Patents

Literature

38results about How to "Reduce post-processing workload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

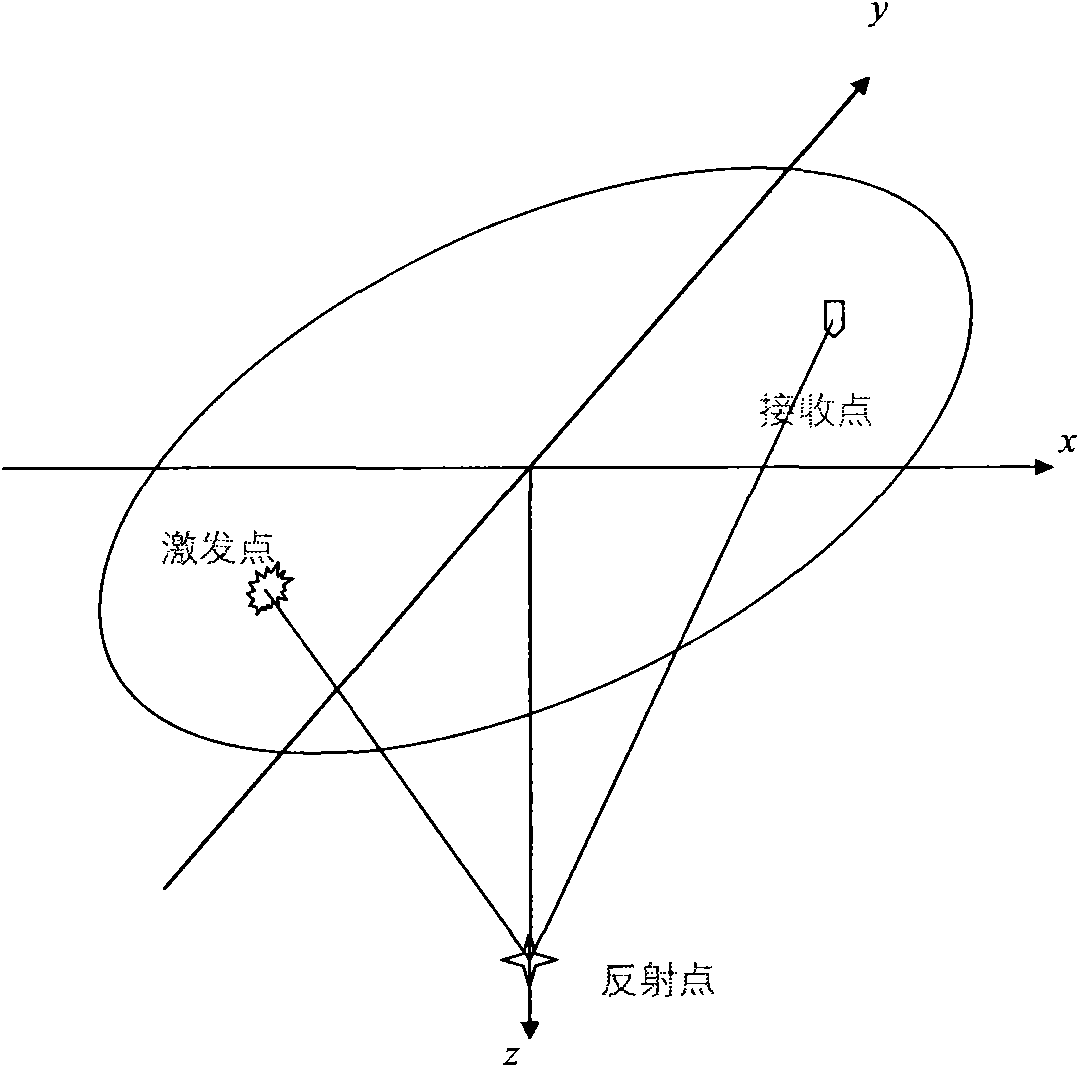

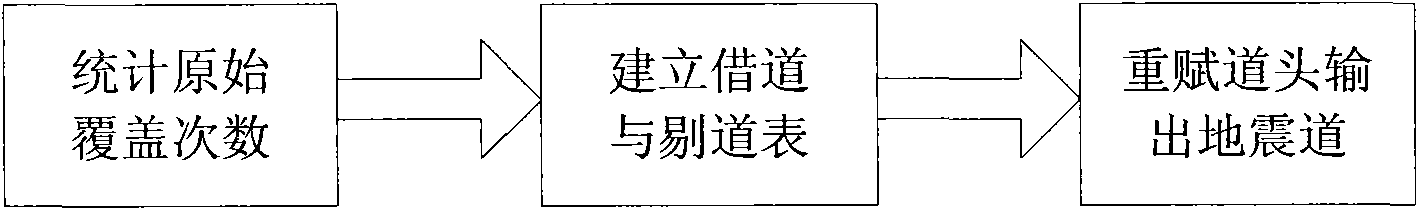

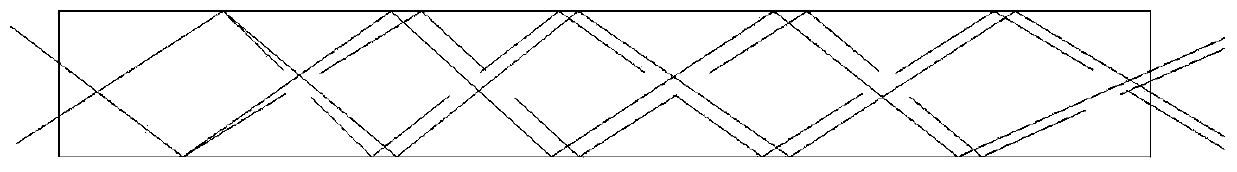

Method and device for realizing binning homogenization in three-dimensional seismic data processing

InactiveCN101614826ARemove the effect of offsetOffset averagingSeismic signal processingGeophoneWorkload

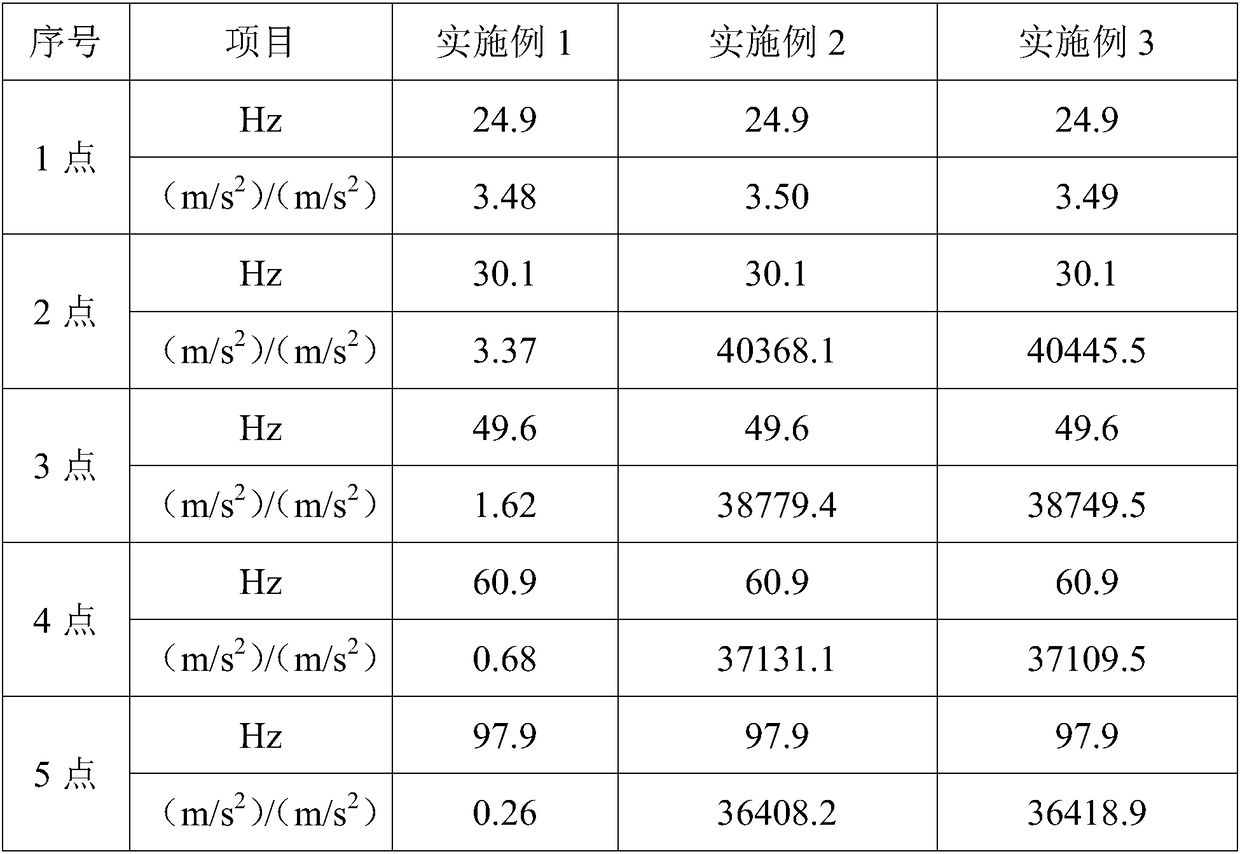

The invention discloses a method and a device for realizing binning homogenization in three-dimensional seismic data processing. The method comprises the following steps: acquiring a three-dimensional seismic data gather and dividing the data gather by using a certain geophone offset as an interval; executing DMO composition on a seismic trace in each interval to obtain DMO composition data volumes; carrying out interpolation trace filling processing of missed seismic traces on each DMO composition data volume so as to obtain corresponding trace filling processing data volumes; along a preset direction, carrying out DMO<-1> processing on each trace filling processing data volume; and forming the data volumes processed by the DMO<-1> into a new gather used for subsequent time offset processing before composition. The invention also discloses a method and a system of the time offset processing before composition of the three-dimensional seismic data. The invention eliminates the influences of the geophone offset, azimuth angles, binning sizes and seismic trace covering times, realizes the homogenization of the binning and guarantees the sufficient utilization of the data and the reduction of subsequent processing workloads.

Owner:王振华

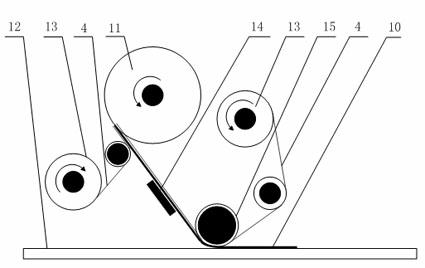

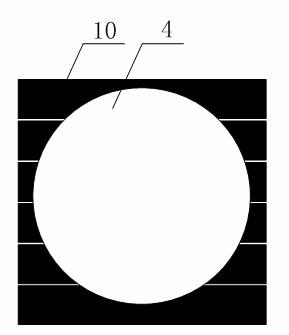

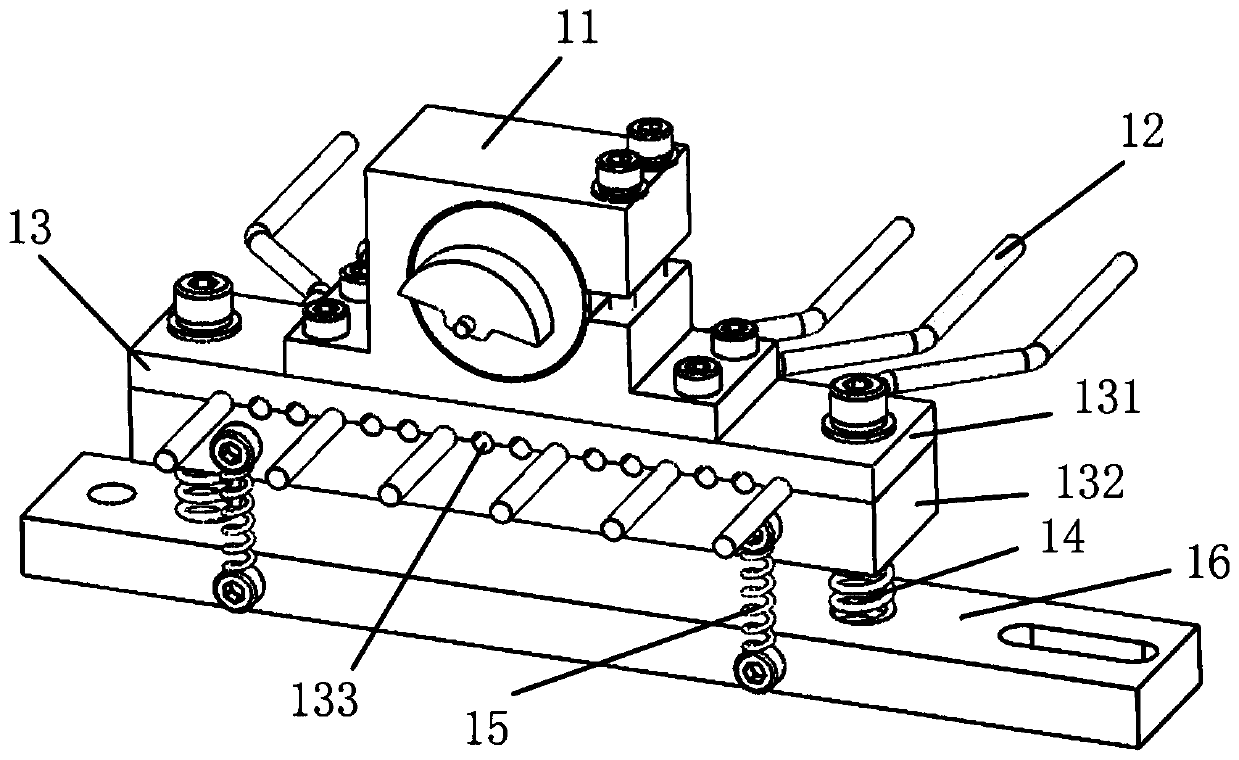

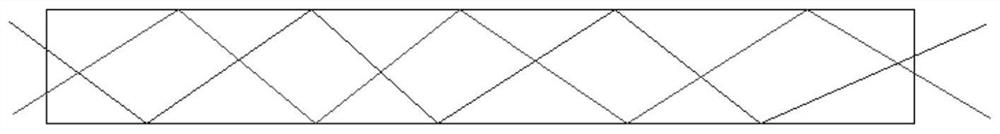

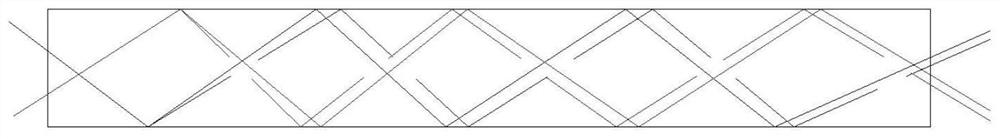

Automatic tape-laying forming method for composite material with hollowed-out structure

The invention relates to an automatic tape-laying forming method for a composite material with a hollowed-out structure, belonging to the field of laying and forming of composite materials. The invention is characterized by comprising the following processes: (1) designing the shape of a prepreg tape according to the shape and dimension of a product, the bandwidth of the prepreg tape and the direction of tape laying so as to further obtain a predetermined fold line path of a cutting knife; (2) precutting the prepreg tape, rolling up strip coils, wherein, the method of double layer back lining paper rolling or single layer back lining paper rolling can be employed to roll up the strip coils, and when one part of predetermined linear path of the predetermined fold line path is related to low-angle cutting, carrying out cutting by using the method of notching fold line cutting; (3) laying the cut prepreg tape on the surface of a die with the head of a laying tape so as to complete automatic tape-laying forming of the composite material with a hollowed-out structure. The invention enables basic functions of a tape-laying machine to be realized and fabrication difficulty of composite materials with a hollowed-out structure to be overcome.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

