Patents

Literature

440results about How to "Curb churn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ecological protection method for high steep side slope

The invention relates to an ecological protection method for a high steep side slope. The method mainly comprises the steps of slope surface treatment, concrete shotcrete and rock bolt support, vegetating hole arrangement, net spreading, spray material preparation, granule spray sowing, maintenance, management, and the like. In the method, guest soil materials such as humus loam rich in organic matters and clay are utilized to undergo a granule reaction after mixed with a granule agent at the moment of spray sowing so as to form a greening template which has the same high order granule structure as natural soil and strong erosion resistance and can suppress water and soil loss. After a diversified mature plant community which is in harmony with surrounding vegetation environment is formed, the slope surface can be protected, which can effectively resist diseases and insect pests and maintain the ecological balance. Post maintenance management and expenses can be saved. All used materials can be naturally degraded, have no pollution to the environment and can purify air and beautify the environment. Equipment of the method does not need to be hung on the slope surface for construction, and spray sowing operations are carried out only below the slope surface, thus the method has high construction speed and safety. The method is suitable for slope surfaces which are difficult to green, and the like, such as various high steep and unstable slope surfaces, bare slope surfaces having high greening expected values, and the like.

Owner:河南国网宝泉抽水蓄能有限公司

Poly-gama-glutamic acid building fertilizer

InactiveCN101117303AGood water solubilityImprove water absorptionFertiliser formsFertilizer mixturesDecompositionPoly(gamma-glutamic acid)

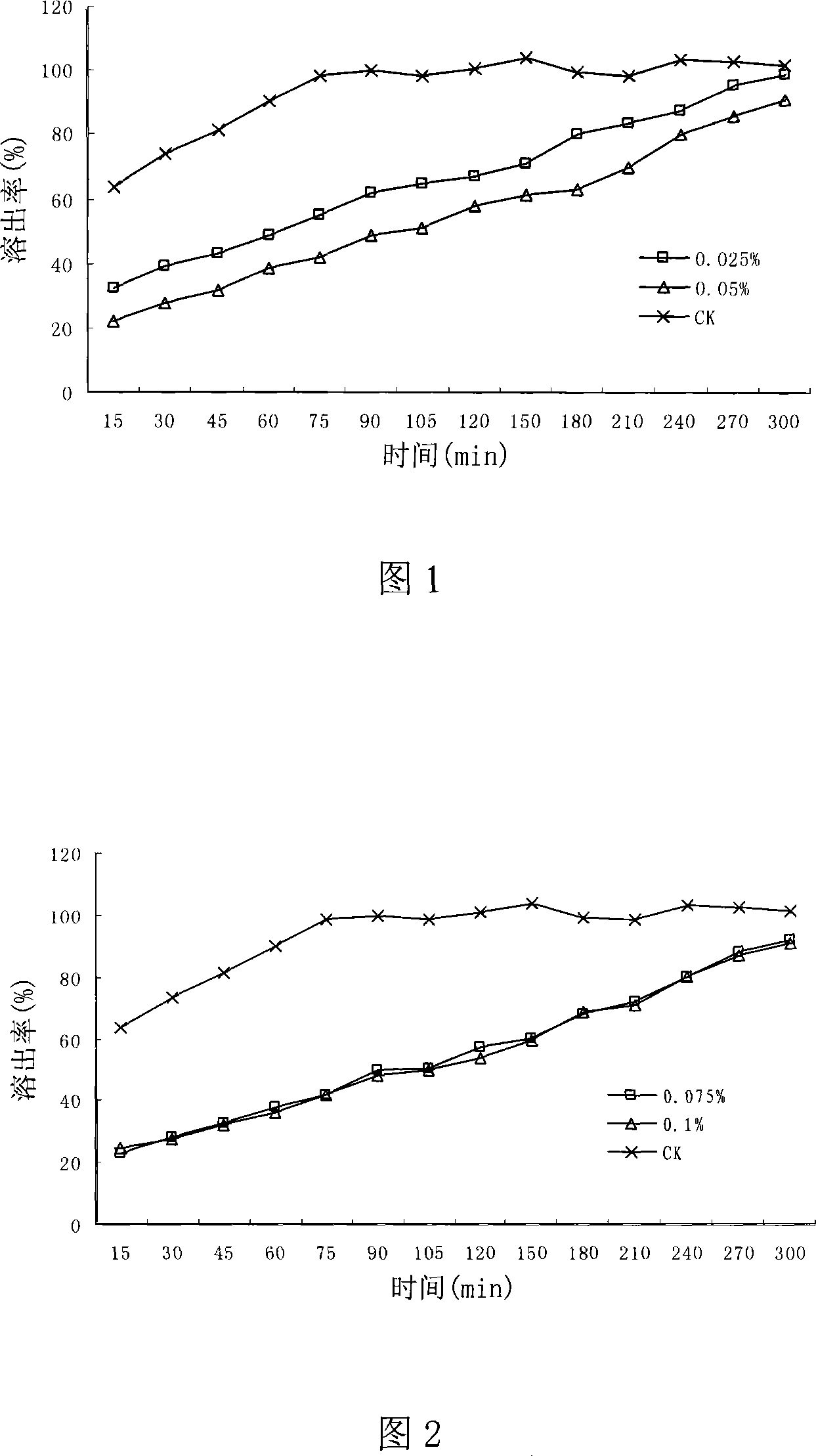

The invention relates to a poly-gamma-glutamic acid synergistic fertilizer for strengthening fertilizer effect, which belongs to the fertilizer field. The invention comprises graininess fertilizer which comprises the poly-gamma-glutamic acid. The contents of the poly-gamma-glutamic acid and fertilizer in weight are as follows: 0.01 to 1 percent of the poly-gamma-glutamic acid and the remained content is fertilizer. The contents of poly-gamma-glutamic acid of the invention are strictly controlled and the poly-gamma-glutamic acid can be conveniently fertilized. The poly-gamma-glutamic acid is combined with to make full use of the feature as absorption promoter of fertilizer of the poly-gamma-glutamic acid, therefore, crops output is further raised. The fertilizer is released slowly and prolonged by around 4 times compared with the traditional fertilizer in soil. The invention promotes crop absorption and inhibits fertilizer ingredient decomposition and loss, therefore, fertilizer use is directly decreased by more than 20 percent. The pollution to environment is reduced without excessive or inappropriate fertilization.

Owner:HUAZHONG AGRI UNIV

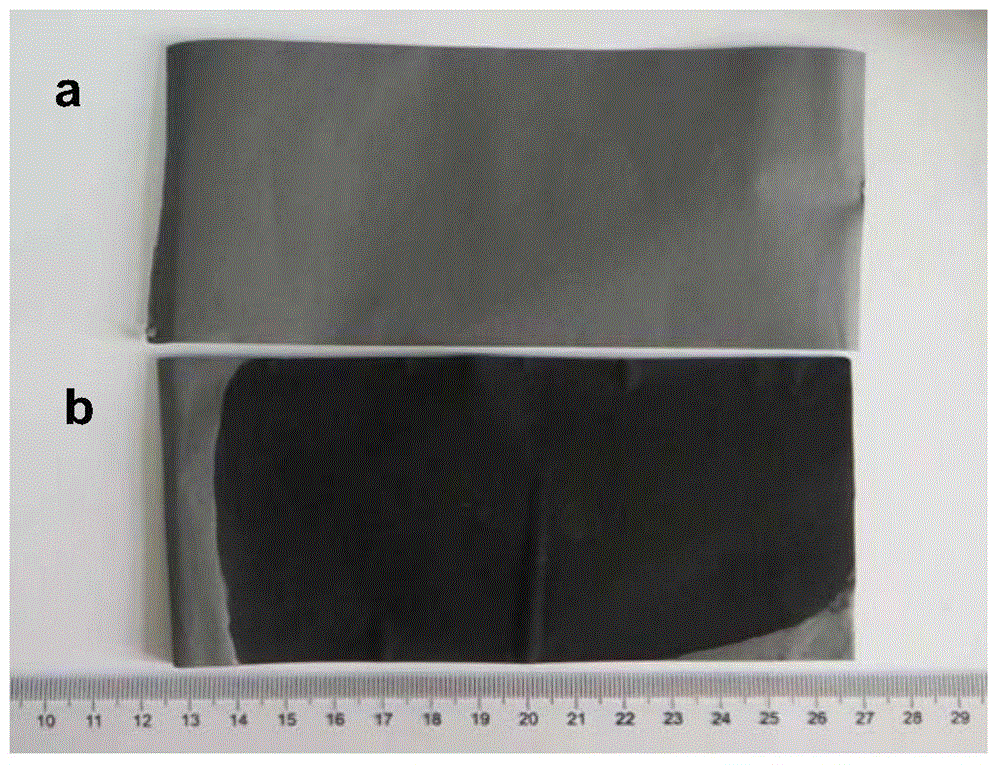

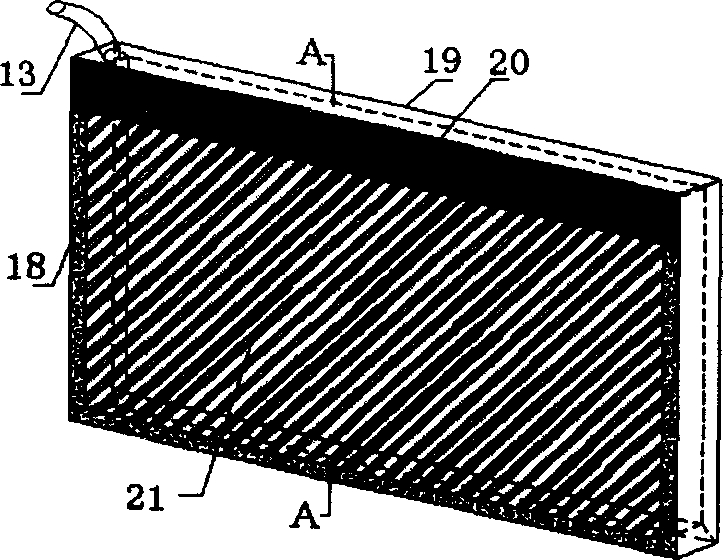

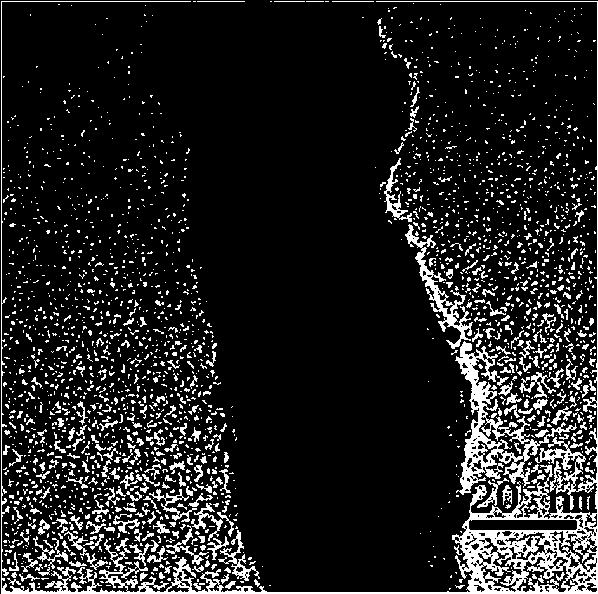

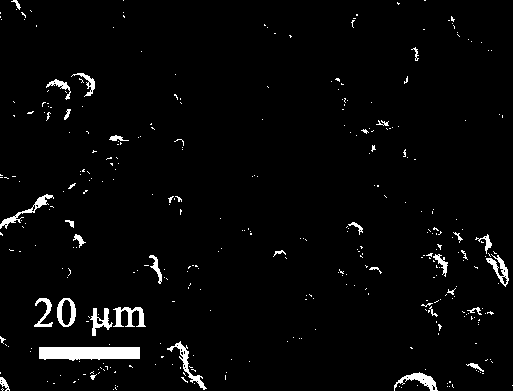

Integrated flexible electrode

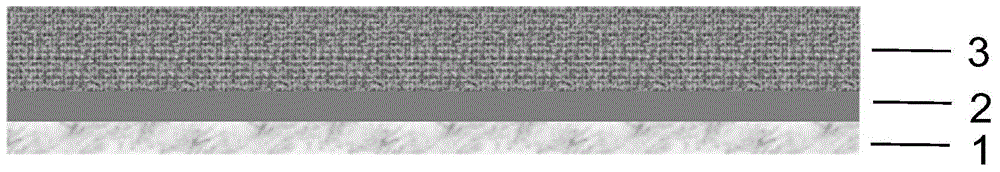

ActiveCN104916809AReduce contact resistanceImprove flexibilityCell seperators/membranes/diaphragms/spacersElectrode carriers/collectorsIntegrated designSlurry

The invention discloses an integrated flexible electrode and belongs to the technical field of electrochemical cells. The integrated flexible electrode is composed of three layers which are successively a polymer layer, a graphene layer and an active material layer. According to the invention, the multi-component integrated design is realized. The graphene layer is formed by dispersing and coating graphene onto the polymer layer. The active material layer is formed by coating slurry onto the graphene layer. After drying, the integrated flexible electrode material is obtained. The integrated flexible electrode material has excellent flexibility and tensile strength and is applicable to flexible cells. A preparation method of the integrated flexible electrode is simple and easy to control, can be applied to various electrode materials and has potential application value. Mass and low-cost preparation can be realized.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

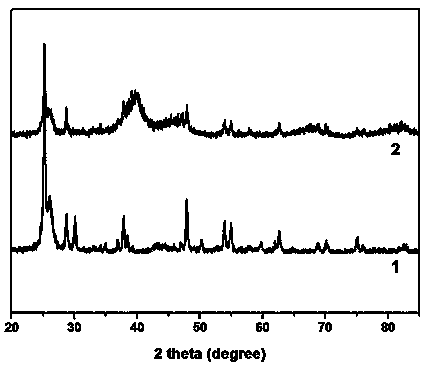

Rare-earth enrichment recovery method from phosphorite

ActiveCN101451200ACurb churnGood crystal formProcess efficiency improvementRare-earth elementRecovery method

The invention discloses a method for enriching and recovering rare earth from phosphorite, which drives a large quantity of rare earth elements to be enriched into a phosphate system and be separated and recovered by inhibiting loss of the rare earth in phosphogypsum through optimizing the technological conditions and adding a calcium sulphate crystal seed and / or an active additive on the premise of not changing the wet-method phosphate process. Compared with the prior art, the method controls proper technological conditions and particularly adds the calcium sulphate crystal seed and / or the active additive, can improve the crystalline morphology of the phosphogypsum, reduce the eutectic effect and the adsorption effect of phosphate rare earth and calcium sulphate, reduce enrichment of the phosphate rare earth and the calcium sulphate to the phosphogypsum, make the enrichment ratio of the rare earth in phosphate reach more than 80 percent, and be favorable for recovering the rare earth from the phosphate. Moreover, the method can meet the requirements of wet-method phosphate production, has simple technique and high content of rare earth in the phosphate, and can adopt proper technology to recover rare earth from the phosphate and realize effective combination of rare earth recovery technology and phosphorization technology.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

