Processing method of laser carving machine

A technology of a laser engraving machine and a processing method, which is applied in the direction of processing models, processes for producing decorative surface effects, decorative arts, etc., can solve problems such as insufficient automation of operations, affecting the smoothness of the work process, and affecting the output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

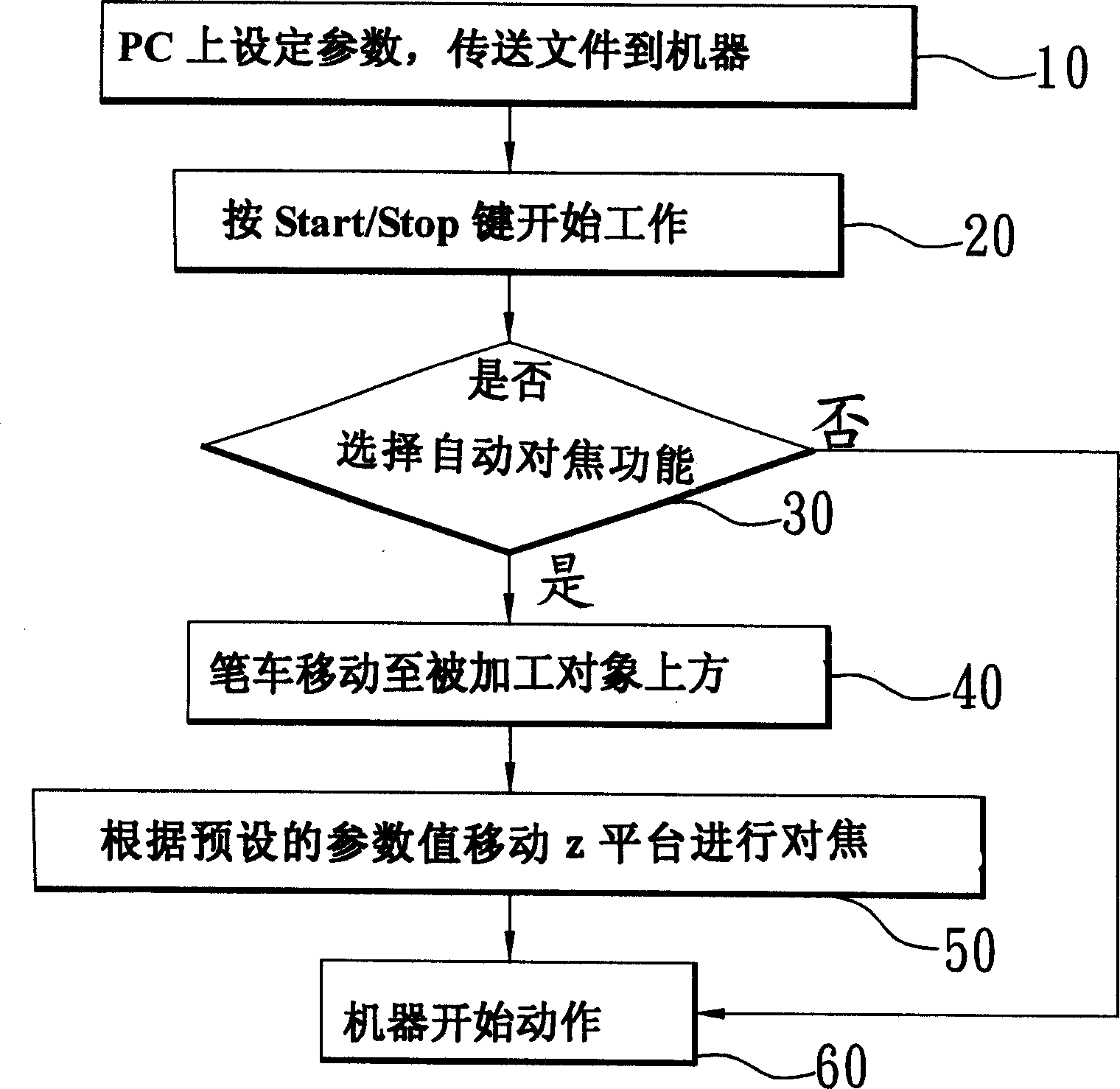

[0026] see figure 2 The step flowchart of the processing method of the present invention shown.

[0027] First, pre-set on the PC various parameters to be input to the laser engraving machine, and transmit the various parameters to the laser engraving machine 10, so that the engraving machine can perform automatic batch operations and various special operations according to the parameters .

[0028] The above-mentioned various parameters include auto-focus parameters or non-auto-focus parameters. Therefore, when the operator uses the control panel to transmit the set parameter file to the laser engraving machine, the operator presses the Start button on the engraving machine. After pressing the key 20, the laser engraving machine will execute or not execute the auto-focus function 30 according to the parameters received.

[0029] If the parameter received by the laser engraving machine is to execute the auto-focus function, the engraving machine proceeds to the next step, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com