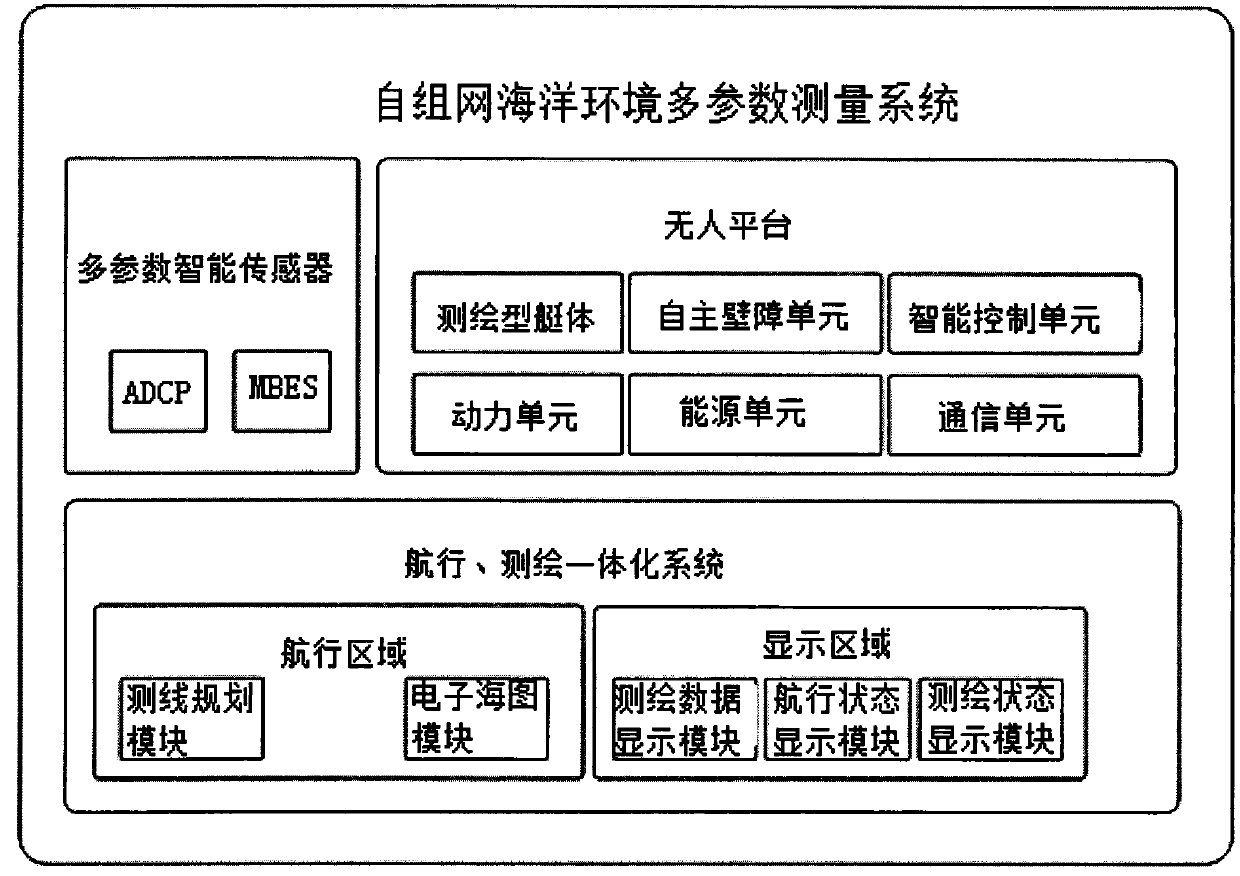

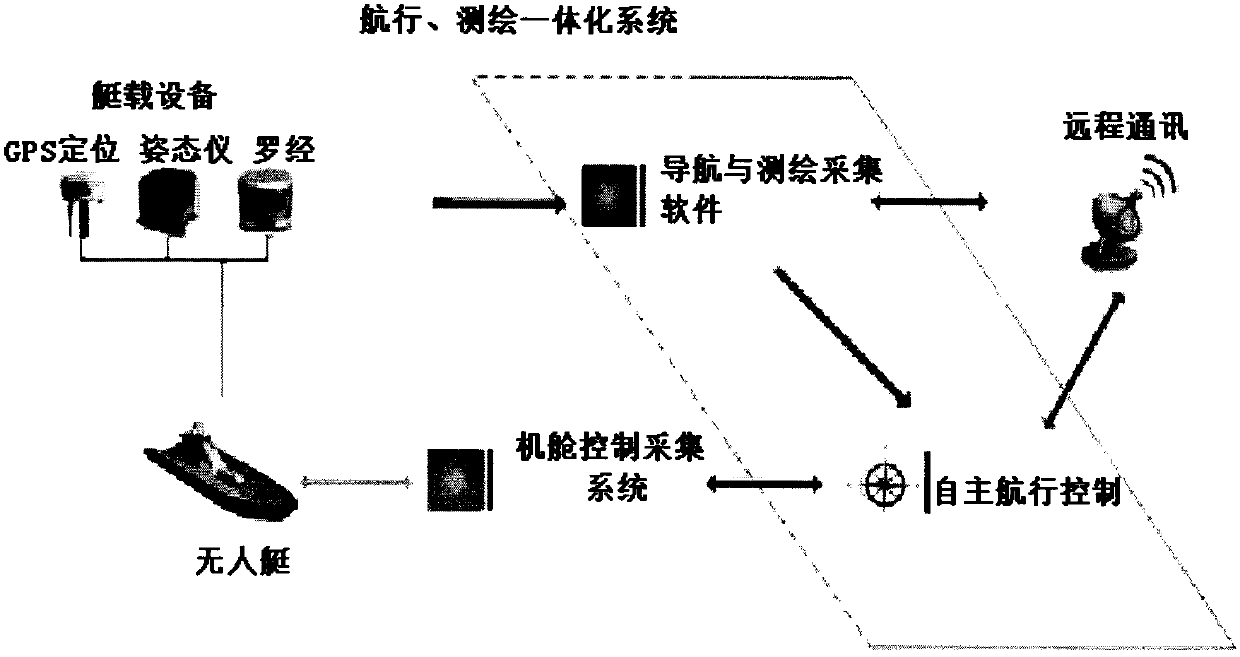

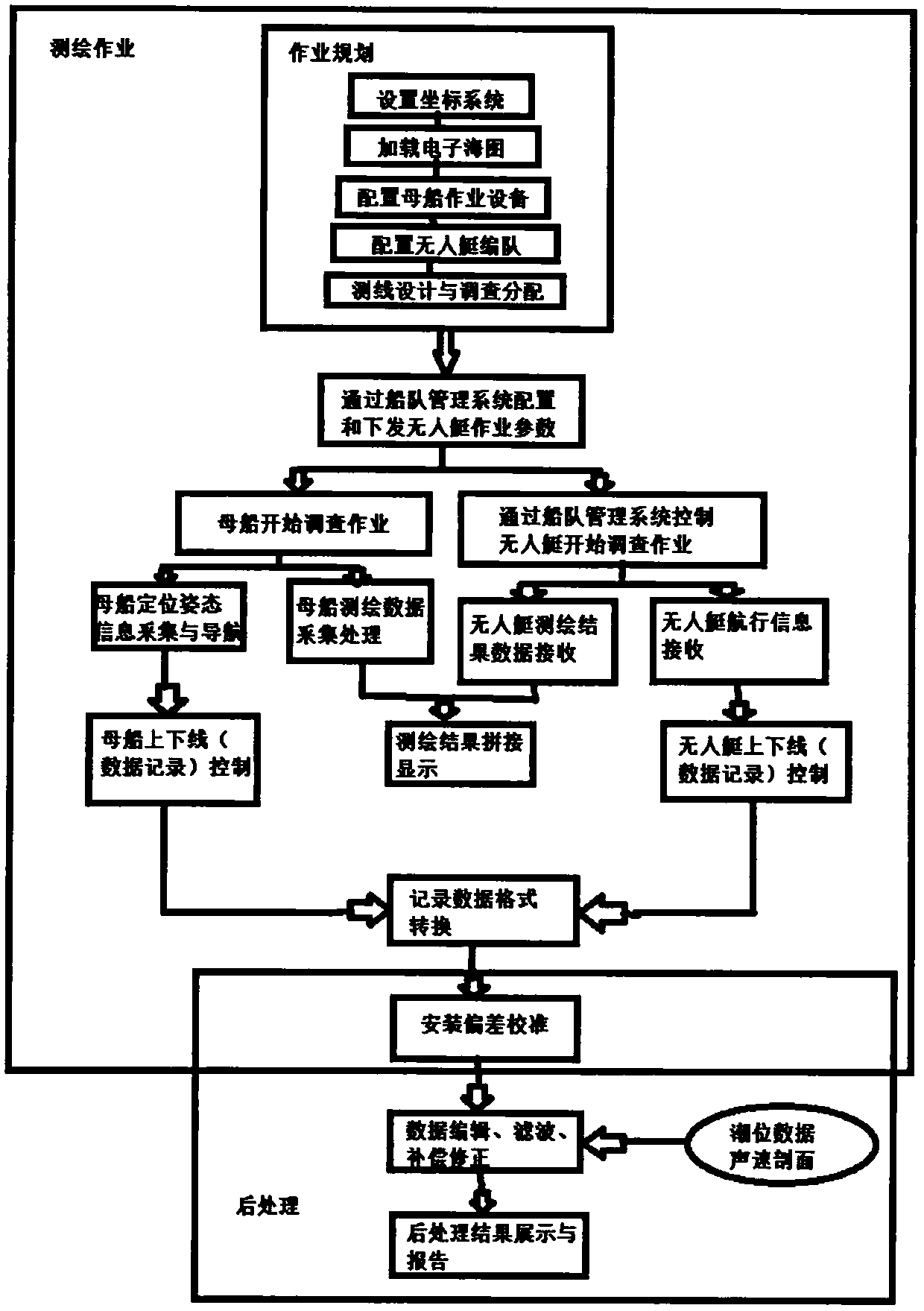

Ad-hoc network marine environment multi-parameter measurement method

InactiveCN110702162AImprove surveying and mapping efficiencyImprove measurement efficiencyMeasurement devicesDoppler velocityData acquisition

The invention provides an ad-hoc network marine environment multi-parameter measurement method. A plurality of unmanned platforms are used for carrying marine environment measurement sensors, and a navigation, surveying and mapping integrated system is used in cooperation to realize networking measurement. The navigation, surveying and mapping integrated system runs in a shore-based or mother shipoperation management center and controls and coordinates the plurality of measurement sensors to work. The measurement sensors comprise a multi-beam echo sounder and an acoustic Doppler velocity profiler, and provides marine environment data acquisition. The unmanned platform is formed by integrating a surveying and mapping type hull, an autonomous obstacle avoidance unit and an intelligent control unit, and is used as a mobile platform for measuring networking measurement of the measurement sensors. The navigation and surveying and mapping integrated system is formed by integrating a collaborative management software module, a surveying and mapping operation module and a multi-source multi-platform surveying and mapping data real-time splicing module, and networking operation and data post-processing are realized. The networking measurement method has the characteristics of high measurement efficiency, high platform and sensor compatibility and the high multi-instrument networking observation and multi-source data fusion level.

Owner:北京方位智能系统技术有限公司

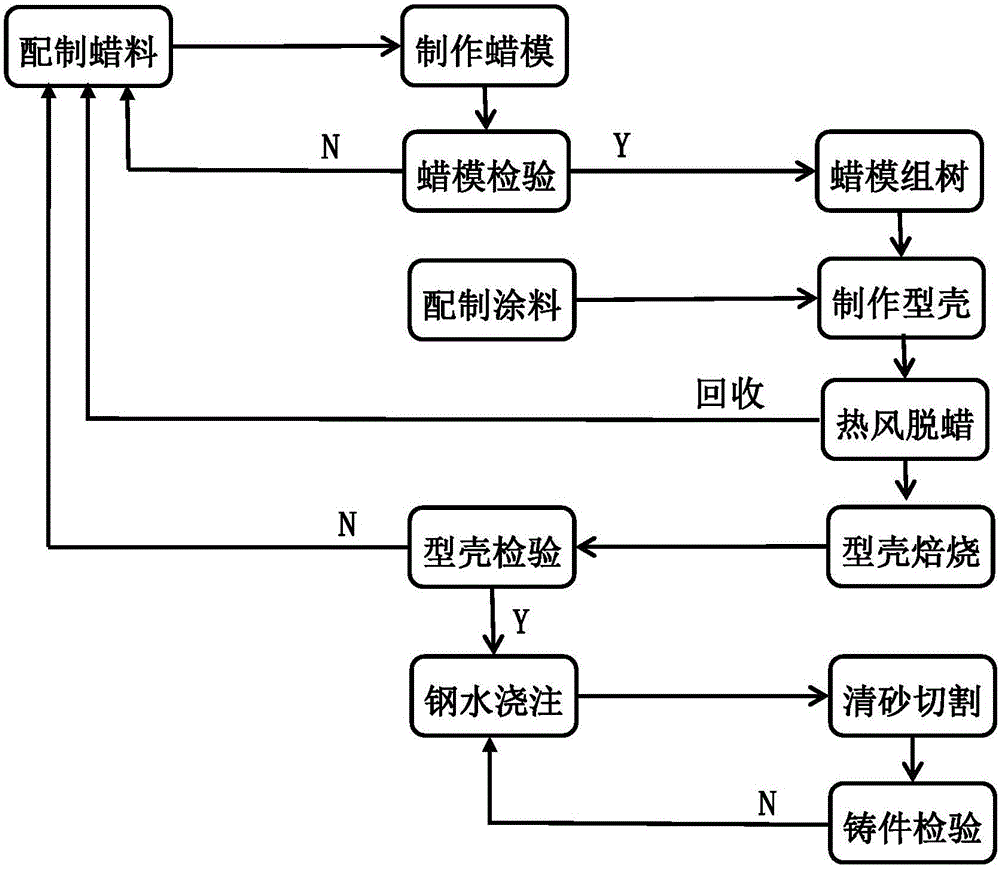

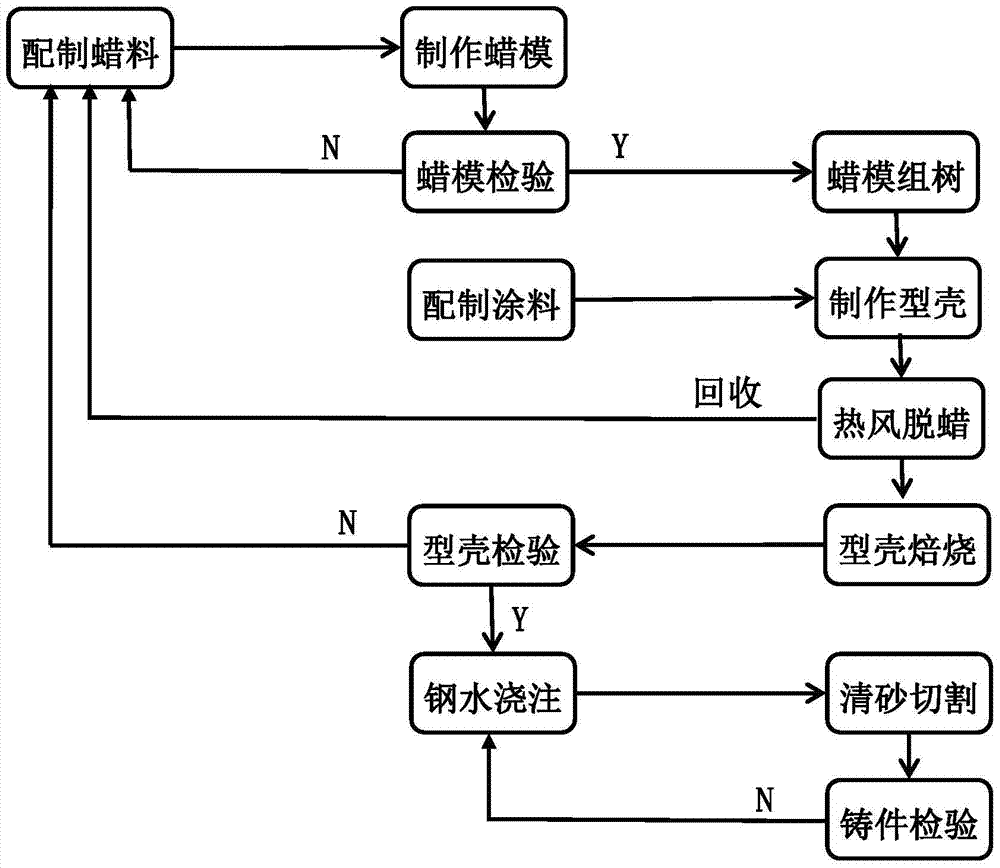

Waterglass-process precise casting process

The invention relates to precise casting processes and independently designs a waterglass-process precise casting process with carbon dioxide hardening and high temperature sand strip in order to solve the problem that defects are prone to occur in chemical method hardening sand-strip processes and low-mould waterglass-process casting. The process includes wax preparation, wax mould making, wax mould checking, wax mould group tree, coating preparation, shell making, hot air dewaxing, shell calcination, shell checking, liquid steel pouring, cleaning cutting and castings examination. By means of the waterglass-process precise casting process, device corrosion, environment pollution and worker personal safety potential hazards which are present in traditional chemical method hardening sand strip processes can be solved, meanwhile, qualities of castings surfaces and interior formation can be greatly improved, the finished product rate of castings is increased, the workload of post-treatment is lowered, working environment of a shell making workshop can be improved, production cost is lowered, and large part production capacity of traditional waterglass shells is greatly increased.

