Patents

Literature

53results about How to "Improve plastering efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic plastering machine

The invention discloses an architectural working device especially a automatic plastering wall machine, which is characterized by the following: using a laser testing wall device and a squareness sensing device on the plastering wall machine; adjusting the plastering wall direction and the squareness of the machine; folding two vertical orbit of the machine; topping with ceiling; arranging plaster plate on the near wall end face of bin of main units; plastering lash on ascending and descending. This invention uses laser present, which possesses high line degree.

Owner:贺启宇

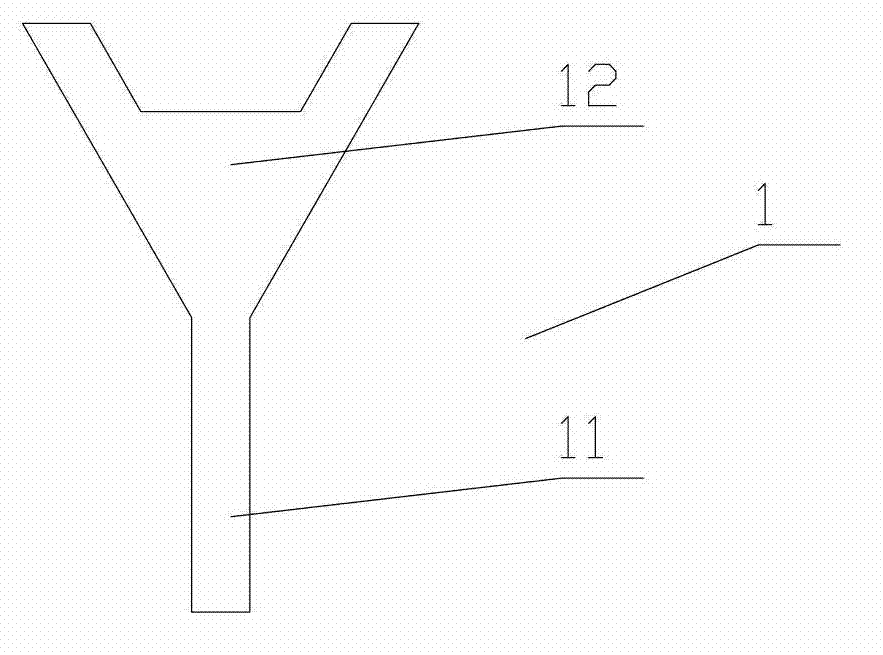

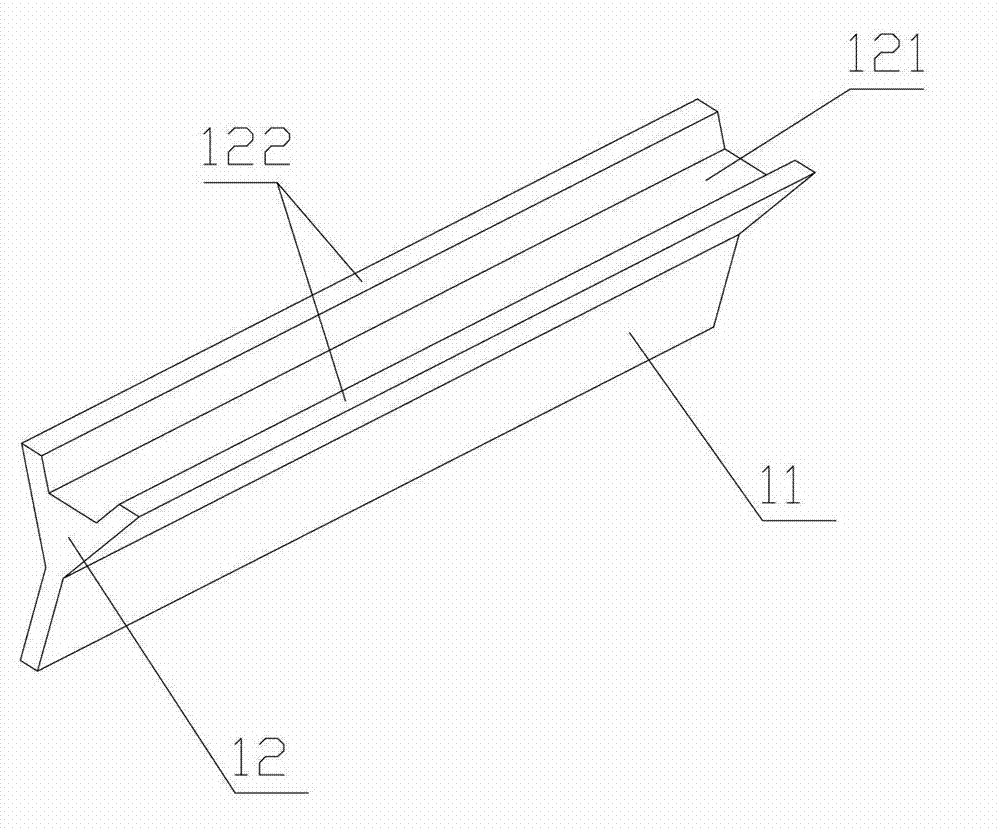

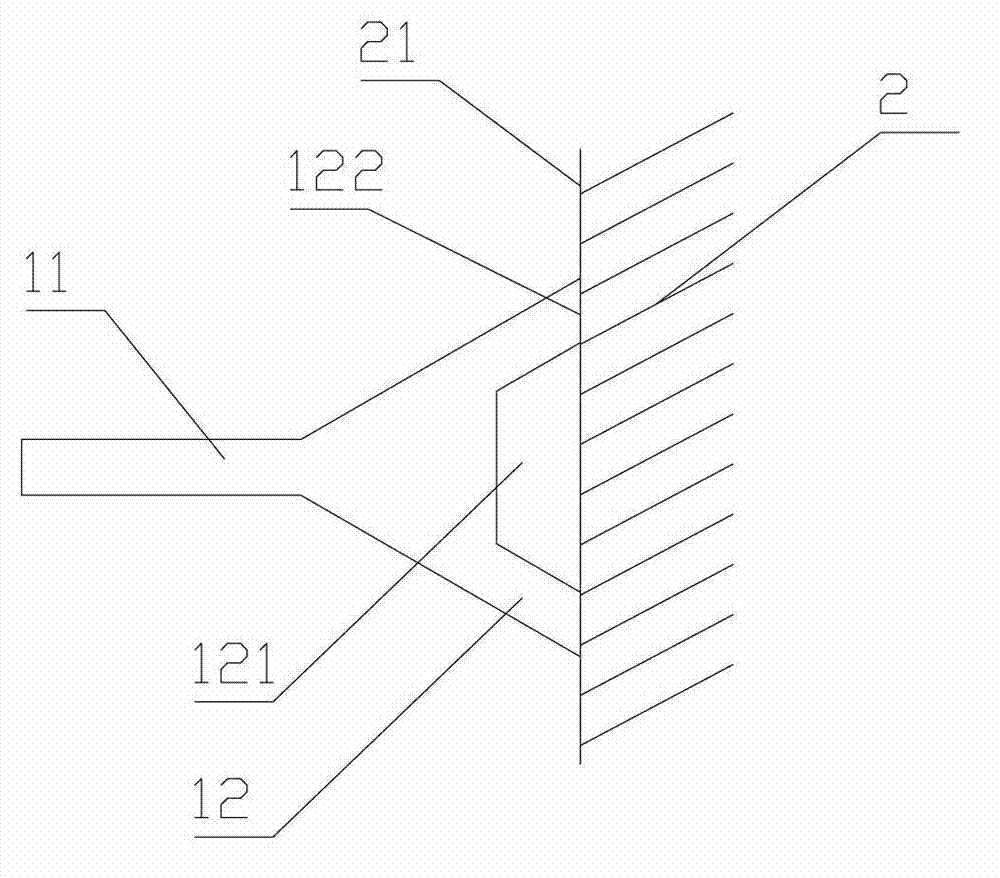

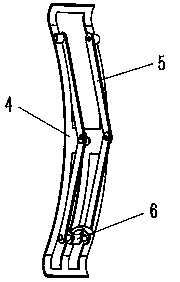

Plastering fillet and constructional plastering method

ActiveCN103088994ASimple structureHigh strengthBuilding constructionsPulp and paper industryBuilding construction

The invention relates to a plastering fillet and a constructional plastering method. The transverse section of the plastering fillet is Y type. The plastering fillet comprises a fixing end and a connecting end which is arranged on the top portion of the fixing end, wherein a groove is formed in the connecting end, and the bottom portion of the groove is a plane. The constructional plastering method comprises the following steps: screeding and plastering; the plastering fillet is adopted to be clamped by a plastering template, the levelness and verticality of the plastering template are controlled through a laser level meter, a pulp shooting machine is used for pulp shooting after fixing the plastering template and plastering fillet together on the back of a wall surface, after mortars covering the connecting end of the plastering fillet, placing to the adhesive connection between the plastering fillet and the wall surface to a fixation degree, at this time, and the pulp shooting machine can be directly used for pulp shooting and plastering. The constructional plastering method constructed with machinery has the advantages of being capable of greatly improving plastering efficiency, shortening construction working period and guaranteeing height and quality of plastering.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Method for plastering construction in architectural decoration

ActiveUS20150059284A1Improve efficiencyImprove construction qualityCovering/liningsBuilding repairsStructural engineeringBuilding construction

A method for plastering construction in architectural decoration comprises the following steps: (1) base treatment; (2) performing construction positioning paying-off according to the required plastering height, and longitudinally installing screeding templates along a wall surface subjected to the base treatment in Step (1) according to the paying-off height, a lateral space between adjacent screeding templates being 1.3 to 1.8 meters; (3) plastering; and (4) laying aside the wall surface subjected to the plastering for 12 to 24 hours till plastering mortar on the wall surface is in a half-dried compact hardened state, and using teeth of a saw blade for grinding the mortar along the two adjacent screeding templates through a ruler till the mortar is even. The method can improve the construction efficiency and guarantee the construction quality.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

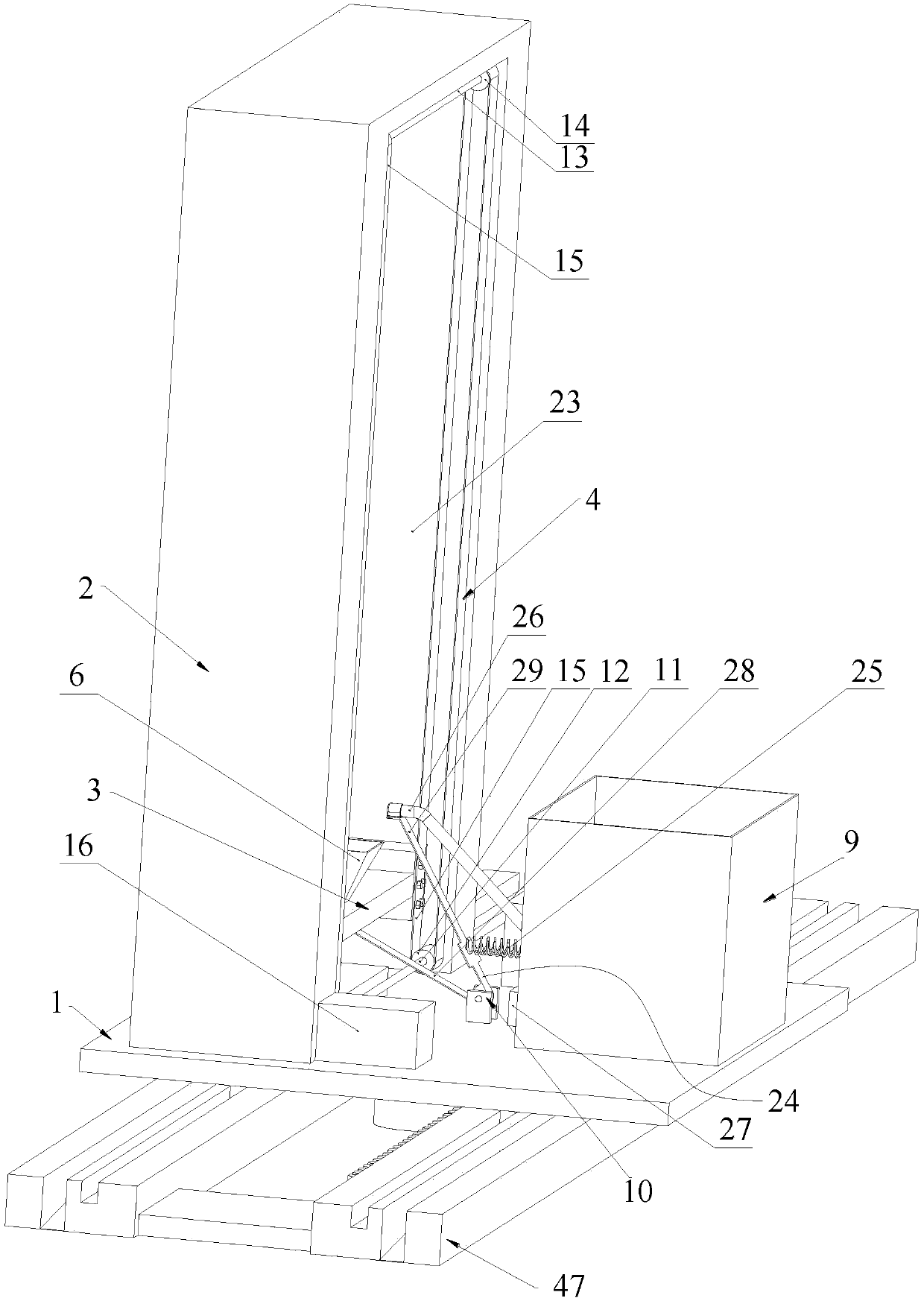

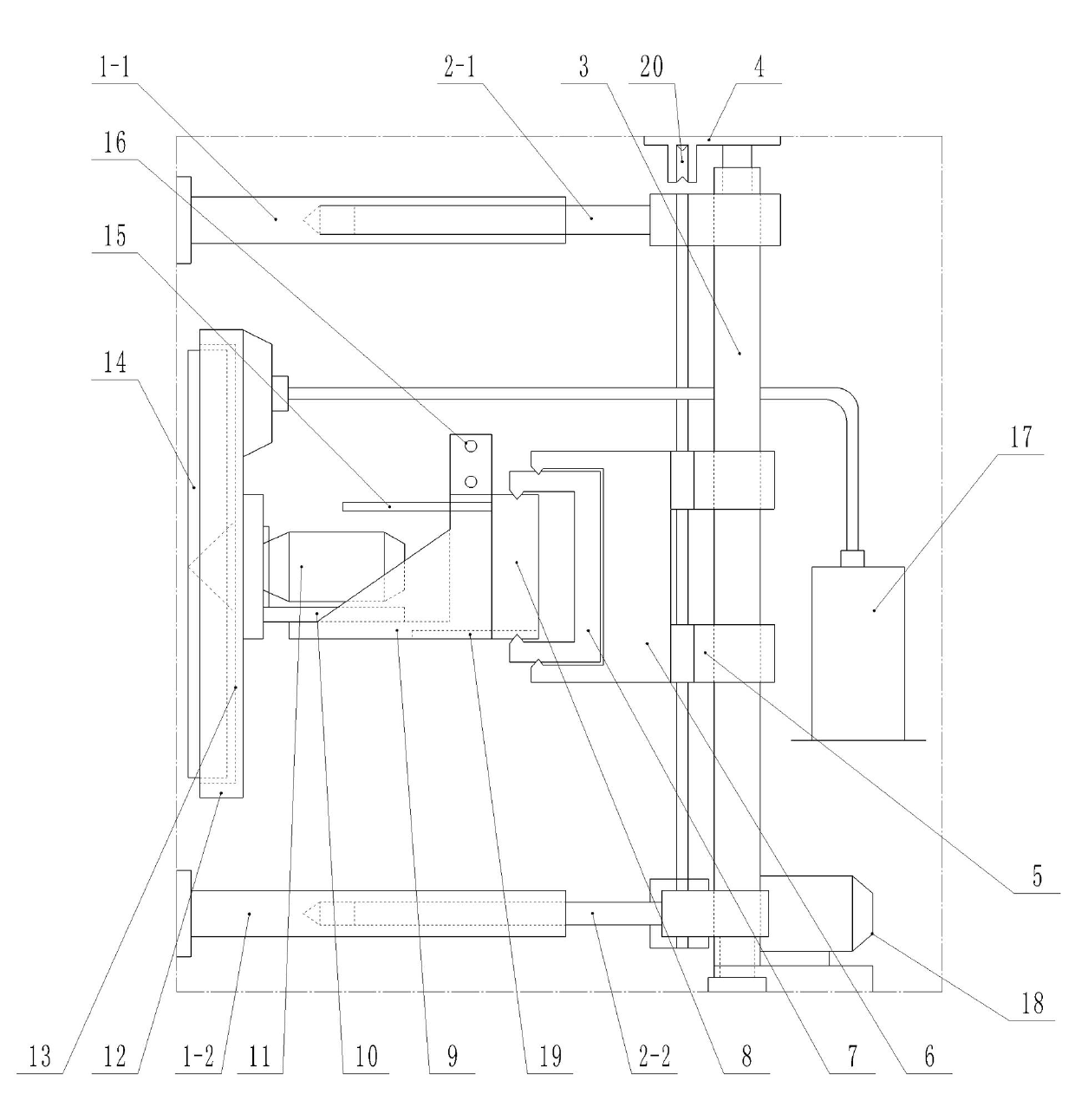

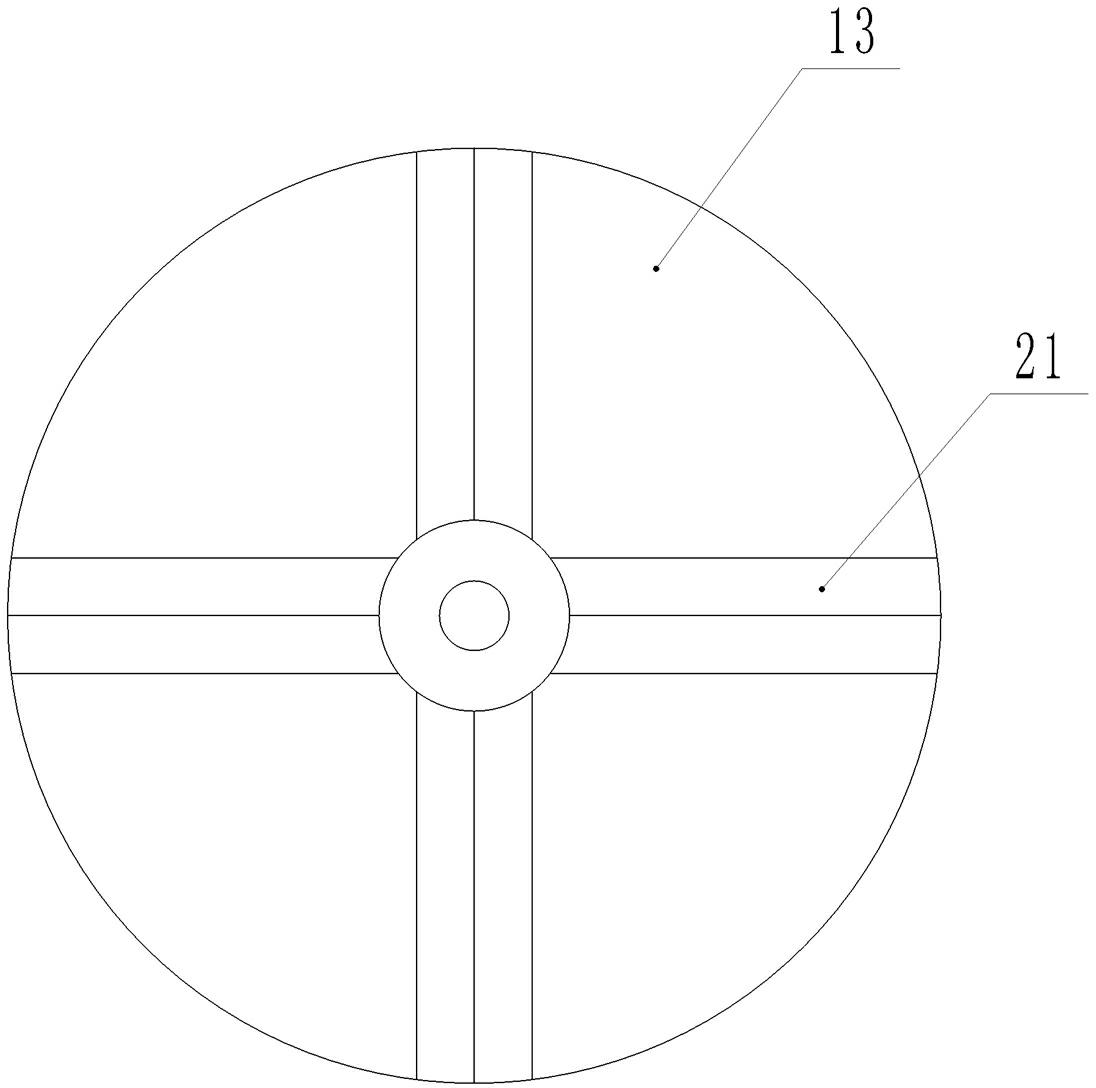

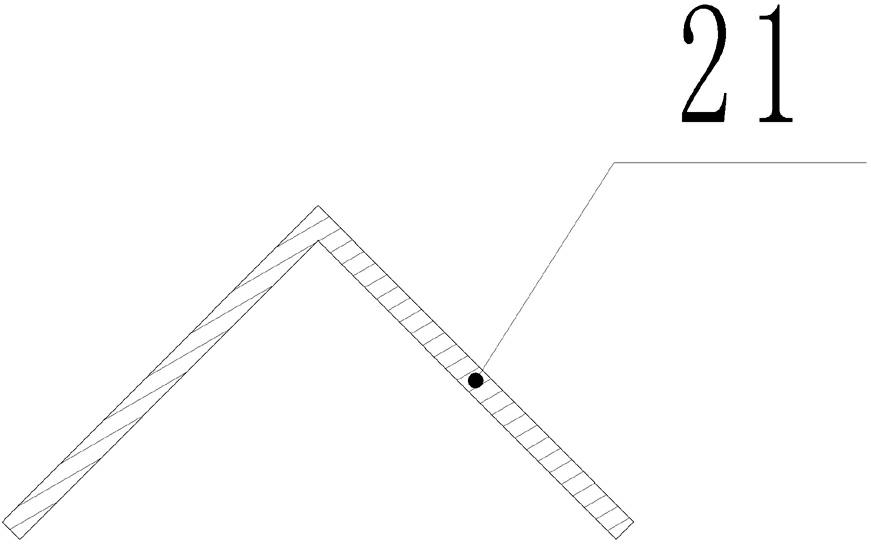

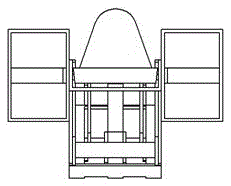

Building wall automatic construction equipment and construction method thereof

InactiveCN108019033AImprove securityHigh degree of automationBuilding constructionsRotary stageHydraulic cylinder

The invention discloses building wall automatic construction equipment. The building wall automatic construction equipment comprises a bearing table; a rotating table is arranged on the top of the bearing table; a steering motor is arranged on one side of the rotating table, and a control cabinet is arranged on the other side of the rotating table; a single chip microcomputer is arranged inside the control cabinet; lifting hydraulic cylinders and a winding mechanism are arranged on the top of the rotating table, and the winding mechanism is arranged between the lifting hydraulic cylinders; a top plate is arranged on the tops of the lifting hydraulic cylinders; a fixed straight rod is arranged on the top of the top plate; telescopic hydraulic cylinders are arranged on the side face of the fixed straight rod; connection transverse rods are arranged at the ends of the telescopic hydraulic cylinders; flattening rollers are arranged at the ends of the connection transverse rods; and a booster pump is arranged on the front side of the fixed straight rod. Compared with a traditional plastering process, a scaffold does not need to be erected, high-place operation of workers is not needed,safety is high, the plastering steps are simplified, the design cost is reduced, unnecessary manpower waste is avoided, the automation degree is high, and the plastering efficiency is improved effectively.

