Patents

Literature

334results about How to "Reliable processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pulverulent polymers crosslinked on the surface

InactiveUS7157141B2Reduce treatmentImprove permeabilityBaby linensGlass/slag layered productsCarboxylic groupMonomer

The present invention relates to a pulverulent polymer post-crosslinked on the surface and absorbing water or aqueous liquids, synthesised from polymerised, optionally pre-crosslinked monomers containing partially neutralised carboxyl groups. The present invention also relates to a process for the post-treatment of the aforementioned polymers and the use of a solution of at least one salt of an at least trivalent cation for restoring the gel permeability of the aforementioned polymers that have been damaged by mechanical action.

Owner:EVONIK OPERATIONS GMBH

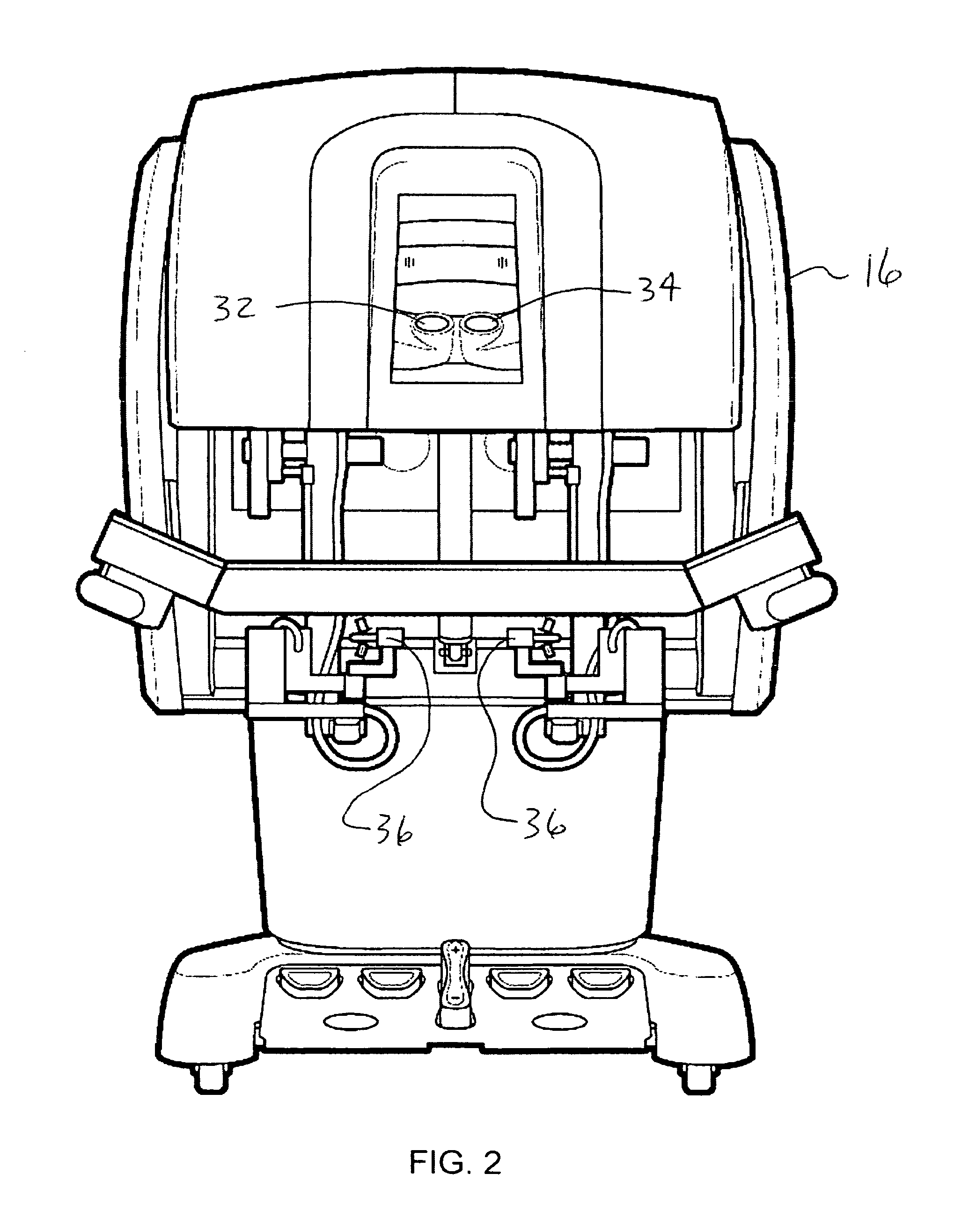

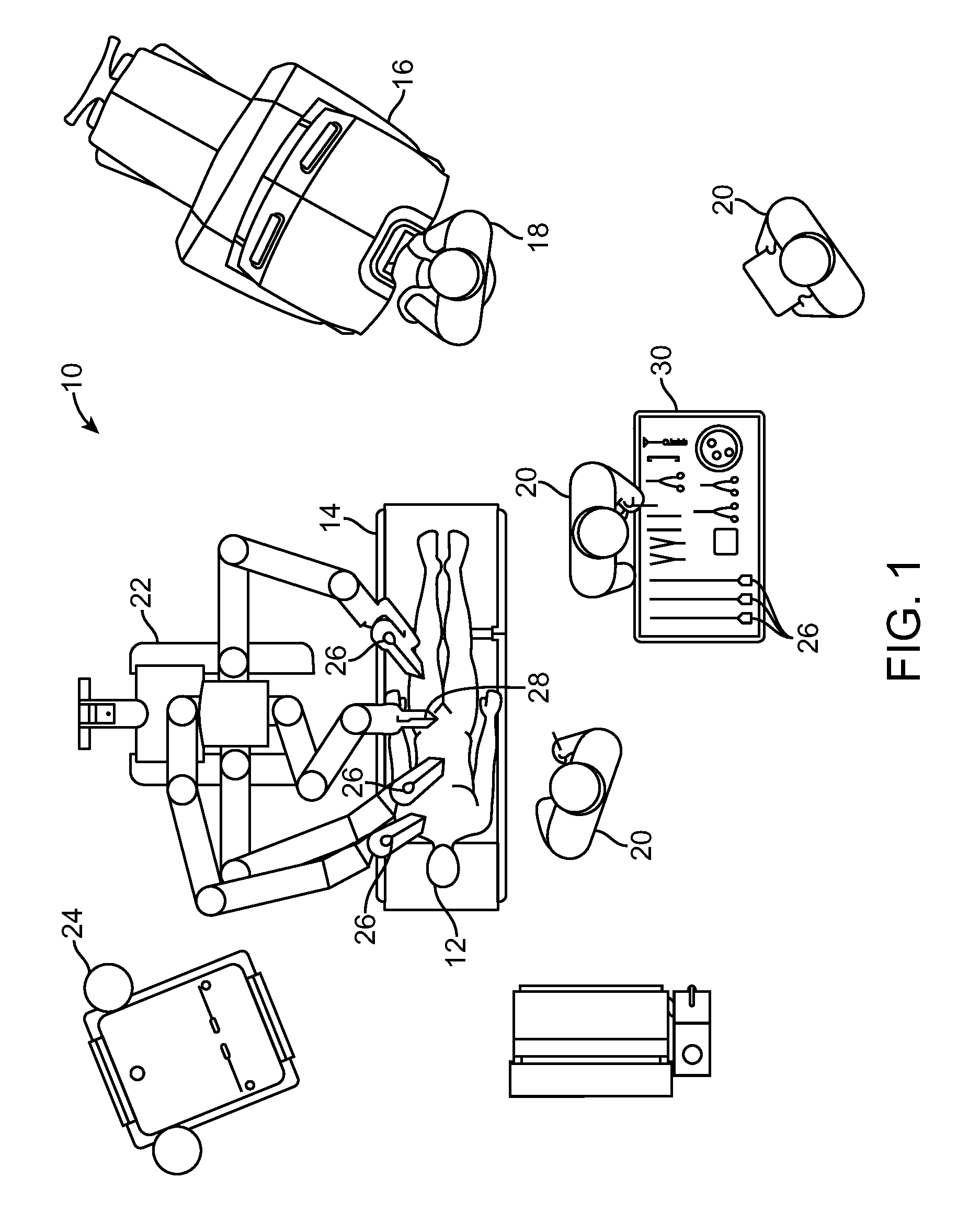

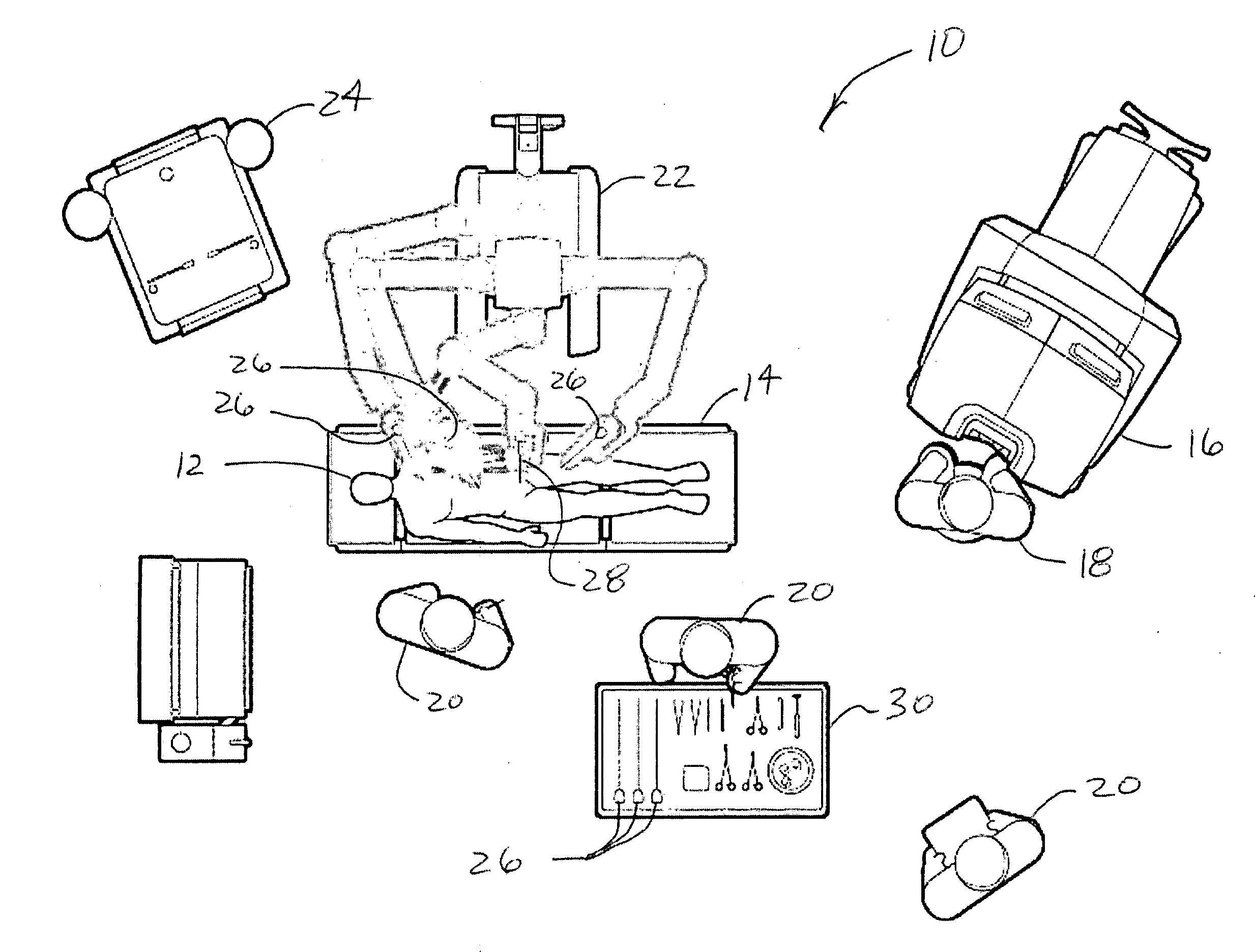

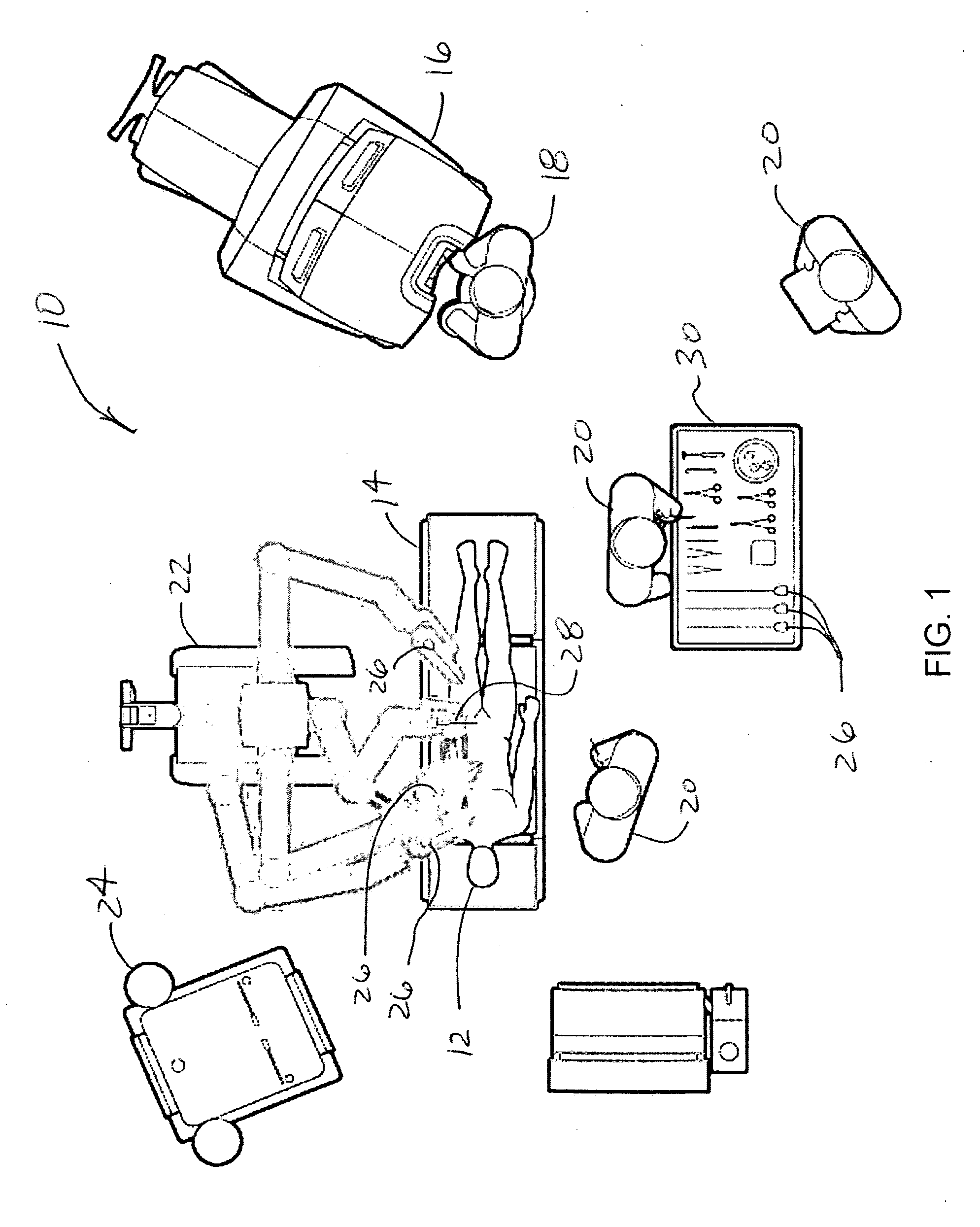

Fiducial marker design and detection for locating surgical instrument in images

ActiveUS9526587B2Reliably imagedReliable processingSurgical navigation systemsDiagnostic recording/measuringDerived DataComputer science

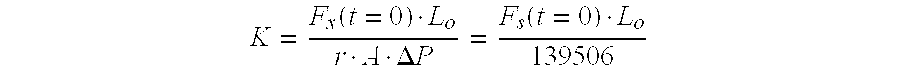

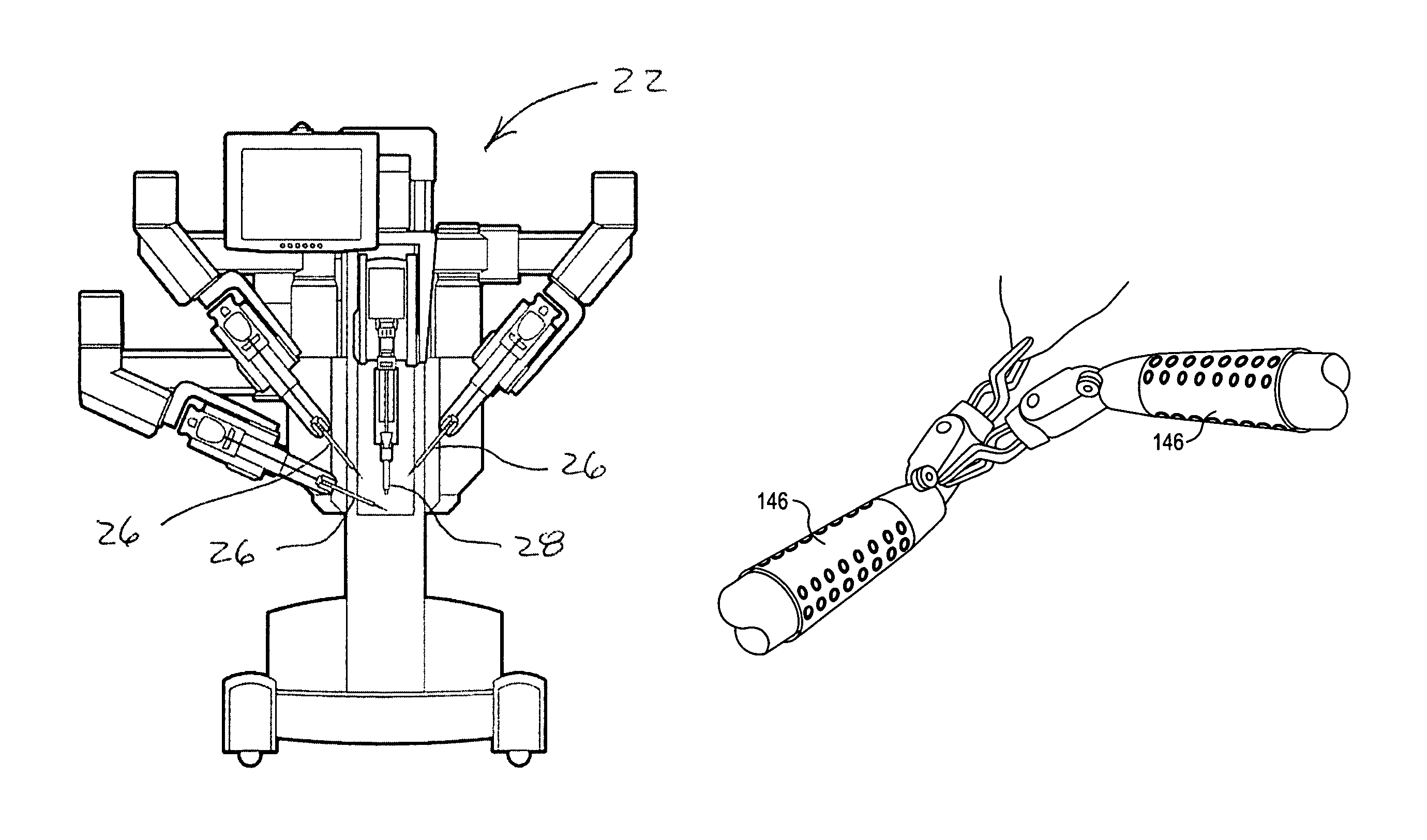

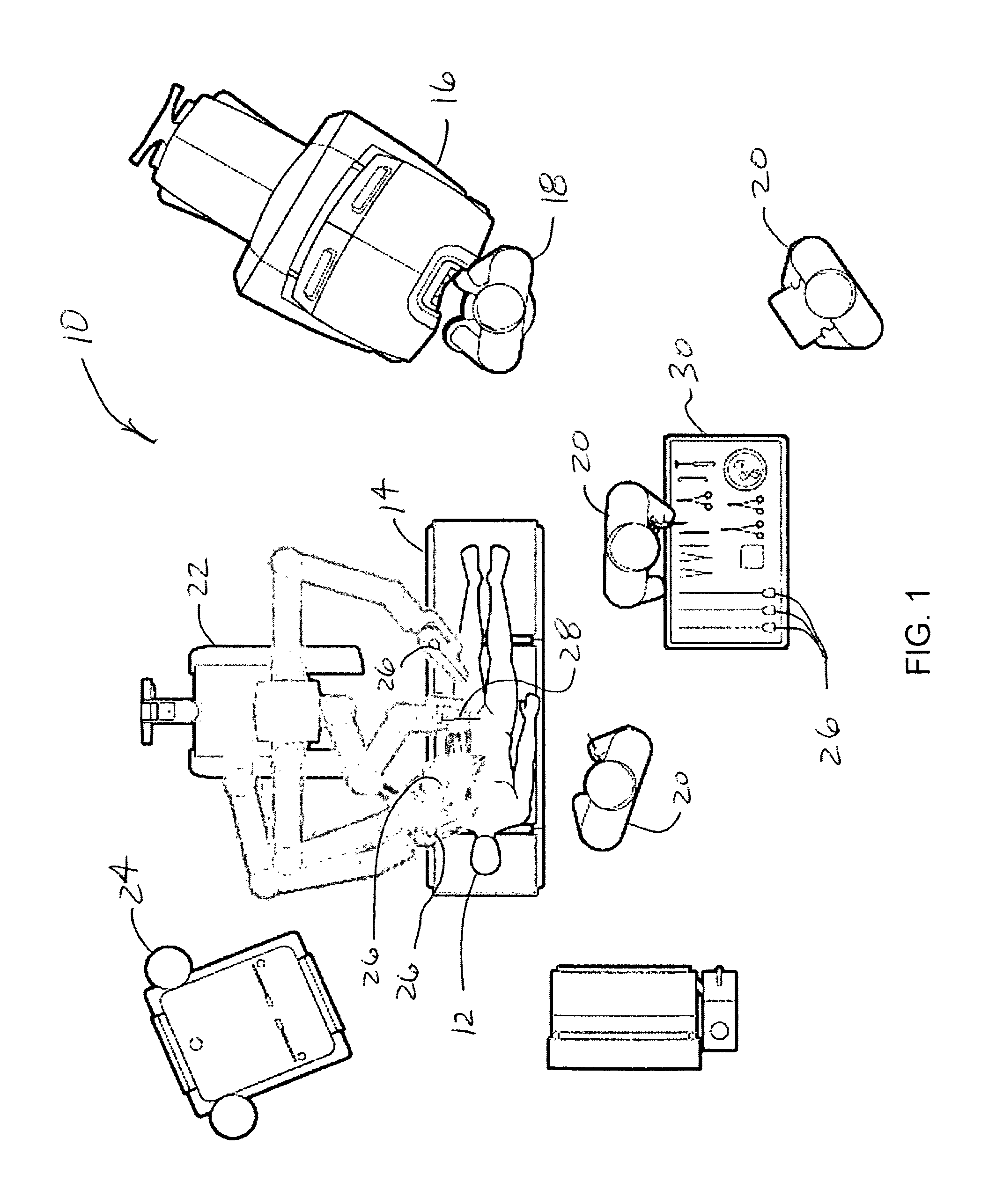

The present disclosure relates to systems, methods, and tools for tool tracking using image-derived data from one or more tool-located reference features. A method includes: capturing a first image of a tool that includes multiple features that define a first marker, where at least one of the features of the first marker includes an identification feature; determining a position for the first marker by processing the first image; determining an identification for the first marker by using the at least one identification feature by processing the first image; and determining a tool state for the tool by using the position and the identification of the first marker.

Owner:INTUITIVE SURGICAL OPERATIONS INC

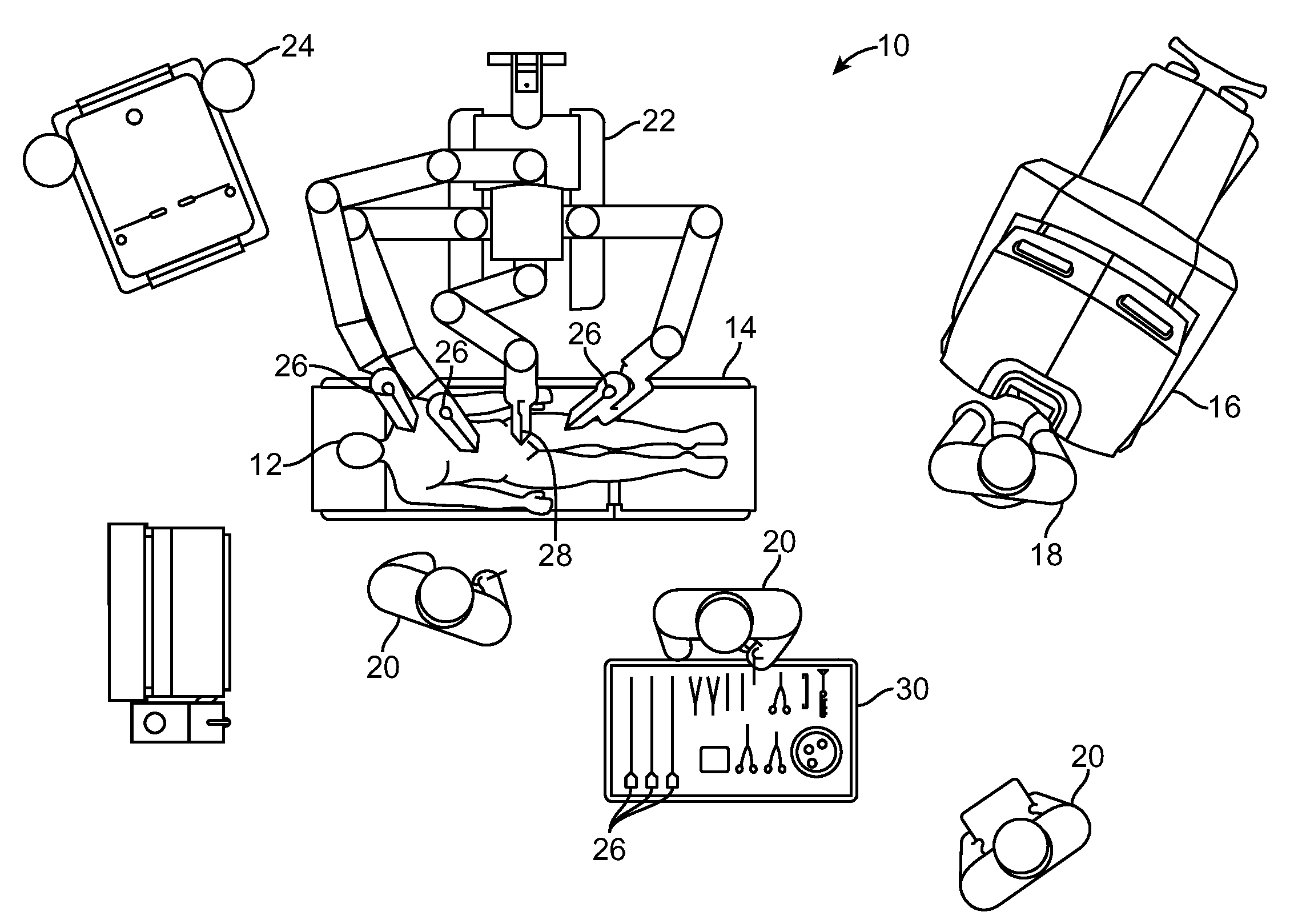

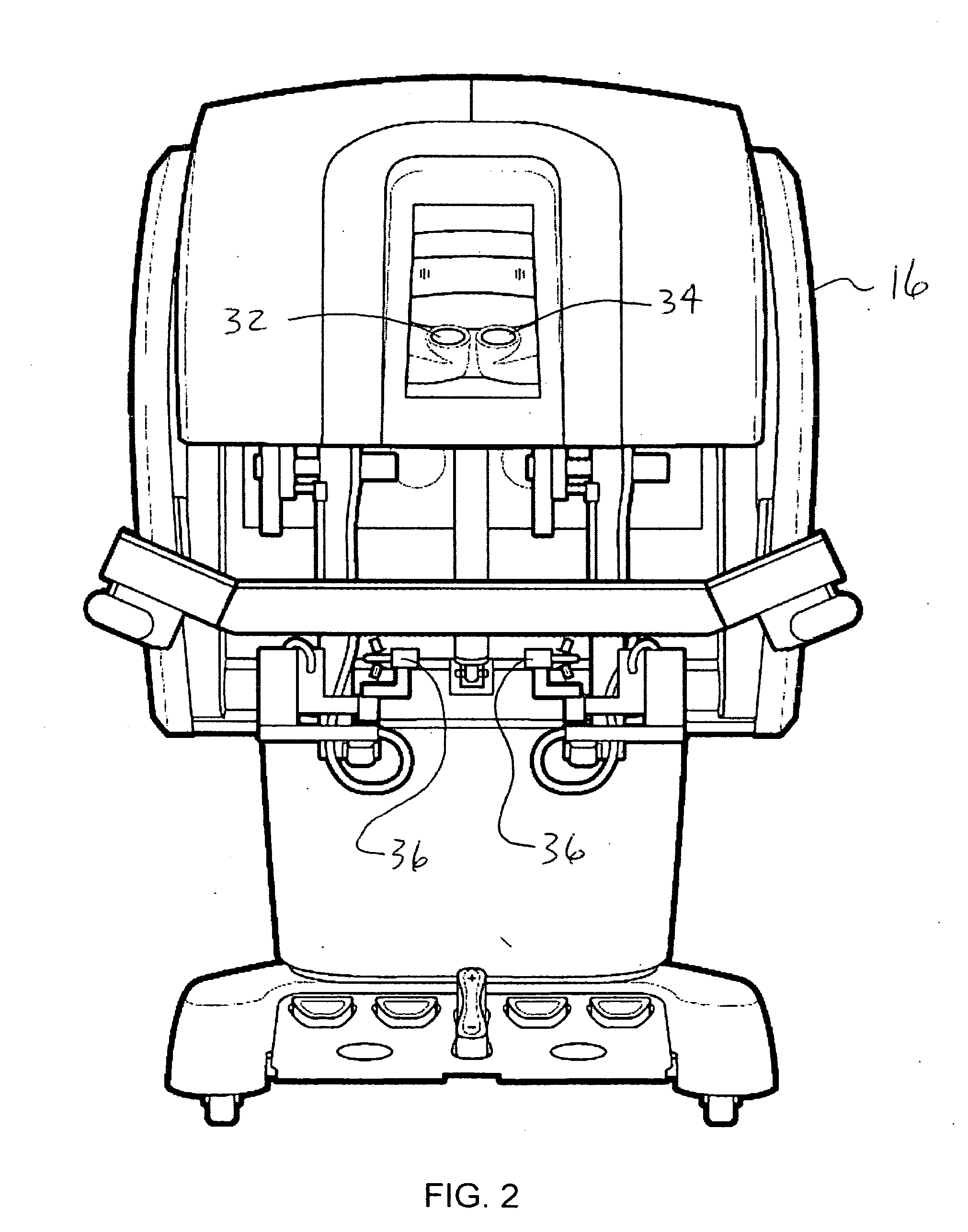

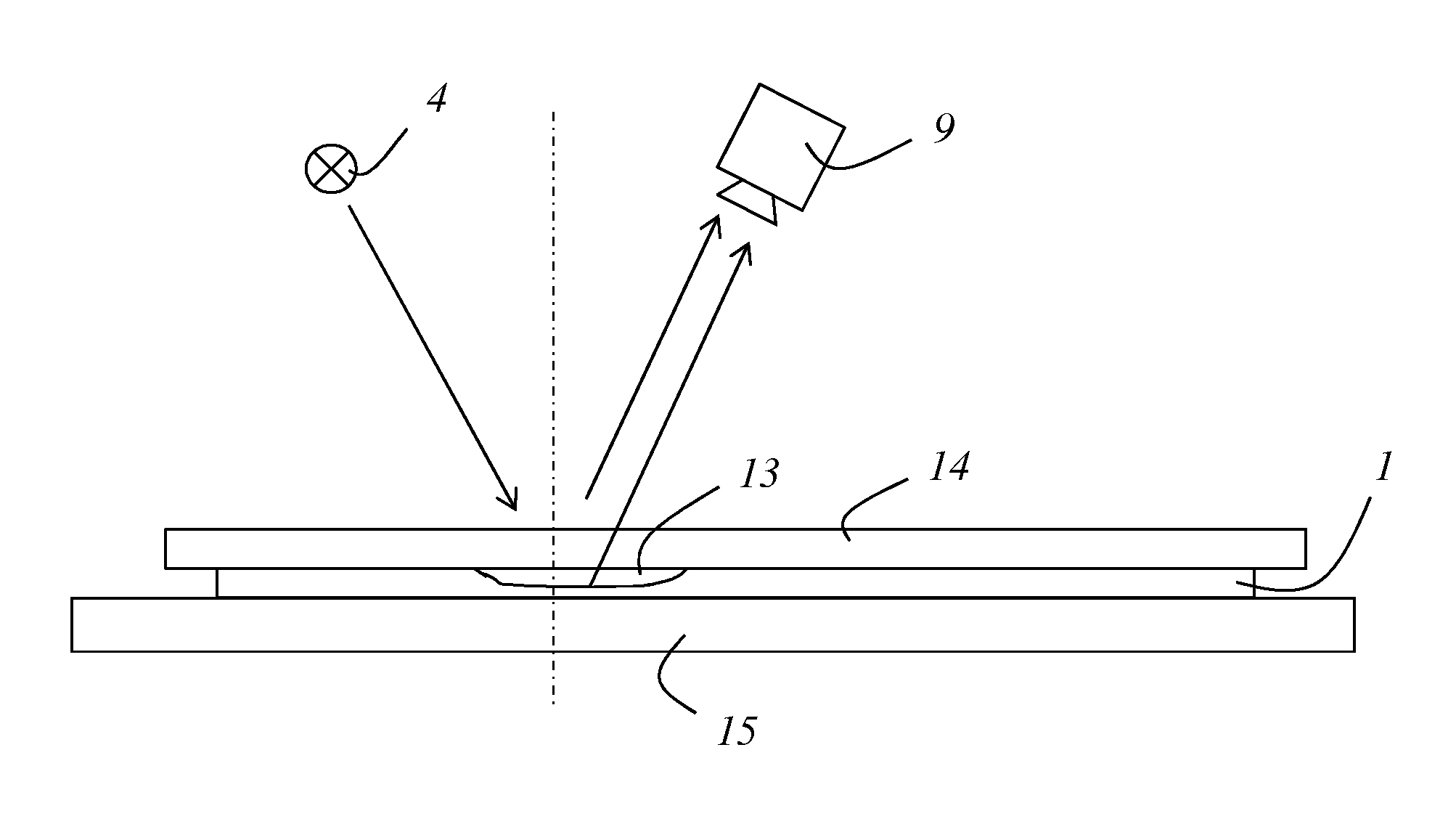

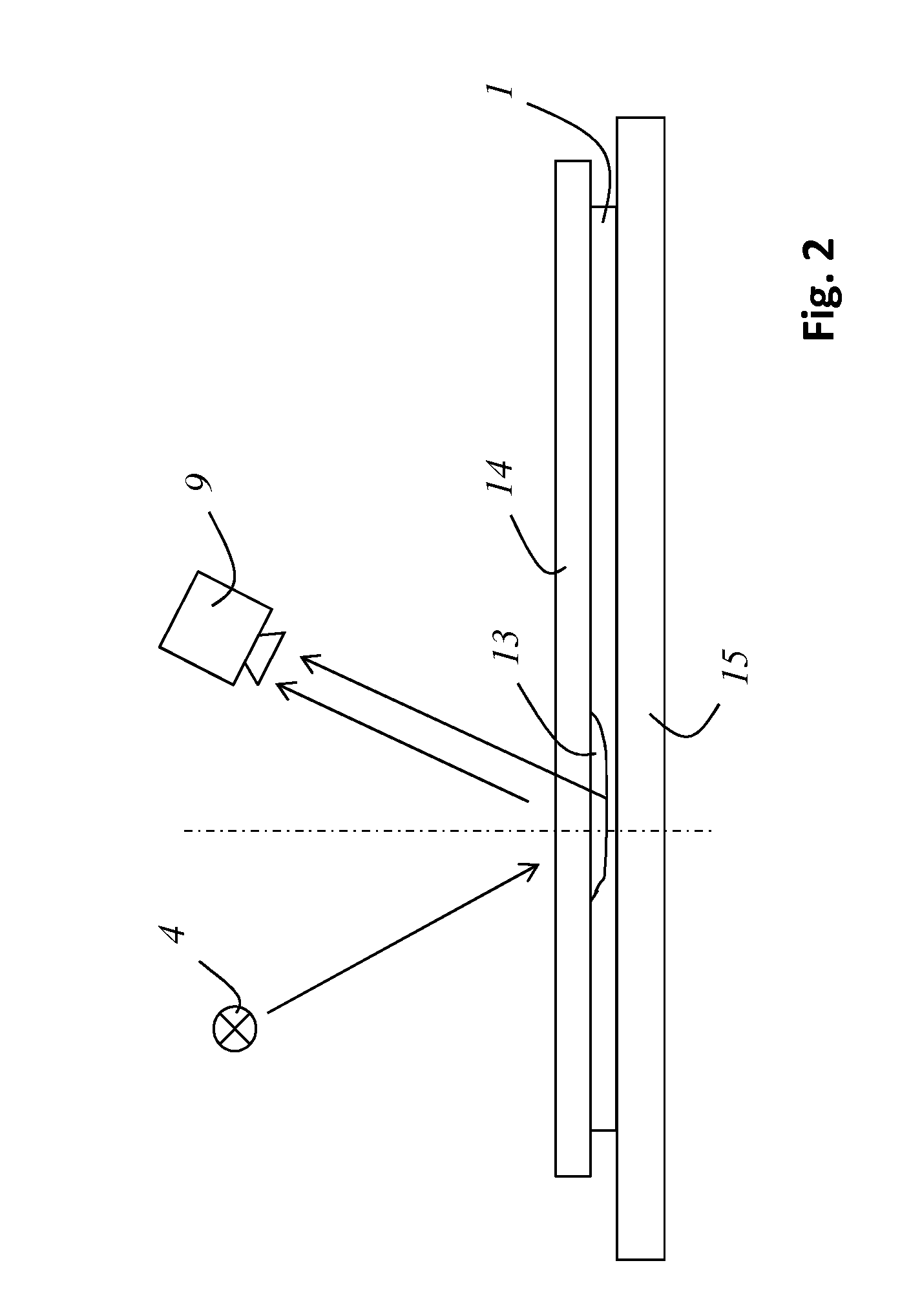

Configuration marker design and detection for instrument tracking

ActiveUS20100168763A1Reliably imagedReliable processingImage enhancementImage analysisDerived DataStereo image

The present disclosure relates to systems, methods, and tools for tool tracking using image-derived data from one or more tool located reference features. A method includes: directing illuminating light from a light source onto a robotic surgical tool within a patient body, wherein the tool includes a plurality of primitive features having known positions on the tool, and wherein each feature includes a spherical reflective surface; capturing stereo images of the plurality of primitive features when the tool is within the patient body, wherein the stereo images are captured by an image capture device adjacent the illumination source so that the illumination light reflected from the imaged primitive features toward the image capture device substantially aligns with spherical centers of the surfaces of the imaged primitive features, and determining a position for the tool by processing the stereo images so as to locate the spherical centers of the imaged primitive features by using the reflected light.

