Plastering device and plastering robot

A technology of plastering board and body, which is applied in the direction of construction and building structure, can solve the problems of inability to plaster the whole wall and low plastering efficiency, and achieves the improvement of plastering efficiency, good plastering quality and high plastering efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

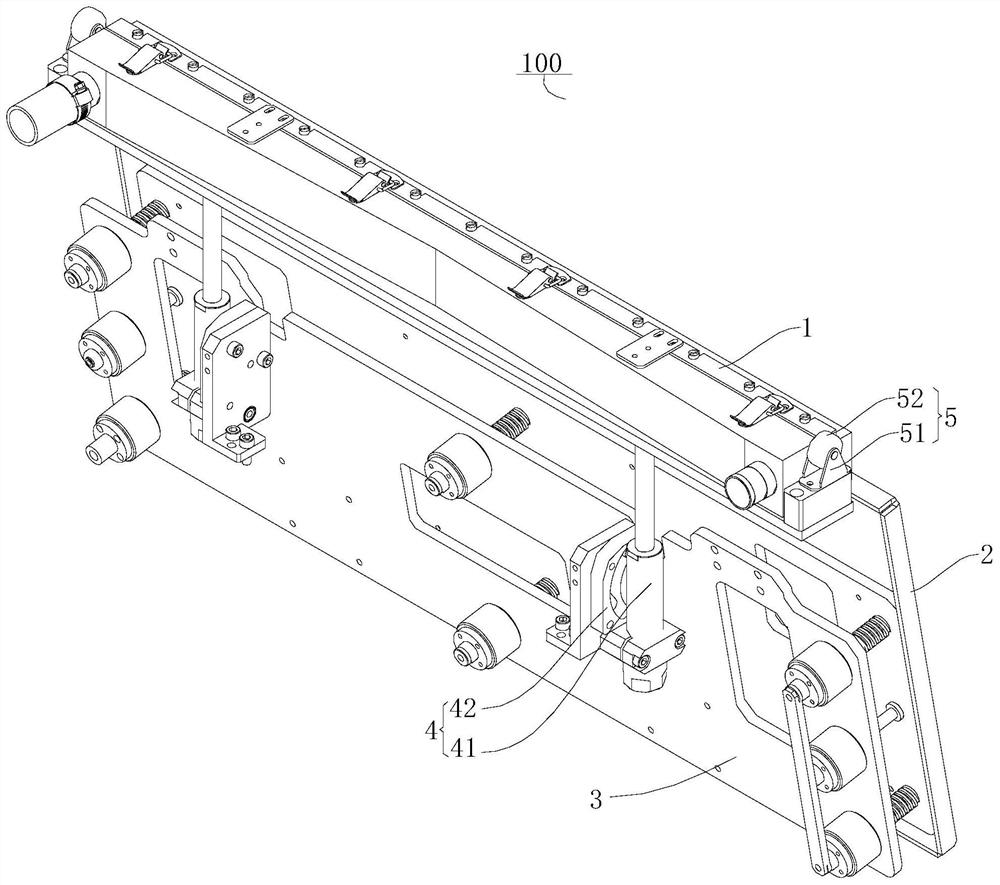

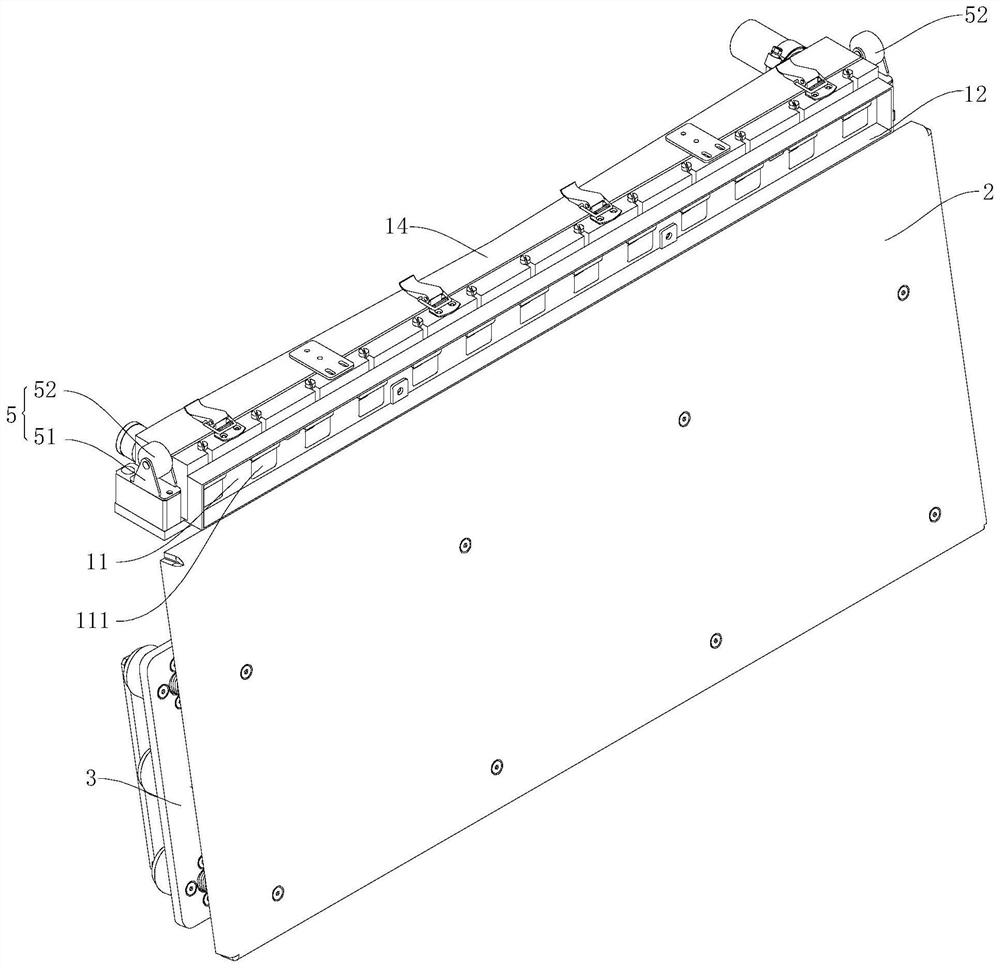

[0156] A plastering device 100, such as figure 1 As shown, it includes: a plastering frame 3, a plastering board 2, a cloth mechanism 1 and an avoidance mechanism 4.

