A Method of Measuring Local Deformation of Dynamic Triaxial Samples of Sand and Gravel Using Electromagnetic Induction Technology

A technical measurement, triaxial sample technology, applied in the preparation of test samples, the use of stable tension/pressure test material strength, measurement devices, etc., to achieve the effect of equipment waterproof and pressure resistance, simple structure, good promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples.

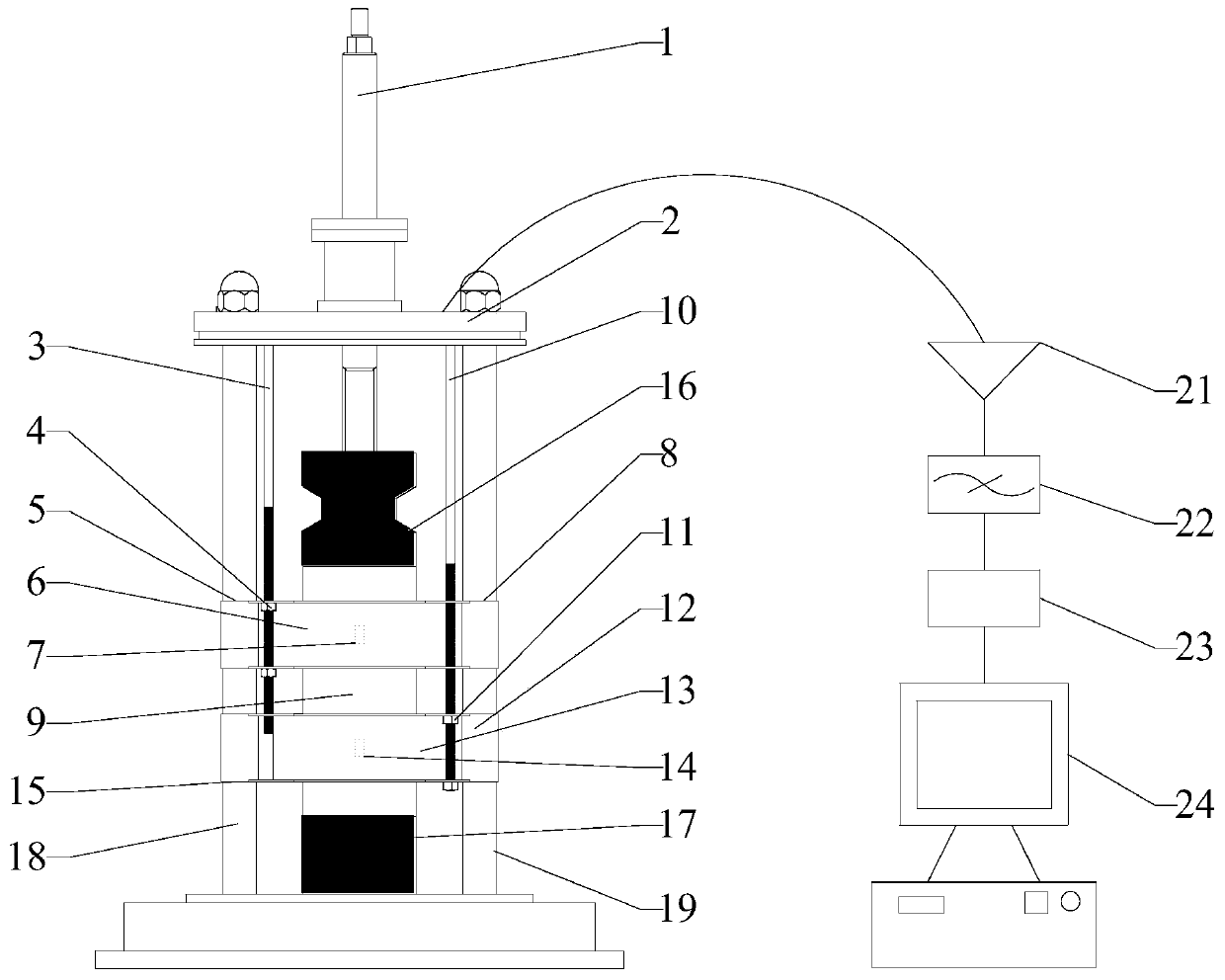

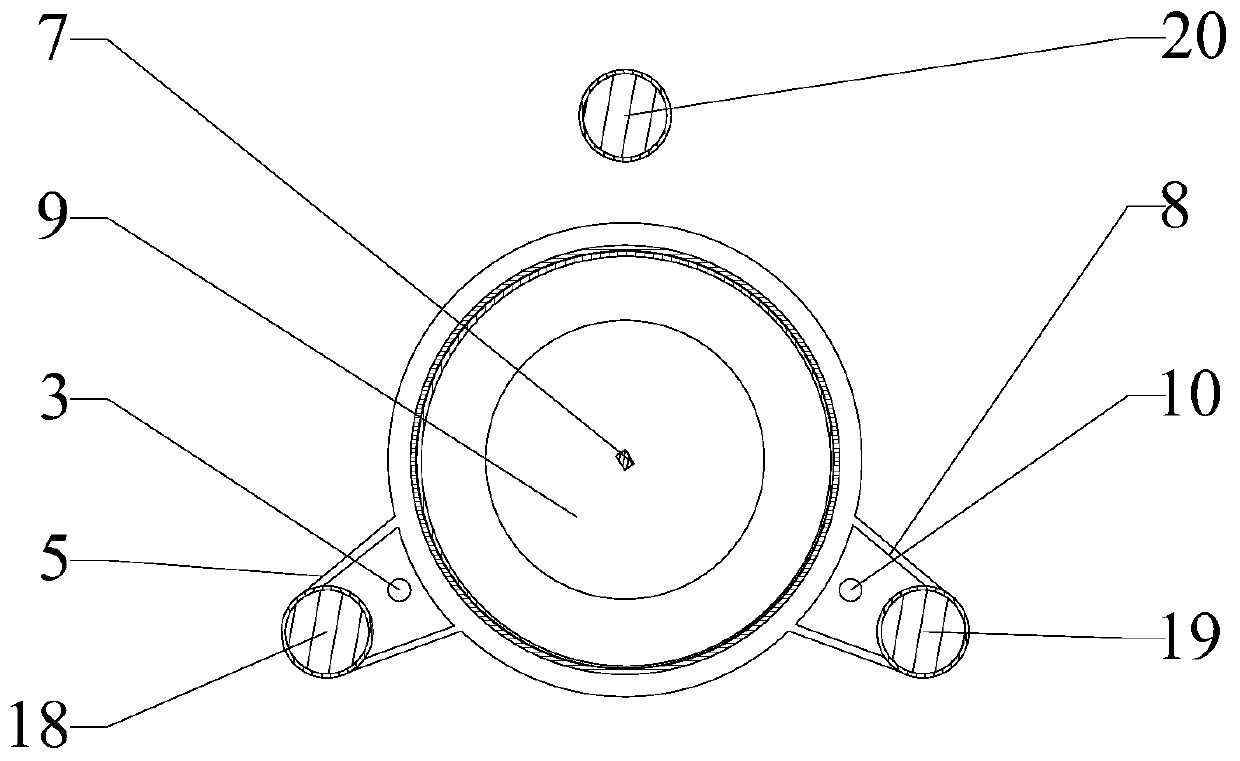

[0026] A method for measuring the local deformation of a dynamic triaxial sample of sand and gravel by using electromagnetic induction technology. The basic principle adopted by the method is the principle of electromagnetic induction, and the internal local deformation of the triaxial sample body is measured based on a medium-sized triaxial tester.

