Rotary integrated valve

An integrated valve and valve piece technology, applied in the field of reversing valves, can solve problems such as single angle of multi-channel valves, complex integrated valve structure, complex control system, etc., achieve corrosion-resistant service life, controllable and adjustable switching speed, avoid The effect of cross contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

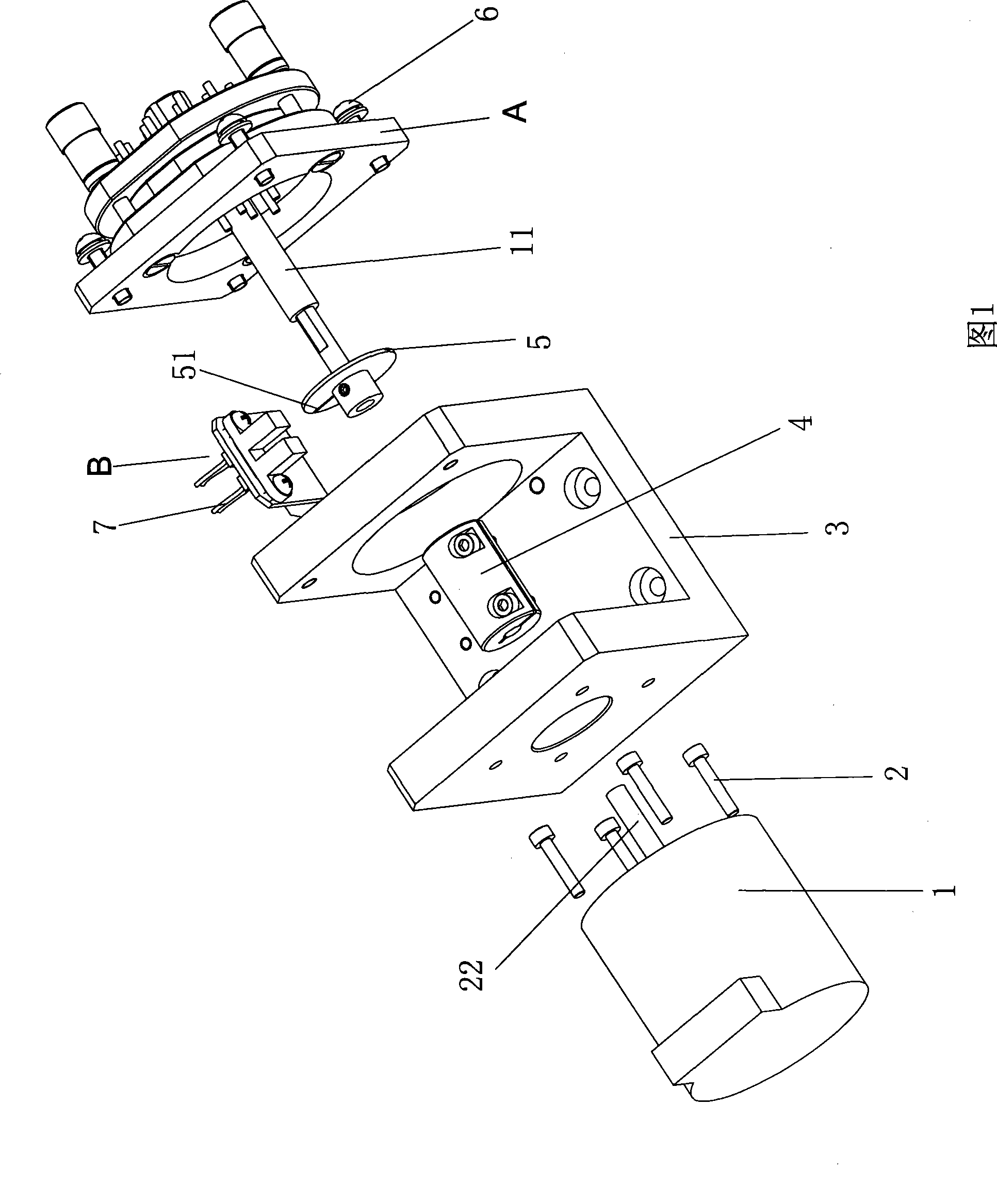

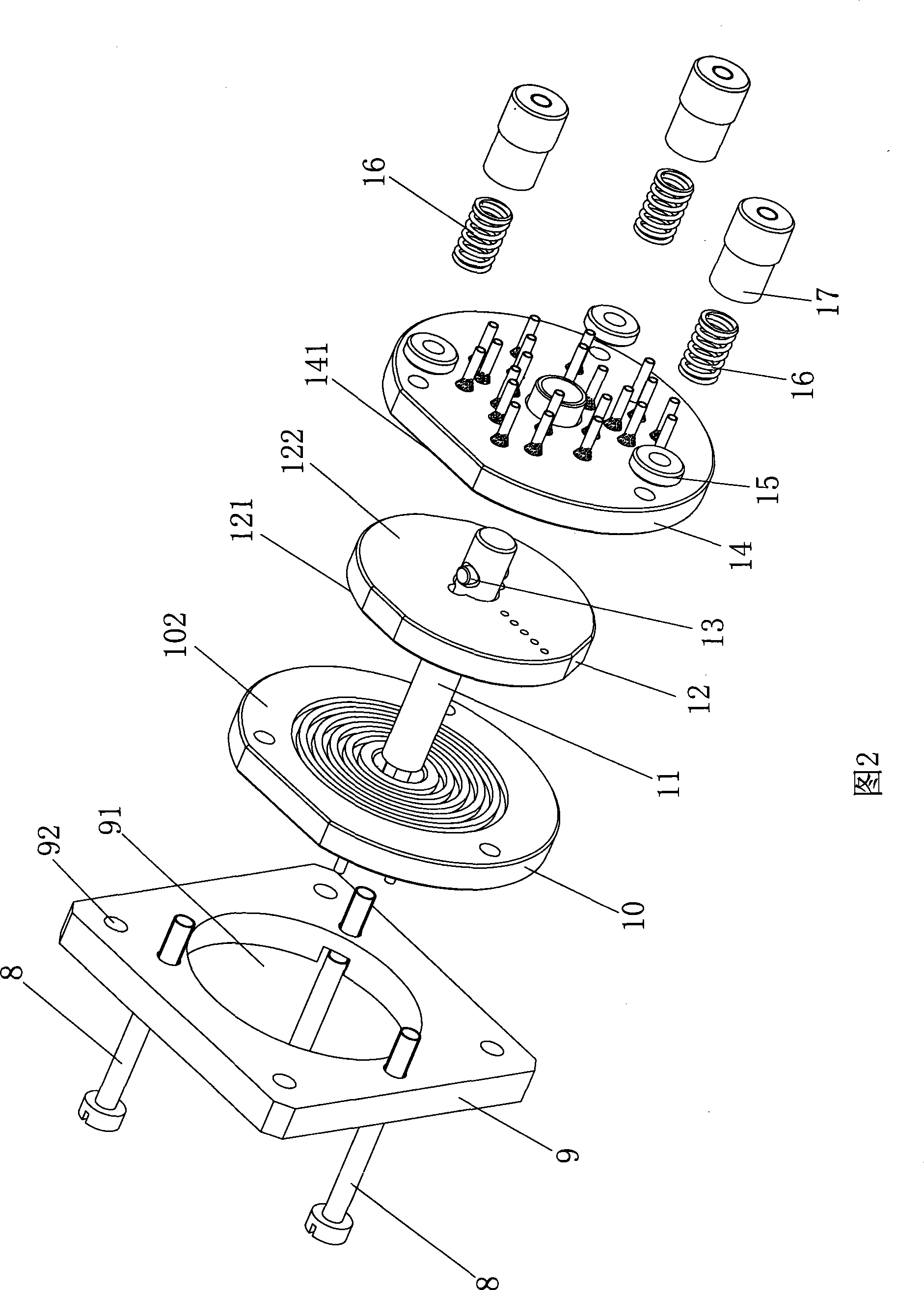

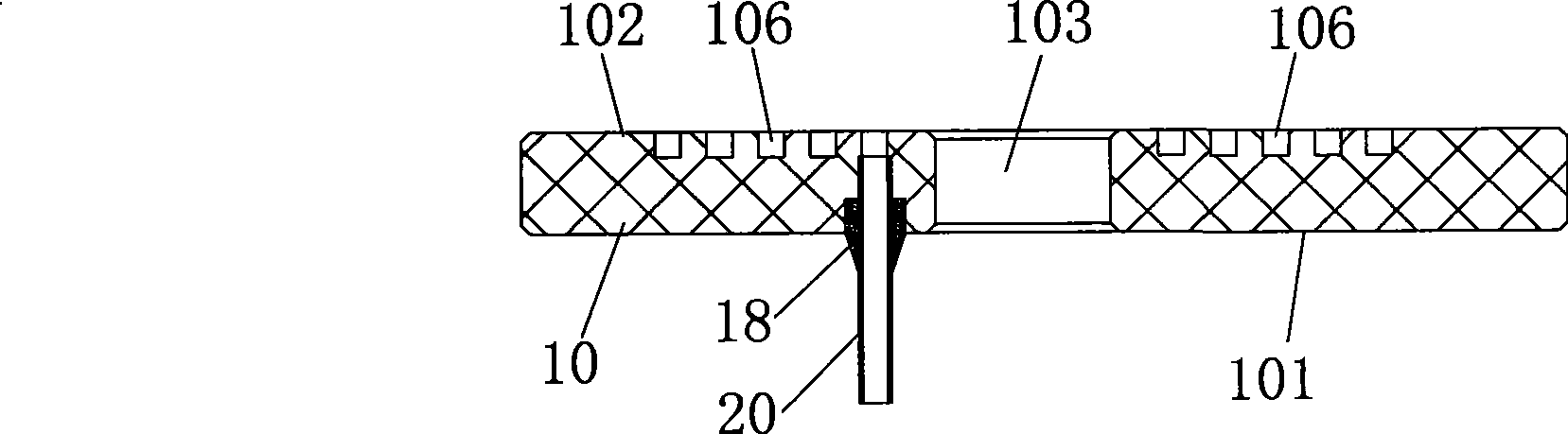

[0042] Figure 1 to Figure 9 As shown, the rotary integrated valve in this embodiment includes a driving mechanism 1 , a base 3 , a valve plate assembly A and a detection component B. The driving mechanism 1 is used to provide power, such as a stepping motor or a servo motor. The driving mechanism 1 is fixed on the base 3 through a fastener 2 , and the valve plate assembly A is fixed on the base 3 through a fastener 6 . The driving mechanism 1 has an output shaft (motor shaft of a stepping motor or a servo motor) 22, and the valve plate assembly A has a rotating shaft 11. The output shaft 22 and the rotating shaft 11 are coaxial and connected by a shaft coupling 4. The driving mechanism 1 drives the rotating shaft 11 to rotate. The detection part B includes a part 5 with a notch 51 and a photoelectric detection element 7 installed on the rotating shaft 11. The initial position of the rotating shaft 11 and the position during the rotation are detected and calibrated through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com