Owner:浙江福瑞科流控机械有限公司

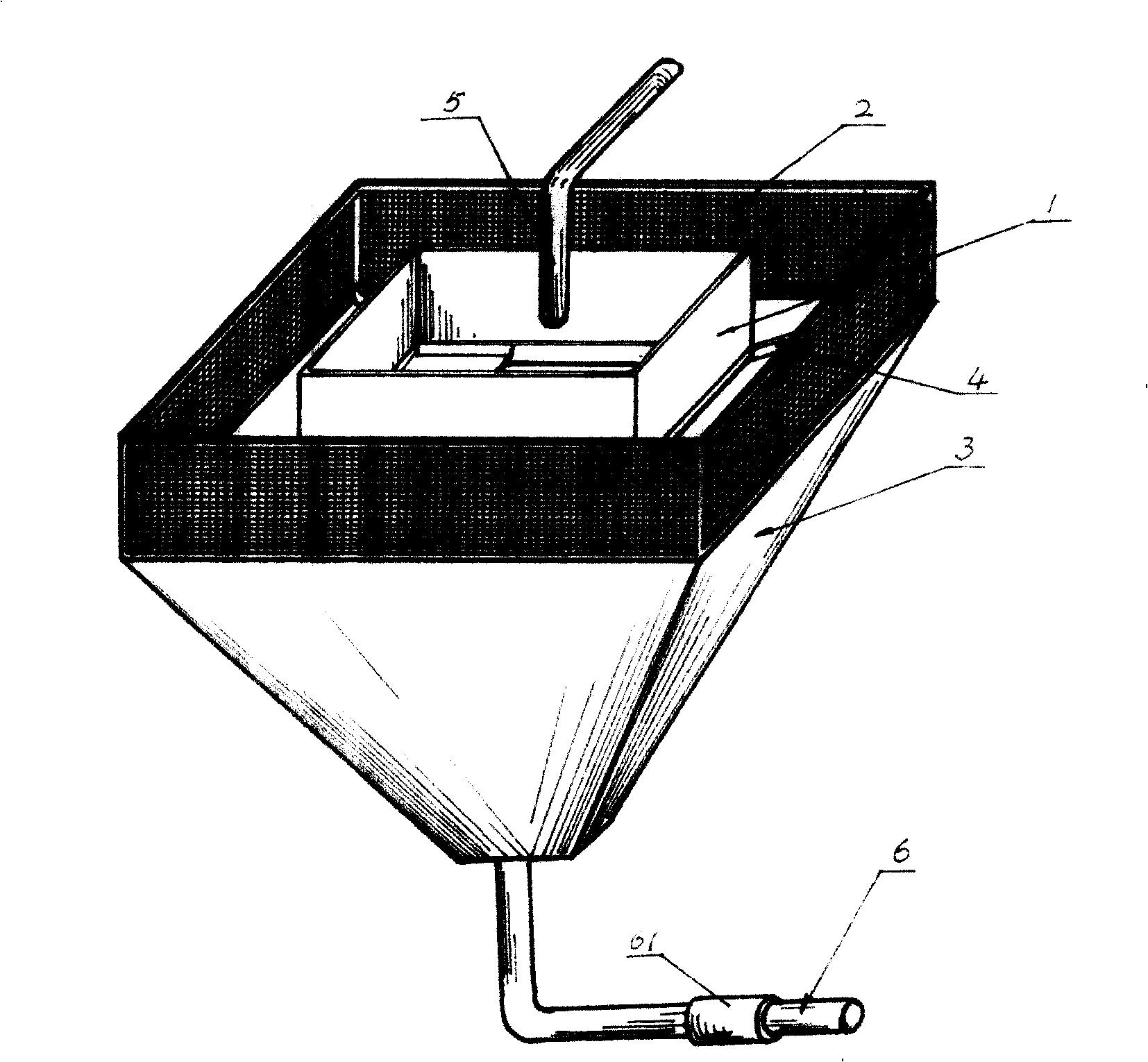

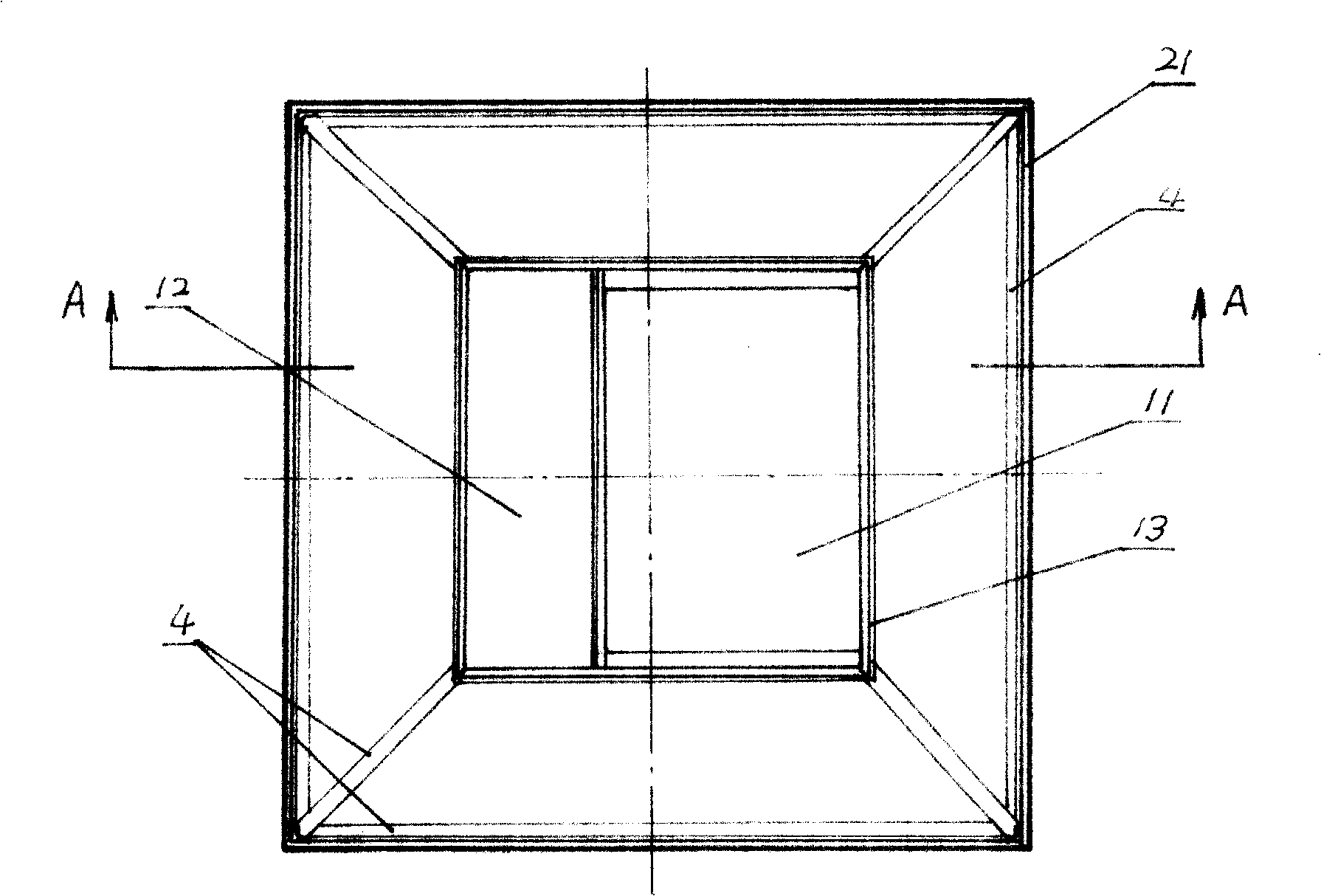

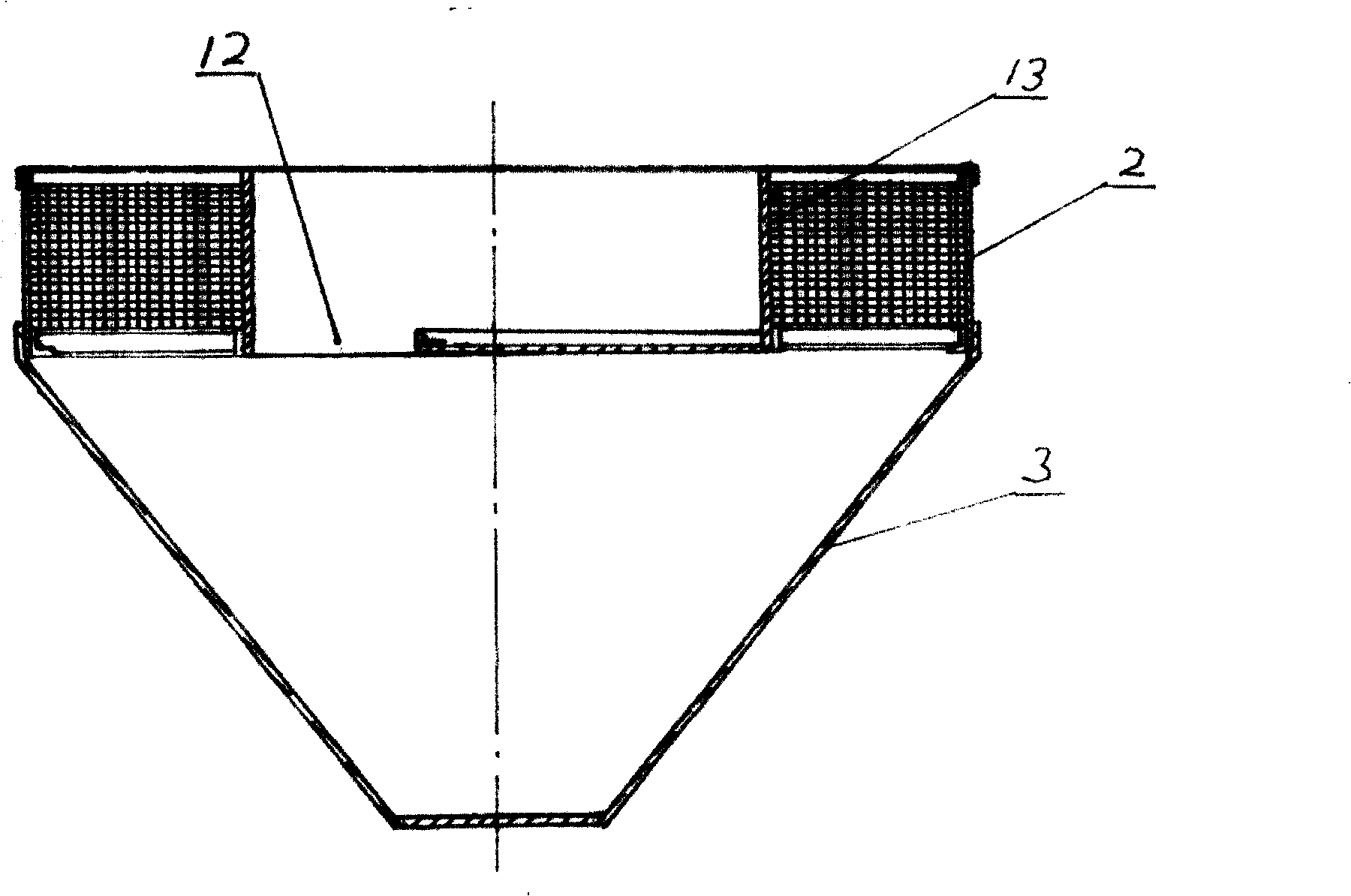

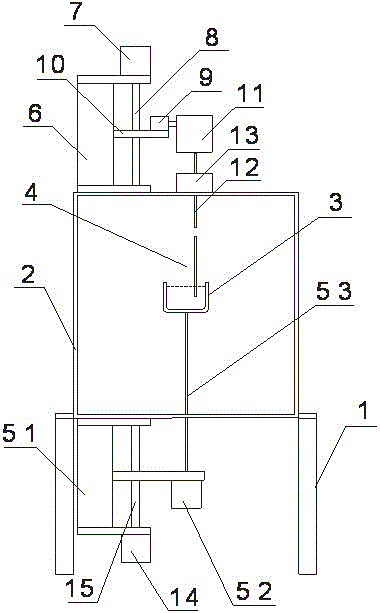

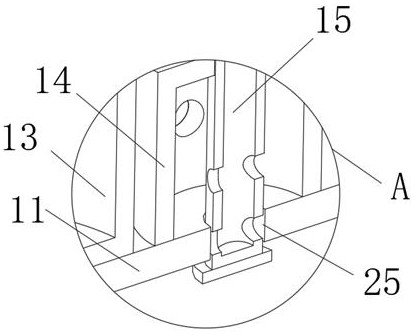

Sewage preprocessing multifunctional solid-liquid separator

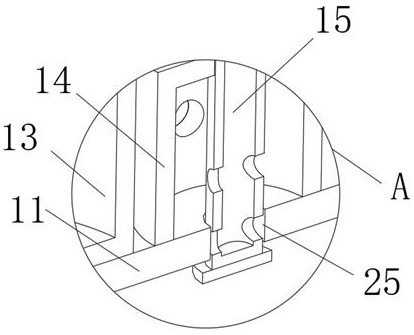

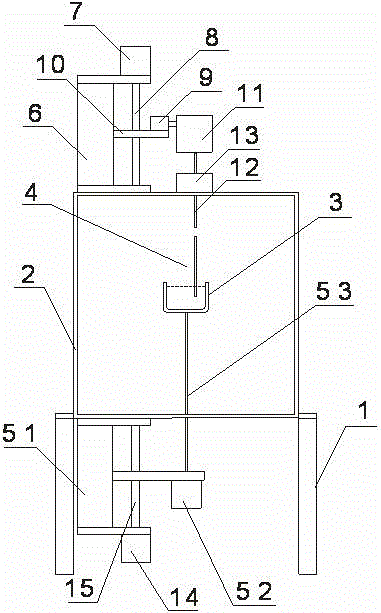

InactiveCN101259344ASimple processEasy to cleanFatty/oily/floating substances removal devicesFiltration circuitsSludgeEngineering

A multi-functional solid-liquid separator for sewage pretreatment is mainly composed of a slowing box (1), an interception net (2), a sewage holding bucket (3), a frame construction (4), an inlet pipe (5) and a sludge pipe (6), wherein, the slowing box (1) is arranged inside the interception net (2), and the sewage holding bucket (3) is arranged under the slowing box and the sewage holding bucket. The top of the slowing box (1) is not sealed, a part of the box bottom (11) is cut off by a sealing bottom (14) and the sewage holing bucket (3) and the rest part is provided with a flushing orifice (12) which is communicated with the sewage holding bucket (3). The slowing box (1) can cause the income water to form fluid with non-continuity and certain splashing flow speed and fluid with gentle drop, the interaction of which can separate the light hair and comparatively heavy solid from the sewage, which are finally discharged from the sewage holding bucket. The separator has advantages of simple structure, high efficiency, low cost and convenience for maintenance.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

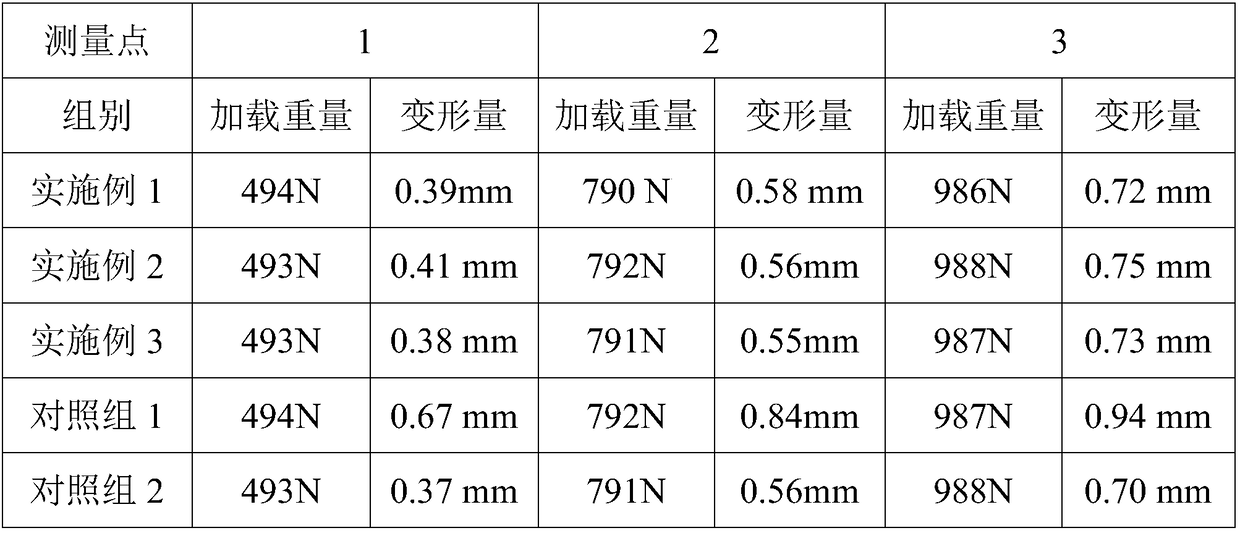

Heat treatment method of wear-resistant cast iron

InactiveCN107641693AImprove mechanical propertiesReduce post-processing workloadWear resistantHardness

The invention discloses a heat treatment method of wear-resistant cast iron. The wear-resistant cast iron is prepared from the following components in percentage by weight: 2.9 to 3.1 percent of C, 6to 8 percent of Cr, 3.0 to 4.0 percent of Mn, 0.6 to 0.8 percent of Ni, 0.5 to 1.0 percent of Si, less than or equal to 0.05 percent of P, less than or equal to 0.03 percent of S and the balance of Fe. The heat treatment method comprises the following steps: putting a wear-resistant casting into a heat treatment furnace at a temperature of below 200 DEG C; heating to 360 to 400 DEG C; preserving heat for 8 hours; heating to 900 to 940 DEG C; preserving heat for 20 to 24 hours, and performing furnace cooling to 650 to 680 DEG C; preserving heat for 8 to 10 hours; performing furnace cooling to 500 DEG C, discharging and performing air cooling to obtain a cast iron part. By adopting the heat treatment method, high toughness is achieved while high hardness is ensured, and the process is simpleand stable.

Owner:湖州正德轻工机械有限公司

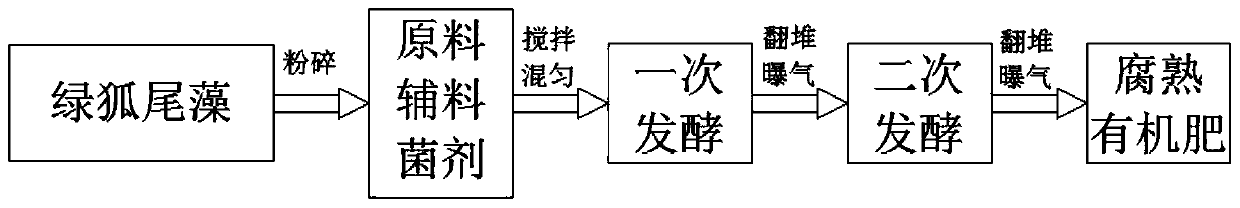

Method for composting cow dung by using myriophyllum elatinoides gaudich

PendingCN110668861AReduce post-processing workloadReduce workloadBio-organic fraction processingExcrement fertilisersMyriophyllumMicrobial agent

The invention relates to the technical field of fertilizer processing, and discloses a method for composting cow dung by using myriophyllum elatinoides gaudich. The cow dung is prepared according to the following steps that S1, compost raw materials required for composting are weighed; S2, preparation of complex microbial agents is performed; and S3, mixing and composting are performed. The linkssuch as mechanical dehydration or natural dehydration of traditional aquatic plant compost are eliminated, the workload and site are reduced, meanwhile, the resource utilization of aquatic plants is realized, so that the harvested aquatic plants can be used as compost raw materials, the workload and the economy cost of subsequent processing of the aquatic plants are reduced, and secondary pollution is avoided; and the raw materials used for composting are agricultural production waste, and waste recycling is realized. The prepared organic fertilizer has good fertilizer effect, the organic matter content (dry weight) reaches 45% or above, the total primary nutrient (dry weight) reaches 5% or above, and the moisture (fresh weight) is 30% or less. The killing rate of alien species of ova of roundworm and escherichia coli is 95% or above, the content of heavy metals (based on drying basis) is lower than the limit standard, and the national standard for organic fertilizers (NY525-2012) canbe met.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

