Perforating device for electric power fitting

A technology of punching device and power fittings, applied in positioning devices, manufacturing tools, boring/drilling and other directions, can solve problems such as accurate positioning, line failure, product unqualified, etc., to ensure punching quality and accurate punching. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

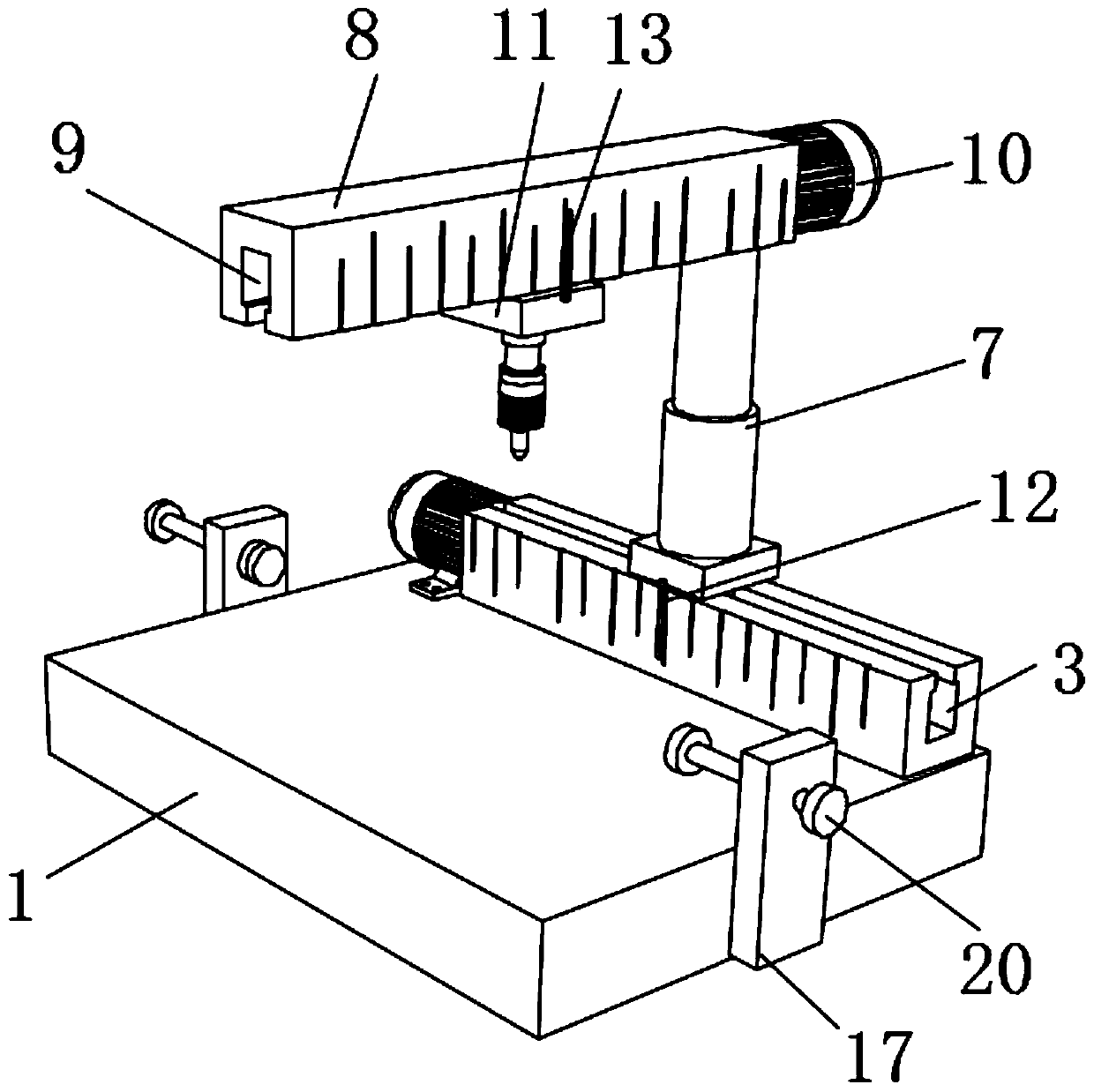

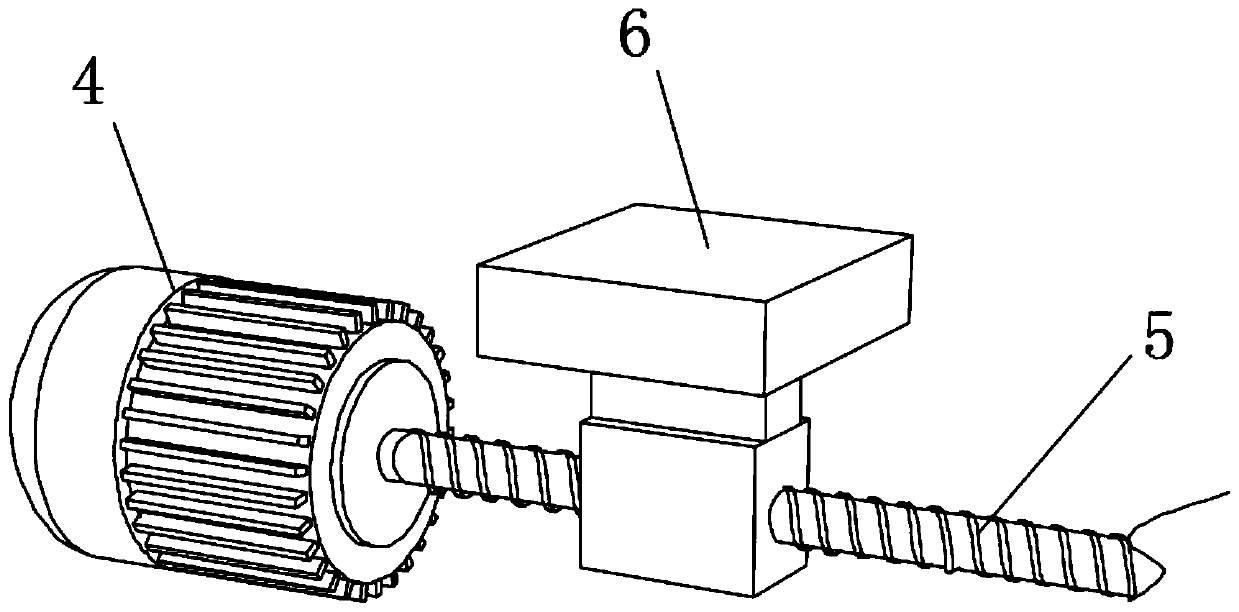

[0025] refer to Figure 1-3 , a punching device for electric power fittings, comprising a base 1 fixedly connected with a first slide rail 2 on one side of the upper end, the upper end of the first slide rail 2 is dug with a first chute 3, and the first chute 3 is slidably connected There is a first slider matching it, and a screw hole is drilled on the first slider, the end of the first slide rail 2 is provided with a first motor 4, and the first motor 4 is fixedly connected to the upper end surface of the base 1, the first The power output end of the motor 4 is connected with a screw rod 5, and the screw rod 5 is threadedly connected with the screw hole on the first slider, and the upper end of the first slider extends to the upper side of the first chute 3 and is fixedly connected with the first fixed seat 6, The upper end of the first fixed base 6 is fixedly connected with the first electric telescopic rod 7, the upper end of the first electric telescopic rod 7 is fixedly ...