[0157] Among them, such as figure 1 As shown, plastering board 2 is connected on plastering frame 3, and is positioned at the front of plastering frame 3.

[0158] The distributing mechanism 1 transports the mortar to the front of the plastering board 2 , and the distributing mechanism 1 has a distributing position above the upper end of the plastering board 2 and an avoidance position below the upper end of the plastering board 2 .

[0159] Avoidance mechanism 4 is rotatably installed on the plastering frame 3, as figure 1 As shown, the distribution mechanism 1 is installed on the avoidance mechanism 4, and the avoidance mechanism 4 can drive the distribution mechanism 1 to move between the distribution position and the avoidance position.

Embodiment 2

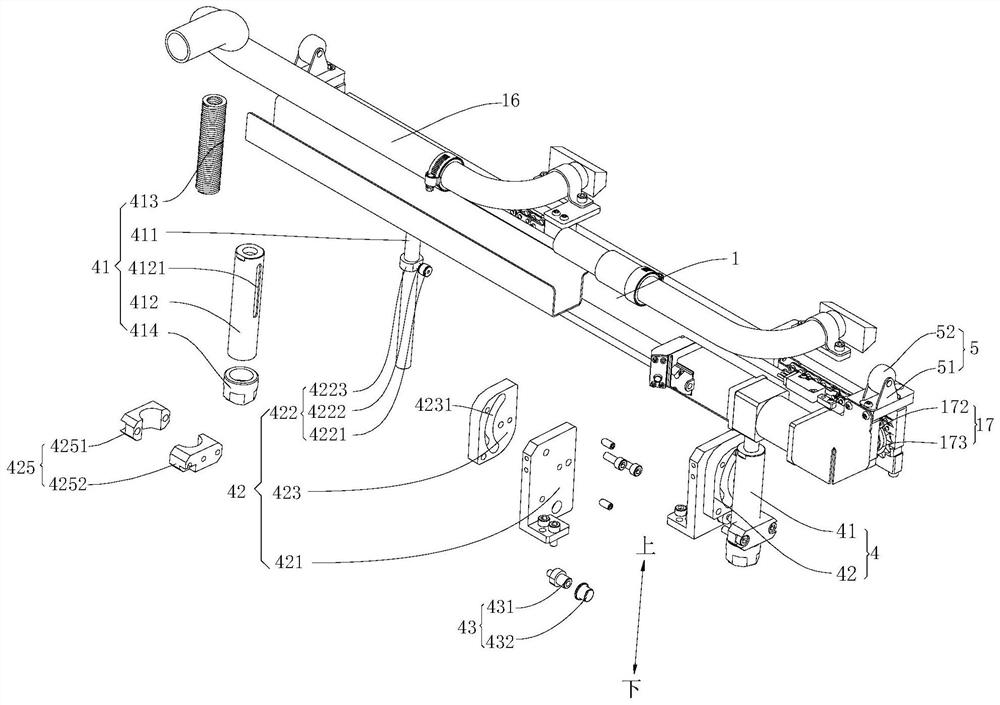

[0161] A kind of plastering device 100, different from Embodiment 1, on the basis of Embodiment 1, such as figure 1 , figure 2 and Figure 4 As shown, the avoidance mechanism 4 includes a swing rod assembly 41 , a guide assembly 42 and a drive assembly 5 .

[0162] Among them, such as figure 1 As shown, one end of the swing rod assembly 41 is rotationally connected with the plastering frame 3 through a rotating member 43, and the other end of the swing rod assembly 41 is fixedly connected with the cloth mechanism 1, as figure 2 As shown, the swing rod assembly 41 is provided with a sliding portion 422 .

[0163] The guide assembly 42 is installed on the plastering frame 3 , the guide assembly 42 is provided with an arc-shaped first guide groove 4231 , and the sliding part 422 can slide along the first guide groove 4231 .

[0164] The driving assembly 5 can drive the swing rod assembly 41 to move from the cloth position to the avoidance position.

[0165] Such as figur...

Embodiment 3

[0167] A kind of plastering device 100, different from Embodiment 2, on the basis of Embodiment 2, such as figure 2 As shown, the swing rod assembly 41 includes a sleeve 412 and a swing rod 411 .

[0168] Wherein, the bottom of sleeve 412 is rotatably connected with plastering frame 3 by rotating member 43, as figure 2 As shown, the outer peripheral wall of the sleeve 412 defines a second guide groove 4121 .

[0169] The swing rod 411 is slidably installed in the sleeve 412 , and one end of the swing rod 411 protrudes from the top of the sleeve 412 and is fixedly connected with the cloth mechanism 1 . Such as figure 2 As shown, the sliding part 422 is installed on the outer peripheral part of the swing rod 411, and extends out of the sleeve 412 from the second guide groove 4121. When the cloth mechanism 1 moves from the cloth position to the avoidance position, the distance between the sliding part 422 and the center of the rotating part 43 The distance gradually decreas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com