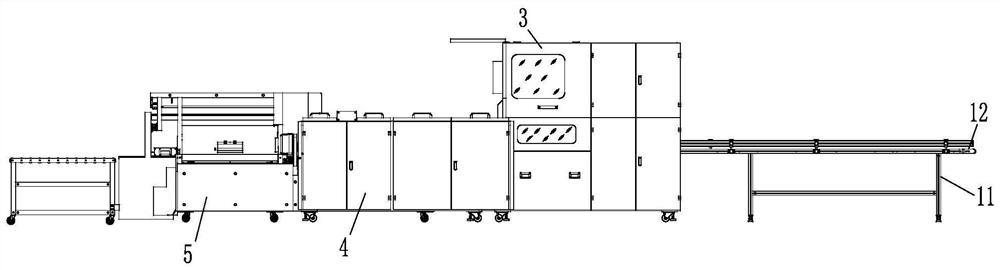

Efficient production line for clothes

InactiveCN109527685AEasy to storeReduce work proceduresClothes making applicancesYarnProduction line

The invention discloses an efficient production line for clothes, which sequentially comprises a knitting machine, a cloth inspecting device, a loosening machine, a fabric placing frame, a cutting machine, a sewing machine, an ironing device and a finishing system from front to back, wherein yarns are knitted into a fabric by the knitting machine, after being rolled into a cloth roll, the fabric is sent to the cloth inspecting device for cloth inspecting operation; after the fabric passes through the cloth inspecting device, the fabric is directly sent to the cloth loosening machine for clothloosening; after the cloth loosening is finished, the fabric is placed on the fabric placing frame; after the fabric is stored on the fabric placing frame, when the fabric needs to be cut, the fabricis pushed to the front of the cutting machine, and after the fabric is cut, the fabric is sent to a sewing machine to be sewed to form clothes, then is sent to an ironing device to be ironed, and thenis sent to a finishing system to be finished to finally form the finished clothes. The efficient production line for the clothes can avoid cloth wrinkles and improve the smoothness of the cloth, thefabric placing frame has a larger capacity of, and the cloth is smoothly distributed and conveyed on the cutting machine, the cutting speed is high.