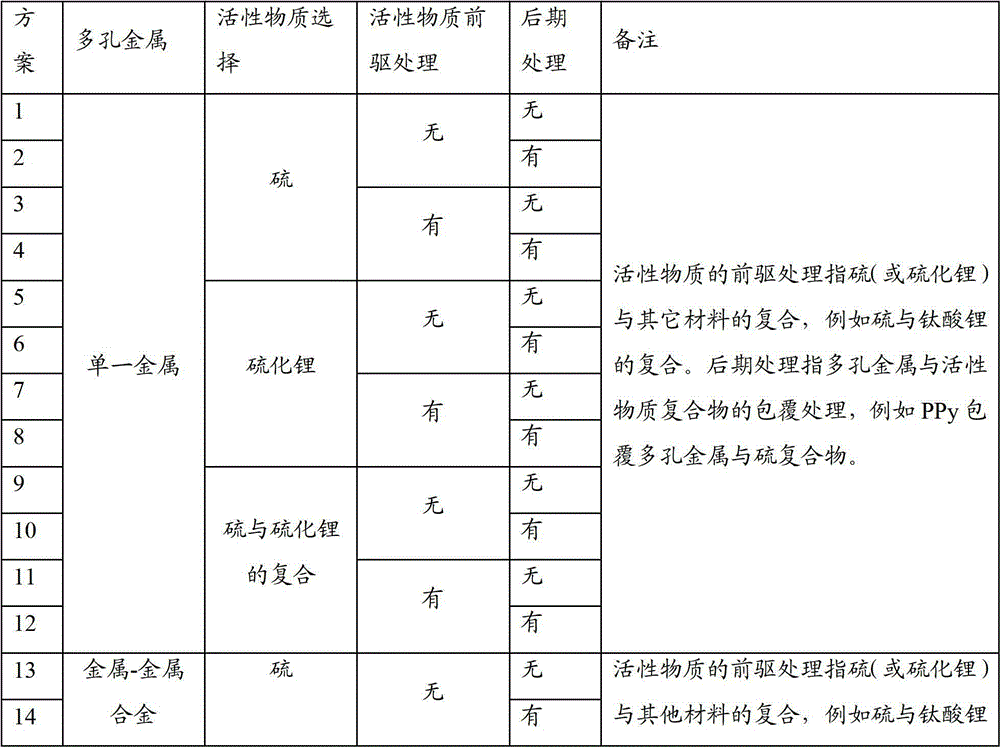

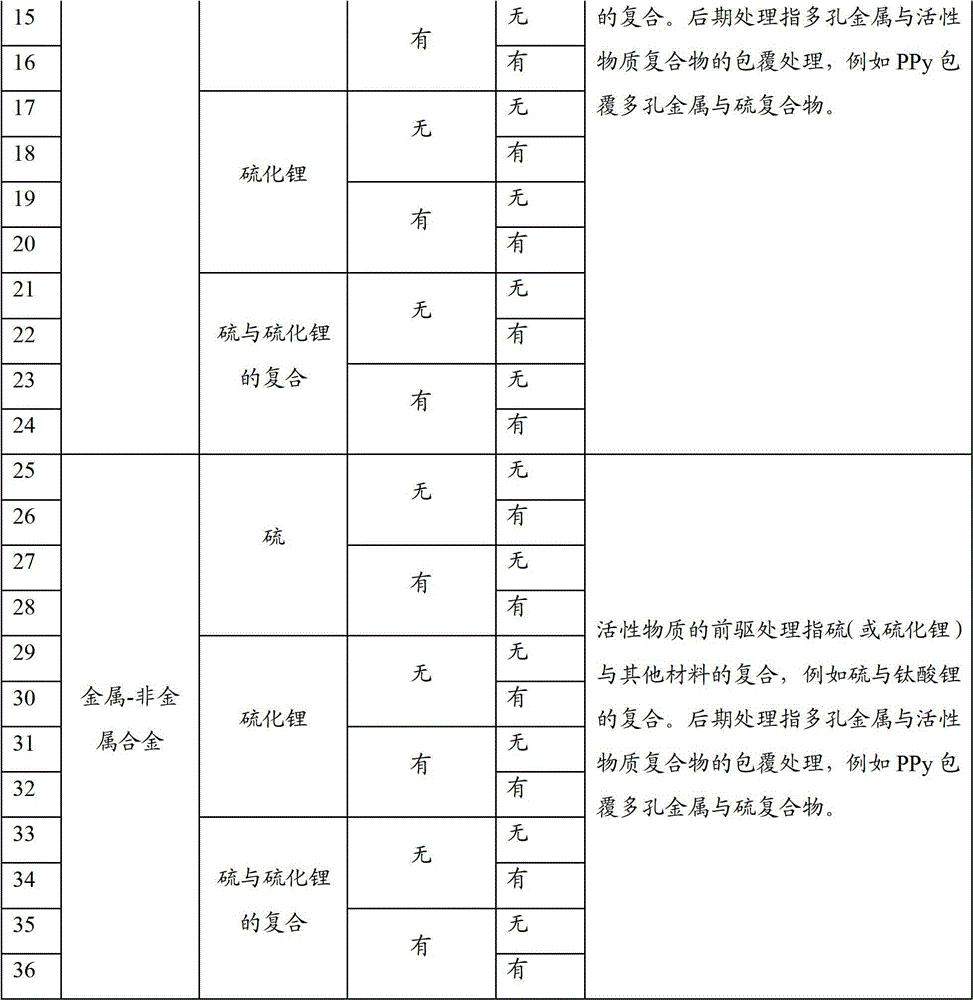

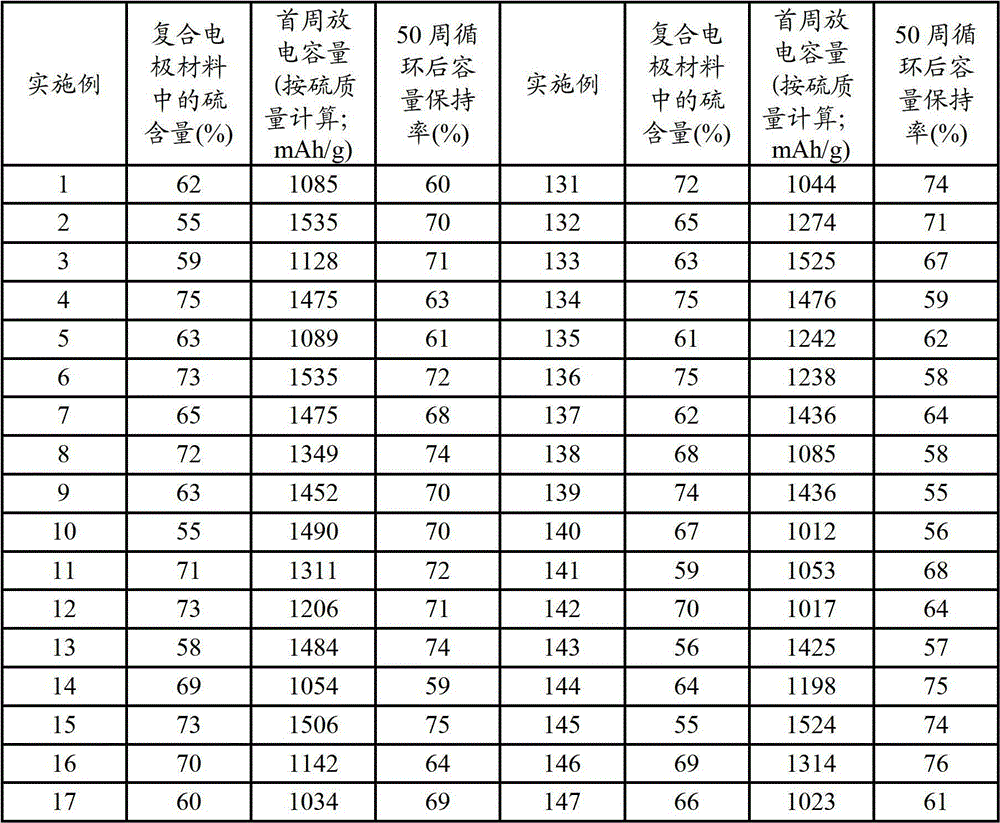

Lithium-sulfur battery anode material comprising porous metal and preparation method thereof

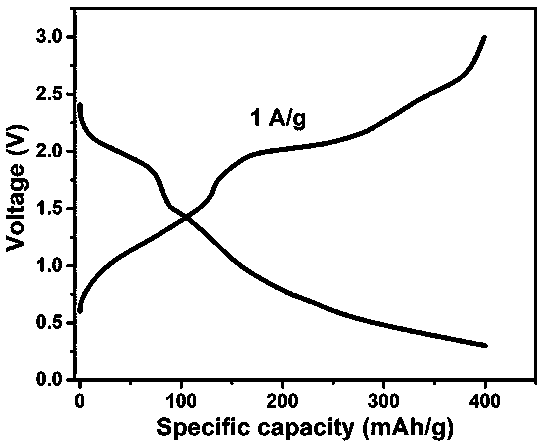

ActiveCN102723470ALarger than surfaceHigh porosityCell electrodesLithium sulfideLithium–sulfur battery

The invention discloses lithium-sulfur battery anode material comprising porous metal. The porous metal is compounded with lithium sulfide so as to be used as the anode material of the lithium-sulfur battery. The invention also discloses a preparation method of the lithium-sulfur battery anode material comprising the porous metal. According to the invention, by utilizing the characteristics of high electric conductivity, high porosity, high specific surface area and the like of the porous metal, elemental sulfur or the lithium sulfide is filled into pores of the porous metal, metal / sulfur composite material can be manufactured, and the utilization rate of the elemental sulfur and the lithium sulfide and the multiplying performance of the composite electrode can be increased; and simultaneously, by utilizing the strong interaction between the porous metal and the elemental sulfur or the lithium sulfide, the elemental sulfur, the lithium sulfide or polysulfide generated in a charge-discharge process can be more firmly attached on the surface of the porous metal, the dissolution of the polysulfide in an electrolyte, the shuttle effect caused by the dissolution of the polysulfide in the electrolyte and the deactivation on an anode and a cathode by redox product of the polysulfide can be restrained, and the circulation stability of a metal / sulfur composite electrode and the lithium-sulfur battery can be increased.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

