Forming mold and method of large-curvature open thin-walled structure composite

A thin-walled structure, forming mold technology, applied in the field of large curvature, can solve the problems of small post-processing workload, high yield, out of tolerance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

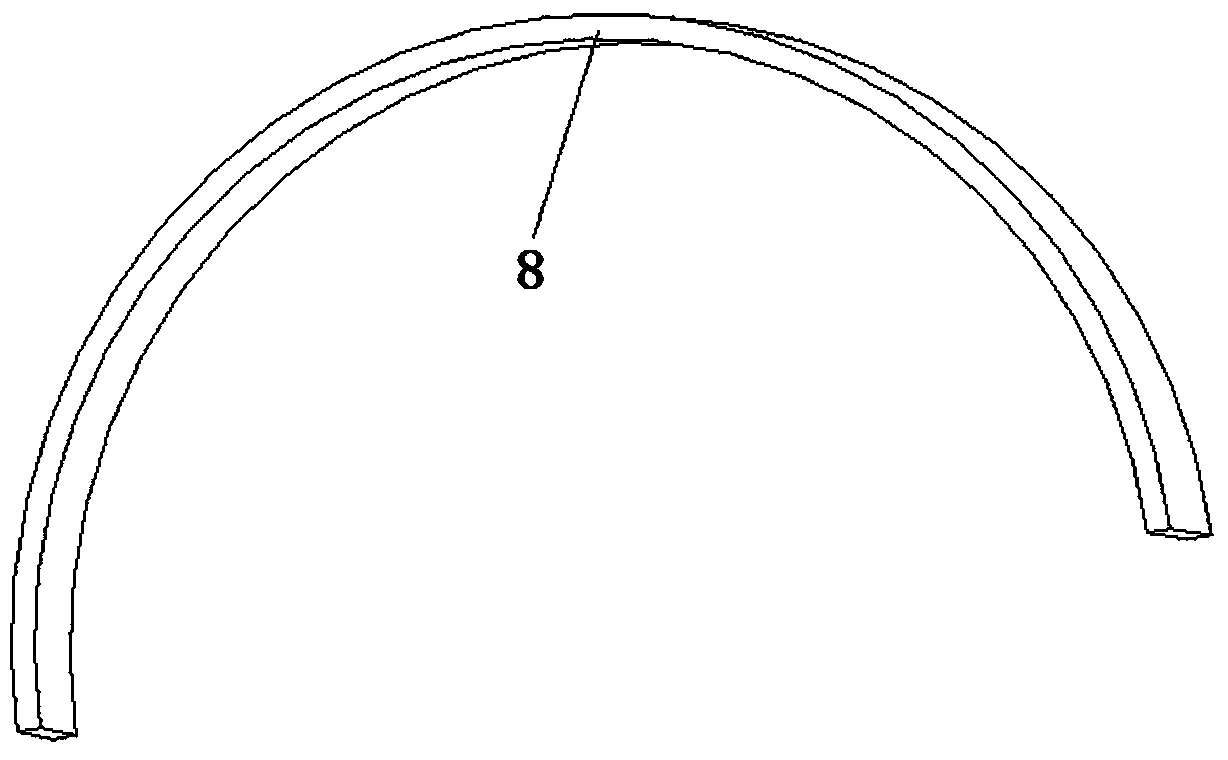

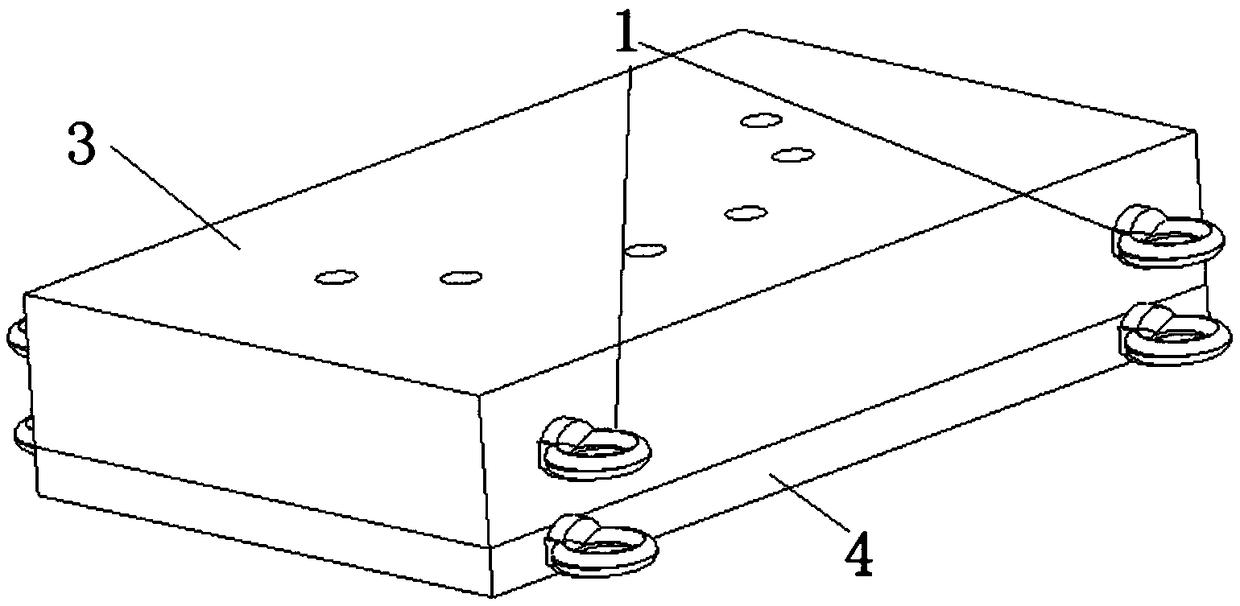

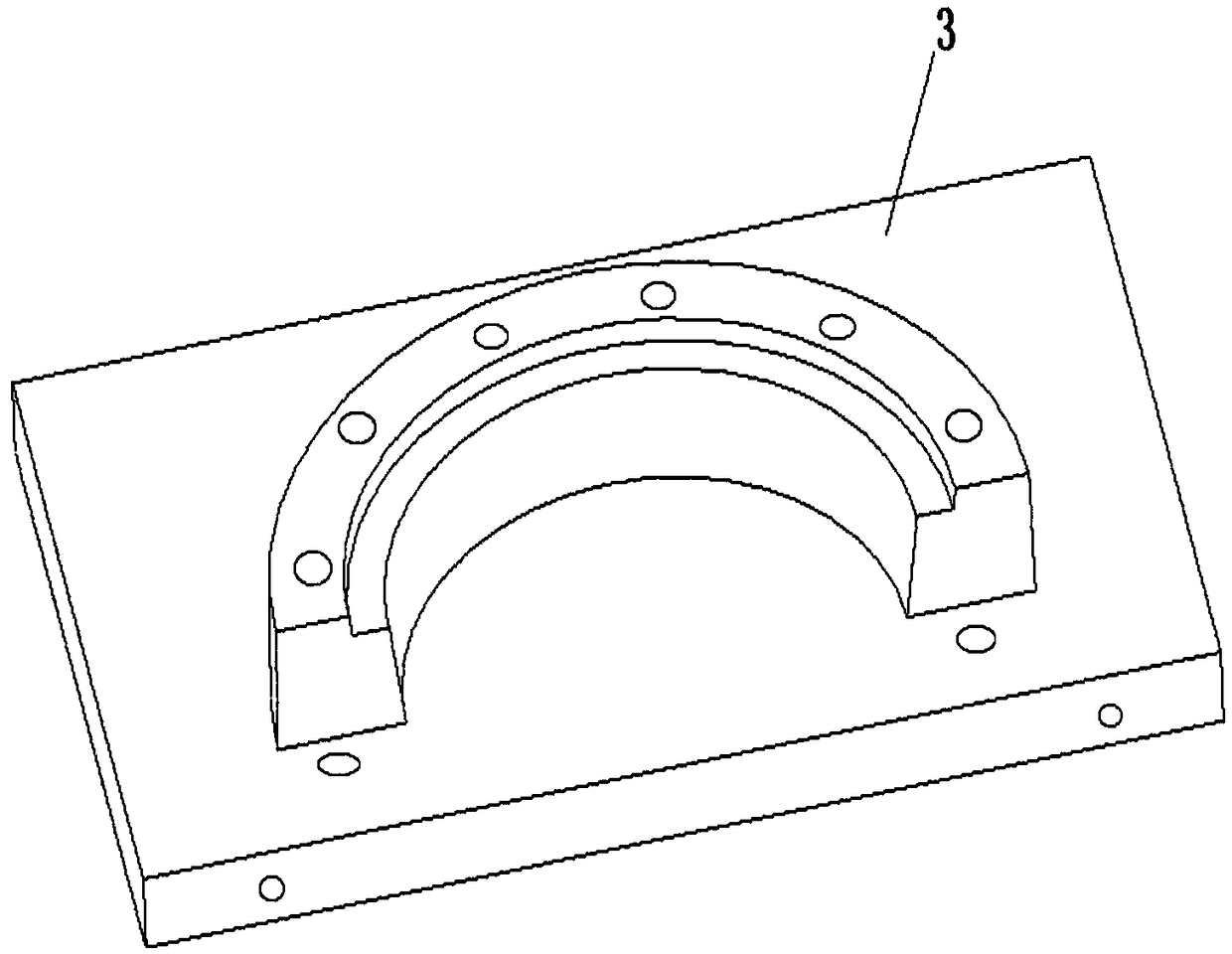

[0044] This embodiment is a mold and a molding method for a certain type of large curvature, open, and thin-walled structure composite material projectile. The mold adopts a semi-closed, single-cavity, side-pressurized structure, including punches, dies, upper covers, side blocks, side sliders, lifting rings and fastening bolts. The mold structure is as follows:

[0045] The die has a rectangular structure, with a sloped semi-circular groove in the middle, and a through hole in the groove, which is integrally matched with the punch, and rings are installed on both sides. Quantity 1 piece.

[0046] The punch is a combined structure of a semi-circular boss and a rectangular bottom plate. There are threaded holes on the top surface and both ends of the boss for locking and fixing the screws on the upper cover. There are steps on the semi-circular boss for Installation and positioning of the upper cover. Threaded holes are provided on the bottom plate for locking and fixing wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com