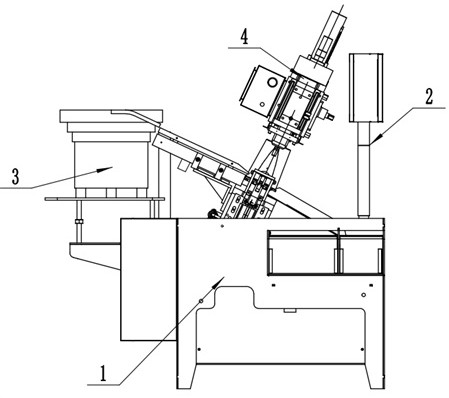

Patents

Literature

120results about How to "Drilling stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

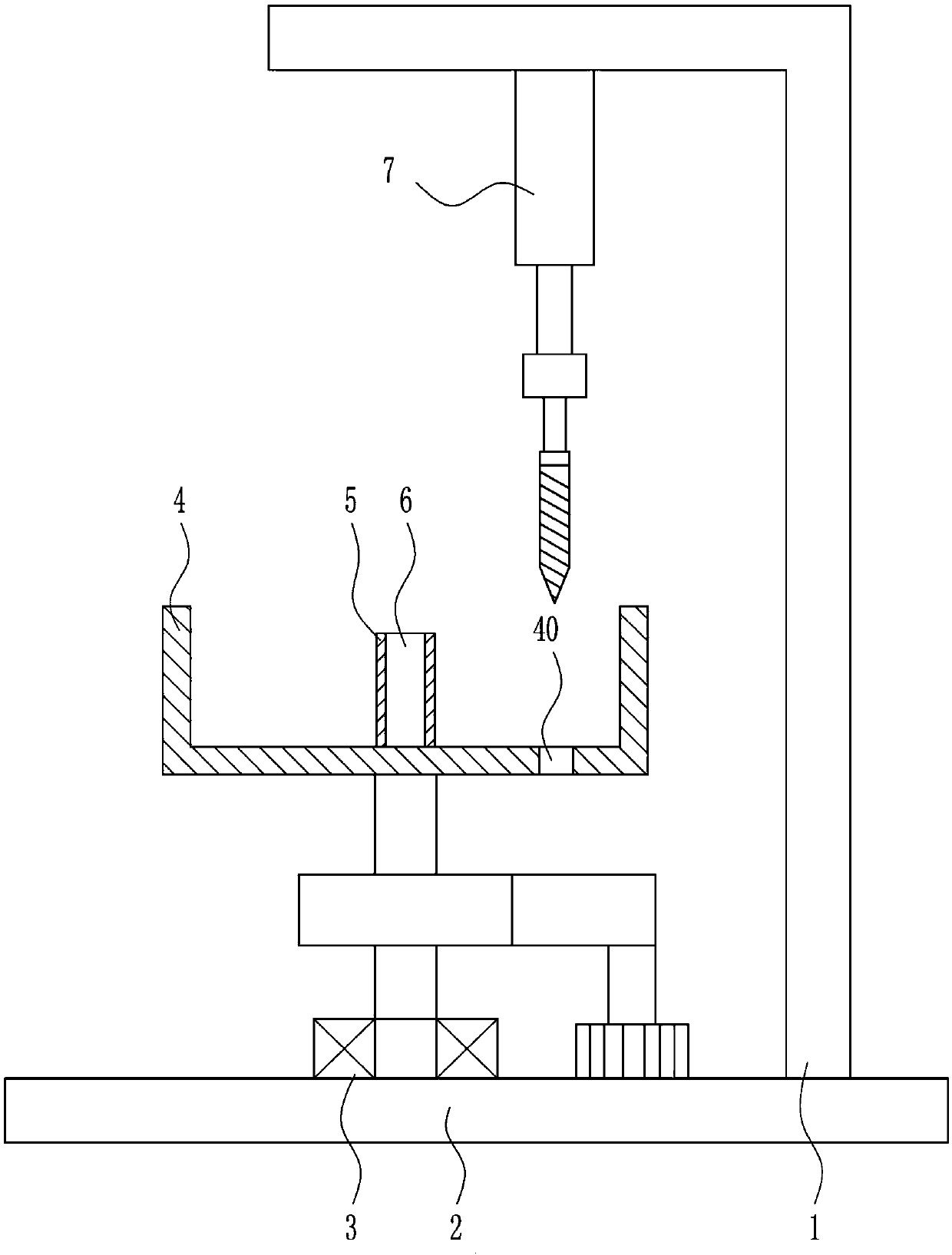

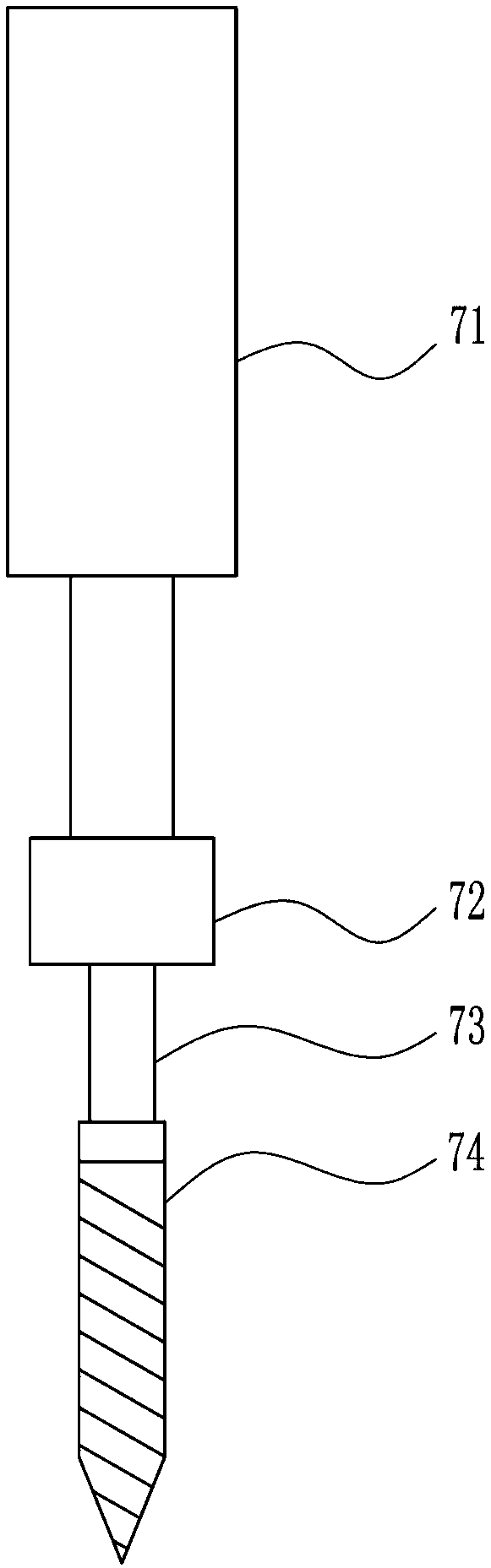

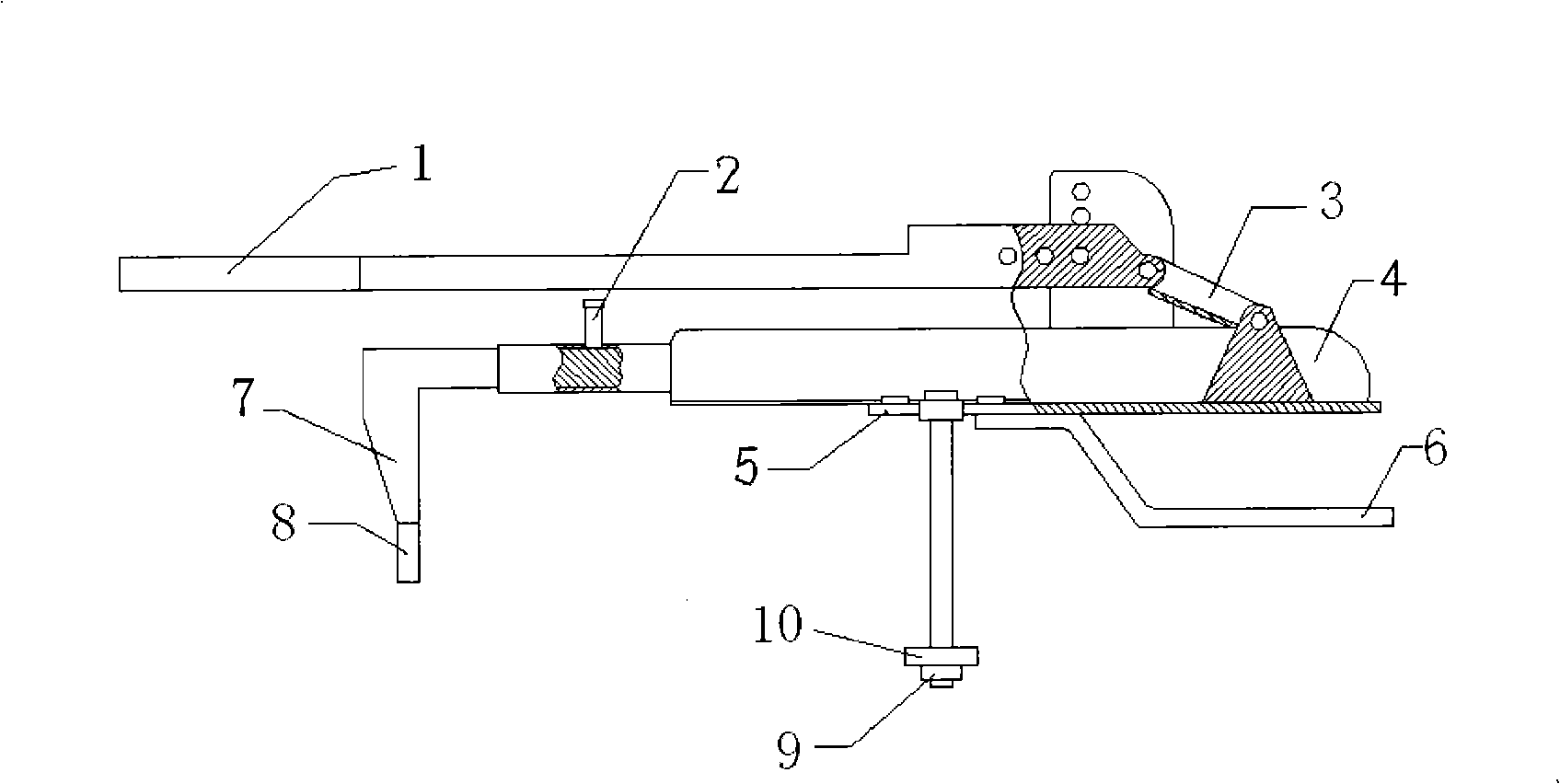

Hardware drilling equipment

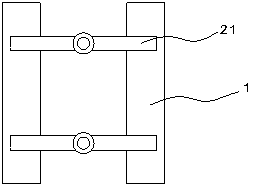

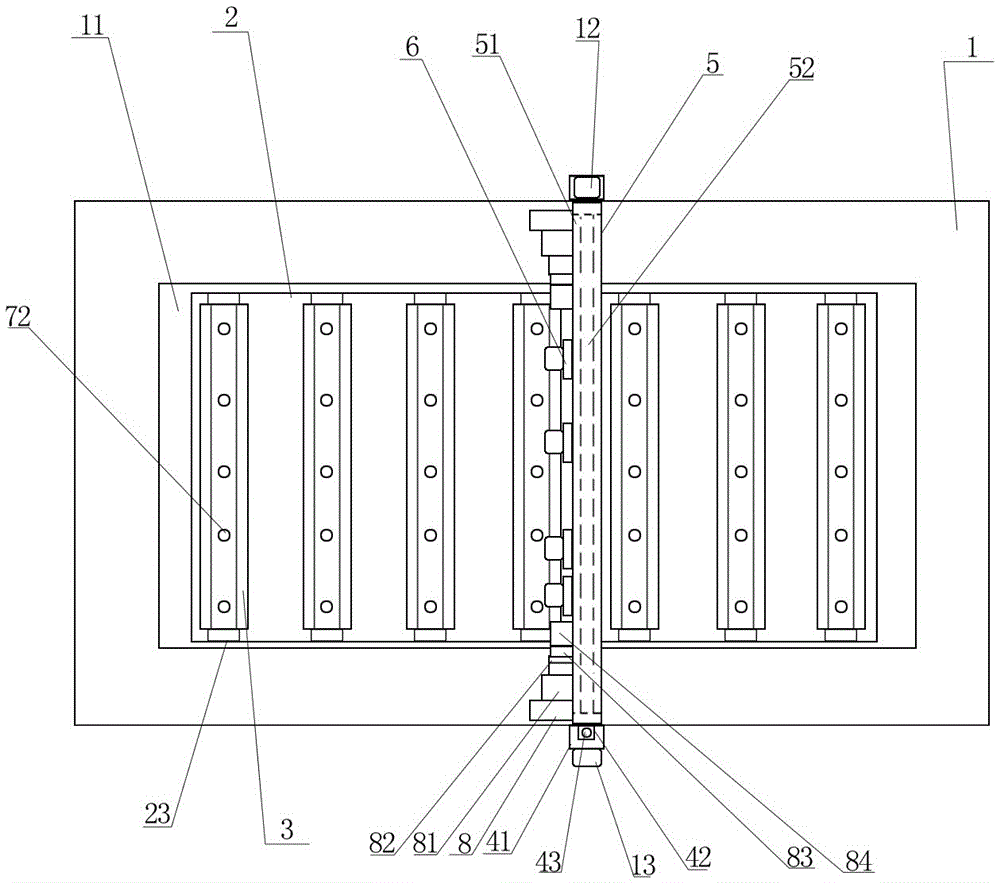

InactiveCN106944640AEasy to adjustEasy clampingPositioning apparatusMetal-working holdersMoving partsDrilling machines