Owner:江阴嘉美针织制衣有限公司

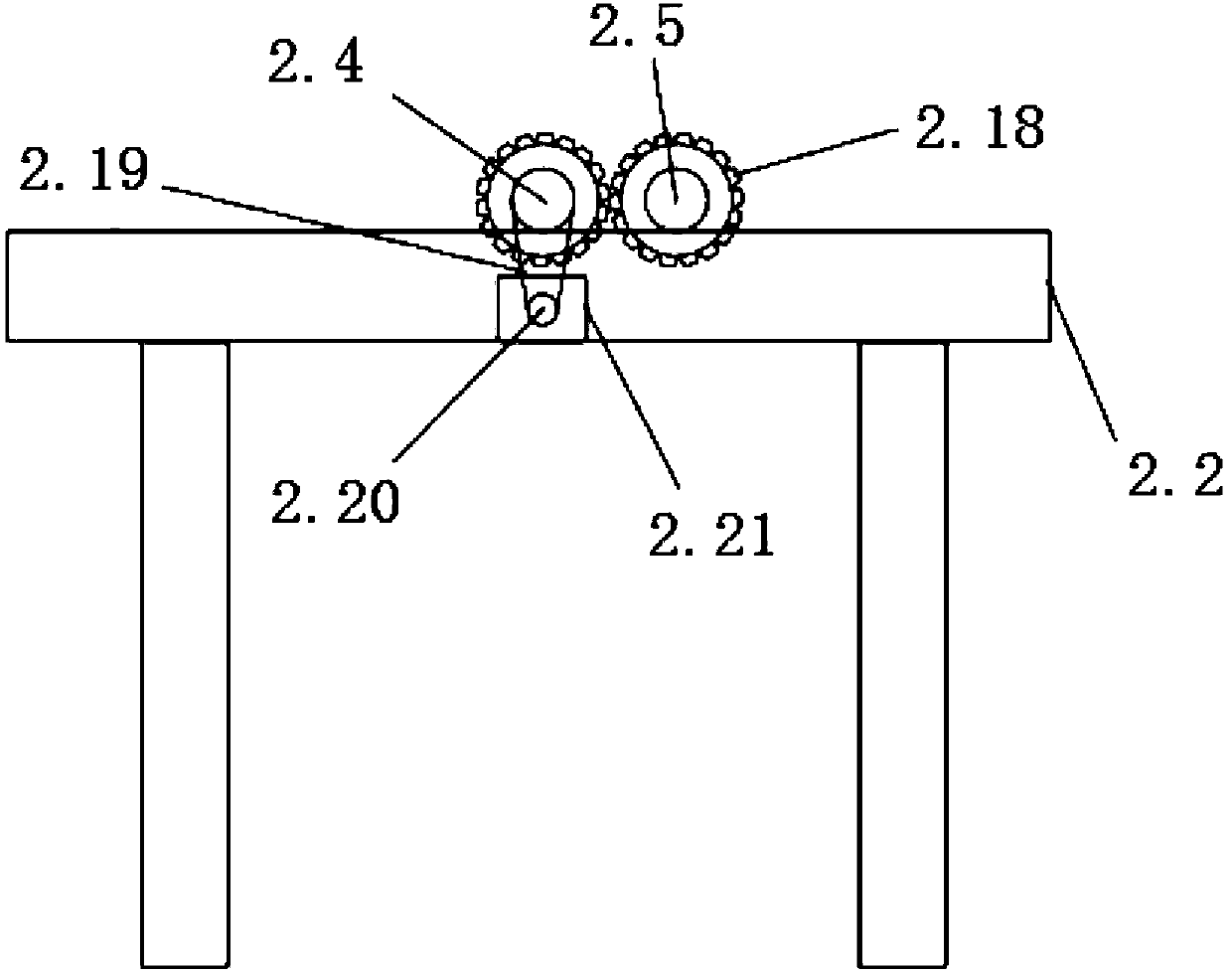

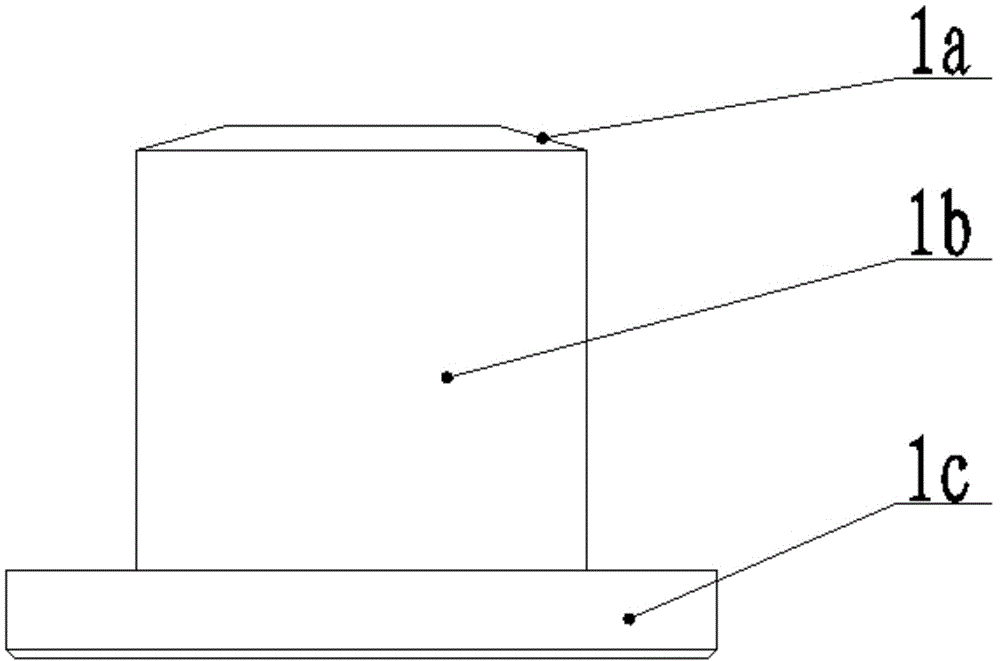

Angular contact ball bearing flexible assembly mold with fore shaft on inner ring