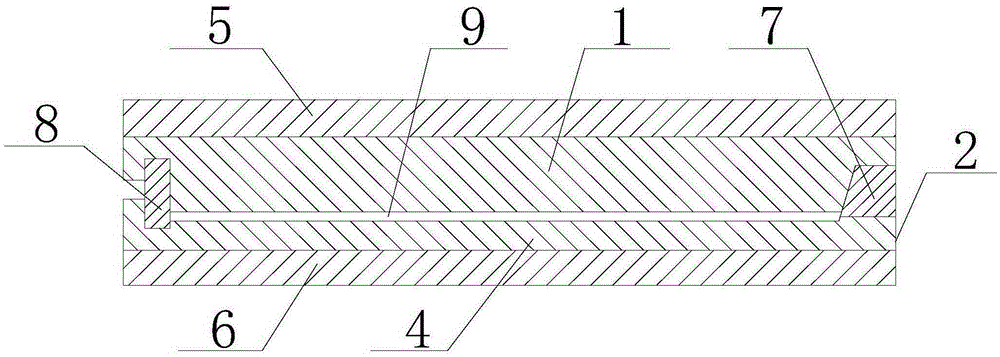

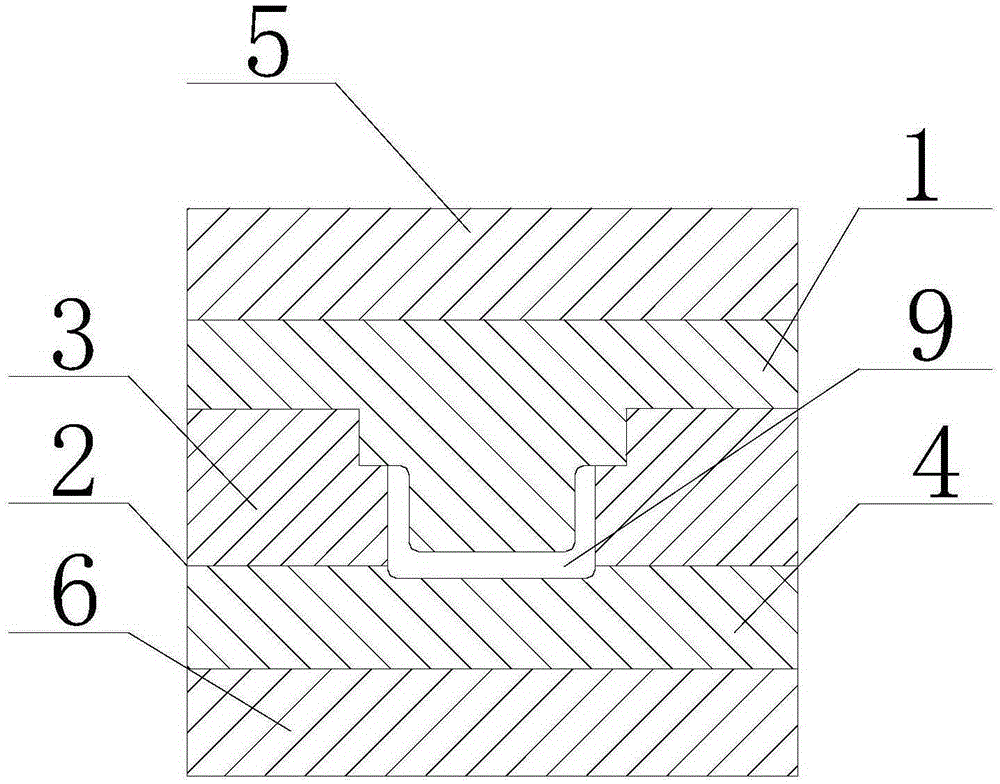

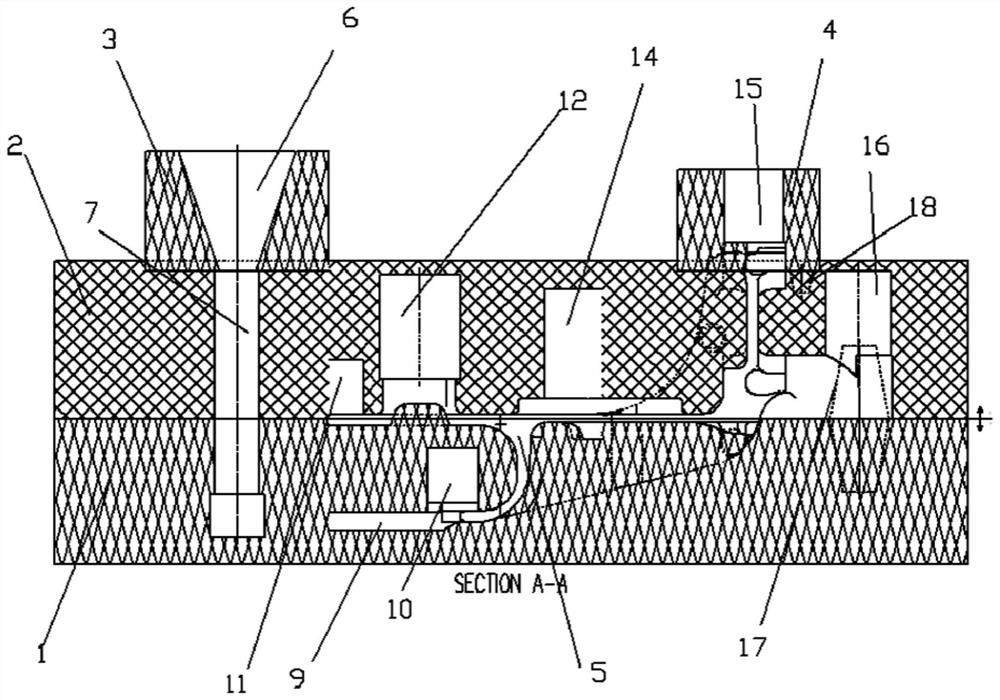

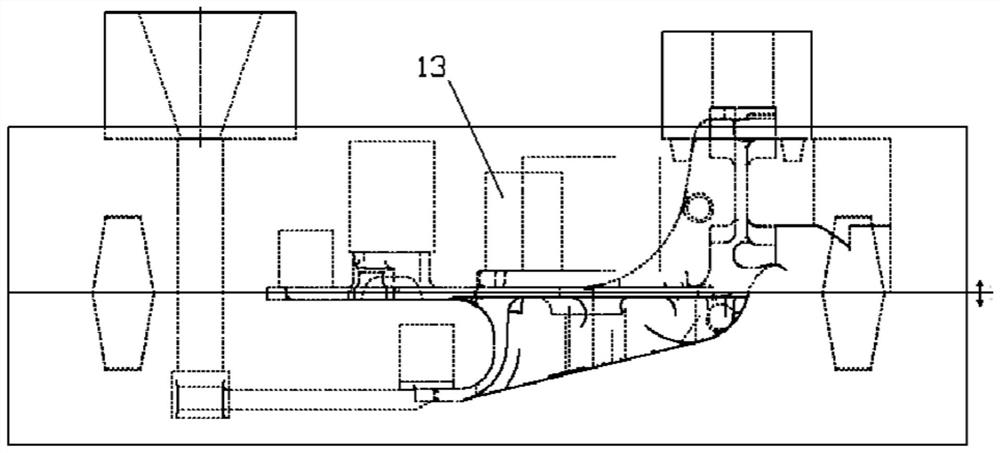

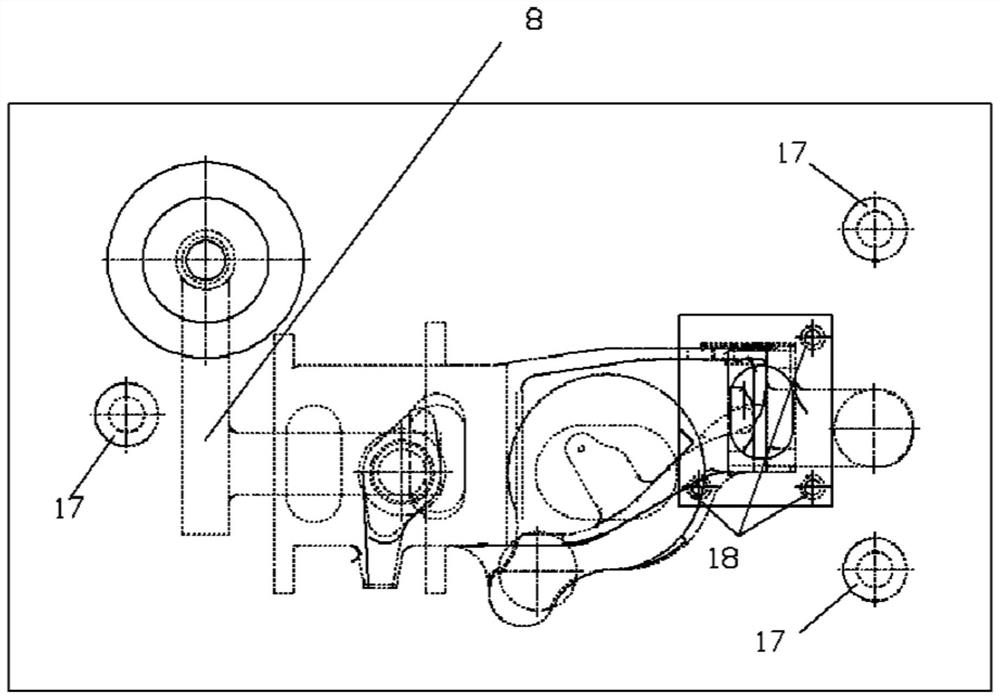

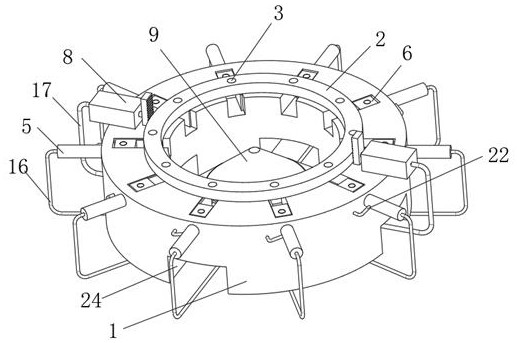

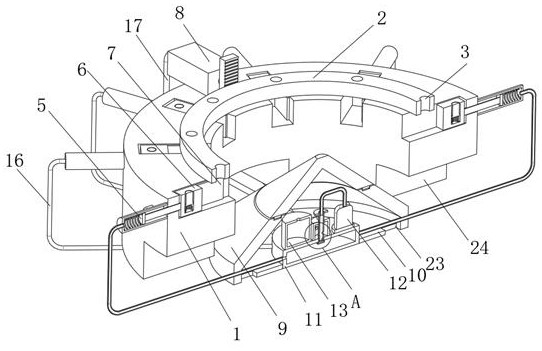

Hot pressing die without ejection rod traces on surfaces of products

InactiveCN105313312AOvercome demoulding resistanceGuarantee the appearance qualityEngineeringMechanical engineering

The invention discloses a hot pressing die without ejection rod traces on surfaces of products. The hot pressing die comprises a convex die and a concave die and is characterized in that the convex die and the concave die are spliced up and down together through clearance fit; a sealed die cavity is formed between the convex die and the concave die; the concave die adopts a combined structure and comprises side die plate and a bottom die plate; the side die plates are arranged on two sides of the top surface of the bottom die plate and are combined to form a groove; the bottom of the convex die is inserted into the groove to form a sealed die cavity; the convex die is mounted on an upper fixing plate; the bottom die plate is mounted on a lower fixing plate. The hot pressing die without ejection rod traces on surfaces of products adopts a combined die; the die can be removed without an ejection mechanism; the high size accuracy of products can be ensured; the die structure is simplified; the manufacturing difficulty and the manufacturing cost of the die are reduced; the surfaces of the products are free of ejection traces; the later treatment workload is effectively reduced; the attractive appearance and the market competitiveness of the products can be ensured.

Owner:SICHUAN D&F ELECTRICAL TECH

Segmented casting method for special-shaped steel casting of subway bogie

The invention relates to a segmented casting method for a special-shaped steel casting of a subway bogie. The method comprises the following steps that the middle portion of an upper rib plate of the casting is parted up and down, and an upper mold is parted in a segmented manner around a circular boss center; a pouring system enters a cavity from the center of a lower rib plate through an ingate; risers are arranged on a machining surface at equal positions; a lower outer mold sand mold, an upper outer mold sand mold, a pouring gate sand supplementing sand core and a segmented sand supplementing sand core are manufactured by using water glass ester hardened sand; after the sand molds are closed, furnace burden is smelted into pouring molten liquid, the casting is poured, and the molten liquid comes in from the pouring system; and cooling is conducted, a box is opened for shakeout, and a casting head is cut to form a casting blank. The casting process of rib plate parallel parting is adopted, it is guaranteed that the internal quality of the whole casting is compact, the product stability is improved, the risers are arranged on the machining surface, the post-treatment workload is greatly reduced, and the working efficiency is improved; and the segmented casting process is adopted, an isolated portion of the upper mold of the casting is formed through the sand supplementing sand core, the overall height of an upper mold outer mold is reduced, the molding sand consumption is reduced, and meanwhile the production efficiency is improved.

Owner:LEADRUN MAODA CASTING JIANGSU

A method for preparing carbon fiber composite automotive parts

ActiveCN106808715BExcellent mechanical propertiesImprove liquidityCoatingsModified carbonTransfer molding

The invention discloses a preparation method for carbon fiber composite automobile parts. The preparation method comprises the following steps of (1) preparing carbon fibers from polyacrylonitrile precursors, processing the carbon fibers by an anodic oxidation method, preparing the carbon fibers into carbon fiber bundles, and then preparing a carbon fiber textile; (2) performing surface modification on the prepared carbon fiber textile by a modified sizing agent made from mono-wall CNTs, PPEK, a modified system and a sizing agent; (3) preparing a Steel / CFRP multicoat through overlapping a modified carbon fiber reinforcement composite and a steel plate; (4) forming the prepared Steel / CFRP multicoat by an RTM mold through a vacuum resin transfer molding forming technology; and (5) demouding the formed Steel / CFRP multicoat to obtain the carbon fiber composite automobile part products. The preparation method disclosed by the invention is low in preparation cost, superior in performance, economic and environmental-friendly, good in stability, easy and simple to operate, and low in preparation difficulty, can meet requirements of batch automatic production, provides reliable technical support of the of carbon fiber components for scaled application in the field of automobile production, and has wide application prospects.

Owner:广东宇豪新材料科技有限公司

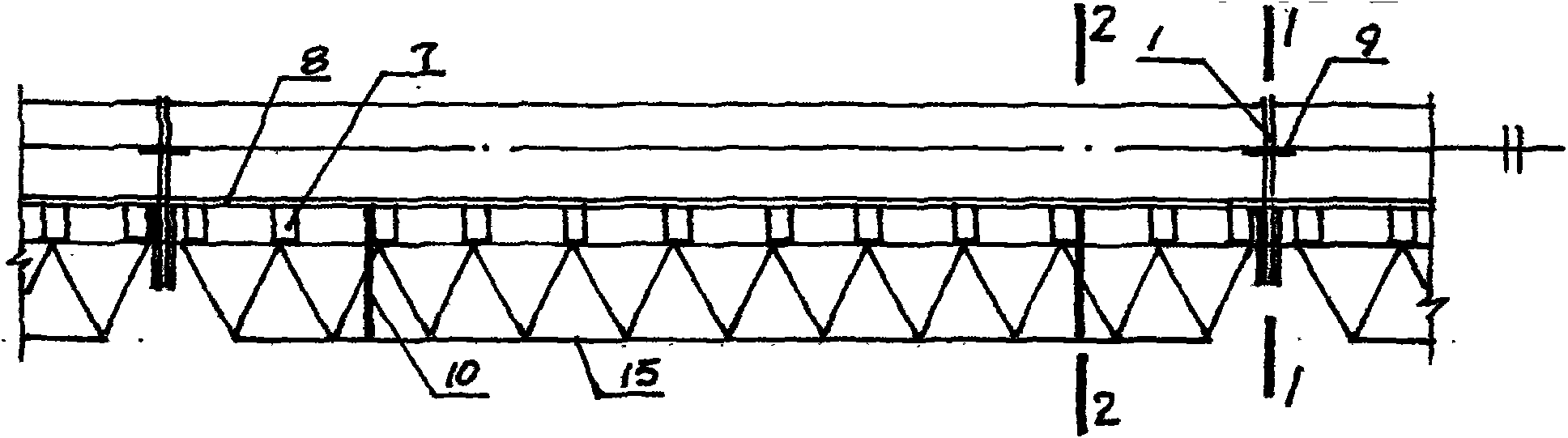

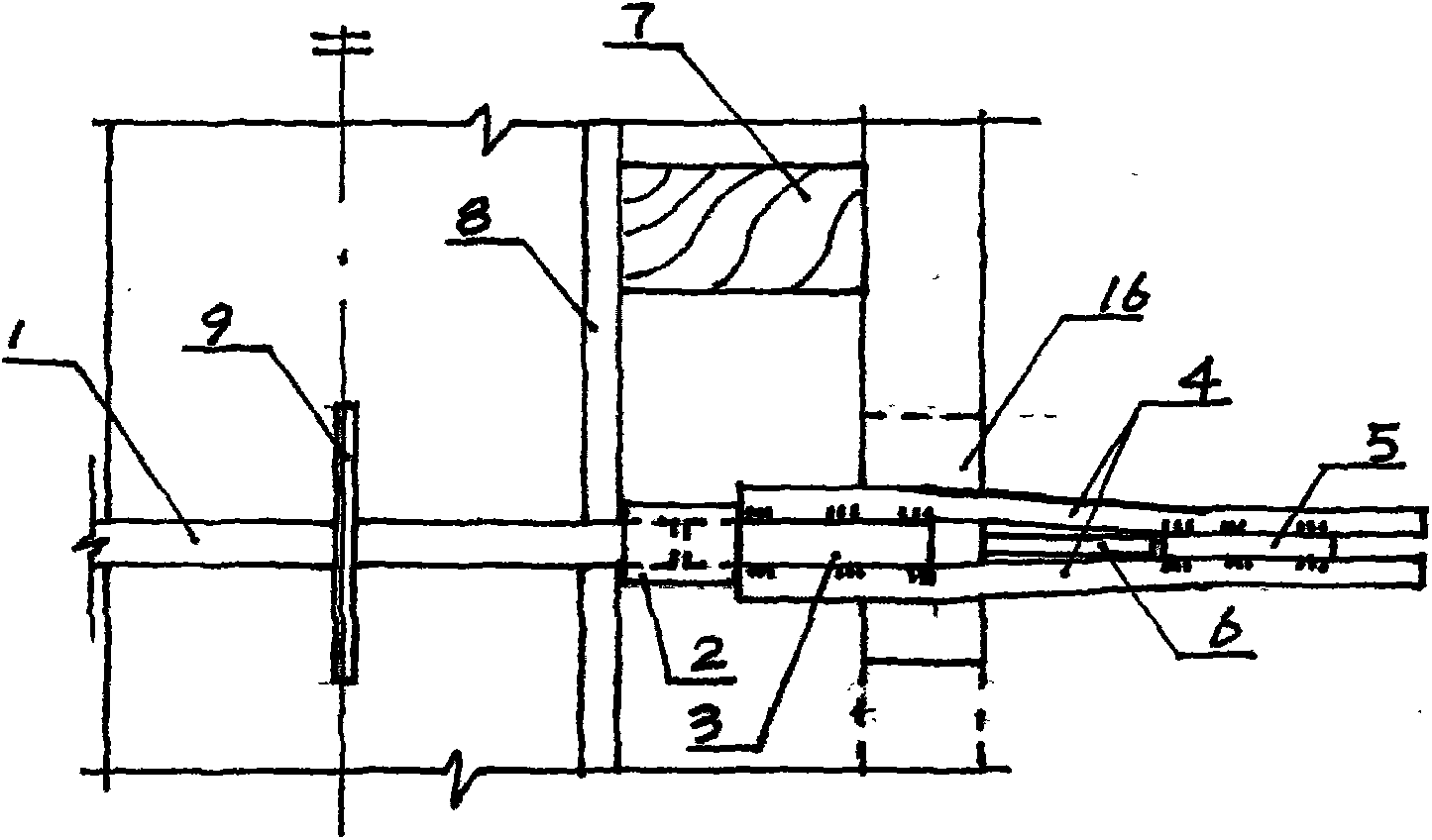

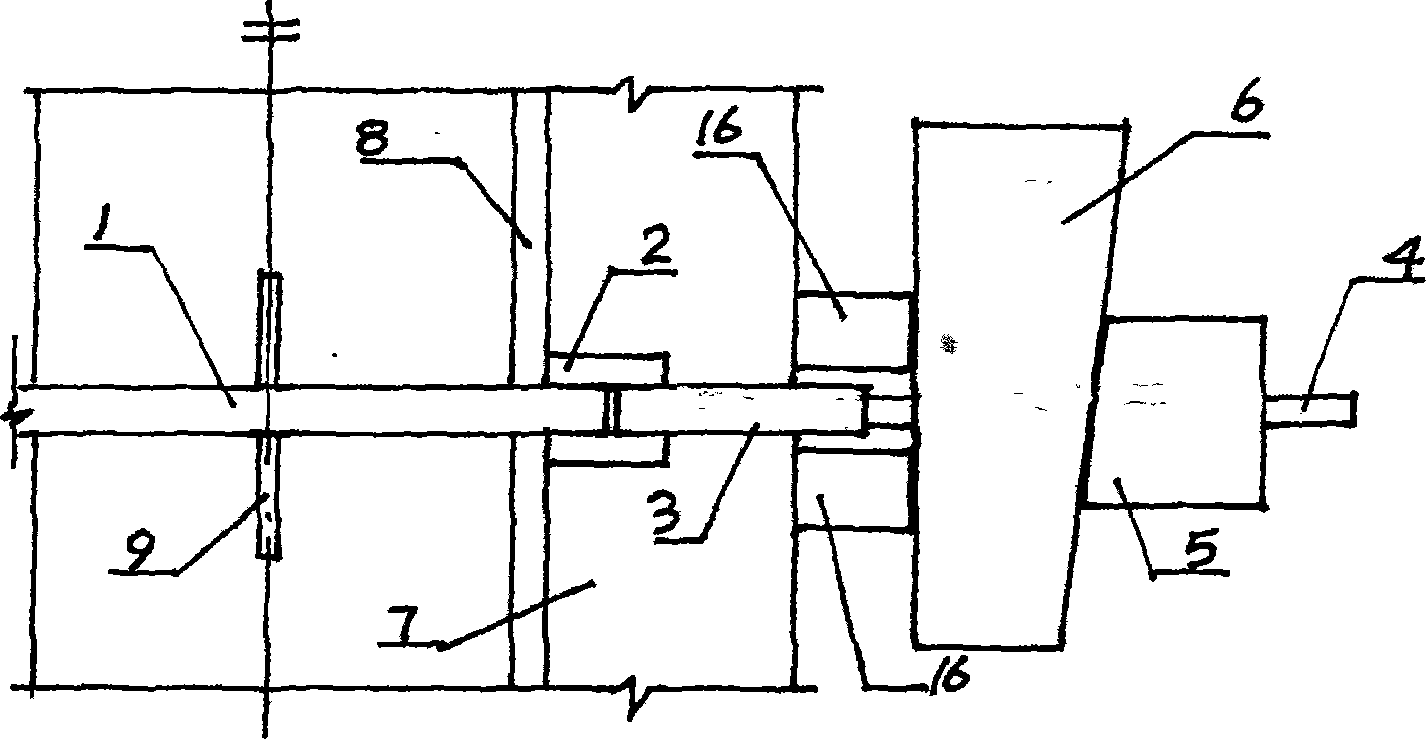

Attached truss type concrete wall form support

InactiveCN103397777AAchieve lateral stabilitySimple structureAuxillary members of forms/shuttering/falseworksEngineeringStructural engineering

An attached truss type concrete wall form support relates to concrete wall form engineering, solves the problem of material and working hour waste as the conventional truss type support is small in rigidity and requires many through-wall pull rods, and includes two trusses, four truss support rods and two sets of external connection tool type through-wall pull rods, wherein truss stabilizing rods, back ridges and the truss are respectively and mutually connected to form a truss plane external stabilizing system, and the truss and the wall form are fastened through the external connection tool type through-wall pull rods, tool type external connection joints can be used in a turnover manner. According to the invention, a truss plane external support member is simplified, the support rigidity is enhanced, the through-wall pull rods are reduced, and the wall form support is applied to larger concrete wall bodies; in addition, the support rigidity is high, the members can be simplified and the through-wall pull rods are few, so that the support efficiency and the working quality are improved, material and operation labor hour are saved.