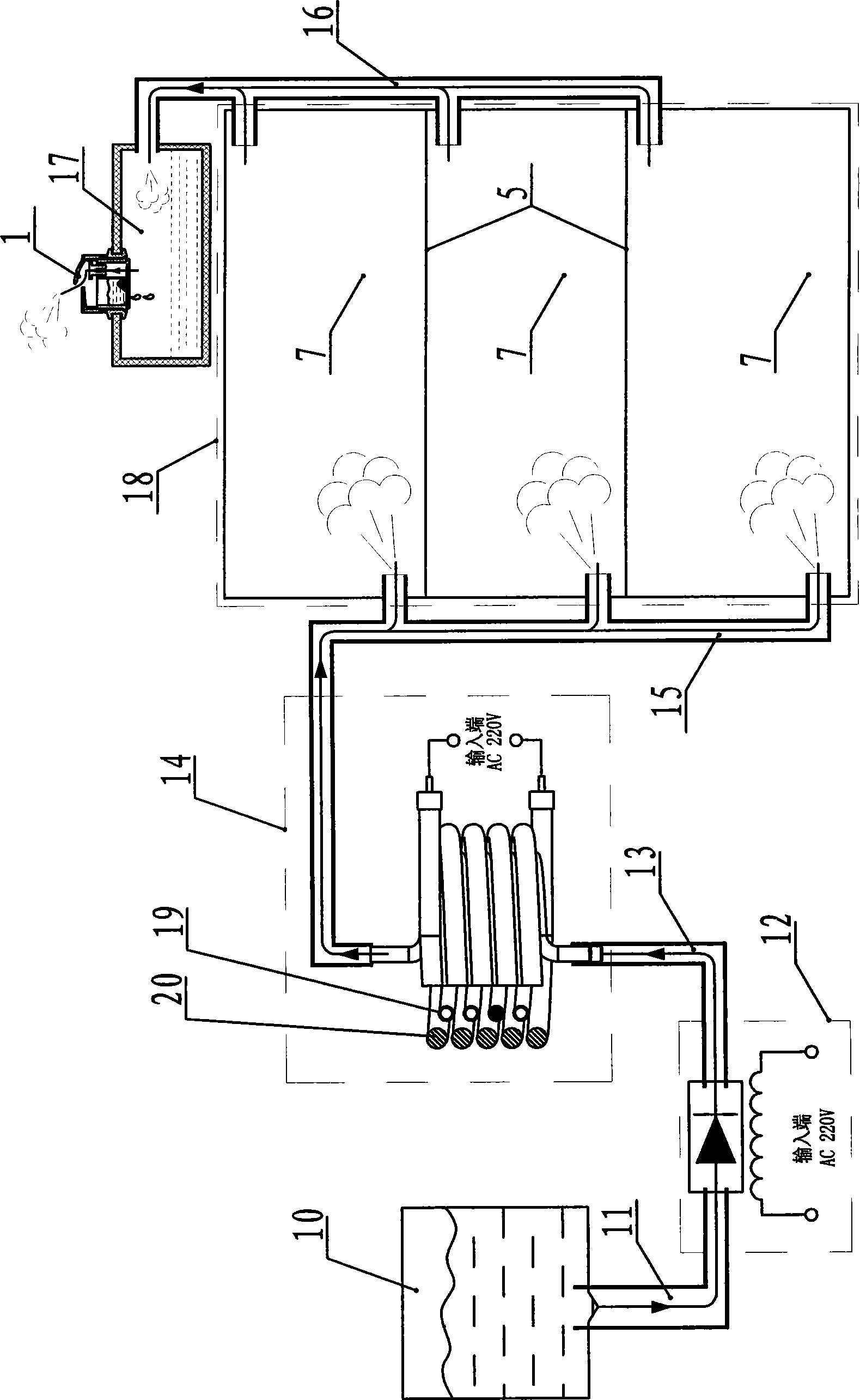

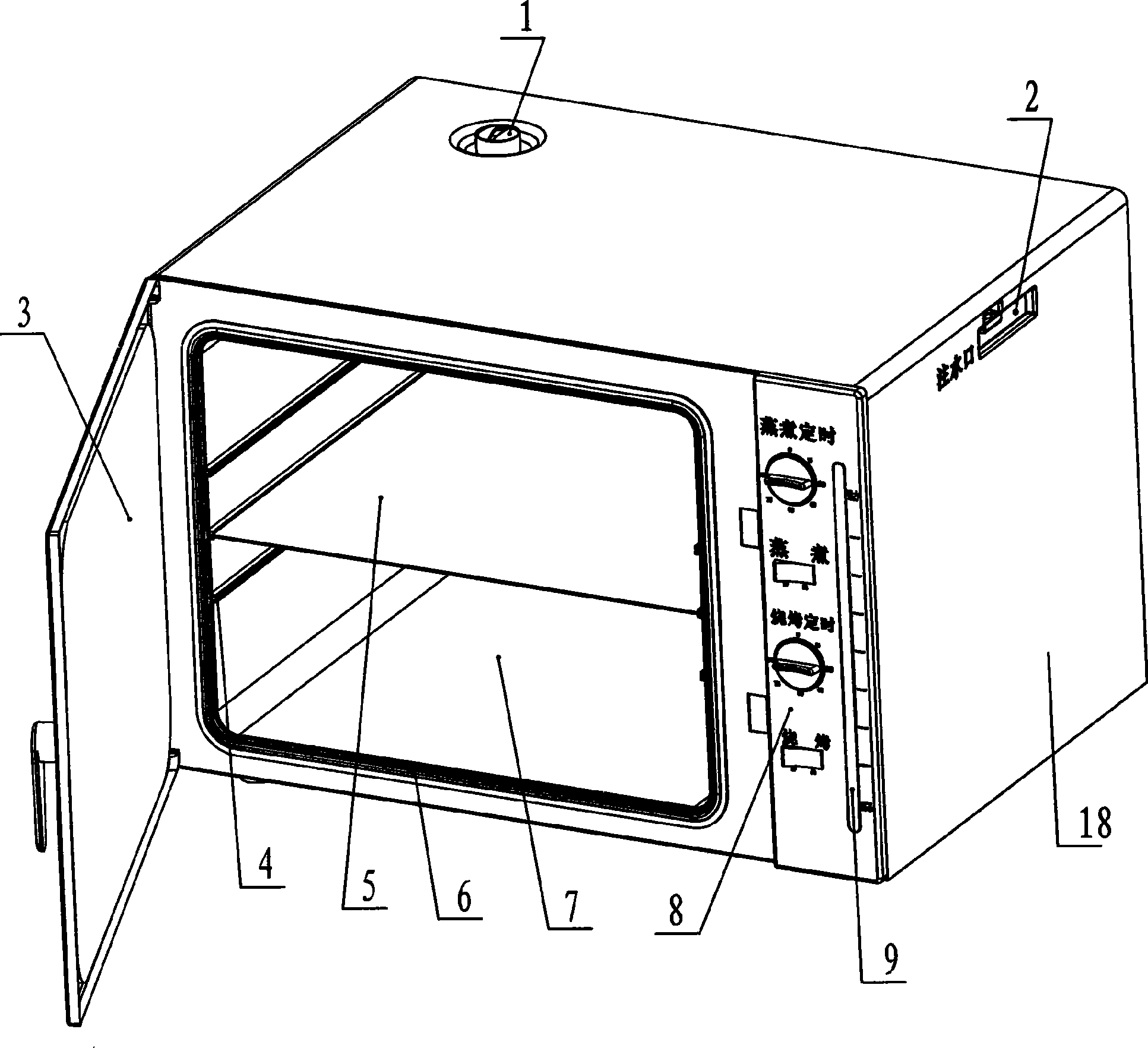

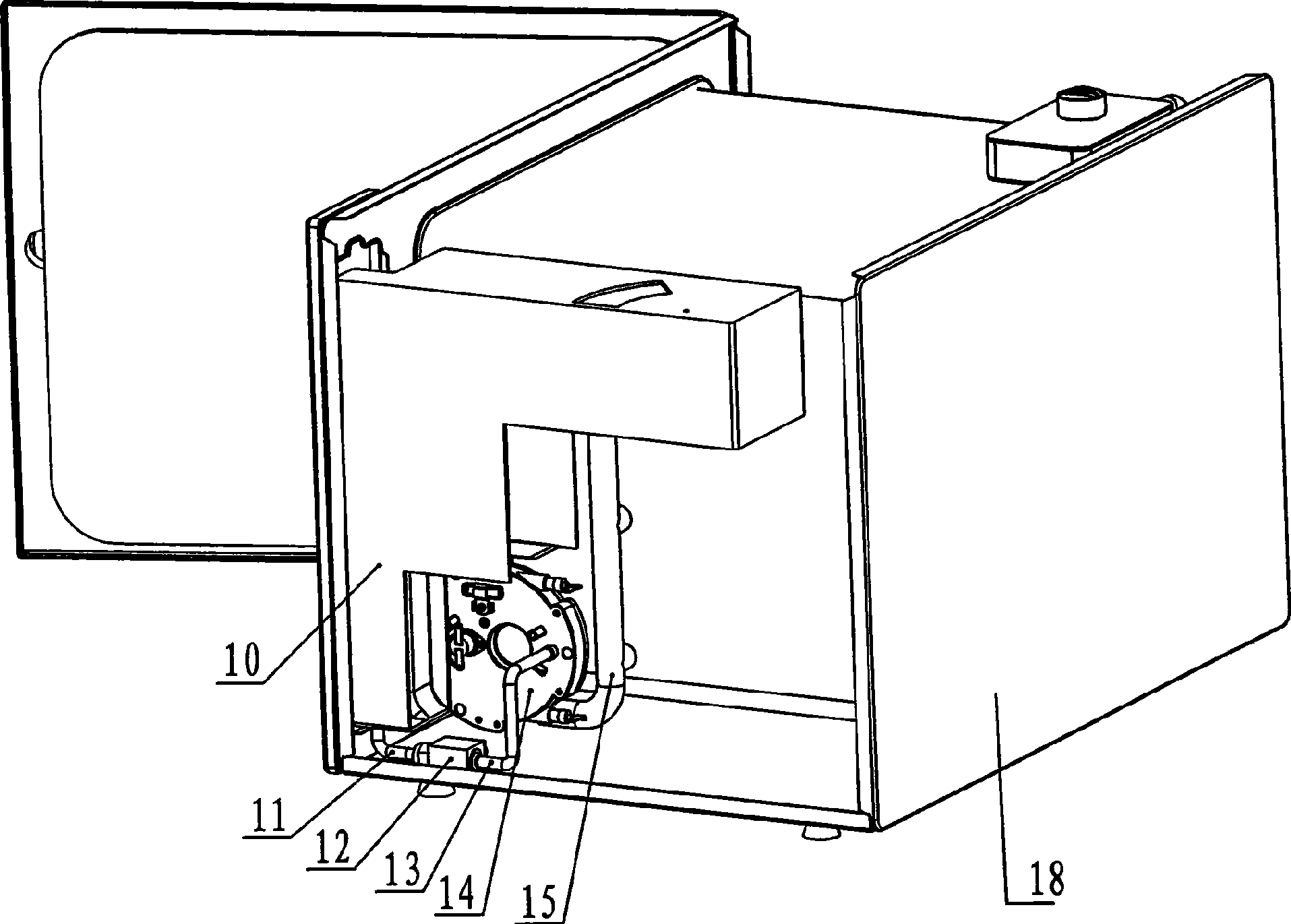

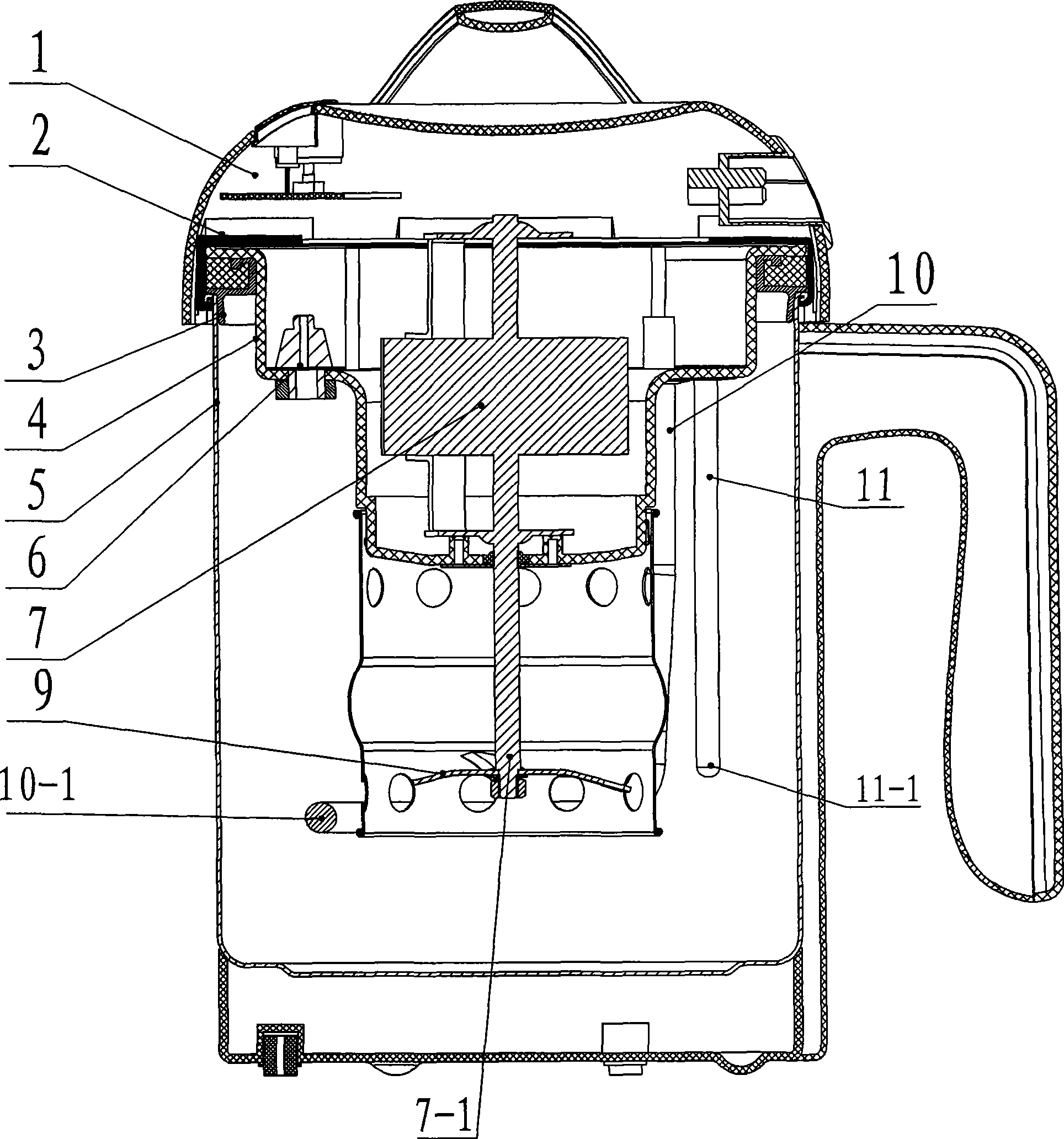

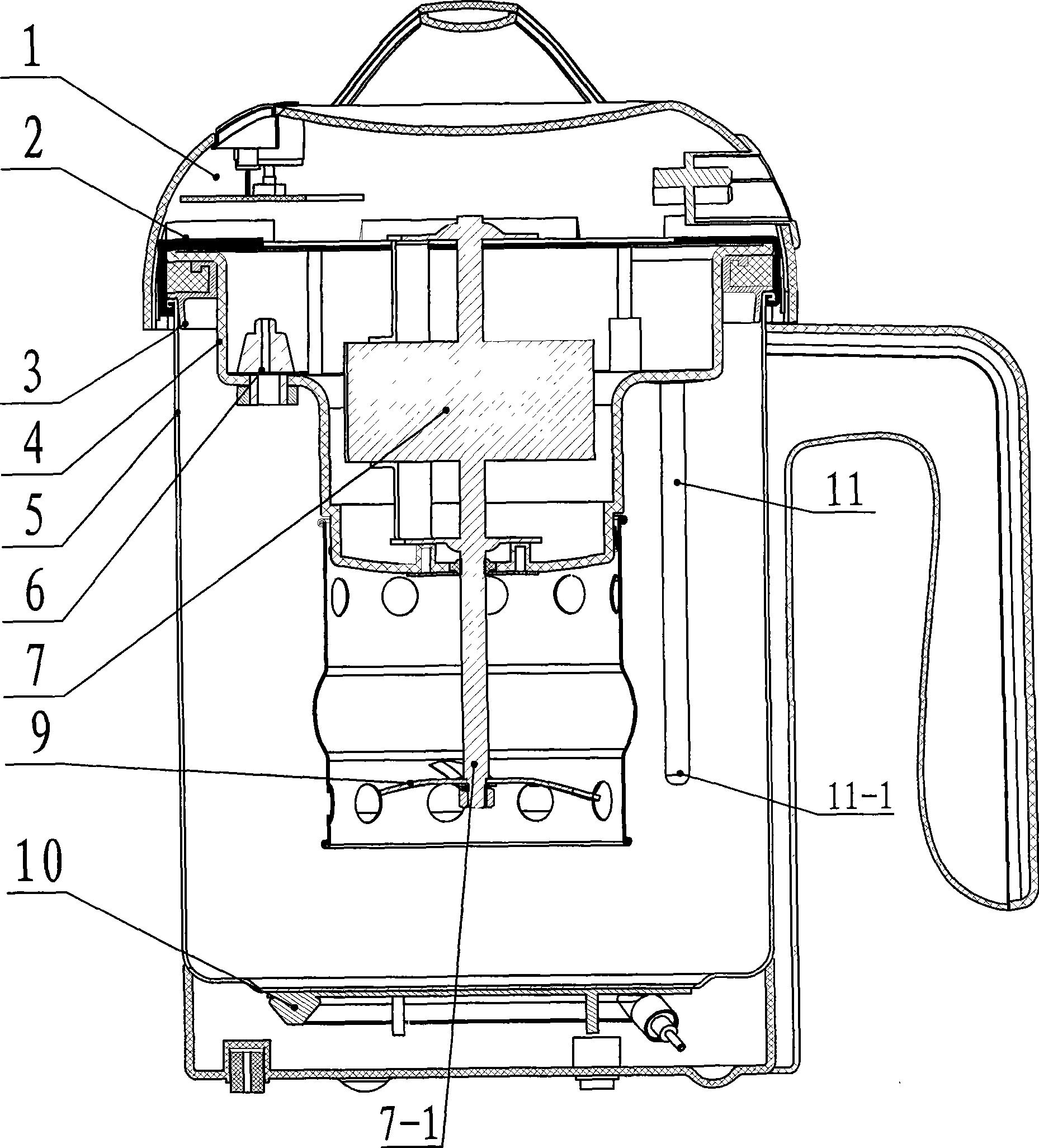

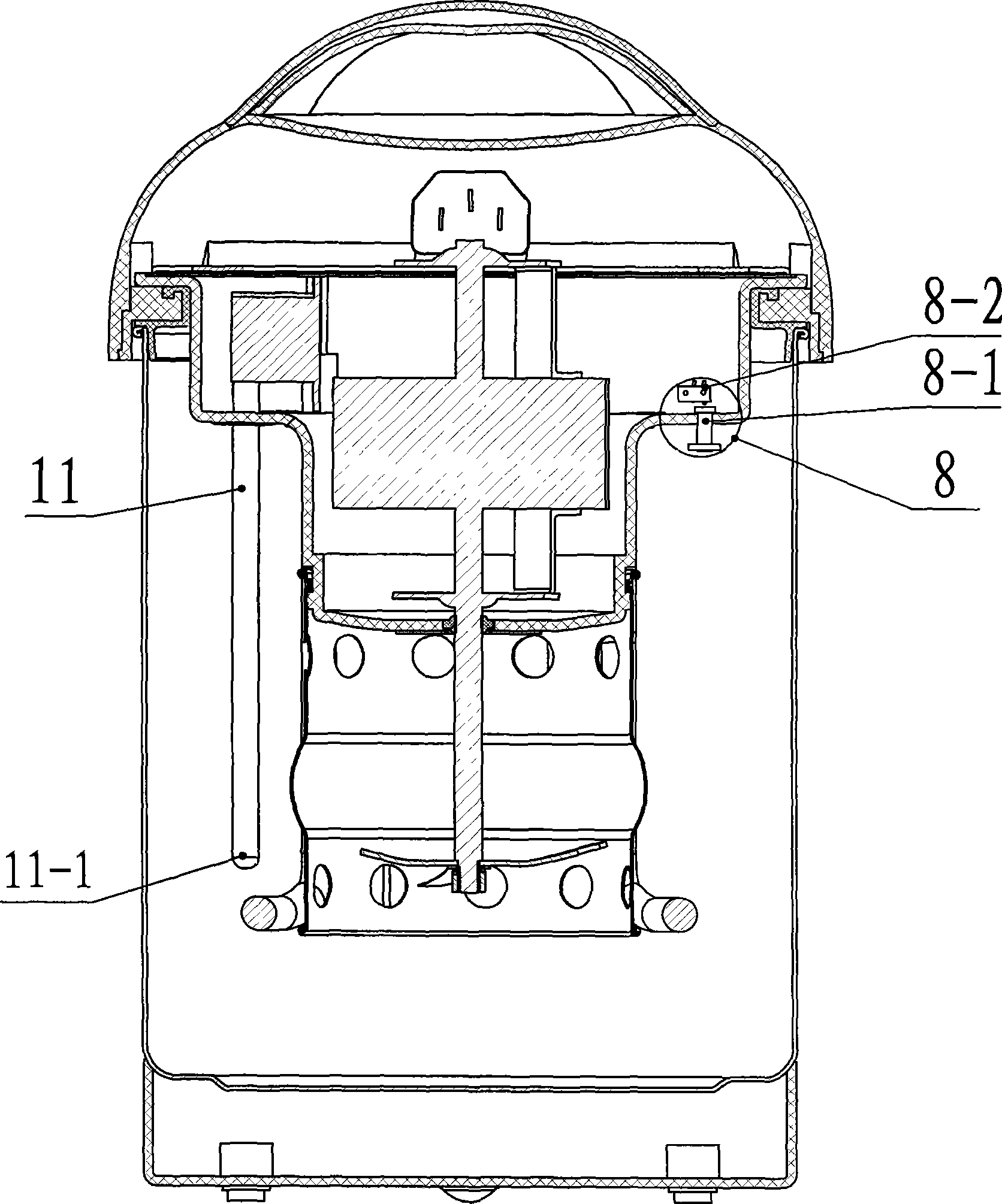

Domestic multifunctional high-temperature electric steaming box

ActiveCN101390706AImplement layered inputSolve the odorMultiple-unit cooking vesselsSteam cookingEngineering

Disclosed is a household multifunctional high-temperature electric steam cooking cabinet, comprising an electric steam cooking cabinet body. The interior of the cooking cabinet body is divided into at least two steam compartments by steam shelves. A steam intake pipe is arranged at the bottom of each steam compartment, and the steam intake pipe is connected with a steam generator. A steam output pipe is arranged at the upper part of each steam compartment and is connected with a juice receiving box which is provided with a micro-pressure valve. The electric steam cooking cabinet is divided into at least two steam compartments by steam shelves, steam is inputted separately in different layers, and food is heated in different steam compartments, thus effectively solving the problem that the flavors of the food mix with one another. Meanwhile, the steam generator can generate high-temperature steam with temperature of 120 DEG C, which can rightly lockup the nutrition and water of the food, thus effectively degrading superabundant fat and salt in the food, restricting the loss of the nutrition of the food, and preventing oxidation and flavor reversion of the food. Therefore, the electric steam cooking cabinet can keep the food at original taste and flavor.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

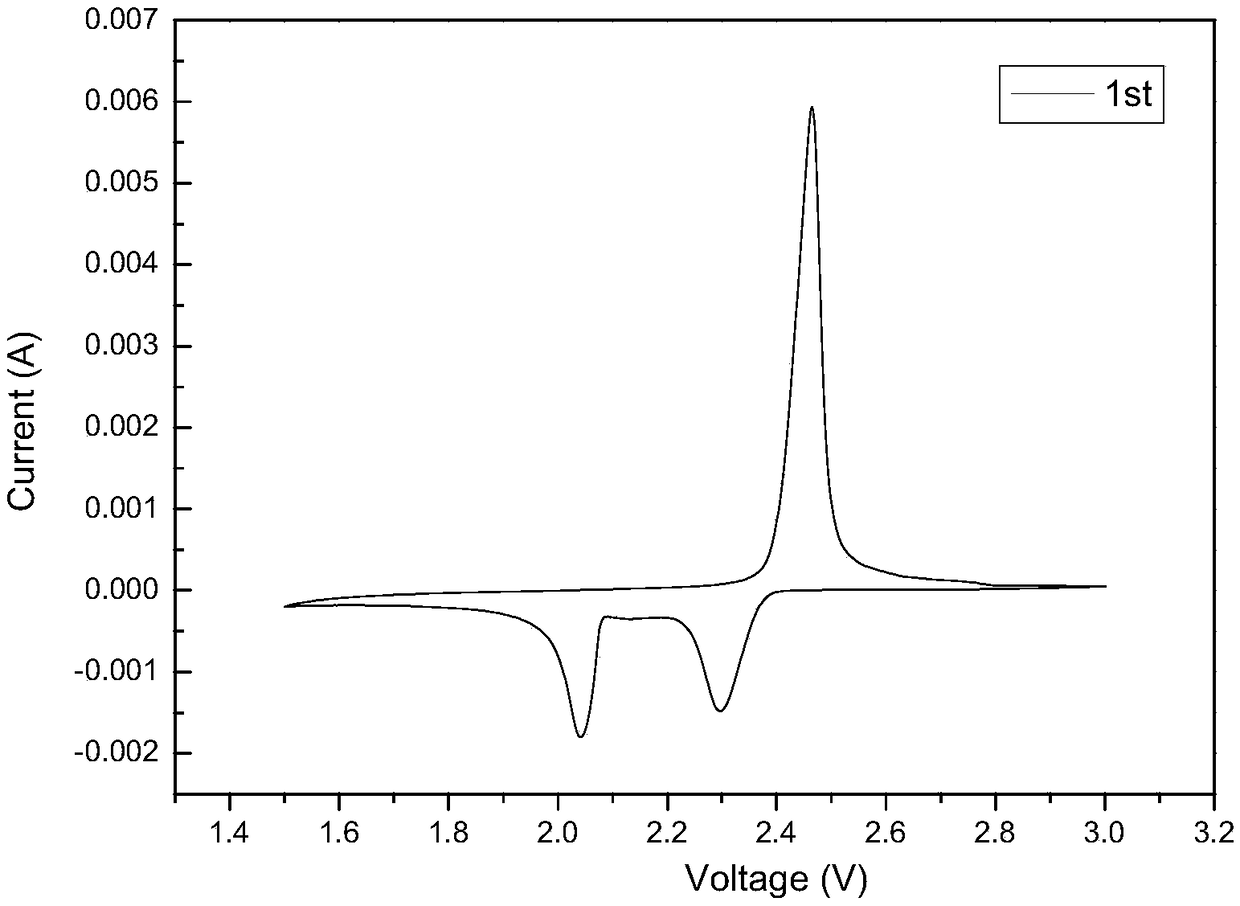

Sulphidepolymer coated sulfur / carbon composite material and preparation method thereof

InactiveCN104241612AIncrease specific volumeImprove cycle stabilityCell electrodesLi-accumulatorsCarbon compositesHigh rate

A sulfide polymer coated sulfur / carbon composite material and a preparation method thereof. The composite material includes composite containing carbon with high surface area and sulfur and a sulfide polymer cladding layer. The preparation method is as below: conducting ball-milling on sulfur and carbon with high surface area in a ball mill and conducting heat treatment on the product under protective atmosphere; dispersing the product in a solution containing polymer monomers and adding a initiator to initiate polymerization; filtering, washing and drying; and conducting heat treatment on the product under protective atmosphere, so as to obtain the sulfide polymer coated sulfur / carbon composite material. The composite material provided by the invention as an anode material for lithium sulfur battery has the following advantages: high surface area carbon material can improve the electronic conductivity of sulfur, and inhibit polysulfide erosion; the sulfide polymer coating layer not only inhibits the loss of polysulfide but also provides part of the capacity. Lithium sulfur battery composed of the composite material has the advantages of high specific capacity, long service life, high rate capability, simple preparation and low cost, and has good application prospect.

Owner:中科派思储能技术有限公司

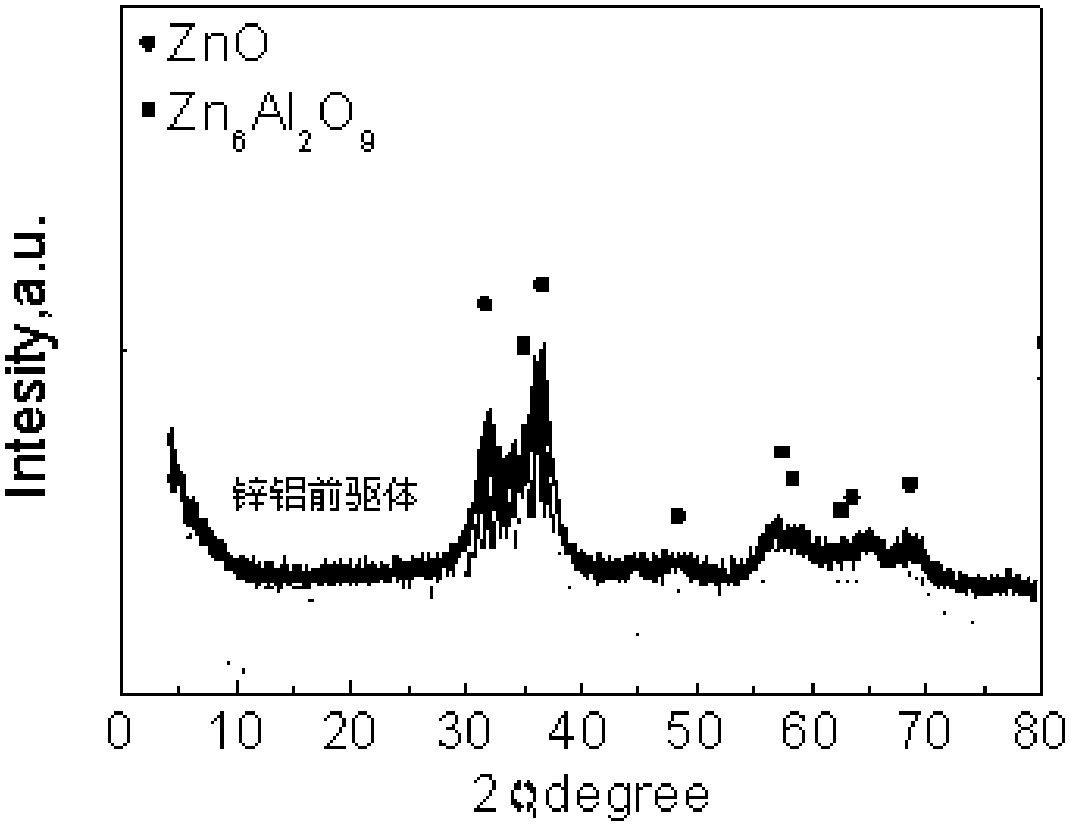

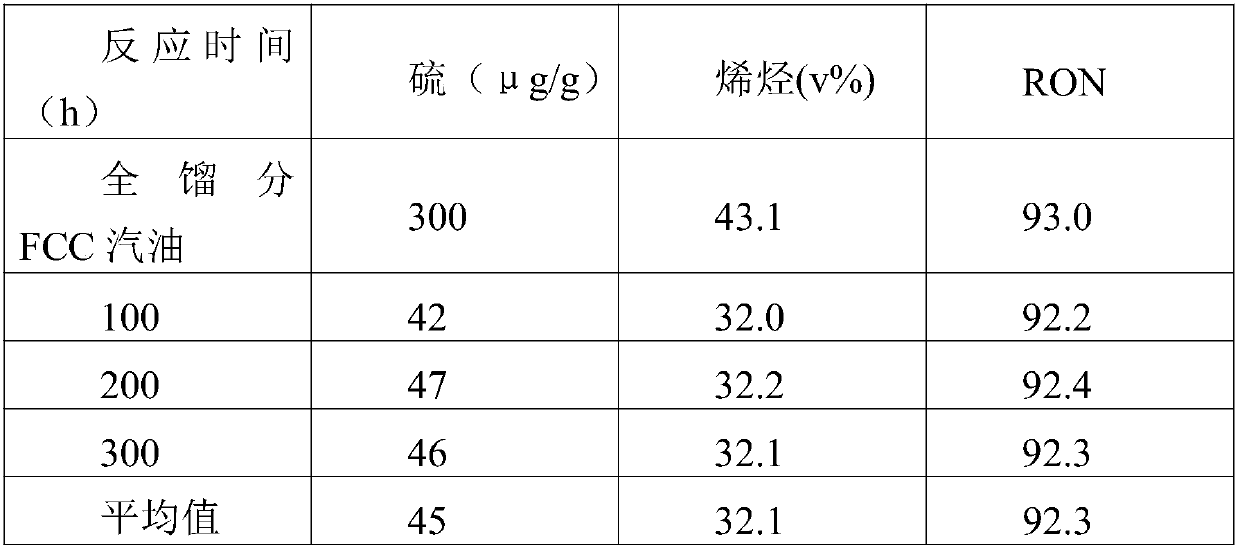

Selective hydrodesulfurization catalyst and preparation method thereof

ActiveCN107583659AReduced hydrothermal treatment processHigh desulfurization activityPhysical/chemical process catalystsRefining to eliminate hetero atomsChemistryComposite oxide

The invention relates to a selective hydrodesulfurization catalyst. The catalyst comprises, by mass, 3-5% of CoO as an active component, 10-13% of MoO3 as an active component, 2-3% of B203 as a carrier modification aid, 1-2% of P2O5 as a carrier modification aid, 1-1.5% of K2O as a carrier modification aid and 75.5-83% of a composite oxide carrier. The catalyst carriers comprise a zinc aluminate spinel-containing zinc oxide-alumina composite oxide prepared by nonconstant pH alternating titration. The catalyst has good desulfurization selectivity and stability.