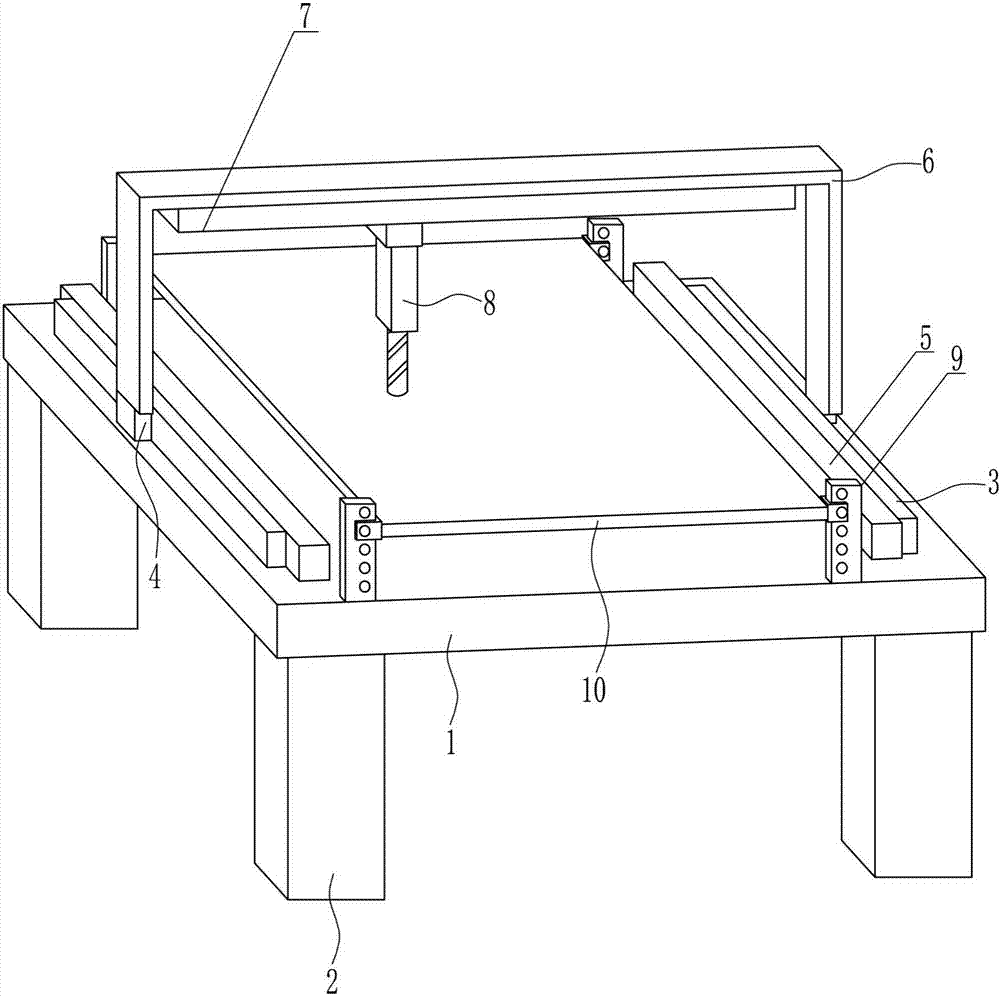

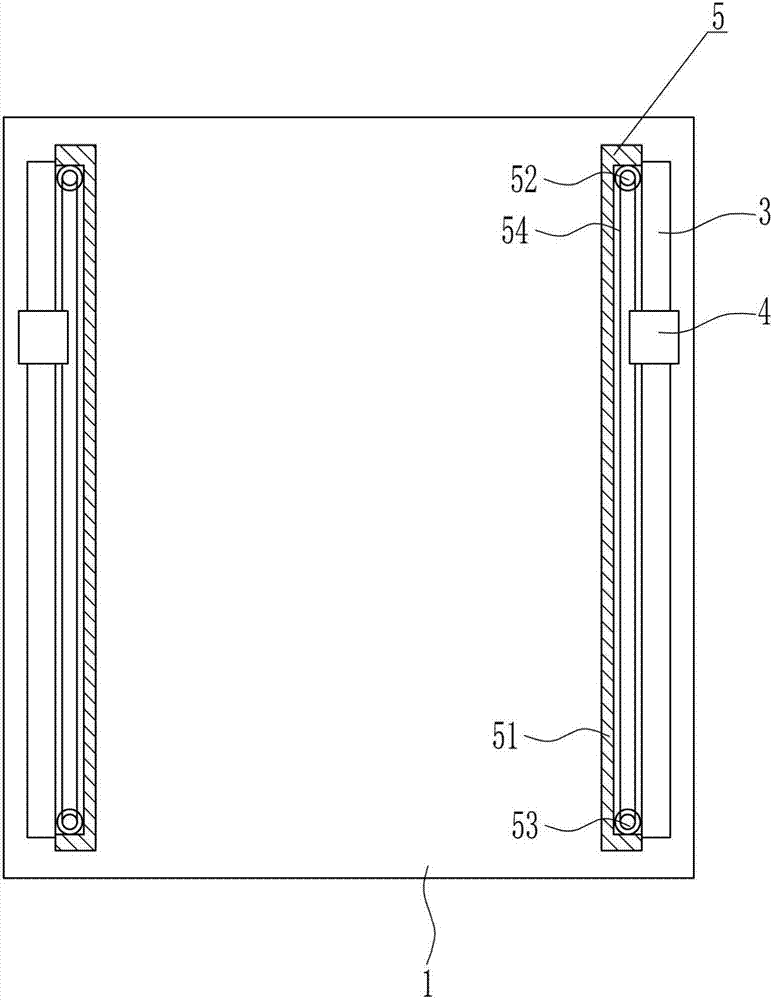

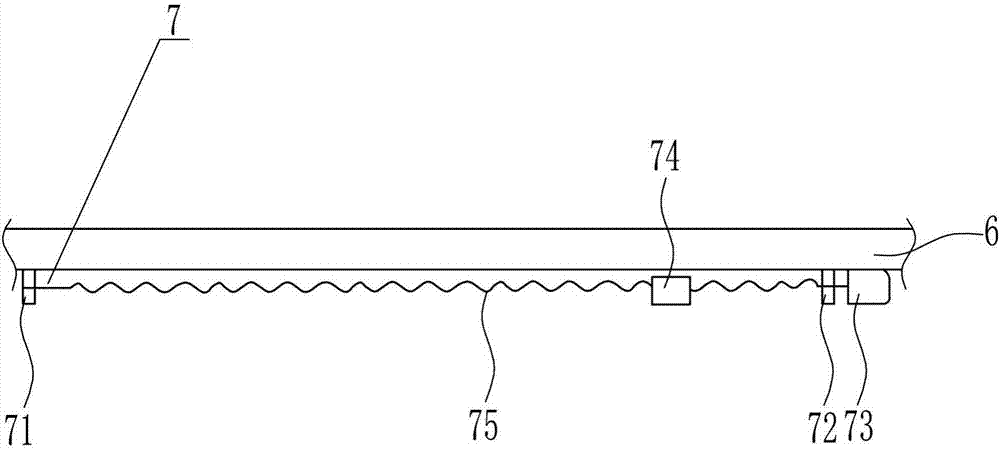

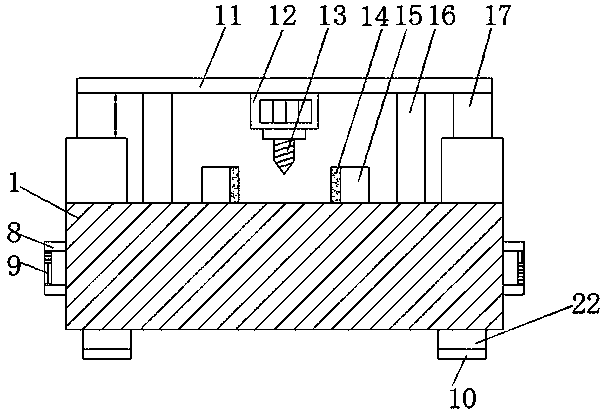

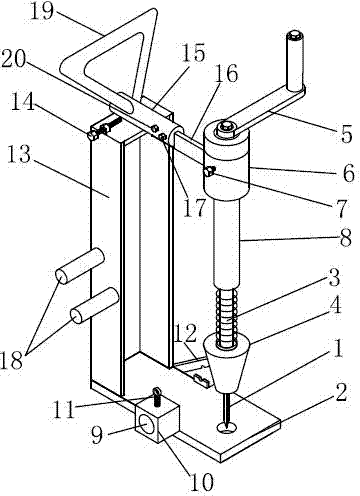

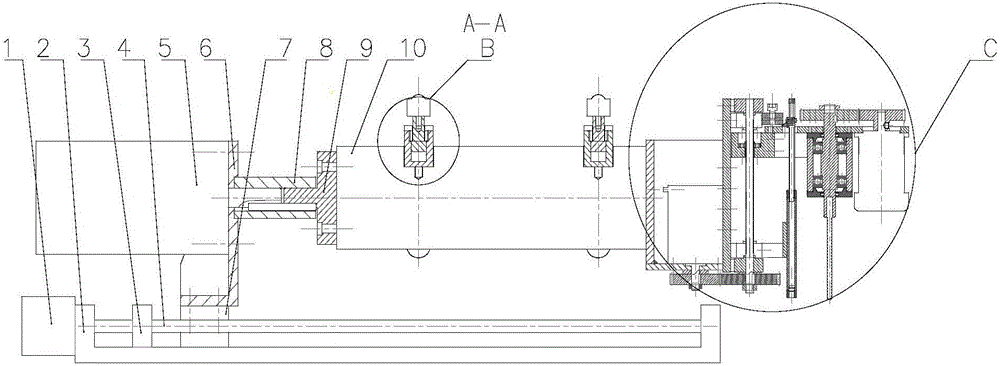

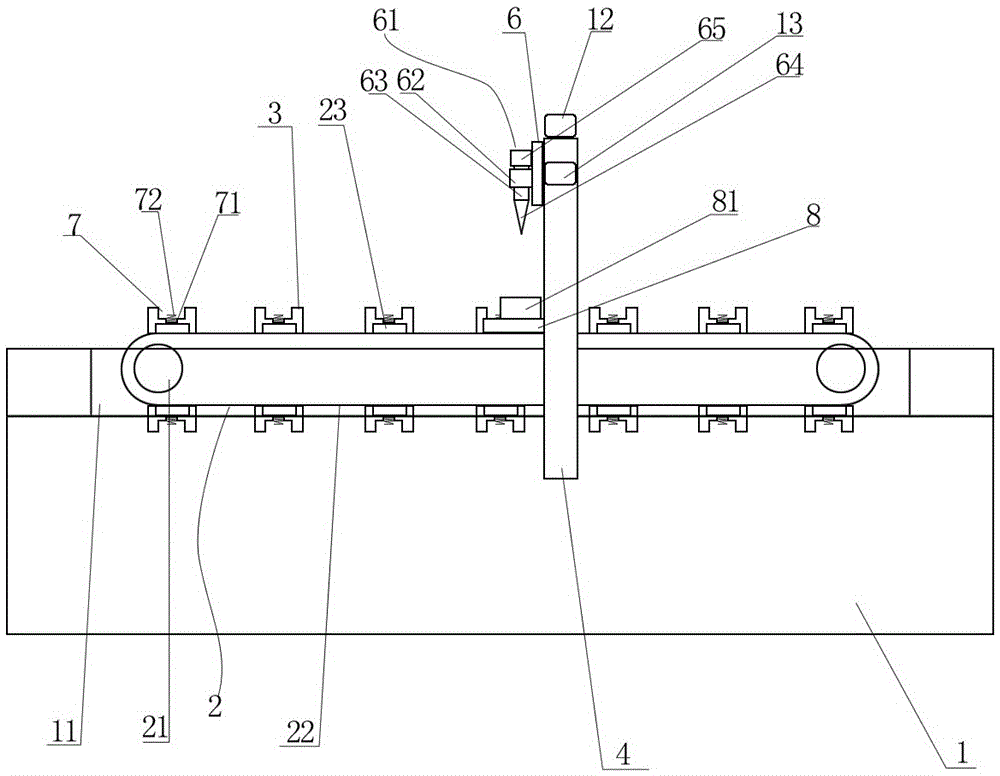

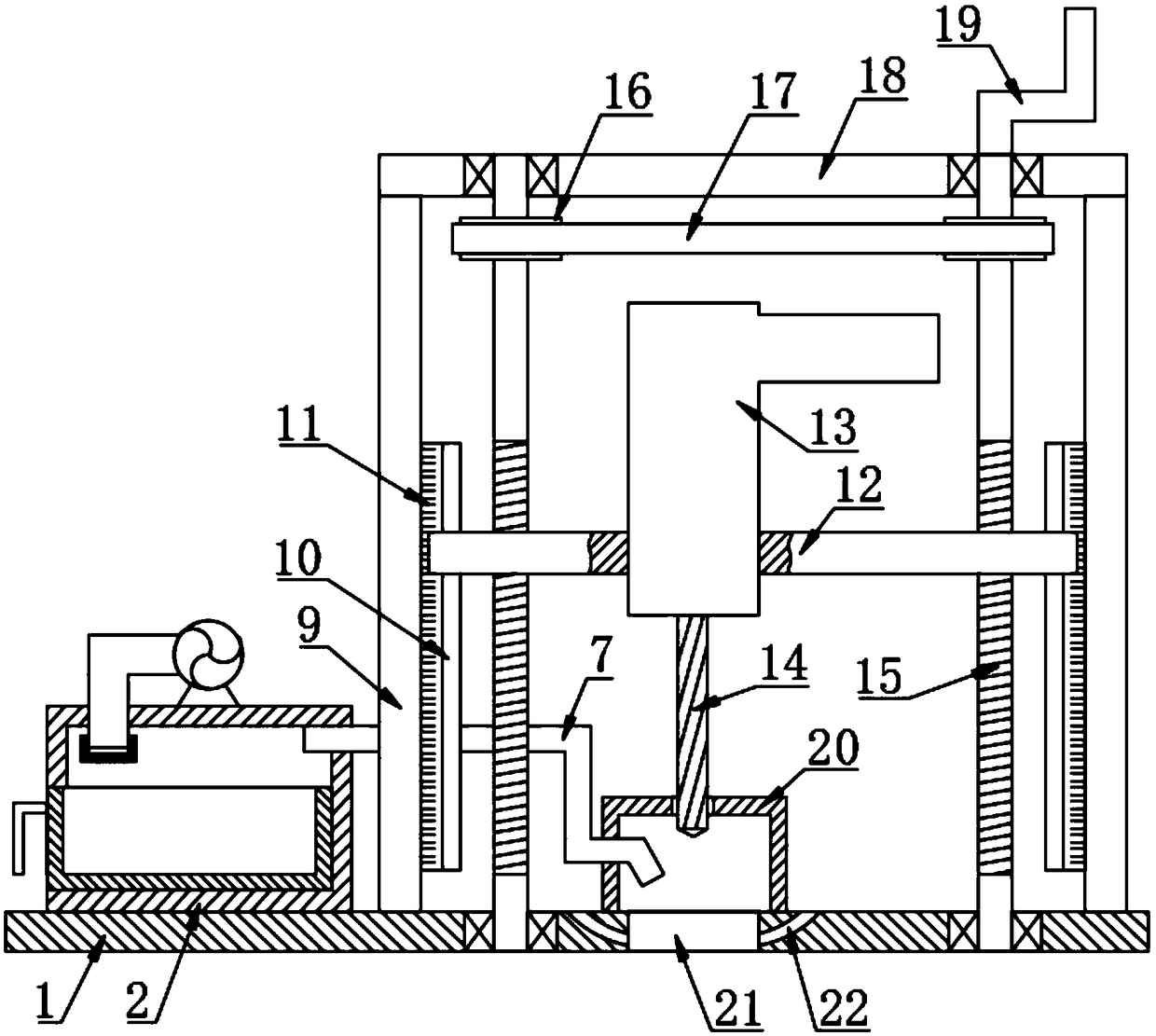

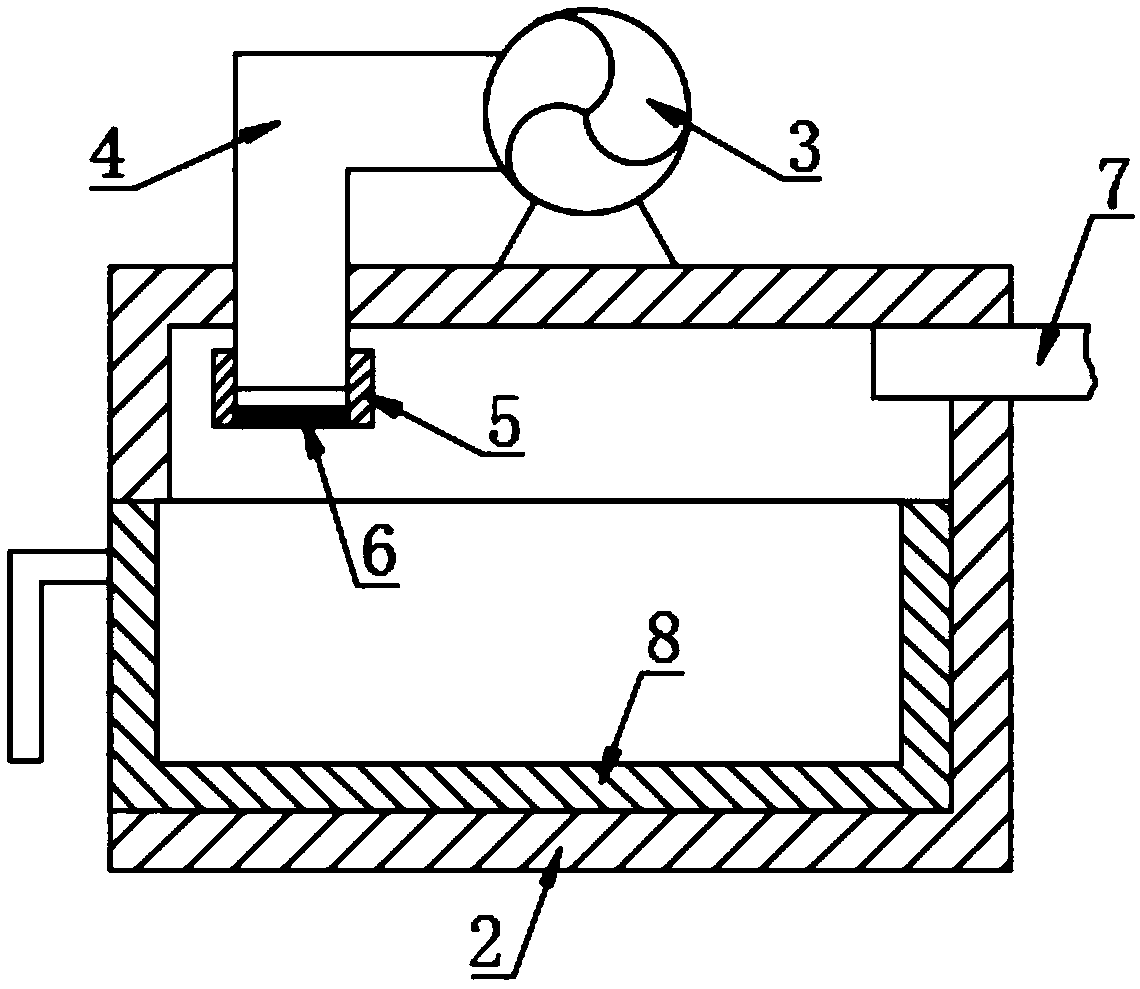

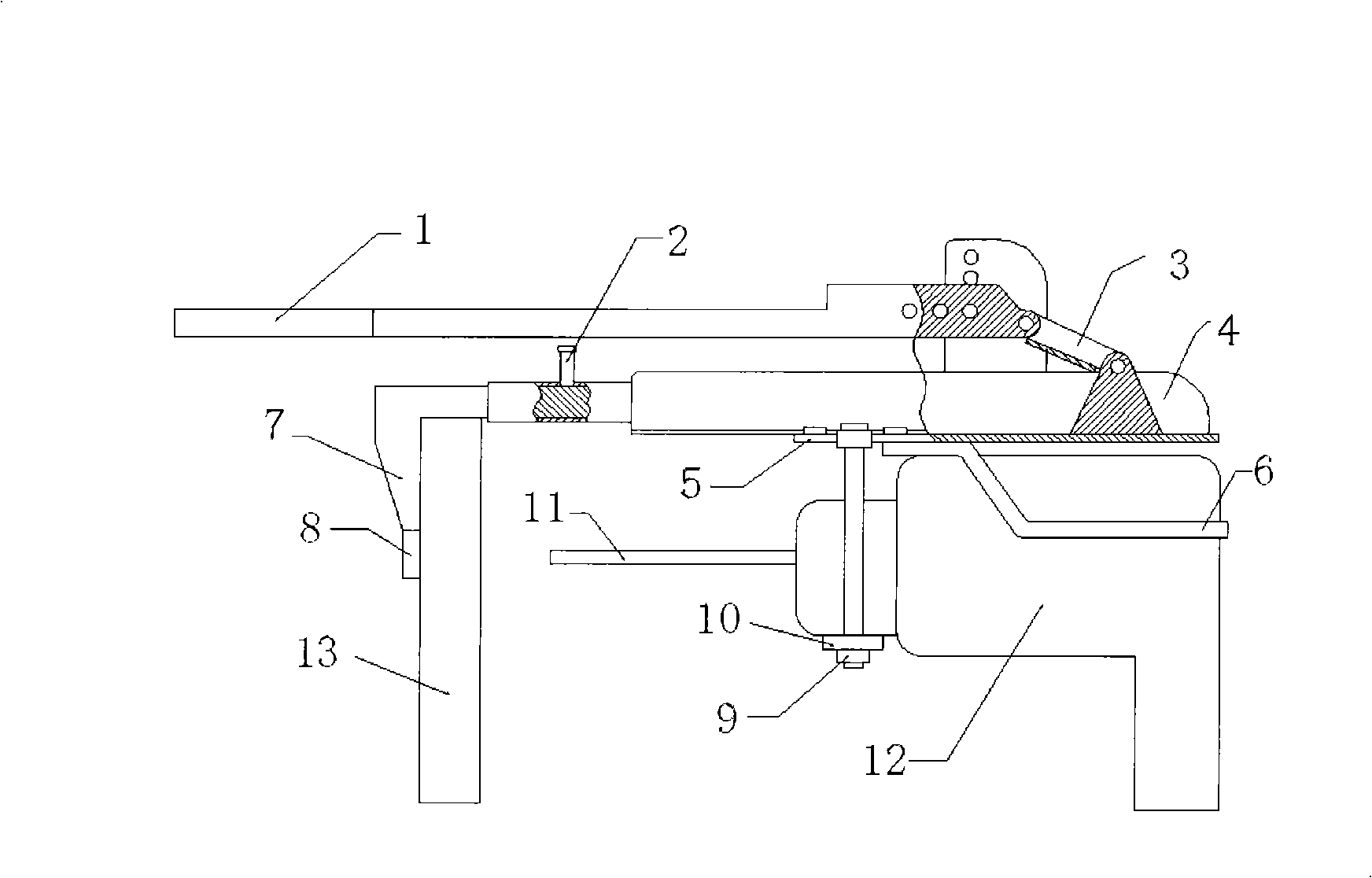

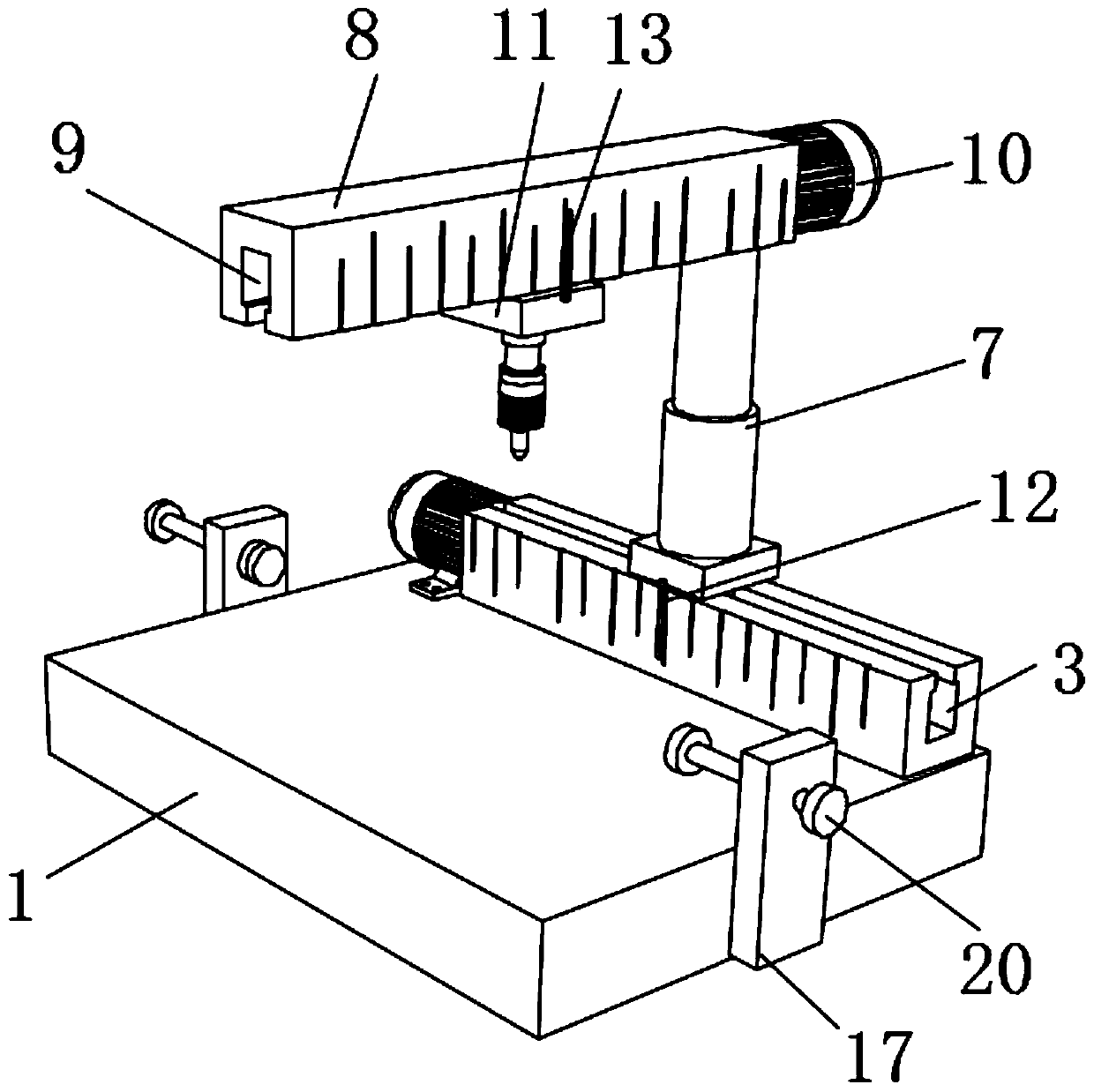

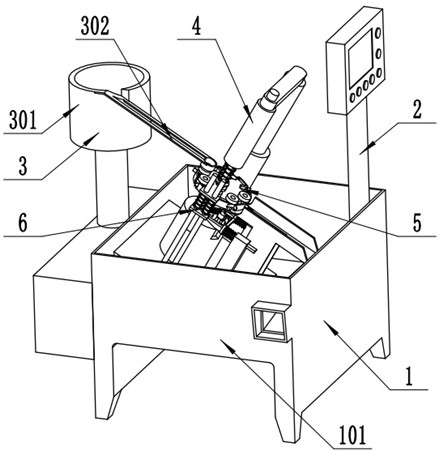

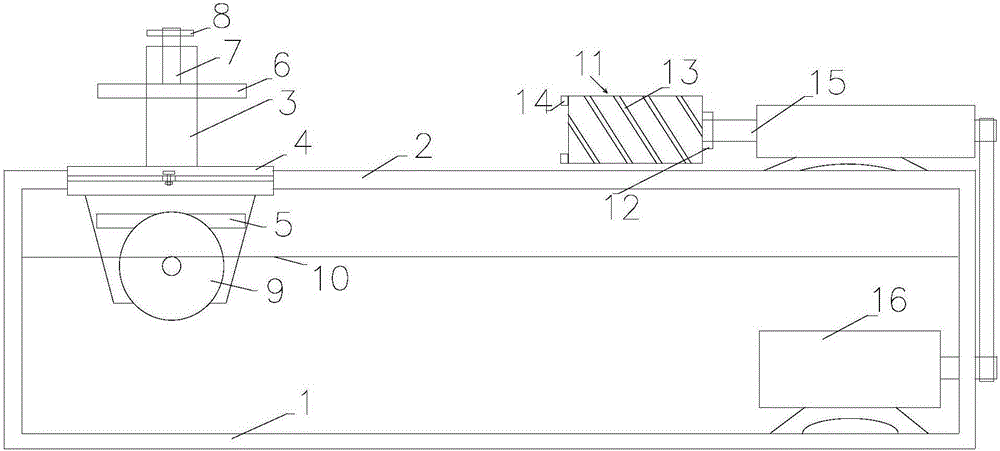

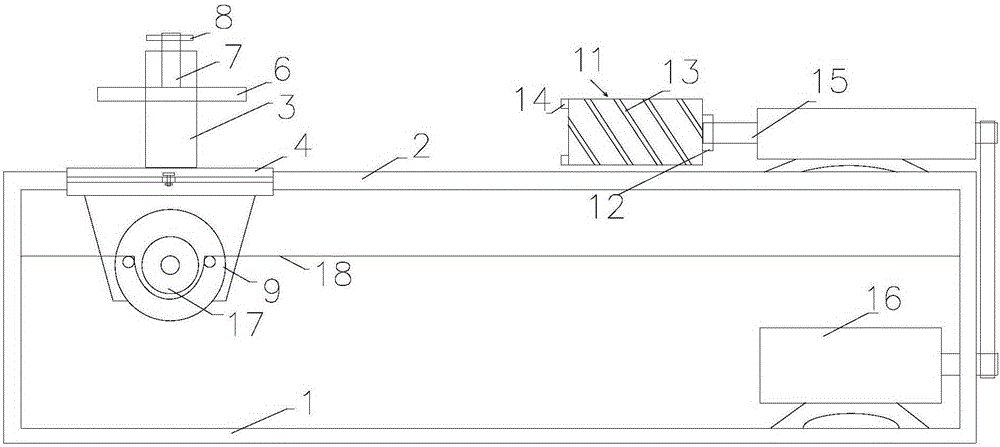

The invention belongs to the technical field of hardware and particularly relates to hardware drilling equipment. The hardware drilling equipment is easy to operate, stable in drilling, good in drilling effect and high in working efficiency, and comprises a base, supporting legs, first sliding rails, a first sliding block, front-back moving devices, an n-shaped support and the like, wherein the supporting legs are arranged at the bottom of the base; the first sliding rails are symmetrically arranged on the left side and the right side of the top of the base; the first sliding block is sliably arranged on the first sliding rails; the front-back moving devices are symmetrically arranged on the left side and the right side of the portion, between the two first sliding rails, of the top of the base; and moving components of the front-back moving devices are connected with the first sliding block. By means of the front-back moving devices and left-right moving devices, a drilling machine can be adjusted to any position, drilling is convenient, and hardware can be well clamped by a clamping device.

Owner:叶宝义

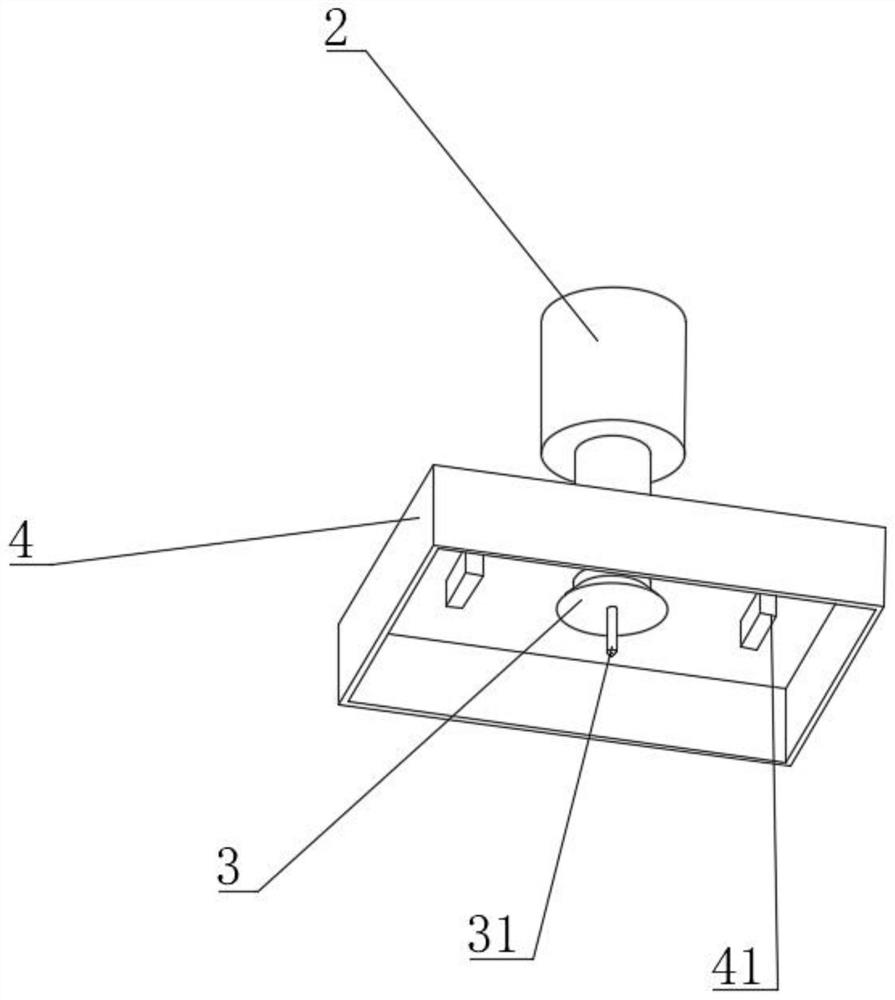

Drilling machine for gear machining

InactiveCN108500322APrevent dumpingReduce labor costsMachine framesPositioning apparatusBlock matchMachining

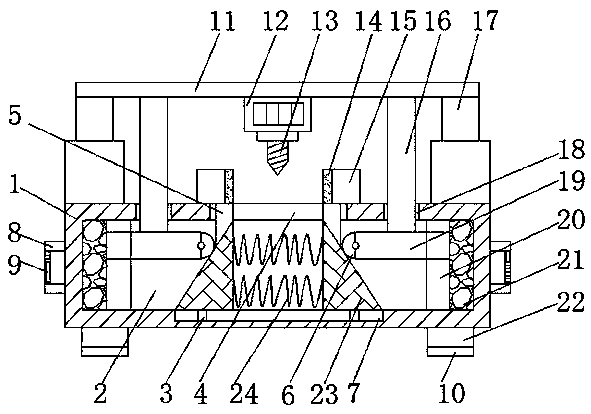

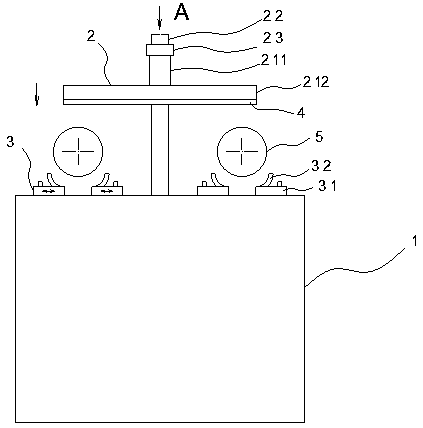

The invention discloses a drilling machine for gear machining. The drilling machine comprises an operation table. Two symmetric electric push rods are fixedly connected to the upper surface of the operation table. A linkage plate is arranged at the tops of the electric push rods. The bottom of the linkage plate is fixedly connected with the upper surfaces of the two electric push rods. The bottomof the linkage plate is fixedly connected with a motor. The output end of the motor is fixedly connected with a drill bit. A cavity is formed in the operation table. A sliding groove is formed in theinner bottom wall of the cavity. A through groove is formed in the inner top wall of the cavity. Two symmetric inclined blocks are arranged in the cavity. The bottom of each inclined block is fixedlyconnected with a sliding block matched with the sliding groove. Each sliding block is connected in the sliding groove in a clamped manner. Two symmetric springs are arranged in the cavity, and the springs are located between the two inclined blocks. The drilling machine for gear machining is high in overall stability and convenient to move, a gear can be automatically clamped, convenience and rapidness are achieved, and the requirements of users can be met.