Owner:胡彦彬

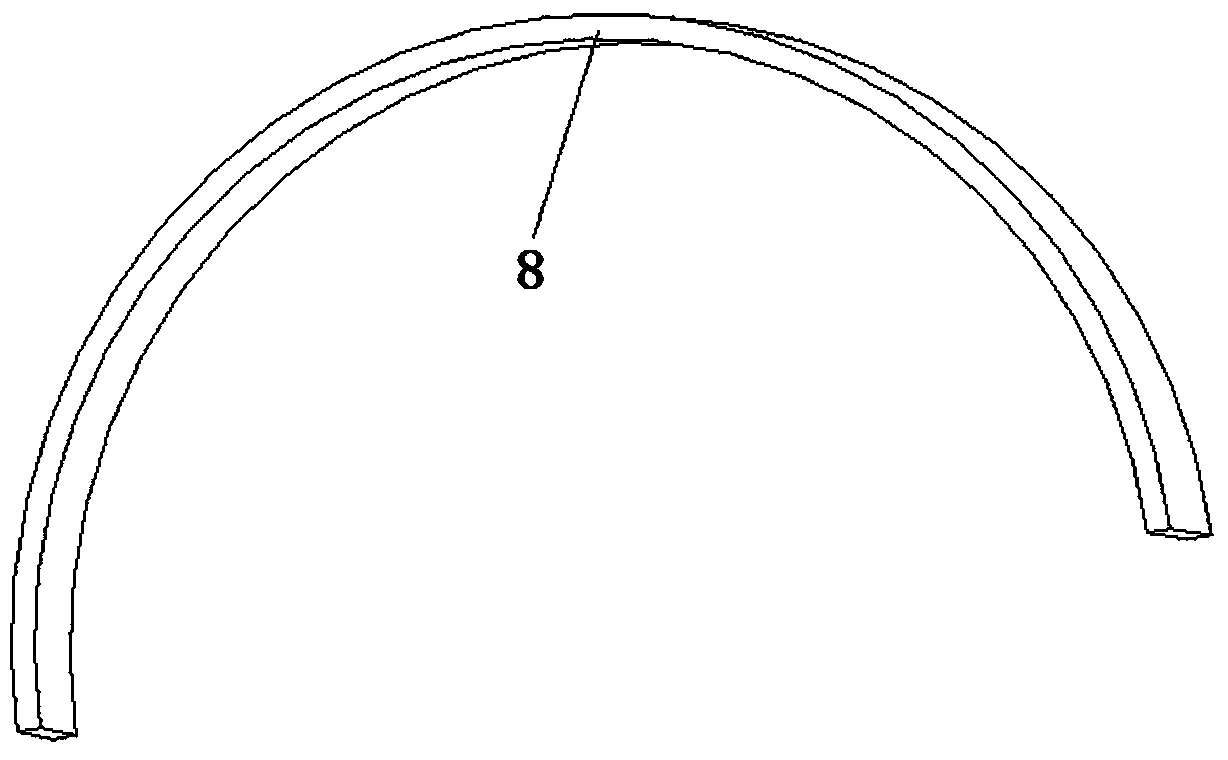

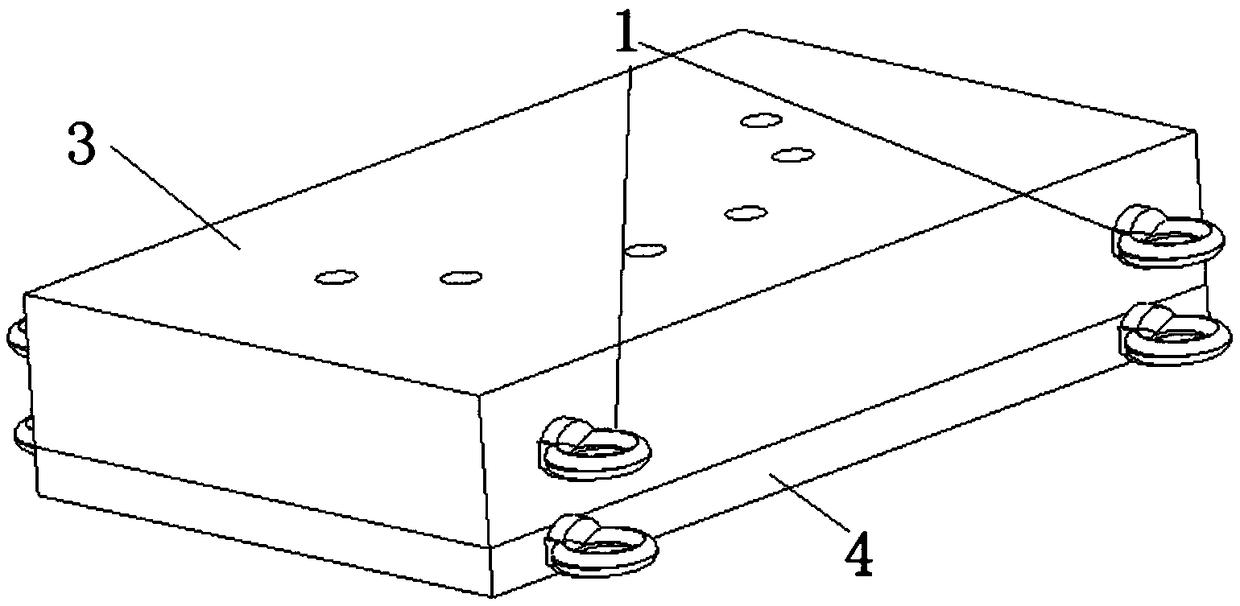

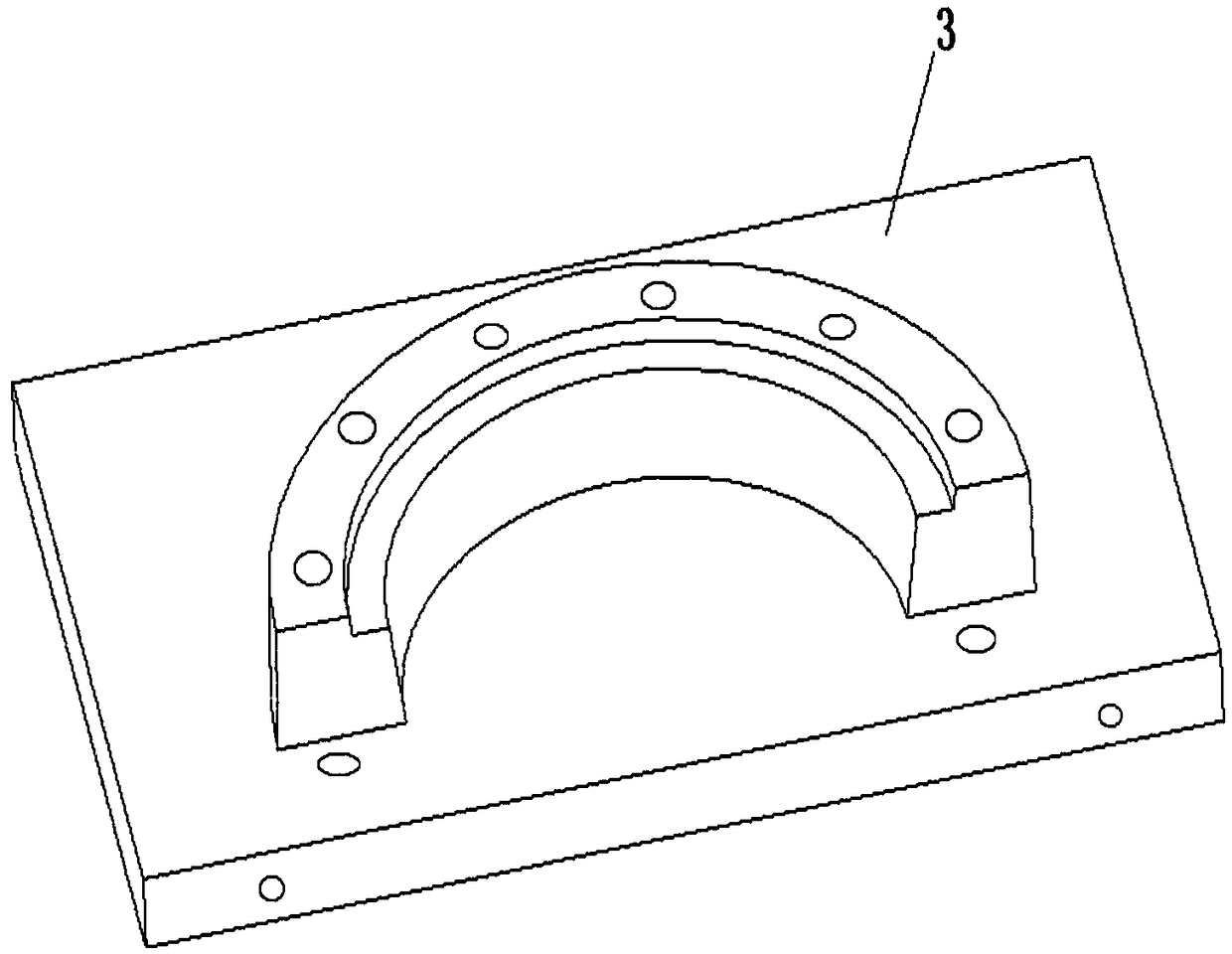

Forming mold and method of large-curvature open thin-walled structure composite

PendingCN108748830AAchieving Lightweight SimplificationReduce post-processing workloadMaterials scienceThin walled

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP

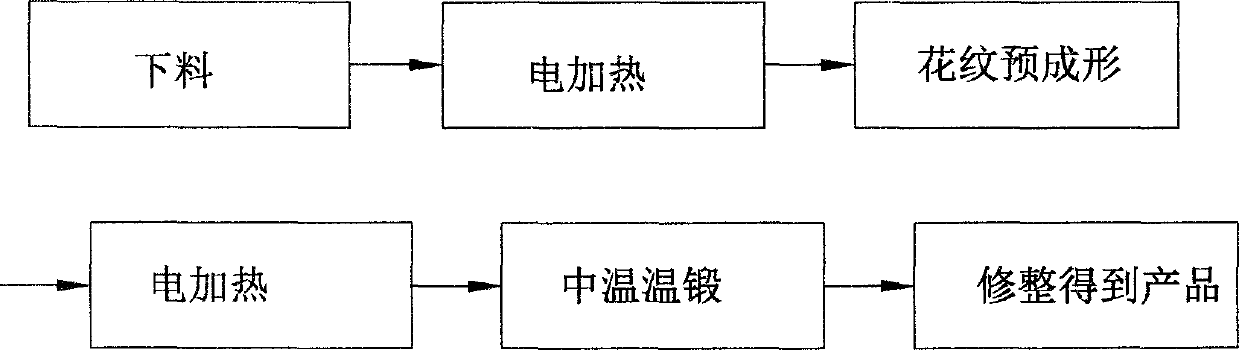

Forging forming process for iron ornamental part product

The invention relates to a forging forming process for an iron ornamental part product. According to the process, low-temperature warm forging pattern preforming is adopted to replace cold forging pattern preforming; moderate-temperature warm forging forming is adopted to replace traditional high-temperature forging forming; electrical heating is adopted to replace fire coal heating; and process flows and the preparation of a mold are reasonably standardized. Compared with the common traditional high-temperature heating forging, by adopting the warm forging forming technology, the surface quality and the heating efficacy of the iron ornamental part product can be remarkably improved, the heating oxidation loss of a material is reduced, and the workshop cost of forging after-treatment is greatly reduced. A low-temperature warm forging and moderate-temperature warm forging forming process is a novel forging forming process with both advantages of high-temperature forging forming and advantages of cold forging forming. According to the forging forming process for the iron ornamental part product, higher forging precision, higher material yield and higher heating and after-treatment efficacy are integrated, and thus, the technical content and the additional value of the iron ornamental part product can be beneficially improved.

Owner:广东鸿图新材料科技有限公司

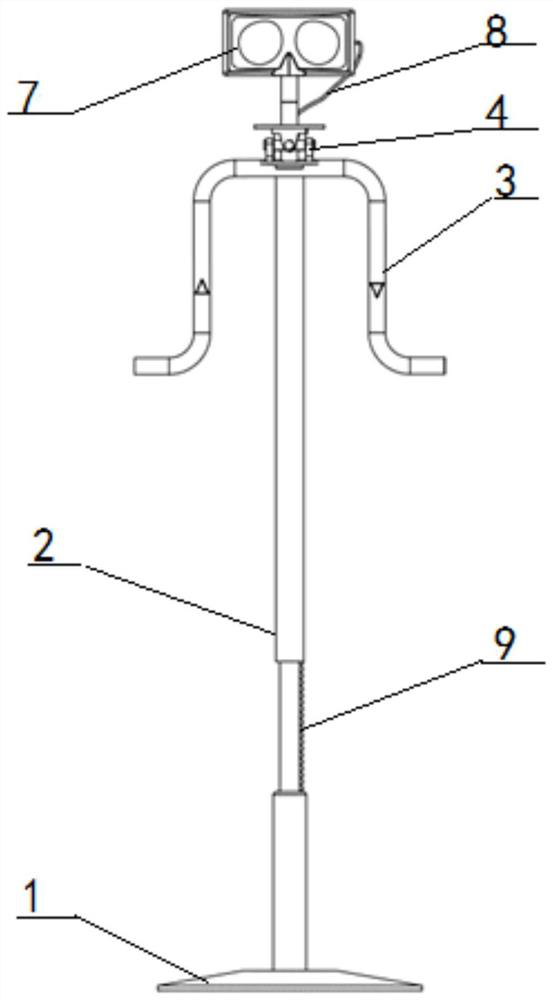

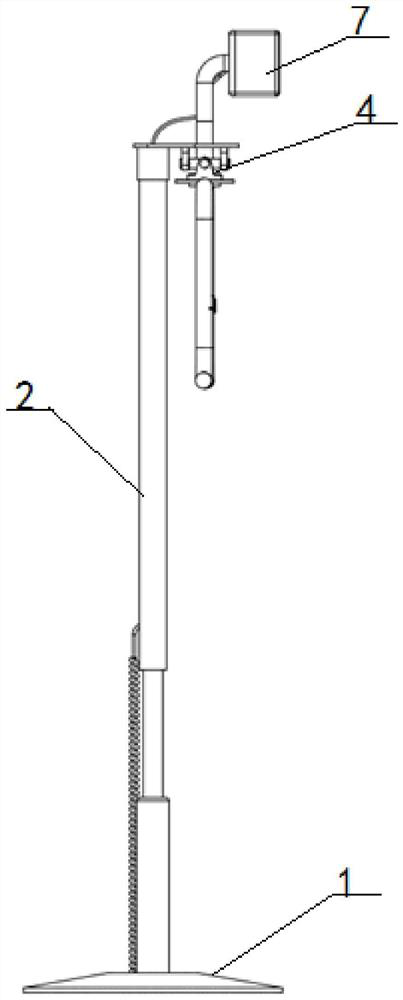

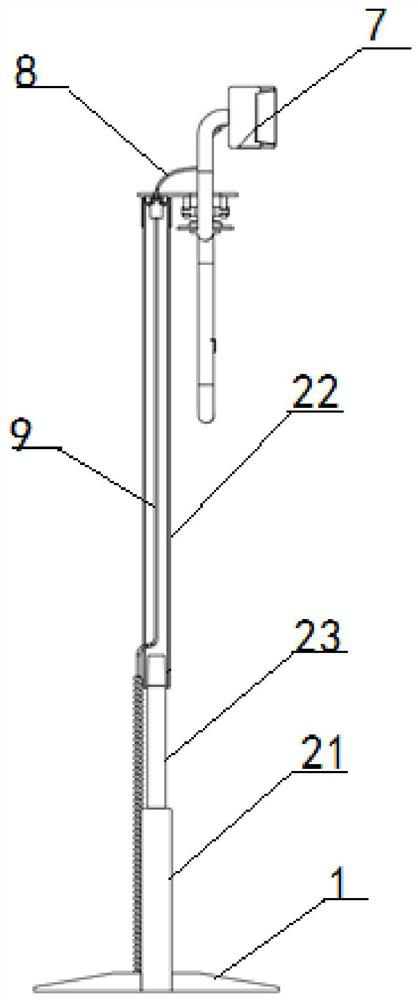

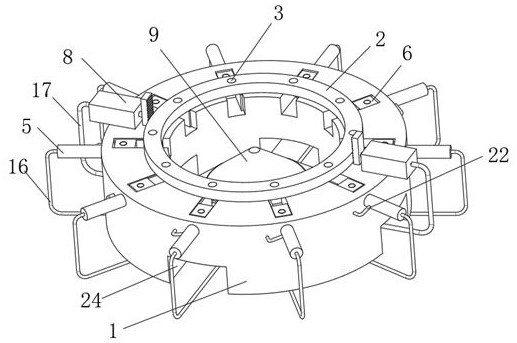

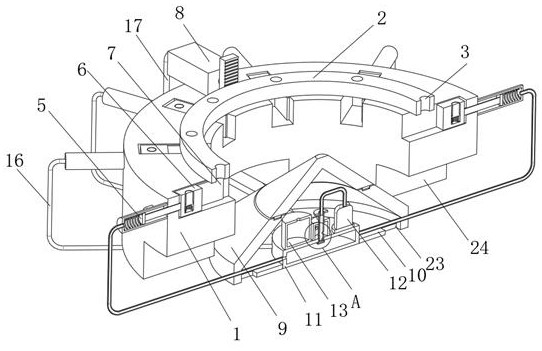

Multi-degree-of-freedom VR motion platform motion recording device/VR telescope

ActiveCN113188026AReduce post-processing workloadSteady recorder motionMachine supportsEnergy efficient computingGyroscopeUniversal joint

The invention relates to a recording device and a VR telescope, in particular to a multi-degree-of-freedom VR motion platform action recording device / VR telescope, and solves the problems that an existing VR motion platform easily causes a result that simulation actions are not matched with VR images, motion data are inconvenient to record manually, and existing VR telescope glasses are inconvenient to use and poor in experience feeling. The recording device and the VR telescope both have two installation modes of forward installation and hoisting. The forward installation and the hoisting both comprise a fixed seat, a pen type electric push rod connected with the fixed seat, a control handle, a hollow universal joint, a rotating bearing, a horizontal rotating assembly, a power supply unit and follow-up equipment. The fixed seat of the forward installation is arranged on a floor, and the fixed seat of the hoisting is arranged on a ceiling. The horizontal rotating assembly of the forward installation is a horizontal rotary plate, and the horizontal rotating assembly of the hoisting is a C-shaped frame. The follow-up equipment is a VR recording device with a gyroscope or VR glasses.