Owner:PETROCHINA CO LTD

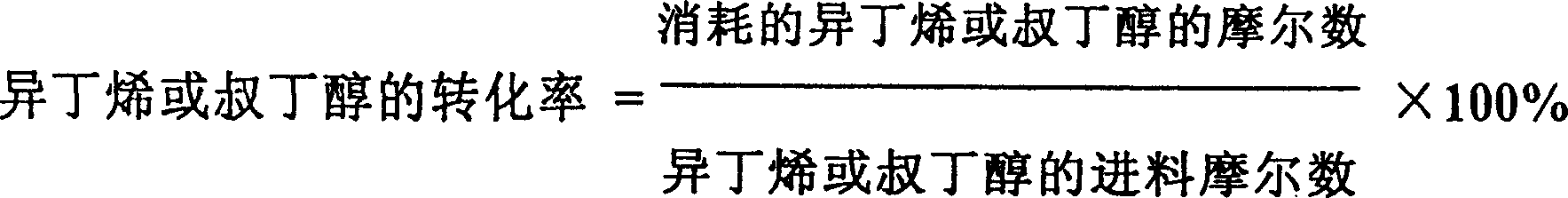

Catalyst for selectively oxidizing tertiary butanol or isobutene to synthesize methyl acrylic aldehyde and its use

ActiveCN1647853AHigh activityImprove thermal conductivityPhysical/chemical process catalystsOrganic compound preparationGas phaseCatalytic oxidation

The present invention provides a kind of catalyst for selectively oxidizing tertiary butanol or isobutene to synthesize methyl acrolein and its preparation process and application in gas phase catalytic oxidizing synthesis of methyl acrolein. The catalyst of the present invention is one kind of composite oxide containing Mo, Bi, Fe, Co, Sb, Pb, Yb, etc. and has high catalytic activity and stability, long service life, isobutene converting rate higher than 95 % and methyl acrolein selectivity over 86 % in the presence of molecular oxygen.

Owner:SHANGHAI HUAYI NEW MATERIAL

Negative pressure water head irrigation system

InactiveCN1788542ACurb churnIncrease production capacityWatering devicesCultivating equipmentsLiquid waterEngineering

The negative water head irrigation system features the so defined water head irrigation technology, which controls the irrigation pressure in negative water head so as to control the soil water content precisely and continuously. The system includes three parts: a negative water head water providing set, an air collecting chamber and a water providing plate. The negative water head water providing set converts water from the water supply tap at normal pressure into irrigation water in certain negative pressure, the air collecting chamber collects escaped air from the irrigation water during irrigation, and the water providing plate provides water to soil and can form air phase and liquid water favorable to moving of air phase to the air collecting chamber.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

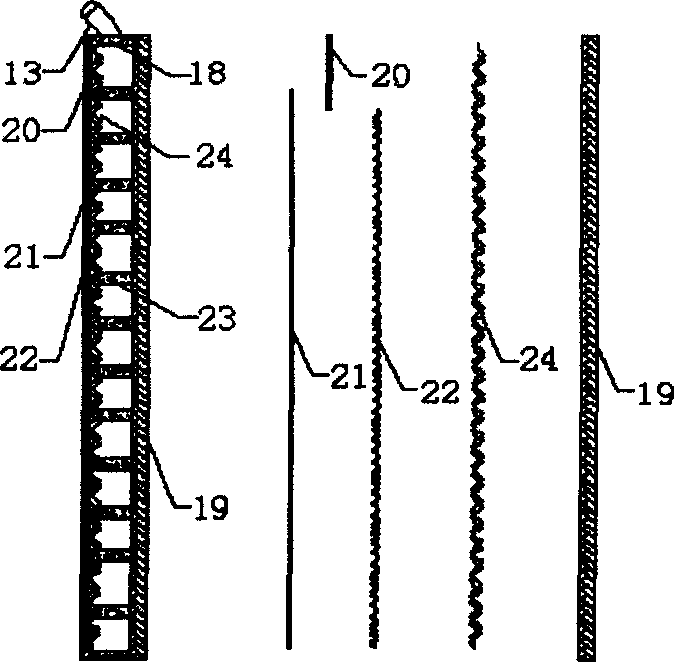

Preparation method of in-situ polymerization solid-state battery

ActiveCN108493486AImprove securityCurb churnFinal product manufactureElectrolyte accumulators manufacturePolymer scienceOrganic solvent

The invention relates to a preparation method of an in-situ polymerization solid-state battery. The preparation method comprises the following steps: step S1, mixing electrolyte salt, an organic solvent, 1-10 percent of acrylic ester and 0.1-1 percent of an initiating agent AIBN to prepare a mixture I, wherein the acrylic ester is one of or more of isopentyl tetraacrylate, pentaerythritol triacrylate and allyl hydroxyethyl ether; step 2, weighing an active substance, acetylene black and positive pole piece made by PVDF according to the mass ratio of 6:3:1, taking a lithium sheet as a negativeelectrode, taking the mixture I as an electrolyte and taking a polypropylene thin film as a diaphragm assembly battery; step S3, putting the battery in a drying box and maintaining for 1-30 minutes after the battery is heated to 40-80 DEG C. The preparation method provided by the invention has the benefit that by adopting an in-situ heat curing technology, the interface problem between the electrolyte and a battery anode and cathode can be better solved.

Owner:武汉新能源研究院有限公司

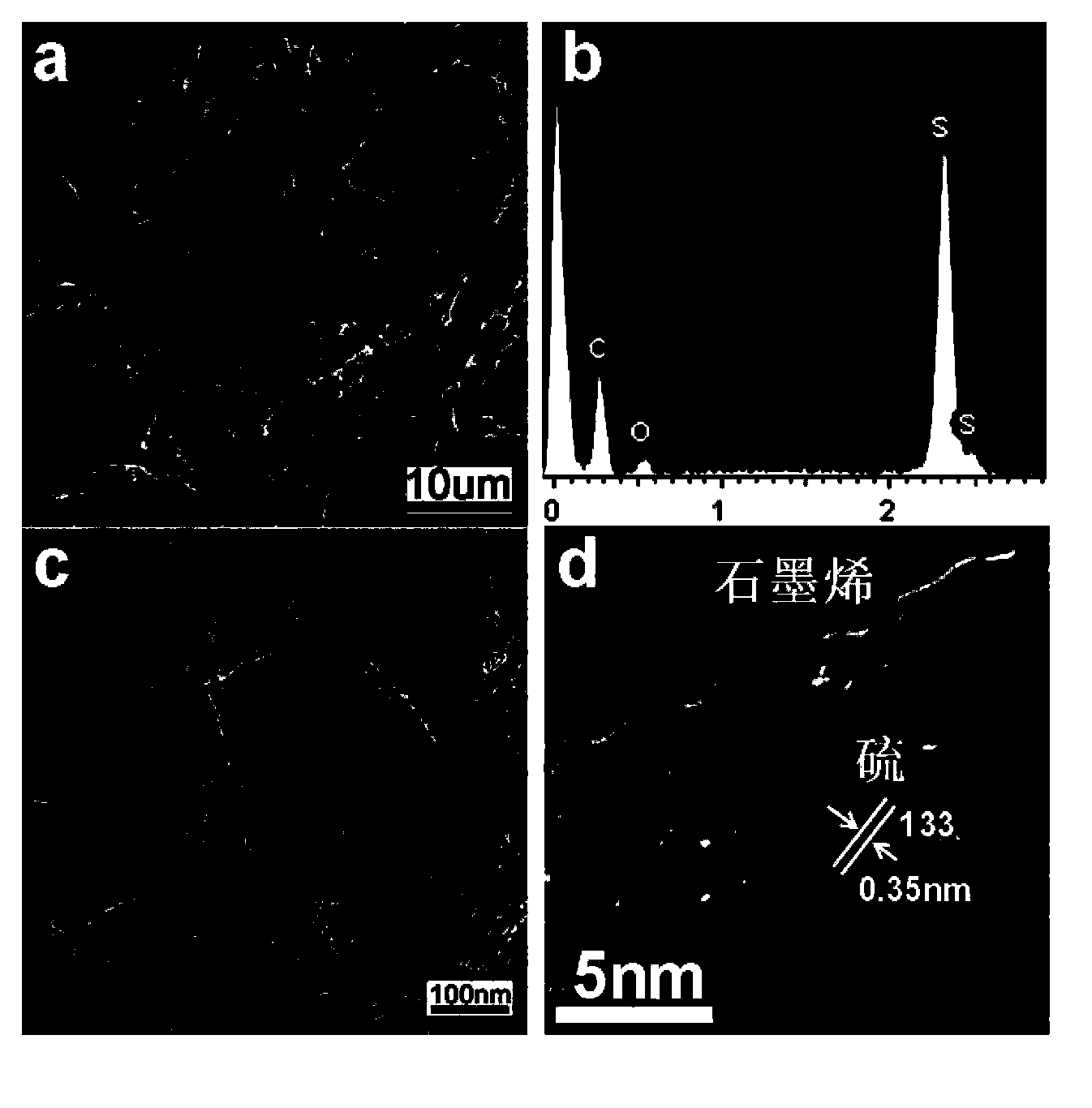

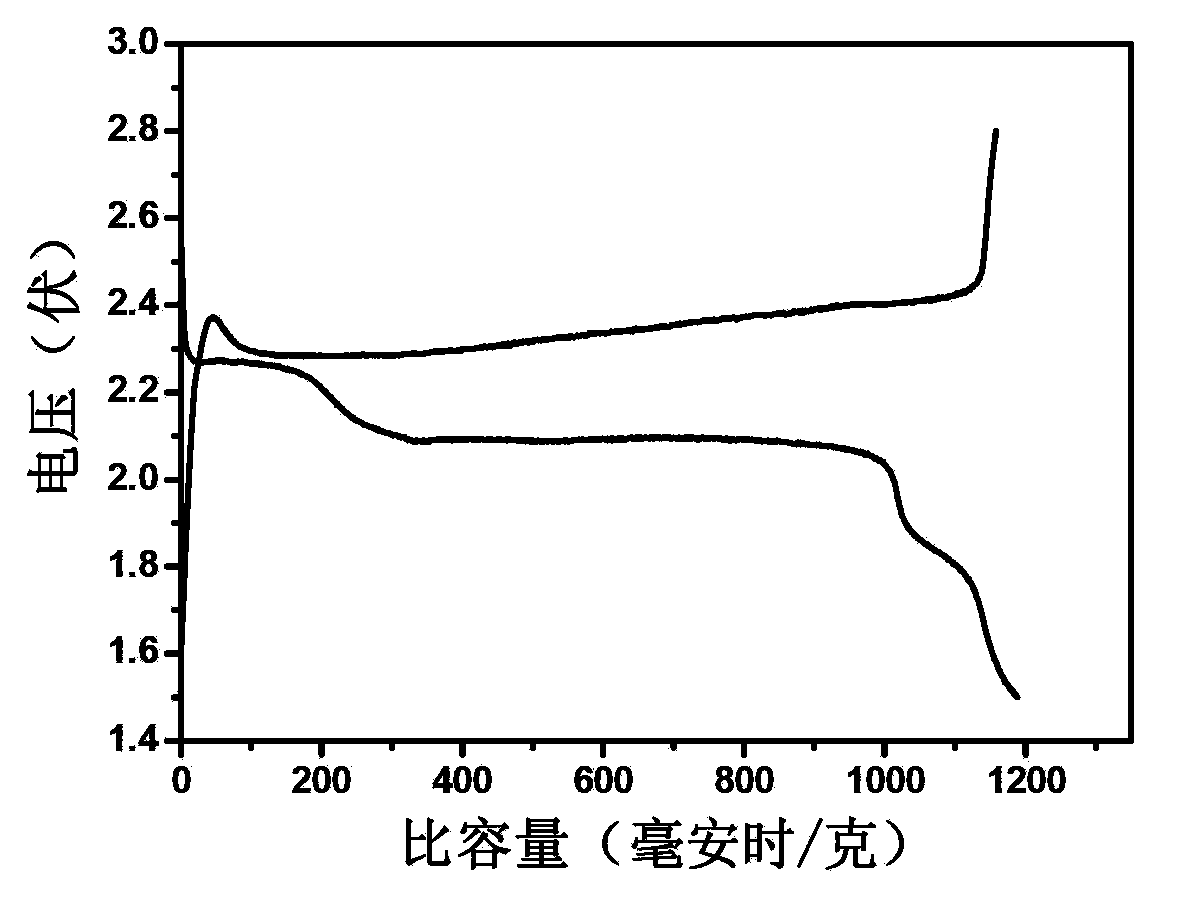

Graphene-sulfur composite electrode material, preparation method and application thereof

ActiveCN103811731AImproved magnification performanceLittle change in resistivityPositive electrodesLi-accumulatorsFreeze-dryingAdhesive

The present invention discloses a graphene-sulfur composite electrode material, a preparation method and an application thereof, and belongs to the field of electrochemical batteries. According to the graphene-sulfur composite electrode material, a uniformly-dispersed graphene oxide aqueous solution, an organic solution of sulfur, and a miscible solvent are subjected to mixing stirring, and then are subjected to a hydrothermal reaction to form a three-dimensional macroscopic body structure with sulfur nanoparticles uniformly distributed and anchored on the fibrous graphene surface, and low temperature freeze-drying is performed to obtain the graphene-sulfur composite material. According to the present invention, the electrode material is the microcosmic structure with sulfur nanoparticles uniformly anchored on the interconnected fibrous graphene surface; and according to the battery design, after the graphene-sulfur material is cut to obtain the corresponding thickness, the obtained material is pressed and then can be directly used as the lithium-sulfur battery positive electrode with no metal current collector, no conductive agent and no adhesive.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

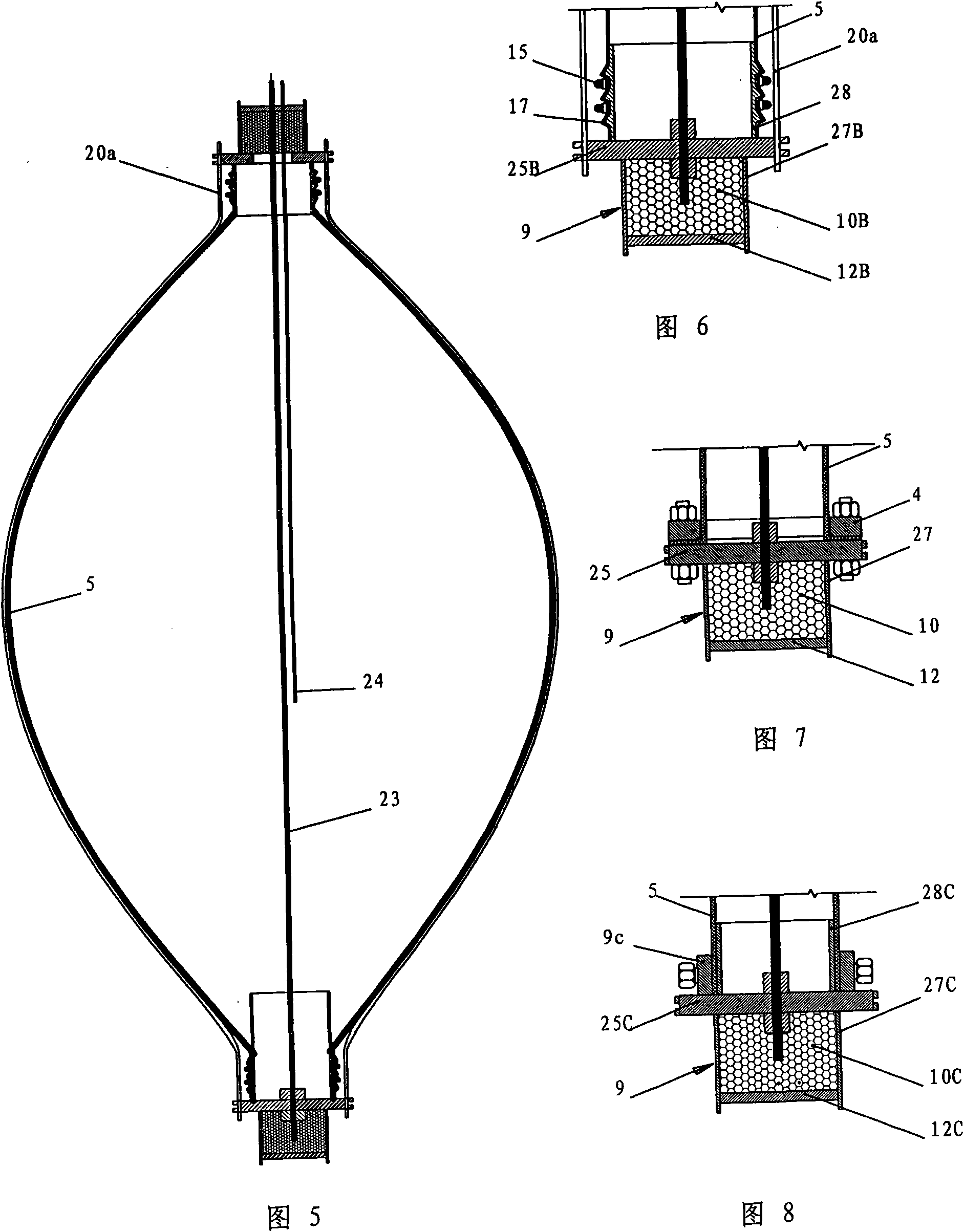

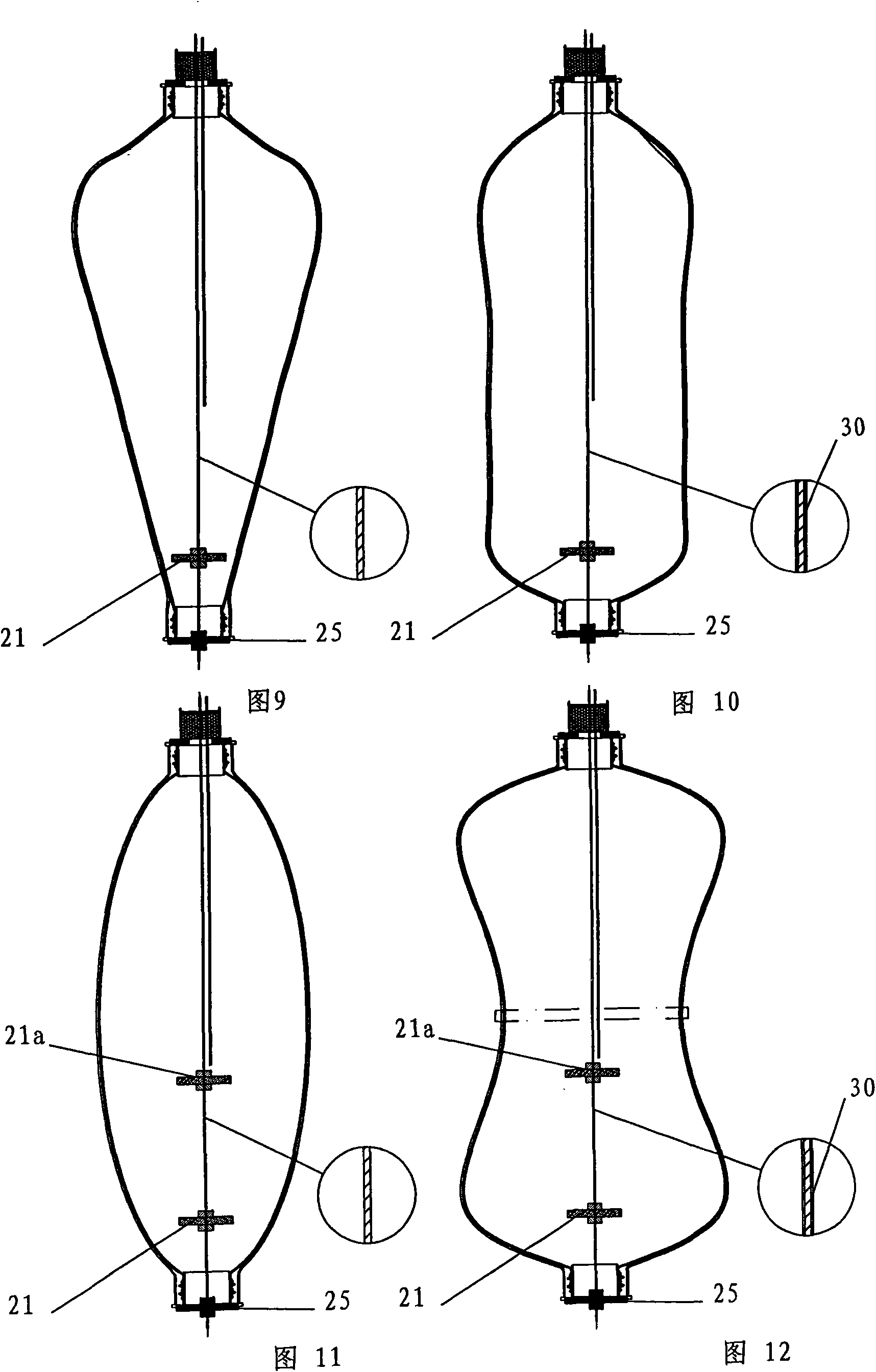

Multiple anti-corrosive controllable expansion extrusion soil anchor and construction method