Owner:XIANGDA CONSTR

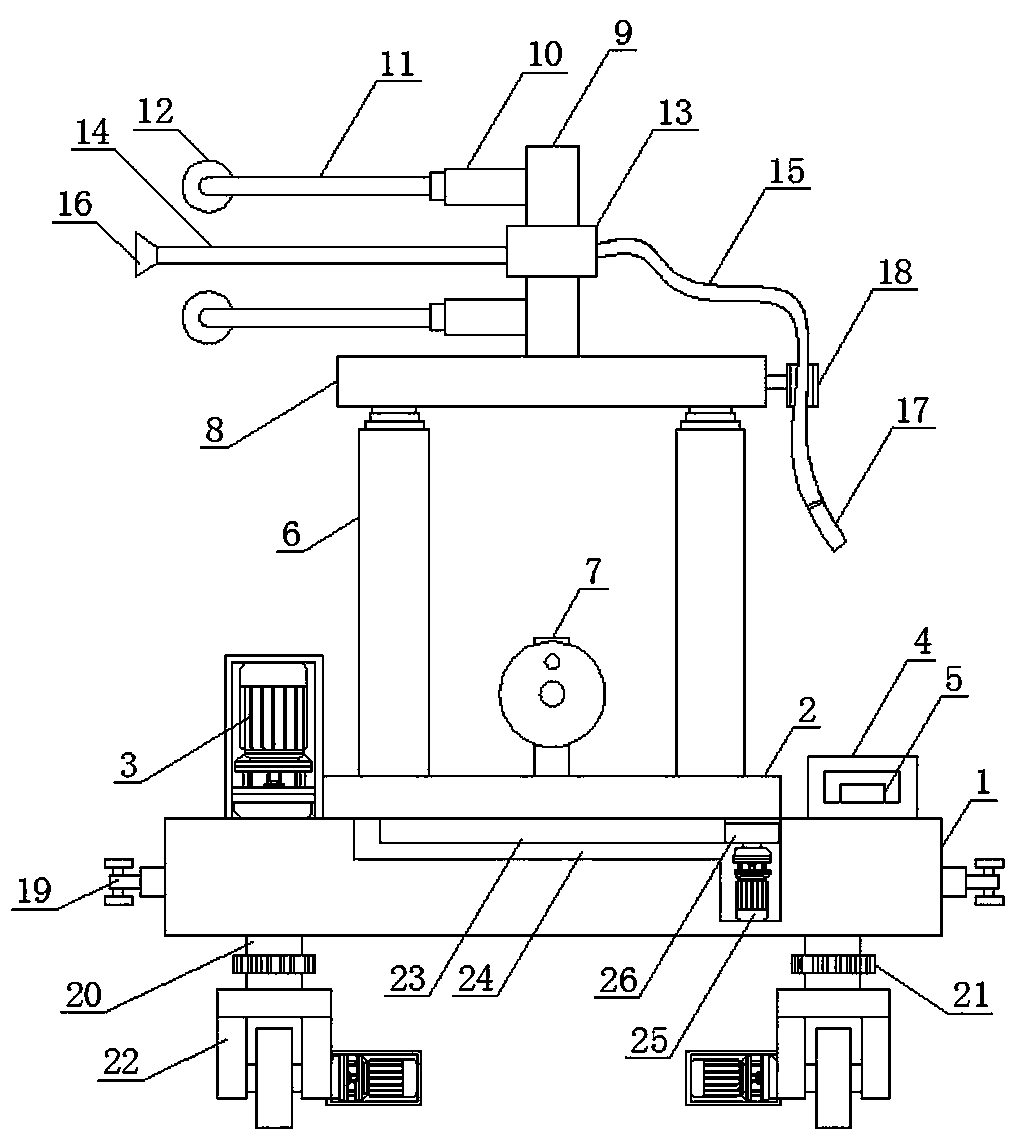

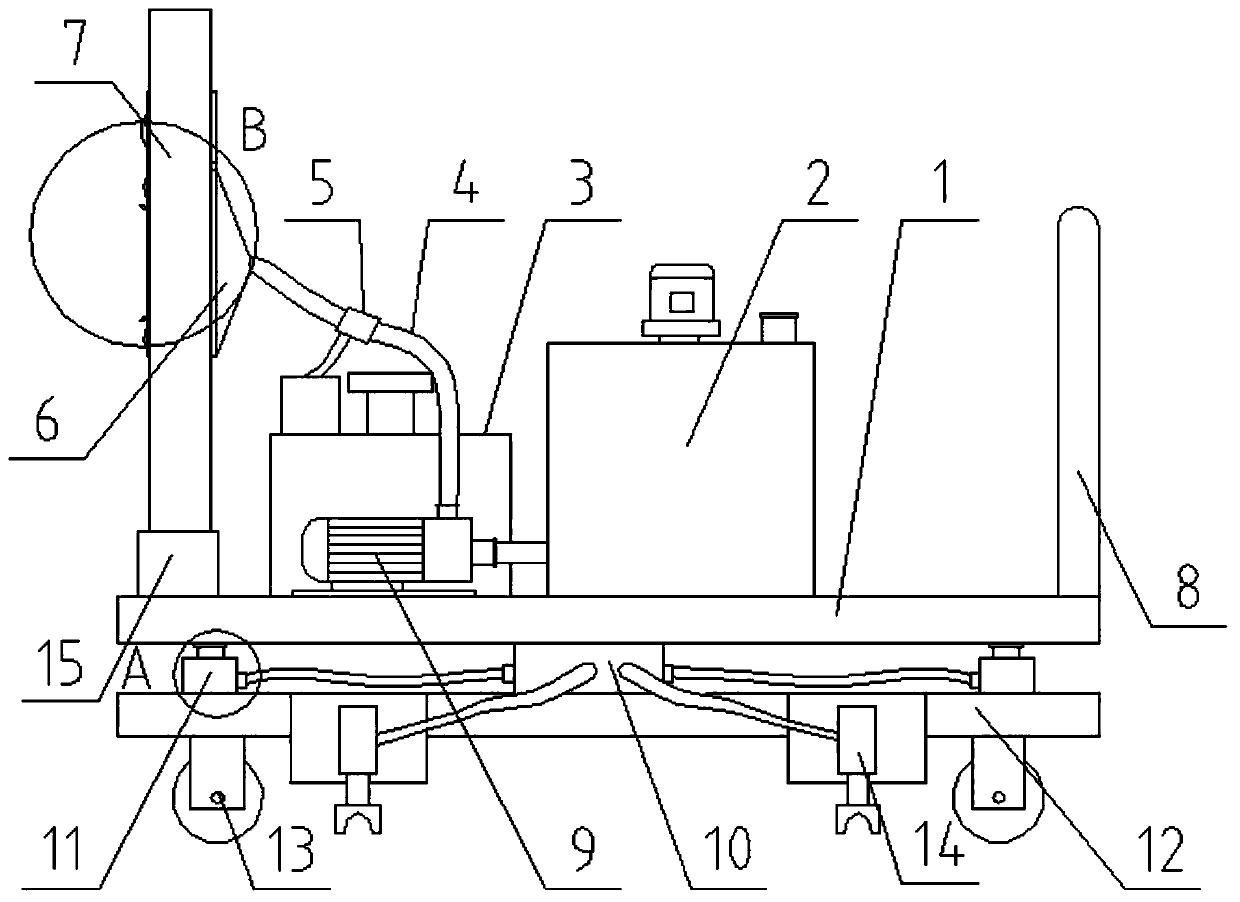

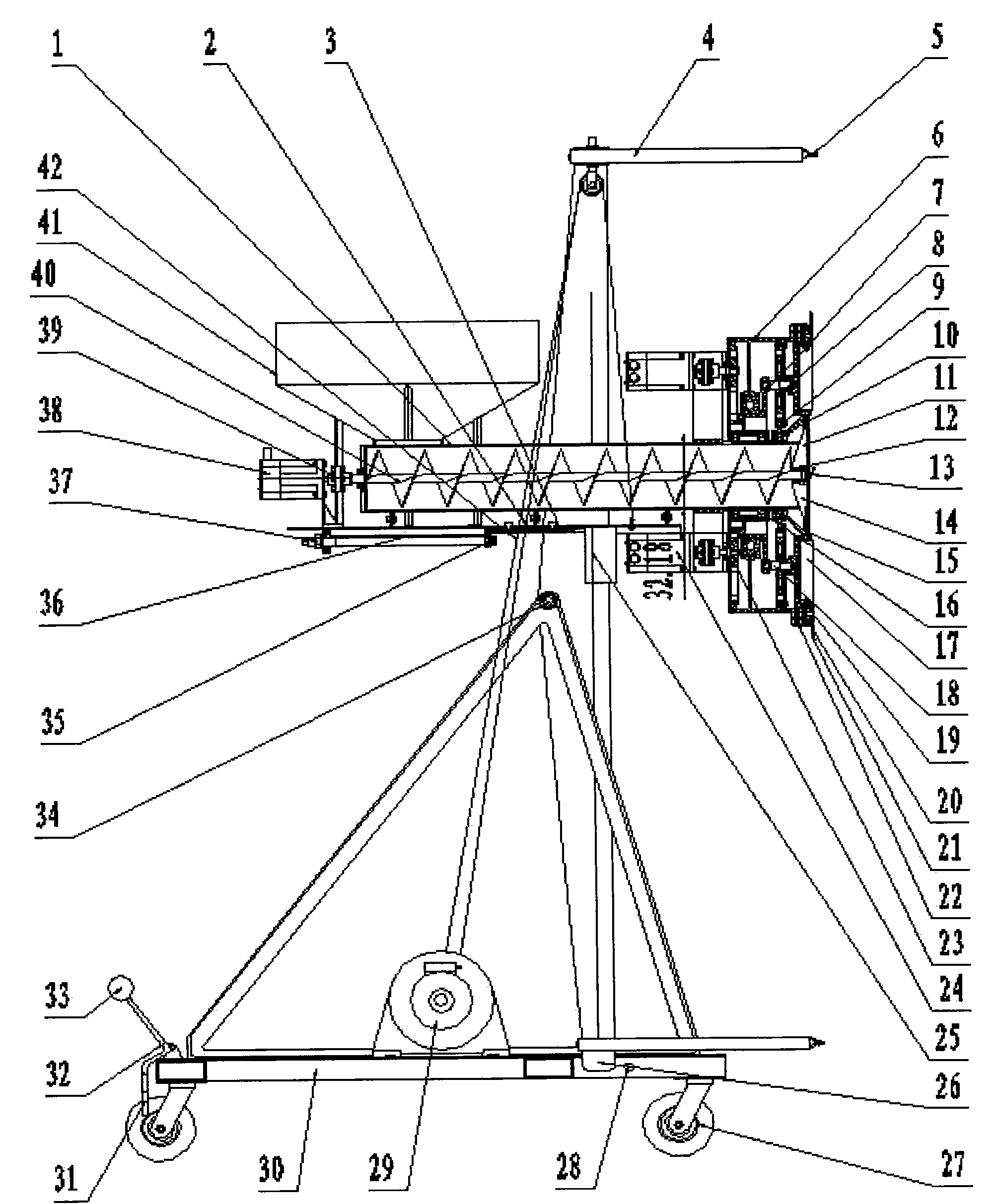

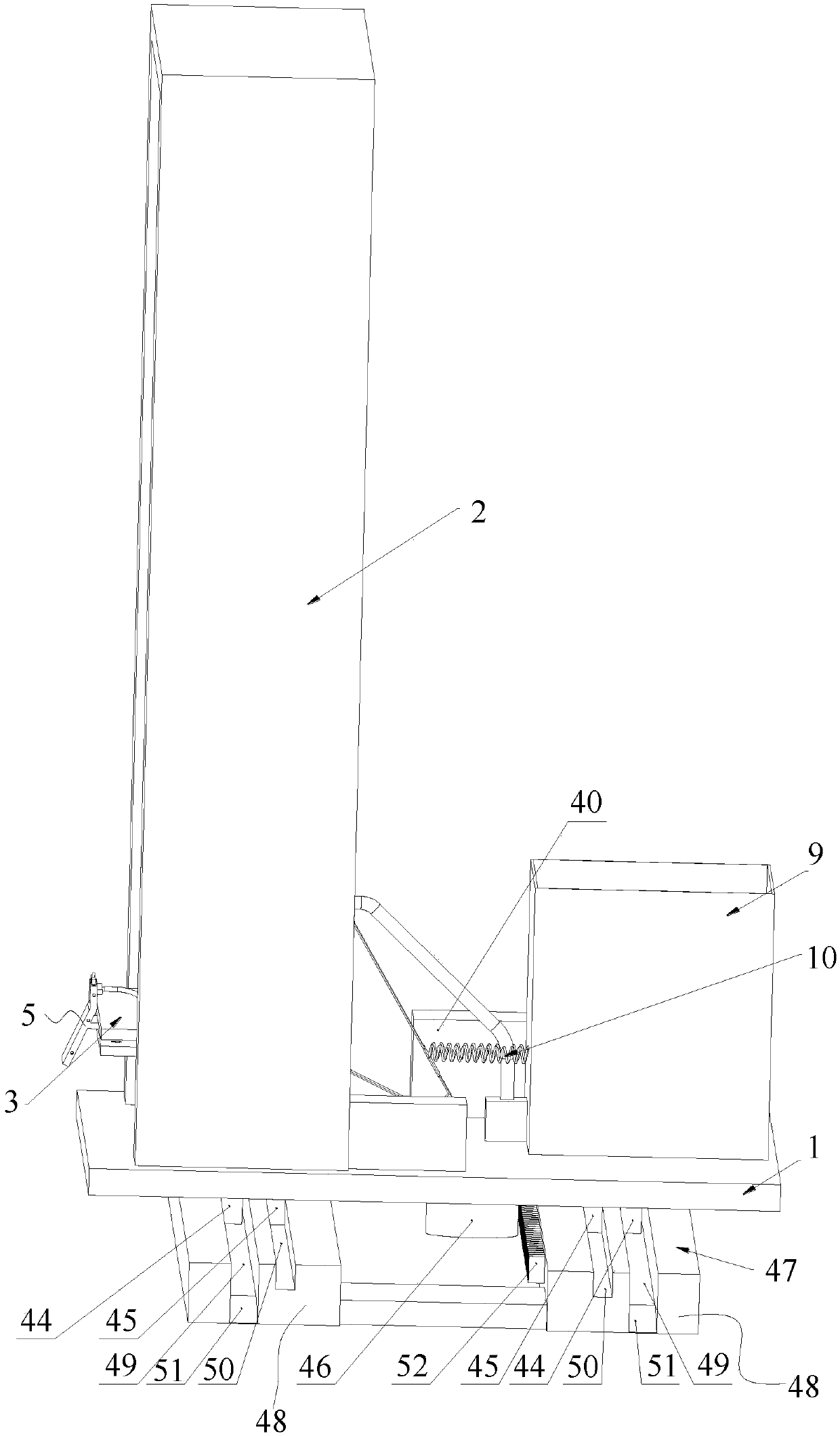

Plastering, galling and automatic mortar-spraying machine

ActiveCN109868977AImprove work efficiencyReduce the amount of manual laborBuilding constructionsGallingFuel tank

The invention discloses a plastering, galling and automatic mortar-spraying machine, which comprises a pedestal plate and a base plate located below the pedestal plate, a hydraulic oil tank and a plurality of hydraulic jacking devices located at the four corners of the base plate are fixedly mounted between the pedestal plate and the base plate, the pedestal plate and the base plate are connectedthrough the multiple hydraulic jacking devices, the multiple hydraulic jacking devices all communicate with the hydraulic oil tank through oil guiding pipes correspondingly, horizontal displacement mechanisms are symmetrically mounted on the side faces of the base plate and communicate with the hydraulic oil tank through oil guiding pipes, and idler wheels are mounted at the four corners of the lower end of the base plate. The plastering, galling and automatic mortar-spraying machine has the three functions of plastering, galling and mortar spraying and has the advantages of high mortar-outletefficiency and horizontal moving plastering, and the problem that the high wall surface cannot be painted is solved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

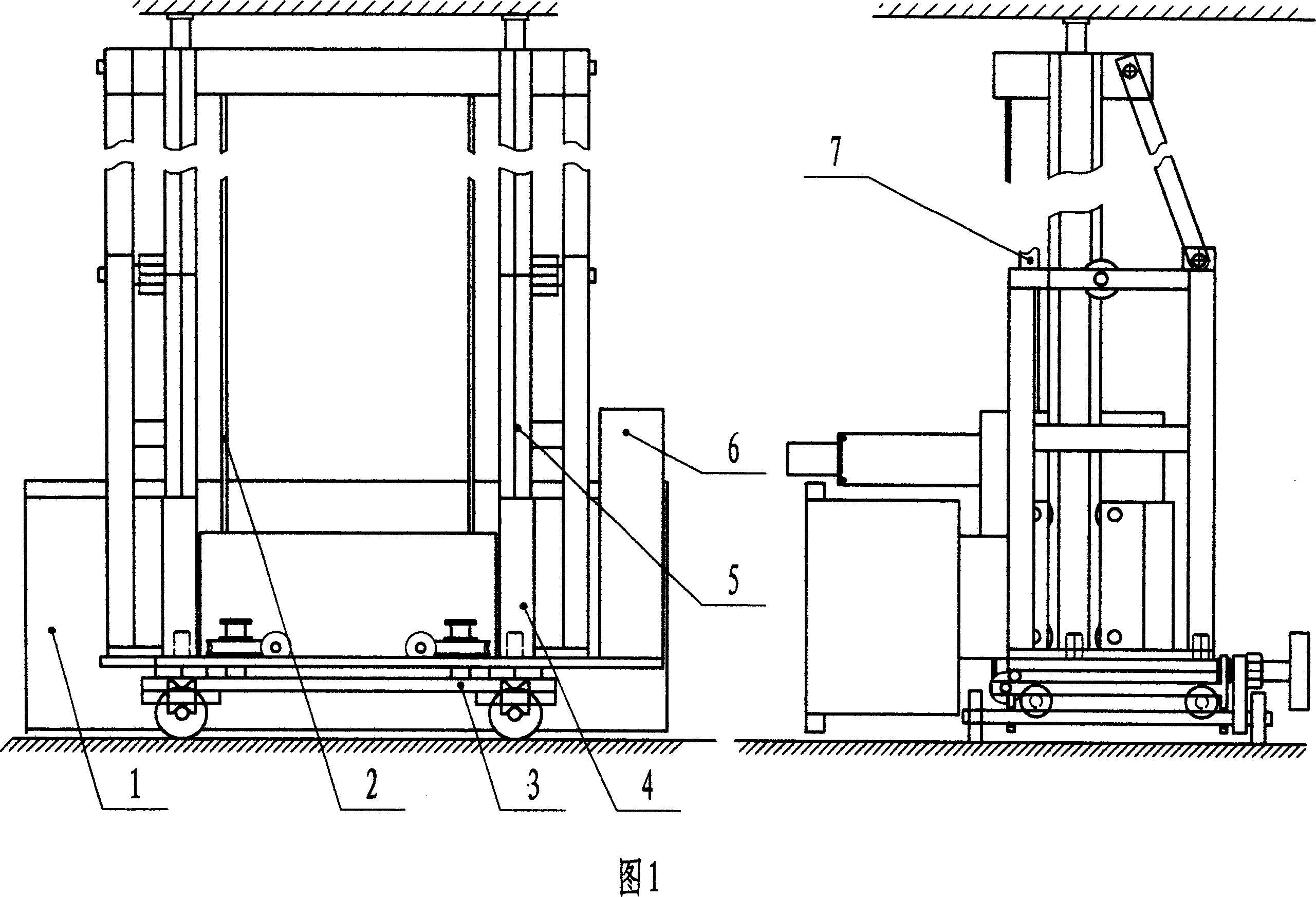

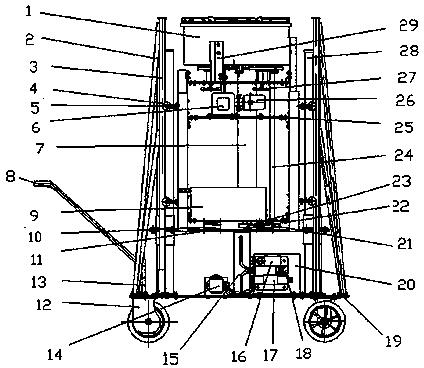

Automatic plastering machine

InactiveCN101328760AImprove flatnessImprove straightnessBuilding constructionsMeasuring instrumentEngineering

The invention provides building construction machinery, in particular to an automatic wall plastering machine, mainly consisting of a base, a frame, a slide bushing, a power tank, a plastering tank, a wire cable, a verticality sensor and a laser wall measuring instrument, wherein a post rod is arranged on the upper end of the frame, and is supported against a ceiling during plastering; the plastering tank can swing up and down, and the upper part and the lower part of the end surface of the plastering tank along the wall are provided with a plastering plate respectively, so that the plastering tank can plaster upwards and downwards, and the ceiling and the floor do not have any blank; and the plastering tank can also be provided with a flashboard capable of sliding left and right, so that the periphery of a door or a window does not have any blank. The verticality sensor and the laser wall measuring instrument are used to adjust verticality and a plastering direction of the wall plastering machine, the plastering thickness of the whole wall can be selected and adjusted in advance so as to save powder materials, thereby the whole planeness and linearity of the wall surface are high, and the adjustment is convenient and reliable.

Owner:贺启宇

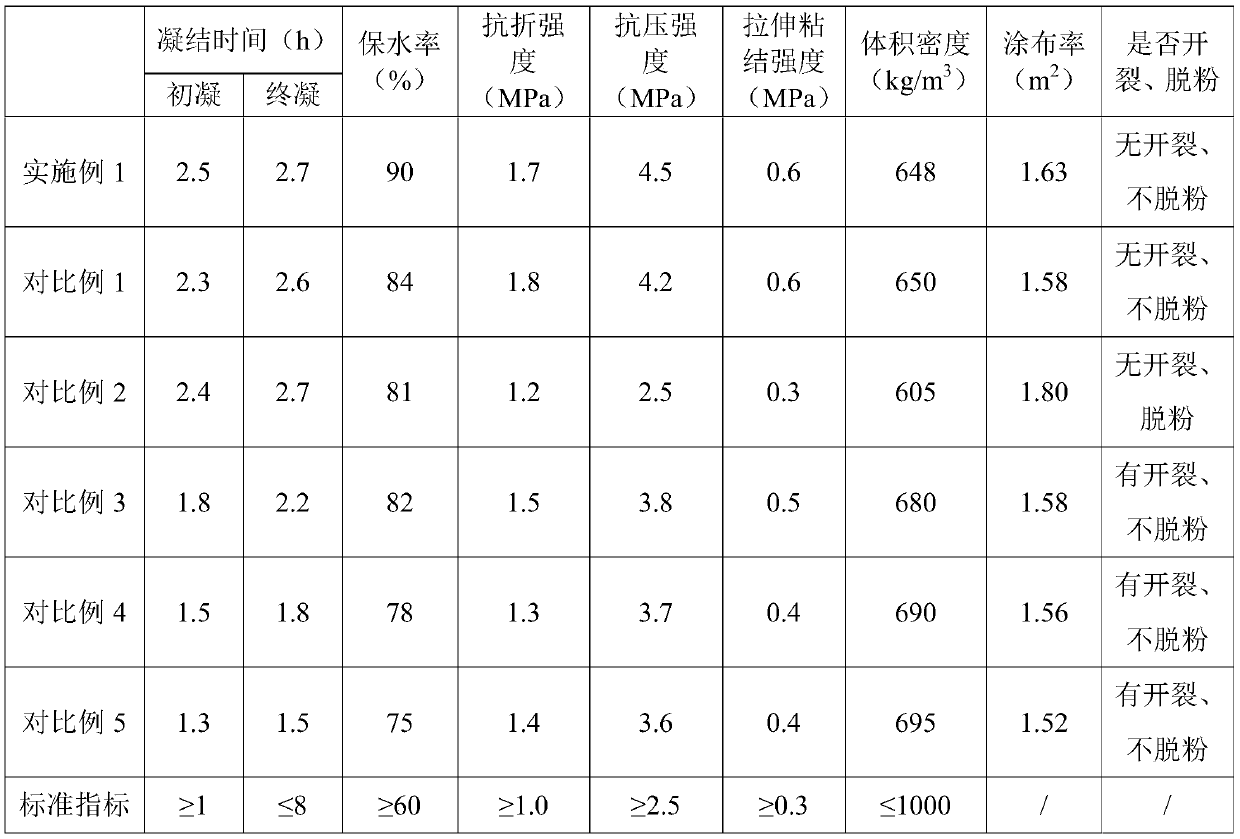

Gypsum-based light plastering material and preparation method thereof

The invention relates to the technical field of buildings, and particularly provides a gypsum-based light plastering material and a preparation method thereof. The first aspect of the invention provides a gypsum-based light plastering material which at least comprises the preparation raw materials in parts by weight: 80-95 parts of gypsum powder, 0.5-2 parts of an alkaline agent, 0.1-0.2 part of awater-retaining agent, 0.1-0.3 part of a mixture, 0.05-0.2 part of a retarder and 0-20 parts of glass microbeads.