Owner:XIAN VIRTUAL RIDING TECH CO LTD +1

Dual-wavelength solder mask device

ActiveCN110719702AQuality improvementReduce post-processing workloadConductive material chemical/electrolytical removalNon-metallic protective coating applicationEngineeringMechanical engineering

The invention discloses a dual-wavelength solder mask device. The dual-wavelength solder mask device comprises a dual-wavelength light source (900), a vibration unit (100), a multimode optical fiber (200) and a DMD digital micromirror (600), wherein a light beam emitted by the dual-wavelength light source (900) is transmitted by the multimode optical fiber (200) and then imaged by the DMD digitalmicromirror (600), the dual-wavelength light source (900) comprises two light sources with different wavelengths, and one light source is a 355nm pulse laser (901); the vibration unit (100) applies high-frequency vibration to the multimode optical fiber (200) at the middle section of the multimode optical fiber (200).

Owner:ZHONGSHAN AISCENT TECH

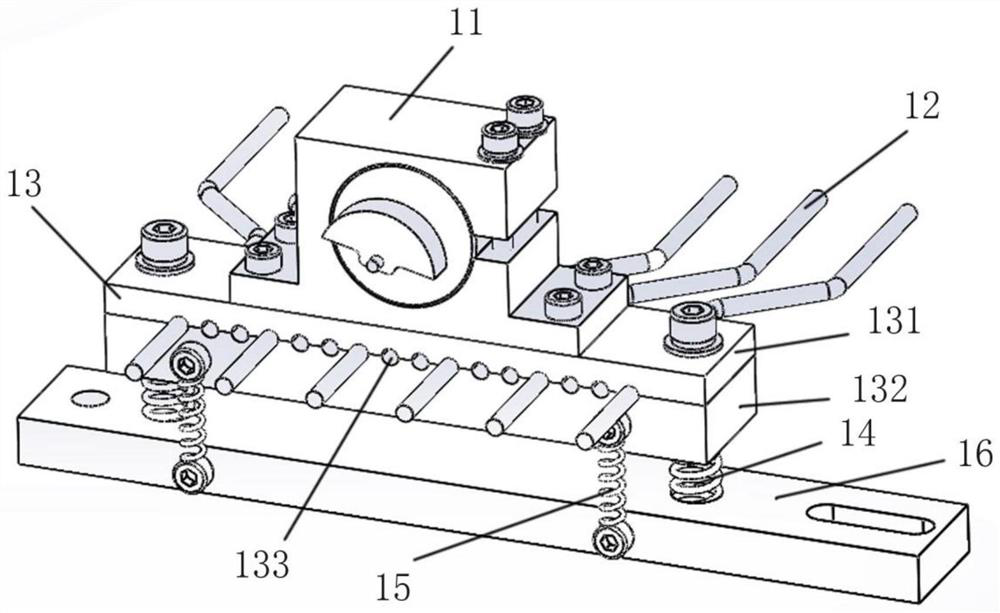

Slewing bearing side hole processing and positioning tool

ActiveCN114571263BSolve the lack of spaceDrilling stabilityPositioning apparatusMaintainance and safety accessoriesHydraulic pumpStructural engineering

The invention belongs to the technical field of slewing bearing processing equipment, and discloses a slewing bearing side hole processing and positioning tool, including a mounting seat and a slewing bearing, the top surface of the mounting seat is provided with a reserved groove, and the outer surface of the mounting seat is fixedly installed There is an installation mechanism, the inner end of the installation mechanism is provided with a push mechanism, and the push mechanism is located inside the reserved groove. In the present invention, by adding a No. 1 distribution sleeve and an adjusting mechanism, after drilling is completed, the pressure oil of the hydraulic pump is introduced into the No. 1 distribution sleeve by controlling the adjusting mechanism, so that the sliding of multiple groups of pushing mechanisms can remove the waste in the reserved groove. It is introduced to realize the automatic cleaning of the wastes on the inner surface of multiple groups of reserved grooves, so as to ensure that the reserved grooves have enough space in the subsequent processing, avoid the accumulated wastes affecting the stable drilling of the drill pipe, and the cleaning is convenient and fast, avoiding too long cleaning time, Reduce the preparation time when replacing the lower set of slewing bearings, and improve the processing efficiency of large-scale slewing bearings.

Owner:招远市金环回转支承有限公司

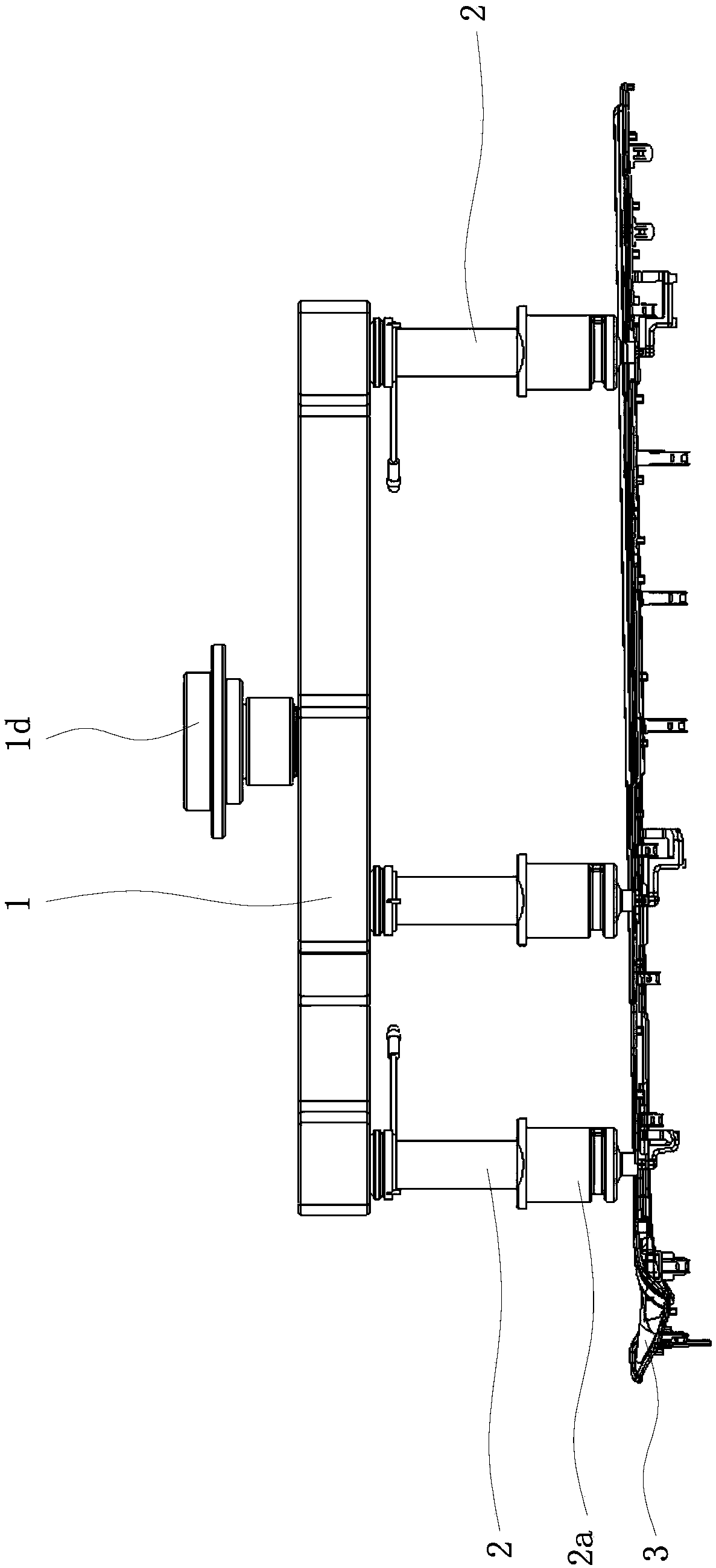

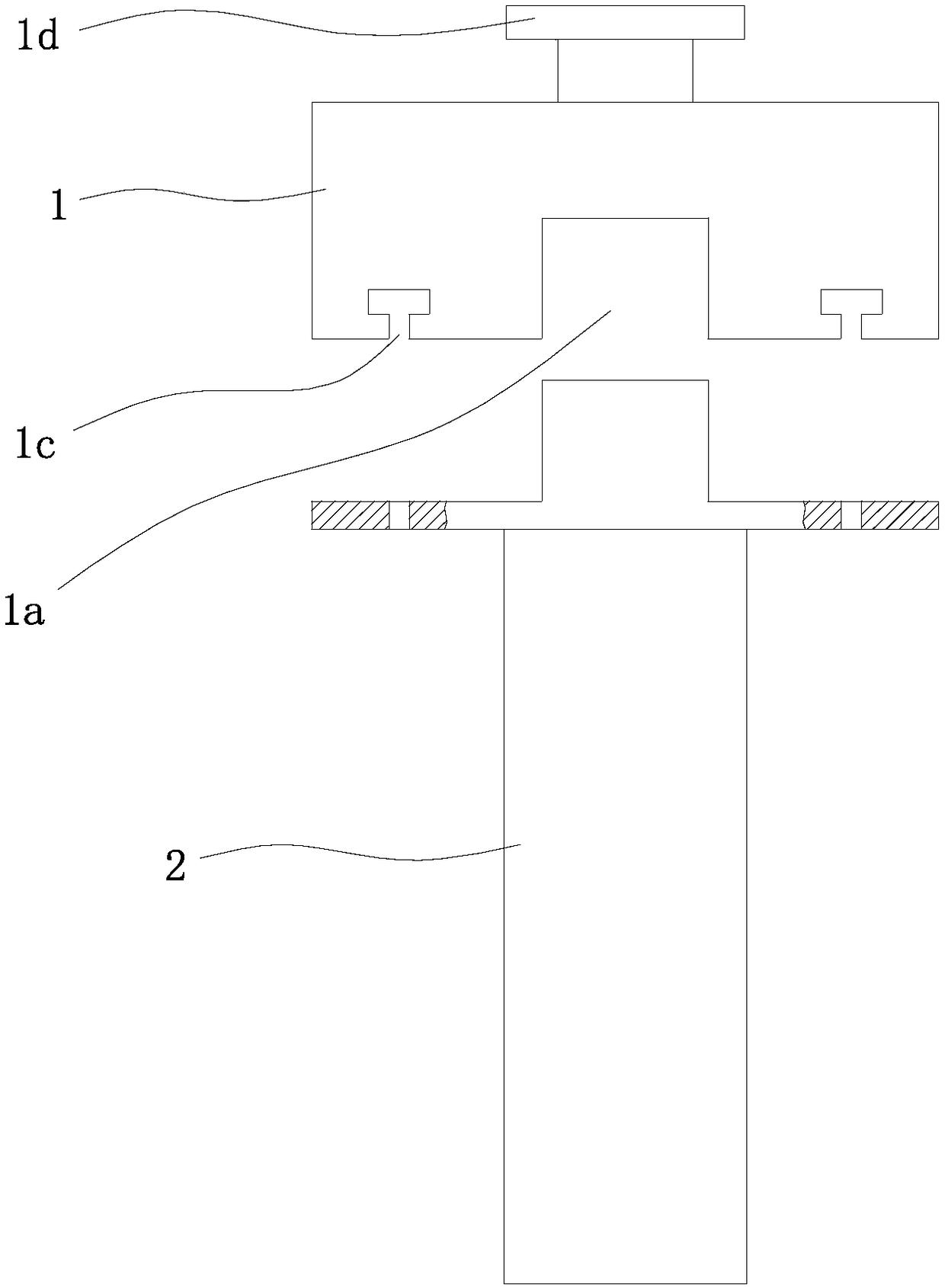

Equipment for directly growing sapphire fairing

ActiveCN104088012AReduce processing difficultyEasy to processPolycrystalline material growthBy pulling from meltCrucibleTorque motor

The invention discloses equipment for directly growing a sapphire fairing. The equipment comprises a rack, a furnace body, a crucible and a capillary guide mold, wherein a rotating component is arranged below the rack and comprises a fixed frame, a rotary motor and a drive rod; the crucible can be driven by the rotary motor to rotate; a support is arranged above the furnace body; a longitudinal moving mechanism and a horizontal moving mechanism are arranged on the support; the horizontal moving mechanism is connected with the longitudinal moving mechanism; a torque motor is arranged on the horizontal moving mechanism; a seed rod fixed frame is arranged on an output shaft of the torque motor; the capillary guide mold is vertically arranged in the furnace body and is installed on the crucible via a fixed clamp; the lower end of the capillary guide mold extends in the crucible; a through hole through which a seed rod can pass is formed in the top of the furnace body; and the seed rod can move horizontally in the through hole. The equipment can effectively reduce the processing difficulty and improve the production efficiency.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

Multi-port injection molding plastic material part forming device and process thereof

PendingCN108481671AIncrease productivitySolve the problem of blending linesPlastic materialsEngineering

The invention discloses a multi-port injection molding plastic material part forming device. The forming device comprises a first injection molding part and at least two second injection molding parts, the second injection molding parts can be connected to flow dividing channels at different positions of the first injection molding part, and the fine adjustment of the positions of the second injection molding parts in sliding grooves can be conducted. First glue inlets and second glue inlets are alternately formed in an injection mold; firstly injection molding is conducted on the first glue inlets; when glue is close to the second glue inlets, injection molding is conducted on the second glue inlets; injection molding of all of the first glue inlets and the second glue inlets is completed, the cavity of the injection mold is filled with the glue, and plastic products are subjected to injection molding. The problem of fusion lines on the surfaces of long strip products is solved, so that the surfaces of the products are more smooth and beautiful, and the mechanical strength of the products and the production efficiency of the injection mold are improved. By adopting a technology ofcontrolling the order of glue injection molding, the surfaces of the products are more smooth, the post-processing workload of the products is reduced, and the quality of the products is improved.

Owner:精英模具(珠海)有限公司

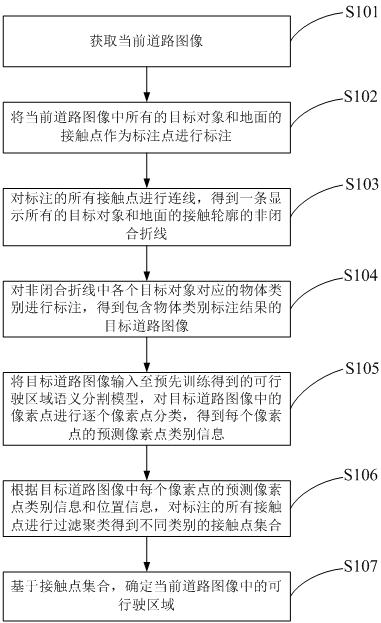

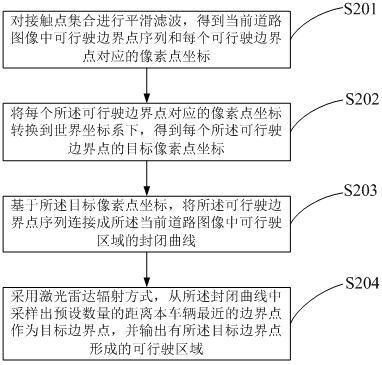

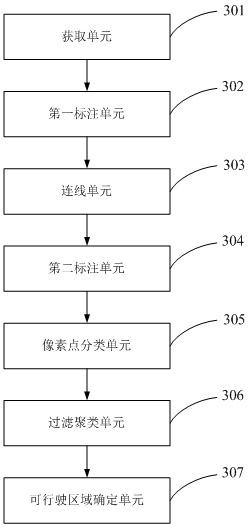

A method and device for detecting a drivable area

ActiveCN112200172BImprove detection efficiencyReduce post-processing workloadCharacter and pattern recognitionComputer graphics (images)Contact spot

Owner:ENBOTAI TIANJIN TECH CO LTD

A device for directly growing sapphire fairing

ActiveCN104088012BReduce processing difficultyEasy to processPolycrystalline material growthBy pulling from meltCrucibleTorque motor

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

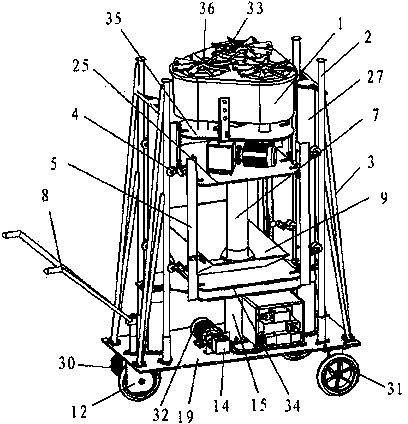

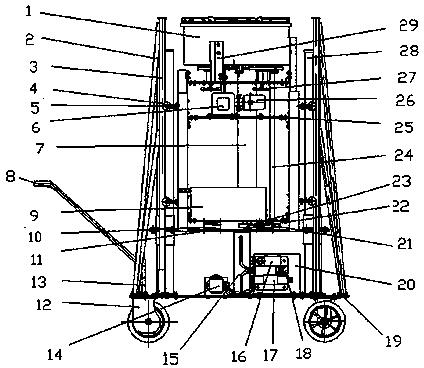

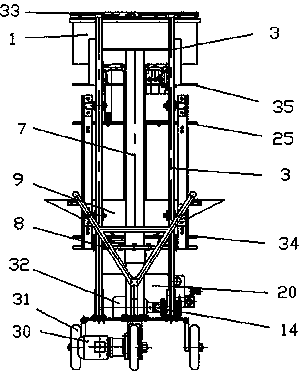

Indoor roof plastering device

The invention discloses an indoor roof plastering device, and belongs to the technical field of building mechanical equipment. The indoor roof plastering device is used for mechanization work of plastering an indoor roof. According to the technical scheme, a plastering head part is located at the highest end of the plastering device, a plastering thickness regulating part is installed in the plastering head part, a feeding part is connected on the lower portion of the plastering head part, a transmission part is located on the lower portion of the plastering head part, the plastering head part and the feeding part are respectively connected with the transmission part, the plastering head part, the feeding part and the transmission part are respectively installed on base plates, the base plates are connected on a lifting frame part which is connected with a hydraulic lifting part, and the hydraulic lifting part and the lifting frame part are installed on a vehicle frame part. By means of the indoor roof plastering device, the indoor roof can be plastered evenly, a combination property between mortar and the roof is good, a parallelism error requirement between the roof and the ground is met, and the plastering quality is guaranteed. The indoor roof plastering device is capable of achieving continuous work, greatly improving plastering efficiency and reducing labor intensity of workers.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Machining and positioning tool for side face hole of slewing bearing

ActiveCN114571263ASolve the lack of spaceImplement automatic cleanupPositioning apparatusMaintainance and safety accessoriesHydraulic pumpEngineering

The invention belongs to the technical field of slewing bearing machining equipment, and discloses a slewing bearing side face hole machining positioning tool which comprises a mounting base and a slewing bearing, a reserved groove is formed in the top face of the mounting base, a mounting mechanism is fixedly mounted on the outer surface of the mounting base, and a pushing mechanism is arranged at the inner end of the mounting mechanism. The pushing mechanism is located in the reserved groove. By additionally arranging the first distribution sleeve and the adjusting mechanism, after drilling is completed, pressure oil of a hydraulic pump is guided into the first distribution sleeve by controlling the adjusting mechanism, so that the multiple sets of pushing mechanisms slide and push out waste materials in the preformed grooves, and automatic cleaning of the waste materials on the inner surfaces of the multiple sets of preformed grooves is achieved; therefore, it is guaranteed that the reserved groove has enough space during subsequent machining, accumulated waste is prevented from influencing stable drilling of the drill rod, cleaning is convenient and rapid, the situation that cleaning time is too long is avoided, the preparation time for replacing a next set of slewing bearings is shortened, and the machining efficiency of large-batch slewing bearings is improved.