Owner:杨秀波

Application method for clamping device of electric cabinet

InactiveCN106826300APrevent slidingReduce vibrationPositioning apparatusMetal-working holdersMechanical engineering

Owner:CHENGDU ZHENZHONG ELECTRIC

Fixing rack for tapping of oil cylinder

InactiveCN104354023ADrilling stabilityReliable processingPositioning apparatusMetal-working holdersEngineeringMechanical engineering

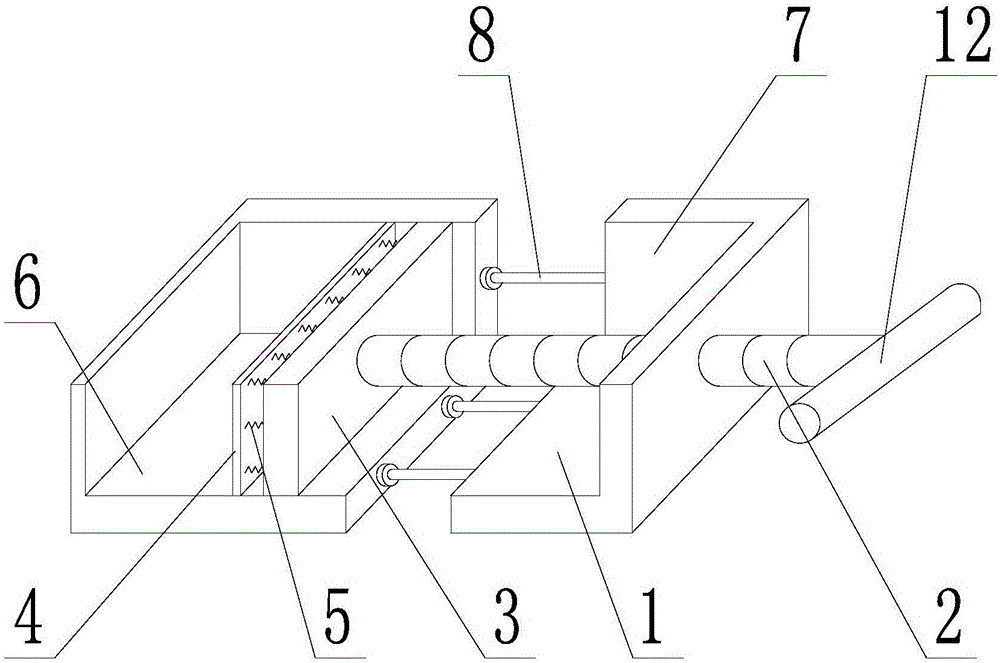

The invention provides a fixing rack for tapping of an oil cylinder. The fixing rack is simple in structure and convenient to process, improves the clamping reliability and comprises a worktable, a pair of lifting mechanisms and a pair of supporting mechanisms, wherein the pair of lifting mechanisms and the pair of supporting mechanisms are respectively arranged on the worktable, and the pair of lifting mechanisms are positioned between the pair of supporting mechanisms; each lifting mechanism comprises a pressing plate, a screw and a nut, the screw is vertically arranged on the worktable, the pressing plate is provided with a middle hole and horizontally sleeves the screw through the middle hole, the nut is connected to the screw and positioned above the pressing plate, and the pressing plate is positioned above the pair of supporting mechanisms; each supporting mechanism comprises a pair of symmetric slide blocks, a circular-arc-shaped support plate is arranged on the slide blocks, and the slide blocks are movably connected to the worktable. The fixing rack is stable and reliable in processing and low in cost.

Owner:HUZHOU HUANFENG MACHINERY

Sound wave method testing method for tunnel surrounding rock loosening circle

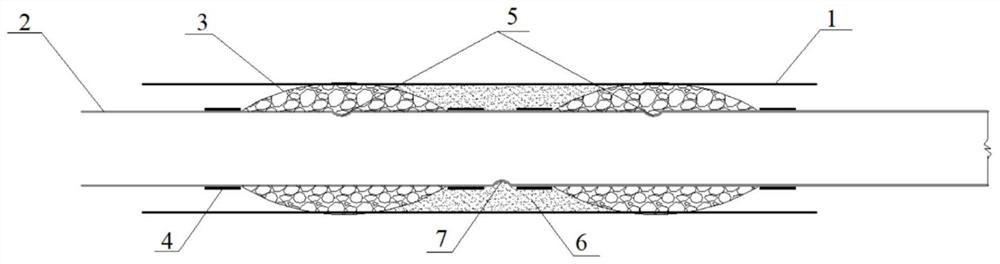

PendingCN111708077AGood water blocking effectDrilling stabilitySeismologySealing/packingReflected wavesEngineering

The invention provides a sound wave method testing method for a tunnel surrounding rock loosening circle. The method comprises the following steps: drilling a test drill hole in tunnel surrounding rock, arranging the grouting type bags on the upper inner wall and the lower inner wall of the drilled hole, placing the hole sealing pipe in the drilled hole, forming a grout overflowing opening and a grout outlet in the outer wall of the hole sealing pipe, enabling a testing instrument to penetrate through the hole sealing pipe, injecting grout into the grouting type bags through the grout outlet,and after grout in the grouting type bags reaches specific strength, injecting the slurry through the grout overflowing opening, injecting water into the hole sealing pipe, after the whole drilled hole is filled with the water, using the water as a coupling agent, using a testing instrument to emit sound waves to tunnel surrounding rock of the tunnel surrounding rock, and determining the range ofthe tunnel surrounding rock loosening circle according to the change condition of the reflection wave velocity of the tunnel surrounding rock. Aiming at complex geology, high ground stress areas and loose and broken surrounding rocks, the invention provides the method for testing the loose circle of the tunnel surrounding rocks by the acoustic wave method, the water plugging effect is improved through the hole sealing pipe, and the hole protection section ensures the drilling stability.

Owner:BEIJING JIAOTONG UNIV +1

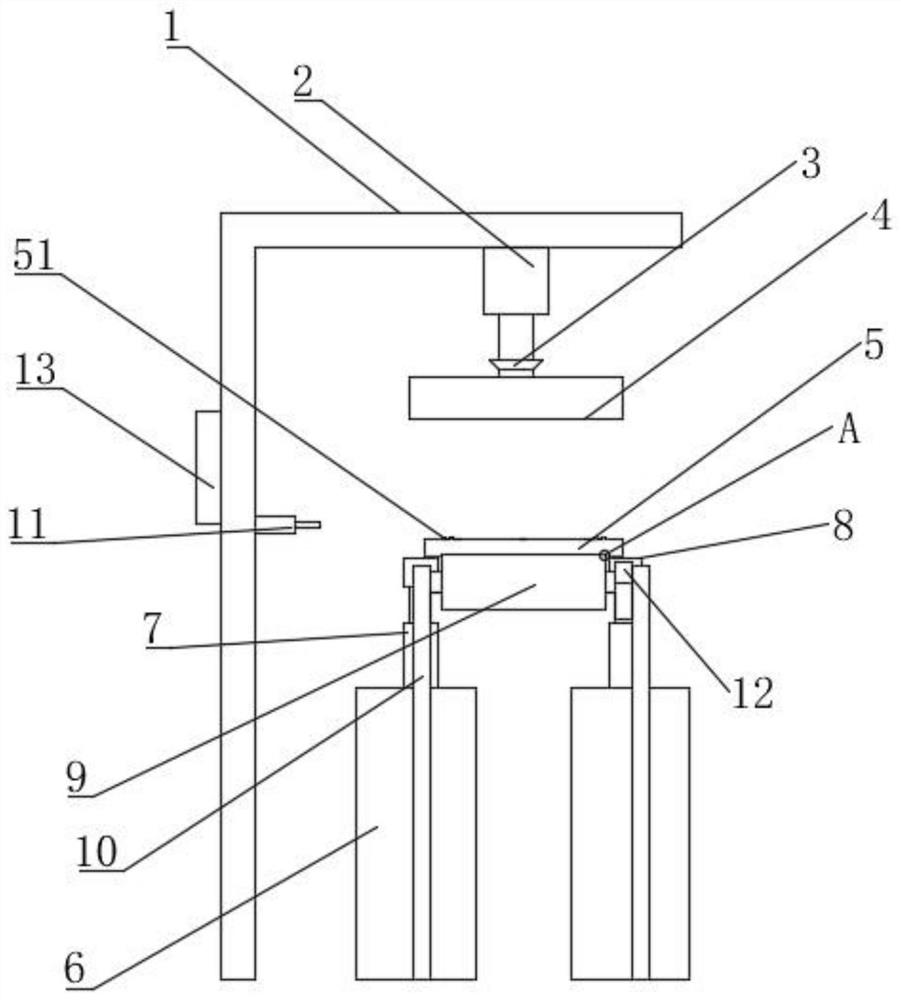

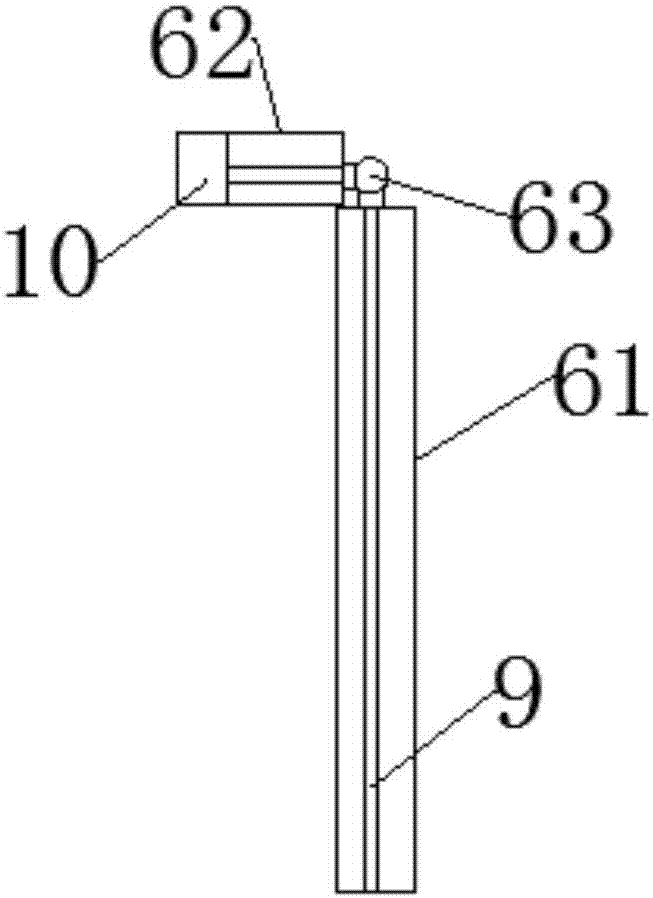

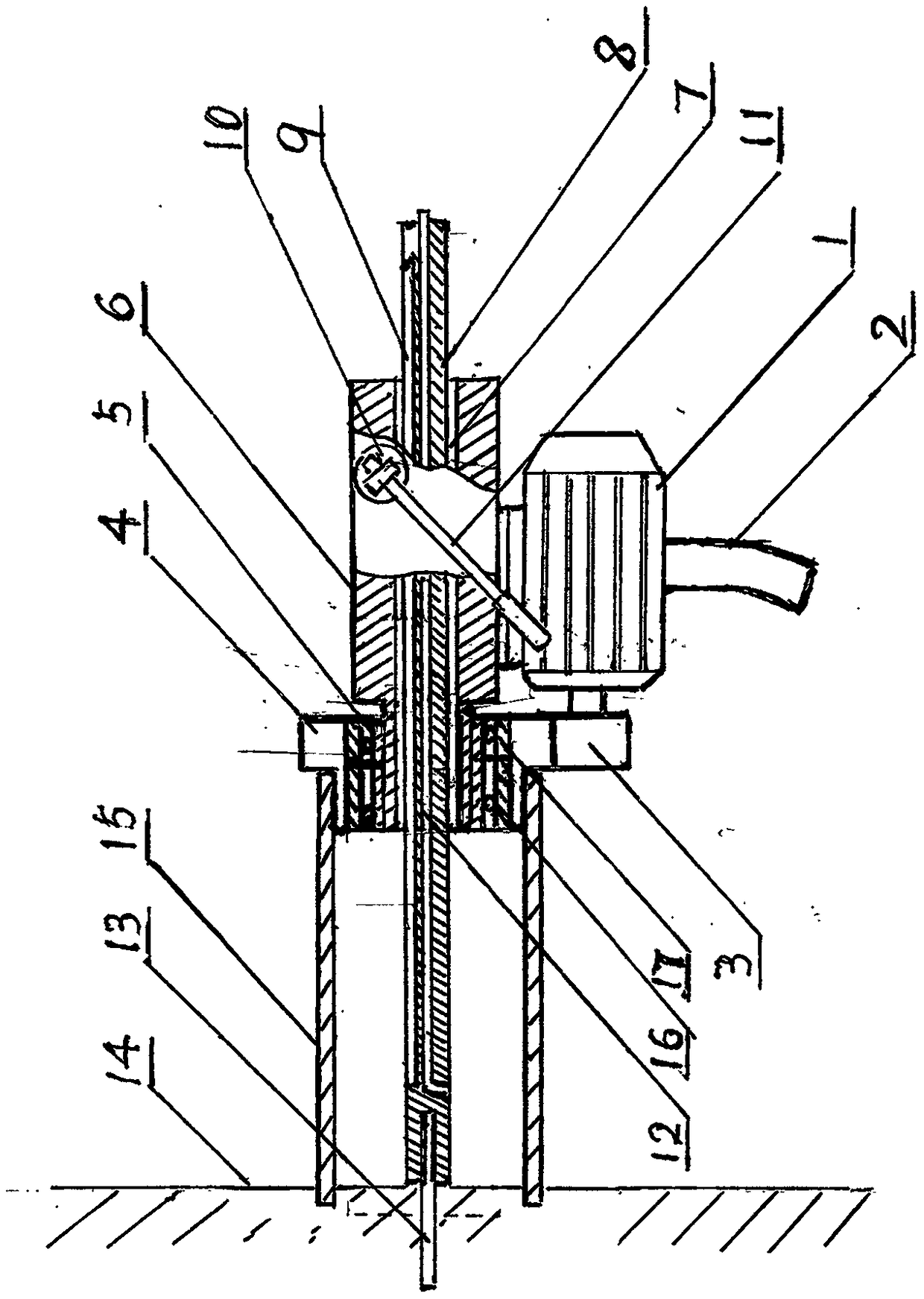

Maintenance tool used by low voltage electrician

The invention discloses a maintenance tool used by a low voltage electrician. The maintenance tool used by the low voltage electrician comprises a hand drill support composed of a stand column, a drill piece supporting plate and a beam, wherein a hand drill is connected to the beam. A counter bore corresponding to a drill bit of the hand drill is formed in the drill piece supporting plate, a wire nose pressing device for clamping a wire nose and a wire breaking cutter of a straw chopper type are arranged on the lateral side of the drill piece supporting plate, the hand drill is hinged to the beam through a second beam, and horizontal and perpendicular positioning pins are further arranged on the beam and the second beam. Two supporting columns are welded to the side faces of the stand column. The hand drill comprises a drill stem of the hand drill, wherein the bottom of the drill stem of the hand drill is connected with a drill chuck through threads, the top of the drill stem of the hand drill is fixedly connected with a rotating handle, and the drill stem of the hand drill is connected into a sleeve of the second beam in a sleeved mode. The maintenance tool used by the low voltage electrician has the advantages of being multiple in using function, convenient to carry and the like. The maintenance tool used by the low voltage electrician is a very practical maintenance tool of the low voltage electrician in maintenance work.

Owner:STATE GRID CORP OF CHINA +2

Cutting tool for drilling

InactiveCN102216009ADrilling stabilityTransportation and packagingTwist drillsEngineeringMechanical engineering

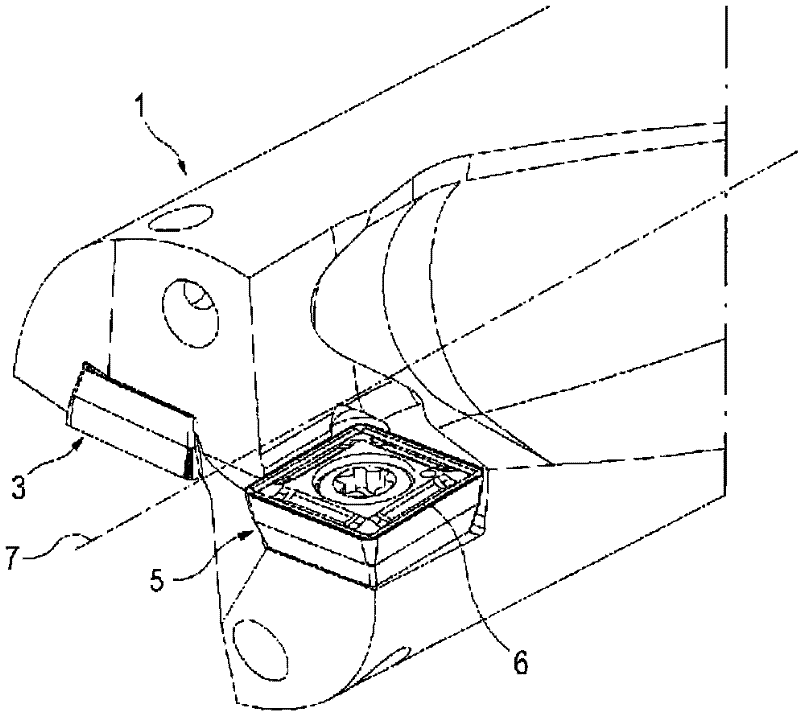

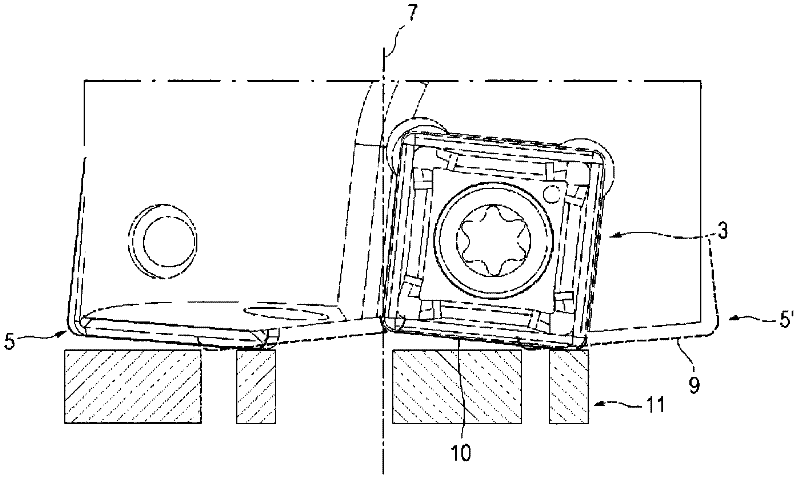

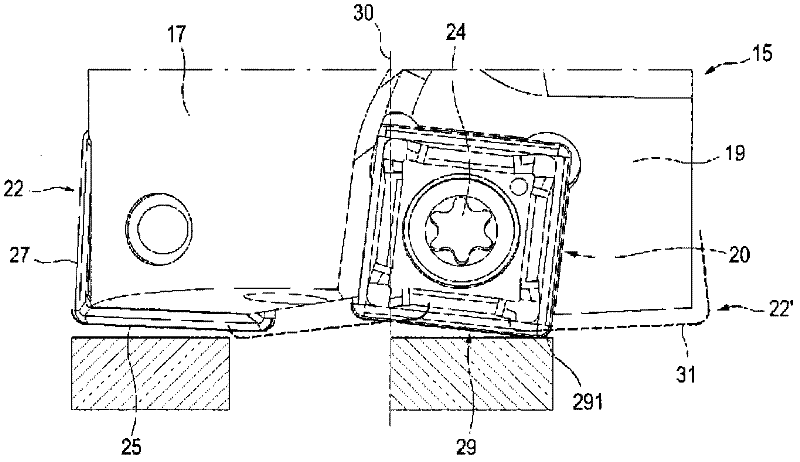

The present invention relates to a cutting tool for drilling having inserts in the same shape and being capable of discharging a chip in a chip flute. The cutting tool comprises: a body including a chip flute; and indexable inner and outer cutting inserts disposed in an insert pocket formed at an end of the chip flute. The inner cutting insert is located close to a central axis of the body compared to the outer cutting insert. The inner and outer cutting inserts have the same shape and include lower cutting edges for depth cutting during drilling. The lower cutting edge of the inner cutting insert is disposed lower than the lower cutting edge of an imaginary cutting insert at a position where the inner cutting insert is overlapped with the imaginary cutting insert where the outer cutting insert is rotated by approximately a half-turn relative to the central axis.