InactiveCN104154130ASimple structureEasy to processBearing componentsBall bearingStructural engineering

The invention relates to an angular contact ball bearing flexible assembly mold with a fore shaft on an inner ring. The angular contact ball bearing flexible assembly mold comprises a mandrel, a positioning block, springs and a base; the mandrel comprises a guide column, a guide surface is arranged on the upper edge of the guide column, and the lower end of the guide column is fixed on a limiting platform; the upper end surface of the positioning block comprises a positioning platform, and a positioning groove is arranged on an outer ring of the positioning platform; the base is a hollow cylinder with an open upper end, a middle hollow part of the base is an unthreaded hole, and the springs are arranged in the unthreaded hole; the mandrel is arranged on the upper part of the springs; the positioning block sleeves the mandrel; the outer side of the positioning block is connected to the base. The angular contact ball bearing flexible assembly mold is simple in structure and easy to machine; a remarkable effect for assembling an angular contact ball bearing with the fore shaft on the inner ring can be realized; in the assembling process, a step for mixing vaseline is canceled, so that the working procedure is reduced, a great amount of vaseline is saved, the cost is reduced, and the assembling efficiency is greatly improved.

Owner:LUOYANG RUNHUAN BEARING TECH CO LTD

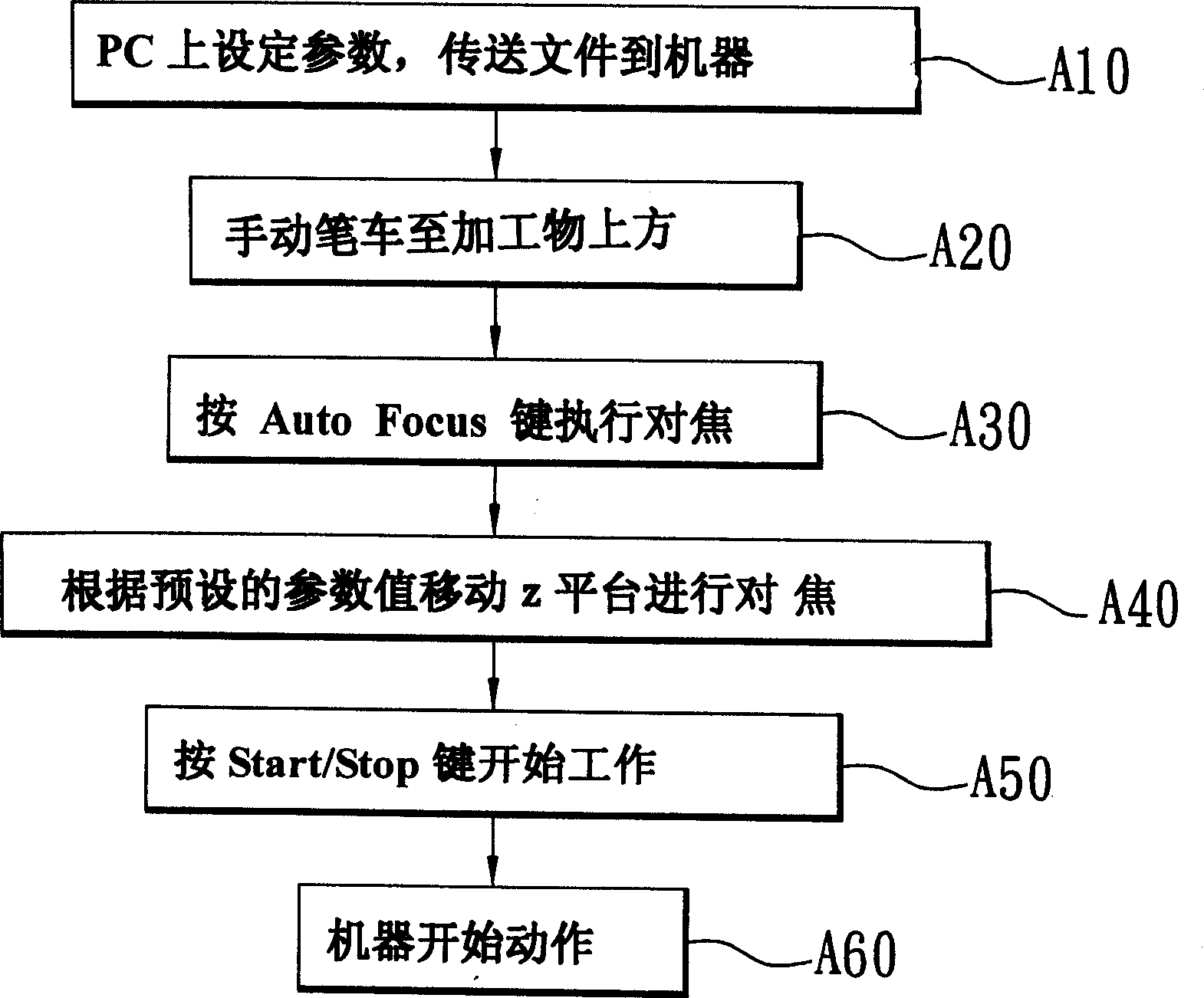

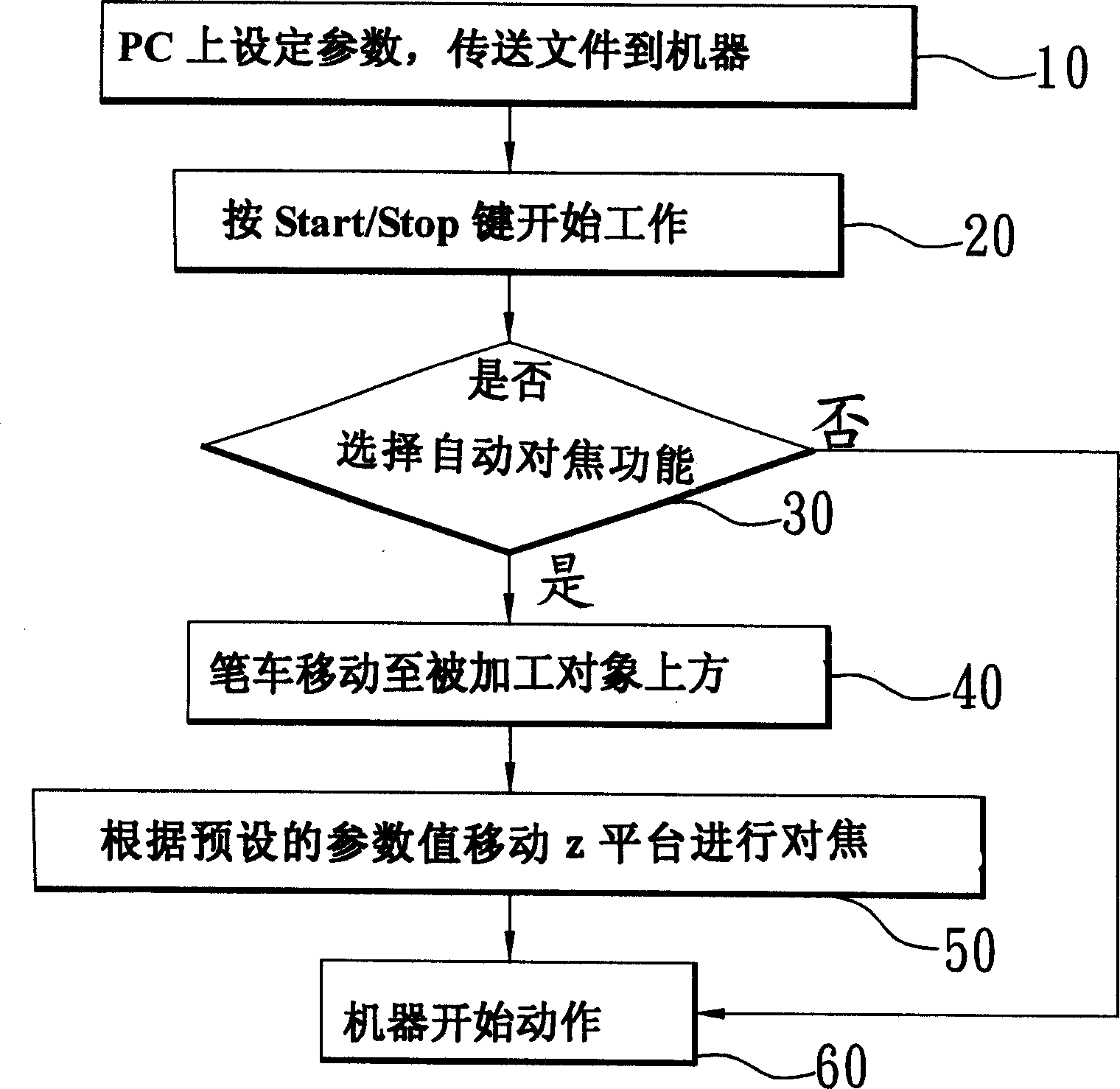

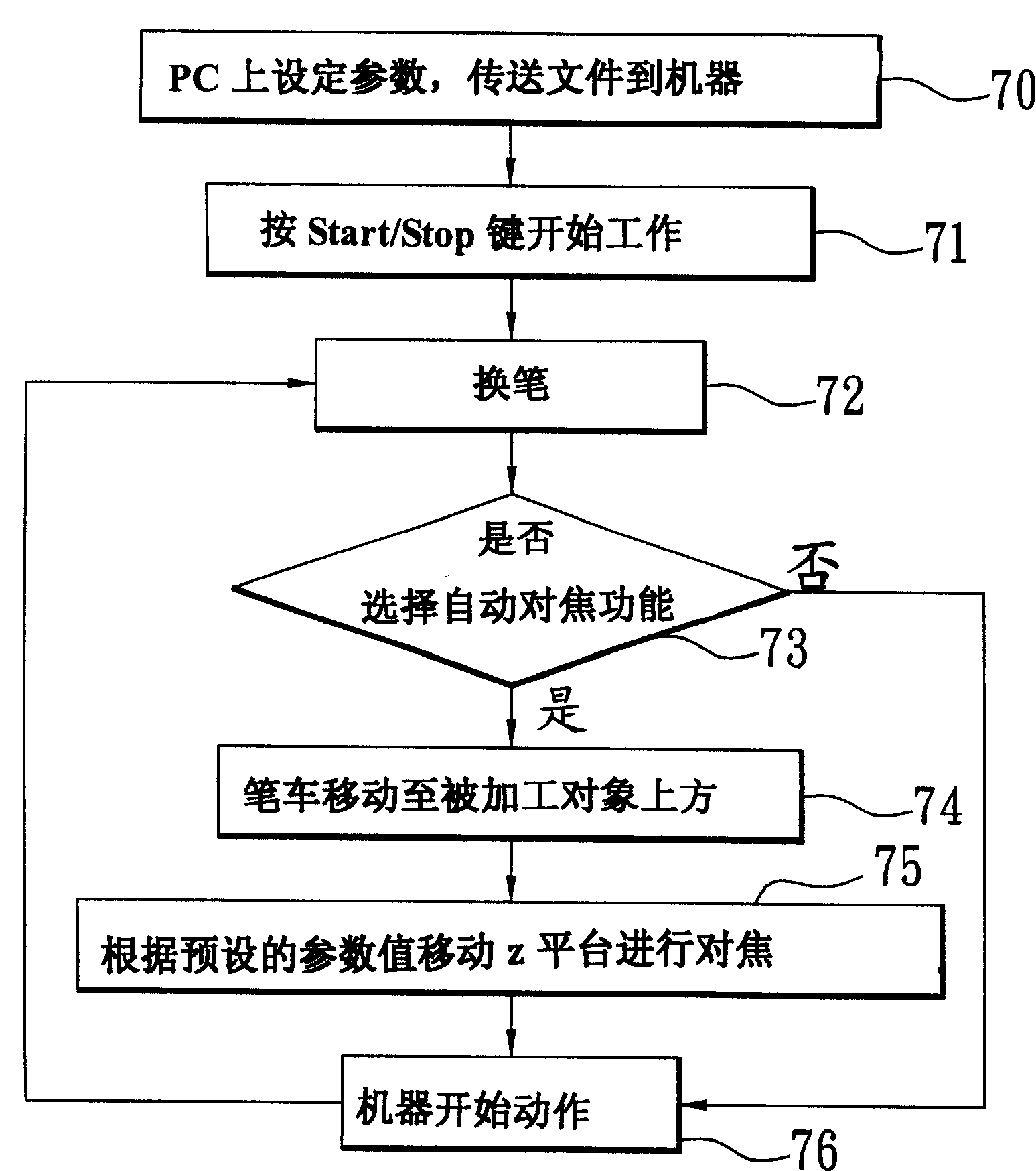

Processing method of laser carving machine

InactiveCN1830684AAutofocusEasy to operateDecorative surface effectsModel makingLaser engravingAutofocus

Owner:XINGYUN COMP

Pressure self-adjusting full-automatic exhaust gas controller

InactiveCN1730799AGuaranteed long-term smoothnessDisadvantages affecting ironingHand ironTextiles and paperSolenoid valveWater filter

The automatic pressure regulating tail steam controller consists of main steam water filter and subsidiary steam water filter. Each of the main steam water filter and subsidiary steam water filter has joint, automatic water outlet and manual spare water outlet in the bottom, float ball and float ball switch, cylinder with repositioning spring and push rod, stroke touch block on the push rod, water filter, solenoid valve and other parts. The automatic pressure regulating tail steam controller operates the tail steam switch automatically and this decreases the operation steps and saves energy.