Owner:INTUITIVE SURGICAL OPERATIONS INC

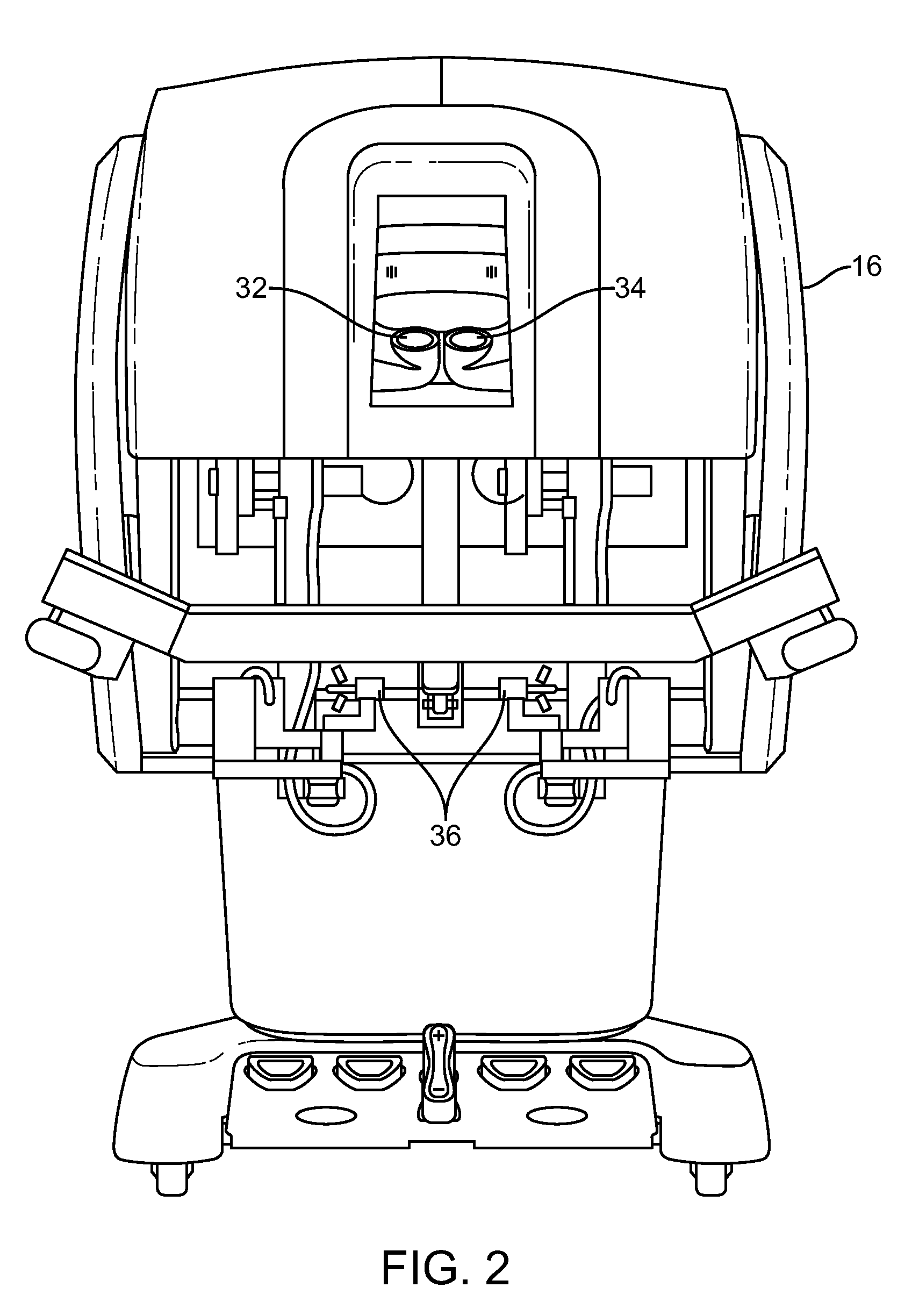

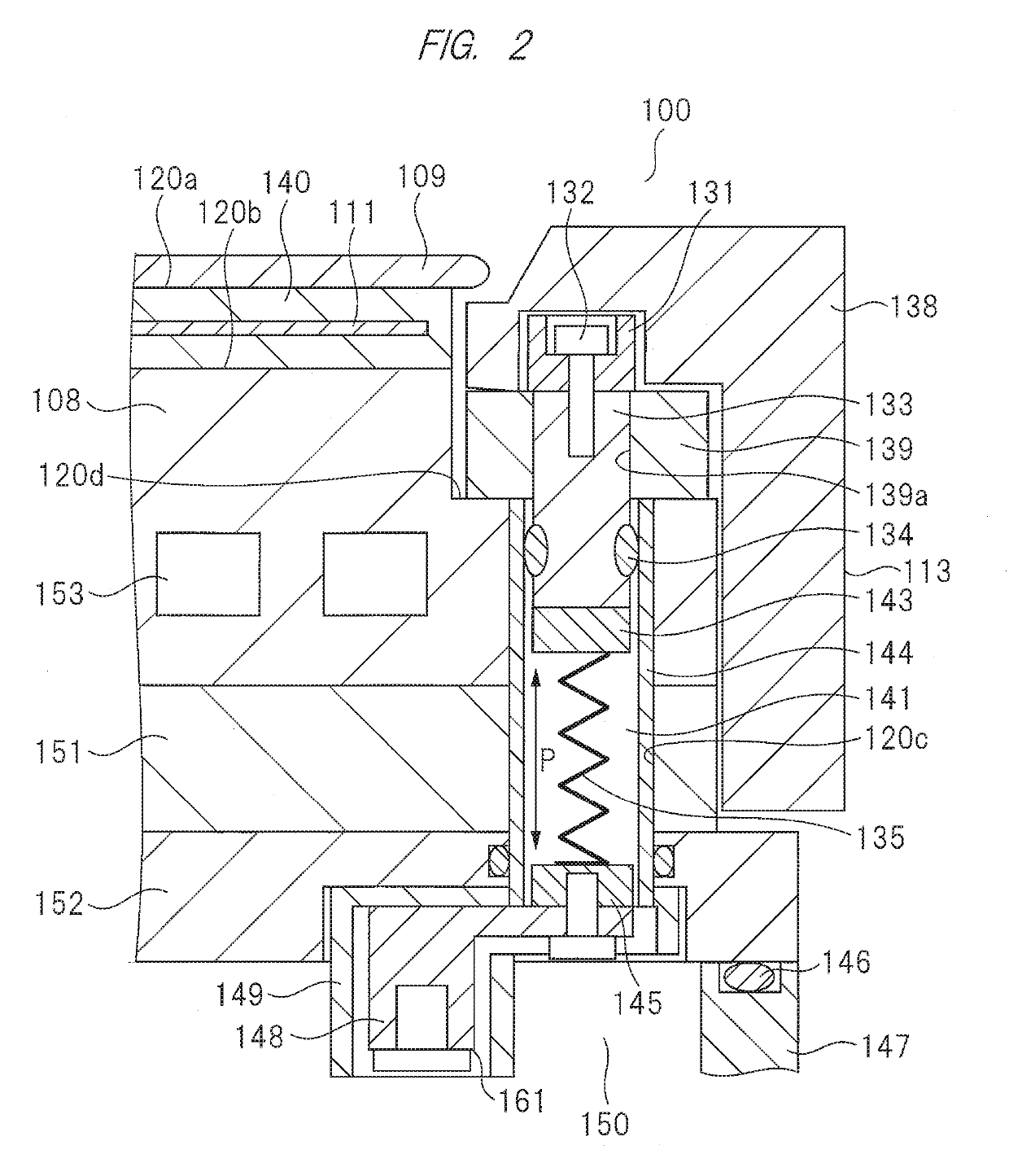

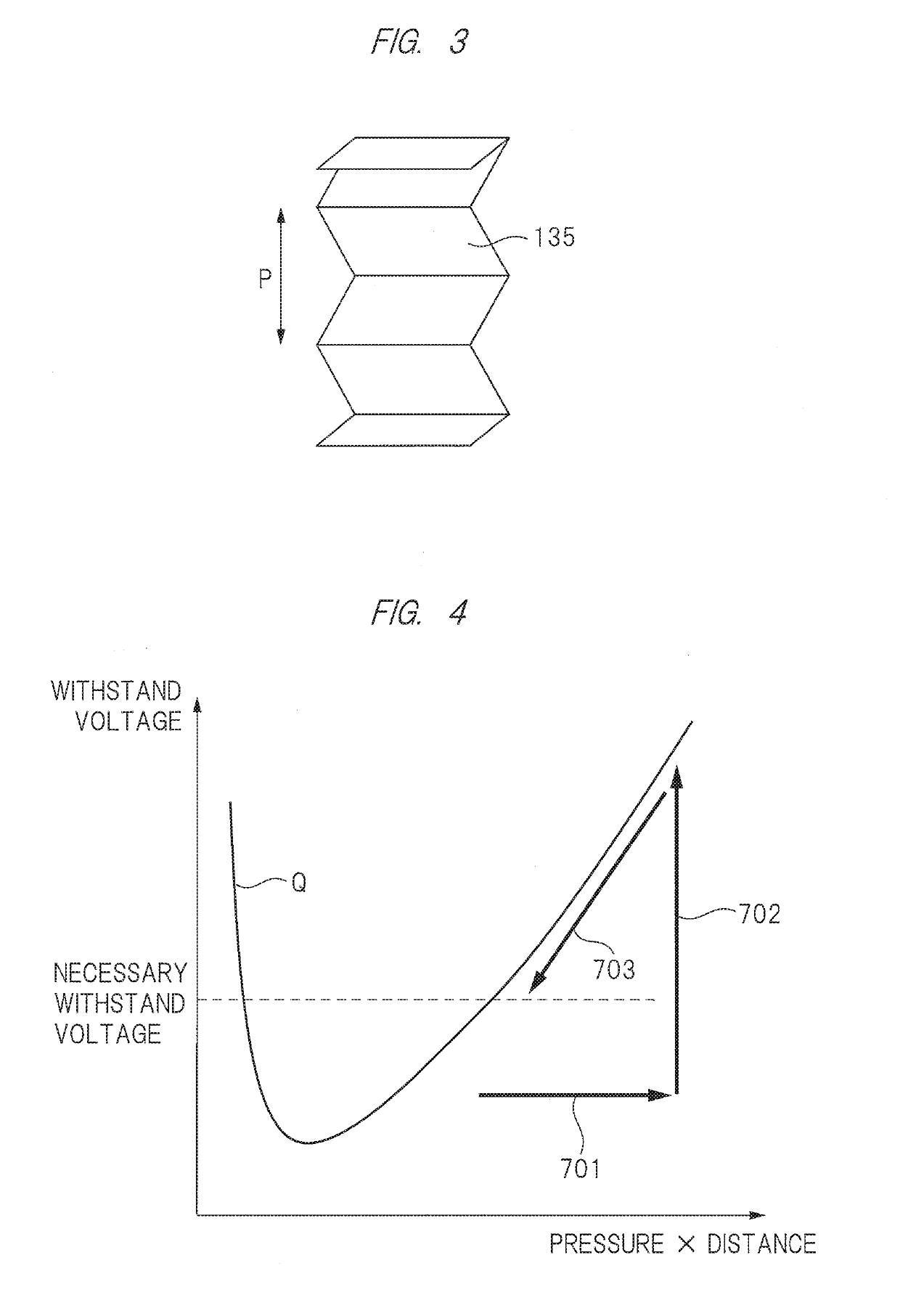

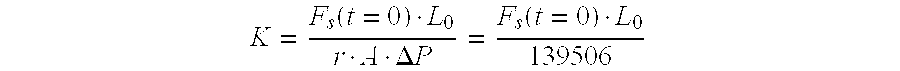

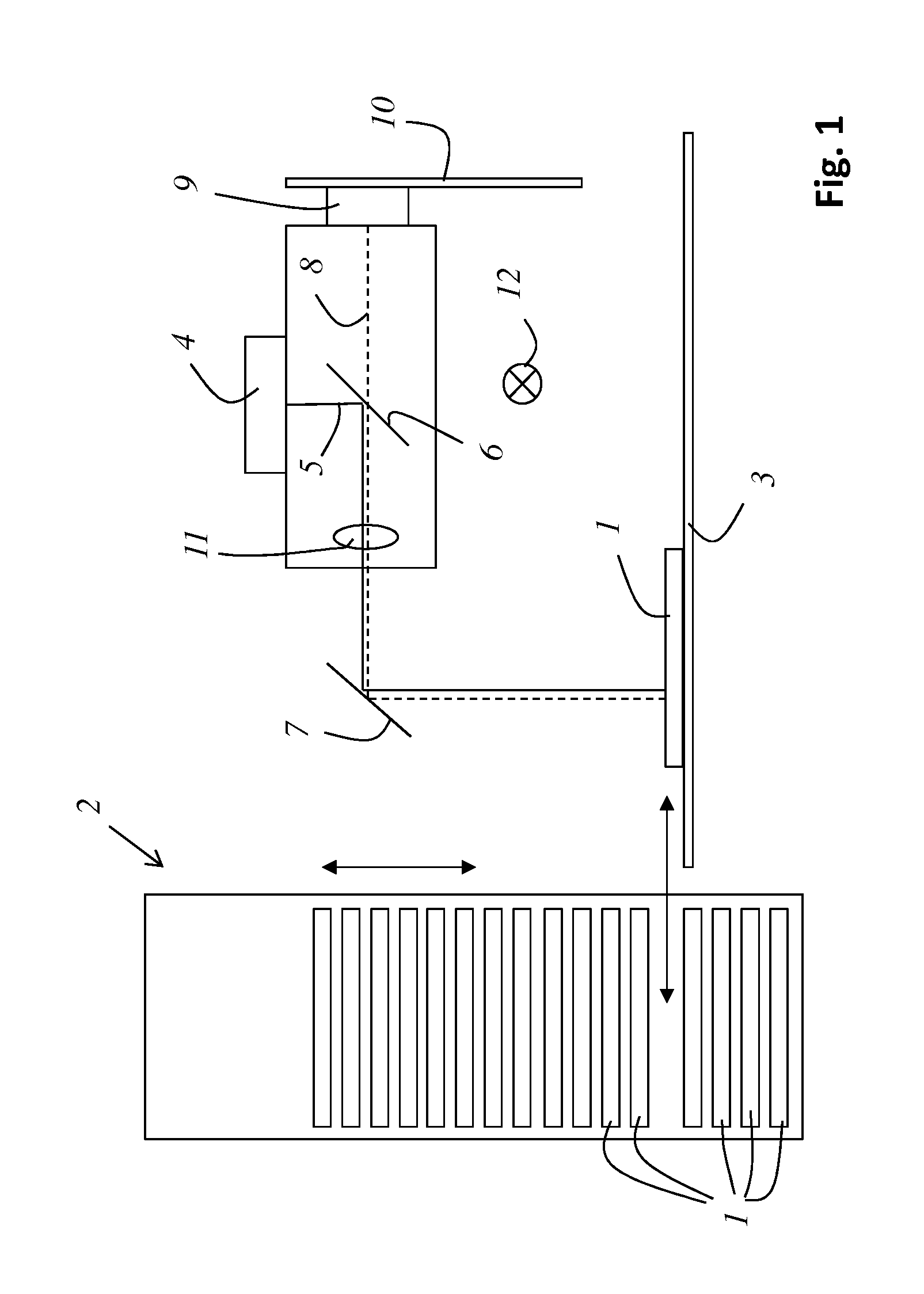

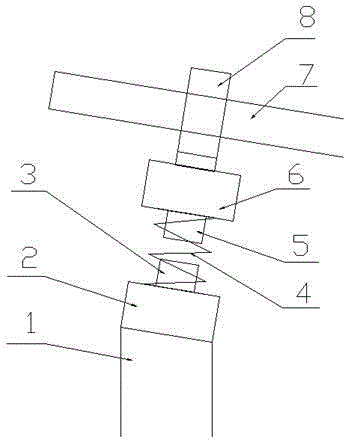

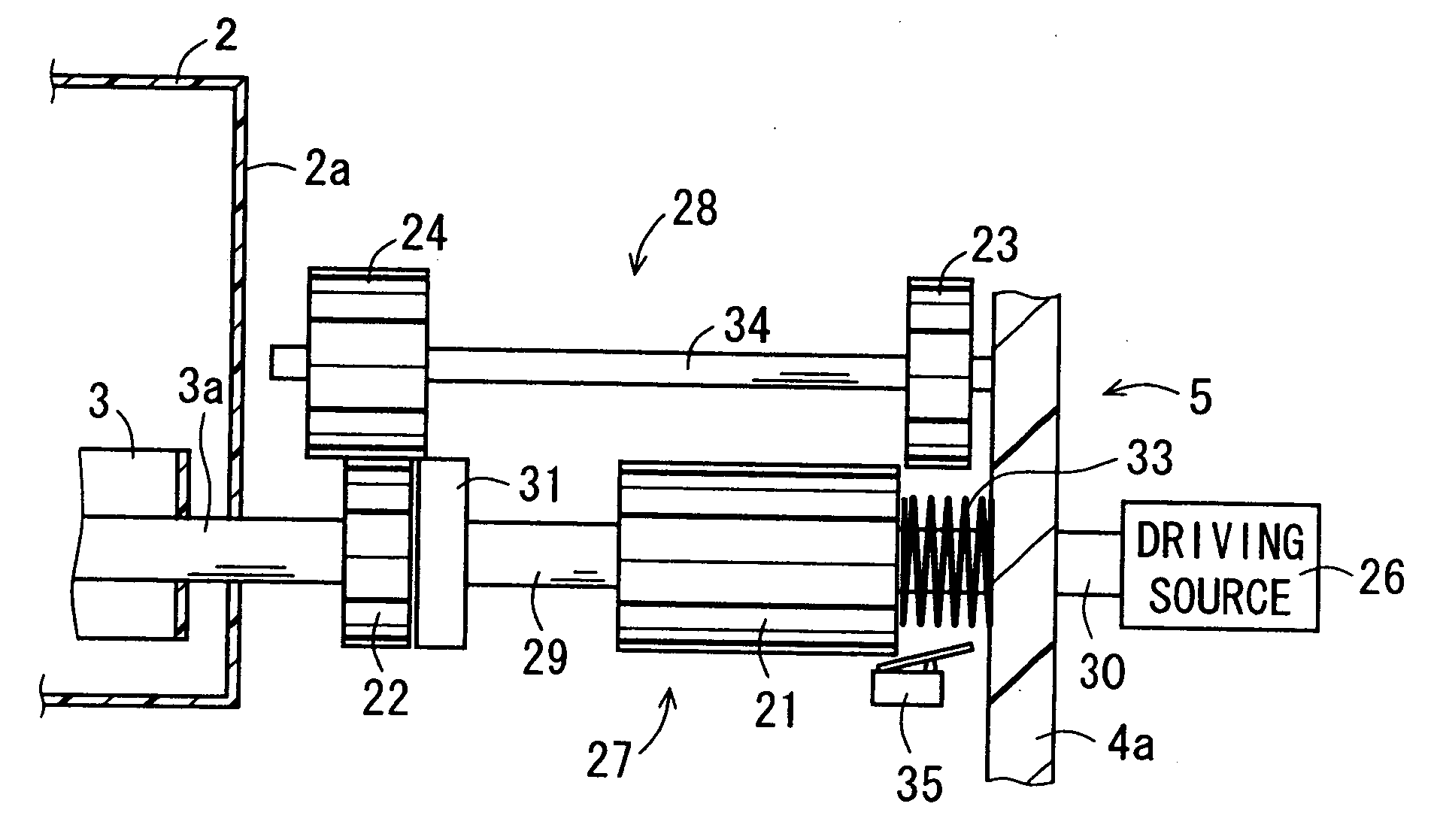

Plasma processing apparatus and plasma processing method

ActiveUS20190198297A1Yield of plasma can be improvedIncrease productionElectric discharge tubesSemiconductor/solid-state device manufacturingElectrical conductorHigh frequency power

The reliability of a plasma processing apparatus can be improved, and the yield of plasma processing can be improved. A plasma etching apparatus 100 has a susceptor ring 113 covering the surface of a sample stage, a conductor ring 131 disposed in the interior of the susceptor ring 113 and to which second high frequency electric power is supplied from a second high frequency power source, and an electric power supply connector 161 configuring a path for supplying the second high frequency electric power to the conductor ring 131. Further, the electric power supply connector 161 includes a plate spring 135 disposed in the interior of an insulating boss 144 disposed in a through hole 120c of the sample stage and having resiliency in such a manner that the plate spring 135 is connected to an upper terminal 143 and a lower terminal 145, is biased in an up-down direction P, and is expanded and contracted.

Owner:HITACHI HIGH-TECH CORP

Fiducial marker design and detection for locating surgical instrument in images

ActiveUS20100168562A1Reliably imagedReliable processingSurgical navigation systemsDiagnostic recording/measuringDerived DataSurgical device

The present disclosure relates to systems, methods, and tools for tool tracking using image-derived data from one or more tool-located reference features. A method includes: capturing a first image of a tool that includes multiple features that define a first marker, where at least one of the features of the first marker includes an identification feature; determining a position for the first marker by processing the first image; determining an identification for the first marker by using the at least one identification feature by processing the first image; and determining a tool state for the tool by using the position and the identification of the first marker.

Owner:INTUITIVE SURGICAL OPERATIONS INC

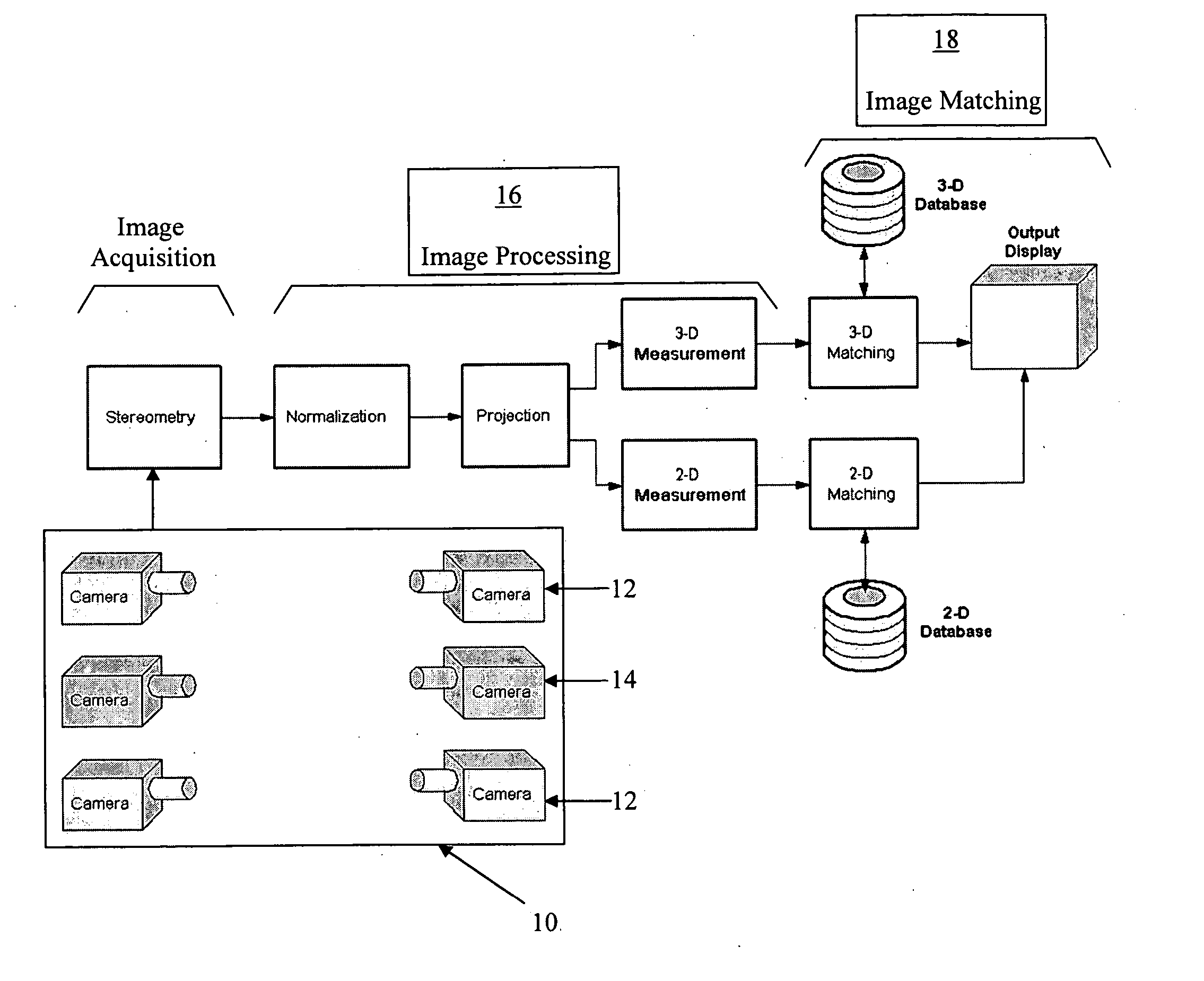

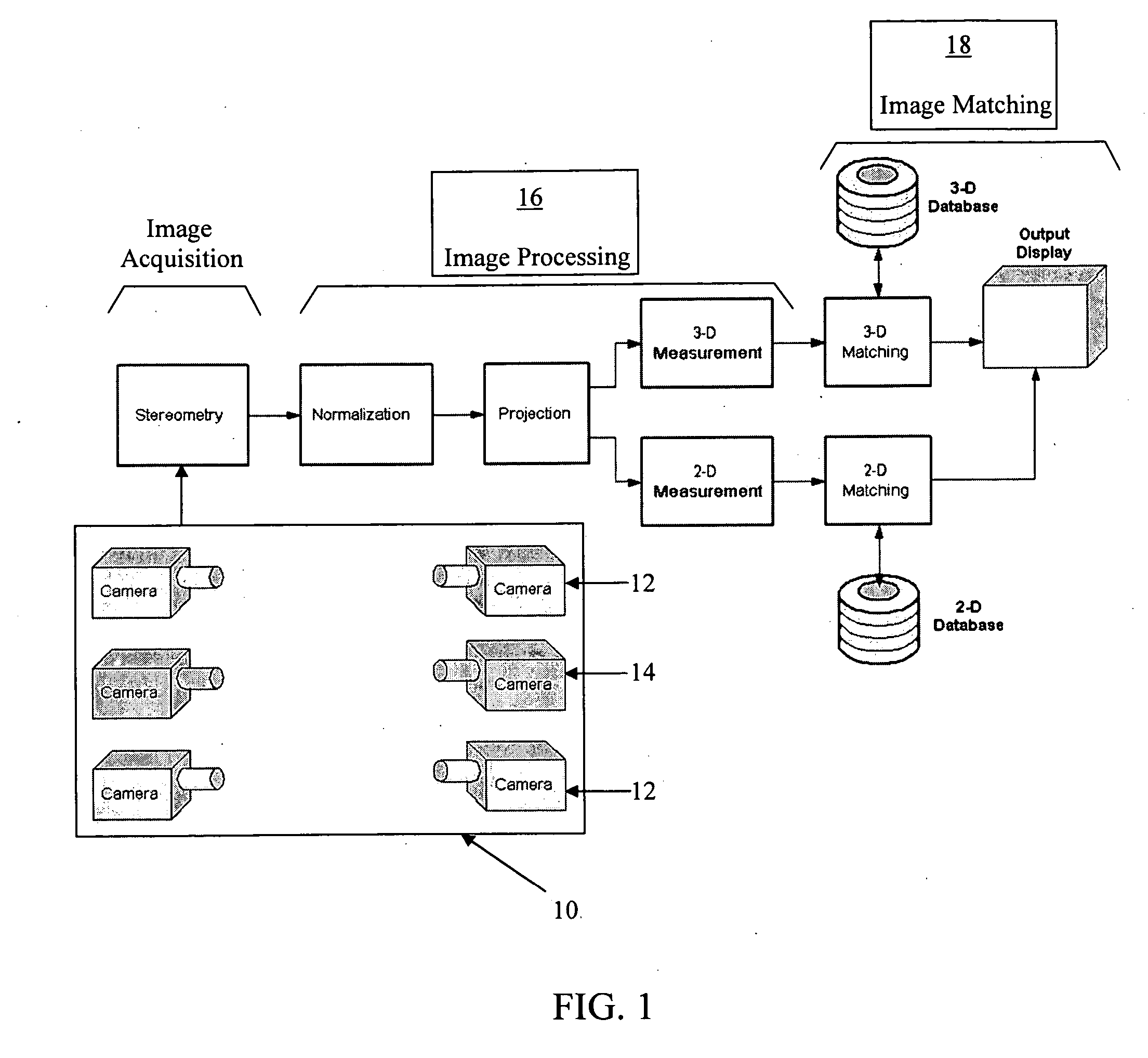

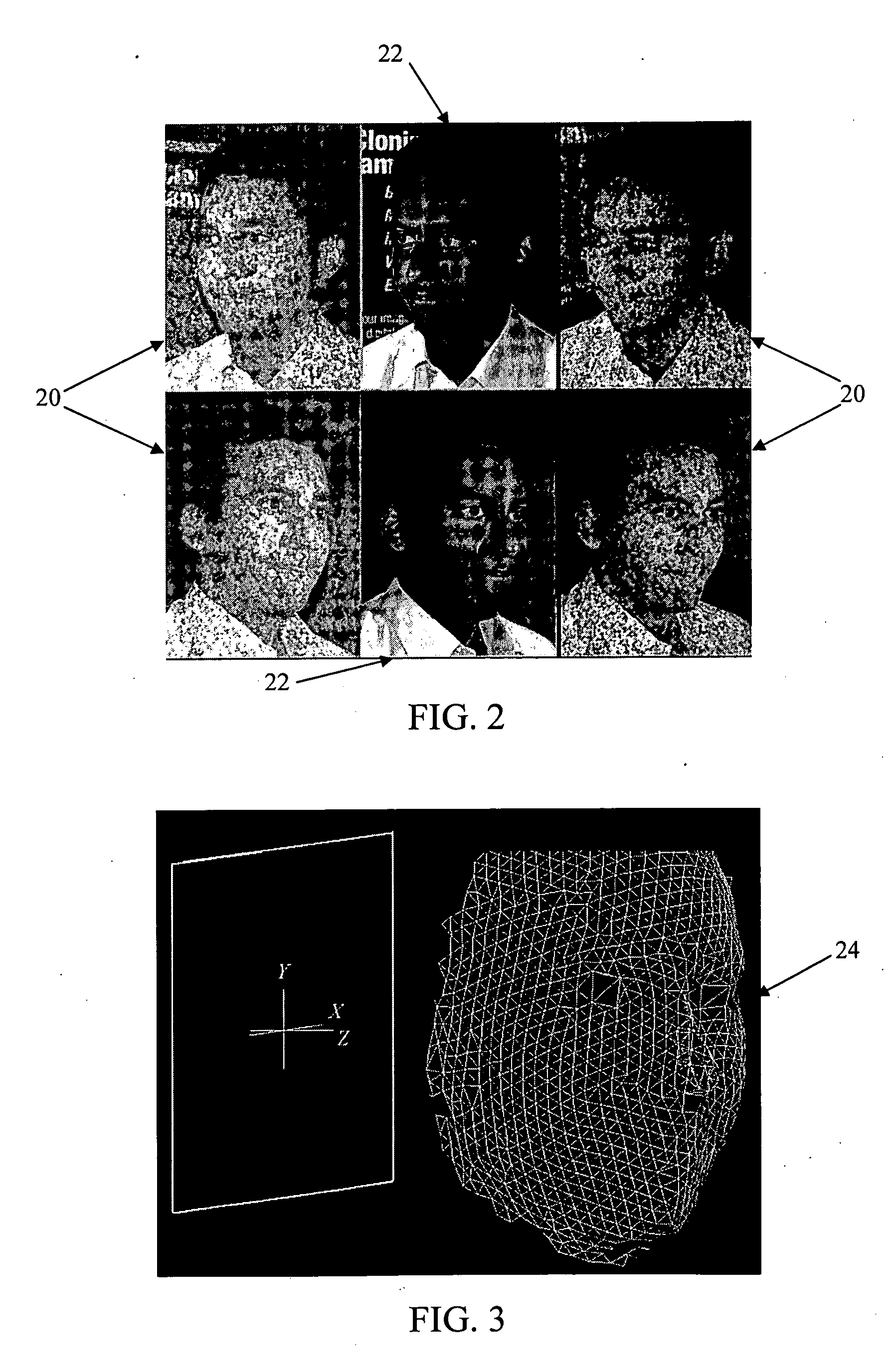

Face recognition system and method

InactiveUS20070127787A1Reliable acquisitionReliable processingCharacter and pattern recognitionColor imageFacial recognition system

A facial recognition system that captures a plurality two-dimensional images of a target face, creates a three-dimensional facial model from the plurality of two-dimensional images of a target face, moves the three-dimensional facial model to a predetermined pose orientation to result in a normalized three-dimensional facial model, extracts measurements from the normalized three-dimensional facial model, and compares the extracted measurements to other facial measurements stored in a data base. Measurement extraction can be enhanced by modifying the data format of the normalized three-dimensional facial model into range and color image data.