Owner:招远市金环回转支承有限公司

A dual-wavelength anti-soldering equipment

ActiveCN110719702BQuality improvementReduce post-processing workloadConductive material chemical/electrolytical removalNon-metallic protective coating applicationEngineeringMechanical engineering

The invention discloses a dual-wavelength anti-soldering device. The dual-wavelength anti-soldering equipment includes: a dual-wavelength light source (900), a vibration unit (100), a multimode optical fiber (200) and a DMD digital micromirror (600), and the light beam emitted by the dual-wavelength light source (900) passes through multiple After the transmission of the mode fiber (200), the DMD digital micromirror (600) is used for imaging, and the dual-wavelength light source (900) includes light sources of two different wavelengths, wherein one light source is a 355nm pulse laser (901); the vibration unit ( 100) Imposing high frequency vibrations to said multimode optical fiber (200) at a middle section of said multimode optical fiber (200).

Owner:ZHONGSHAN AISCENT TECH

A water glass precision casting process

The invention relates to a precision casting process. Aiming at the problems of the chemical method hardening and desanding process and low-mode water glass method castings that are prone to defects, etc., a carbon dioxide hardening and high temperature desanding process is independently designed. The water glass method precision casting process includes the preparation of Wax materials, wax mold making, wax mold inspection, wax mold assembly tree, coating preparation, mold shell making, hot air dewaxing, mold shell roasting, mold shell inspection, molten steel pouring, sand cleaning and cutting, and casting inspection. It eliminates equipment corrosion, environmental pollution, and hidden dangers to the personal safety of employees in the traditional chemical hardening and desanding process. The working environment reduces the production cost and greatly improves the production capacity of traditional water glass shells.

Owner:浙江福瑞科流控机械有限公司

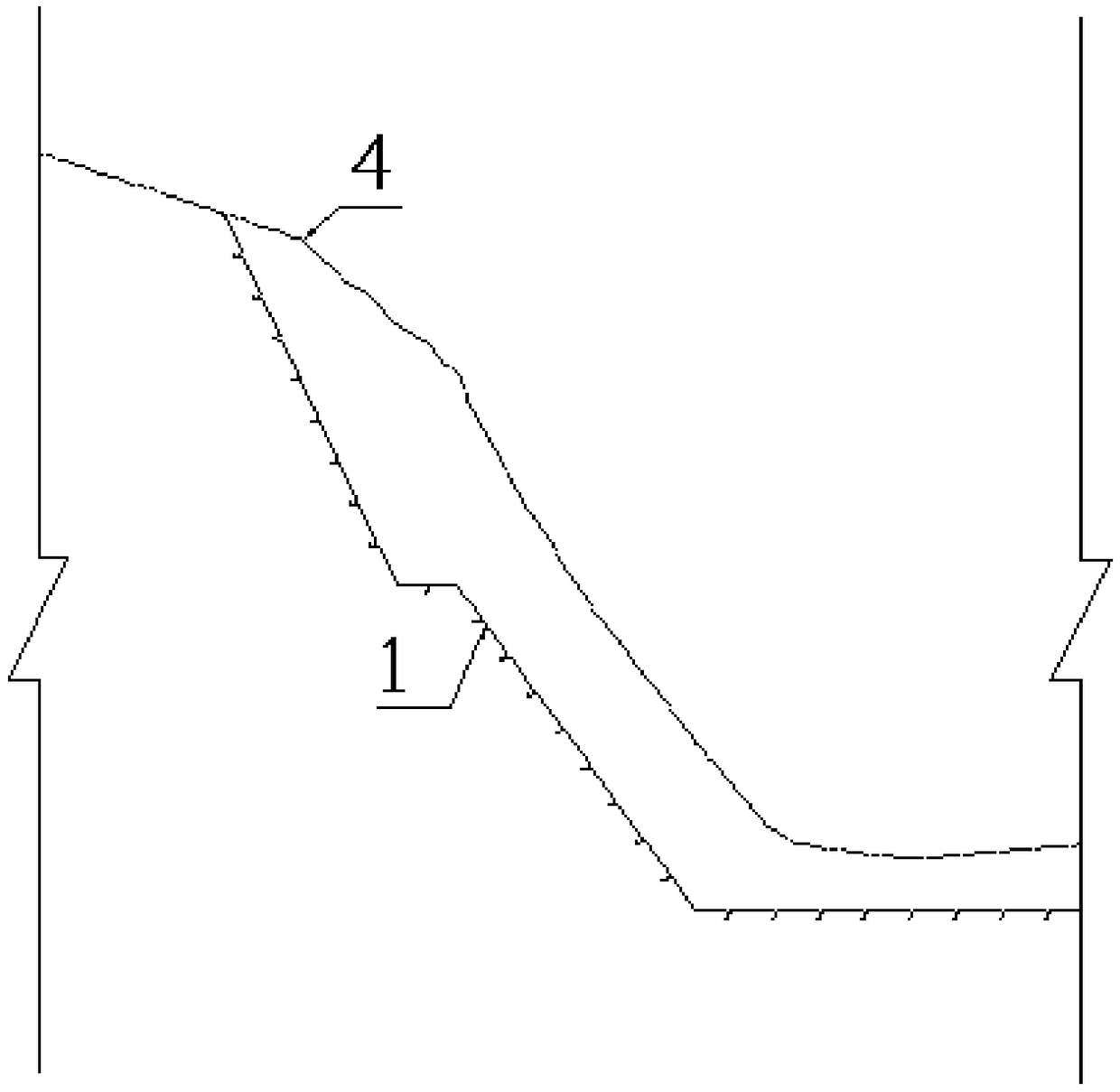

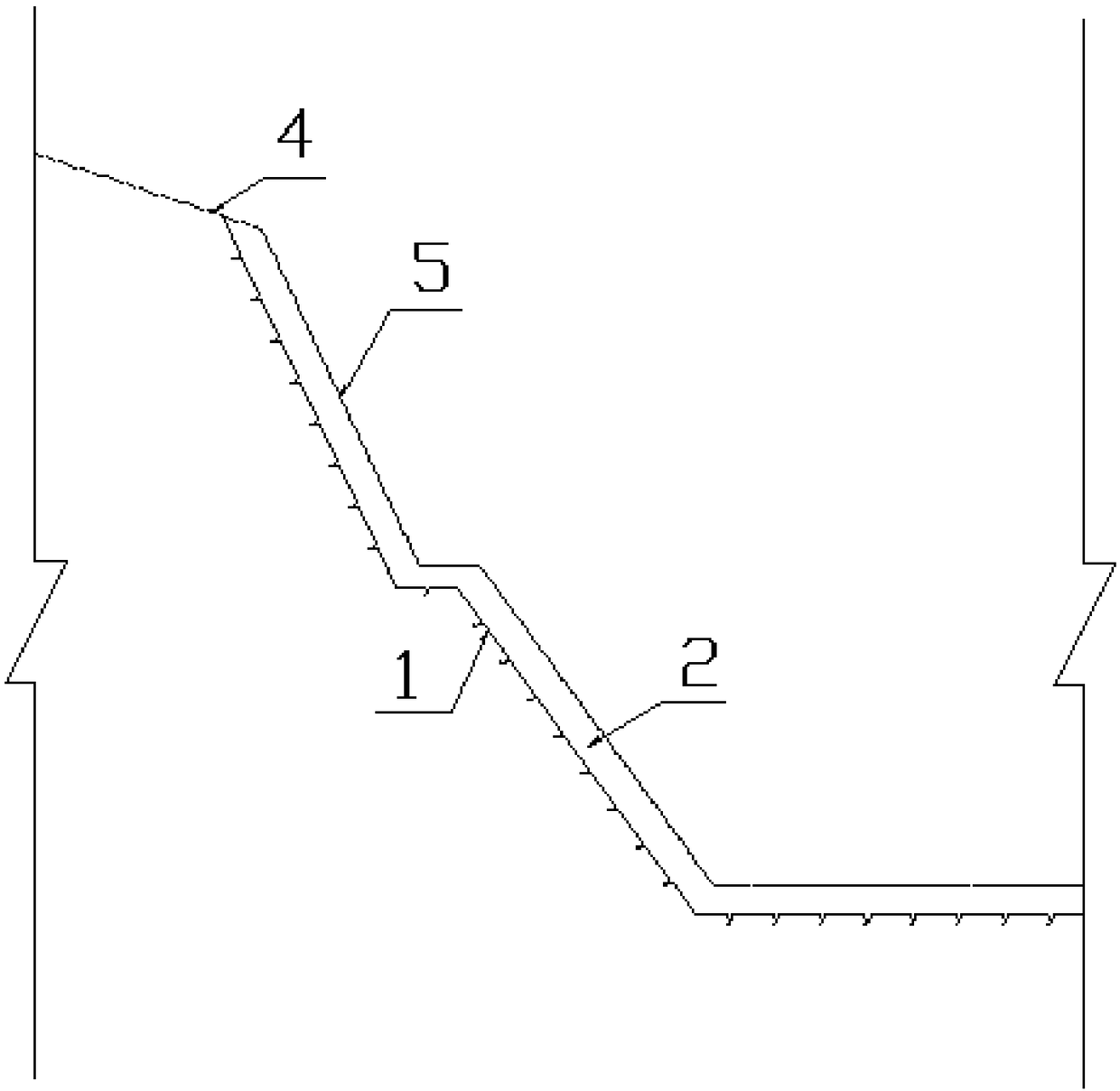

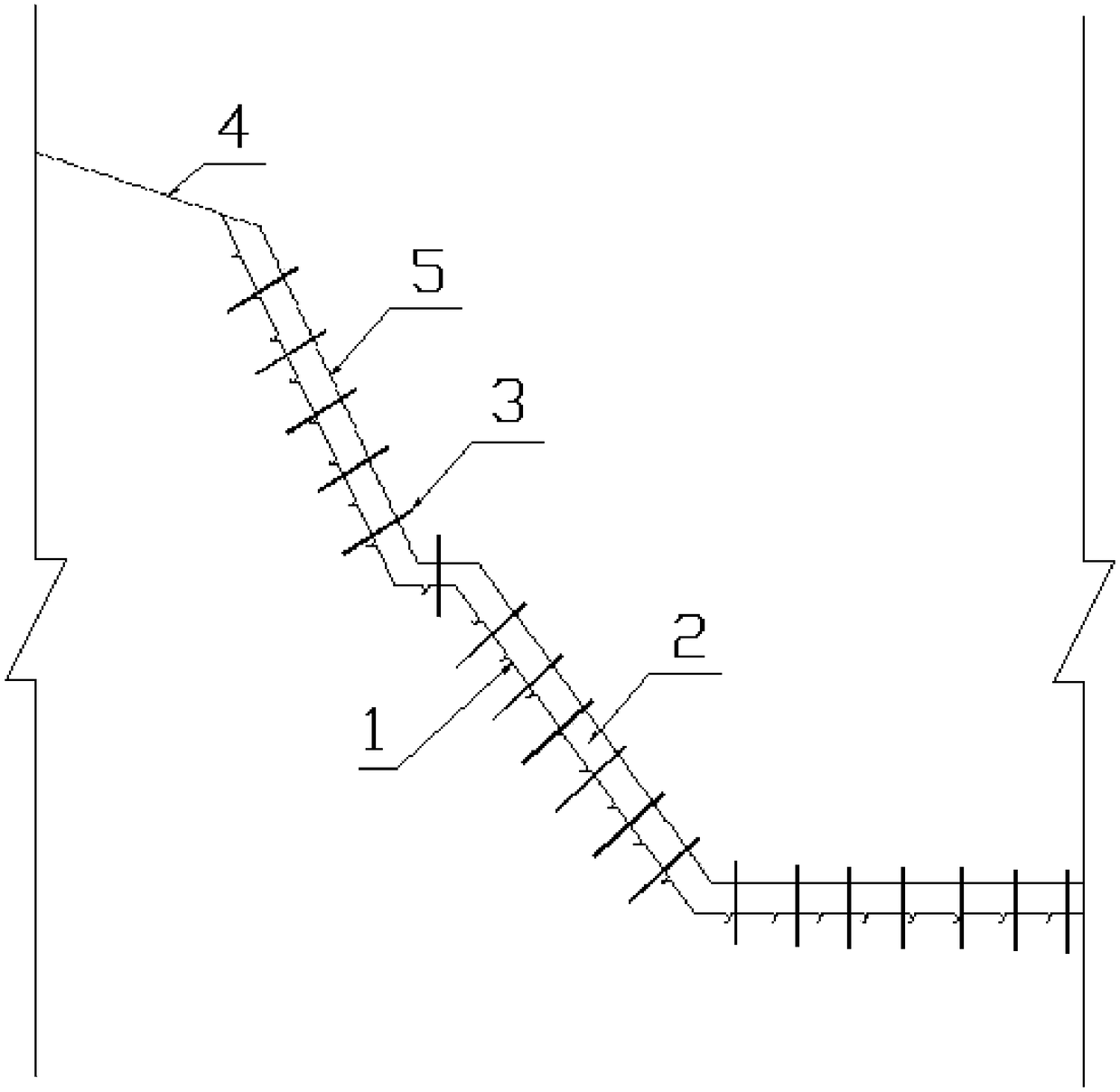

Method for controlling slope excavation rock mass unloading and relaxation

InactiveCN108166512AReduce riskReduce post-processing workloadExcavationsBulkheads/pilesHydroelectricityEnvironmental geology

The invention relates to a method for controlling slope excavation rock mass unloading and relaxation, and belongs to the technical field of building, hydroelectricity and other engineering construction. The method can effectively control the unstability problem during slope excavation. On the premise of not affecting the time limit for a project, primary stabilization is conducted after excavation by preserving a ballasting layer, secondary stabilization is conducted by anchoring a rock mass through grouted rockbolts, secondary excavation is conducted finally, and the ballasting layer is anchored in the reserved part of a slope toe. The method can effectively guarantee safety and stability of a slope, improves the deformation capacity, fully conducts stress adjustment, lowers the unstability probability of the slope, and achieves the purposes of improving safe stability and economy.