Embodiment 2

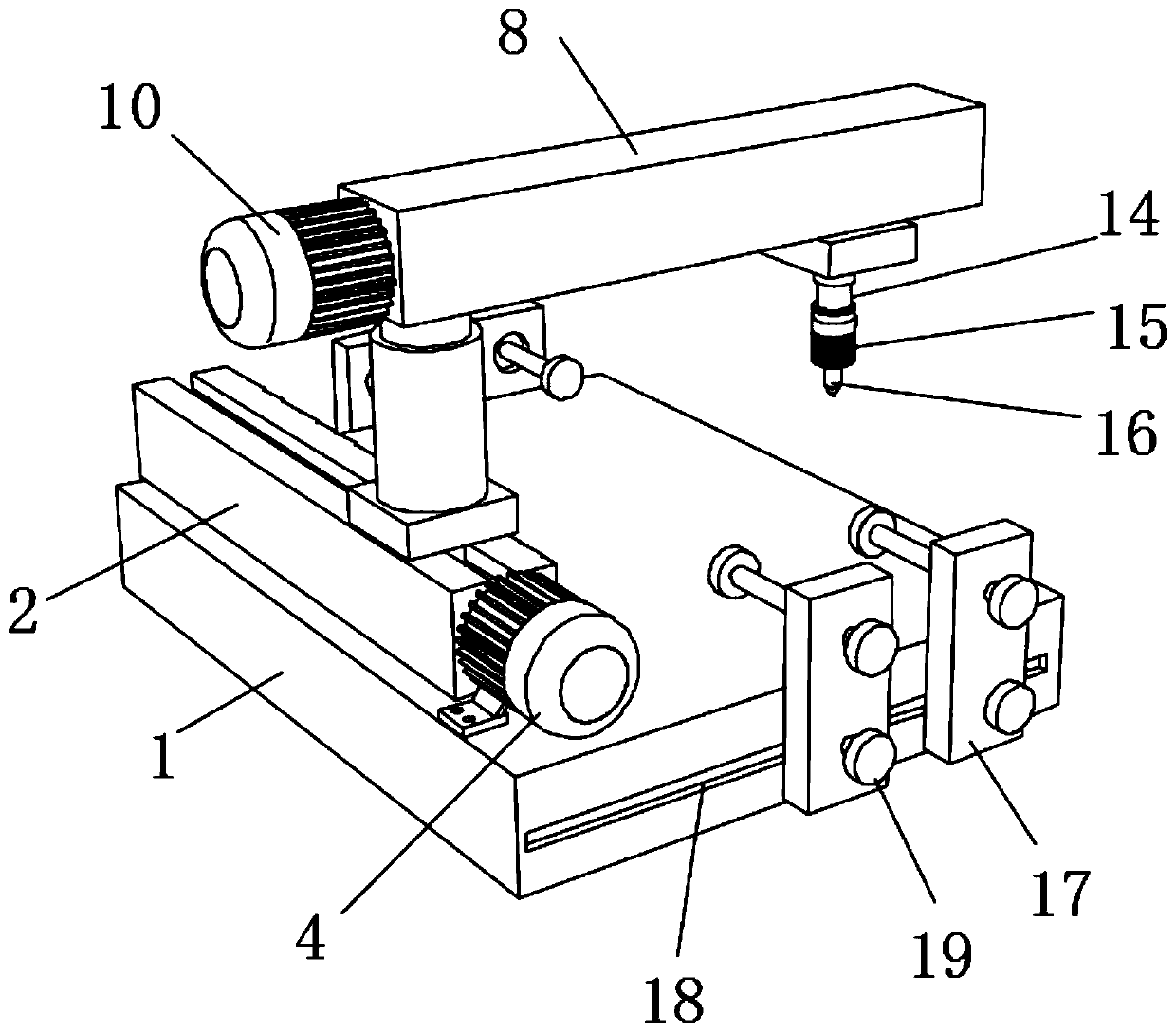

[0031] refer to figure 2 , a punching device for electric power fittings. Compared with Embodiment 1, this embodiment has a locking screw hole dug on the clamping seat 17, and an I-shaped locking member 19 is threadedly connected to the locking screw hole. The side end of the base 1 is dug with a third chute 18 matching the end of the I-shaped locking member 19, and there are multiple pairs of clamping parts.

[0032] Working principle: The position of the clamping part can be adjusted according to the size of the hardware, that is, loosen the I-shaped locking part 19, then push the clamping seat 17 to the required position along the third chute 18, and tighten the I-shaped locking part 19 That is, a plurality of clamping parts can make the fixing of the hardware more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com