Turn-plate type sample-sending device of testing machine

A testing machine and turntable technology, which is applied in the direction of analyzing materials and instruments, to achieve the effects of strong applicability, improved automation level, and elimination of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

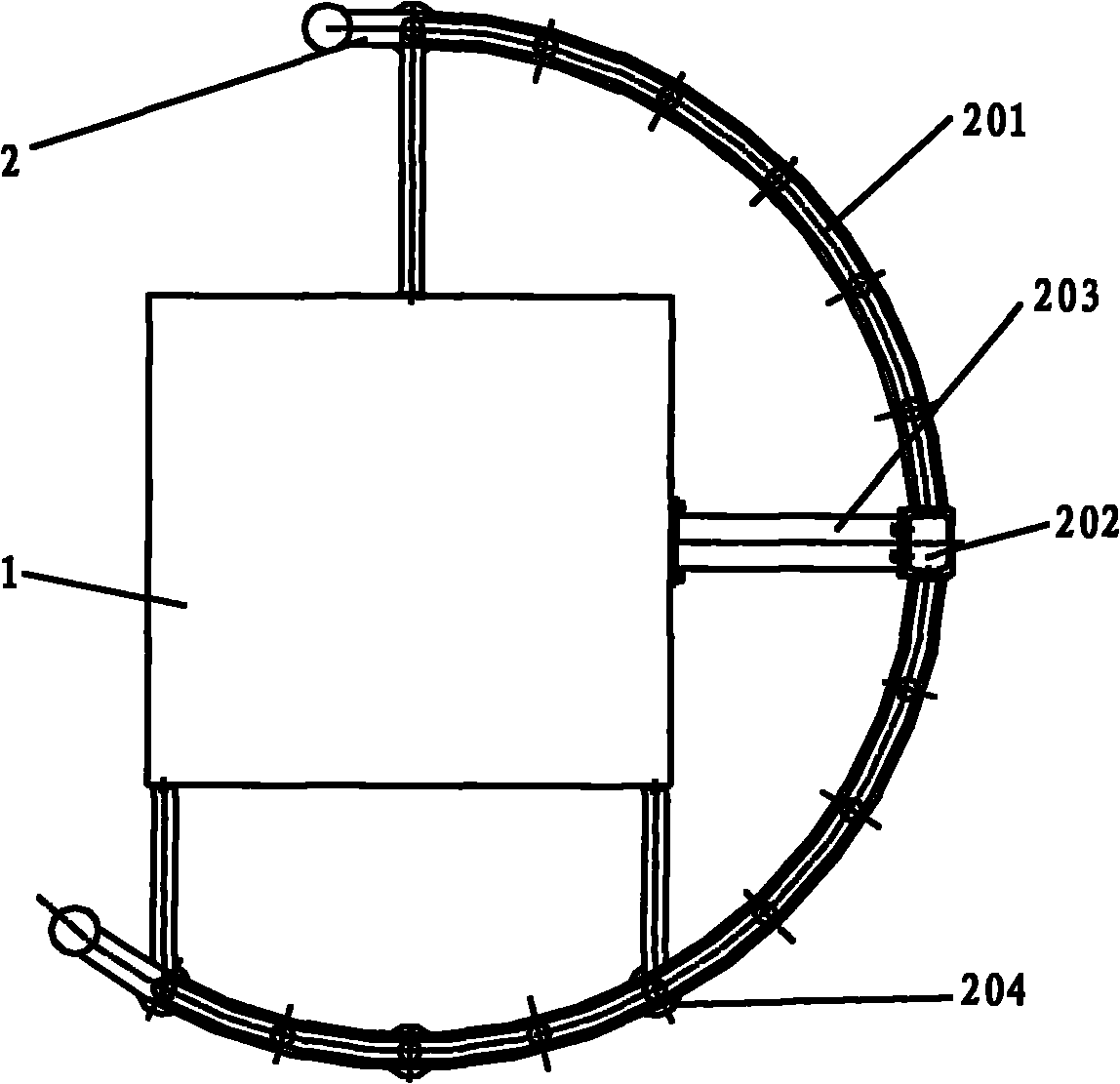