InactiveCN101550696AEasy constructionFast constructionExcavationsBulkheads/pilesSlurryExpansion joint

Multiple anti-corrosive controllable expansion extrusion soil anchor, including anchorage segment, free-tensioned segment, outer anchor, grouting pipe, at least one power transmission member and more than one loading plates, the anchorage segment includes controllable expansion extrusion soil apparatus for geotechnical engineering use, which includes upper sleeve components, lower sleeve components and expansion extrusion barrel which is filled of cement-based slurry or cement-based slurry containing expansion agent inside. The construction method of the multiple anti-corrosive controllable expansion extrusion soil anchor includes inject the cement-based slurry or cement-based slurry containing expansion agent into the expansion extrusion barrel of deep anchor hole. The objective is to provide a multiple anti-corrosive controllable expansion extrusion soil anchor and construction method which is suitable for complicated, flaccidity, corrosivity stratum, being capable of repressing anchorage slurry loss and controlling expansion size of anchorage segment, high bearing capacity, good durability, low cost.

Owner:CHINA JINGYE ENG TECH CO LTD +1

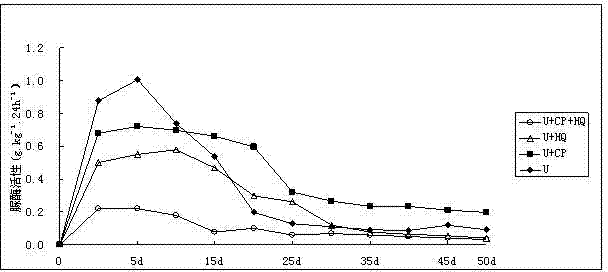

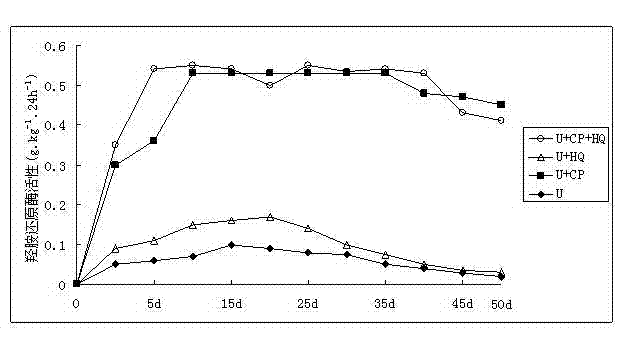

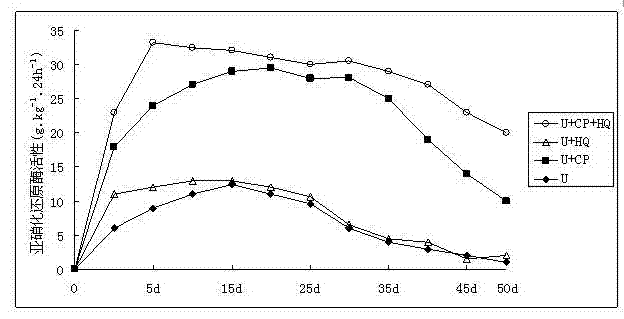

Preparation for inhibiting soil nitrogen loss as well as preparation method and application thereof

InactiveCN102249817AInhibition of hydrolysis rateResponse speed blockSoil lifting machinesAgriculture gas emission reductionSolventPollution

The invention discloses a preparation for inhibiting soil nitrogen loss as well as a preparation method and an application thereof. The preparation is prepared from the following raw materials in percentage by mass: 1-40% of 2-chloro-6-trichloromethylpyridine, 0-5% of hydroquinone, 5-20% of accessory ingredient and 35-90% of solvent. The preparation disclosed by the invention can be evenly dispersed in an aqueous phase, and the preparation and a nitrogenous fertilizer are evenly applied into soil so as to effectively alleviate speed of urea to be hydrolyzed into ammonia under the urease action and also effectively inhibit the process of oxidizing NH<4+> into NO<3->; NO<2-> and NO<3-> leaching loss is reduced, and NOX and N2 can be further prevented from escaping because of denitrification; and the utilization rate of the nitrogen fertilizer is improved so as to improve the quality and the yield of the crops and lighten pollution to environment by the nitrogen fertilizer.

Owner:ZHEJIANG AOFUTUO CHEM

Fire retardant treatment process for wood

InactiveCN102615684AAvoid churnCurb churnPressure impregnationWood impregnation detailsFire - disastersEngineering

A fire retardant treatment process for wood comprises the following steps: firstly, preparing a fire retardant solution 1 and a fire retardant solution 2; then putting the wood into an immersion tank; then vacuumizing the immersion tank to form negative pressure in the immersion tank; then using the negative pressure in the immersion tank to pump the fire retardant solution 1 into the immersion tank; then pressurizing the immersion tank to ensure that the fire retardant solution 1 is immersed into the wood as deep as possible; then discharging redundant fire retardant solution 1 into a fire retardant solution 1 storage tank; after that, vacuumizing the immersion tank to form negative pressure; then using the negative pressure in the immersion tank to pump the fire retardant solution 2 into the tank; then pressurizing the immersion tank to ensure that the fire retardant solution 2 is immersed into the wood as deep as possible; then discharging the redundant fire retardant solution 2 into a fire retardant 2 storage tank; then taking out the well immersed wood; and finally, drying the wood to complete the fire retardant treatment for the wood. According to the fire retardant treatment process for wood, the fire retardant efficiency is high, the fire retardant solution in the wood can be effectively prevented from losing, the smoke and poison gas in the wood can be inhibited from releasing in a fire disaster, and the fire retardant treatment cost for the wood is low.

Owner:GUANGDONG YIHUA TIMBER IND

Combined cultivation method for water and soil conservation for sloping farmlands

InactiveCN102498779AReduce churnLoss avoidance or mitigationSoil-working methodsContour plowingBiology

A combined cultivation method for water and soil conservation for sloping farmlands relates to cultivation methods for water and soil conservation and solves the problem that using the single cultivation technique for holding water is unsatisfactorily effective. The combined cultivation method includes: firstly, adjusting ridges of sloping farmlands on downward slopes and inclined slopes under ridge plowing adjusted into transverse slope ridges, and adopting contour farming and belt planting; secondly, building ridges, and planting protective plant belts on the ridges; thirdly, subsoiling forfarming; fourthly, performing furrow damming; and fifthly, performing no-tillage conservation tillage. Furrow subsoiling and furrow damming are technically combined and integrated according to soil and weather characteristics of a black soil area, so that water and soil loss is reduced or avoided for sloping farmlands to the greatest extent, water and soil are conserved, water utilization rate isincreased, and crop yield is increased evidently. By the method, soil saturation and infiltration speed ratio is increased by 24.1% in processing treatment, water utilization rate is increased by more than 15%, crop yield is 30kg per mu, and 100 Yuan per mu is increased..