Owner:JASON PLASTERBOARD JIAXING

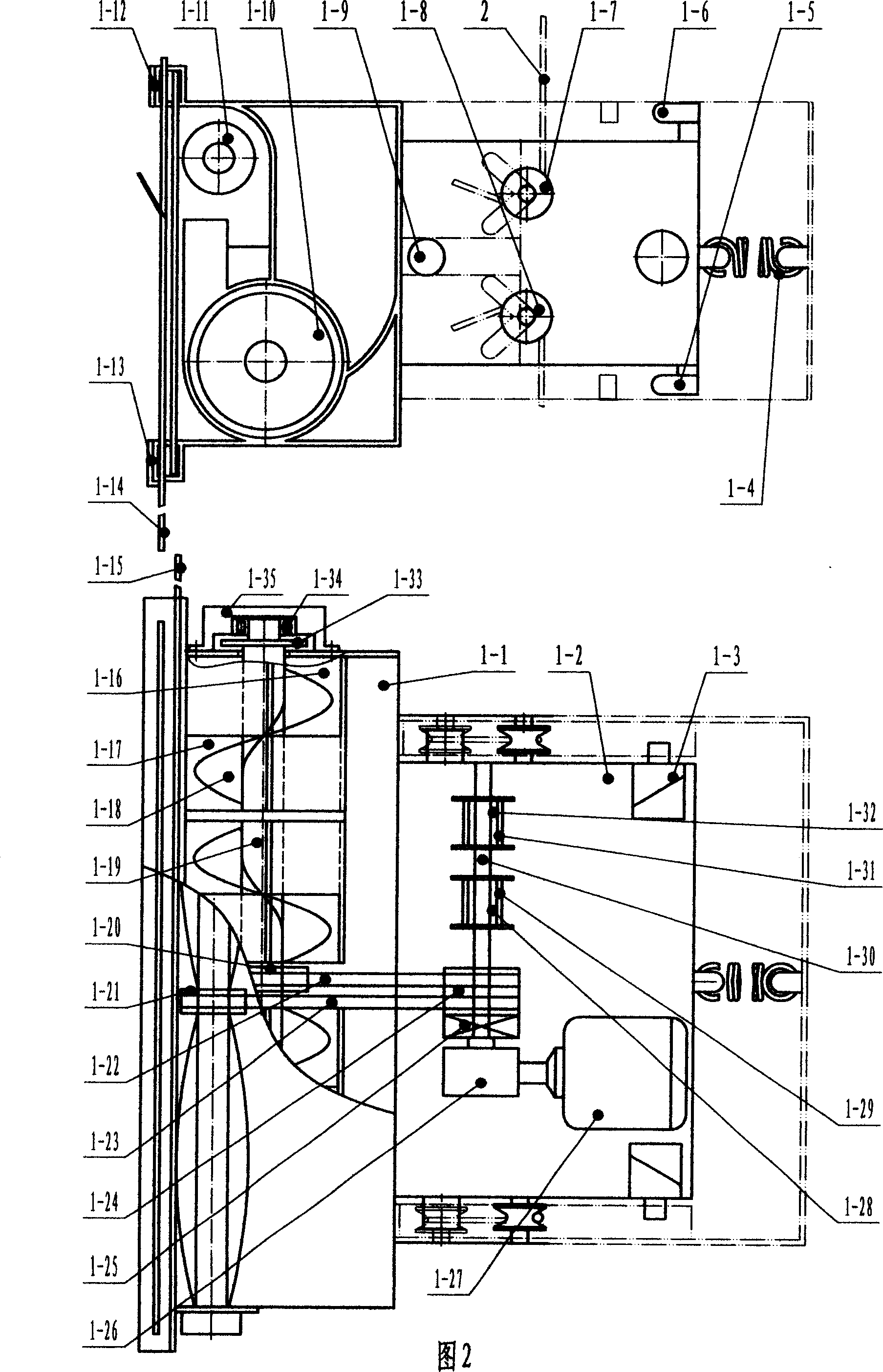

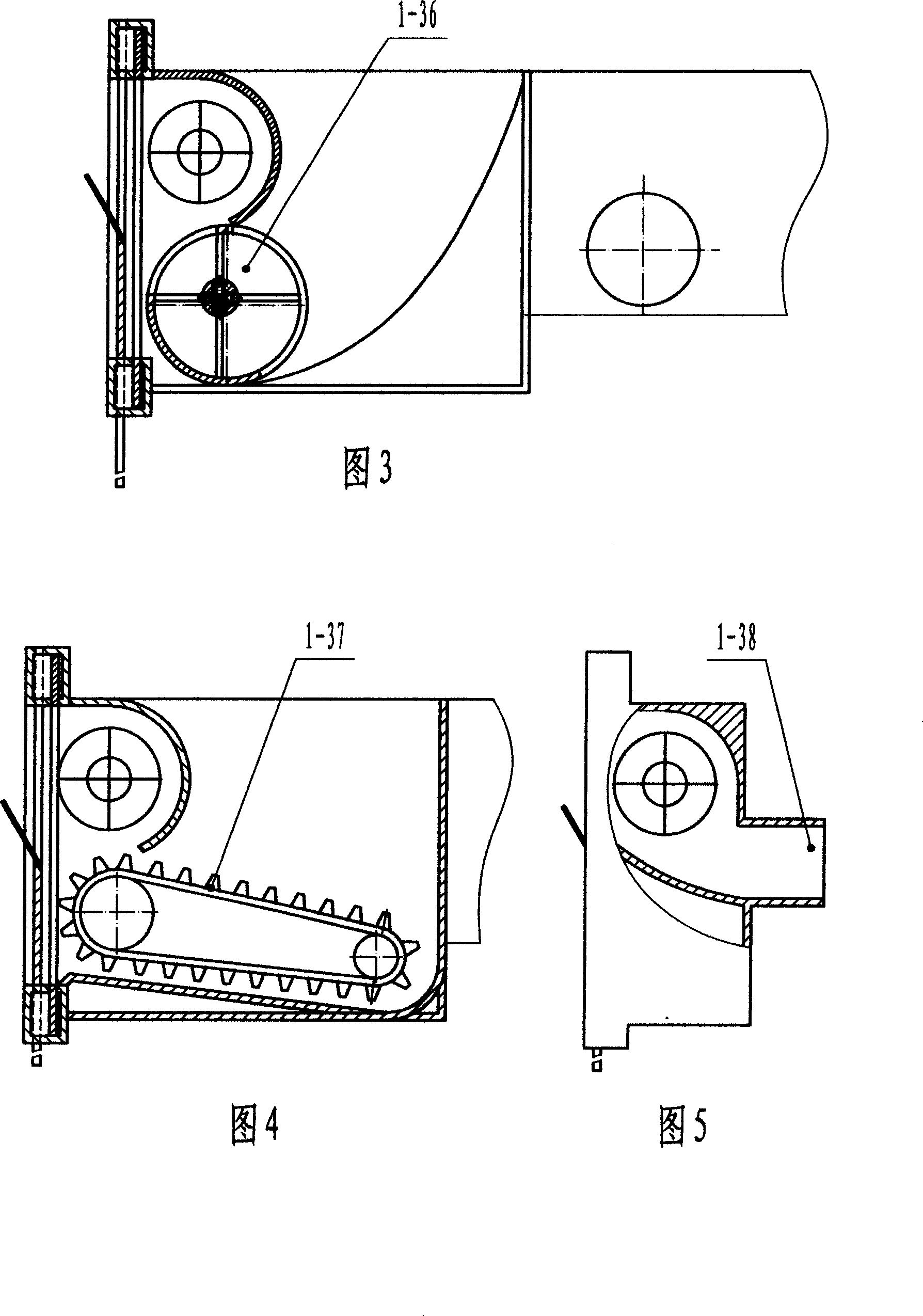

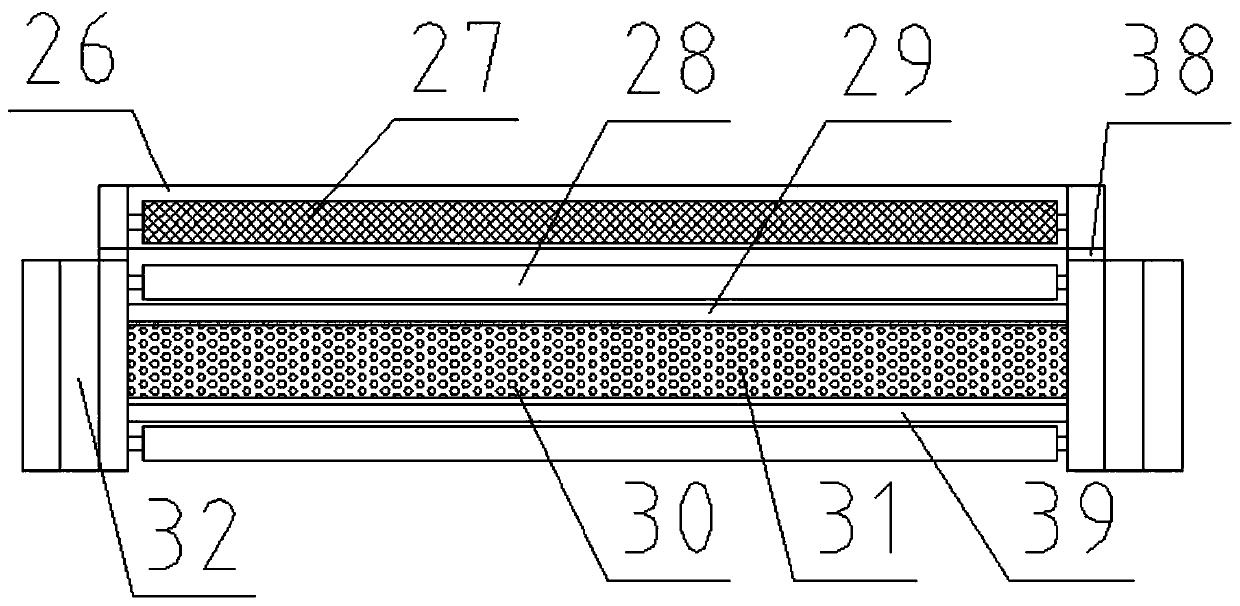

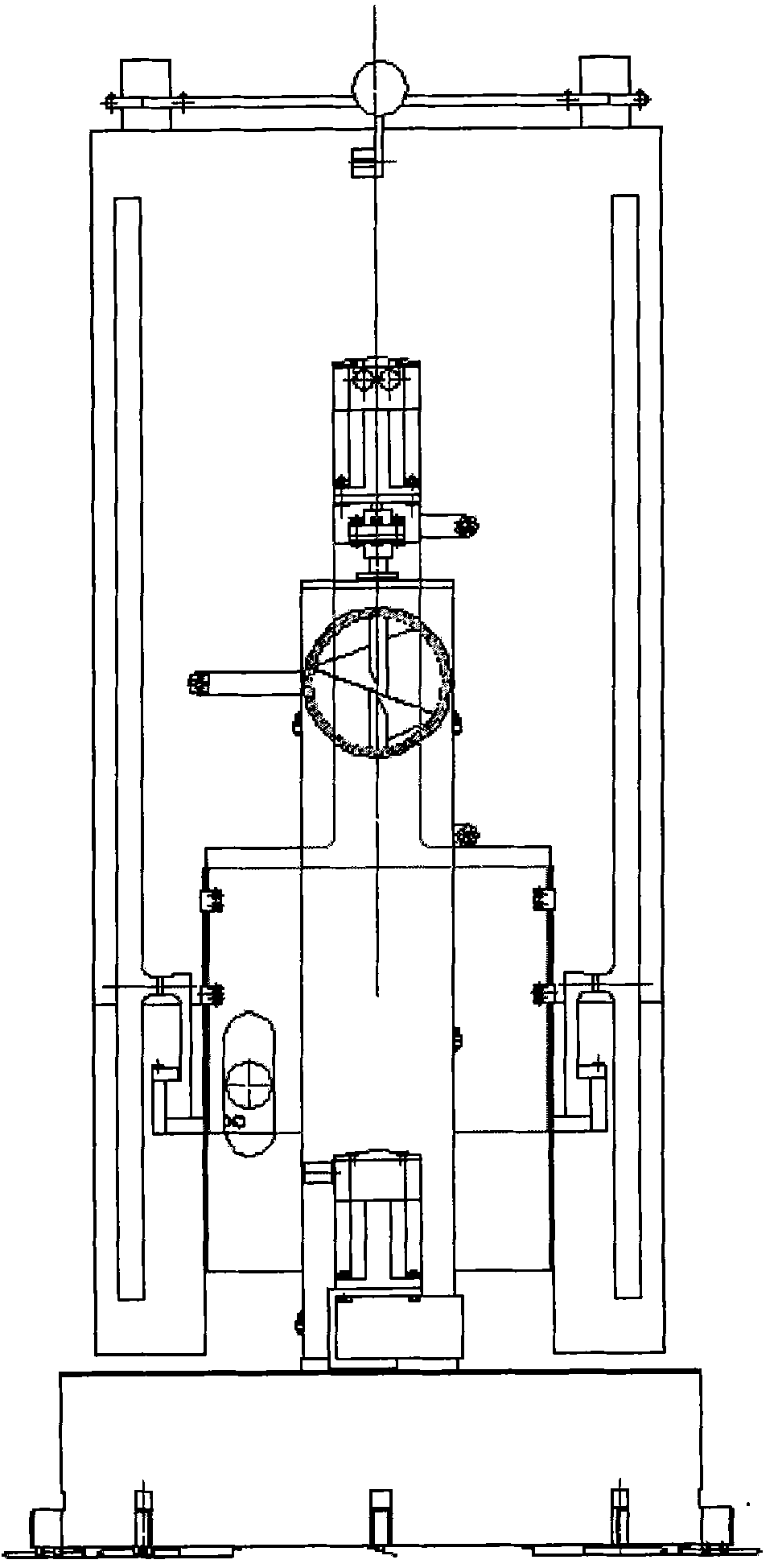

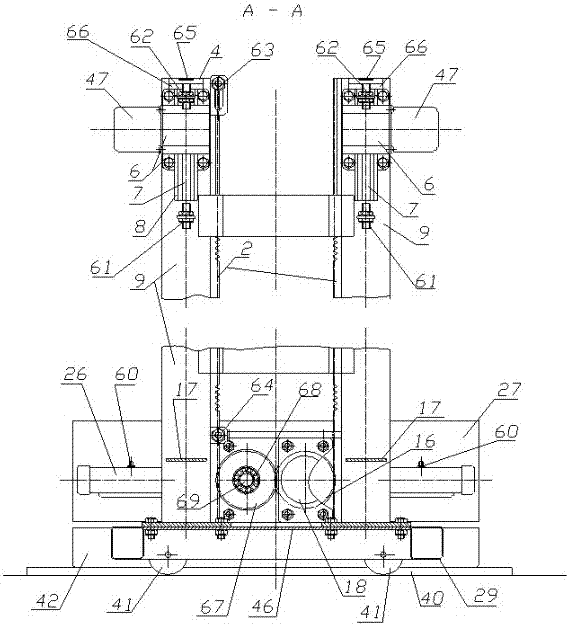

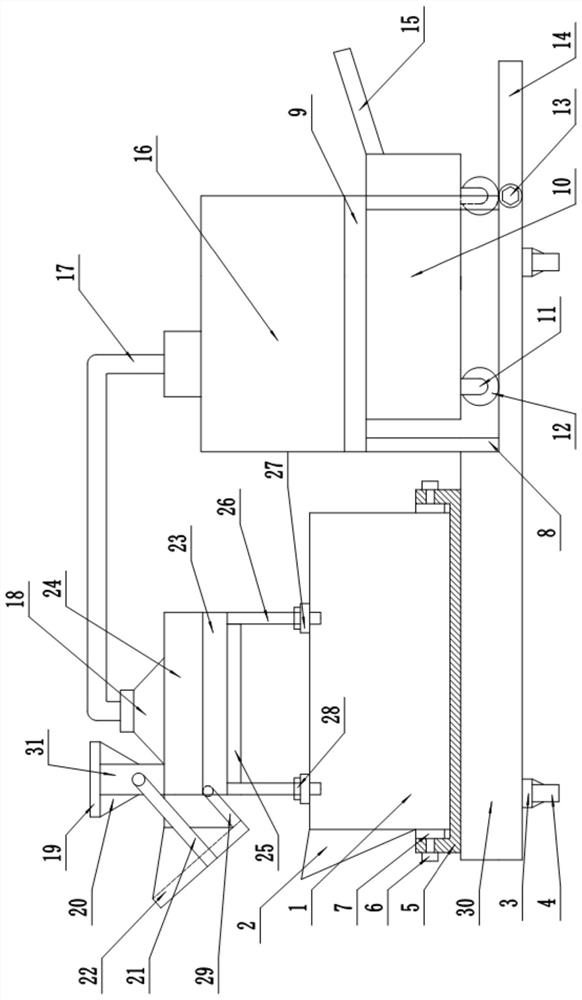

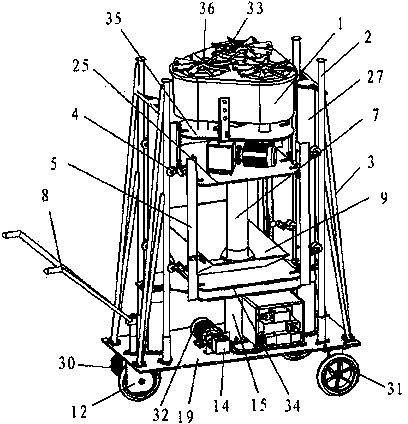

Differential type plastering device

InactiveCN102121306AImprove plastering efficiencyGood combinationBuilding constructionsSystem structureImpeller

The invention belongs to the technical field of building machinery, and relates to a differential type plastering device. The device comprises a mortar conveying mechanism, a differential plastering mechanism, an oscillation guide rail mechanism, a mortar thickness control device and a universal support cart, wherein the differential plastering mechanism is sleeved at the front end of a sleeve of a helical conveyor of the mortar conveying mechanism, is fixed along the axial direction, and is arranged on a support frame plate of the oscillation guide rail mechanism together with the mortar conveying mechanism through a support sliding plate, thus forming the core component of the differential type plastering device which is formed by variation of a differential wheel system structure; and the spiral conveyer of the mortar conveying mechanism conveys mortar to a centrifugal dash impeller on the end face of a small hollow central gear at the front end of the sleeve, so that the mortar is dashed to the wall surface. The differential type plastering device has a reasonable structure and excellent performance, can well simulate manual plastering, and can realize mechanical plastering for building walls.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

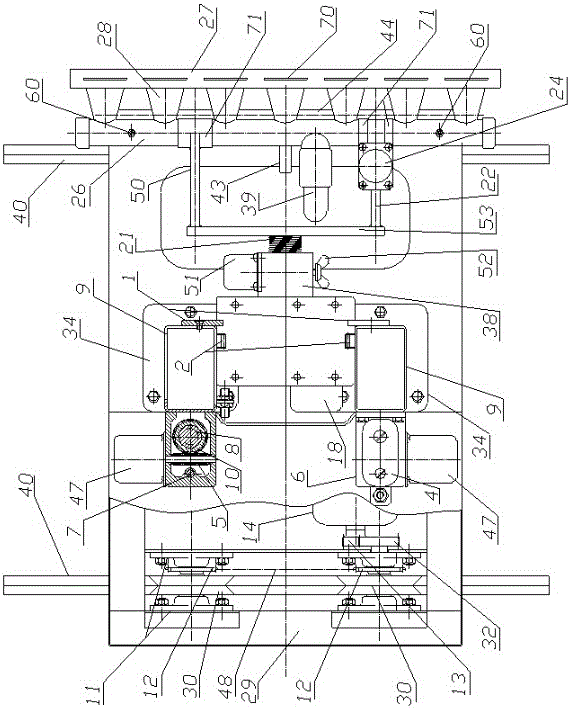

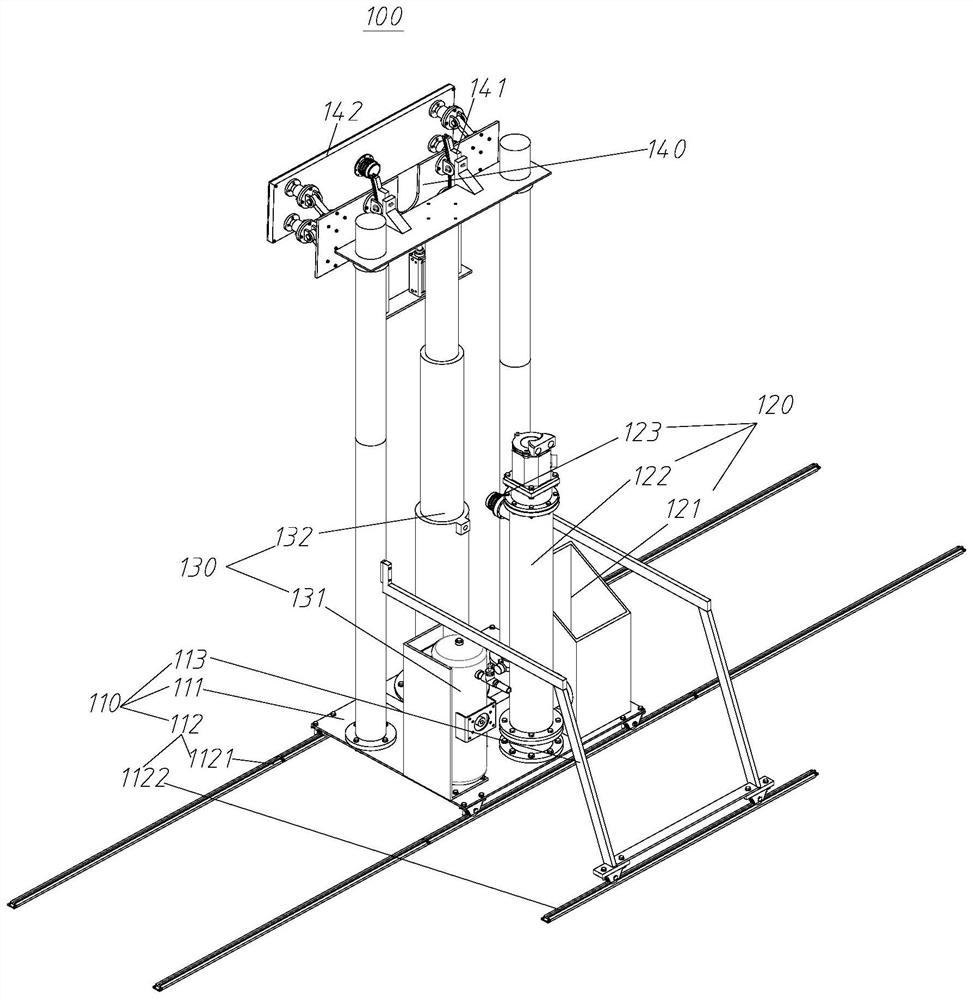

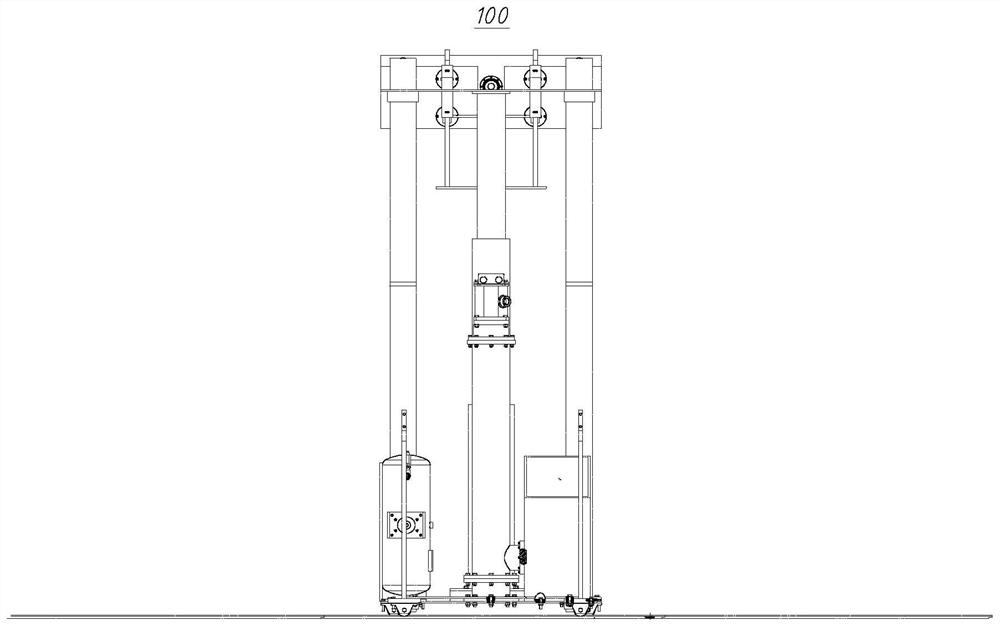

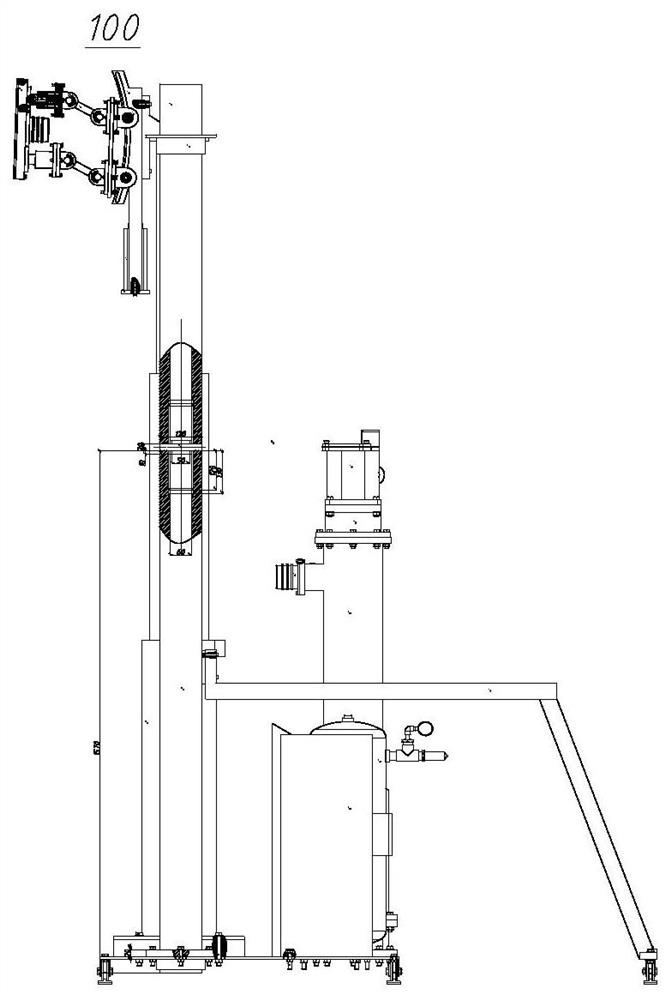

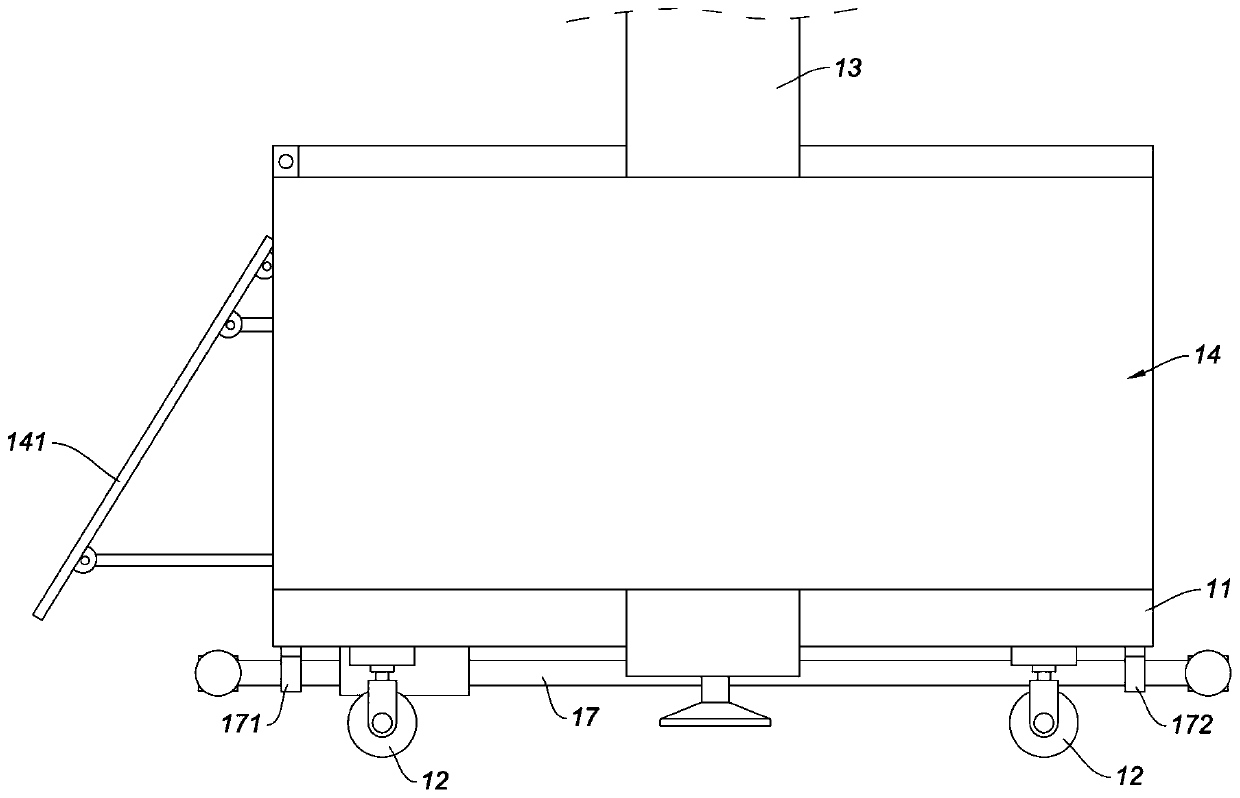

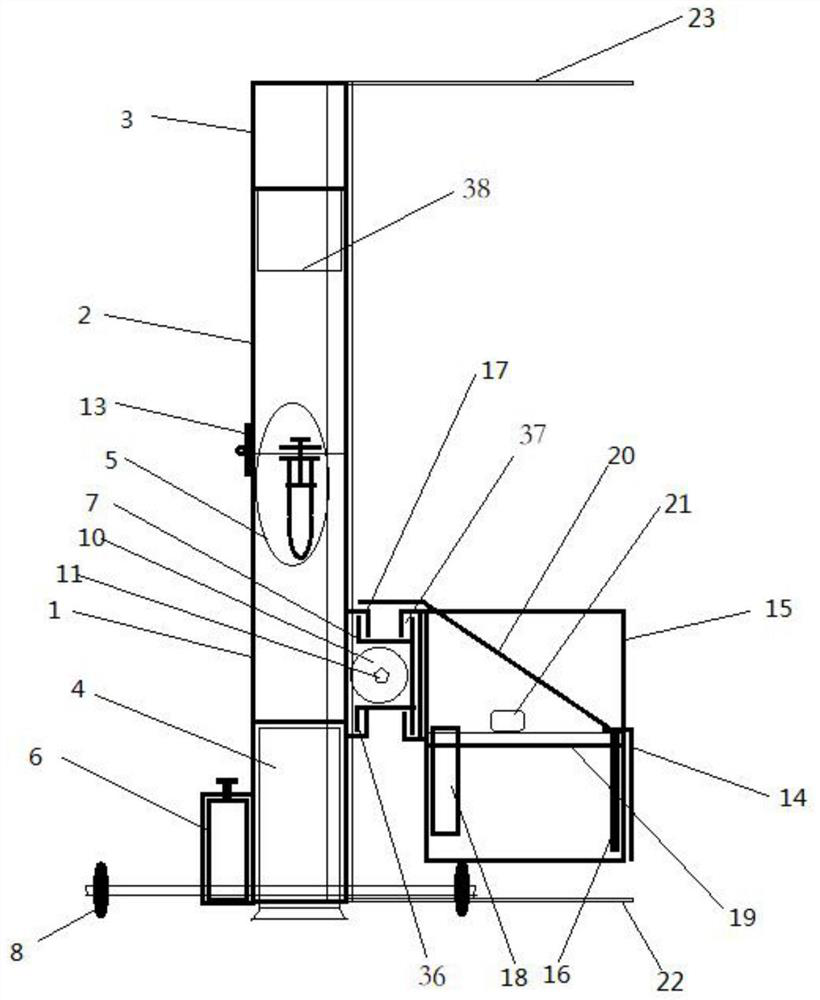

Automatic injecting and pasting machine system for walls and ceilings and control method thereof

ActiveCN105888216AReduce power consumptionLight structureBuilding constructionsFailure rateVertical plane

The invention relates to an automatic injecting and pasting machine system for walls and ceilings and a control method thereof, which belong to the field of construction machinery. The automatic injecting and pasting machine system comprises a vertical lifting rod mechanism, a special pasting arm, a plaster storage tank integrated with a plaster stirring pump, a horizontal traveling trolley, an air compressor and a control circuit. The automatic injecting and pasting machine system is characterized in that the vertical lifting rod mechanism is vertically installed by fasteners on a horizontal platform of the horizontal traveling trolley through a pair of mounting flange at the bottom of the vertical lifting rod and a reinforcement mounting plate adjacent to the left pipe wall at the bottom; the entire pasting arm is fixed by fasteners on the right vertical plane or top horizontal plane of a lifting base of the vertical lifting mechanism through an arm holder base plate; the control circuit is a PLC (Programmable Logic Controller) circuit. The automatic injecting and pasting machine system has the advantages of simple and light-weight structure, small motor power consumption, low failure rate, low cost, high automation degree, and high pasting efficiency; the system can paste both walls and ceilings.

