Vertical lifting mechanism for automatic-semiautomatic wall surface pasting machine

A vertical lifting mechanism and technology of lifting mechanism, which can be applied in building structure, construction and other directions, can solve the problems of easy damage, high power consumption of lifting mechanism motor and heavy load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

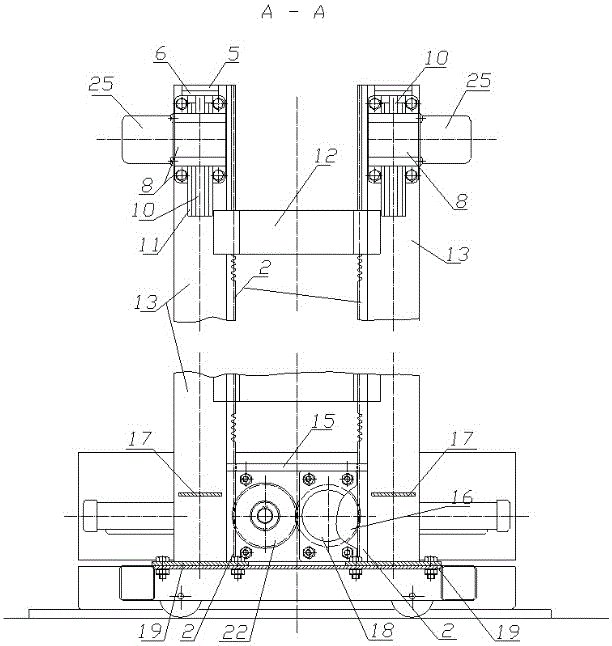

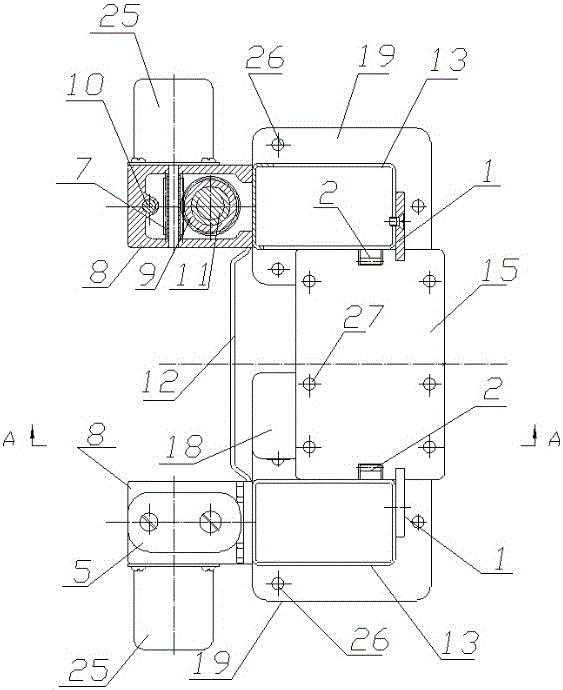

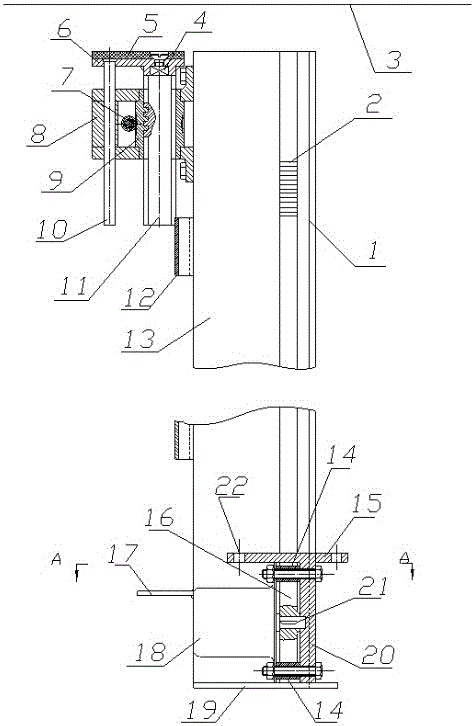

[0017] Such as Figure 3~Figure 6 As shown, a vertical lifting mechanism of a wall automatic semi-automatic plastering machine includes a pair of vertical lifting rods 13 and a lifting mechanism. The vertical lifting rods 13 are a pair of vertical lifting rods 13 with a rectangular cross-sectional shape, and A pair of racks 2 are symmetrically arranged along the vertical height direction of the vertical lifting rod 13 on the inner side outer wall, and a pair of guide rails 1 arranged symmetrically along the vertical height direction of the vertical lifting rod 13 are close to the right pipe wall. The left side between the vertical lifting rods 13 is provided with several pulling rods 12 along the height direction, and the mounting flange 19 that is provided at the bottom of the vertical lifting rods 13 and the reinforcement mounting plate 17 that is provided with near the bottom left pipe wall are both It is used to install the vertical elevating rod 13 on the horizontal platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com