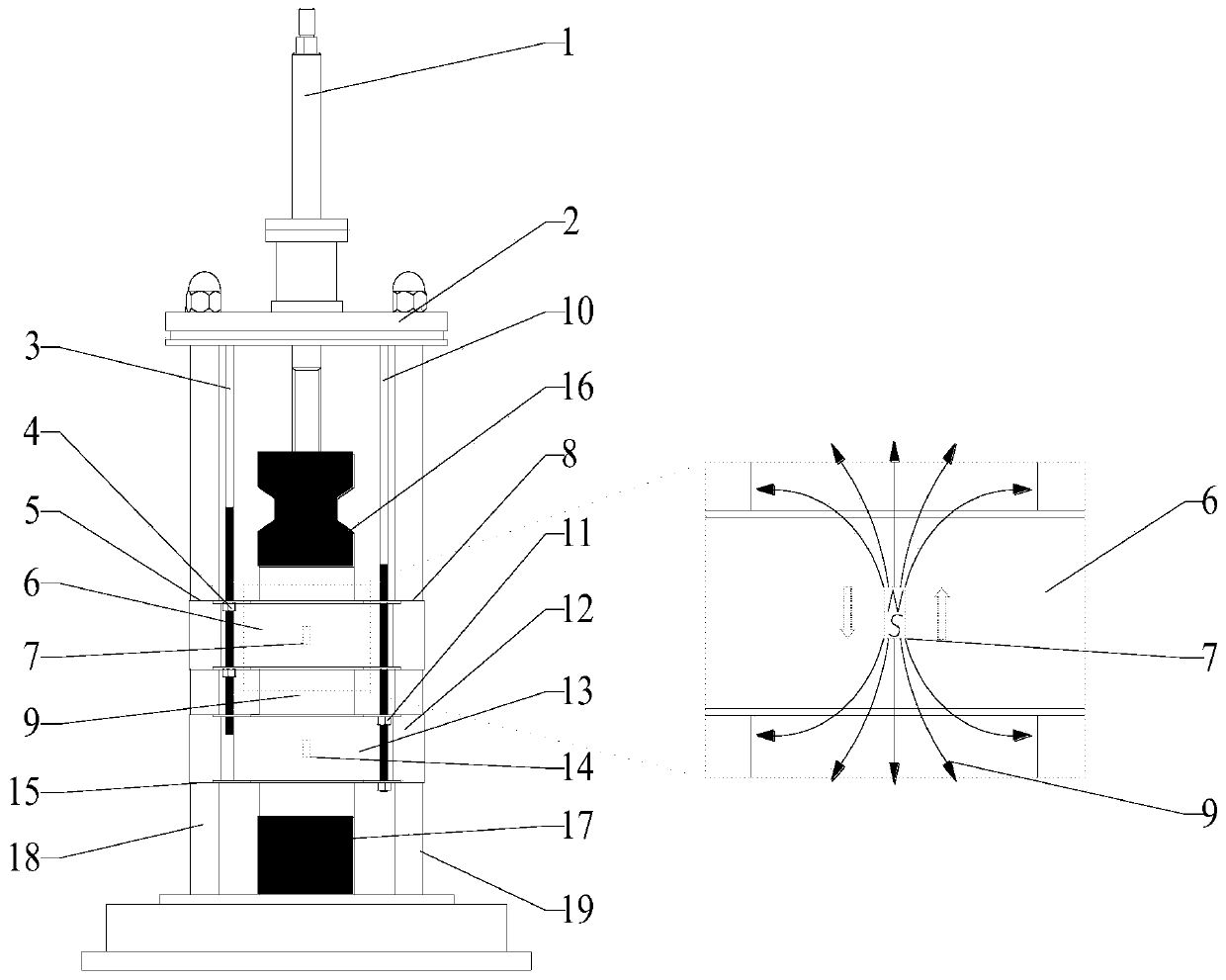

[0027] The principle of electromagnetic induction based on this method is briefly introduced as follows: Principle of electromagnetic induction: When a closed circuit moves to cut the magnetic induction line in a magnetic field, an induced electromotive force will be generated in the circuit, and the induced electromotive force generated is called an induced voltage.

[0028] Calculate the electromotive force, as shown in formula (1):

[0029] E=B·L·v (1)

[0030] Among them, B represents the magnetic field strength. Since the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com