Owner:TAEGUTEC

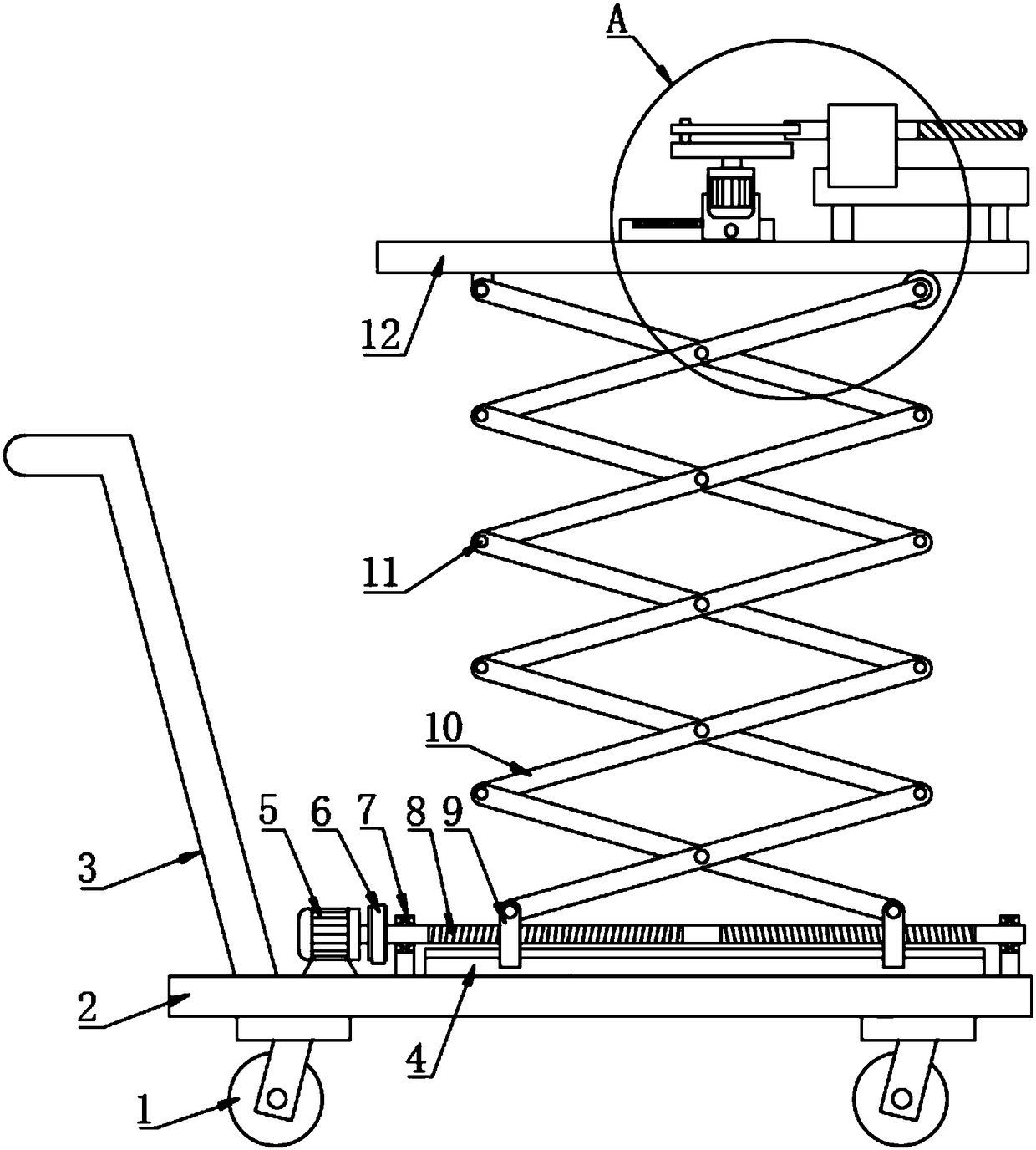

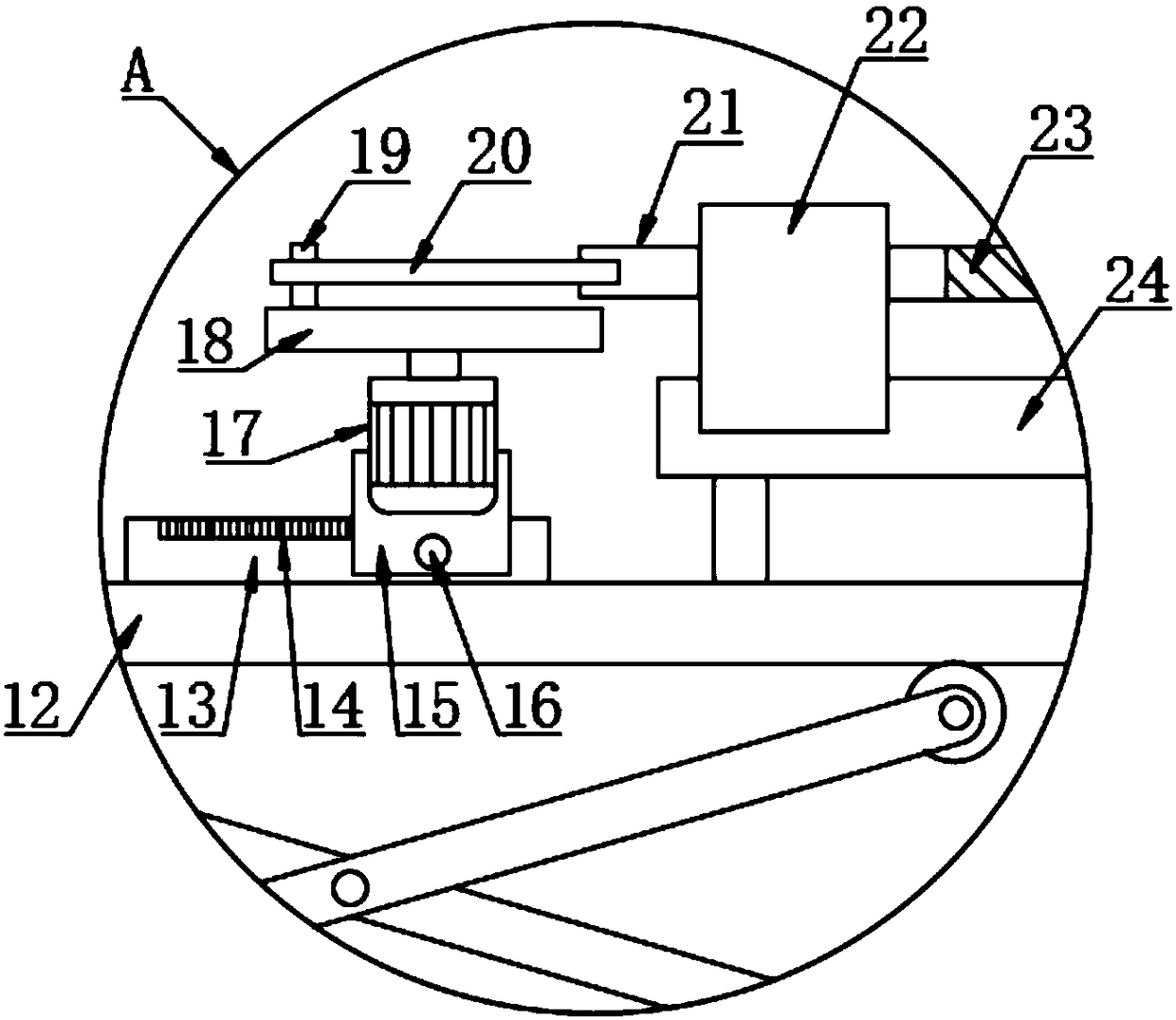

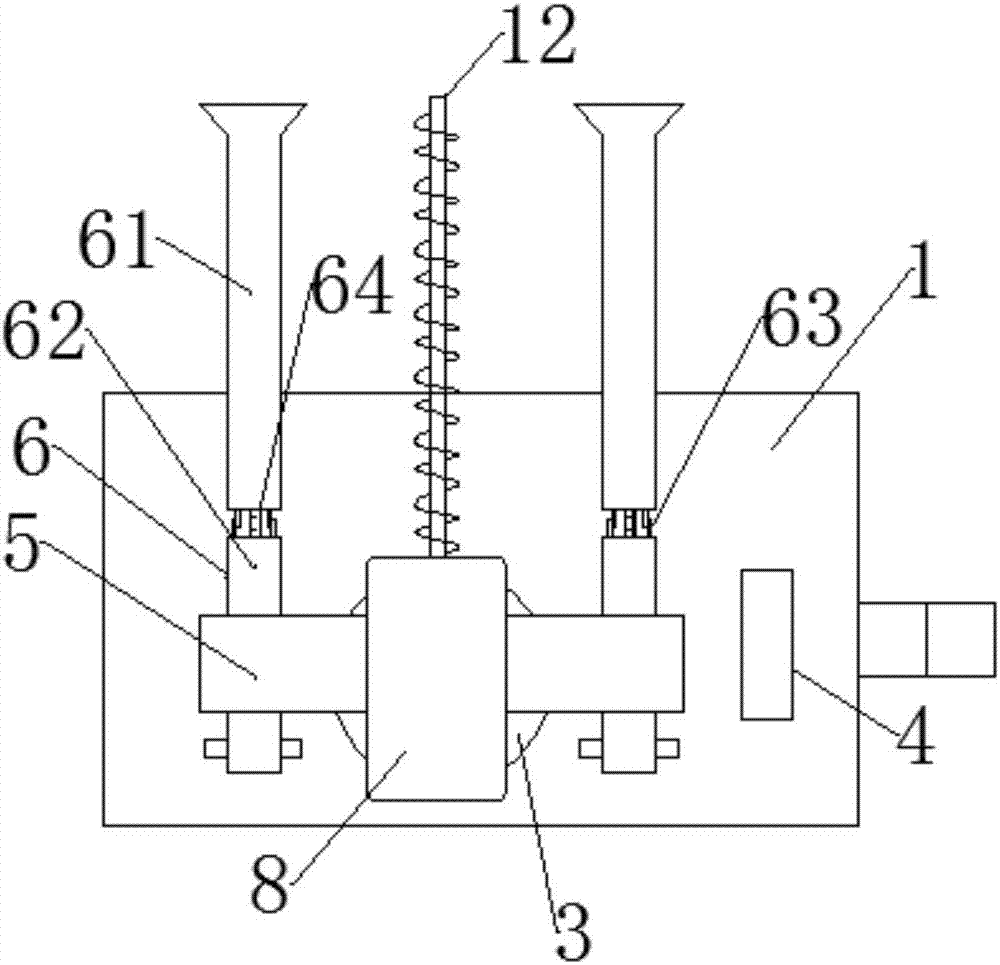

Lifting type wall boring device capable of adjusting boring depth

The invention discloses a lifting type wall boring device capable of adjusting boring depth, which comprises a base; the top part of the base is provided with front and back slide rails; the upper part of every slide rail is glidingly connected with left and right moving bases, upper parts of the moving bases are hinged with struts, left and right struts are intersected; the bottom end of the strut at the upper part is hinged with the top end of the strut at the lower part through a link rod, the upper part of the strut is provided with a top plate; the top part of the base is further fixedlyprovided with a first reducing motor, and a motor shaft at the right end of the first reducing motor is connected to the left end of the front side screw; the top part of the top plate is fixedly provided with a second slide rail through a bracket, the upper part of the second slide rail is glidingly connected with an electric drill, and the right side of the electric drill is connected with a drill bit. The boring height is adjustable, thus the trouble and risk of manually combining along with the electric drill are avoided; the boring depth can be adjusted in advance, thereby boring holes with different depths conveniently; the boring is more accurate.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

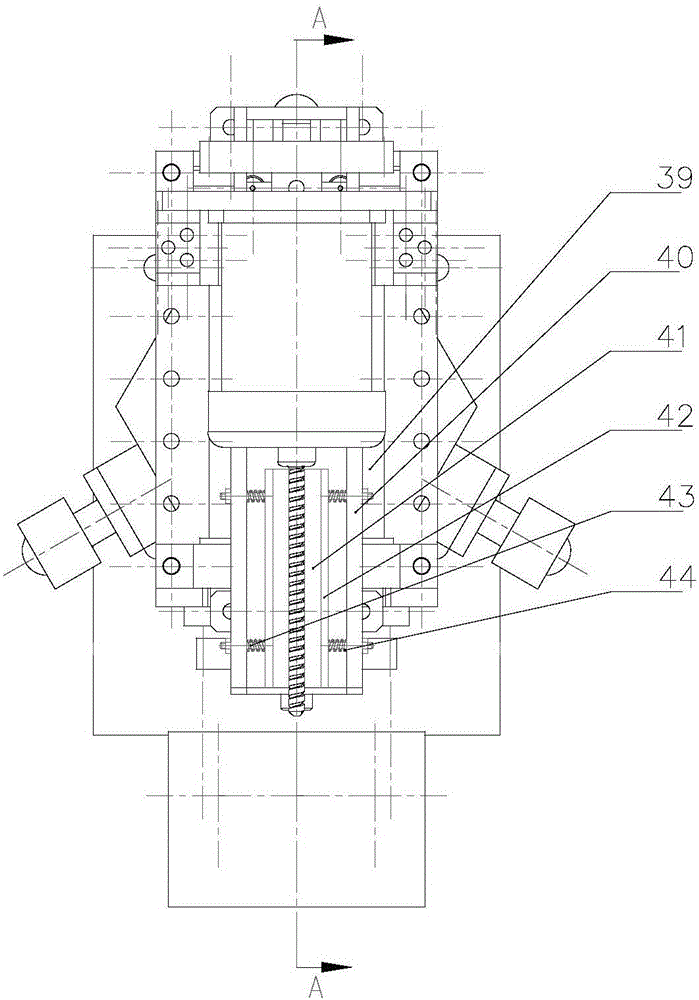

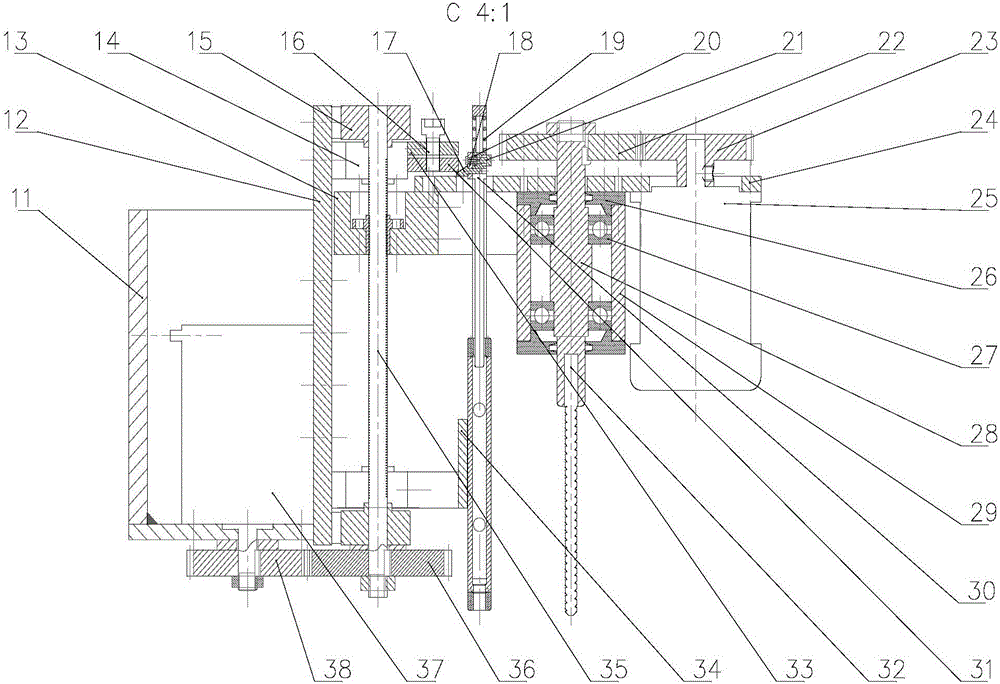

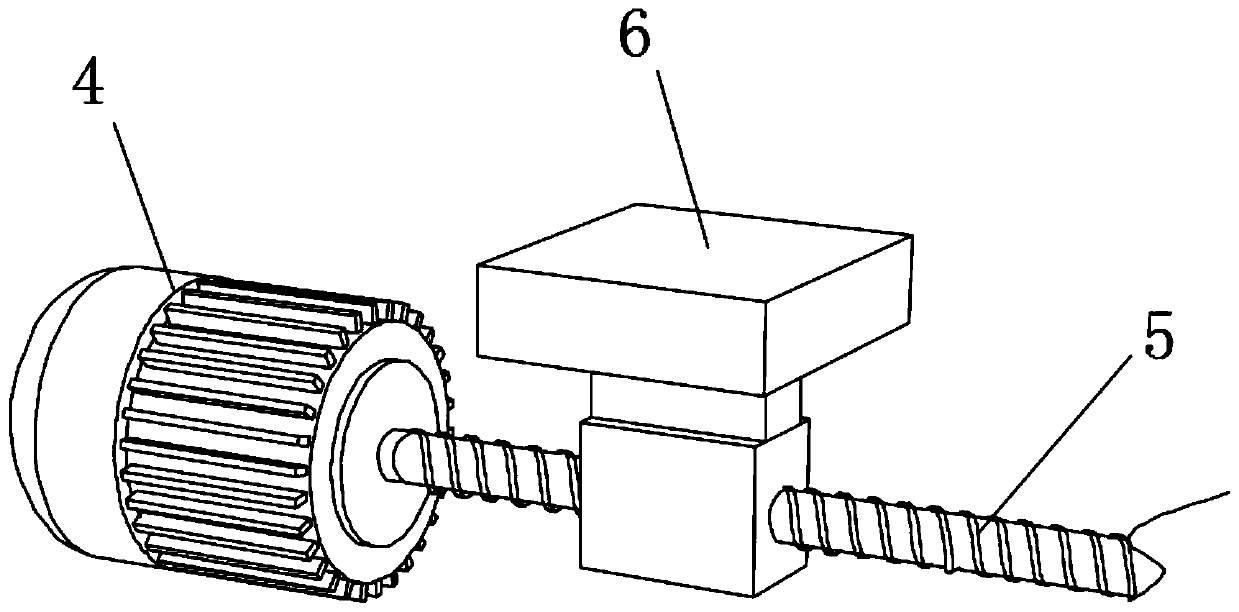

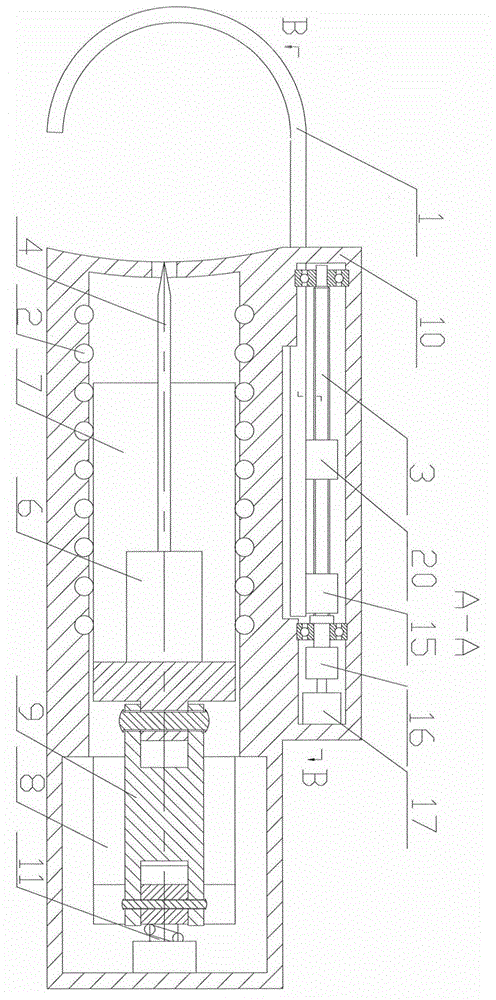

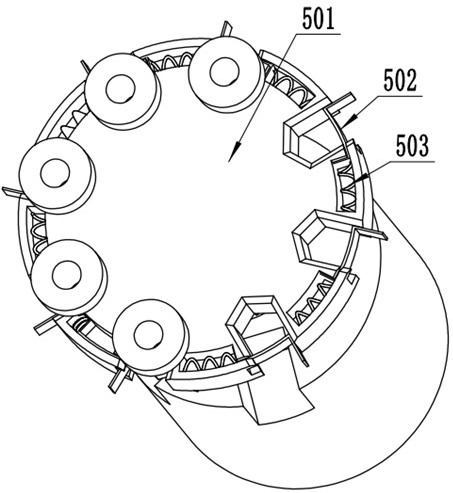

Tunnel supporting drilling robot

ActiveCN105781436AHigh positioning accuracySimple structureReciprocating drilling machinesConstructionsLoop controlEngineering

The invention provides a tunnel supporting drilling robot which comprises a brushless direct current motor for the power source of a drill bit, a gear reducer, a support structure of an overall tunnel supporting robot, namely an improved universal bullseye wheel, a screw sliding table, a rotary motor, a coupler, a photoelectric coded disk feedback system, an electric cabinet and an automatic ejection mechanism, wherein a miniature screw sliding table is adopted for feeding of a drilling device; the power of the screw sliding table is a stepper motor; the screw sliding table is positioned and driven along the axial direction of a tunnel; the rotary motor is positioned along the periphery of the tunnel; the photoelectric coded disk feedback system is used for achieving accurate positioning; the electric cabinet is arranged at the tail part of the overall robot; the automatic ejection mechanism of a wedge block anchor rod is especially designed for achieving automatic insertion of the anchor rod; and various parts are tightly matched to form the tunnel supporting robot. A tunnel supporting drilling structure employing improved universal bullseye wheels arranged at three angles of 120 degrees along the circumference direction of the tunnel is utilized; position close-loop control is adopted; and charged self locking of a stepping driver is utilized, so that the positioning accuracy is high; the structure is simple; and drilling is flexible.

Owner:HARBIN ENG UNIV

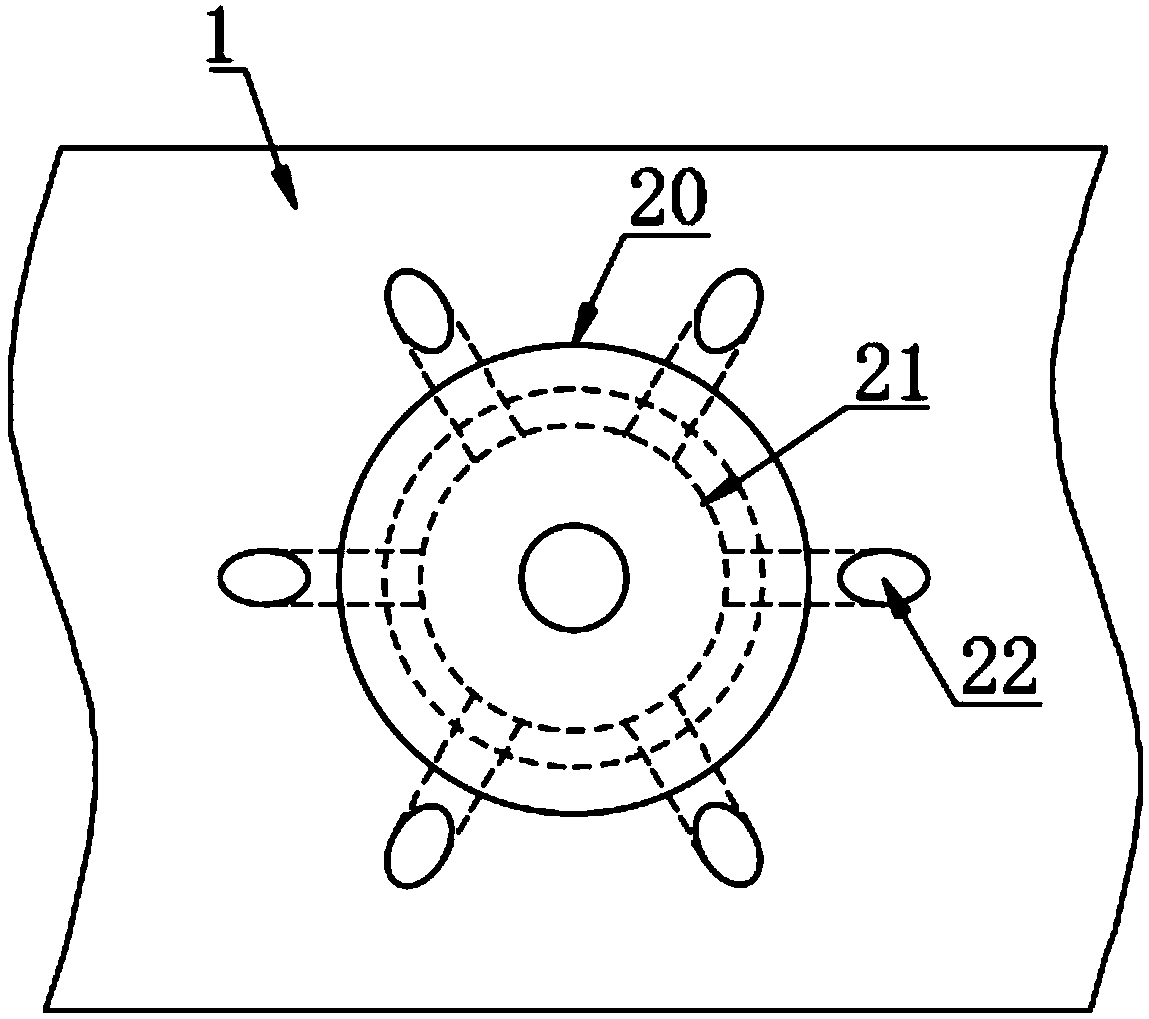

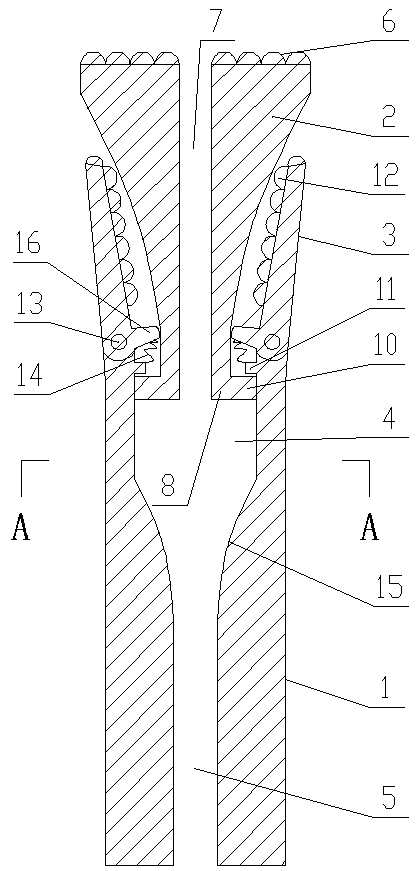

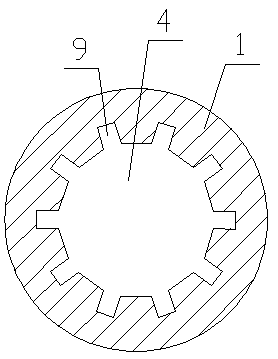

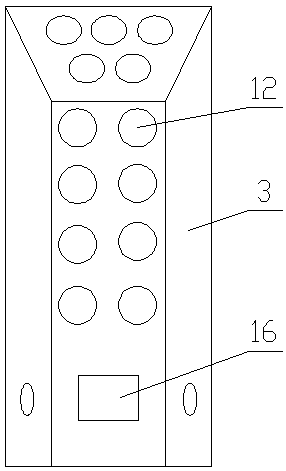

Drilling device for water pump impeller machining

InactiveCN107552828AEasy drillingGuaranteed hole symmetryPositioning apparatusMetal-working holdersImpellerEngineering

The invention relates to a drilling device, in particular to a drilling device for processing water pump impellers. The technical problem to be solved by the present invention is to provide a drilling device for processing water pump impellers. In order to solve the above-mentioned technical problems, the present invention provides such a drilling device for water pump impeller processing, including brackets, etc.; There is a fixed shaft, the periphery of the fixed shaft is provided with a rubber pad, the top right side of the base is connected with a bracket, the inner top of the bracket is provided with a drilling mechanism, the drilling mechanism is set on the upper right side of the placement frame, and the bottom right side of the placement frame is opened. first via. The invention achieves the effects of high safety and high working efficiency. The first drill bit and the second drill bit rotate together to ensure the symmetry of the drilled hole and improve the working efficiency at the same time. The process is more stable and the drilling is more precise.