Owner:陈光焕

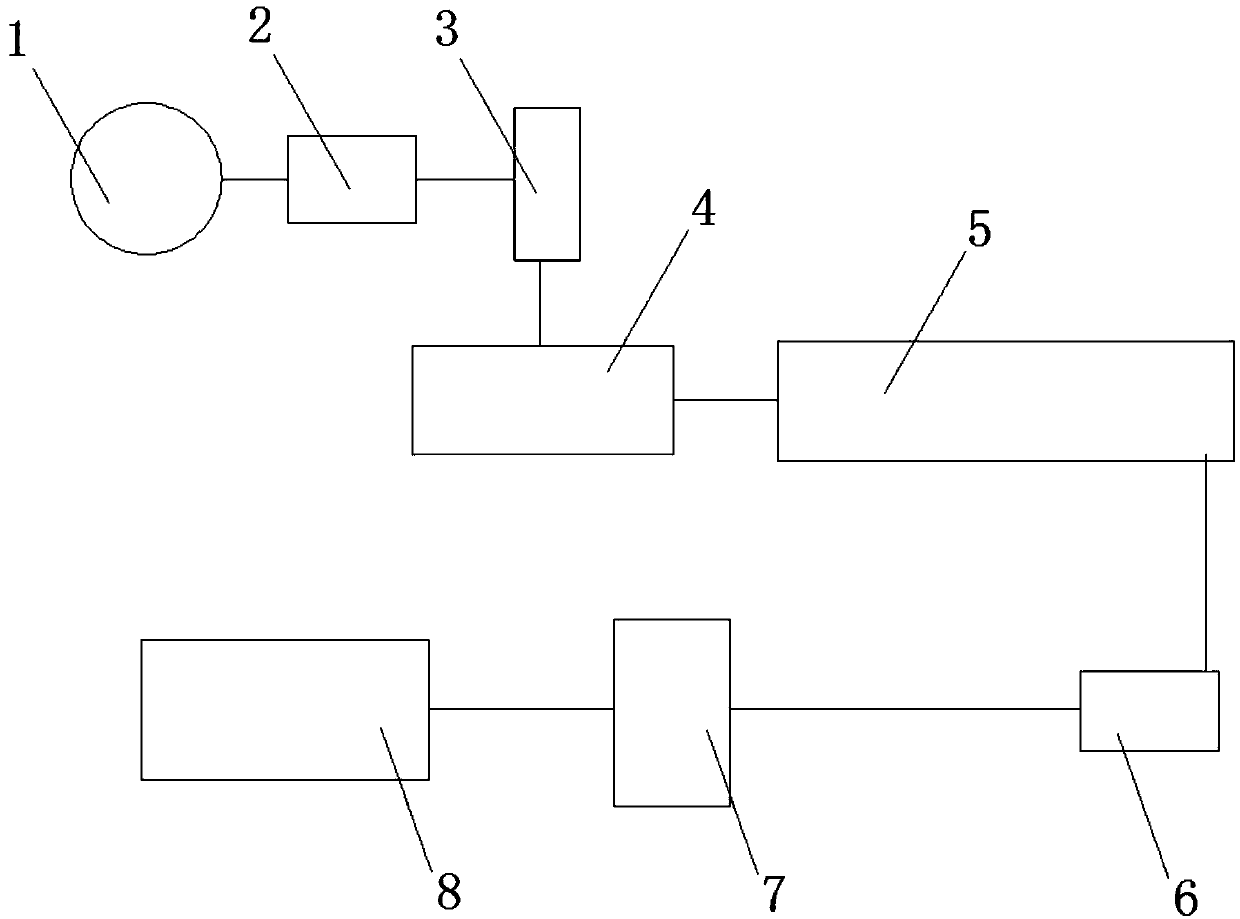

Intelligent conveying system for bobbin film sleeving and packaging production line

PendingCN112777026AIncrease installed capacityReduce work proceduresWrapping material feeding apparatusConveyor wrappingManufacturing engineeringBobbin

The invention relates to an intelligent conveying system for a bobbin film sleeving and packaging production line. The system comprises a conveying system, a large and small head detection system, a film sleeving system, an automatic arrangement system and a packaging system which are sequentially arranged. The film sleeving system comprises a film storage assembly, a film feeding assembly, a bagging assembly and an overturning assembly, wherein the film feeding assembly is arranged below the film storage assembly, a bagging assembly is arranged on one side of the lower portion of the film feeding assembly and is in butt joint with the overturning assembly. The conveying system comprises a rack and a conveying belt arranged on the rack. The conveying belt comprises a plurality of small conveying belts with the same length. The large and small head detection system comprises a first limiting switch, a second limiting switch, a third limiting switch and a control system, wherein the second limiting switch and the third limiting switch are arranged on one side of the small conveying belt closest to the film sleeving system, and the small conveying belt closest to the film sleeving system is arranged below the film conveying assembly. The automatic film sleeving, packaging and conveying process of bobbins is achieved, and the production efficiency is improved.

Owner:无锡凡琉智能科技有限公司

Bar drilling machine convenient to use

InactiveCN108067650AEasy to useReduce work proceduresMetal working apparatusBoring/drilling machinesDrilling machinesComputer engineering

The invention discloses a bar drilling machine convenient to use and relates to the technical field of drilling. The bar drilling machine convenient to use comprises a bottom plate. The two sides of the bottom of the bottom plate are fixedly connected with bases. The surface of the bottom plate is fixedly connected with a controller. One side of the top of the bottom plate is fixedly connected with a top plate through a supporting column. The bottom of the top plate is fixedly connected with an air cylinder. The bottom of the air cylinder is fixedly connected with a drilling device. The top ofthe bottom plate is fixedly connected with two supporting legs, the top ends of the two supporting legs are fixedly connected with a fixing plate, and a first motor box is fixedly connected to the bottom of the fixing plate and located between the two supporting legs. According to the bar drilling machine convenient to use, the problems that a traditional drilling device is relatively singular instructure and the operation process is very complex can be effectively solved, operation is easy, the labor amount of a worker is effectively reduced, the drilling efficiency is improved, and therefore the economical benefits are further improved for an a factory.

Owner:江苏明雨耐磨材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com