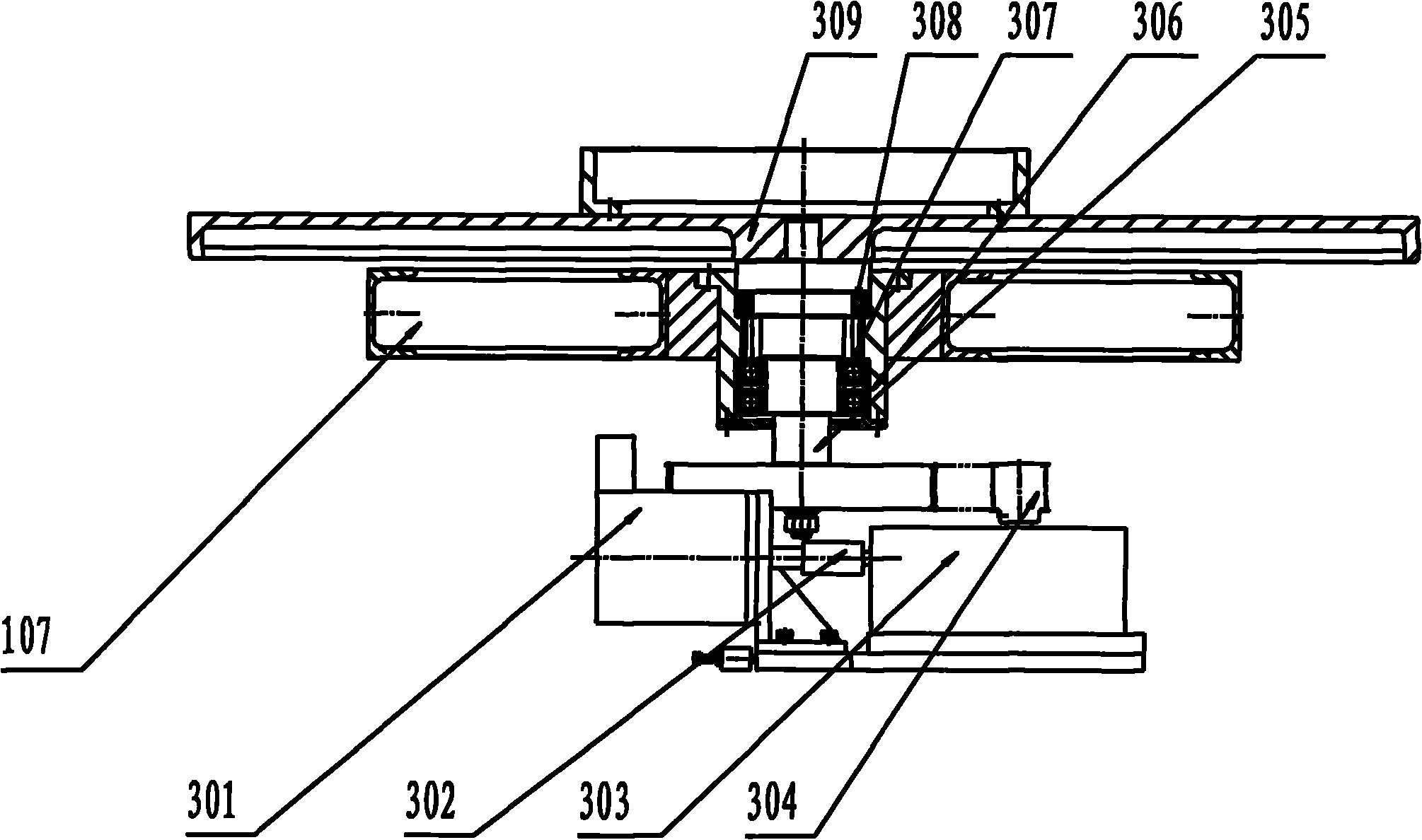

[0024] Such as Figure 4 The rotary table sample feeding device of the testing machine shown includes a machine base 1, a guardrail frame 2 arranged on the periphery of the machine base 1 for dividing the working range of the testing machine, a turntable 309 arranged on the machine base 1 and a transmission for providing power. device.