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

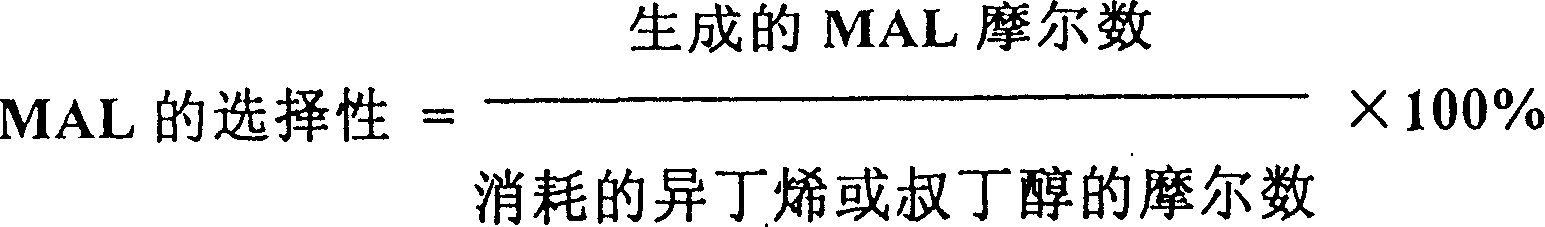

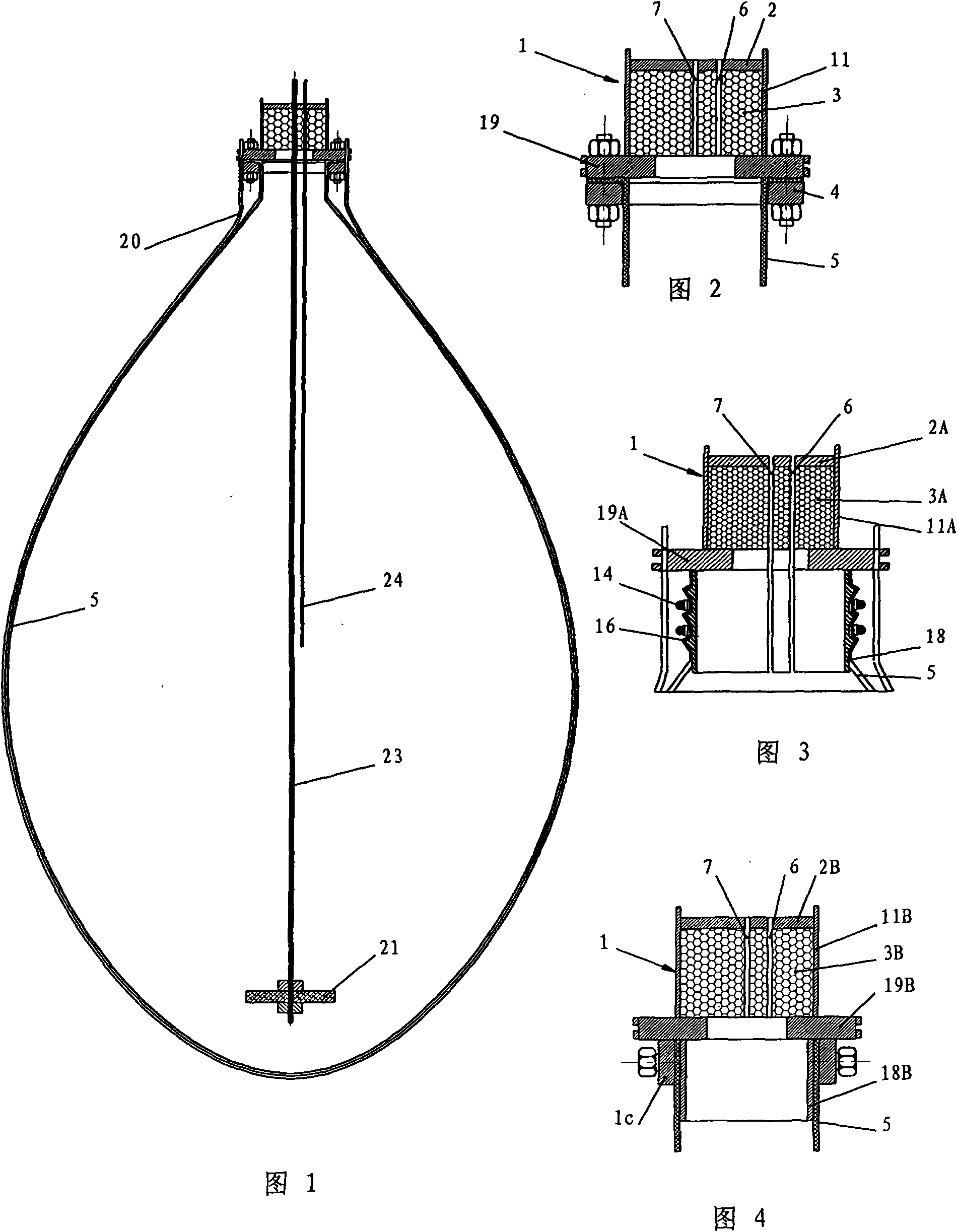

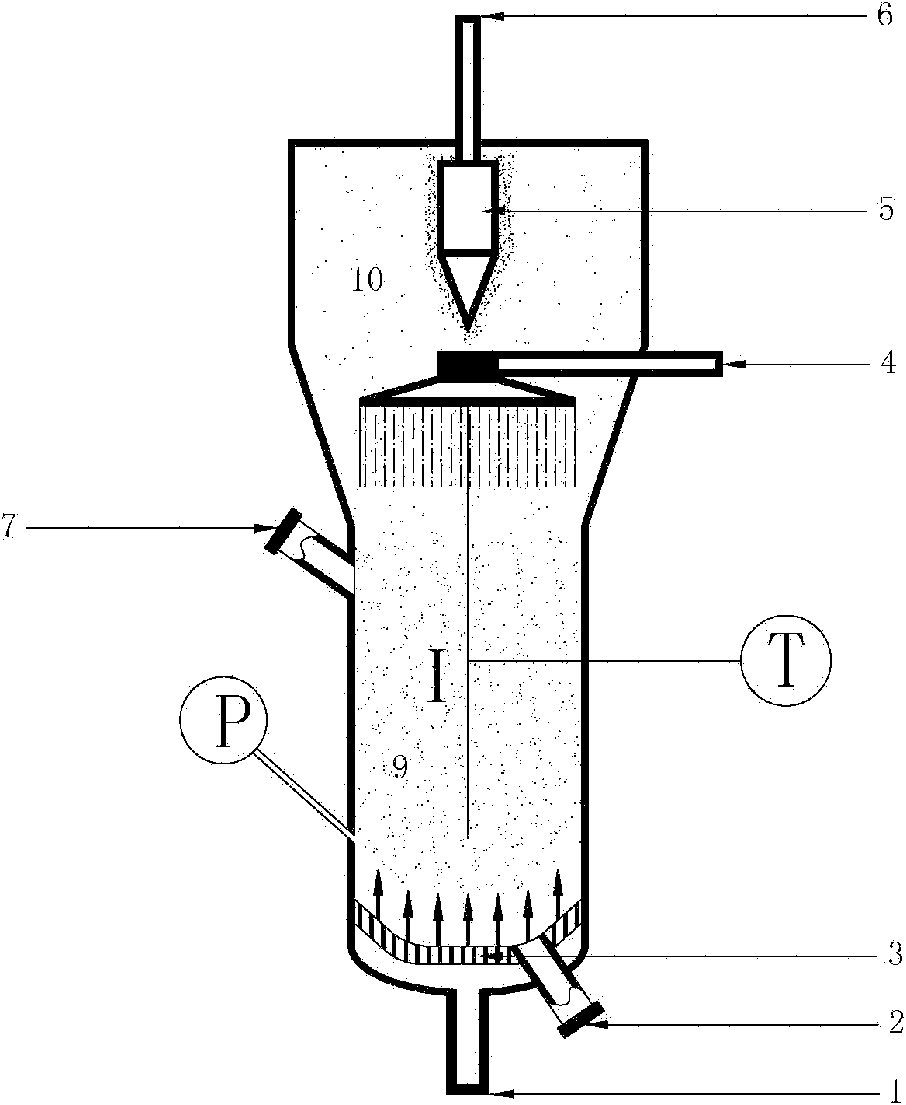

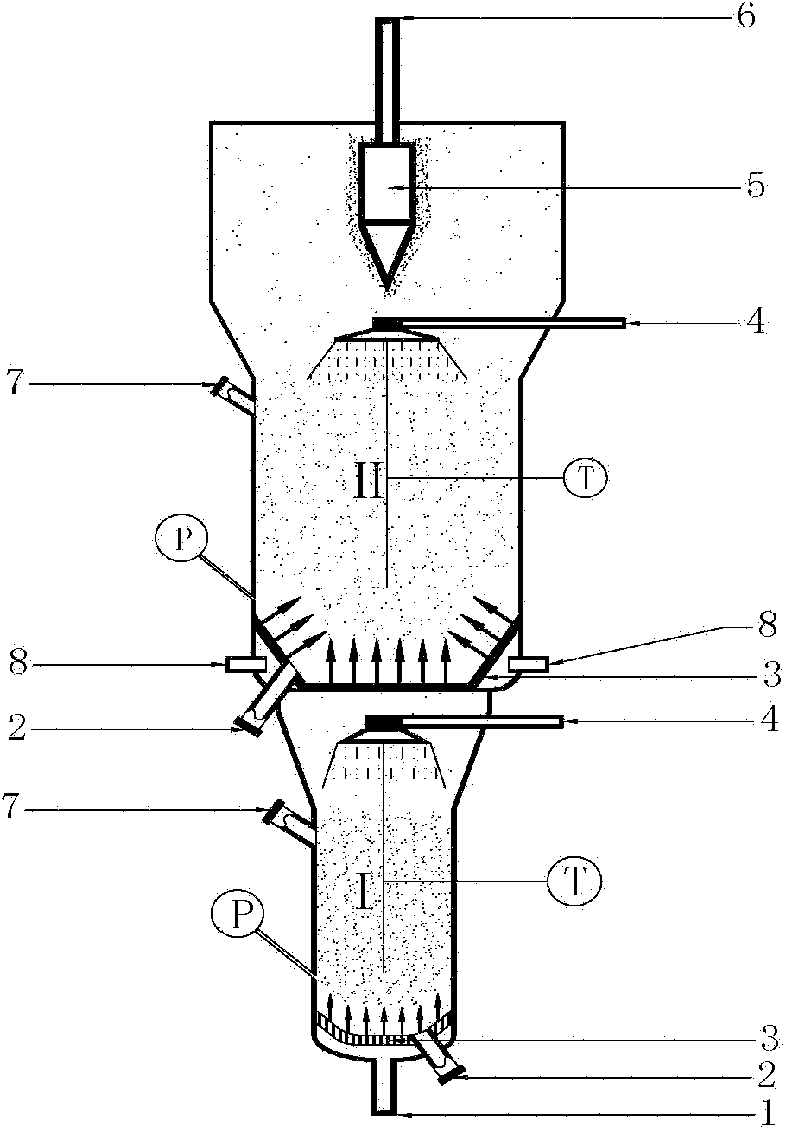

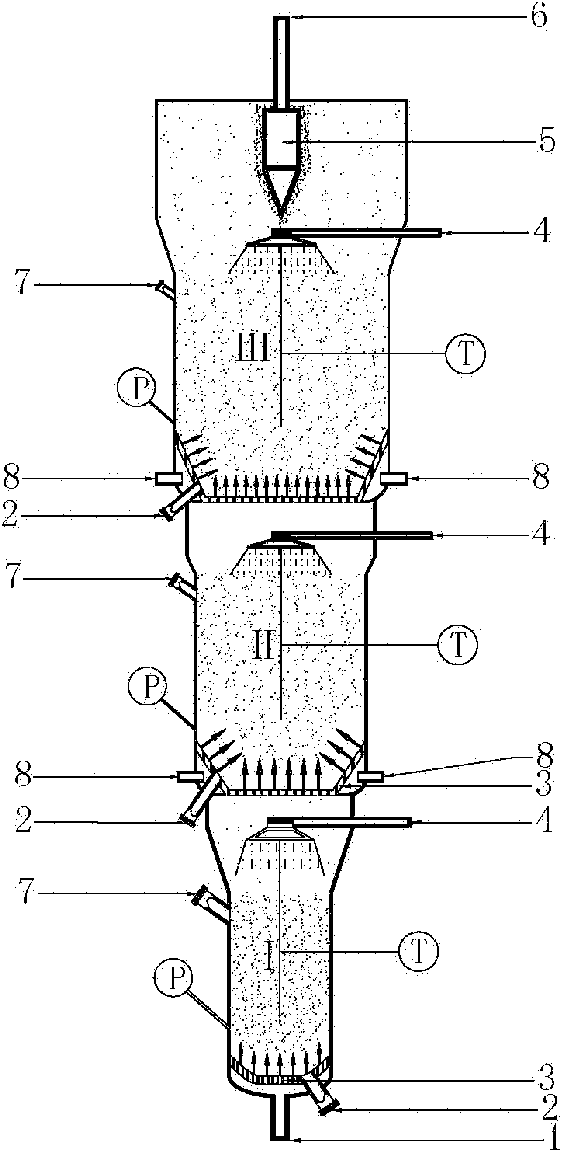

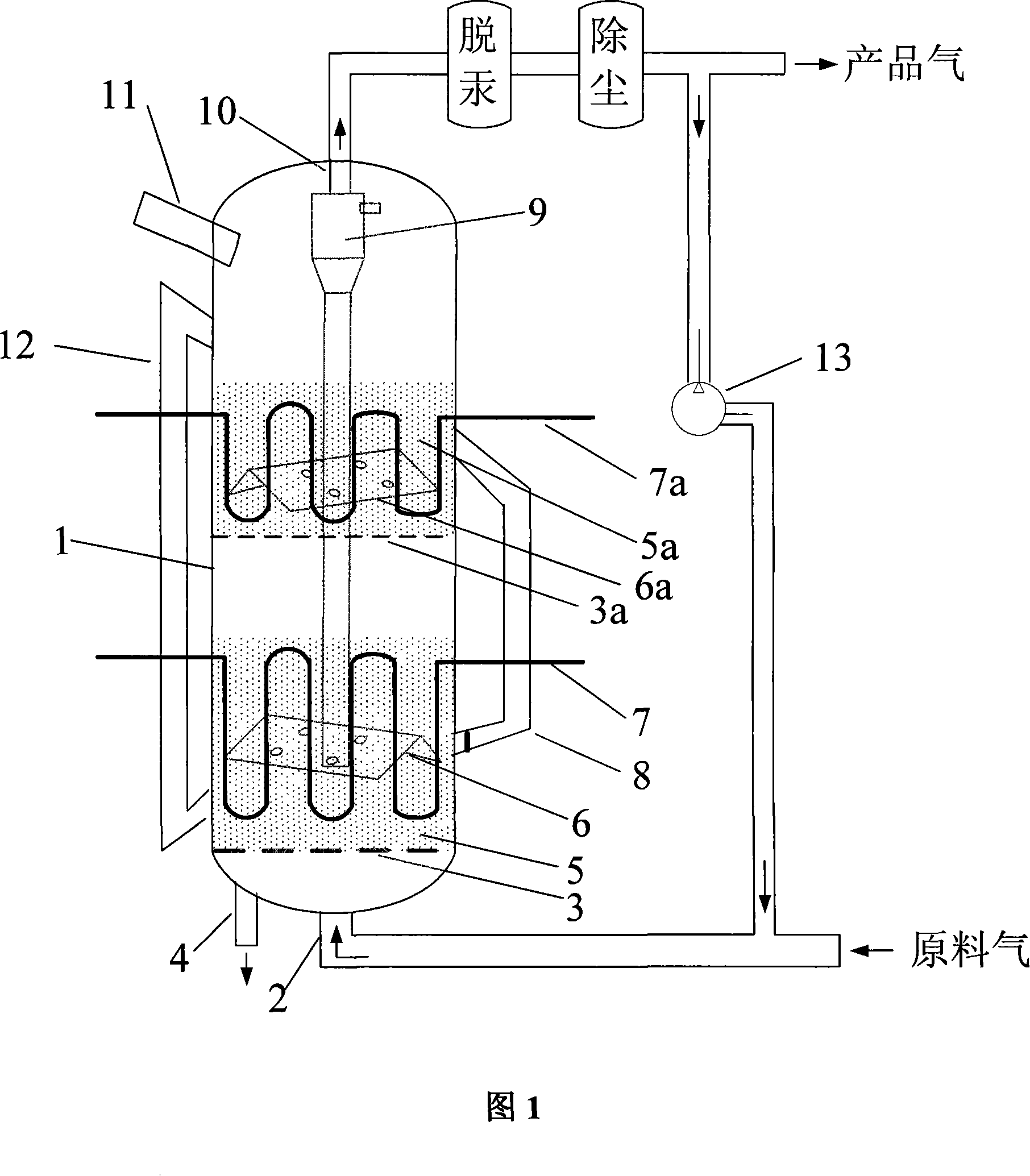

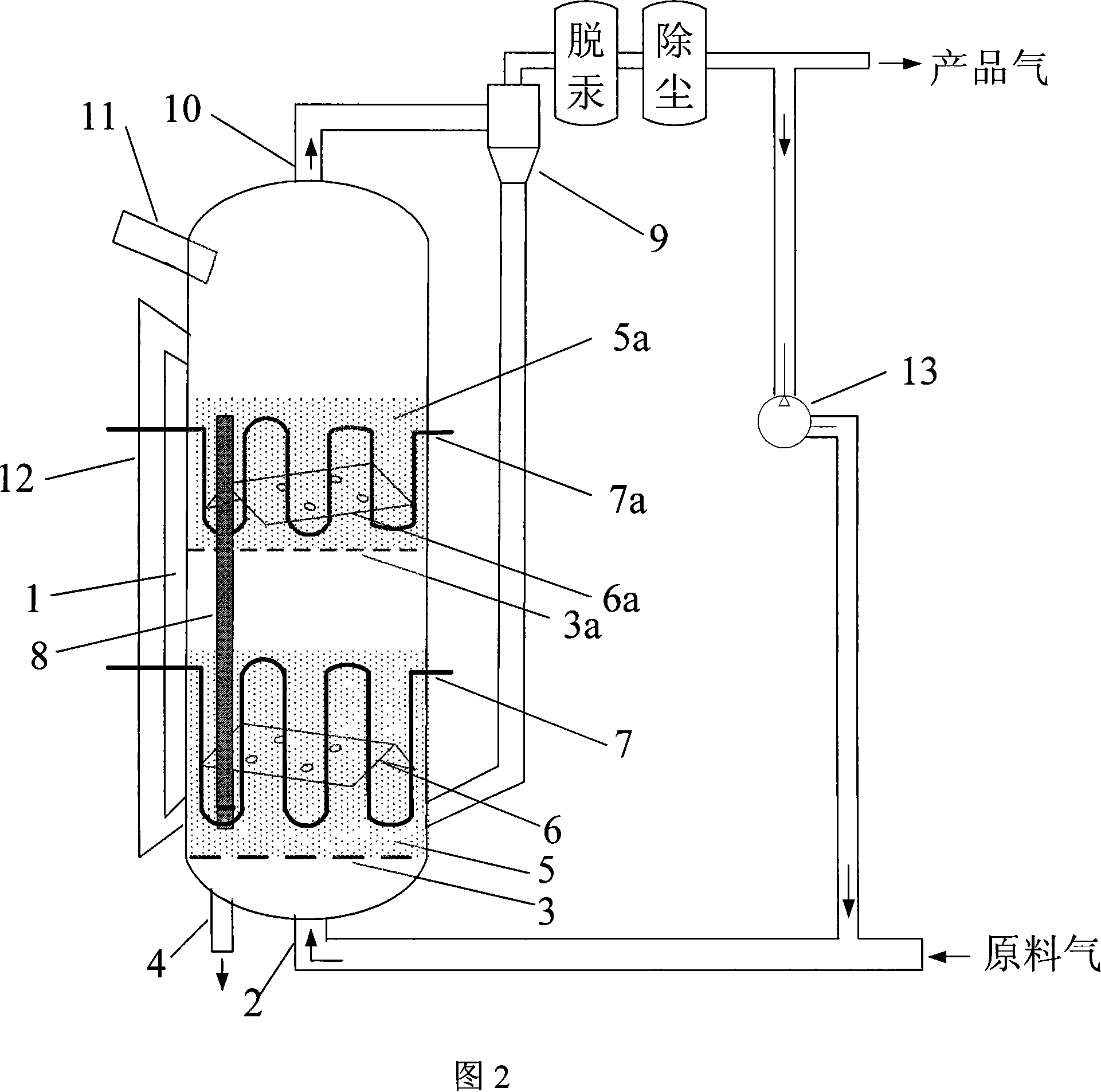

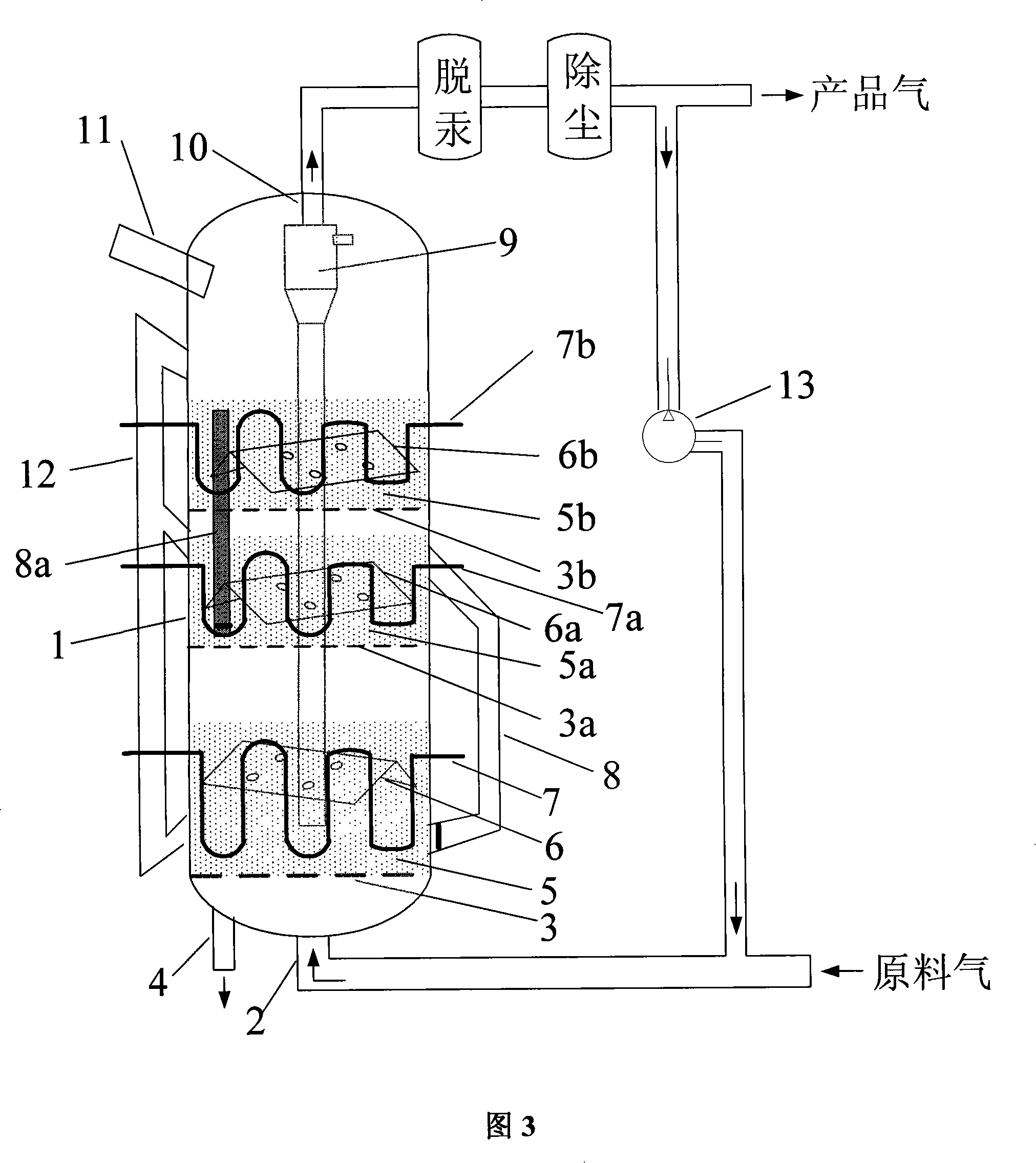

Fluidized bed reactor and method for methanation of gas mixture containing H2 and CO

ActiveCN102600771AReduce the numberExtend your lifeHydrocarbon from carbon oxidesChemical/physical processesGas solidContact high

The invention relates to a fluidized bed reactor and a method for methanation of gas mixture containing H2 and CO. The fluidized bed reactor of the invention comprises a material gas inlet 1, a catalyst outlet 2, a gas-solid separator 5, a product gas outlet 6, a catalyst inlet 7 and a material gas lateral line inlet, wherein one or more gas distribution plate 3 is arranged in the fluidized bed reactor in order to divide the reactor into several fluidized bed layers to form several catalyst dense-phase zones; a cooling water spraying device 4 is arranged above each layer of the catalyst dense-phase zone in order to control temperature of the reactor. Because the circulating cooling water directly contacts high-temperature product gas, the reactor of the invention strengthens heat transfer, is easy to control reaction temperature, reduces heat loss during the heat transfer and improves heat utilization rate during the reaction. The reactor has the advantages of large production flux, big operation elasticity, high CO conversion rate, high selectivity of produced methane, less catalyst dosage, high utilization rate of heat quantity and so on, so that the reactor has good industrial application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Orchard grass intercropping method

InactiveCN105993478AReduce disease incidenceImprove fertilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDiseaseTree trunk

The invention relates to the technical field of agriculture, and provides an orchard grass intercropping method. The method comprises the following steps: zones are divided, wherein grass is planted between orchard lines, and straws are laid within a range of 0.5m from tree trunks; plowing is carried out, wherein an EM inoculant is spread to grass planting zone soil, and plowing is carried out after 20-30 days; seed soaking is carried out, wherein grass seeds are soaked with the EM inoculant for 4-12h, and are air-dried at a shaded and ventilated place; sowing is carried out, wherein a sprinkler irrigation treatment is carried out with a diluted composite bacterial fertilizer, and uniform sowing is carried out with a sowing amount of 12-15kg / Mu when the soil is moist; management is carried out, wherein watering is carried out after sowing, and sprinkler irrigation is carried out with a diluted EM inoculant when seedlings uniformly shoot; and maintenance is carried out, wherein a grass height is maintained at 10-20cm, and a mixture of trimmed-off grass and straws is laid within a range of a tree base. The method has water-retaining, fertilizer-retaining and drought-resisting functions. With the method, farm chemical is not applied, and the effect of green manure is good. Chemical fertilizer is saved, and disease degree can be reduced from the source. Soil salinization can be effectively ameliorated, and fruits can be green and organic.

Owner:北京百丰生物科技集团有限公司

Method for deep dephosphorization by using embedded lanthanum oxide composite resin

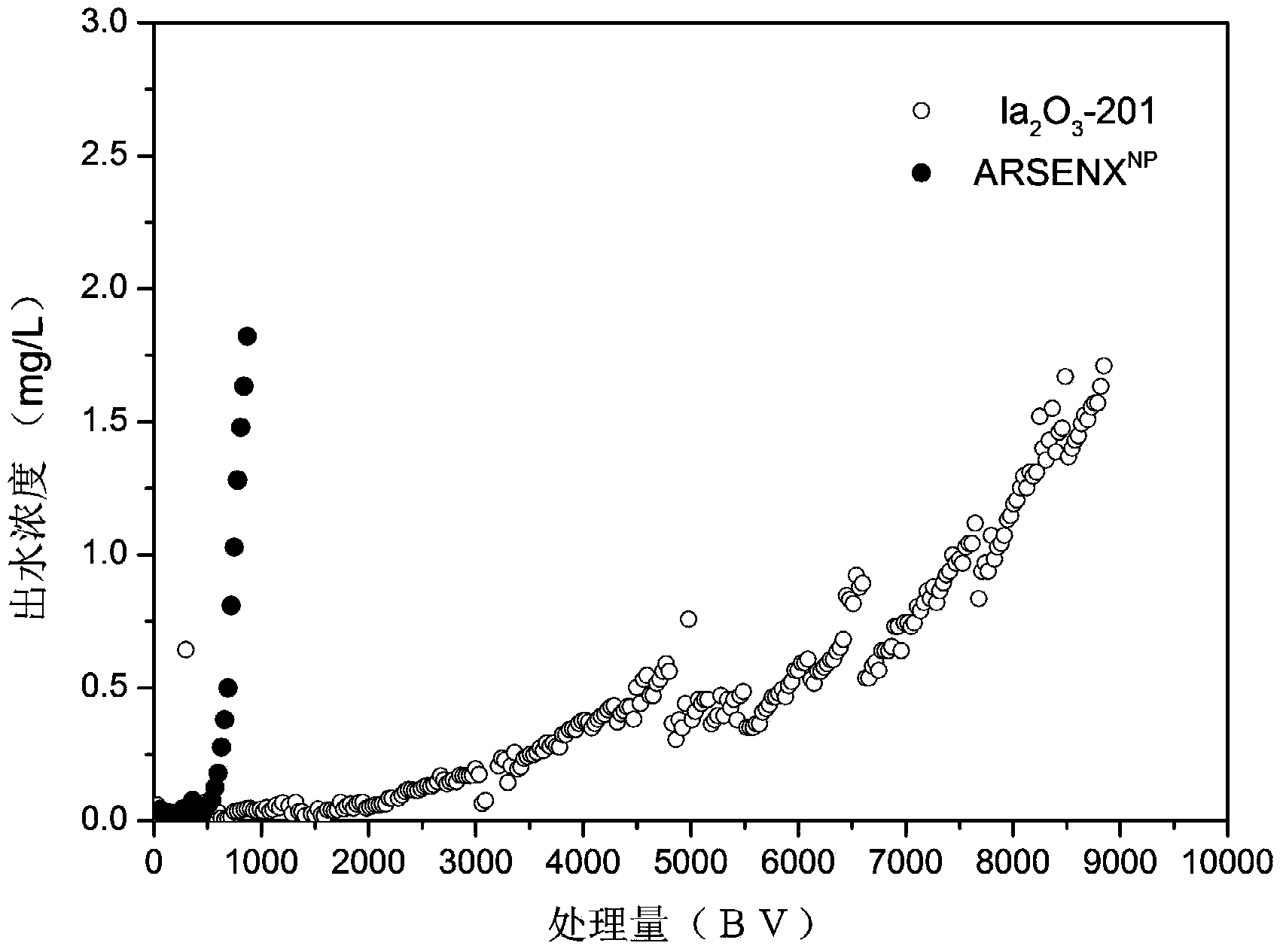

ActiveCN104138750ALarge adsorption capacityHigh selectivityOther chemical processesCombustible gas purificationIonChemistry

A method for preparing embedded lanthanum oxide composite resin mainly includes the steps that strong basicity anion exchange resin is added into a lanthanum nitrate solution, the mixture is fully stirred for reaction and then filtered, the resin is placed in a sodium hydroxide solution, reacts at the constant temperature, and then is filtered and washed to be neutral, and the processed resin is treated in a thermal mode to obtain the embedded lanthanum oxide composite resin. The method for dephosphorization by using the embedded lanthanum oxide composite resin includes the steps that the composite resin is placed in a glass adsorption column, and waste water polluted by phosphate flows downstream through the static bed column adsorption device filled with the adsorption material, wherein the temperature of the waste water is controlled to be 10 DEG C-50 DEG C, and the pH is controlled to be 2-10; when the concentration of the phosphate in outlet water is larger than 0.5 mg / L, a mixed solution of sodium hydroxide and sodium chloride is adopted for desorption, and the desorbed adsorption material can be recycled. When a polluted water body contains a great deal of co-existing ions such as sulfate radical, chloride ions and nitrate, the concentration of the phosphate in the phosphorus waste water treated through the lanthanum oxide composite resin can be reduced below the town sewage discharge standard, and secondary pollution is avoided.