Owner:杜海燕

U-shaped bolt bottom plate drilling device

InactiveCN112222463AImprove work efficiencyReduce vibrationWork clamping meansPositioning apparatusElectric machineStructural engineering

The invention discloses a U-shaped bolt bottom plate drilling device, the device comprises a supporting body, supporting columns are arranged below the supporting body, a second motor is fixed to thesupporting columns, a rotating shaft is installed at the output end of the second motor, a conveying belt is rotationally fixed to the rotating shaft, a first electric telescopic rod is fixed to the upper portion of the supporting body, a first motor is fixed to the movable end of the first electric telescopic rod, a drill bit is installed at the output end of the first motor, an outer cover shellis fixed to an outer shell of the first motor, electromagnetic magnets are installed on the outer cover shell, a carrier is installed on the conveying belt, an infrared locator and a controller are arranged in the middle of the supporting body, placing tables are symmetrically arranged on the two sides of the conveying belt, second electric telescopic rods are installed on the placing tables correspondingly, and supporting blocks are installed at the movable ends of the second electric telescopic rods correspondingly. The U-shaped bolt bottom plate drilling device can achieve continuous drilling of a U-shaped bolt bottom plate and collection of scraps.

Owner:HUBEI HAILIAN TECH CONSULTATION CO LTD

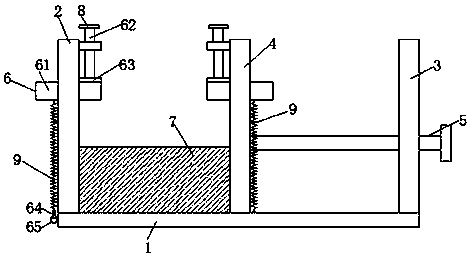

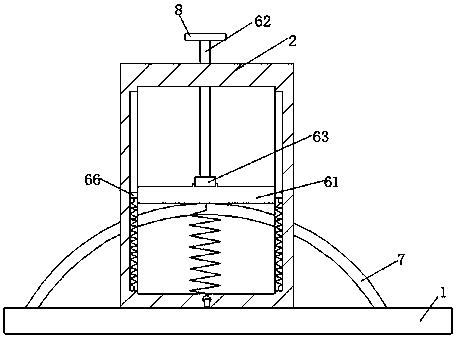

Precision type metal pipe drilling device

InactiveCN105478848APlay a shock absorbing effectReduce work intensityLarge fixed membersPositioning apparatusEngineeringHigh pressure

The invention discloses a precision type metal pipe drilling device. The device comprises a hollow rack and is characterized in that a groove is formed in the top of the rack, a rack conveyor is horizontally arranged in the groove, a plurality of connectors at equal intervals are correspondingly arranged at two side ends of a conveying belt of the rack conveyor, a metal pipe fixing base is connected between every two connectors and crosses over the conveying belt, a strip-shaped groove is formed in each metal pipe fixing base and is used for accommodating a to-be-machined metal pipe, a plurality of round holes are formed in the bottom of each strip-shaped groove at equal intervals, high-pressure springs are correspondingly and perpendicularly arranged in the holes, fixing blocks are arranged at the top of the rack and located between the rack conveyor and a vertical spiral rod, a telescopic rod is arranged on each fixing block, the telescopic rods on two sides of the rack conveyor correspond to each other, a connection block is arranged at the front end of each telescopic rod, a rotating device is arranged at the front end of each connection block, and a pressing plate is connected to each rotating device. The precision type metal pipe drilling device has the advantages of convenience in use, high efficiency, high precision and the like.

Owner:SUZHOU YONGTONG STAINLESS STEEL CO LTD

Drilling equipment for processing electric appliance switch element

InactiveCN108022777ASimple device structureEasy to adjustElectric switchesPositioning apparatusEngineeringThreaded rod

The invention discloses drilling equipment for processing an electric appliance switch element, and the equipment comprises a substrate. One side of the substrate is vertically provided with a fixed plate, and a side, far from the fixed plate, of the substrate is provided with a limiting plate. An adjustment plate is disposed between the limiting plate and the fixed plate, and two ends of a side,close to the limiting plate, of the adjustment plate are respectively provided with a threaded rod. The limiting plate is provided with threaded holes cooperating with the threaded rods, and a to-be-processed electric appliance switch element is clamped between the fixed plate and the adjustment plate. The fixed plate and the adjustment plate are respectively provided with a limiting device. Through the cooperation of the fixed plate and the adjustment plate, the equipment can limit the axial movement of the to-be-processed electric appliance switch element, and can limit the vertical movementof the to-be-processed electric appliance switch element through the cooperation of a threaded compression bar, a fixing compression plate and a fixing hook. The limiting of the threaded compressionbar and the fixing hook locates at two sides of the fixing compression plate, and is in opposite directions, thereby enabling the to-be-processed electric appliance switch element to be stable duringdrilling. The equipment is simple in structure, and is convenient to adjustment.

Owner:ANHUI KAICHENG ELECTRIC APPLIANCE CO LTD

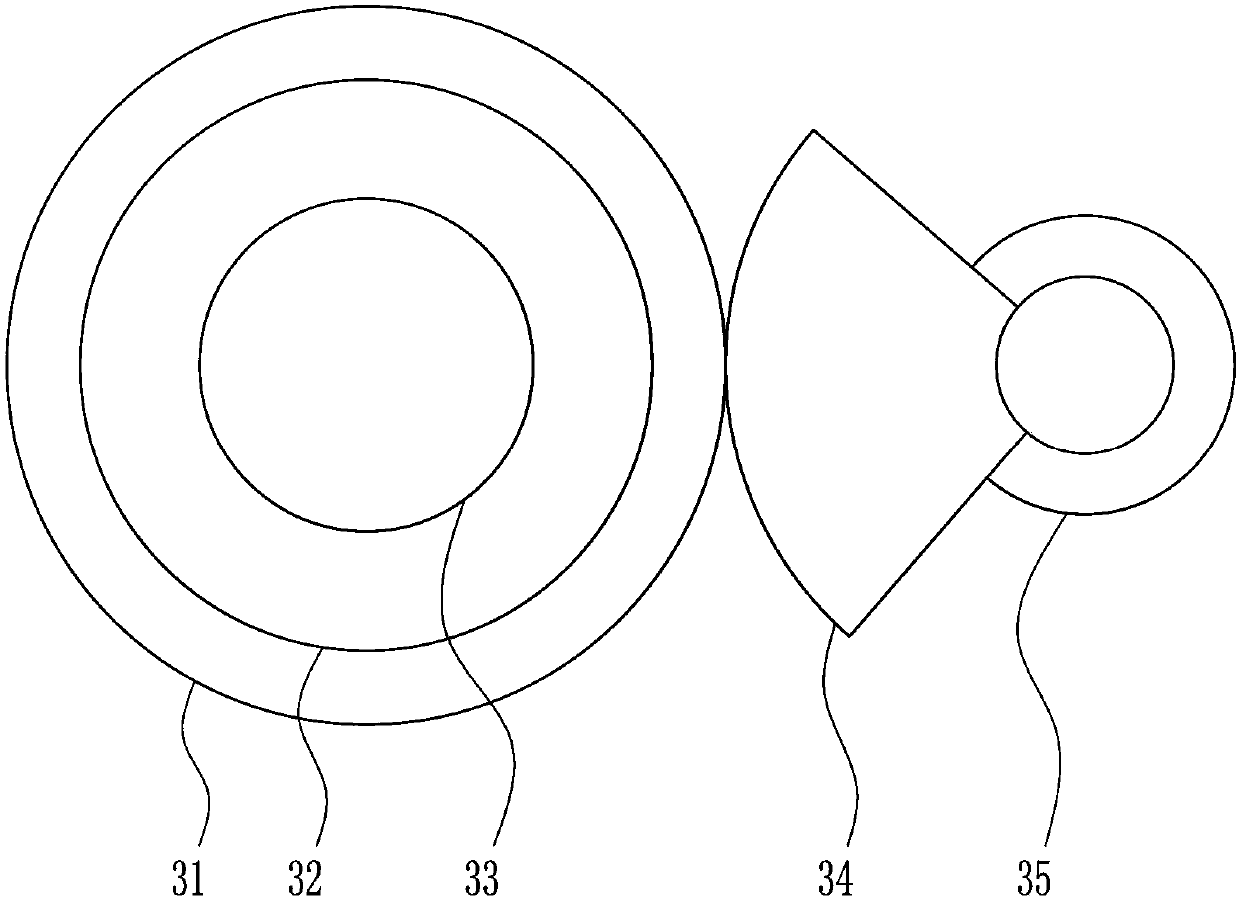

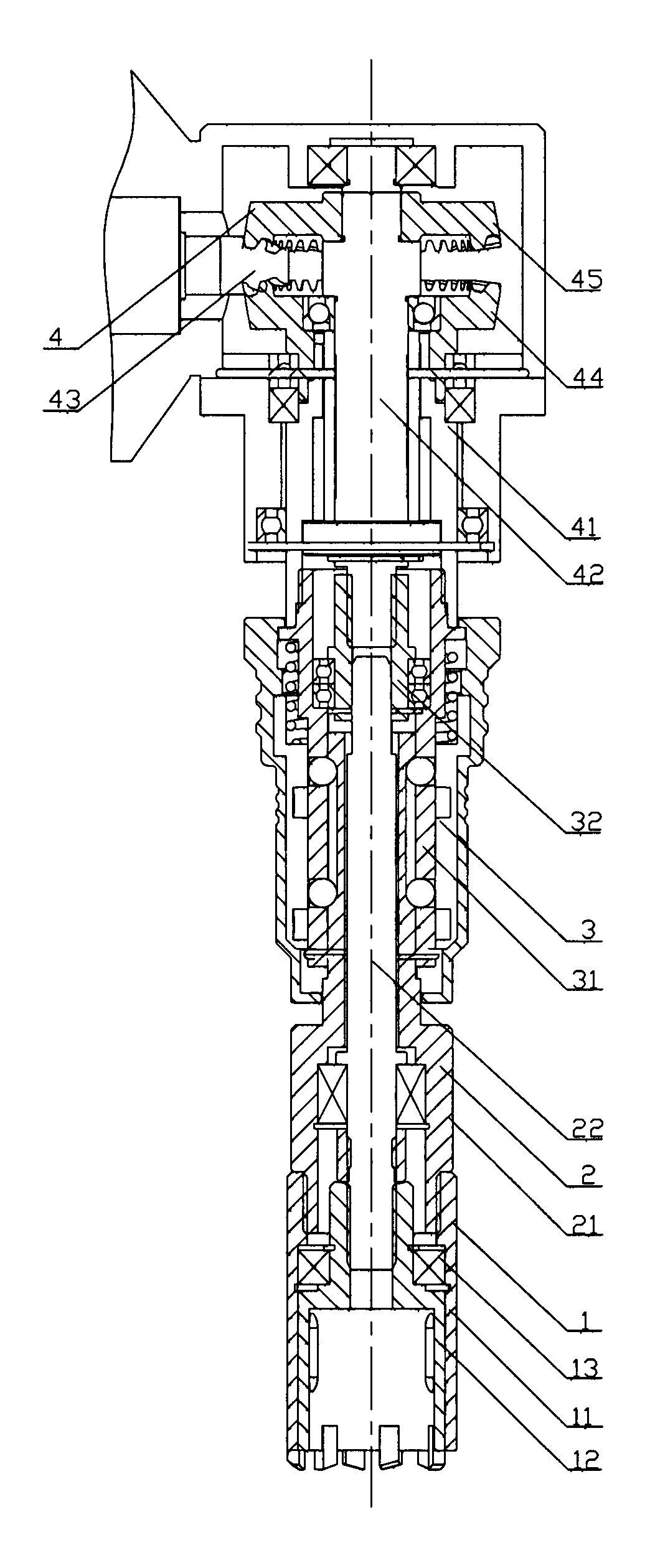

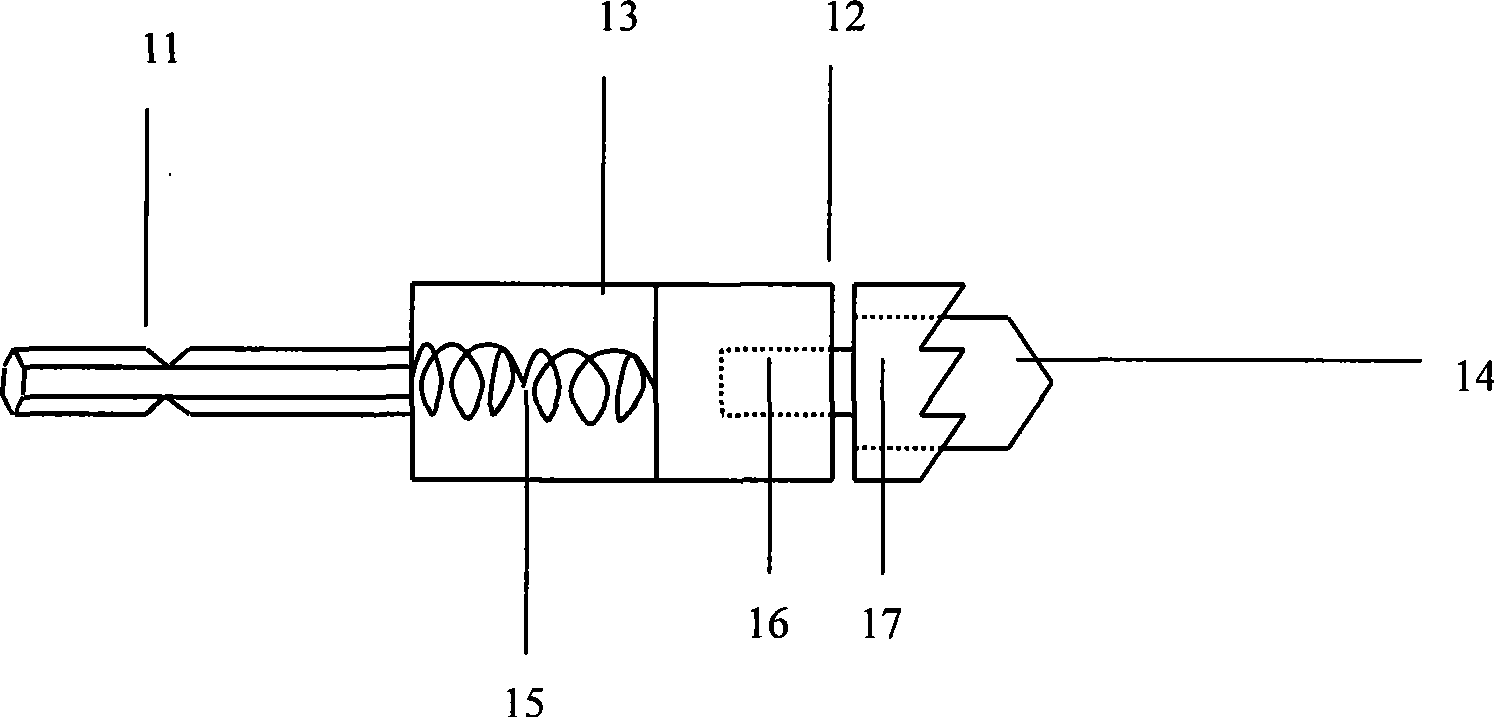

Rotary bisection drill

InactiveCN103551631ANo shock vibrationNo torsion resistanceTransportation and packagingDriving apparatusEngineeringCutting force

The invention discloses a rotary bisection drill. The rotary bisection drill comprises an outer drill bit which is adaptive to a first driving shaft and rotates around a rotary center along a first direction and an inner drill bit which is adaptive to a second driving shaft and rotates around the rotary center along a direction which is opposite to the rotating direction of the outer drill bit; the first driving shaft and the second driving shaft are concentric; the outer drill bit and the inner drill bit comprise bit bodies and cutting edges; the cutting edges are arranged at the same end of the outer bit body and the inner bit body; the cutting edges of the outer drill bit and the inner drill bit form into rotary bisection movement along with rotation of the drill bits. The rotary bisection drill has the advantages of being efficient in drilling, strong in self-advancing capability, free of impact vibration, self-balancing in cutting force, stable and reliable and applicable to rapid drilling for concrete, stone, wood, metal and geological drilling.

