Indoor roof plastering device

A technology for plastering trays and bottom plates, which is applied in construction, building structure and other directions, can solve the problems of no plastering machine, increase the processing workload, etc., so as to reduce labor intensity, improve plastering efficiency, and reduce post-processing workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

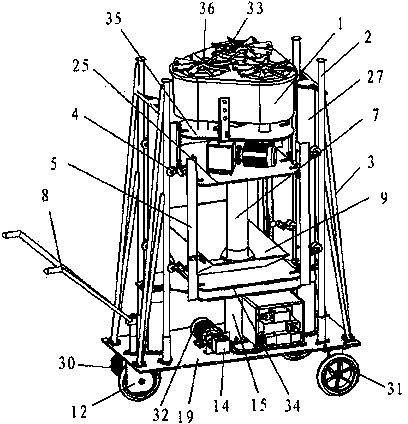

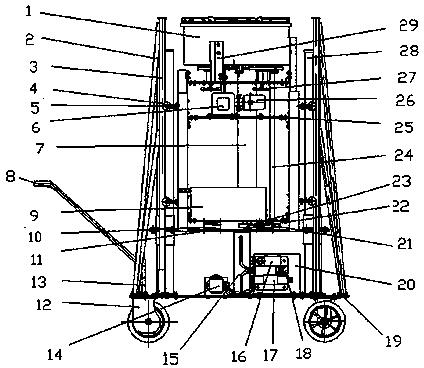

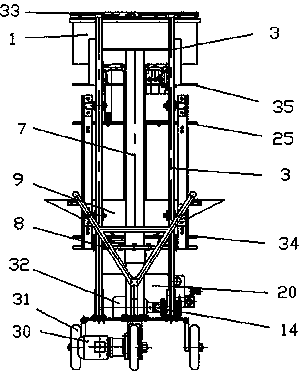

[0022] The overall structure of the present invention includes a plastering head part, a plastering thickness adjusting part, a feeding part, a transmission part, a hydraulic lifting part, a lifting frame part and a vehicle frame part. The plastering head part is located at the top of the device, the plastering thickness adjustment part is installed in the plastering head part, the feeding part is connected under the plastering head part, the transmission part is located under the plastering head part, and the transmission part is respectively connected with the plastering head part. The ash head part and the feeding part are connected, and the plastering head part, the feeding part and the transmission part are respectively installed on the bottom plate, and these bottom plates are connected to the lifting frame part, and the lifting frame part is connected with the hydraulic lifting part, and the hydraulic lifting part and the lifting frame part mounted on the frame part. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com