Owner:IRIS INT

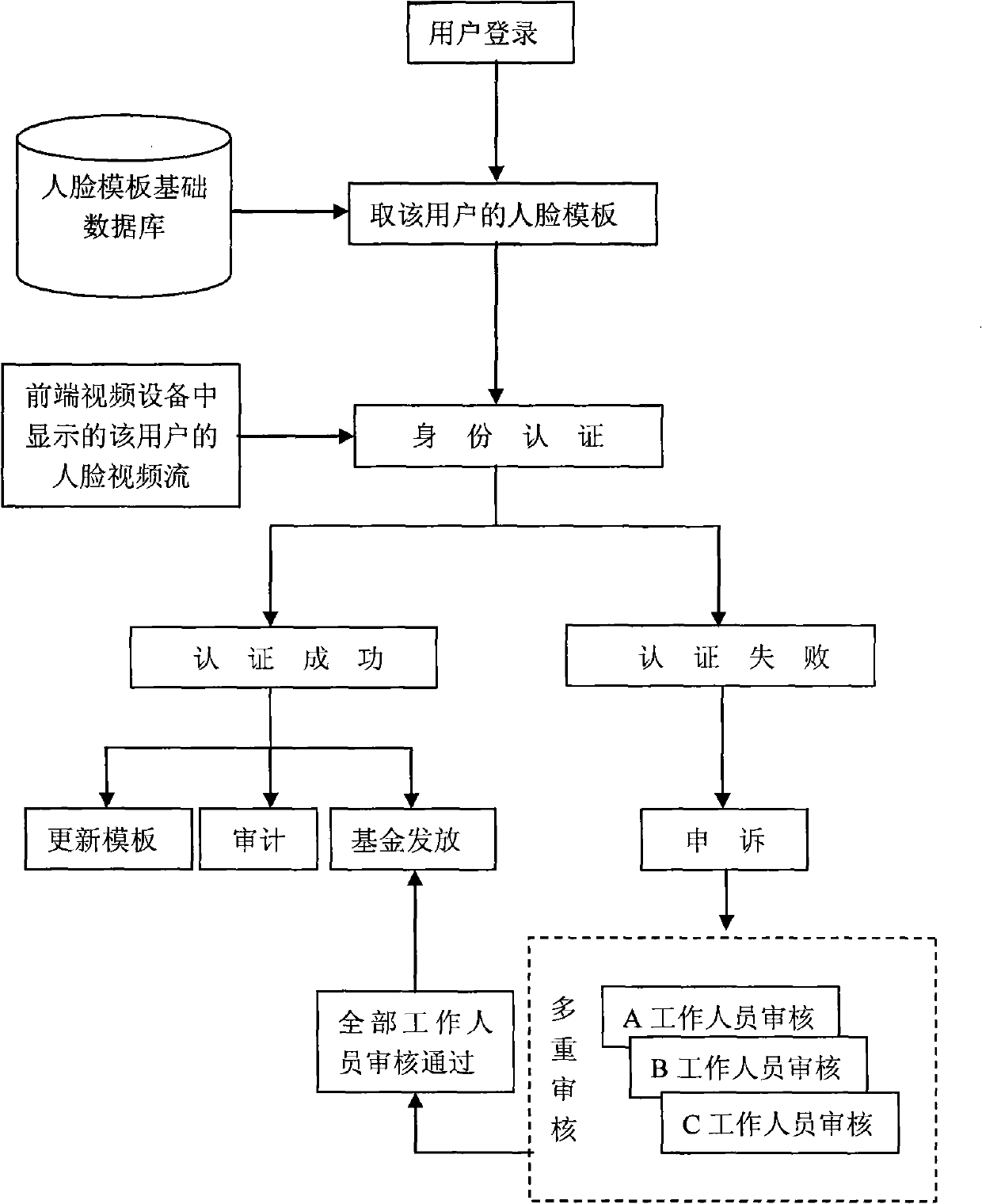

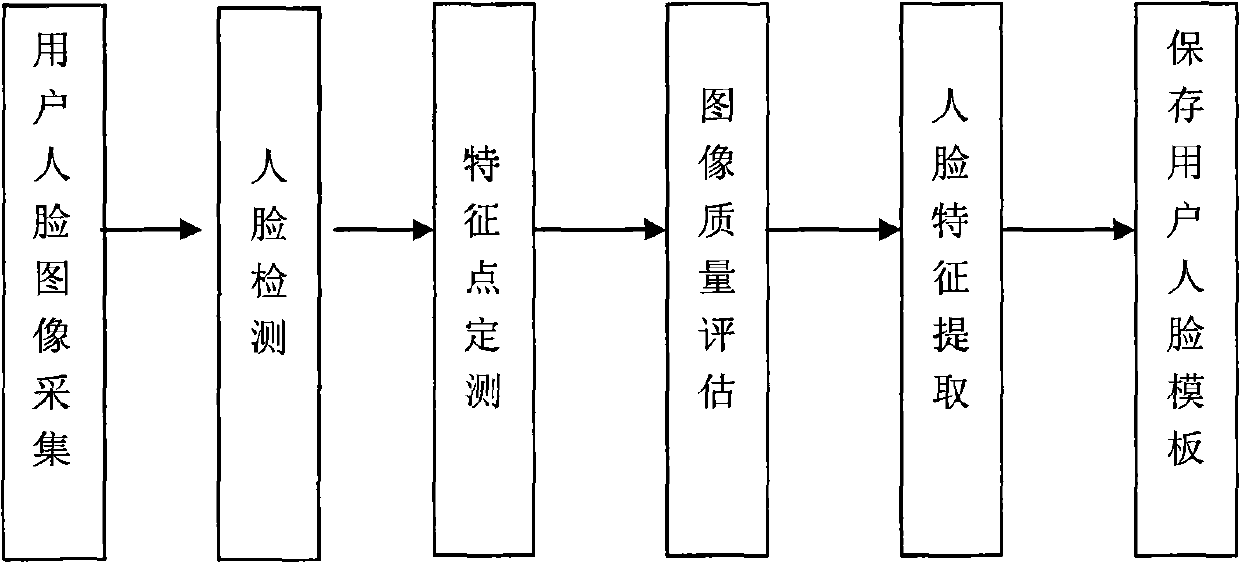

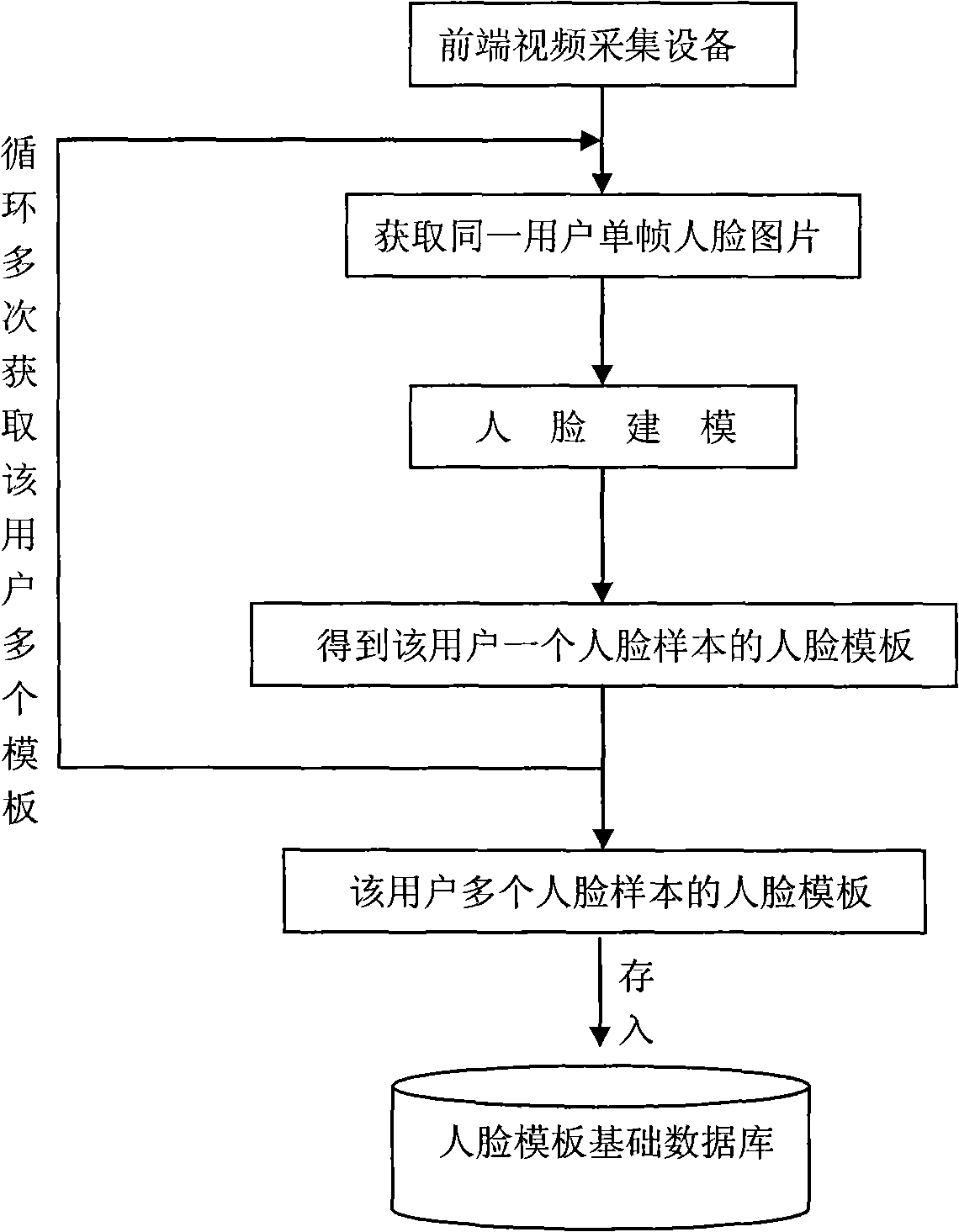

Social insurance identity authentication method based on face recognition and living body detection

InactiveCN101770613AEfficiently buildPrevent counterfeitingFinanceCharacter and pattern recognitionProcess moduleTemplate based

The invention relates to a social insurance identity authentication method based on face recognition and living body detection, which comprises implementation steps as follows: a face template base database is established and a social insurance user logs on to an identity authentication module which completes the combination of face recognition and living body detection,, a face template online update module, an audit query module, a complaint processing module and a multiple auditing module. The authentication method runs in the following way that: a user logins to generate a face template of the user, the identity authentication module which combines face recognition and living body detection is used to perform identity authentication of face video streams of the user displayed in a front-end video device; if authentication succeeds, auditing is performed while updating the template, and social insurance fund is issued; if authentication fails, a complaint program is used for multiple auditing, and if auditing by all staff passes, the social insurance can be issued. The method can improve the service quality and working efficiency of social insurance processing and can effectively restrain the loss of the social insurance fund.

Owner:智慧眼科技股份有限公司

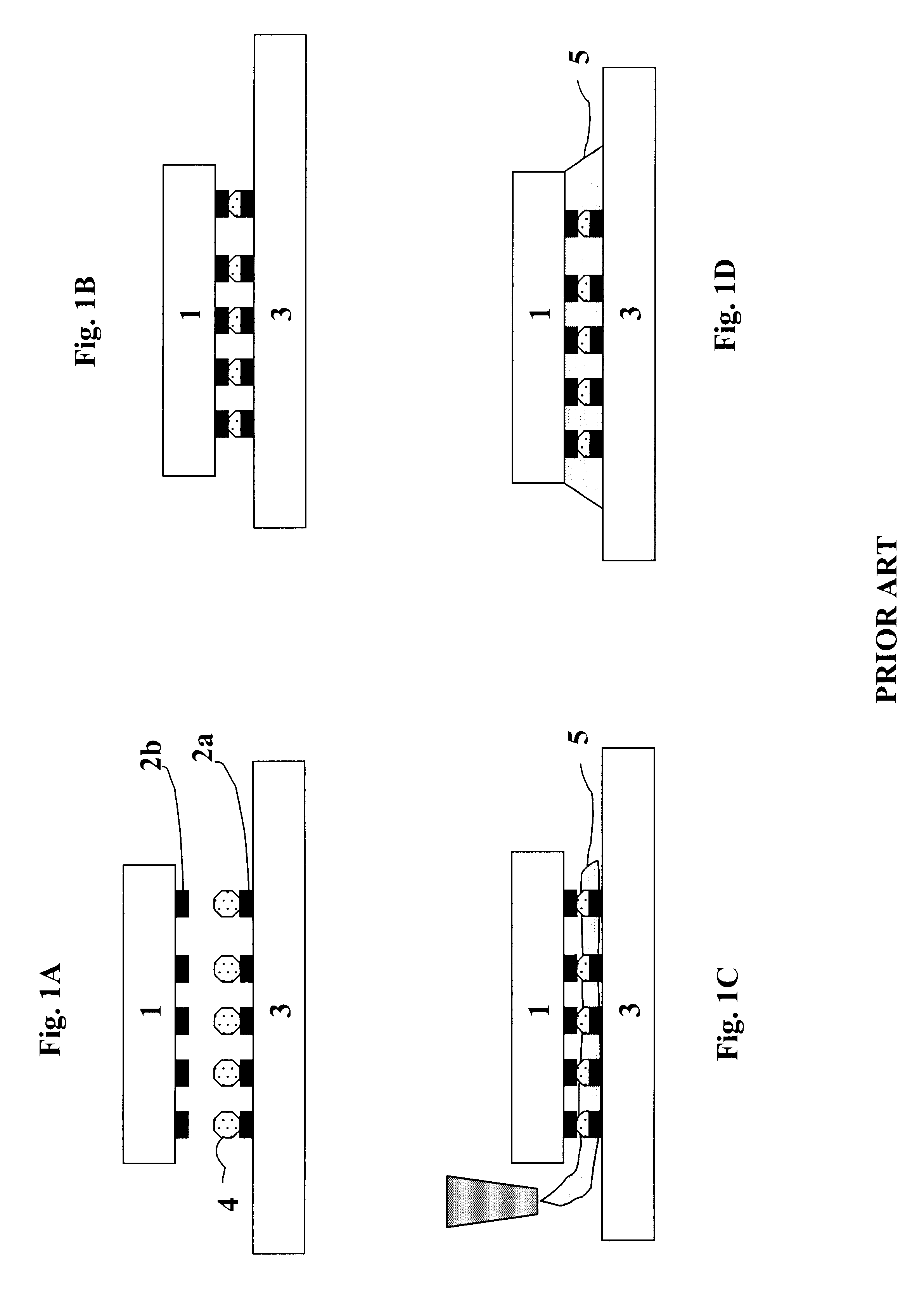

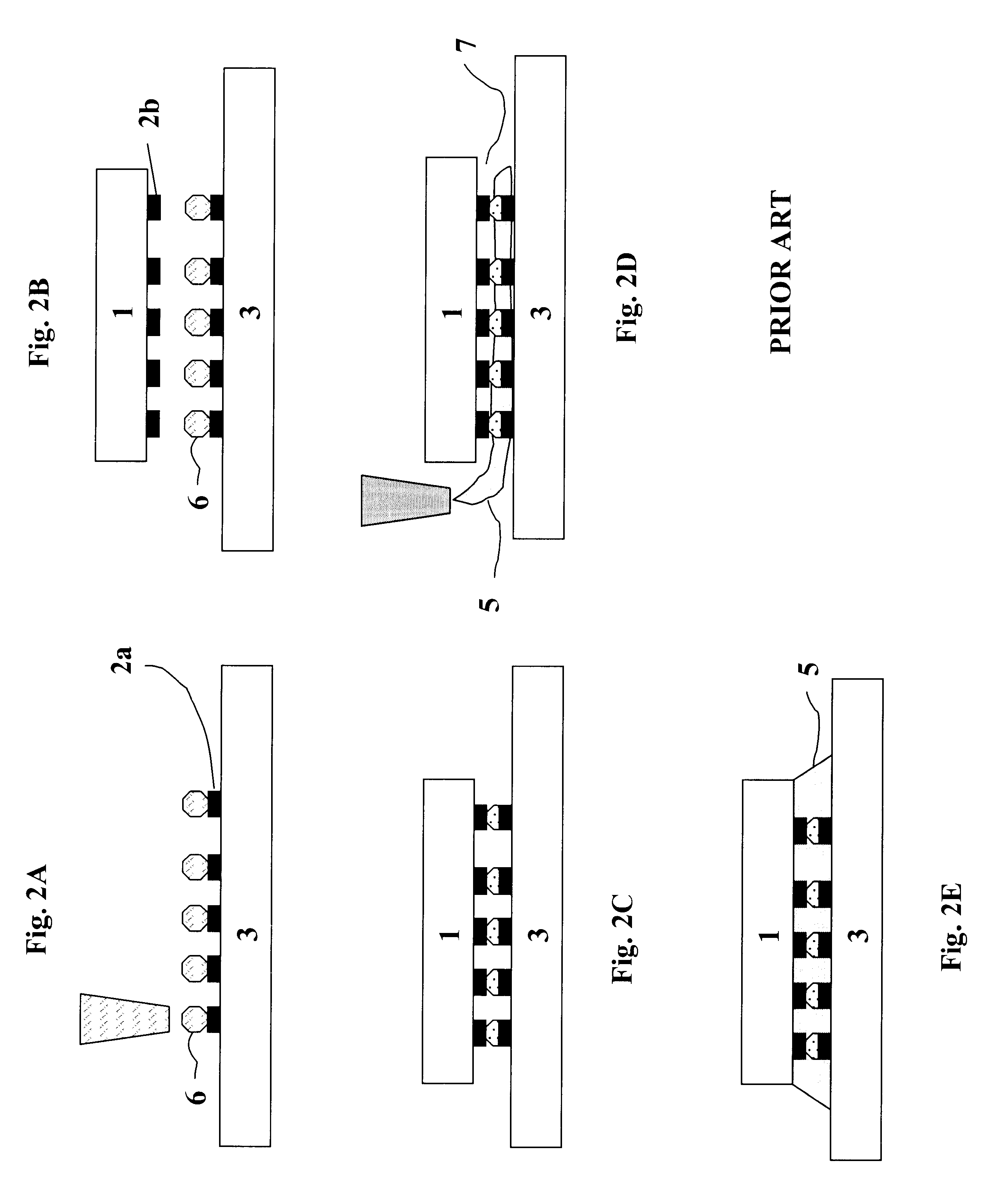

Flip-chip assembly of semiconductor devices using adhesives

InactiveUS6555414B1Simplified and reliable and cost-effective assembly processSimplified and reliable and processPrinted circuit assemblingContact member assembly/disassemblyAdhesiveOn board

The present invention is related to a flip-chip-on-board (FCOB) assembly technology applicable for mounting large chips with high I / O count or small pitch, mounted on low-cost or low-grade substrates. The assembly technology uses both an isotropically conductive adhesive (ICA) and a non-conductive material (NCA) in the same assembly cycle. The thermocompression step establishes at the same time the electrical and mechanical interconnections and the curing of the adhesives.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

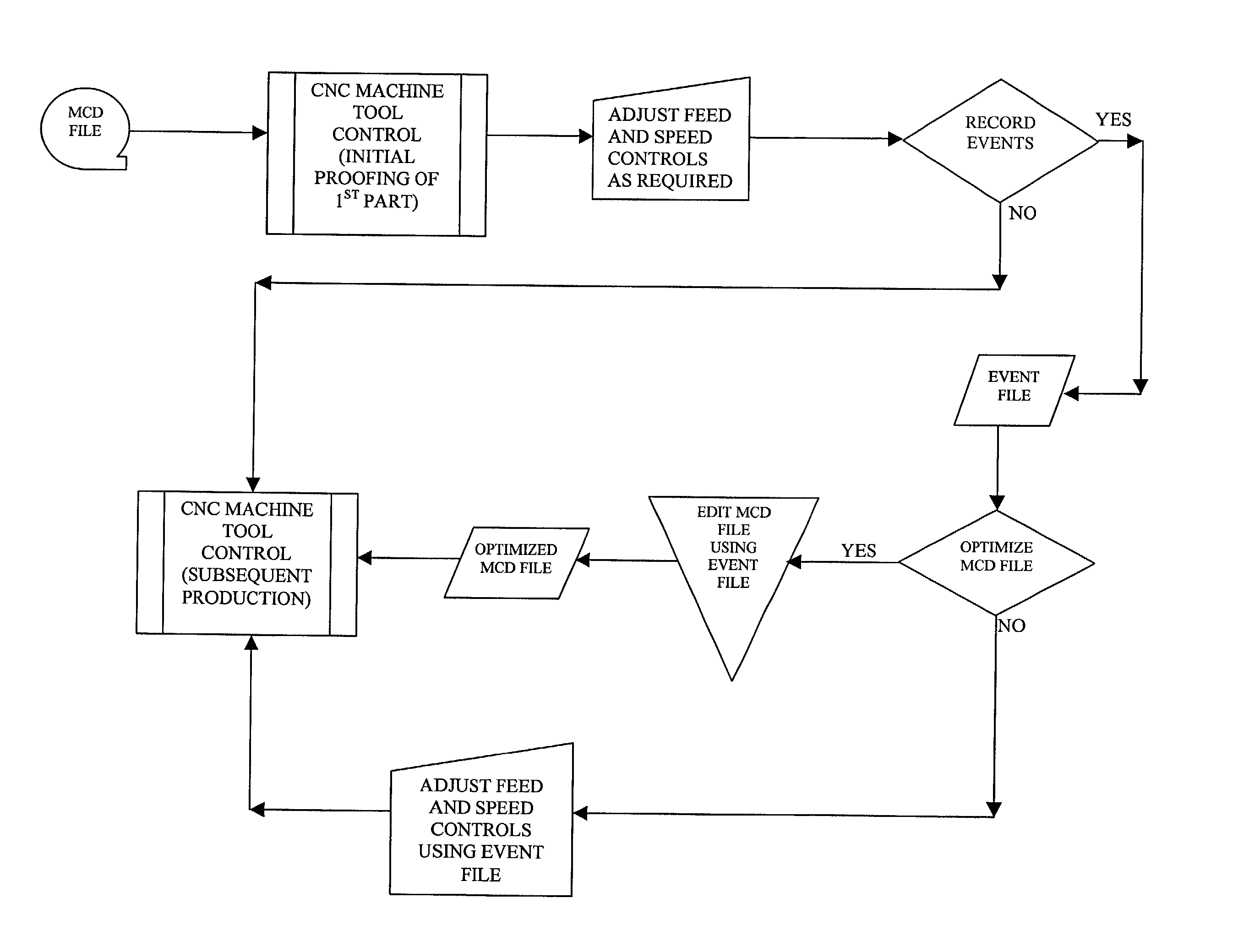

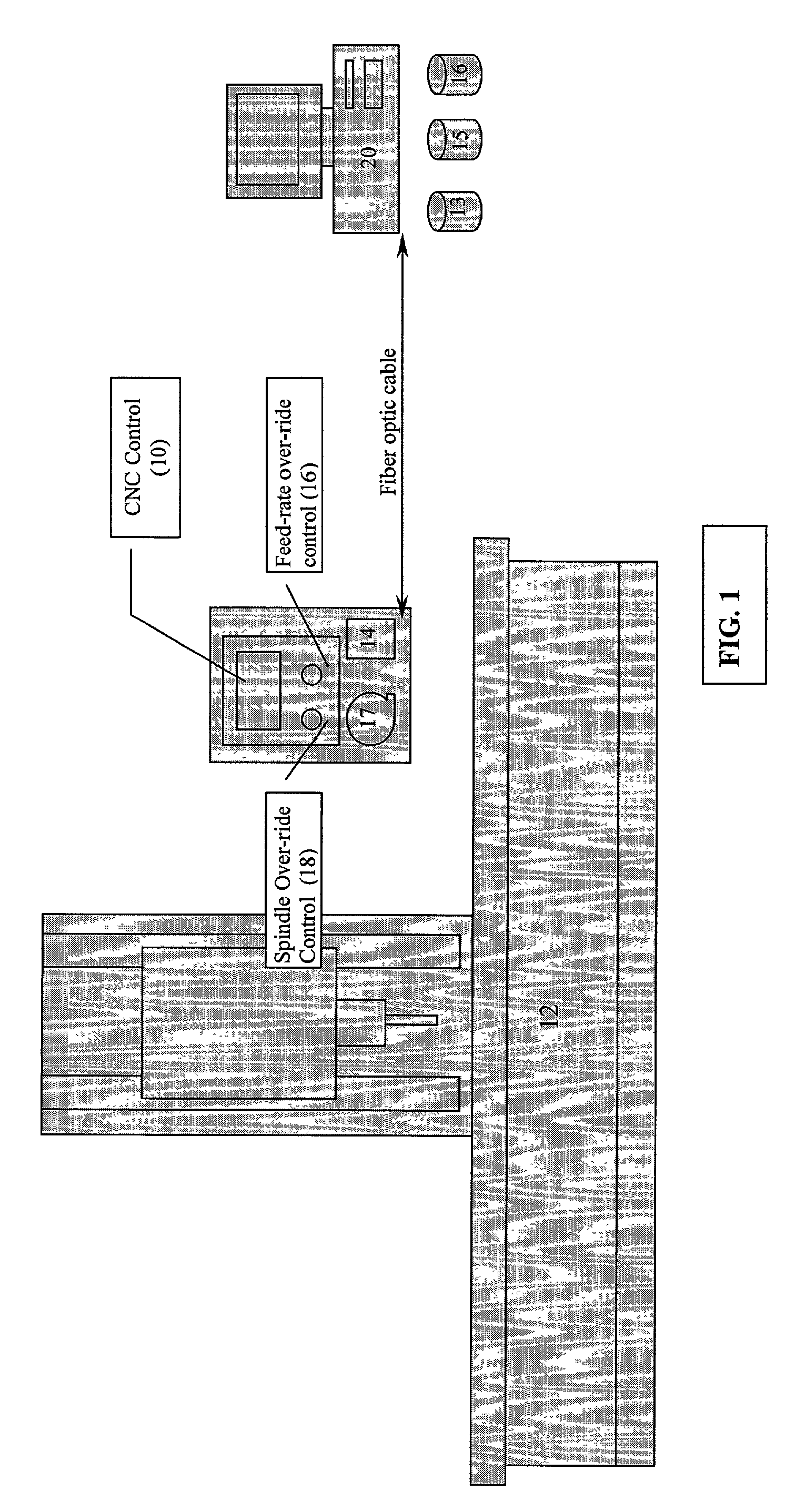

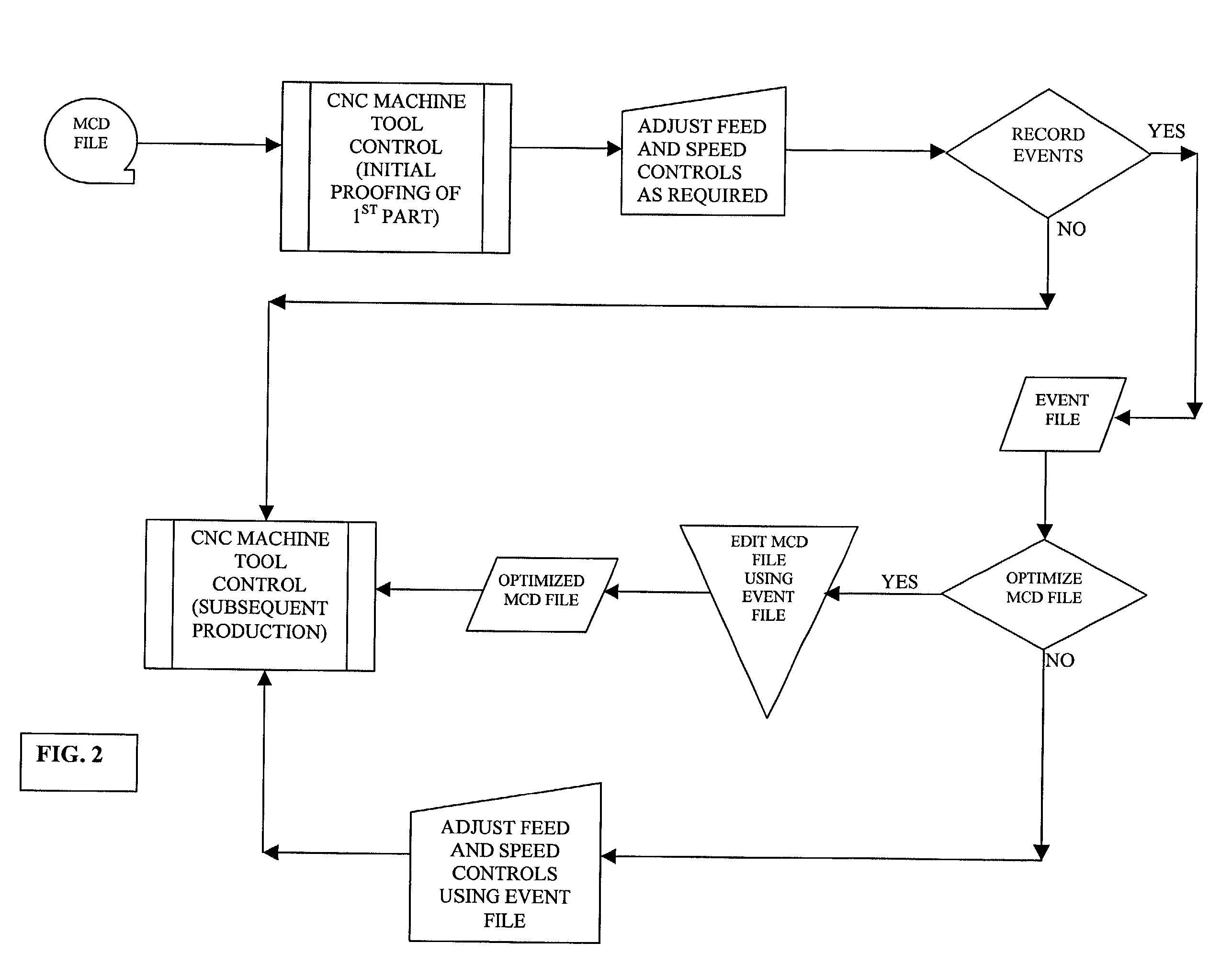

Hybrid CNC control system

InactiveUS20020091460A1Accurate recordReliable processingSpecial data processing applicationsNumerical controlVisual BasicNumerical control

The present invention demonstrates an improved CNC Control system, which integrates operator-induced changes into the pre-programmed CNC machining process. The improved CNC Control system develops a Human Activity Storage Program (HASP), which is used for subsequent production in conjunction with and simultaneously with the Numerical Control Program thereby enhancing the production process by integrating the skilled machinist's input into the production process. The numerical control program of a CNC machine is interfaced with an IBM compatible personal computer (PC) to make information relative to the block number, feed-rate and / or spindle speed over-ride values available at the personal computer. If the CNC Control has been re-configured properly (with regard to the ladder interface and operating system) a PC computer is not required. During the machining of a part the machine operator will manually over-ride the feed-rate and / or the spindle speed to optimize machining performance. Through the use of VISUAL BASIC OR C++programming modules and routines, the spindle speed and feed-rate controls (located at the CNC Control) are polled at frequent or 5OO ms intervals. The status or over-ridden values of these controls are correlated to the active block number in use during each polled sequence and this information is written to an "event file". After the subject part has been completed, one of two options can be used. An "edit phase" is initiated which utilizes the information in the "event file" to reconstruct the MCD file. After the edit phase is complete, the resultant output "Optimized MCD" can be used to produce like parts with confidence that all motion is running at peak performance and all programmed trajectories are maintained. The cycle can be repeated again (if desired) to ensure even greater efficiency while cutting. In the alternative, the event file can be employed to "command" the CNC Control with respect to feed-rate and / or spindle speed over-ride settings.