Owner:POWERCHINA CHENGDU ENG

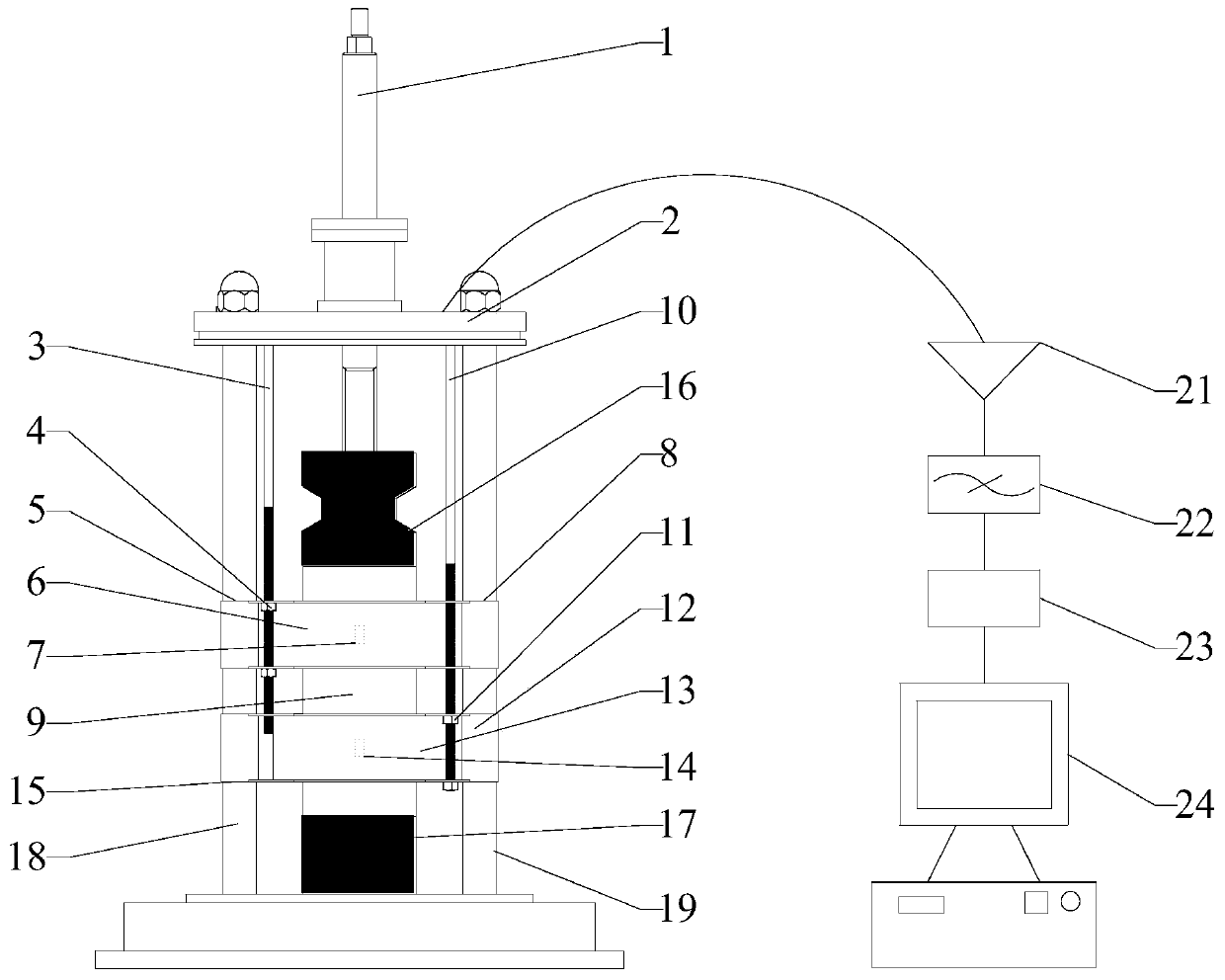

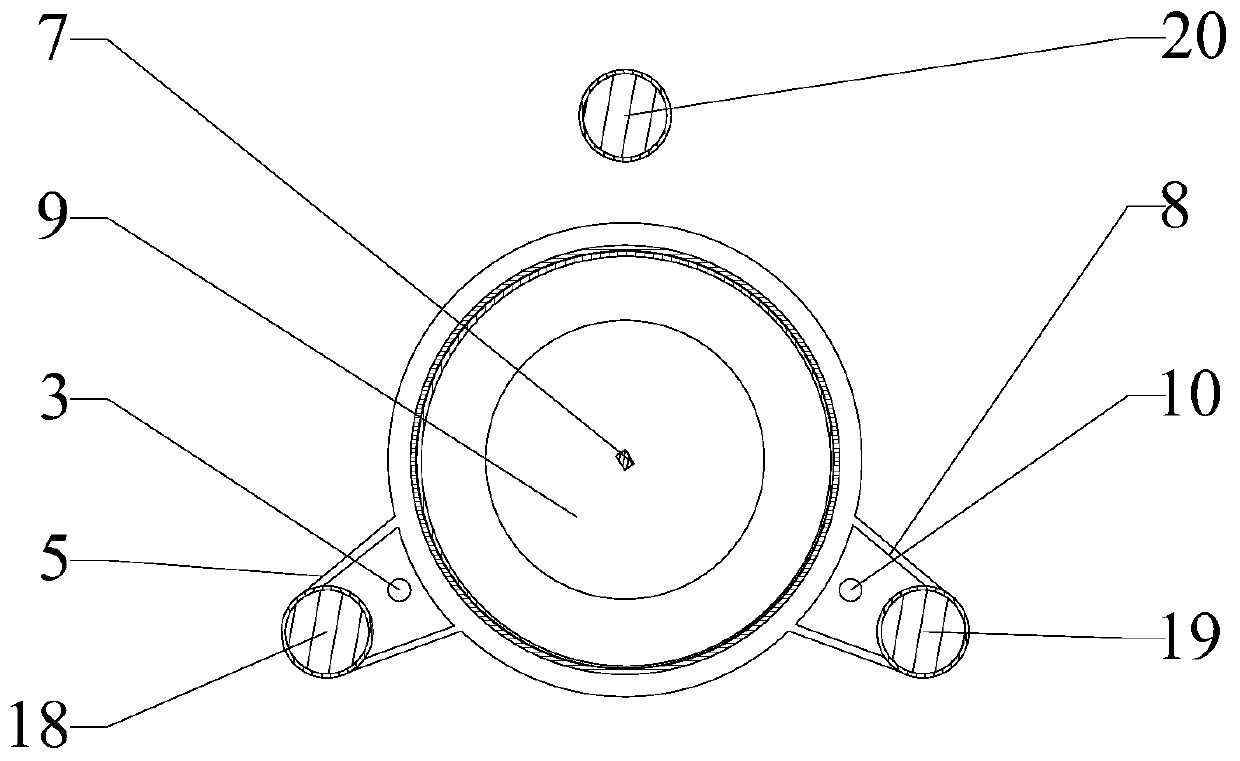

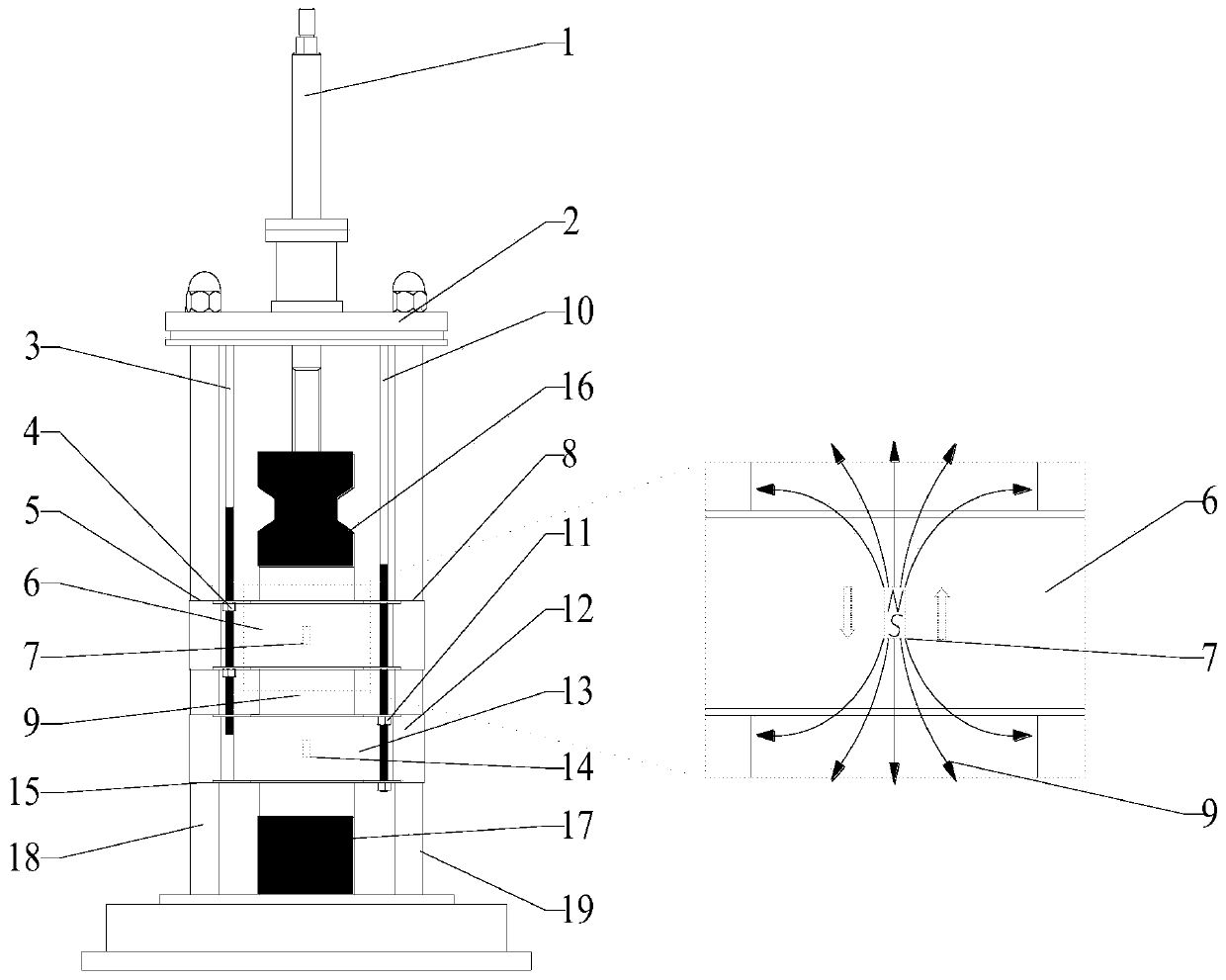

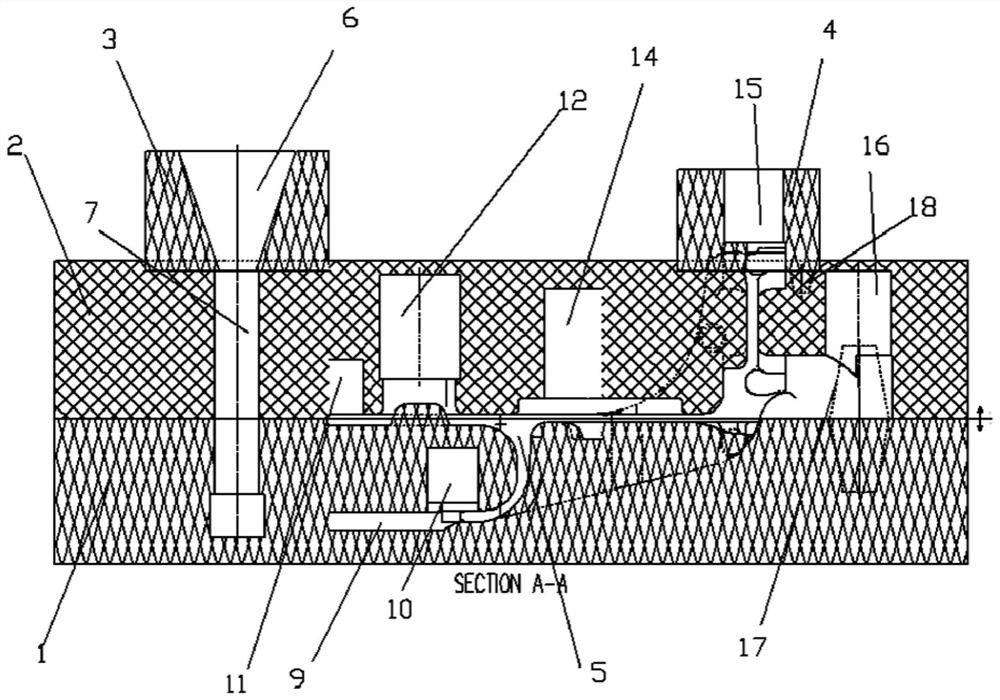

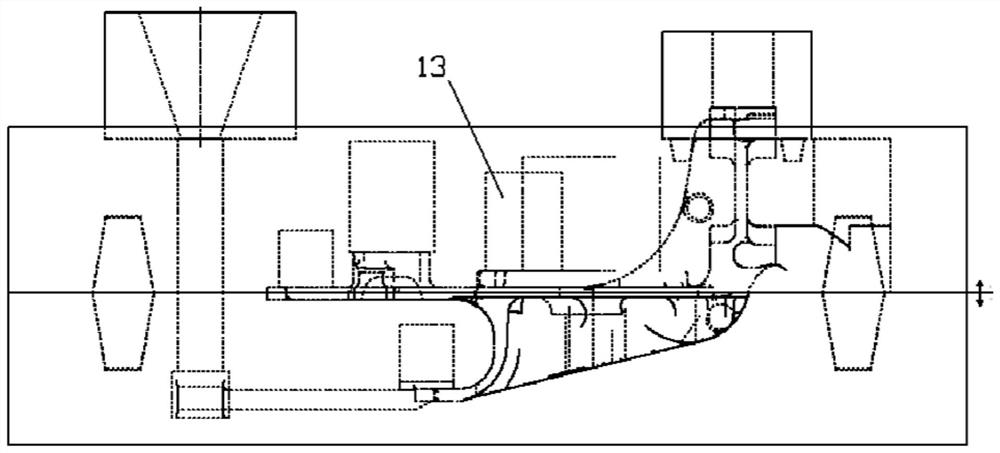

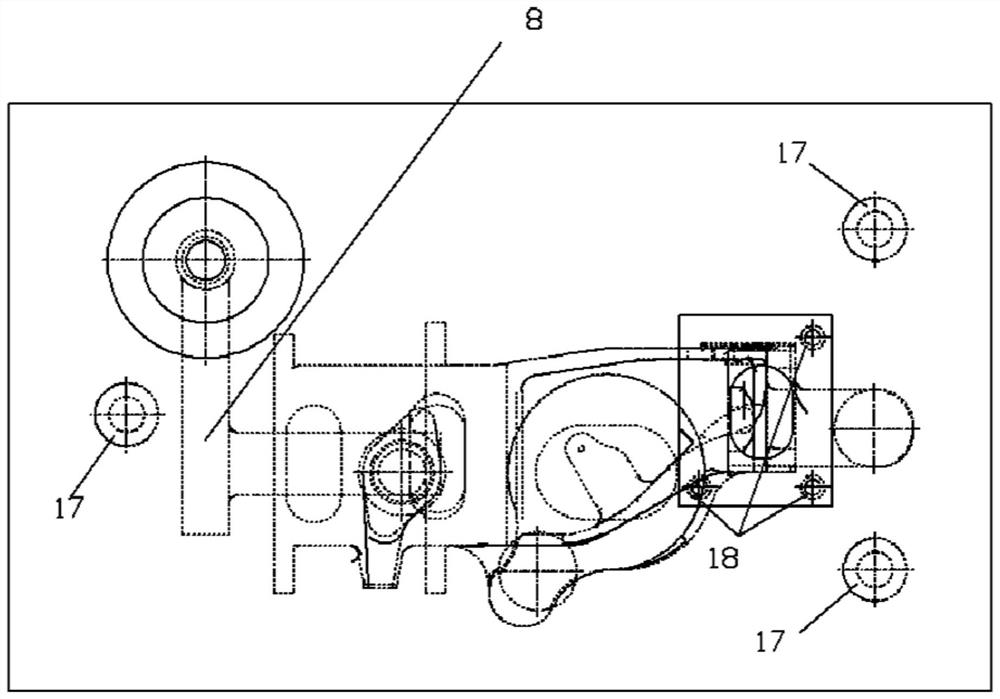

A Method of Measuring Local Deformation of Dynamic Triaxial Samples of Sand and Gravel Using Electromagnetic Induction Technology

ActiveCN108458932BWon't disturbNo interferencePreparing sample for investigationMaterial strength using tensile/compressive forcesIntegratorSignal amplifier

The invention provides a measurement method for sand-gravel material dynamic triaxial sample local deformation by utilizing the electromagnetic induction technology, and belongs to the technical fieldof geo-technical testing. By adopting an electromagnetic induction principle, inner local deformation of a triaxial sample is measured based on a middle-sized triaxial apparatus, and granular magnetsin testing equipment are located inside the sample; an annular coil is placed inside a pressure chamber and surrounds the sample; the annular coil is externally connected with a signal amplifier, a filiter and a voltage integrator. The measurement method comprises the steps that a conventional test method is adopted to prepare the sample by using the middle-sized triaxial apparatus, the magnets are embedded, and sample forming is completed; the coil and other equipment are installed and erected; installation, ventilation, saturation and consolidation are carried out on the sample, and the sample is connected with a loading device; under the circumstance of pressurization, calibration is performed on the measuring apparatus for conducting the test, and test data is acquired. According to the method, the structure is reasonable, the assembly is simple, the test operation is convenient and reduces interference on the sample during the test process, and the method can accurately measure the interesting local deformation inside the sand-gravel material triaxial sample.

Owner:DALIAN UNIV OF TECH

Stone etching solution and preparation method thereof

The invention relates to a stone etching solution and a preparation method thereof, and belongs to the technical field of stone processing. The preparation method comprises the following steps modifying corncobs through a pre-emulsification technology in emulsion polymerization to prepare alkali-treated corncob powder grafted acrylate emulsion; then compounding the alkali-treated corncob powder grafted acrylate emulsion with a corrosion solution; diluting with water to prepare the stone etching solution. According to the stone etching solution and the preparation method thereof, etched surfaces of stones are rapidly wetted, small-particle dust covers the stones while the stones are corroded and softened, and films are formed on the surfaces of the stones so as to effectively prevent the small-particle dust in subsequent treatment from flying off, reduce the dust rising rate and reduce damages, caused by the dust in a stone etching process, to workers; the stone etching solution and thepreparation method thereof have the advantages of high working efficiency, simple technology, labor saving and time saving, and raw material saving and have a wide application prospect.

Owner:常州海瑞纺织品有限公司

Segmental Casting Method for Special-shaped Steel Castings of Subway Bogies

Owner:LEADRUN MAODA CASTING JIANGSU

A kind of manufacturing method of tantalum, niobium or its alloy additive

ActiveCN105855566BImprove liquidityShort processAdditive manufacturing apparatusGraphicsComputer printing

The invention provides a tantalum or niobium or tantalum and niobium alloy additive manufacturing method. The method comprises the following steps that firstly, tantalum powder or niobium powder or tantalum and niobium alloy powder is prepared for 3D printing; and secondly, the prepared tantalum powder or the prepared niobium powder or the prepared tantalum and niobium alloy powder for 3D printing is put into a 3D printer for printing, and then a tantalum or niobium or tantalum and niobium alloy metal product is prepared. By means of the manufacturing method, the cost of raw materials is low, the technological process is simple, the manufactured powder with good fluidity can be directly printed into metal products and artificial material implants according to design drawings or figures converted by scanning bones amputated by doctors, the production process is quick, and post-treatment workload is little.

Owner:湖南华翔医疗科技有限公司

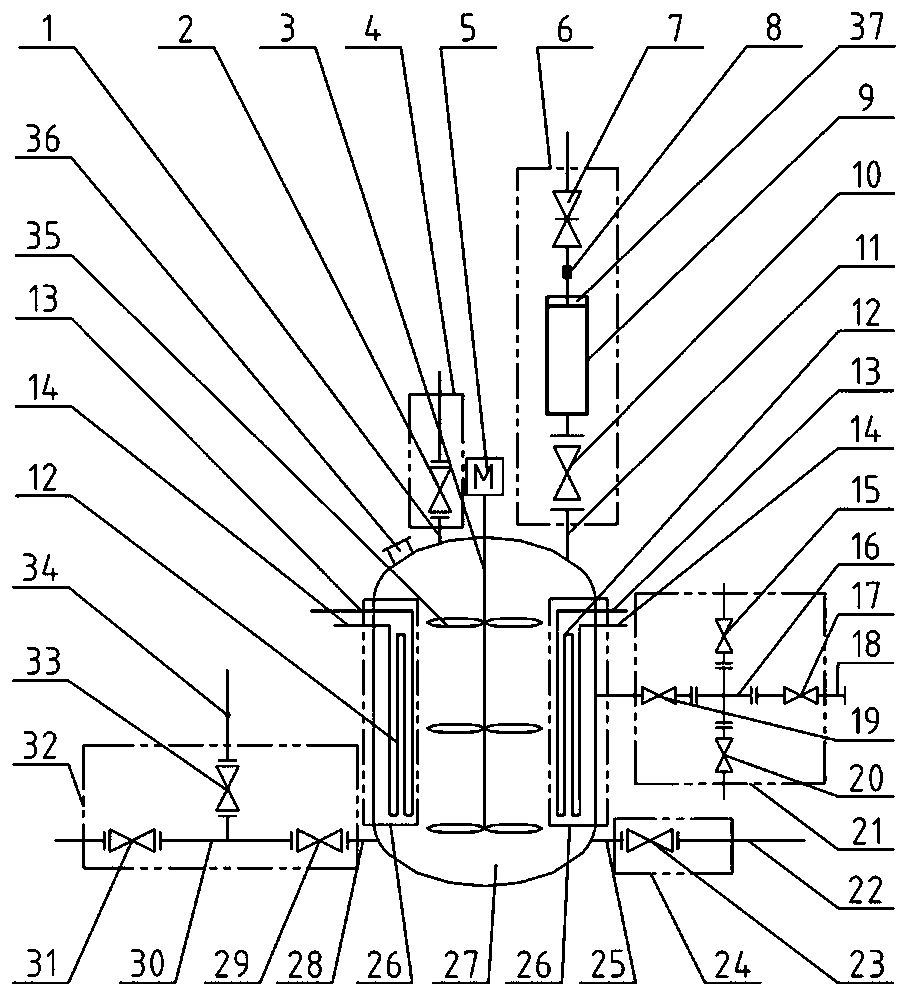

Fermentation tank

InactiveCN108624471AImprove the efficiency of fermentation operationsGuaranteed qualityBioreactor/fermenter combinationsBiological substance pretreatmentsChemical industryAgricultural engineering

The invention provides a fermentation tank, and solves the technical problems that preparative working items for fermentation-related operations are cumbersome because the existing fermentation tank has no special and simple devices for feeding a culture, sampling, distributing the culture, discharging, heating and cooling a fermentation solution and other operations, and the stable quality of a production material cannot be guaranteed. The fermentation tank comprises a fermentation tank body, wherein a stirring motor is arranged at the middle position of the upper surface of the fermentationtank body; the stirring motor is connected with a stirring shaft in the inner cavity of the fermentation tank body; stirrers are arranged on the stirring shaft; a culture feeding device is arranged onthe fermentation tank body; a sampling and culture-distributing device is arranged on the middle part of the outer side of the fermentation tank body; a steam sterilizing and discharging device is arranged on one side of the lower end of the fermentation tank body; an oxygen inflating device is arranged on the other side of the lower end of the fermentation tank body; and a fermentation solutionheating and cooling device is arranged in the inner cavity of the fermentation tank body. The fermentation tank can be widely applied to material fermenting operations in the field of medicines and chemical industry.

Owner:RUSHAN HANWEI BIO TECHN & SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com