Owner:江苏九星建设工程有限公司

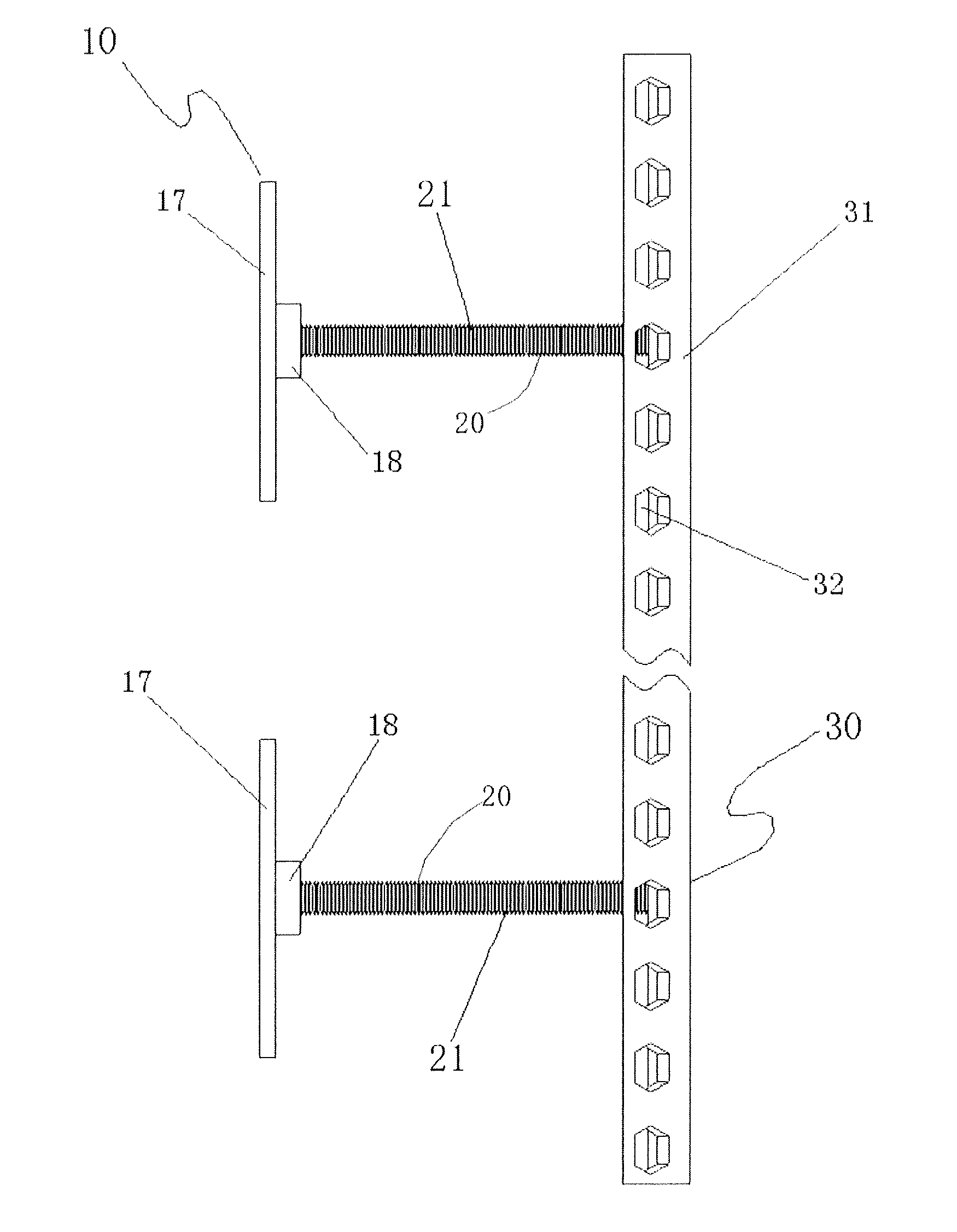

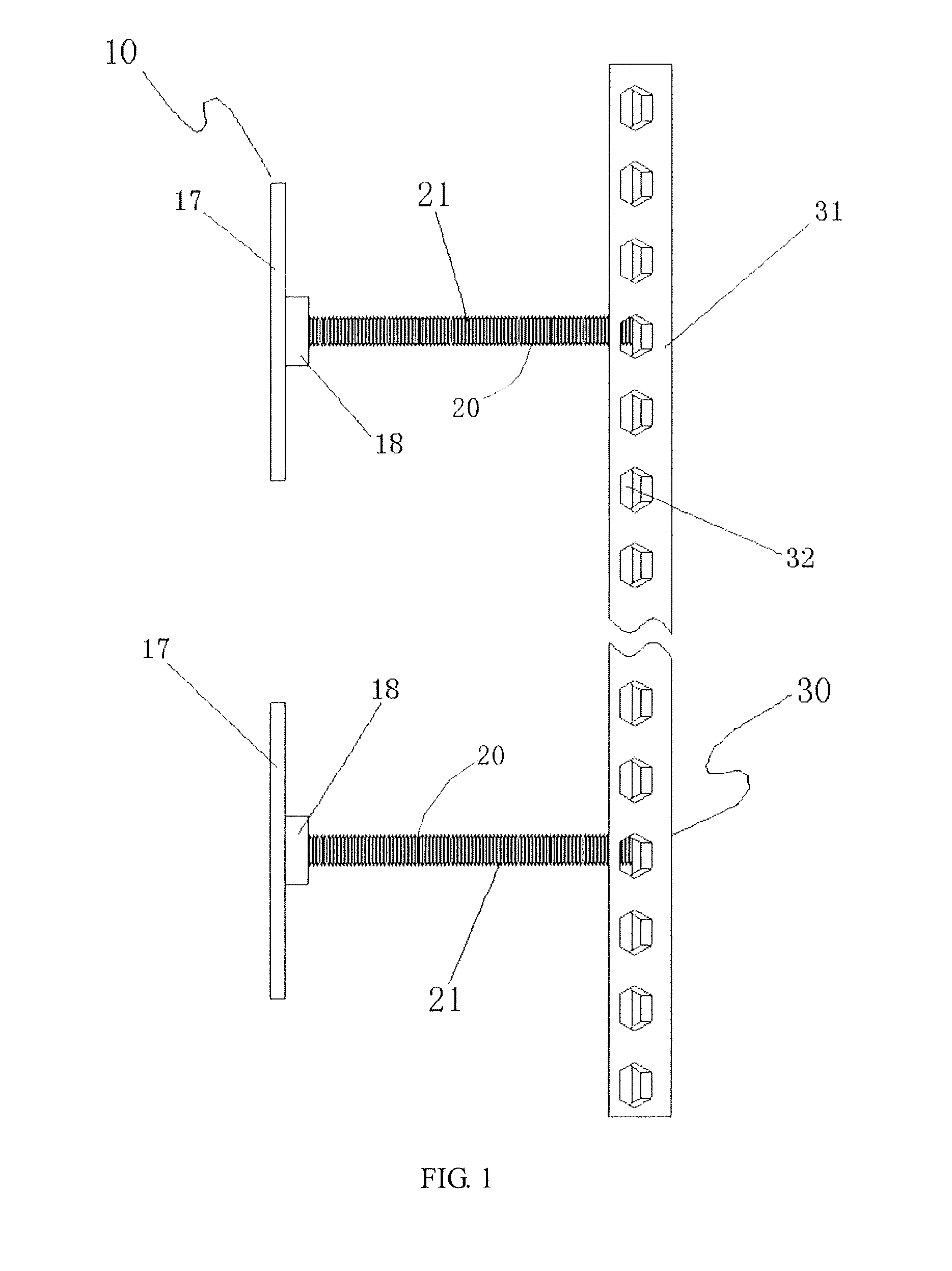

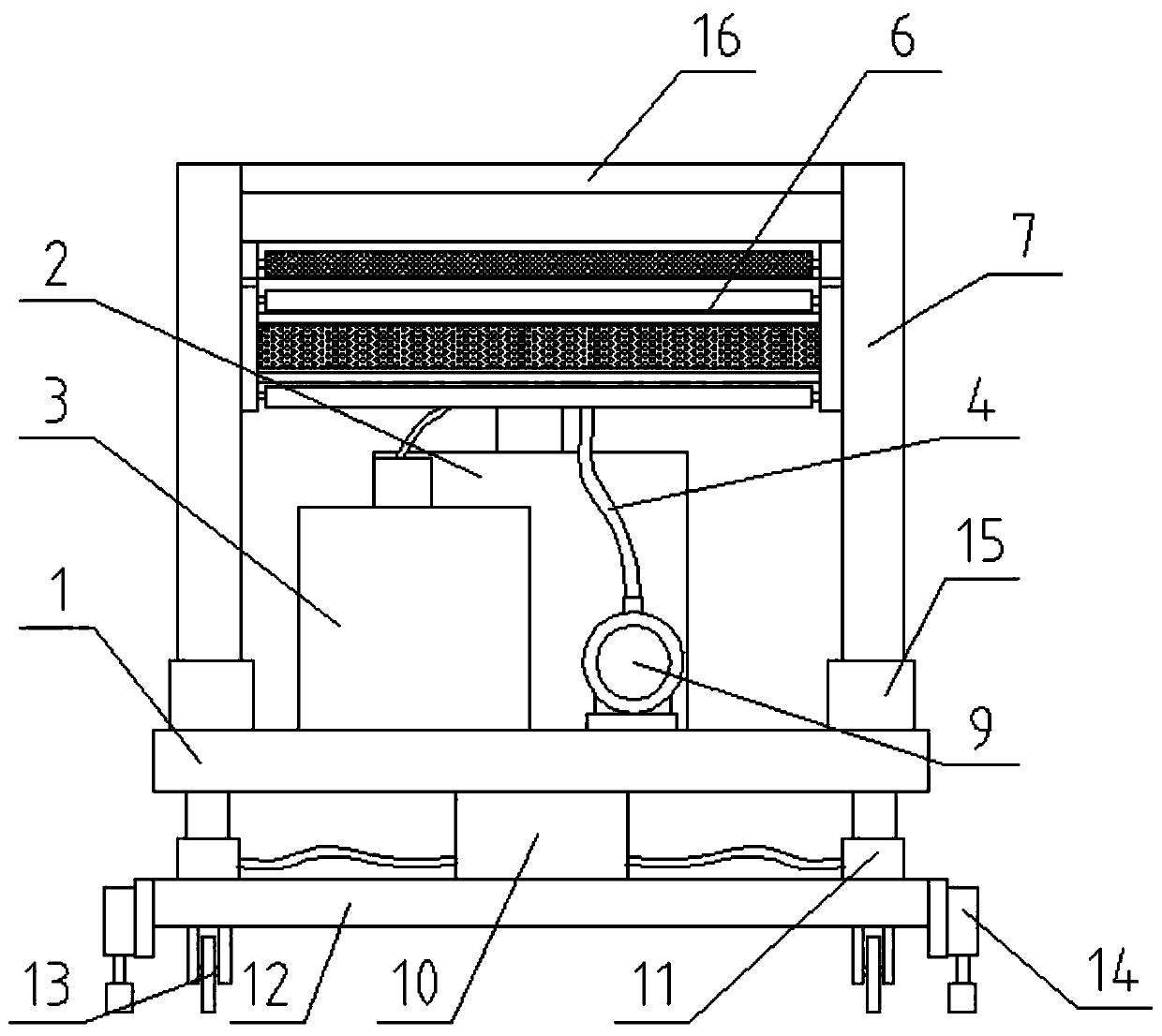

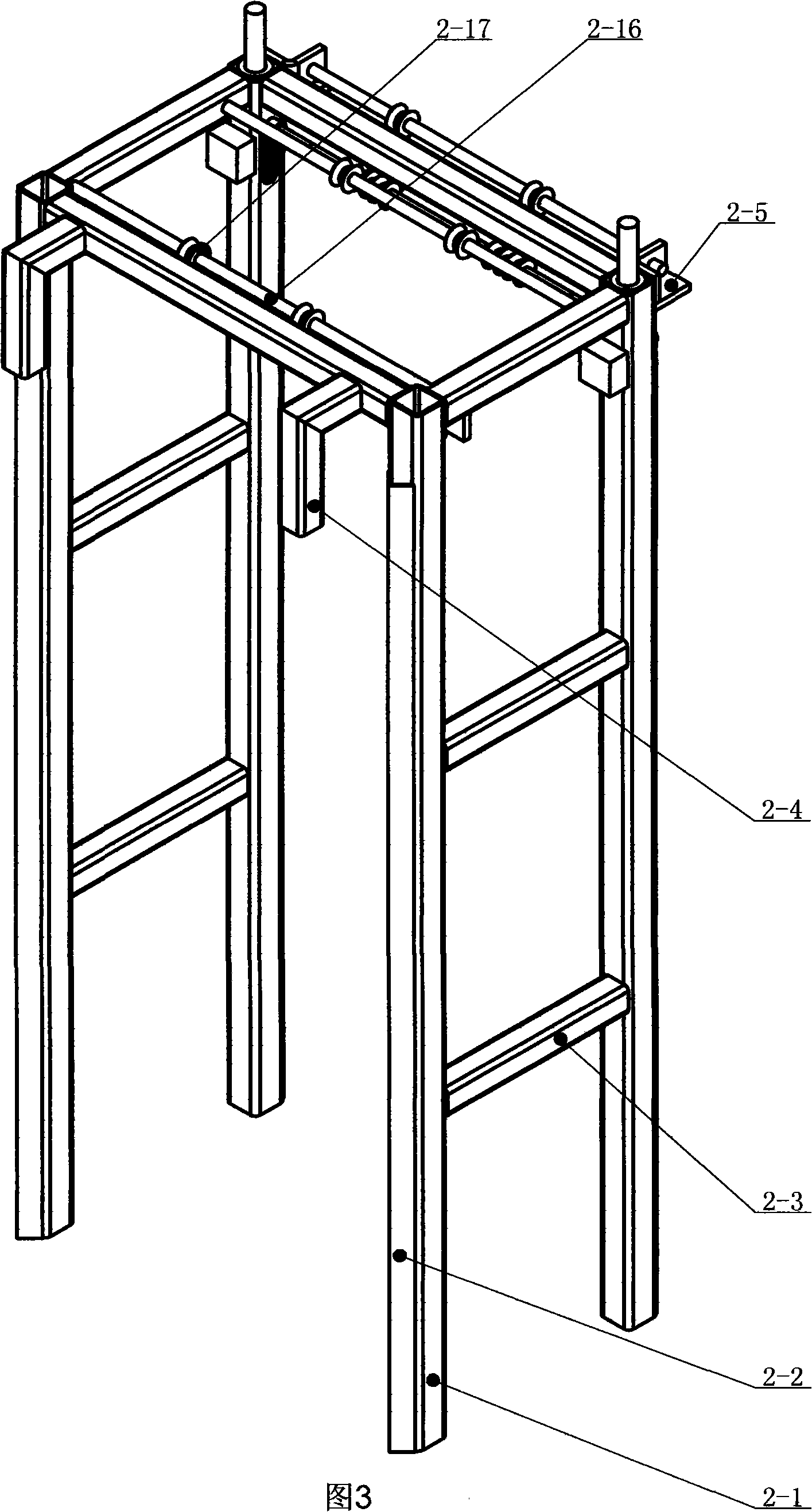

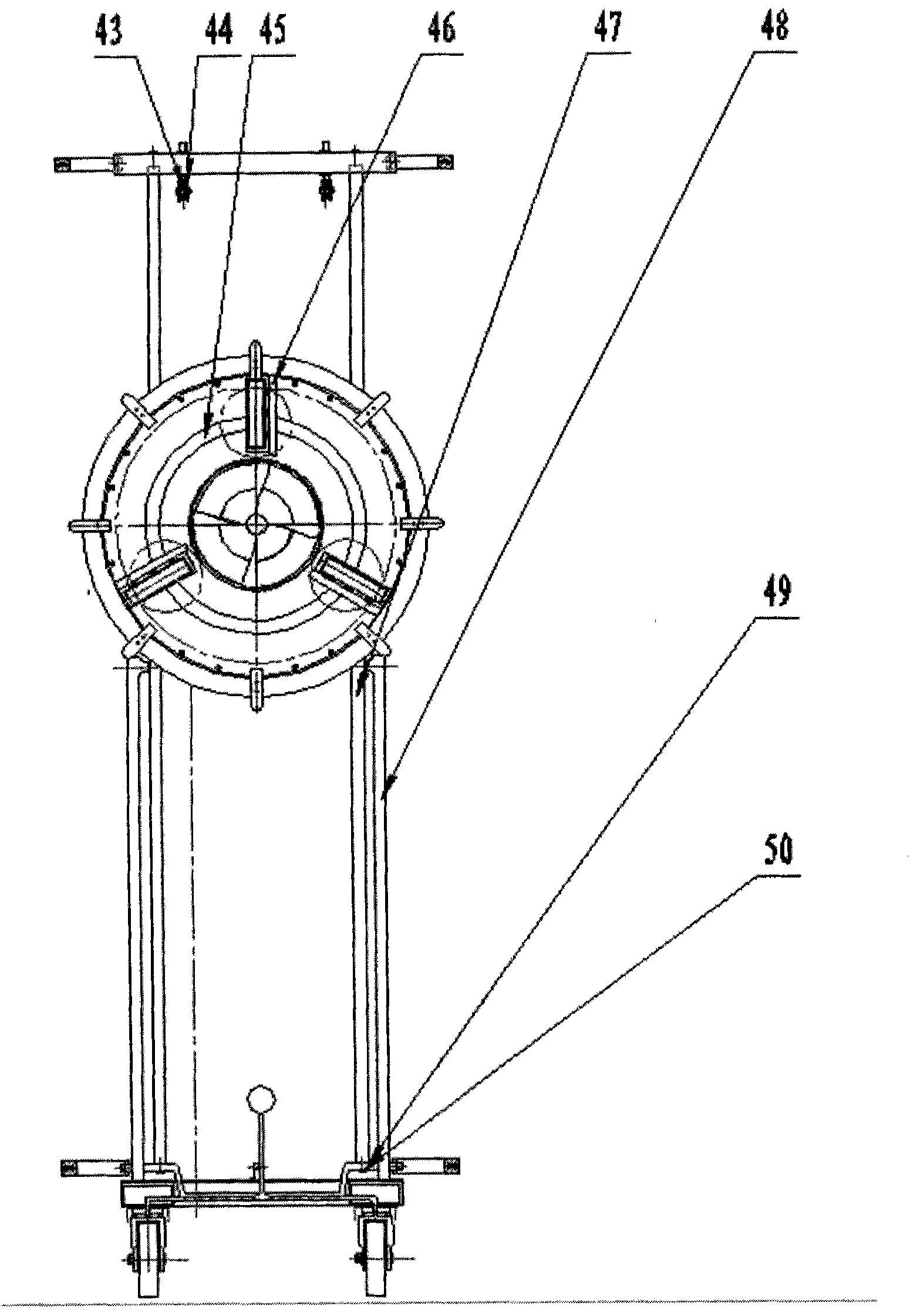

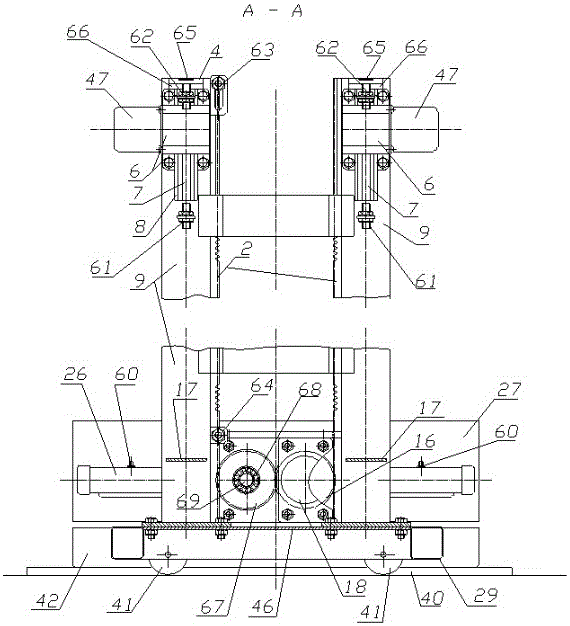

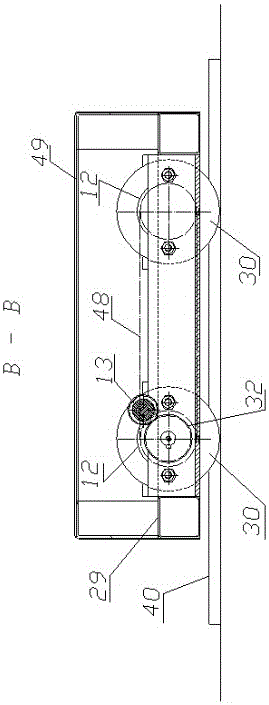

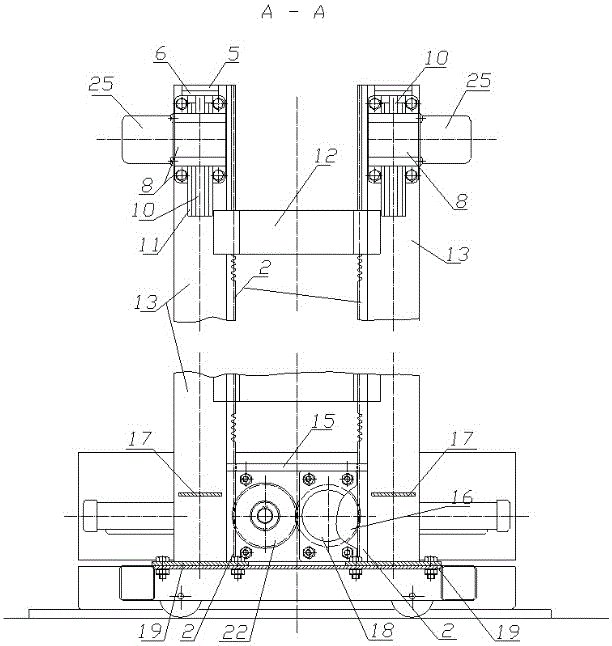

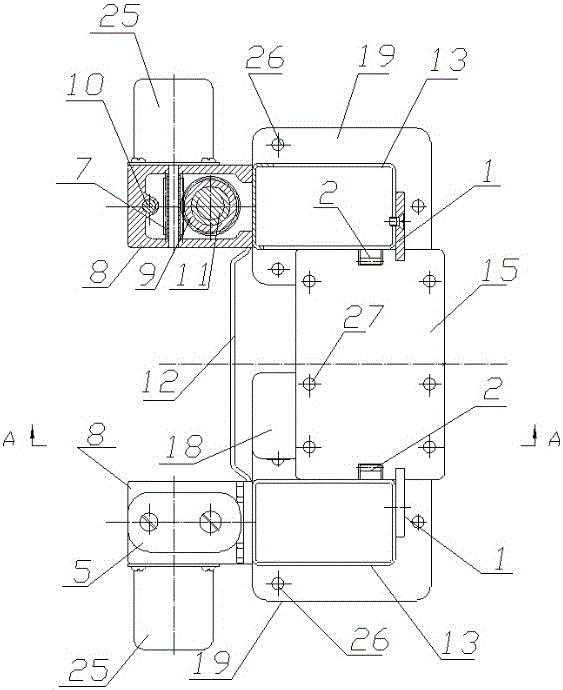

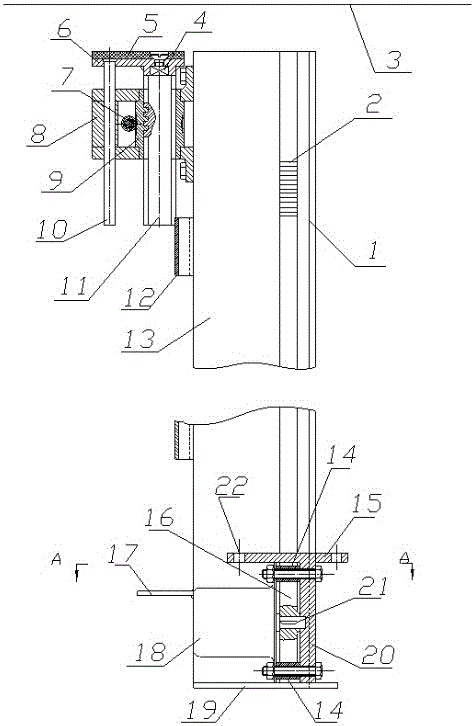

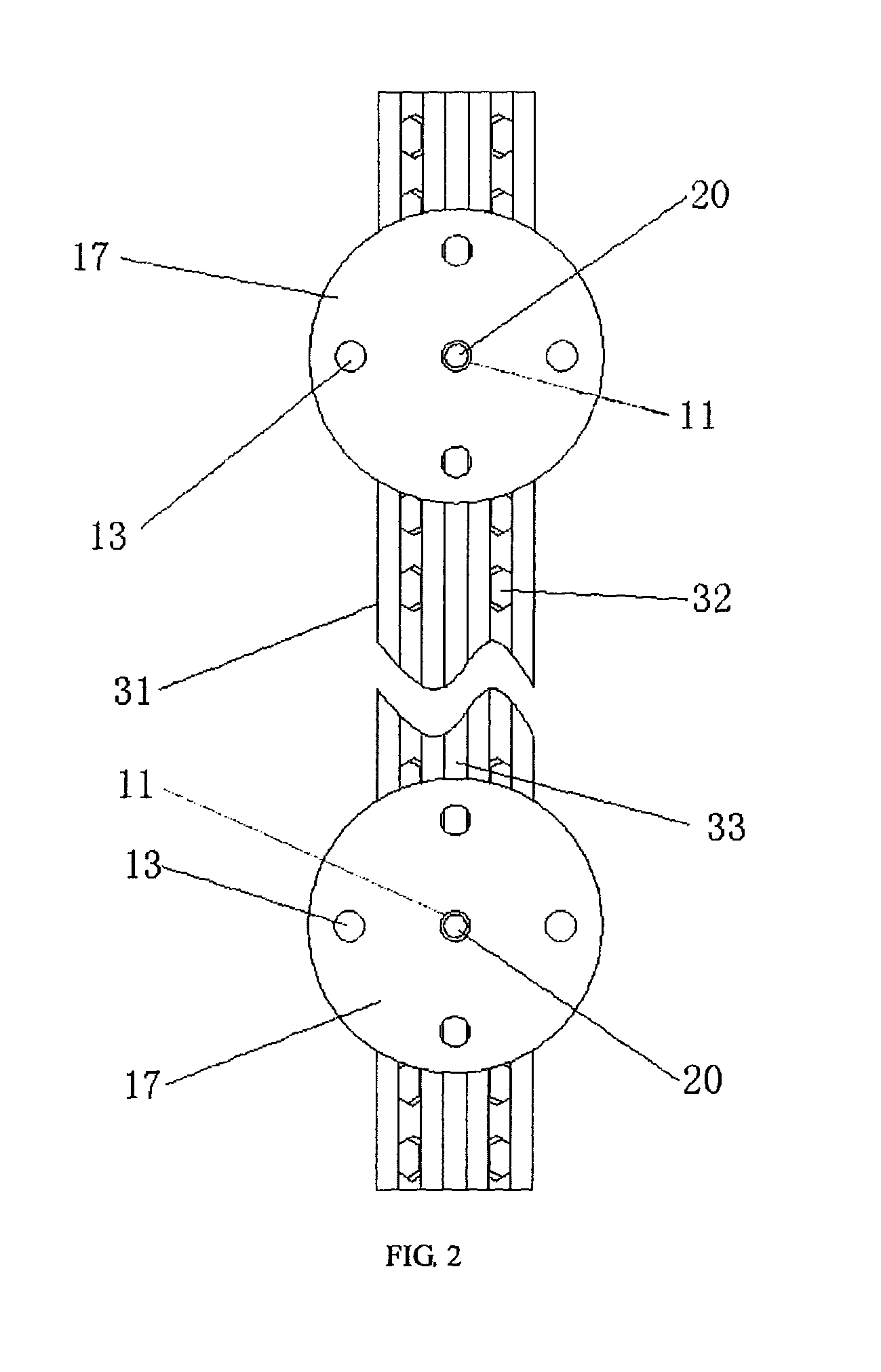

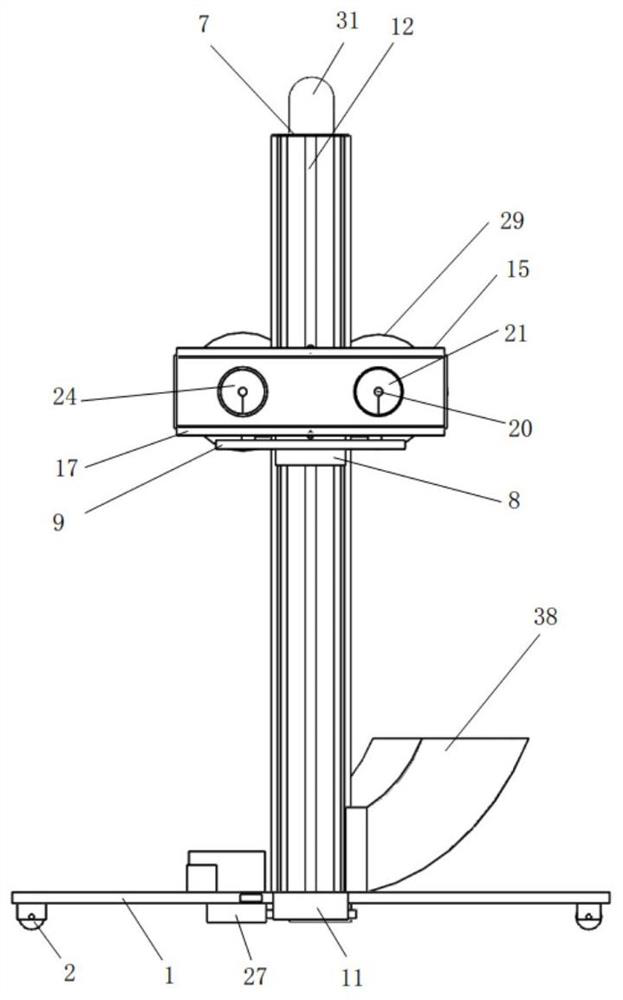

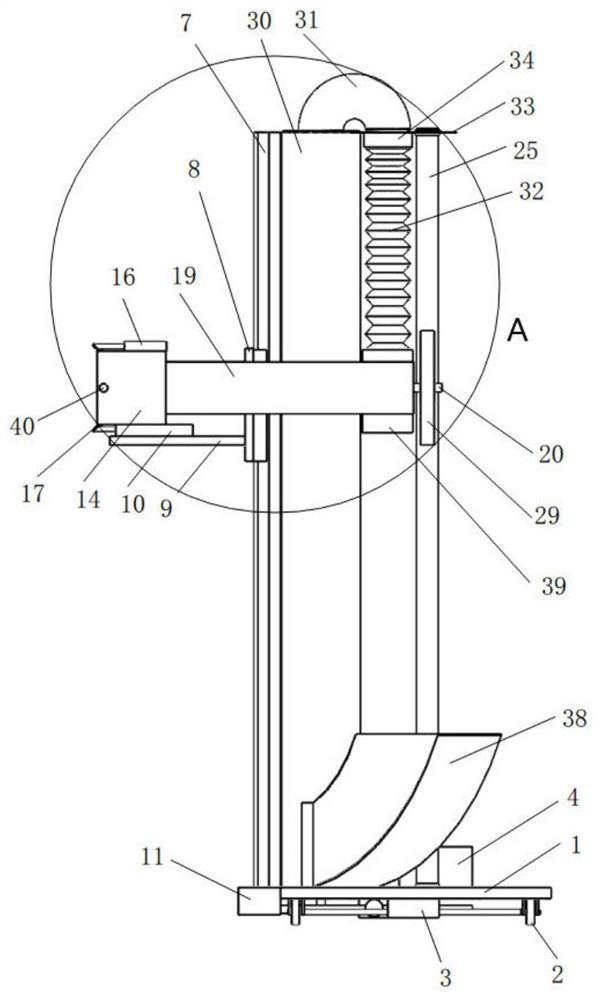

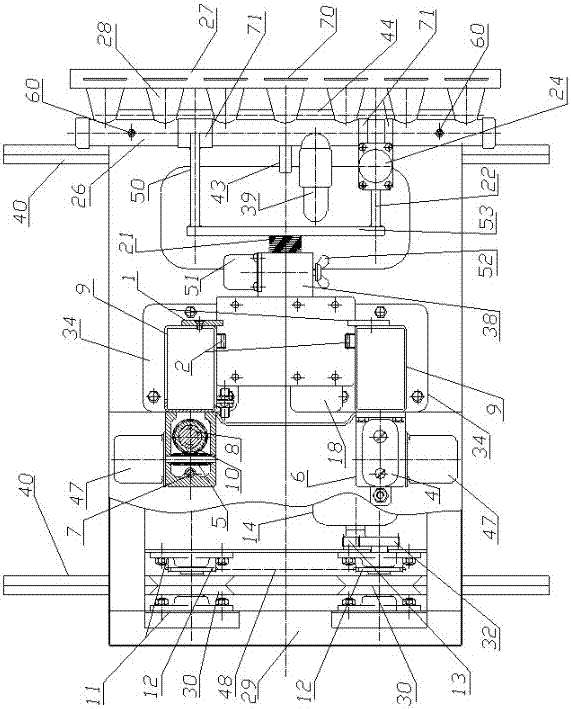

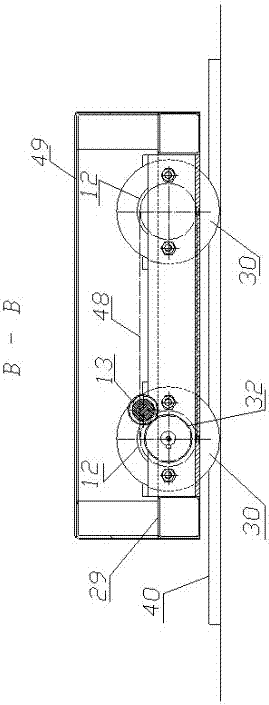

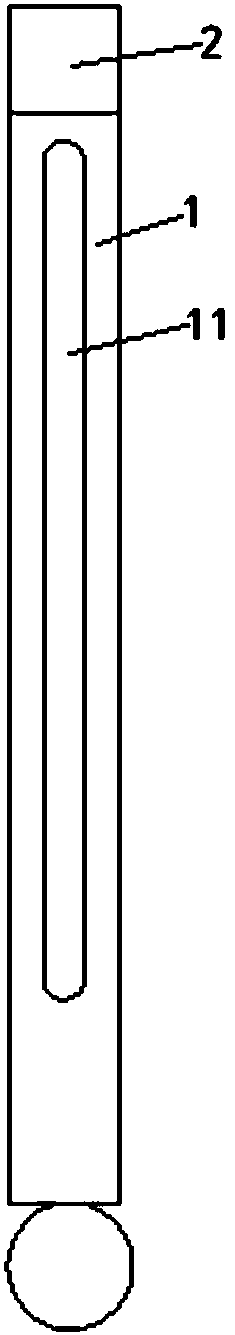

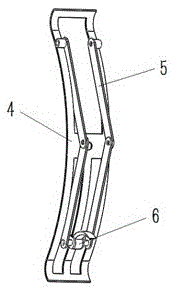

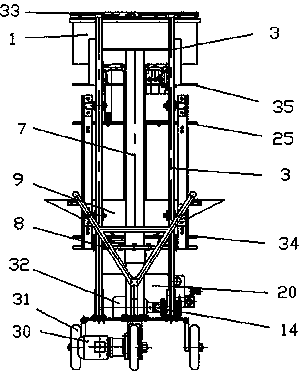

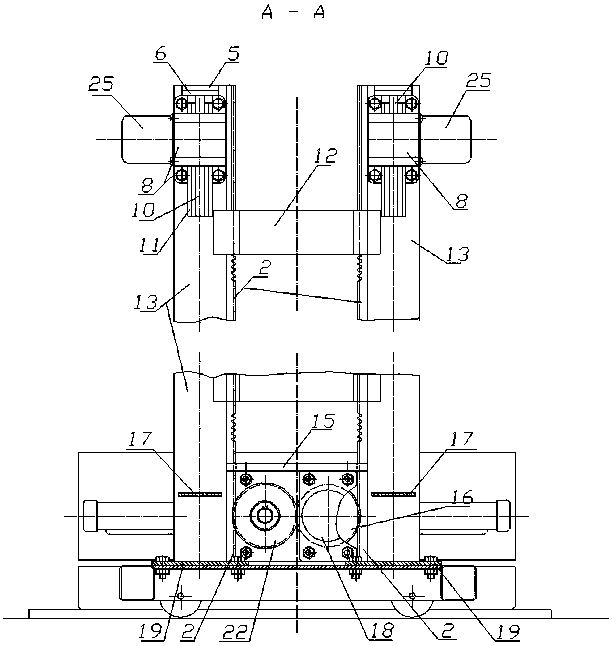

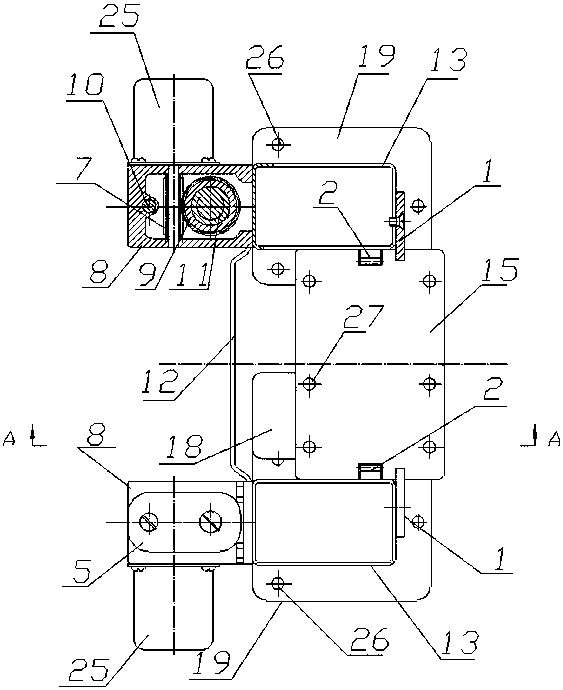

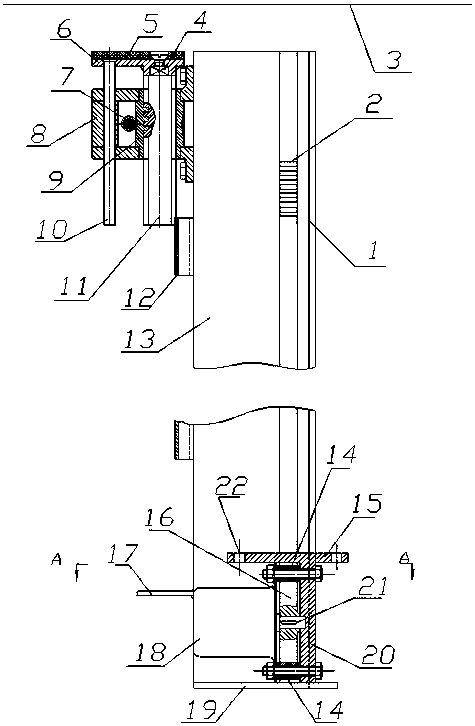

Vertical lifting mechanism for automatic-semiautomatic wall surface pasting machine

ActiveCN105952123ALight structureImprove plastering efficiencyBuilding constructionsFailure rateEngineering

The invention relates to a vertical lifting mechanism for an automatic-semiautomatic wall surface pasting machine in the field of building machinery. The vertical lifting mechanism comprises a pair of vertical lifting rods and a lifting mechanism. The vertical lifting mechanism is characterized in that the sections of the vertical lifting rods are rectangular, a pair of rack are symmetrically arranged on the outer walls of the relative inner sides of the vertical lifting rods along the vertical height direction, a pair of guide rails which are symmetrically arranged along the vertical height direction of the vertical lifting rods cling to the right-side pipe walls, a plurality of traction rods are arranged on the left sides between the pair of the vertical lifting rods along the height direction, mounting flanges are arranged at the bottoms of the vertical lifting rods, reinforcing mounting plates are arranged on the left-side pipe walls close to the bottoms, and automatic lifting rod locking and positioning mechanisms are arranged at the upper parts of the pair of the vertical lifting rods; the lifting mechanism comprises a lifting seat, a lifting motor and a pair of mutually meshed climbing gears. The vertical lifting mechanism has the advantages of simple and light structure, low motor power dissipation, failure rate and cost and high pasting efficiency.

Owner:嘉兴笼列电子商务有限公司

Method for plastering construction in architectural decoration

ActiveUS9255413B2Improve efficiencyImprove construction qualitySunshadesCovering/liningsBuilding constructionArchitectural engineering

A method for plastering construction in architectural decoration comprises the following steps: (1) base treatment; (2) applying mortar on the wall surface according to the required plastering depth, and longitudinally installing screeding templates along a wall surface subjected to the base treatment in Step (1) according to the plastering depth, a lateral space between adjacent screeding templates being 1.3 to 1.8 meters; (3) plastering; and (4) laying aside the wall surface subjected to the plastering for 12 to 24 hours till plastering mortar on the wall surface is in a half-dried compact hardened state, and using teeth of a saw blade for grinding the mortar along the two adjacent screeding templates through a ruler till the mortar is even. The method can improve the construction efficiency and guarantee the construction quality.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