Owner:ALLEN WILLIAM D

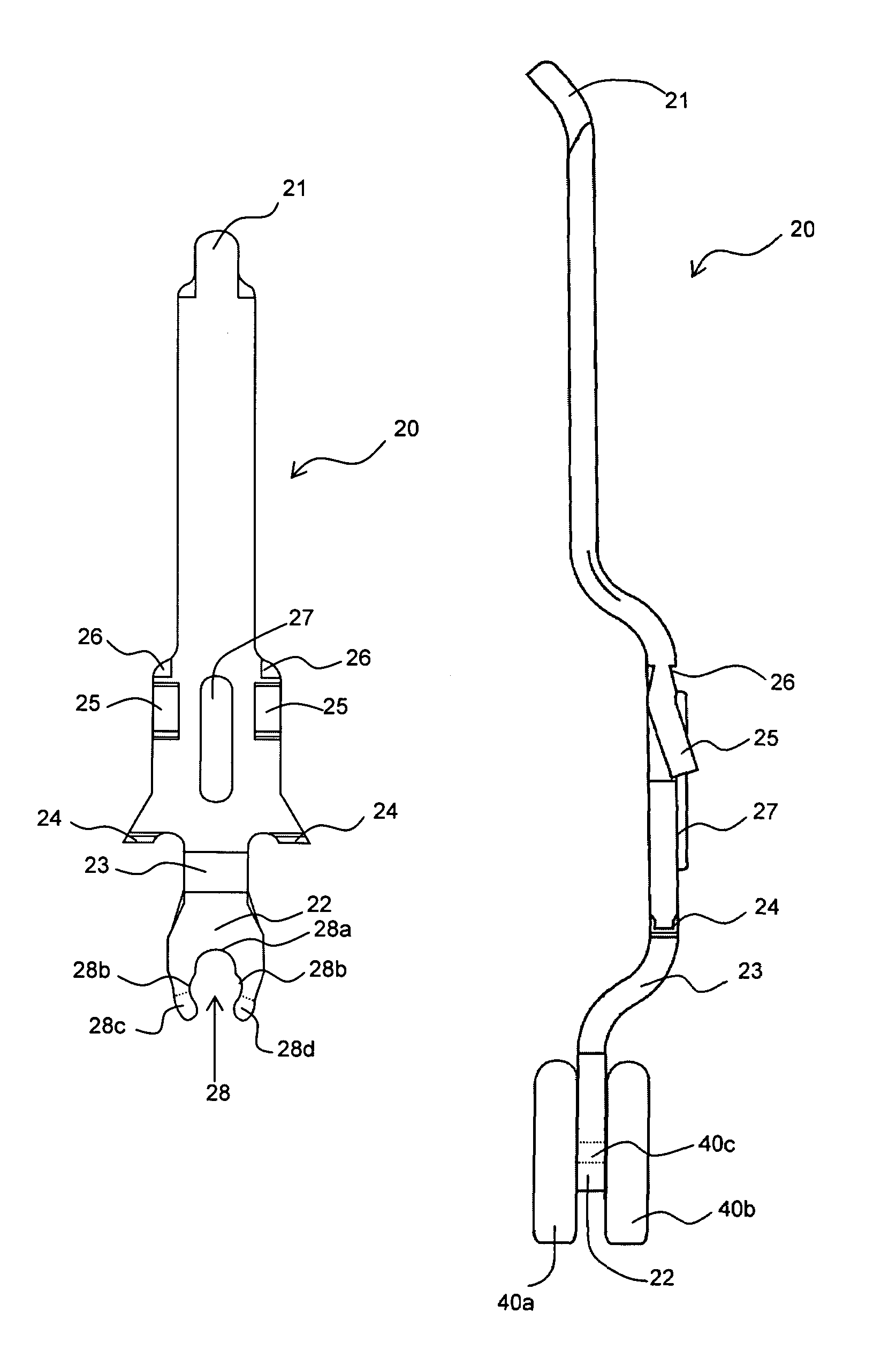

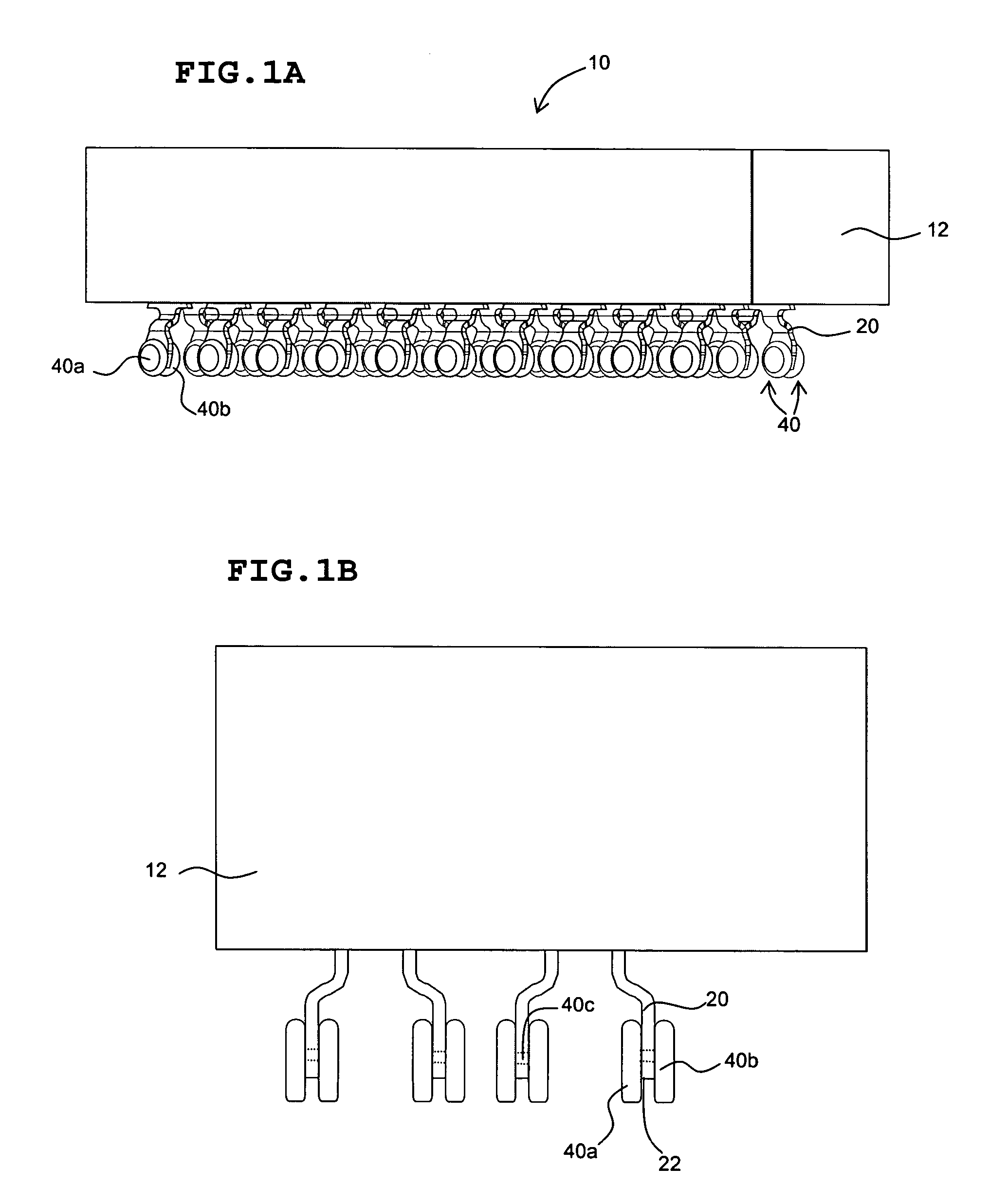

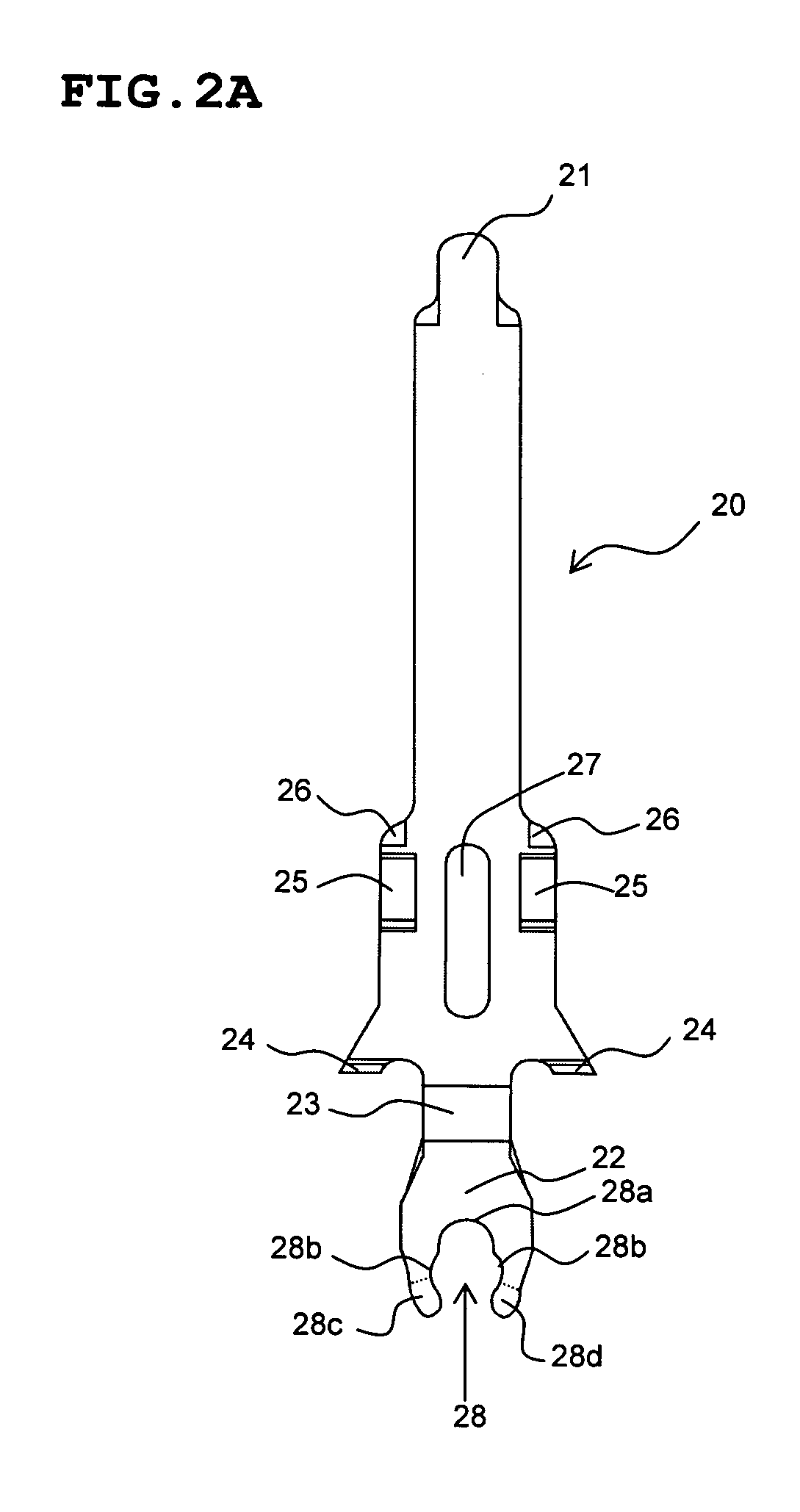

Connector having improved contacts with fusible members

ActiveUS6969286B1Good coplanarityFirmly connectedPrinted circuit assemblingLine/current collector detailsEngineeringElectrical connector

An electrical connector includes a connector body, a plurality of cores and a plurality of electrically conductive contacts disposed in the cores of the connector body. Each of the contacts includes a fusible member attached thereto. Each of the fusible members includes an intermediate portion and two support members disposed on opposite sides of the intermediate portion. The support members are arranged to hang down below a tail portion of the contacts.

Owner:SAMTEC

Stereolithographic resins with high temperature and high impact resistance

InactiveUS6989225B2High modulusHigh elongation at breakAdditive manufacturing apparatusImpression capsMeth-Cationic polymerization

A liquid radiation-curable composition that comprises(A) at least one polymerizing organic substance comprising a mixture of(1) at least one alicyclic epoxide having at least two epoxy groups; and(2) at least one difunctional or higher functional glycidylether of a polyhydric compound;(B) at least one free-radical polymerizing organic substance comprising a mixture of(1) optionally, at least one trifunctional or higher functional (meth)acrylate compound; and(2) at least one aromatic di(meth)acrylate compound;(C) at least one cationic polymerization initiator;(D) at least one free-radical polymerization initiator;(E) optionally, at least one hydroxyl-functional aliphatic compound; and(F) at least one hydroxyl-functional aromatic compound;wherein the concentration of hydroxyl groups in the radiation-curable composition is at least about 1.1 equivalent OH groups per kilogram;wherein the concentration of epoxy groups in the radiation-curable composition is at least about 5.5 equivalent epoxy groups per kilogram; andwherein the amount of trifunctional or higher functional (meth)acrylate compound (B)(1) is from 0% to about 3% of the composition and the amount of aromatic di(meth)acrylate compound (B)(2) is at least 10% of the composition.

Owner:3D SYST INC

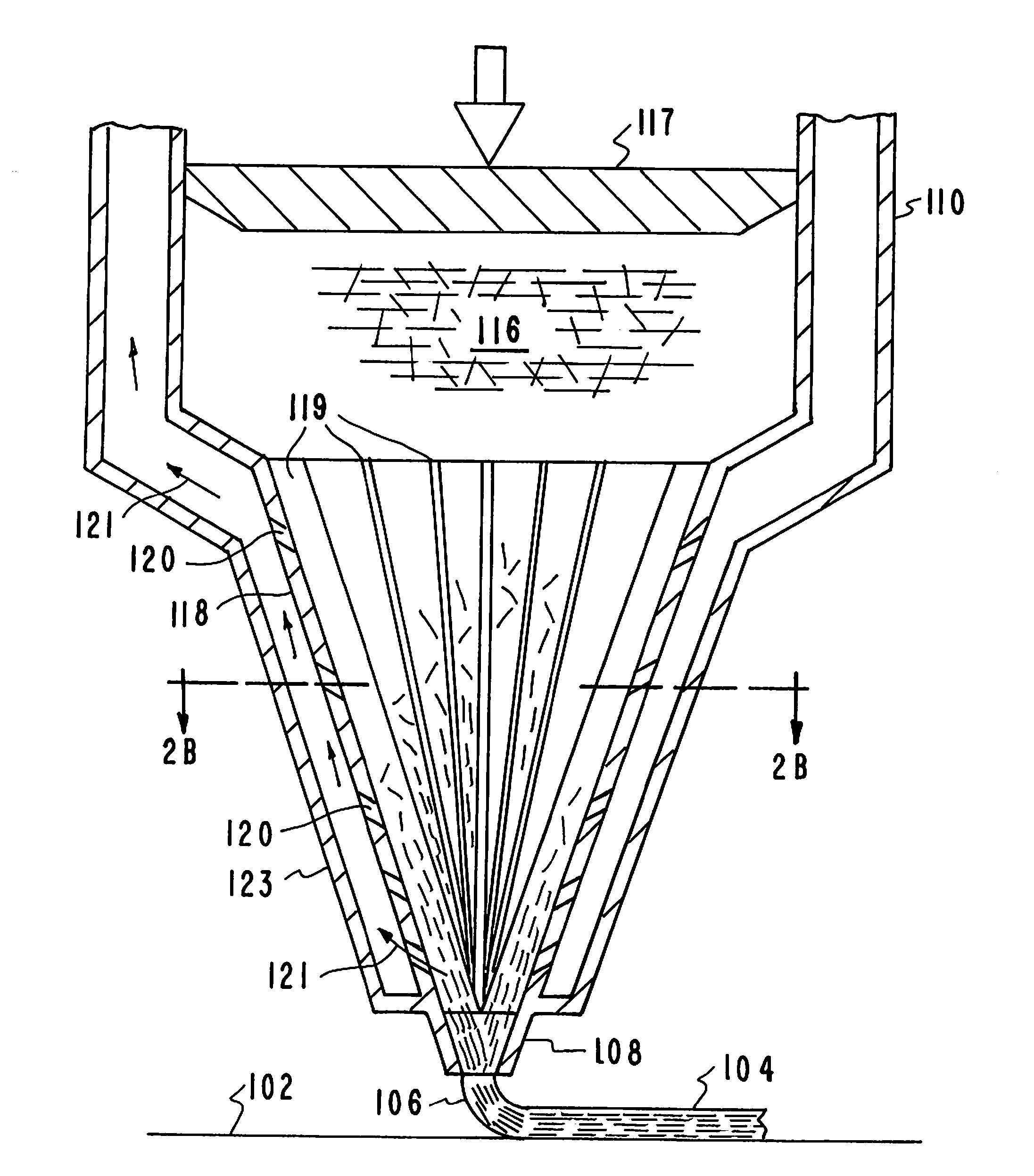

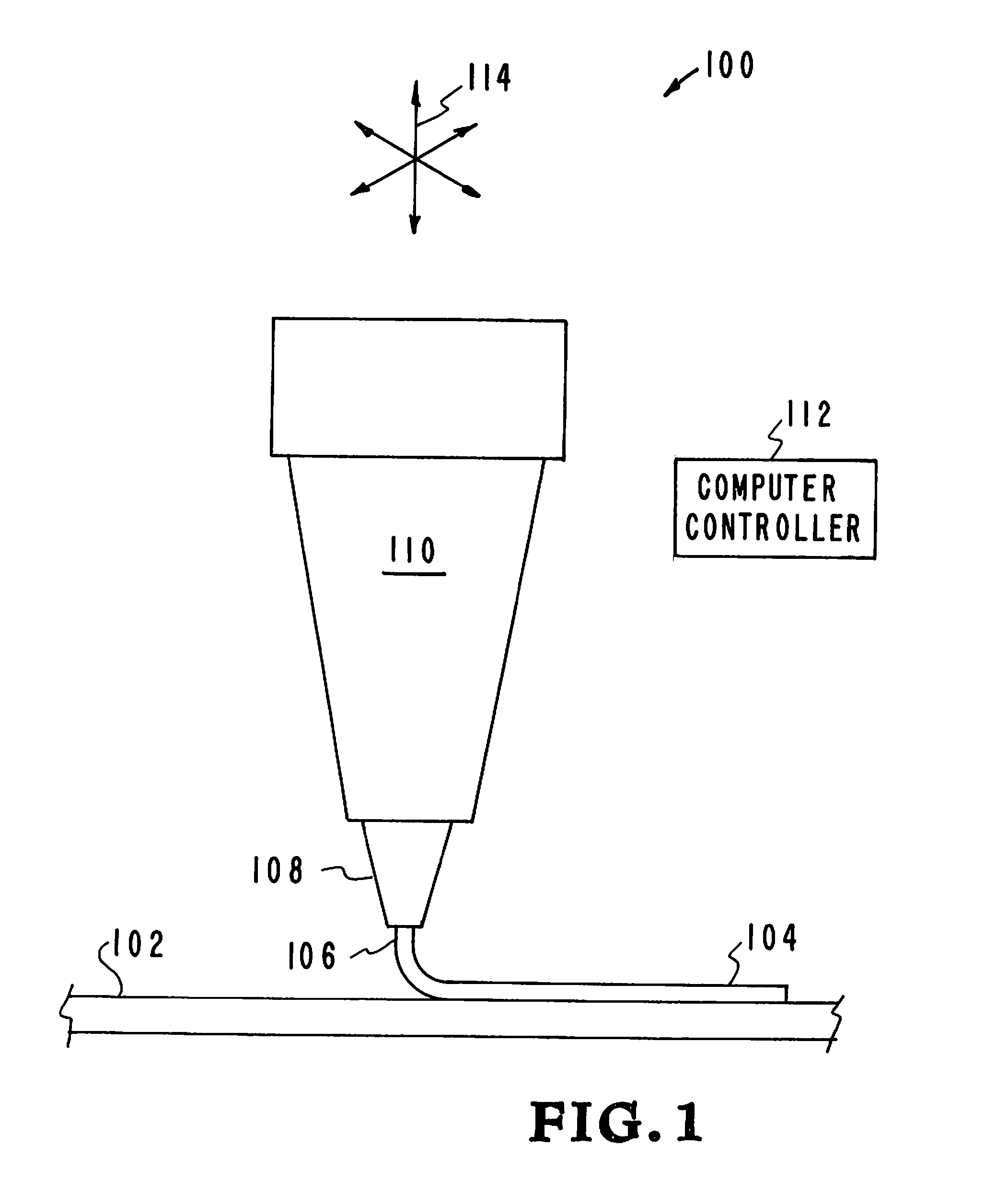

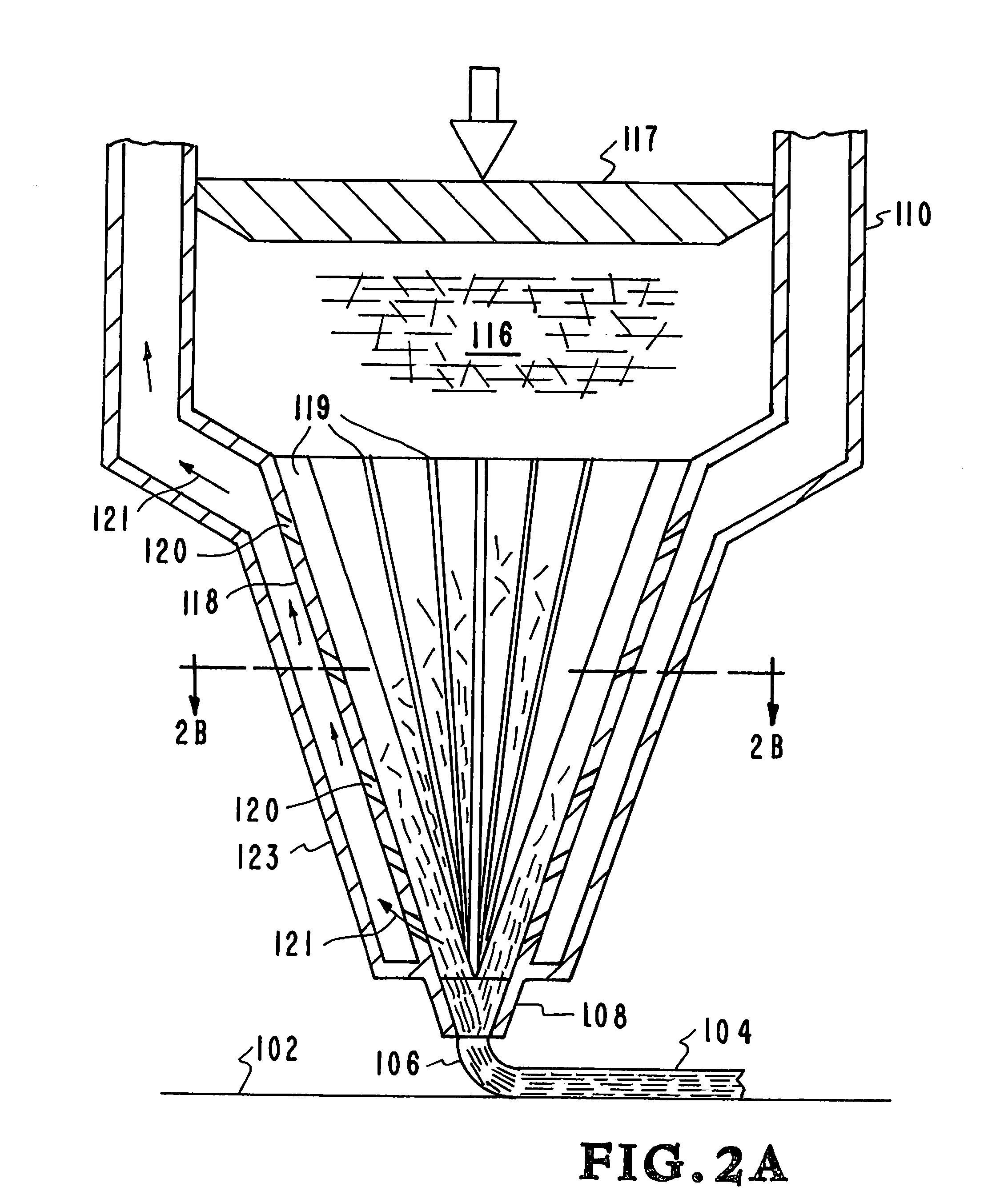

Additive manufacturing of short and mixed fibre-reinforced polymer

ActiveUS20170015061A1Improve performanceReliable processingAdditive manufacturing with liquids3D object support structuresMethacrylateCarbon fibers

Additive manufacturing of a fibre-reinforced polymer (FRP) product using an additive manufacturing print head; a reservoir in the additive manufacturing print head; short carbon fibers in the reservoir, wherein the short carbon fibers are randomly aligned in the reservoir; an acrylate, methacrylate, epoxy, cyanate ester or isocyanate resin in the reservoir, wherein the short carbon fibers are dispersed in the acrylate, methacrylate, epoxy, cyanate ester or isocyanate resin; a tapered nozzle in the additive manufacturing print head operatively connected to the reservoir, the tapered nozzle produces an extruded material that forms the fibre-reinforced polymer product; baffles in the tapered nozzle that receive the acrylate, methacrylate, epoxy, cyanate ester or isocyanate resin with the short carbon fibers dispersed in the acrylate, methacrylate, epoxy, cyanate ester or isocyanate resin; and a system for driving the acrylate, methacrylate, epoxy, cyanate ester or isocyanate resin with the short carbon fibers dispersed in the acrylate, methacrylate, epoxy, cyanate ester or isocyanate resin from the reservoir through the tapered nozzle wherein the randomly aligned short carbon fibers in the acrylate, methacrylate, epoxy, cyanate ester or isocyanate resin are aligned by the baffles and wherein the extruded material has the short carbon fibers aligned in the acrylate, methacrylate, epoxy, cyanate ester or isocyanate resin that forms the fibre-reinforced polymer product.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

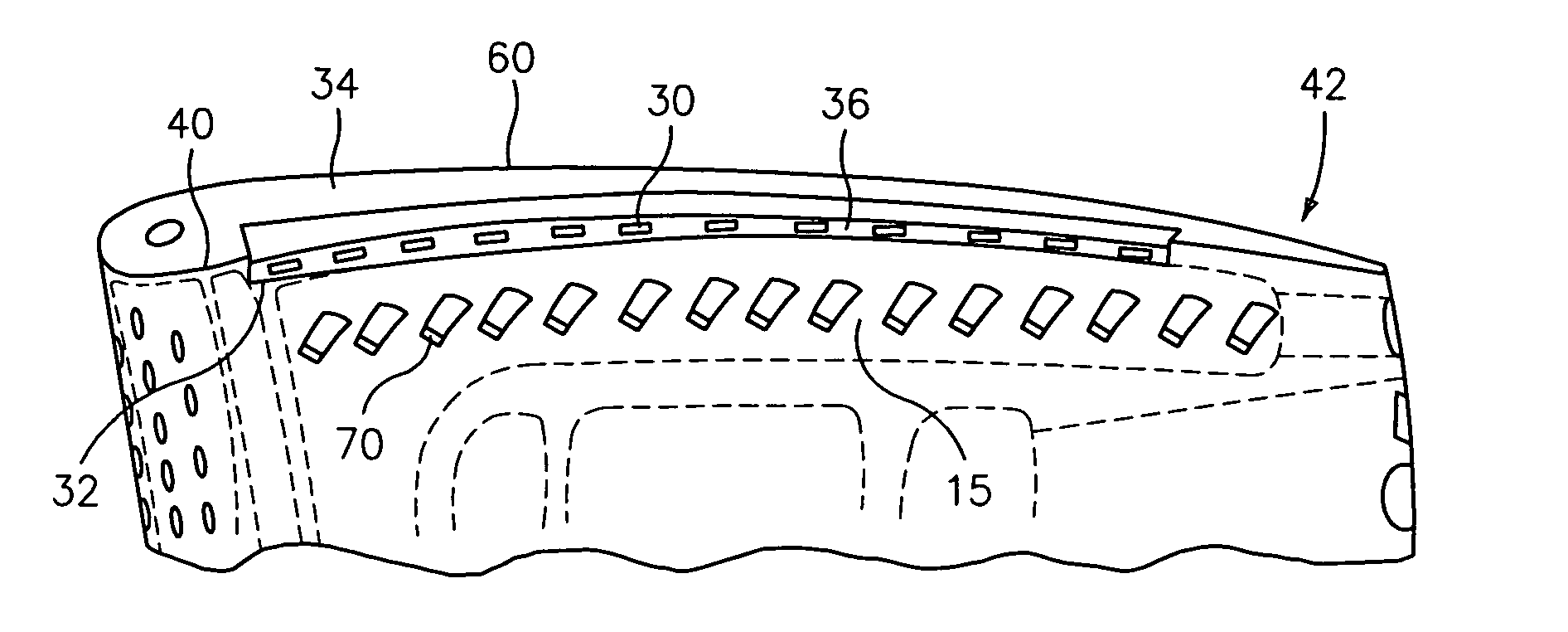

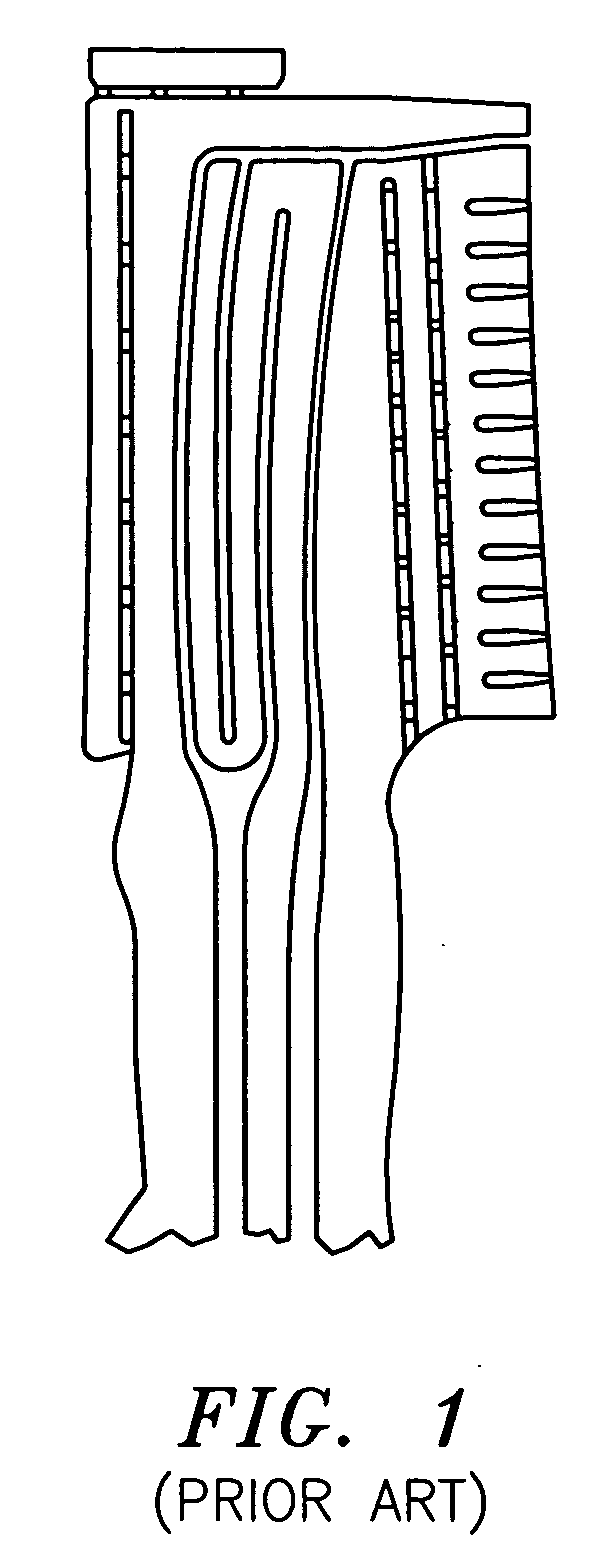

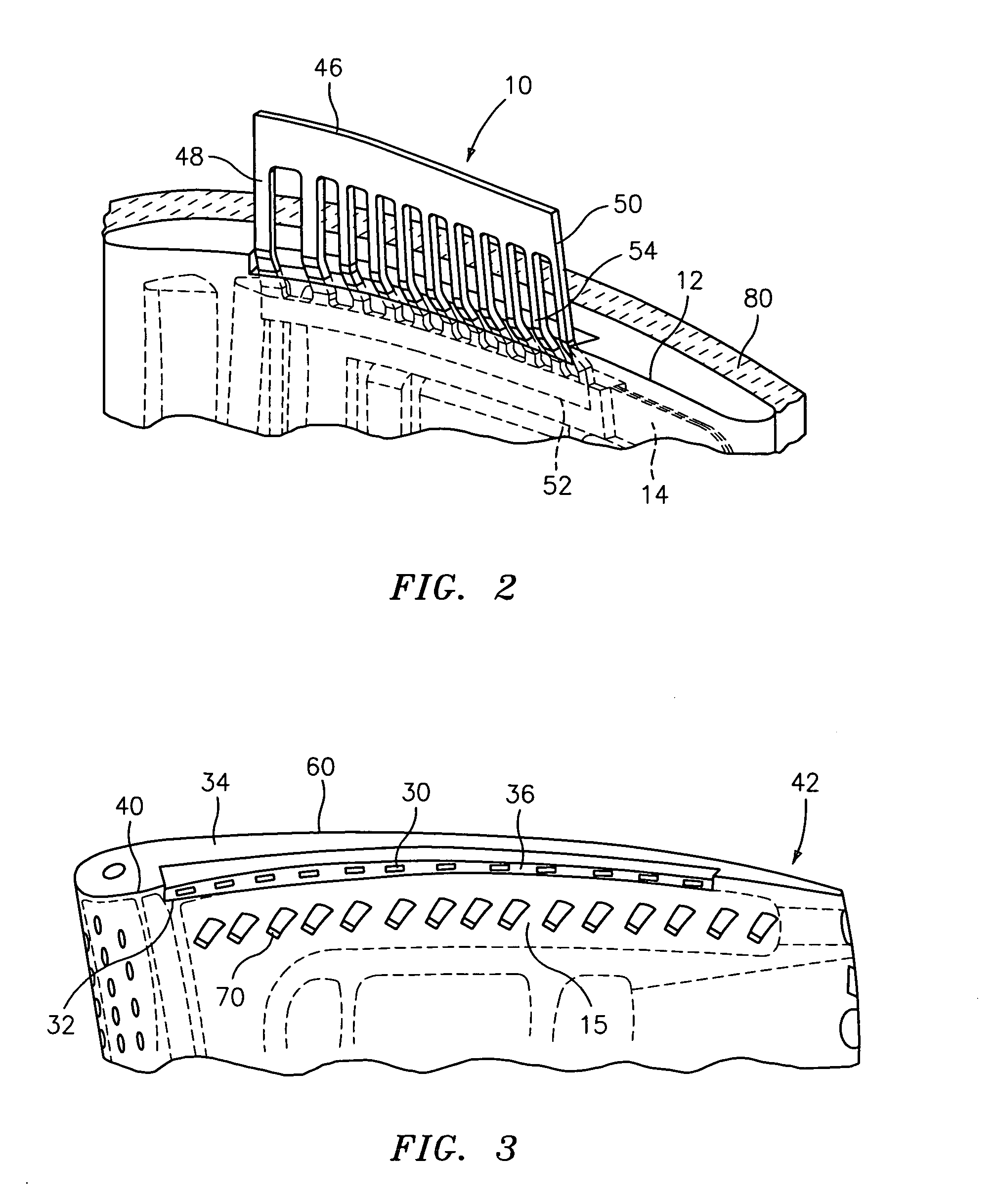

RMC-defined tip blowing slots for turbine blades

InactiveUS20080131285A1Easy to useReliable processingPropellersPump componentsTurbine bladeSpray nozzle

A process for forming an airfoil portion of a turbine engine component, such as a turbine blade, is described. The process comprises the steps of placing a ceramic core having a configuration of a passageway to be formed in the airfoil portion within a mold, attaching a refractory metal core element to the ceramic core to stabilize a tip region of the ceramic core, and casting the airfoil portion.