Owner:SUZHOU TINGENS IISAW TECH

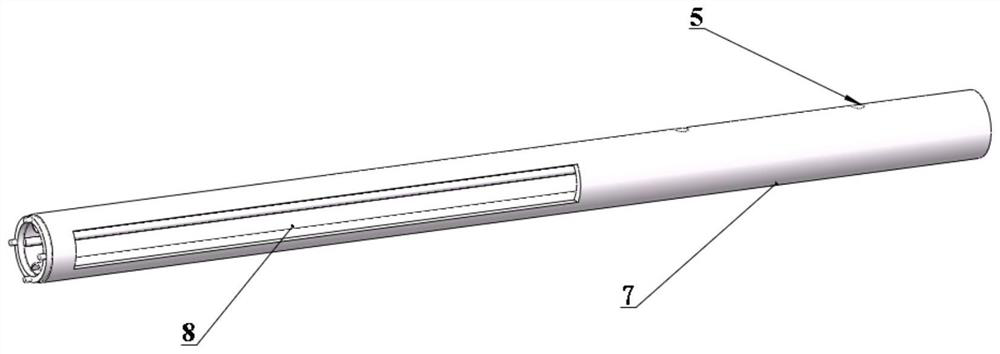

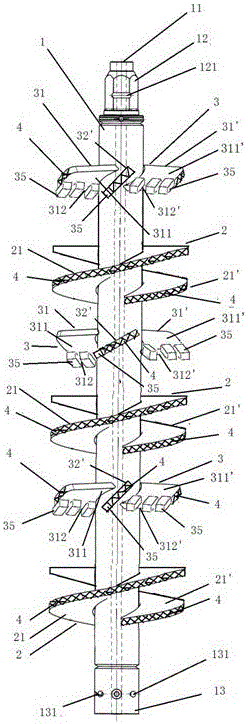

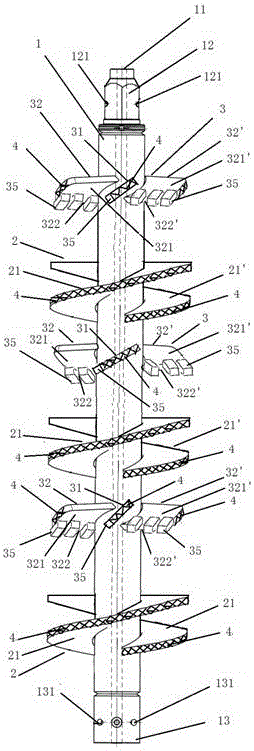

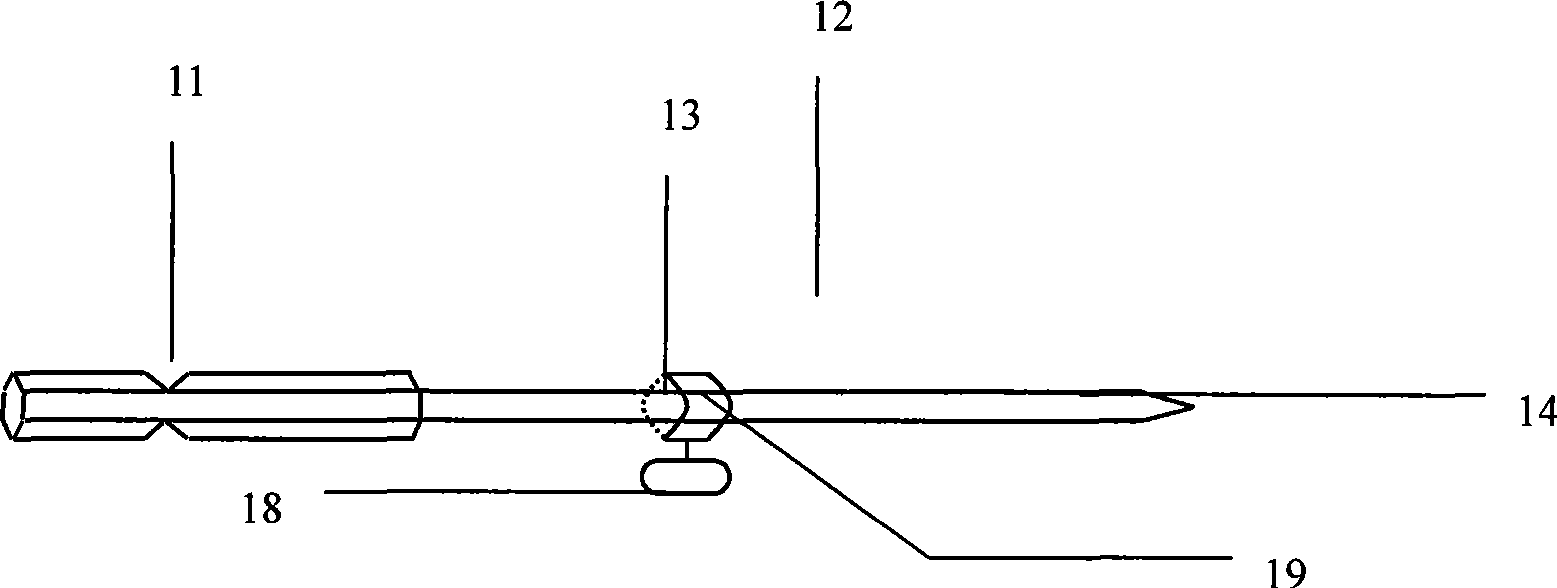

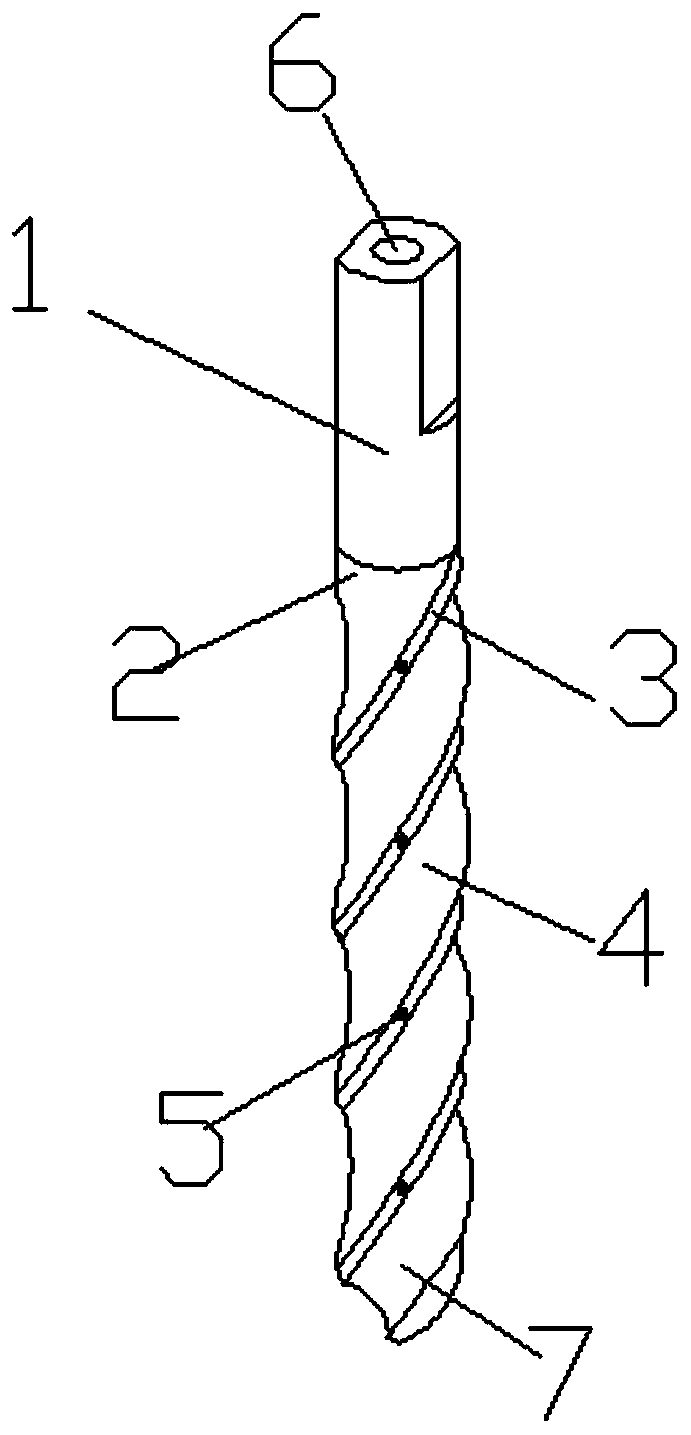

Drill rod

A drill rod comprises a hollow rod body comprising an outer hexagonal joint and an inner hexagonal joint, a plurality of sets of spiral wings comprising dual-end spiral wings, a plurality of sets of cutting blades comprising two first blades and two second blades and wear-resisting plates; the outer hexagonal joint and the inner hexagonal joint are provided with a semicircular groove and a pin hole respectively; the multiple sets of spiral wings are arranged on the outer wall of the hollow rod body at equal intervals in a radial mode; the multiple sets of cutting blades are arranged on the outer wall of the hollow rod body at equal intervals, first blade faces of the first blades are arranged horizontally, and the first lower edges of the blades are blade edges inclined downwards; second blade faces of the second blades are arranged upwards and downwards, and the second lower edges of the second blades are blade edges inclined downwards; the first blades and the second blades are arranged at equal angle intervals in the radial direction of the hollow rod body; the wear-resisting plates are arranged on the dual-end spiral wings of the spiral wings and a free end arc face of the first and second blades of the cutting blades. The drill rod has the advantages that drilling and excavating are stable, stirring is uniform and the blades resist wear, and the drilling and excavating efficiency is improved.

Owner:SHANGHAI GUANGDA FOUND ENG

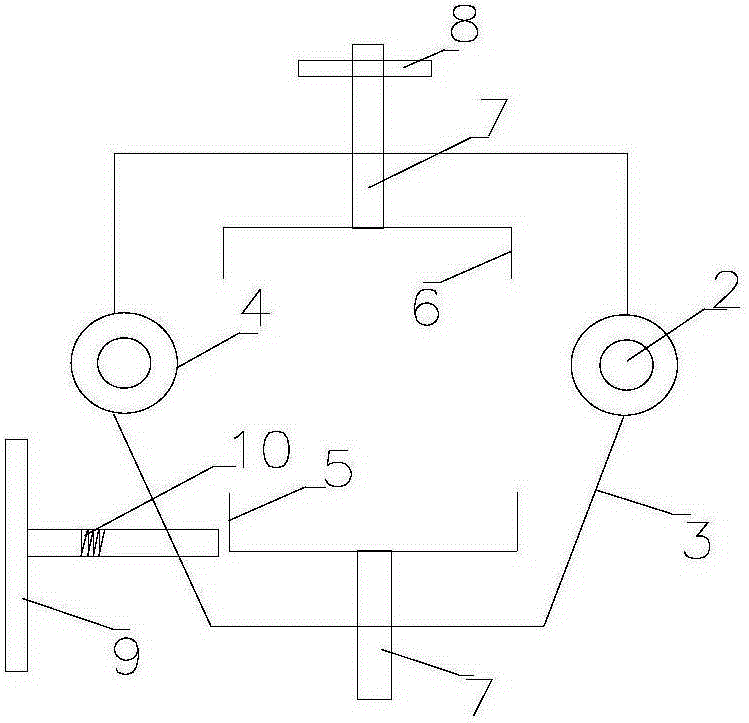

Furniture wood board dustproof punching device

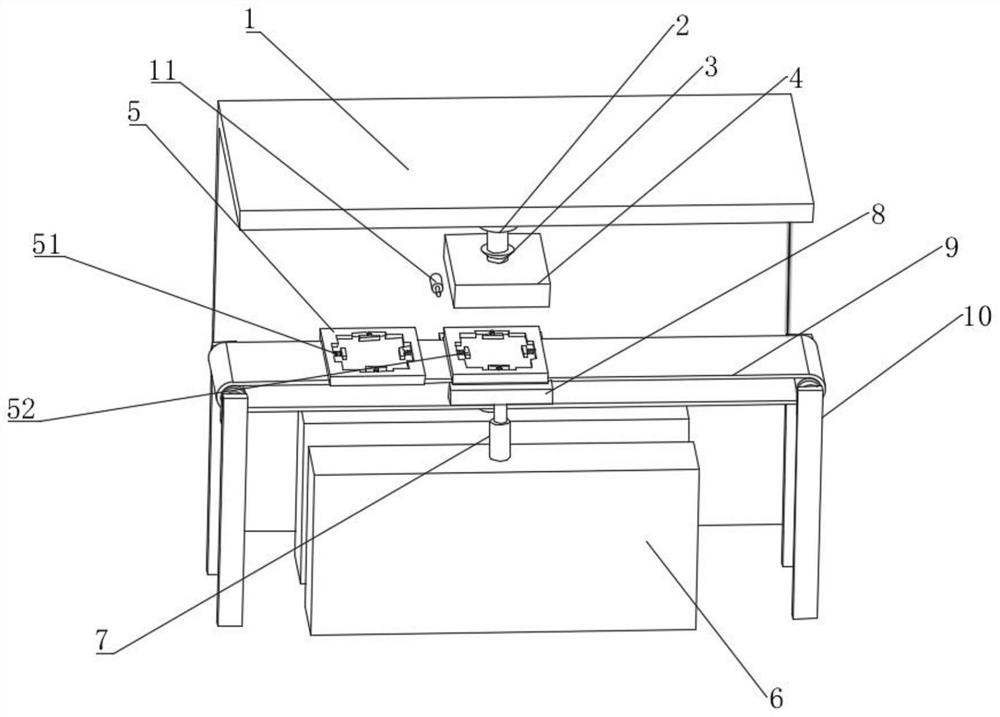

PendingCN108789655ADrilling stabilityDrilling effect is goodDrilling machinesBark-zones/chip/dust/waste removalScrapEngineering

The invention discloses a furniture wood board dustproof punching device. The furniture wood board dustproof punching device comprises a base. A left support plate and a right support plate are fixedly arranged on the top of the base. Sliding rails are symmetrically and fixedly arranged on the opposite faces of the left support plate and the right support plate. A lifting plate is in sliding connection between the sliding rails and provided with an opening, an electric drill is fixedly connected to the opening position, and a drill bit is fixedly arranged at the bottom of the electric drill. The base is provided with a dust collecting port for the drill bit to pass. A top plate is fixedly arranged on the tops of the left support plate and the right support plate, a left threaded rod and aright threaded rod are rotationally connected between the top plate and the base, penetrate the lifting plate and are in threaded connection with the lifting plate, and a rotation handle is further fixedly connected to the top end of one threaded rod. The part, located above the dust collecting port, of the top of the base is further fixedly provided with a dustproof cover. The rotation handle isrotated to control descending of the lifting plate, then, drilling can be conducted, manual electric drill hand holding is not needed, drilling is stable, and labor saving and safety are achieved; andthe dustproof cover is further fixedly arranged above the dust collecting port, and wood scraps are prevented from flying all around in the drilling process.

Owner:陈海荣

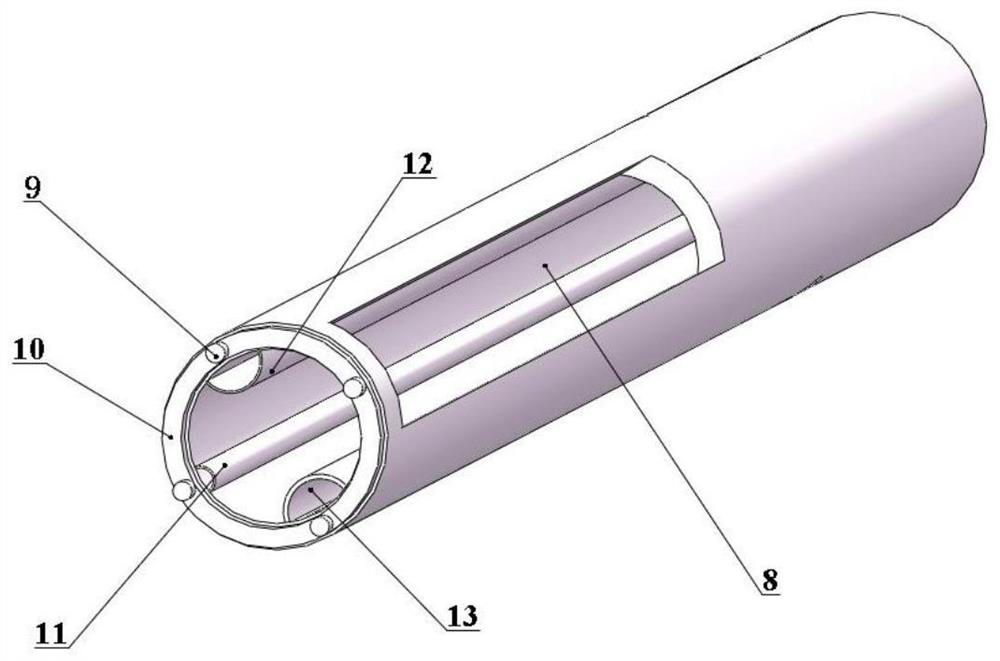

Injection type mine drill bit type reamer

ActiveCN108756757AActs as an axial sliding fitEasy to recycleDrill bitsReaming toolsHigh pressure waterHigh pressure

The invention discloses an injection type mine drill bit type reamer. The injection type mine drill bit type reamer comprises a drilling and reaming hole rod, a drilling and reaming cutter and a plurality of reaming cutters. The center line of the drilling and reaming hole rod is arranged in the front-rear direction, and a cylinder-shaped high pressure water cavity is coaxially formed at the frontend of the drilling and reaming hole rod and the front end of the high pressure water cavity is open. A water injection hole is formed in the drilling and reaming hole rod in the center hole direction, the front end of the water injection hole communicates with the high pressure water cavity, the rear end of the drilling and reaming cutter is slidably connected into the high pressure water cavity, the reaming cutters are evenly formed along the front end face of the drilling and reaming hole rod in the peripheral direction, and the inner side of the front portion of the reaming cutters are inpressing-pushing fit with the conical surface of the reaming cutters. The injection type mine drill bit type reamer adopts the method of adjusting water pressure to separately perform drilling and reaming operations, has the advantages of simple structure, convenient operation, small size, light weight, flexible and reliable technology, unified power source of drilling reaming and hole reaming, stable hole reaming, easy recovery of cutters and implement of edge drilling while reaming, greatly improves the reliability of bolt anchoring, and ensures the safety of workers in borehole operation.

Owner:HENAN POLYTECHNIC UNIV

Drilling machine

InactiveCN104588732ASimple structureReasonable designWork clamping meansLarge fixed membersDrive motorInductor

A drilling machine belongs to the technical field of mechanical processing equipment. The drilling machine comprises a substrate. A workpiece fixing mechanism and a drilling mechanism are fixedly arranged on the substrate. The workpiece fixing mechanism comprises a rotating table and a pneumatic clamping device. The drilling mechanism comprises a driving motor, a drilling rod and a drilling head. The drilling machine is simple in structure and reasonable in design. By arranging the rotating table on the substrate, a workpiece can rotate 360 degrees, and drilling in different positions is convenient. By arranging the pneumatic clamping device, the workpiece is more stable in drilling. By arranging a dust absorption device, dust in a drill hole can be removed in time, and drilling precision is improved. By arranging an infrared inductor, drilling depth can be hold quickly and accurately.

Owner:新昌县成丰机械配件厂

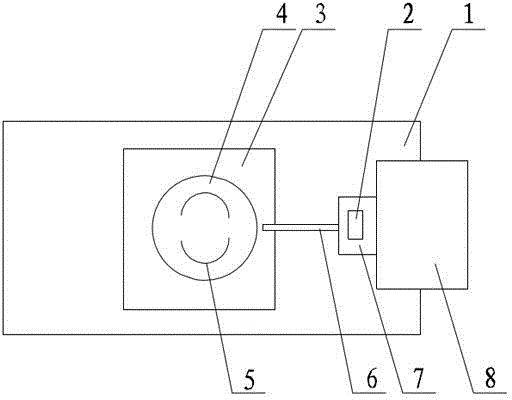

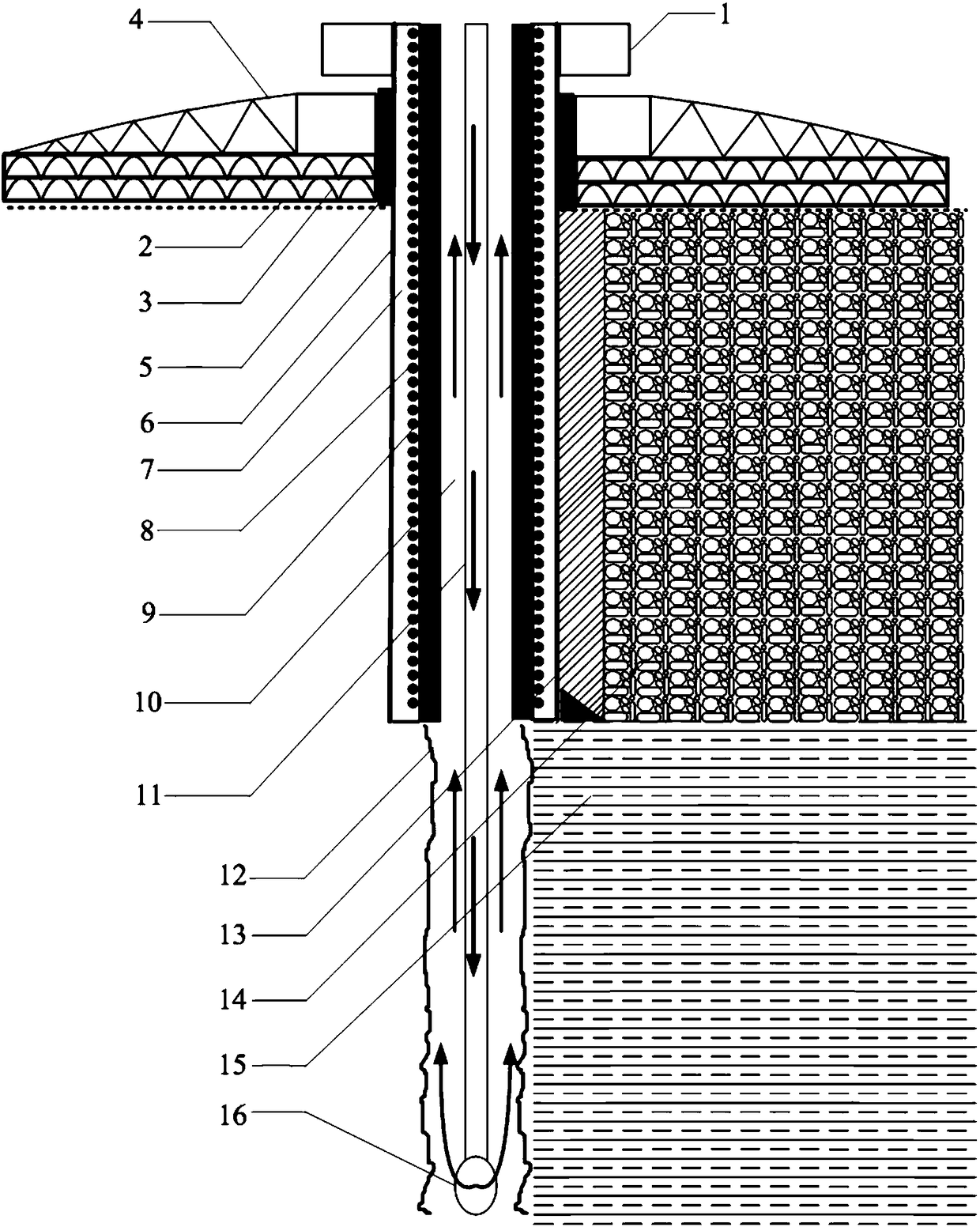

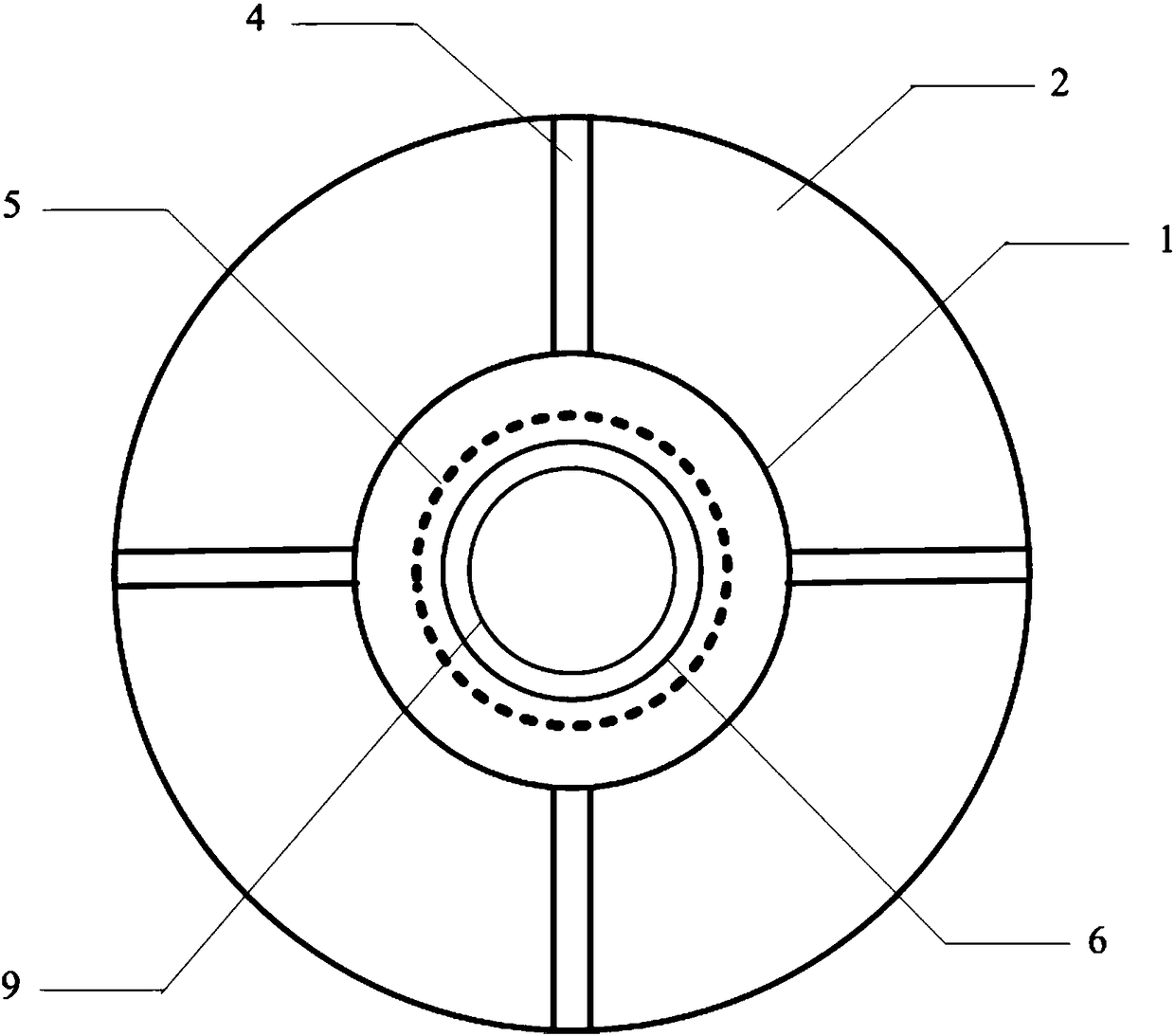

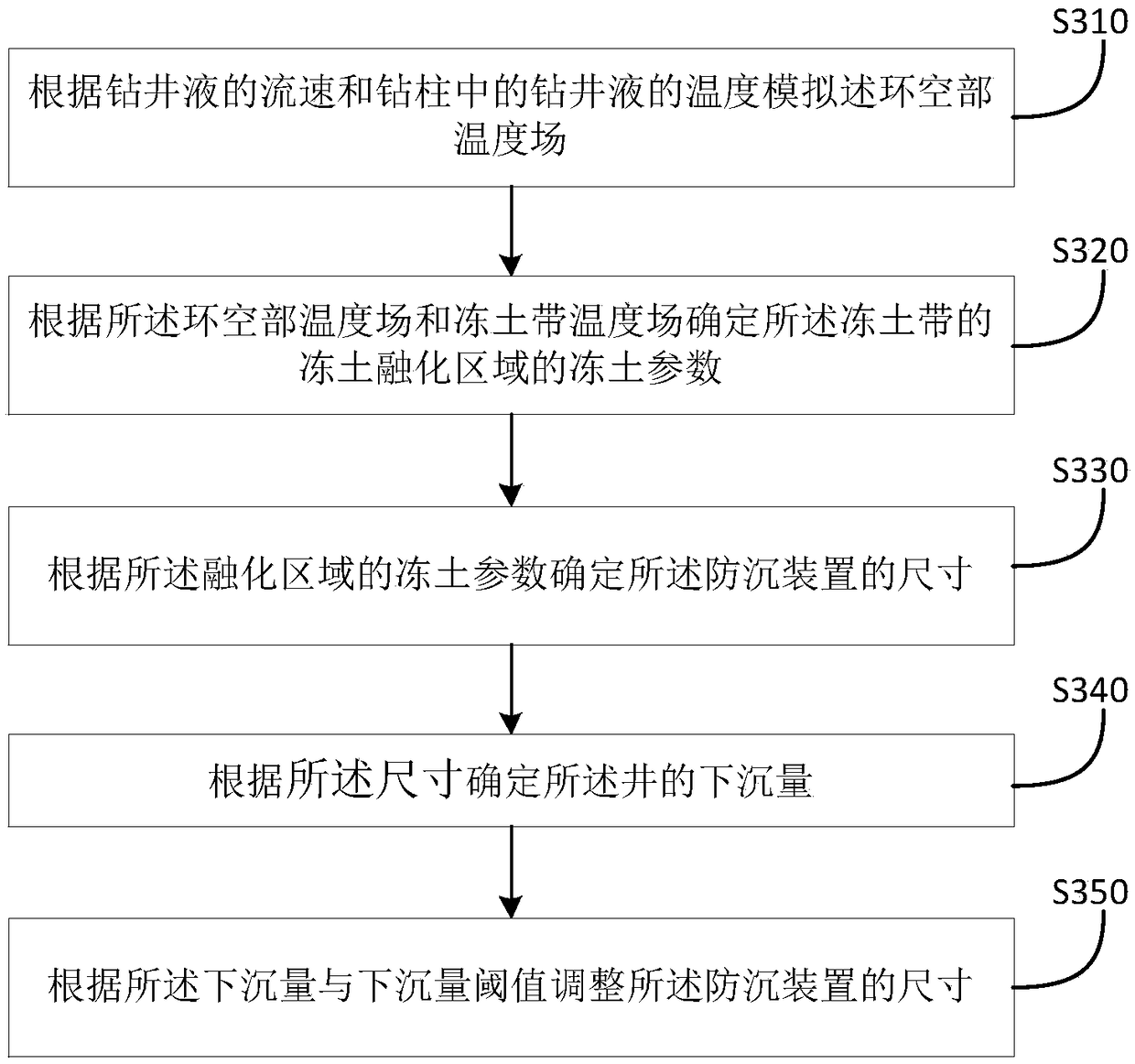

Anti-settling device, verification method and device thereof and device for preventing sedimentation of well

The embodiment of the invention provides an anti-settling device, a verification method and device thereof and a device for preventing sedimentation of a well, and belongs to the field of well drilling. The anti-settling device is arranged in a well opening area of the well during well drilling and used for preventing sedimentation of the well. The anti-settling device includes an anti-settling base and a connection locking device, an opening corresponding to the well opening is formed in the center of the anti-settling base, and the anti-settling base is distributed in the well opening area during well drilling. The connection locking device is arranged on the opening and used for connecting and locking a sleeve arranged in the well with the anti-settling base. The device for preventing sedimentation of the well includes the anti-settling base and the verification method used for the anti-settling base. The anti-settling device, the verification method and device thereof and the device for preventing sedimentation of the well can achieve reduction of pressure intensity of various well drilling devices on the well opening and a tundra under the well opening and further decrease thesedimentation amount of the well to achieve stable well drilling.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Industrial drilling machine

InactiveCN107379283ASolve highSolving Mobility IssuesWorking accessoriesStone-like material working toolsEngineeringDrilling machines

The invention discloses an industrial drilling machine which comprises a base, rollers and a motor. The two sides of the motor are fixedly connected with connecting rods. A stretchable rod is fixedly connected with the middle portion of the upper end of the motor. One ends of the connecting rods are fixedly connected with the stretchable rods, a folding sliding rod is fixedly connected to the top end of each stretchable rod, each folding sliding rod is composed of a front sliding rod, a rear sliding rod, a connecting piece and a wire, fixing pieces are in shaft connection, the two sides of the front sliding rods and the two sides of the rear sliding rods are each provided with a copper rail, a limiting block is installed at one end of each copper rail, a sliding base is connected to one end of each folding sliding rod in a sliding mode, a drilling machine body is fixedly connected to one end of each sliding base, and a drill bit is connected to one end of the drilling machine body in an inserted mode. By adding the folding sliding rods and the sliding bases, drilling is more stable, the drilling quality is good, by adding the long drill bits, the problem that drilled holes are shallow is solved, and by adding the rollers and the stretchable rod, the problems that the drilling height is limited and movement is not convenient are solved.