Owner:HEBEI YANYONG ENVIRONMENTAL TECH CO LTD

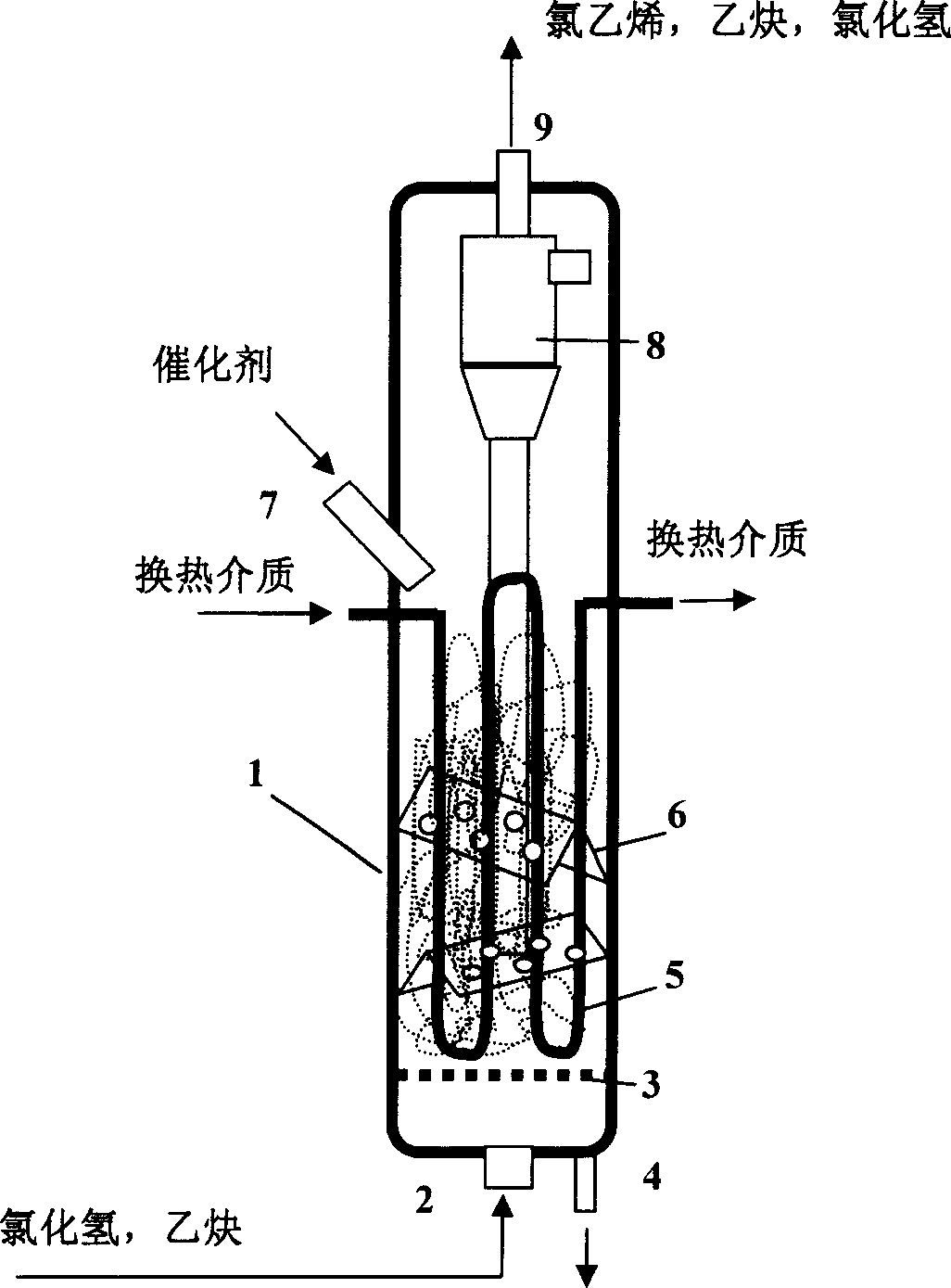

Method for preparing vinyl chloride by circulating fluidized bed reactor and device thereof

InactiveCN101121635AExtend your lifeReduce dosagePreparation by halogen halide additionFluidized bedEngineering

The present invention discloses a method to prepare chloroethylene by a circulated flow bed reaction device and the corresponding device, which belongs to the chemical technical process and device technology region. Two or more than two gas distributing devices are arranged inside of the flow bed, which divide the flow bed into two or more than two catalyzer zones; a fan is arranged outside of the flow bed, which can make part of products circulate after being pressured and then enters the flow bed again; the design can make the catalyzer zones in a better flow state so as to guarantee the much better heat-exchange effect between the bed level and the heat-exchange interface; besides, the stability of the device and the elasticity of the operation can be enhanced; the low-temperature catalyzer zone in the upper level can decrease the temperature for the reaction gas, and then extract the included hydrargyrum so as to decrease the environment pollution because of the losing of hydrargyrum; the catalyzer in each catalyzer zone is circulated termly so as to use the catalyzing function for hydrargyrum enough. The flow bed reaction device and technology in the present invention has the advantages of high transfer ratio of ethyne, good diathermancy, even temperature of the bed level, good controlled ability and elastic operation and so on.

Owner:XINJIANG TIANYE GRP +1

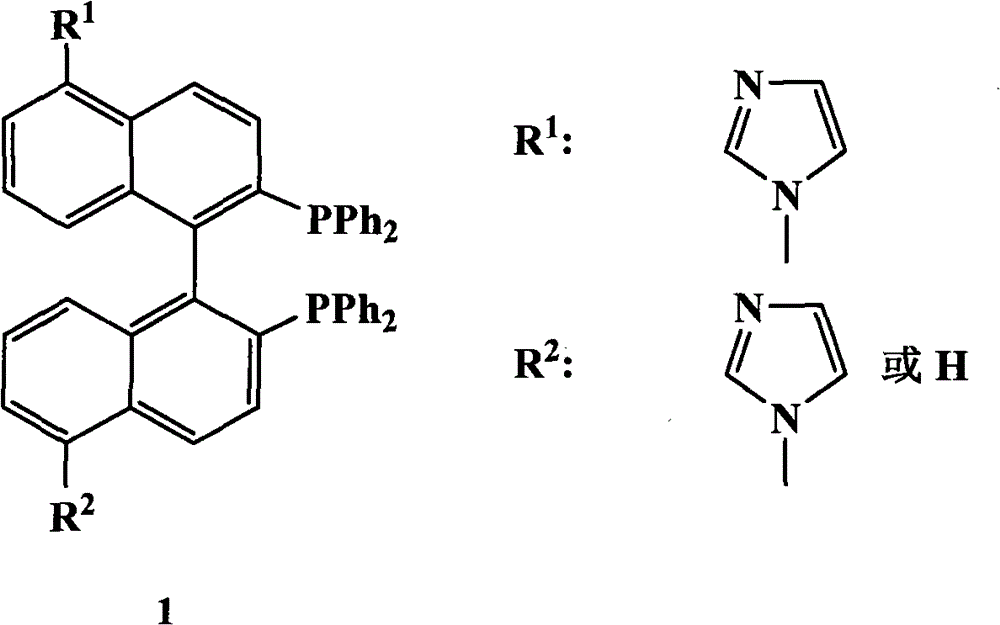

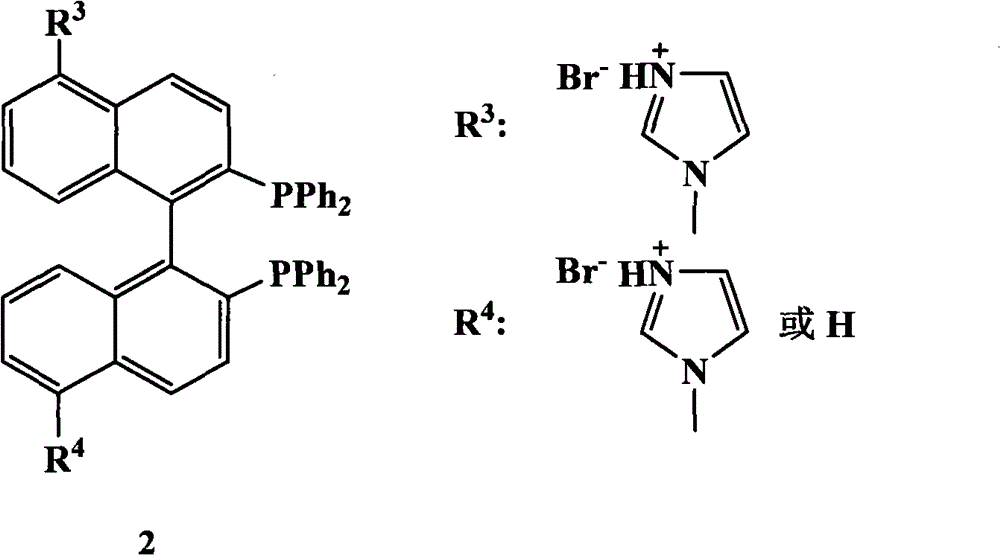

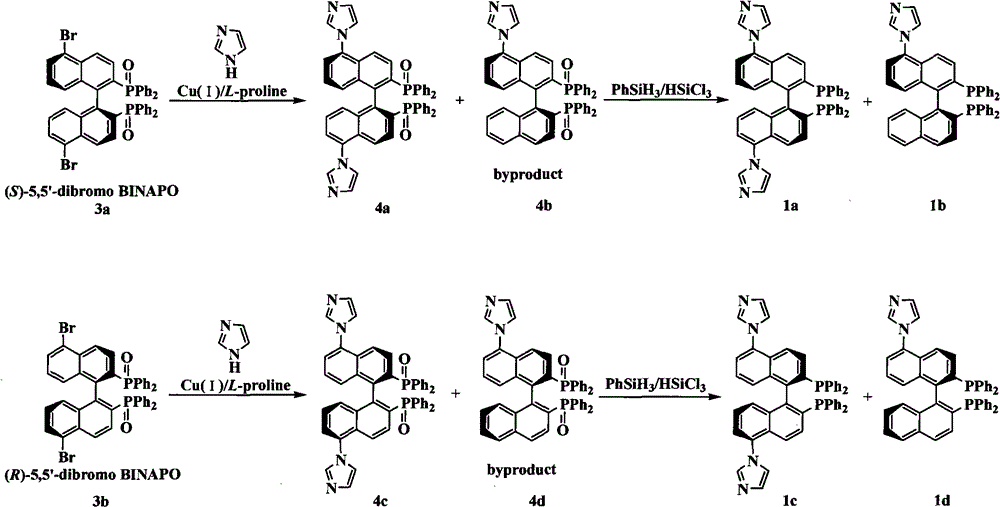

Chiral diphosphine ligand and chiral catalyst, and preparation and application method thereof

ActiveCN103059064AHigh affinityReduced activityOrganic compound preparationGroup 5/15 element organic compoundsCyclic processDiphosphines

The invention relates to a chiral diphosphine ligand and a chiral catalyst, and a preparation and application method thereof. The preparation method of a BINAP (2,2'-bis(diphenylphosphino)-1,1'-binaphthyl) chiral diphosphine ligand based on novel imidazole and imidazole cation modification. Imidazole and imidazole cation are introduced to the 5,5'- position of the BINAP molecule framework to synthesize the chiral diphosphine ligand. The assembly of the imidazole and imidazole cation into the chiral diphosphine ligand molecule can effectively enhance the stability of the chiral catalyst in an ionic liquid and the affinity with the imidazole ionic liquid, and avoids loss of the catalyst in the cyclic process. The imidazole-modified chiral diphosphine ligand has the following chemical structural formula, wherein the spatial configuration of the imidazole-modified chiral diphosphine ligand is S type or R type.

Owner:山东聚强绿洲生物科技有限公司

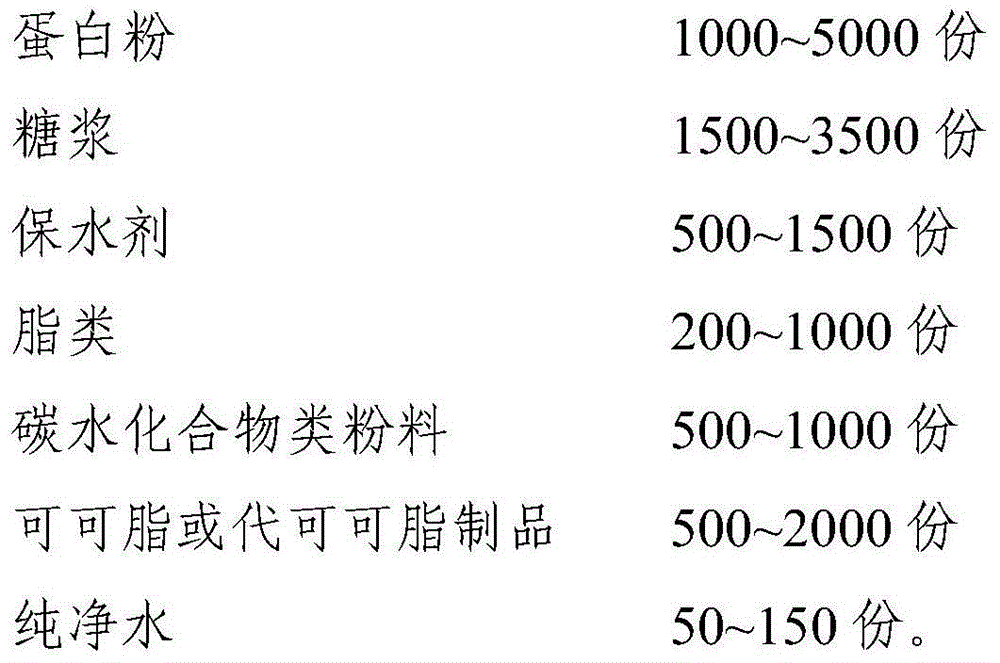

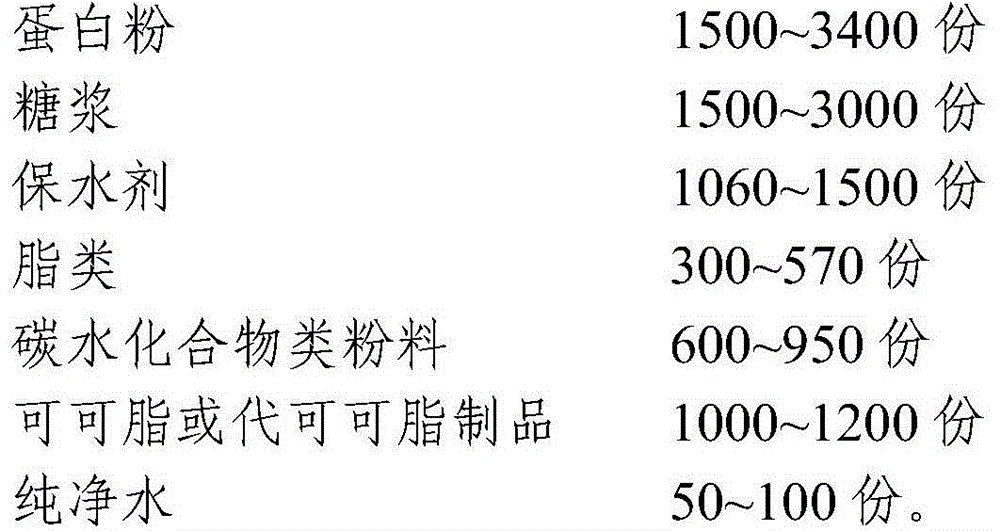

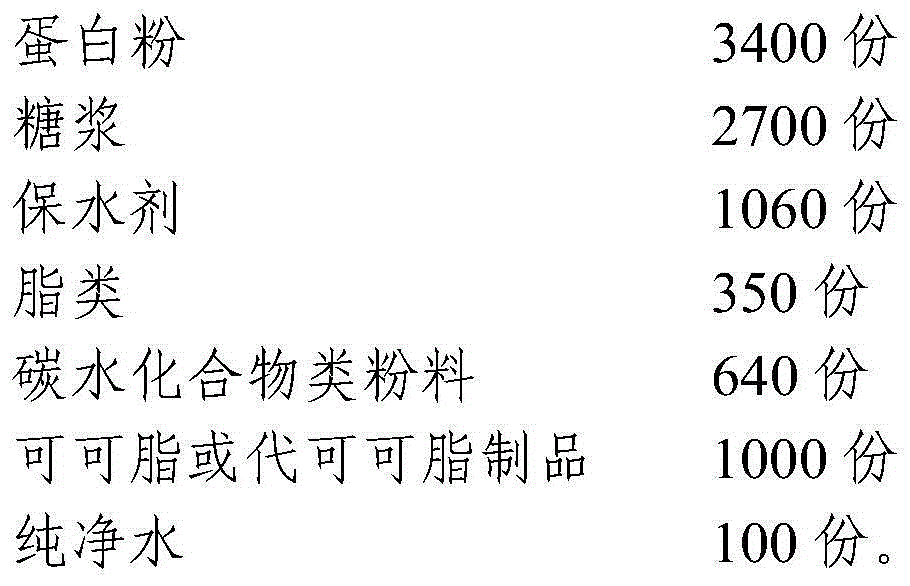

Preservation-resisting energy bar and making method thereof

InactiveCN104522644ADelicate tasteSweet tasteFood ingredient functionsFood preparationButter cocoaFlavor

The invention relates to a preservation-resisting energy bar which is prepared from the following raw materials in parts by weight: 1000-5000 parts of protein powder, 1500-3500 parts of syrupy, 500-1500 parts of a water-retaining agent, 200-1000 parts of lipid, 500-1000 parts of carbohydrate, 500-2000 parts of a cocoa butter or cocoa butter substitute product and 50-150 parts of pure water. The energy bar made by using the formula and the method provided by the invention is fine and smooth in taste, fragrant and sweet in flavor, convenient to carry over and unlikely to deteriorate and is particularly applicable to special purposes such as long-term wild sports and military training as certain moisture and soft taste are still maintained after being preserved for a long time.