Owner:UNITED TECH CORP

Pulverulent polymers crosslinked on the surface

InactiveUS20050020780A1Improved gel permeabilityImprove liquiditySynthetic resin layered productsCellulosic plastic layered productsPolymer scienceMonomer

The present invention relates to a pulverulent polymer post-crosslinked on the surface and absorbing water or aqueous liquids, synthesised from polymerised, optionally pre-crosslinked monomers containing partially neutralised carboxyl groups. The present invention also relates to a process for the post-treatment of the aforementioned polymers and the use of a solution of at least one salt of an at least trivalent cation for restoring the gel permeability of the aforementioned polymers that have been damaged by mechanical action.

Owner:EVONIK DEGUSSA GMBH

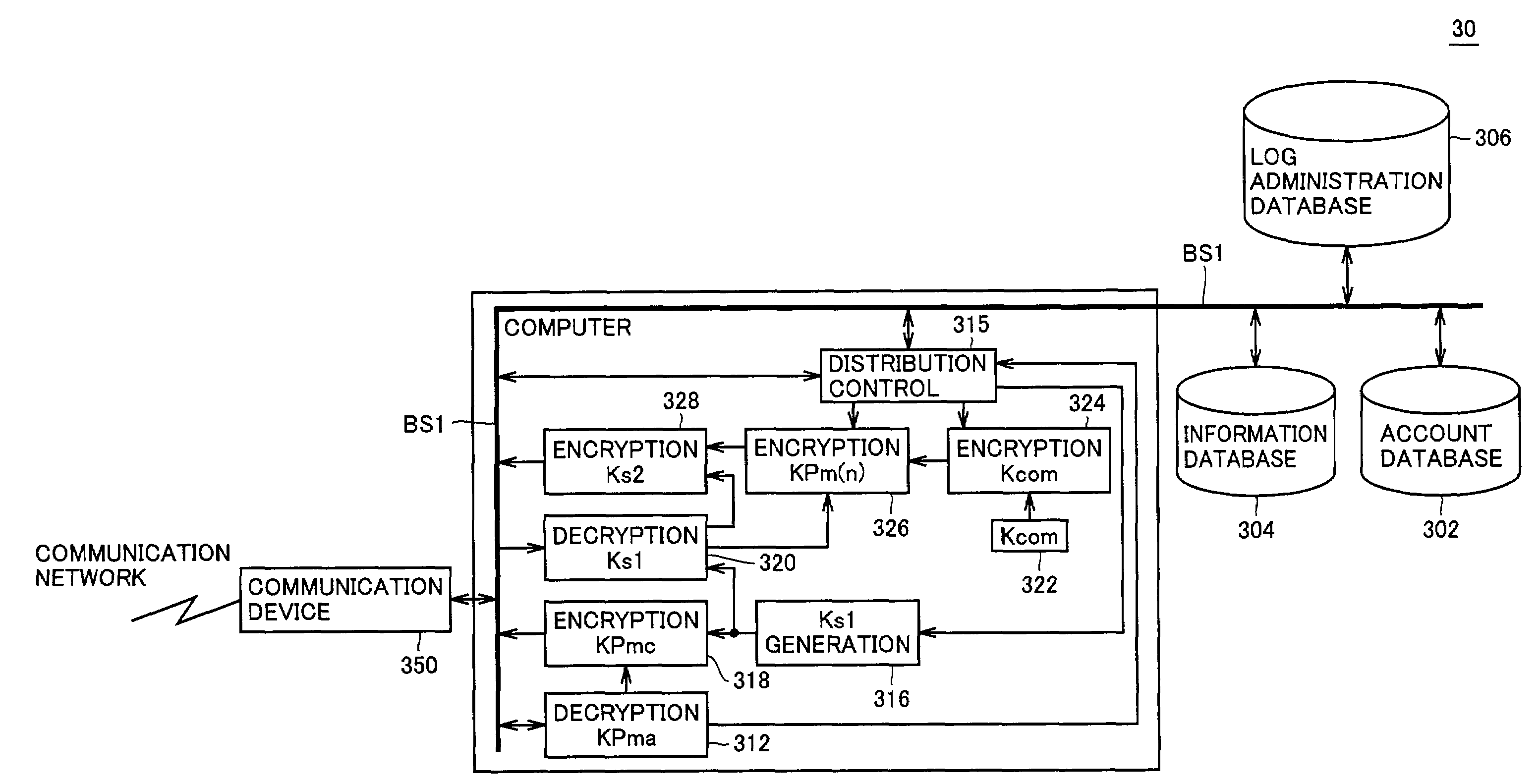

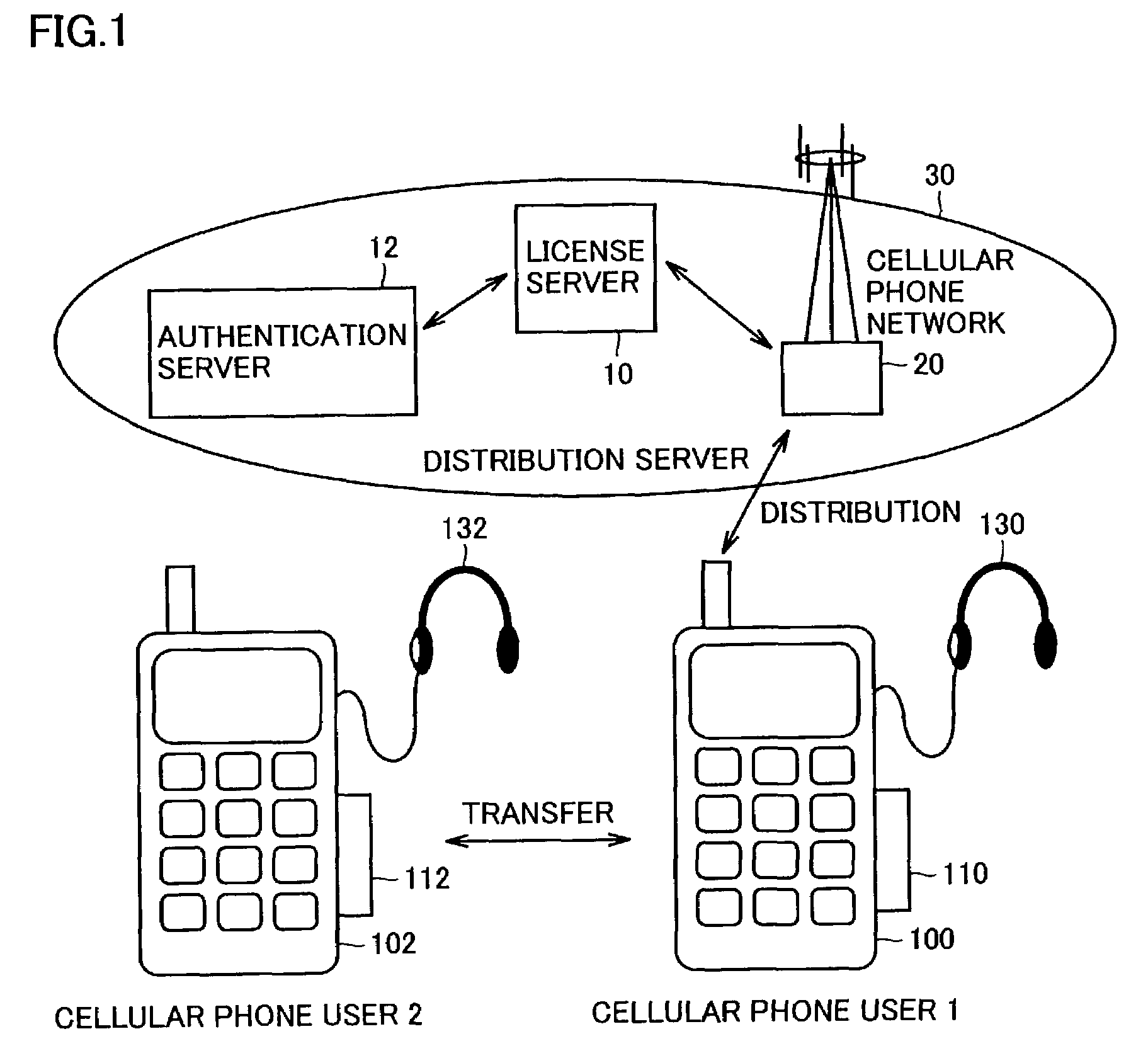

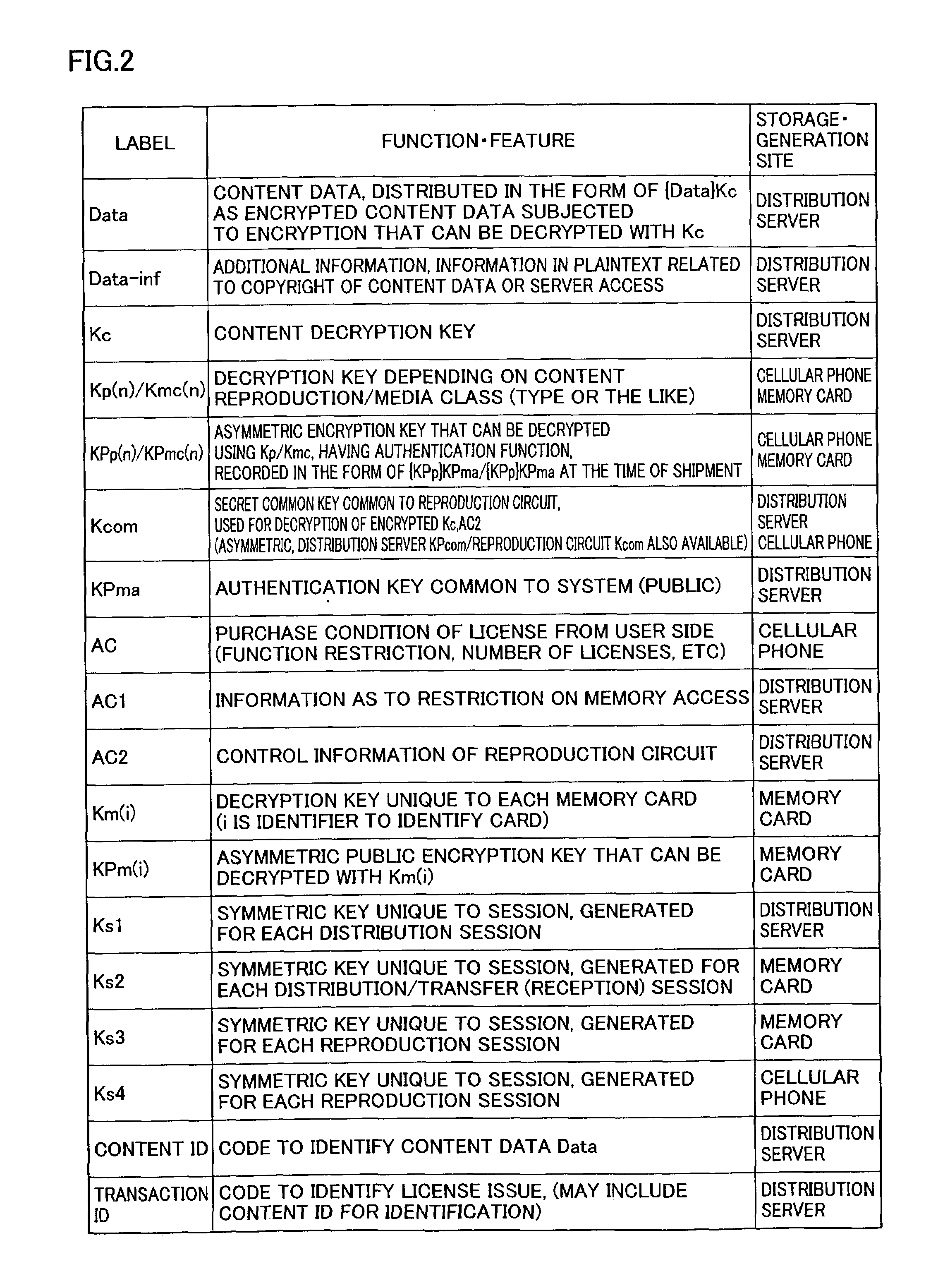

Memory card and data distribution system using it

InactiveUS7340055B2Reliability of distribution processImprove reliabilityDigital data processing detailsUser identity/authority verificationDistribution systemData storing

A memory card (110) conducts an authentication process with a server based on data stored in an authentication data hold unit (1400). The memory card (110) extracts a first session key (Ks1) from a server by a decryption process and a transaction ID from the data applied on a data bus (BS3). The memory card (110) generates a second session key (Ks2) through a session key generation unit (1418), and transmits to the server, as the keys to encrypt content data in receiving decryption of content data, the second session key (Ks2) and a key (KPm(1)) unique to the memory card (110) in an encrypted state with the first session key (Ks1). The transaction ID and the second session key (Ks2) stored in the log memory (1460) are used in the redistribution process.

Owner:SANYO ELECTRIC CO LTD +2

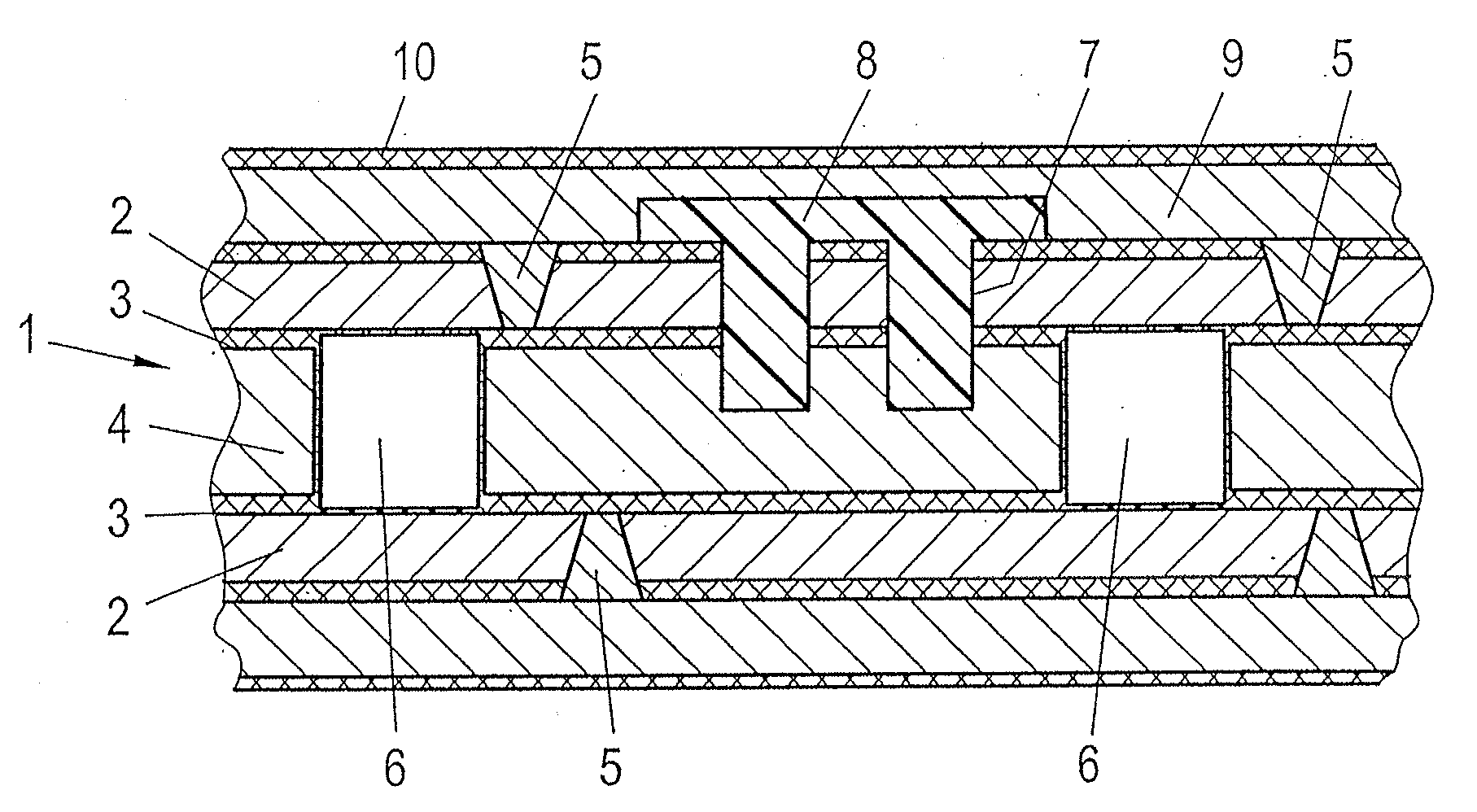

Method for producing a multilayer printed circuit board, adhesion prevention material and multilayer printed circuit board and use of such a method

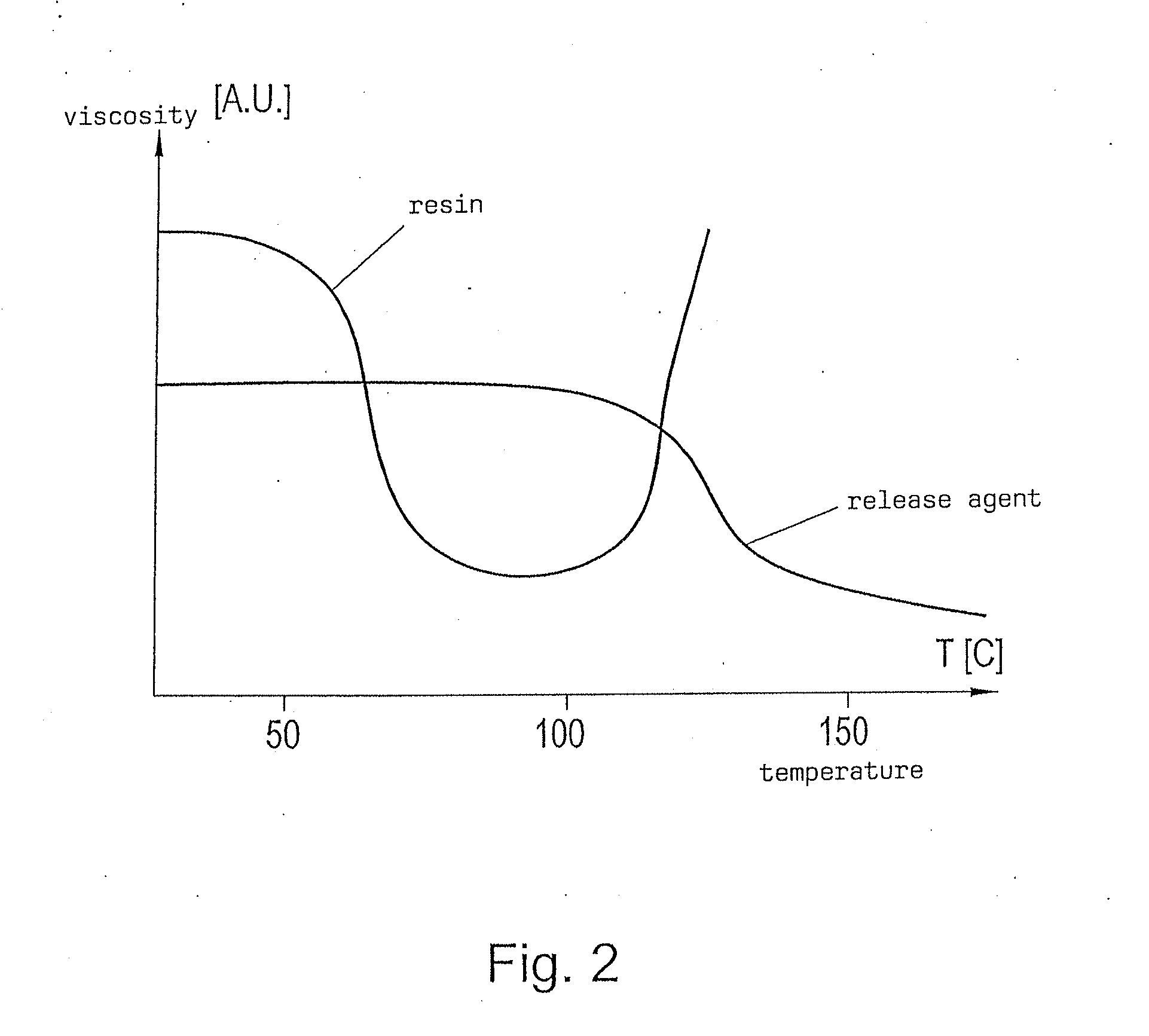

ActiveUS20110272177A1Readily and reliably applicable material preventing adhesionReadily and reliablyPrinted circuit aspectsCoatingsSolventFatty acid

In a method for producing a multilayer printed circuit board from a plurality of conducting or conductive and non-conducting or insulating layers or plies to be connected to each other, in particular to be pressed together, wherein after connecting at least partially planar layers at least a partial region (11) thereof is removed, and wherein in order to prevent adherence of the partial region (11) to be removed a material (8) preventing adhesion is applied in accordance with the partial region to be removed onto a layer (9) which adjoins the partial region to be removed, it is provided that the material (8) preventing adhesion is formed by a mixture comprising a release agent on the basis of at least one metal soap, preferably the fatty acid salts of Al, Mg, Ca, Na and Zn, a binding agent, and a solvent, whereby a partial region to be removed can be removed easily and reliably after appropriate treatment and / or processing steps of the multilayer printed circuit board. In addition, an adhesion prevention material and a use of the method in connection with the production of a multilayer printed circuit board (1) are provided.

Owner:AT & S AUSTRIA TECH & SYSTTECHN AG

Pulverulent polymers crosslinked on the surface

InactiveUS7507475B2Improved gel permeabilityImprove liquiditySynthetic resin layered productsCellulosic plastic layered productsPolymer scienceMonomer

The present invention relates to a pulverulent polymer post-crosslinked on the surface and absorbing water or aqueous liquids, synthesised from polymerised, optionally pre-crosslinked monomers containing partially neutralised carboxyl groups. The present invention also relates to a process for the post-treatment of the aforementioned polymers and the use of a solution of at least one salt of an at least trivalent cation for restoring the gel permeability of the aforementioned polymers that have been damaged by mechanical action.

Owner:EVONIK DEGUSSA GMBH

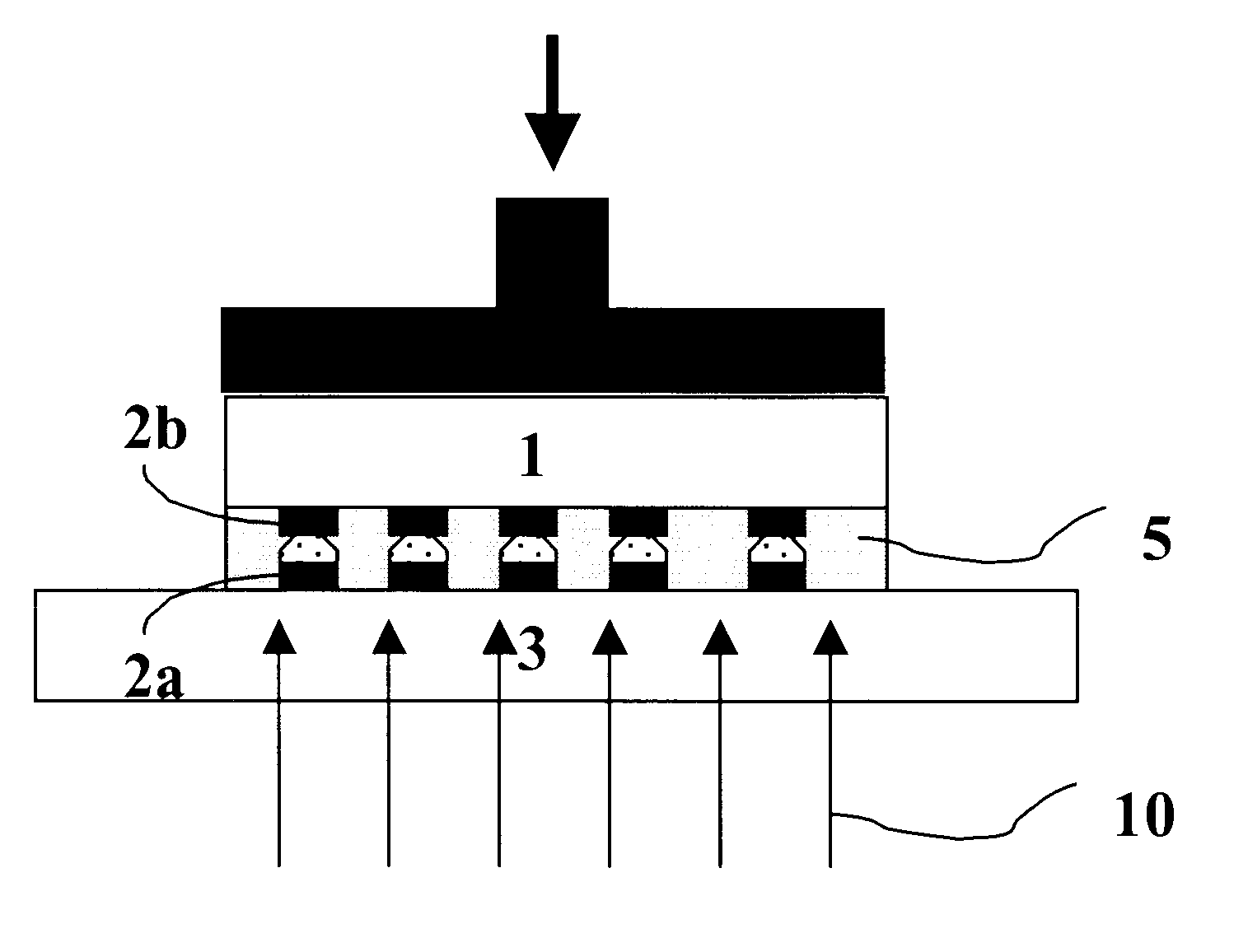

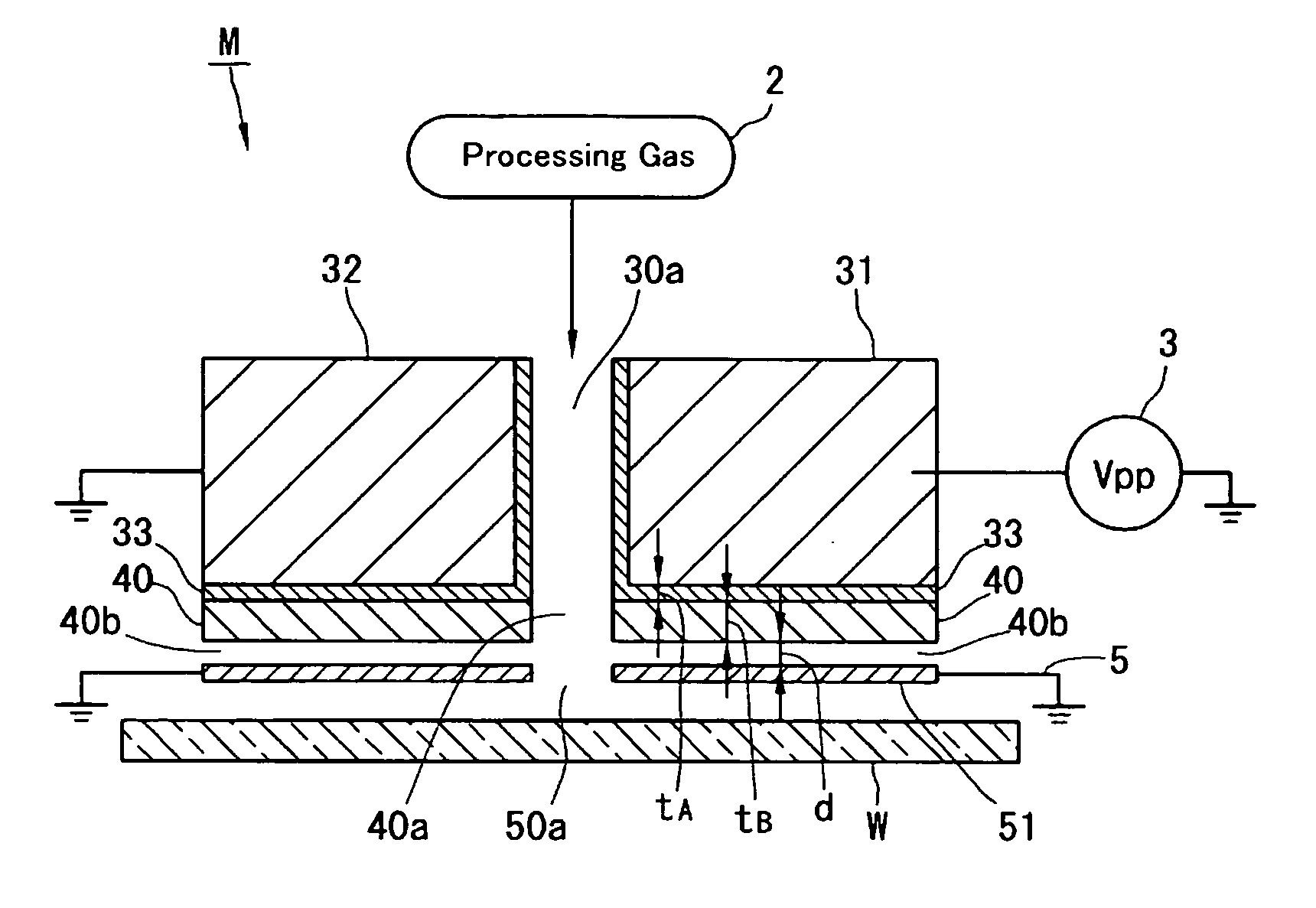

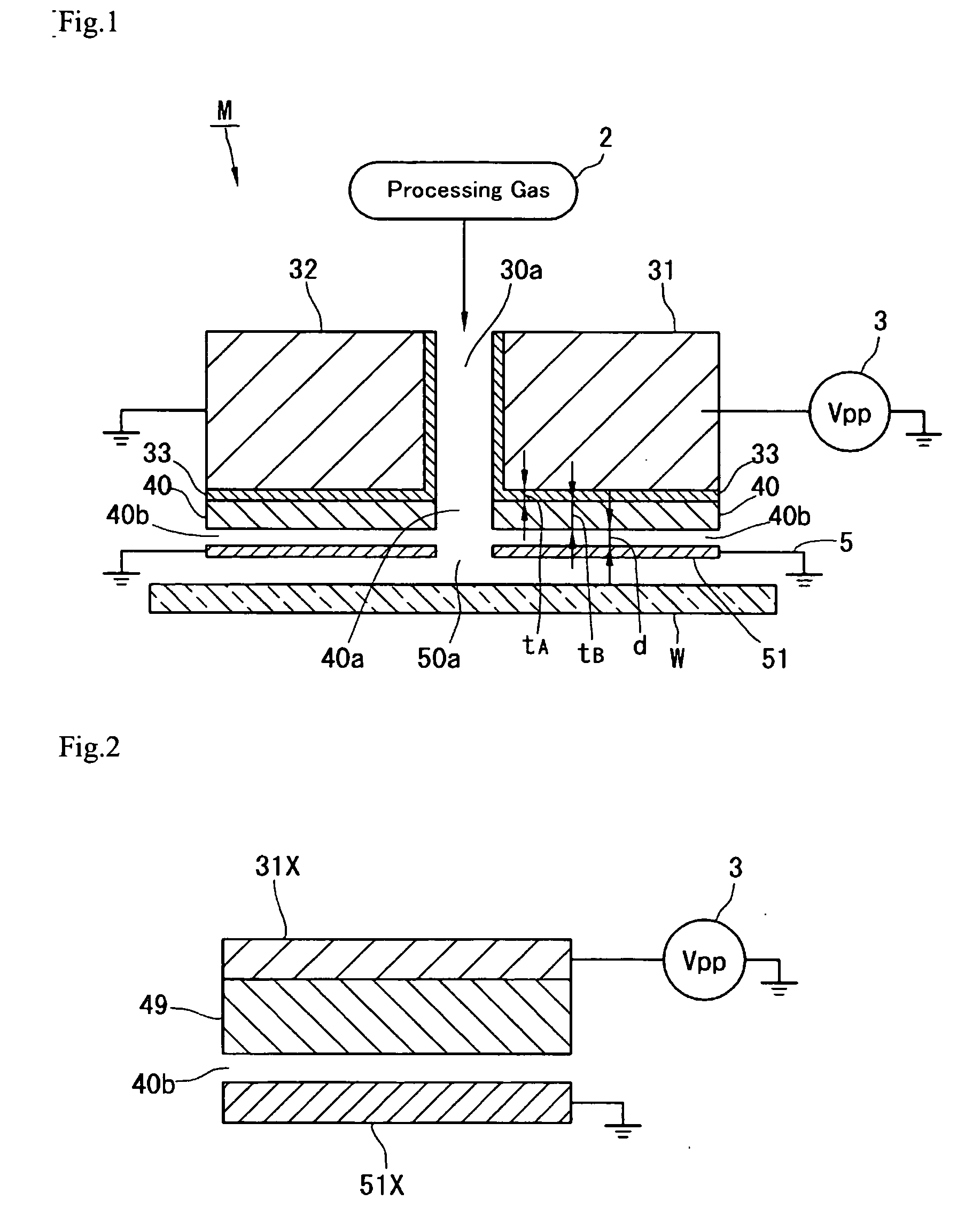

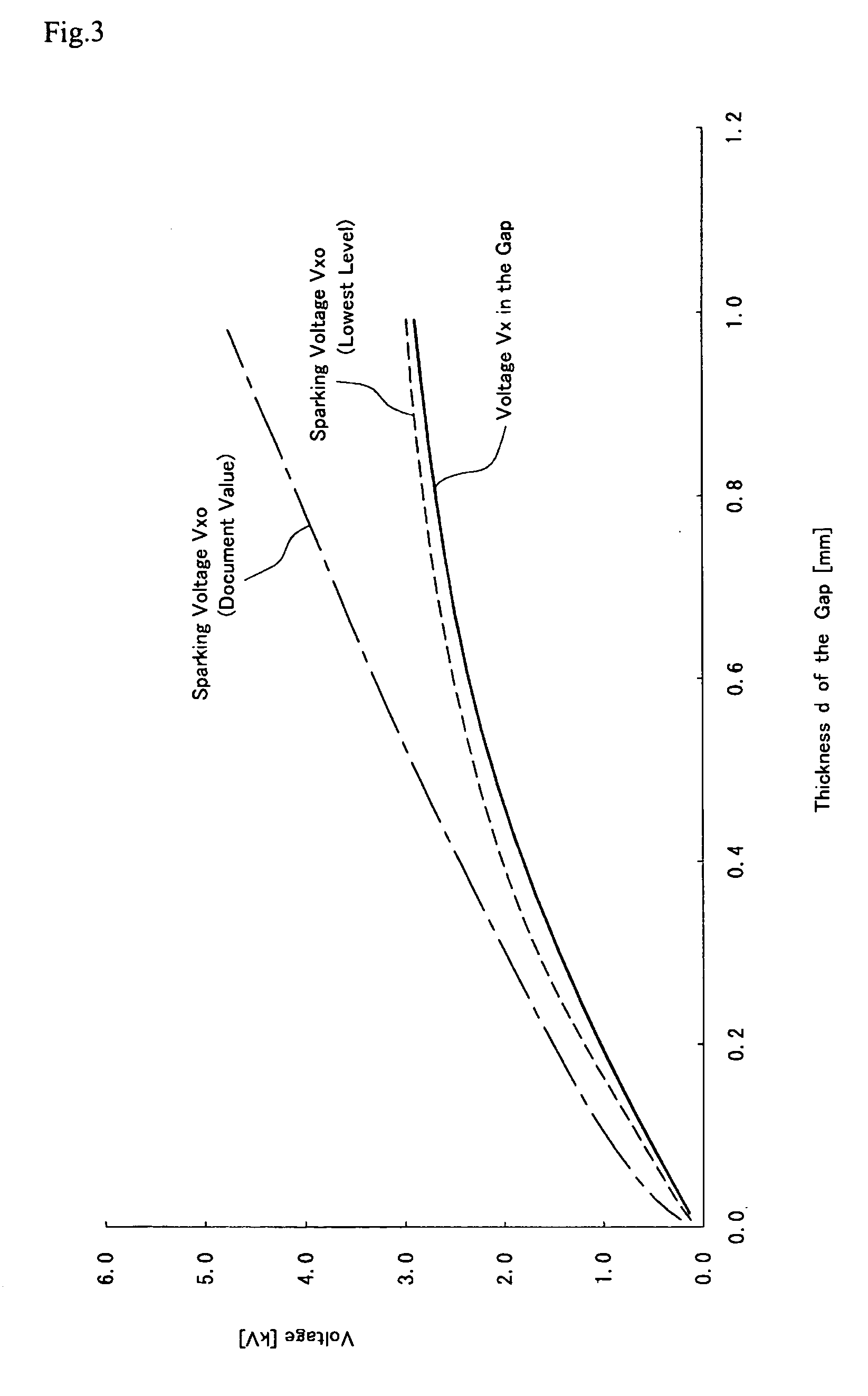

Plasma processing apparatus and method for manufacturing thereof

InactiveUS20070002515A1Avoid conductionAvoid arcingElectric discharge tubesSemiconductor/solid-state device manufacturingDielectricEngineering

A plasma processing apparatus is provided on the side to be directed to a workpiece W of electrodes 31, 32 with a conductive member 51 through an insulating member 41. The insulating member 41 is sandwiched between the electrodes 31, 32 and the conductive member 51. The dielectric constant and the thickness of the insulating member 41 are established such that the voltage applied to a gap 40b formed between the insulating member 41 and the conductive member 51 becomes smaller than the sparking voltage. Owing to this arrangement, electrical discharge can be prevented from occurring in the gap 40b and thus, the processing quality can be enhanced.

