Angular contact ball bearing flexible assembly mold with fore shaft on inner ring

An angular contact ball bearing and elastic assembly technology, which is applied in the field of assembly and bearing processing, can solve the problems of assembly efficiency, repeated cleaning, waste of petroleum jelly, etc., and achieve the effect of improving assembly efficiency, reducing working procedures, and saving petroleum jelly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

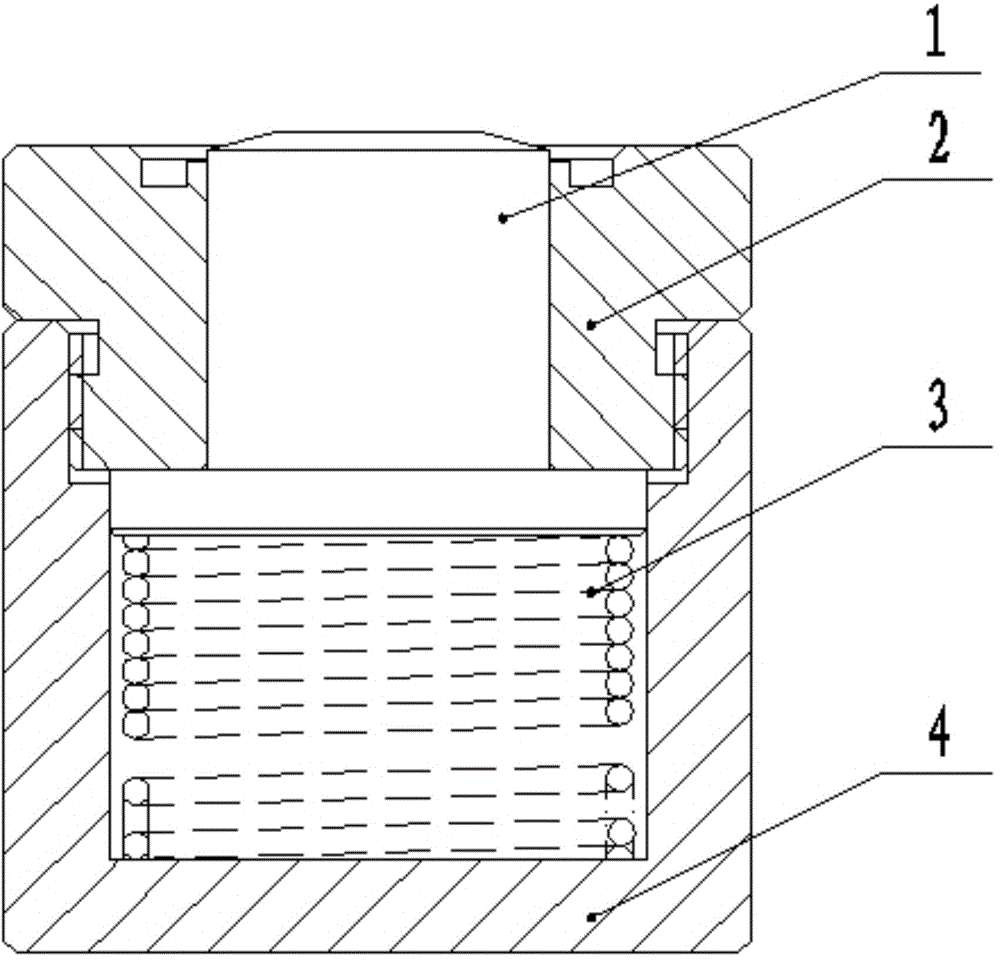

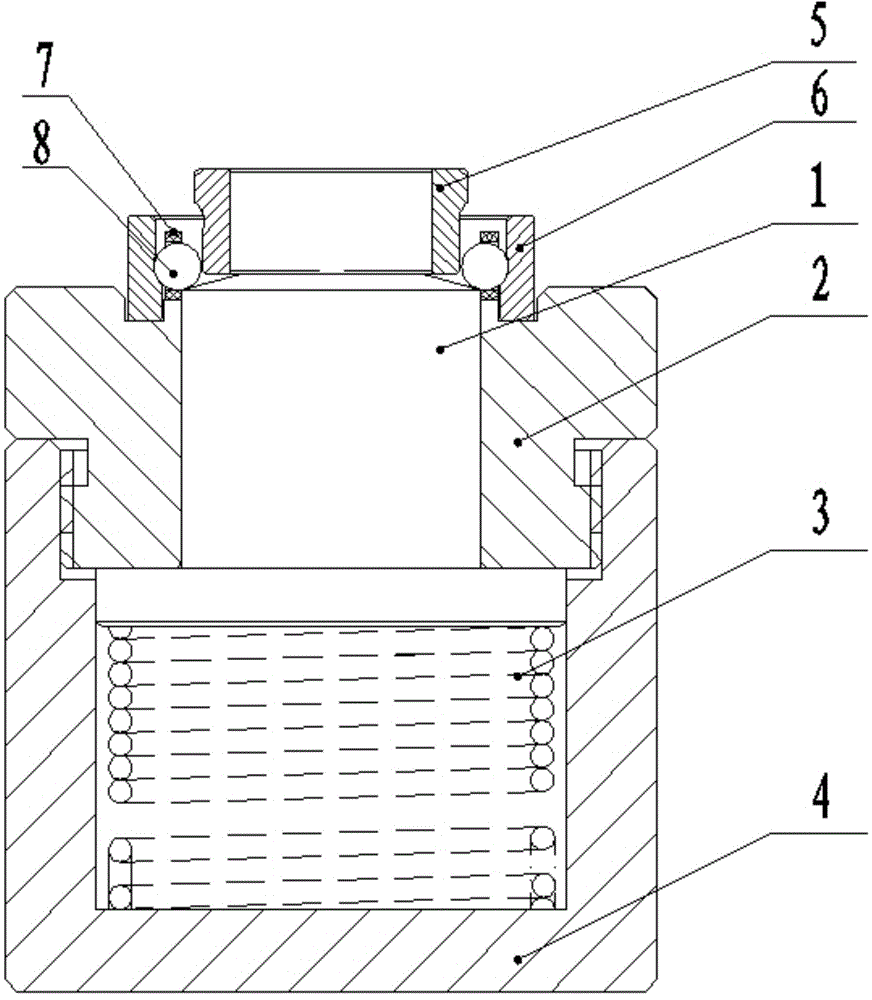

[0027] as attached Figure 1~5 Shown:

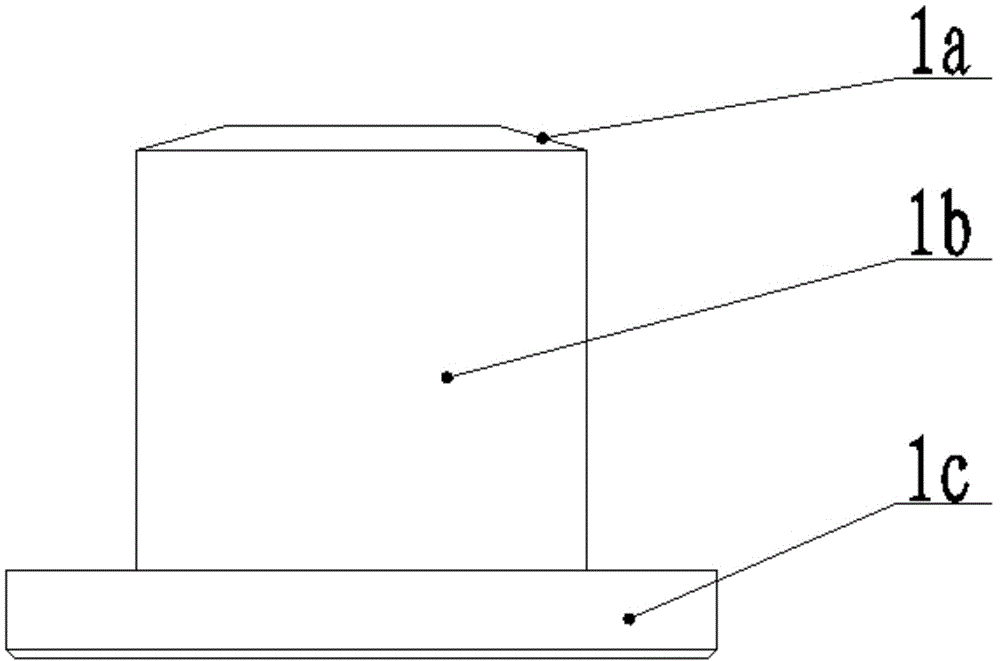

[0028] The elastic assembly mold of the angular contact ball bearing with a locking inner ring in the present invention includes a mandrel 1, a positioning block 2, a spring 3, and a base 4; the mandrel 1 includes a guide column 1b, and a guide surface is set on the upper edge of the guide column 1b 1a, the guide surface 1a is an inwardly inclined slope. The lower end of the guide column 1b is fixed on the limit platform 1c; the upper end surface of the positioning block 2 includes a positioning platform 2a, and the outer ring of the positioning platform 2a is provided with a positioning groove 2b; the base 4 is a hollow cylinder with an open upper end , the middle hollow part is the light hole 4b, the spring 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com