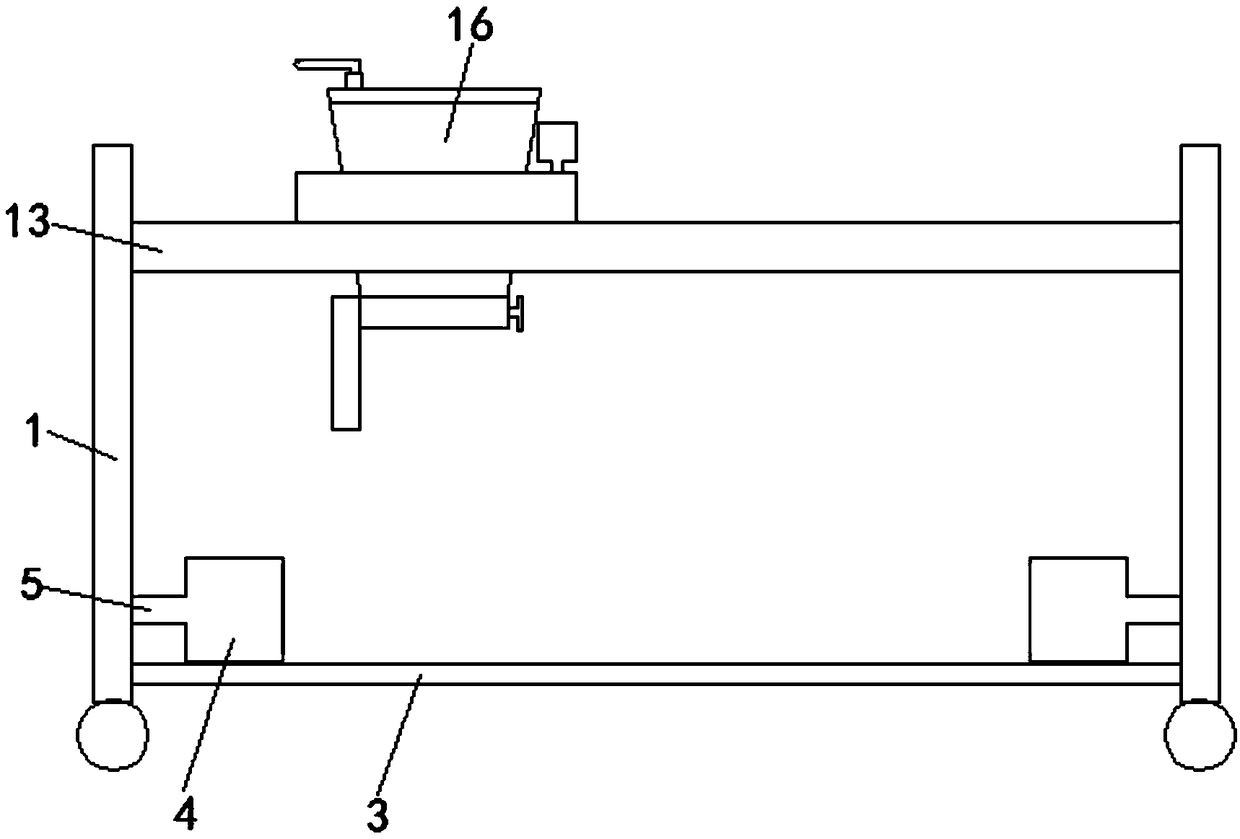

Plastering device for buildings

The invention discloses a plastering device for buildings, which comprises a base; two upright posts; a lifting seat movably arranged between the two upright posts; a lifting mechanism used for driving the lifting seat to reciprocate up and down; a plastering plate arranged on the lifting seat; a storage hopper fixed on the lifting seat; a material conveying pump arranged at the lower part of thematerial storage hopper and used for conveying the mortar in the material storage hopper to a plastering plate through a first pipeline; a mortar box fixed on the base; a feeding mechanism used for conveying the mortar in the mortar box into the storage hopper when the lifting seat is in the lowest position. The storage hopper is used for storing a small amount of mortar, and the mortar box is used for storing a large amount of mortar, so that the weight of the lifting seat can be effectively reduced; when the lifting seat is positioned at the lowest position, the mortar in the mortar box is conveyed to the storage hopper through the feeding mechanism, so that the requirement of the structure on a pump is low, the problem of frequent and large-scale bending of pipelines is avoided, and thereliable mortar conveying can be ensured.

Owner:江苏中鑫项目管理有限公司 +1

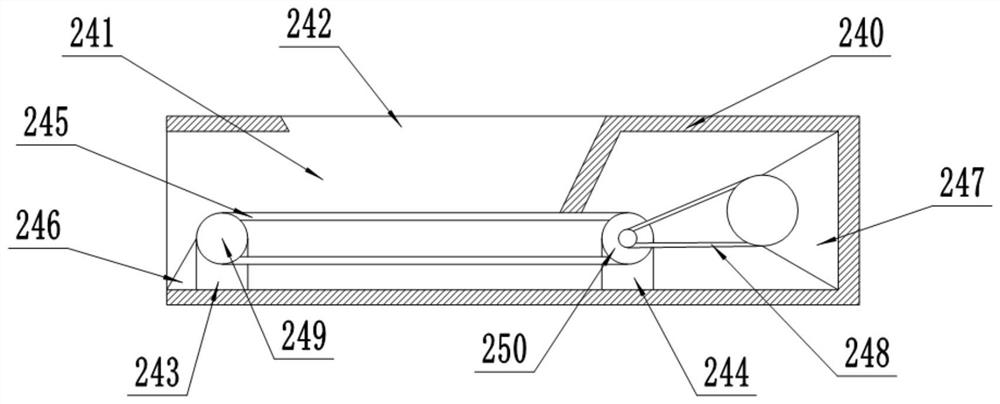

Full-automatic continuous plastering device for decoration construction

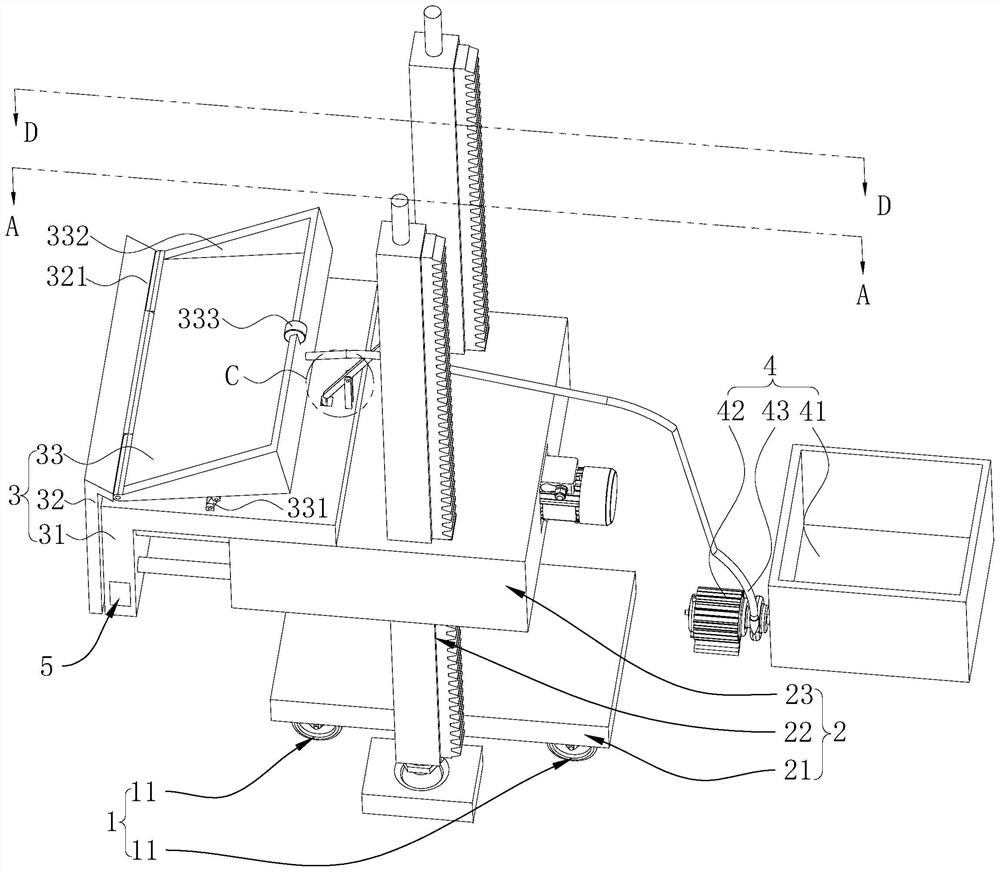

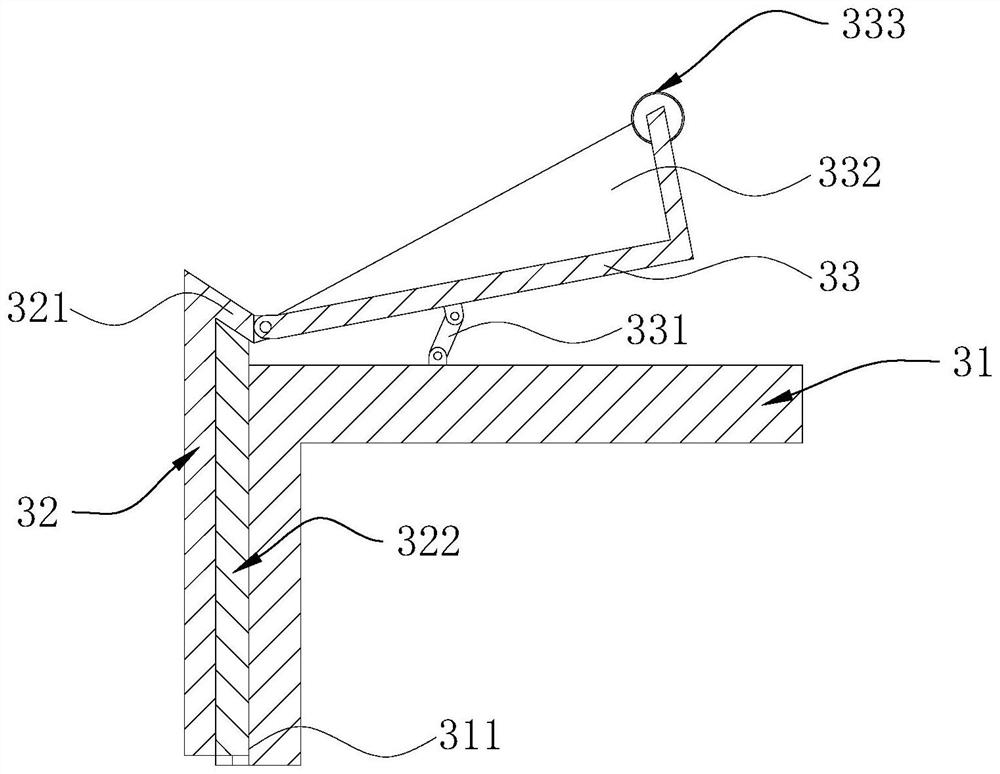

ActiveCN112922279AHigh degree of automationImprove plastering efficiencyBuilding constructionsSlide plateIndustrial engineering

The invention discloses a full-automatic continuous plastering device for decoration construction. The full-automatic continuous plastering device comprises a moving part, a support piece and a continuous plastering part, wherein the moving part comprises a support plate and a moving power part, and the moving power part is arranged on the support plate; the support piece comprises a support sliding plate, a lifting sliding support seat and a lifting power part, the support sliding plate is arranged on the support plate, the lifting sliding support seat is arranged on the support sliding plate, and the lifting power part is arranged on the support sliding plate; and the continuous plastering part comprises a plastering part, a relay conveying part and a mortar conveying part, the plastering part is arranged on the lifting sliding support seat, the relay conveying part is arranged on the plastering part, and the mortar conveying part is arranged on the relay conveying part. The full-automatic continuous plastering device has the advantages of high degree of automation, high plastering efficiency, high plastering quality and stable plastering quality, the labor intensity of workers can be obviously reduced, and the construction period can be obviously shortened.