Owner:LIANGXI HAOXING IND DESIGN OFFICE

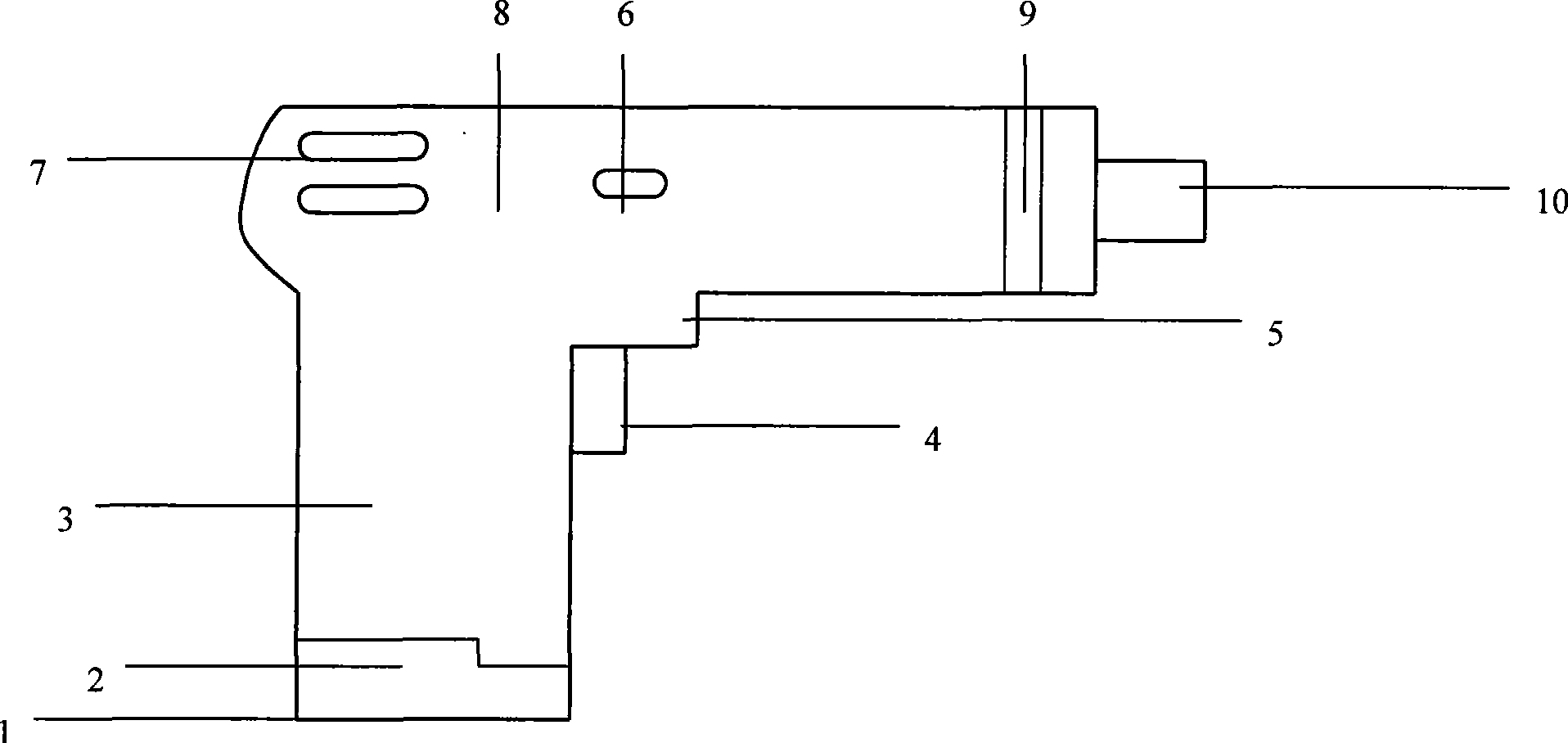

Portable chargeable multifunctional skull brad awl

InactiveCN101507647AIncrease drilling speedDynamic stabilitySurgeryClosed head injuryNeurosurgical Procedure

The invention relates to a portable rechargeable multifunctional skull drill and application thereof. The skull drill is a novel multifunctional neurosurgical electric tool, can be used for checking, diagnosing, preventing, treating and researching severe closed craniocerebral injury patients, particularly extremely severe craniocerebral injury patients, has simple structure, easy operation, low use cost, small volume, symmetrical force application, stable drilling, and improved utilization safety, and is more suitable for emergent treatment of pre hospitals, 120 ambulances, low level hospitals and emergency rooms in large size hospitals to provide possibility of early and super-early neurosurgical operation interference so as to greatly facilitate protraction of emergency medical treatment, achieve the aim of reducing the pre-hospital death rate of battling craniocerebral injury, and improve the effects and quality of the emergent medical treatment. The portable rechargeable multifunctional skull drill can be effectively combined into a complete set as a portable craniocerebral injury first-aid equipment kit which can be applied to field fight first aid for various battling craniocerebral injuries.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

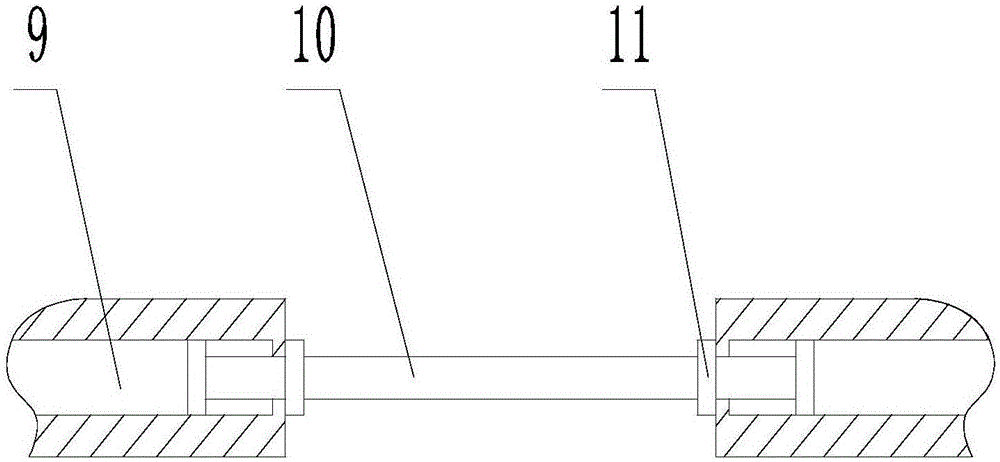

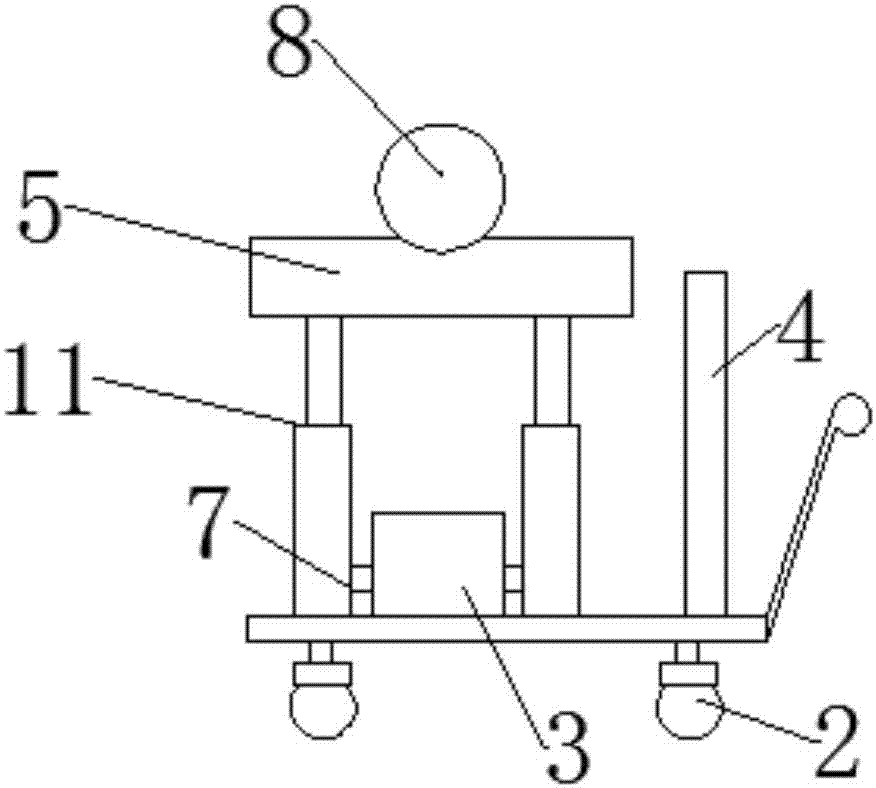

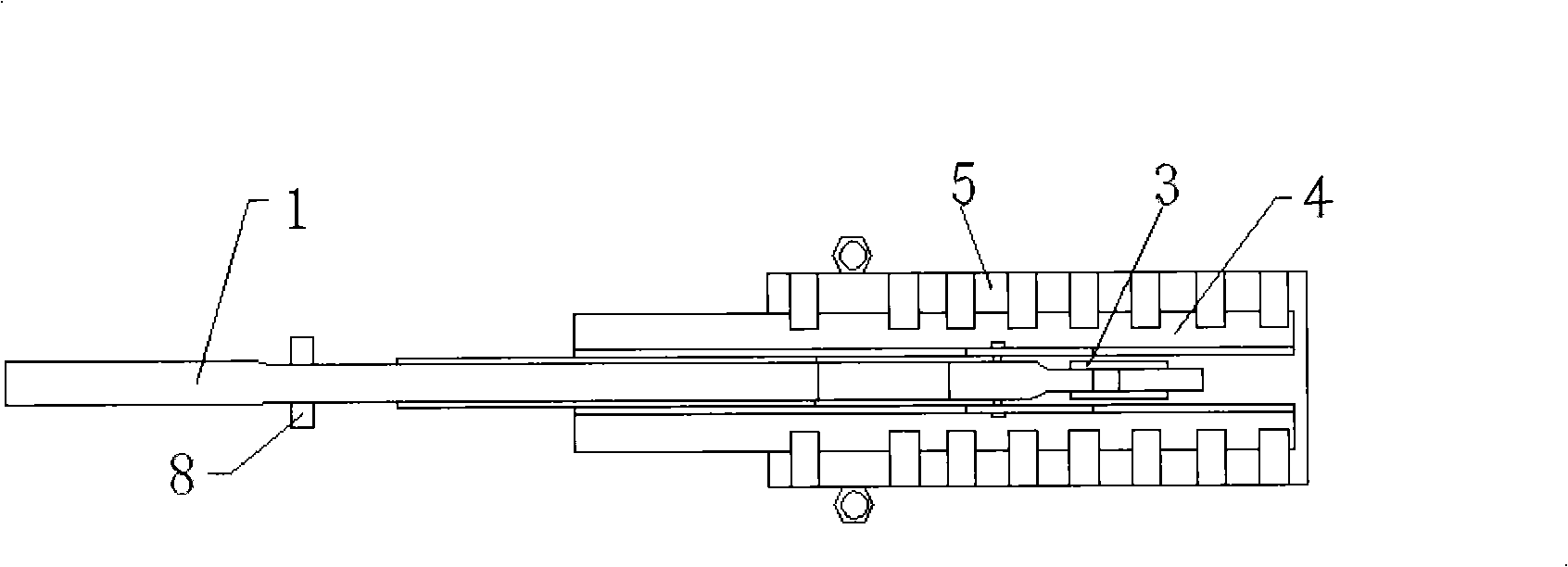

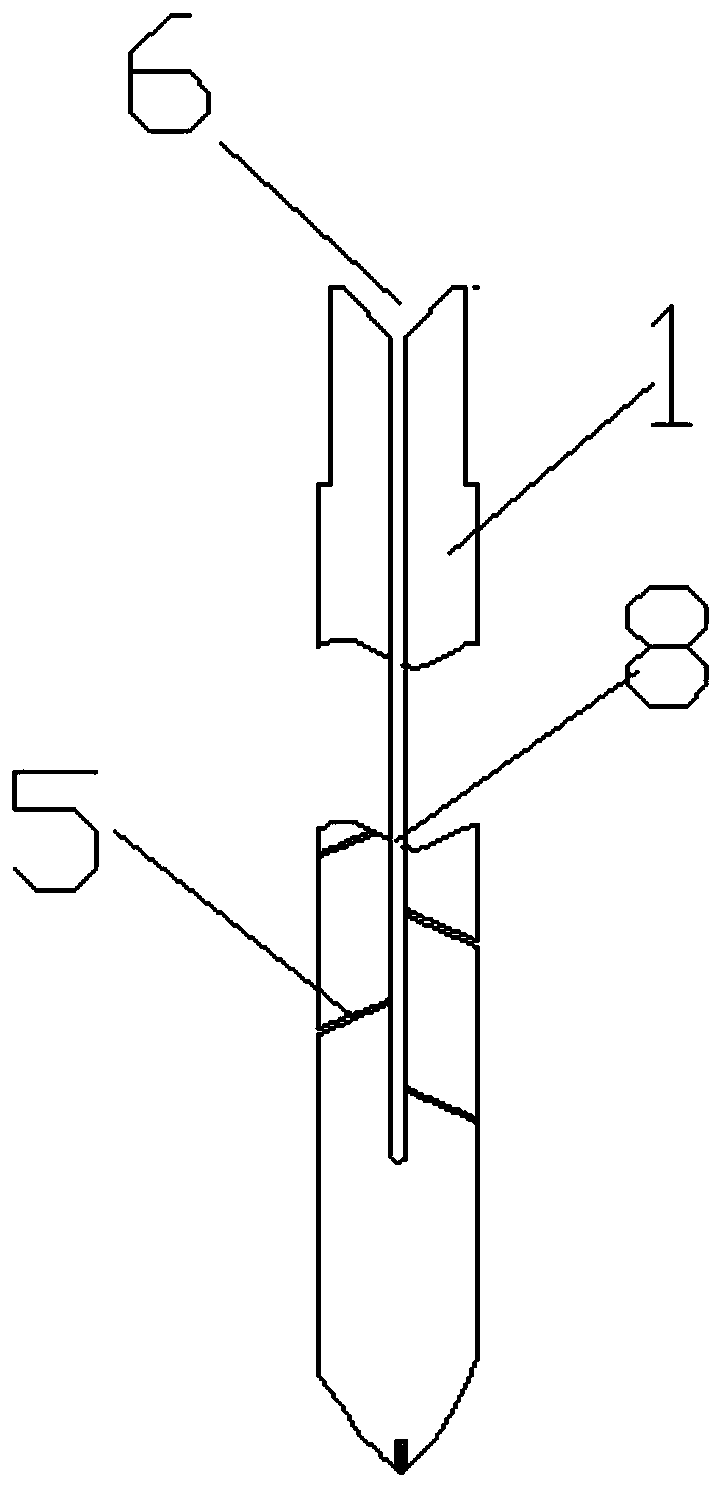

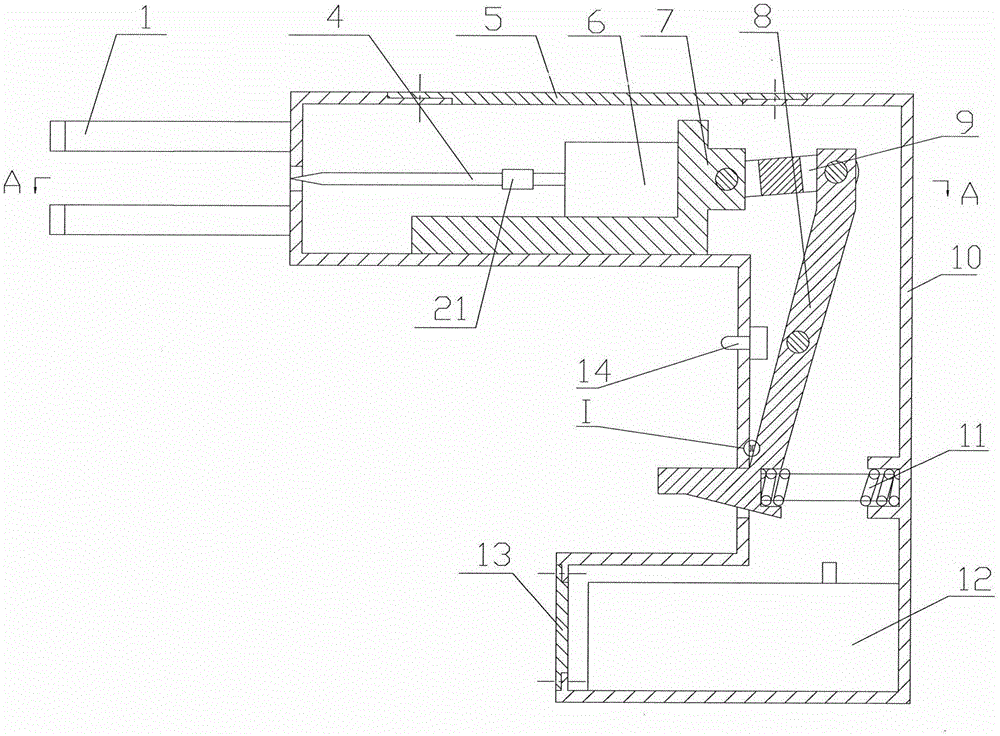

Device capable of making pistol drill more convenient to use and method of use thereof

InactiveCN101352764AEasy to useImprove drilling qualityPortable drilling machinesSheet steelSlide plate

The invention relates to a device which can lead a pistol drill to be more conveniently used and is characterized by including a long slide plate that can move front and back; one end of the long slide plate is connected with one end of a tension rod by a connection rod; the lower end of the long slide plate is provided with a long pressing plate and a bracket; a pressing plate which can lead the head of a drill pistol to penetrate is vertically arranged below the long pressing plate by a location nut; the other end of the long slide plate is provided with a draw hook with a round ring by a stud arranged on a loop bar. A method which can lead the pistol drill to be more conveniently used includes that: leading the body of the pistol drill to penetrate the pressing plate and simultaneously leading the body to closely cling on the long pressing plate and the bracket; hanging the draw hook on a steel plate which sticks closely; holding the tension rod by one hand, arranging the tension rod on the front and drawling slowly to the back until the aiguille of the drill butted with the steel plate; after starting the pistol drill, drawing the tension rod to the back by the other hand; the other end of the tension rod drives the connection rod to lead the long slide plate to slide to the front, which pushes the pistol drill to drill until the drilling is finished. The device has the advantages of reducing vibration when drilling as well as easier, more convenient, safer and more stable drilling.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

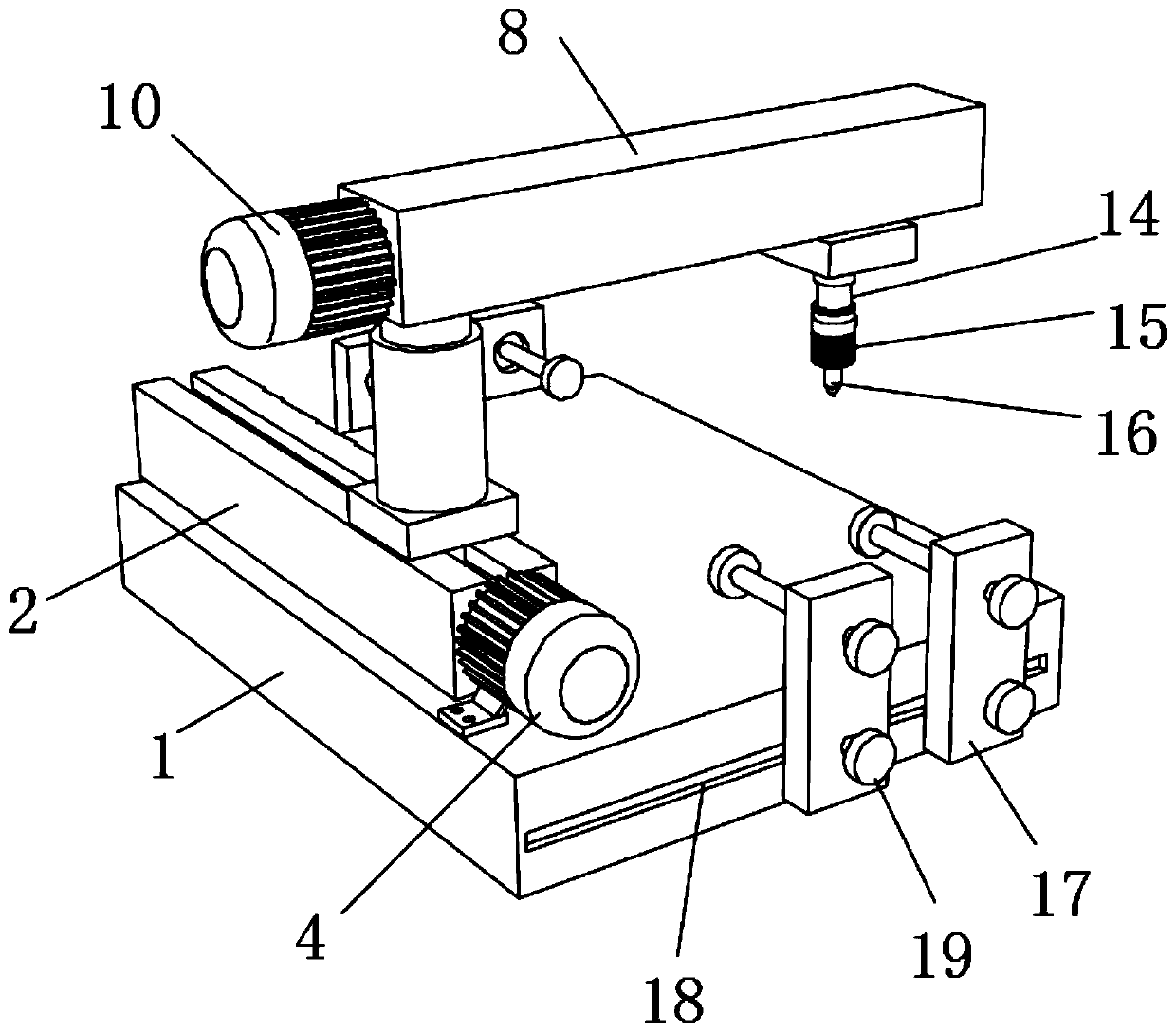

Connecting part machining tool capable of reducing vibration

InactiveCN107486727AEasy to drillDrilling stabilityLarge fixed membersPositioning apparatusEngineeringMachine tool

The invention discloses a connecting part machining tool capable of reducing vibration. The connecting part machining tool comprises a base. A placement table is arranged on the base and connected with a lifting mechanism. The lifting mechanism can drive the placement table to move. Pressing devices are arranged on the two sides of the placement table. A guide screw is arranged on each pressing device in a penetrating manner. The guide screws are fixed to the base. Each guide screw is provided with a nut screwed with the guide screw. One end of each pressing device penetrates the base, and each pressing device can move in the axis direction of the corresponding guide screw. According to the connecting part machining tool, a flange is fixed among the placement table and the pressing devices, the flange is prevented from generating large vibration in the drilling process, drilling of a drill bit is more stable, and therefore the machining precision is improved.