Owner:BEIJING COMPETITOR SPORTS SCI & TECH

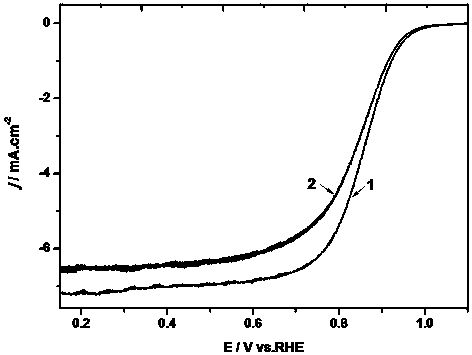

Method for preparing titanium tungsten oxide coated carbon nano-tube platinum-supported electro-catalyst

InactiveCN103394350AImprove conductivityHigh activityCatalyst carriersCell electrodesElectron transmissionCarbon nanotube

The invention provides a method for preparing a titanium tungsten oxide coated carbon nano-tube platinum-supported electro-catalyst, belonging to the technical field of fuel cells. According to the method, titanium tungsten oxides are uniformly coated on the surfaces of carbon nano-tubes by adopting a sol-gel method, and titanium tungsten oxide coating layers with high crystallinity and high conductivity are formed through heat treatment so as to support a platinum catalyst. On one hand, the highly-crystalline titanium tungsten oxides are uniformly coated on the carbon nano-tubes, so that electron transmission channels are constructed, the conductivity is enhanced, the corrosion to a support is avoided effectively, the loss of the catalyst is inhibited, and the activity, stability and platinum utilization rate of the catalyst are improved greatly. On the other hand, the decomposition of an intermediate product, namely hydrogen peroxide, of oxygen reduction is accelerated by the titanium tungsten oxide coating layers, so that the yield of hydrogen peroxide is reduced, the influence on the catalyst and electrolyte membranes caused by hydrogen peroxide is reduced, and then, the service life of a fuel cell system is prolonged. The method provided by the invention has the advantages that the method is simple, the industrial production is facilitated, and the prepared catalyst can be applied to the fuel cells which take proton exchange membranes as electrolytes.

Owner:CHONGQING UNIV

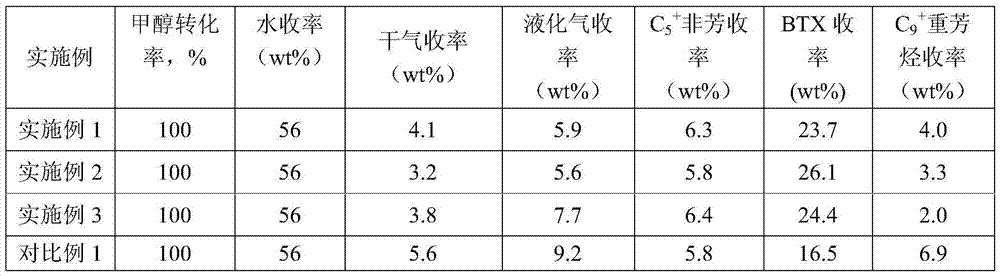

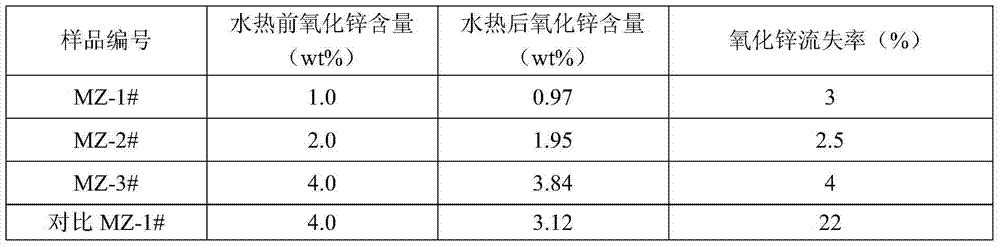

Methanol to aromatic catalyst containing two molecular sieves and preparation method

ActiveCN105435839AReduce manufacturing costSuppress generationMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveActive component

The invention relates to a methanol to aromatic catalyst containing two molecular sieves and a preparation method. The methanol to aromatic catalyst comprises, based on the weight of the catalyst, 40 wt%-85 wt% of the total content of a zinc-aluminium compound modified ZSM-5 molecular sieve and a nickel modified Y-shaped molecular sieve, 0.5 wt%-5.0 wt% of rare earth oxide and the balance aluminium oxide binder, wherein the ratio of the weight content of the zinc-aluminium compound modified ZSM-5 molecular sieve to the modified Y-shaped molecular sieve is 9:1-1:1. The invention further discloses a method for preparing the catalyst. The methanol to aromatic catalyst is used in a methanol to aromatic process, has high light weight aromatic yield and is low in dry gas and liquefied gas productivity. The wastage rate of zinc oxide active components of the catalyst is low, and the stability is high.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Graphene/graphene oxide coat composite electrode, battery and preparation method thereof

ActiveCN109004192ASmall volume changeCurb churnNon-aqueous electrolyte accumulator electrodesComposite electrodeHigh energy

The invention discloses a graphene / graphene oxide coated composite electrode, a battery and a preparation method thereof. In the electrode, graphene (oxide) can be precisely and closely coated on thesurface of an active material. The method comprises the following steps: contacting an electrode loaded with an active material with a graphene oxide dispersion liquid, utilizing the chemical interaction force of the active material and the graphene oxide in the liquid phase to achieve the coating of the graphene oxide on the surface of the active material, and obtaining the coating of the graphene on the surface of the active material by calcining treatment. The structure of precise and close coating of graphene oxide on the electrode can alleviate the problems of large volume change and serious loss of active material during charging and discharging of electrode materials with high energy density, and thus effectively improve the cycling stability of the materials. The graphene / grapheneoxide coated composite electrode disclosed by the invention has the advantages of simple operation and high efficiency, is suitable for continuous operation and large-scale production, and has wide application value and popularization significance.

Owner:ZHENGZHOU UNIV

Polyamide, synthesis method and application thereof, and polyamide product

The invention discloses a polyamide, a synthesis method and application thereof, and a polyamide product. The synthesis method comprises the following steps: feeding: proportionally adding dibasic acid monomer, diamine monomer and other reaction assistants into a reaction kettle; charging shielding gas into the reaction kettle until the pressure in the reaction kettle is 0.2-1.0 MPa, wherein the shielding gas contains 60-100 vol% of CO2; heating the reaction kettle to perform prepolymerization reaction on the mixture in the reaction kettle, discharging after the prepolymerization reaction is finished, drying the prepolymerization product, and carrying out solid-phase tackification to obtain the polyamide. The terminal amino content and terminal carboxyl content in the polyamide prepared by the synthesis method are low. The polyamide disclosed by the invention is applicable to a manufacturing material of electric and electronic equipment, automobile part, office supply or home supply. The invention also discloses a manufacturing material of electric and electronic equipment, automobile part, office supply or home supply.

Owner:KINGFA SCI & TECH CO LTD +2

Automatic pressure soybean milk machine and method for producing soybean milk

ActiveCN101485422AControl pressure valueFully emulsifiedBeverage vesselsFood preparationAdditive ingredientDrive shaft

The invention provides an automatic pressure soybean milk machine, and belongs to the technical field of household food cuisine. The machine comprises a machine seat provided inside with a driving motor supplying power, blades arranged at the tail end of a driving shaft of the motor, a cup body, a cup cover arranged above the cup body, a heating element, a temperature detecting device and a circuit board of a control circuit; the cup cover and the mouth of the cup body are provided with sealing elements; under the state of closed cover, a sealed cavity is formed in the cup body, the continuous rise of pressure in the sealed cavity is allowed after heating, and a pressure relief device is also arranged; and air can be discharged by the pressure relief valve when the pressure in the cup body is higher than the preset pressure P0. The temperature for cooking the soybean milk can reach more than 106 DEG C; when the soybean milk is continuously cooked in the sealed cavity, the overflow phenomenon cannot happen so as to shorten the process of cooling the soybean milk and saving time; moreover, the cooked soybean milk is fully emulsified and well cooked; and due to the continuous and quick heating, the loss of the nutrient contents in the food is inhibited in the heating process, so that the cooked soybean milk is fragrant and pure, and tastes good.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

Edible mushroom flavor paste and production method thereof

The invention relates to an edible mushroom flavor paste and a production method thereof, and belongs to a food processing technology. The entire plants of edible mushrooms are cleaned and screened to remove impurities, and then are subjected to washing, flavor-optimizing, limited-dehydrating, crushing, blending, sterilizing and other treatments so as to produce a sauce seasoning which has well palatability and intense aromas and flavor. The production method provided by the invention can be used for widening the application range of edible mushroom and increasing the varieties of the sauce seasonings; in addition, the product has high protein and high dietary fiber without any artificially synthesized additives, and is convenient, healthy and nutrient serving good item.

Owner:JILIN WEIYIKANG BIOLOGICAL SCI & TECH

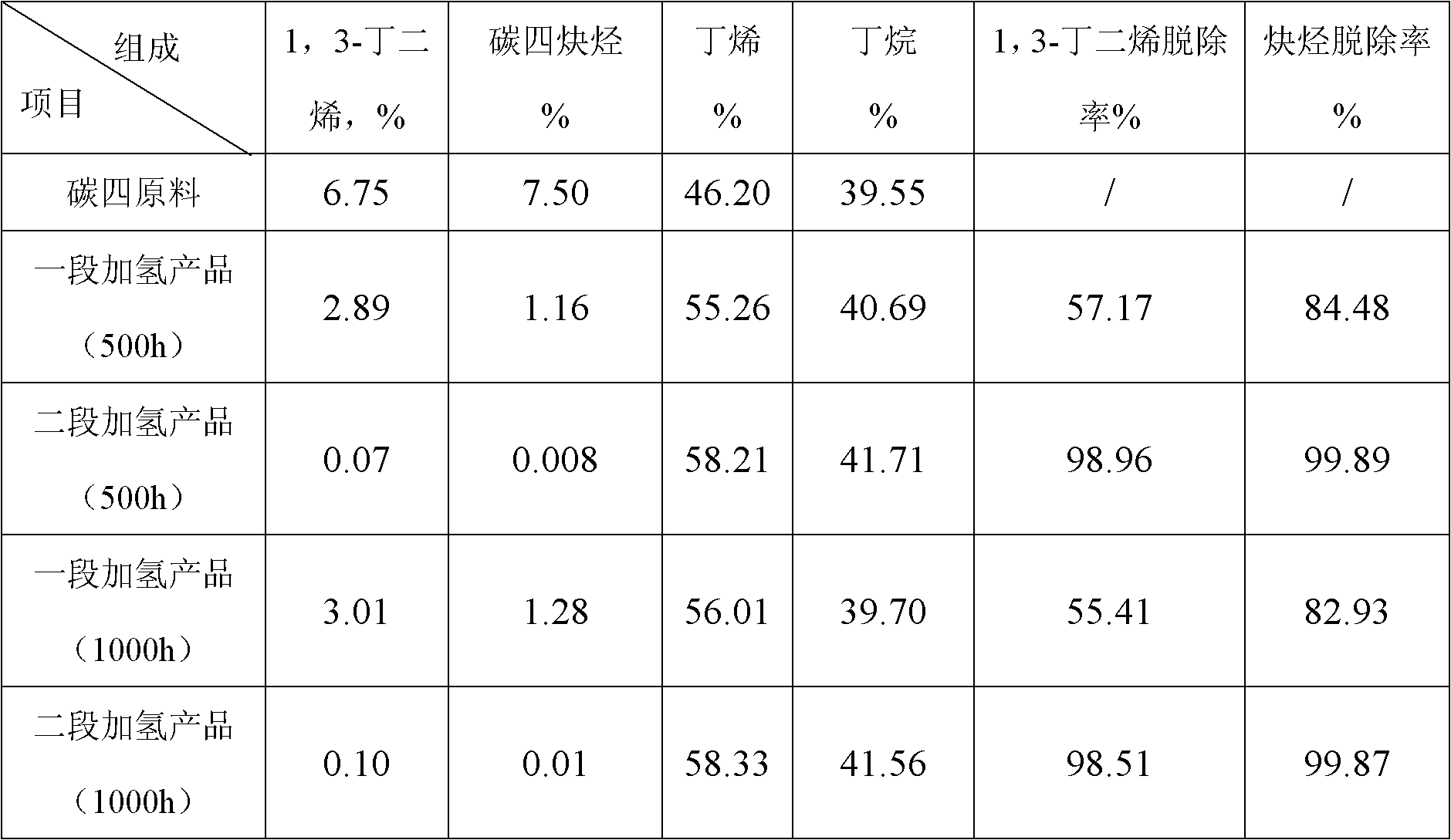

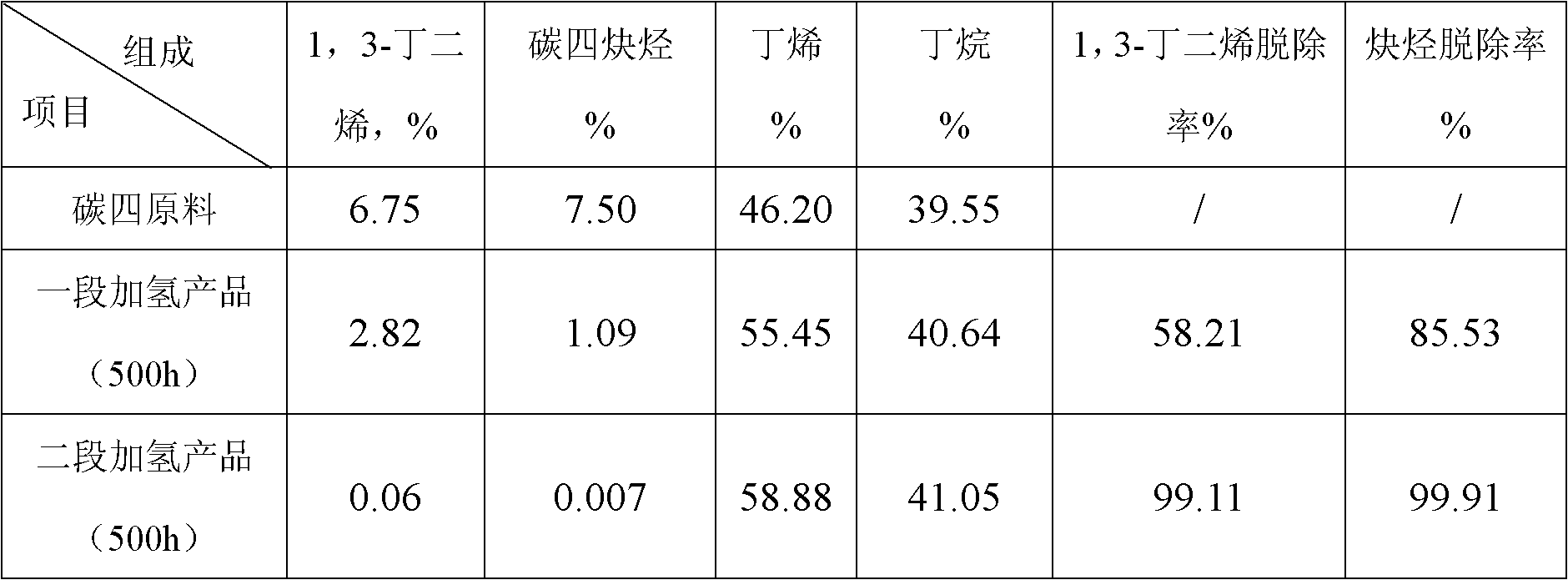

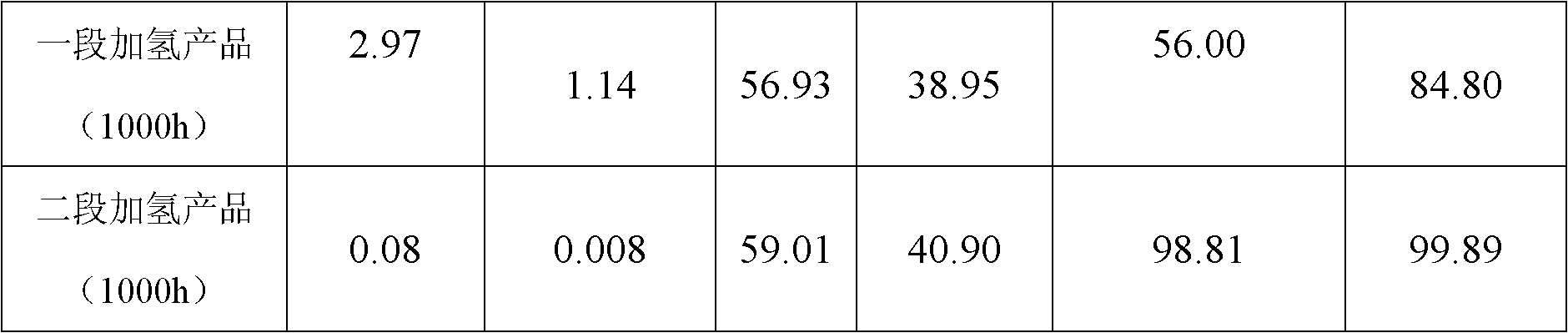

Hydrogenation method of C4 fraction containing rich alkynes and dialkenes

InactiveCN103045304AAlkyne highHigh content of diolefinsGaseous mixture working upHydrogenation reactionReaction temperature

The invention relates to a hydrogenation method of C4 fraction containing rich alkynes and dialkenes. A raw material containing C4 fraction and H2 enter two hydrogenation reactor which are connected in series; each reactor is telescopic, wherein the inner tube is filled with a catalyst, and the outer tube is filled with a heat removal medium which is 8-18 DEG C new water; the mol ratio of the hydrogen to the inlet total alkyne and dialkene content of the first reactor is 1.0-6.0, the mol ratio of the hydrogen to the inlet total alkyne and dialkene content of the second reactor is 1.0-6.0, the reaction temperature of the reactor inlet is 20-60 DEG C, the reaction pressure is 0.5-4.0 MPa, and the liquid hourly space velocity is 1.0-30 h<-1>; the reaction product is cooled and enters a gas-liquid separation tank to be separated; and the catalyst in the reactor is an aluminum-oxide-supported palladium-base catalyst or copper-base catalyst. The alkyne content in the material hydrogenated by the method is less than 100 mu g / g, and the dialkene content is less than 1000 mug / g. The material hydrogenated by the method can be used as domestic liquefied gas or methylethylketone raw material.

Owner:PETROCHINA CO LTD

Fluidized bed reactor for preparing vinyl chloride by hydrogen chloride and acetylene reaction and method

InactiveCN1900036APromote conversionInhibit transformationPreparation by halogen halide additionChemical/physical processesPtru catalystFluidized bed

The fluidized bed reactor for preparing vinyl chloride through reaction between hydrogen chloride and acetylene and preparation process belongs to the field of chemical technology. The fluidized bed reactor includes fluidized bed, reactant material gas inlet, heat exchange pipes, member, cyclonic separator, reacted gas outlet, catalyst feeding port and catalyst removing port connected successively to the wall of the fluidized bed. After the catalyst in the molar ratio to the reactant material of 1.01-1.1 to 1 is fed, hydrogen chloride and acetylene are introduced are converted through reaction into vinyl chloride completely, and the reacted product is made to enter the post equipment through the gas outlet. The present invention has simple reaction member, high bubble crushing effect, low catalyst loss, greatly strengthened gas-solid contact, high vinyl chloride product purity and other advantages.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com