Owner:IANGSU COLLEGE OF ENG & TECH

Plastering device and plastering robot

ActiveCN112012444AImprove plastering efficiencyImprove efficiencyBuilding constructionsStructural engineeringMaterial distribution

The invention discloses a plastering device and a plastering robot, wherein the plastering device comprises a plastering frame, a plastering plate, a material distribution mechanism and an avoidance mechanism. The plastering plate is mounted on the plastering frame and positioned in front of the plastering frame; the material distribution mechanism conveys mortar to the front of the plastering plate; and the material distribution mechanism is provided with a material distribution position located above the upper end of the plastering plate and an avoidance position located below the upper endof the plastering plate, the avoidance mechanism is rotatably installed on the plastering frame, the material distribution mechanism is installed on the avoidance mechanism, and the avoidance mechanism is capable of driving the material distribution mechanism to move between the material distribution position and the avoidance position. According to the plastering device, when the material distribution mechanism is located at the material distribution position and the plastering plate cannot continue to move upwards for plastering, the avoidance mechanism is capable of driving the material distribution mechanism to rotate relative to the plastering plate and contract downwards at the same time, so that the material distribution mechanism is switched to the avoidance position, the plastering plate is incapable of continuing to move upwards, the whole building is plastered continuously, the plastering quality is good, and the plastering efficiency is high.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

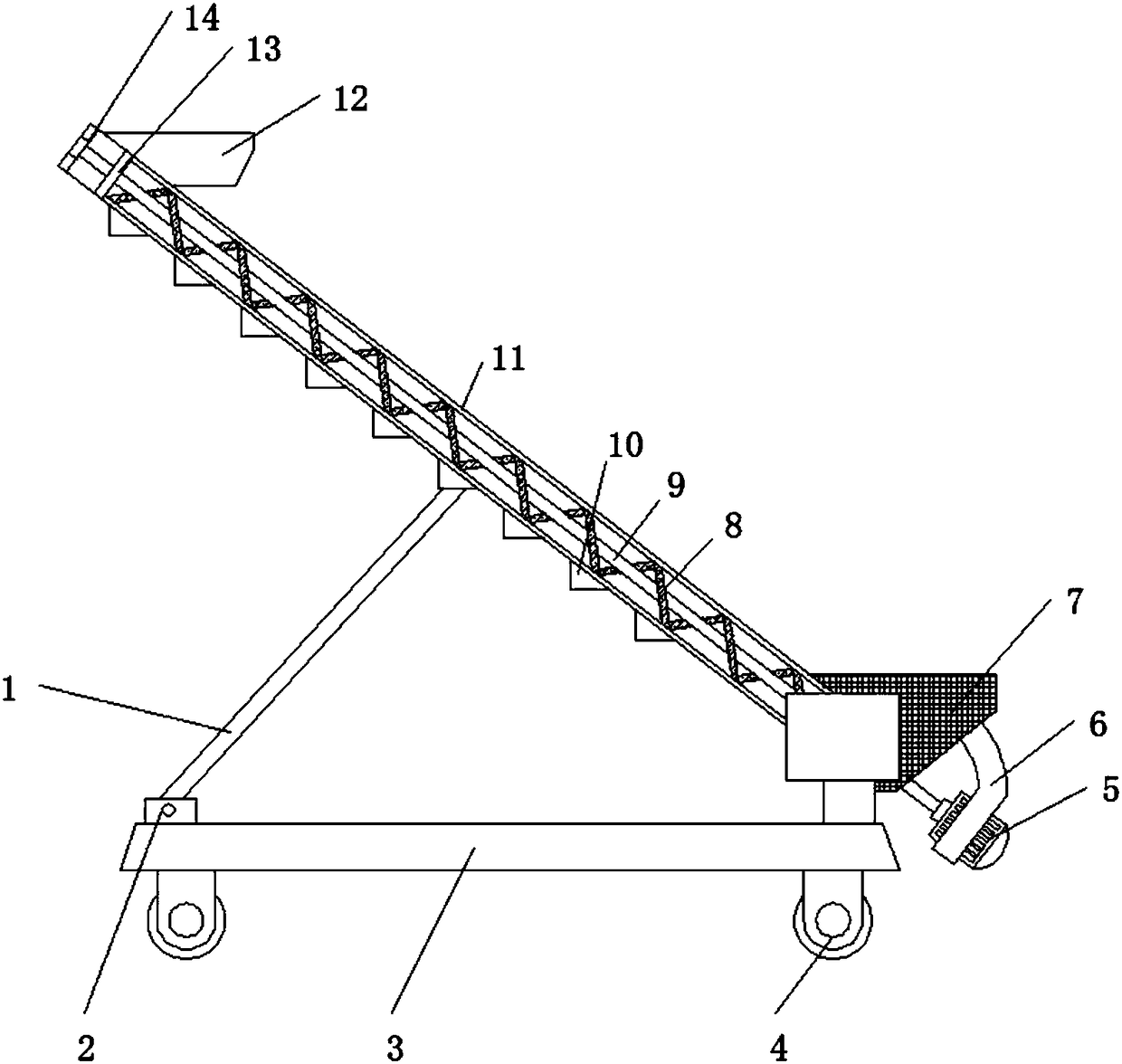

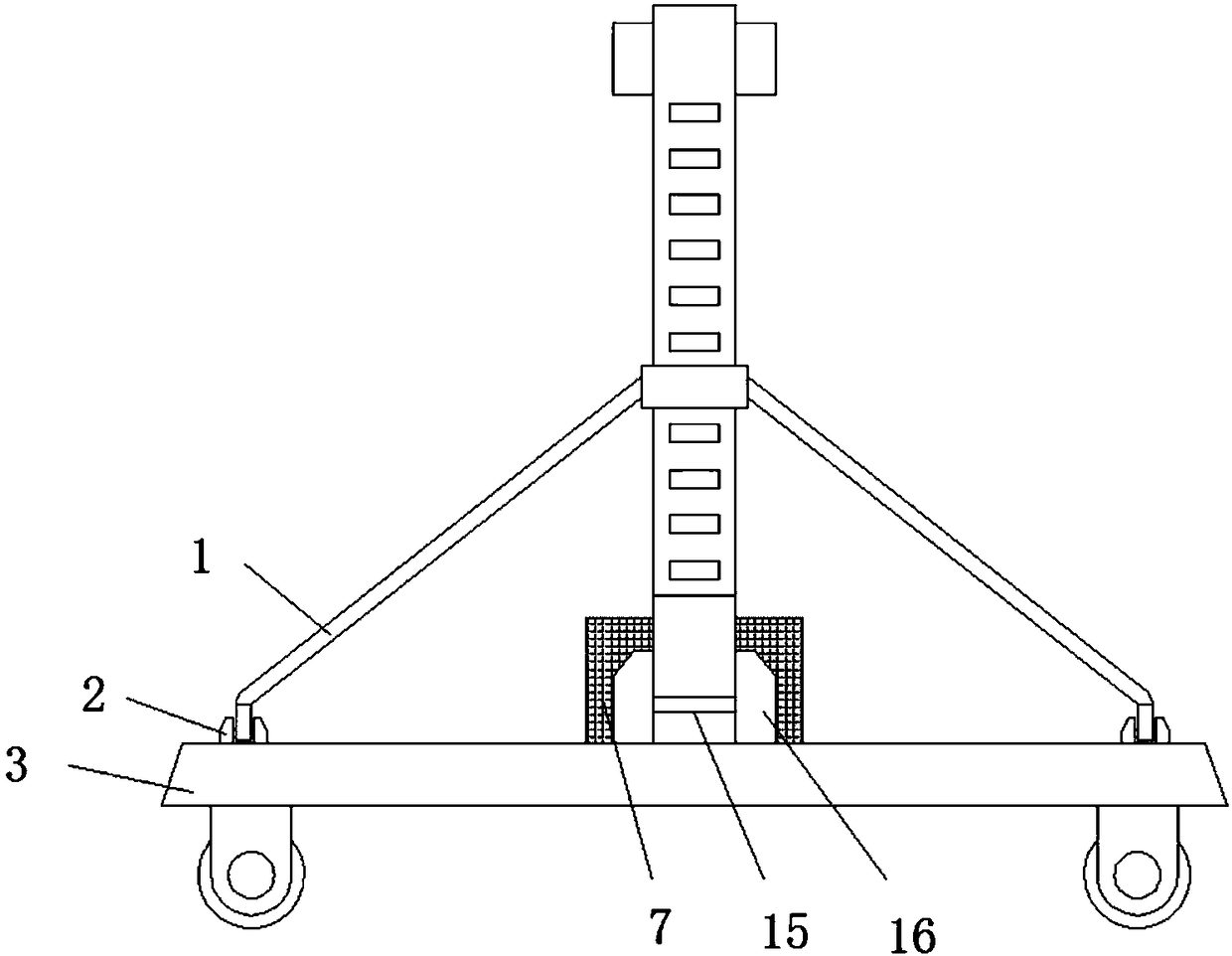

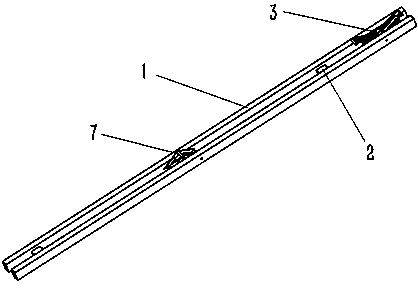

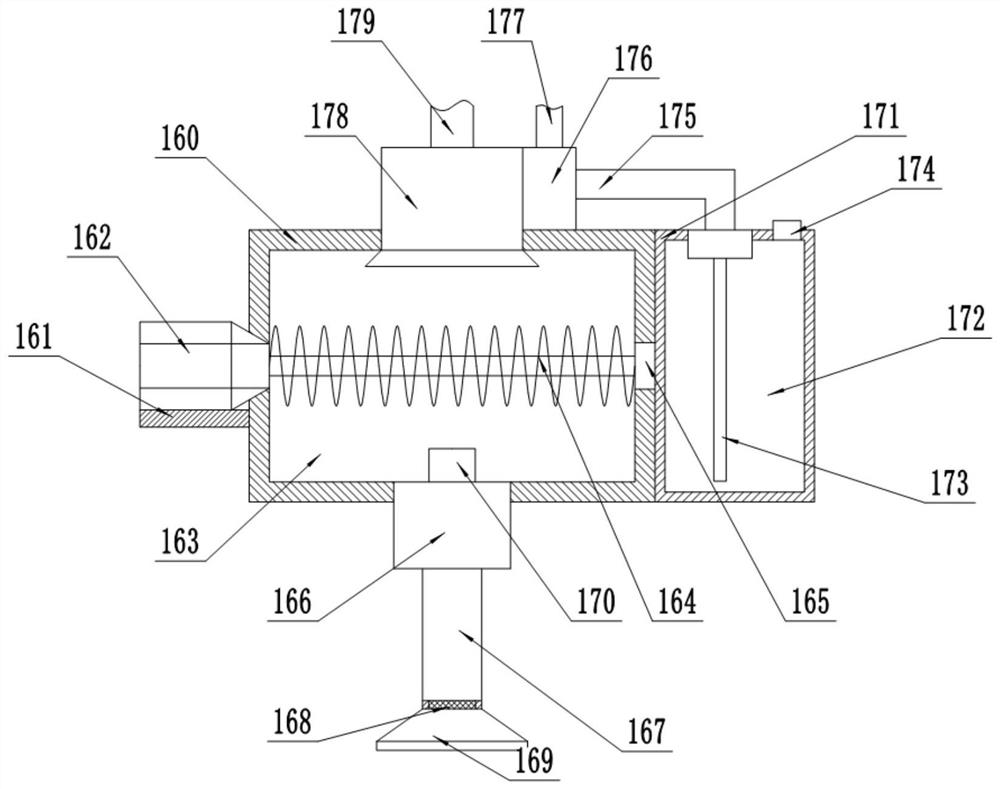

Cement conveying device for building construction outer wall plastering

InactiveCN108516304AImprove stabilityImprove feeding efficiencyBuilding constructionsPackagingSpiral bladeArchitectural engineering

The invention discloses a cement conveying device for building construction outer wall plastering. The cement conveying device comprises a bottom plate, wherein universal wheels are arranged on the lower portion of the bottom plate, one side of the upper part of the bottom plate is connected with a supporting frame through a mounting clamp, and a mounting support is welded to the center line at the other side of the upper part of the bottom plate; and a material conveying pipe is rotationally connected above the mounting support through a rotating shaft, and a feeding hopper is welded to the bottom of the material conveying pipe, a motor is fixed below the feeding hopper through a machine frame, and one end of the motor penetrates through the feeding hopper through a rotating rod and is inserted into the material conveying pipe. According to the cement conveying device, the material conveying pipe is fixed on the mounting support on the bottom plate through the rotating shaft so that the angle and height of the material conveying pipe can be adjusted, and the application range of the device is improved; and according to the device, cement is conveyed from the feeding hopper at oneend of the material conveying pipe to a discharging hopper at the other end of the material conveying pipe through spiral blades, so that when the device is used, the material conveying efficiency ishigher, and the plastering efficiency is improved.

Owner:CHENGDU YANXINGGUO TECH CO LTD

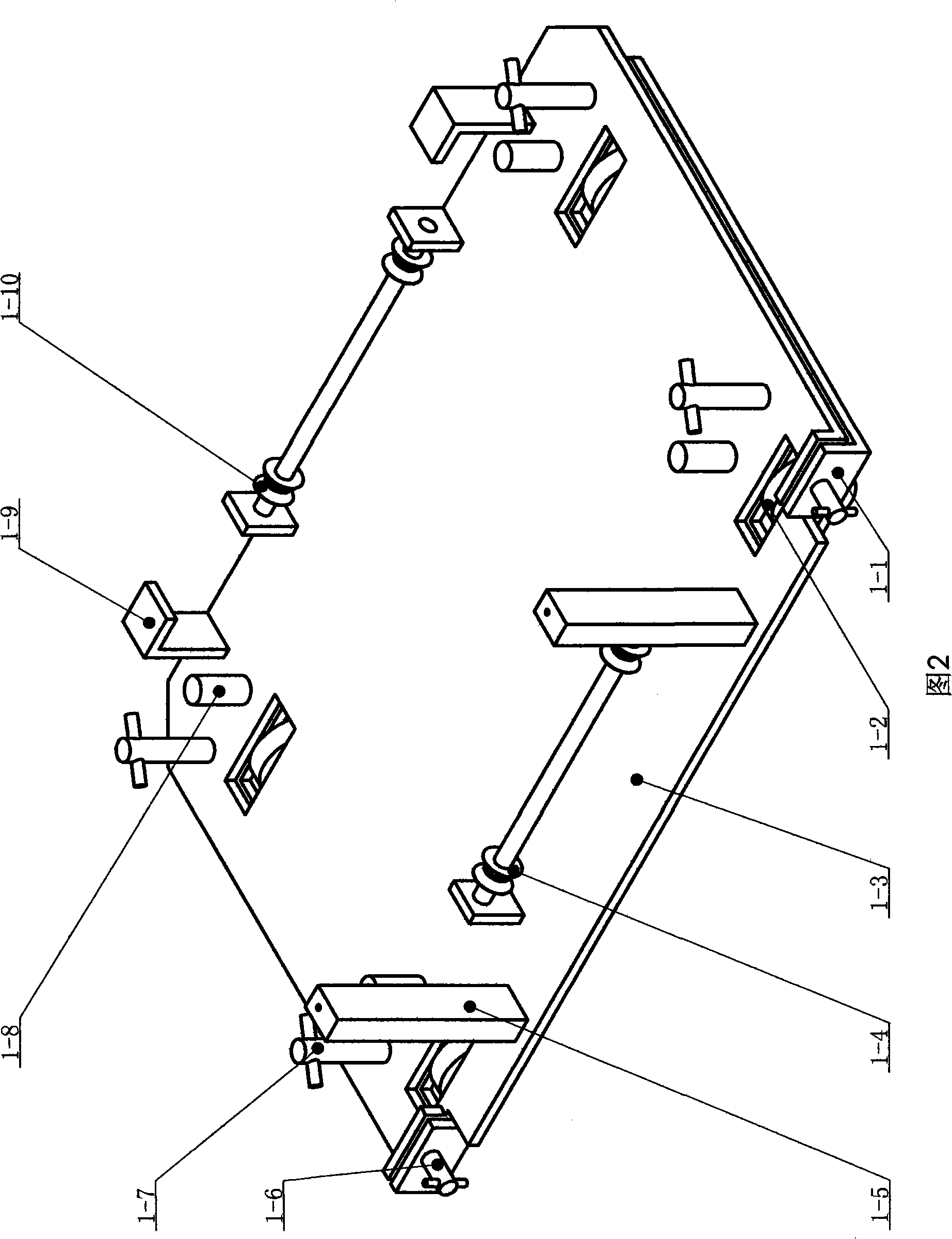

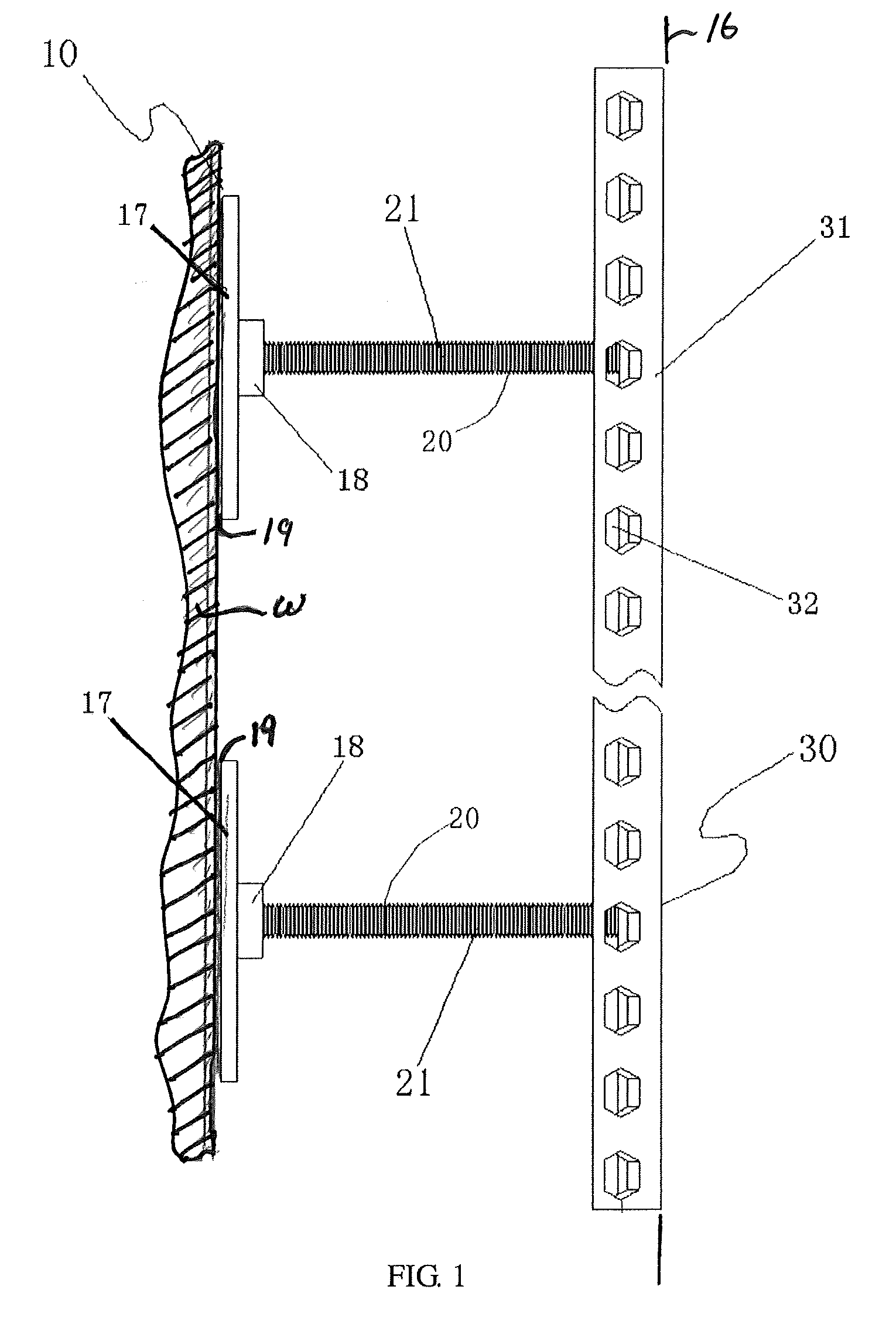

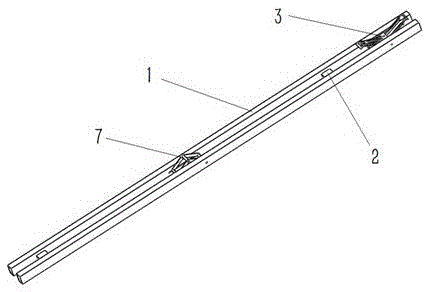

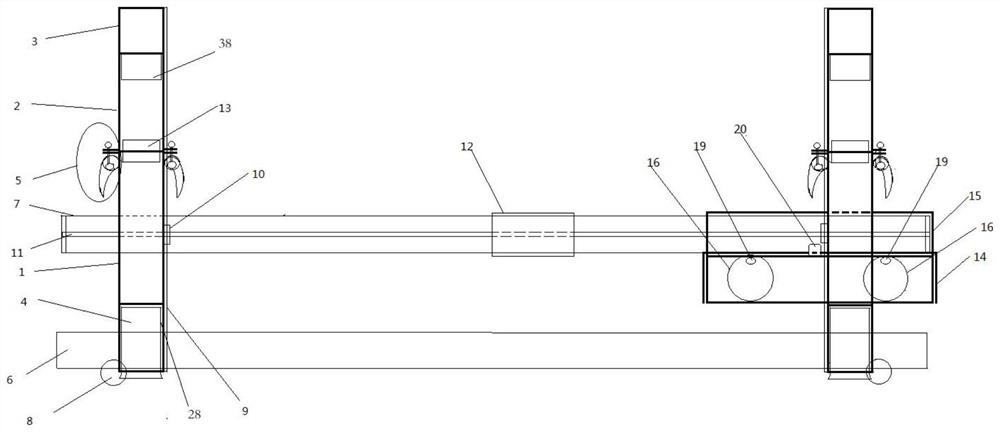

Guide rail type wall plastering machine

InactiveCN103821328AReduce physical laborControl verticalityBuilding constructionsOperabilityMechanical engineering

The invention relates to a guide rail type wall plastering machine. The guide rail type wall plastering machine comprises a guide rail system, a plastering system and a pumping machine, wherein the plastering system is arranged on the guide rail system and can move along the guide rail system back and forth, and the pumping machine is connected with the plastering system to convey raw material. The guide rail system comprises a guide rail rod, a fixed part and a supporting part used for supporting the guide rail rod, and the fixed part is arranged on the guide rail rod and used for being fixed on a wall space; the plastering system comprises a plastering plate, a conveying pipe, a hand shank and angle adjusting devices, the conveying pipe is connected with the plastering plate and used for conveying the raw material, the hand shank is used for fixing the plastering plate, and the angle adjusting devices are arranged on the hand shank and the plastering plate. The guide rail type wall plastering machine has the following advantages of relieving manual labor of workers, reducing construction cost, improving plastering quality, being small in size, light in weight, convenient to install and transport, flexible in operation, almost capable of meeting requirements of plastering construction operation in all areas of the wall space, easy to use, high in operability, capable of accurately controlling perpendicularity and flatness of plastered faces and convenient and rapid to install and commission, and the workers can operate the equipment expertly without any experience.

Owner:WUHAN UNIV

Adjustable automatic plastering device

PendingCN112252683AAvoid cumbersomeShorten the timeBuilding constructionsReciprocating motionStructural engineering

The invention provides an adjustable automatic plastering device. The device comprises a movable base, a plastering executing mechanism, a feeding mechanism and a lifting mechanism, wherein the feeding mechanism and the lifting mechanism are arranged on the movable base, the plastering executing mechanism is arranged on the lifting mechanism, the feeding mechanism is connected with the plasteringexecuting mechanism, the movable base is used for bearing the plastering executing mechanism, the feeding mechanism and the lifting mechanism which are arranged on the movable base, and the movable base does reciprocating motion in the first direction; the lifting mechanism can reciprocate in the second direction; the plastering executing mechanism comprises a plastering plate and a plastering adjusting part, and the plastering plate is provided with a discharging port; and the feeding mechanism comprises a material box, a conveying pump and a conveying pipeline, the material box is used for loading plastering mortar, the conveying pipeline is connected with the plastering plate, and the conveying pump is used for conveying the mortar in the material box to the plastering plate through theconveying pipeline and conveying the mortar out through the discharging port in the plastering plate, so that the plastering plate evenly plasters the mortar conveyed out through the discharging port.

Owner:广东海洋大学寸金学院

An automatic plaster spraying and plastering machine system for walls and ceilings and its control method

ActiveCN105888216BReduce power consumptionLight structureBuilding constructionsFailure rateVertical plane

The invention relates to an automatic injecting and pasting machine system for walls and ceilings and a control method thereof, which belong to the field of construction machinery. The automatic injecting and pasting machine system comprises a vertical lifting rod mechanism, a special pasting arm, a plaster storage tank integrated with a plaster stirring pump, a horizontal traveling trolley, an air compressor and a control circuit. The automatic injecting and pasting machine system is characterized in that the vertical lifting rod mechanism is vertically installed by fasteners on a horizontal platform of the horizontal traveling trolley through a pair of mounting flange at the bottom of the vertical lifting rod and a reinforcement mounting plate adjacent to the left pipe wall at the bottom; the entire pasting arm is fixed by fasteners on the right vertical plane or top horizontal plane of a lifting base of the vertical lifting mechanism through an arm holder base plate; the control circuit is a PLC (Programmable Logic Controller) circuit. The automatic injecting and pasting machine system has the advantages of simple and light-weight structure, small motor power consumption, low failure rate, low cost, high automation degree, and high pasting efficiency; the system can paste both walls and ceilings.

Owner:江苏九星建设工程有限公司

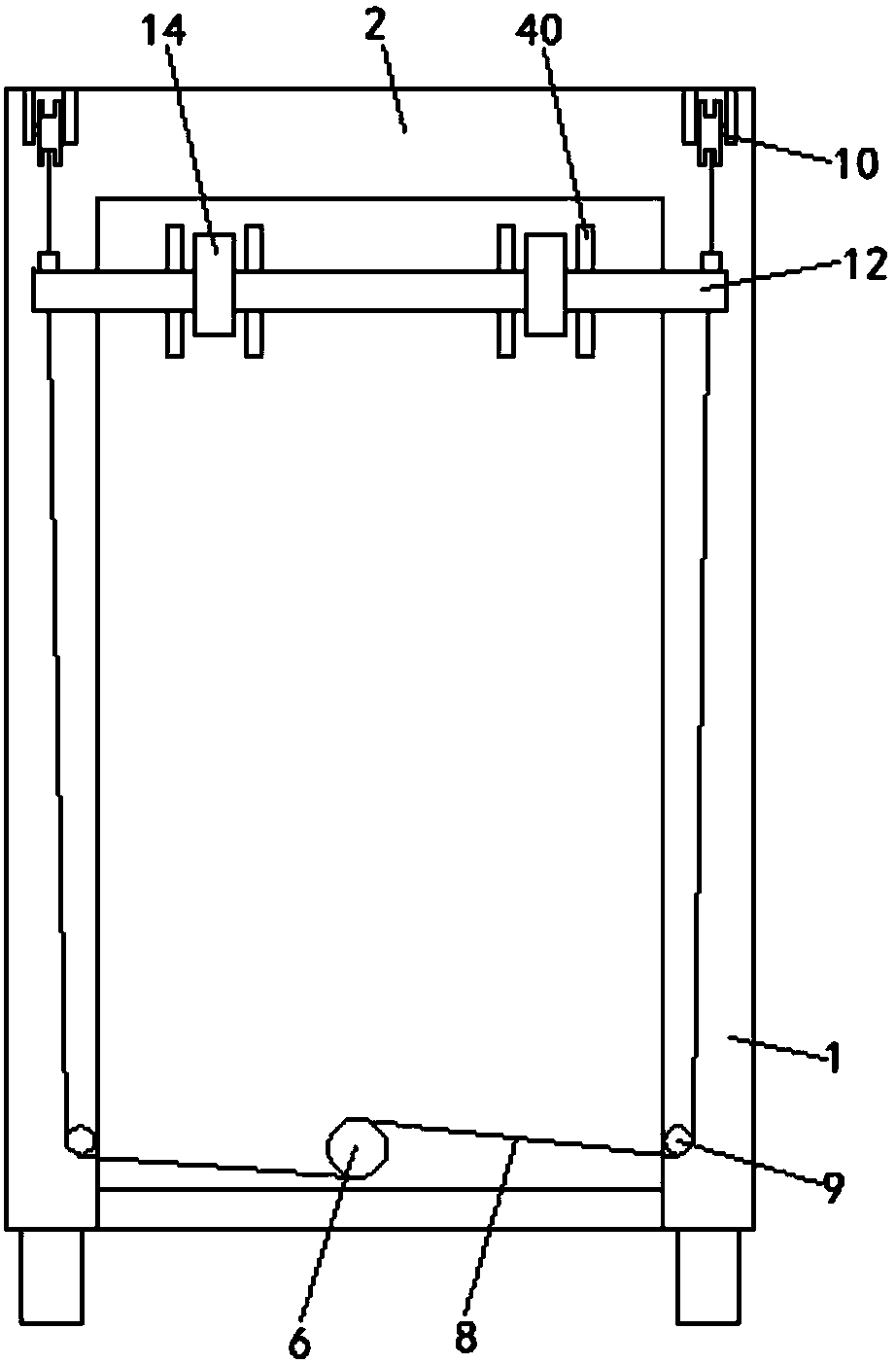

Wall surface plastering equipment in building field

InactiveCN108316616AImprove the level ofIncrease pressureBuilding constructionsArchitectural engineeringPulley

The invention discloses wall surface plastering equipment in the building field. The equipment comprises a support frame, wherein the support frame consists of four upright posts, two transverse rodsand two connecting rods through connection; every two upright posts are connected through the transverse rod to form one single frame; the two single frames are fixedly connected through the connecting rod; a first motor is fixedly arranged between the connecting rods; the output end of the first motor is provided with a first connecting rod; one end, far away from the first motor, of the first connecting rod is provided with a rope winding shaft; two rope winding grooves are formed in the rope winding shaft; a steel cable is fixedly arranged in the rope winding grooves; a first pulley and a second pulley are arranged in the upright post; grooves are formed in mutually approaching sides of the upright posts between each group of single frames; load bearing rods are movably arranged betweenthe grooves. The wall surface plastering equipment has the beneficial effects that the labor work intensity is low; the operation is simple; the use is convenient; in addition, the plastering levelness is greatly enhanced; the labor investment is further reduced, so that the plastering efficiency is improved.