Owner:CHENGDU LINGCHUAN SPECIAL IND

Hole forming drill bit with lubricating oil guide-in hole

InactiveCN110560750ACompact connectionEasy to useTransportation and packagingTwist drillsDrill floorPetroleum engineering

The invention discloses a hole forming drill bit with a lubricating oil guide-in hole. A drill handle, a drill body, a cutting edge, a scrap guiding groove, oil discharging ports, an oil storing groove, a drill bit body, an oil conveying pipe, a positioning head and a spring are included. The hole forming drill bit with the lubricating oil guide-in hole has the beneficial effects that the oil discharging ports which are inclined downwards in multiple directions are uniformly formed in the cutting edge, so that lubricating grease can more easily flow to the portion of the cutting edge during gradual rising of the temperature of the drill bit body; the oil storing groove is in the shape of an inverted cone, so that the lubricating grease can flow into the oil conveying pipe very convenientlyand fast under the gravity effect; the positioning head is driven by the spring to freely stretch out and draw back, a hole needing to be punched can be positioned more conveniently, and it can alsobe avoided that the positioning head is damaged; the two sides of the drill handle are each provided with a cutting plane, and the cutting planes are symmetrical about each other; and it is preventedthat the drill handle slips on a drill table, so that a drill stem is fixed more stably.

Owner:常州市阿凡达工具制造有限公司

Wall traceless safety water drilling machine

PendingCN109291261ADrilling labor-savingDrilling stabilityWorking accessoriesStone-like material working toolsEngineeringPinion

The invention relates to drilling machinery, in particular to a wall traceless safety water drilling machine. The wall traceless safety water drilling machine comprises a motor, a transmission device,a water drill bit, a wall fixing device, a guide rail 8 and a water pipe, wherein the wall fixing device comprises an expansion screw which is fixed on a wall and the guide rail which is in threadedconnection with the expansion screw, and the expansion screw and the guide rail are fixed to the center of a drilling hole; a sliding block is provided with a longitudinal central cavity, and the guide rail penetrates through the central cavity of the sliding block; a rack is arranged on the top surface of the guide rail, and a pinion meshed with the rack is arranged at the rear end of the slidingblock; the front end of the sliding block is a hollow cylinder, a driven gear is installed through a bearing, the water drill bit is installed on the driven gear, and the driven gear is meshed with adriving gear of the output shaft of the motor. The wall traceless safety water drilling machine has the beneficial effect that the sliding block 6 with the longitudinal central cavity 7 are arranged,the sliding block 6 with the longitudinal central cavity 7 can move along the guide rail, the expansion screw is fixed to the center of a wall drilling hole, the guide rail is fixed on the expansionscrew, the water drill is drilled in the drill hole namely the center of the drill hole through, the drilling wall core is removed after drilling hole, and no fixed mark is left on the wall, then, thesliding block 6 of an installation motor moves along a center guide rail, so that the drilling is labor-saving, stable, safe and positive in drilling.

Owner:任聪磊

Perforating device for electric power fitting

InactiveCN111299649APrecise punchingGuaranteed punching qualityMeasurement/indication equipmentsLarge fixed membersControl theoryScrew thread

The invention discloses a perforating device for an electric power fitting. The perforating device for the electric power fitting comprises a base, wherein one side of the upper end of the base is fixedly connected with a first sliding rail; a first chute is formed in the upper end of the first sliding rail; the interior of the first chute is connected, in a sliding manner, with a first sliding block which is matched with the first chute; a screw hole is formed in the first sliding block; a first motor is arranged at an end part of the first sliding rail; a power output end of the first motoris connected with a screw rod; the screw rod is in threaded connection with the screw hole in the first sliding block; the upper end of the first sliding block extends to the upper side of the first chute and is fixedly connected with a first fixed seat; the upper end of the first fixed seat is fixedly connected with a first electric telescopic rod; the upper end of the first electric telescopic rod is fixedly connected with a second sliding rail; scale marks are respectively marked at the side ends of the first sliding rail and the second sliding rail; and the side ends of the first fixed seat and a second fixed seat are respectively and fixedly connected with a transverse pointer and a longitudinal pointer. The perforating device for the electric power fitting is simple in structure andconvenient to operate, and can realize accurate perforating of fitting so as to ensure perforating quality.

Owner:青岛正为能源科技有限公司

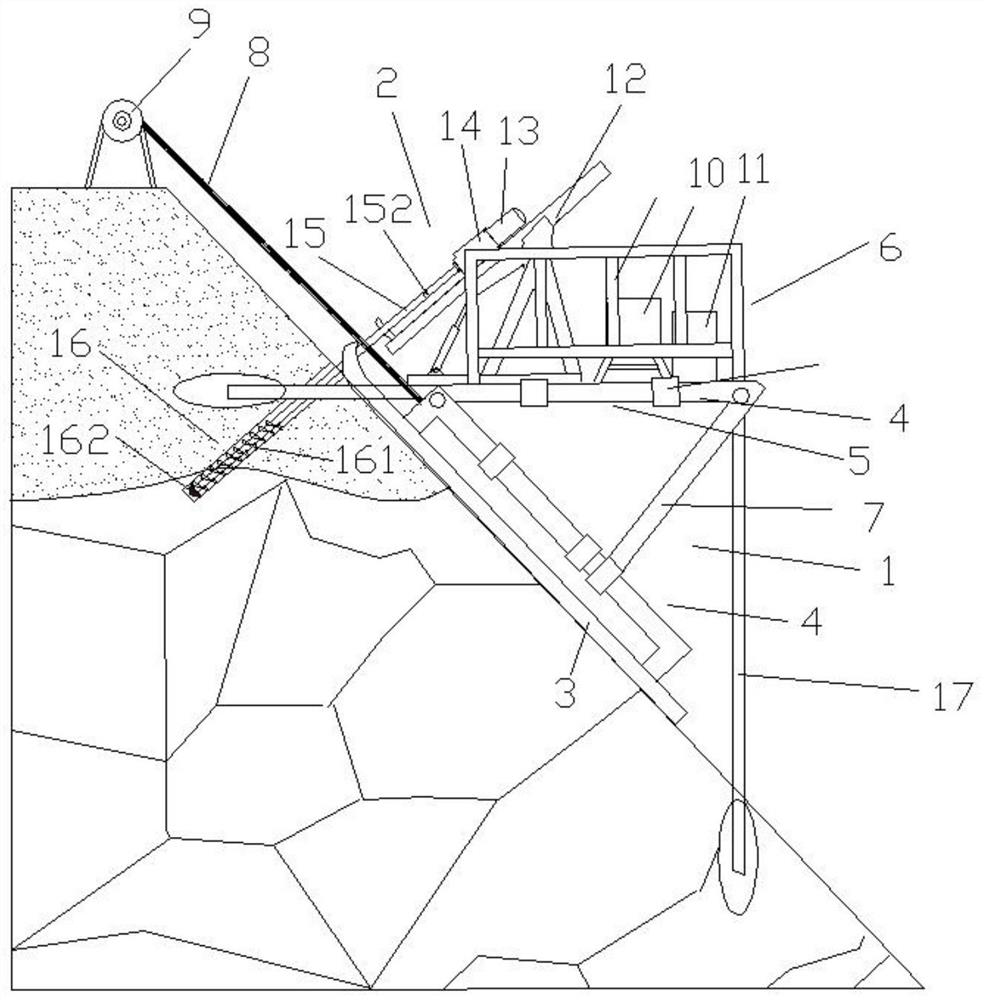

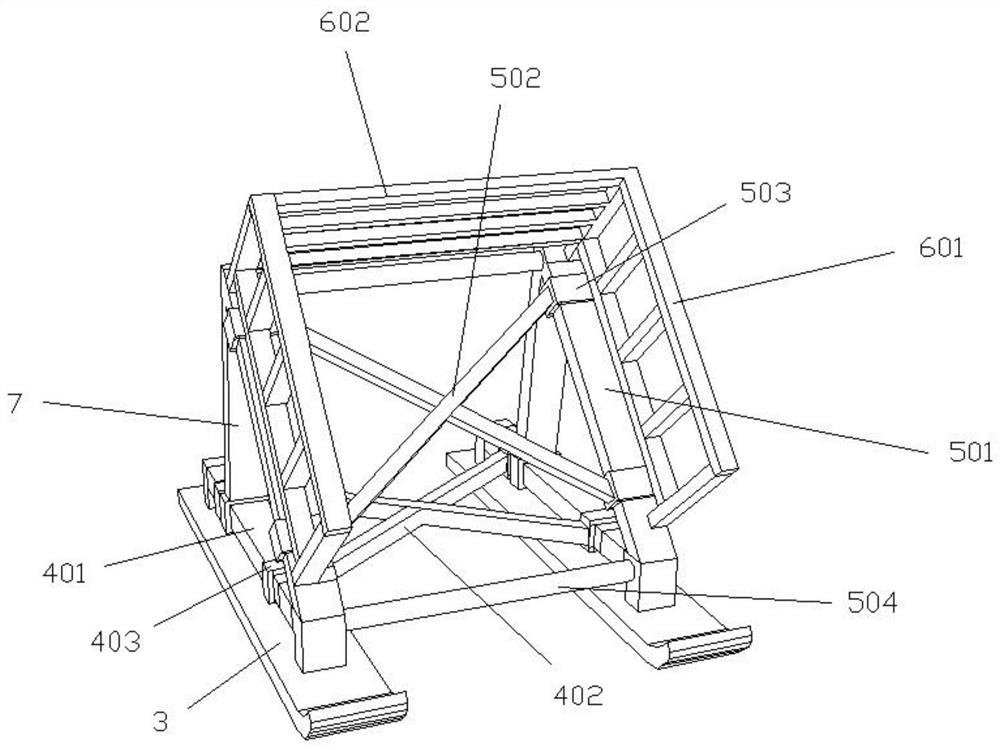

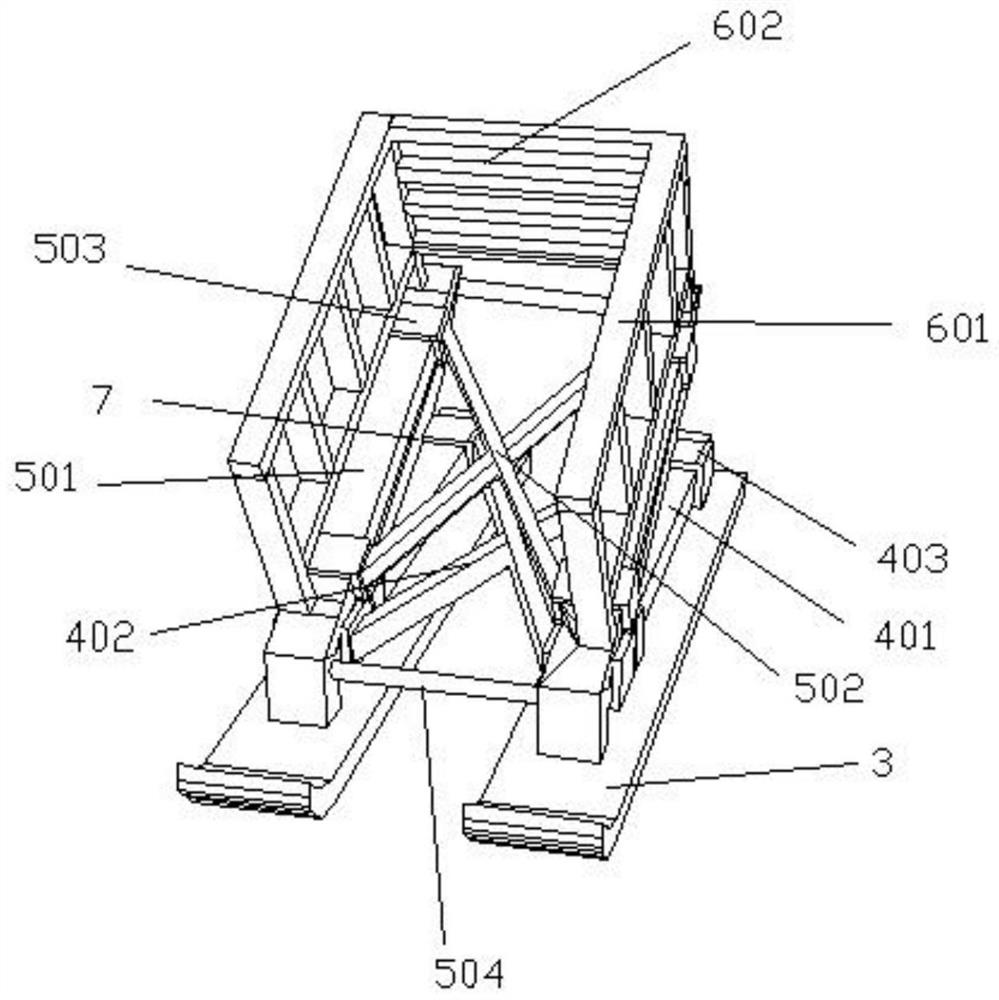

Construction method of a drilling device for complex high and steep slopes

The invention discloses a construction method of a drilling device for complex high and steep slopes. The drilling device comprises a drilling machine support, a drilling machine base and a drilling machine. The drilling machine bracket includes a slide plate, on which there is a chassis, the front end of the chassis is hingedly connected with the front end of the platform, the supporting member is hingedly connected with the platform, and connected with the chassis fastener, and the width of the chassis and the platform can be adjusted; the drilling machine includes a power distribution system , air pressure system, gears, rock drilling components, soil drilling components, drill pipes and drill bits; construction methods include: 1) Pull the drilling machine bracket to the designated position; 2) Expand the bracket and lock it; 3) Adjust the chassis and platform Angle; 4) Install the drilling machine; 5) Start drilling. The invention solves the problem of difficult drilling of complex high and steep slopes, can be adapted to various rock and soil strata, and can deal with complex slope conditions such as unevenness and lush forests. It is flexible in action, safe and reliable in performance, and can fully cope with existing Reinforcement works for complex high and steep slopes.

Owner:DALIAN UNIV OF TECH

Moso bamboo drilling machine

ActiveCN105128094ARealize safety hazardRealize huggingStationary drilling machinesCane mechanical workingCouplingShort arms

The invention discloses a moso bamboo drilling machine. A hollow rack is composed of a machine body, a top end detachable plate and a bottom detachable plate; a pushing seat is installed in an upper cavity inside the machine body; a drilling head is connected with a first motor fixed to the pushing seat through a second coupling; a small hole is formed in the portion, directly facing the drilling head, of the machine body; the middle of an L-shaped push rod is fixed to the machine body through a hinge; one end of the L-shaped push rod is connected with a connecting rod through a hinge, and a short arm at the other end of the L-shaped push rod extends out of the machine body; the other end of the connecting rod is connected with the pushing seat through a hinge; a pair of travel switches are installed between the portion, close to the short arm, of the front face of the L-shaped push rod and the machine body; a spring is installed between the back side of the short arm of the L-shaped push rod and the machine body; a plurality of clamping rings are installed on a first nut and a second nut, and the first nut and the second nut are located inside a cavity in the side face of the machine body; the two sides of each clamping ring are clamped in clamping grooves. A moso bamboo is clamped through the clamping rings by shifting a bilateral switch, and then the moso bamboo is drilled by pressing the short arm of the L-shaped push rod. The operation is convenient, safe and efficient.

Owner:杭州杭睿科技有限公司

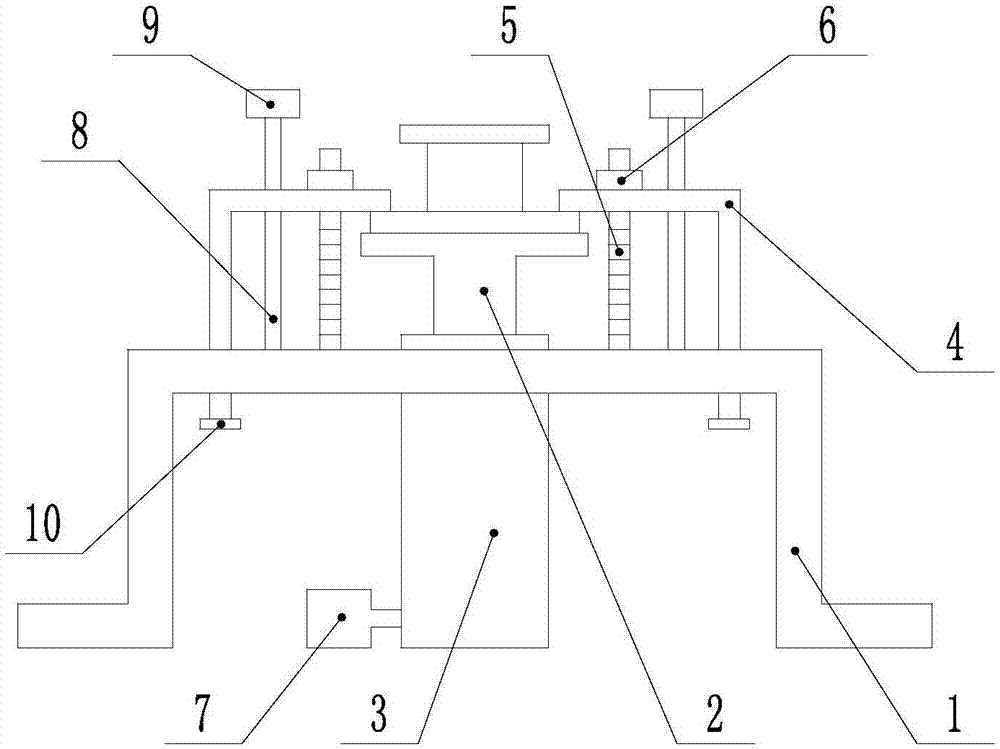

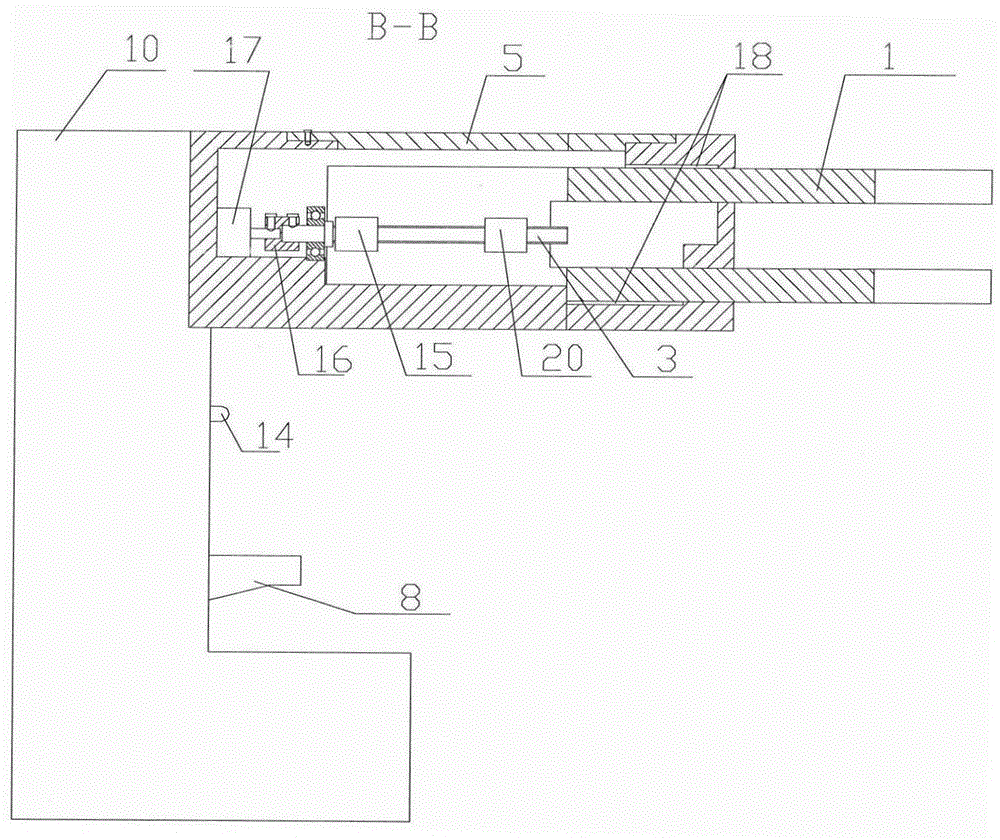

Automatic numerical control drilling and tapping equipment

ActiveCN113523361ADrilling stabilityHigh degree of automationThread cutting feeding devicesThread cutting machinesProcessing accuracyEngineering

The invention discloses automatic numerical control drilling and tapping equipment, and relates to the field of metal processing. The automatic numerical control drilling and tapping equipment comprises a base, a control panel and a feeding device are arranged on the base, the control panel controls the whole device, the base comprises a shell, an inclined plane pad is arranged in the shell, and a drilling and tapping device, a material moving device and a pressing device are arranged on the inclined plane pad. Materials are placed in a storage bin of the feeding device, conveyed to the material moving device through a feeding sliding rail, fixed by the pressing device, drilled and tapped by the drilling and tapping device and finally slid out of the material moving device. The material moving device can automatically contain the materials of the feeding device and automatically lower the drilled and tapped materials when a grooved plate rotates, and a locking device can keep the materials stable during drilling and tapping, and therefore the machining precision is improved.

Owner:佛山市台创机械制造有限公司

Processing machine for wooden bucket for wasp breeding

InactiveCN105196389ADrilling stabilityQuality improvementStationary drilling machinesWood turning toolsMechanical engineeringDrilling machines

The invention discloses a processing machine for a wooden bucket for wasp breeding. The processing machine comprises a rack, a drill bit, a mounting rack and a hand wheel. A power device, a drilling machine shaft driven by the power device, and guide rails extending in the axial direction of the drilling machine shaft are arranged on the rack. The drill bit is detachably mounted on the drilling machine shaft. The mounting rack is detachably arranged on the guide rails in a sliding mode, and provided with a clamping portion, and the clamping portion is used for clamping or loosening wood. The hand wheel is arranged on the mounting rack, and used for pushing the mounting rack to slide along the guide rails. A drilling machine is stable in drilling, the quality of holes is good, drilling efficiency is high, an operator is far away from the drill bit and a rotating component, and high safety is achieved.

Owner:天峨县全盛蜂业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com