Owner:SEKISUI CHEM CO LTD

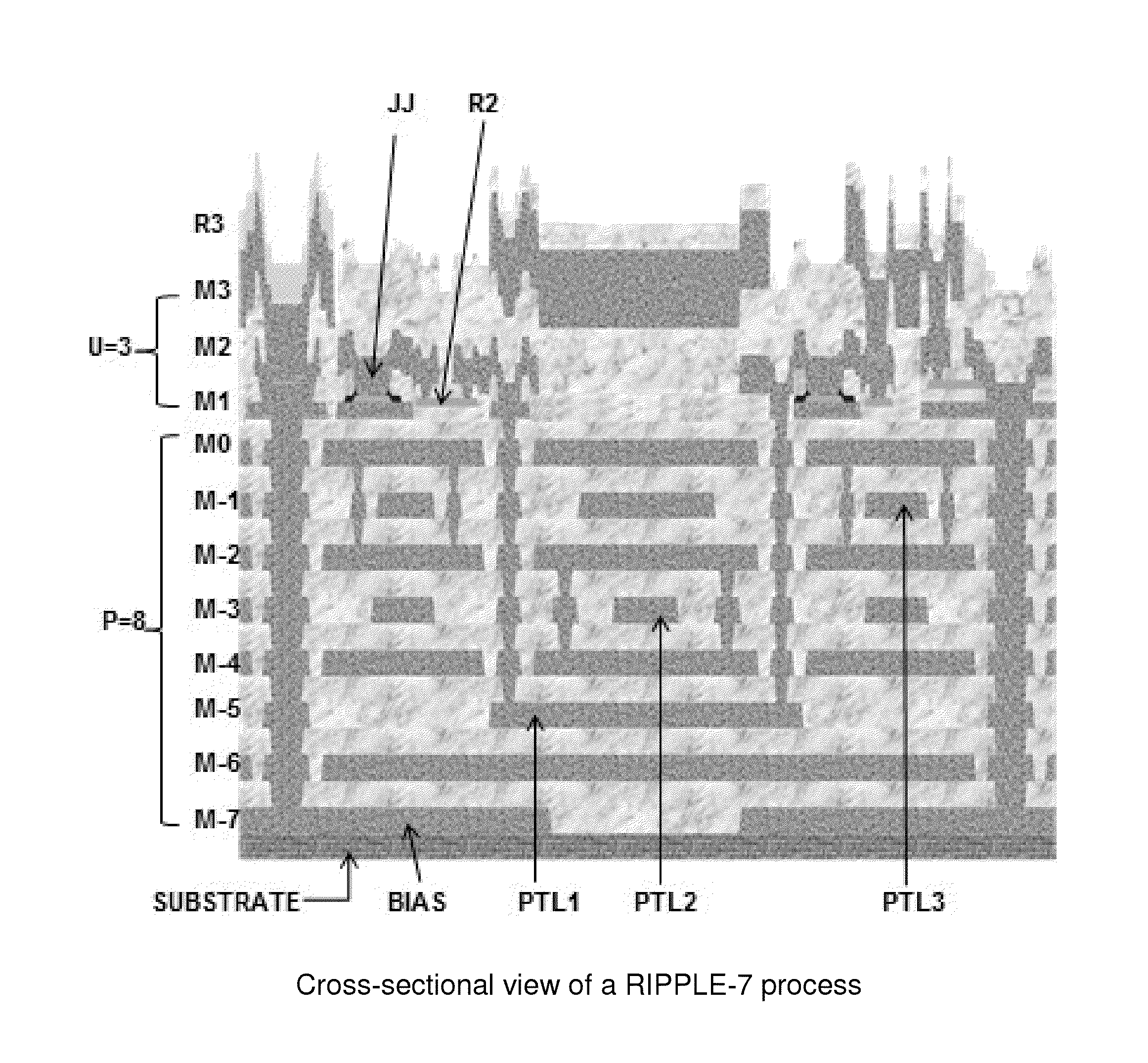

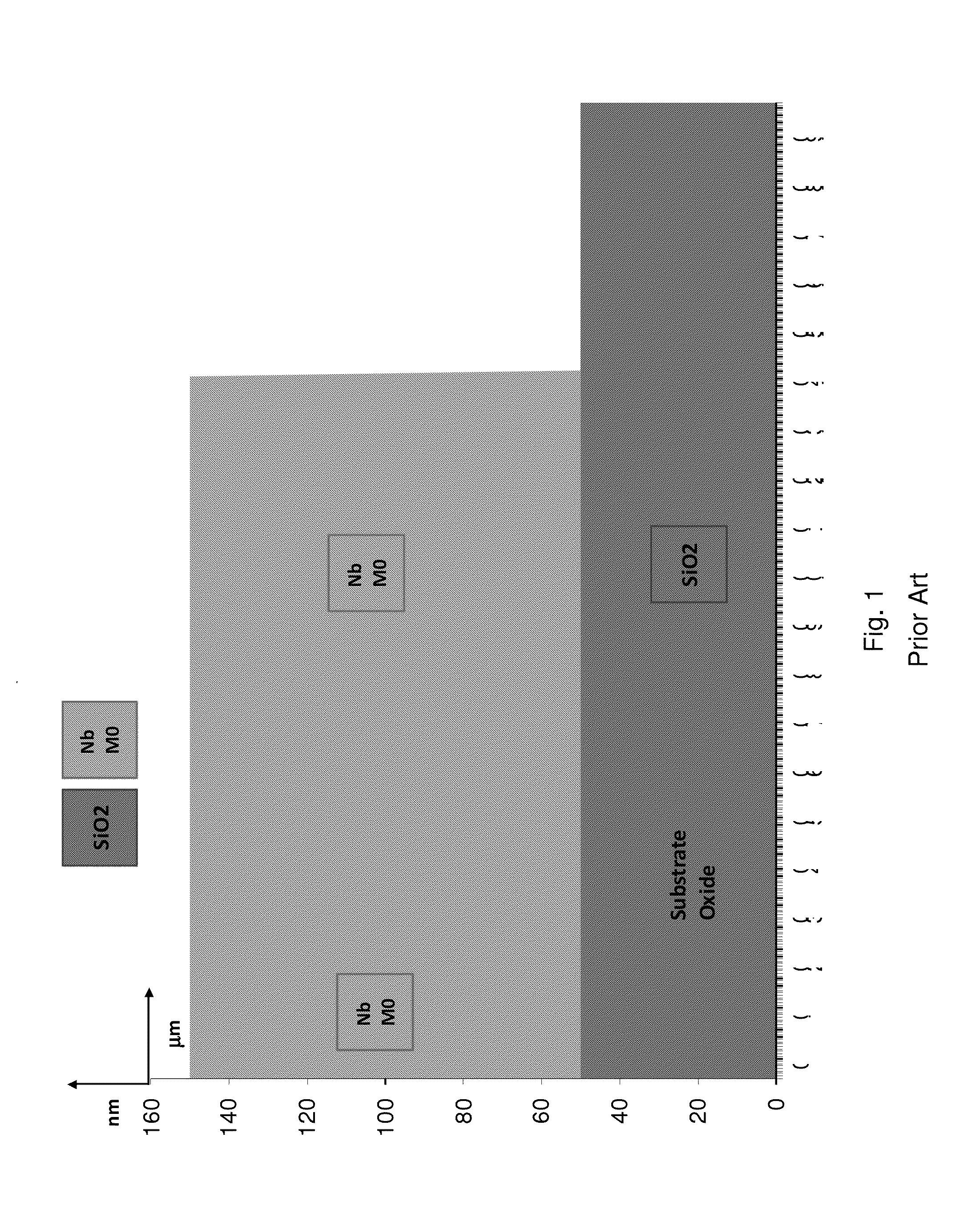

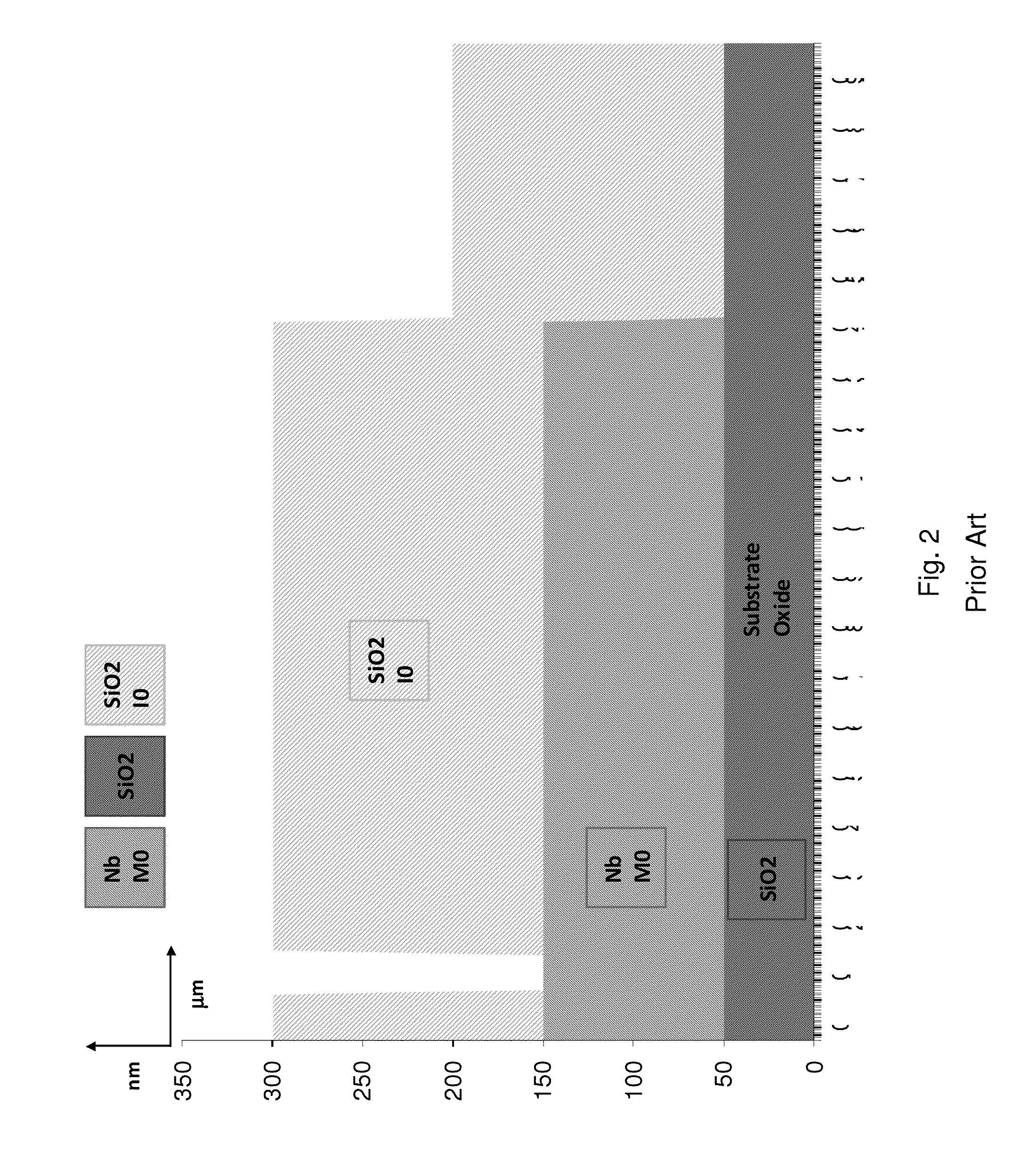

Method for increasing the integration level of superconducting electronics circuits, and a resulting circuit

ActiveUS20150119253A1Fast planarizationReliable processingSuperconductors/hyperconductorsSemiconductor/solid-state device detailsNiobiumSilicon dioxide

A method for increasing the integration level of superconducting electronic circuits, comprising fabricating a series of planarized electrically conductive layers patterned into wiring, separated by planarized insulating layers, with vias communicating between the conductive layers. Contrary to the standard sequence of patterning from the bottom up, the pattern of vias in at least one insulating layer is formed prior to the pattern of wiring in the underlying conductive layer. This enables a reduction in the number of planarization steps, leading to a fabrication process which is faster and more reliable. In a preferred embodiment, the superconductor is niobium and the insulator is silicon dioxide. This method can provide 10 or more wiring layers in a complex integrated circuit, and is compatible with non-planarized circuits placed above the planarized wiring layers.

Owner:SEEQC INC

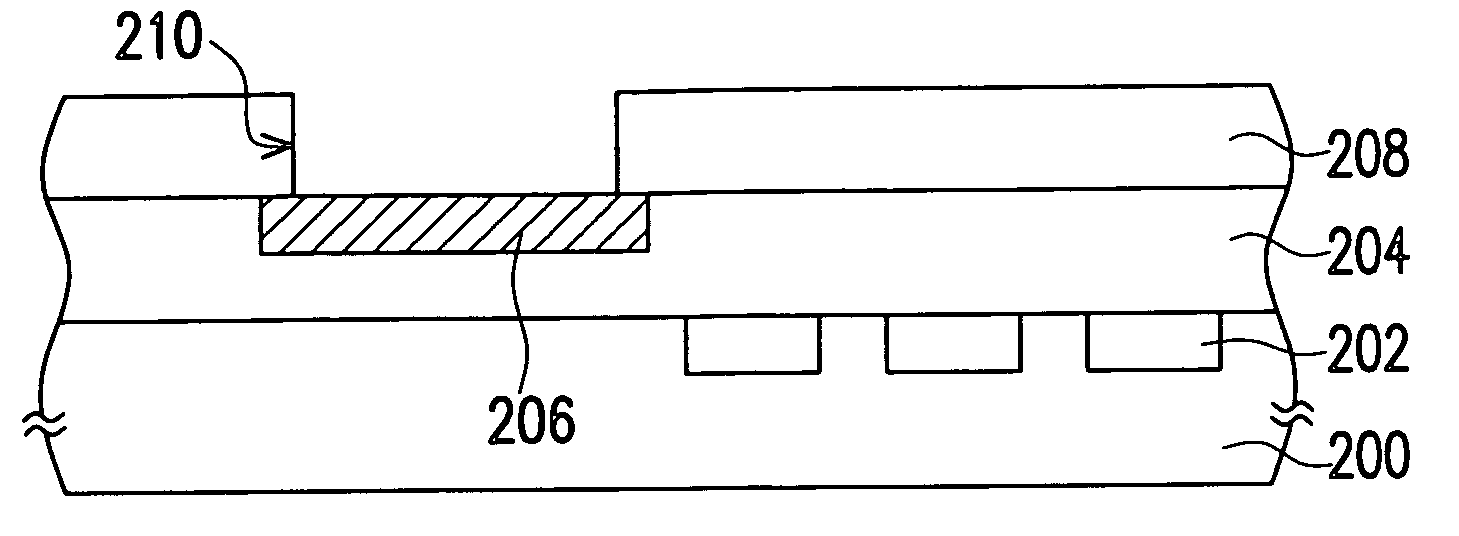

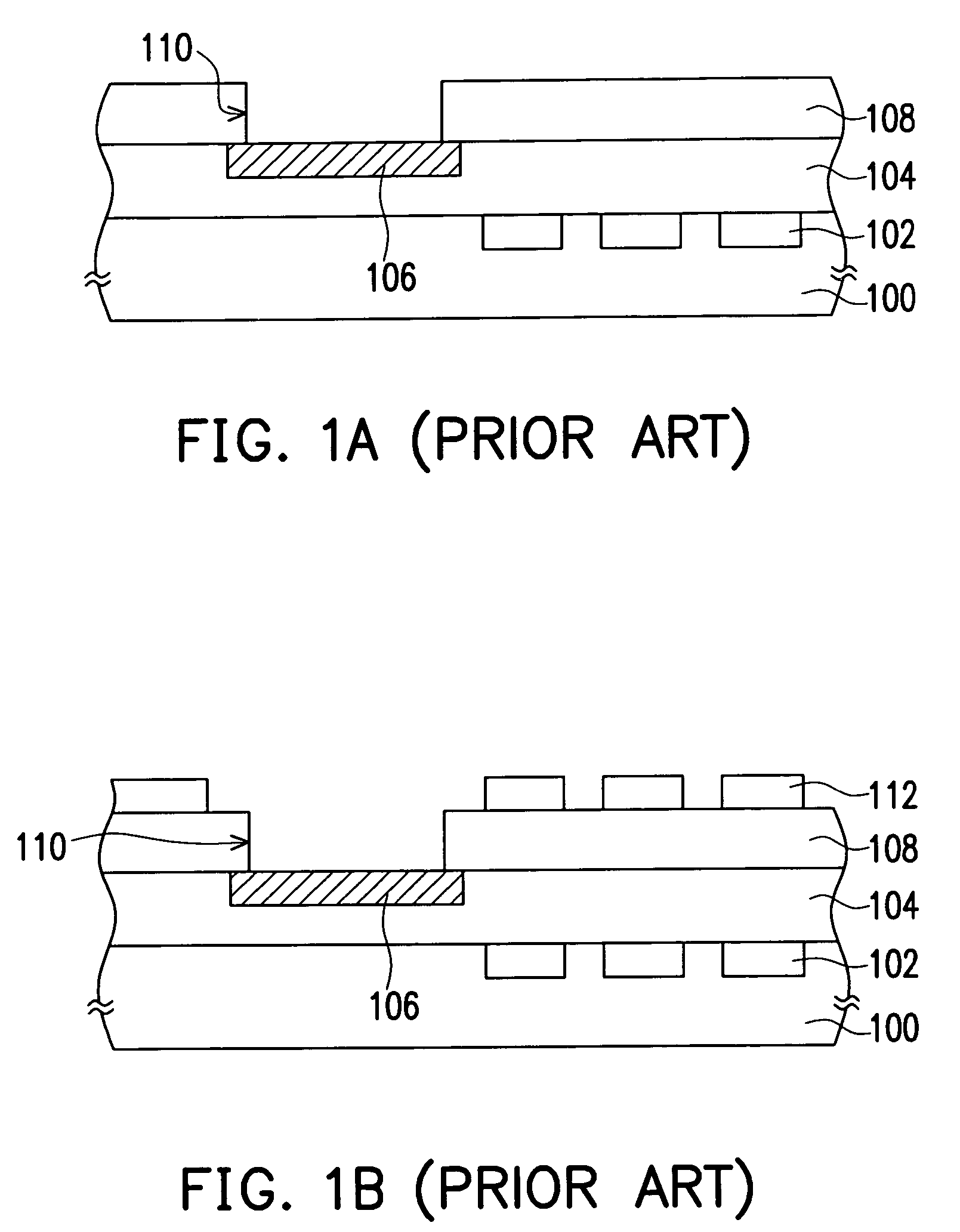

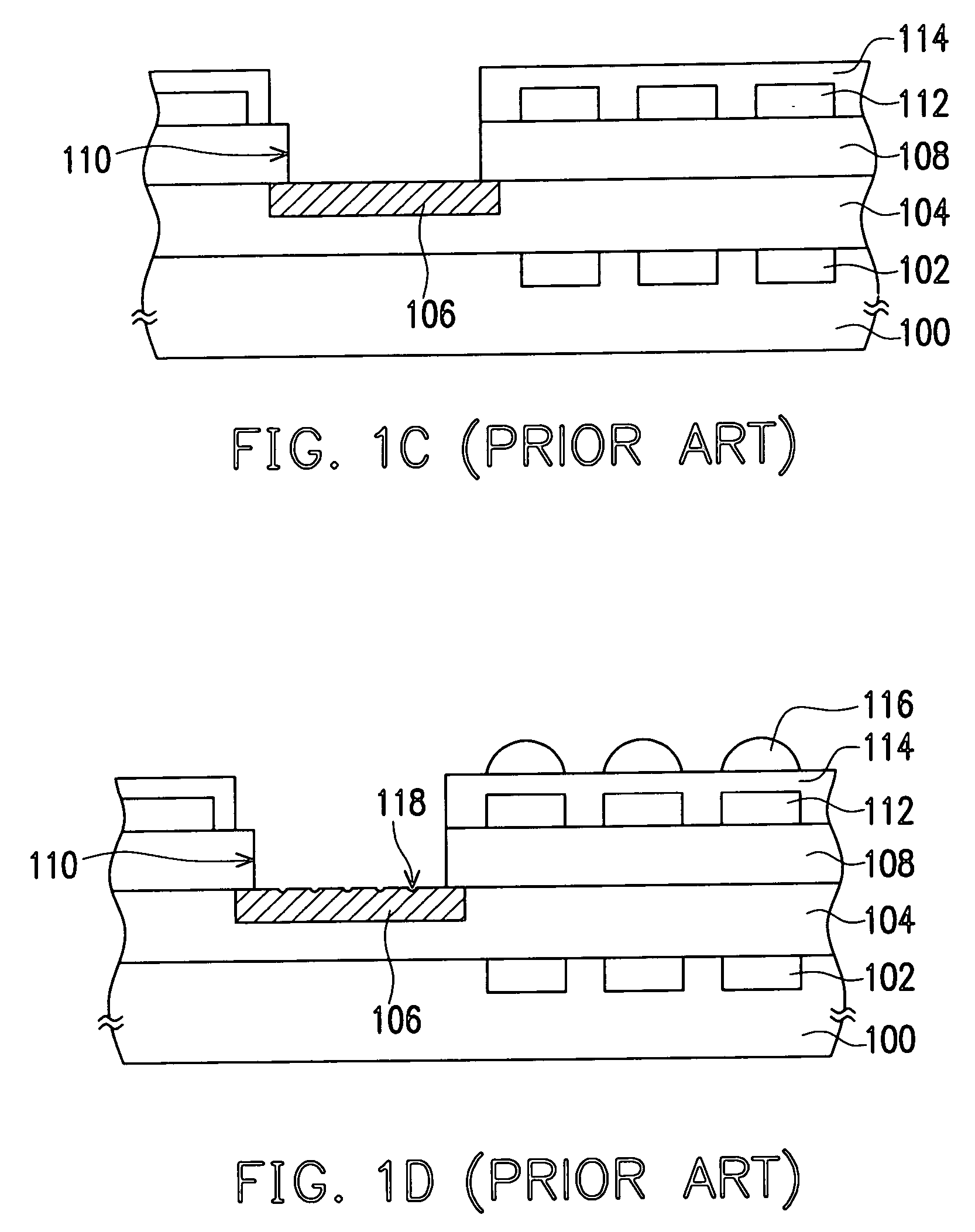

Manufacturing method of image sensor device

InactiveUS20050101043A1Avoid corrosionReliable wiring processSolid-state devicesSemiconductor/solid-state device manufacturingColor gelEngineering

A manufacturing method of image sensor device is provided. The image sensor device is suitable for a substrate having at least one bonding pad. Wherein a plurality of photodiode sensing areas are formed on the substrate, at least a dielectric layer is formed over the substrate and the bonding pad is disposed in the dielectric layer. Wherein a first cover layer having an opening is disposed over the dielectric layer, wherein a portion of the bonding pad is exposed within the opening, forming a second cover layer over the first cover layer and the opening, and forming color filters over the second cover layer, then forming a planarization layer over the second cover layer and the color filters, and forming a plurality of micro lenses over the planarization layer.

Owner:UNITED MICROELECTRONICS CORP

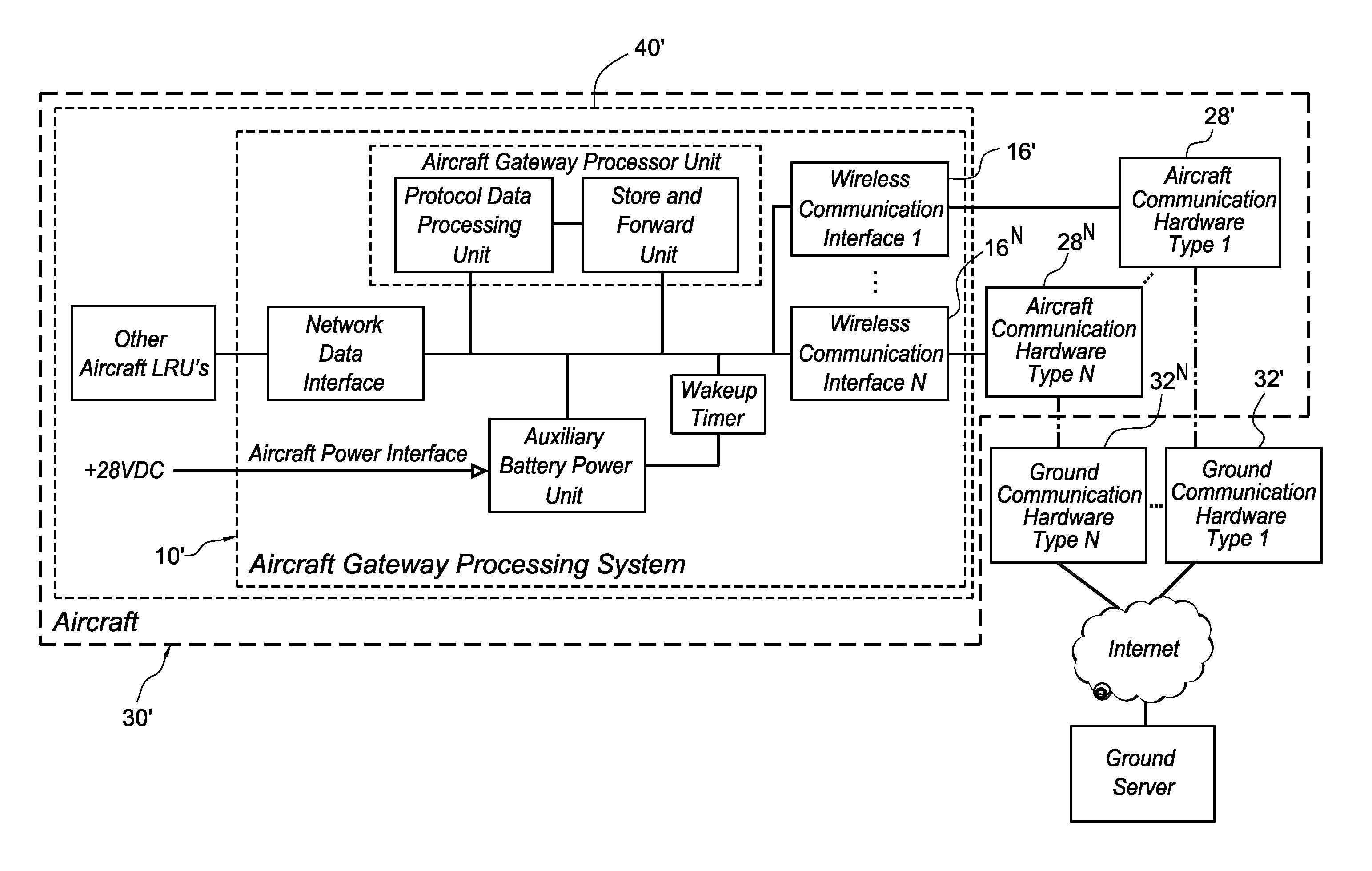

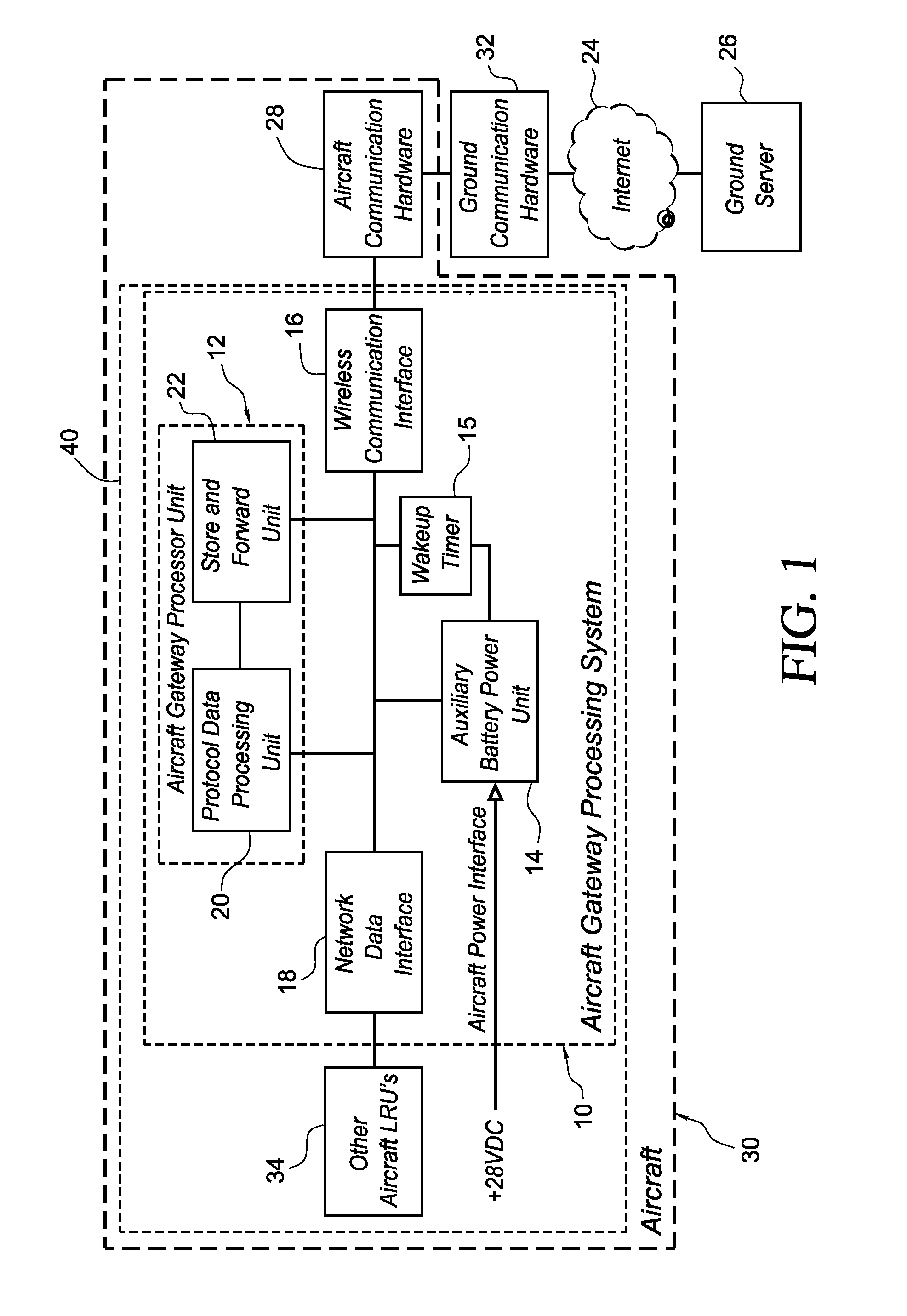

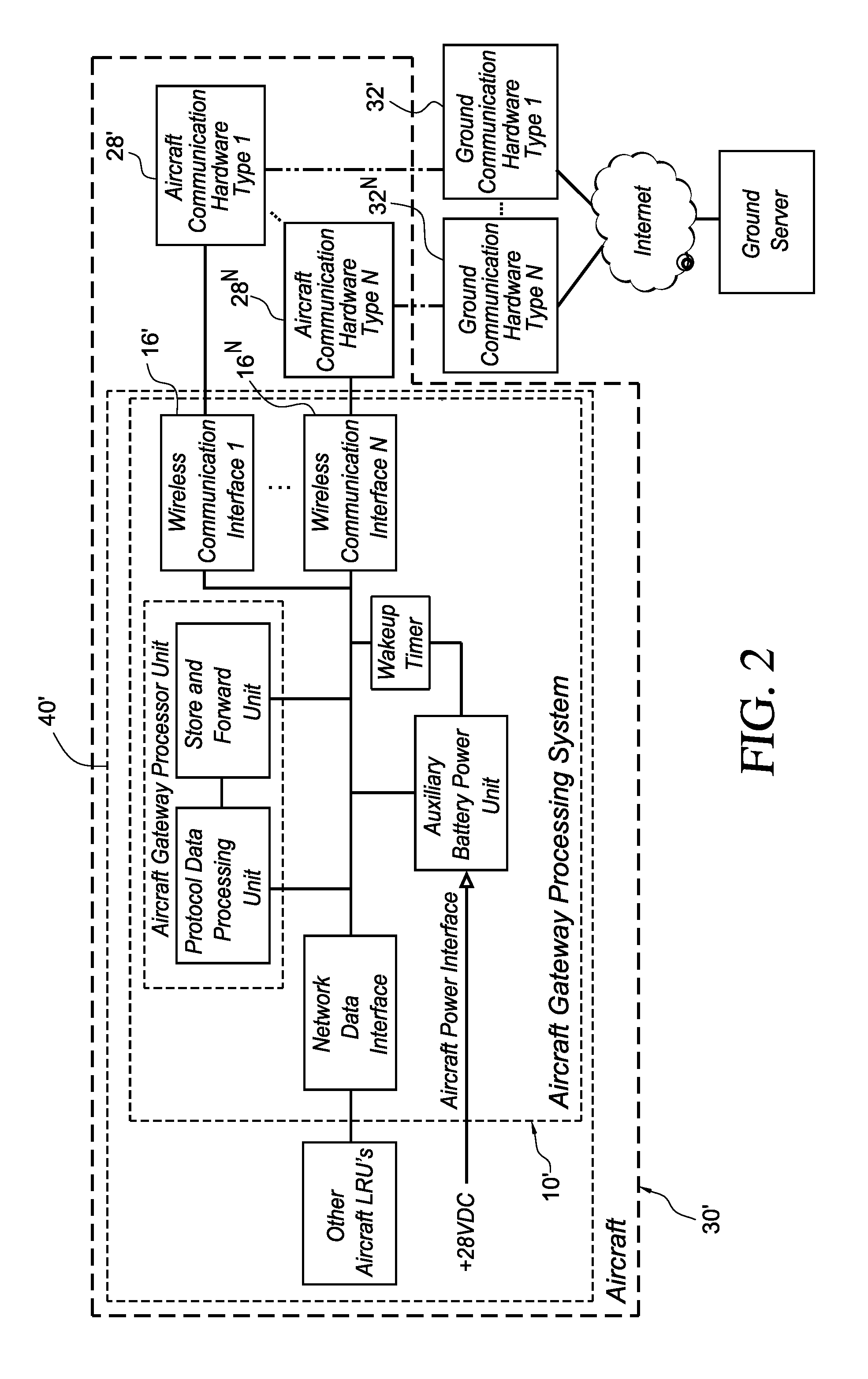

Wireless aircraft gateway with auxiliary battery power

InactiveUS8493906B1Improve communication reliabilityImprove reliabilityRadio transmissionCommunication interfaceStore and forward

An aircraft gateway processing system for wirelessly transferring data between an aircraft and a ground server. The aircraft gateway processing system includes an aircraft gateway processor unit that includes a protocol data processing unit; and, a store and forward unit operably connected to the protocol data processing unit. An auxiliary battery power unit is operably connected to the aircraft gateway processor unit and configured to provide self-powered operation of the aircraft gateway processing system in the event of a loss of aircraft power during communications or initiation of communication when aircraft power is not available. At least one wireless communication interface is operably connected to the aircraft gateway processor unit for connection to the internet and ultimately to a ground server connected to the internet. At least one network data interface is operably connected to the aircraft gateway processor unit and operably connectable to another aircraft unit.