Owner:胡红辉

Construction method for preventing hollowing and cracking of wall plastering

PendingCN112942709AAvoid secondary processingNo adhesionCovering/liningsArchitectural engineeringAdhesive glue

The invention discloses a construction method for preventing hollowing and cracking of wall plastering. The construction method comprises the following steps: (a) wall surface treatment is conducted, specifically, firstly, the surface of a to-be-constructed wall is cleaned to remove falling dust and residual soil blocks and dirt on the wall, and a plastering structural surface is watered and uniformly wetted; and (b) primary gluing is conducted on the wall surface, specifically, building glue is evenly mixed and then smeared on the to-be-constructed wall surface through a brush. The construction method has the beneficial effects that firstly, the building glue is smeared on the surface layer of the treated wall surface, it is guaranteed that the dust attachment phenomenon cannot occur in the using process of the wall surface, and the plastering quality is improved; a steel wire mesh is hung on the surface of the wall surface, so that the wall surface is smooth, mortar is attached to the wall surface, the hollowing phenomenon cannot occur in the later period, the anti-cracking effect is good, and the wall surface quality is improved; and spray-type moisturizing treatment is adopted, so that water is uniformly sprayed to the wall surface, the wall surface maintenance effect is improved, and wall surface cracking can be effectively avoided.

Owner:福建筑兆建设有限公司

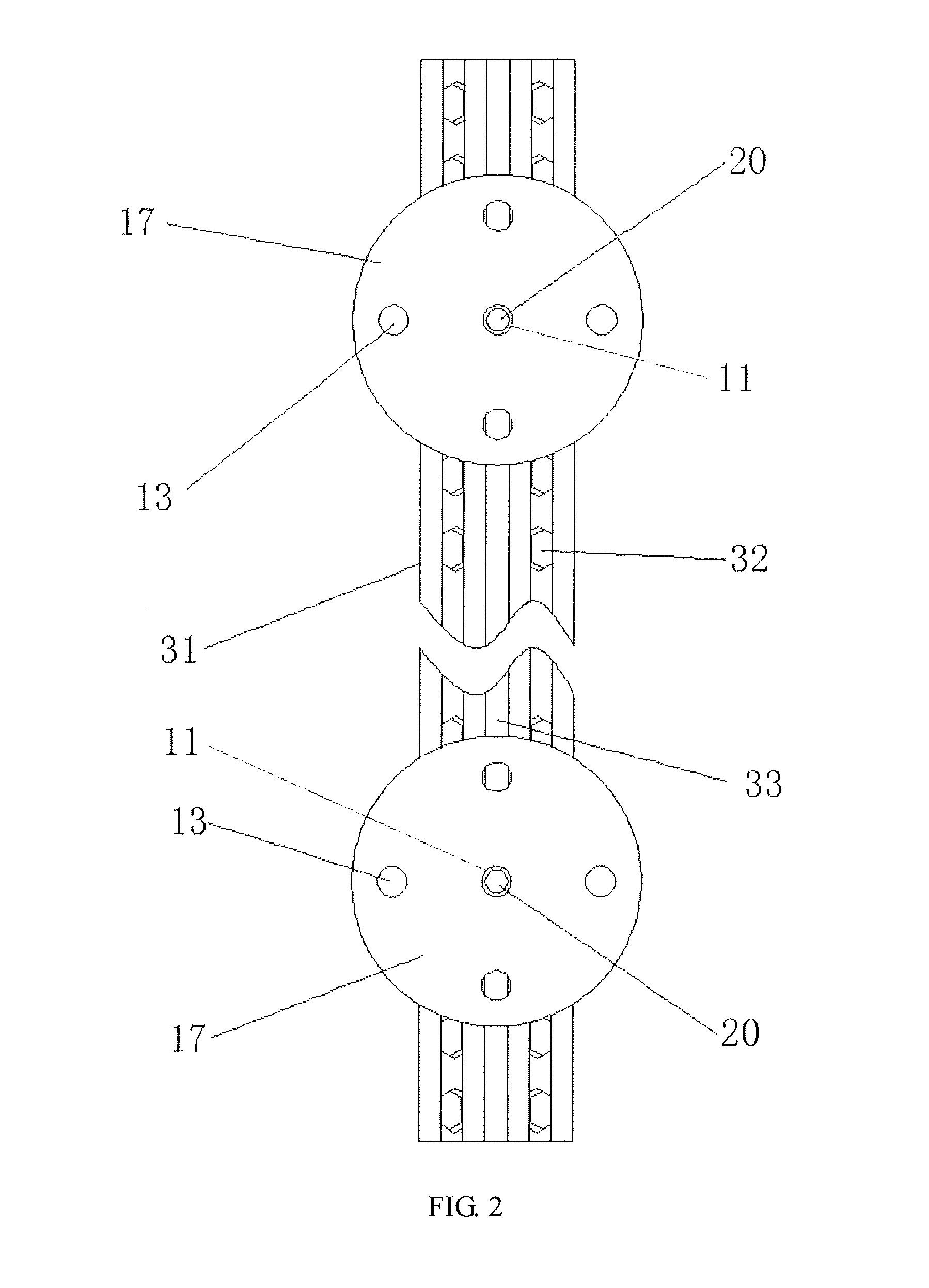

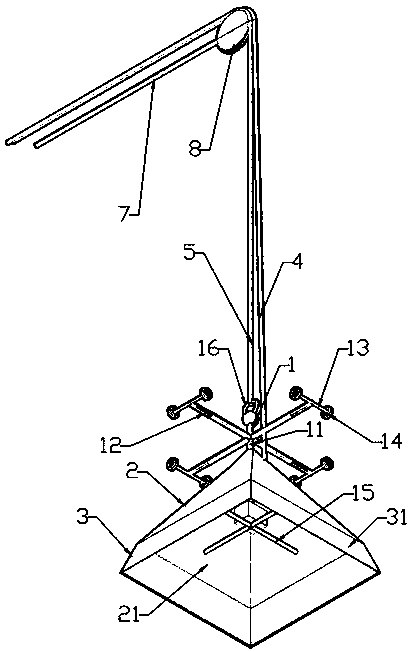

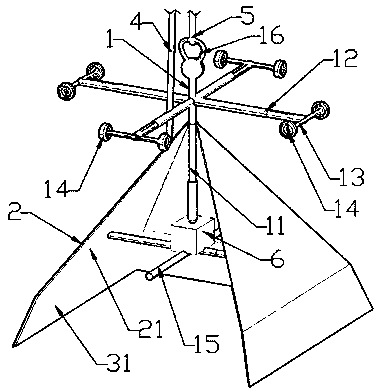

Flue plastering device and method

The invention discloses a flue plastering device and method. The flue plastering device comprises a supporting frame; the supporting frame comprises a vertical rod, and a hopper fixedly sleeves the middle of the vertical rod; the hopper is formed by four oblique plates in an enclosing mode, wherein the lower ends of the four oblique plates incline outwards correspondingly; a plastering plate is fixedly arranged below each oblique plate, wherein the lower end of the plastering plate is arranged in an outward-inclining mode; the side ends of every two adjacent plastering plates are fixedly connected, and a plastering frame in a hopper shape is formed; a flexible concrete conveying pipe is arranged at the upper end of the hopper, the upper end of the flexible concrete conveying pipe is fixedto a flue opening, and the lower end of the flexible concrete conveying pipe is adjacent to the top of the hopper; and concrete flows outside the four oblique plates of the hopper under the self-weight effect and is guided to all the plastering plates through the oblique plates, then the plastering frame is driven to ascend along with the vertical rod in the mode of lifting the vertical rod upwards, and the inner wall of a flue is subjected to multi-face plastering. According to the flue plastering device and method, the plastering efficiency and the plastering quality are high, and the four faces of the flue can be plastered synchronously at a time.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

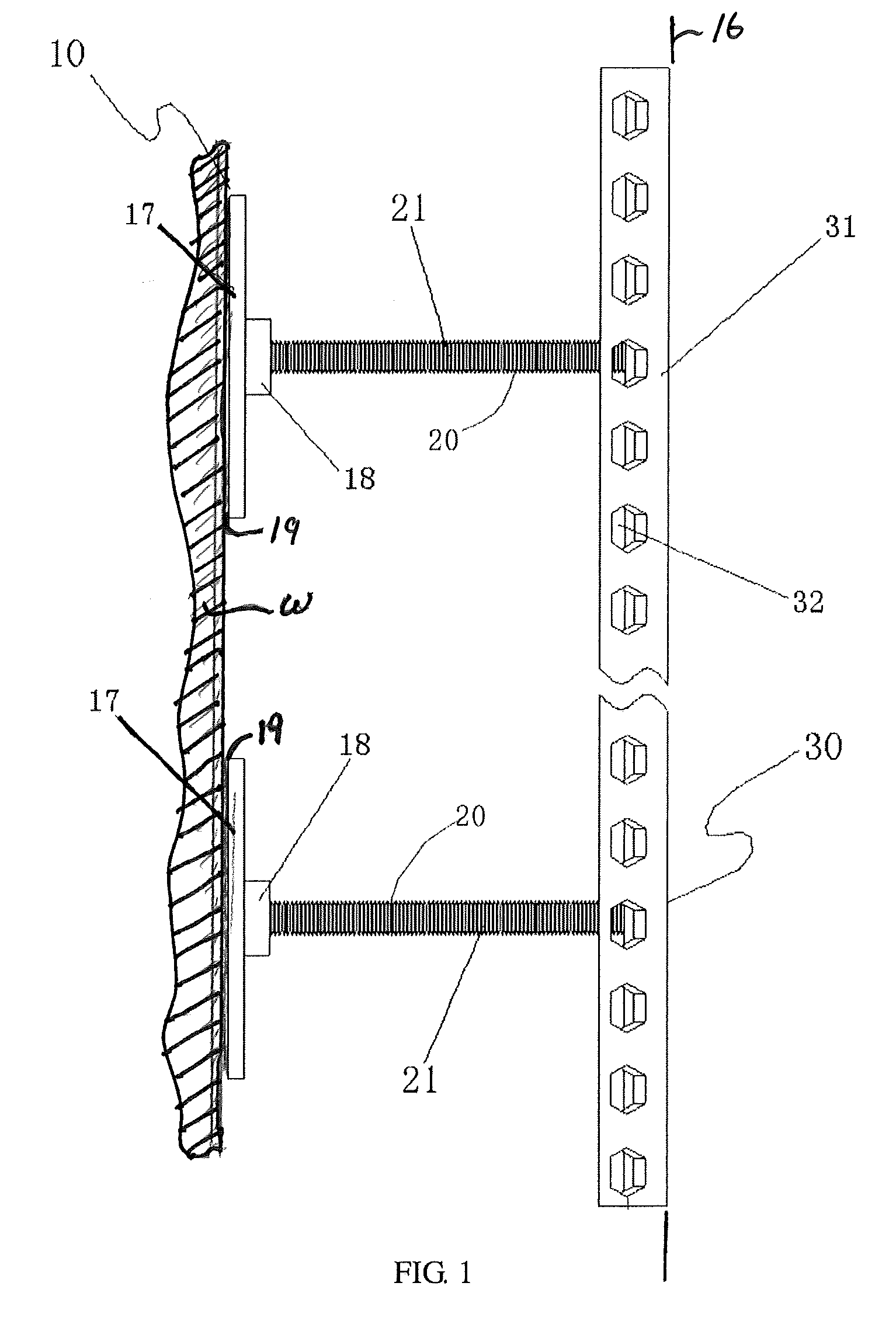

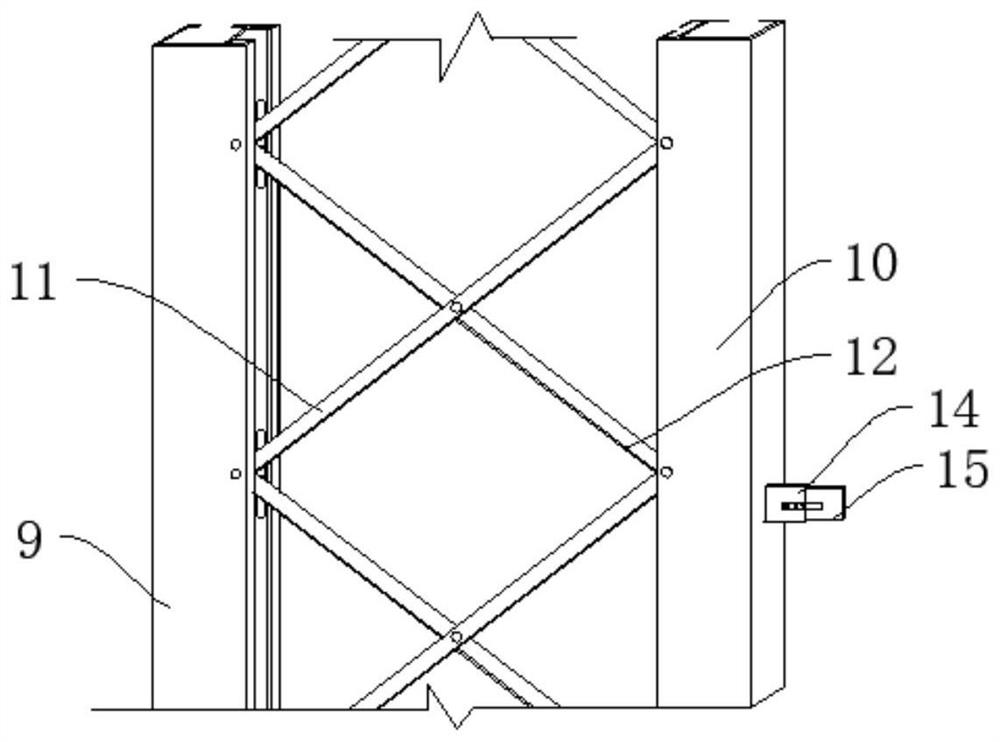

Rail-mounted millstone pasting machine

InactiveCN102677877AImprove plaster qualityImprove plastering efficiencyBuilding constructionsAgricultural engineeringMillstone

The invention discloses a rail-mounted millstone pasting machine, which includes a pasting device and is characterized in that the pasting device is arranged on a lateral movement assembly, the lateral movement assembly is glidingly arranged on a vertical guide rail, the vertical guide rail is connected with a positioning stander, and the pasting device is connected with a lifting device; the positioning stander includes two groups of positioning racks, and each group of positioning rack includes an upper wall connection piece and a lower wall connection piece, which are arranged horizontally and connected with two ends of the vertical guide rail respectively; the lateral movement assembly includes a main rail rack, a lateral track and a traveling dolly, which are arranged horizontally, wherein the lateral track is glidingly matched with the main rail rack, the traveling dolly is glidingly matched with the lateral track, and the main rail rack is glidingly matched with the vertical guide rail through a vertical rail pair; and the pasting device is arranged on the traveling dolly and is connected with the lifting device through the vertical rail pair. The rail-mounted millstone pasting machine can be suitable for various wall surface pasting, and has the advantages of high pasting quality, low labor intensity for works, high pasting efficiency, less leaked plaster, small plaster consumption, and low cost.

Owner:陶宝魁

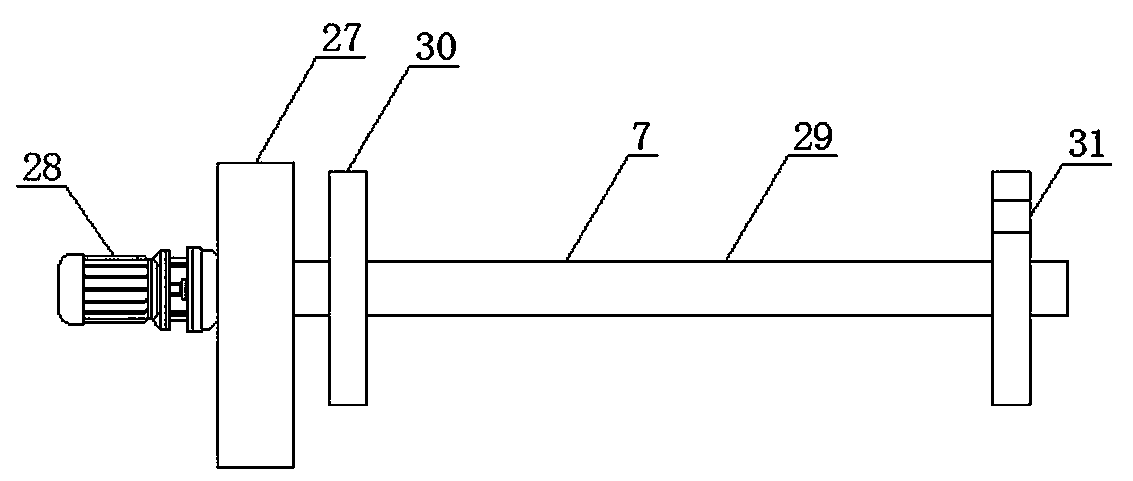

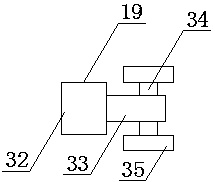

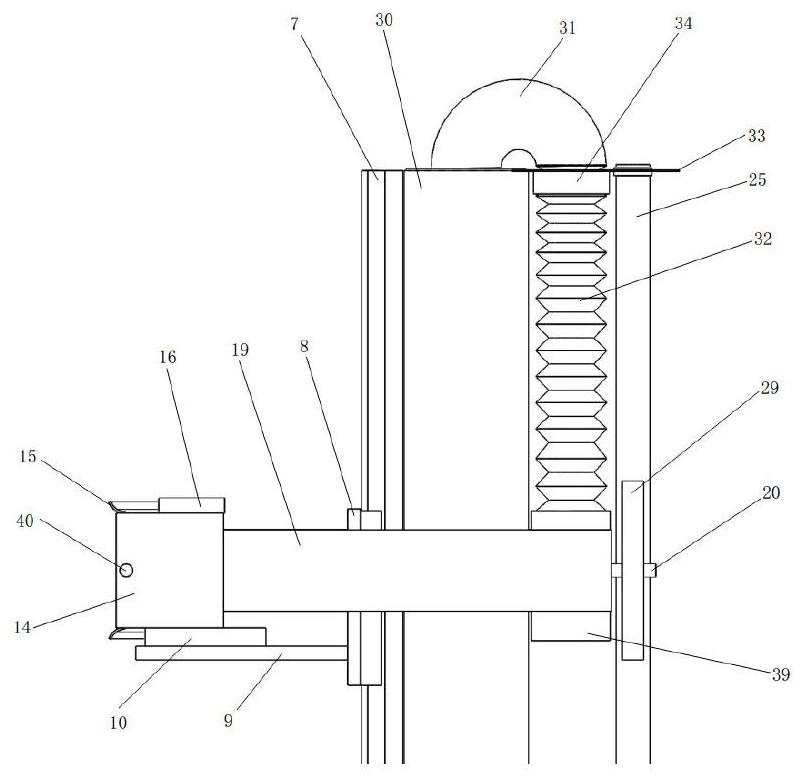

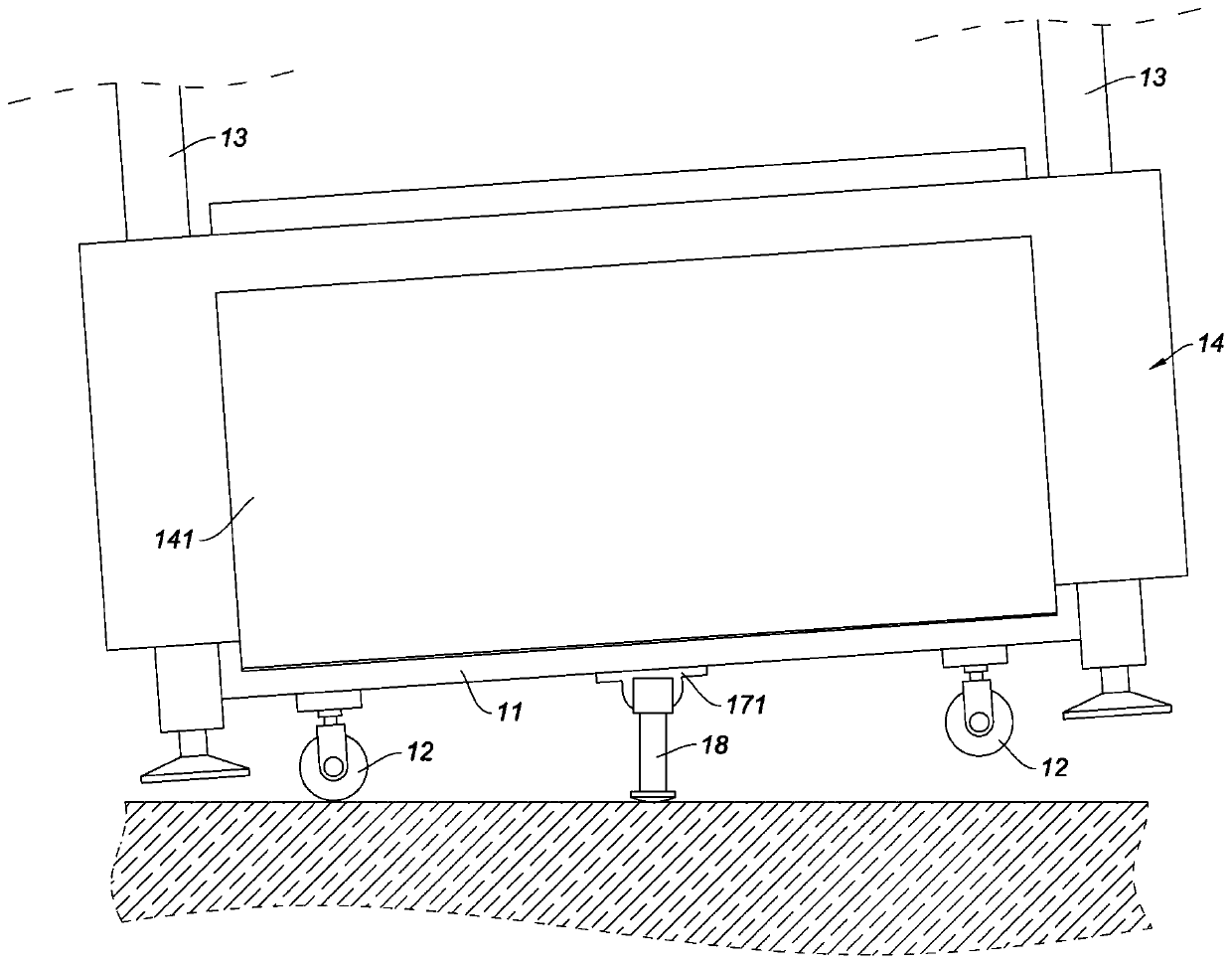

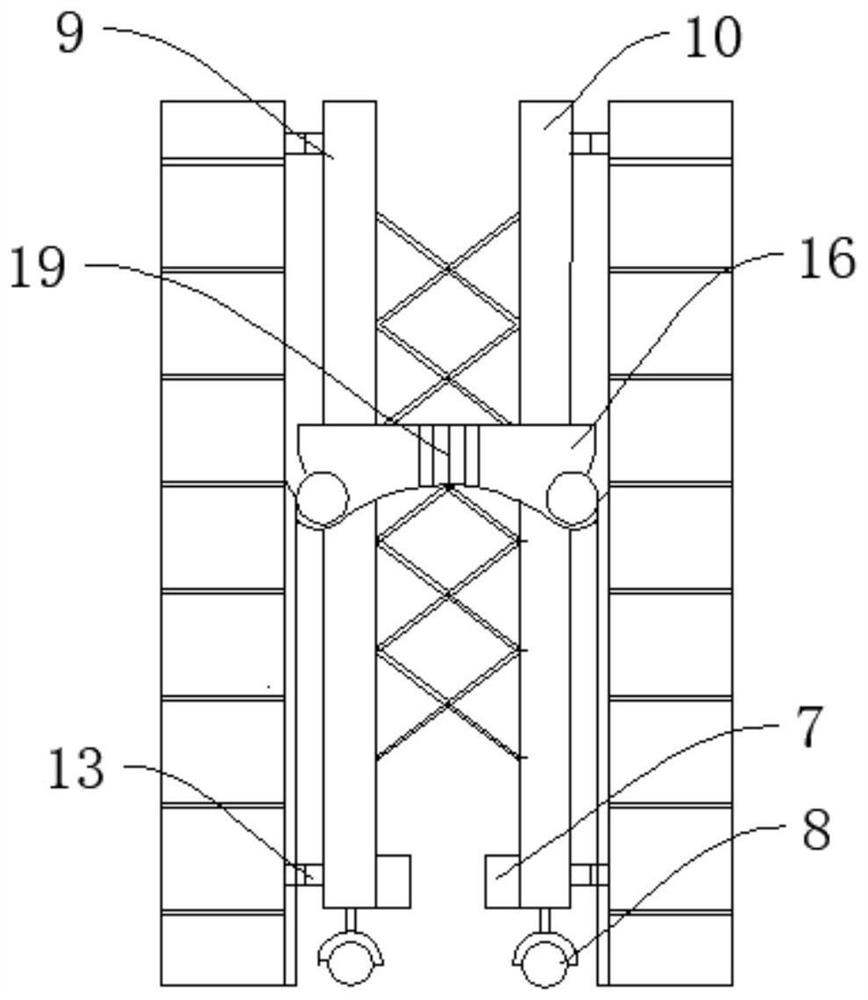

Wall plastering machine capable of assisting in travelling

The invention relates to a wall plastering machine capable of assisting in travelling. The wall plastering machine comprises a bottom frame, a vertical rail and a plastering main machine, and furthercomprises an auxiliary travelling mechanism; the vertical rail is mounted on the bottom frame, and the plastering main machine is mounted on the vertical rail; universal travelling wheels are furthermounted on the bottom frame; the auxiliary travelling mechanism comprises a power device, a rotating shaft, one or more first grounding rods and one or more second grounding rods; the rotating shaft is rotatably mounted on the bottom frame, and the power device is used for driving the rotating shaft to rotate; the first grounding rods are mounted at one end of the rotating shaft, and the second grounding rods are mounted at the other end of the rotating shaft; grounding ends are arranged on the first grounding rods and the second grounding rods correspondingly, and the grounding ends of the first grounding rods and the grounding ends of second grounding rods are arranged in the mode of simultaneously landing and lifting off. The wall plastering machine has the characteristics that the labor intensity of workers can be relieved, the wall plastering machine is overall moved to a next plastering station easily and quickly, then the plastering efficiency is improved, and benefits are increased advantageously.