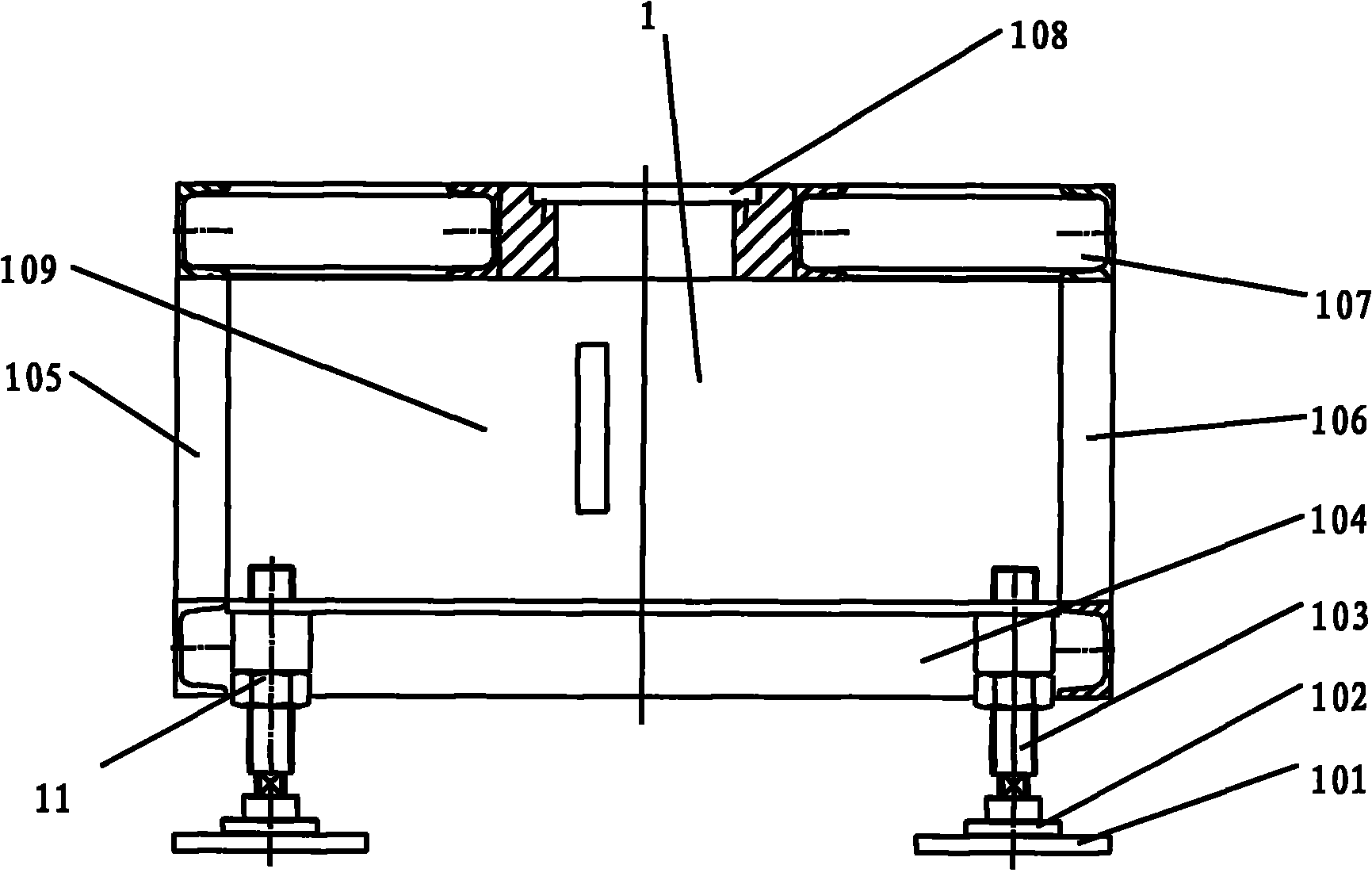

[0025] Such as figure 1 As shown, the machine base 1 is a box space, the left and right side plates 105, 106 and the upper and lower plates 104, 107 of the box space are welded in a rectangular shape surrounded by four pieces of channel steel, and the front and rear sides of the box space Two sliding doors 109 are also provided on the side; a steel plate 108 is welded in the center of the channel steel frame of the upper plate 107, and a stepped hole is processed to place the bearing seat in the transmission device; Four steel plates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com