Owner:ROCKWELL COLLINS INC

Method in the preparation of samples for microscopic examination, and apparatus for checking the coverslipping quality of samples

ActiveUS20130217065A1Fast and reliable inspectionReliable analysisImage enhancementImage analysisMicroscopic examComputer science

Owner:LEICA BIOSYST NUSSLOCH

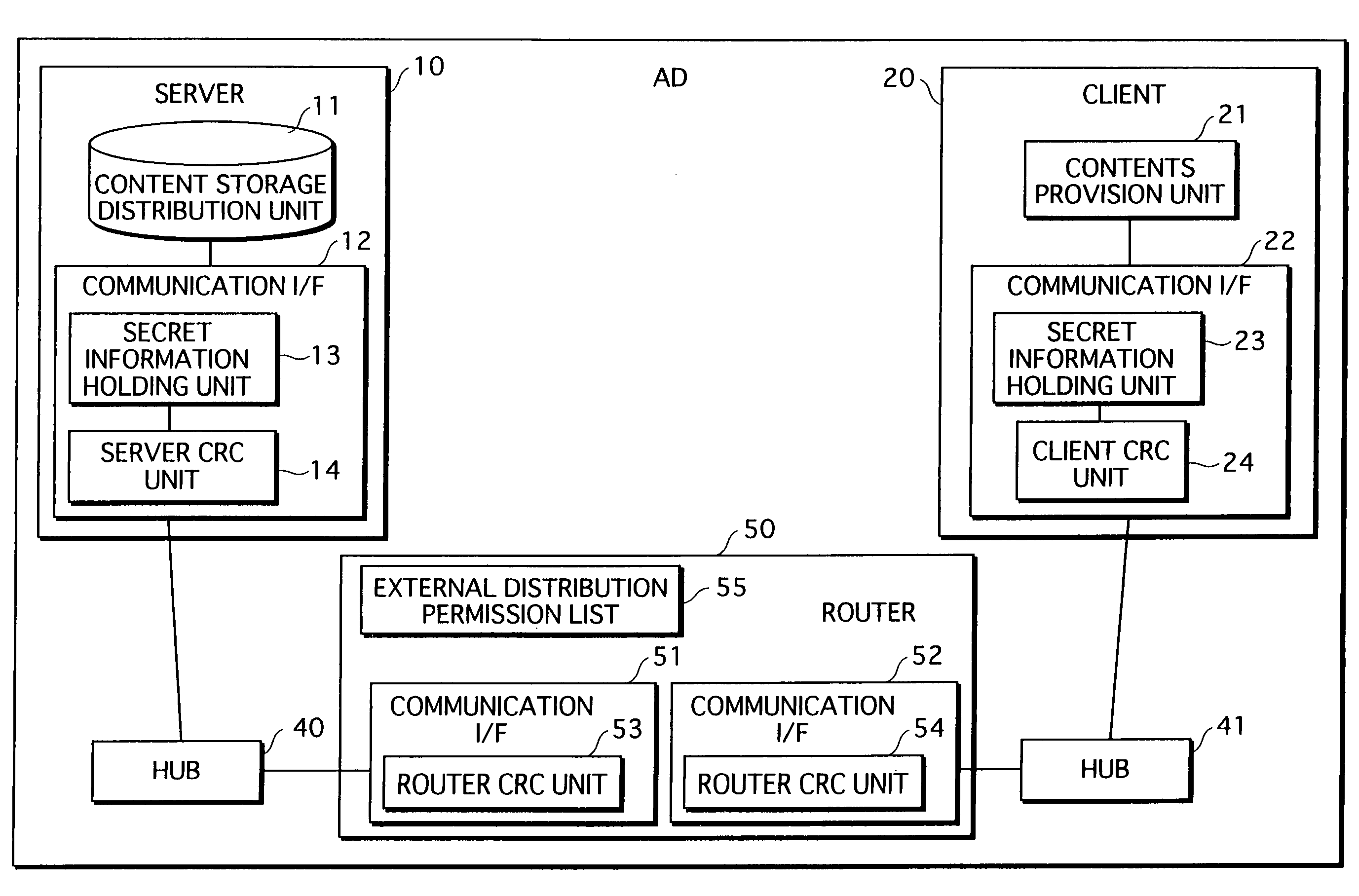

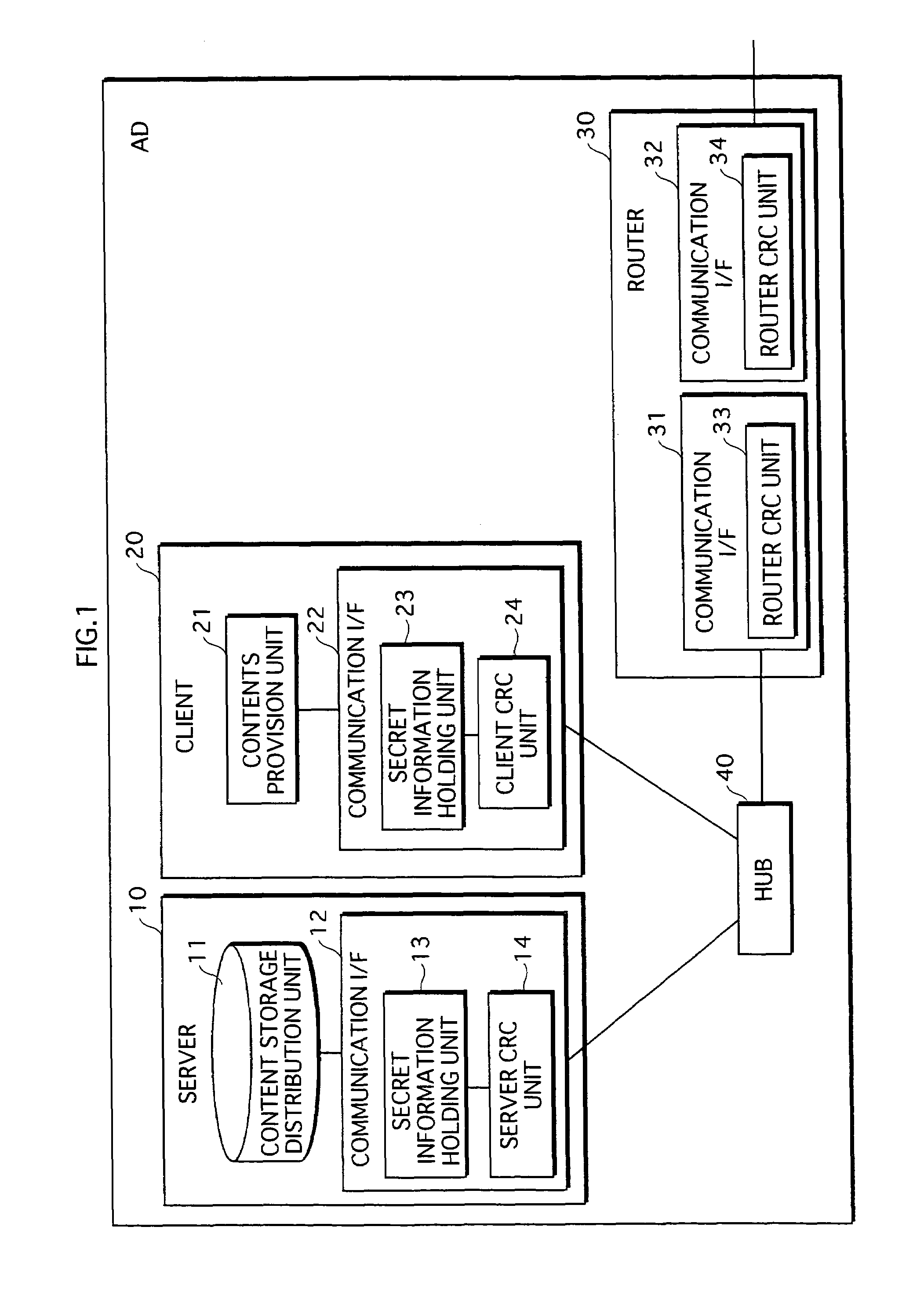

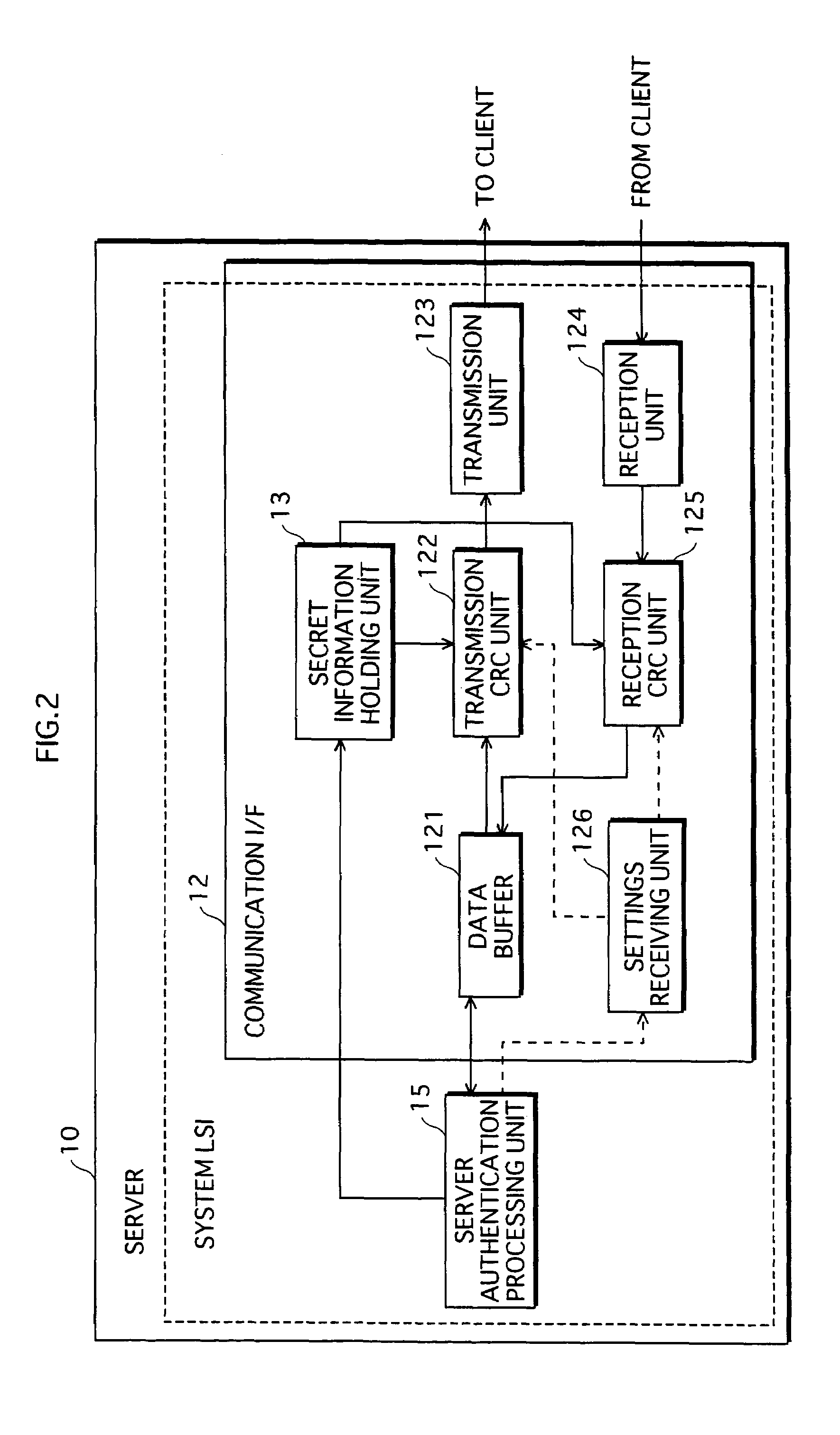

Transmission/reception system

InactiveUS7457410B2Authentication processing is reliableInhibit transferKey distribution for secure communicationError preventionClient-sideAuthorized domain

A server and a client hold common secret information in respective secret information holding units. A server Cyclic Redundancy Check (CRC) unit in the server generates a CRC code after adding the secret information to communication data, and transmits the communication data with the CRC code attached. A client CRC unit of the client generates a CRC code after adding the secret information to communication data, and checks whether or not an error has occurred in the communication data on the communication path. Since the client holds the secret information, the client determines that an error has not occurred, and obtains the communication data. On the other hand, a router, which does not hold the secret information, is unable to obtain the communication data. This prevents the communication data from being transferred to devices outside an authorized domain.

Owner:PANASONIC CORP

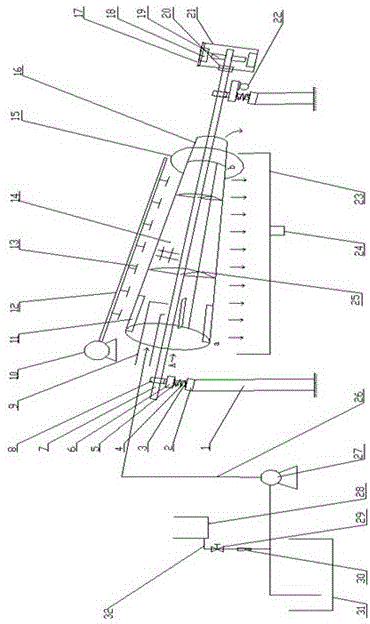

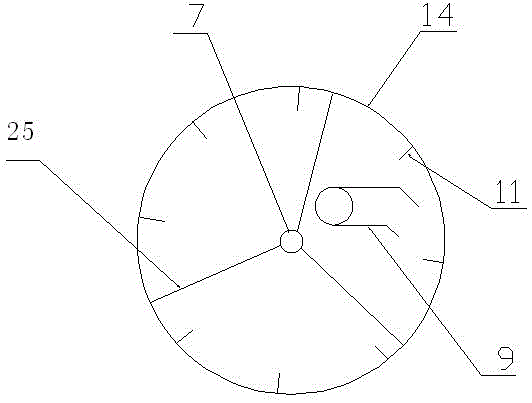

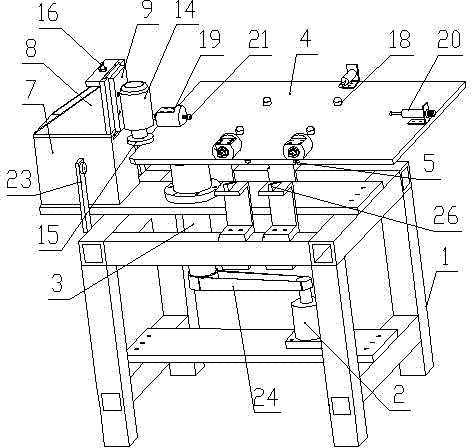

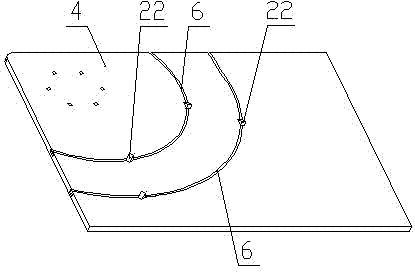

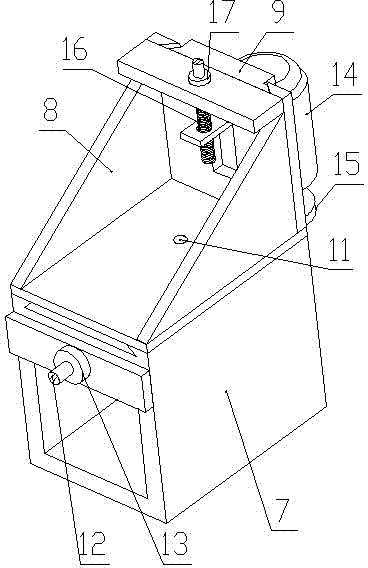

Sewage filtering device

ActiveCN105056603AReduce energy consumptionLess investmentWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationSewage treatmentSewage

The invention belongs to the technical field of sewage treatment equipment, and in particular relates to a sewage filtering device. The sewage filtering device is composed of a hydraulic rotary filter cylinder system, a back-flushing device, a supporting device and a hydraulic speed regulation device, wherein the hydraulic rotary filter cylinder system is composed of a rotary shaft (7), a sewage inlet tube (9), blades (11), a filter screen (14) and a filter screen frame (25). The sewage filtering device is characterized in that the two ends of the rotary shaft are fixed on a bearing (8), the circular-ring-shaped filter screen frame is arranged on the rotary shaft, a conical-cylinder-shaped filter screen with two opened ends is arranged on the outer surface of the filter screen frame, the diameter of an a end of the filter screen is larger than that of a b end of the filter screen, the blades are uniformly arranged on the inner surface of the filter screen frame at the a end, the sewage inlet tube (9) is arranged in the filter screen frame in a suspending manner, and the opening of the sewage inlet tube (9) is aligned with one of the blades. The sewage filtering device synchronously performs a filter treatment and multi-effect clogging prevention, and rotation and speed regulation are driven by hydraulic power, so that the energy consumption is reduced, the failure rate is low, equipment cost is low, machining is simple and easy to implement, and the operation of the equipment is more stable and reliable.

Owner:GEJIU DINGYI TECH CO LTD

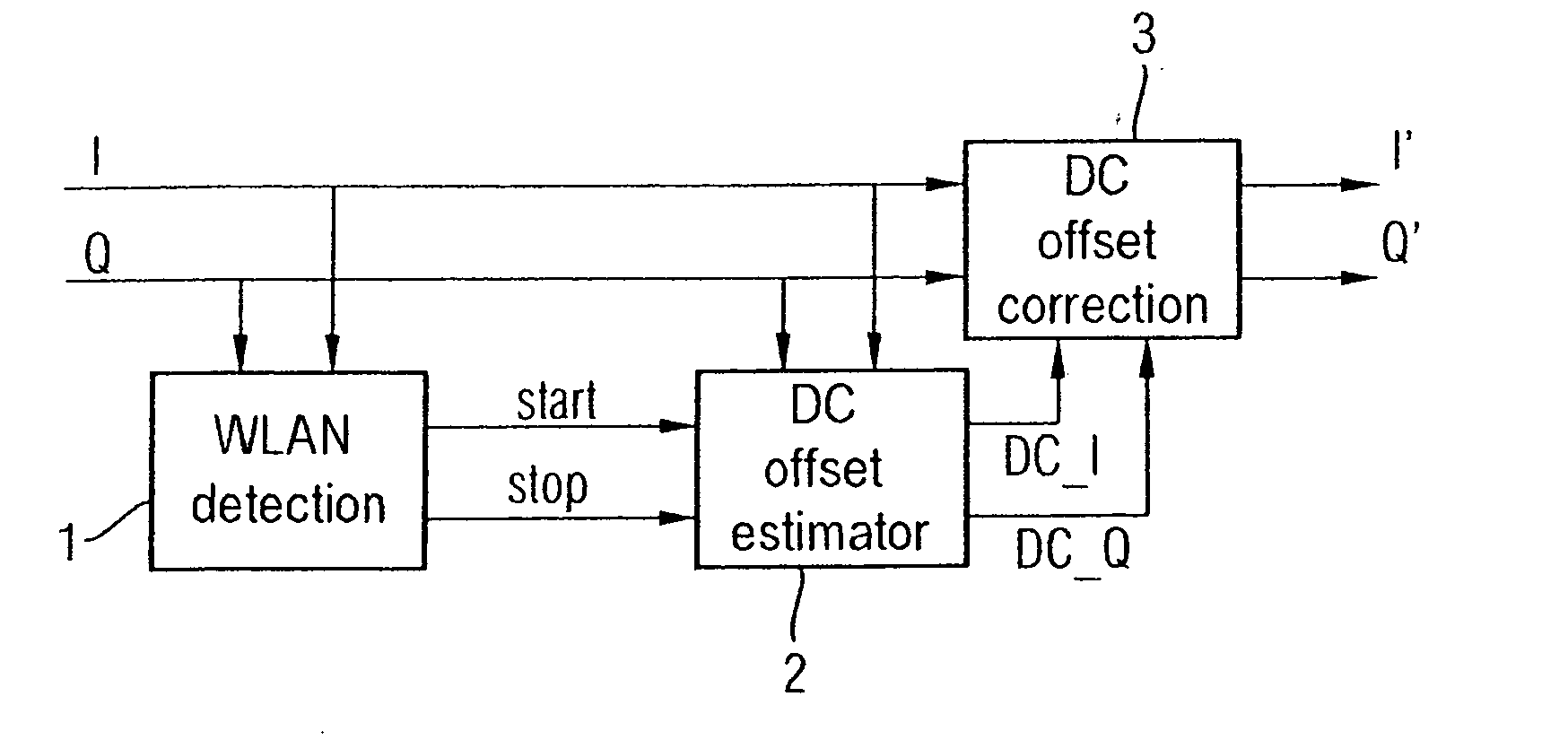

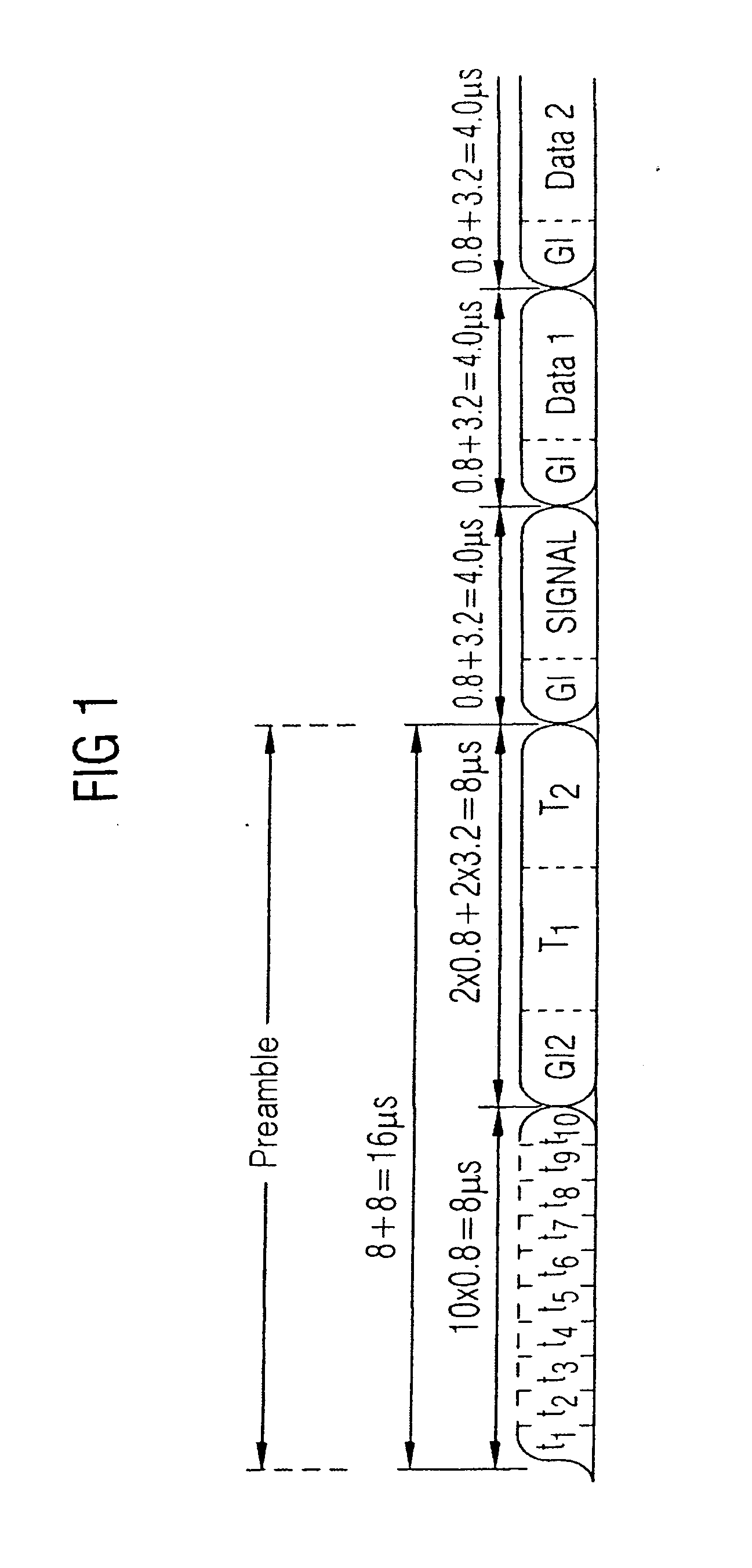

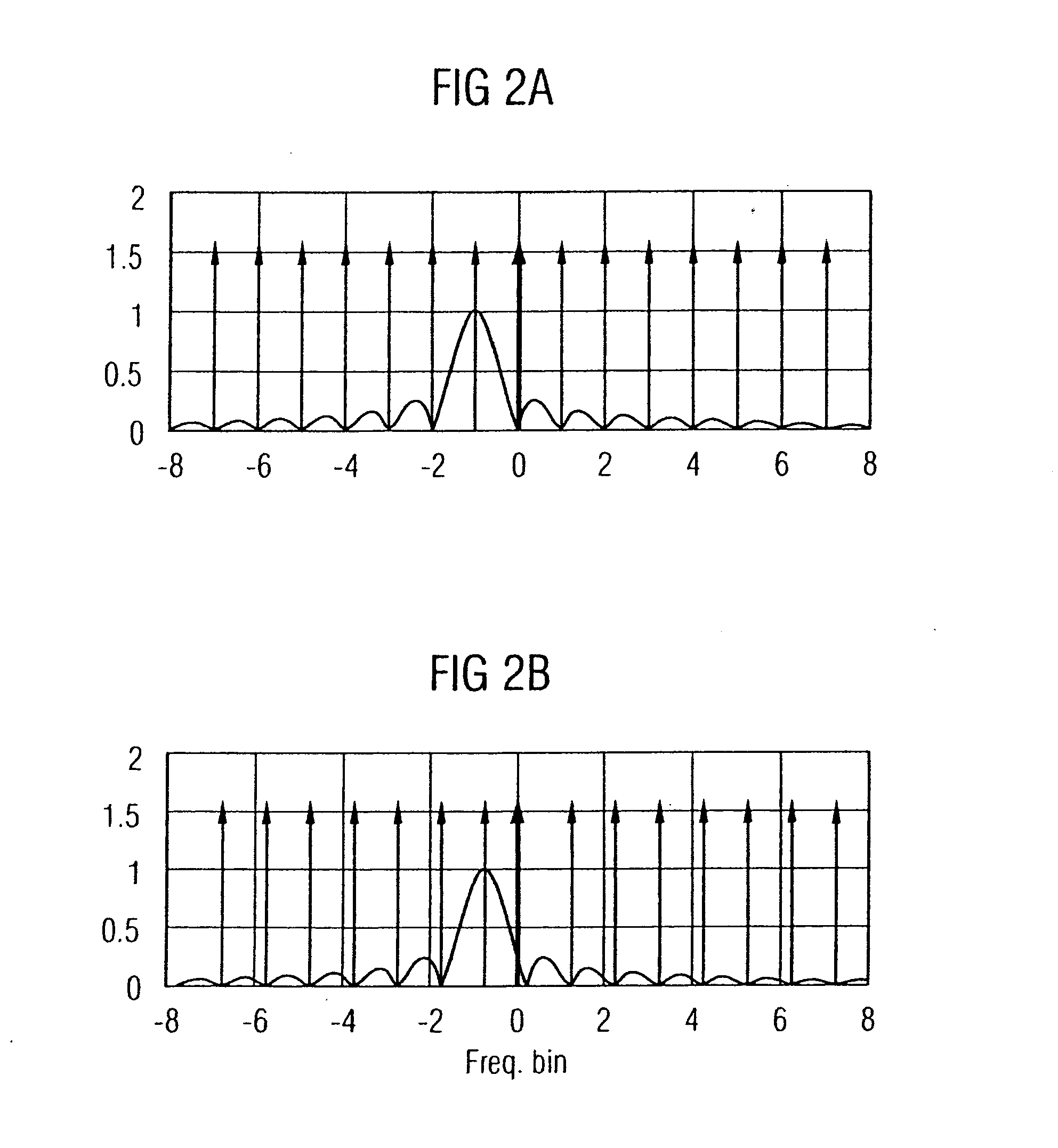

DC offset estimation and compensation in OFDM radio receivers by weighted averaging over a section of the training sequence

InactiveUS20050025041A1Reduce the impactImprove reliabilityError preventionDc level restoring means or bias distort correctionRadio receiverEngineering

Each burst of an OFDM signal which is transmitted, for example, on the basis of the IEEE 802.11a / g WLAN Standard contains a preamble with a sequence of ten short training signals. The DC offset is derived from the mean value of the signal over a measurement section of the training signal sequence, with a first subsection of the measurement section in time being weighted with a rising weighting function, and a last subsection of the measurement section in time being weighted with a falling weighting function. A central subsection, which is not weighted, may be located between the two. The signal is accumulated in this way over the measurement section, and the result is divided by the sum of the weights of the subsections. Using this procedure, the averaging process has better filter characteristics than the noise contribution from the actual signal.