Owner:FOSHAN TUPO MACHINERY MFG CO LTD

A bucket plastering connection device for an automatic plastering machine

The invention discloses a bucket plastering connection device for an automatic plastering machine, comprising a first wheel base, a transverse pulley, a locking seat, a locking rod, a locking pad, a first supporting column, and a first supporting bottom plate , loading box, second wheel seat, roller, locking valve, discharge plate, handle of loading box, stirring and cleaning device, main pipe, discharge cover, first motor bottom plate, first motor, linkage rod, limiting hopper, Fixed base plate, feeding device, second supporting base plate, second supporting column and footing plate, etc.; the present invention has reasonable and simple structure, low production cost, convenient installation and complete functions. Automatically feed the plastering machine, which saves a lot of manpower and reduces the work intensity of the construction personnel.

Owner:安徽秋旻建设工程有限公司

A rail type wall plastering machine

InactiveCN103821328BReduce physical laborControl verticalityBuilding constructionsOperabilityEngineering

Owner:WUHAN UNIV

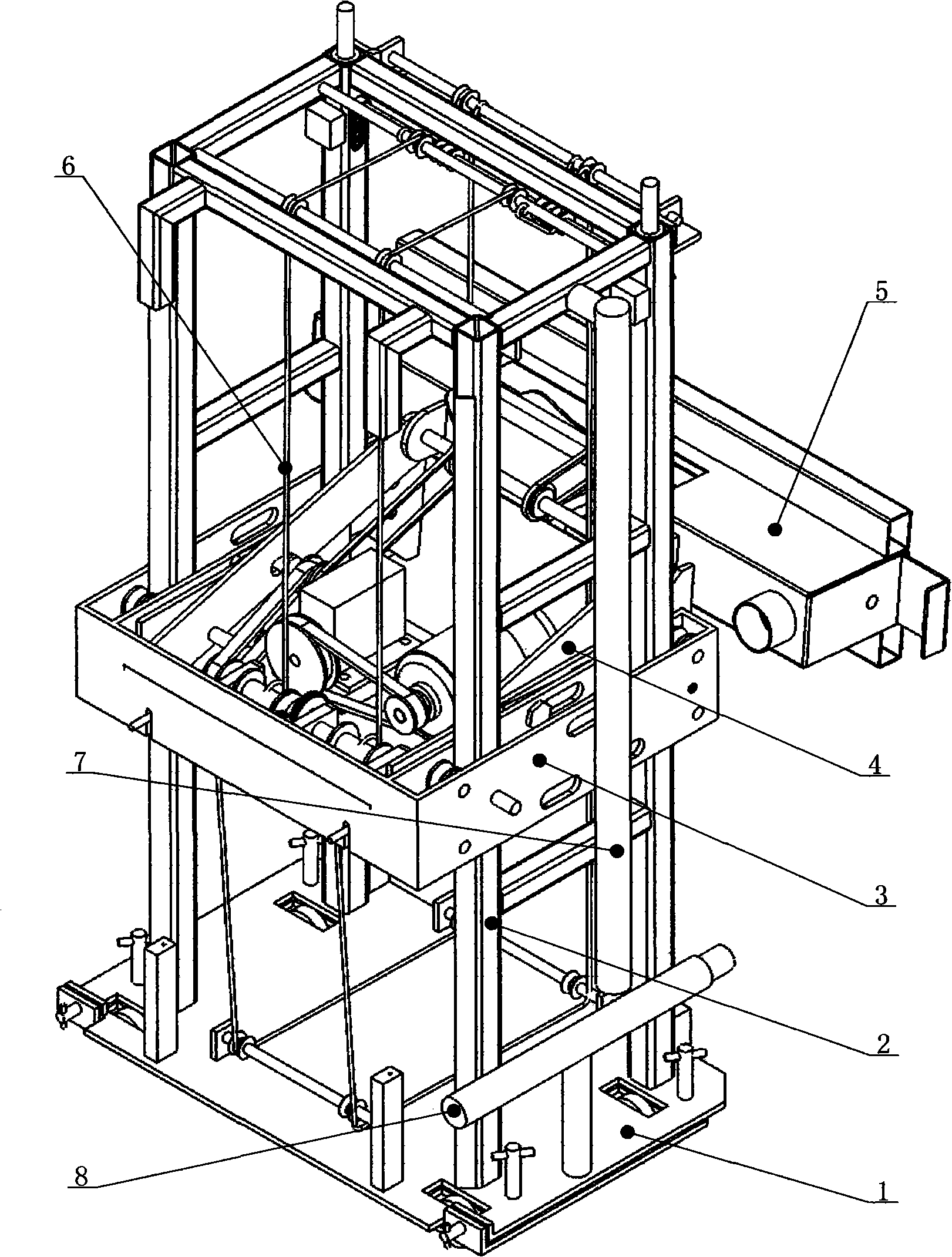

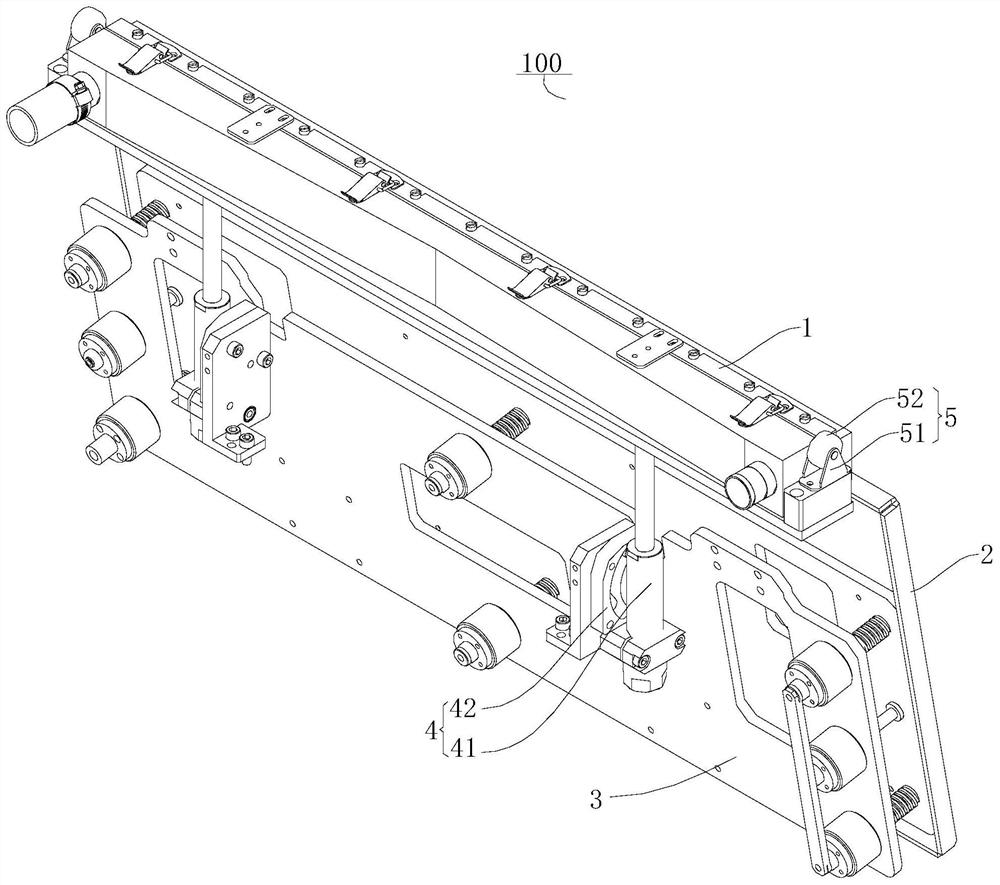

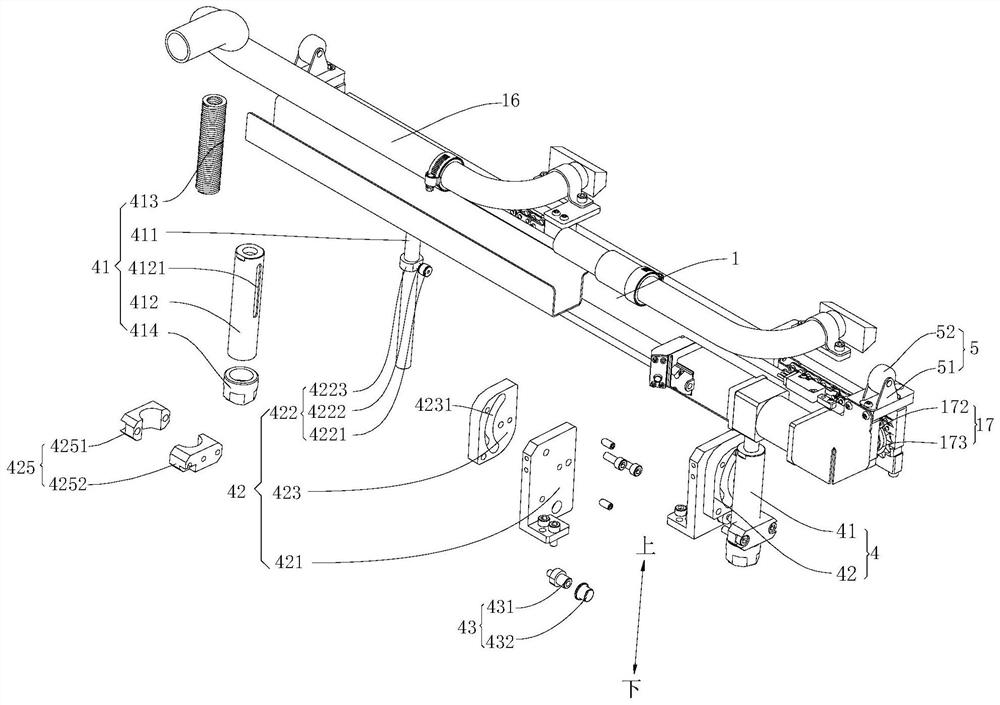

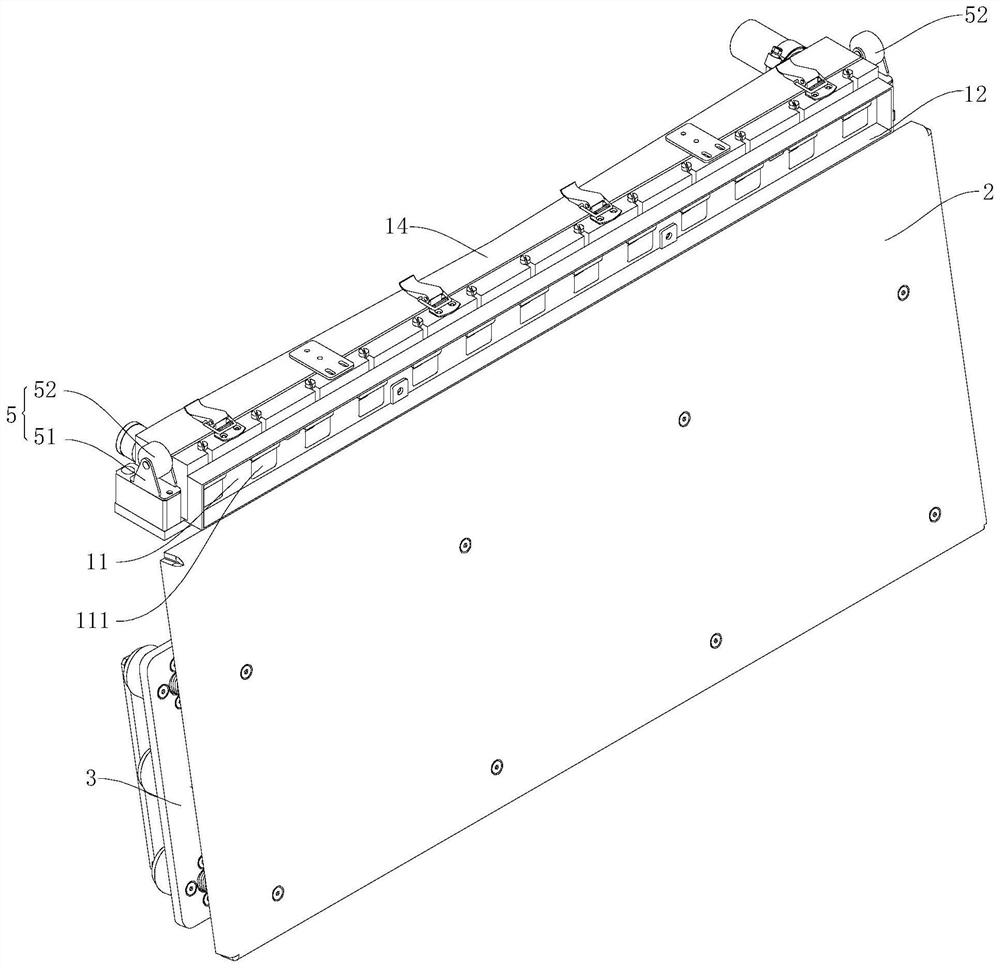

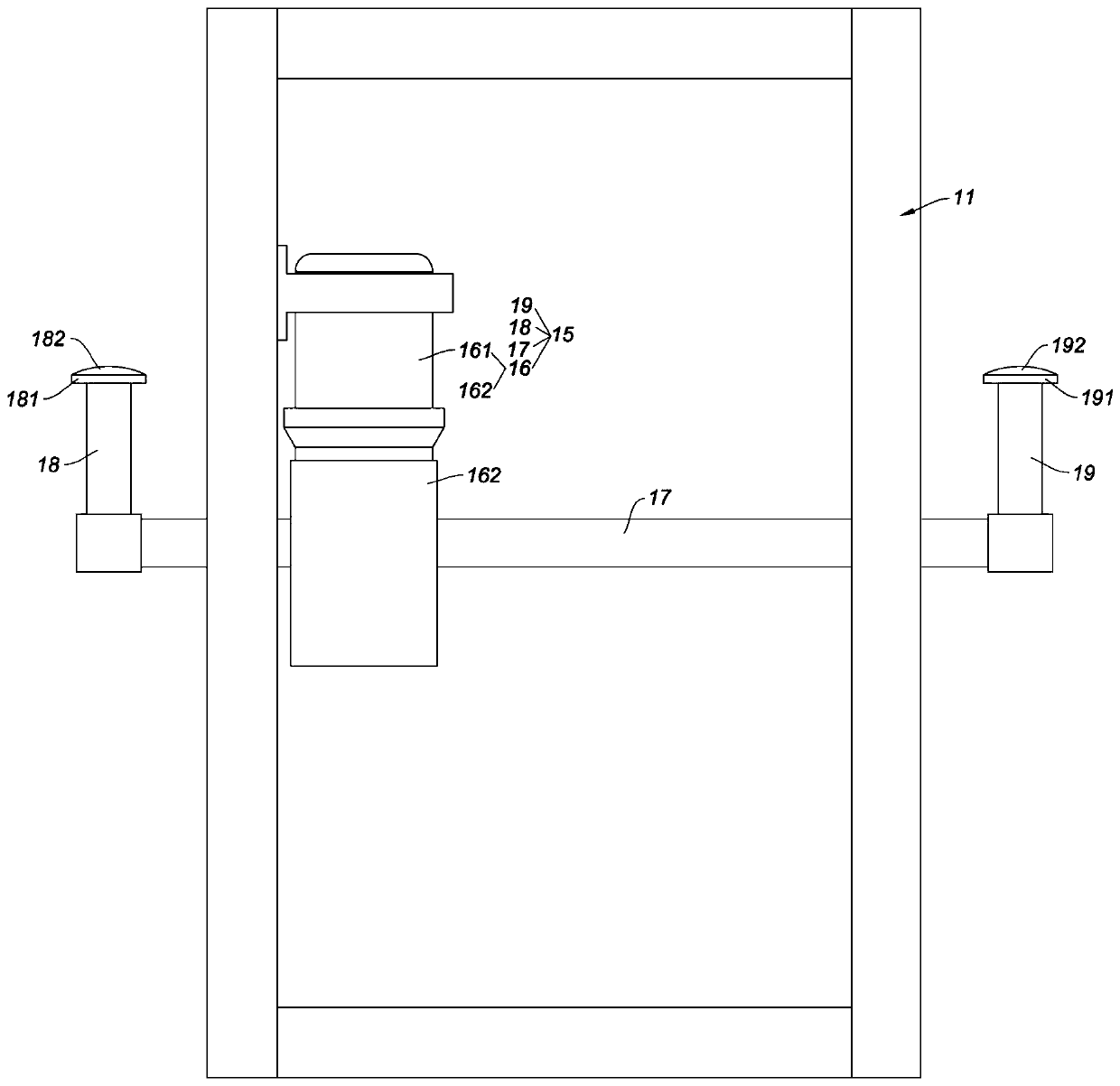

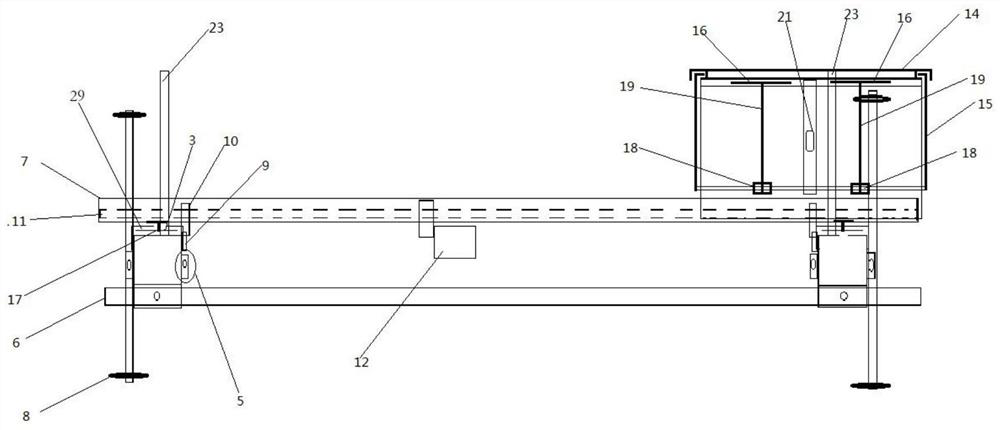

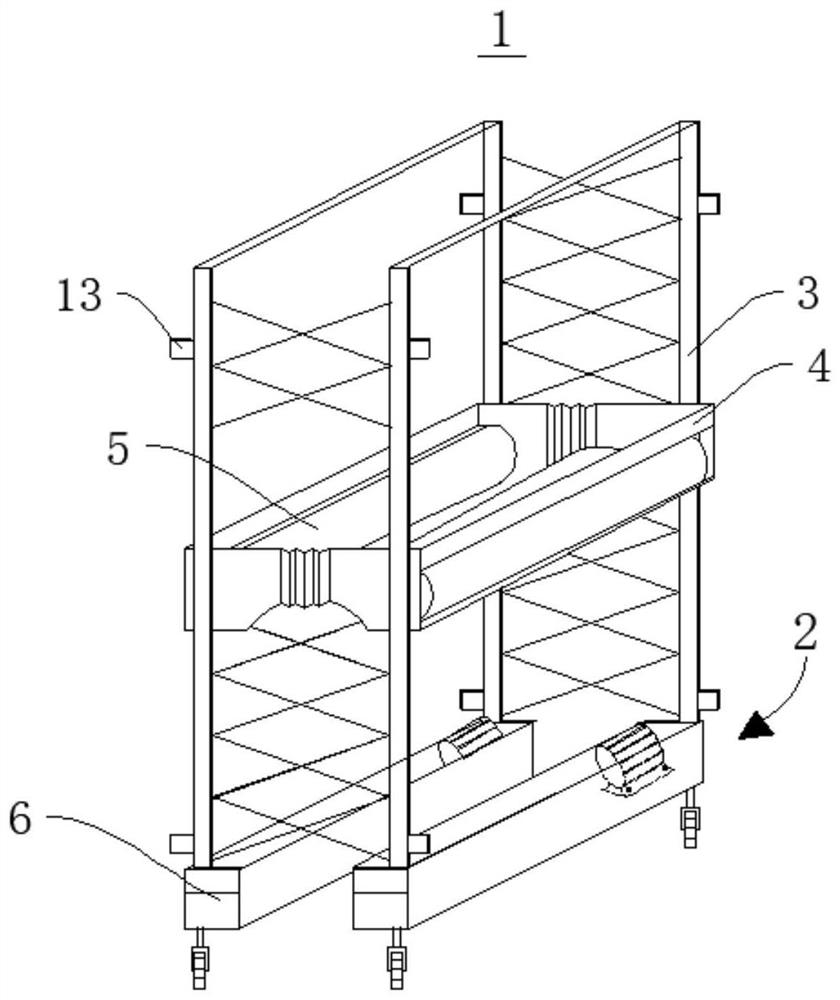

Plastering machine capable of plastering multiple sections of wall surfaces in one-time positioning mode

ActiveCN114150842AAvoid pollutionPrevent fallingBuilding constructionsElectric machineryStructural engineering

The invention relates to the technical field of building machinery, in particular to a plastering machine capable of plastering multiple sections of wall surfaces in a one-time positioning mode, the plastering machine comprises a horizontally-arranged rail and two stand column assemblies, the rail is connected with the two stand column assemblies through connecting pieces, the rail is in sliding connection with the connecting pieces, and the connecting pieces are in sliding connection with the stand column assemblies; a rotating shaft is rotationally arranged on the rail, a rotating shaft motor is arranged on the guide rail, rotating teeth sleeve the rotating shaft, a rack is fixedly arranged on the side edge of the stand column assembly, and the rotating teeth are meshed with the rack; a hopper component is arranged on the rail in a sliding mode, a plastering plate is arranged on the side, away from the rail, of the hopper component, a lifting mechanism is arranged on the hopper component, and a soft storage roller shutter belt is arranged on the hopper component. The multi-section wall plastering device has the beneficial effects that multiple sections of walls can be plastered through one-time positioning, time is saved, and the plastering efficiency is improved; by arranging the soft material storage roller shutter belt, the ceiling is prevented from being polluted by excess materials, and meanwhile the excess materials are prevented from falling onto the ground.

Owner:熊静

Indoor roof plastering device

The invention discloses an indoor roof plastering device, and belongs to the technical field of building mechanical equipment. The indoor roof plastering device is used for mechanization work of plastering an indoor roof. According to the technical scheme, a plastering head part is located at the highest end of the plastering device, a plastering thickness regulating part is installed in the plastering head part, a feeding part is connected on the lower portion of the plastering head part, a transmission part is located on the lower portion of the plastering head part, the plastering head part and the feeding part are respectively connected with the transmission part, the plastering head part, the feeding part and the transmission part are respectively installed on base plates, the base plates are connected on a lifting frame part which is connected with a hydraulic lifting part, and the hydraulic lifting part and the lifting frame part are installed on a vehicle frame part. By means of the indoor roof plastering device, the indoor roof can be plastered evenly, a combination property between mortar and the roof is good, a parallelism error requirement between the roof and the ground is met, and the plastering quality is guaranteed. The indoor roof plastering device is capable of achieving continuous work, greatly improving plastering efficiency and reducing labor intensity of workers.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

A masonry plastering construction mechanism

ActiveCN111321904BGuaranteed flatnessAdjustable thicknessBuilding material handlingArchitectural engineeringStructural engineering

Owner:CHINA FIRST METALLURGICAL GROUP

A vertical lifting mechanism of an automatic and semi-automatic wall plastering machine

ActiveCN105952123BLight structureImprove plastering efficiencyBuilding constructionsFailure rateSemi automatic

The invention relates to a vertical lifting mechanism for an automatic-semiautomatic wall surface pasting machine in the field of building machinery. The vertical lifting mechanism comprises a pair of vertical lifting rods and a lifting mechanism. The vertical lifting mechanism is characterized in that the sections of the vertical lifting rods are rectangular, a pair of rack are symmetrically arranged on the outer walls of the relative inner sides of the vertical lifting rods along the vertical height direction, a pair of guide rails which are symmetrically arranged along the vertical height direction of the vertical lifting rods cling to the right-side pipe walls, a plurality of traction rods are arranged on the left sides between the pair of the vertical lifting rods along the height direction, mounting flanges are arranged at the bottoms of the vertical lifting rods, reinforcing mounting plates are arranged on the left-side pipe walls close to the bottoms, and automatic lifting rod locking and positioning mechanisms are arranged at the upper parts of the pair of the vertical lifting rods; the lifting mechanism comprises a lifting seat, a lifting motor and a pair of mutually meshed climbing gears. The vertical lifting mechanism has the advantages of simple and light structure, low motor power dissipation, failure rate and cost and high pasting efficiency.

Owner:嘉兴笼列电子商务有限公司

Plastering construction method and plastering device

PendingCN114775961AHigh adhesive forceHigh bonding strengthBuilding material handlingAdhesive cementArchitectural engineering

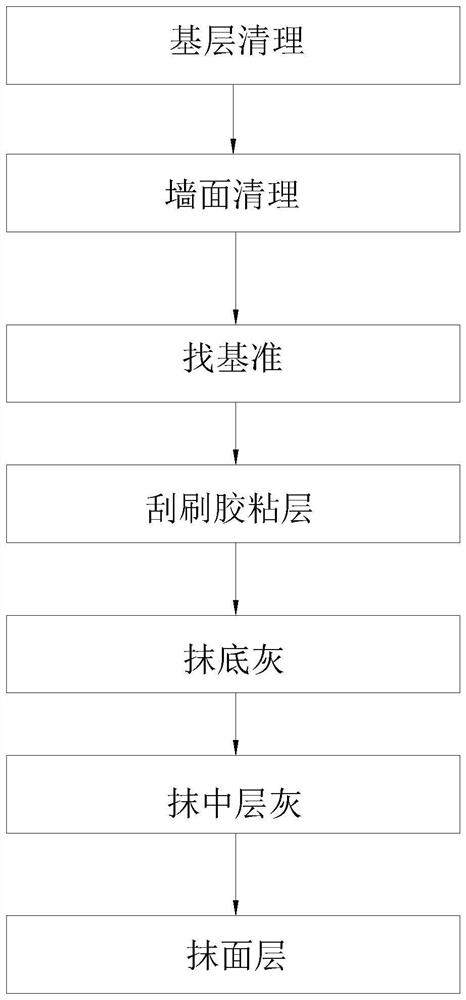

The invention relates to a plastering construction method and a plastering device. The plastering construction method comprises the following steps that S1, a base layer is cleaned, specifically, residual mortar, dust and oil stains on a wall surface are removed, and gap defects are filled; s2, wall surface wetting is conducted, specifically, water is sprayed on the surface for wetting, and water permeates into the wall surface by 8-10 mm; s3, a benchmark is found, and a vertical plane 25-100 mm away from the wall face serves as a datum plane with the wall face as the benchmark; s4, scraping and brushing an adhesive layer: scraping and brushing the adhesive layer on the wall surface by adopting an adhesive; s5, smearing bottom ash, brushing and doping 20% building glue cement paste on the adhesive layer before smearing the bottom ash, and then smearing mortar bottom ash doped with 7% building glue aqueous solution; s6, smearing middle-layer ash, namely smearing mortar middle-layer ash doped with 7% of building glue aqueous solution after the bottom ash is initially set; and S7, plastering a surface layer: after the middle-layer ash is initially set, coating with mortar to form the surface layer. The bonding strength of the plaster and the wall surface is effectively improved.

Owner:重庆渝能建筑安装工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com