Owner:INTEL CORP

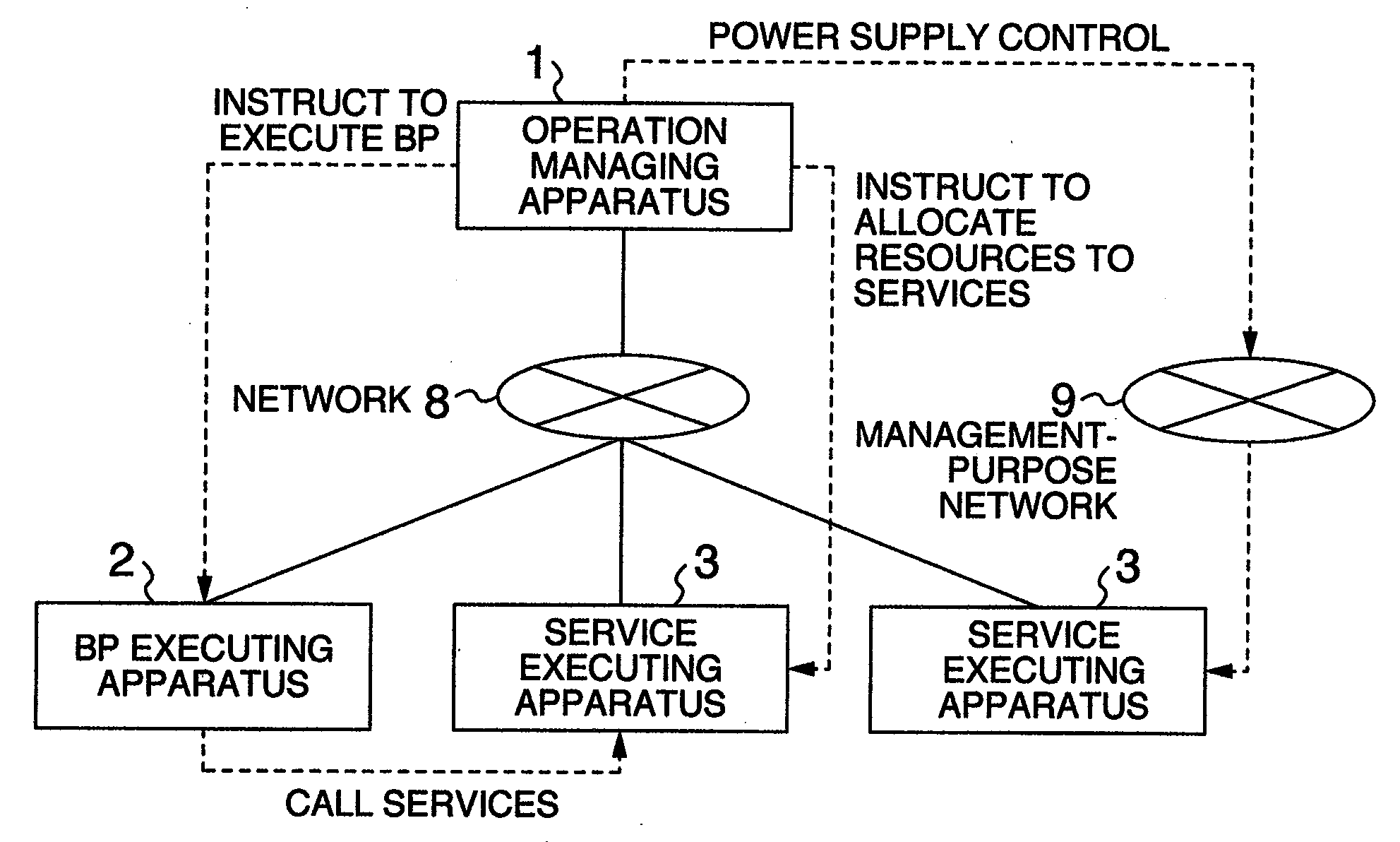

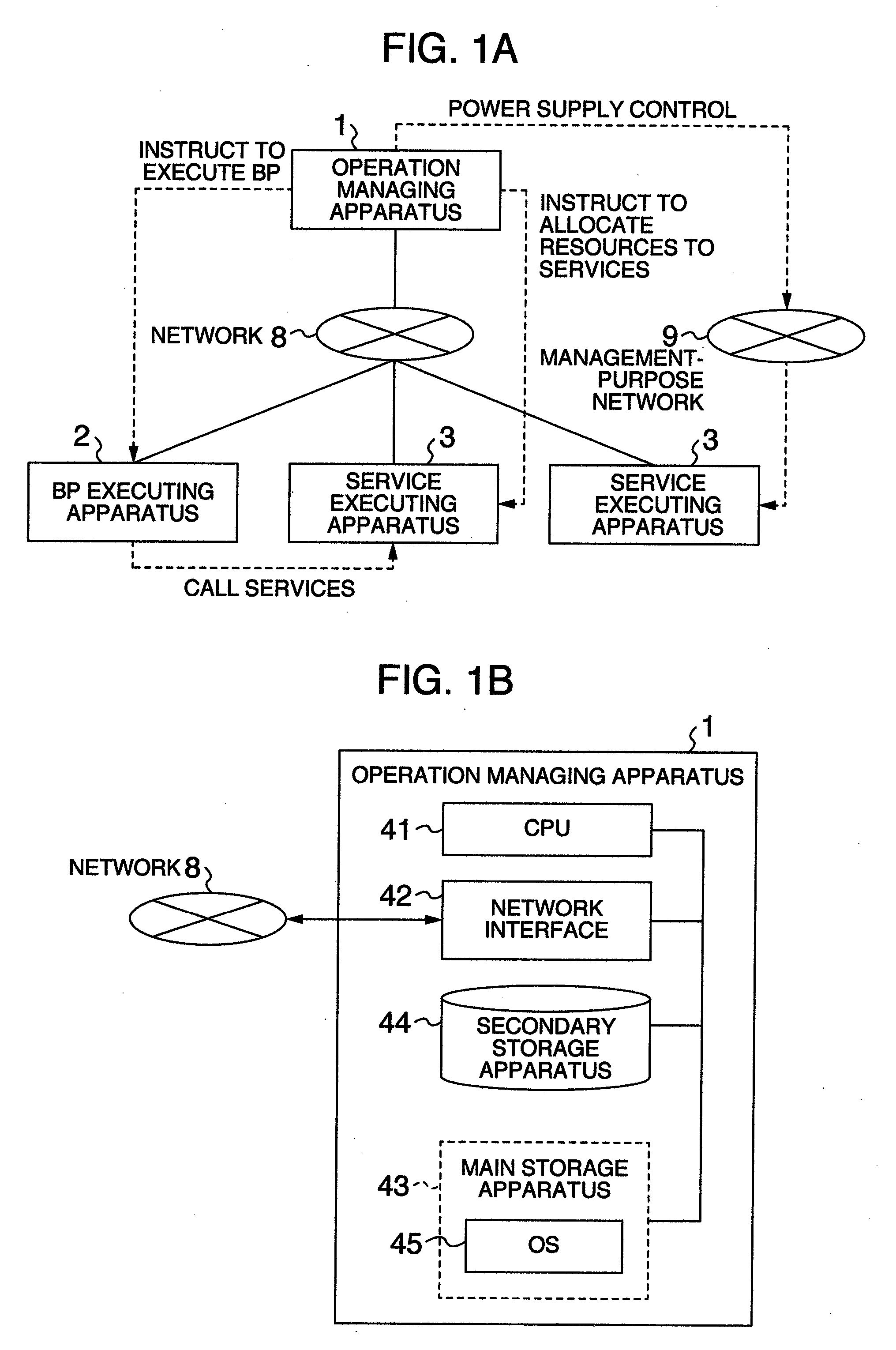

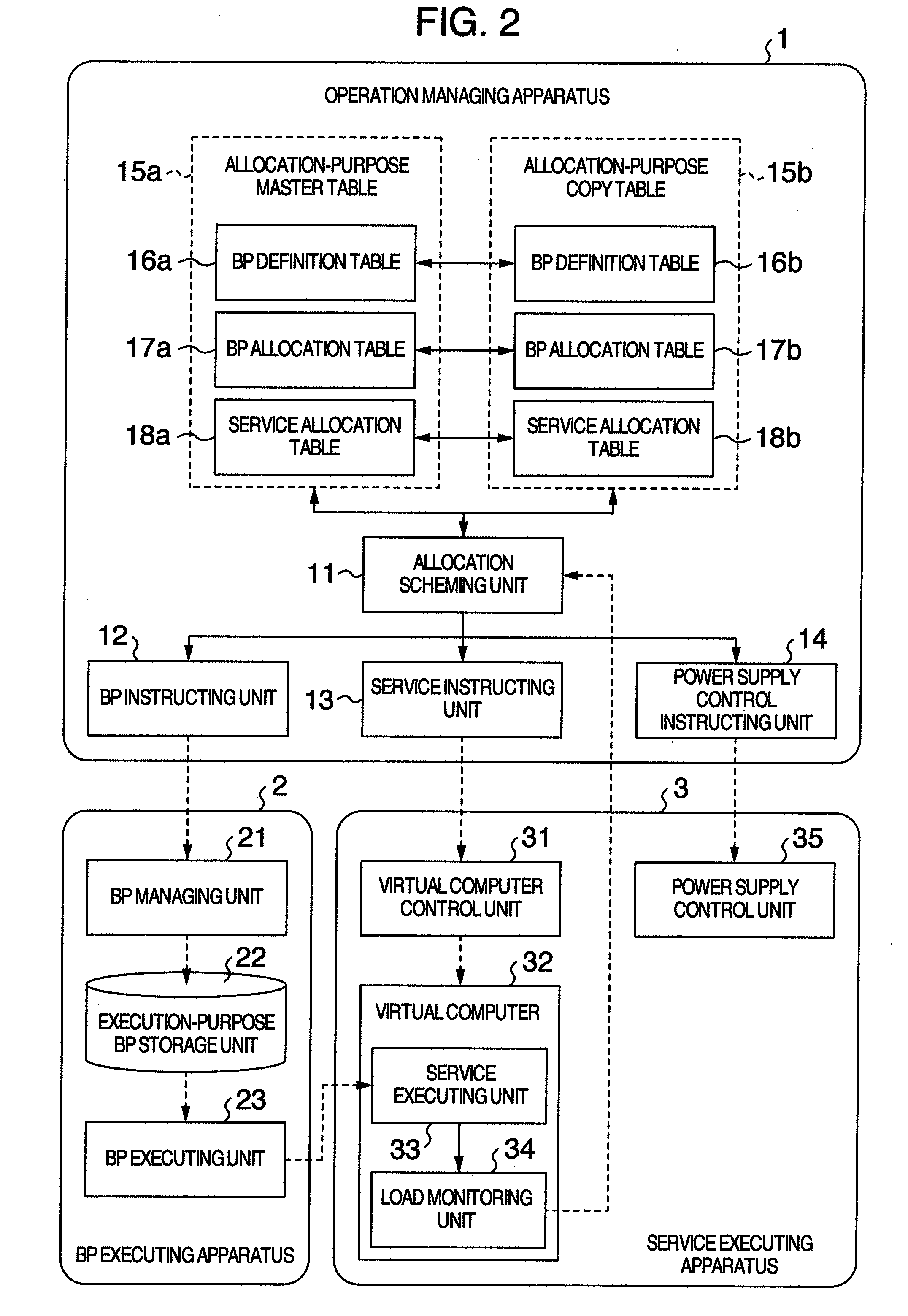

Resource allocating method, resource allocation program, and operation managing apparatus

InactiveUS20090144741A1Minimize the numberImprove reliabilityMultiprogramming arrangementsMemory systemsResource allocationOperating system

Owner:HITACHI LTD

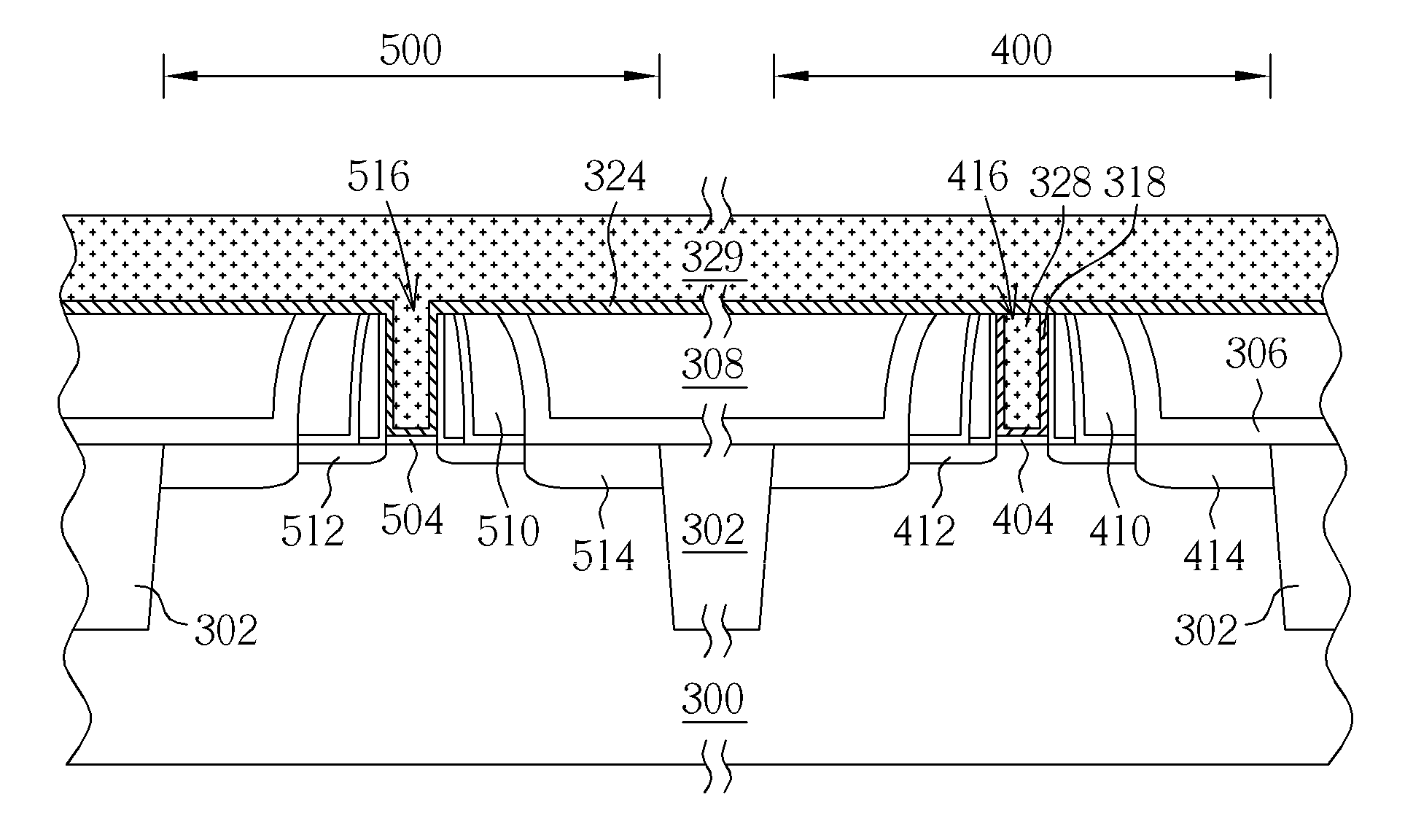

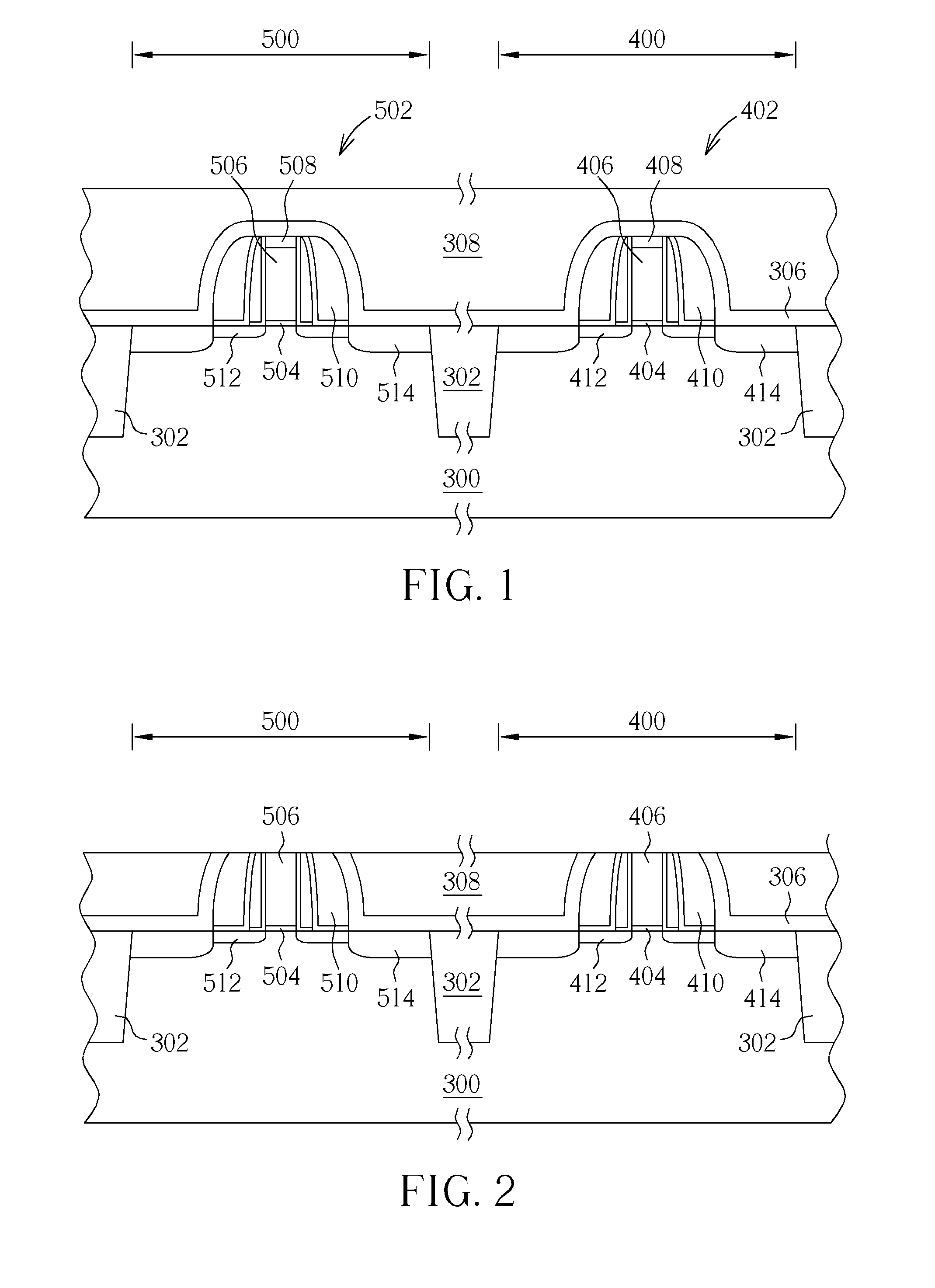

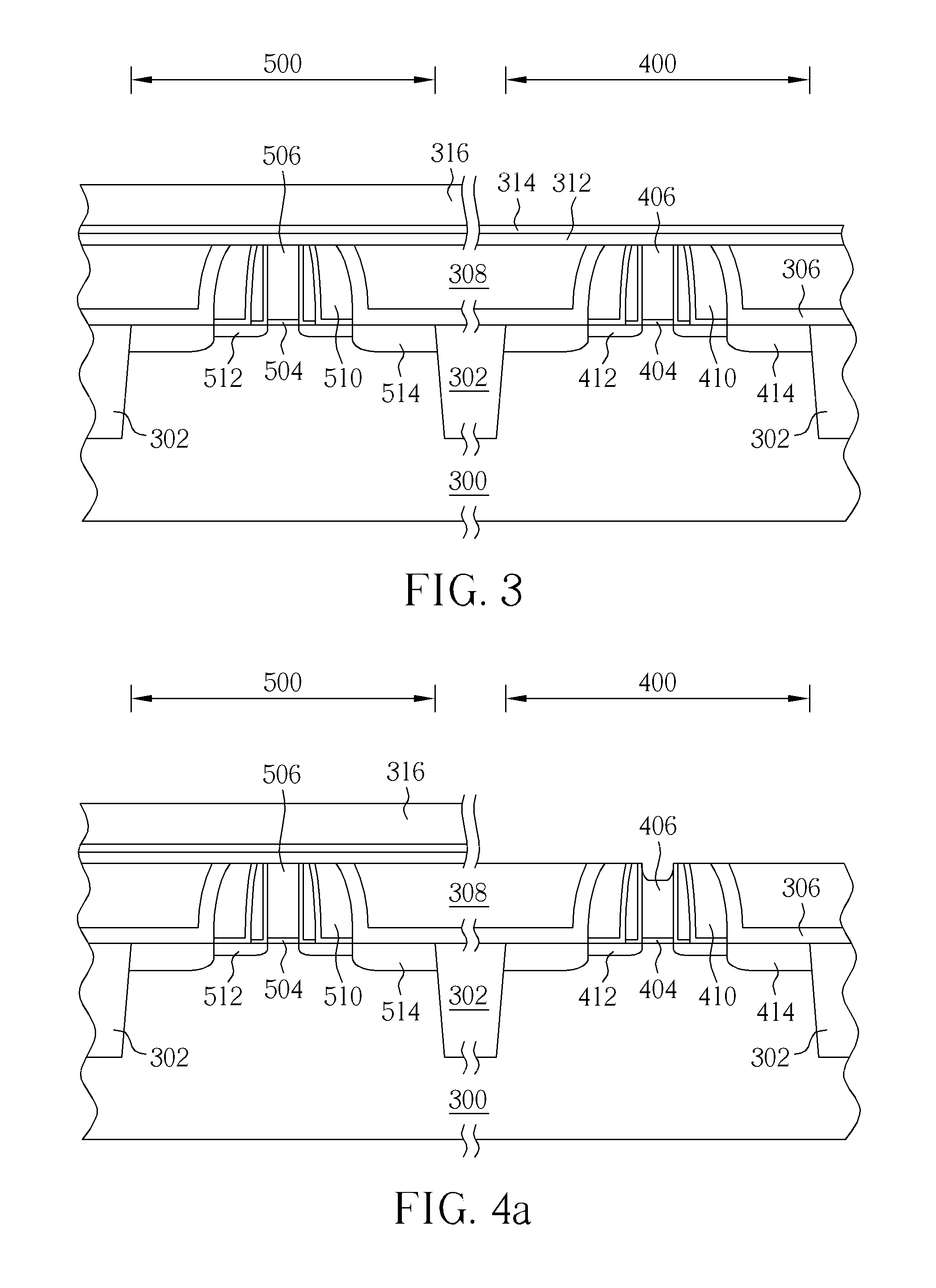

Method of Manufacturing Semiconductor Device Having Metal Gate

ActiveUS20120220113A1Reliable cmp processRaise reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorMaterials science

The present invention provides a method of manufacturing semiconductor device having metal gate. First, a substrate is provided. A first conductive type transistor having a first sacrifice gate and a second conductive type transistor having a second sacrifice gate are disposed on the substrate. The first sacrifice gate is removed to form a first trench and then a first metal layer and a first material layer are formed in the first trench. Next, the first metal layer and the first material layer are flattened. The second sacrifice gate is removed to form a second trench and then a second metal layer and a second material layer are formed in the second trench. Lastly, the second metal layer and the second material layer are flattened.

Owner:UNITED MICROELECTRONICS CORP

Edge grinding machine for arc angle of glass

ActiveCN103170885AAchieve precision grindingSimple structureEdge grinding machinesNumerical controlFlat glass

Owner:CONPROFE TECH GRP CO LTD +1

Developer collecting apparatus and image forming apparatus having the same

ActiveUS20060269305A1Reliably carry-outReliable accommodationElectrographic process apparatusImage formationEngineering

Owner:SHARP KK

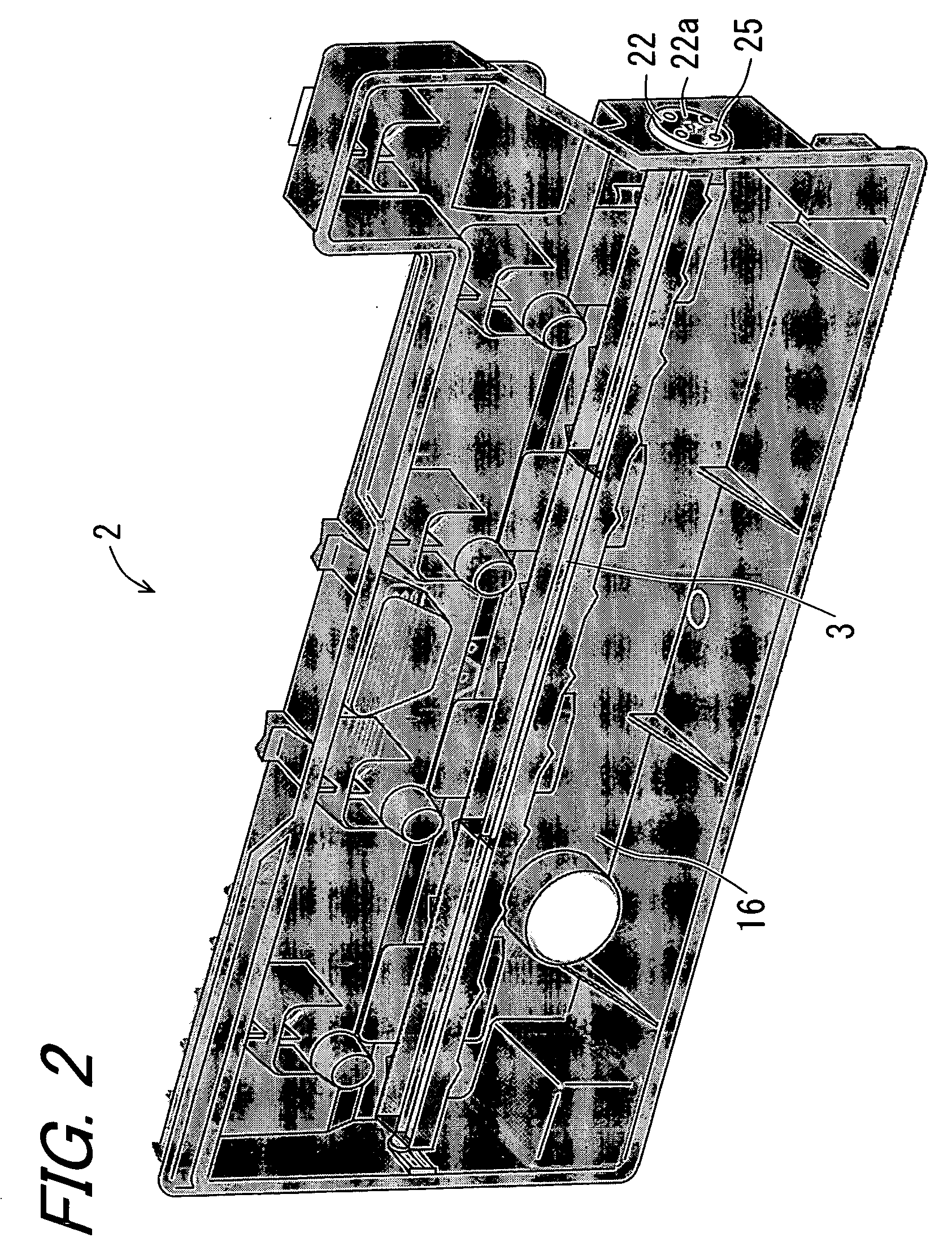

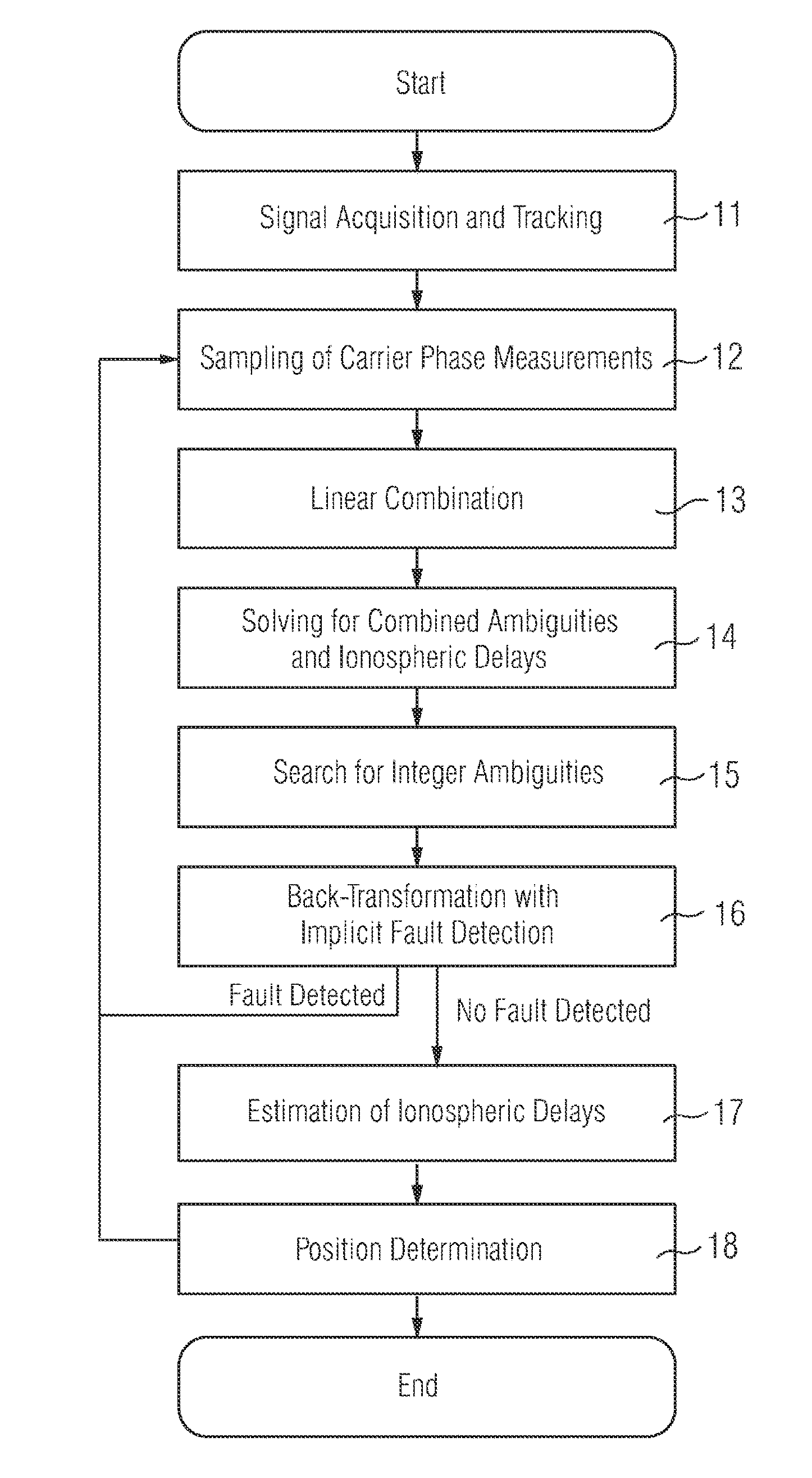

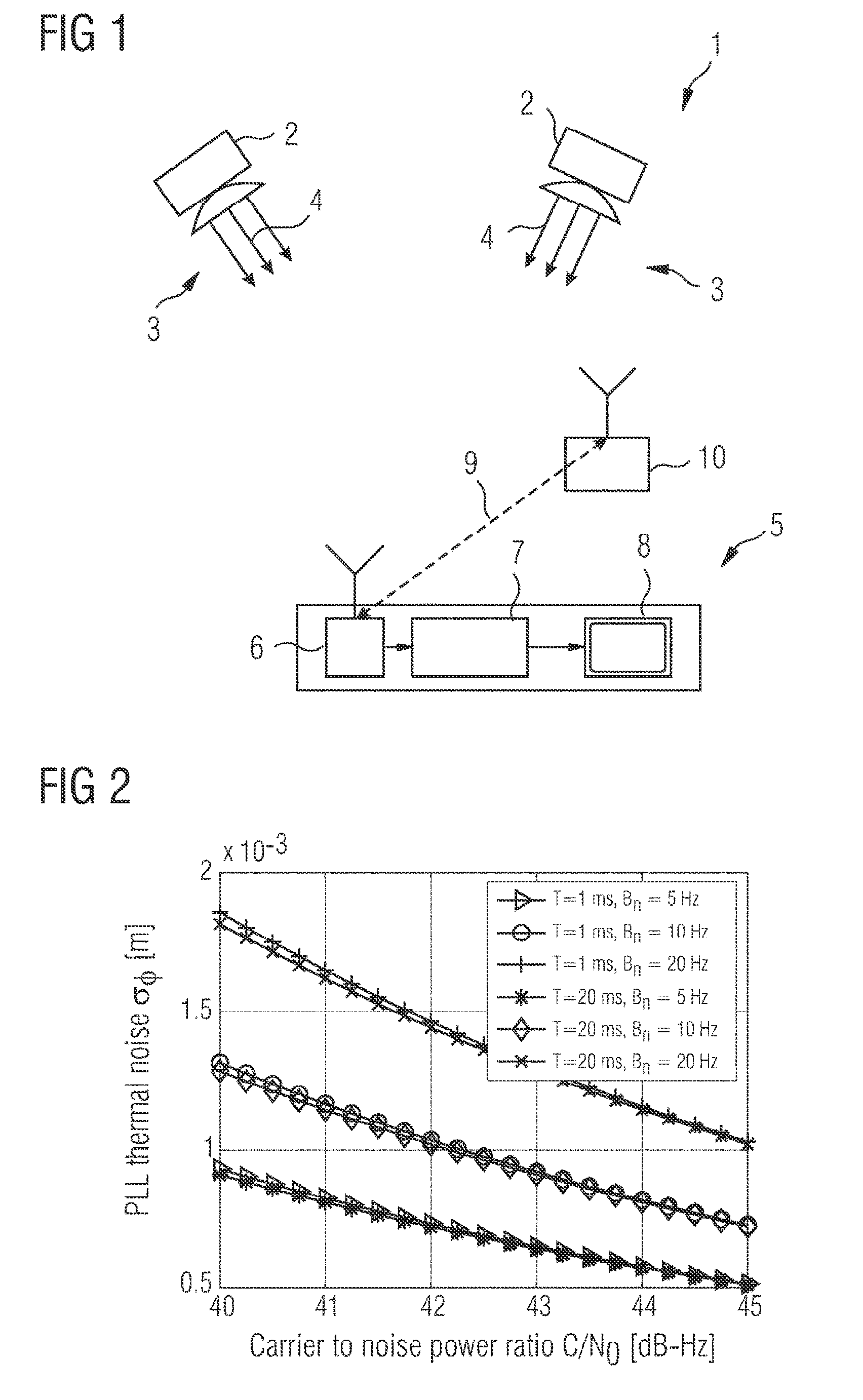

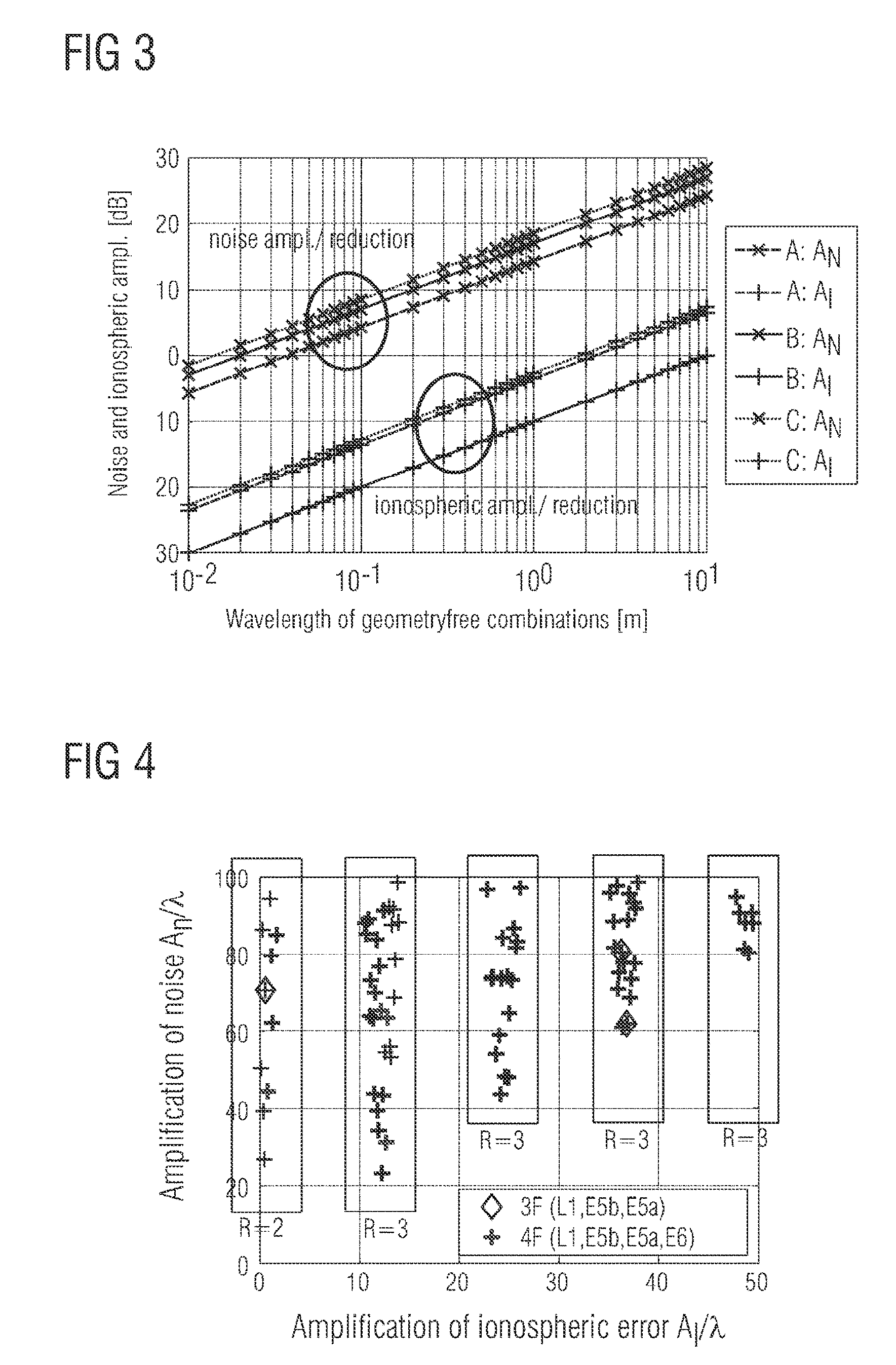

Method for processing a set of signals of a global navigation satellite system with at least three carriers

ActiveUS8094065B2Reduce in quantityReliable processingPosition fixationSatellite radio beaconingWeight coefficientCarrier signal

A method for processing a set of navigation signals of a global navigation satellite system with at least three carrier signals is disclosed in which the processing of the navigation signals is based on a linear combination of the carrier signals to a combined signal. The weighting coefficients are selected such that the combined phase signal is free from geometry and free from frequency-independent disturbance variables.

Owner:DEUTSCHES ZENTRUM FUER LUFT & RAUMFAHRT EV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com